Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

123results about How to "Reduce combustion efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Catalyst for clarifying exhaust emission from internal combustion engine, method for preparation thereof and method for clarifying exhaust emission from internal combustion engine

ActiveUS20050095188A1Improve the overall coefficientReduce combustion efficiencyCombination devicesNitrogen compoundsParticulatesExternal combustion engine

A catalyst which efficiently removes particulate matter, SOF, sulfate, and SOOT and the like from the exhaust gas from such an internal combustion engine as a diesel engine without inducing a rise in the back pressure of the engine is provided. The catalyst for the purification of the exhaust gas of an internal combustion engine is formed by using an open flow honeycomb containing in the channel walls thereof such pores as possess an average diameter in the range of 10-40 μm.

Owner:UMICORE SHOKUBAI JAPAN CO LTD +1

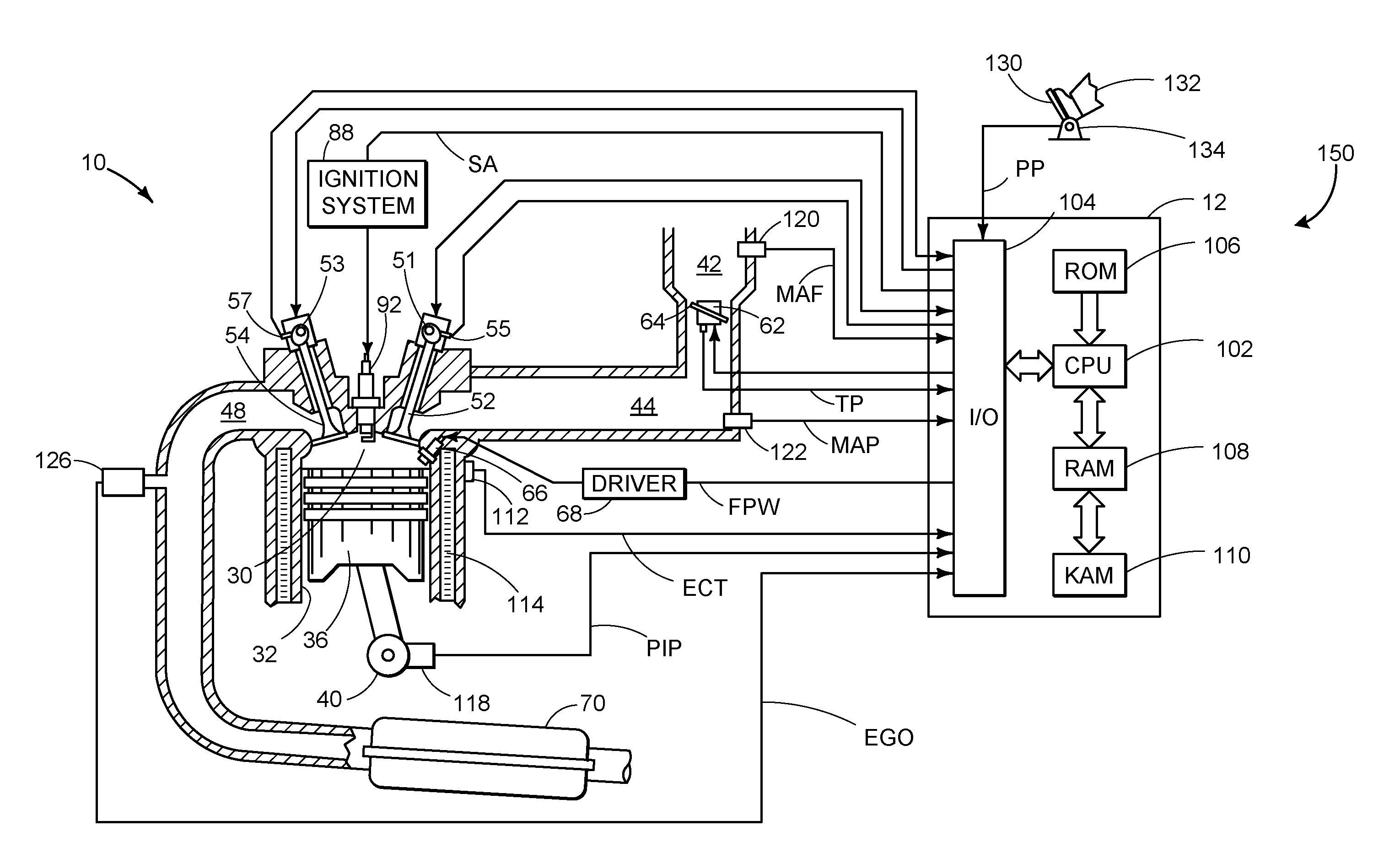

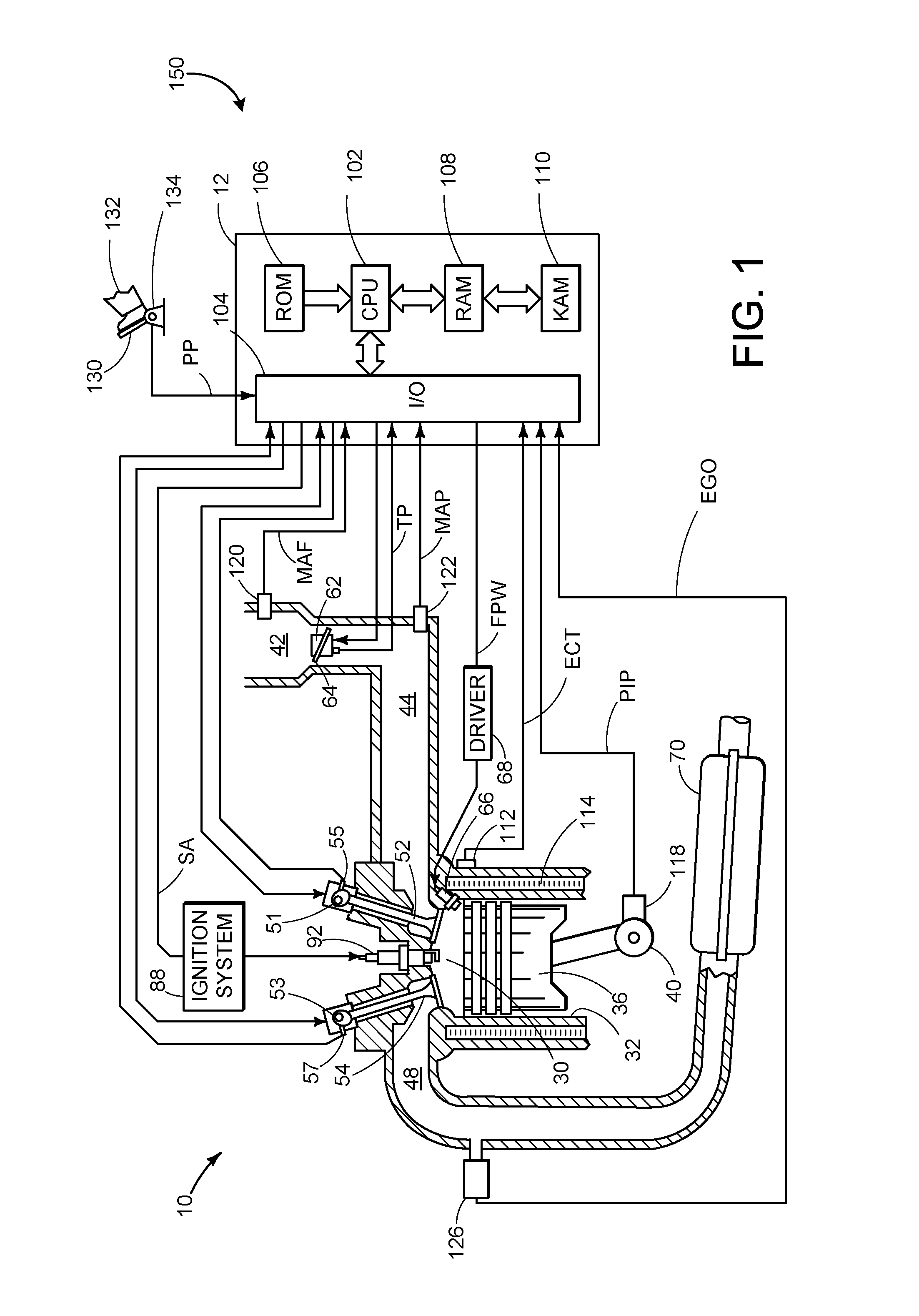

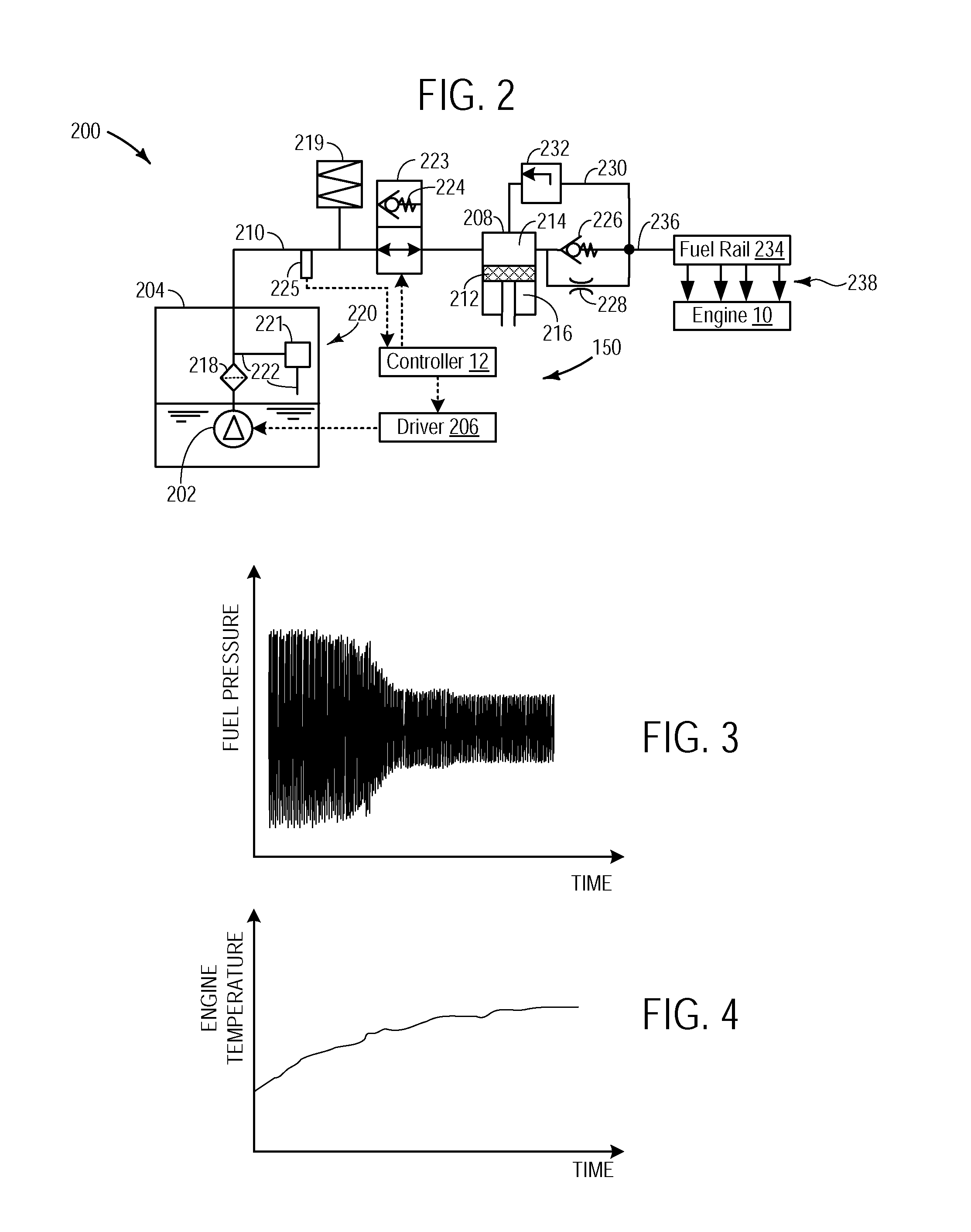

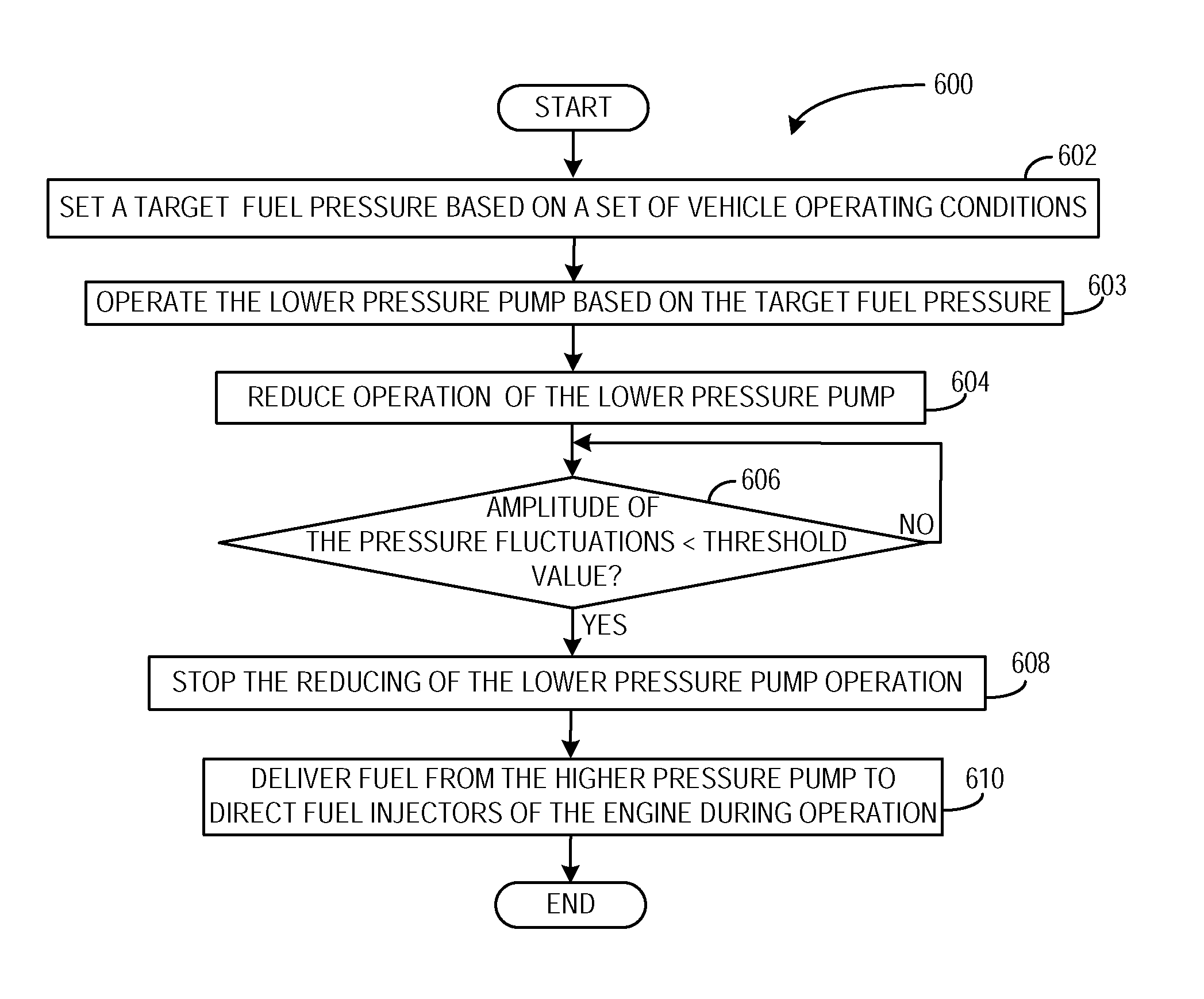

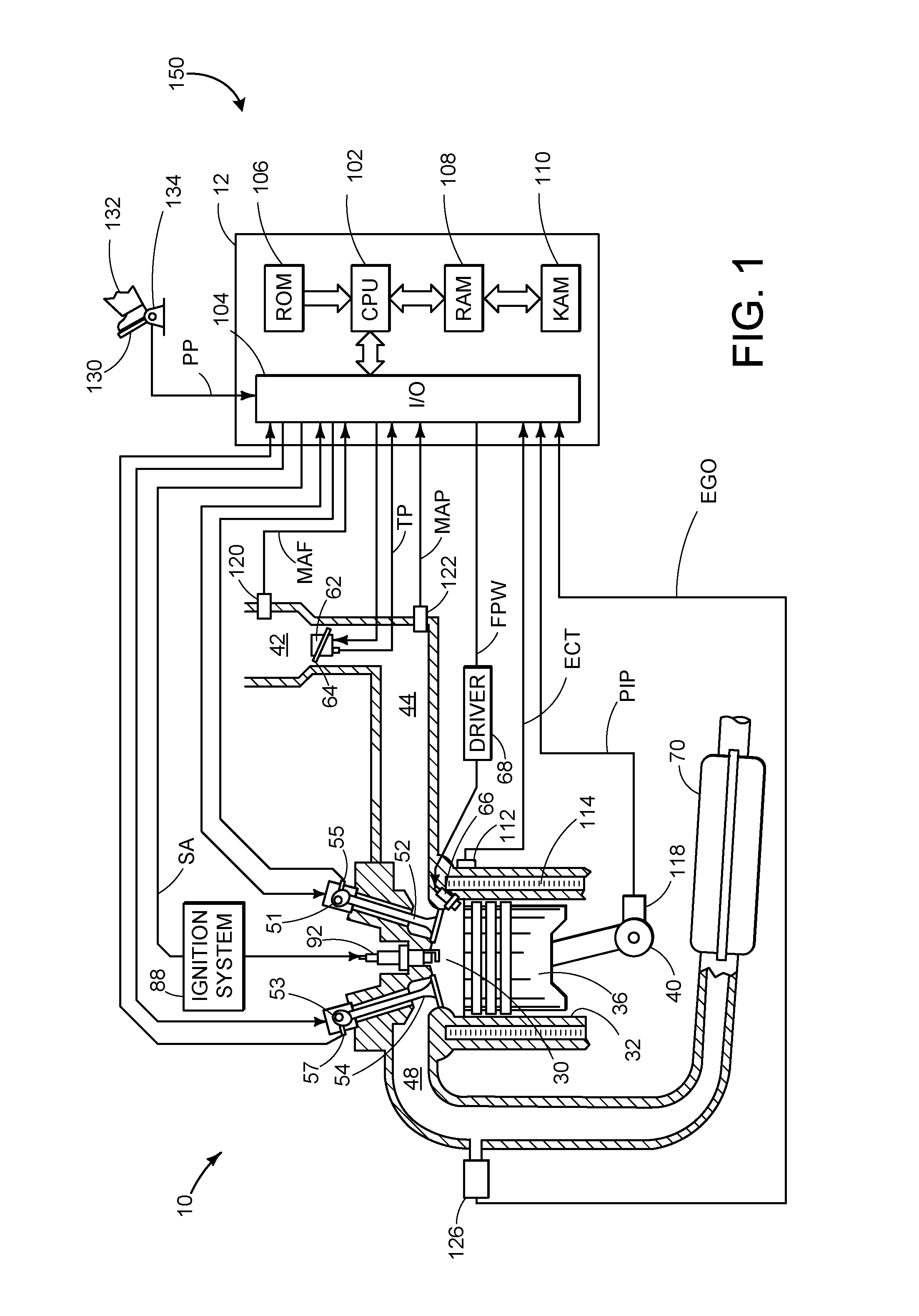

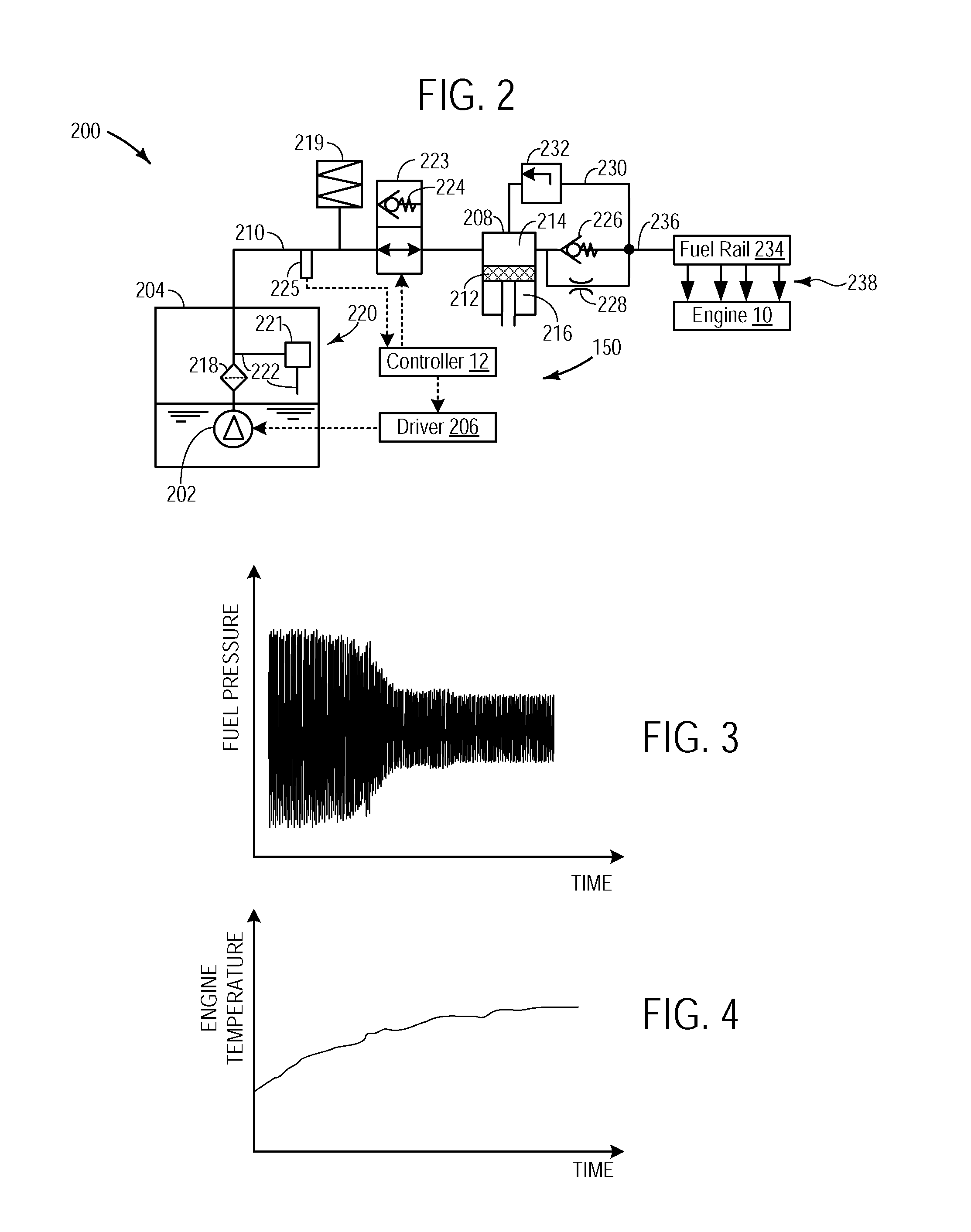

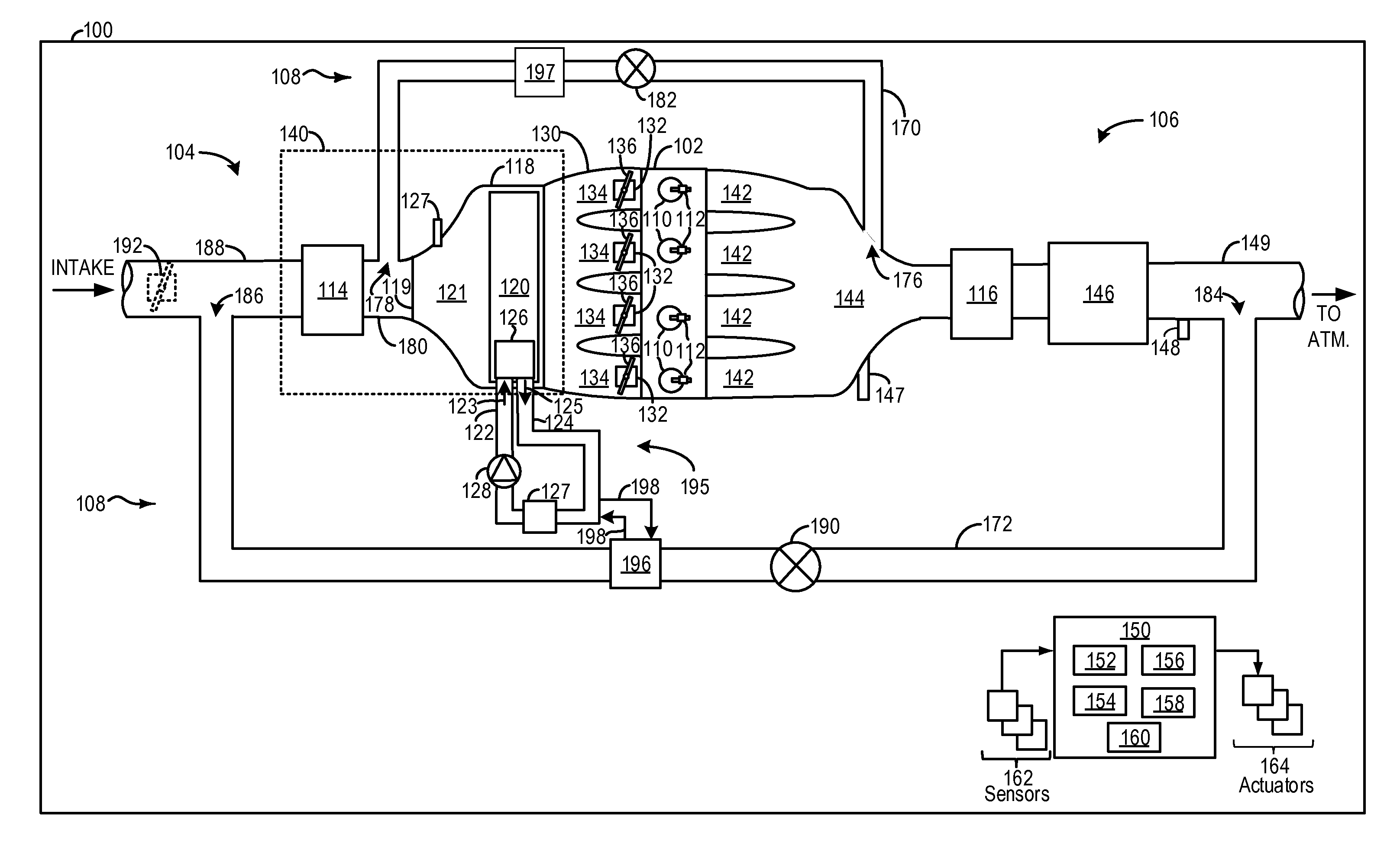

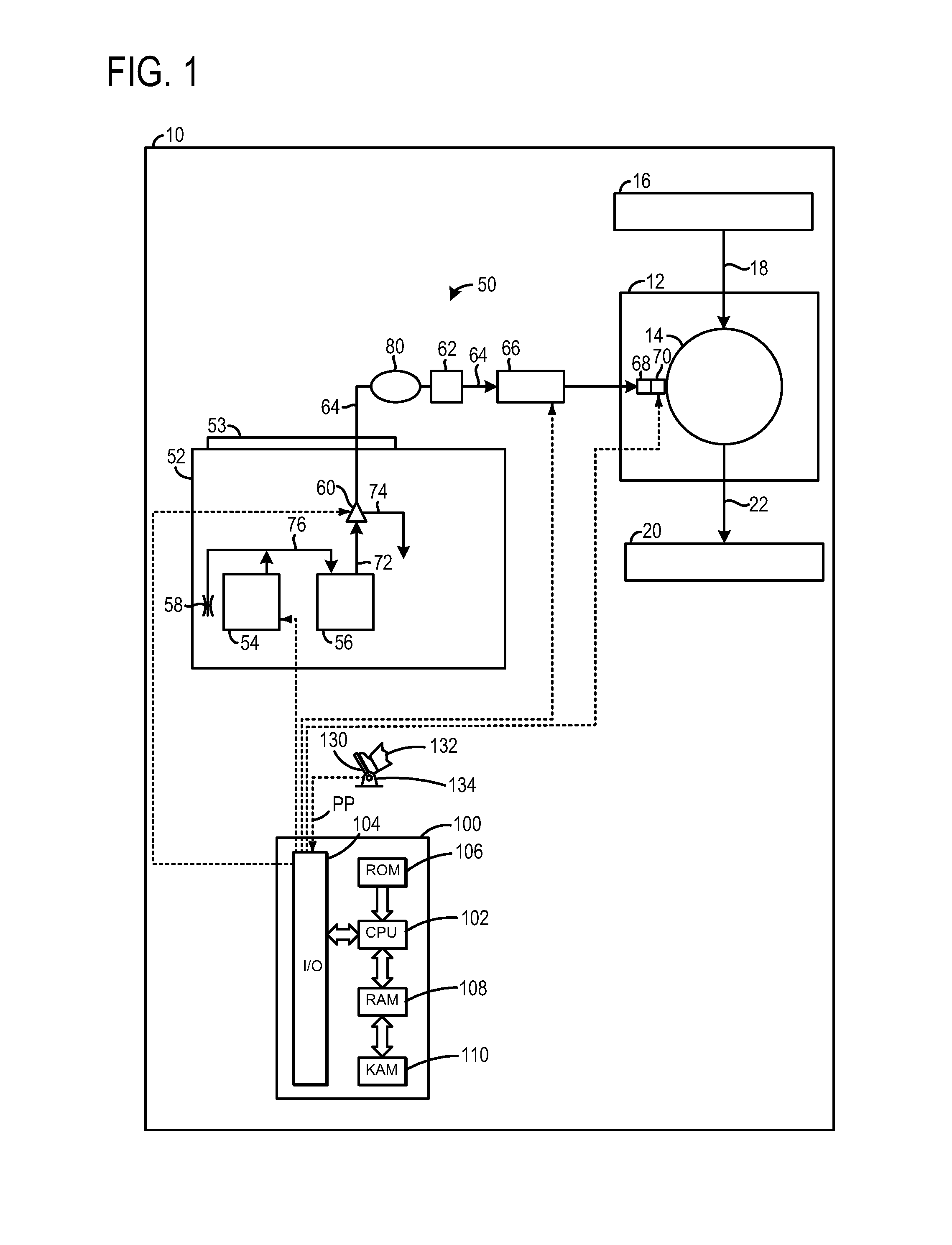

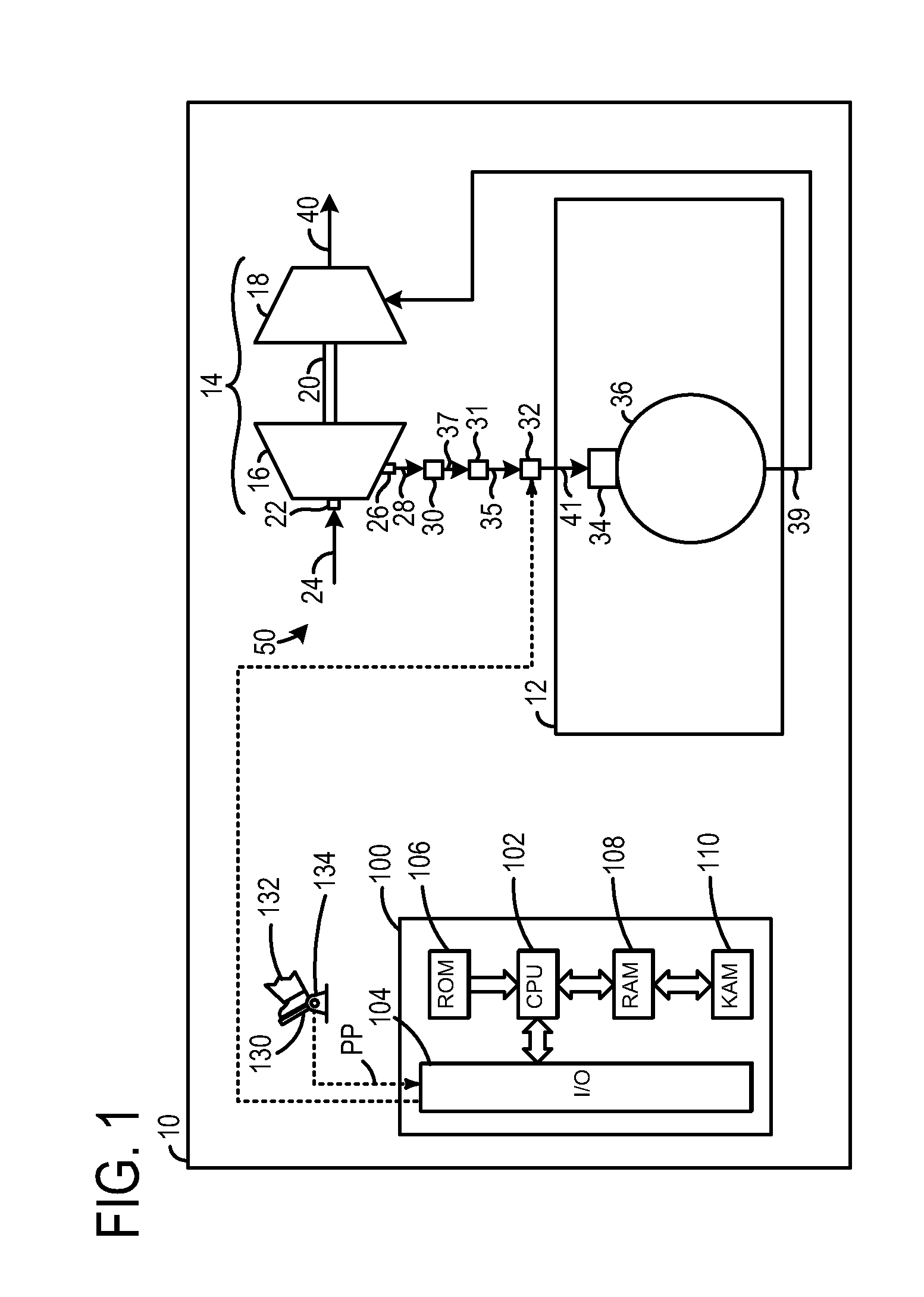

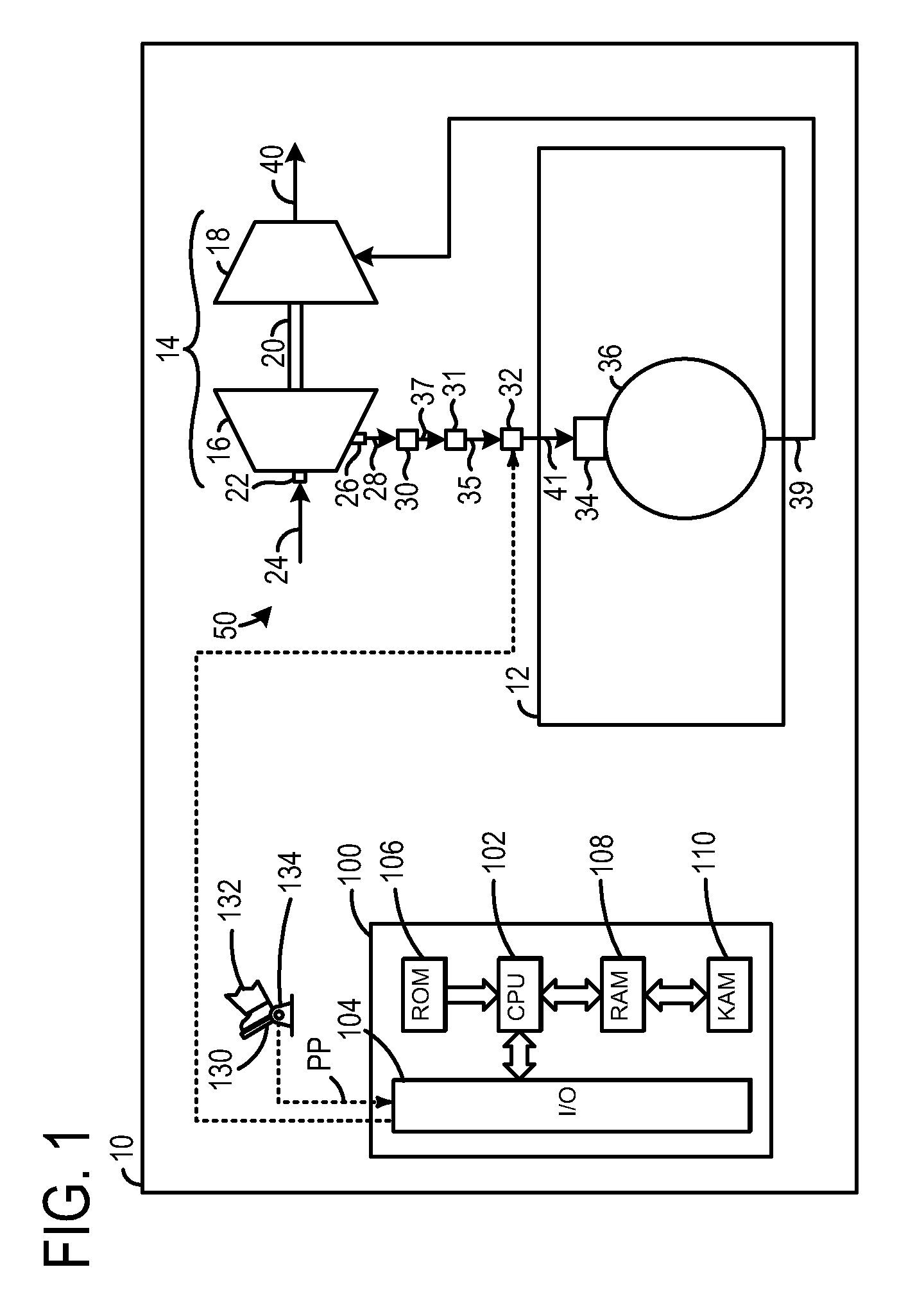

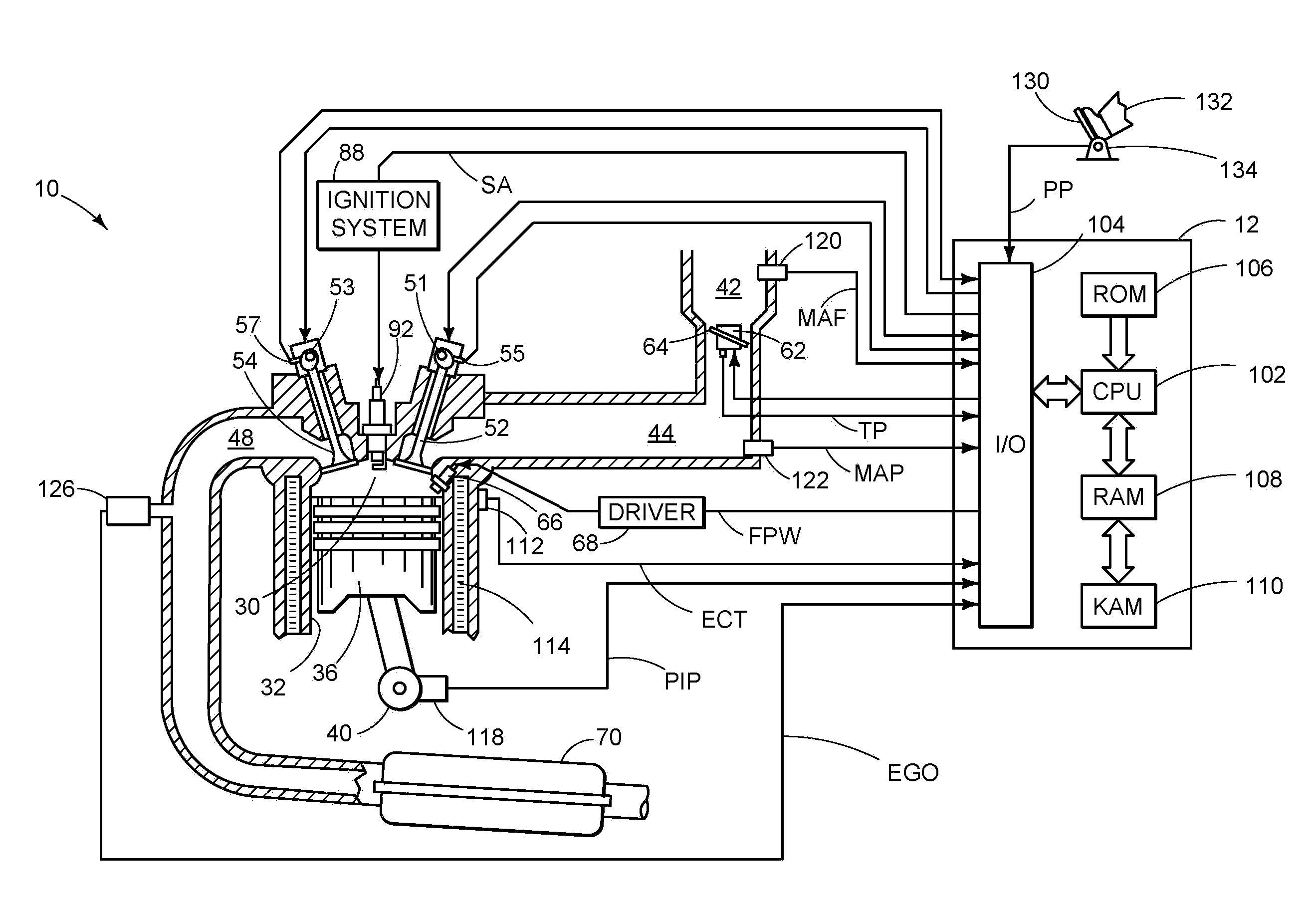

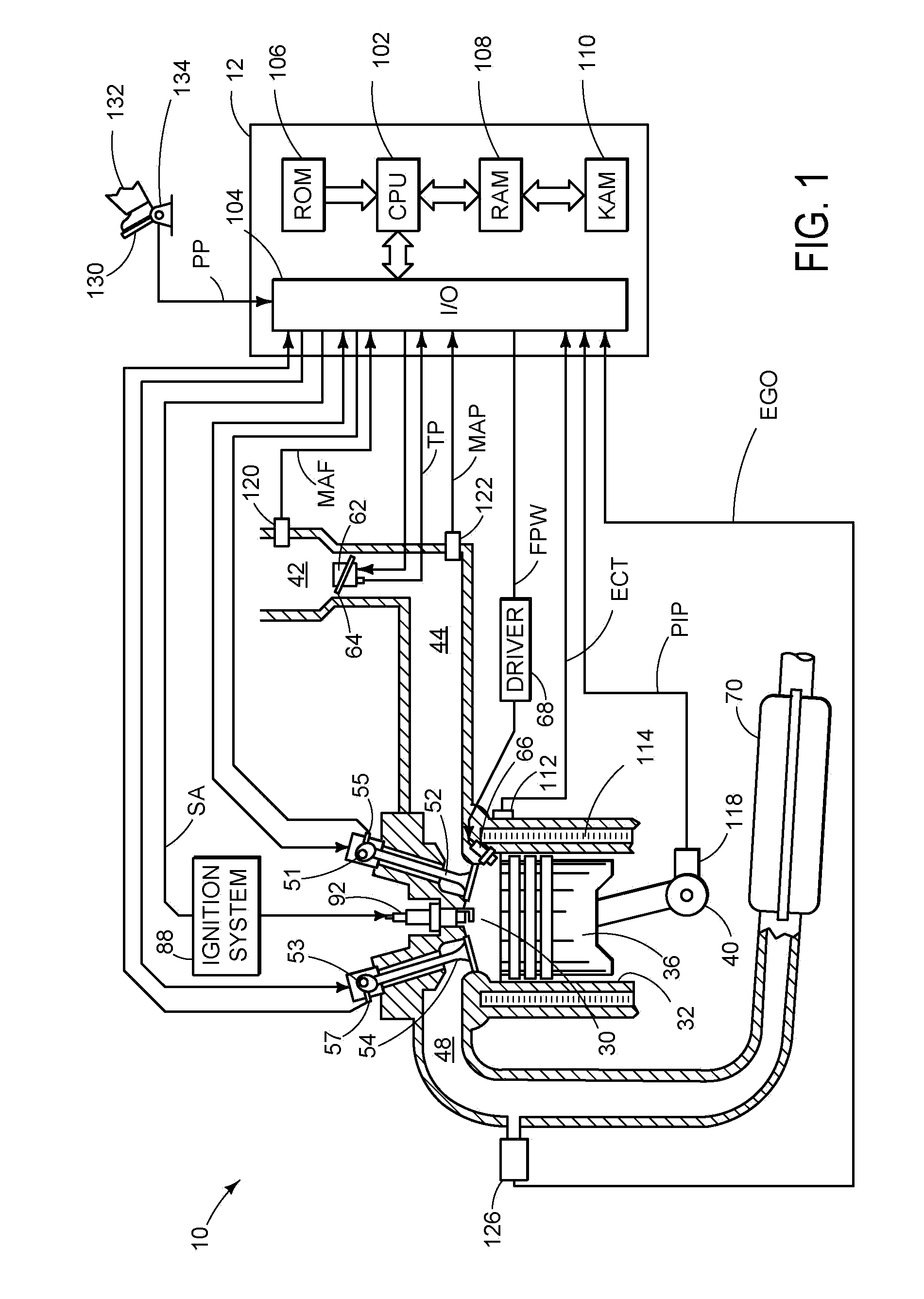

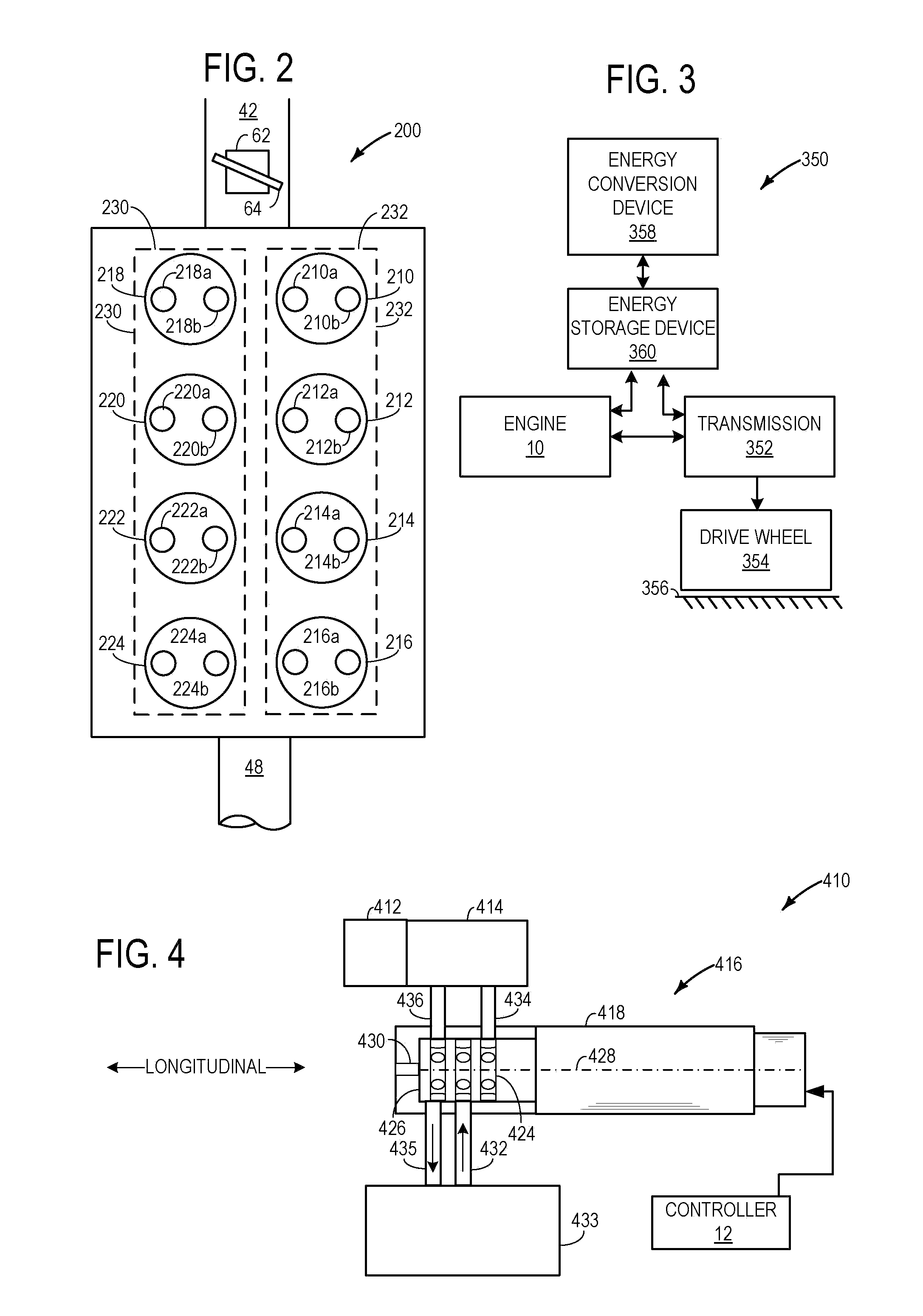

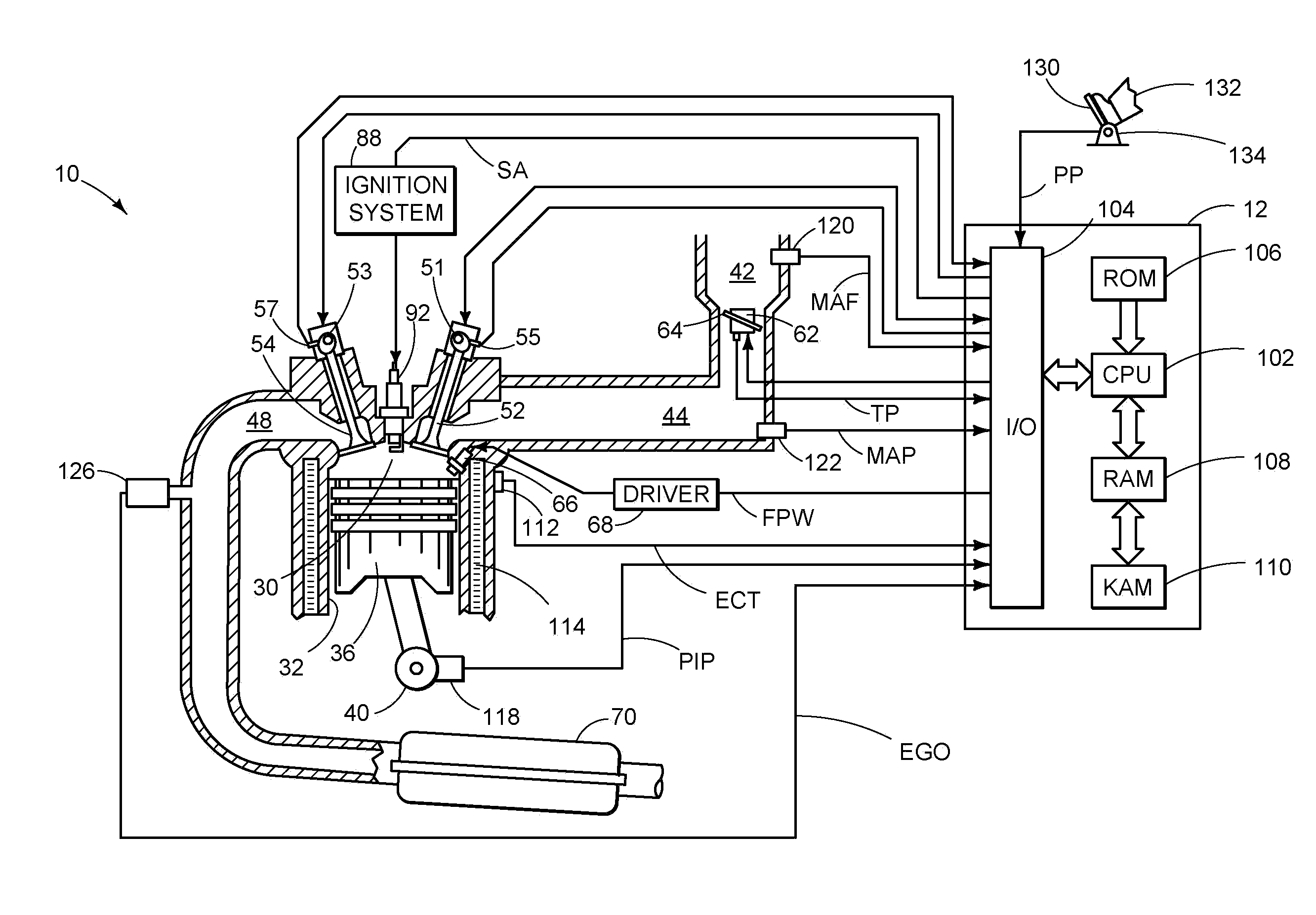

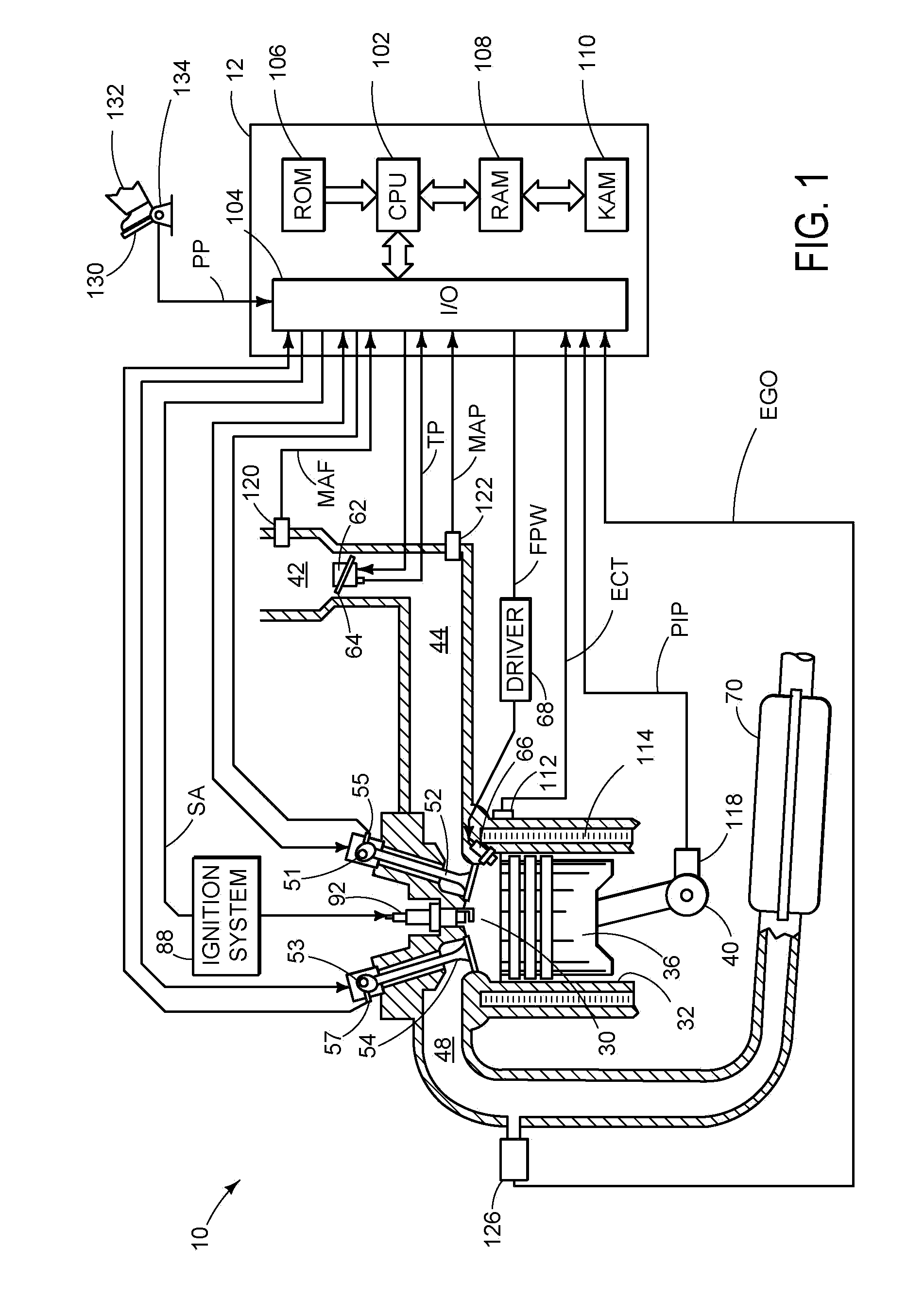

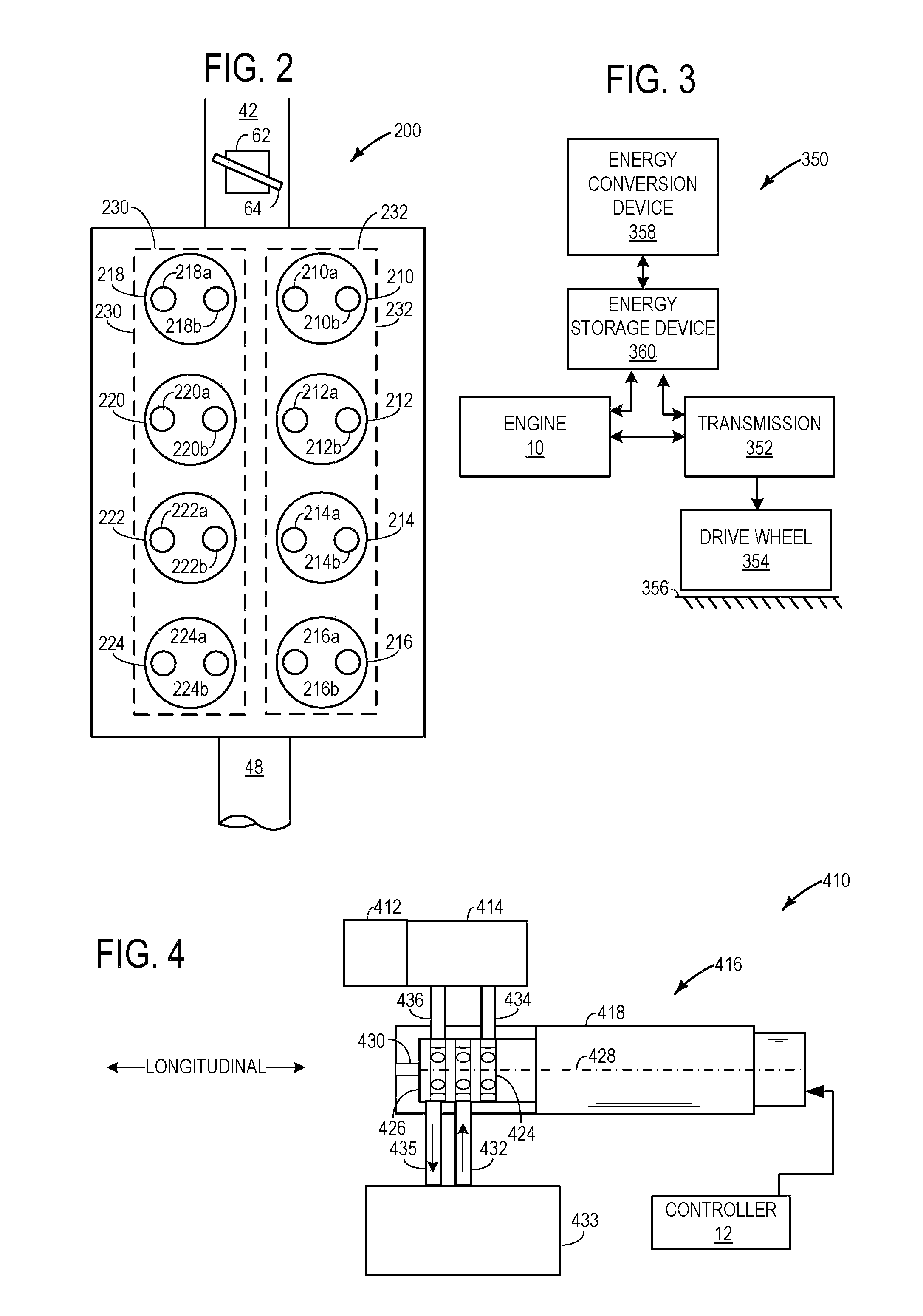

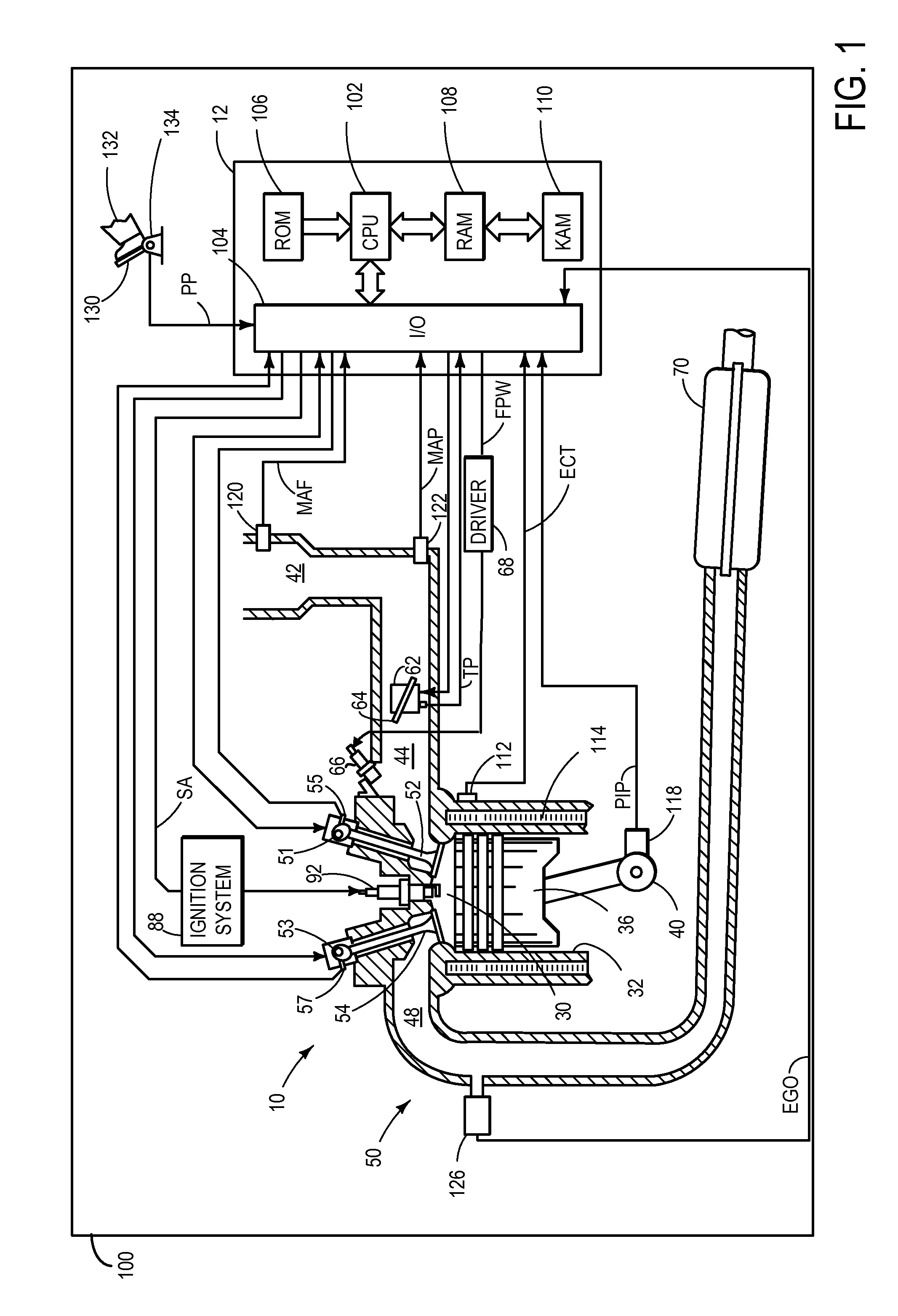

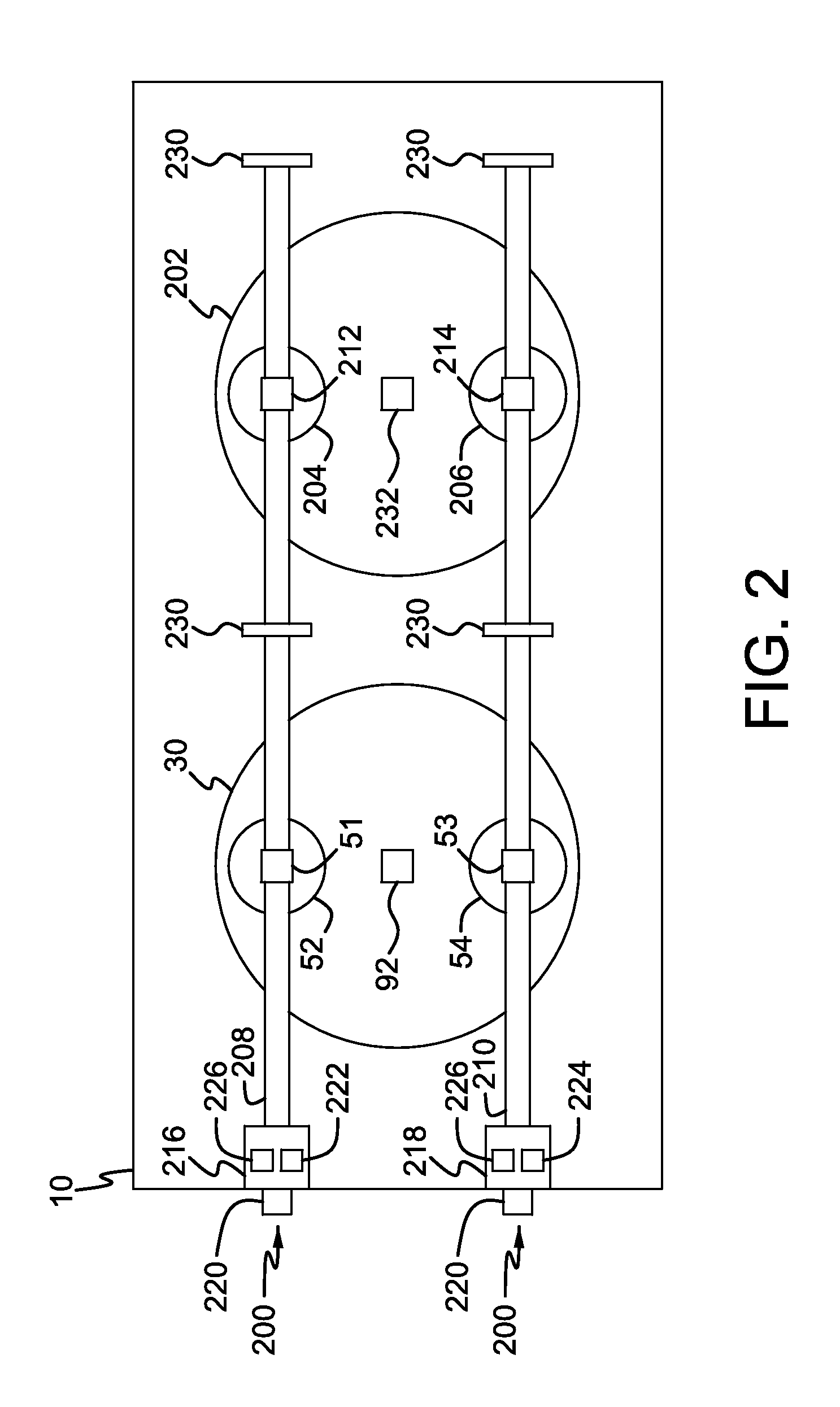

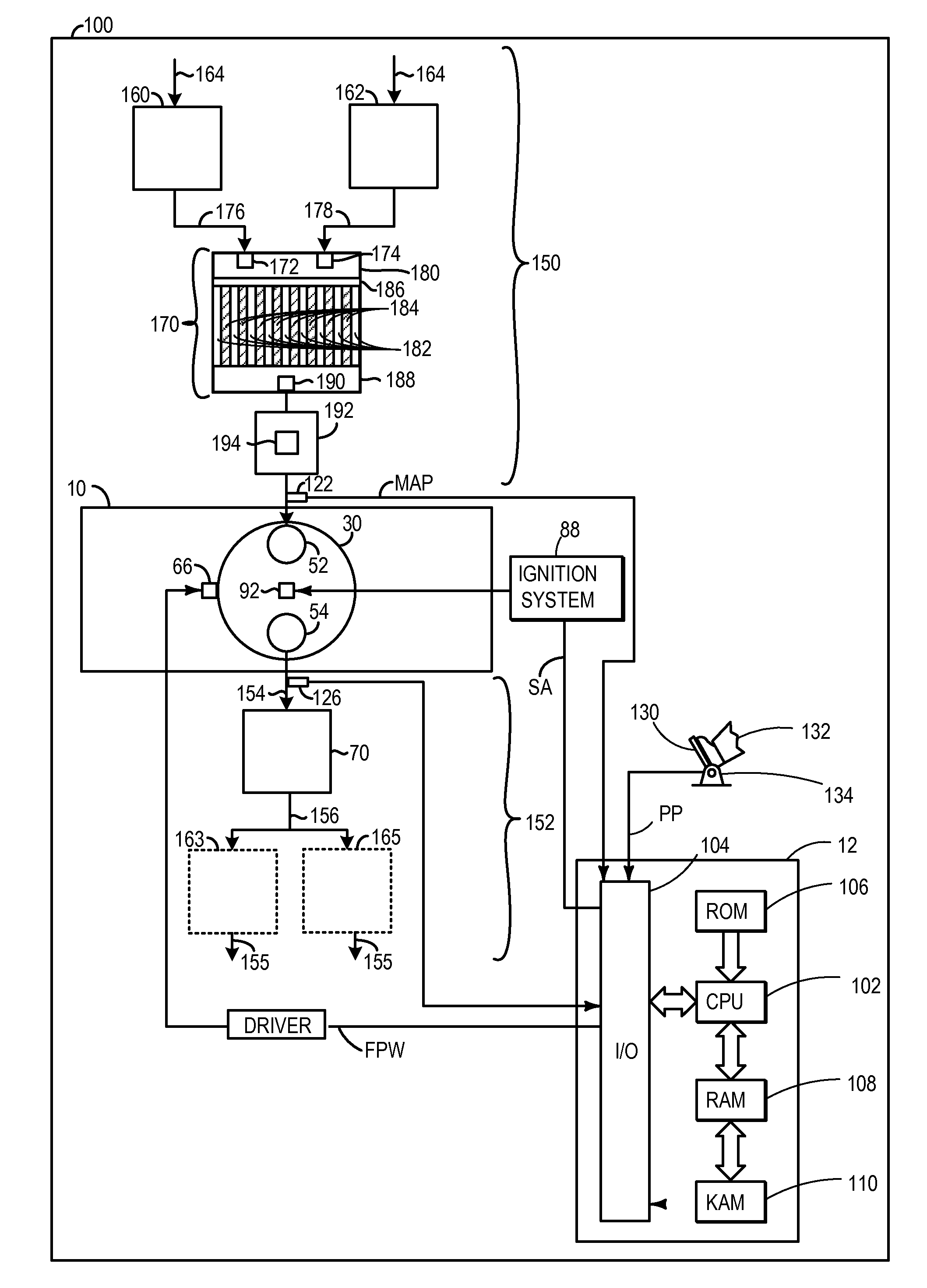

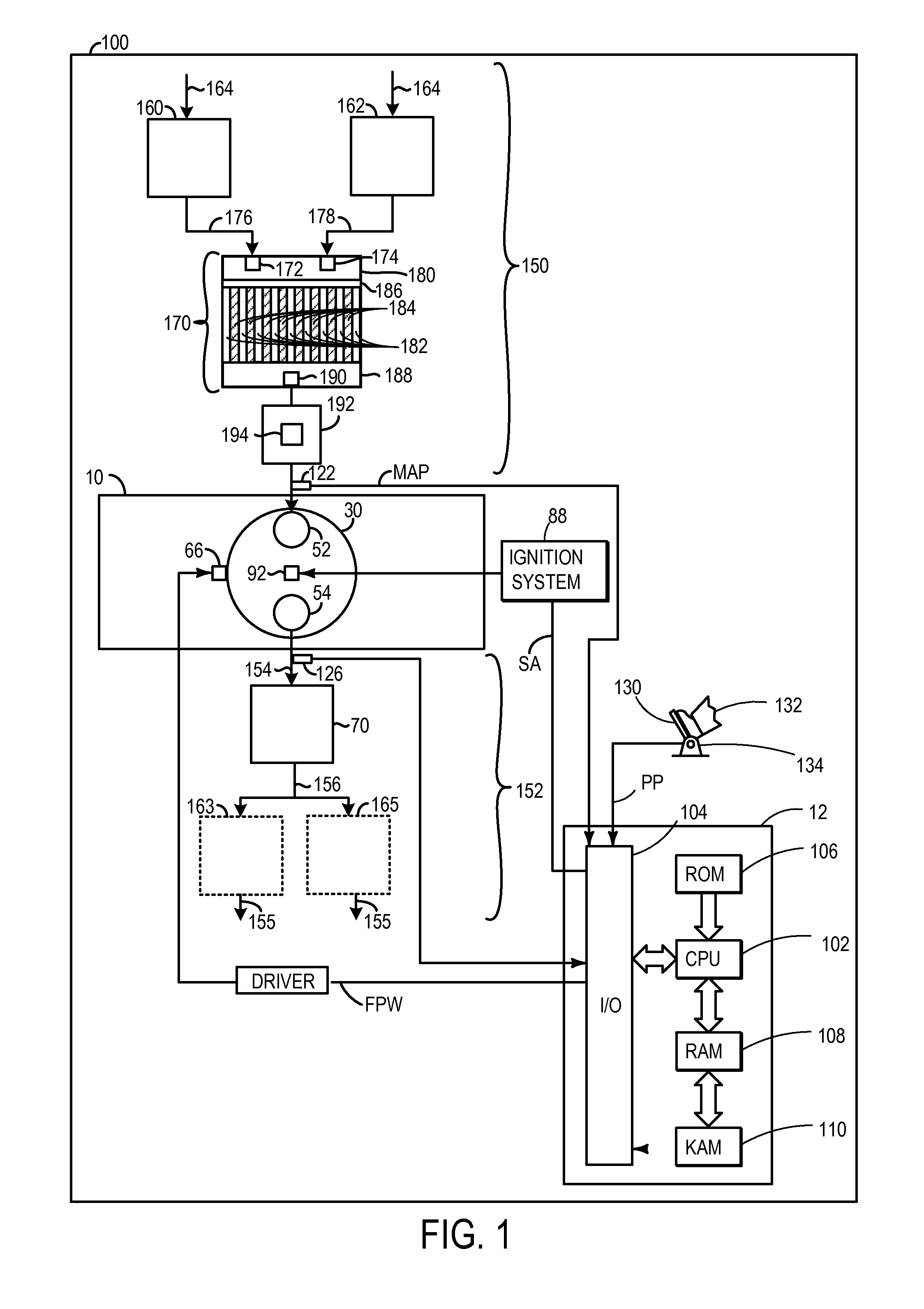

Fuel delivery system control strategy

