Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

165results about How to "Realize linear motion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

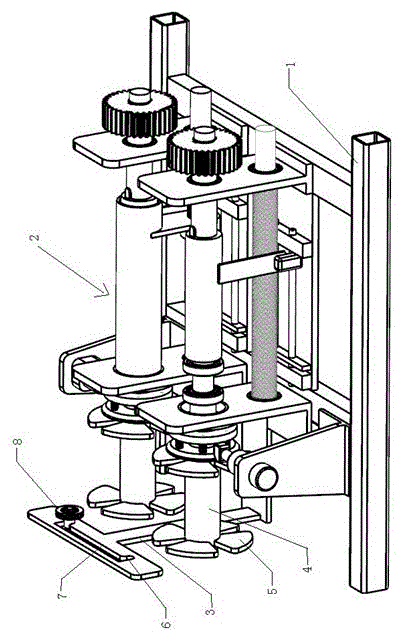

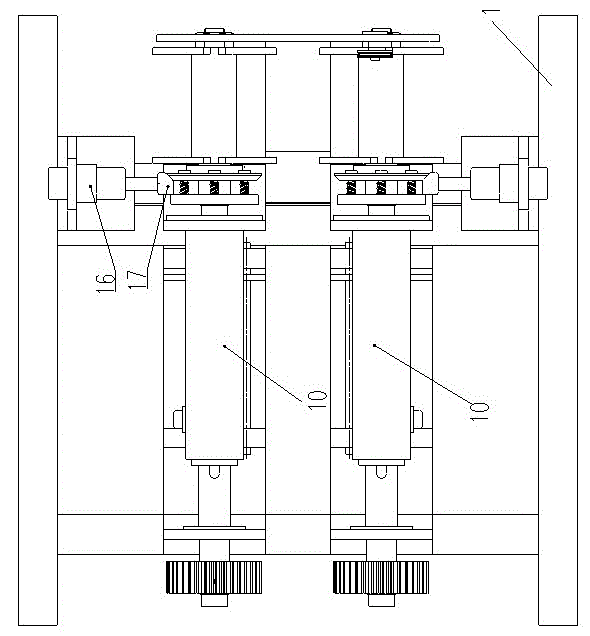

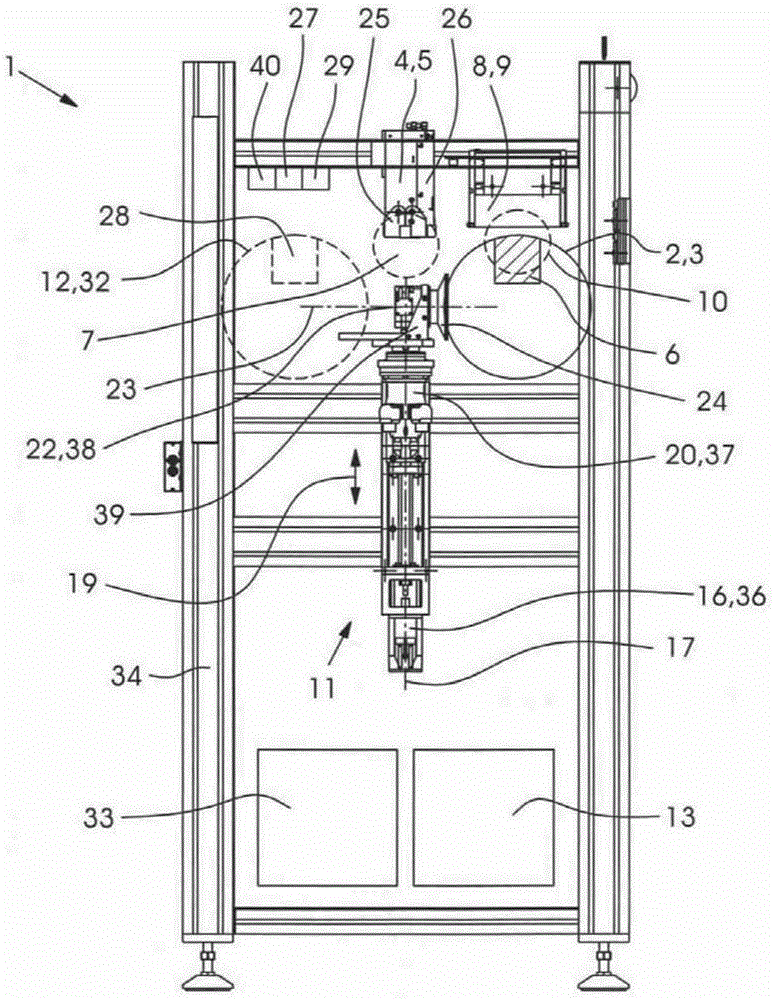

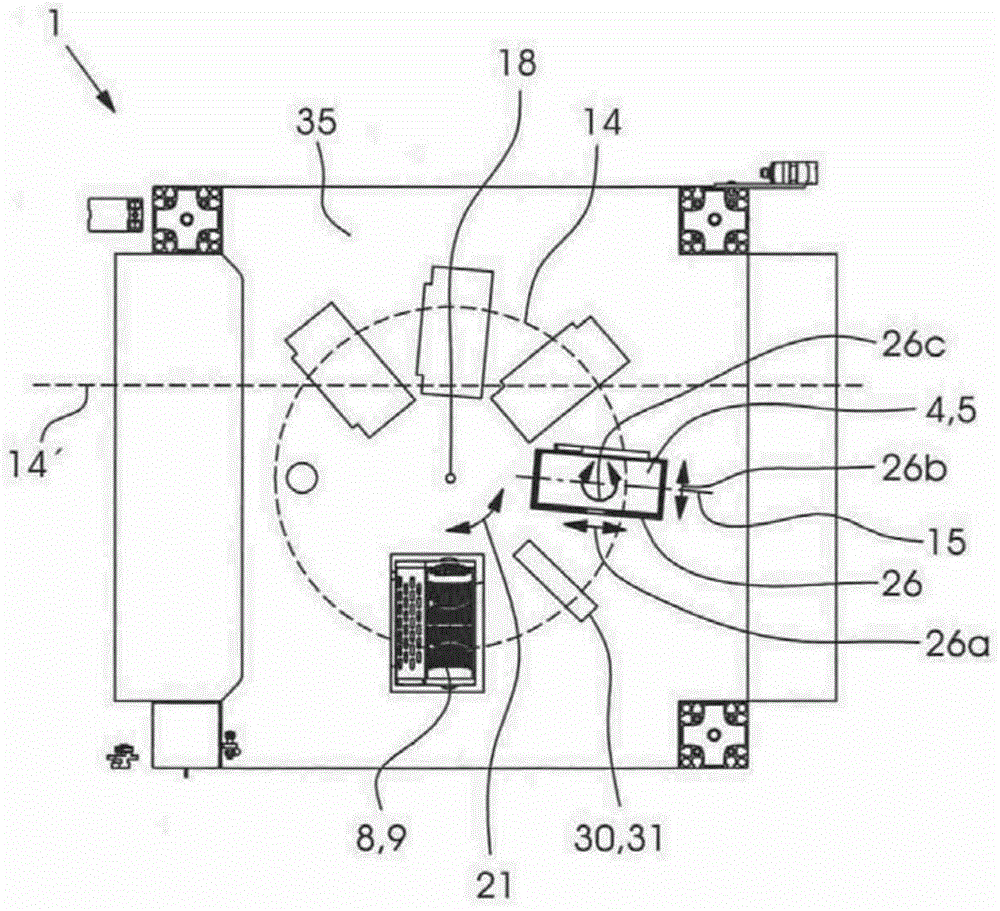

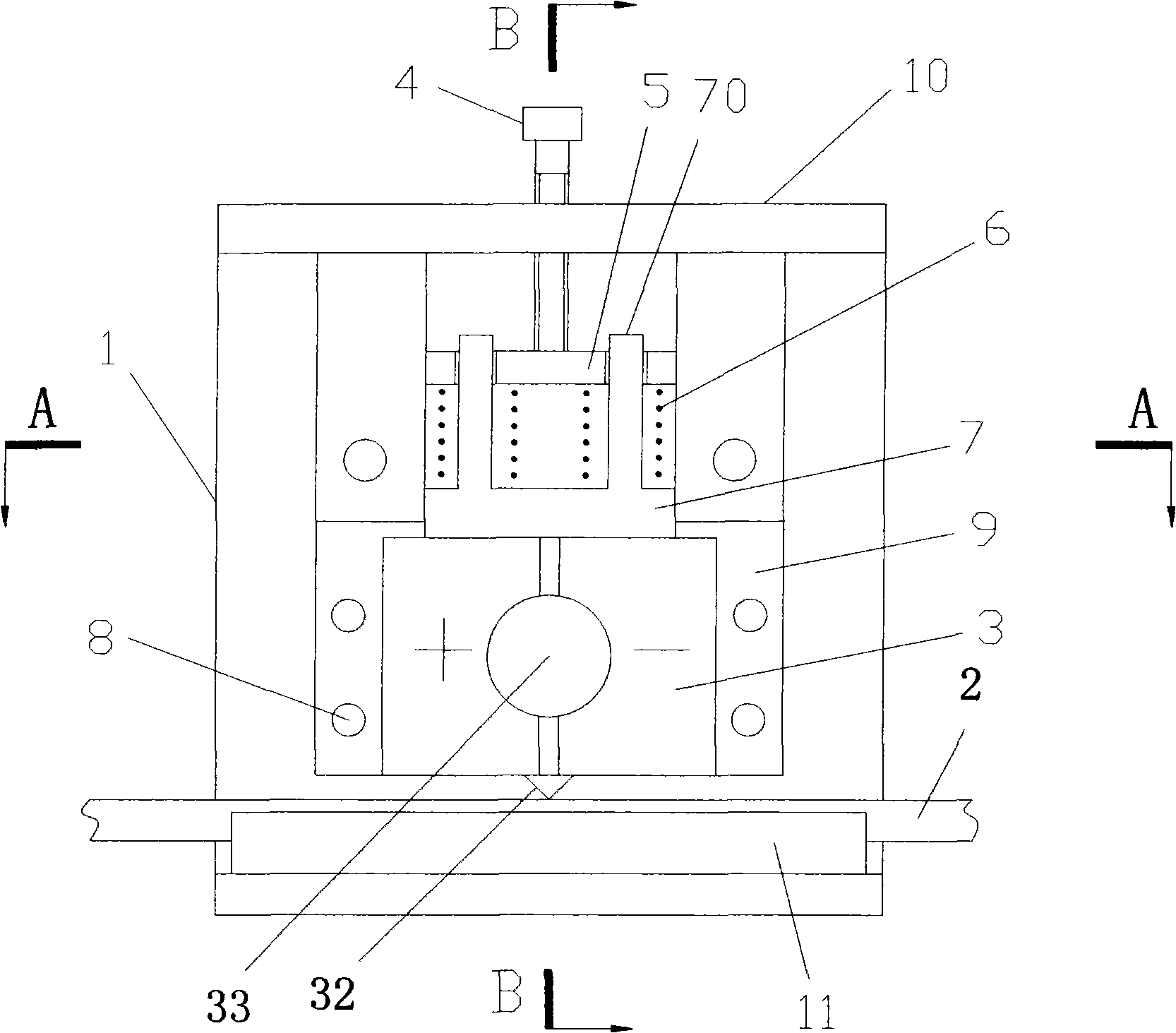

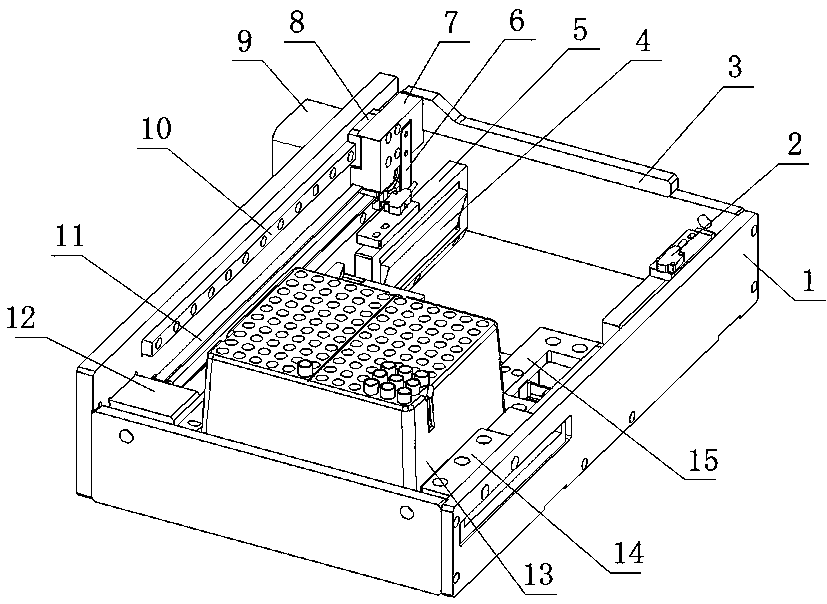

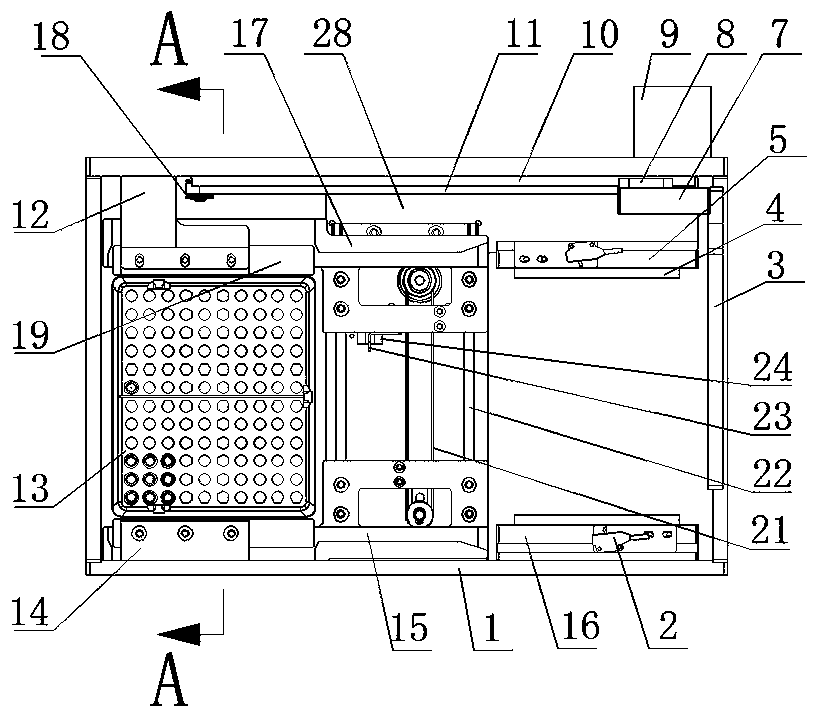

Vacuum suction wall-climbing robot and using method thereof

ActiveCN105235764ARealize linear motionAchieve continuous motionVehiclesWall climbingClimbing robots

The invention belongs to the technical field of intelligent robots and specifically provides a wall-climbing robot and a using method thereof. The vacuum suction wall-climbing robot comprises a box body (1), a transmission mechanism (2), guide mechanisms (3) and suction mechanisms (4). The transmission mechanism (2) comprises two synchronous belt sets (11) in square crossing. Each synchronous belt set (11) is driven by a motor (8). The suction mechanisms (4) are installed on the two ends of the synchronous belt sets (11). Each suction mechanism comprises an electric push rod (21) and a sucker group (25) arranged under the electric push rod (21), wherein the suction and the release of the sucker group (25) are controlled by a solenoid value. Through coordinated control of