Automatic feeding punching equipment and automatic punching method

An automatic feeding and equipment technology, applied in metal processing equipment, feeding devices, manufacturing tools, etc., can solve the problems of lack of feeding devices, high cost, manual feeding, etc., and achieve the effect of reducing procurement costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to fully understand the technical content of the present invention, the technical solutions of the present invention will be further introduced and illustrated below in conjunction with specific examples, but not limited thereto.

[0034] In this case, the rod-shaped workpiece 41 can be a series of rod-shaped materials such as copper rods, iron rods, and alloy rods.

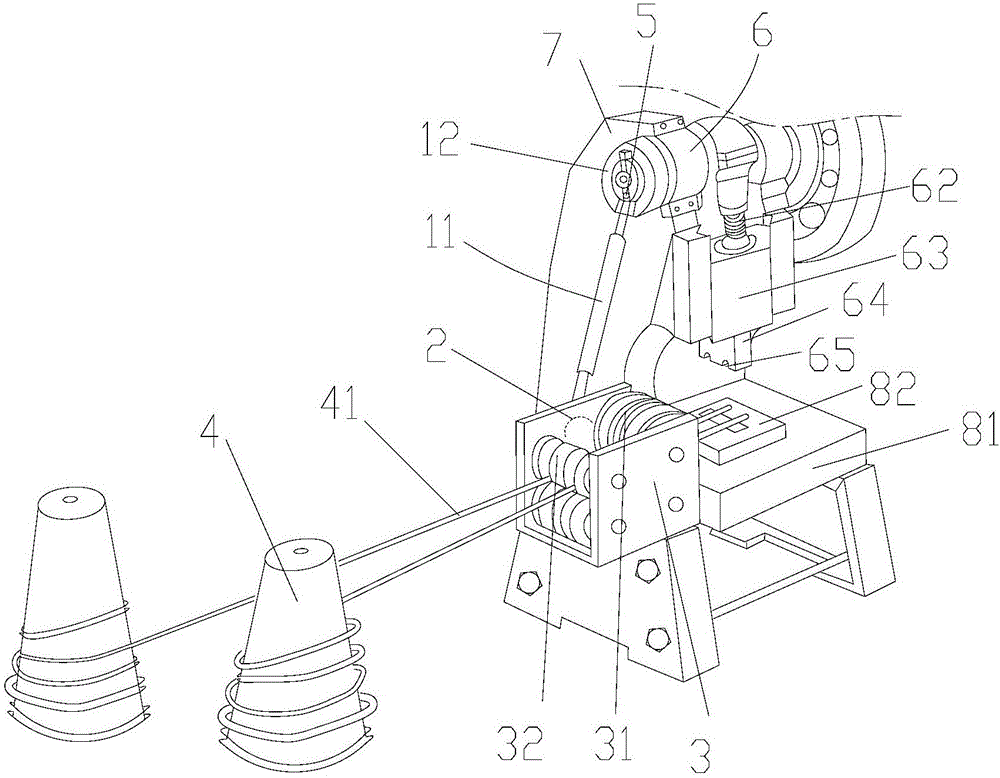

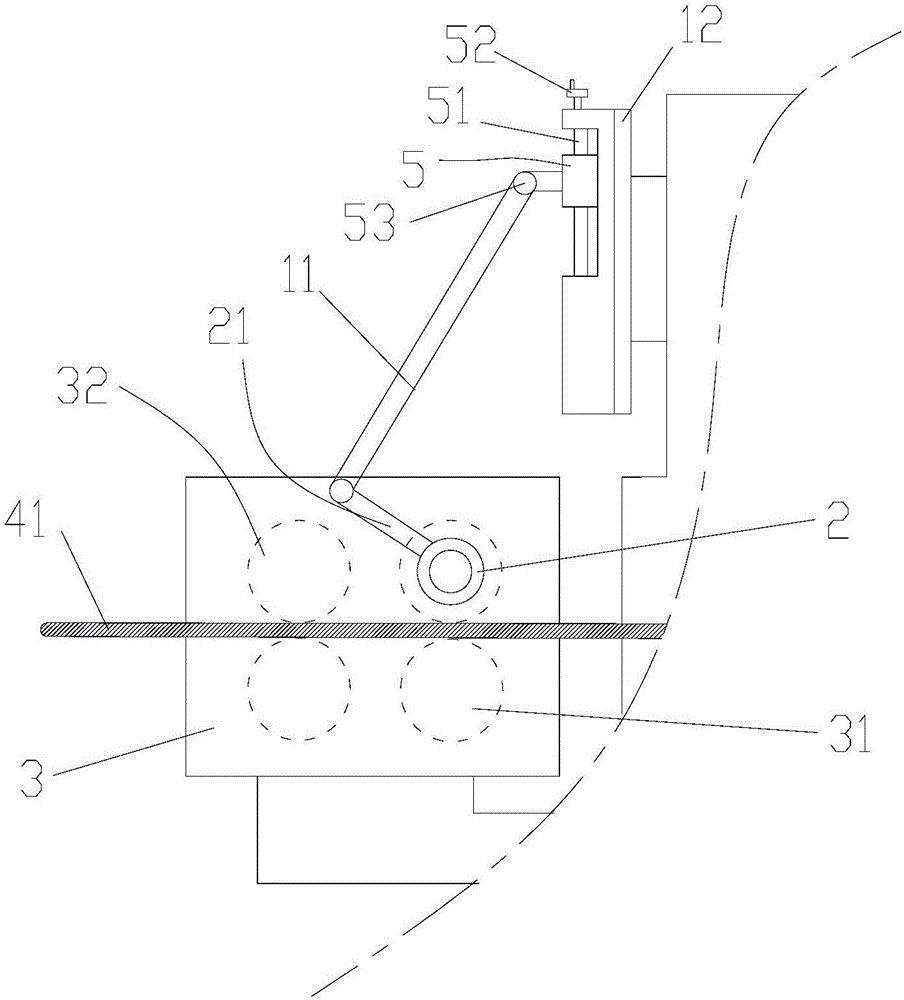

[0035] Such as Figure 1-2 Shown specific embodiment, the present invention a kind of punching equipment of automatic feeding, comprises punching device, also comprises the feeding device that is located at the feeding side of punching device (existing punch equipment can be adopted), and feeding device comprises feeding device Seat 3 and transmission rod 11, feeding seat 3 is provided with driving wheel group 31; , the upper end of the transmission rod 11 is connected to the transmission disc 12 fixed on the outer end of the main shaft of the punching device; wherein, the transmission rod 11 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com