ActiveUS20110106393A1Improve combustion efficiencyEmission reductionAnalogue computers for vehiclesElectrical controlEngineeringHigh pressure

A method for a fuel delivery system coupled to an engine is disclosed, the fuel delivery system including a lower pressure pump (LPP) fluidly coupled upstream of a higher pressure pump (HPP). The method may include during operation of both the HPP and LPP, adjusting operation of the LPP in response to pressure fluctuations at an inlet of the HPP.

Owner:FORD GLOBAL TECH LLC

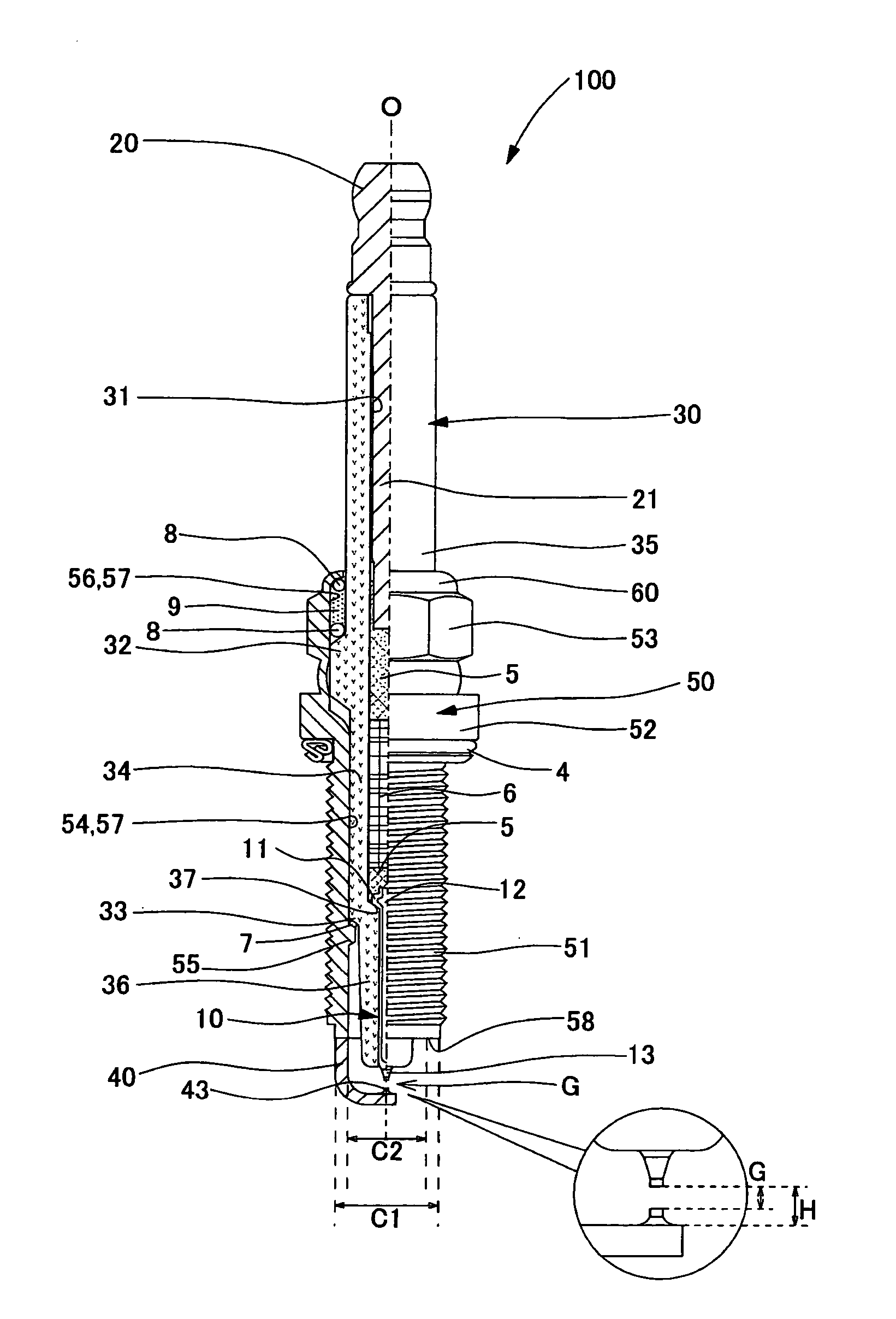

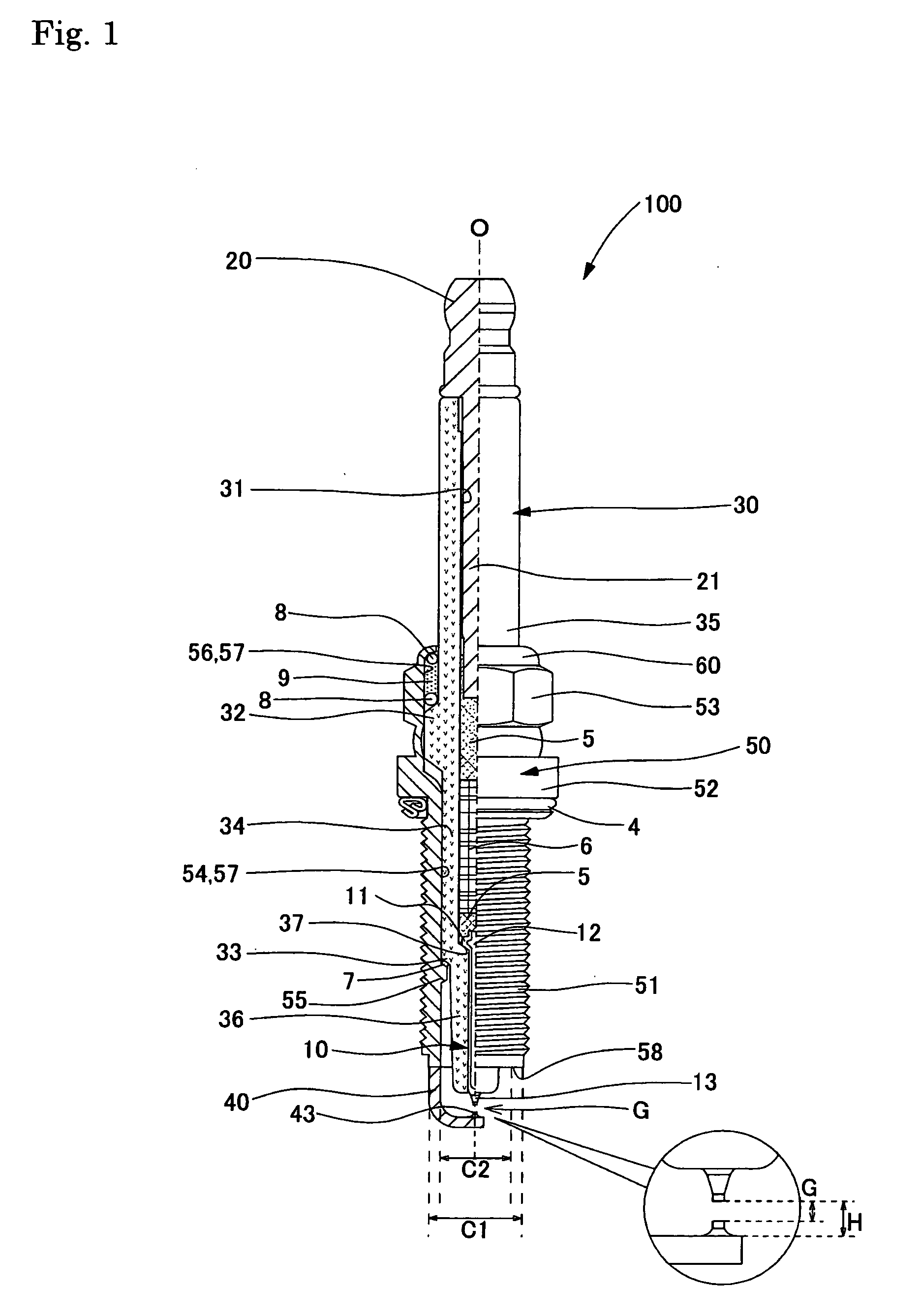

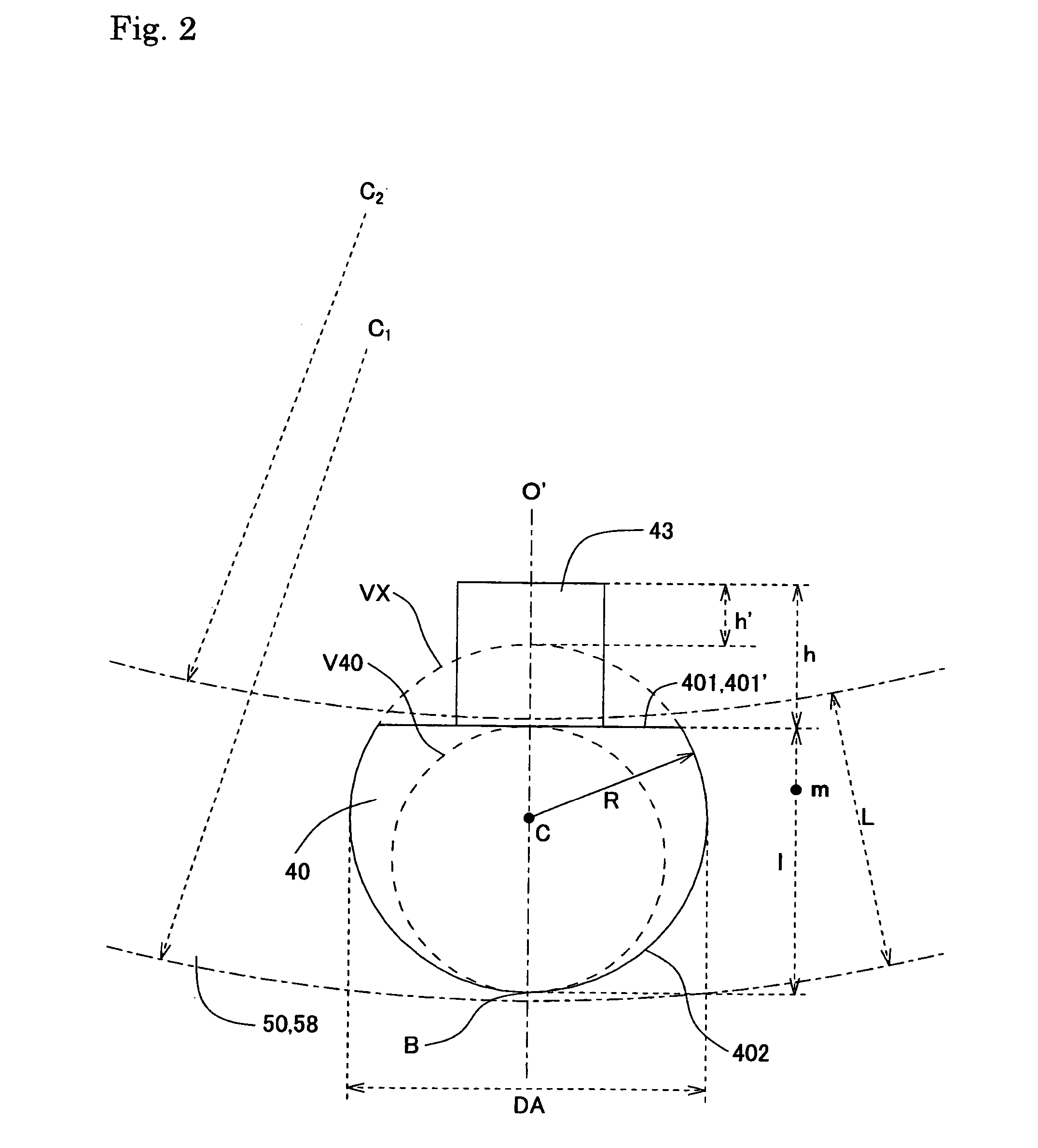

Spark plug and method for producing spark plug

ActiveUS20070080618A1Improve cooling effectReduce combustion efficiencyFuel injection apparatusMachines/enginesBiomedical engineeringSpark plug

A spark plug comprising: a center electrode extending in a direction of an axis of said spark plug; a cylindrical insulator which has a shaft hole, and which holds said center electrode in said shaft hole in a state where a tip end of said center electrode is projected from a tip end face of said insulator; a metal shell which holds said insulator; and a ground electrode in which one end is joined to a tip end face of said metal shell, and which extends from said one end toward another end, wherein said ground electrode has an inner side face which faces said center electrode, and an outer side face which is a back face with respect to said inner side face, said outer side face is formed as an arcuately curved face when viewed from a side of said another end in an extending direction of said ground electrode, and a columnar noble metal tip is joined to said inner side face.

Owner:NGK SPARK PLUG CO LTD

Fuel delivery system control strategy