the motor at one end of each guide rail, the suckers and the solenoids for controlling the suction of the suckers, the motors can drive the guide rails to move linearly in certain directions; the solenoid valves for the suckers can achieve the suction and the release of the suckers, so that the robot can move continuously in the certain directions.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY +2

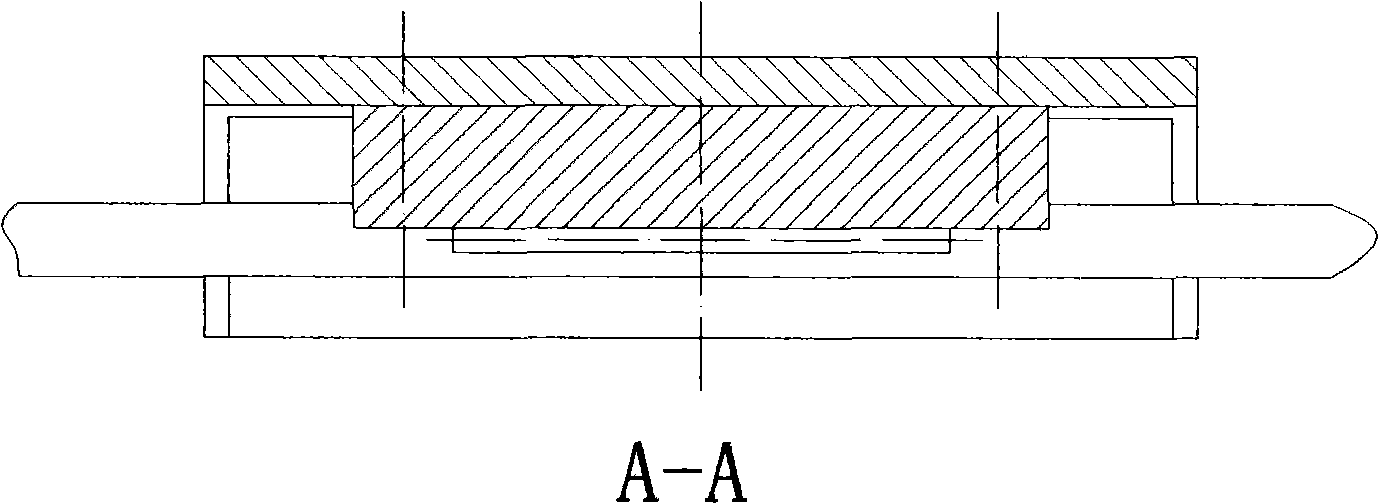

Single-driving foot sandwiched transducer type longitudinal bending linear ultrasonic motor

InactiveCN101072000AIncrease amplitudeRealize linear motionPiezoelectric/electrostriction/magnetostriction machinesTransducerEngineering

The disclosed variation pole is quadrangular body with rectangular section thinned gradually from two ends to central section. Drive feet are located at middle position of the pole. Piezoelectric ceramic piece in longitudinal vibration and piezoelectric ceramic piece in bending vibration are respectively installed on inner and outer sides of bolts on two flange bolts. Two end plates are installed on outer sides of bolts on two flange bolts. Through two flange bolts, two end plates, two groups of piezoelectric ceramic piece, and thin copper sheet are fastened and integrated to two larger ends of the pole. Advantages are: simple structure, smooth operation, large output thrust, and motion in high speed.

