Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

83results about How to "Realize the purpose of automatic feeding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

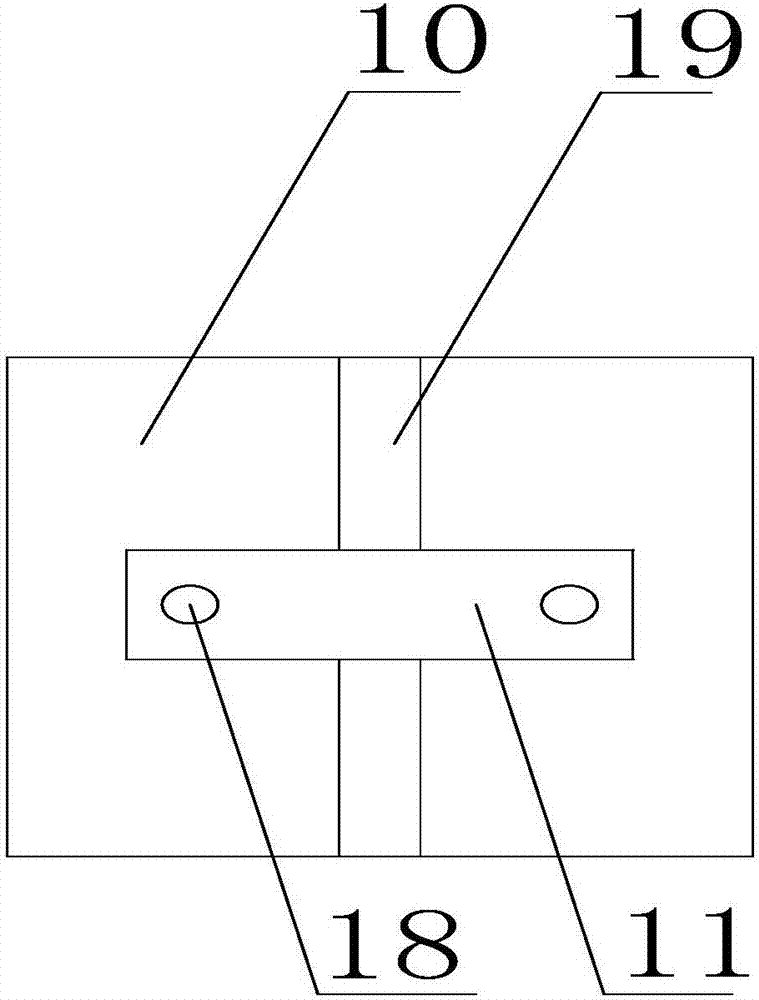

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

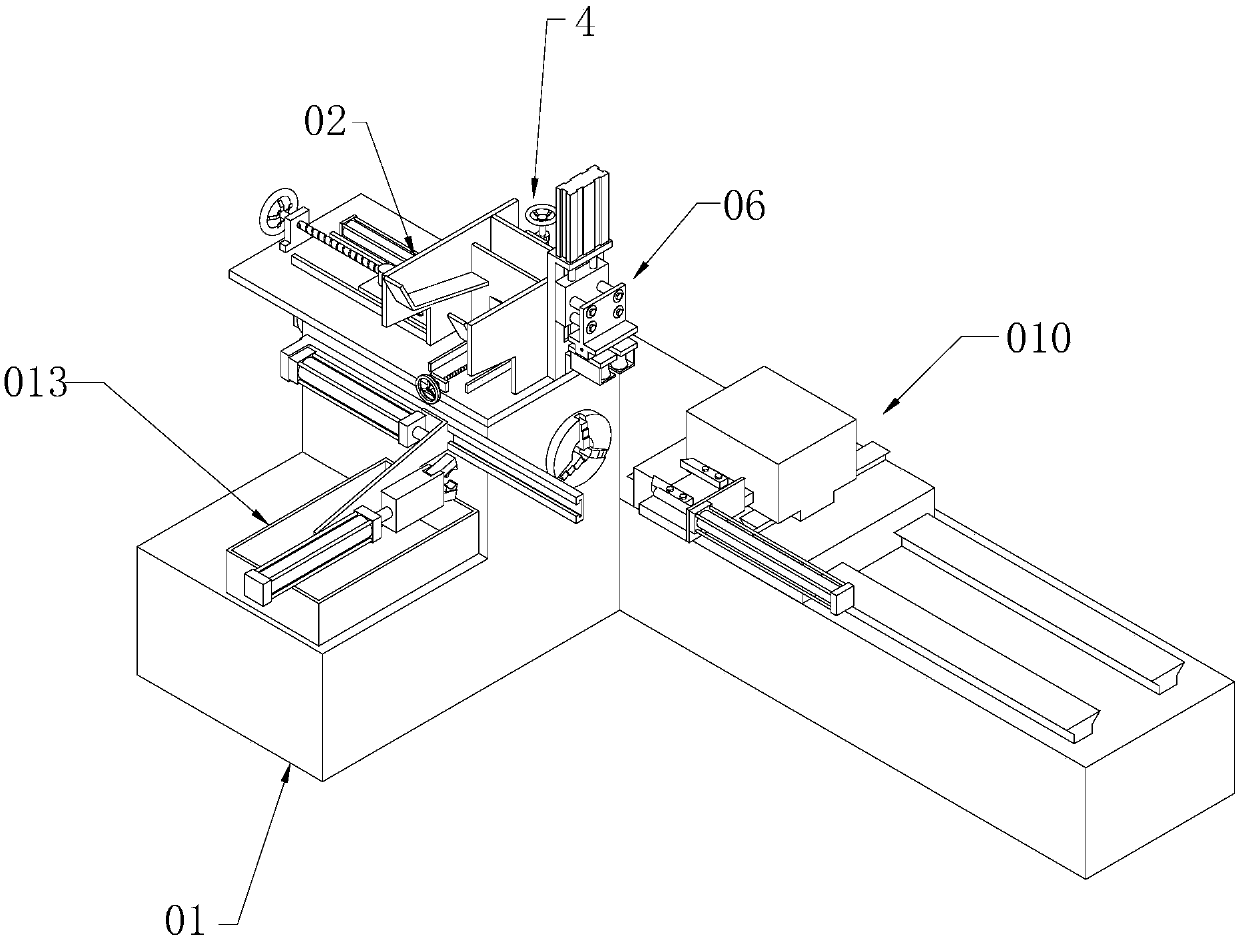

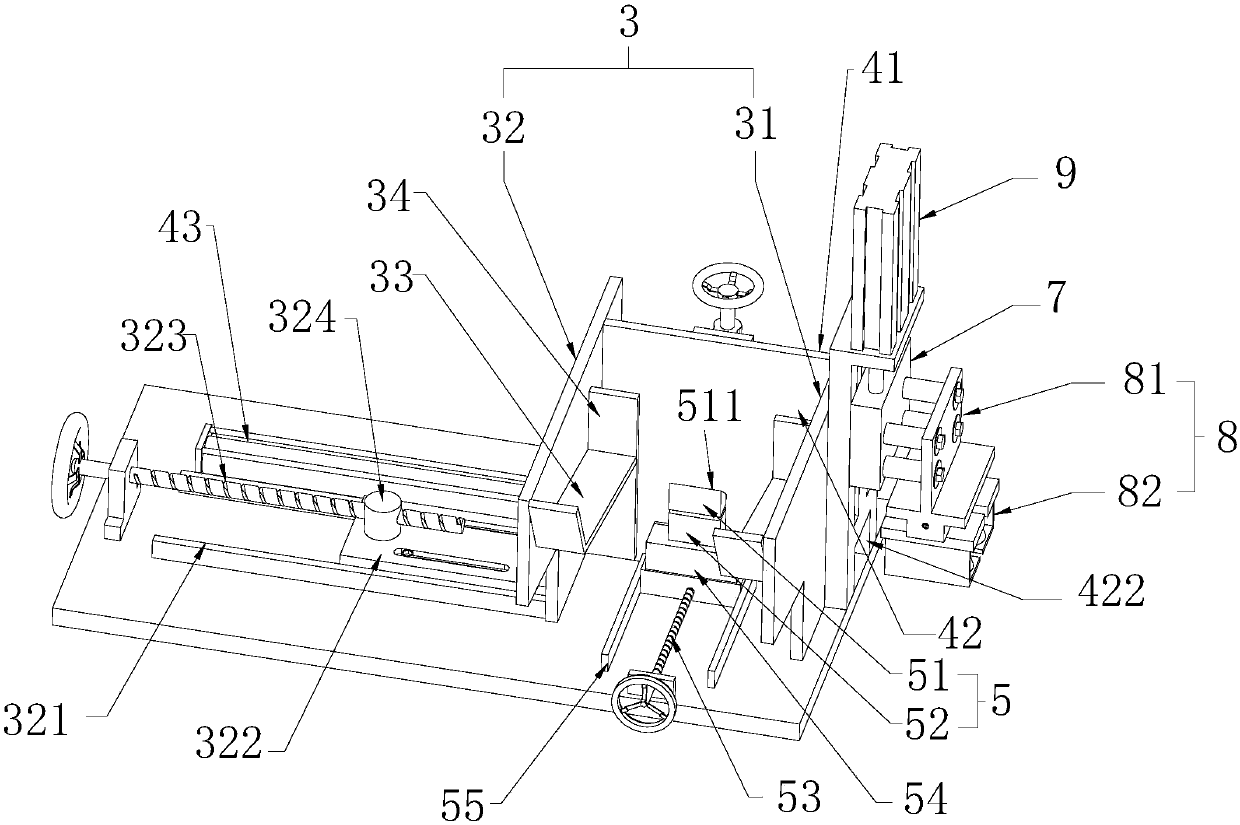

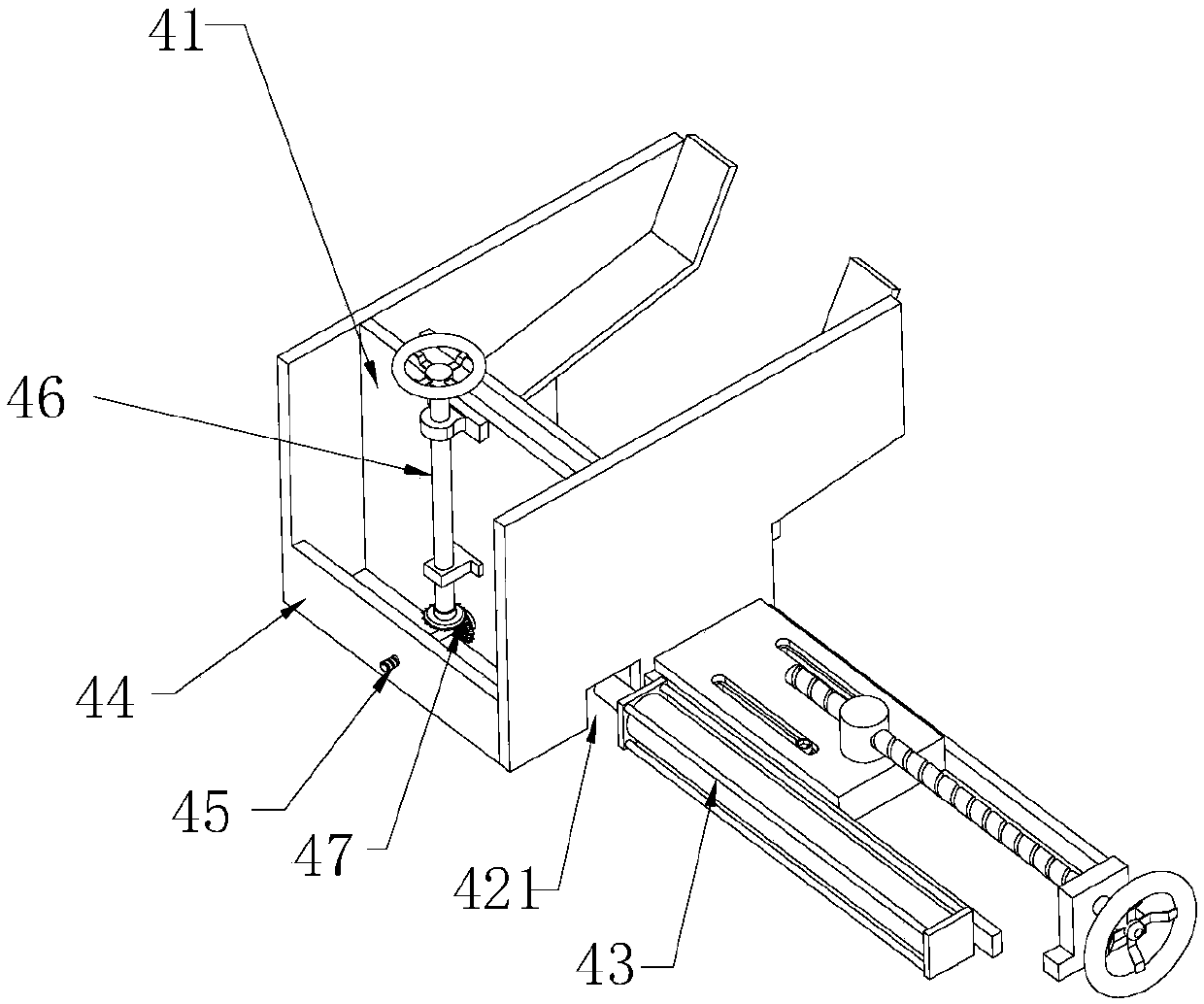

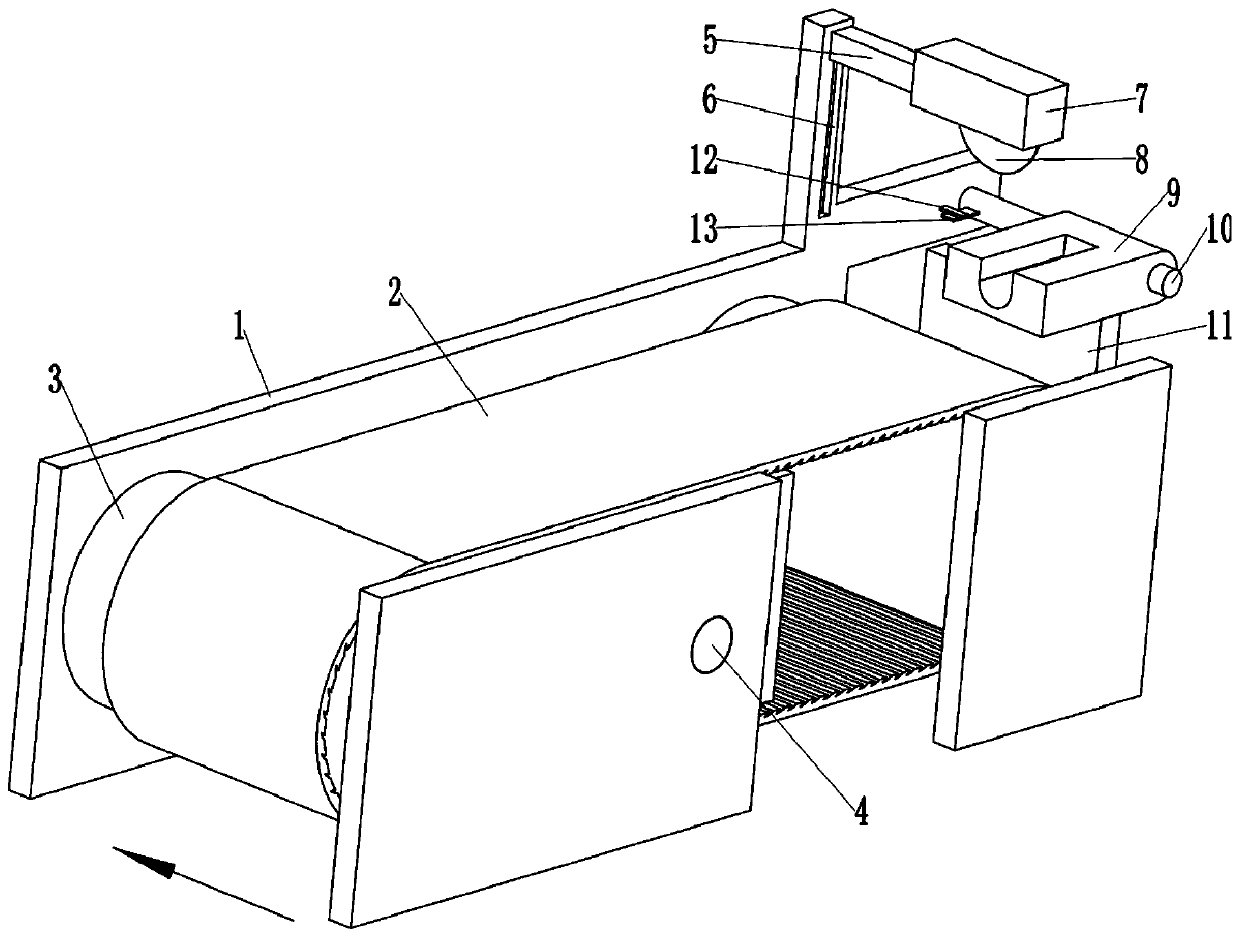

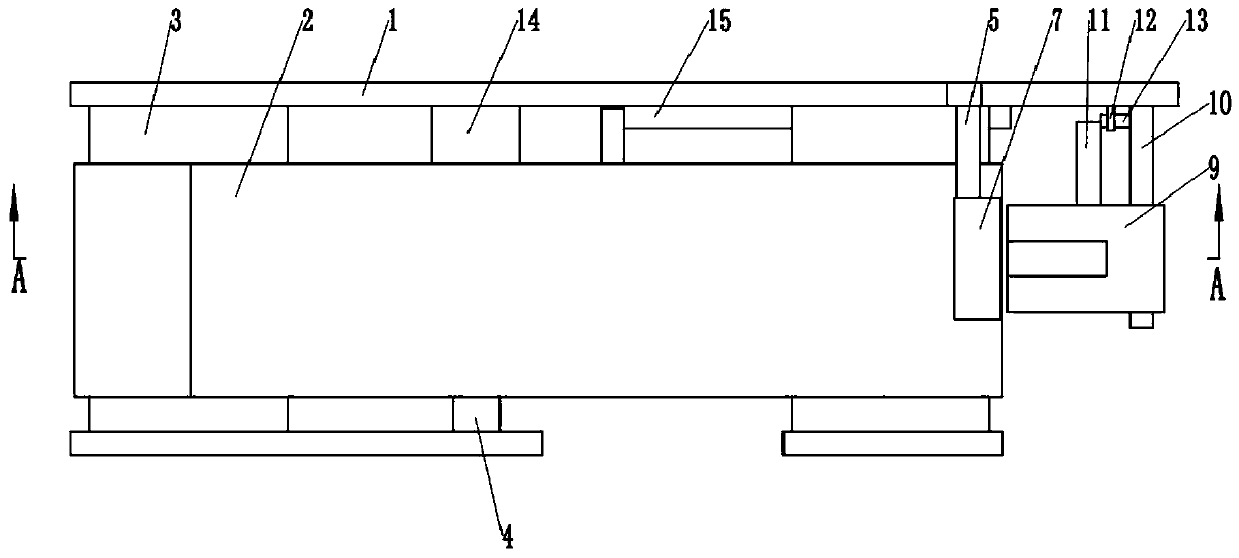

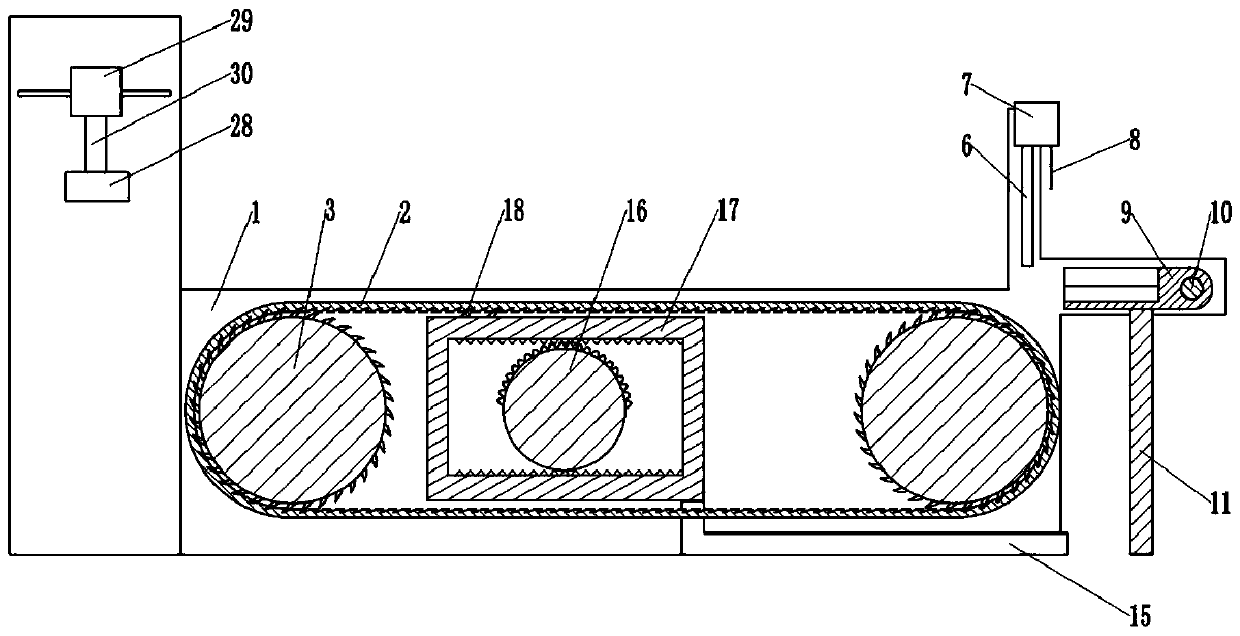

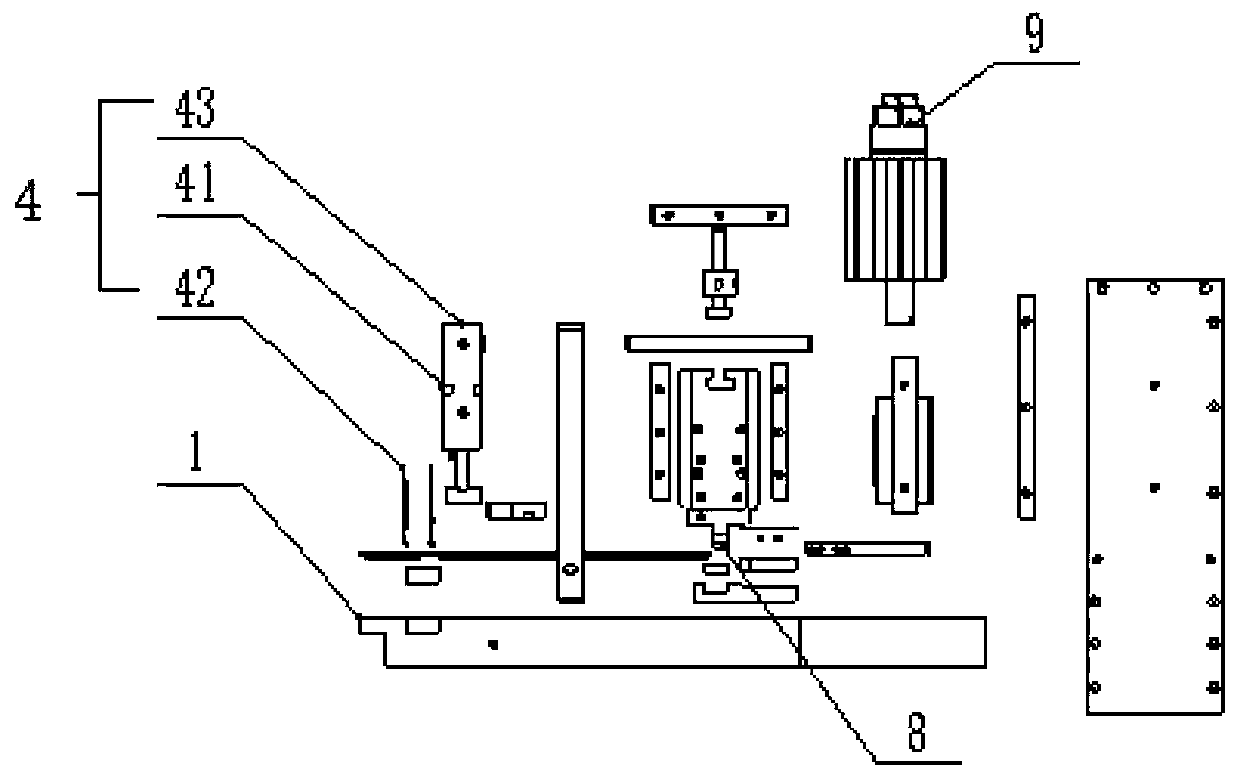

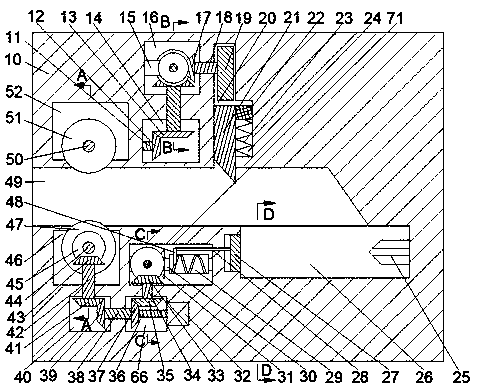

Fully automatic bar processing turning machine

ActiveCN109249036ARealize stackingRealize the purpose of automatic feedingAutomatic conveying/guiding stockTurning machinesNumerical controlFully automatic

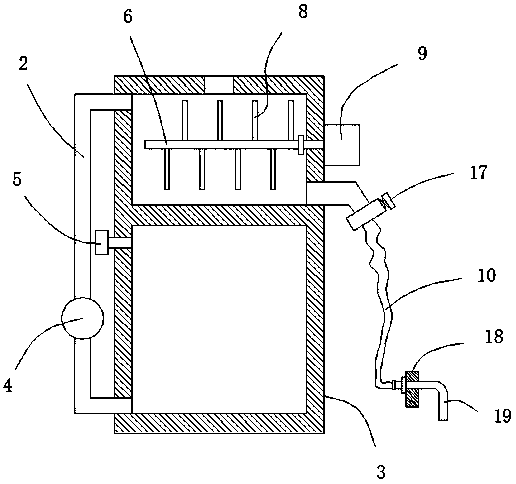

The invention relates to the field of bar turning, and discloses a fully automatic bar processing turning machine. The turning machine comprises a rack, a supplying unit, a feeding unit, a processingunit and a discharging unit which are arranged on the rack, wherein the processing unit comprises an electric main shaft and a numerical control cutter frame which is used for turning, the supplying unit comprises a storage hopper which is used for storing bars, an arrangement mechanism used for arranging the bars and a pushing power element used for pushing bars into the feeding unit one by one,the feeding unit comprises a feeding rack which moves on the part between the arrangement mechanism and the electric main shaft, a clamping mechanism which is used for clamping the bars and a pushingpower member which is used for pushing the bars into the electric main shaft, the discharging unit comprises a discharging hopper which is arranged on the rack, a discharging rack which is slidaby arranged and a discharging clamping claw which is used for clamping the bars. The supplying unit and the feeding unit supply the bars to the processing unit one by one, the processed bars are grabbed through the discharging unit to complete discharging, and fully automatic bar processing is achieved.