ActiveUS8483932B2Improve combustion efficiencyEmission reductionAnalogue computers for vehiclesElectrical controlEngineeringHigh pressure

A method for a fuel delivery system coupled to an engine is disclosed, the fuel delivery system including a lower pressure pump (LPP) fluidly coupled upstream of a higher pressure pump (HPP). The method may include during operation of both the HPP and LPP, adjusting operation of the LPP in response to pressure fluctuations at an inlet of the HPP.

Owner:FORD GLOBAL TECH LLC

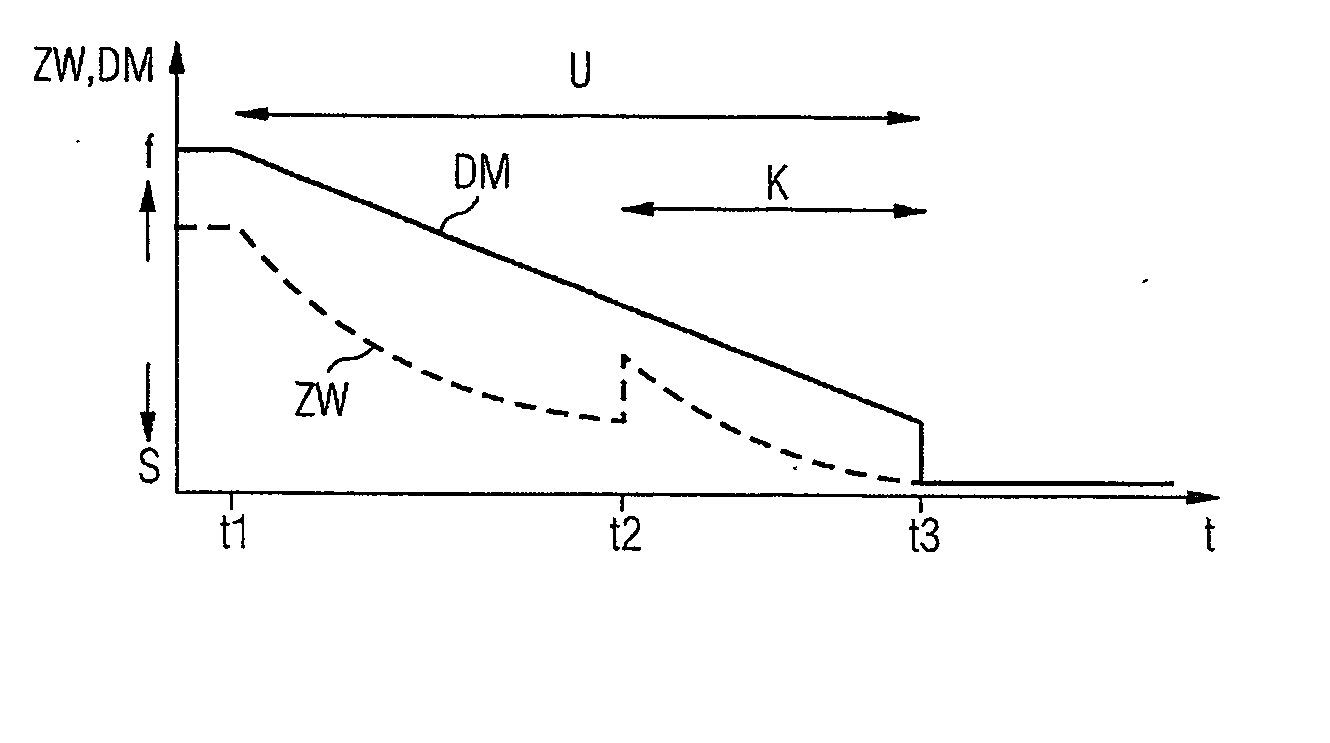

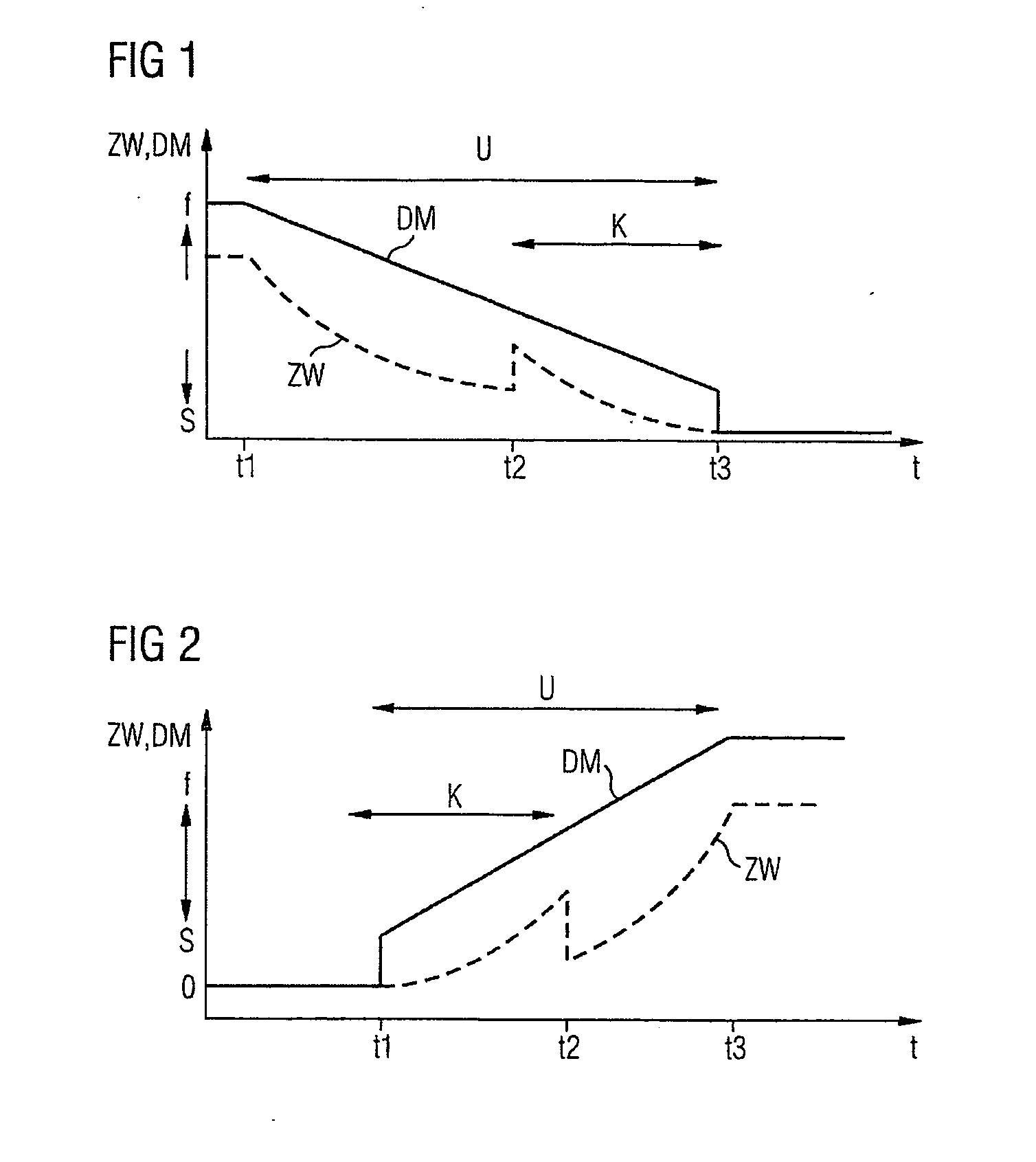

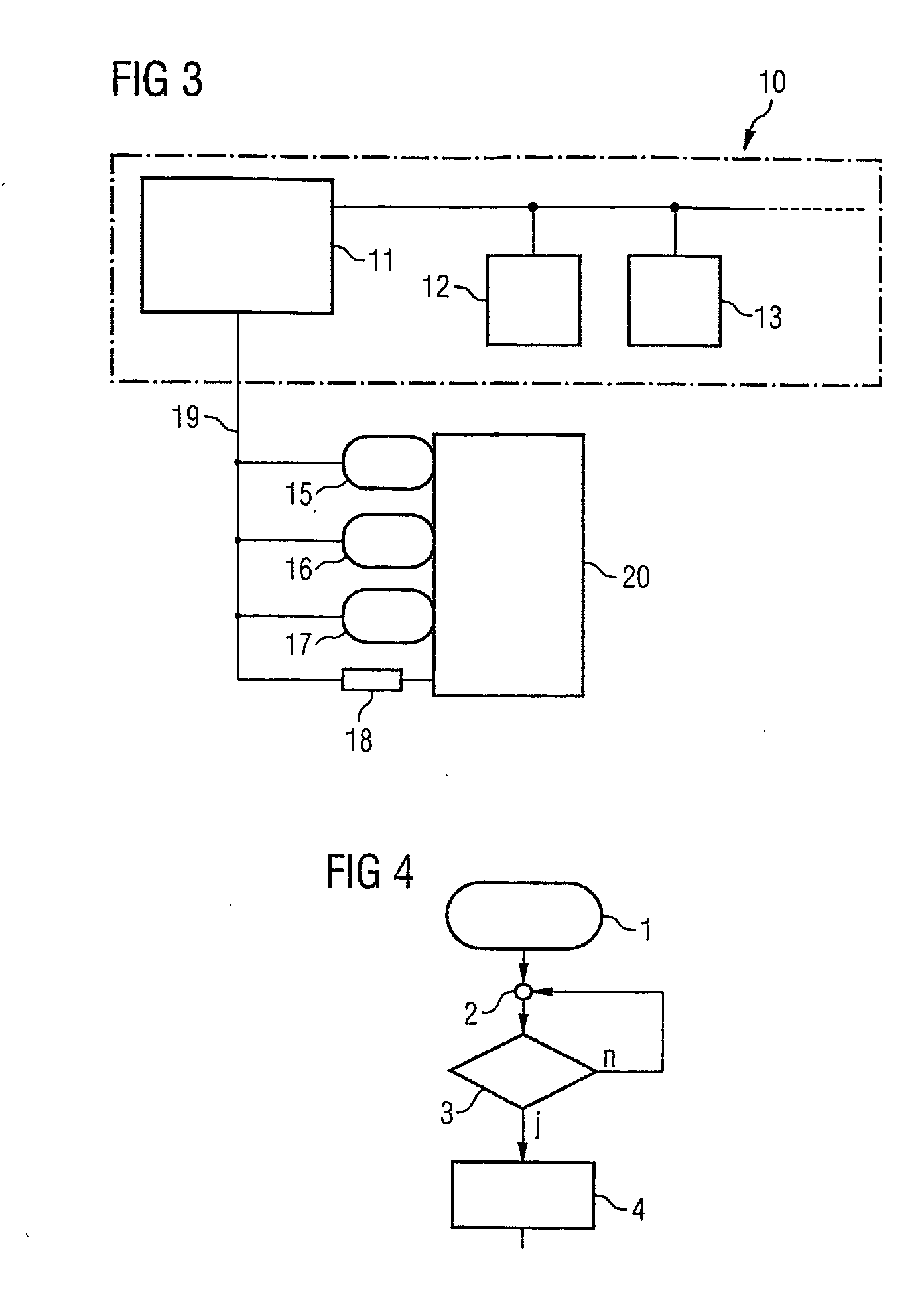

Method and device for controlling the transition between normal operation and overrun fuel cut-off operation of an otto engine operated with direct fuel injection

ActiveUS20060231068A1Delay in buildupTorque reduction is essentially greaterElectrical controlInternal combustion piston enginesMultiple injectionEngineering

The problem during overrun fuel cut-off operations, i.e. cut-off of fuel injection during trailing throttle conditions of the vehicle, is that the transition entails an undue torque jump, resulting in the smooth operation of the engine and the driving comfort of the passengers of the vehicle being affected. The aim of the invention is to reduce the torque jump. Said aim is achieved by injecting fuel into a cylinder of the Otto engine in a multiple injection process, at least a partial quantity of the fuel that is to be injected being injected during the compression phase, whereby the quantity of air that is taken in advantageously decreases because no internal cooling takes place while the efficiency is advantageously reduced due to the lesser degree of swirling, resulting in lower torque. Overall, torque (DM) is reduced to a significantly greater extent than by merely adjusting the spark angle (ZW) while smooth operation of the Otto engine is not affected.