Owner:HARBIN INST OF TECH

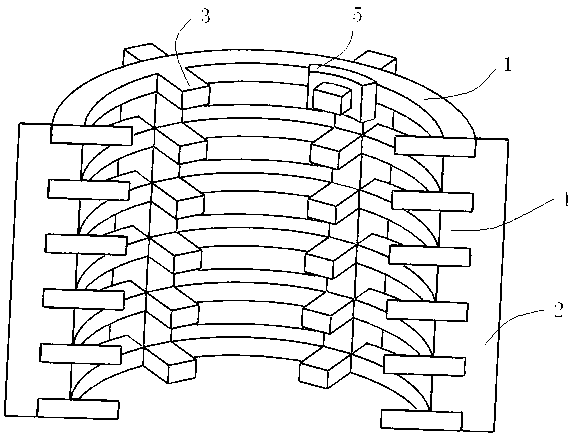

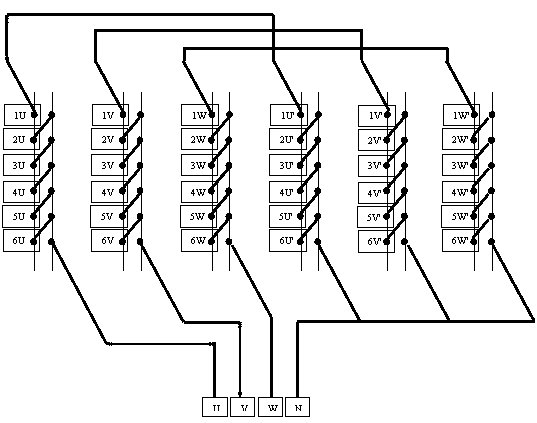

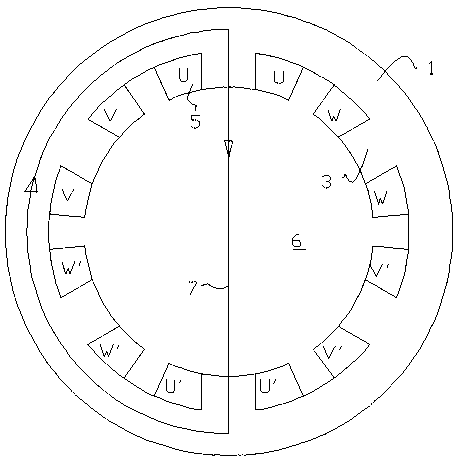

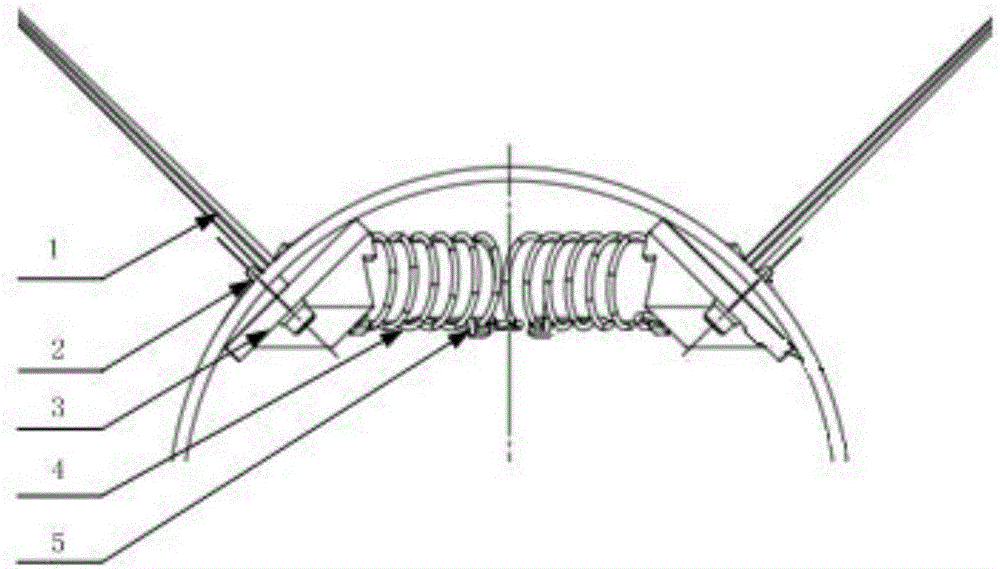

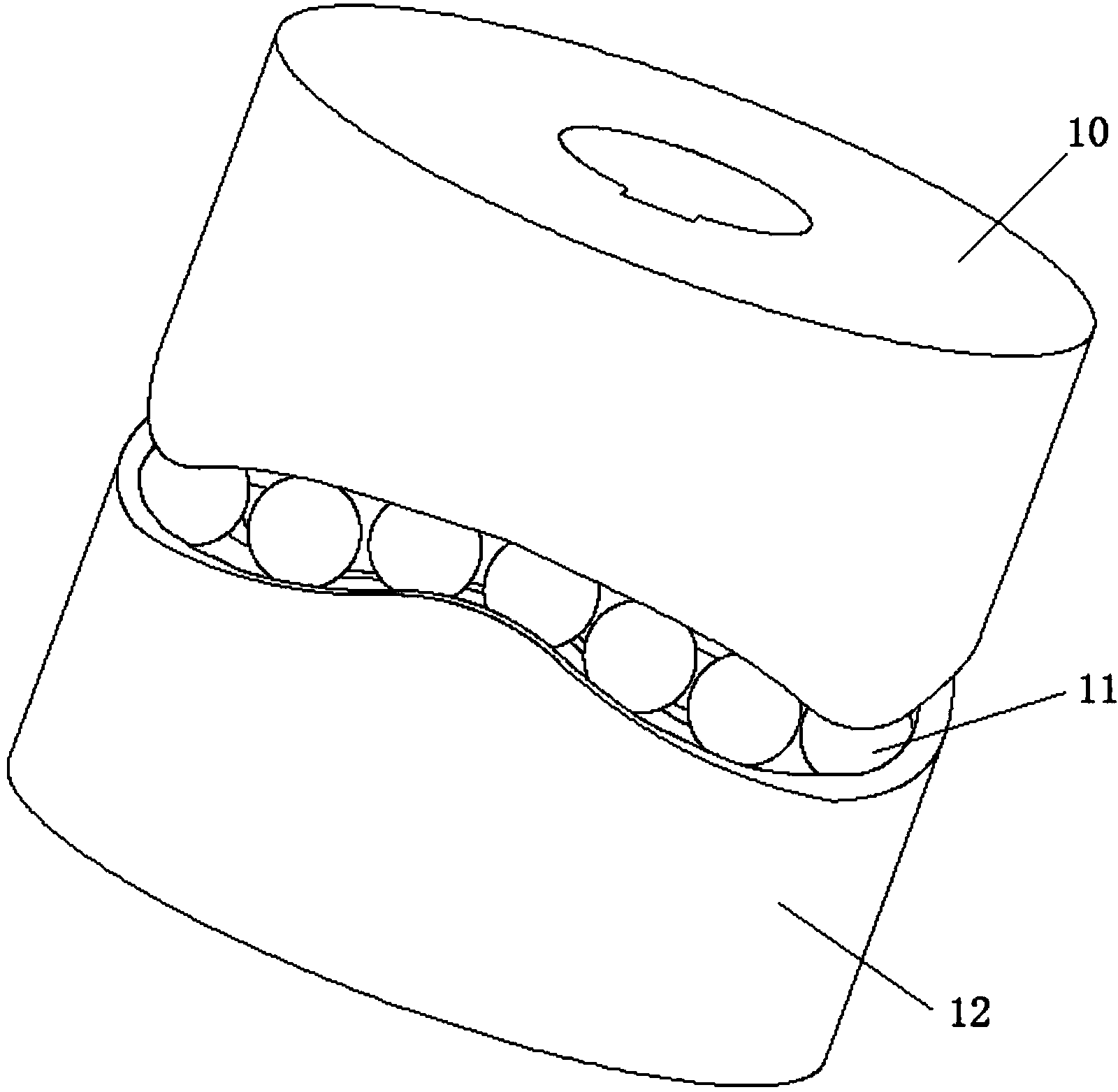

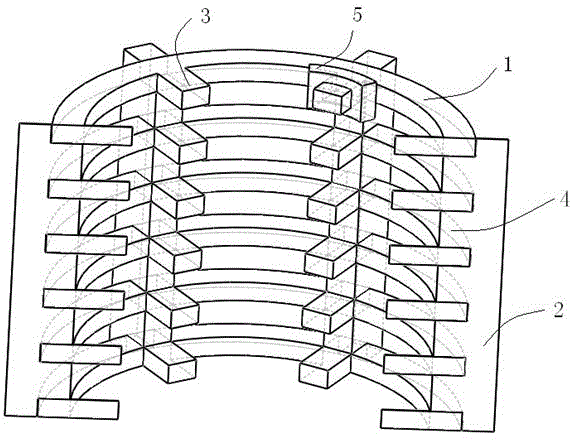

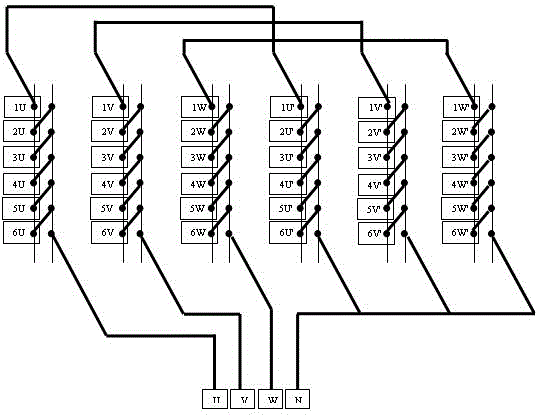

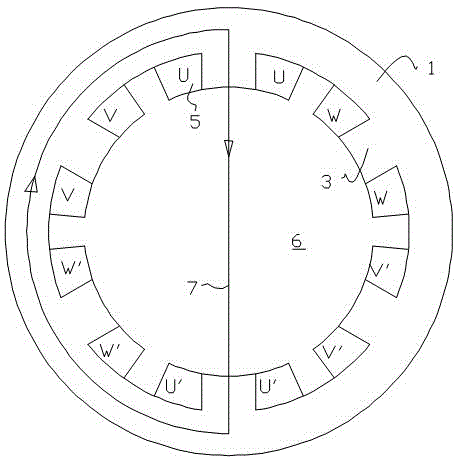

Multifunctional electromagnetic stirrer

The invention discloses a multifunctional electromagnetic stirrer, comprising six layers of annular cores (1) which are horizontally arranged, six rack cores (2) which are vertically arranged and thirty-six identical solenoid coil windings (5); the six layers of annular cores are mutually independent layer by layer, are aligned vertically and are separated at intervals; the inner wall of each layer of annular core is provided with six salient poles (3); the six rack cores are uniformly distributed on the outer walls of the annular cores; each rack core is provided with five salient poles (4); the salient poles of the rack cores are inserted into the intervals, which are vertically separated, of the annular poles; the salient poles of each rack core and the salient poles of the six layers of annular cores are located on the same circumference; the top surfaces of the salient poles of each rack core are inserted into the inner walls between the salient poles of the annular cores; the thirty-six solenoid coil windings are respectively sleeved on each salient pole of the annular cores; and three-phase low-frequency alternating current is supplied by a variable-frequency power source. According to the multifunctional electromagnetic stirrer, the structure is simple, the size is small, magnetic leakage is small, and the working efficiency is high.