Owner:台州八球机电有限公司

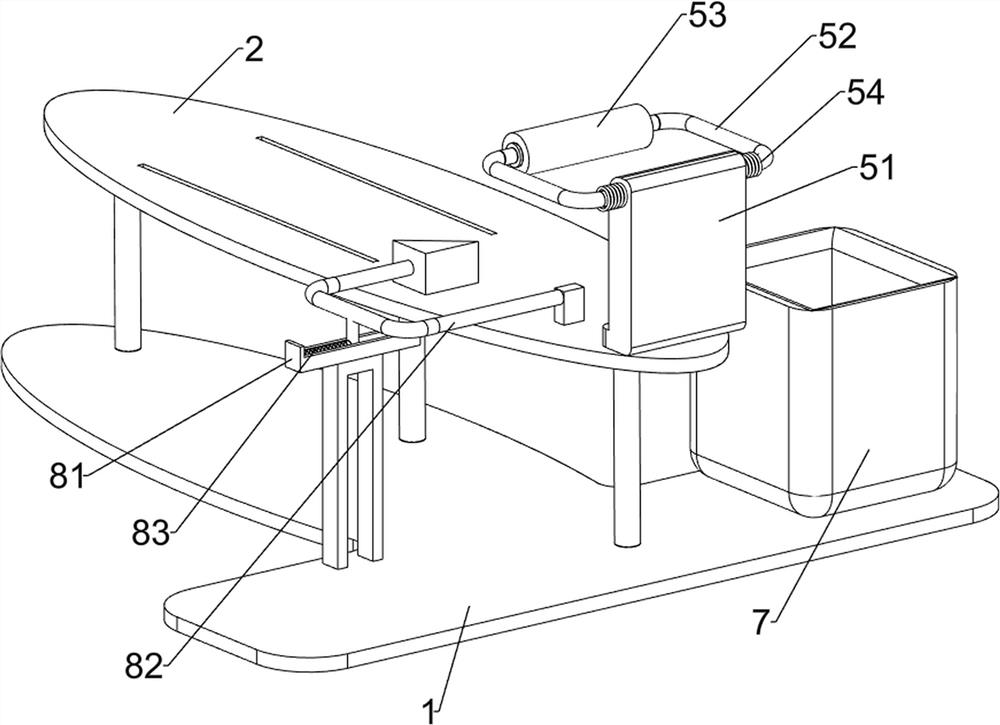

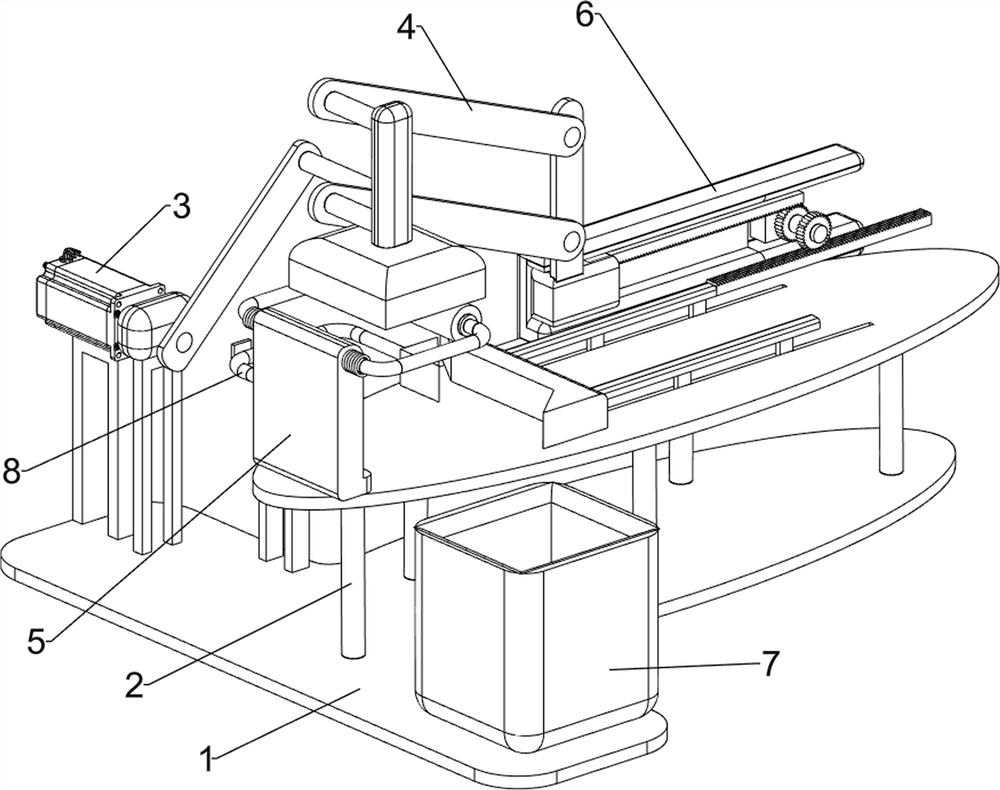

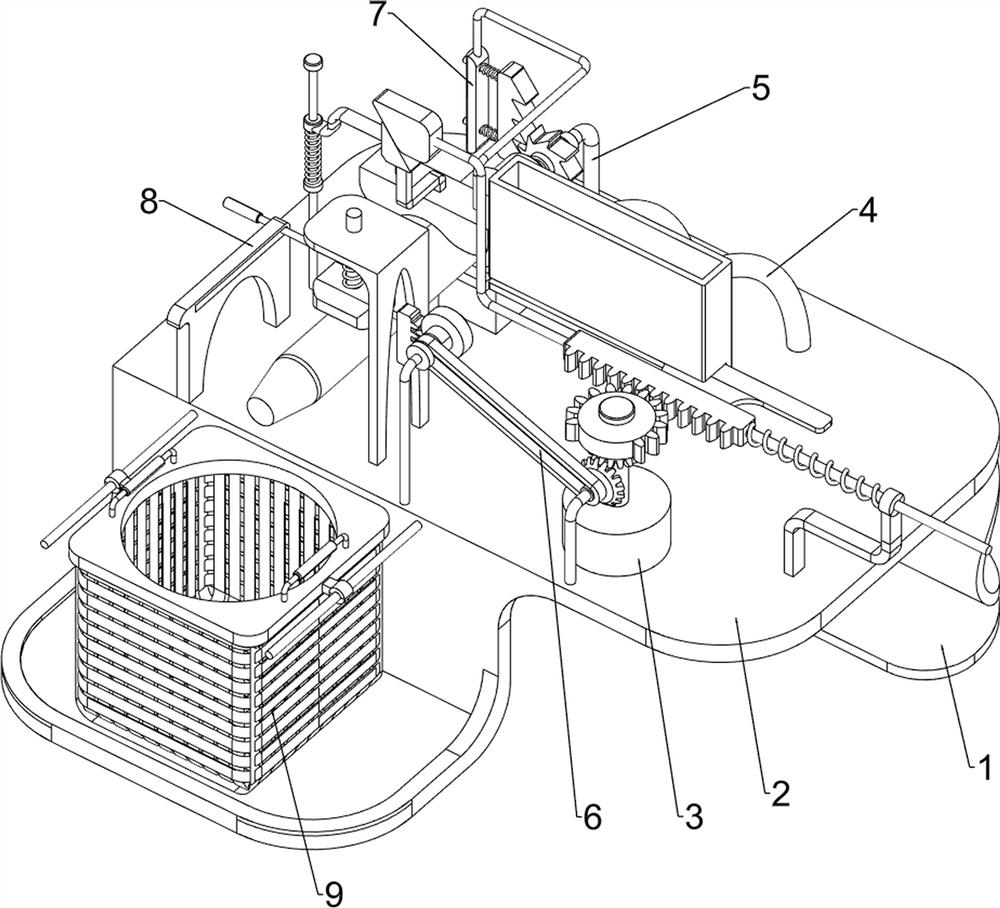

Trademark rubbing equipment for shoe boxes

PendingCN112248671AStamp position specificationReduce workloadStampingIndustrial engineeringSupport plane

The invention relates to rubbing equipment, in particular to trademark rubbing equipment for shoe boxes. The trademark rubbing equipment for shoe boxes can improve the standard degree of a stamping position while automatically printing the shoe boxes . The trademark rubbing equipment for shoe boxes comprises a bottom plate, supporting frames, a clamping mechanism, a labelling mechanism, a feedingmechanism and a servo motor; the five supporting frames are evenly arranged on the bottom plate; the clamping mechanism is arranged in the middle of the supporting frames in a sliding mode; the labeling mechanism is arranged on one side of the supporting frames in a sliding mode; the feeding mechanism is arranged on the supporting frames; and the servo motor is installed on the side, close to thelabeling mechanism, of the bottom plate. Through the design of the labeling mechanism, printing and stamping on paper shoe boxes by trademark printing pieces can be achieved, manual stamping is not needed, the workload of workers is reduced, and the stamping position of each paper shoe box is more standard; and through the design of a discharging mechanism, paper shoe boxes can be pushed down rightwards for automatic discharging.

Owner:韩凯

Cold-rolled strip surface burr removing mechanism

InactiveCN106985031ARealize the purpose of automatic feedingEdge grinding machinesGrinding carriagesArchitectural engineering

The invention discloses a mechanism for removing burrs on the surface of a cold-rolled steel strip, which includes a base and a motor, the base is provided with a first roller and a second roller, the first roller is provided with a first transmission rod, and the first transmission rod is provided with a There is a belt, the second roller is provided with a second transmission rod, the second transmission rod is connected to the output end of the motor, and the belt is also set on the second transmission rod, and the base is still provided with a fixed platform and a connecting rod. There is a chute, a slider is arranged in the chute, a positioning rod and a cross bar are arranged on the slider, a polishing layer is arranged on the bottom of the cross bar, a sleeve is arranged on the top of the connecting rod, and a connecting block is arranged on the sleeve , the connecting block is provided with a movable rod, and one end of the movable rod is provided with a grinding head. The present invention can remove burrs from the upper surface and from the surface of the steel strip, and is applicable to steel strips of different widths and thicknesses.

Owner:SICHUAN XINGGUANG STEEL CO LTD

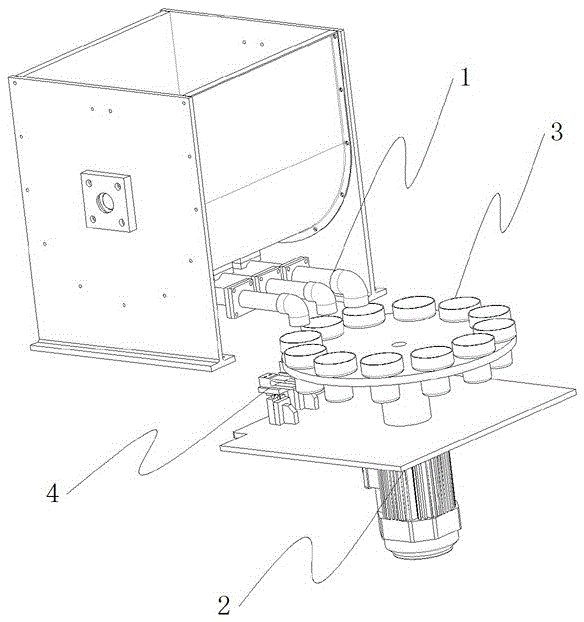

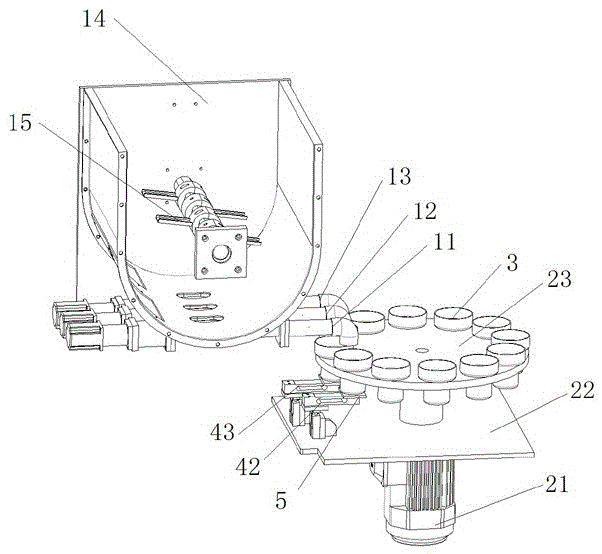

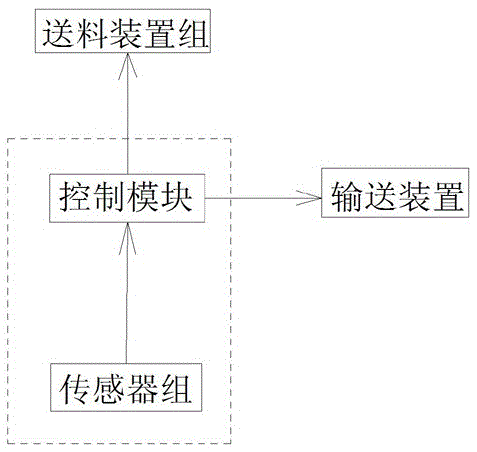

Multi-station weighing machine and method

ActiveCN105466533AShorten weighing timeFast weighingSpecial purpose weighing apparatusEngineeringMechanical engineering

The invention discloses a multi-station weighing machine and method. The multi-station weighing machine is provided with a feeding device group, a conveying device, a material weighing container group and a control system. The feeding device group is provided with at least two feeding devices, and each feeding device is provided with a material inlet and a material outlet. The conveying device is provided with a plurality of conveying stations which are successively arranged in the arranging direction of the material outlet. The material weighing container group is composed of a plurality of material weighing containers, and each material weighing container is correspondingly installed on one conveying station. The control system is provided with a control module and a sensor group electrically connected with the control module, and the control module is electrically connected with the feeding device group and the conveying device. The multi-station weighing machine has the advantages that the weighing speed is high, the weighing precision is high, material overflow is prevented, the size is small, the cost is low, the operation is easy, the structure is simple, the maintenance is simple, etc.

Owner:ZHUHAI HUALI FRICTION MATERIAL

Ring forming device for silver strips

PendingCN112170575AReduce manufacturing costUniform ring formationMetal-working feeding devicesPositioning devicesElectric machineryEngineering

Owner:张 治平

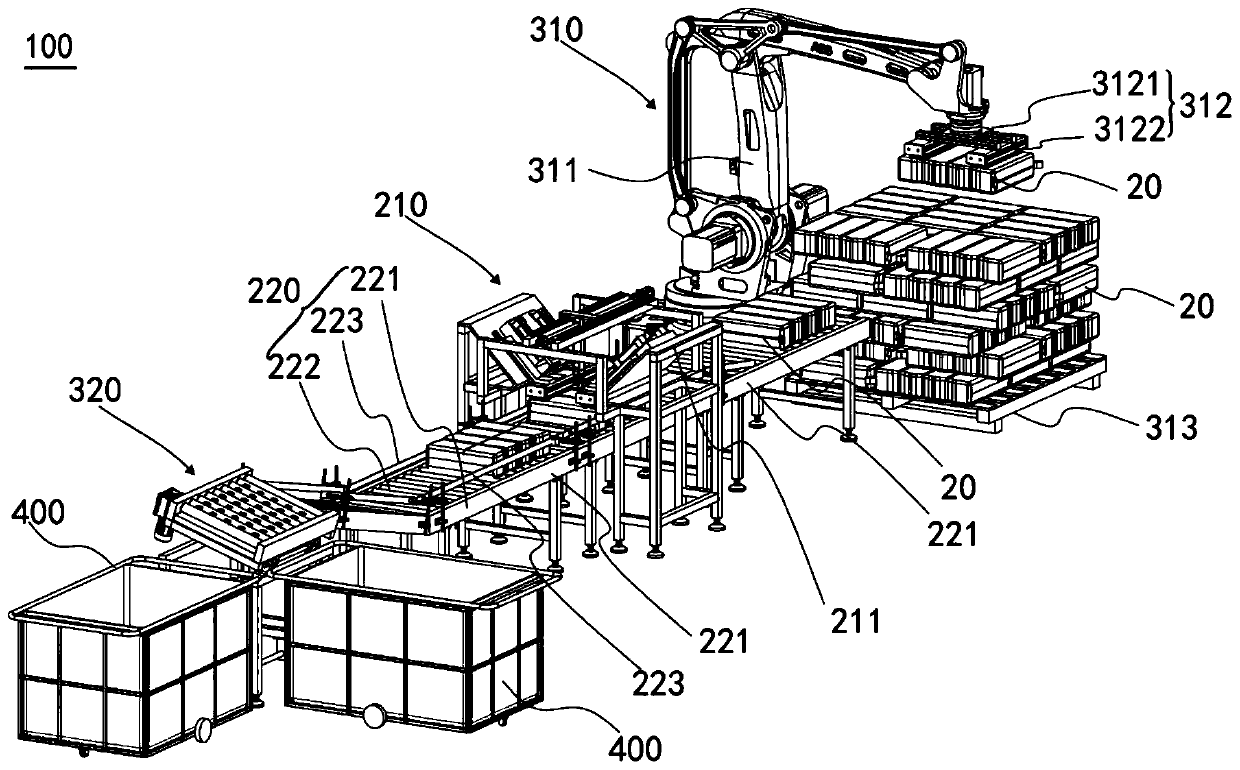

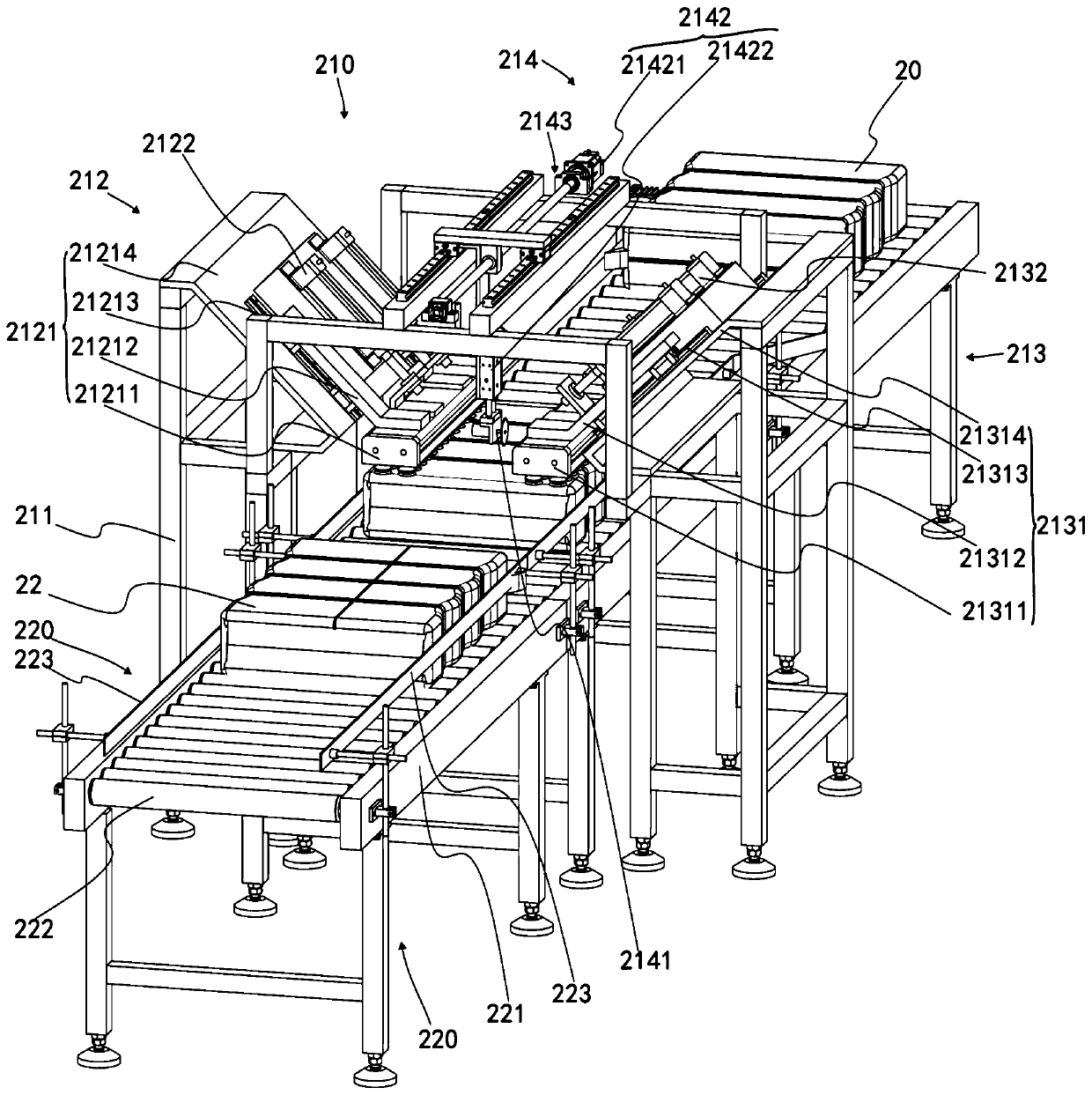

Package separating device and package separating method thereof

The invention discloses a package separating device and a package separating method of the package separating device. The package separating device comprises a bag opening mechanism and an unloading mechanism. The bag opening mechanism comprises a bag separating support, a first clamping component, a second clamping component and a cutting component, the first clamping component is installed on the bag separating support for obtaining the top of a cotton yarn package, the second clamping component is installed on the bag separating support for obtaining the top of the cotton yarn package, andthe cutting component is movably connected to the bag separating support for cutting the top of the cotton yarn package. The unloading mechanism comprises an unloading support, an unloading bearing component, an unloading fixing component and an unloading driving component, the unloading bearing component is rotationally connected to the unloading support, the unloading fixing component is arranged on the unloading bearing component for fixing the opened cotton yarn package, the unloading driving component is arranged on the unloading support and connected to the unloading bearing component, and the unloading driving component is used for driving the unloading bearing component to rotate to pour out cheese in the cotton yarn package. The package separating device is high in bag separatingefficiency.

Owner:GUANGDONG ESQUEL TEXTILES CO LTD

Feed and water feeding integrated device for Congjiang pig raising

PendingCN109169327AEasy to addEasy to operateAnimal watering devicesAnimal feeding devicesEngineeringIntegrated devices

Owner:从江县宰便镇禹甸香猪发展有限责任公司

Method for removing burrs on surface of stainless steel strip

InactiveCN107214580ARealize the purpose of automatic feedingClear applicableEdge grinding machinesGrinding carriagesMotor driveMetallurgy

The invention discloses a method for removing burrs on the surface of a stainless steel strip. The method comprises the following steps that firstly, the steel strip is placed on a first rolling shaft and a second rolling shaft, positioning rods are loosened, the eights of sliding blocks are adjusted, and a polishing layer is made to be attached to the upper surface of the steel strip; the positioning rods are screwed, then bolts are loosened, the heights of connection blocks are adjusted, movable rods are rotated, and polishing heads on the movable rods are made to be attached to the side surface of the steel strip; the bolts are screwed, a motor is started, the motor drives the first rolling shaft and the second rolling shaft to rotate, the first rolling shaft and the second rolling shaft drive the steel strip to move when being rotated, and in the movement process of the steel strip, the polishing heads and the polishing layer remove the burrs of the steel strip. By means of the method, the burrs on the upper surface and the side surface of the steel strip can be removed, and meanwhile the method is suitable for steel strips different in width and thickness.

Owner:SICHUAN XINGGUANG STEEL CO LTD

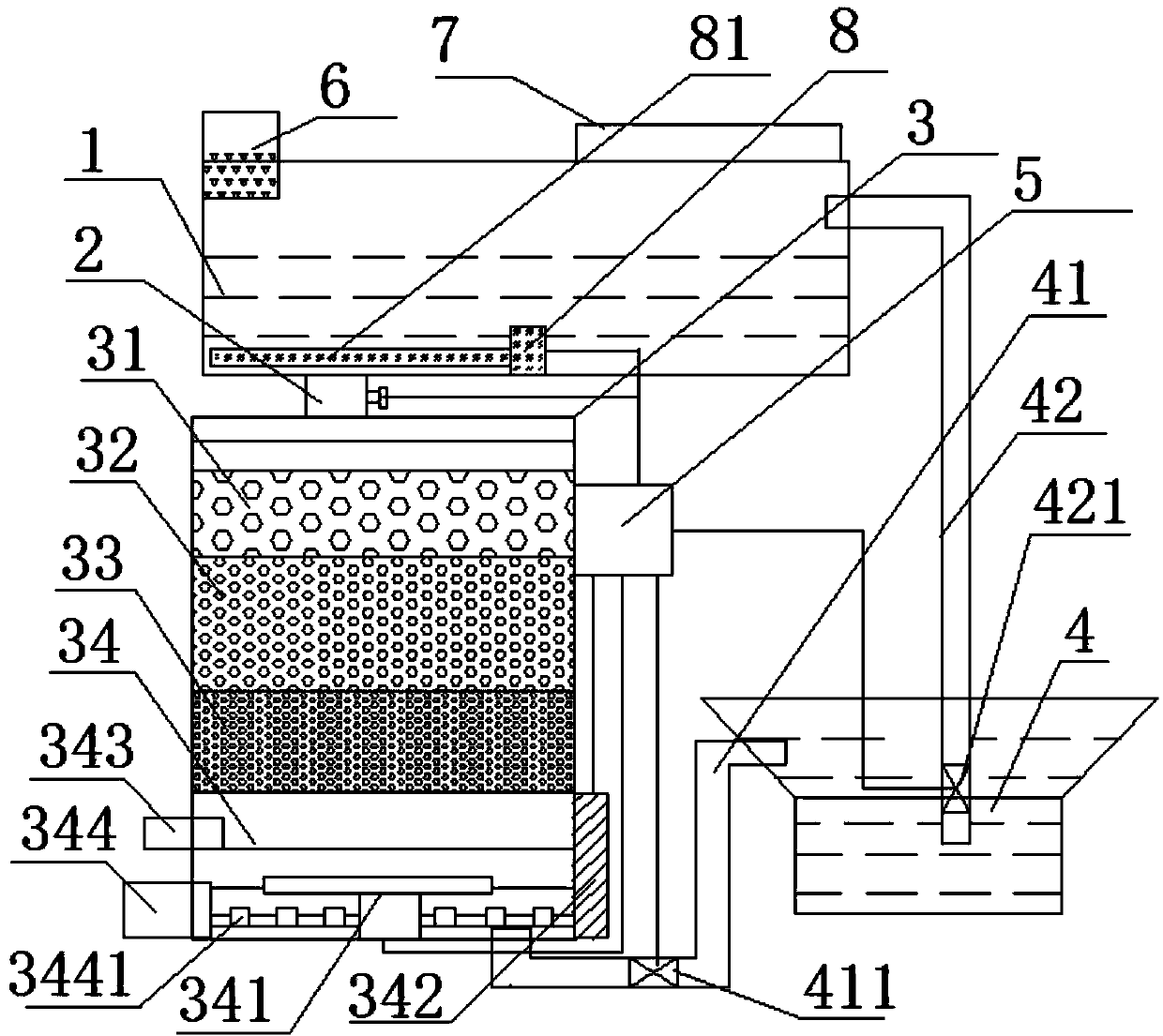

Solar fish tank control system with sterilization, feeding and washing functions

ActiveCN103583460AWell mixedAccelerated Disinfection and SterilizationPisciculture and aquariaAutomatic controlWater cycling

The invention relates to a solar fish tank control system with the sterilization, feeding and washing functions, and belongs to the technical field of fish tank waste-water utilization. The solar fish tank control system comprises a fish tank, a sterilization filter, a control chip, a fodder containing box, a washing device, a solar power generation unit and a standing chamber. The sterilization filter is provided with a coarse filtering layer, a fine filtering layer, an adsorption layer and a sterilization chamber, a stirrer is arranged on the inner side of the bottom of the sterilization chamber, and an ultraviolet ray generator, an alum containing box and an ozone generator are respectively arranged on the outer side of the sterilization chamber. The control chip is connected with a blow-off pipe electromagnetic valve, the stirrer, an ultraviolet ray electromagnetic switch, an ozone electromagnetic switch, an alum containing electromagnetic switch, a fodder discharging electromagnetic switch, a cycling motor, a first water pump and a second pump. According to the solar fish tank control system, waste water can be filtered, sterilized and disinfected, water cycling can be automatically controlled, the solar energy is used for generating power, automatic washing can be achieved, the aims of cycling water, automatic feeding and saving energy are accordingly achieved, and the solar fish tank control system is high in sterilization speed, good in sterilization effect and convenient to use at the same time.