Owner:VITESCO TECH GERMANY GMBH

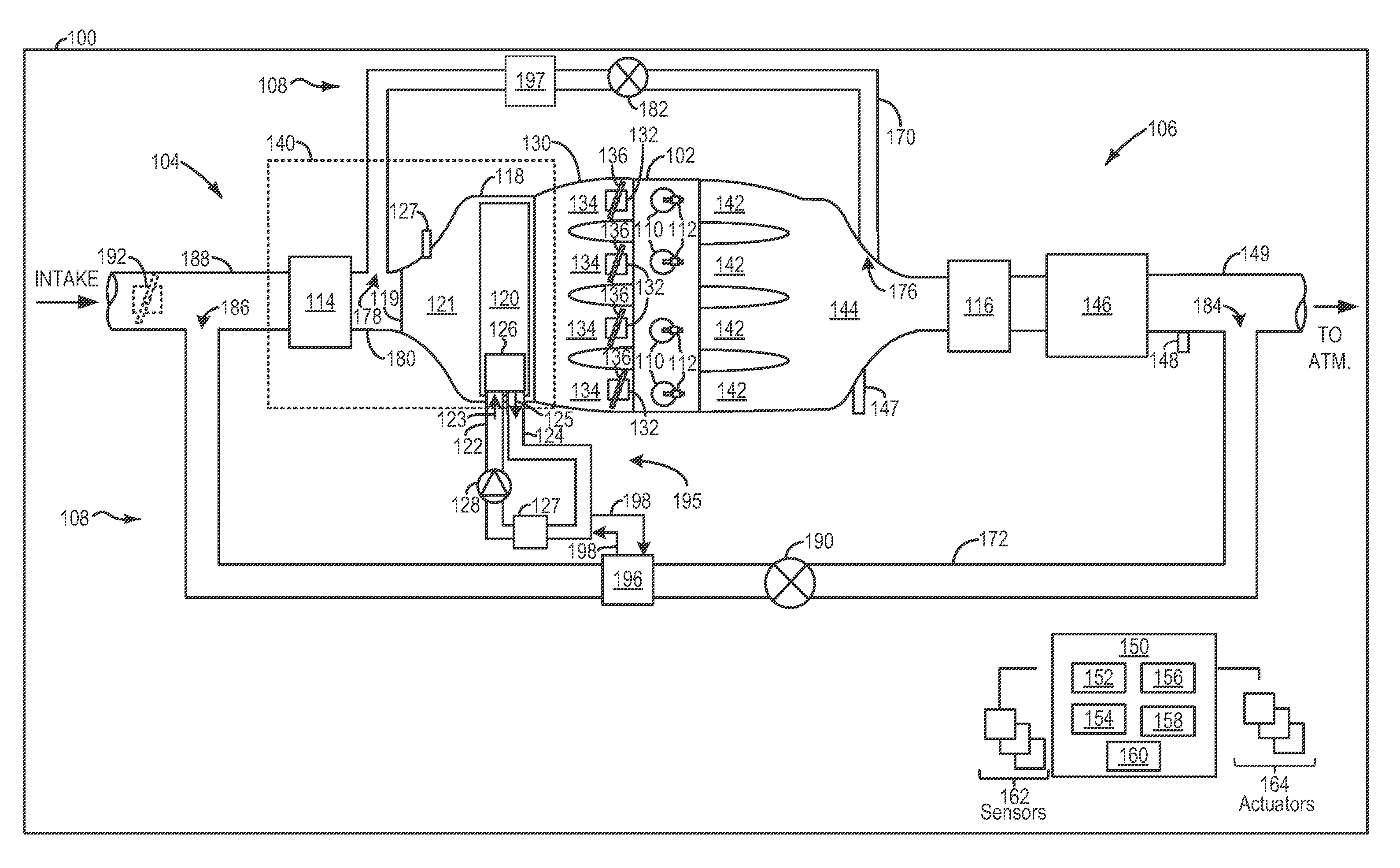

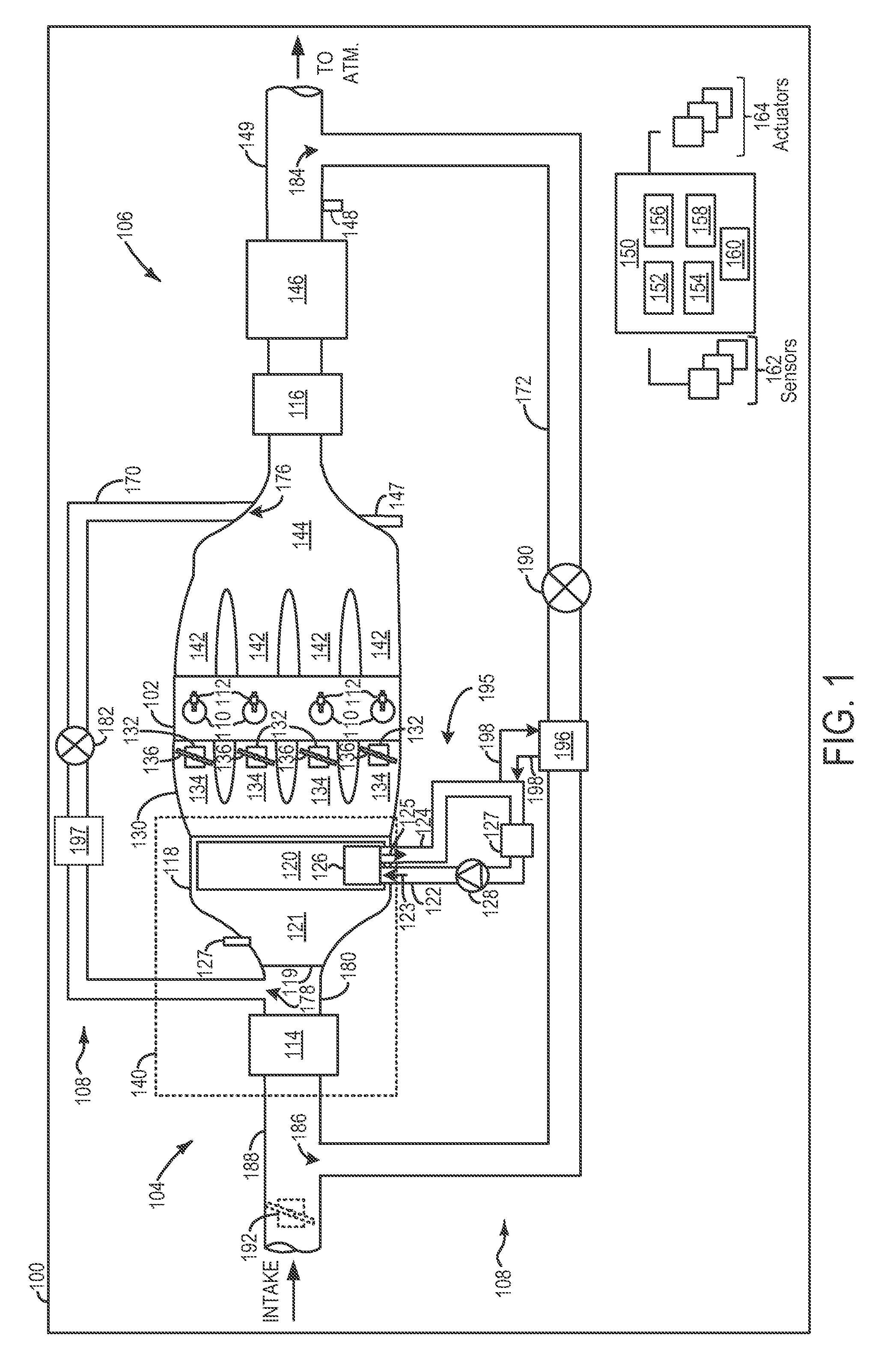

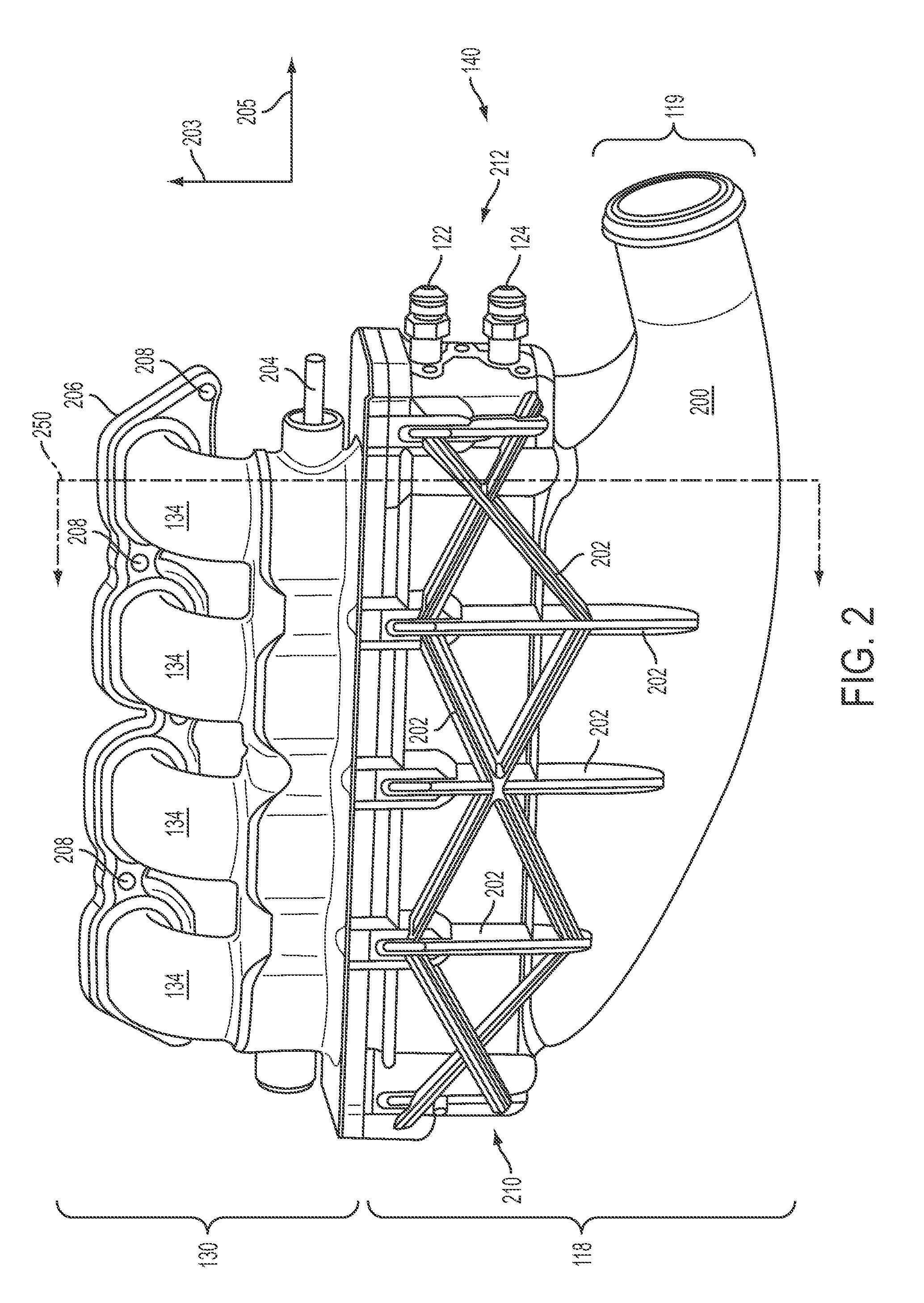

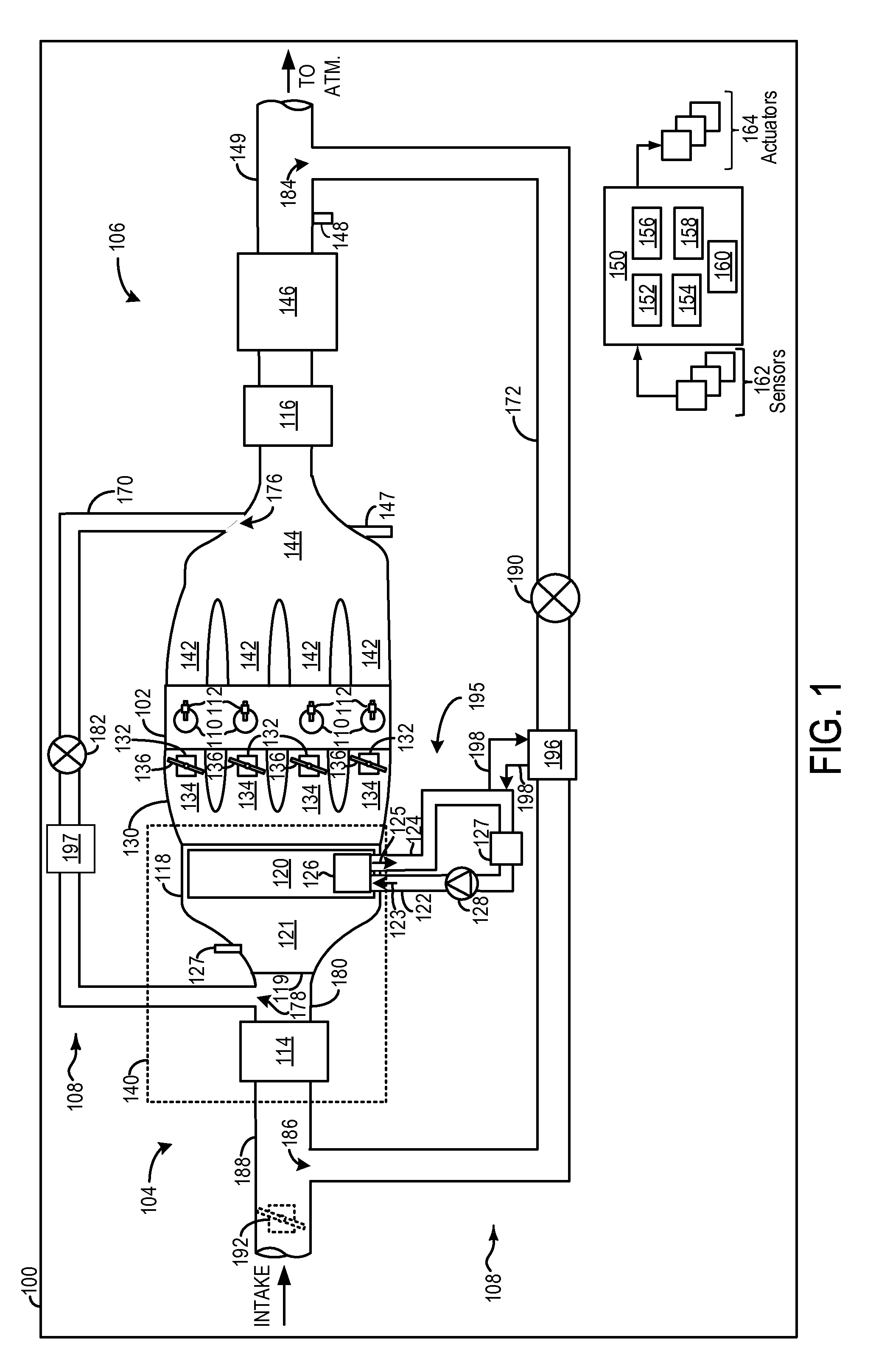

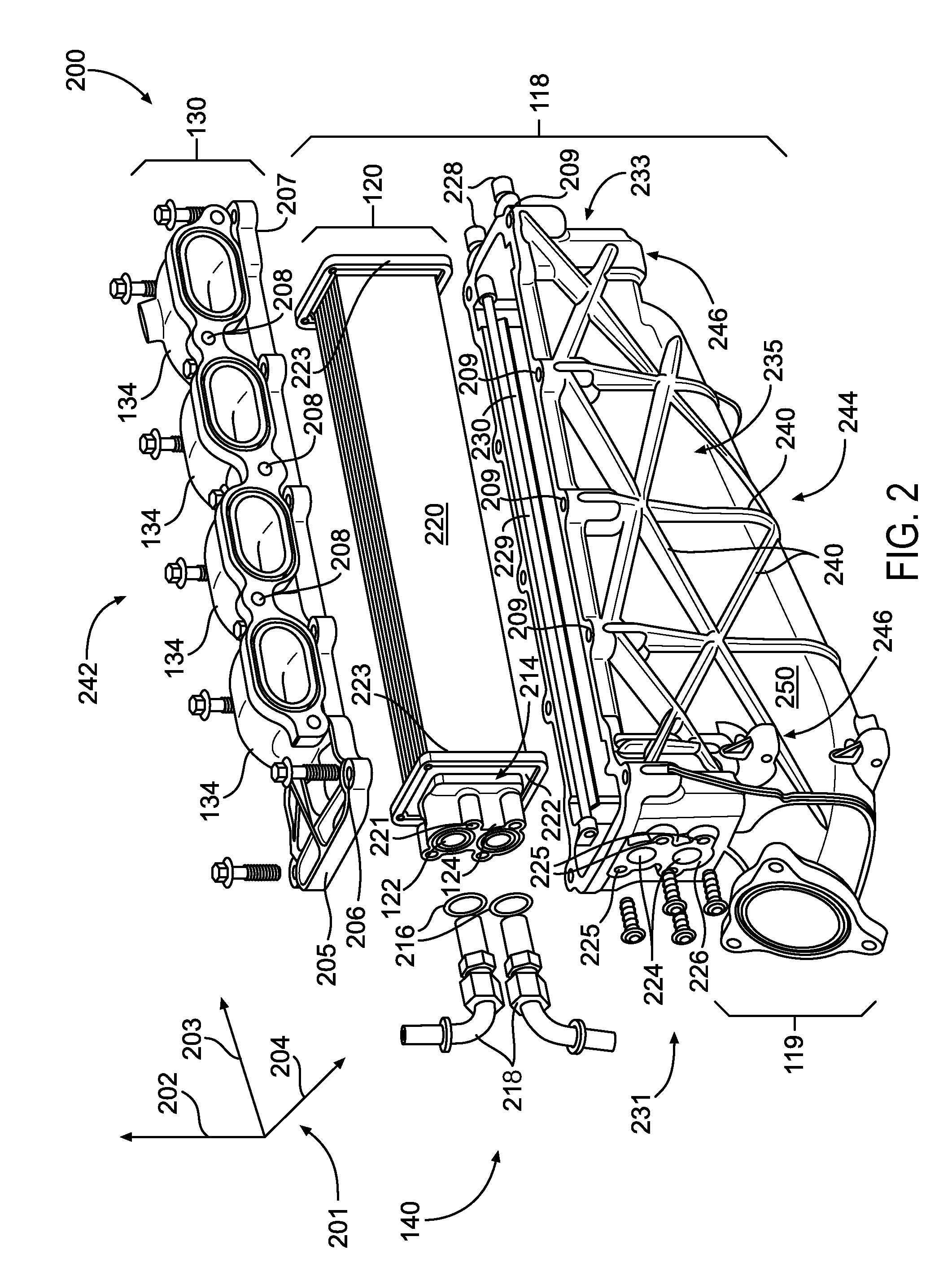

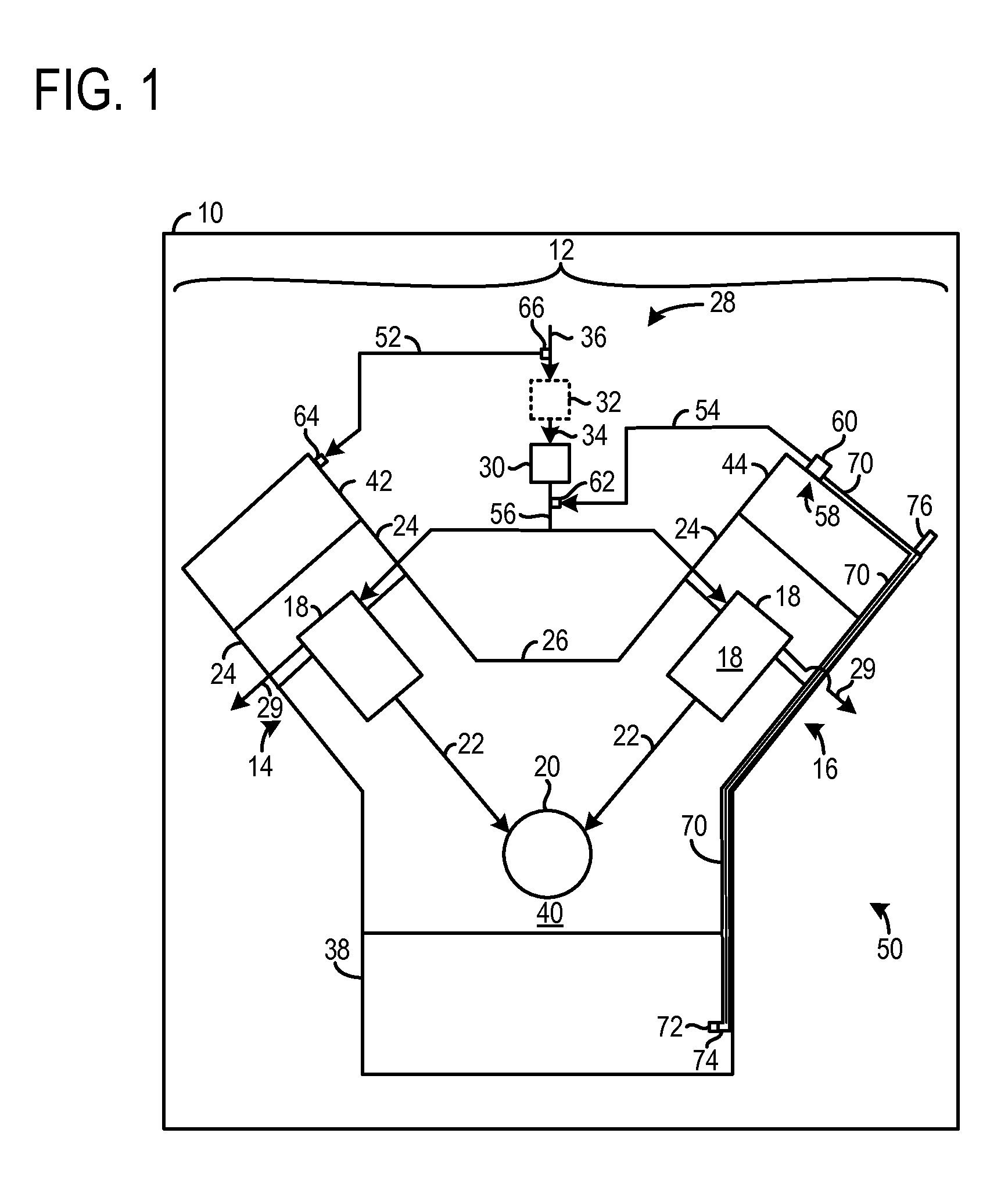

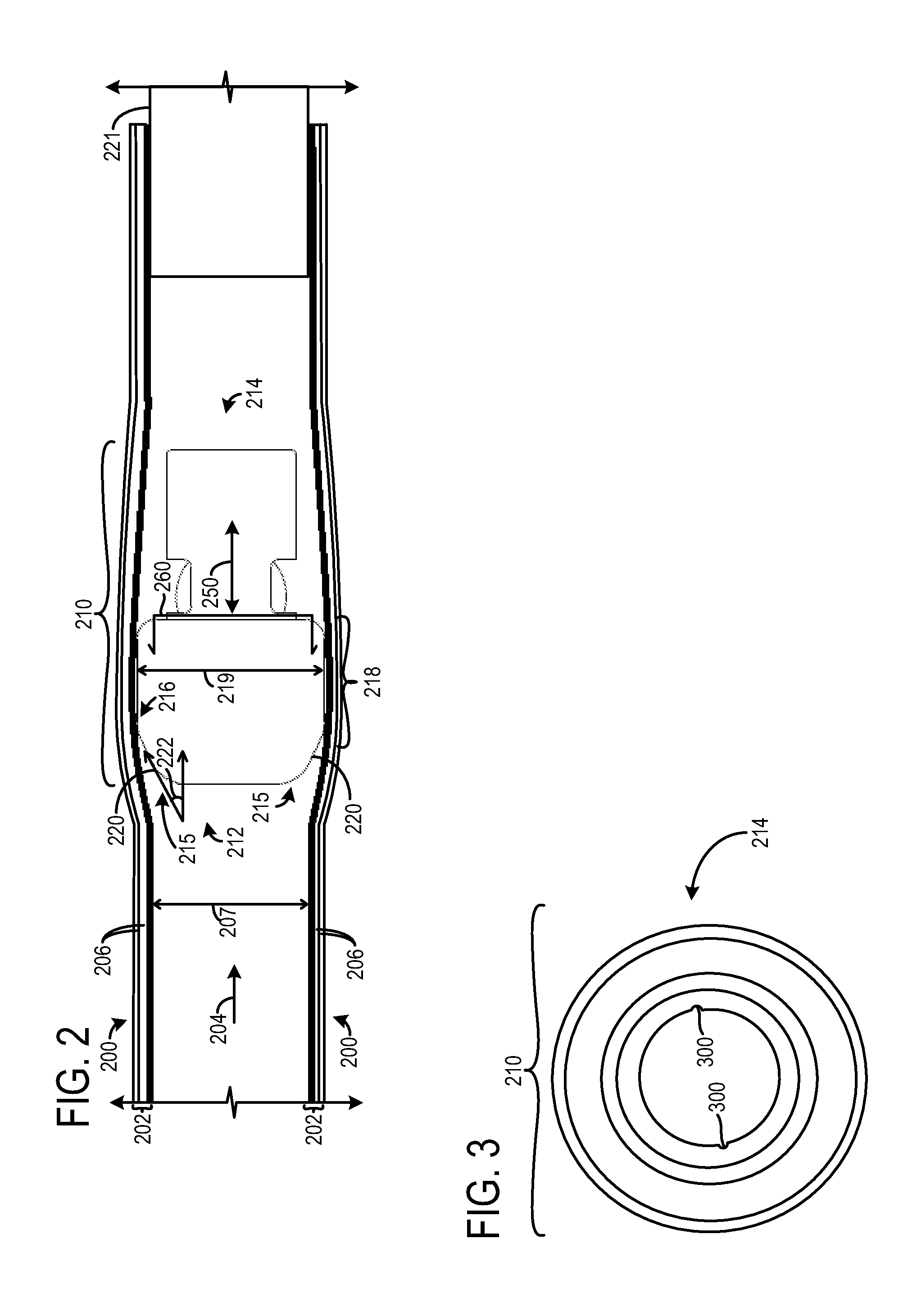

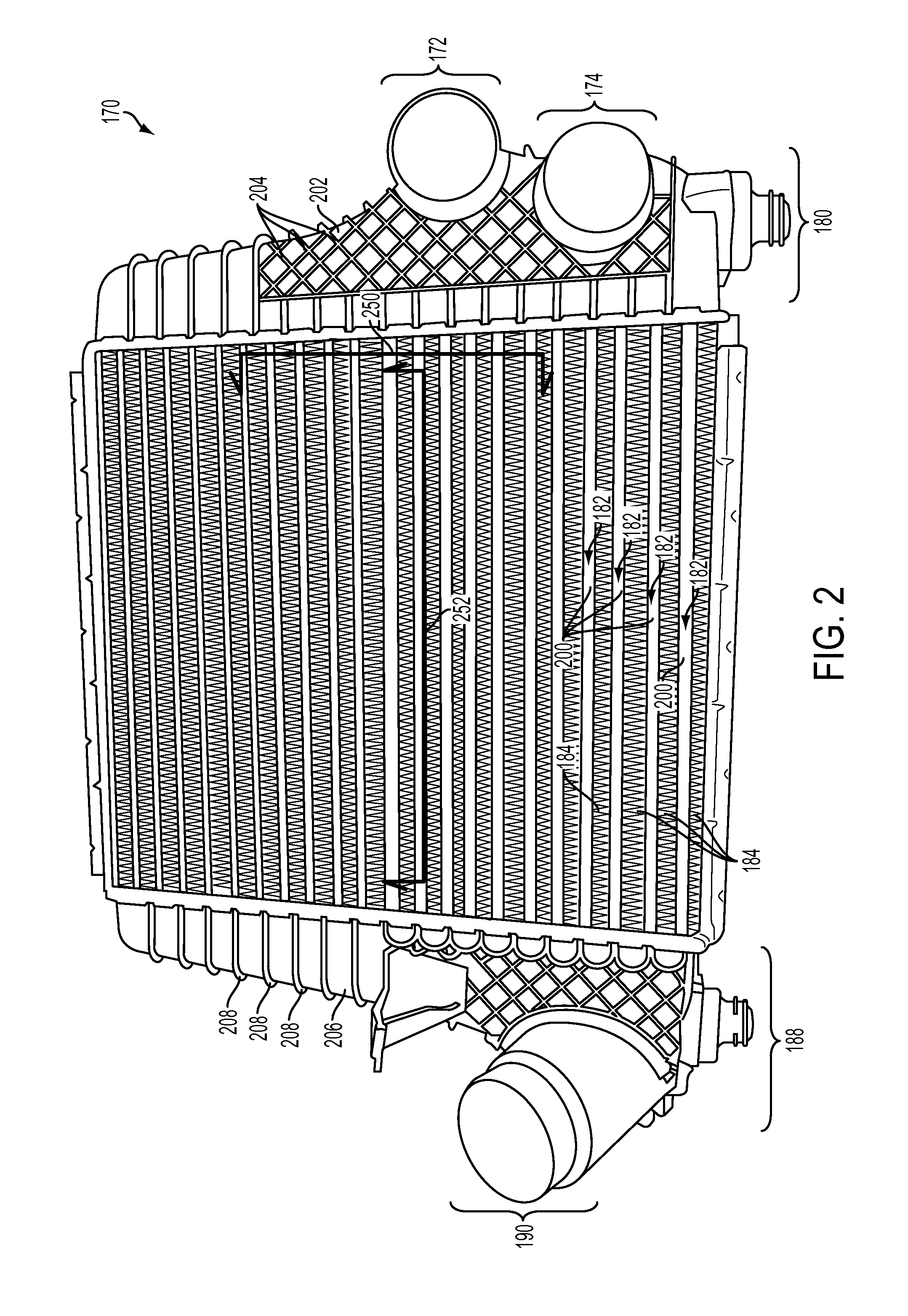

Intake system with an integrated charge air cooler

ActiveUS9145858B2High power outputEmission reductionInternal combustion piston enginesNon-fuel substance addition to fuelChillerCoolant

An intake assembly in an engine is provided. The intake assembly includes a compressor and a plenum in fluidic communication with the compressor, the plenum having an integrated charge air cooler including a coolant inlet and a coolant outlet in fluidic communication with a coolant passage and cooling plates extending into a plenum enclosure and coupled to the coolant passage. The intake assembly further includes a throttle body coupled to the plenum.

Owner:FORD GLOBAL TECH LLC

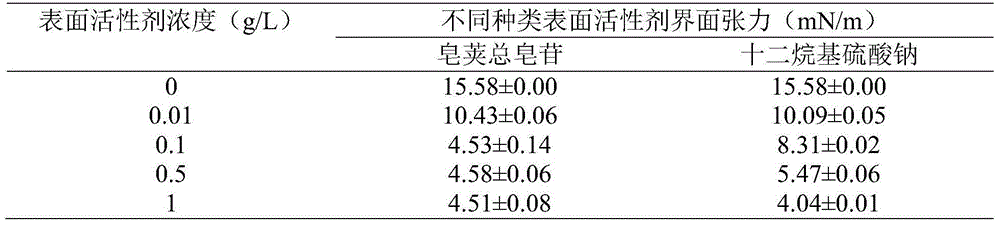

Application of plant source surface active agent

InactiveCN104874329AHas an activation effectIncrease gasification rateNon-ionic surface-active compoundsOther chemical processesEmulsionResource utilization

The invention relates to a total saponnis extraction technology of a honeylocust extract and an application field thereof. The total saponnis extraction technology is characterized in that the total saponnis is a plant source nonionic type surface active agent, and has the interfacial tension reduction property, emulsion activity, wetting property, temperature-resistant and salt-tolerant property, dispersant solubilizing and the like, so as to provide the applicability in the fields of recovery, storage and transportation of crude oil; the green surface active agent from the plant, namely the honeylocust, is applied to the bulk industrial purpose, so the resource utilization rate of the honeylocust is improved, the recovery rate of crude oil is improved, the storage and transportation cost of crude oil is reduced, and the pollution to the environment is reduced.