Owner:BAOSHAN IRON & STEEL CO LTD

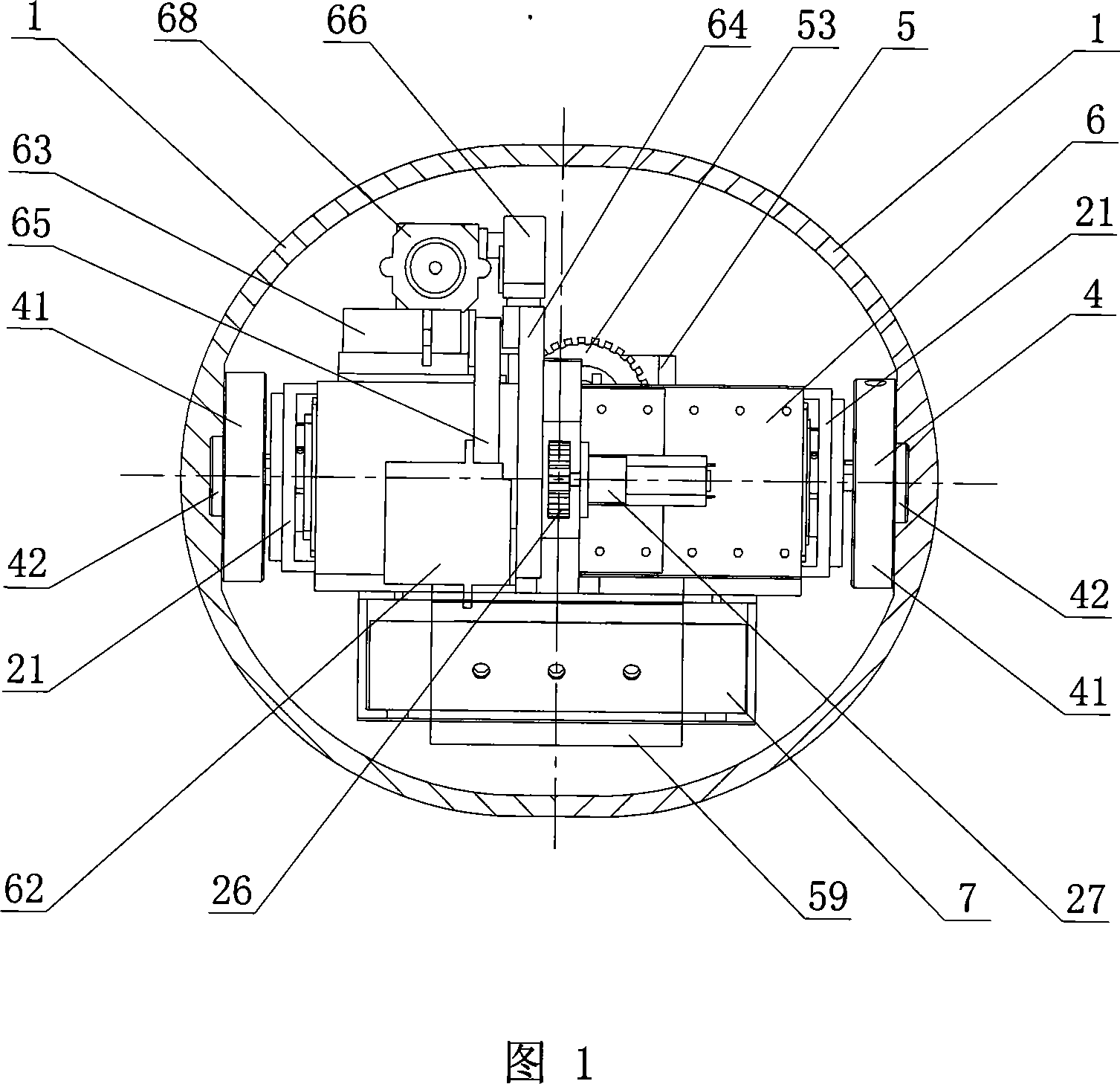

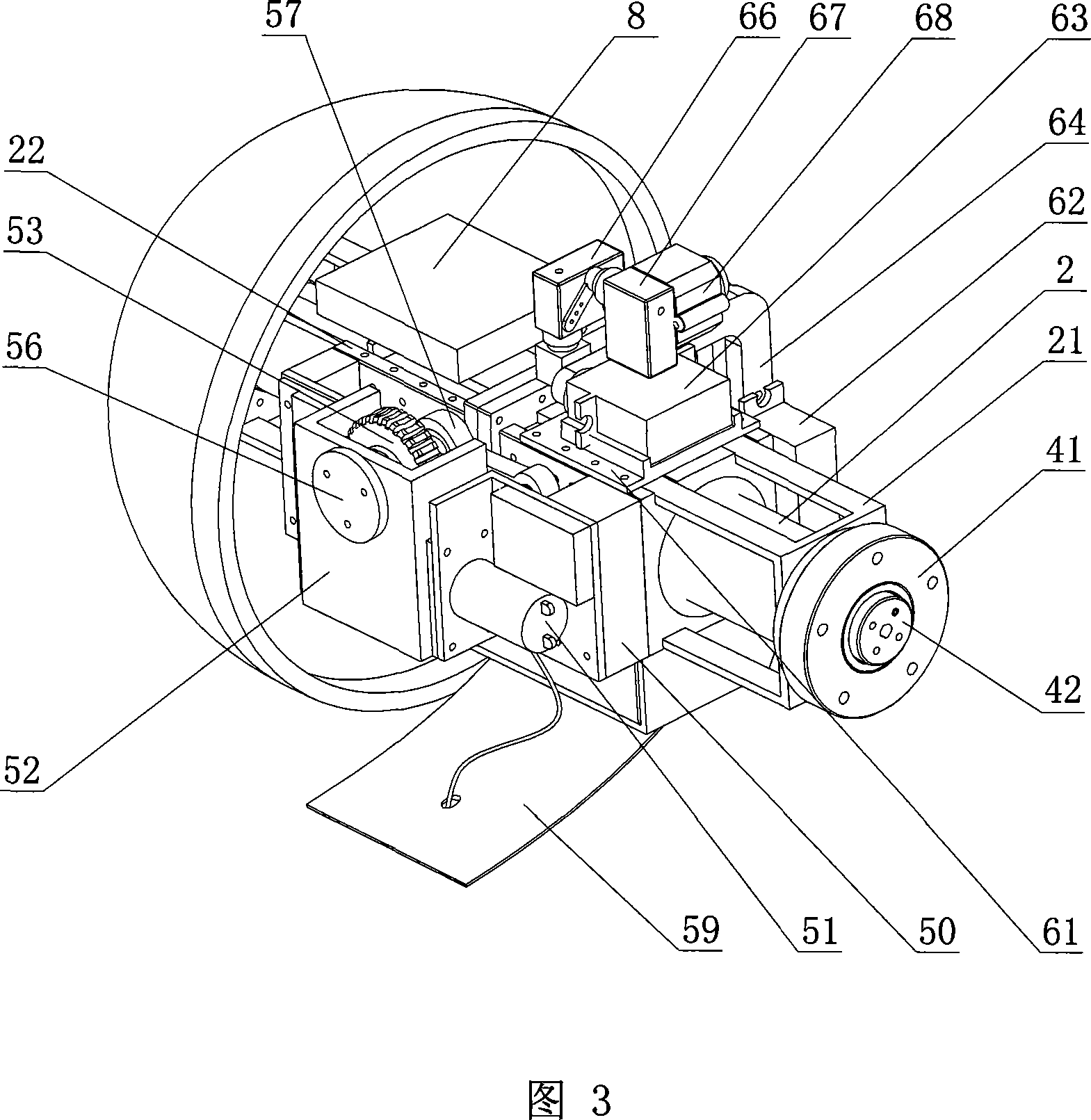

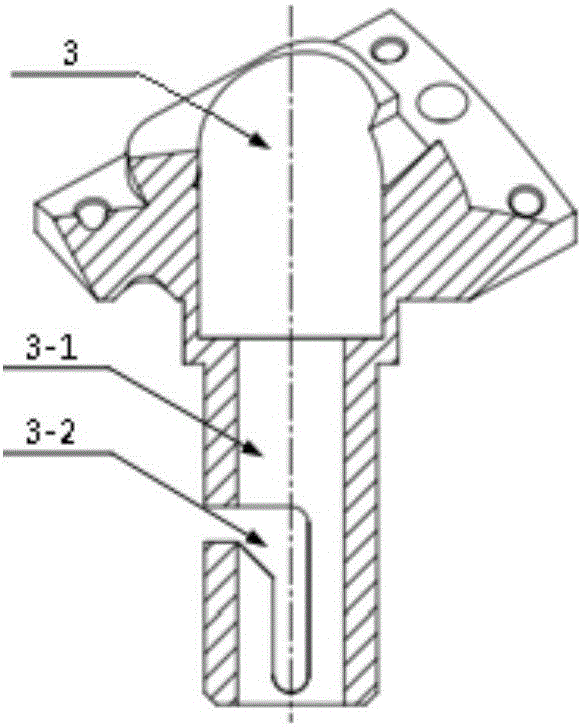

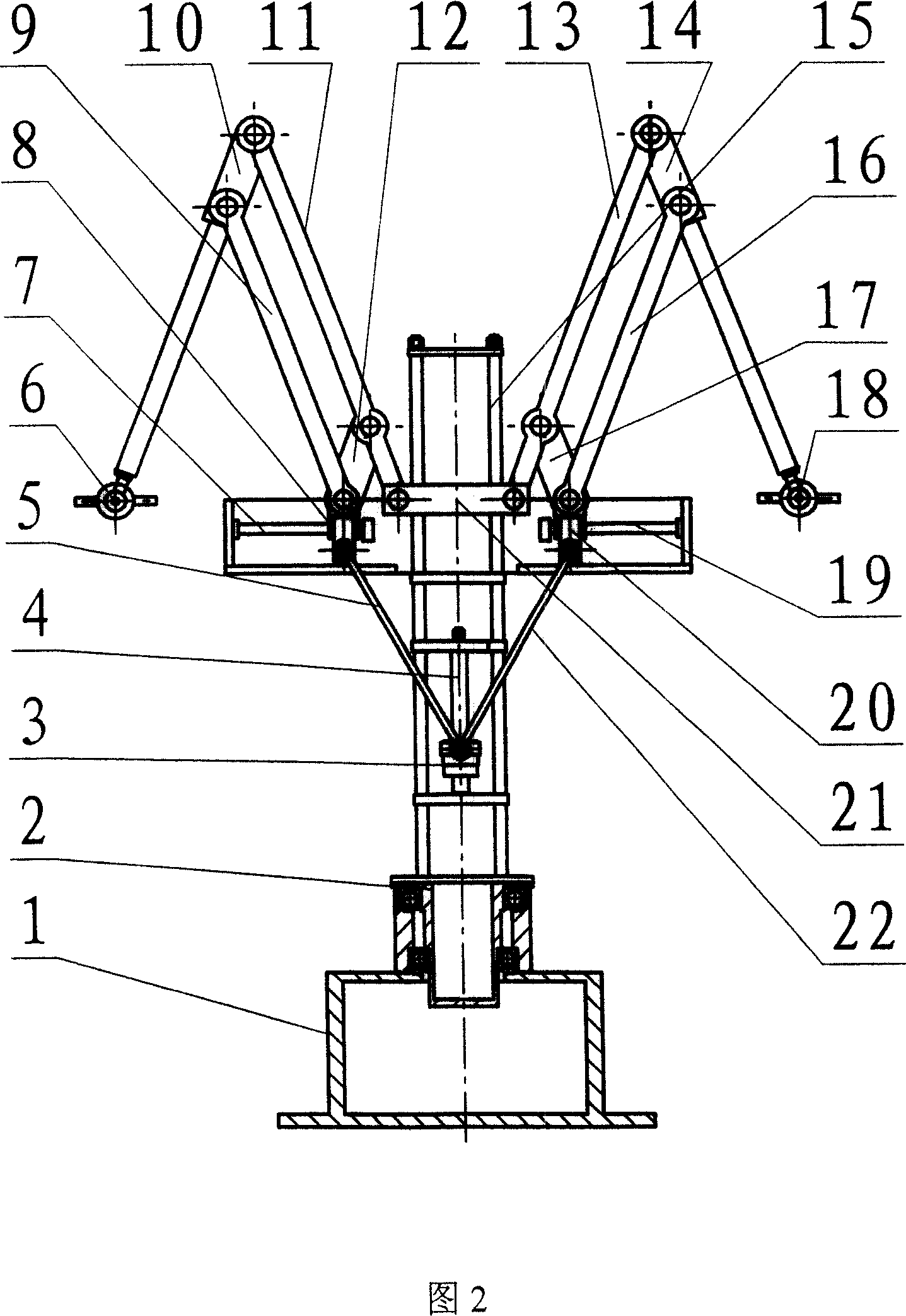

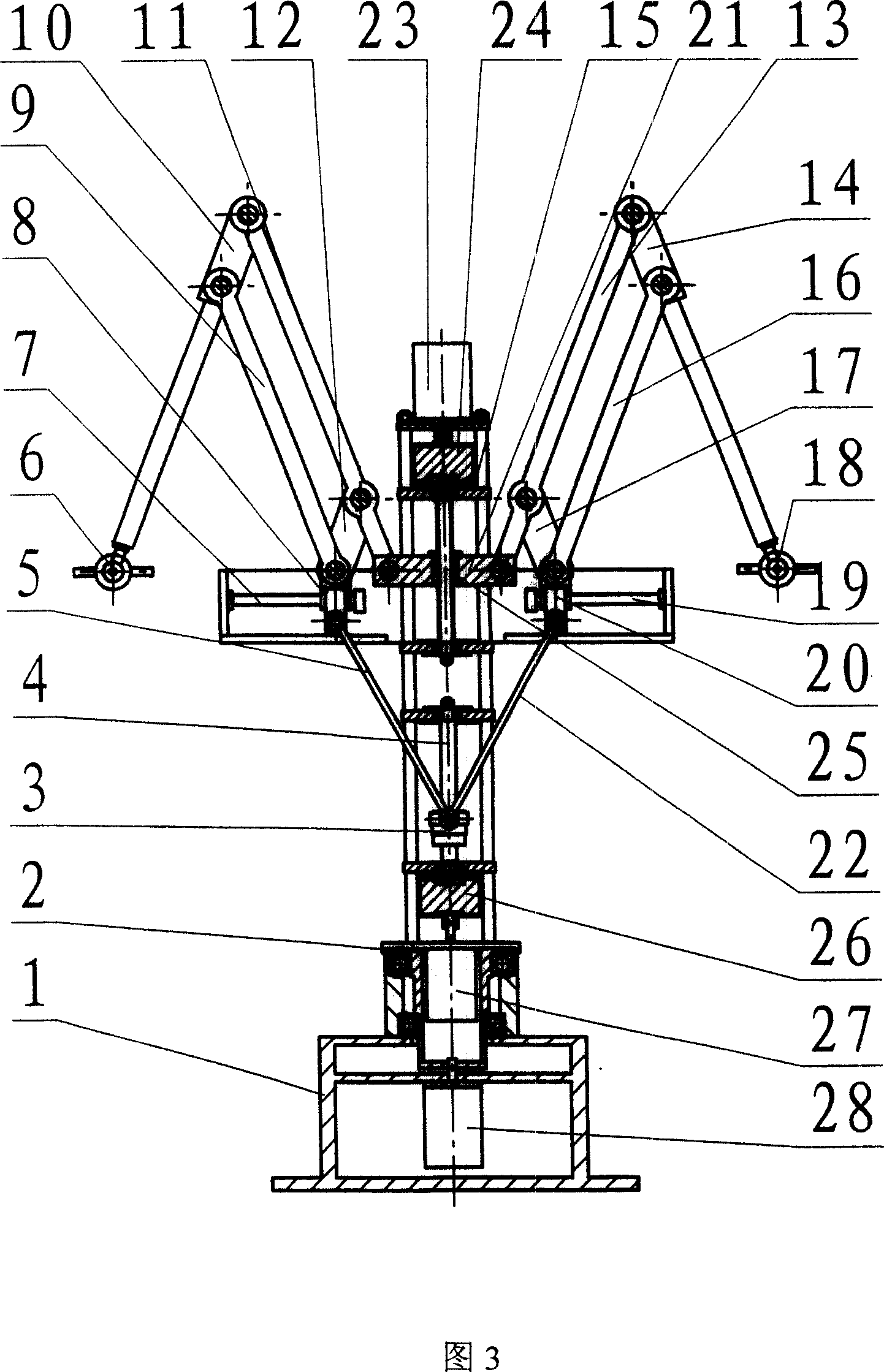

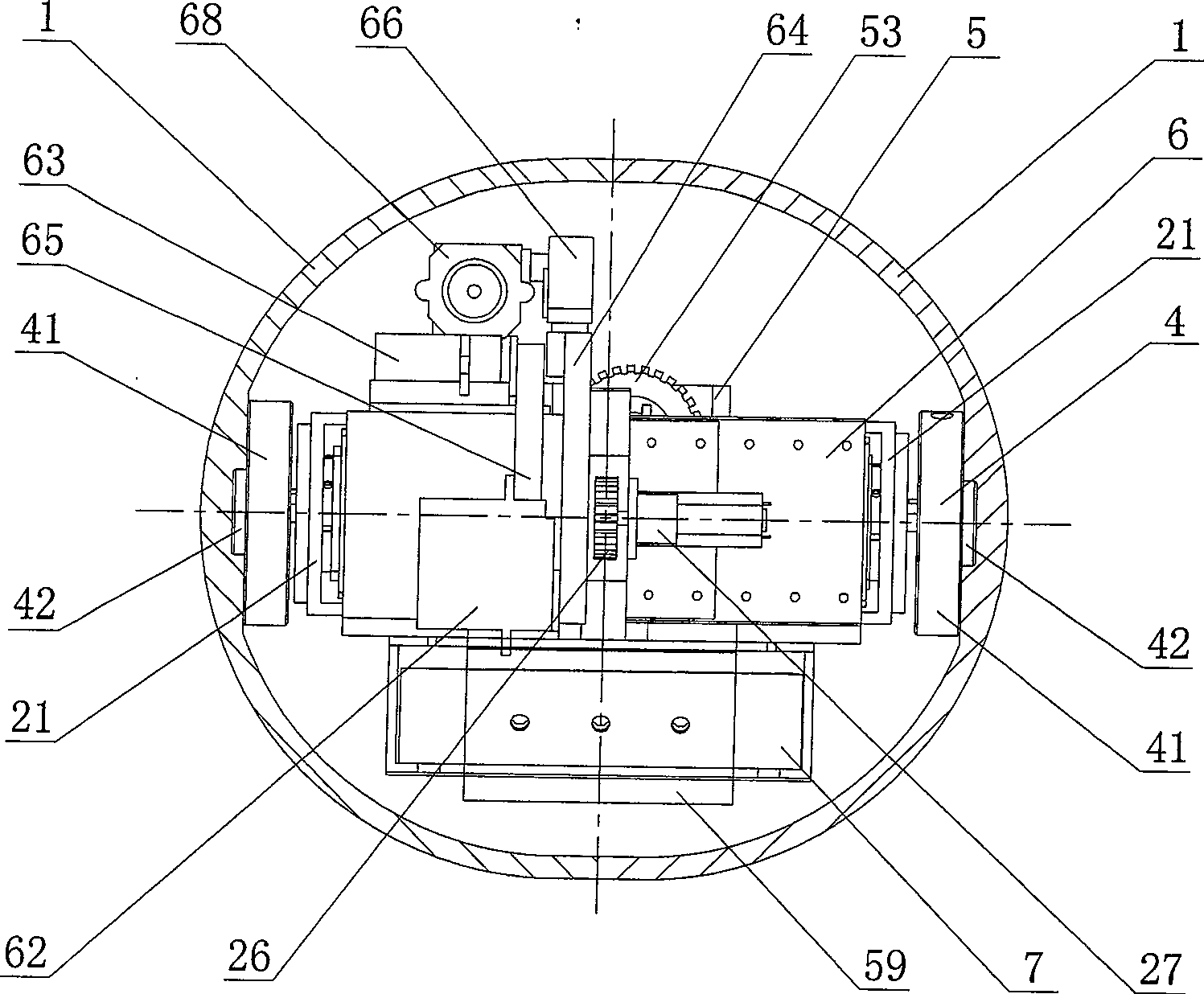

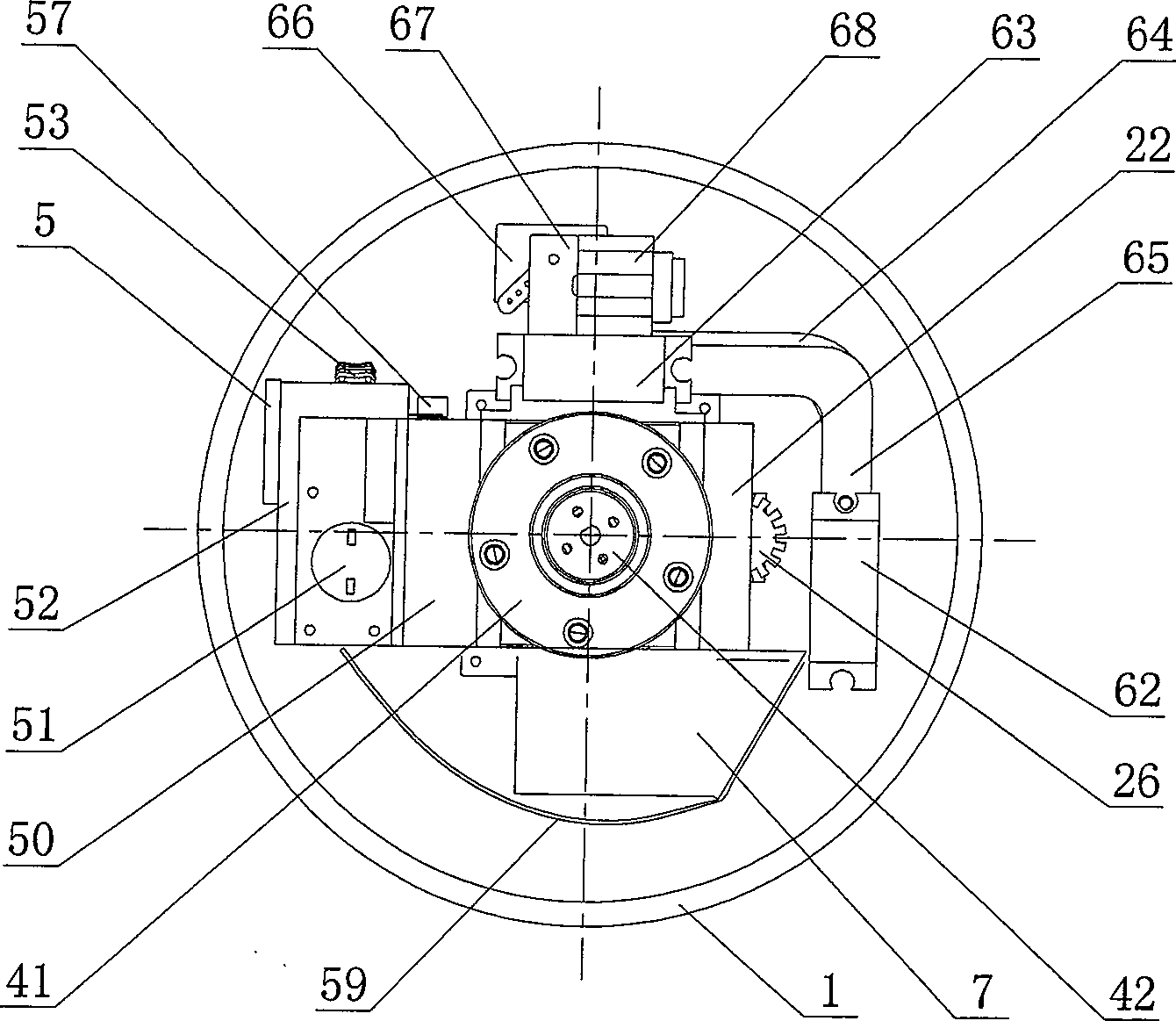

Multiple sporting state spherical robot

The invention discloses a multiple-motion spherical robot, which comprises two hemi-spherical casings and a screw extender for unfolding or folding the two hemi-spherical casings, wherein the screw extender comprises a fixed support, a driving element and two extender groups, the driving element is mounted at the middle of the fixed support, the two extender groups are respectively mounted at two ends of the fixed support, one end of each extender group is connected with the driving element while another end is provided with a driving motor for rotating the hemi-spherical casing. The invention has three motion states as spherical state, two-wheel state, and jump state, with easy carriage, transmission and arrangement, to move on complex landforms.

