High-voltage PTC liquid heating assembly for heat management of new energy automobiles

A new energy vehicle and thermal management technology, applied in electric vehicles, ohmic resistance heating, heating/cooling equipment, etc., can solve the problems of insufficient heat supply and high production cost of new energy vehicles in winter, and achieve reliability and safety. The effect of saving heating cost and reducing the weight of the assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Specific embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

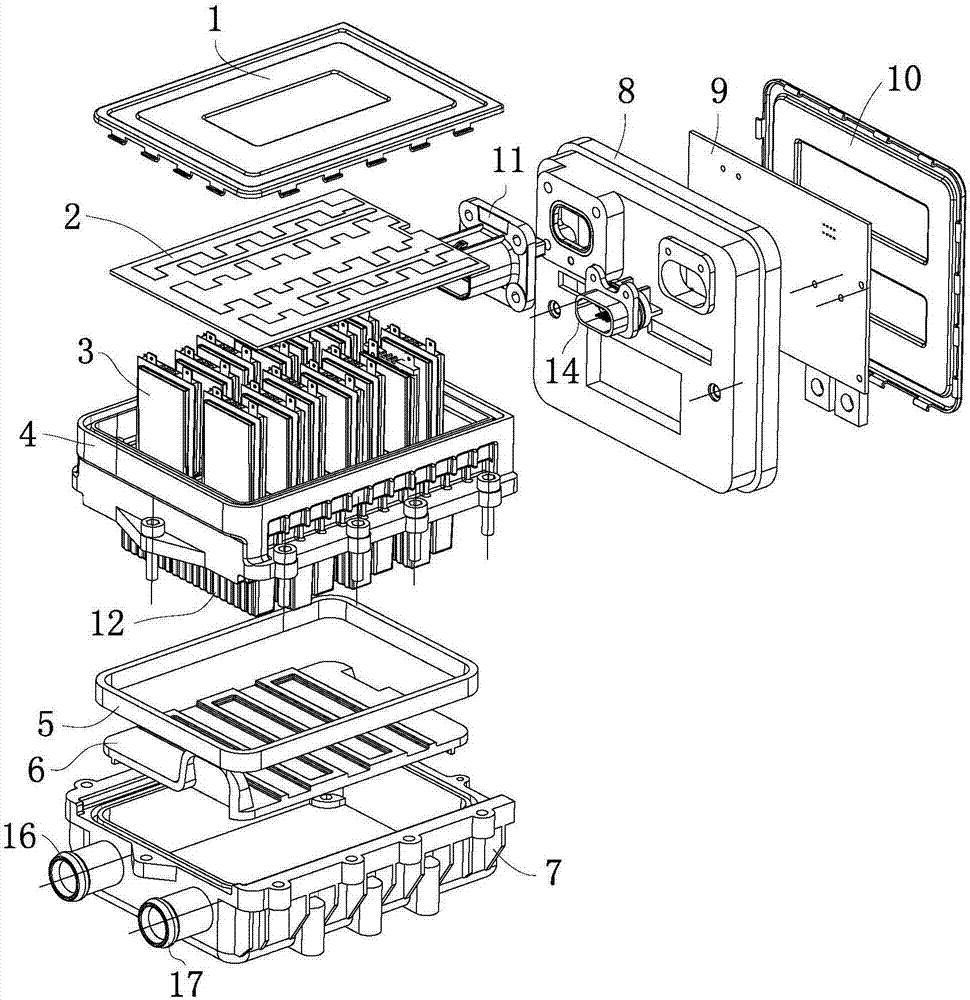

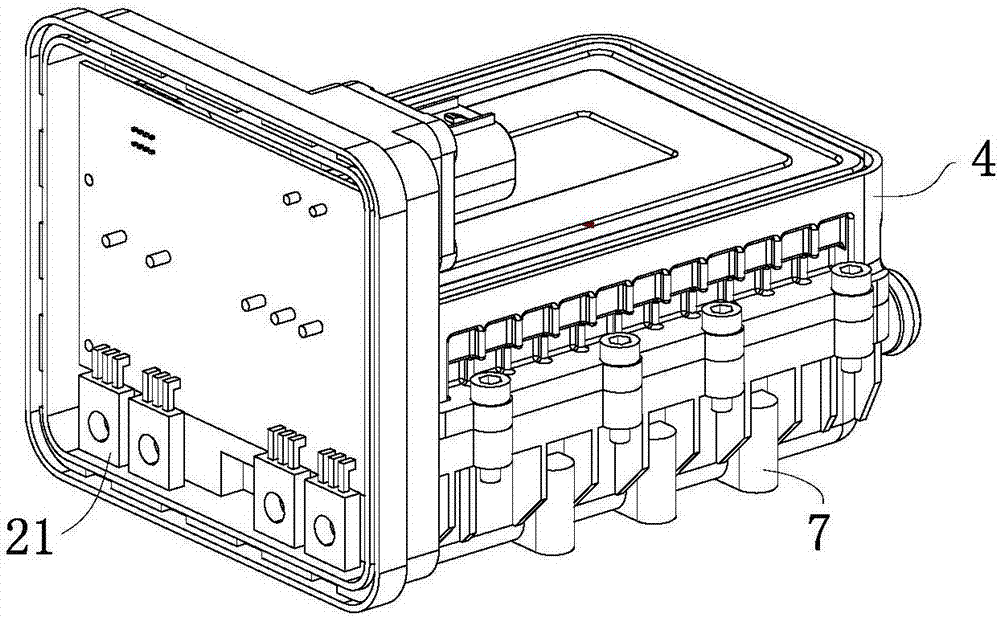

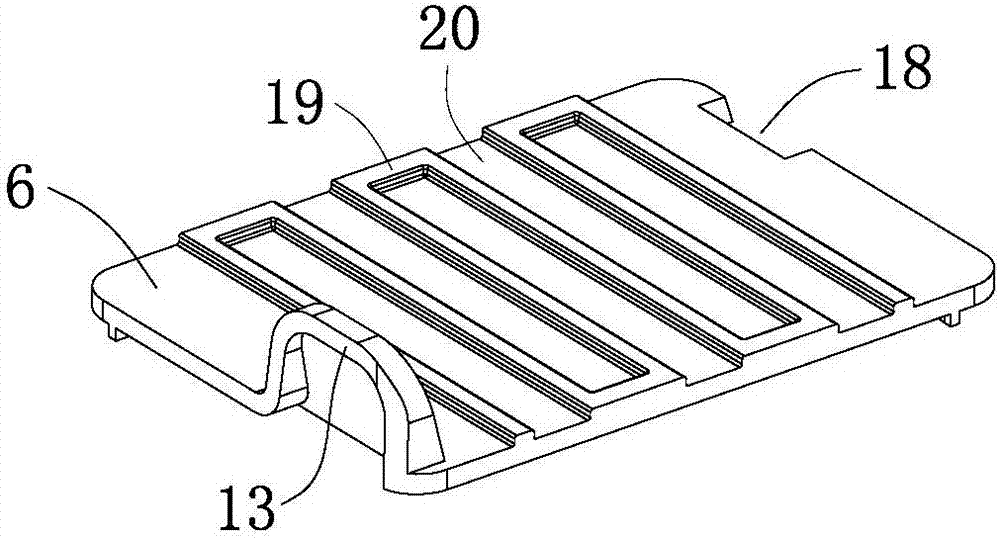

[0023] Such as figure 1 , figure 2 with Figure 4 As shown, the present invention is provided with heating aluminum seat 4 and water tank 7, and heating aluminum seat 4 and water tank 7 are fastened and fastened by screw, forms heating cavity, and the top of heating aluminum seat 4 is provided with cover plate 1; Heating aluminum seat 4 and The inner circumference of the junction of the water tank 7 is provided with a sealing ring 5, and the sealing ring 5 is used to prevent the water in the heating cavity from flowing out. Water tank 7 is plastics.

[0024] The heating aluminum base 4 is provided with a plurality of PTC heating component grooves, and each PTC heating component groove is provided with a PTC heating component 3 , and all the PTC heating components 3 are connected to a circuit board 2 . Fins 12 are provided on the outer wall ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com