Owner:SHENYANG INST OF APPL ECOLOGY CHINESE ACAD OF SCI

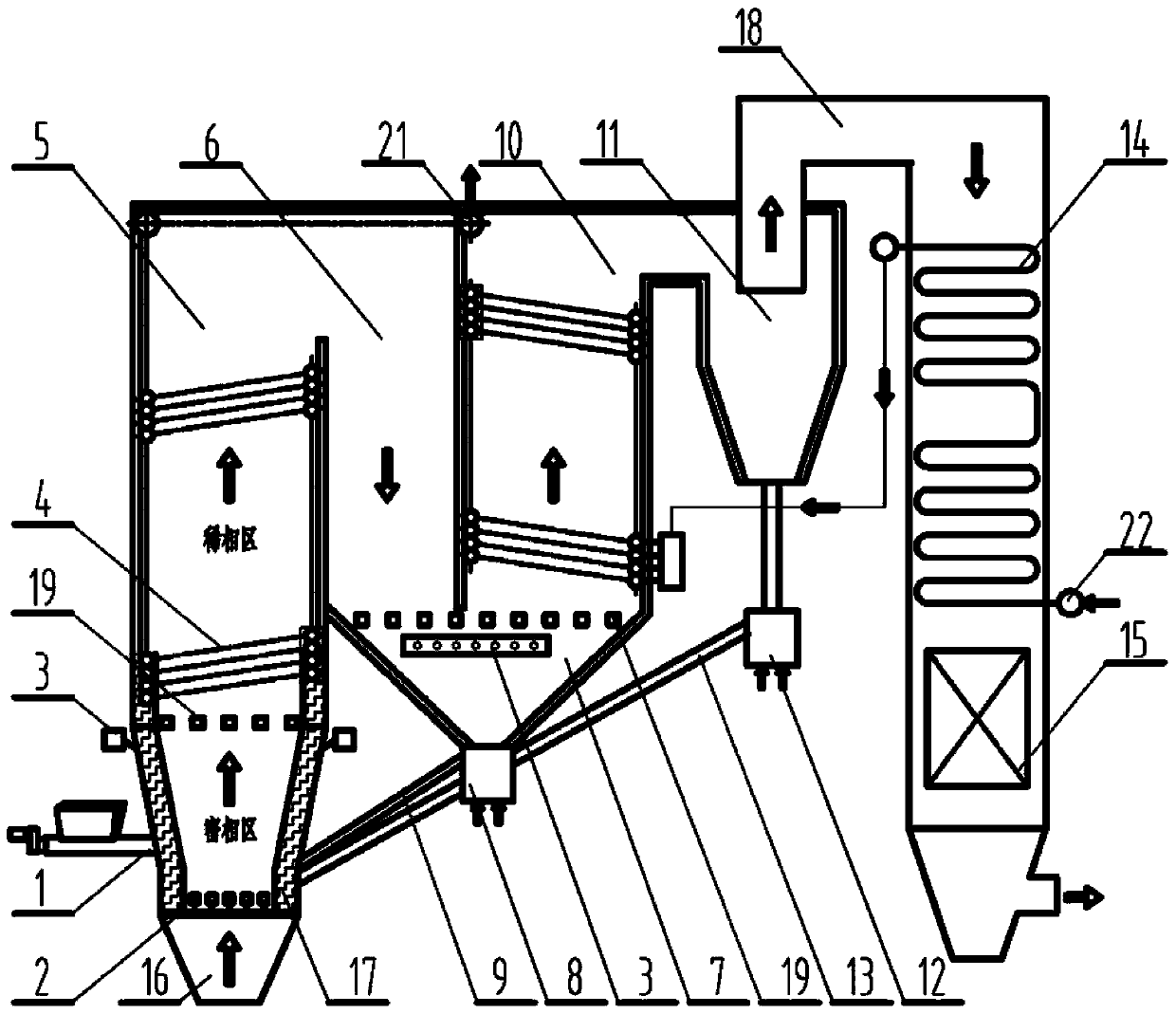

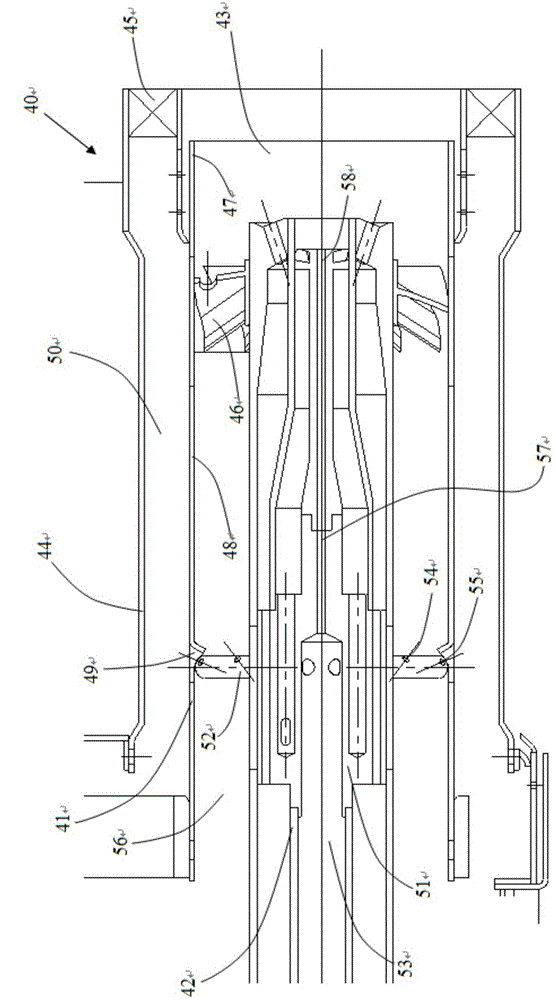

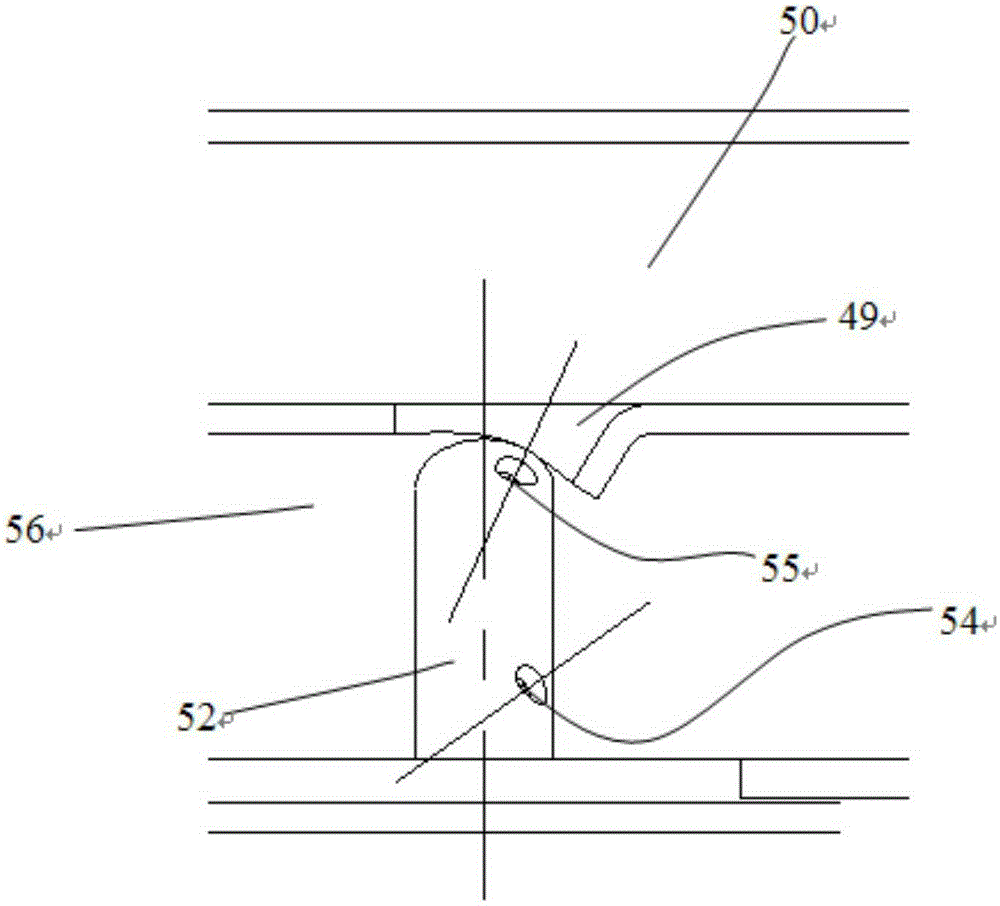

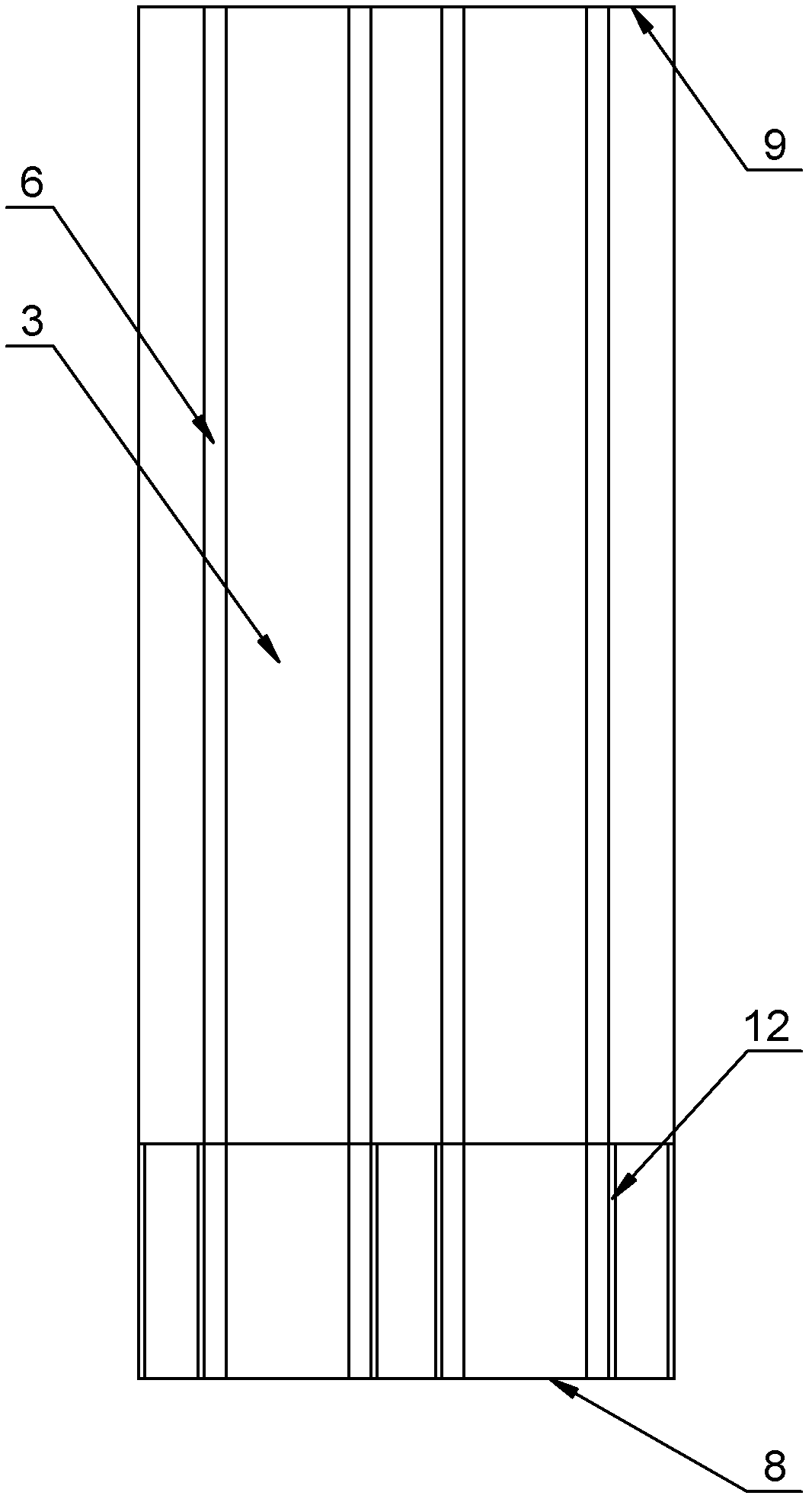

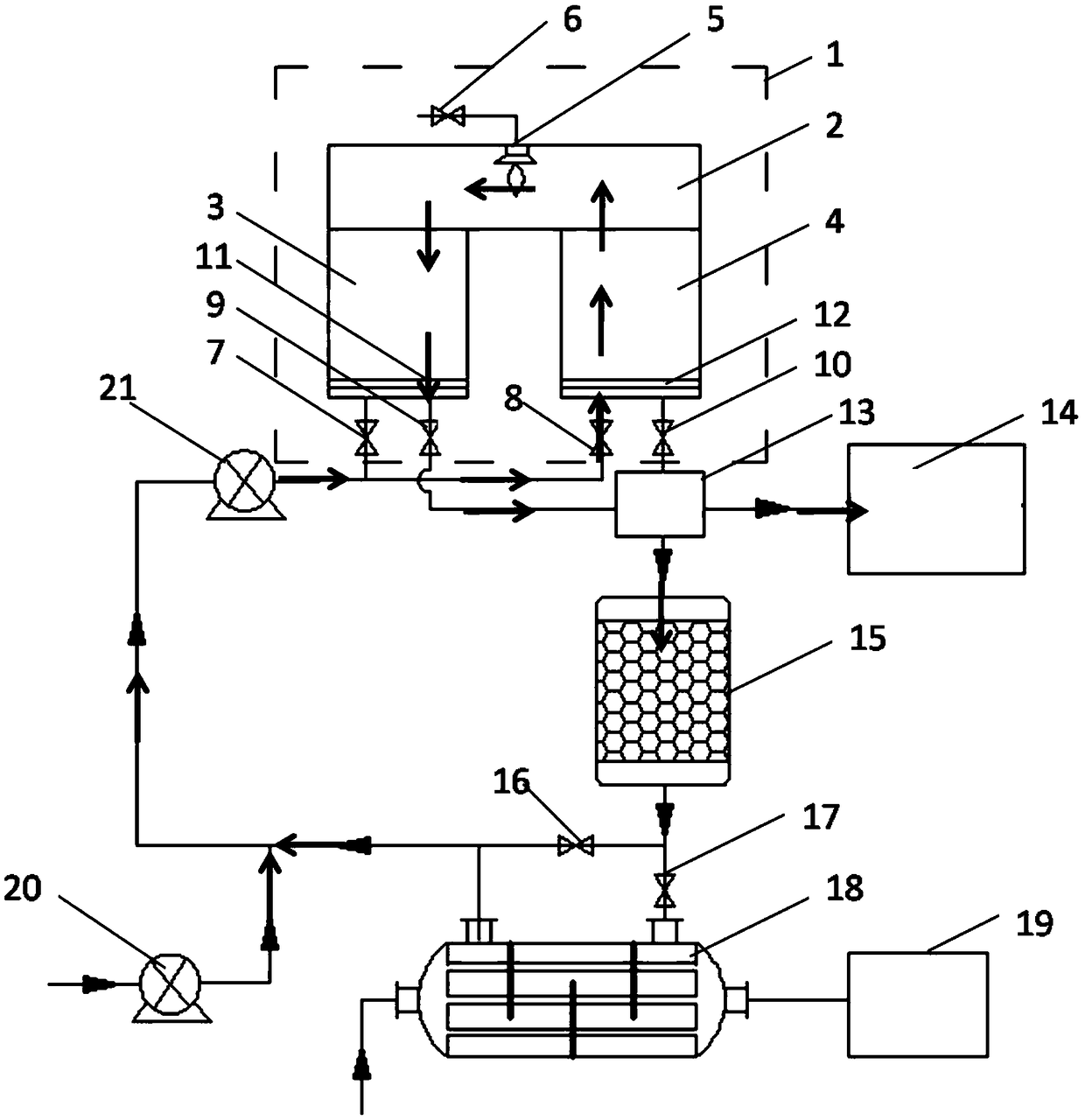

Heat-conduction oil furnace of horizontal circulating fluidized bed

ActiveCN103423869AWide fuel adaptabilityHigh temperature flue gas process is longFluidized bed combustionStorage heatersCirculating fluidized bed boilerCombustion chamber

The invention discloses a heat-conduction oil furnace of a horizontal circulating fluidized bed, and relaters to combustion equipment of the circulating fluidized bed for inferior coal, solid wastes, urban and industrial sludge and biomass fuels, in particular to a heat-conduction oil heating device. The heat-conduction oil furnace is mainly composed of a feeding device, a main combustion chamber, an auxiliary combustion chamber, an after-combustion chamber and a cyclone separator, wherein heat-conduction oil coils are arranged in the main combustion chamber and the after-combustion chamber, an economizer and an air pre-heater can be arranged behind the cyclone separator, and a waste heat boiler can also be arranged behind the cyclone separator. The heat-conduction oil heating device adopts a horizontal circulating fluidized bed technology, changes the traditional structural style adopting a chain grate furnace to heat, changes the single-stage and vertical circulating structure of the traditional fluidized bed boiler, effectively reduces the height of the boiler, and reduces the requirement on the construction height of plants. Through reasonable structural layout, the problem that the circulating fluidized bed boiler is easily abraded is effectively solved, and the heat-conduction oil heating device has wide adaptability to fuels, has high combustion efficiency, and has lower pollutant discharging quantity.

Owner:BEIJING NOWVA ENERGY TECH CO LTD

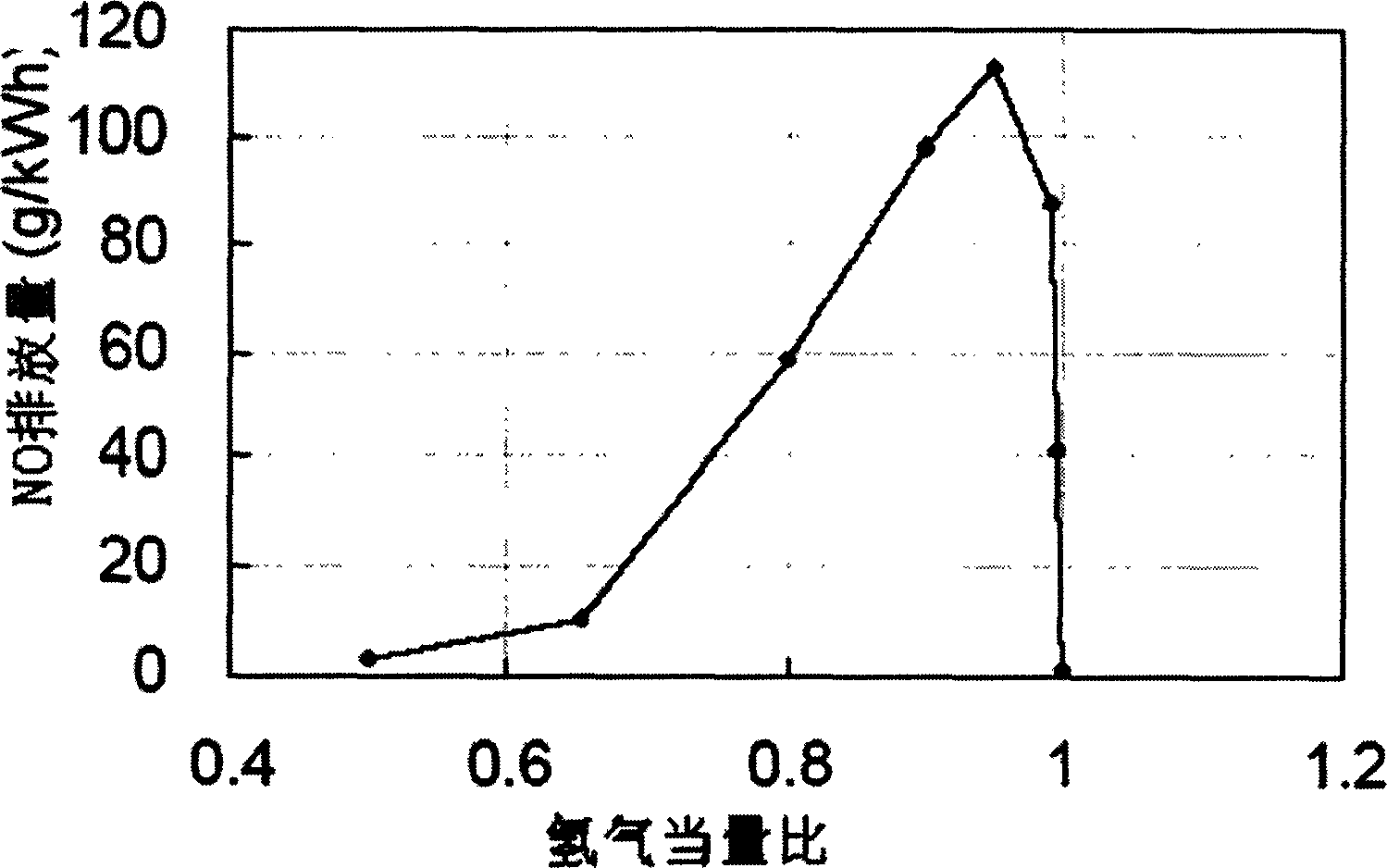

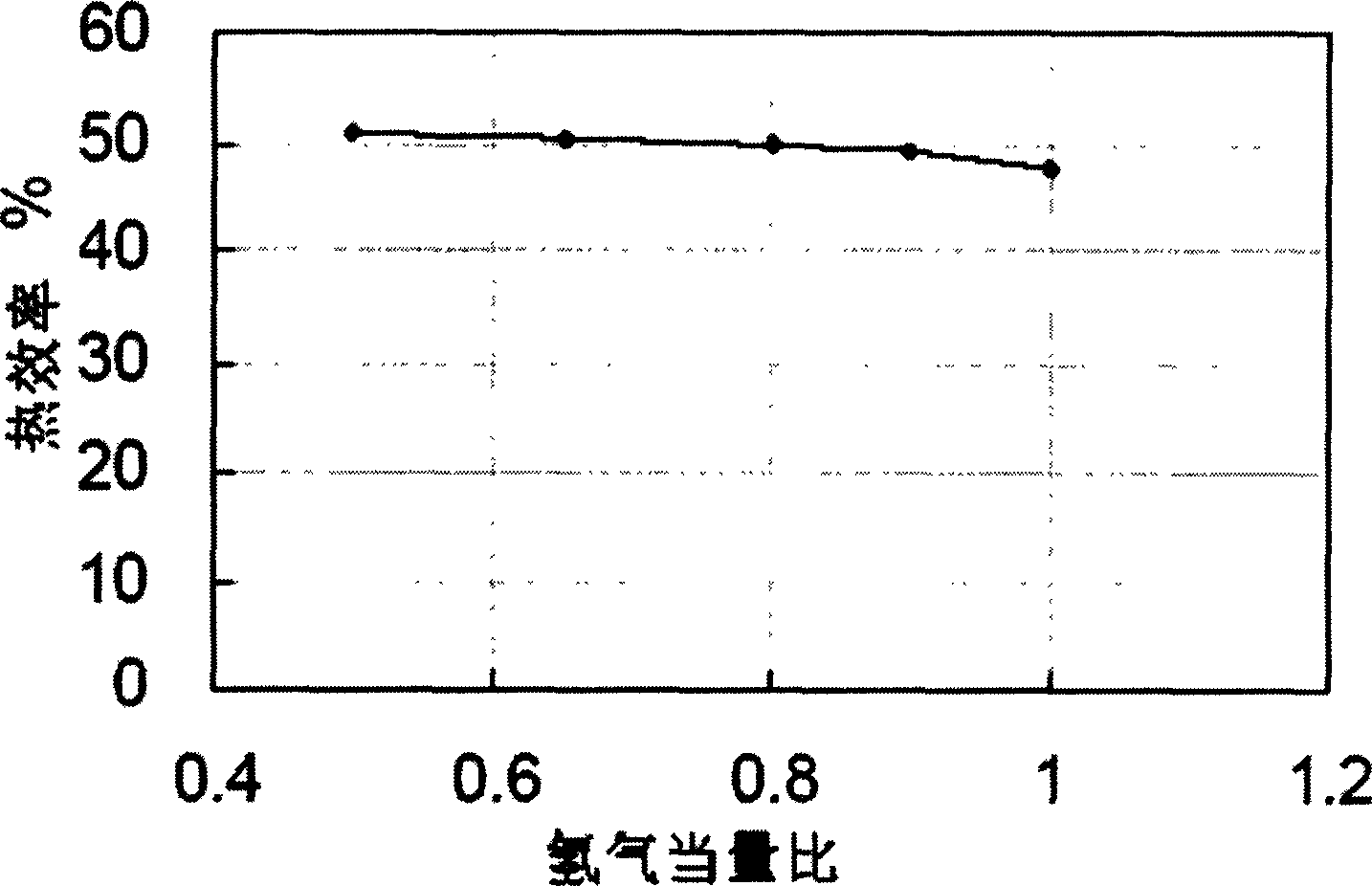

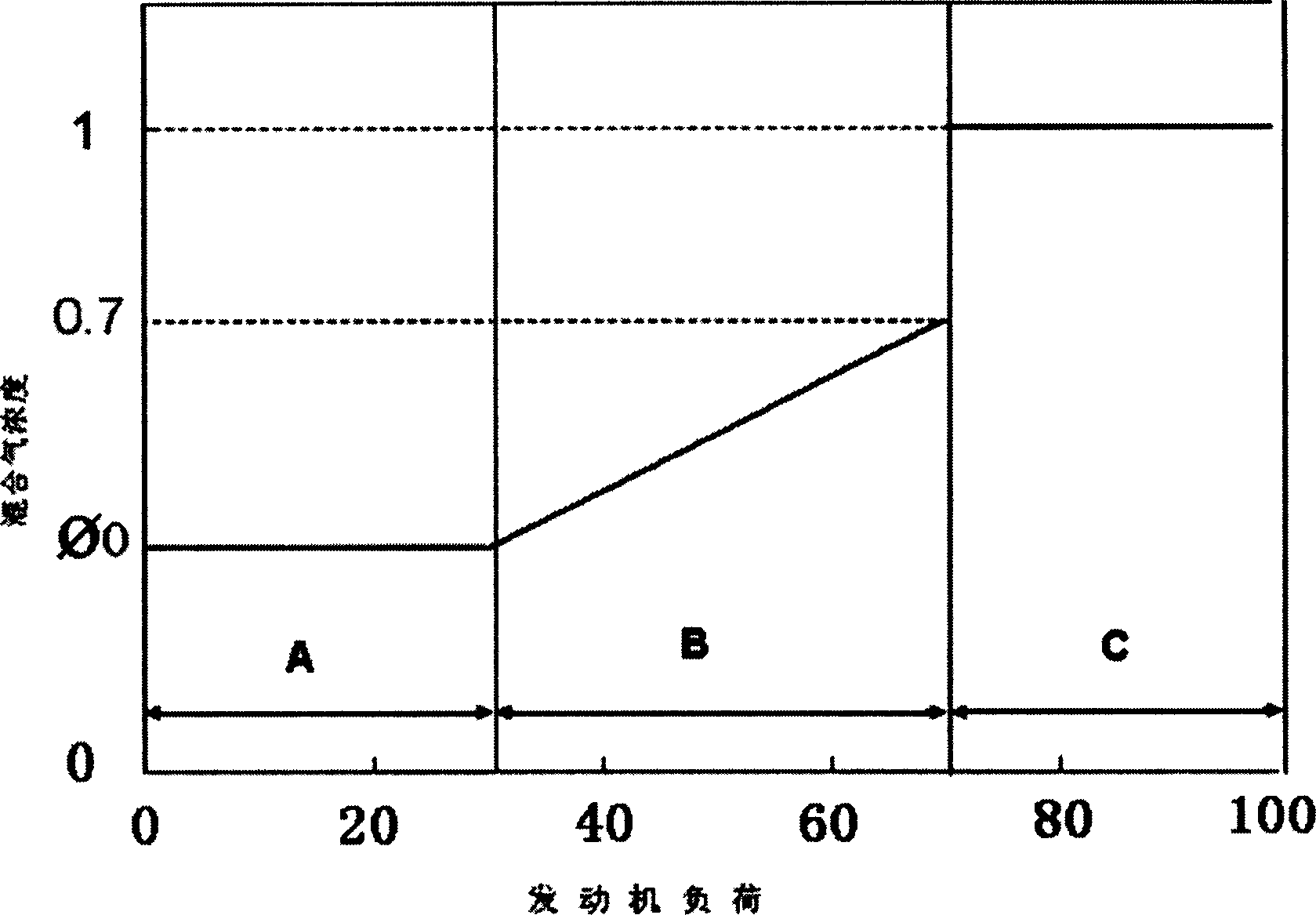

Combustion controlling system of hydrogen engine

InactiveCN1644899ASufficient power outputReduce generationElectrical controlInternal combustion piston enginesHydrogenCombustion

A kind of hydrogen engine combustion control system and its control method are provided. The control of concentration of hydrogen-air mixture by throttle, distributive value, and EGR is divided into 3 steps (1) when an engine in idle or under 30% rated load, engine runs in a very low air / fuel ratio phi 0, the output power of the engine is controlled by throttle. (2) when in 30%-70% rated load, the concentration of mixture is adjusted from phi0 to 0.7. (3) when over 70% rated load, engine should run in equivalent air / fuel ratio, then output power is controlled by ERG.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

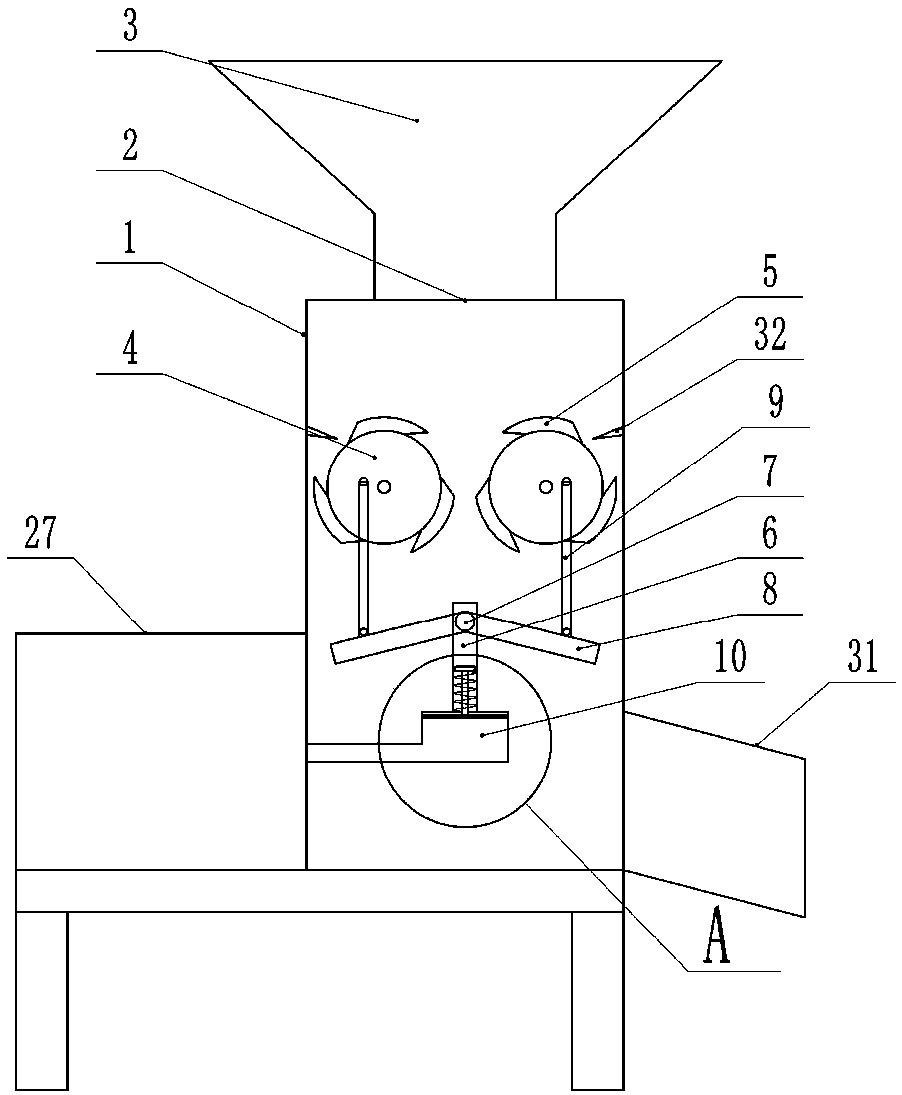

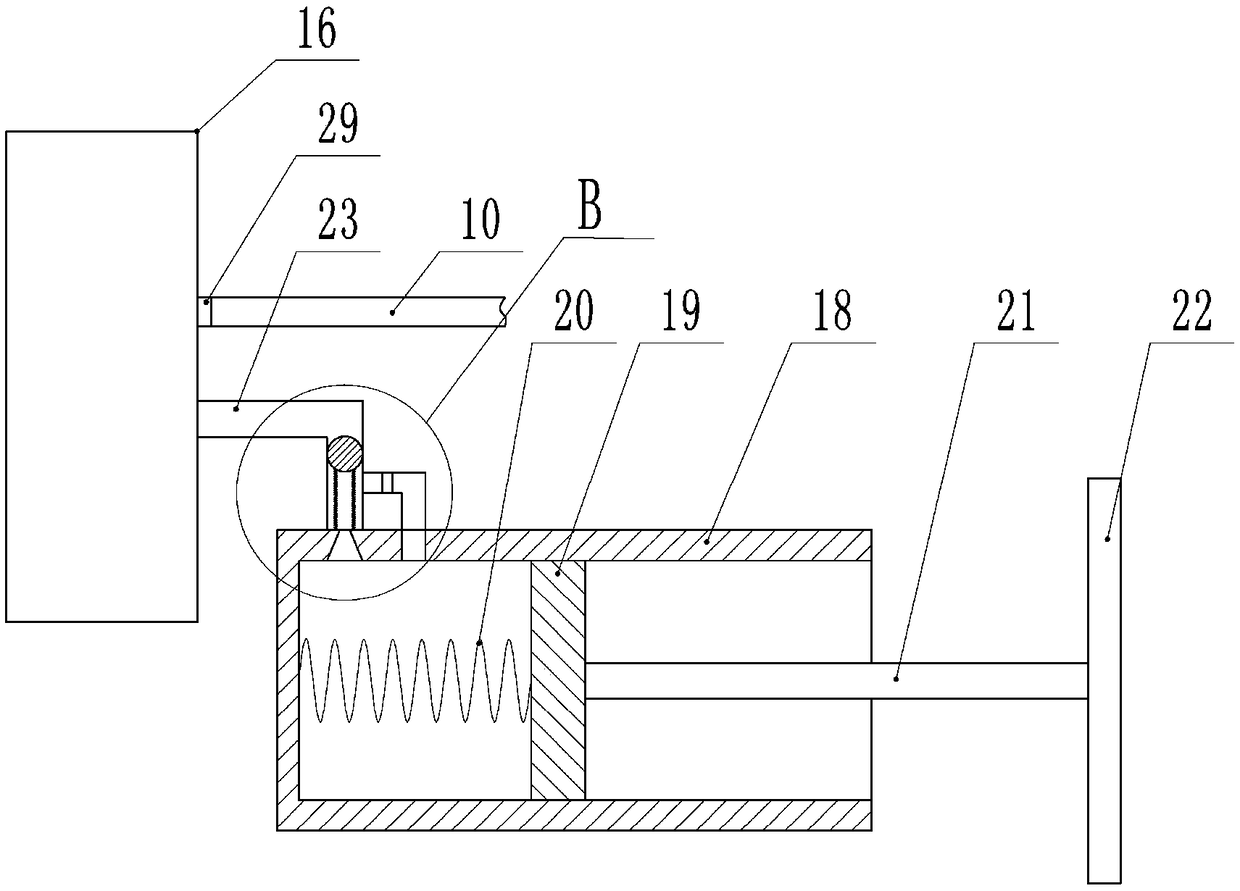

Method for reducing coal-firing boiler NOx discharge and its implementing device

InactiveCN101055075AReduce combustion efficiencyImprove combustion efficiencyPulverulent fuel combustion burnersCombustion using catalytic materialCombustorNitrogen

A method for reducing the NOx exhaust of a boiler, organizing multistage main coal powder burner to burn, and spraying hierarchical fuel to the flame center at the downstream of the main burner, the hierarchical fuel is decomposed quickly under high temperature and oxygen-deficient condition to generate great amount of CHi group, the CHi group then deoxidizes the NOx generated in the main burner area to N2, the selective non-catalytic deoxidize for NOx is proceeded by nitrogen group on a section with flame average temperature is 850-1150 DEG C, the fuel is then synergized by alkali metal salt, at last the fuel that not burnt is burnt by burning wind. A device for realizing the method which is disposed with a fuel classification nozzle, a reducing reagent nozzle and an air classification nozzle on a unidirectionalflow coal powder burner, the position of the fuel classification nozzle is at the section place of the flame center; the reducing reagent nozzle is at the place with an average temperature is 850-1150 DEG C of the section; the air classification nozzle is determined by the hierarchical fuel detention period 0.5-1 S.

Owner:TONGJI UNIV

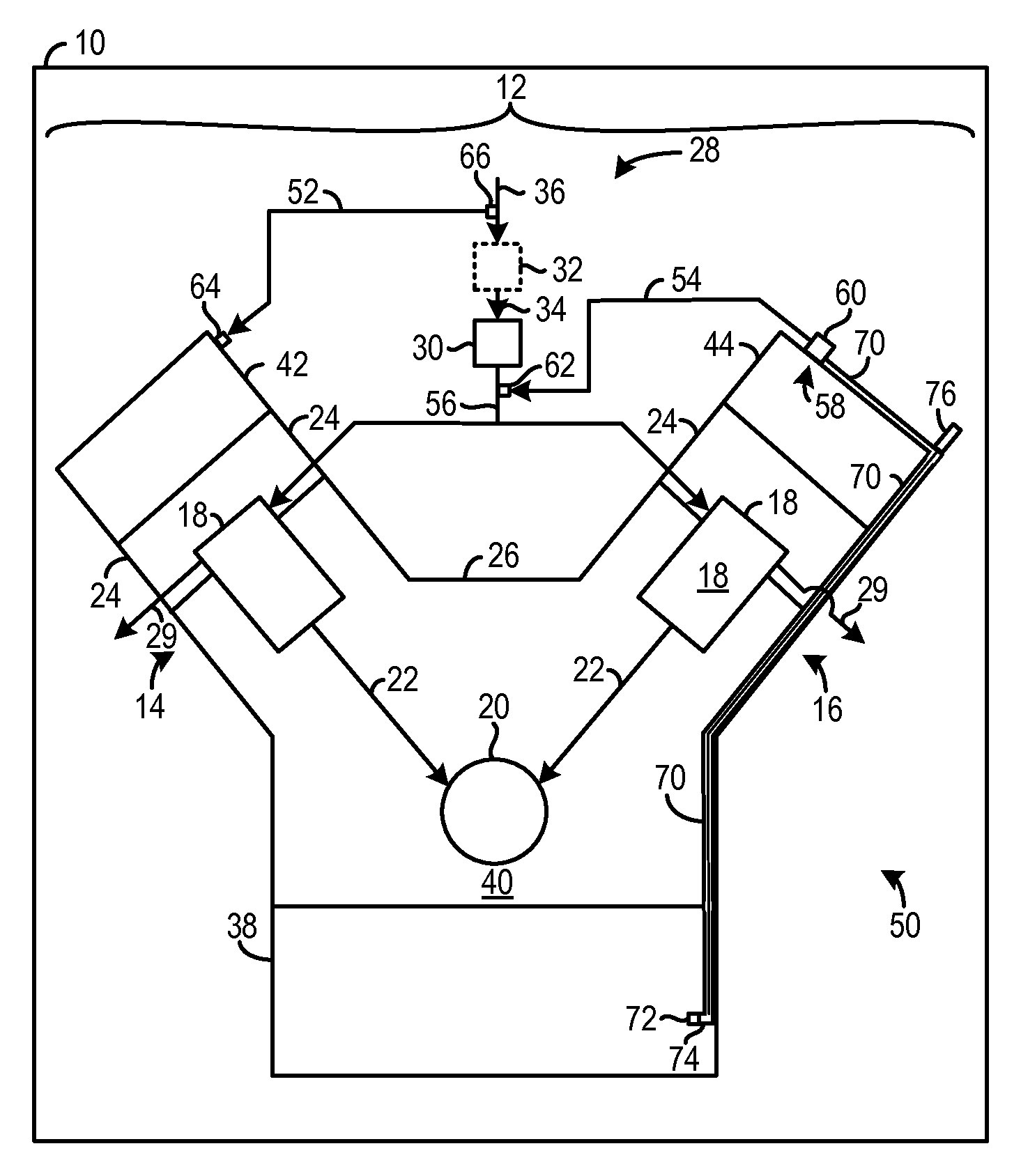

Active airpath bypass system

ActiveUS20160177881A1High power outputEmission reductionNon-fuel substance addition to fuelInternal combustion piston enginesEngineeringSliding contact

Methods and systems are provided for regulating airflow through a charge air cooler integrated in an intake assembly. In one example, an engine intake assembly comprises a plenum having an integrated charge air cooler (CAC), a first header seal positioned around a circumference of a first CAC header, and a first rotatably movable seal positioned in a bypass passage of the plenum. The first movable seal interfaces via sliding contact with the first header seal and adjusting a position of the first movable seal may vary the amount of airflow through the bypass passage.