Owner:NAT UNIV OF DEFENSE TECH

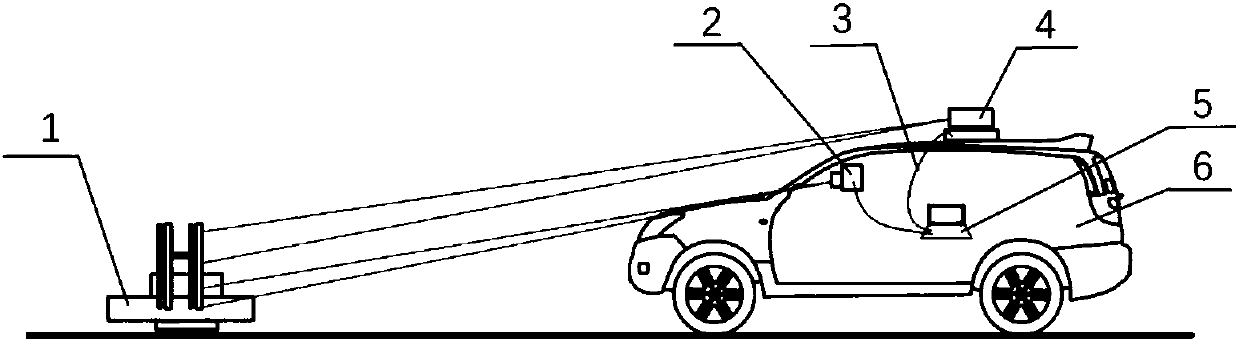

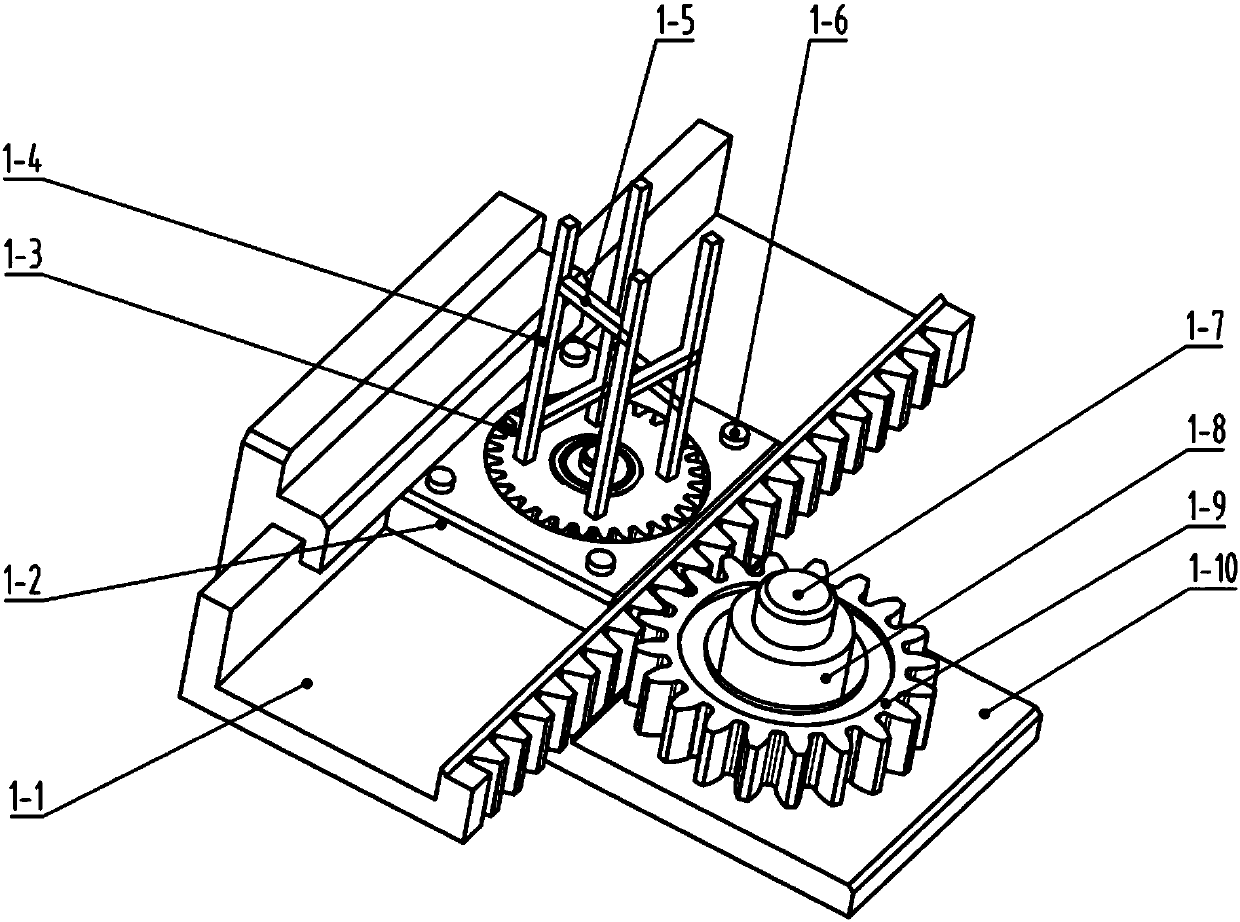

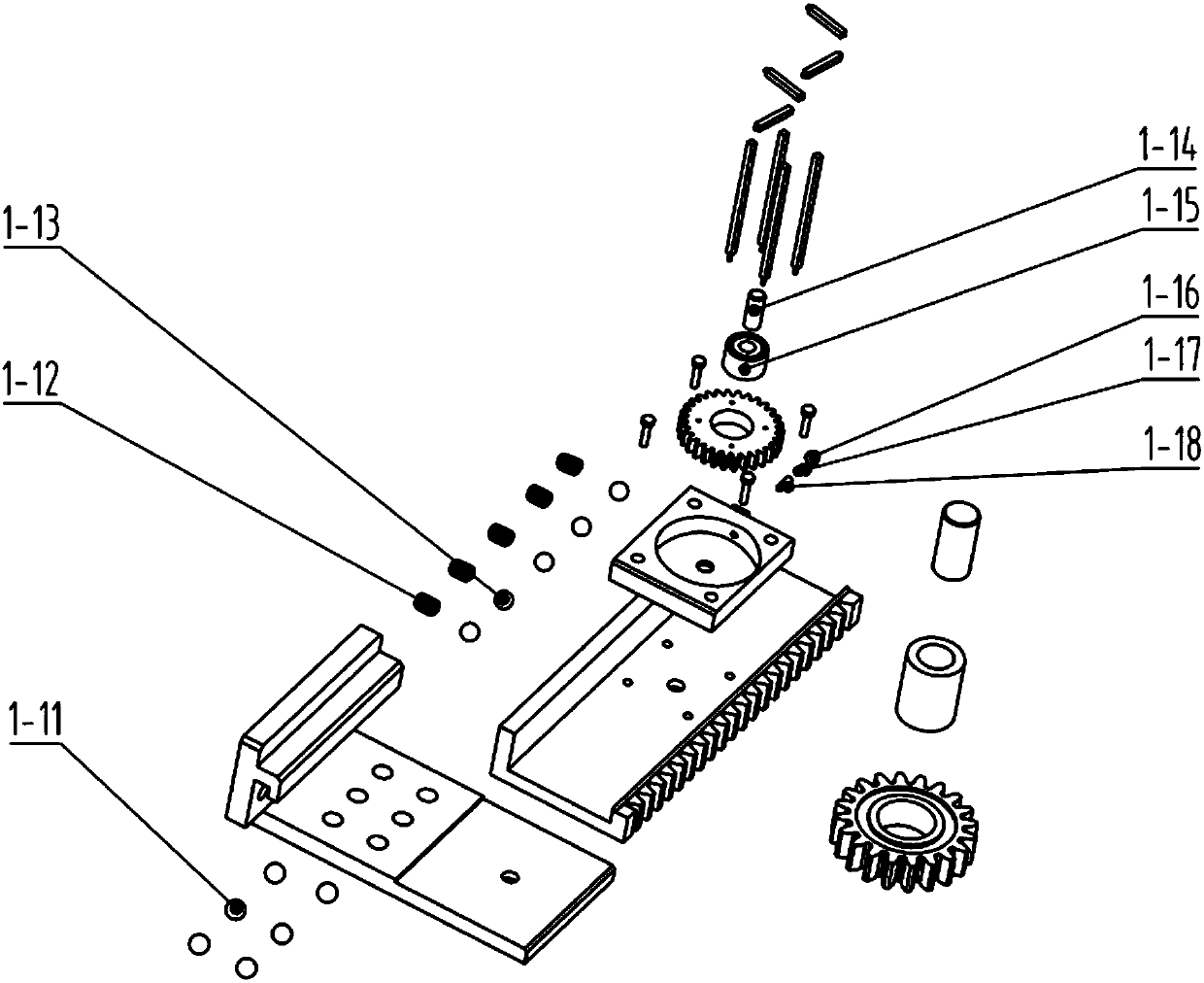

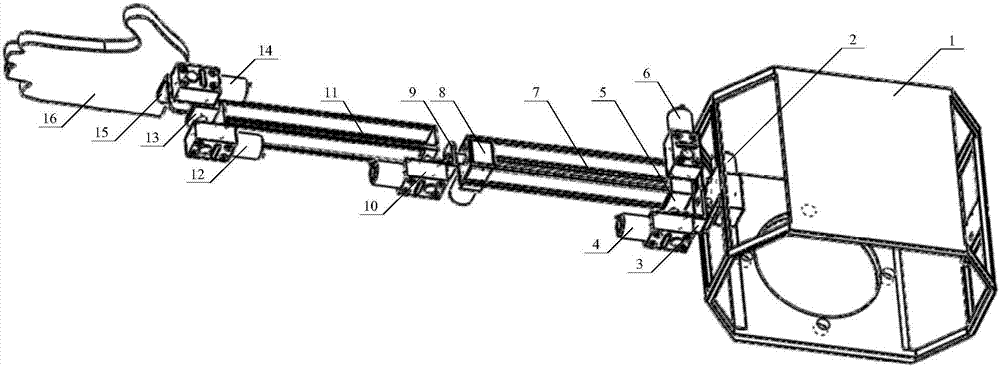

Calibration device based on laser radar and camera fusion as well as calibration method thereof

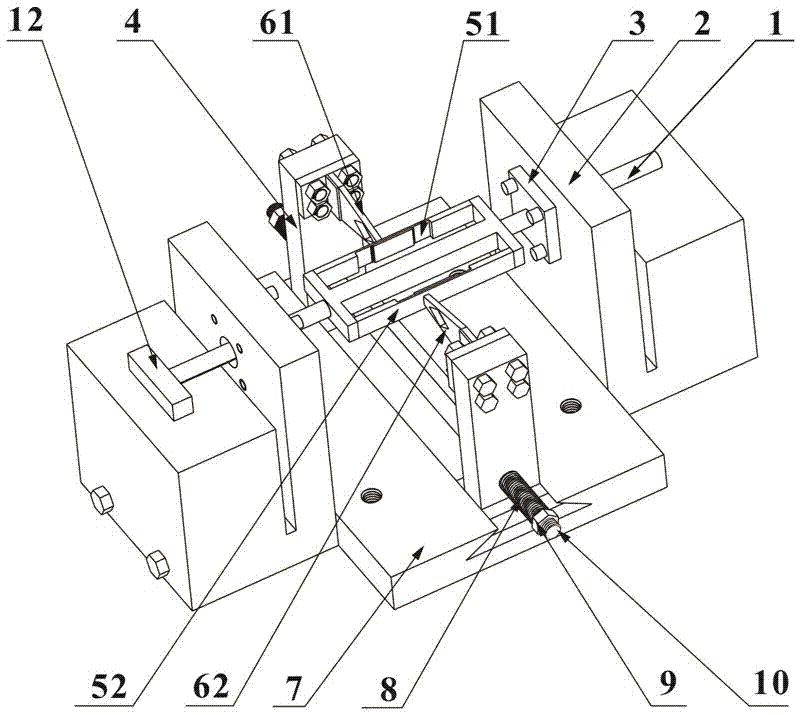

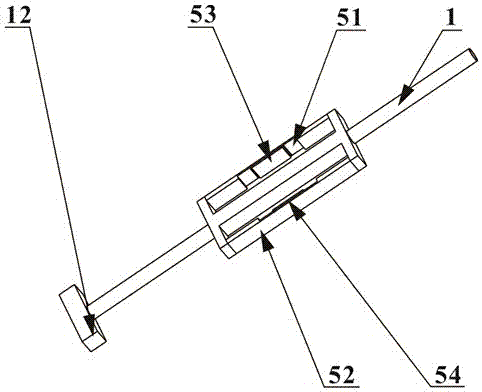

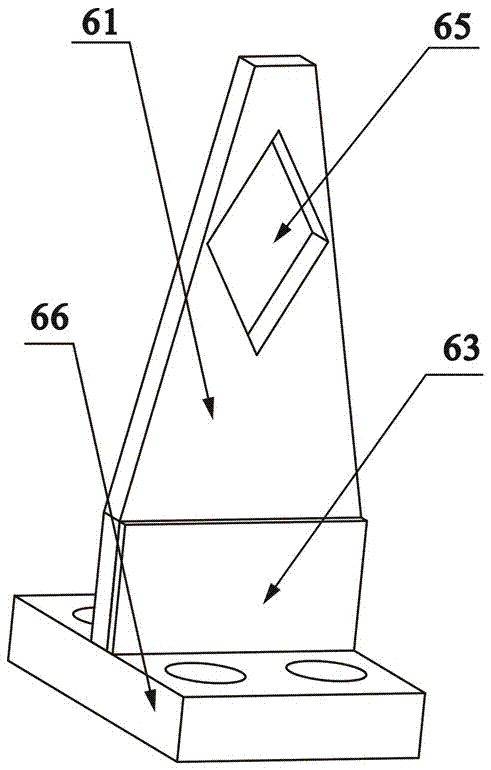

PendingCN108564630ASimple structureRealize linear motionImage analysisWave based measurement systemsRadarMaterials science

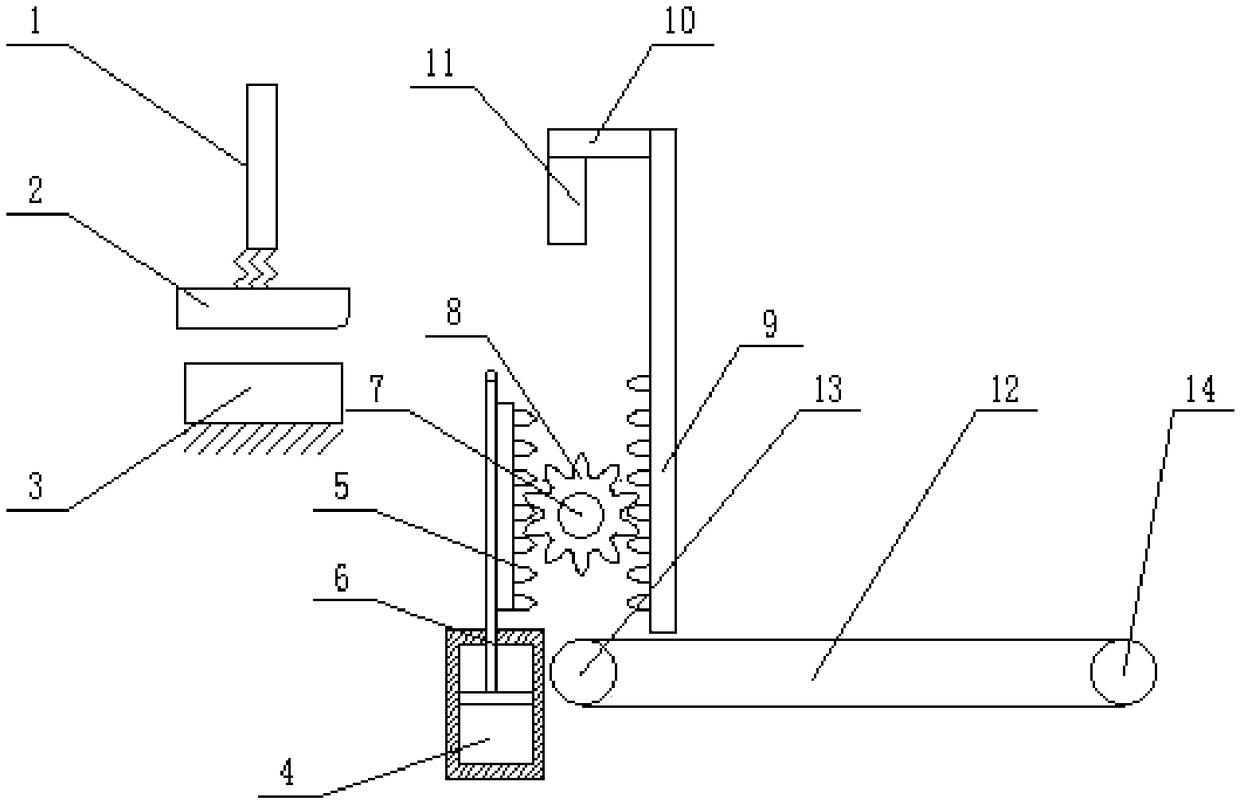

The invention belongs to the technical field of intelligent automobile environmental perception and particularly relates to a calibration device based on laser radar and camera fusion as well as a calibration method thereof. The calibration device comprises a rack, a base plate, a turnplate, a calibration long rod, a calibration short rod, a screw, a gear shaft, a gear bearing, a gear, a bottom plate, a bottom plate steel ball, a limiting spring, a limiting steel ball, a turnplate shaft, a turnplate bearing and a spring locking mechanism. According to the calibration device based on laser radar and camera fusion as well as the calibration method thereof, which are provided by the invention, the calibration device is simple in structure, can be operated manually, can move and rotate in a two-dimensional plane and can calibrate the three-dimensional coordinates of a scanning point. The defect that the single sensor cannot acquire environmental information accurately and integrally is overcome, and a series of difficulties that the position of the scanning points is difficult to determine, the calibration process is tedious and the scanning points are discrete and discontinuous are overcome.

