Manipulator type feeding machine for numerical control machine tool

A technology of CNC machine tools and manipulators, applied in metal processing, tool storage devices, manufacturing tools, etc., can solve the problems of increasing costs, reducing production and processing efficiency, and wasting human resources, so as to reduce waste, improve utilization efficiency, and reduce production costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with specific embodiments. The exemplary embodiments and descriptions of the present invention are used to explain the present invention, but not as a limitation to the present invention.

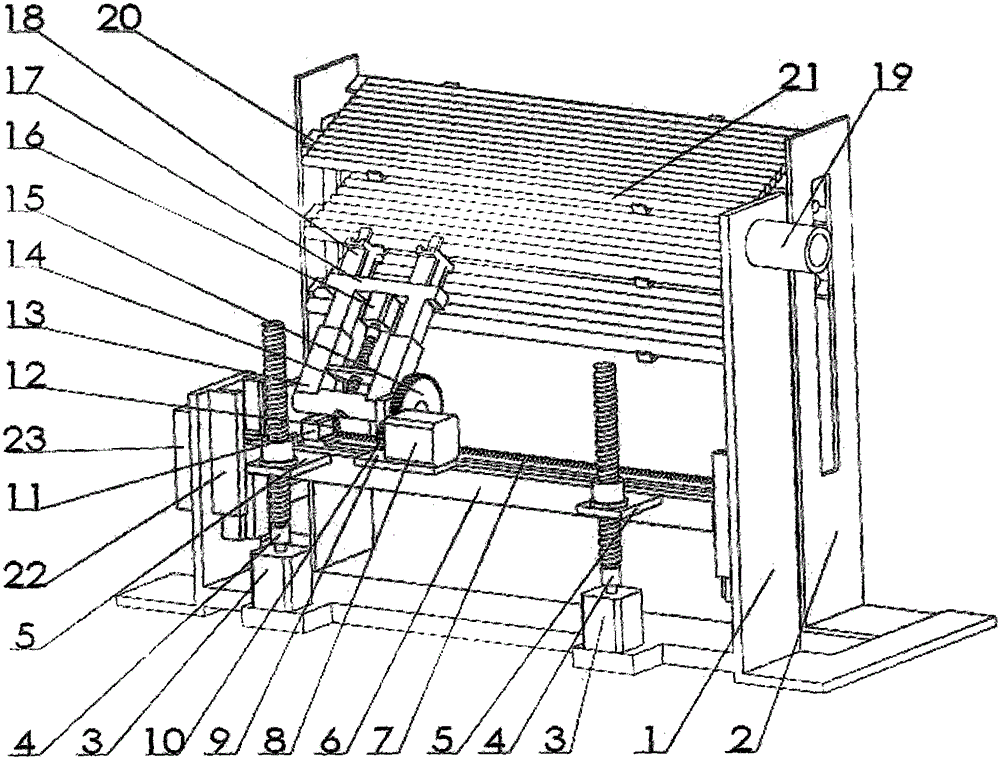

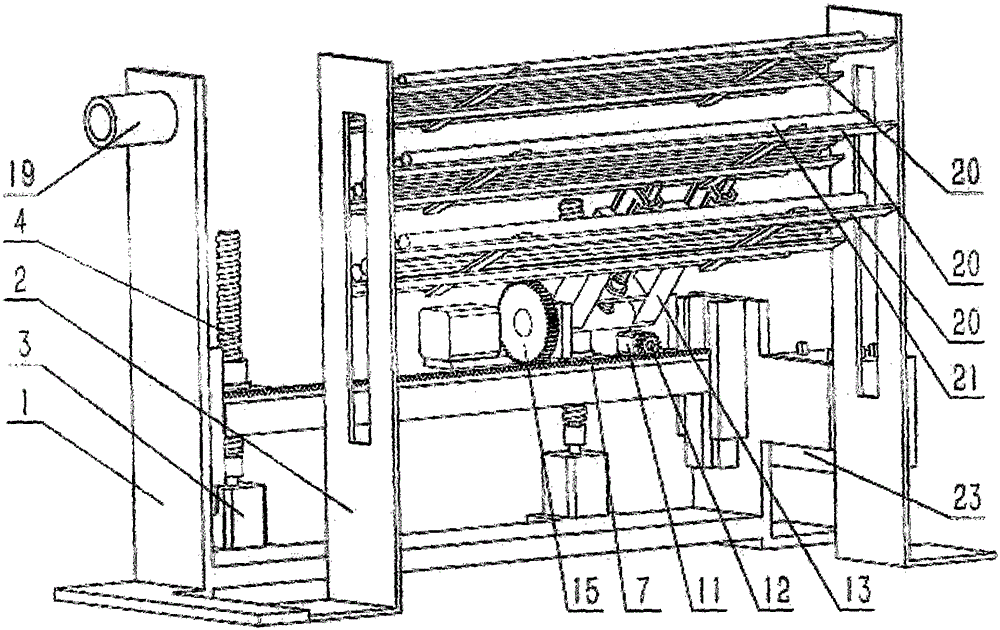

[0014] Such as figure 1 , figure 2 As shown, a manipulator-type CNC machine tool feeding machine includes a frame 1, a workpiece placement rack 2, two feeding height adjustment motors 3, two feeding height adjustment screw screws 4, two height adjustment screw mounting frames 5, and a feeding Guide rail 6 and feeding slider 9, feeding motor 11, feeding rack 7 and feeding gear 12, retrieving motor 8, retrieving main gear 10 and retrieving slave gear 15, retrieving rack 13, retrieving height adjustment motor 16 and Feed height adjustment lead screw 14, reclaim slide block 17 and reclaim manipulator 18, console 23, frame 1 two ends are provided with feed height adjustment slide rail 22 in vertical direction, frame 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com