Owner:FORD GLOBAL TECH LLC

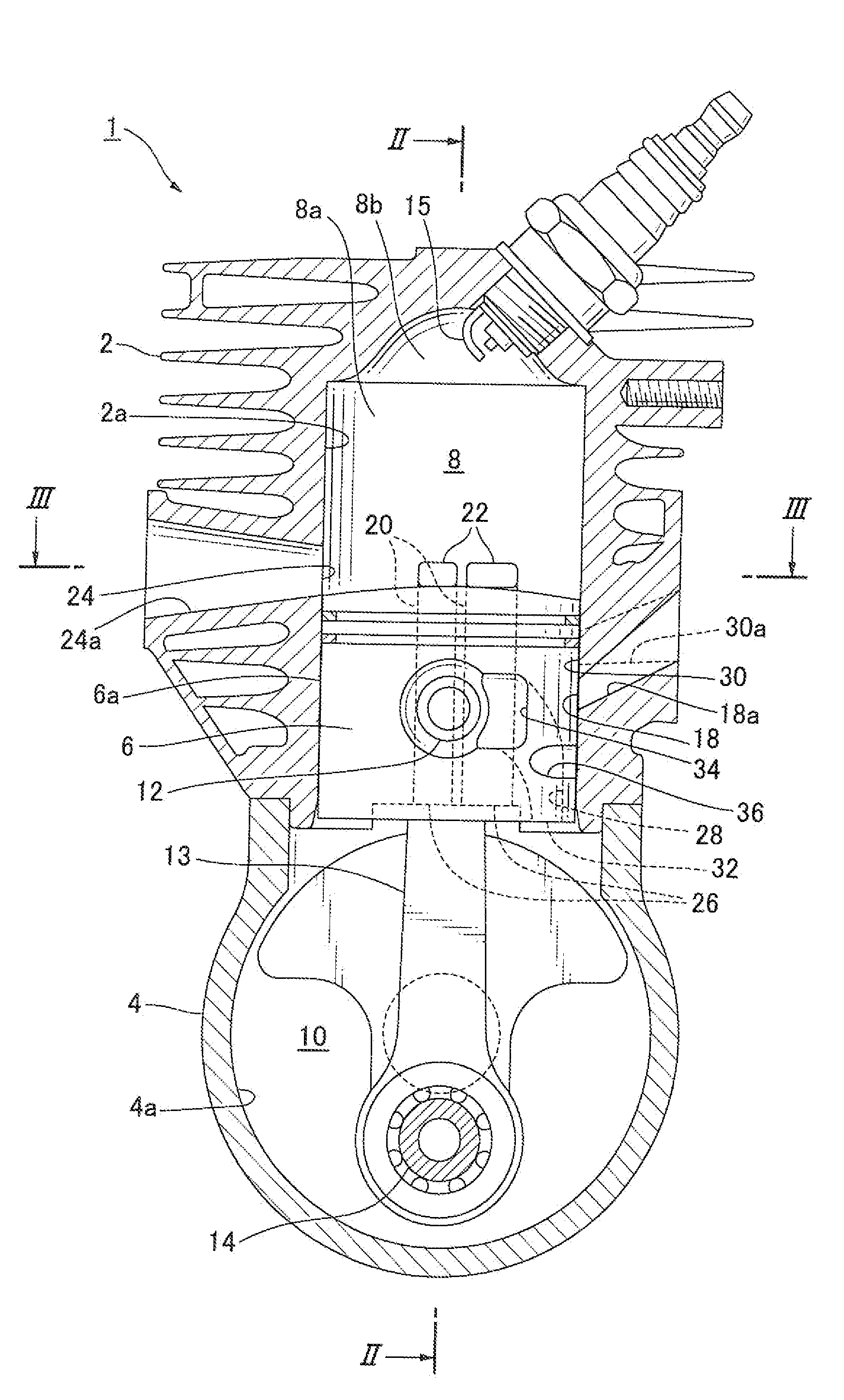

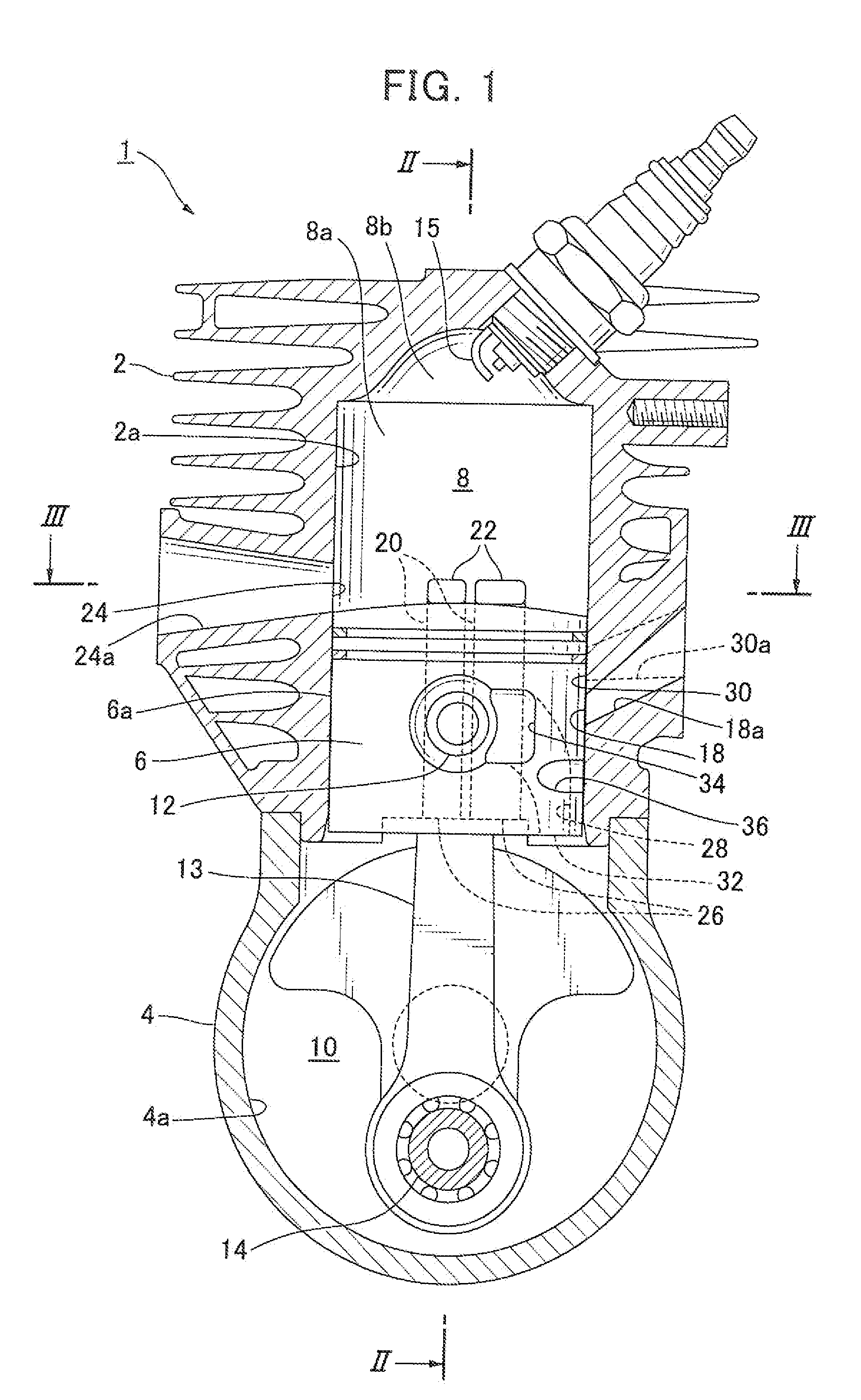

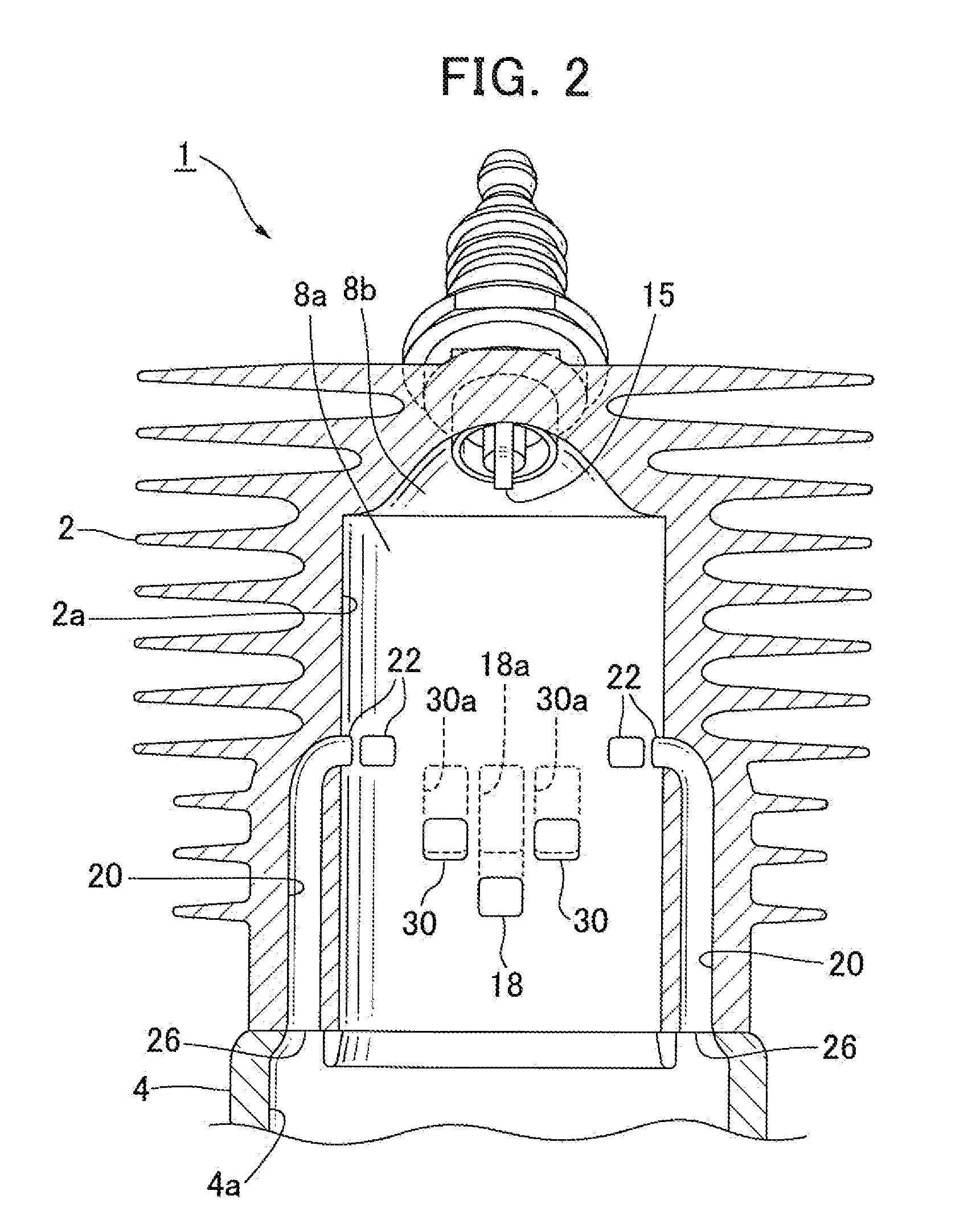

Two-stroke engine

ActiveUS20110079206A1Reduce combustion efficiencyCombustion-air/fuel-air treatmentCombustion enginesTop dead centerEngineering

In a two-stroke engine (1) according to the present invention, a piston (6) has a communication passage (28) opened to a crank chamber (10). An air intake port (30) is provided on an inner surface (2a) for causing air to flow into the communication passage (28). After a scavenging port (22) is closed by an outer surface (6a) of the piston (6) moving from the bottom dead center to the top dead center, the communication passage (28) is opened in the outer surface (6a) of the piston so as to communicate with the air intake port (30) and the scavenging port (22).

Owner:YAMABIKO CORP

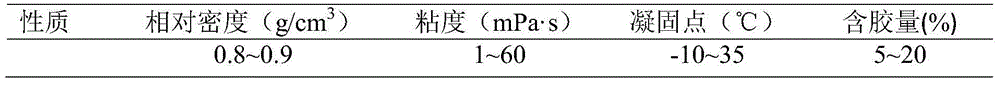

Pretreatment combination method of hazardous waste

ActiveCN109253453ACalorific value stableAvoid it happening againIncinerator apparatusChemical reactionLiquid viscosity

The invention belongs to the technical field of waste incineration and particularly discloses a pretreatment combination method of hazardous waste. The pretreatment combination method includes the steps of firstly, performing solid, liquid and semi-solid classification on the waste, and placing the classified waste into a storage; secondly, performing property detection on the hazardous waste which needs to be incinerated to determine the heat value, volatile component, halogen content, heavy metal content, combustibility, liquid viscosity and chemical reactivity; thirdly, performing compatibility analysis which includes theoretical analysis and experimental analysis on the waste of the storage; fourthly, performing combination calculation according to the heat value, volatile component, halogen content and heavy metal content, and guaranteeing heat value stability; fifthly, determining the combination quantity of different waste according to the calculation results in the fourth step,and mixing. The method has the advantages that the method is mainly used for hazardous waste combination, and the problem that potential safety hazards are easily caused by the incineration of different kinds of hazardous waste is solved.

Owner:XINZHONGTIAN ENVIRONMENTAL PROTECTION

Engine system having a backflow valve and method for operation thereof

ActiveUS9140153B2Reduce the amount requiredAccelerate emissionsLubricant conduit arrangementsMachines/enginesBackflowPetroleum engineering

An engine system is described. The engine system includes an oil drain passage in fluidic communication with an oil separator. The engine system further includes a backflow valve positioned at an outlet of the oil drain line, the backflow valve having a first configuration where the valve provides a predetermined amount of oil backflow into the oil drain passage and a second configuration where the valve inhibits oil backflow into the oil drain passage.

Owner:FORD GLOBAL TECH LLC

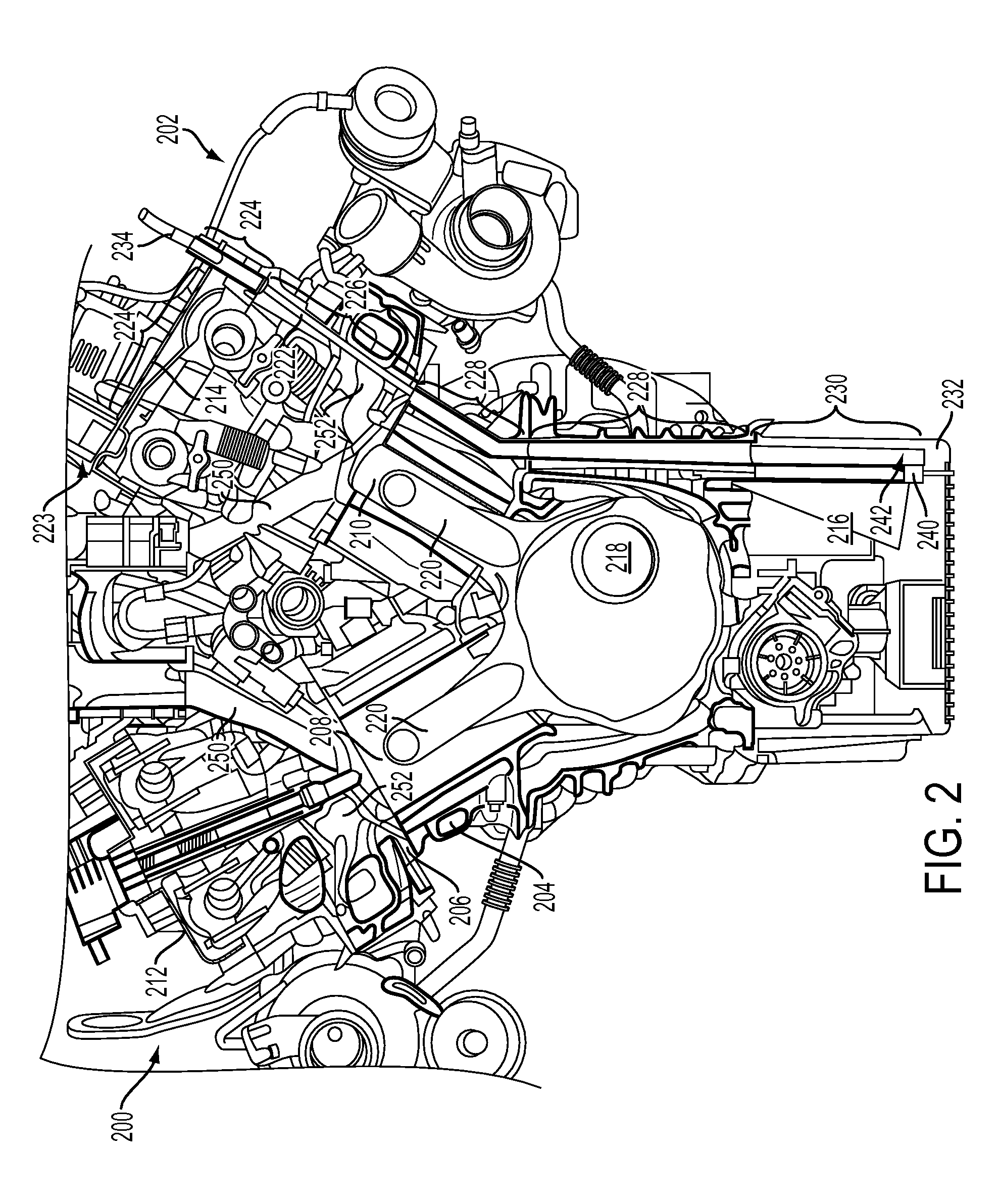

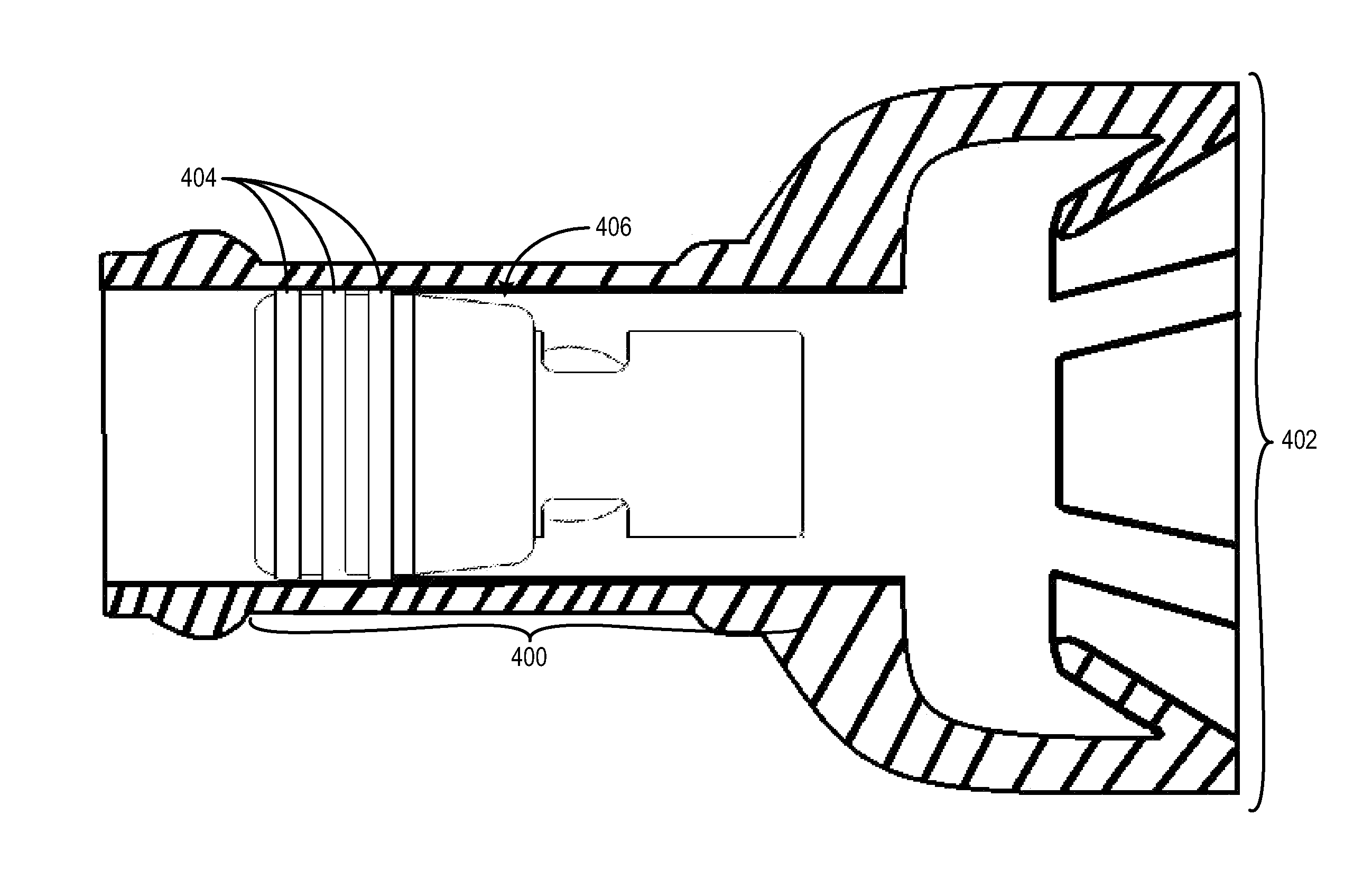

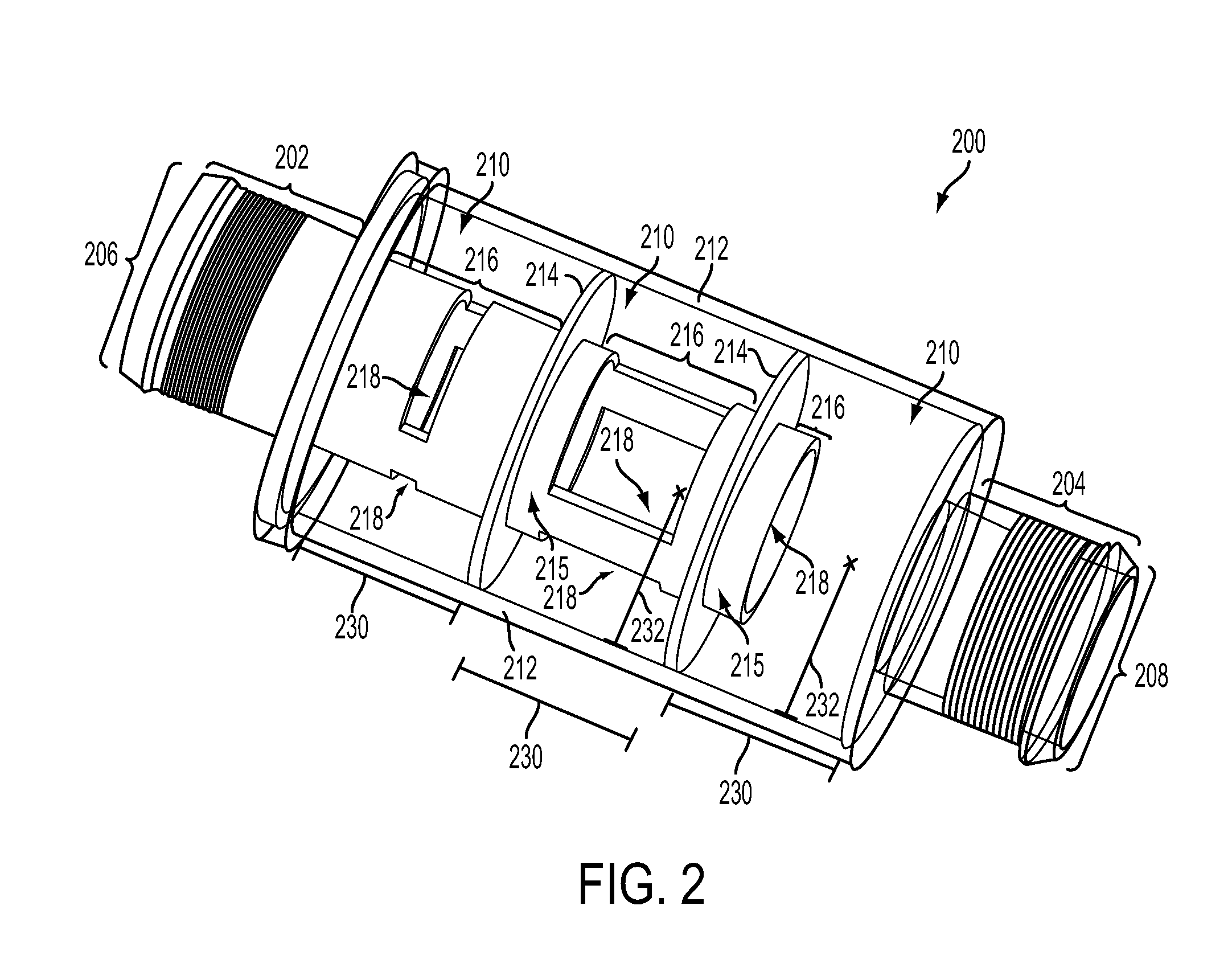

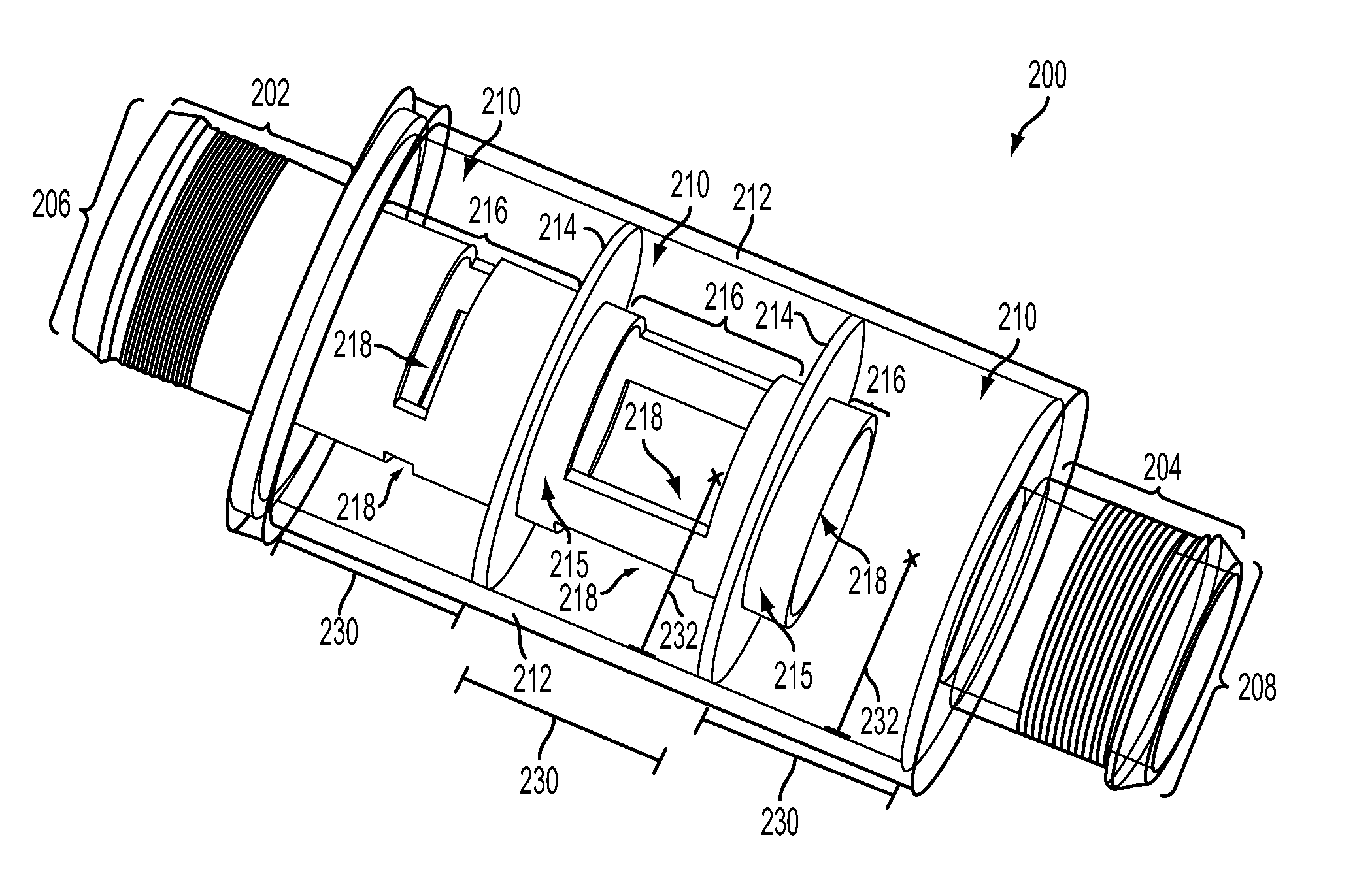

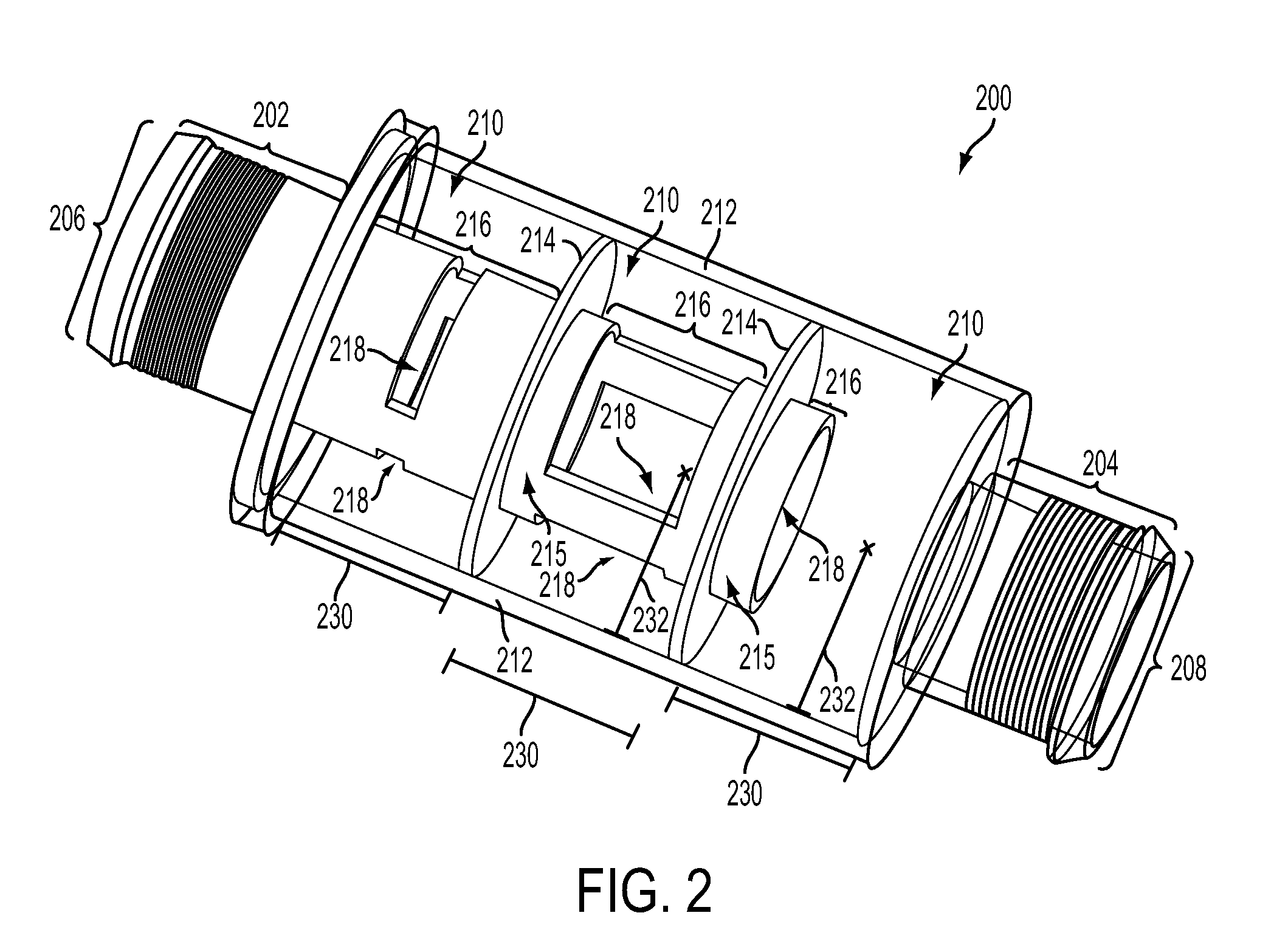

Fuel delivery system including integrated check valve

ActiveUS20150068491A1Reduce fuel consumptionNegatively affectedValve members for absorbing fluid energyCombustion enginesNoise, vibration, and harshnessEngineering

A fuel delivery system is provided to reduce the pressure pulsations and noise vibration and harshness of direct injection systems. The fuel delivery system includes an elastic fuel line positioned between a first fuel pump and a second fuel pump and a check valve positioned in the elastic fuel line near the inlet of the high pressure pump, the check valve including an external housing having a peripheral surface with a greater diameter than an unstretched inner diameter of the elastic fuel line.