Owner:中山市创星电器有限公司

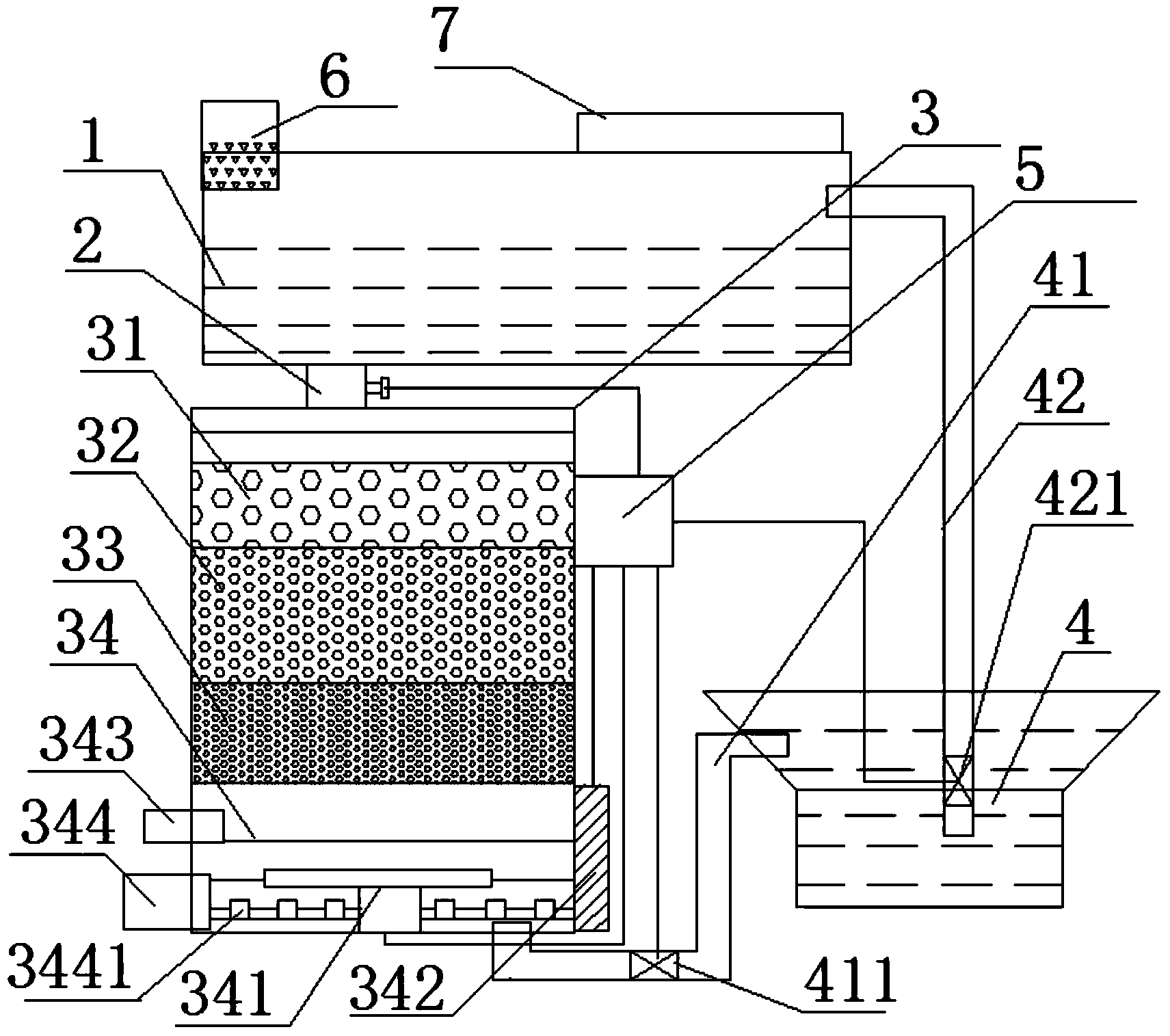

Solar fishbowl control system with sterilization and feeding functions

InactiveCN103621460AWell mixedAccelerated Disinfection and SterilizationAgricultural fishingMultistage water/sewage treatmentAutomatic controlUltraviolet

The invention relates to a solar fishbowl control system with sterilization and feeding functions, and belongs to the technical field of fishbowl wastewater utilization. The system comprises a fishbowl, a sterilization filter, a control chip, a feed placement box, a solar power generation unit and a standing chamber, wherein the sterilization filter is provided with a rough filtering layer, a fine filtering layer, an adsorption layer and a sterilization chamber; a stirrer is arranged on the inner side of the bottom of the sterilization chamber; an ultraviolet generator, an alum placement box and an ozone generator are arranged on the outer side of the sterilization chamber respectively; a discharge pipe electromagnetic valve, the stirrer, an ultraviolet electromagnetic switch, an ozone electromagnetic switch, an alum placement electromagnetic switch, a feed discharging electromagnetic switch, a first water pump and a second water pump are connected to the control chip. According to the system, wastewater can be filtered, sterilized and disinfected, water circulation can be automatically controlled, and solar energy can be used for generating power, so that the aims of water recycling, automatic feeding and energy saving are fulfilled; moreover, the system is high in sterilization speed and convenient to use, and has a good sterilization effect.

Owner:徐丽丽

Intelligent conveying device for food and beverage production

ActiveCN112357866APrevent production process impactImprove work efficiencyConveyorsLiquid bottlingControl engineeringBottle

The invention relates to the technical field of food and beverage production, and discloses an intelligent conveying device for food and beverage production. The intelligent conveying device comprisesa mounting block. According to the intelligent conveying device for food and beverage production, a beverage bottle is placed between left and right clamping plates, then a push rod is pushed to drive a moving block to move along a driving frame, the moving block drives an inserting rod to move through a mounting spring, and the inserting rod drives a first push block to move, so that the first push block drives a second push block to move left and right along a mounting frame; the second push block drives a limiting plate to move, and the limiting plate drives two connecting rods to move, sothat the two connecting rods drive the clamping plates to move; beverage bottles of different sizes are clamped by adjusting the distance between the two clamping plates; meanwhile, a limiting rod moves into a clamping groove under the action of a reset spring to be connected with the clamping groove in a clamped mode, thus, the position of the first push block is fixed, and the influence on theproduction process due to toppling of the first push block is prevented; and the problem that only beverage bottles of one size can be clamped is solved.

Owner:BENGBU KUNPENG FOOD & BEVERAGE

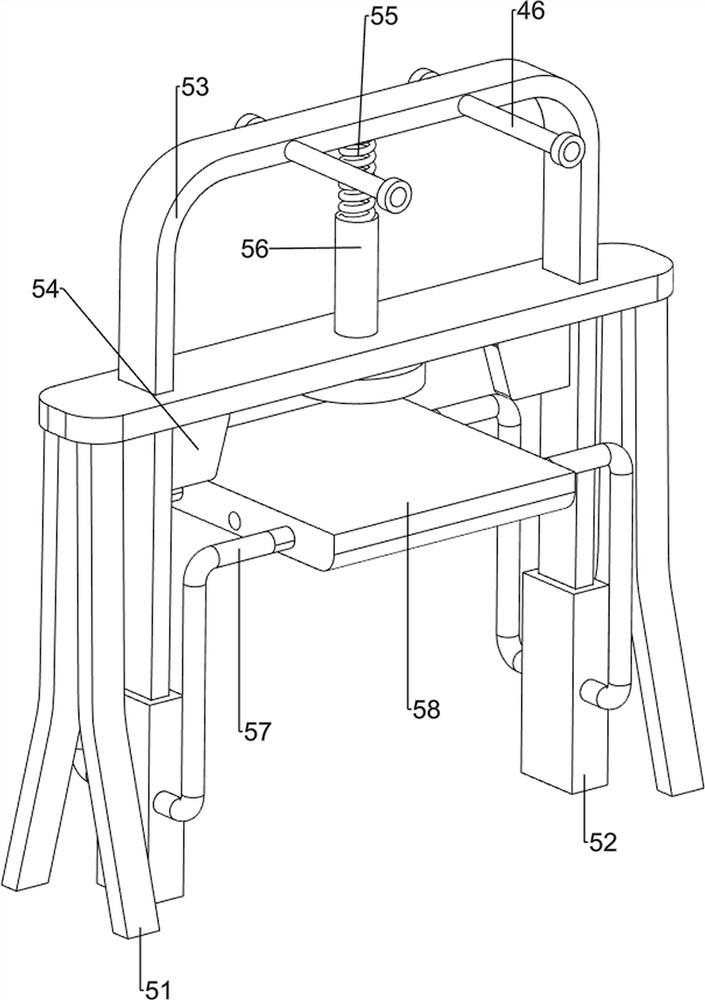

Equipment for trimming to-be-delivered books

InactiveCN112372681ATrimmingReduce the risk of being accidentally injured by a knifeMetal working apparatusBaseboardStructural engineering

The invention relates to trimming equipment, in particular to equipment for trimming to-be-delivered books. The invention provides equipment, capable of automatically trimming books and fixing the books during trimming, for trimming the to-be-delivered books. The equipment for trimming the to-be-delivered books comprises a baseboard, a first air cylinder, a first top column, a trimming mechanism,a pressure mechanism and a first support, wherein the first air cylinder is arranged on the baseboard; the first top column is arranged on the first air cylinder; the trimming mechanism is arranged onthe baseboard; the pressure mechanism is arranged in the middle of the upper surface of the baseboard; and the first support is arranged on the baseboard. According to the equipment for trimming theto-be-delivered books, by designing the trimming mechanism, the books can be trimmed, labor is replaced by the machine (trimming mechanism), thus the books are trimmed to be flatter, and a worker doesnot need to hold a knife to trim the books manually, so that the risks of accidental injuries caused by the knife to the worker are reduced at the same time; and by designing the pressure mechanism,the books on a table board can be pressed downwards and fixed, and the pressure mechanism matches work of the trimming mechanism more, so that the books are not liable to move in trimming processes.

Owner:张金花

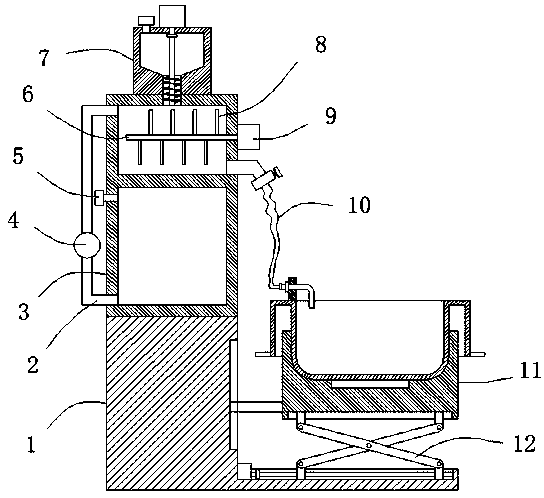

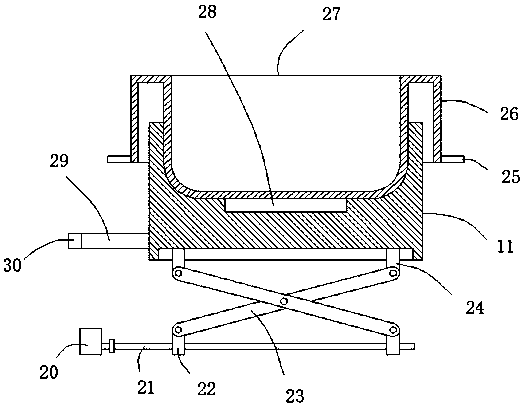

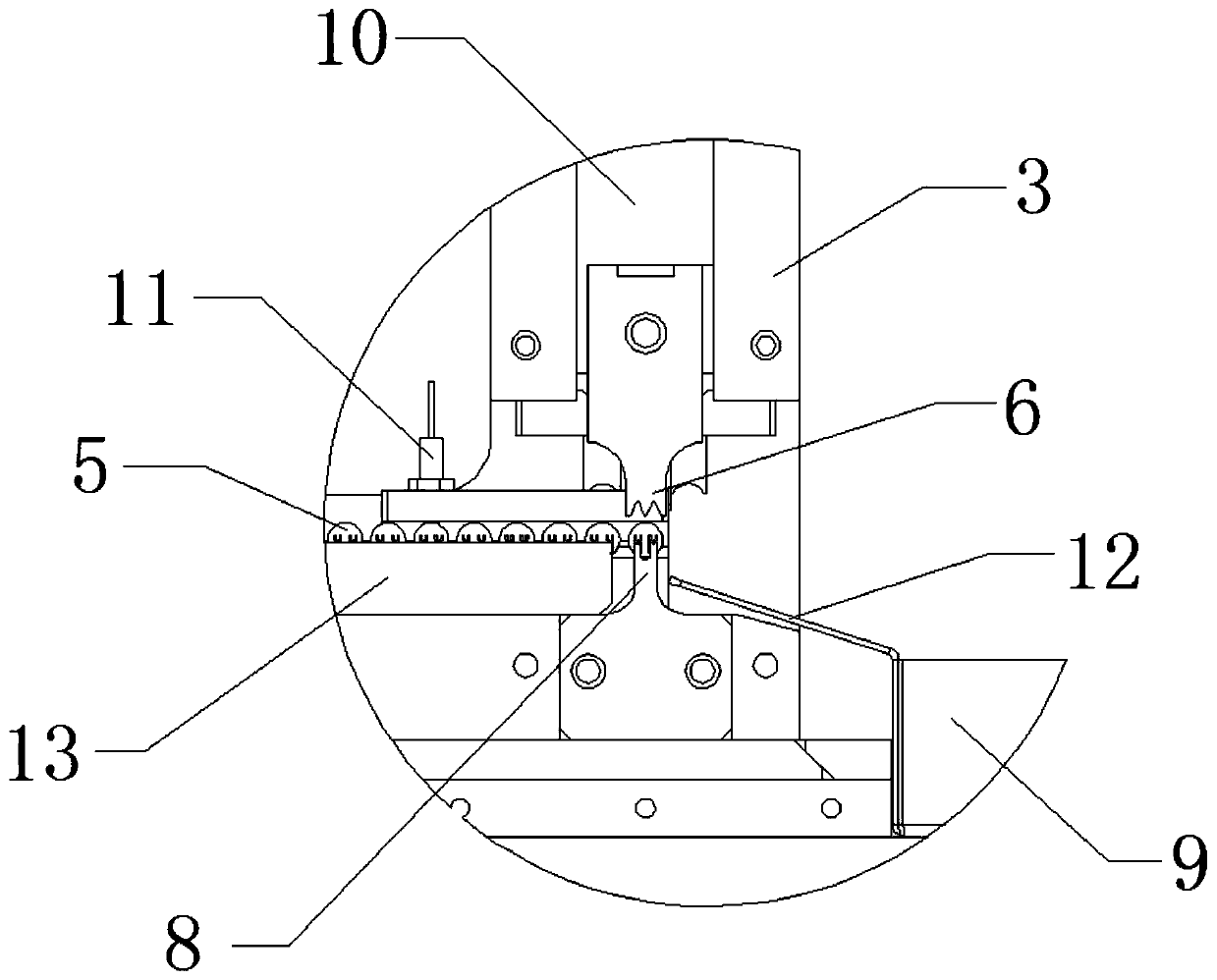

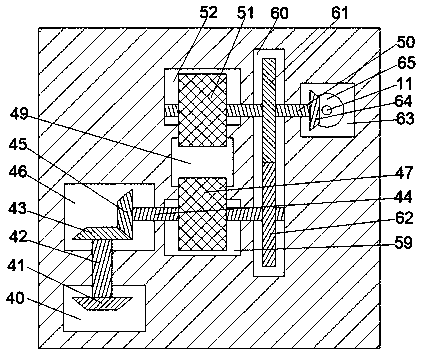

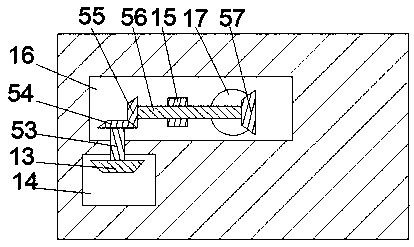

Dyeing device for mouth part of porcelain cup

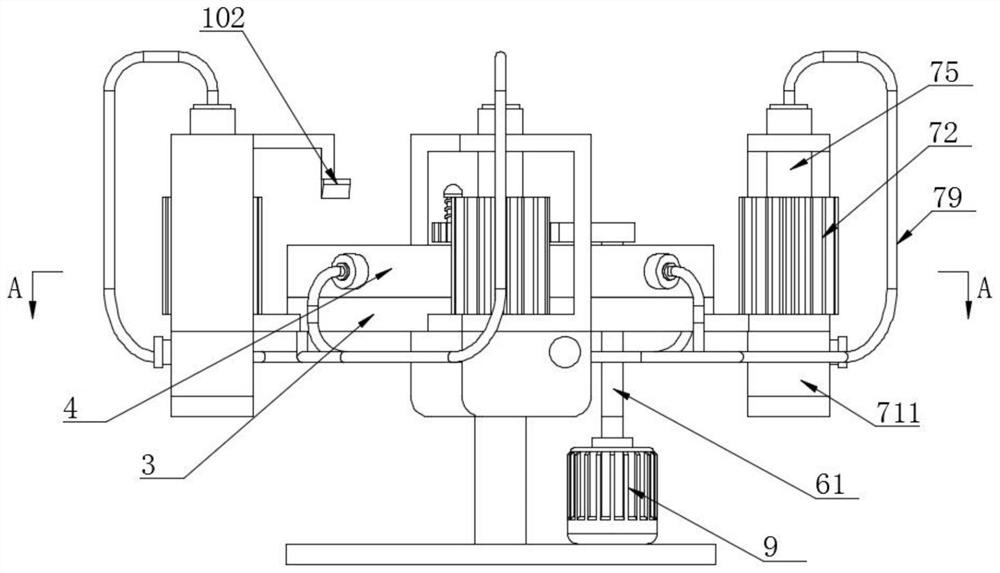

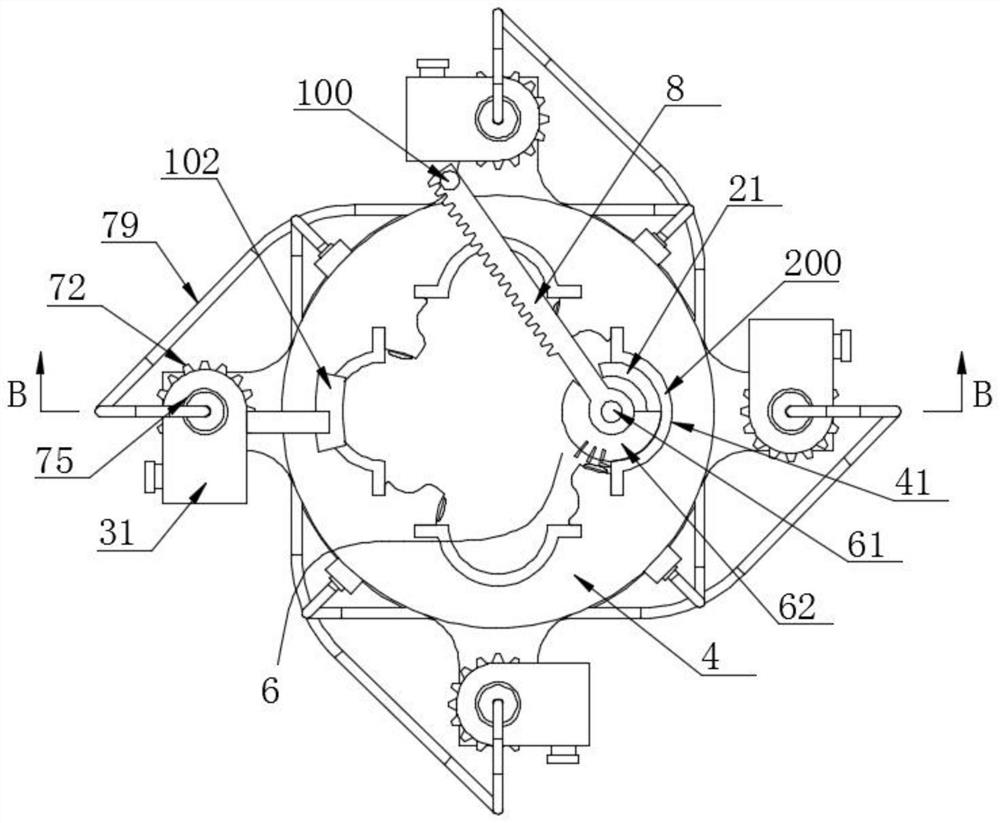

InactiveCN112373183ARealize the purpose of automatic feedingEasy to useRotary pressesPrinting press partsEngineeringMechanical engineering

The invention relates to a dyeing device, in particular to a dyeing device for a mouth part of a porcelain cup. The invention provides a dyeing device for the mouth part of the porcelain cup, which can dye the mouth part of the porcelain cup automatically, and can stir pigments. The dyeing device for the mouth part of the porcelain cup comprises a supporting paint frame, a first fixed rod, a handle, a second fixed rod, a straight gear, a pressing feeding mechanism, and a discharging coating mechanism, wherein the first fixed rod is arranged on the supporting paint frame; the handle is arrangedon the first fixed rod in a sliding mode; the second fixed rod is arranged at one side of the supporting paint frame; one side of the second fixed rod is rotatably equipped with the straight gear; the pressing feeding mechanism is arranged on the supporting paint frame; and the discharging coating mechanism is arranged on the supporting paint frame. The discharging coating mechanism can be matched with the pressing feeding mechanism for pressing the porcelain cup and coloring the porcelain cup without manually coloring, so that dyeing of the porcelain cup is more uniform.