Owner:JILIN UNIV

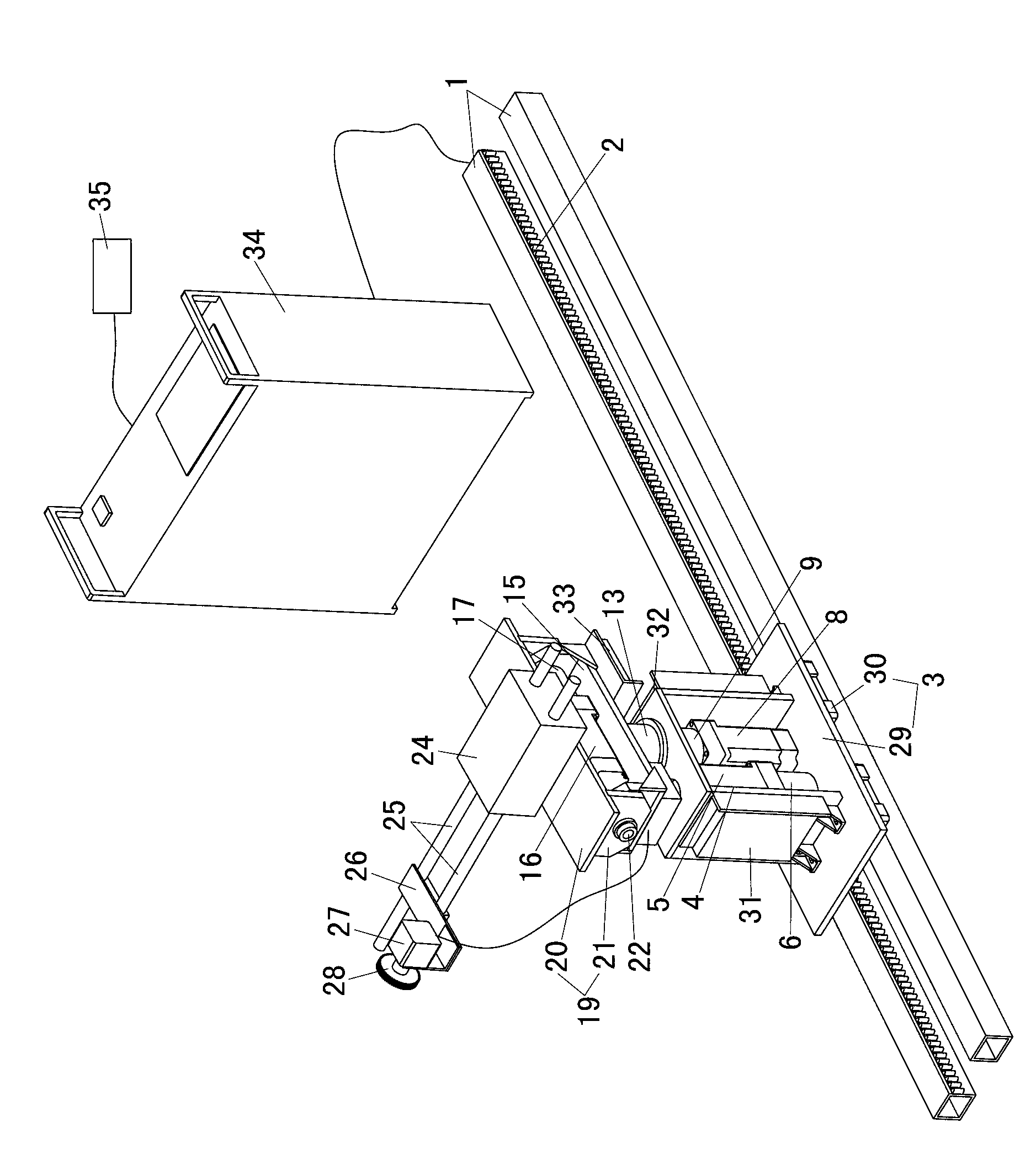

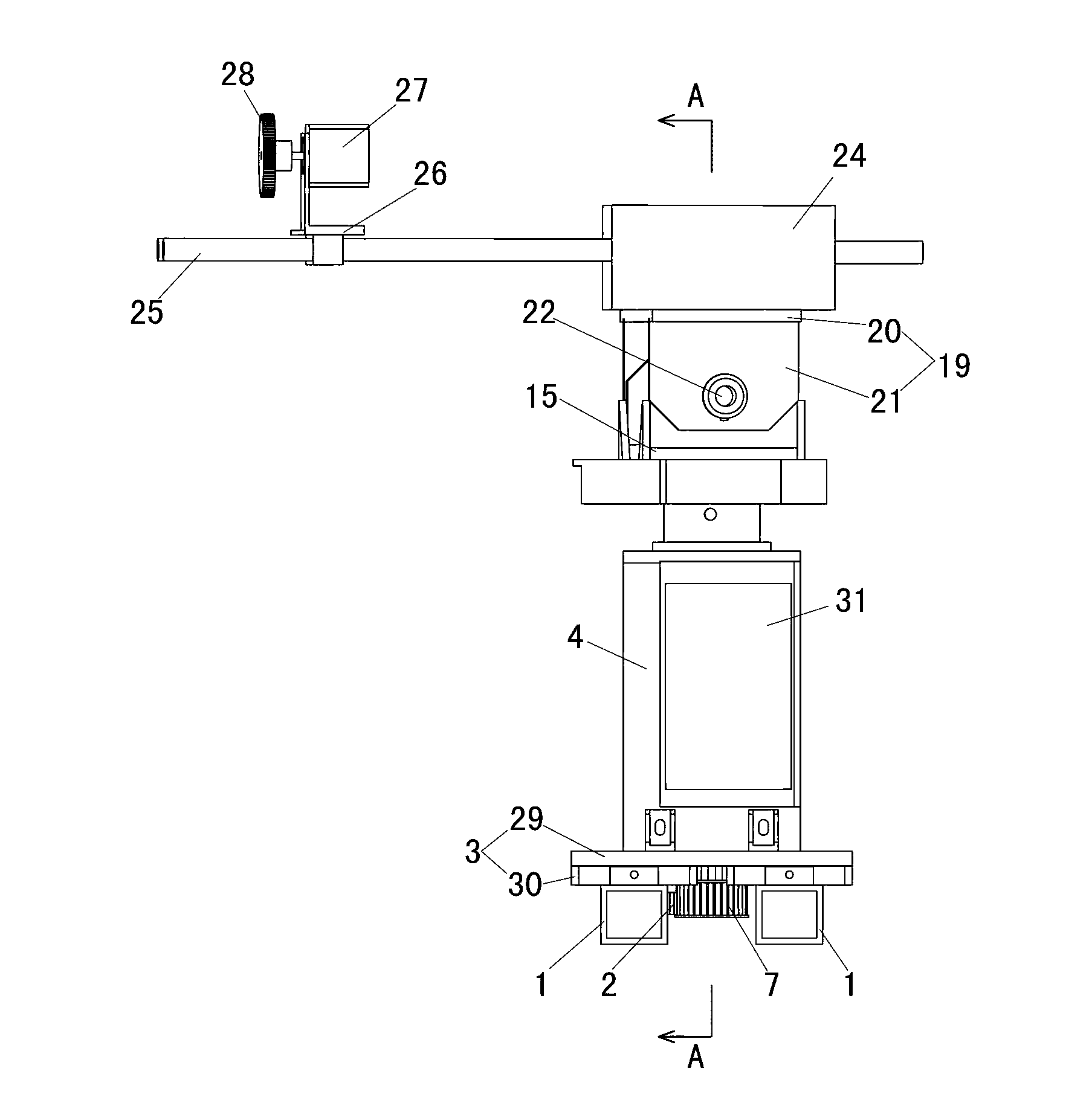

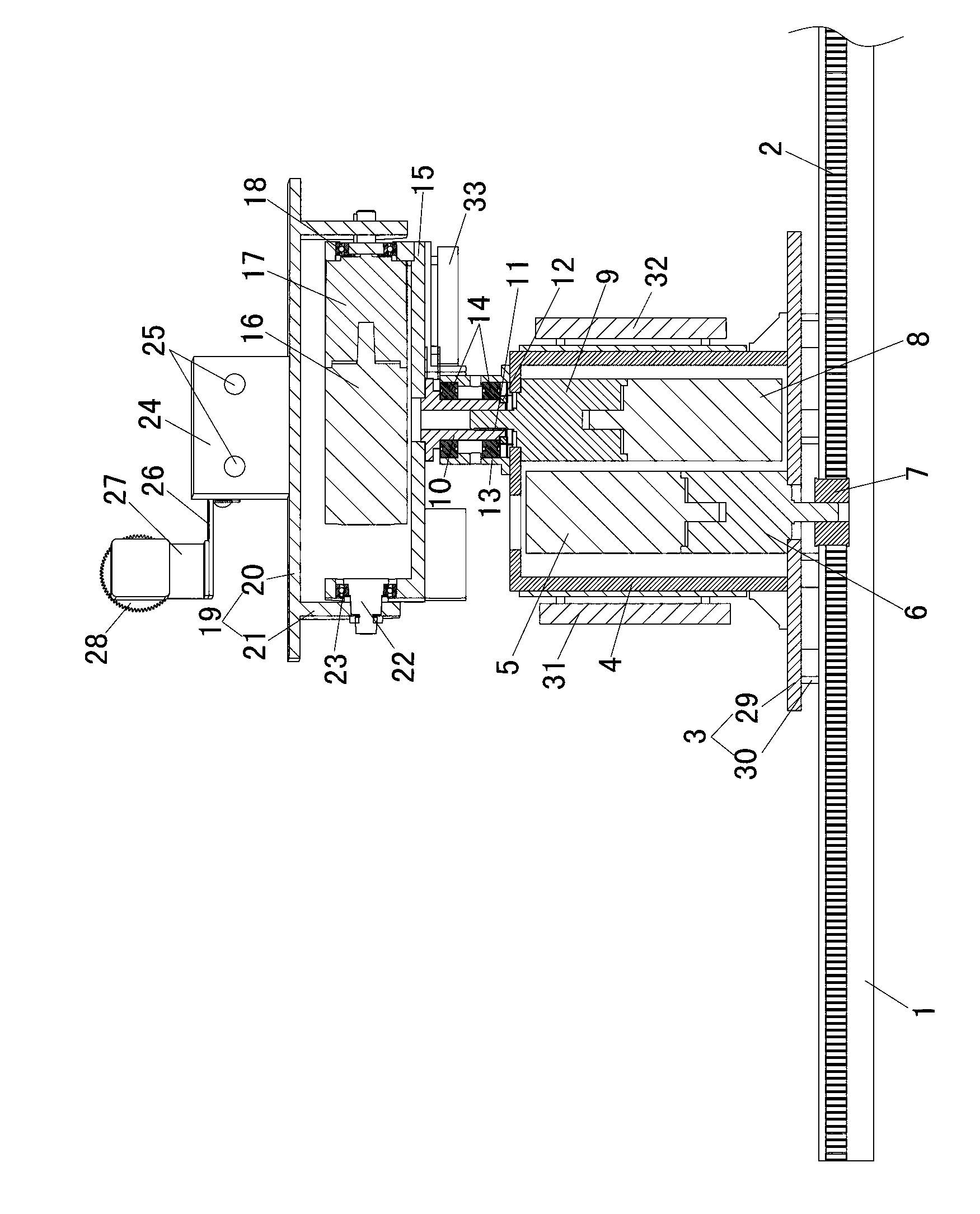

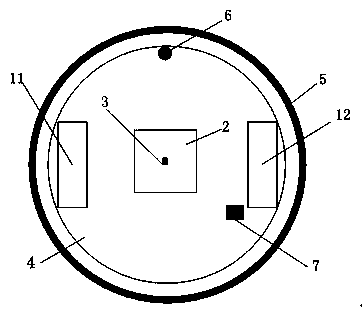

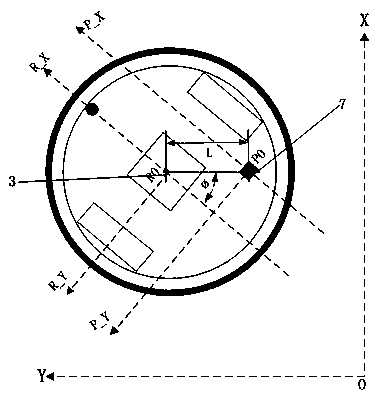

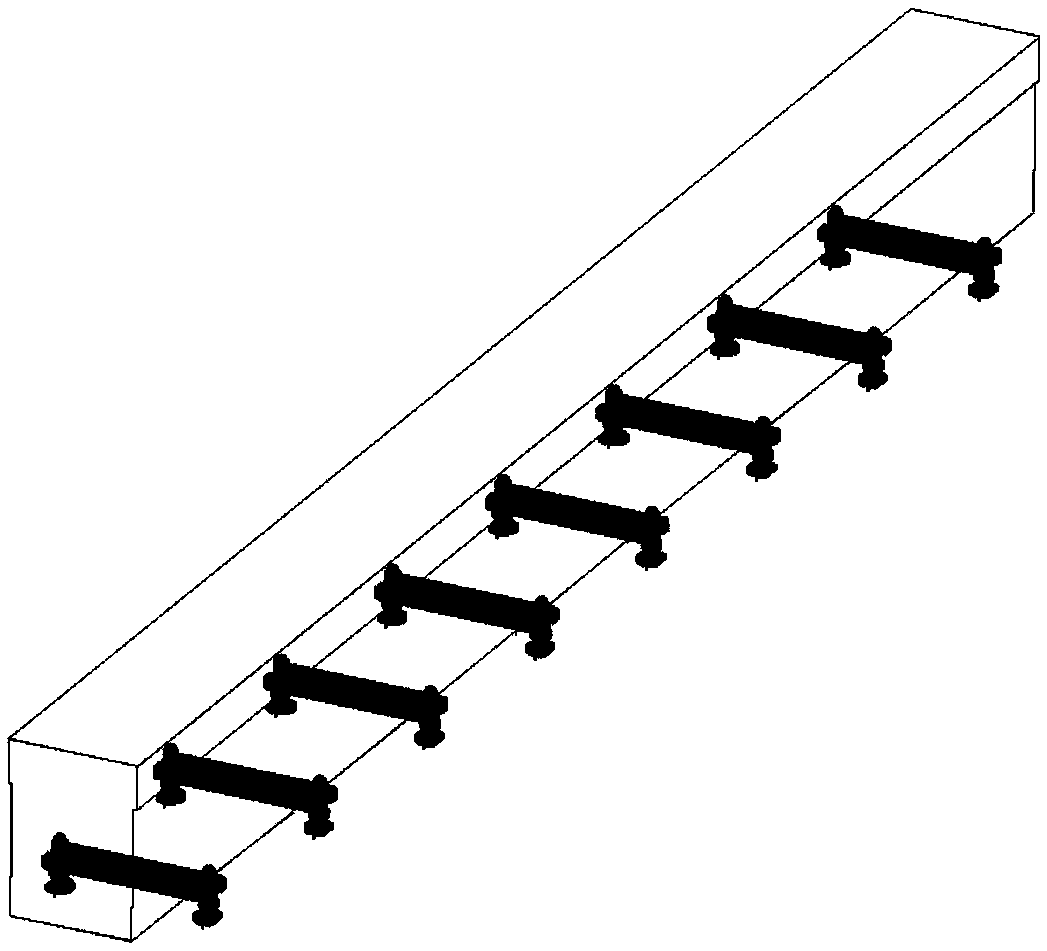

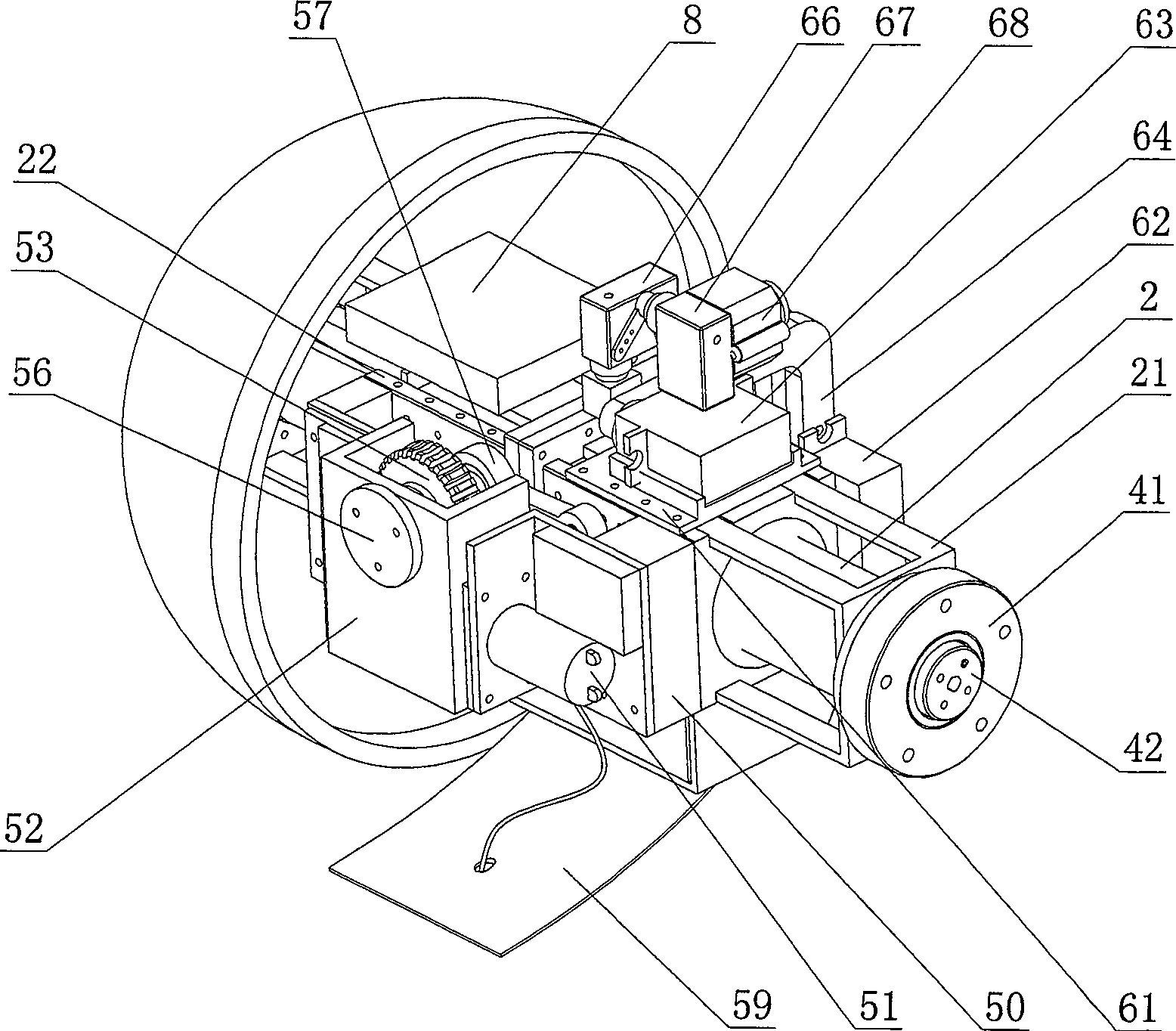

Photography motion control device

InactiveCN102853229ASimple structureEasy to operateStands/trestlesCamera body detailsMovement controlEngineering

The invention discloses a photography motion control device and belongs to the technical field of devices controlling cameras. The photography motion control device comprises two tracks, where the two tracks are placed horizontally and are parallel with each other, a rack is installed on the inner side of one of the two tracks along the length direction of the track, a linear motion control device is arranged on the two tracks, the linear motion control device comprises a base which is located above the two tracks, a box body is arranged above the base, a first electric motor is installed inside the box body, an output shaft of the first electric motor faces downwards vertically and is connected with an input end of a first speed reducer, an output shaft of the first speed reducer penetrates through the box body and the base downwards and then is connected with a gear, and the gear is located between the two tracks and is engaged with the rack. the photography motion control device is simple in structure, convenient to operate and maintain and capable of achieving linear motion, so that the device can be controlled conveniently to achieve rotation motion, pitch angle motion and focusing motion, multidirectional and multi-angle shooting of cameras can be achieved, and the three-dimensional high-definition shooting effect is achieved.