Owner:FORD GLOBAL TECH LLC

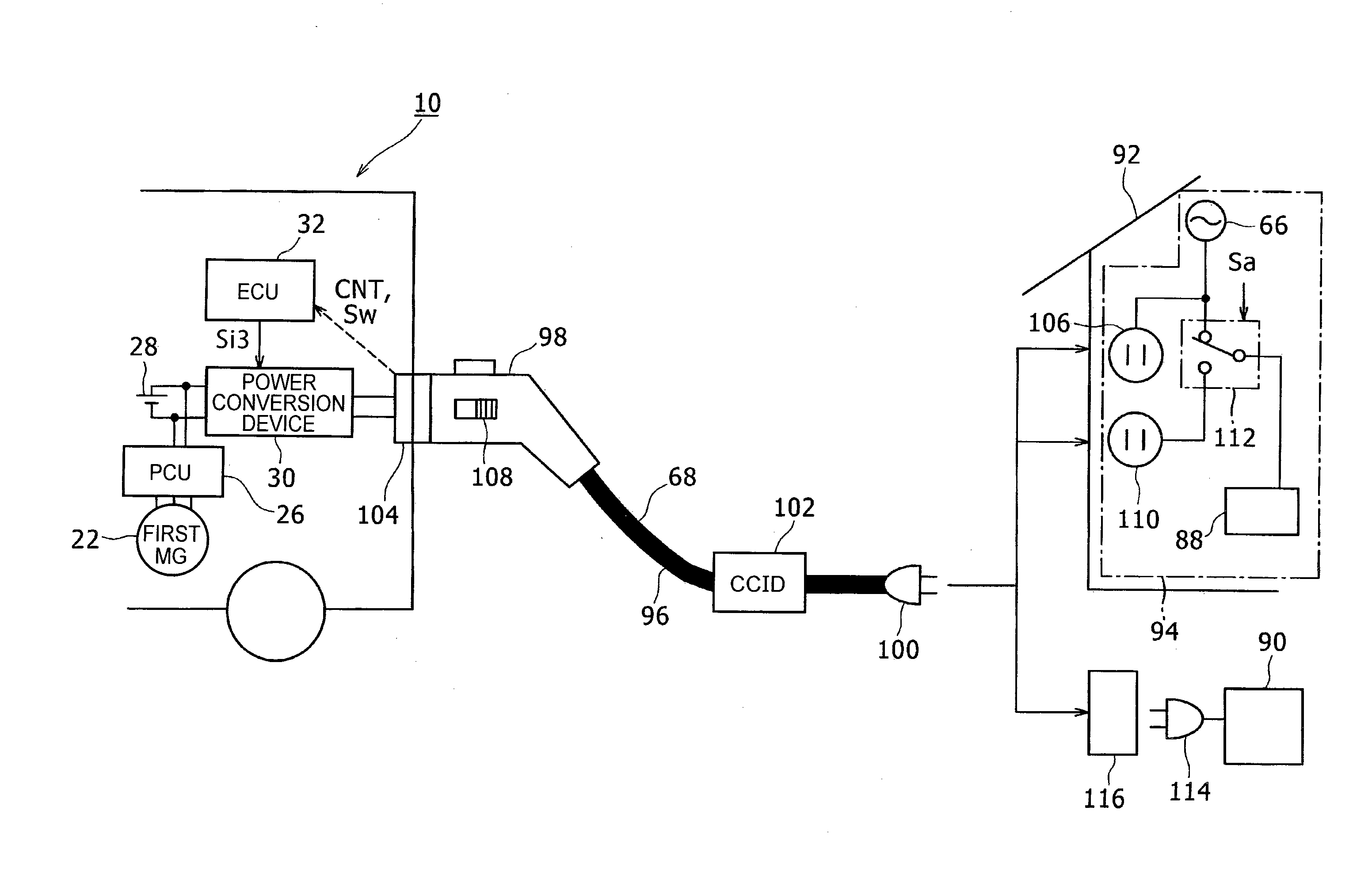

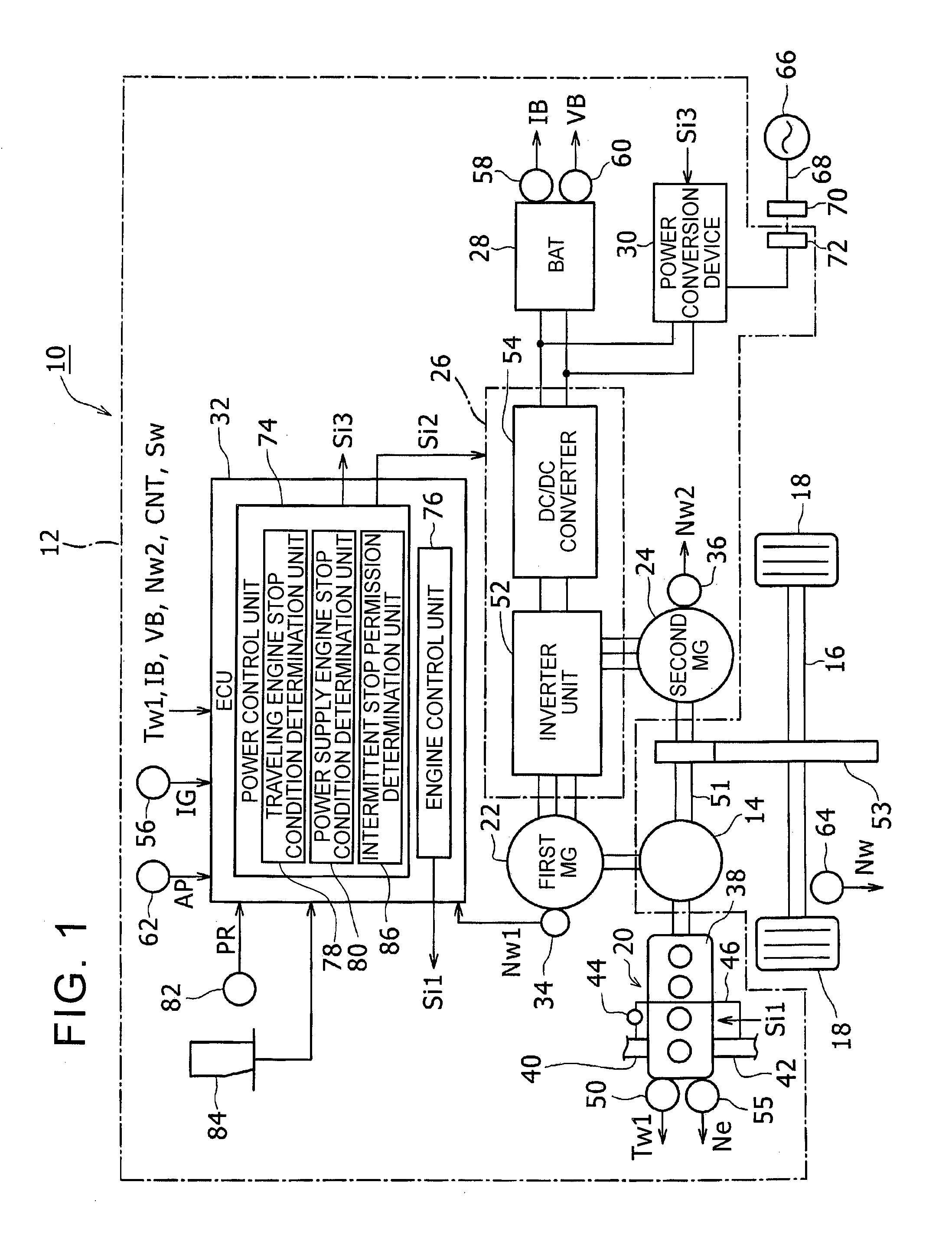

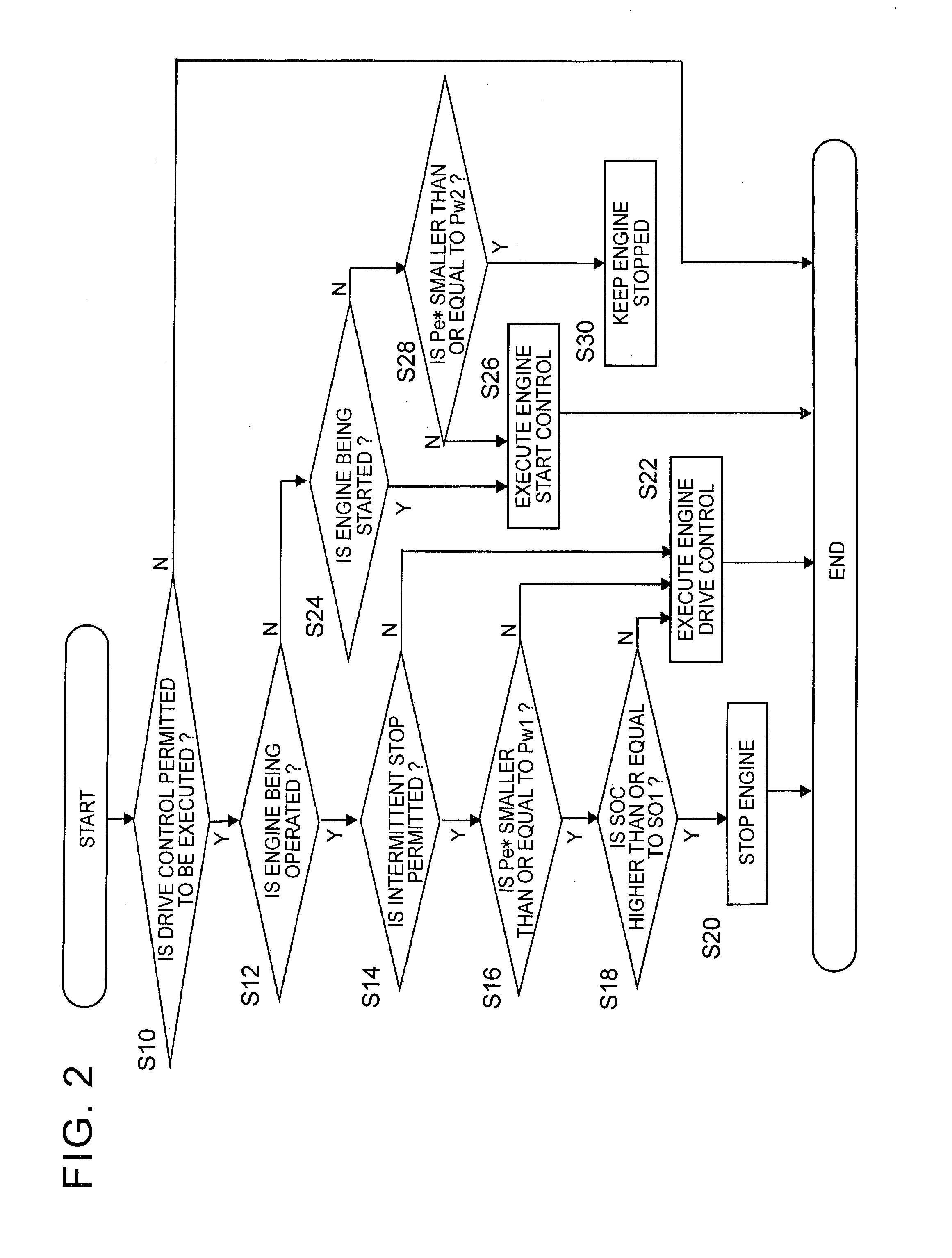

Control system for vehicle, vehicle, and control method for vehicle

ActiveUS20150210179A1Improve fuel economyDegradation of combustionHybrid vehiclesElectrical controlElectricityControl system

A control system for a vehicle including an engine, an electrical storage unit and a generator driven by the engine, the control system includes a socket and a controller. The socket is configured to supply electric power from the generator or the electrical storage unit to a device outside the vehicle in a travel stop state. The controller stops the engine when a preset condition is satisfied. The controller sets a first range and a second range in which the condition is satisfied. The first range is the range in a case where electric power is supplied to the device outside the vehicle and the second range is the range in another case. The first range is narrower than the second range.

Owner:TOYOTA JIDOSHA KK

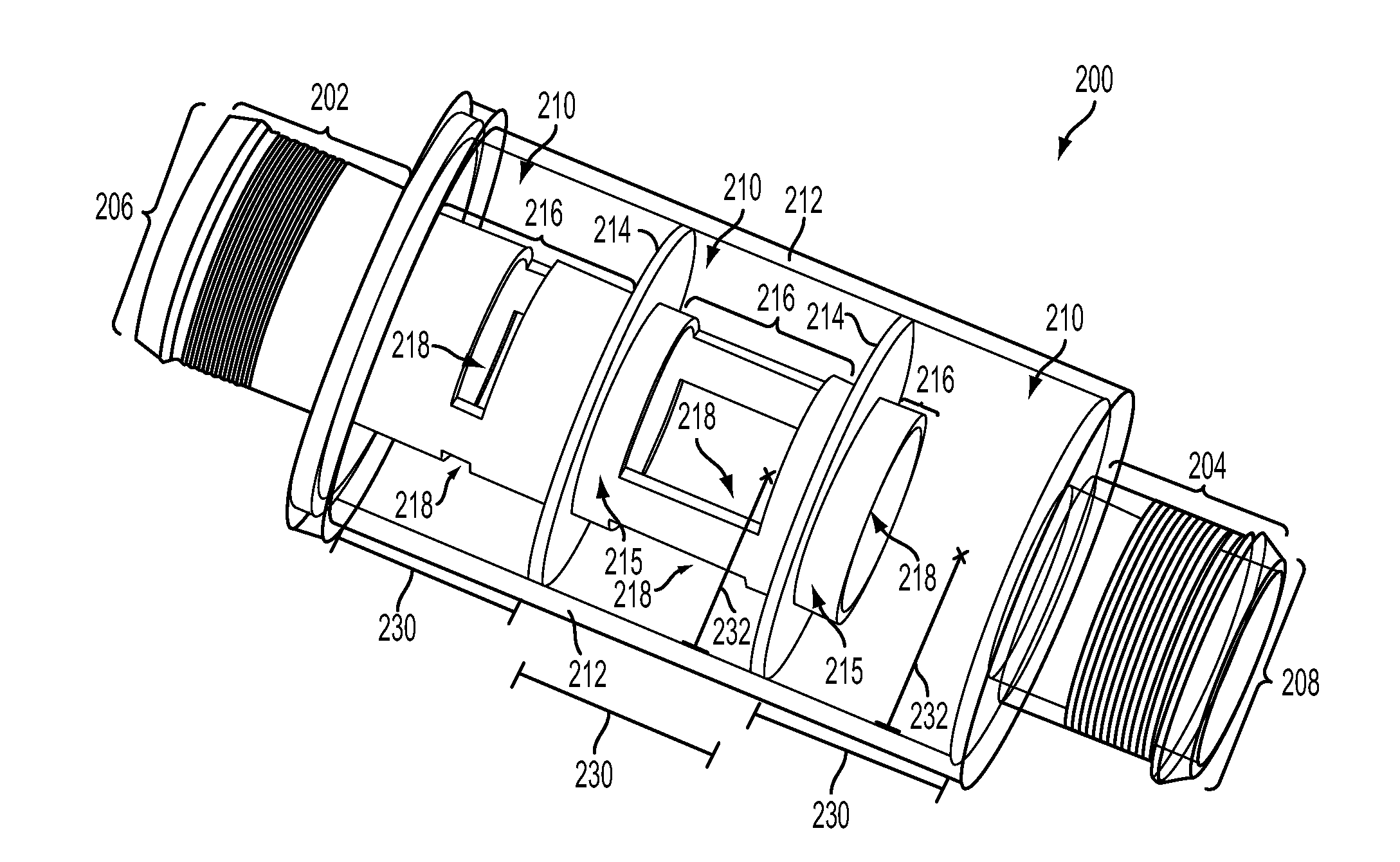

Intake system having a silencer device

ActiveUS20150107935A1Reduce customer satisfactionSatisfaction keeps decreasingInternal combustion piston enginesIntake silencers for fuelEngineeringExpansion chamber

An intake silencer device is described herein. The intake silencer device includes an outer housing and a plurality of sequential arranged expansion chambers separated by walls. The intake silencer device further includes an inner tube positioned in each of the sequential chambers, each of the inner tubes including an opening providing fluidic communication between an interior of the tube and the corresponding expansion chamber, a size of the openings increasing in size sequentially in a downstream direction.

Owner:FORD GLOBAL TECH LLC

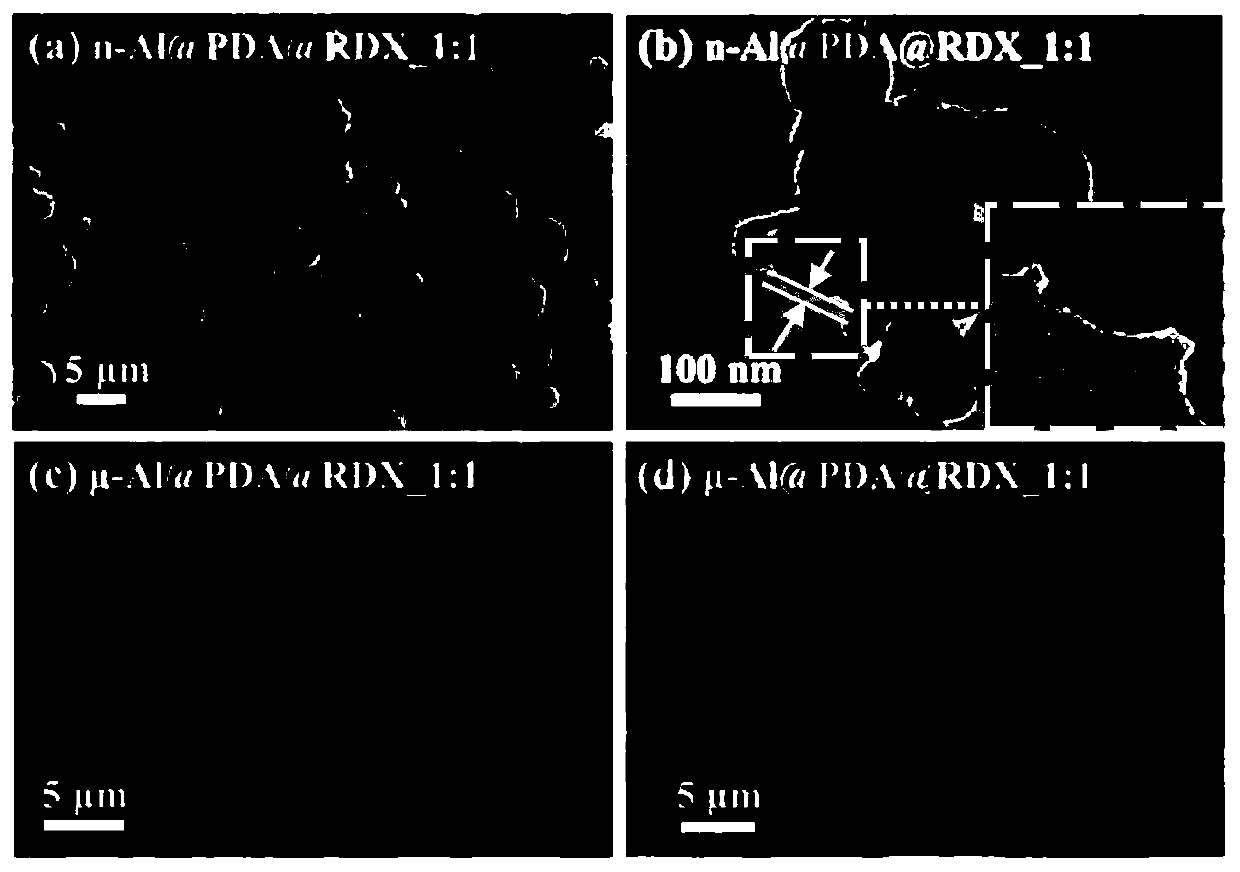

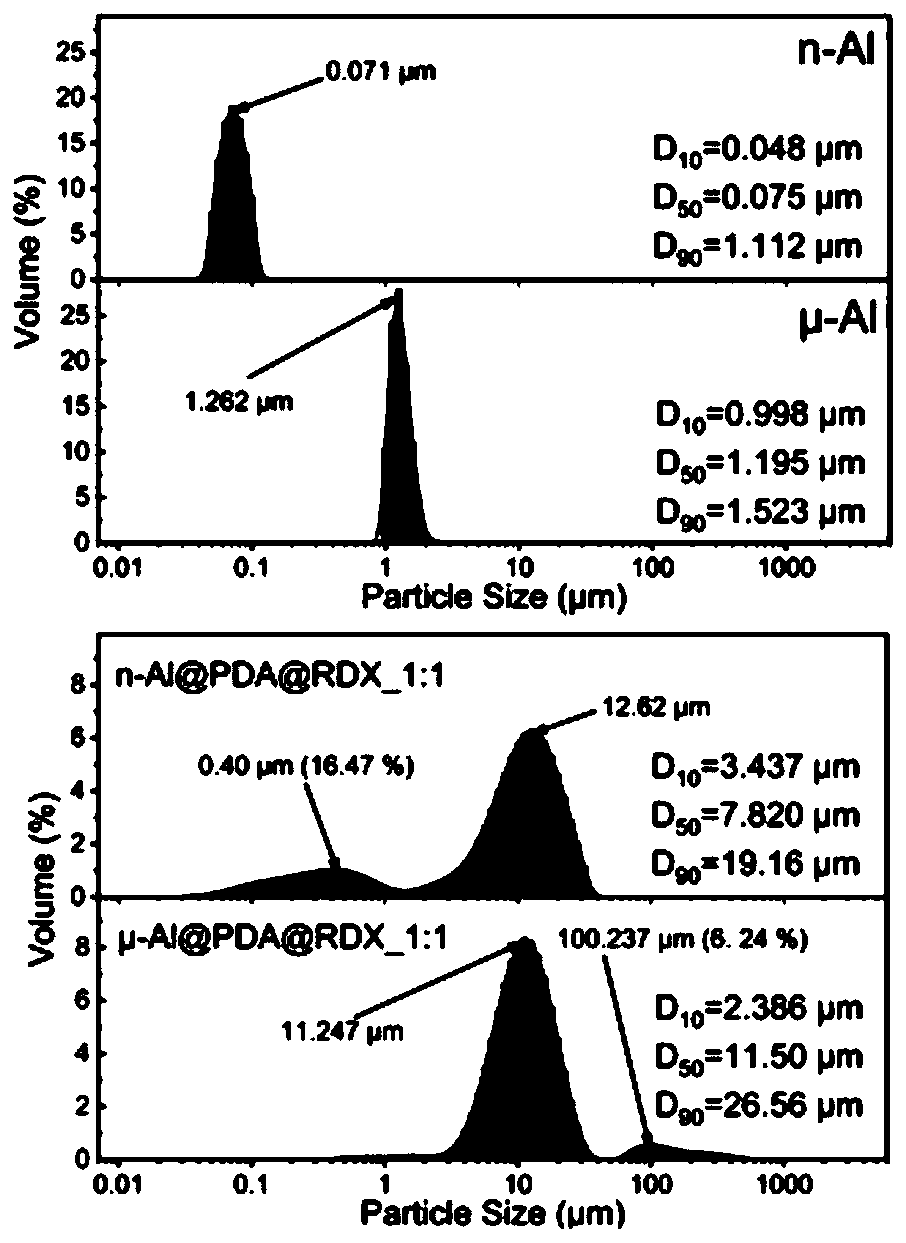

Composite solid propellant based on aluminum powder coated with nitramine oxidant and preparation method

PendingCN110885280AReduce combustion efficiencyAffect performanceExplosive working-up apparatusPressure gas generationSpray GranulationMetallic aluminum

The invention relates to a composite solid propellant based on aluminum powder coated with a nitramine oxidant and a preparation method. Dopamine surface-modified aluminum powder (Al@PDA) is coated with a nitramine oxidant (such as cyclotrimethylenetrinitramine, RDX) through a spraying drying technology to form compact core-shell-structured microspheres (Al@PDA@RDX) so as to replace RDX and Al intraditional propellant. Composite microspheres adopting interface interactions between the metal aluminum powder and the nitramine oxidant are adopted so that the oxidant and the aluminum powder in the propellant are in close contact, and can rapidly react when the propellant is combusted, and adverse influences of oxidant decomposition product diffusion and agglomeration of aluminum powder on propellant combustion can be suppressed. The preparation is simple and convenient, a spray granulation process, and industrialized production is liable to achieve. The composite solid propellant is simple in preparation method, and contents of components in a formula can be accurately controlled.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Intake system having a silencer device

ActiveUS9175648B2Satisfaction keeps decreasingReduce audible frequencyInternal combustion piston enginesSilencing apparatusEngineeringExpansion chamber

An intake silencer device is described herein. The intake silencer device includes an outer housing and a plurality of sequential arranged expansion chambers separated by walls. The intake silencer device further includes an inner tube positioned in each of the sequential chambers, each of the inner tubes including an opening providing fluidic communication between an interior of the tube and the corresponding expansion chamber, a size of the openings increasing in size sequentially in a downstream direction.

Owner:FORD GLOBAL TECH LLC

Oil control valve degradation detection and cleaning strategy

ActiveUS20100122861A1Improve engine performanceEasy to controlHybrid vehiclesValve arrangementsExhaust valveCombustion

A method for operating an oil control valve coupled to a cam phaser configured to adjust a position of at least one cam between hard stops, the oil control valve included in an internal combustion engine having an intake valve and / or an exhaust valve controlled via the cam phaser. The method including operating the oil control valve responsive to cam position feedback information, the oil control valve adjusted in a first relationship based on the feedback information and operating the oil control valve in a cleaning mode during select combustion conditions by abruptly switching the oil control valve between two states responsive to the cam position feedback information. The oil control valve adjusted in a second relationship based on the feedback information, the second relationship including more abrupt adjustment than the first relationship.

Owner:FORD GLOBAL TECH LLC

Oil control valve degradation detection and cleaning strategy

ActiveUS8136616B2Improve engine performanceEasy to controlHybrid vehiclesValve arrangementsCombustionExhaust valve

A method for operating an oil control valve coupled to a cam phaser configured to adjust a position of at least one cam between hard stops, the oil control valve included in an internal combustion engine having an intake valve and / or an exhaust valve controlled via the cam phaser. The method including operating the oil control valve responsive to cam position feedback information, the oil control valve adjusted in a first relationship based on the feedback information and operating the oil control valve in a cleaning mode during select combustion conditions by abruptly switching the oil control valve between two states responsive to the cam position feedback information. The oil control valve adjusted in a second relationship based on the feedback information, the second relationship including more abrupt adjustment than the first relationship.

Owner:FORD GLOBAL TECH LLC

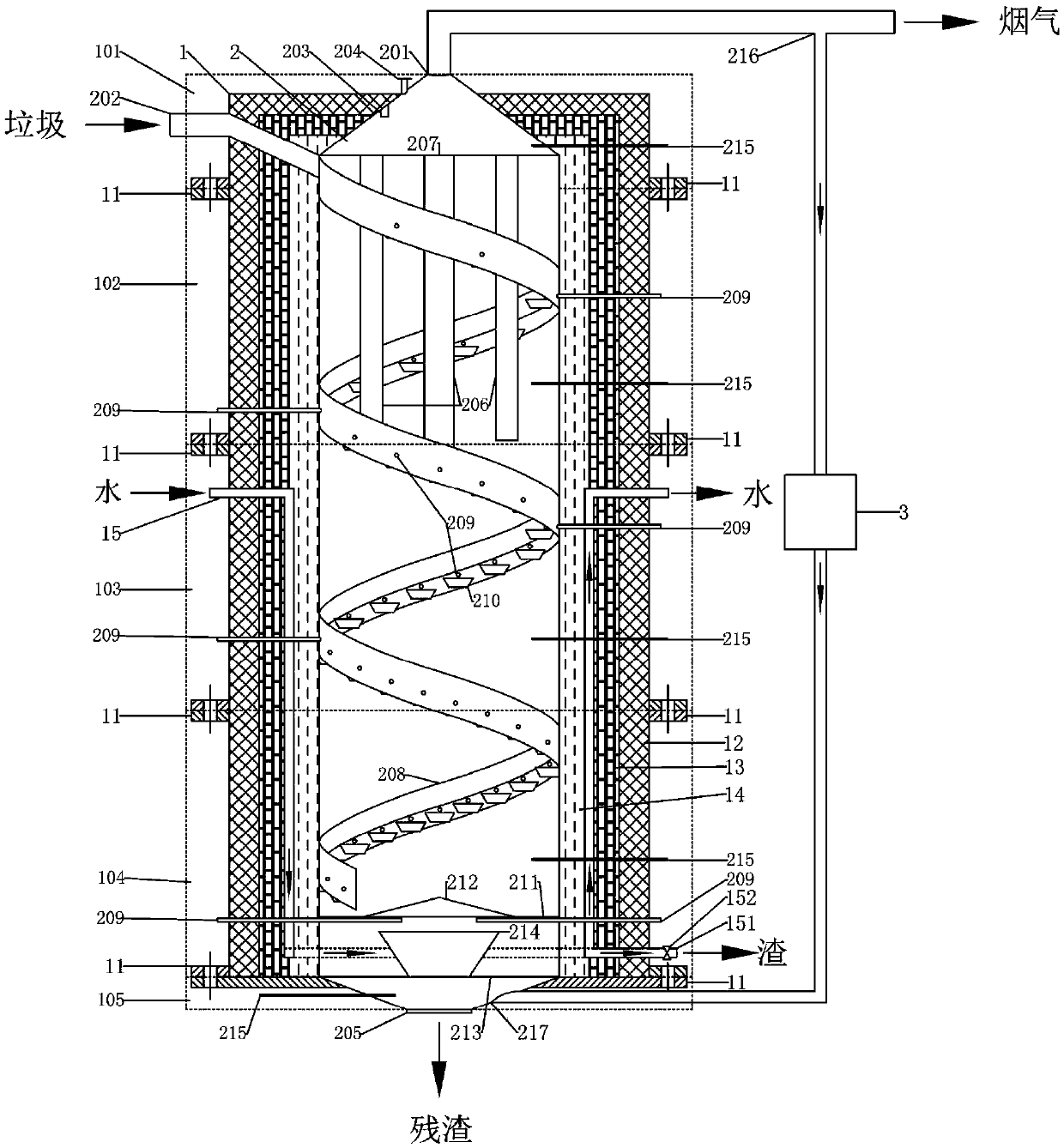

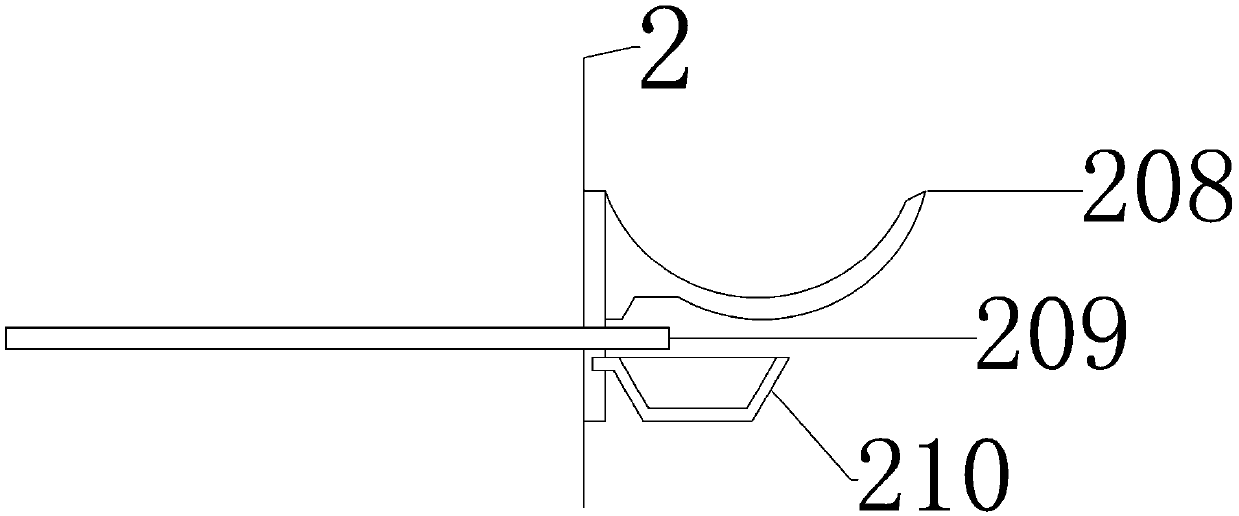

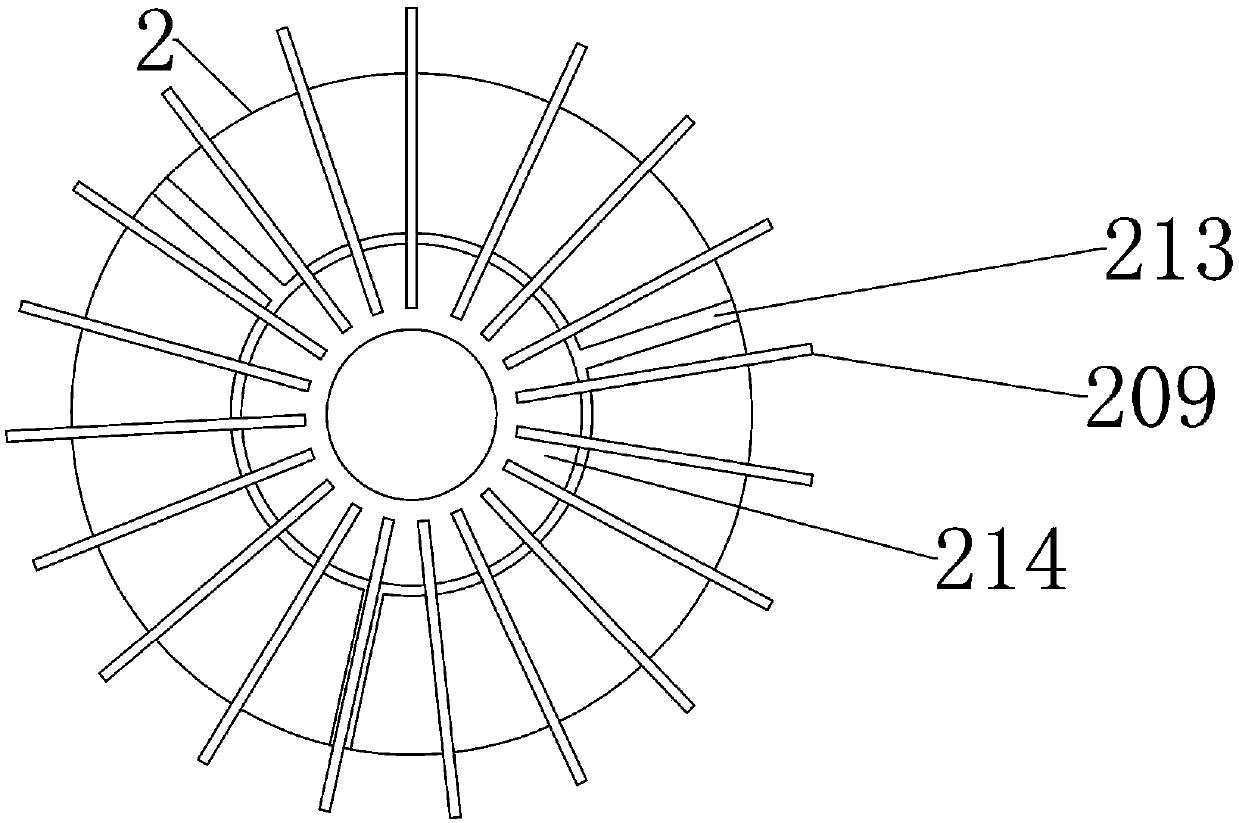

Brown's gas-burning solid organic waste pyrolyzing furnace

ActiveCN109681884ALow costInhibitionSpecial form destructive distillationIncinerator apparatusHeat conductingCrucible

The invention relates to the field of solid waste pyrolyzing devices, and discloses a Brown's gas-burning solid organic waste pyrolyzing furnace which comprises a housing and a cavity positioned inside the housing, wherein the housing is equipped with a main gas exhaust port, a pressure detector, an overpressure relief valve, an inductive ash-discharging electric valve and a feeding port; the cavity is equipped with smoke-guiding gas columns, a guiding chute, Brown's gas burning guns, wall-hanging crucibles, a heat conducting plate and a crucible basin; the wall-hanging crucibles and the crucible basin are filled with a metal material; and through an external fan of the Brown's gas-burning solid organic waste pyrolyzing furnace, part of burnable gas generated from the pyrolyzing process can flow back to the Brown's gas-burning solid organic waste pyrolyzing furnace. A kind of clean burning energy, namely Brown's gas, is utilized for the Brown's gas-burning solid organic waste pyrolyzing furnace; and the Brown's gas-burning solid organic waste pyrolyzing furnace has the advantages that the environment-friendly property is achieved, the cost is low, the occupied area is small, and solid organic waste can be efficiently, continuously and massively treated.