Owner:甘伟新

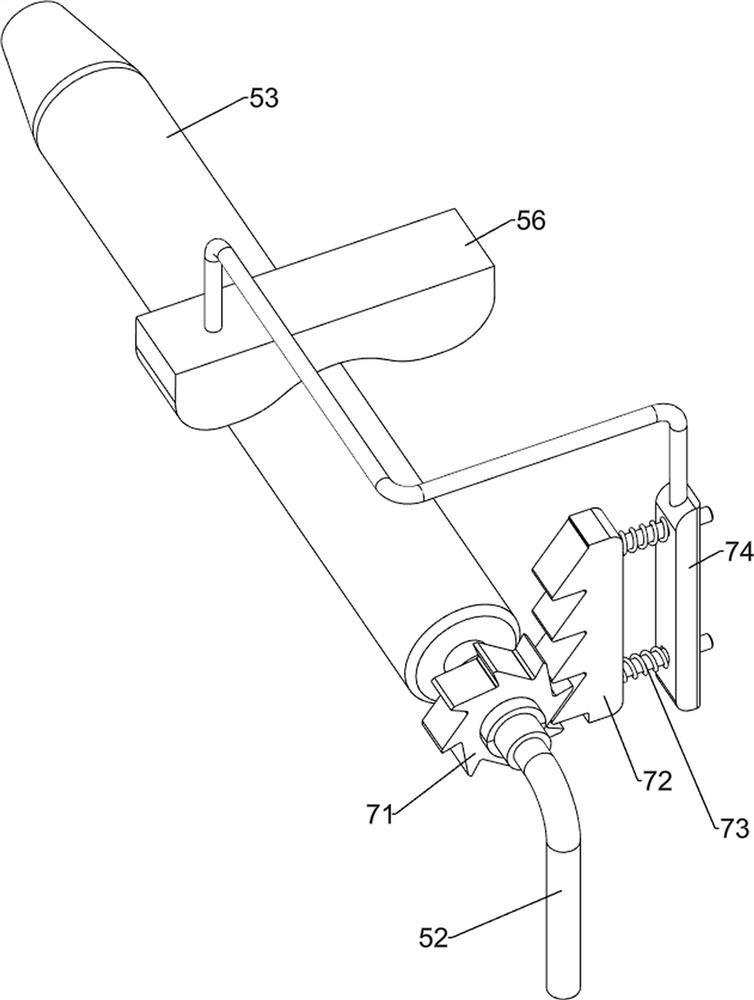

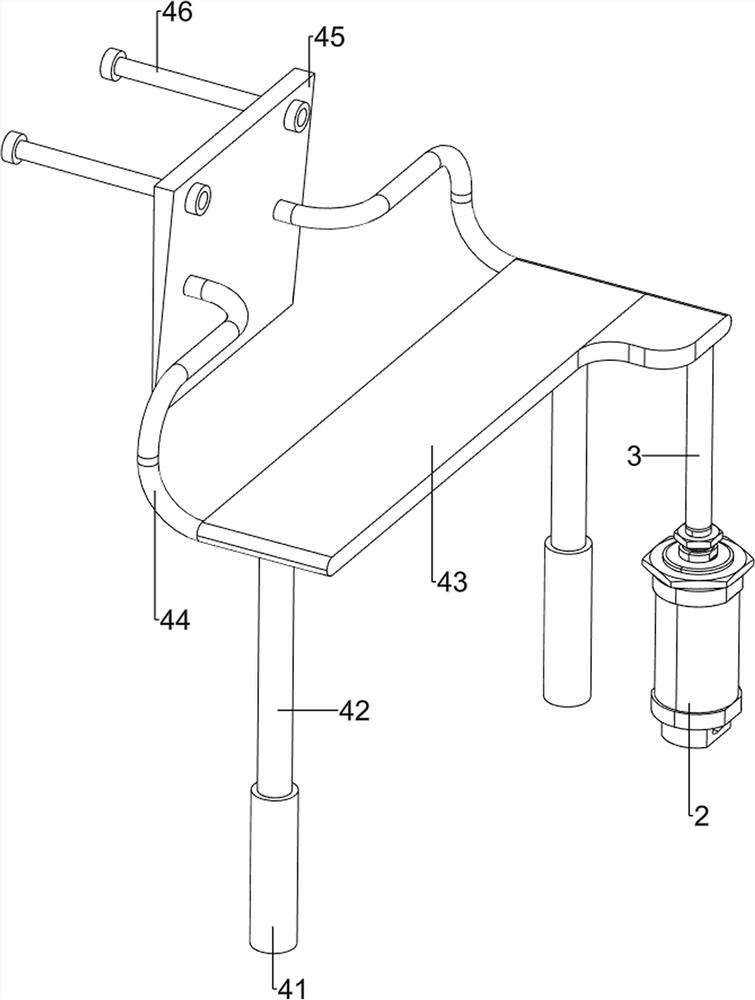

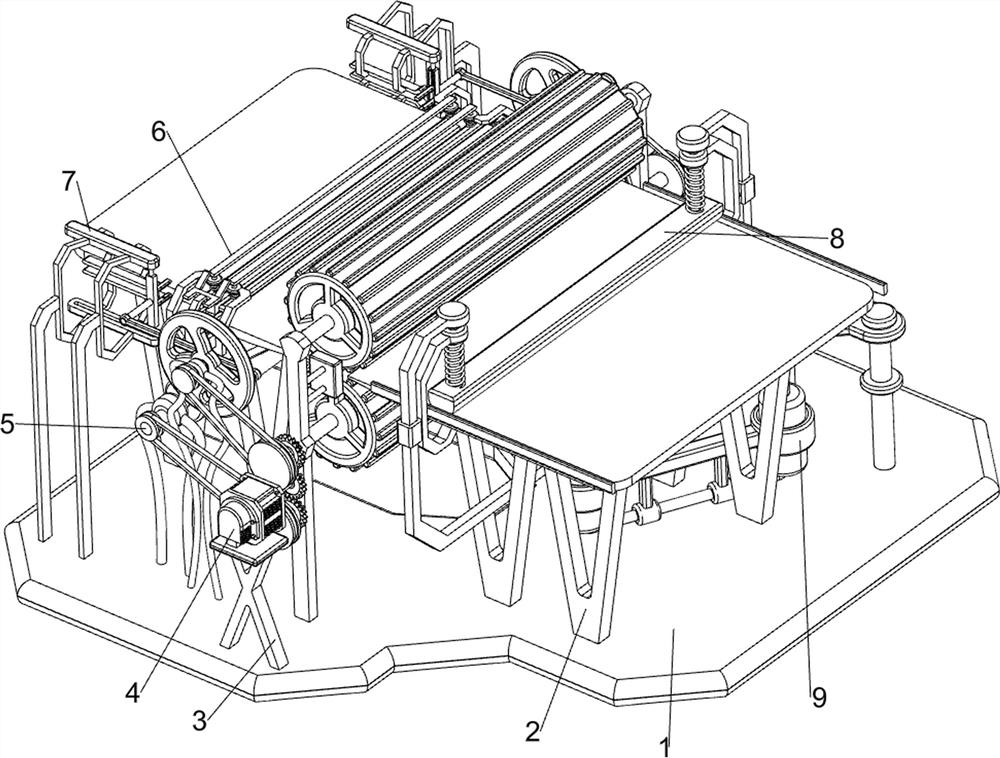

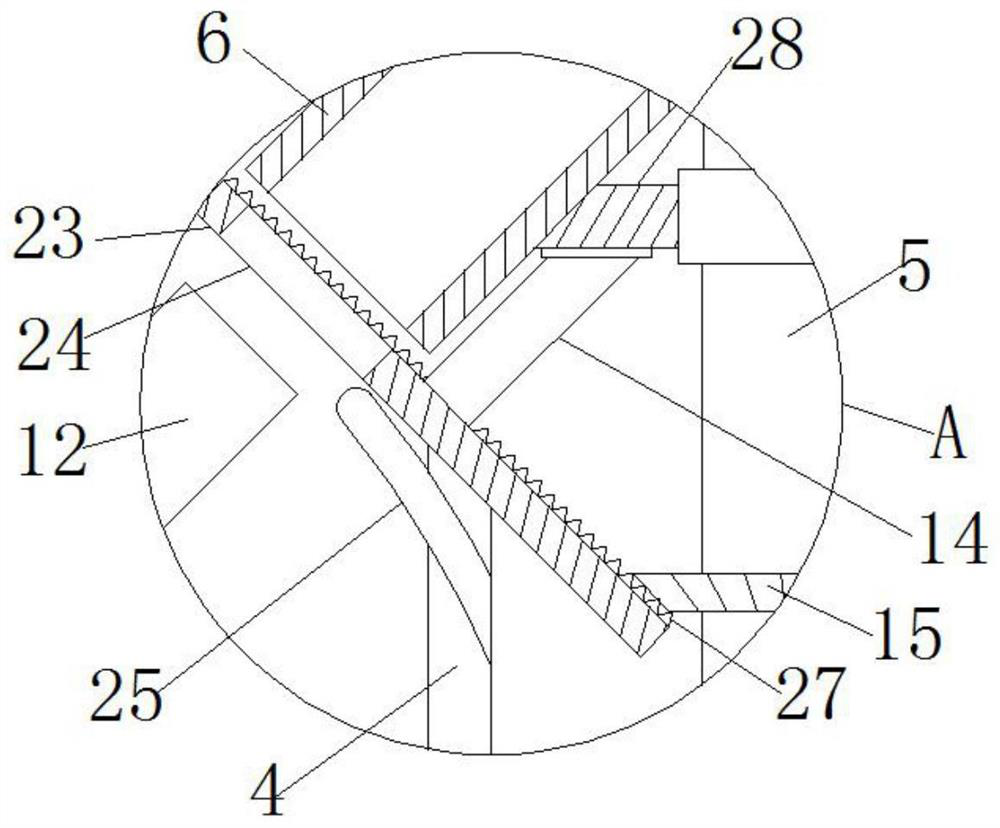

Wood corner cutting equipment for furniture

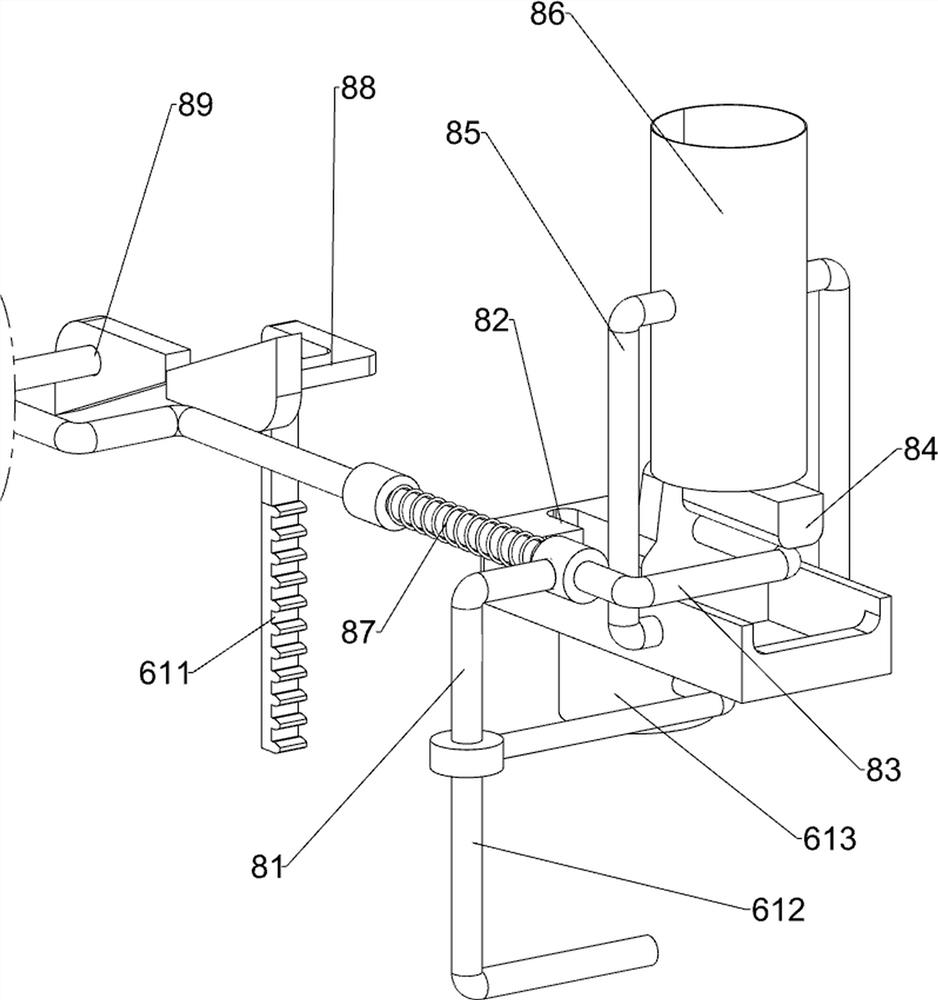

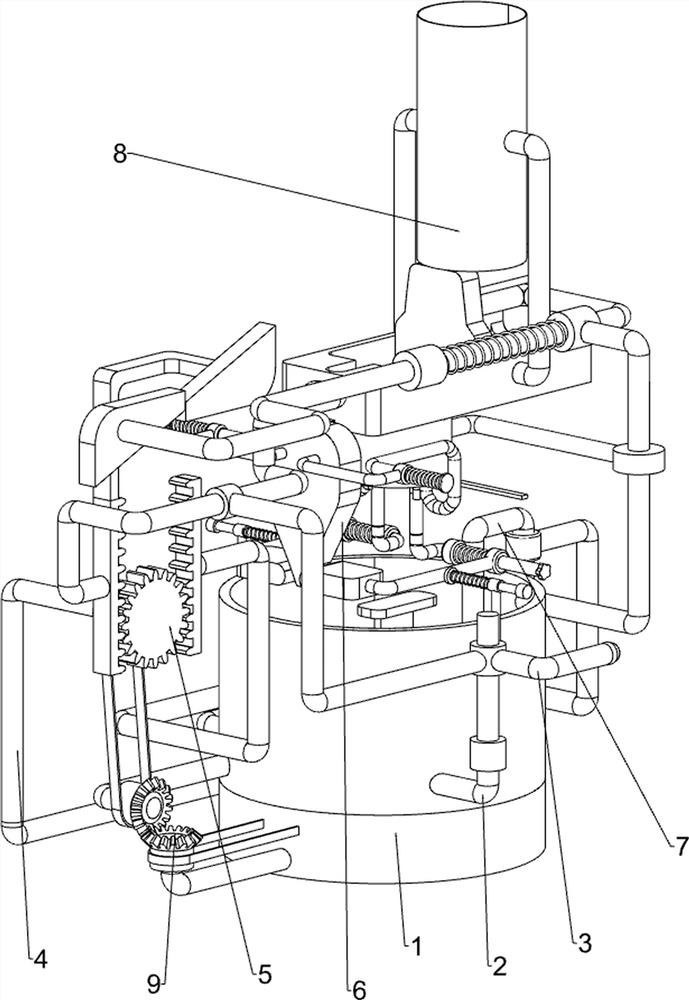

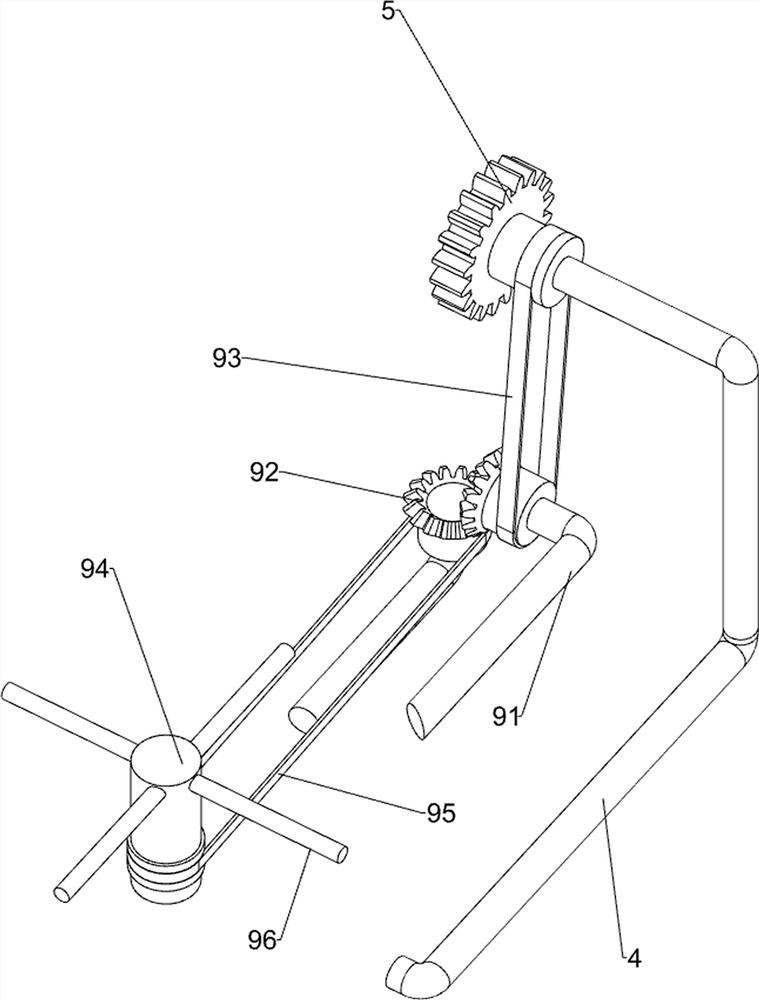

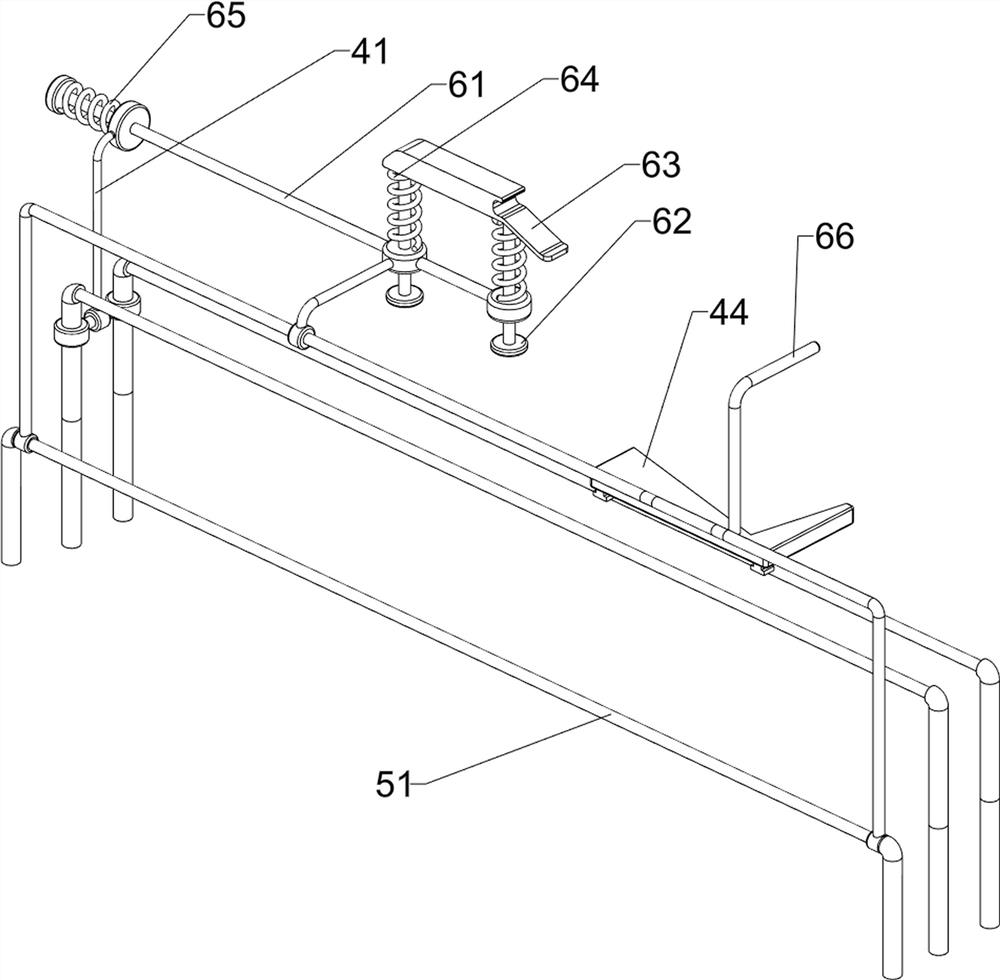

ActiveCN112621897AAchieve automatic feedingRealize the purpose of automatic feedingFeeding devicesGripping devicesElectric machineryAgricultural engineering

The invention relates to cutting equipment, in particular to wood corner cutting equipment for furniture. According to the wood corner cutting equipment for the furniture, automatic feeding is conducted before wood corner cutting, automatic clamping is conducted during wood corner cutting, and automatic pushing-out is conducted after wood corner cutting. The wood corner cutting equipment for the furniture comprises a base and a saw blade, and the saw blade is arranged on one side of the top of the base; a placing assembly, arranged at the top of the base; a motor, arranged on the placing assembly; and a pushing assembly, arranged on the side, close to the placing assembly, of the top of the base, wherein components of the pushing assembly are connected with components of the placing assembly. The effects of automatic feeding before wood corner cutting, automatic clamping during wood corner cutting and automatic pushing-out after wood corner cutting are achieved.

Owner:NANJING YUZHI INTELLIGENT TECH CO LTD

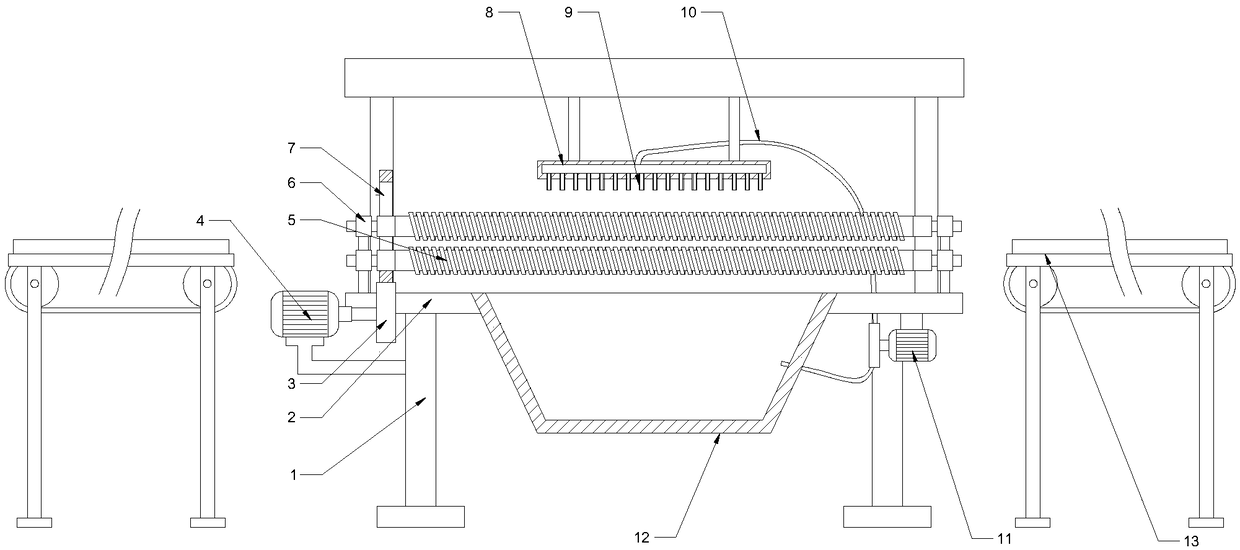

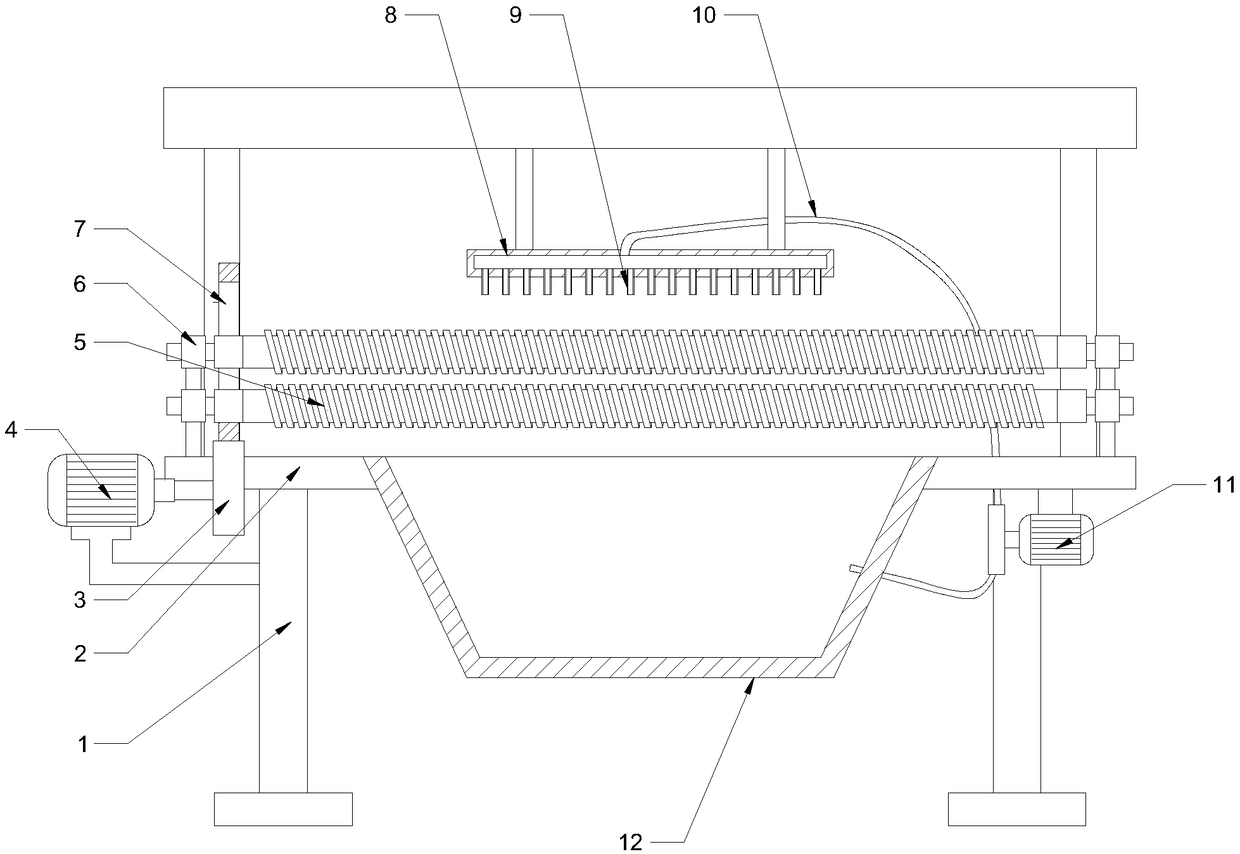

Automatic feeding and discharging washing device

PendingCN108787590AReduce manufacturing costHigh degree of automationCleaning using toolsCleaning using liquidsMechanical engineeringWater supply

The invention relates to the field of workpiece washing equipment, in particular to an automatic feeding and discharging washing device. The automatic feeding and discharging washing device comprisesa spraying head, a spraying pipe, a water sucking pipe, a water gathering groove, a water supply pump and pipe piece conveying belts, and further comprises a working table; the pipe piece conveying belts are arranged on the two sides of the working table, a feeding mechanism is arranged on the pipe piece conveying belt at one end of the working table, a discharging mechanism is arranged on the pipe piece conveying belt at the other end of the working table, and a washing device is arranged on the working table. In the working and moving process of the automatic feeding and discharging washingdevice, cylindrical workpieces are automatically washed, automatic feeding, washing and discharging can be achieved, the automatic degree is high, the washing effect is good, efficiency is high, and the manual washing production cost is reduced.

Owner:犍为恩典机械电镀有限公司

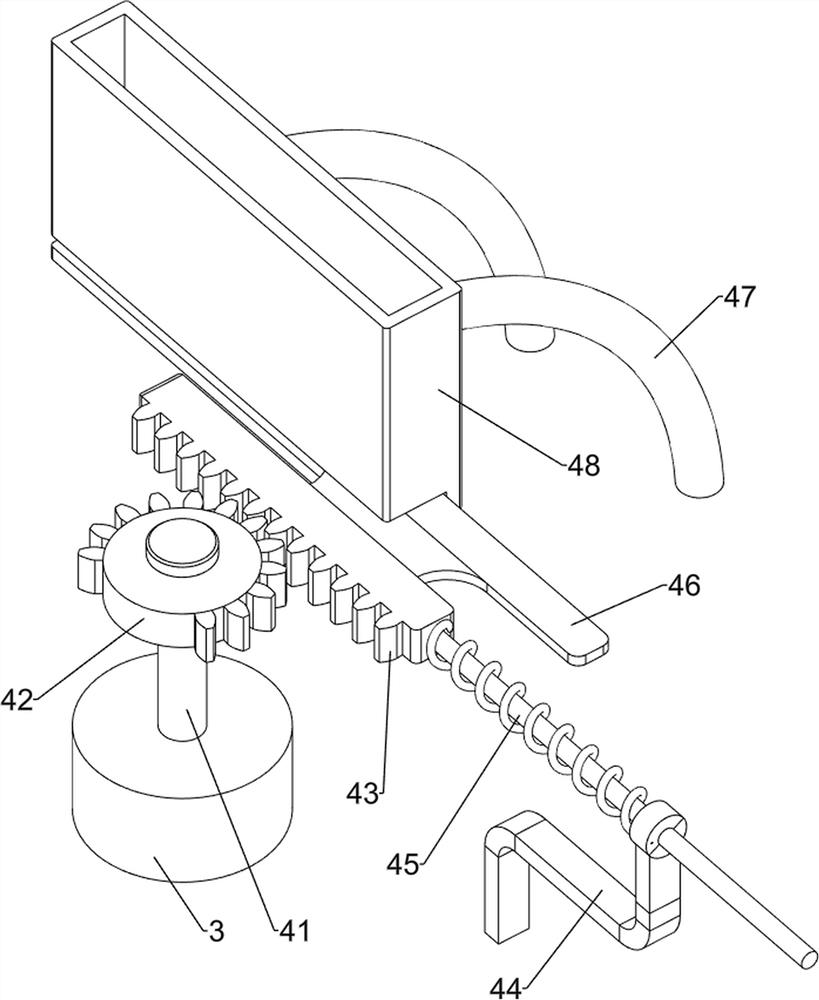

Aluminum material cutting device with automatic feeding function

ActiveCN111036975AAvoid technical problems with poor air qualityAutomatic shippingShearing machinesMaintainance and safety accessoriesGear wheelEngineering

The invention relates to the technical field of aluminum material machining equipment, and discloses an aluminum material cutting device with an automatic feeding function. The aluminum material cutting device comprises a rack and a feeding unit, wherein the feeding unit comprises a conveying belt and a driving structure used for driving the conveying belt, wherein the conveying belt is straightened and arranged on the rack, the driving structure is arranged in the conveying belt, the driving structure comprises a driving gear and a rectangular frame, the rectangular frame is slidably connected with the rack, a rack is arranged in the rectangular frame, the driving gear is an incomplete gear, the driving gear is rotatably connected with the rack, and the driving gear is engaged with the rack; and a one-way locking piece for one-way clamping is arranged between the rectangular frame and the conveying belt. The scheme of the invention can solve the technical problem that aluminum materials cannot be automatically fed and cut in the prior art.

Owner:重庆市金久装饰工程有限责任公司

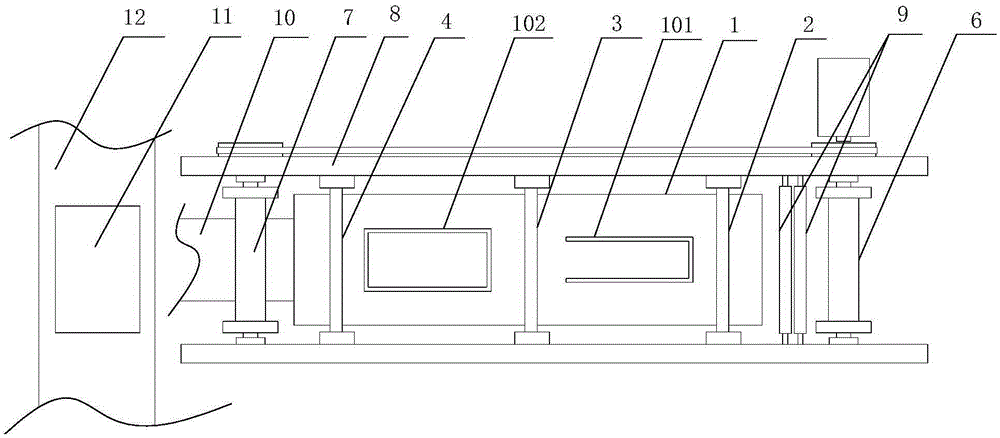

Automatic blanking packing bag continuity machining equipment

InactiveCN105329498AIncrease productivityRealize the purpose of automatic feedingWrapping material feeding apparatusPunchingEngineering

The invention discloses automatic blanking packing bag continuity machining equipment. The automatic blanking packing bag continuity machining equipment comprises a pressing-type platform, a first pressing strip, a second pressing strip, a third pressing strip, an upper pressing plate, a material discharging roller set, a waste material wind-up roller, a rack, an output mechanism, a first driving mechanism, a second driving mechanism and a third driving mechanism. An edge sealing groove and a punching blanking groove are formed in the pressing-type platform in sequence. The material discharging roller set and the waste material wind-up roller are located at the two ends of the pressing-type platform respectively, are arranged on the rack and are both driven by the third driving mechanism. The material discharging roller set comprises a first material discharging roller and a second material discharging roller. The first pressing strip, the second pressing strip and the third pressing strip are all located above the pressing-type platform and are all driven by the first driving mechanism. The upper pressing plate is located above the pressing-type platform and is driven by the second driving mechanism. A pressing head and a punching head are arranged at one end, closing to the pressing-type platform, of the upper pressing plate. The output mechanism is located below the punching blanking groove and is used for gathering falling materials punched by the punching head and conveying the falling materials out. According to the automatic blanking packing bag continuity machining equipment, the production efficiency of packing bags is improved greatly.

Owner:BENGBU ZHONGBANG PACKAGING FACTORY

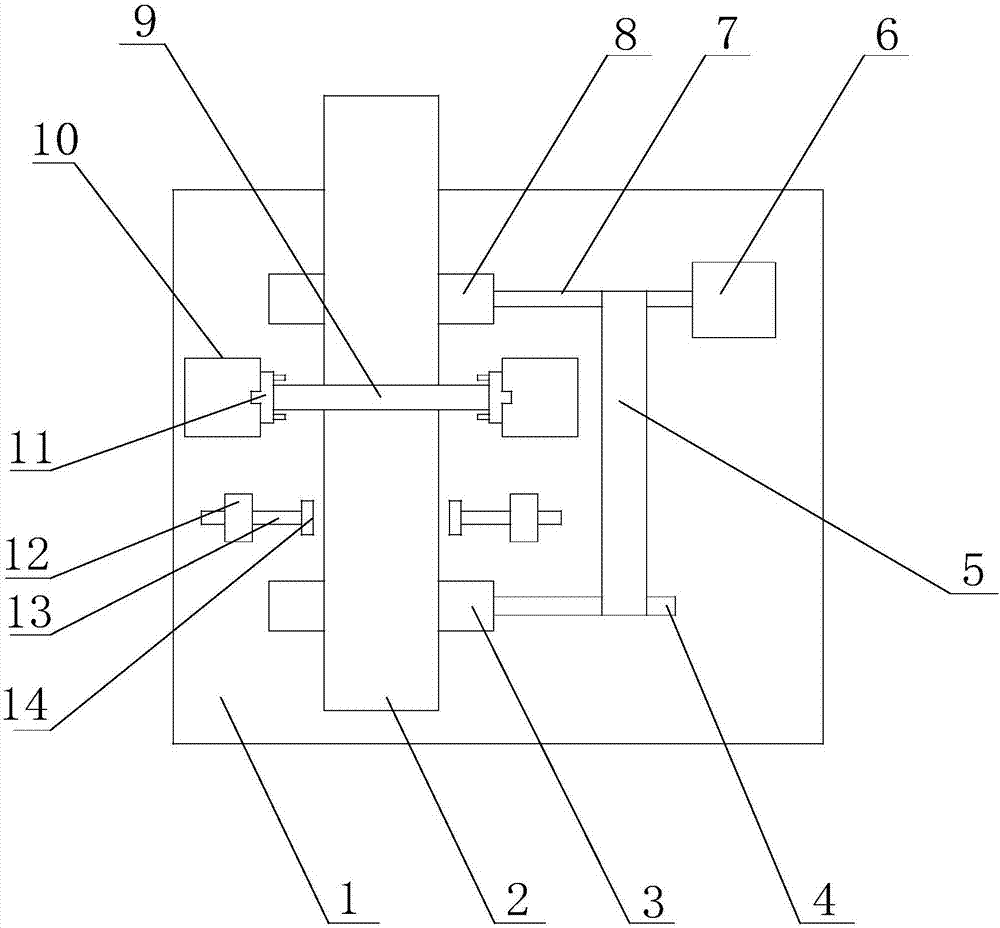

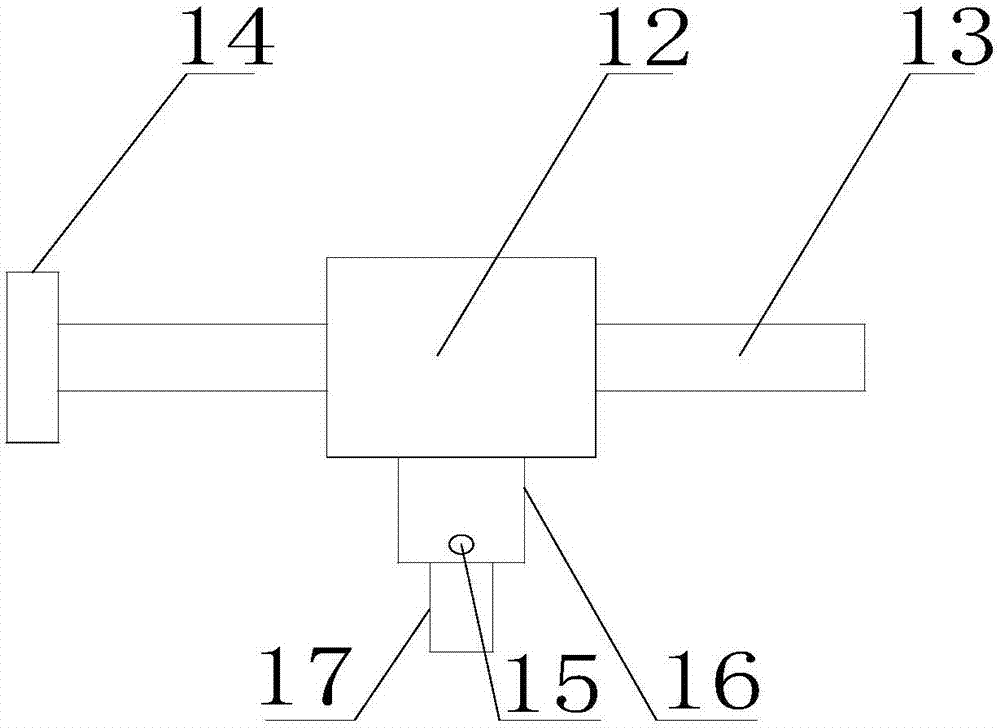

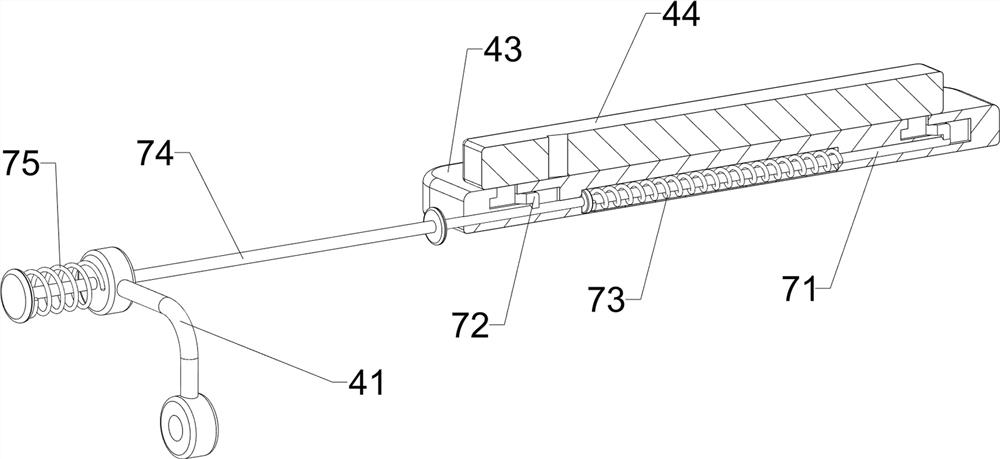

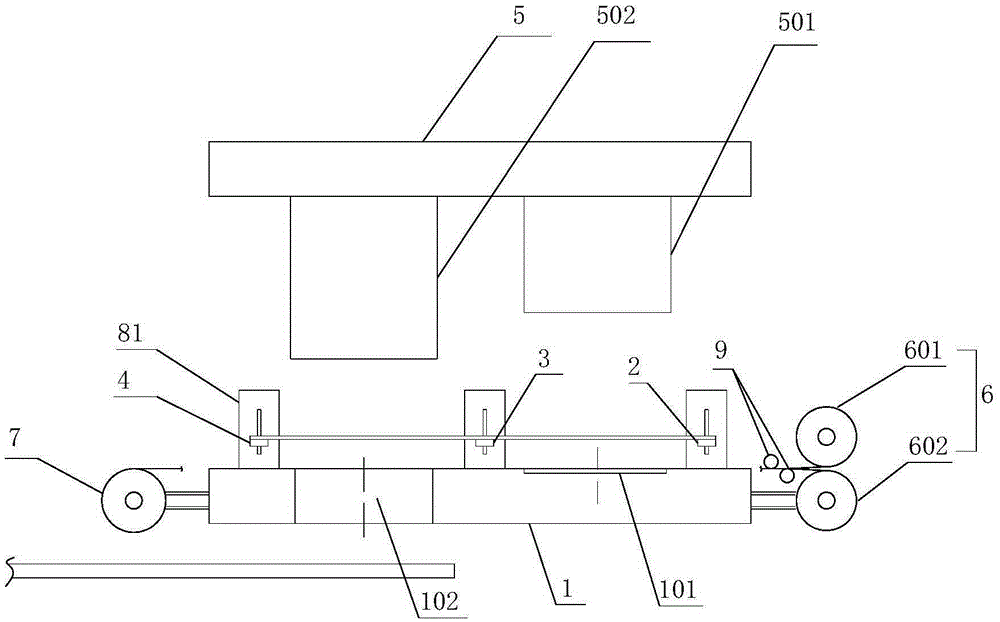

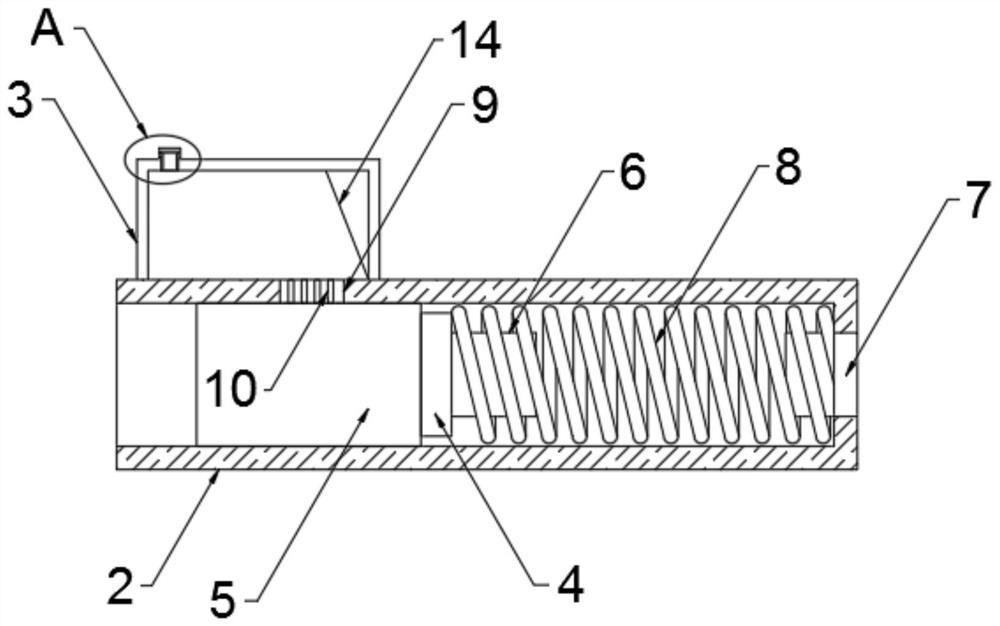

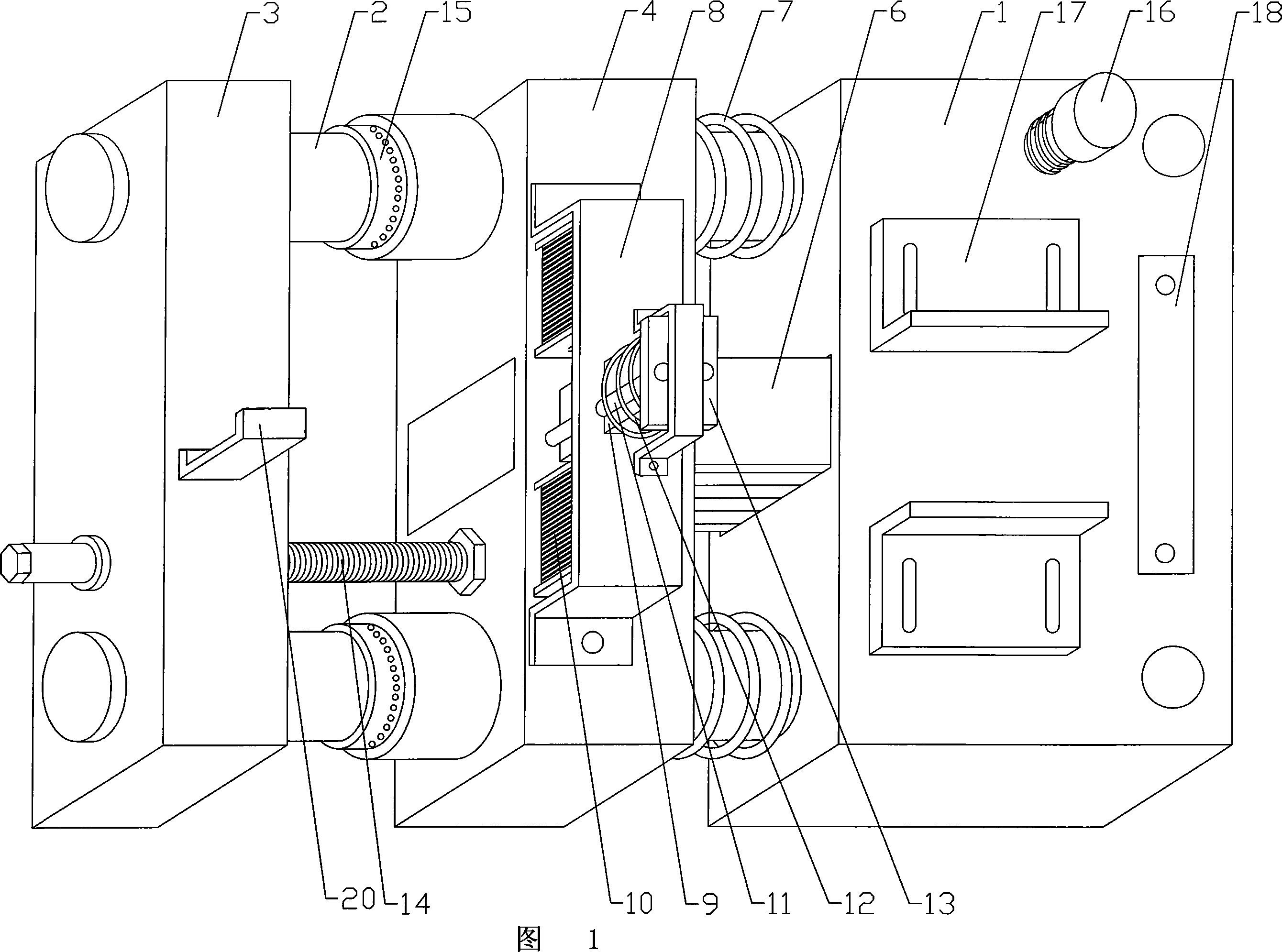

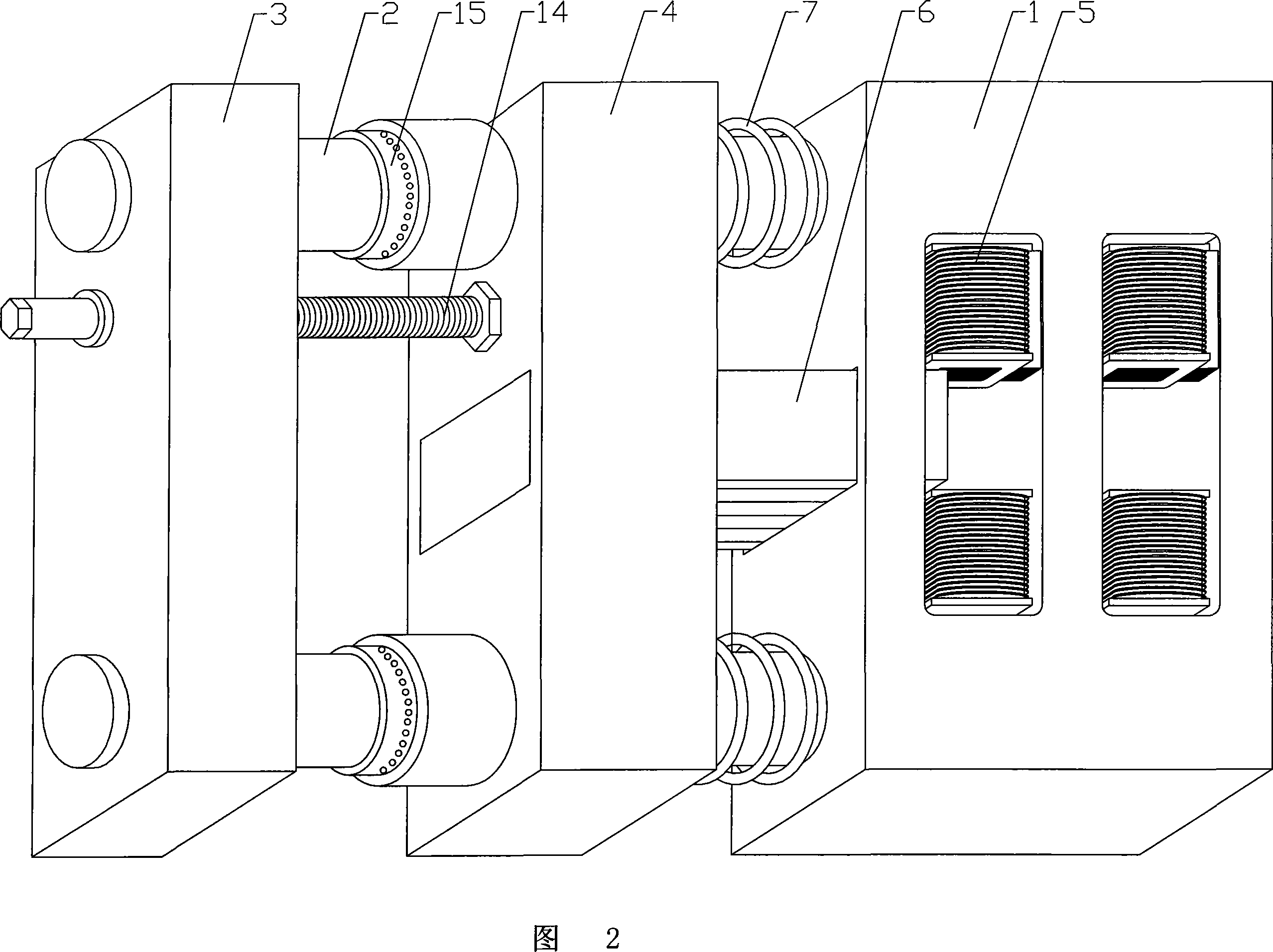

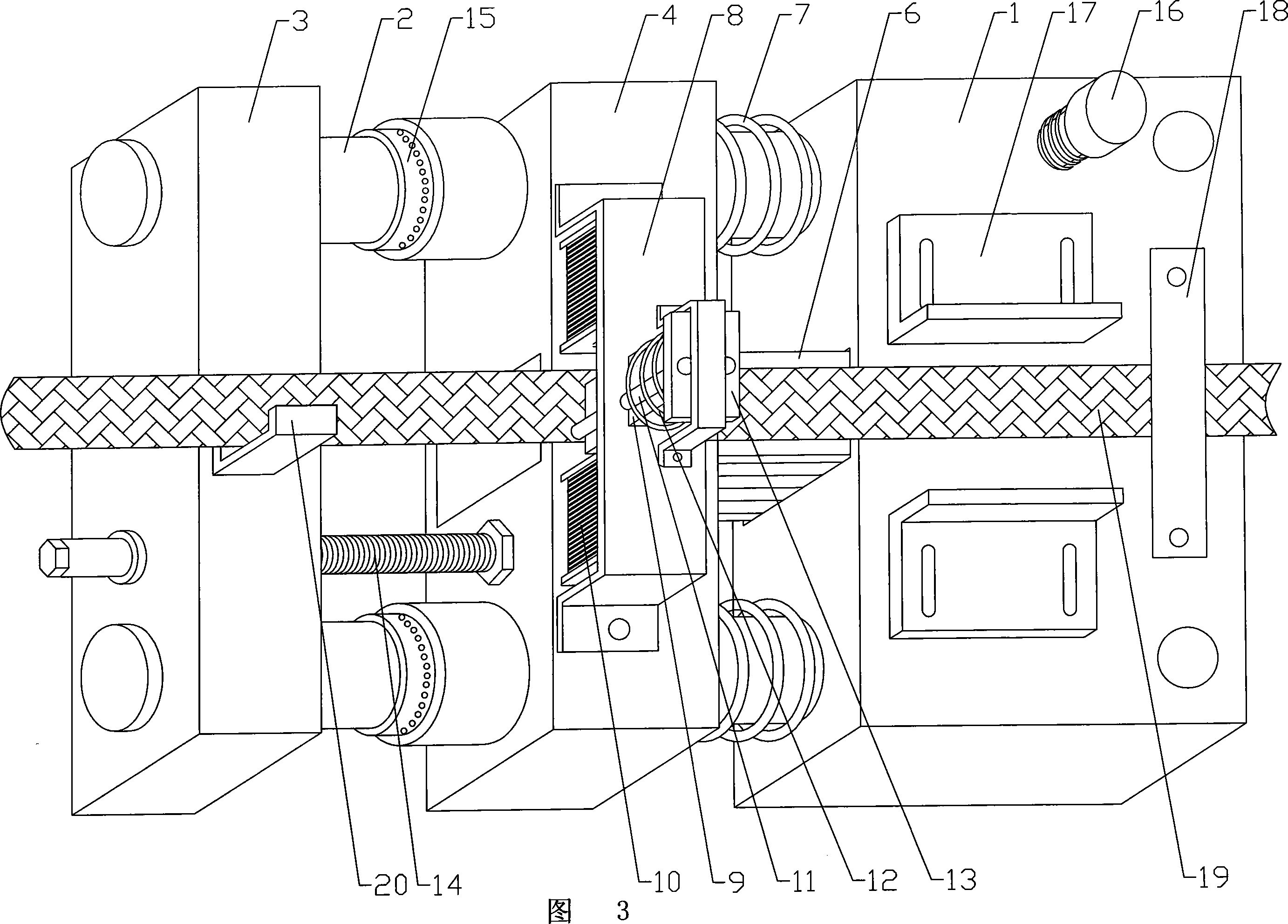

Electronic detonator chip leg wire riveting device and processing flow based on same

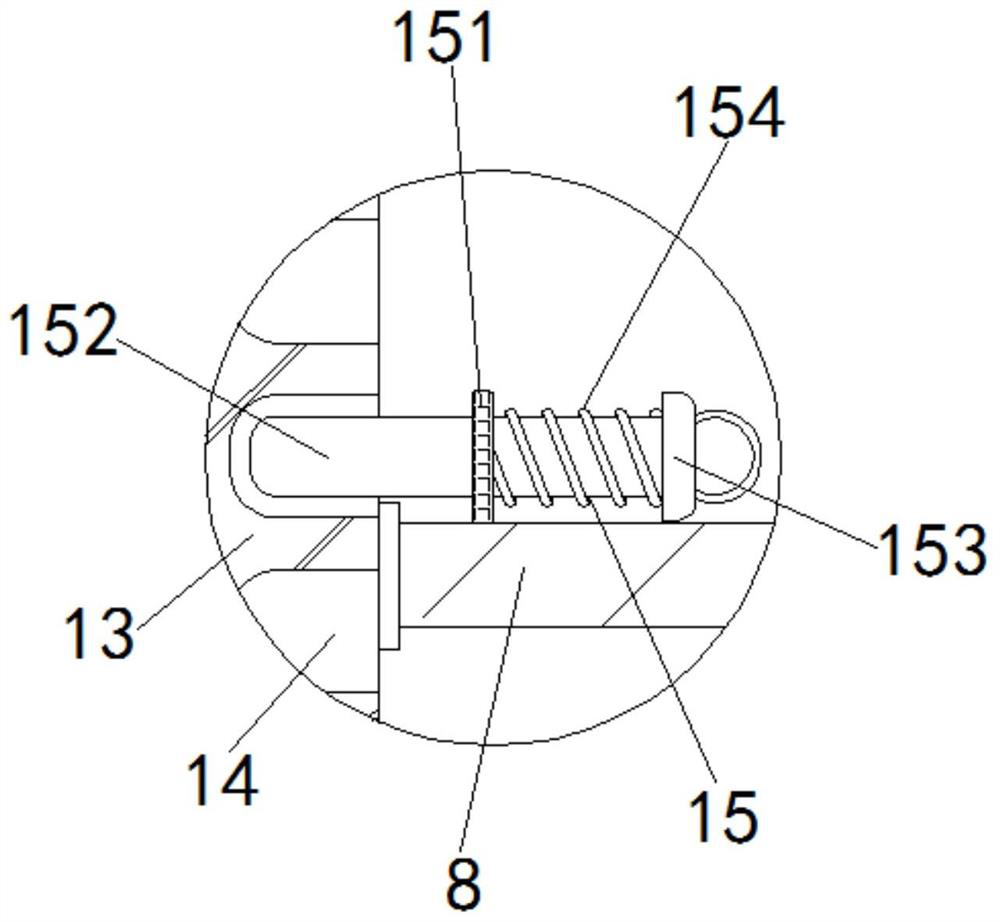

PendingCN111023920AReduce labor intensityRealize the purpose of automatic feedingAmmunition fuzesControl engineeringMechanical engineering

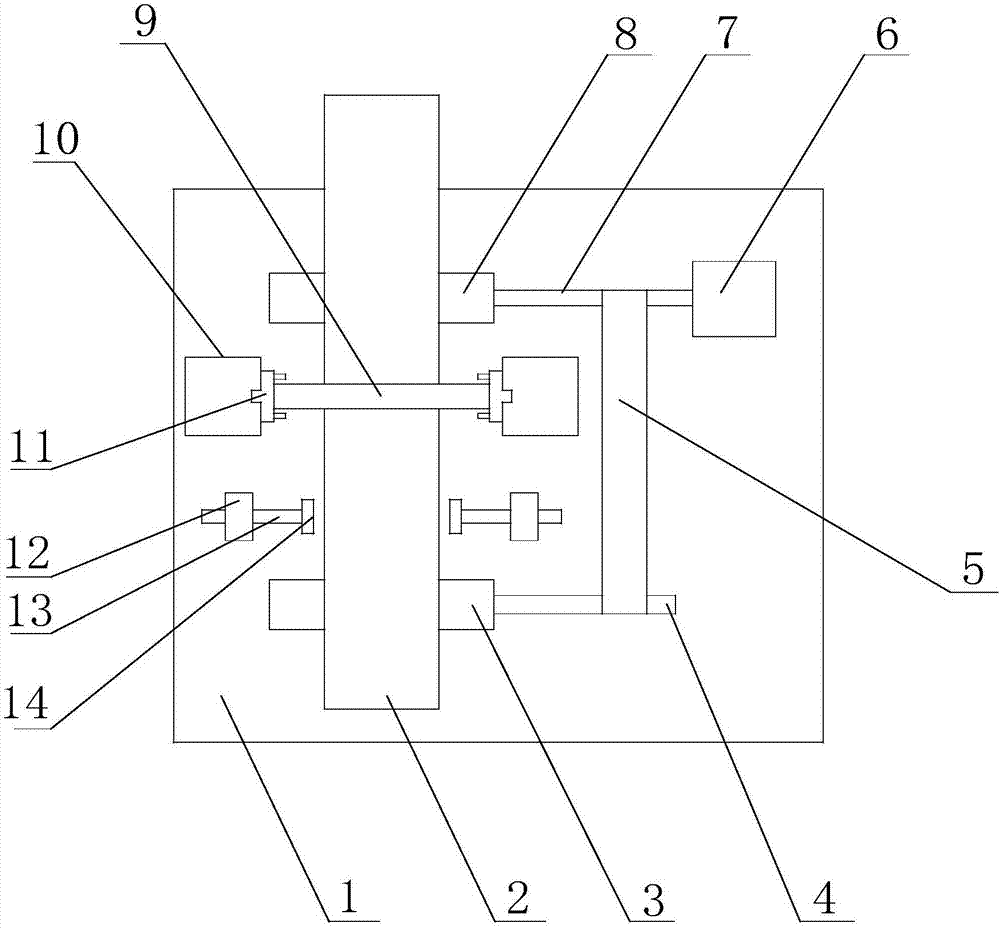

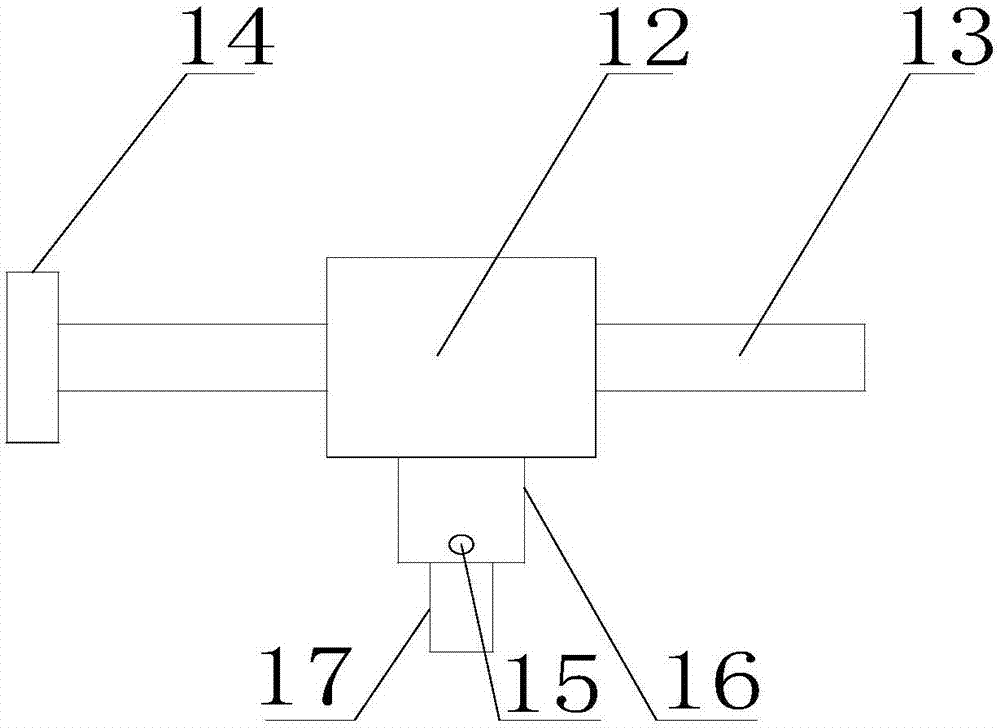

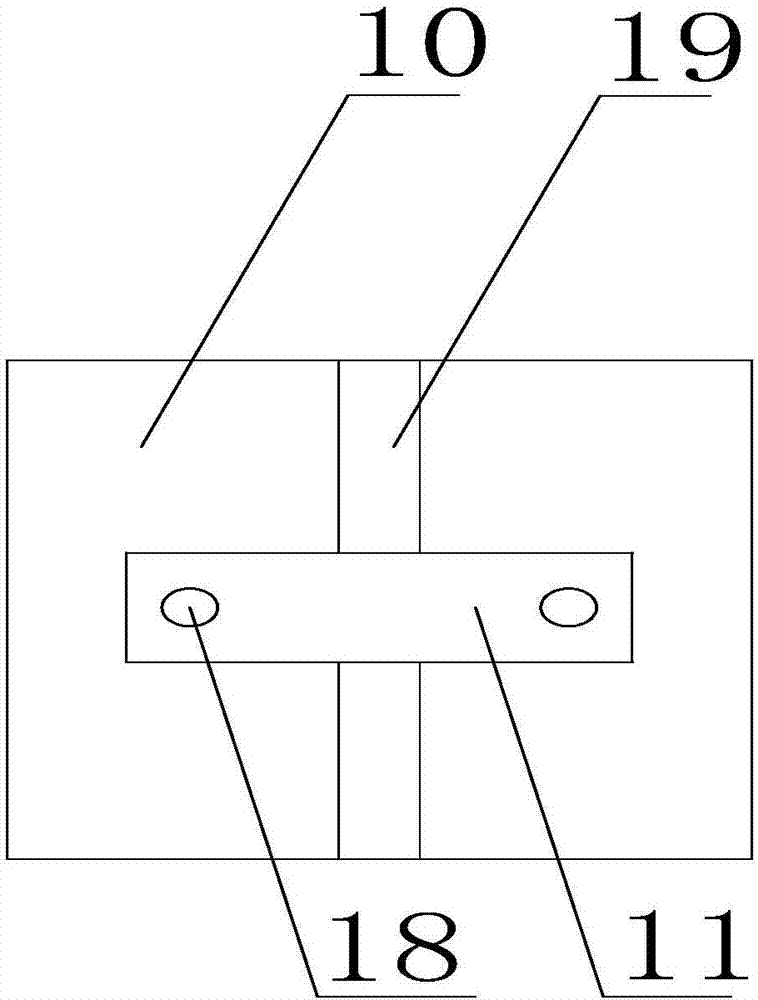

The invention relates to an electronic detonator chip leg wire riveting device and a processing flow based on the same. The device comprises a terminal machine, an output shaft of the terminal machine, a sliding rail, a stepping feeding mechanism, an upper riveting knife, a bottom plate, a lower riveting knife, a recycling box, a sliding block and a guide rail. The flow further comprises the following steps that the stepping feeding mechanism is matched to push a electronic detonator chip to move towards the tail end of the guide rail until the electronic detonator chip is moved to the properposition; the output shaft of the terminal machine drives the sliding block to move downwards in the sliding rail, and the upper riveting knife is driven to move downwards, and is matched with the lower riveting knife to rivet a leg wire and the electronic detonator chip; the electronic detonator chip which is in butt joint with the leg wire is taken down, the above steps are repeated for competing processing on all electronic detonator chips. According to the device, the purpose of automatic feeding of the electronic detonator chips during riveting of the electronic detonator chips and leg wires is achieved, the labor intensity of operators is reduced, and the equipment production efficiency is improved.