Owner:广东蓝新氢能源科技有限公司

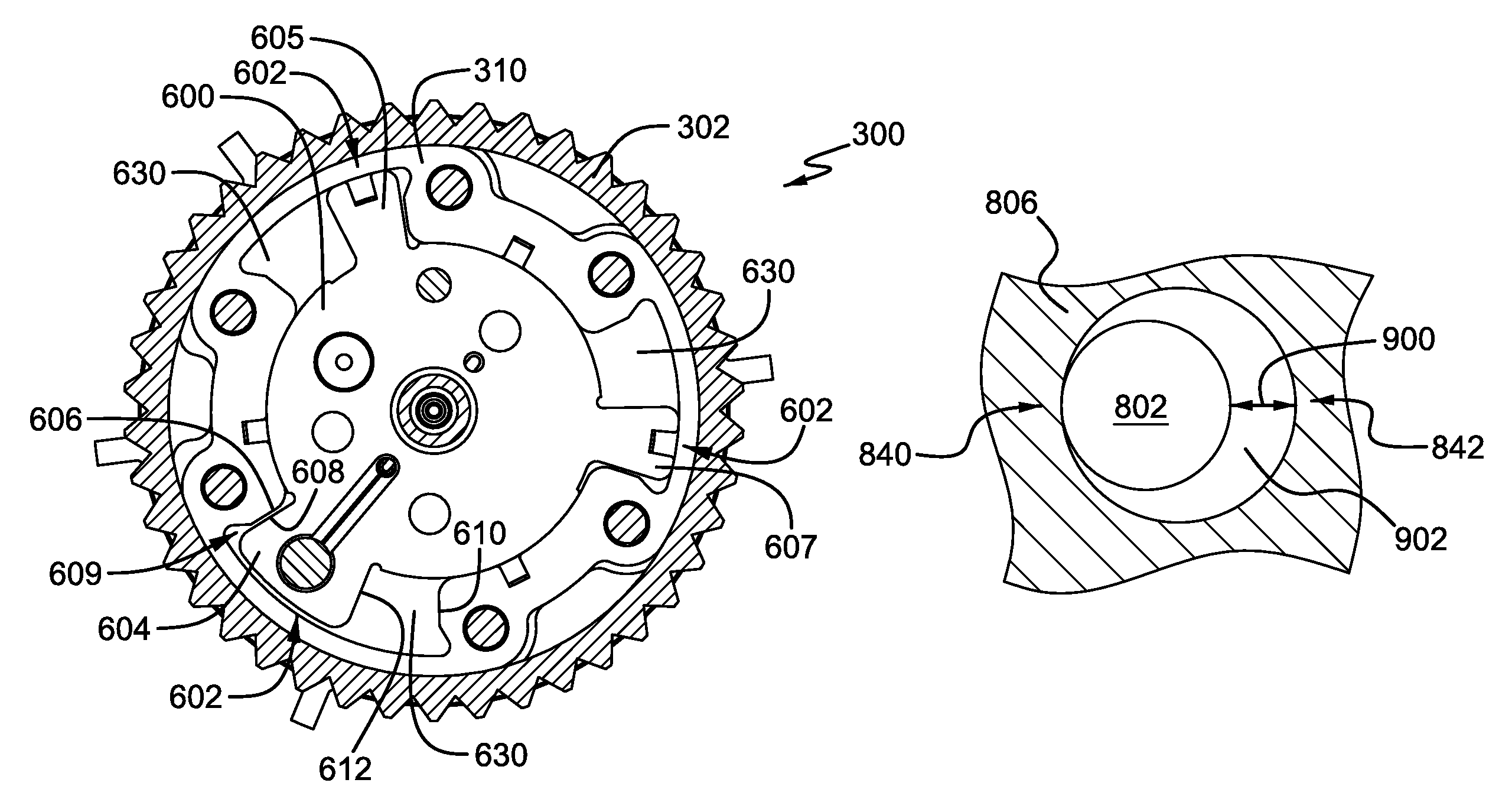

Variable cam timing system and method

ActiveUS9021998B2Improve combustion efficiencyEmission reductionValve arrangementsYielding couplingEngineeringPhase control

A phase control apparatus in a variable cam timing (VCT) system of an engine is described herein. The phase control apparatus includes a locking pin coupled to a vane, the locking pin extending into a locking pin recess in a cover plate in a locked configuration, the locking pin and locking pin recess having a backlash and a housing at least partially enclosing the vane and spaced away from the vane forming a gap in the locked configuration.

Owner:FORD GLOBAL TECH LLC

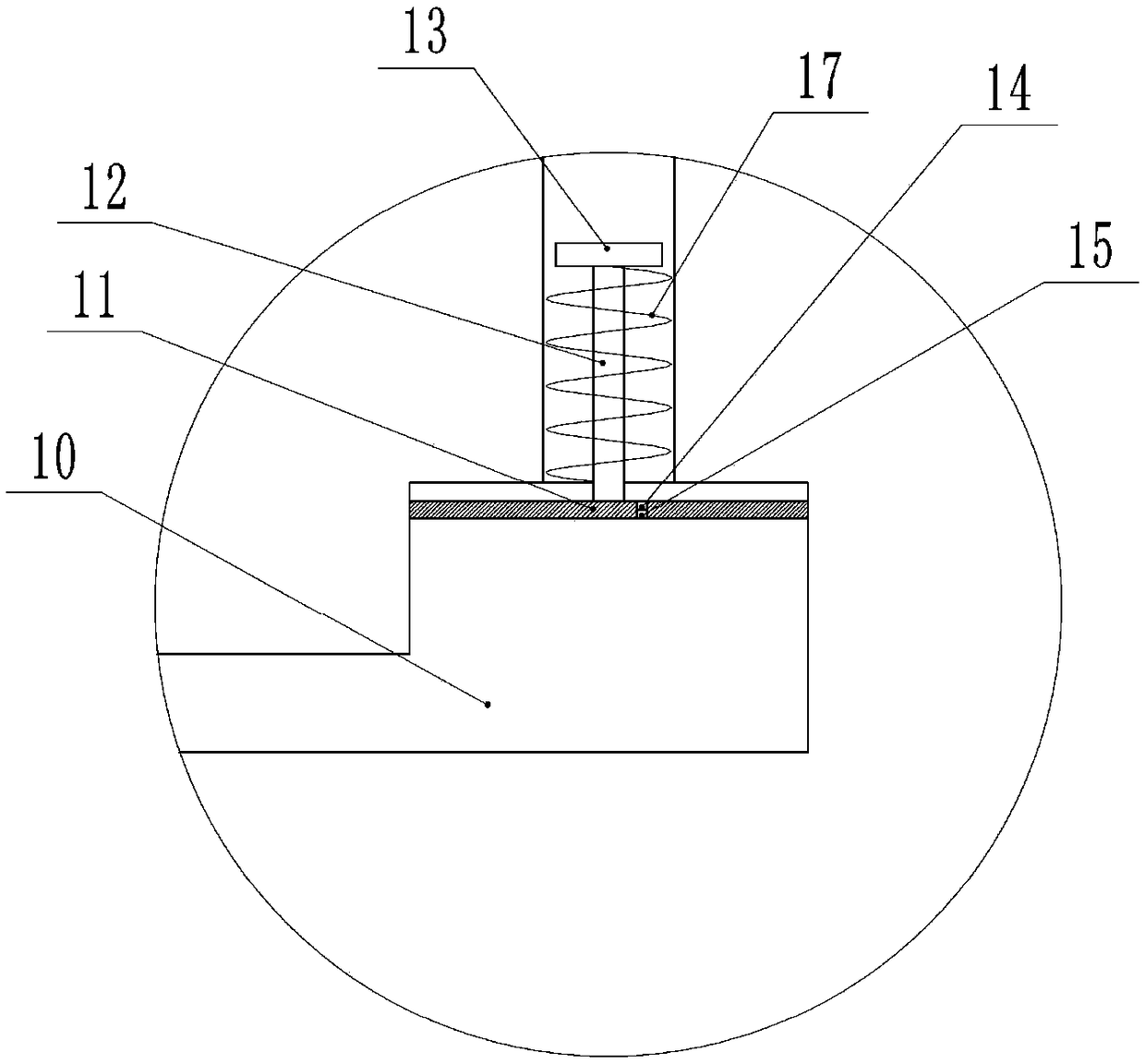

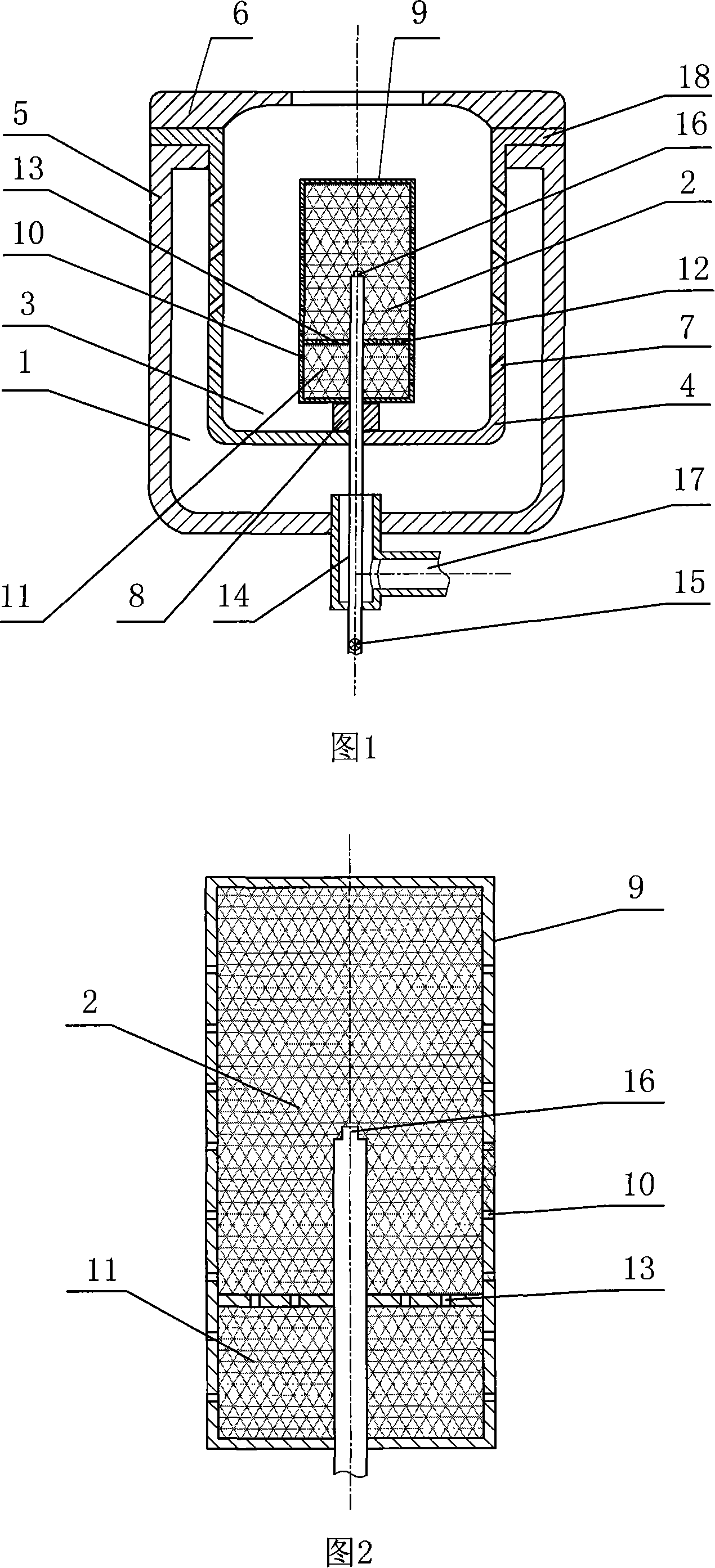

Highly effective liquid fuel evaporation combustion device

InactiveCN101149149AOvercoming weak vaporization abilityImprove leakageLiquid fuel evaporation burnersGaseous fuel burnerCombustion chamberEvaporation

This invention is a high efficiency liquid fuel vaporizing combustion device. It includes air chamber, vaporizing chamber and combustion chamber. There is combustion barrel is arranged between air chamber and combustion chamber. Its superior edge extends along horizontal radial direction and forms a ring shaped flange. The lower part of flange connects to air chamber barrel body, the bottom of which connects to air pipe. The radial wall of combustion barrel is arranged with air hole. The center of combustion barrel bottom has vaporizing tank, the center of which is arranged with fuel conveying pipe and nozzle. The internal wall of vaporizing tank has division plate, on which has the communicating hole communicating to the vaporizing chamber. The radial wall of vaporizing tank has fuel releasing hole. There is supporting gasket between vaporizing tank and combustion barrel bottom. Heat transferring medium is arranged inside of vaporizing chamber. This invention is adequate for equipment coordination such as boiler, kitchen range and air conditioner.

Owner:傅学正

Central region combustor with staged combustion function

InactiveCN105180213AReduce stabilityReduce combustion efficiencyContinuous combustion chamberCycloneCombustor

The invention relates to the field of low-emission combustion chambers, in particular to a central region combustor with the staged combustion function. The problem that the requirement for the high outlet temperature can hardly be met by a combustion chamber can be solved. The central region combustor comprises a central body assembly and a nozzle assembly. The central body assembly is provided with a central barrel, an outer central body wall and a first-stage cyclone. A main fuel channel is formed between a nozzle shell and the central barrel. An auxiliary fuel channel is formed between the outer central body wall and the central barrel. The nozzle assembly is provided with the nozzle shell and a fuel spray rod. The nozzle shell is provided with a fuel path. The fuel spray rod is provided with main fuel injection holes and auxiliary fuel injection holes. Auxiliary fuel through holes corresponding to the auxiliary fuel injection holes one to one are formed in the central barrel. By the adoption of the central region combustor, the emission performance of a combustion chamber at the high flame temperature can be optimized; and due to the additional arrangement of the auxiliary fuel channel, the impact effect of cooling air on a downstream central backflow region is eliminated, and instable combustion and reduction of combustion efficiency of a central region are prevented.

Owner:AECC SHENYANG ENGINE RES INST

Cleaning agent for gasoline system

InactiveCN102108310AEmission reductionReduce pollutionLiquid carbonaceous fuelsFuel additivesCombustion chamberPreservative

The invention relates to a new cleaning agent for a gasoline system and belongs to the technical field of fuel additives. The cleaning agent for the gasoline system, which is provided by the invention, consists of a cleaning dispersant, a nano micro-explosion component, an antioxidation stabilizer, a preservative, an antifriction protective agent, a basic solvent and other components. The cleaning agent is treated by a microencapsulation process. The cleaning agent for the gasoline system can be used in gasoline engines to clean pollutants generated in combustion and deposits in oil paths and combustion chambers so as to save oil, protect environment and maintain automobiles.

Owner:北京红豪特高科技发展有限公司

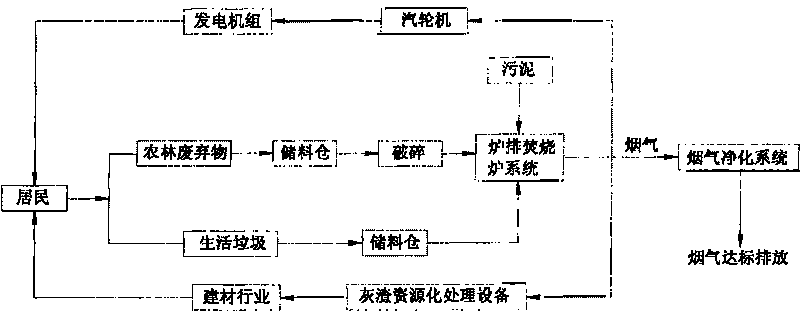

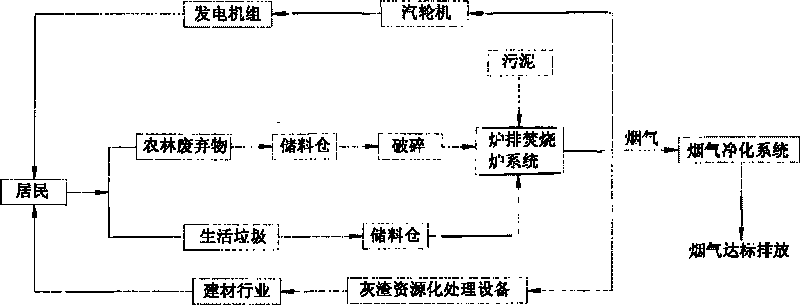

Method for mixed burning of agriculture and forestry waste, sludge and household garbage by using grate furnace

The invention relates to the technical field of energy environmental engineering and provides a method for mixed burning of agriculture and forestry waste, sludge and household garbage by using a grate furnace. The method comprises burning the agriculture and forestry waste, sludge and household garbage in a grate garbage burning furnace, igniting by using agriculture and forestry waste, and adding household garbage and sludge in the furnace to realize mixed burning when the temperature of the furnace rises to 850 DEG C, wherein the mass percent of the agriculture and forestry in the mixed fuel is within 40 percent, the mass percent of sludge in the mixed fuel is within 30 percent, the burning temperature of the grate burning furnace is controlled at 850 to 1000 DEG C, and the smoke gas generated by burning stayed in the furnace is controlled above two seconds. The invention is low in the cost, improves the burning efficiency of the garbage burning furnace, solves the problem of pollution caused by the sludge, ensures that the agriculture and forestry waste can be recycled, reduces discharge of pollutants, particularly heavy metal and dioxin and reduces the consumption of fossil energy.

Owner:SOUTHEAST UNIV

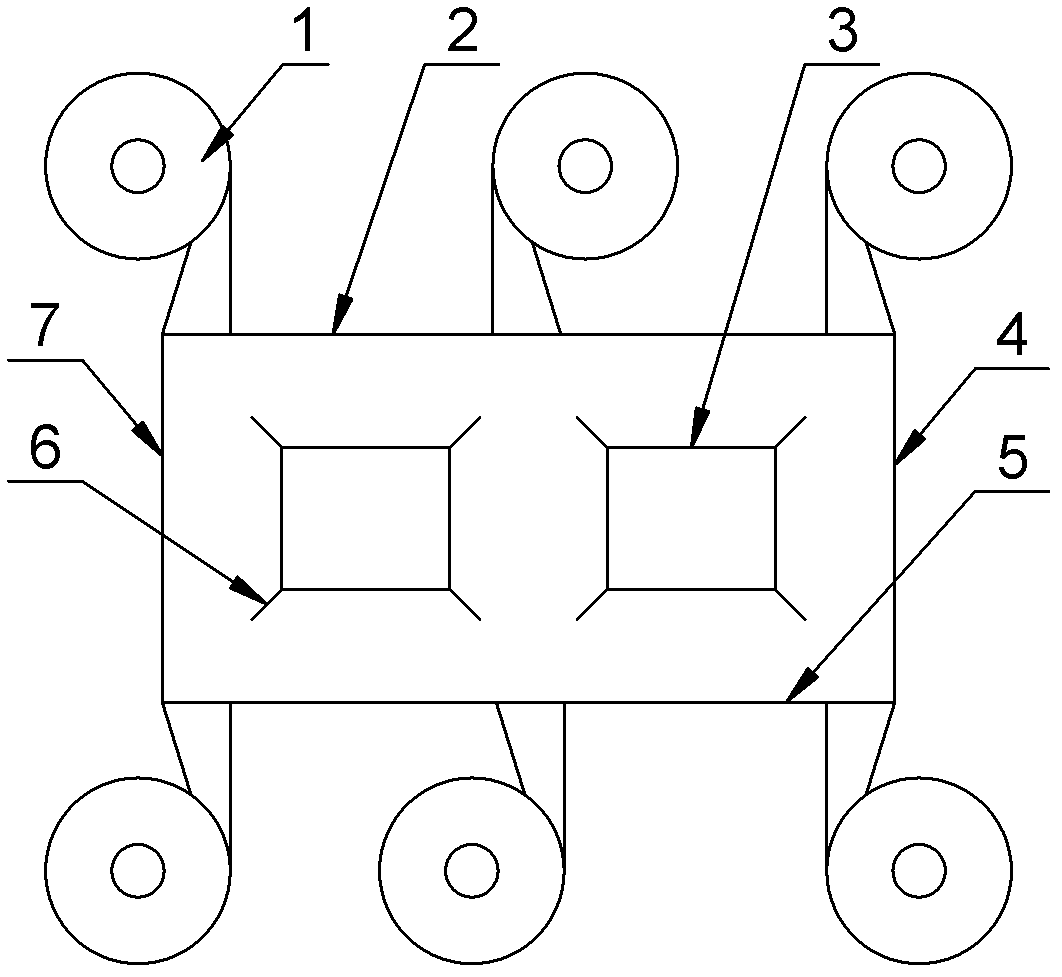

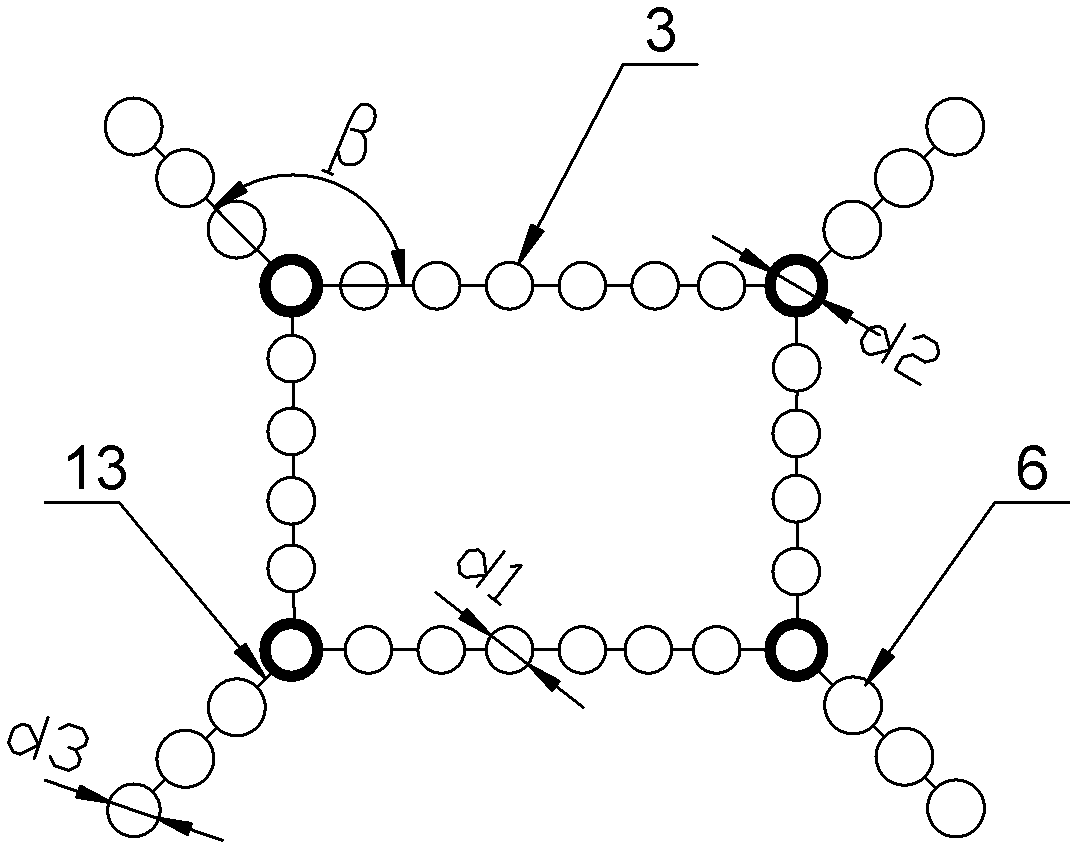

Circulating fluidized bed boiler having water cooling reinforcement structure

ActiveCN103216822AHigh strengthEnsure safetyFluidized bed combustionApparatus for fluidised bed combustionCombustionFluidized bed

The invention provides a circulating fluidized bed boiler. The circulating fluidized bed boiler comprises a hearth and a water cooling column, wherein the water cooling column is arranged in the hearth and is formed through enclosing a plurality of column membrane water cooling walls, an angle is formed between adjacent column membrane water cooling walls, the outside of the water cooling column at the corner of the adjacent column membrane water cooling walls of the plurality of column membrane water cooling walls is provided with at least one reinforcement wall formed by water cooling tubes and extending out of the whole height of the water cooling column, and the reinforcement wall protrudes toward the inside of the hearth from the water cooling column. A structure for increasing the strength of the circulating fluidized bed water cooling column is provided through utilizing the above technical scheme of the invention. The structure has the advantages of no occupying of the space in the column, increase of the strength of the hearth water cooling column, guarantee of the safe running of the water cooling column, and reduction of unfavorable influences to the combustion of a hearth fuel as possible.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

Air cooler and method for operation of an air cooler

ActiveUS20140216367A1High densityIncrease temperatureCoolant flow controlInternal combustion piston enginesEngineering

An air cooler line is provided. The air cooler lines includes a first air cooler having a plurality of air flow conduits, each of the air flow conduits including an inlet, and a first air flow deflector extending across peripheral portions of the inlets and fixedly coupled to the air flow conduits and a second air cooler having a plurality of air flow conduits, each of the air flow conduits including an inlet, and a second air flow deflector extending across peripheral portions of the inlets and fixedly coupled to the air flow conduits, the second air flow deflector differing in at least one of size and geometry than the first air flow deflector.

Owner:FORD GLOBAL TECH LLC

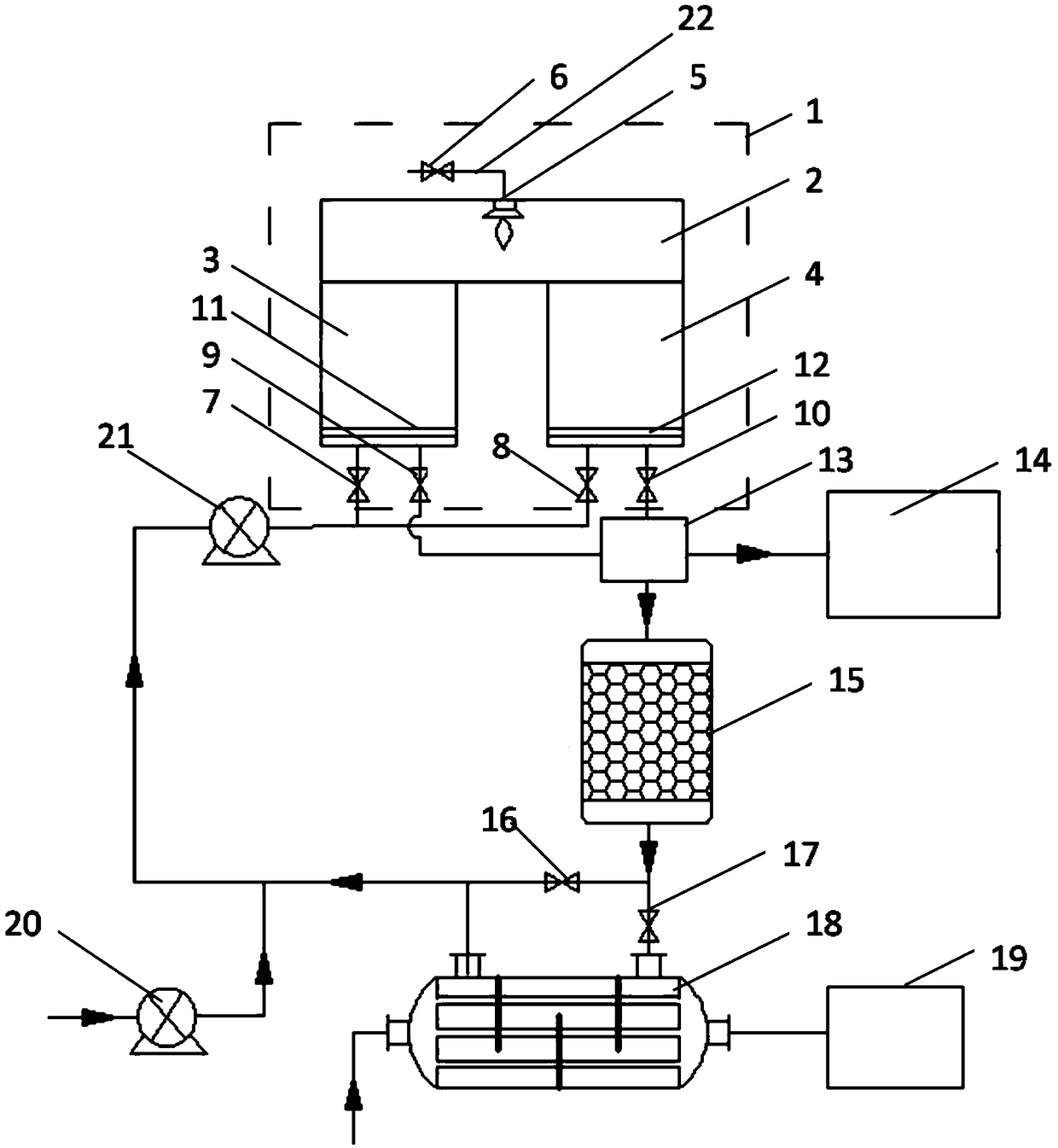

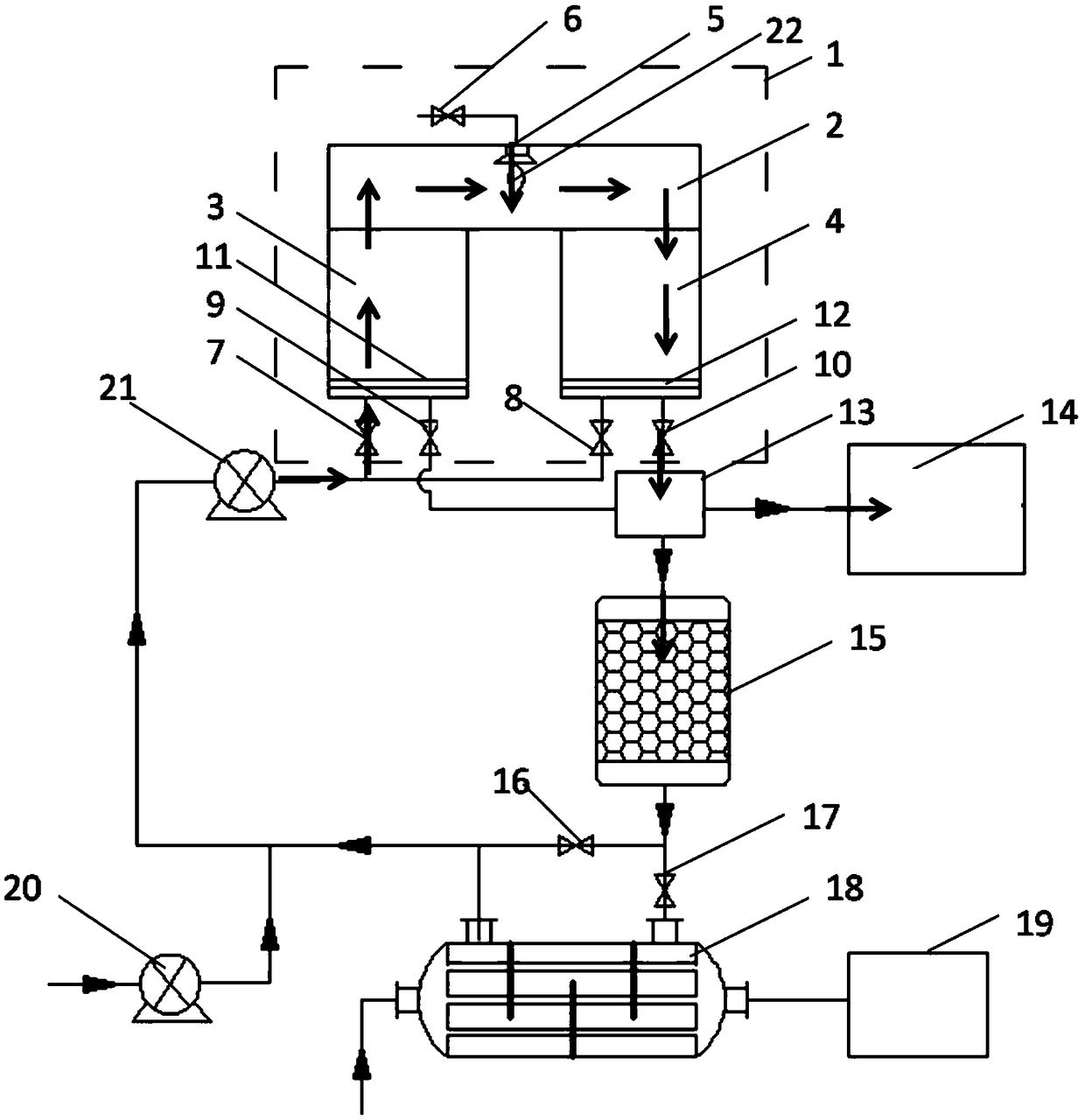

VOCs thermal oxidation treatment-based comprehensive waste heat recycling system and recycling method

ActiveCN109000269AImprove combustion efficiencyImprove utilization efficiencyClimate change adaptationIncinerator apparatusWaste heat recovery unitCombustion chamber

The invention discloses a VOCs thermal oxidation treatment-based comprehensive waste heat recycling system and recycling method. The system comprises a heat storage type incinerator, a flow divider, an absorption type refrigerating machine, an adsorption bed, a circulating fan and an air supplementing fan. The method comprises the following steps that part of smoke generated by a combustion chamber is conveyed to the absorption type refrigerating machine, the other part is conveyed to the adsorption bed, desorbed gas discharged from the adsorption bed is conveyed into the combustion chamber for combustion, part of the generated secondary smoke is conveyed to the absorption type refrigerating machine, the other part of the generated secondary smoke is conveyed to the adsorption bed, and then the secondary desorbed gas discharged from the adsorption bed is conveyed into the combustion chamber for combustion; Air supplementing processes are carried out in the whole process. According to the system and the method, the waste heat recovery adopts echelon heat extraction, specifically, the heat storage chamber is used for storing heat, the absorption type refrigerating machine is used forextracting heat, domestic hot water is used for heating and desorption hot air sources are used, and according to the gas temperature requirements of different waste heat utilization modes, the wasteheat is utilized to the maximum extent, and the energy utilization efficiency is improved.

Owner:TONGJI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com