Owner:杭州晋旗电子科技有限公司

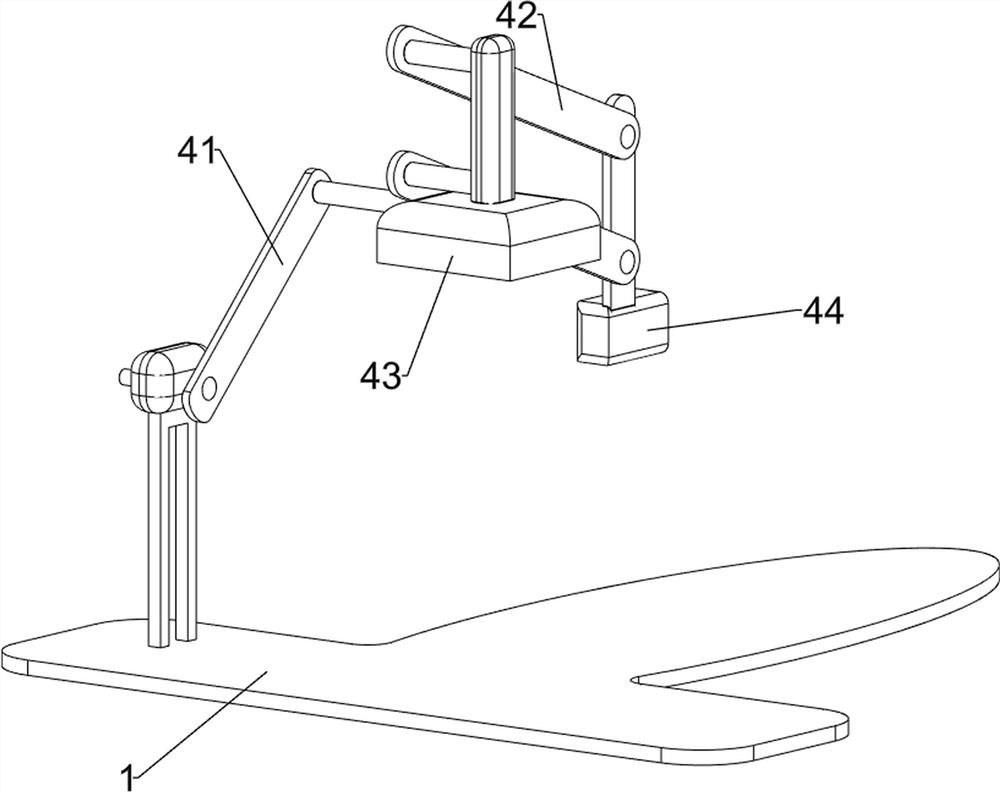

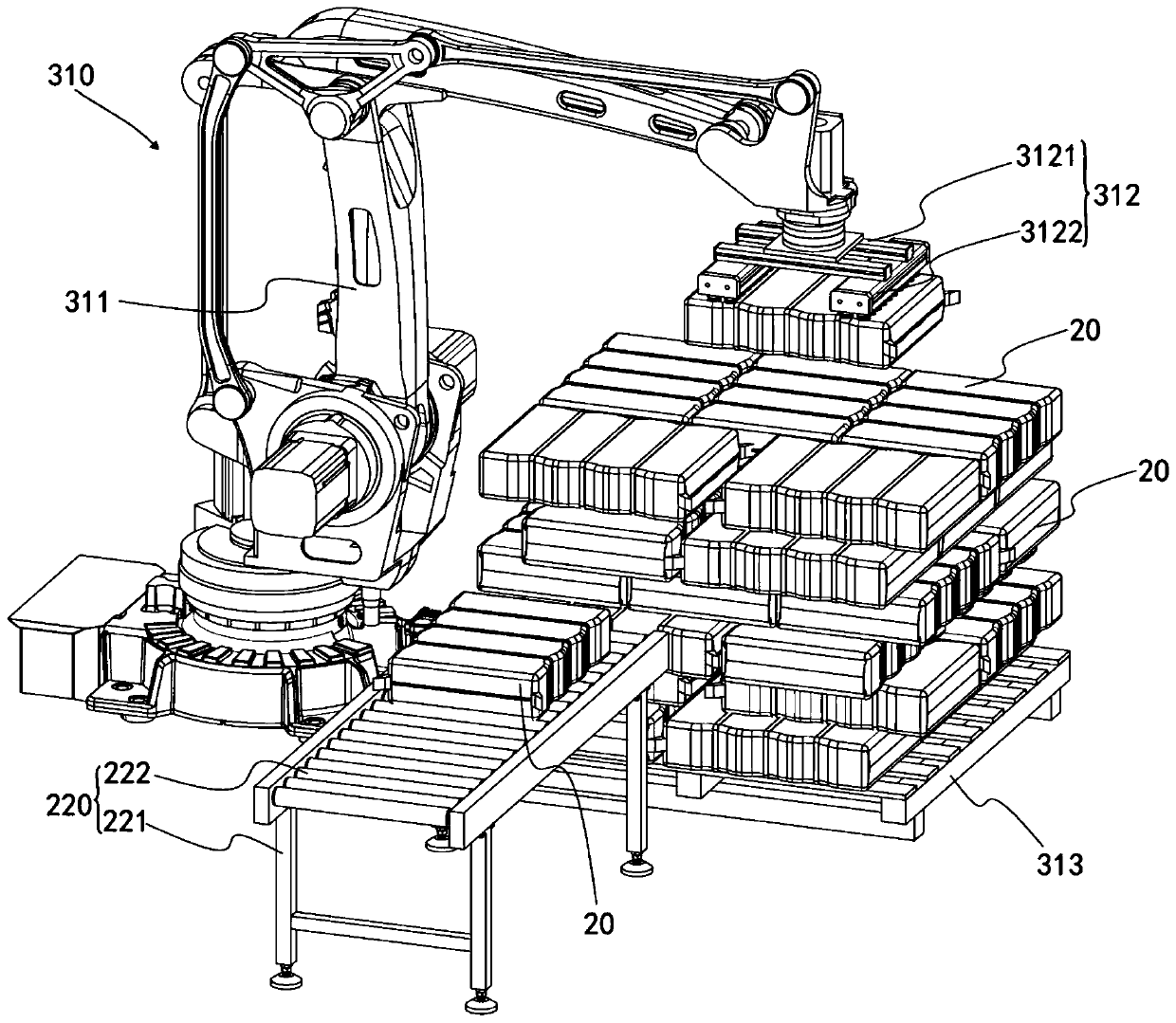

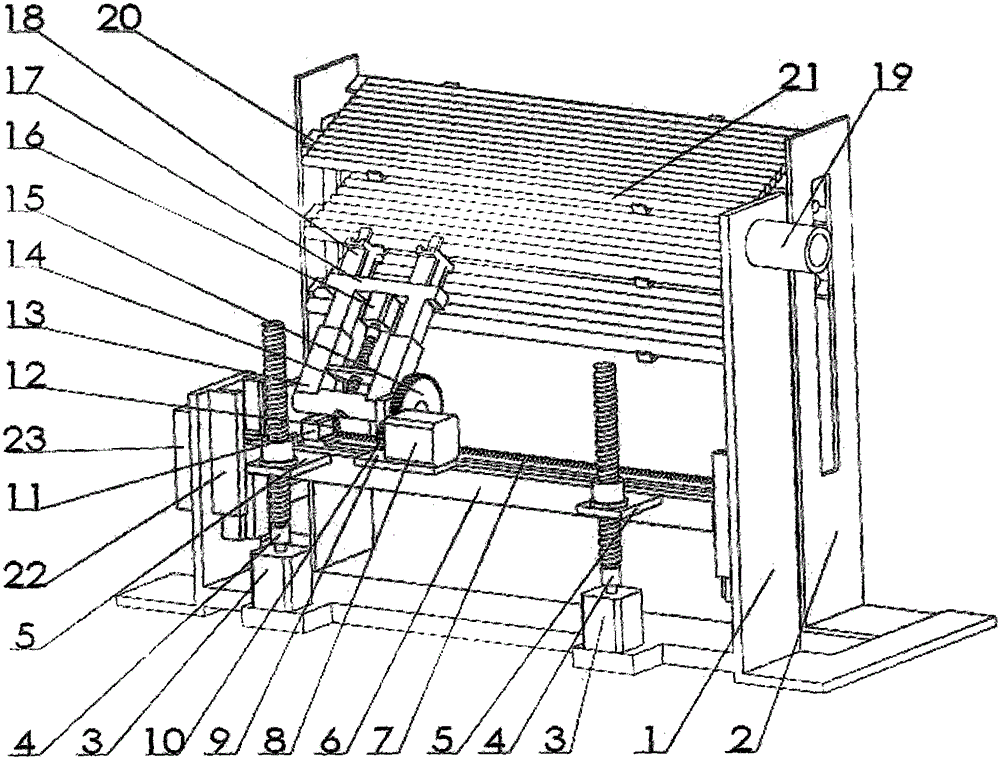

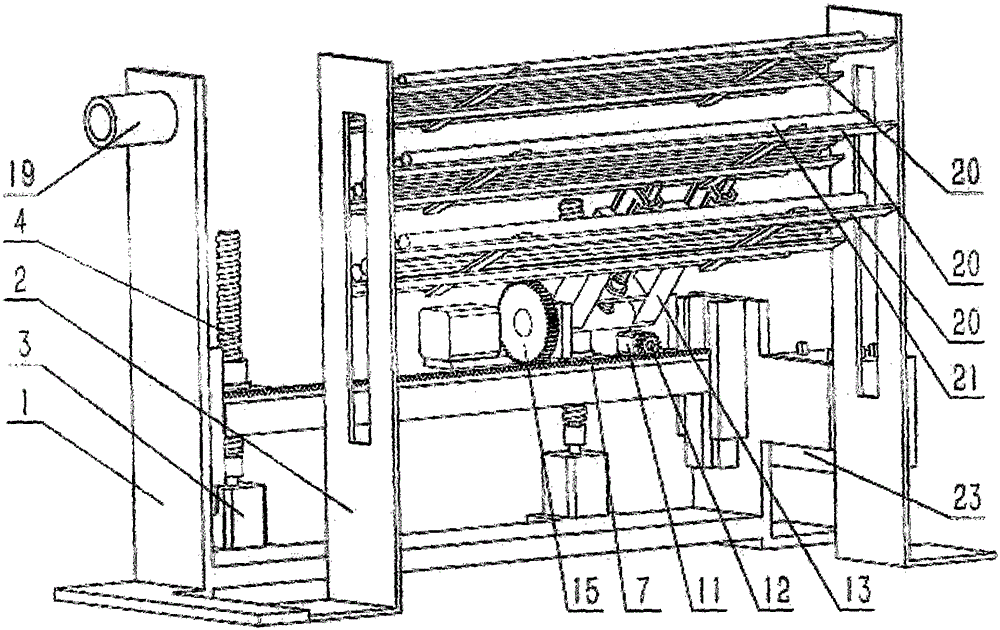

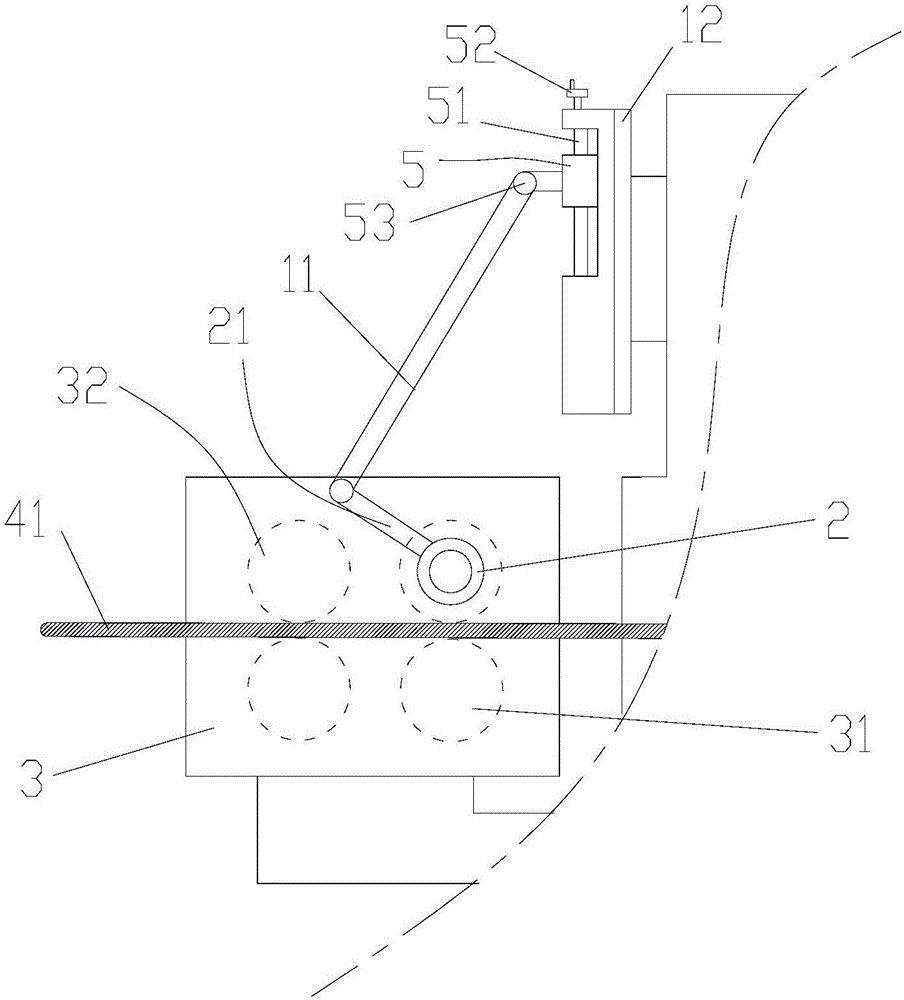

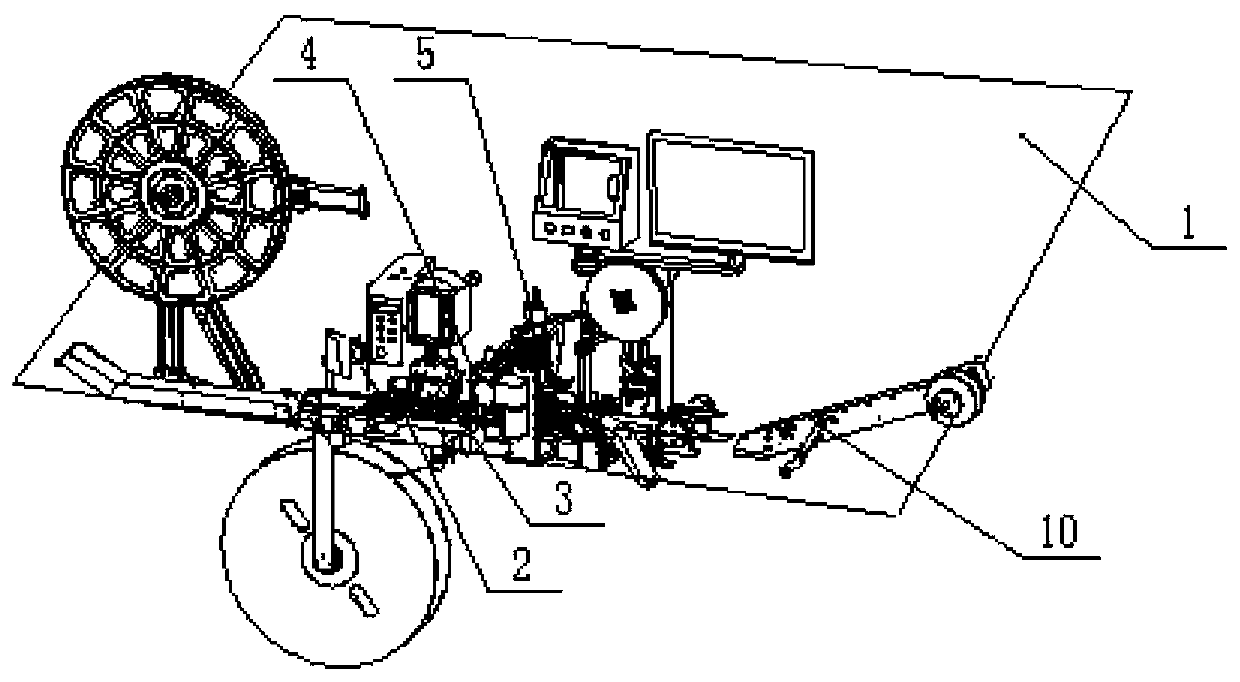

Manipulator type feeding machine for numerical control machine tool

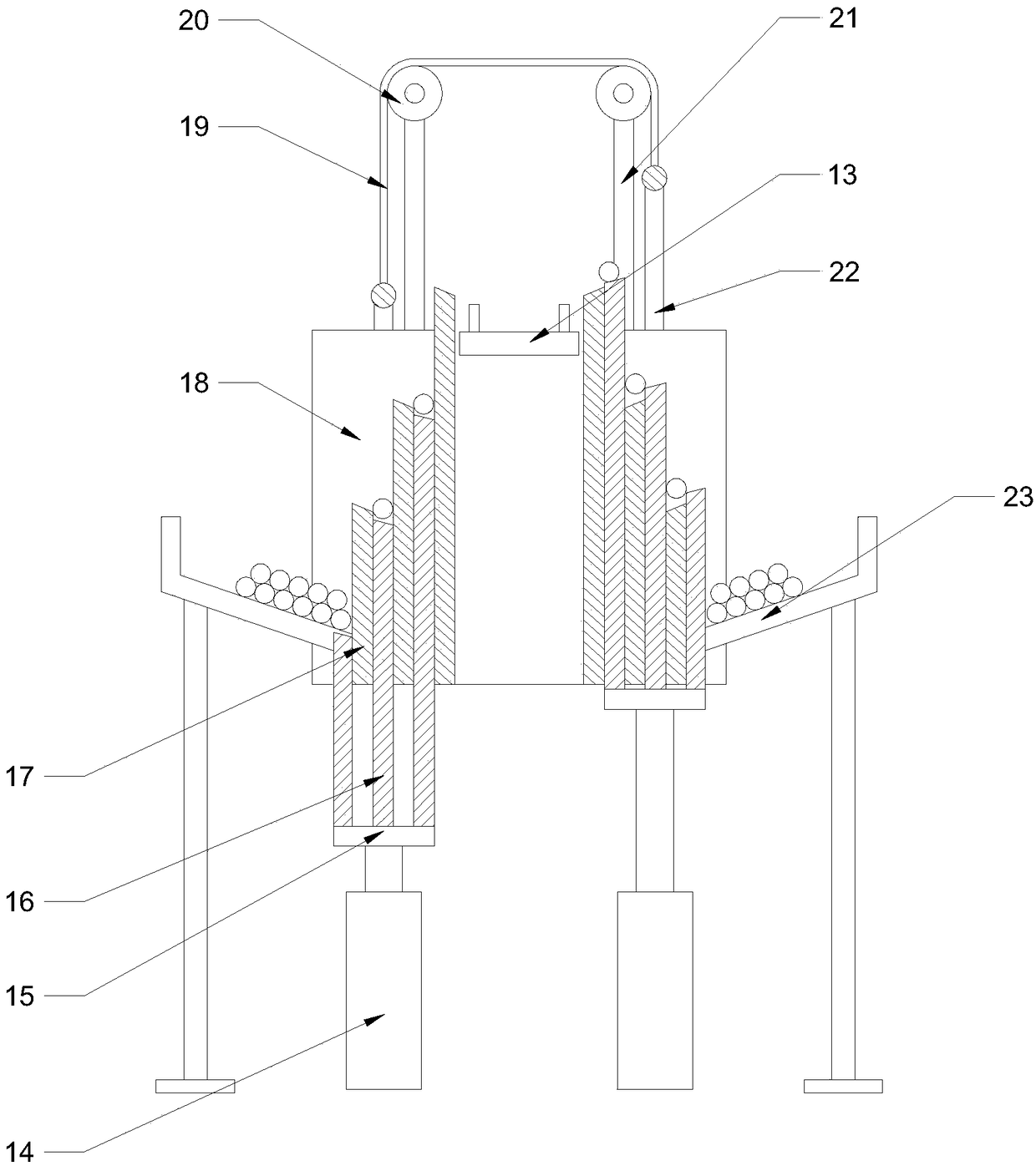

ActiveCN105127826ARealize the purpose of automatic feedingImprove utilization efficiencyWork tools storageMetal working apparatusNumerical controlEngineering

The invention discloses a manipulator type feeding machine for a numerical control machine tool. The manipulator type feeding machine comprises a rack, a workpiece placing rack, two feeding height adjusting motors, two feeding height adjusting lead screws, two height adjusting lead screw mounting rack, a feeding guide rail, a feeding sliding block, a feeding motor, a feeding tooth rack, a feeding gear, a discharging motor, a discharging driving gear, a discharging driven gear, a discharging rack, a discharging height adjusting motor, a discharging height adjusting lead screw, a discharging sliding block, a discharging manipulator and a console. Through the arrangement of a series of structures in feeding, the purpose of automatic feeding to the numerical control machine tool is realized; the utilization efficiency of the numerical control machine tool is improved, and human resource waste is reduced, so that the production cost is reduced.

Owner:江苏安托智能装备科技有限公司

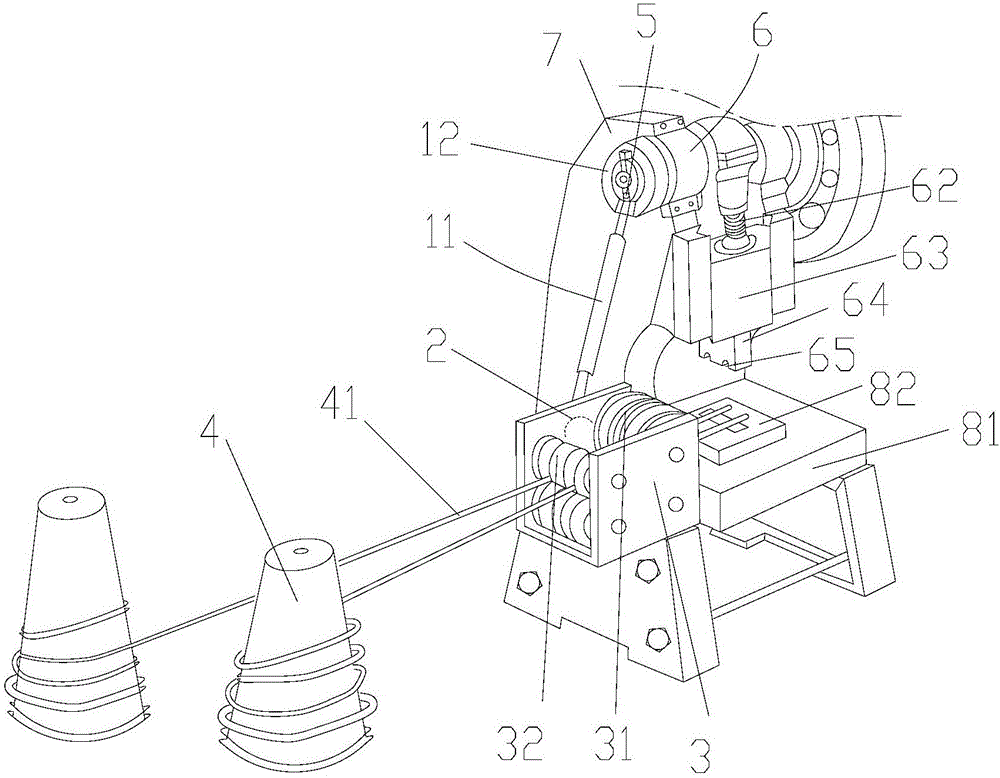

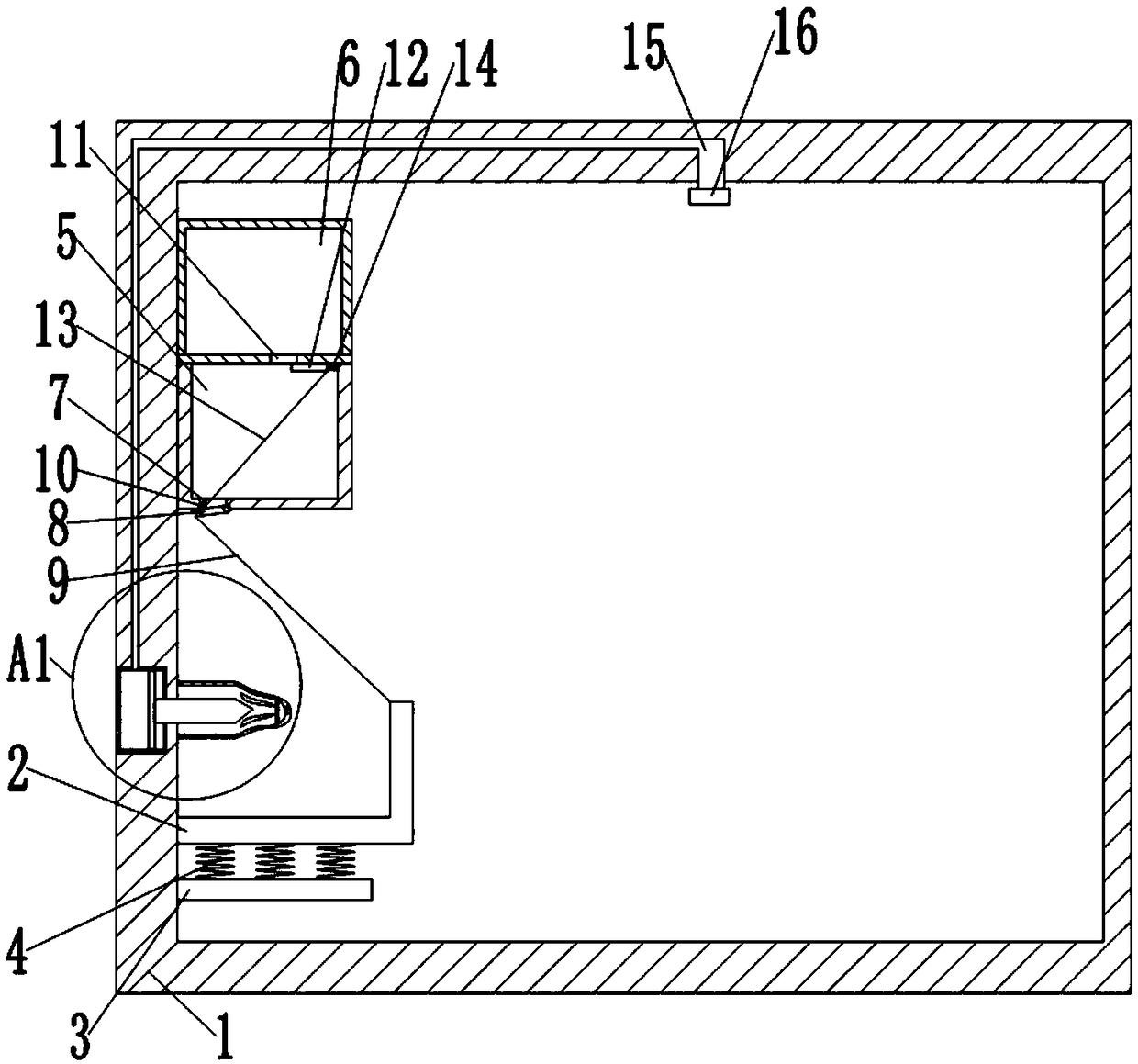

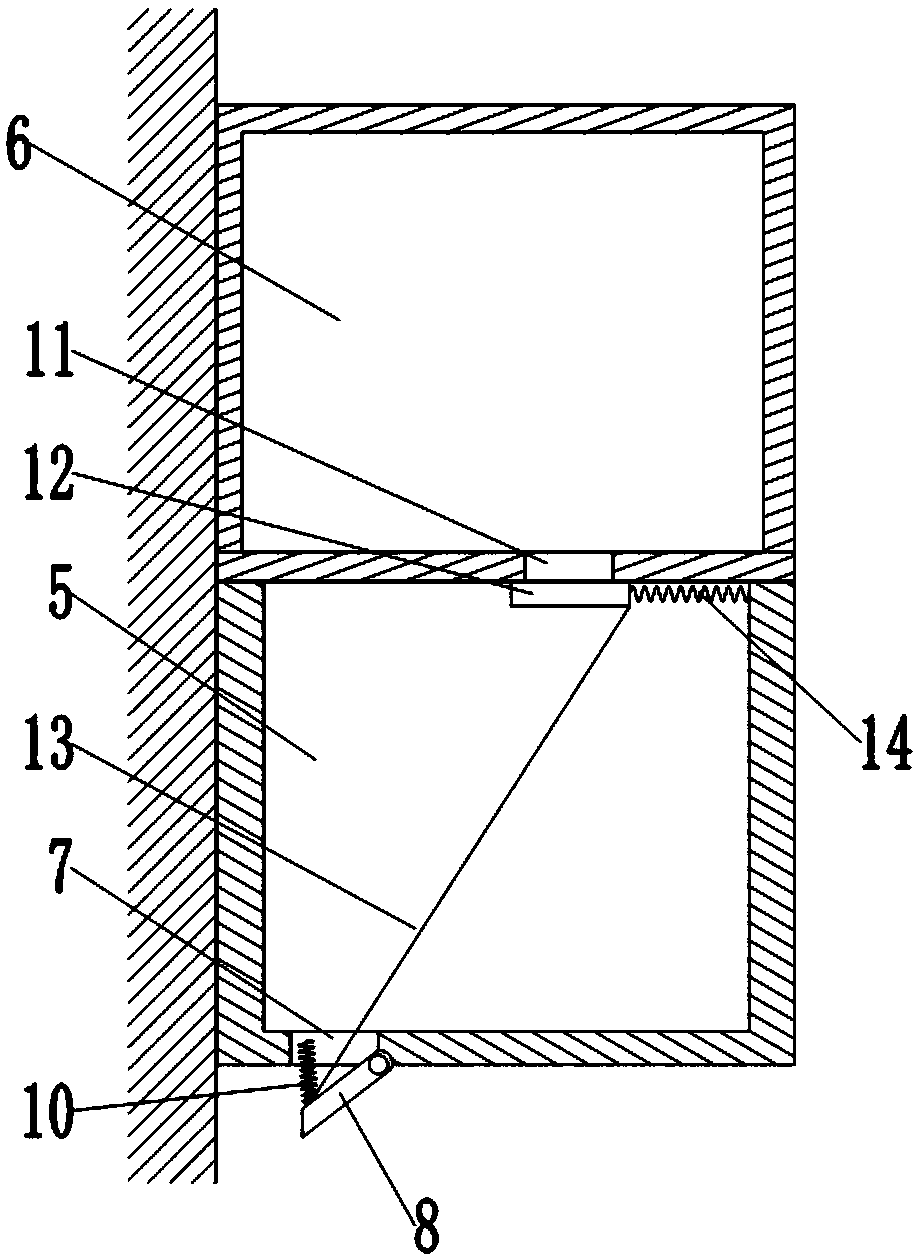

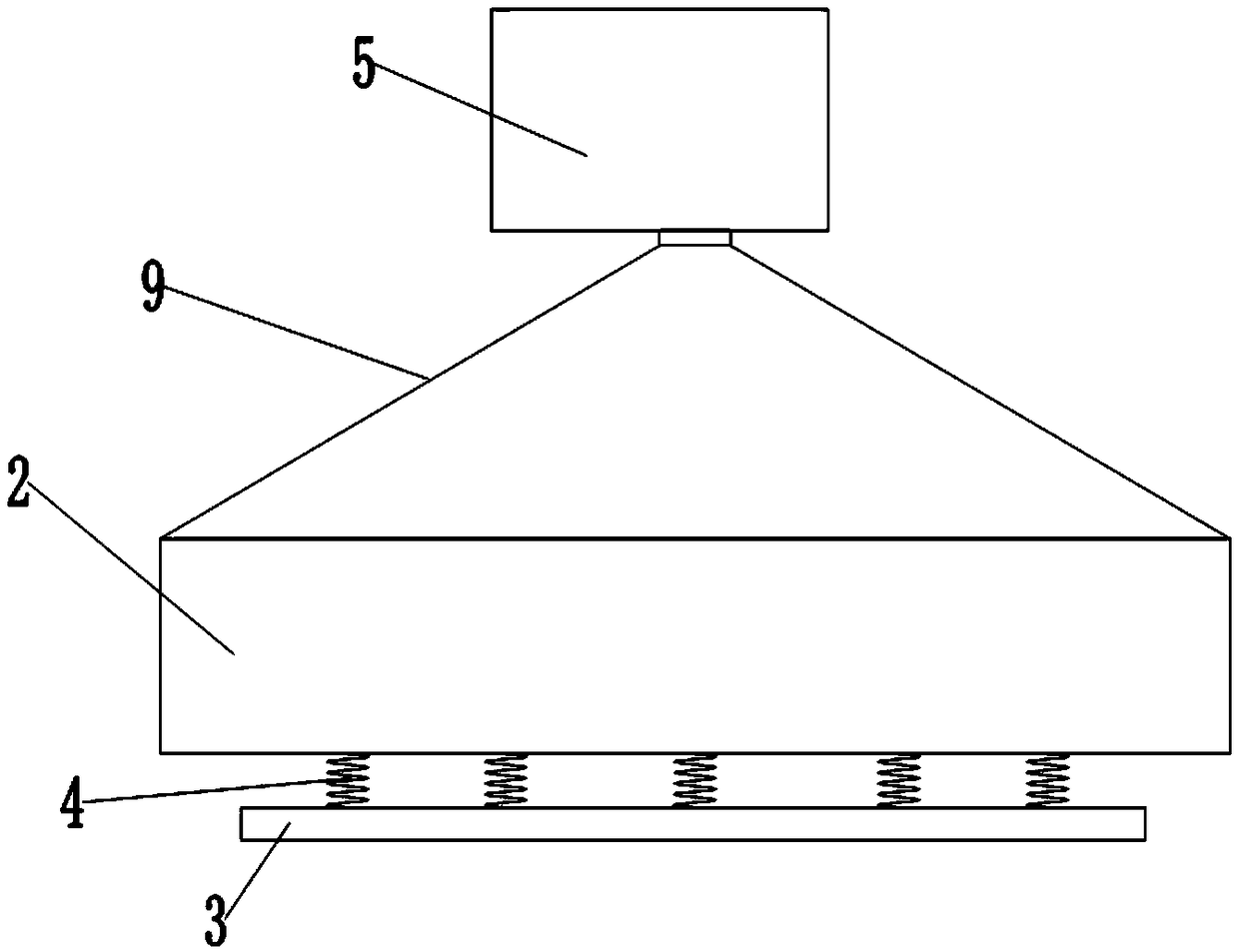

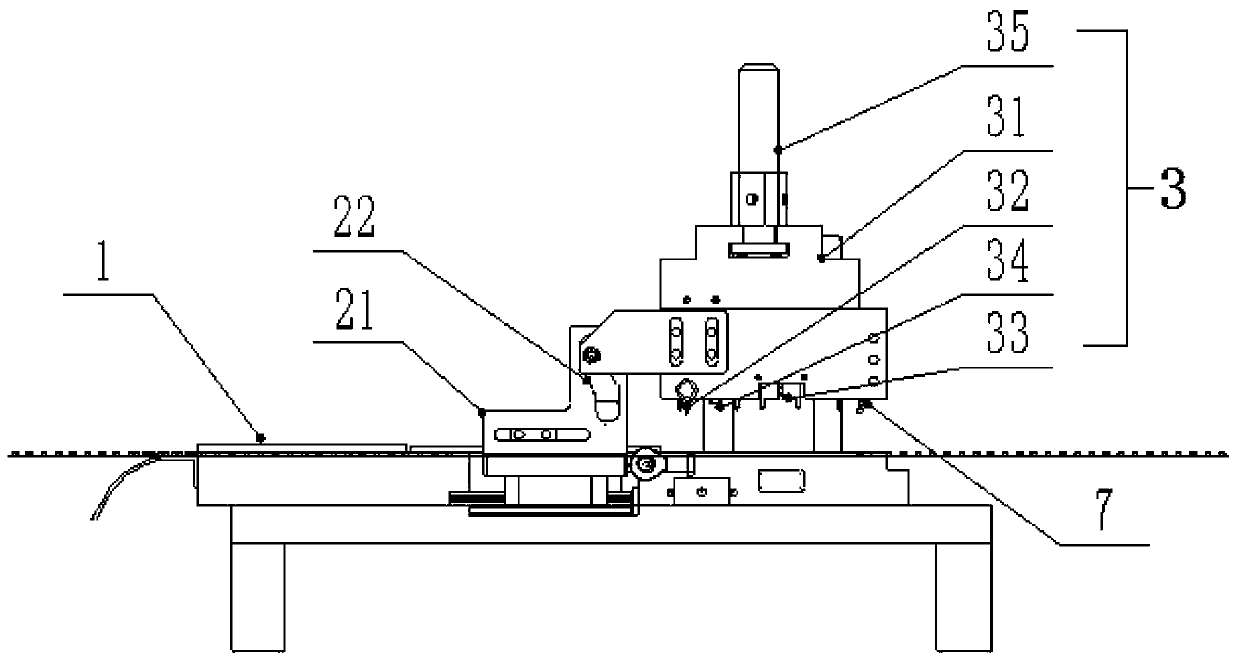

Automatic feeding punching equipment and automatic punching method

ActiveCN106180448ARealize the purpose of automatic feedingReduce procurement costsMetal-working feeding devicesPositioning devicesDrive wheelPunching

The invention discloses an automatic feeding punching device and an automatic punching method. The automatic feeding punching equipment comprises a punching device and a feeding device which is arranged on the feeding side of the punching device. The feeding device comprises a feeding seat and a transmission rod. The feeding seat is provided with a drive wheel set. The outer end of the drive wheel set is provided with a swing rod through a unidirectional transmission part, and the outer end of the swing rod is connected to the lower end of the transmission rod. The upper end of the transmission rod is in transmission connection with a transmission disc fixed to the outer end of a main shaft of the punching device. Due to transmission of the unidirectional transmission part, the drive wheel set can rotate in the single direction so as to drive a rod-shaped workpiece to be fed synchronously. According to the automatic feeding punching device and the automatic punching method, the transmission rod is driven while power of the punching main shaft is used, then the unidirectional transmission part is used for providing a synchronous periodic power source for the drive wheel set of the feeding device, and the purpose of automatic feeding for punching is achieved.

Owner:佛山市承安集团股份有限公司

Transport device for cattle and sheep

ActiveCN108719081ARealize the purpose of automatic feedingSimple structureAnimal housingAnimal ForagingEngineering

The invention relates to the technical field of transport devices, and particularly discloses a transport device for cattle and sheep. The transport device comprises a compartment and a rearing trougharranged in the compartment in a vertical sliding mode. A first storage portion and a second storage portion are arranged above the rearing trough. The first storage portion and the second storage portion are respectively provided with a discharge port and a valve plate. The two valve plates are in linkage, that is, the valve plate of the second storage portion is just closed when the valve plateof the first storage portion is open. At the same time, the valve plate of the first storage portion is in linkage with the rearing trough, that is, the valve plate of the first storage portion is open when the rearing trough slides downward. This device utilizes the phenomenon that the cattle and the sheep will generate downward force onto the rearing trough when foraging in the rearing trough in the hungry state, downward movement of the rearing trough is in linkage with the valve plates of the storage portions, so that the device can provide quantitative forage to the cattle and the sheepduring transportation.

Owner:丁道勇

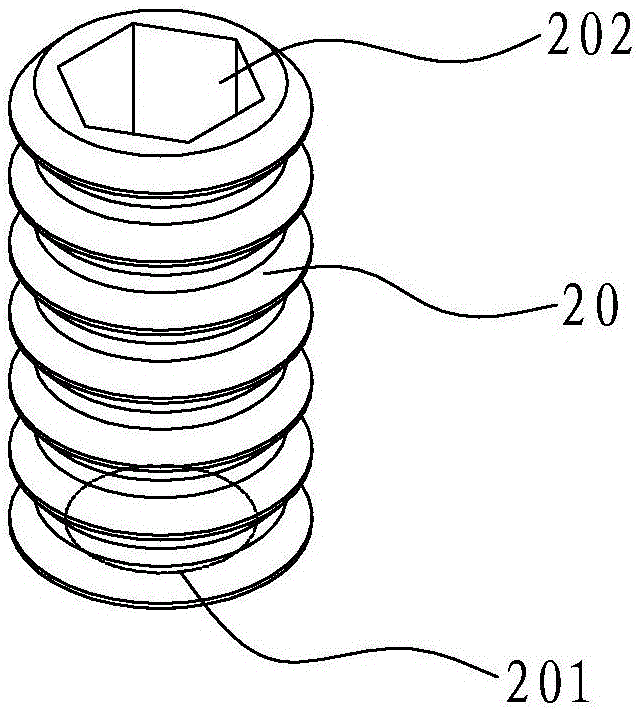

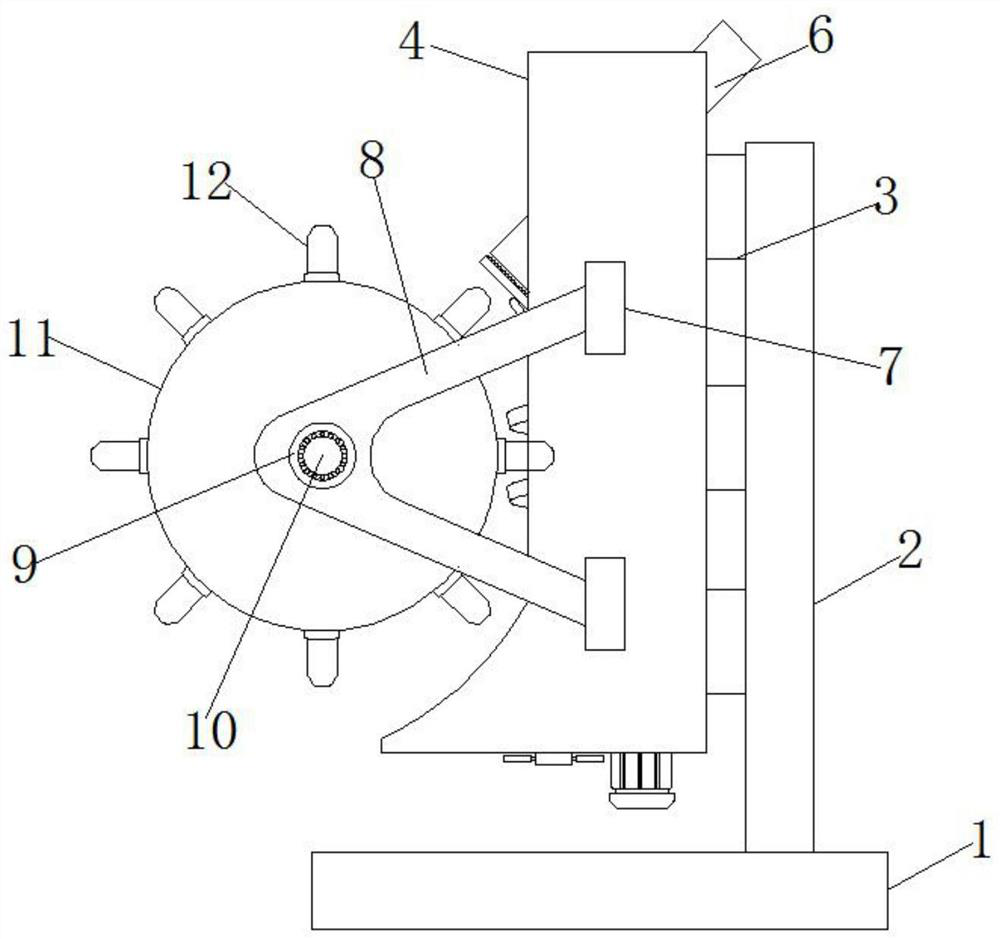

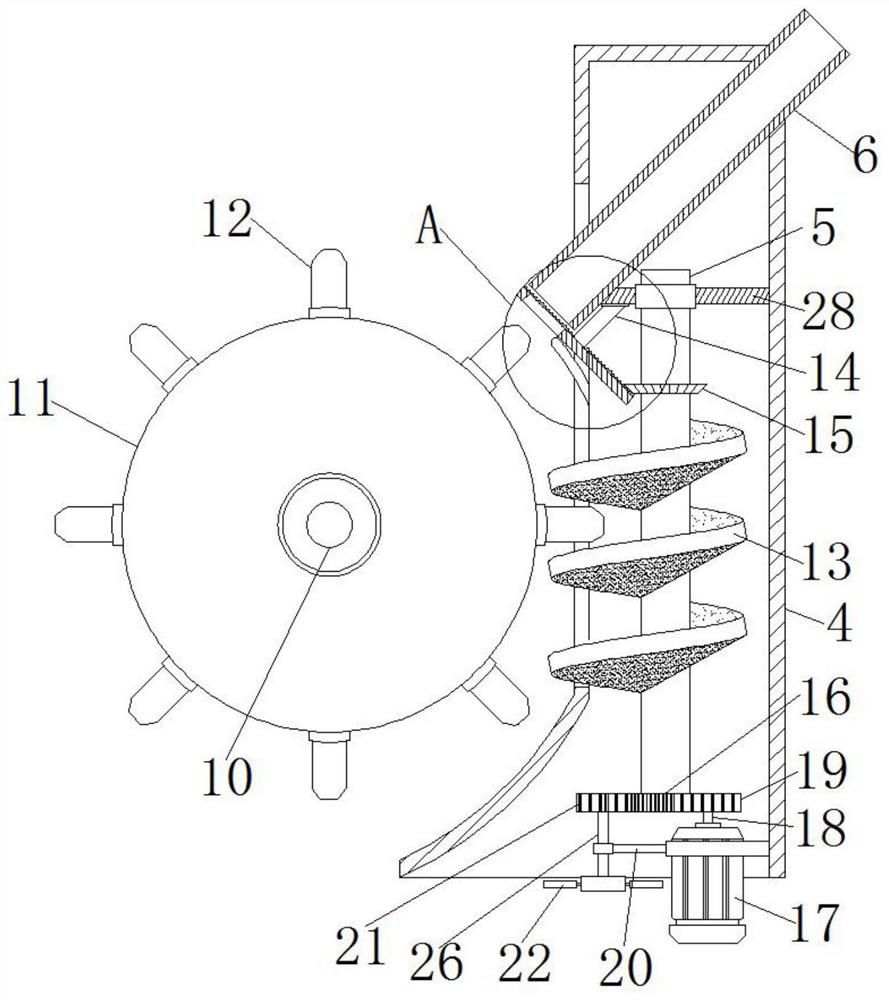

Automatic feeding device for firefighting nozzle locking fasteners

ActiveCN105947552ARealize the purpose of automatic feedingConvenient subsequent lock settingJigging conveyorsEngineeringFastener

Disclosed is an automatic feeding device for firefighting nozzle locking fasteners. One locking fastener is conveyed to a first conveying rail in a vibration mode through a vibration discharging plate, is conveyed to a first discharging end opening and pushes a transverse section. When a sinking groove of the locking fastener faces forwards, the end of the transverse section is inserted into the sinking groove and drives the locking fastener to be pushed by the later locking fastener to move away from the first discharging end opening. When a steel strip drives the locking fastener to return towards the first discharging end opening, the locking fastener gradually gets away from the transverse section under the action of gravity. When the locking fastener abuts against a second feeding end opening, the locking fastener can get away from the transverse section and enter a second conveying pipeline, and the steel strip continues to move towards the first discharging end opening, so that the locking fastener keeps the conveying direction that the sinking groove is backward in the second conveying pipeline all the time. When a concave spherical surface of the locking fastener faces forwards, the end of the transverse section can not be inserted onto the concave spherical surface, so that the locking fastener is pushed by the later locking fastener and gets away from the first discharging end opening, the steel strip moves towards the first discharging end opening and abuts against the first discharging end opening, and the next locking fastener is screened.

Owner:FUJIAN NANAN GUANGWEI FIRE FIGHTING EQUIP CO LTD

Fish feed feeding device for fishpond culture and feeding method thereof

PendingCN113455441ARealize automatic fillingRealize the purpose of automatic feedingPhotovoltaic supportsBatteries circuit arrangementsInternal cavityEngineering

The invention discloses a fish feed feeding device for fishpond culture and a feeding method thereof. The fish feed feeding device comprises a bearing bottom plate, a feeding pipe is installed at the top end of the bearing bottom plate through an angle adjusting mechanism, a fish feed box is fixedly connected to one side of the top end of the outer wall of the feeding pipe, and a feeding hole communicating with an inner cavity of the fish feed box is formed in the top end of the outer wall of the feeding pipe; and a sliding block is slidably arranged in an inner cavity of the feeding pipe, a piston sleeve fixedly sleeves the outer wall of the sliding block, a magnetic conductive block is fixedly connected with one end of the sliding block, a reset spring sleeves the magnetic conductive block, and an electromagnet is fixedly connected with one end of the inner cavity of the feeding pipe in a penetrating mode. The electromagnet in the feeding pipe is powered on to generate magnetic attraction force to attract the magnetic conductive block, the sliding block and the piston sleeve are driven to move, the piston sleeve and the sliding block are rapidly reset in cooperation with the elastic reset force of the reset spring, fish feed in the feeding pipe is pushed out and injected into a fishpond, so that the purposes of automatic filling and automatic feeding of the fish feed are achieved, and therefore, the use convenience of the fish feed feeding device is improved.

Owner:谈启龙

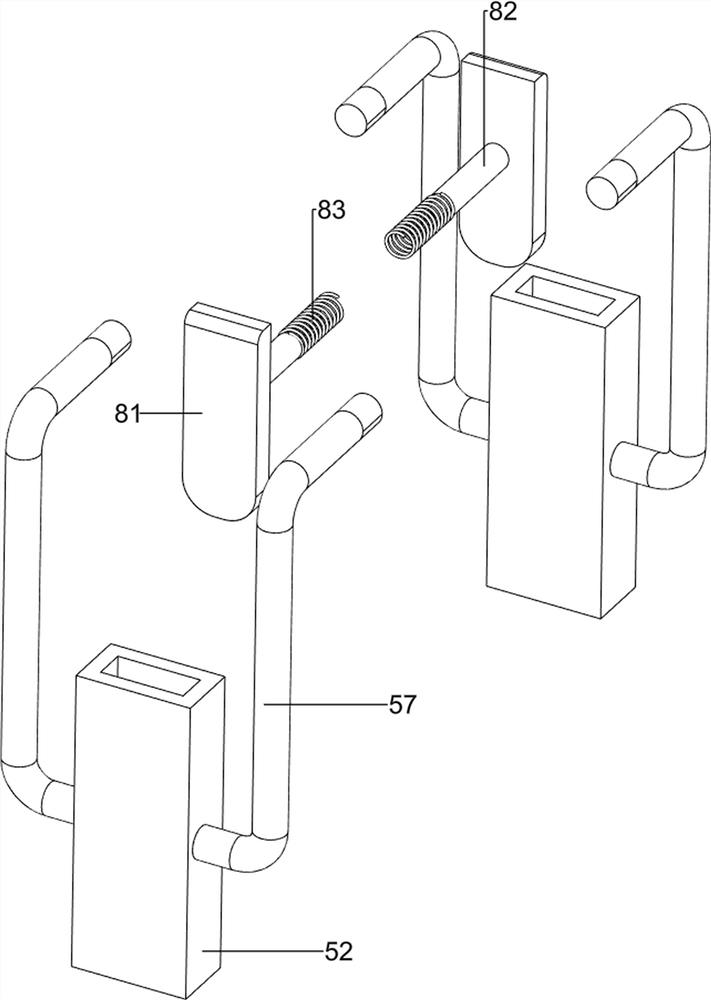

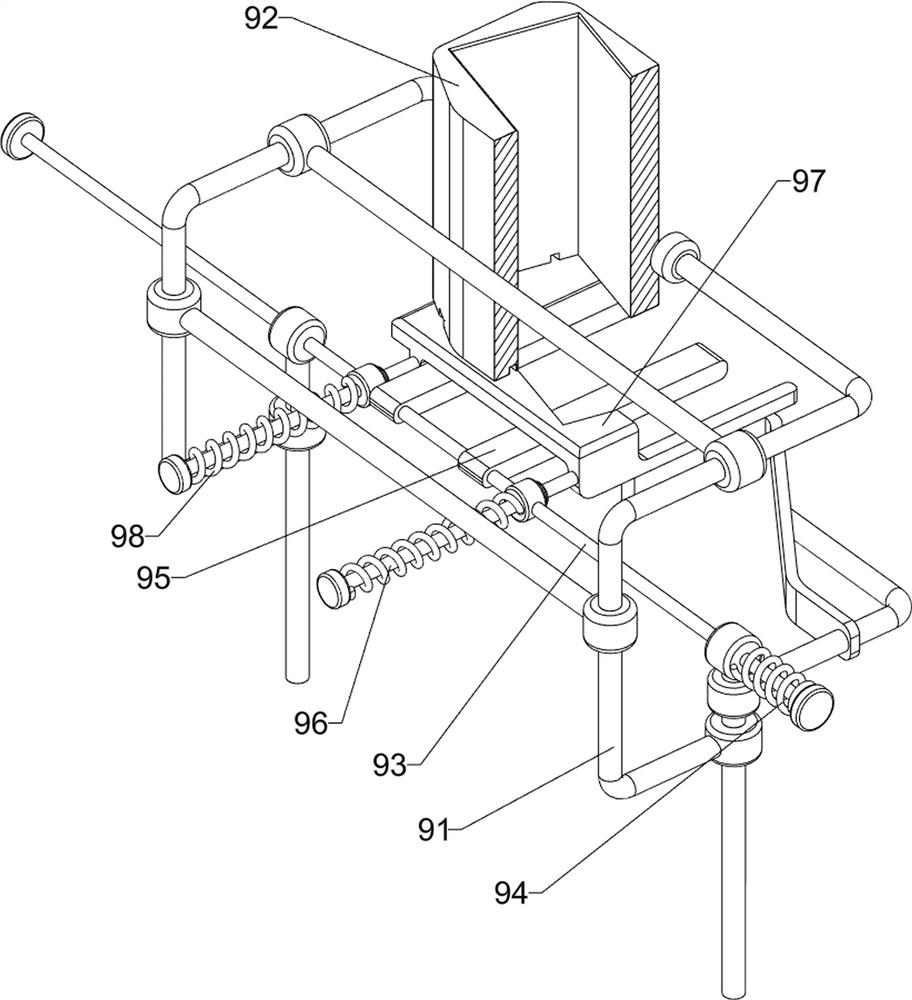

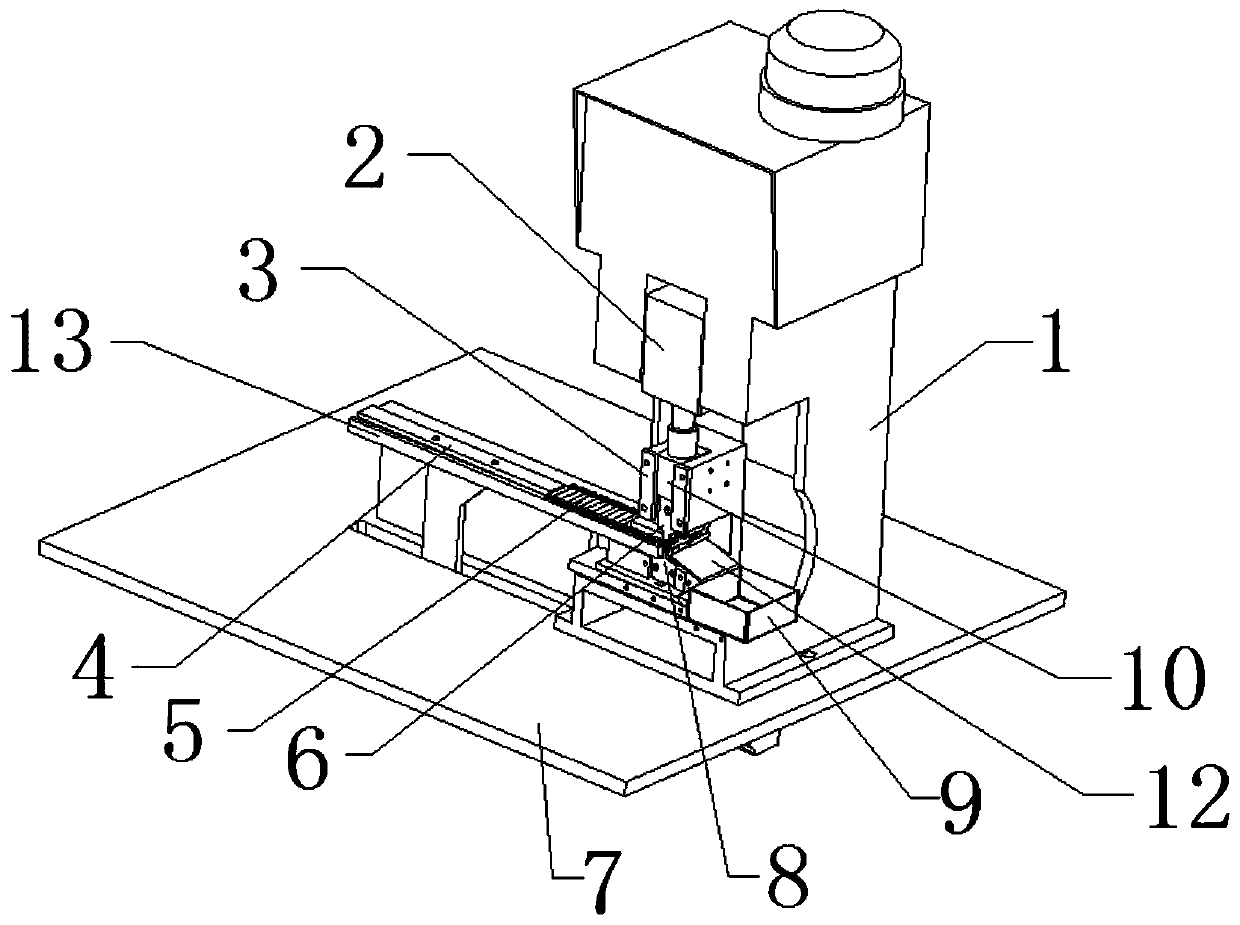

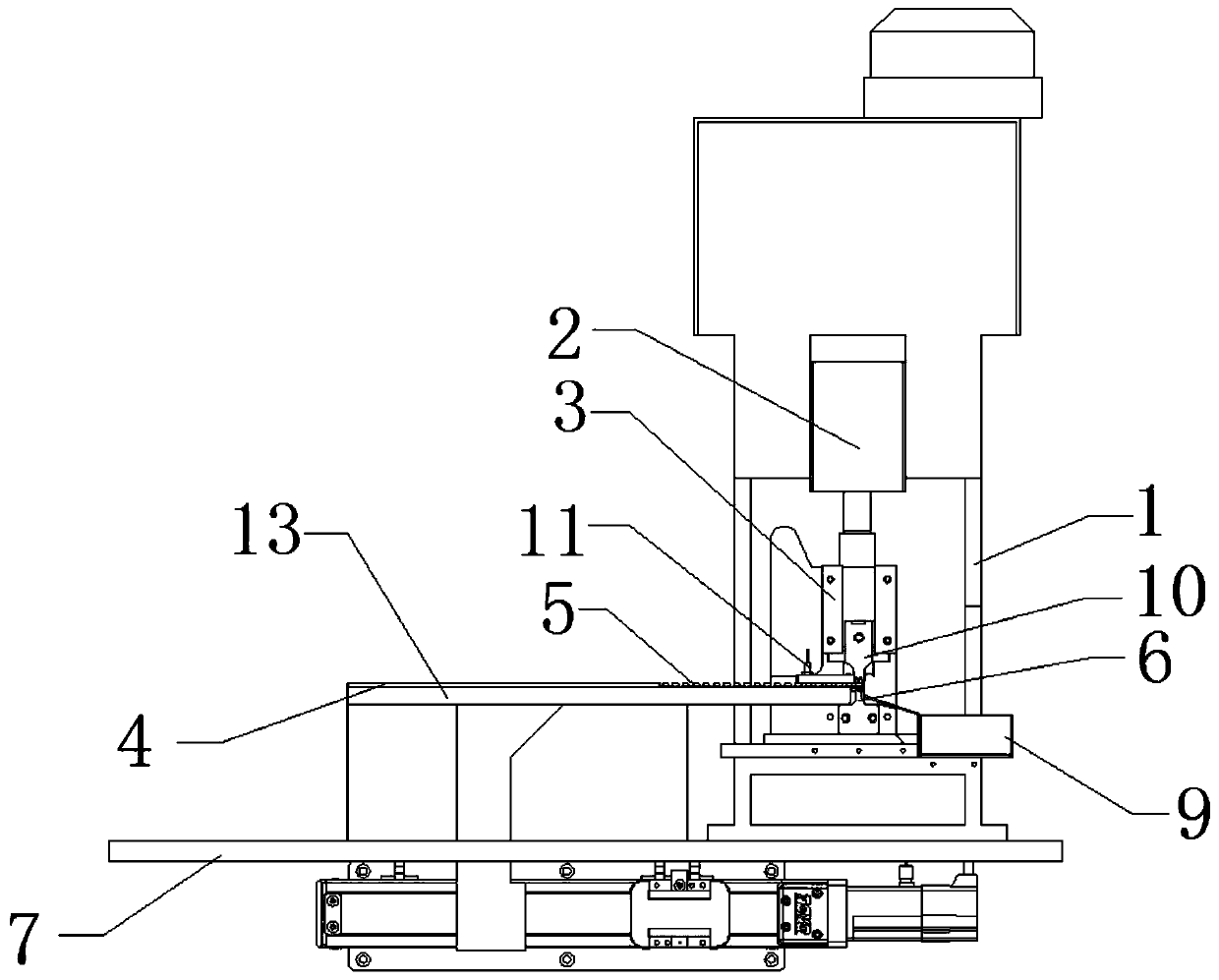

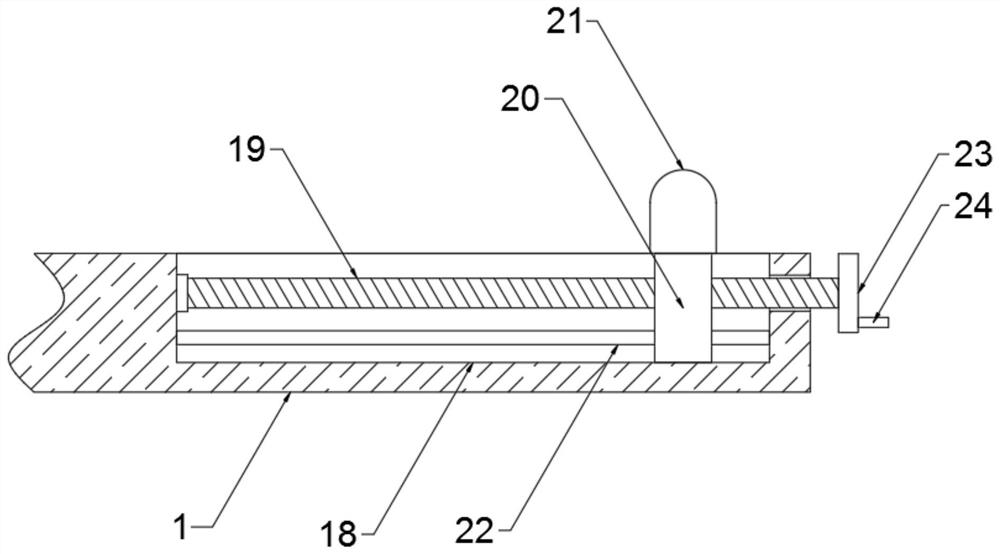

Electronic detonator bridge wire mounting equipment

PendingCN111351402AIncrease productivityRealize the purpose of automatic feedingAmmunition fuzesWorkbenchElectrical and Electronics engineering

The invention relates to the technical field of electronic detonators, in particular to electronic detonator bridge wire mounting equipment. The electronic detonator bridge wire mounting equipment comprises a workbench, and a conveying mechanism for intermittently conveying a material strip is arranged on the workbench. The workbench is provided with a riveting device, a first detecting device, asecond detecting device and a rolling machine wheel from the starting end of the conveying mechanism to the tail end in sequence, the riveting device is used for riveting bridge frames on the materialstrip to be connected and formed with bridge wires, the first detecting device is used for detecting mounting of the bridge wires on electronic detonators, the second detecting device is used for detecting whether the appearances of the electronic detonators are qualified or not, and the rolling machine wheel is arranged on the workbench and used for rolling a carrying belt. The electronic detonator bridge wire mounting equipment has the advantages of replacing manual operation, achieving mechanical automatic production, and improving the production efficiency.

Owner:东莞市弘腾自动化智能科技有限公司

Auto-feeder

InactiveCN101121188ASimple structureReduce energy consumptionMetal-working feeding devicesPositioning devicesFailure ratePunch press

An automatic feeding device comprises a fixing base fixed on a punch; one end of a guide way is connected with the fixing base and the other end is fixed on a guide way rack; a slipper block is installed with a pressure feed component and a control mechanism controls the slipper block to move along the guide way. The inside of the fixing base is equipped with an electromagnetic winding and the slipper block is equipped with a driving block made of a magnetic inductive material; the control mechanism controls the power of electromagnetic winding and the driving block drives the slipper block to move with the action of the electromagnetic winding; the slipper block is equipped with a return mechanism. By adopting the electromagnetic winding and driving block, the automatic feeding device can drive the slipper block to move to realize automatic feeding. Moreover, the automatic feeding machine boasts of simple structure, little energy consumption, low manufacture cost and low failure rate.

Owner:吕一鸣

Rapid wood cutting device

InactiveCN111037475ARealize the purpose of automatic feedingAvoid manual feeding operationsImpeller wheelsBlast gunsWood splinterWood cutting

The invention discloses a rapid wood cutting device. The cutting device comprises a machine body, wherein an input cavity with a leftward opening is formed in the machine body, a separation cavity isformed below the right side of the input cavity, a separation knife is fixedly arranged on a right end wall of the separation cavity, storage cavities capable of being opened from the right end of themachine body are formed on a front end wall and a rear end wall of the separation cavity correspondingly, and a shearing cavity with a downward opening is formed in the right side on an upper end wall of the input cavity. The device is advantaged in that processing efficiency can be improved by utilizing the characteristics of wood, a large amount of wood chips generated by traditional cutting operation can be avoided, and the body health of workers is protected.

Owner:温州市景润机械科技有限公司

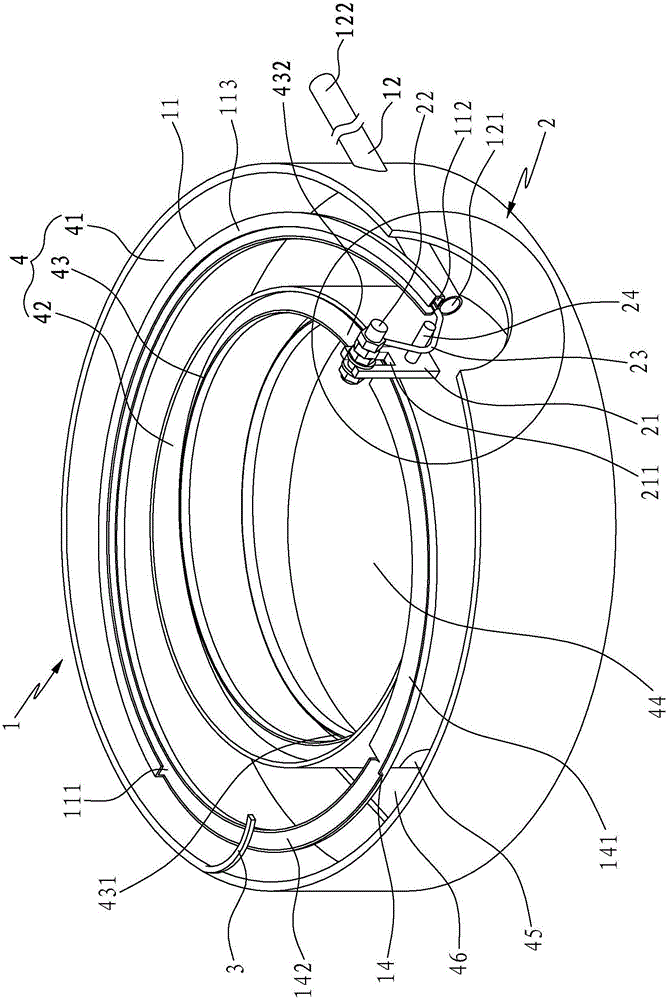

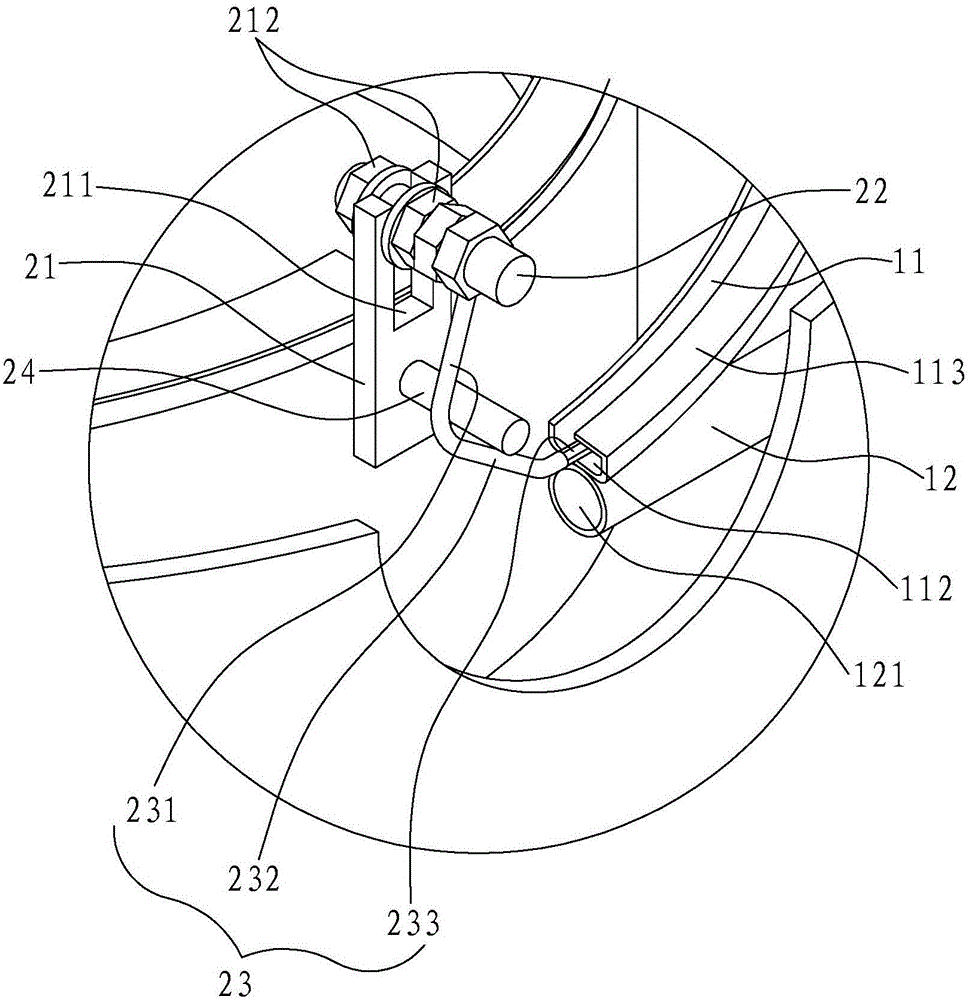

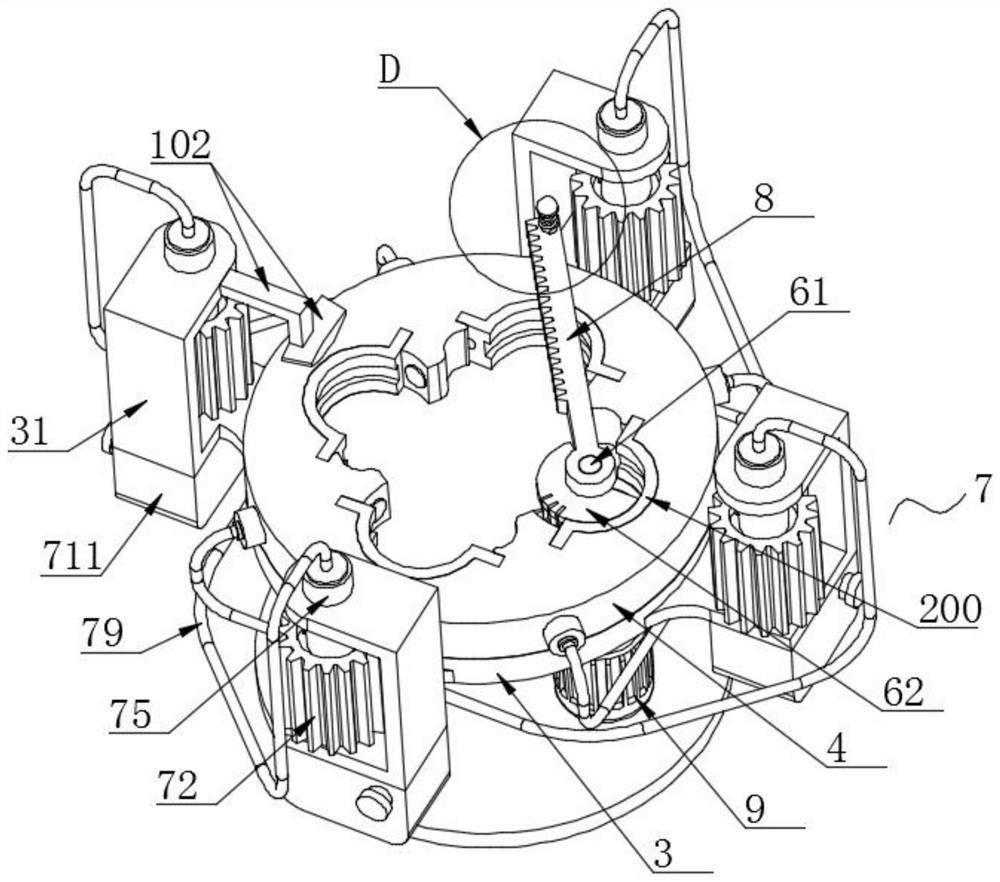

Medical respirator slotting device

PendingCN113043362ARealize automatic glue feedingRealize the purpose of automatic feedingLiquid surface applicatorsCoatingsEngineeringMachining

The invention discloses a medical respirator slotting device, and particularly relates to the technical field of respirator production equipment. The medical respirator slotting device comprises a rack and a hoop; the upper end of the rack is fixedly connected with a circular plate; a disc-shaped mounting frame is rotatably connected to the outer side of the circular plate; four plate frames are fixedly connected to the outer side of the disc-shaped mounting frame in the circumferential direction; the upper end of the disc-shaped mounting frame is fixedly connected with a rotary disc; four material placing grooves are formed inside the rotary disc in the circumferential direction; a glue feeding passage is formed between every two adjacent material placing grooves; and glue feeding sponges are fixedly connected to the interiors of the ends, close to the material placing grooves, of the four glue feeding passage. According to the invention, through rotation of a crescent block and the rack, on one hand, station switching can be intermittently conducted by 90 degrees, and on the other hand, machining, cleaning and gluing can be carried out on the hoop; automatic glue feeding can be implemented through meshing of the rack and a gear and vertical movement of the gear; and meanwhile, the aim of automatic blanking can be implemented through contact of a pressing column and a wedge-shaped block.

Owner:李建华

Cutting equipment for cloth bag production

ActiveCN112809793AAchieve automated deliveryRealize the purpose of automatic feedingBag making operationsPaper-makingGear wheelWorkbench

The invention relates to cutting equipment, and especially relates to cutting equipment for cloth bag production. The invention aims at providing the cutting equipment for cloth bag production, enabling a cloth notch to be smooth, realizing automatic cloth conveying, and reducing potential safety hazards. The cutting equipment for cloth bag production comprises a base, workbenches, a support, a transmission mechanism and a cutting mechanism, wherein the two workbenches are connected to the top side of the base; the support is connected to the top side of the base; the transmission mechanism is connected to the top side of the support; and the cutting mechanism is connected to the top side of the base. According to the invention, through cooperation of a servo motor, a conveying cylinder, a tooth-missing gear and a first belt conveying assembly, automatic cloth conveying is achieved, and the purpose of automatic loading is realized.

Owner:南京中隐客归网络科技有限公司

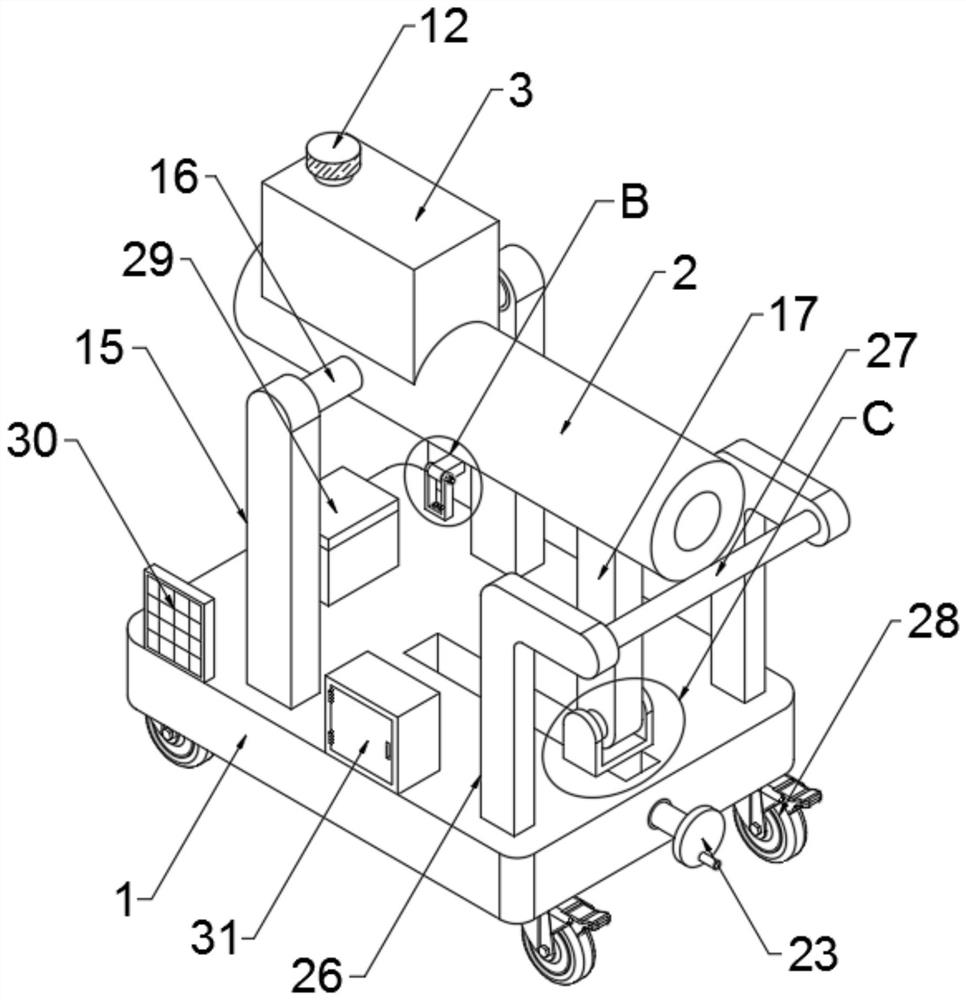

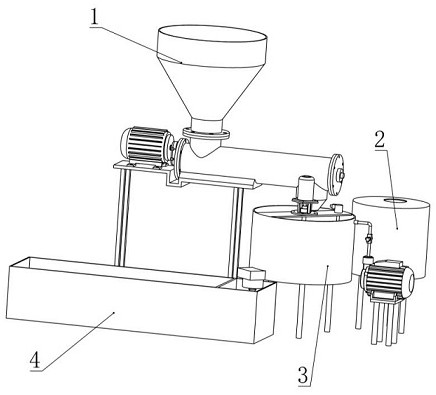

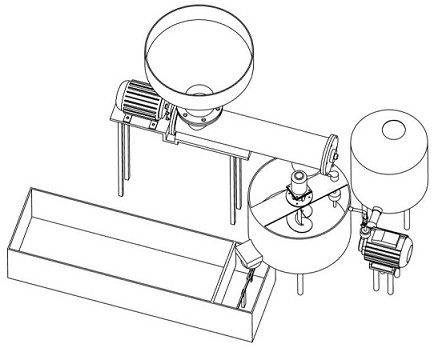

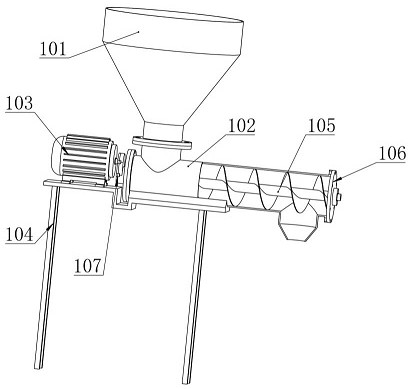

Automatic pig feed mixing and feeding device

PendingCN112369339AApplicable feeding requirementsAvoid spoilage and wasteRotary stirring mixersTransportation and packagingAnimal scienceElectric machine

The invention discloses an automatic pig feed mixing and feeding device. The device comprises a spiral feeding mechanism, a water supply mechanism, a mixing and stirring part, a feeding trough part and a control device. Dry pig feed is fed into a mixing and stirring tank through the spiral feeding mechanism, feed supply is achieved through rotation of a spiral conveying auger, different supply speeds can be achieved by controlling the rotating speed of a motor, different feeding requirements can be met, a water level control switch is installed in a mixing tank to control a feeding motor and abooster pump, the aim of adding enough mixtures for stop supply is achieved, meanwhile, a stirring motor automatically mixes the feed, so that the feed can be used immediately after being prepared, and deterioration and waste of the feed are avoided.

Owner:王黑子

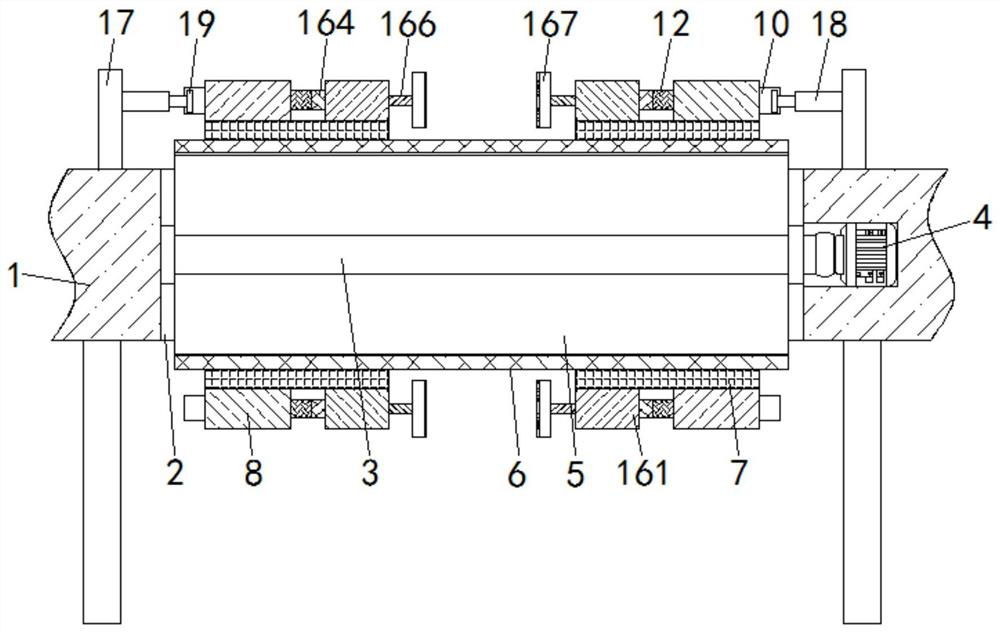

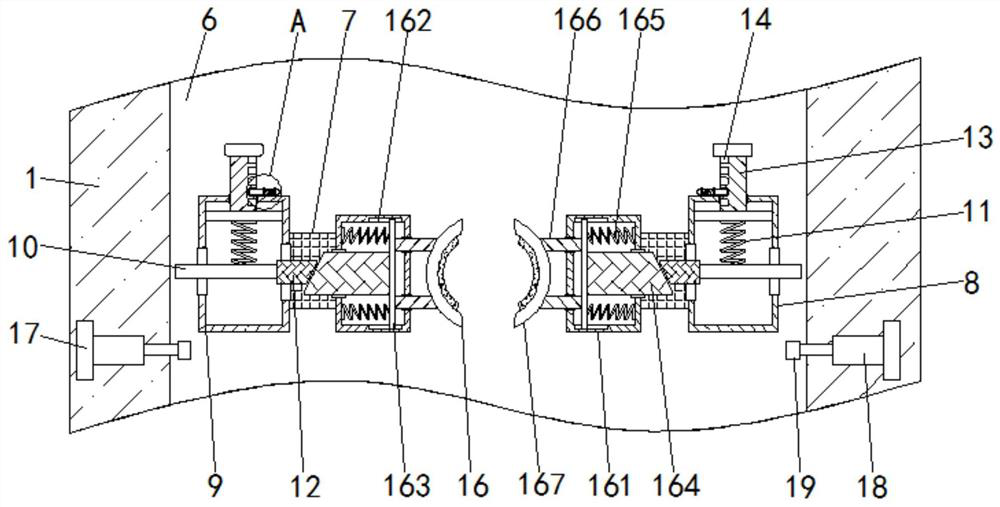

A cylindrical polishing machine

ActiveCN111843687BRealize the purpose of automatic feedingEasy to polishEdge grinding machinesGrinding drivesDrive wheelPolishing

The invention discloses a cylindrical polishing machine, which comprises a base, a vertical rod is fixedly installed on the top of the base, a transmission wheel is fixedly installed on the bottom of the rotating rod, and a motor is fixedly installed on the inner wall of the processing cylinder. , and the inner side of the motor is movably installed with an output shaft, the top of the output shaft is fixedly installed with a driving wheel, the outer side of the motor is fixedly installed with a sleeve rod, and the inner side of the sleeve rod is movably sleeved with a transmission rod, and the transmission rod A fan blade is fixedly installed at the bottom of the feeder, a feeding wheel is movably installed on the end of the support rod close to the feeding pipe, and a feeding port is opened on the inner side of the feeding wheel, and a transmission gear is fixedly installed on the outer edge of the feeding wheel. . In the present invention, a running wheel is fixedly installed on the outer side of the rotating rod, and the outer side of the rotating wheel meshes with the transmission teeth on the outer edge of the feeding wheel, so that when the rotating rod rotates, the rotating wheel will drive the feeding wheel to rotate, and The workpiece is dropped to the outside of the fixed rod, thereby realizing the purpose of automatic feeding.

Owner:枣庄恒信精密机械股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com