Owner:郑鹏 +2

Control method for carpet deviation during robot movement, chip and robot cleaner

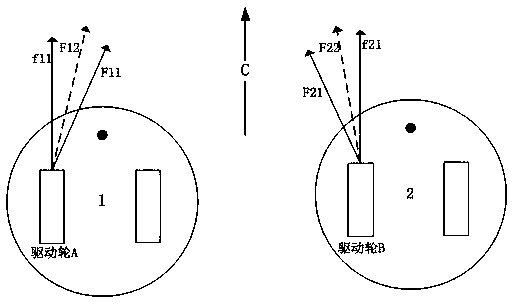

ActiveCN109394095AImprove accuracyRealize linear motionAutomatic obstacle detectionTravelling automatic controlSensing dataDrive wheel

The invention discloses a control method for carpet deviation during robot movement, a chip and a robot cleaner. The control method comprises the following steps: carrying out fusion calculation on the current position coordinates of the robot according to sensing data of a sensor at every first preset time, calculating the deviation amount of the robot relative to the preset direction according to the relative position relation between the current position and the initial position of the robot, and carrying out accumulation to obtain a deviation statistical value; and calculating the collecting times for position coordinates in the second preset time, carrying out averaging, thus obtaining a deviation average value, determining the condition that the robot deviates from the preset direction according to the deviation average value, and setting a corresponding PID proportionality coefficient for synchronously adjusting the speed of left and right drive wheels of the robot, wherein thedeviation angle of the robot is reduced. With the control method, the accuracy in detecting the carpet deviation of the robot is improved, and thus the robot is effectively controlled to maintain thegood linear walking effect.

Owner:AMICRO SEMICON CORP

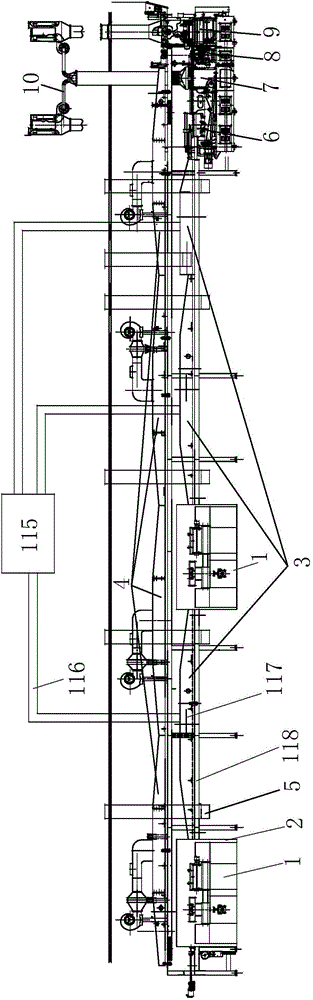

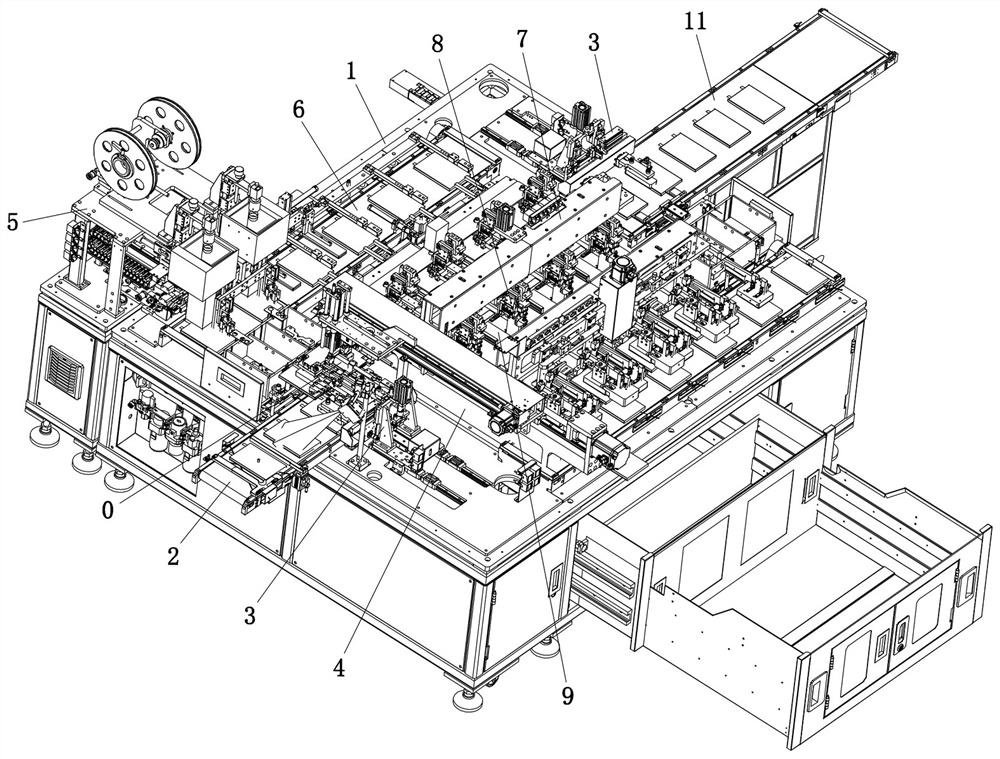

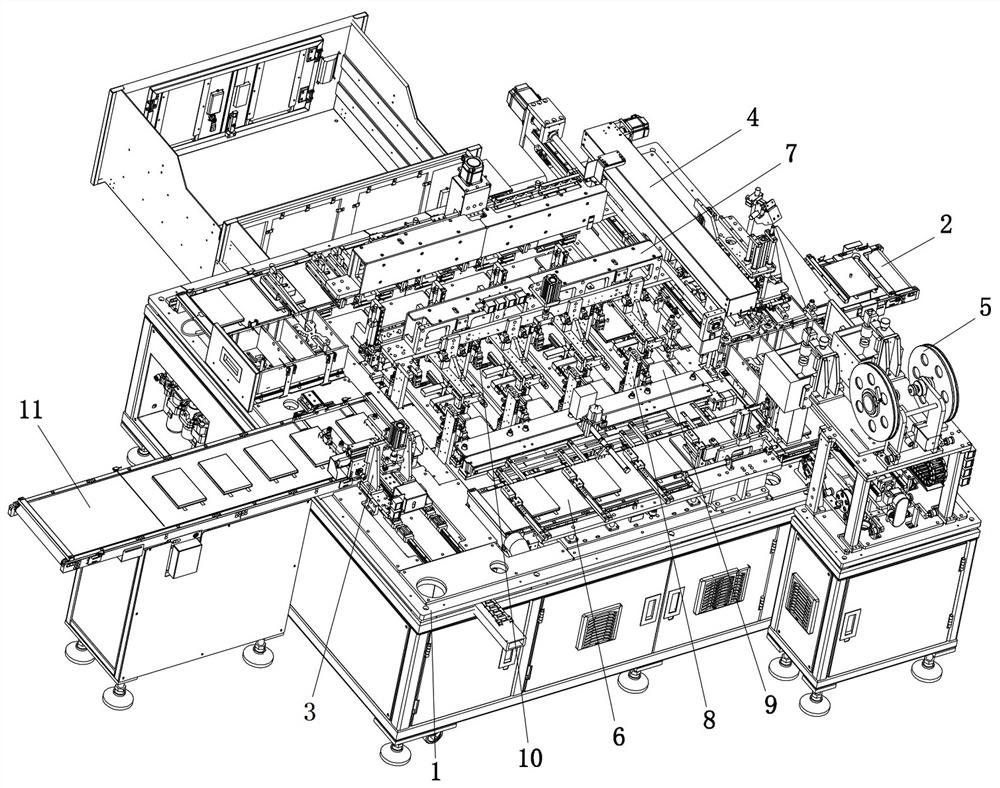

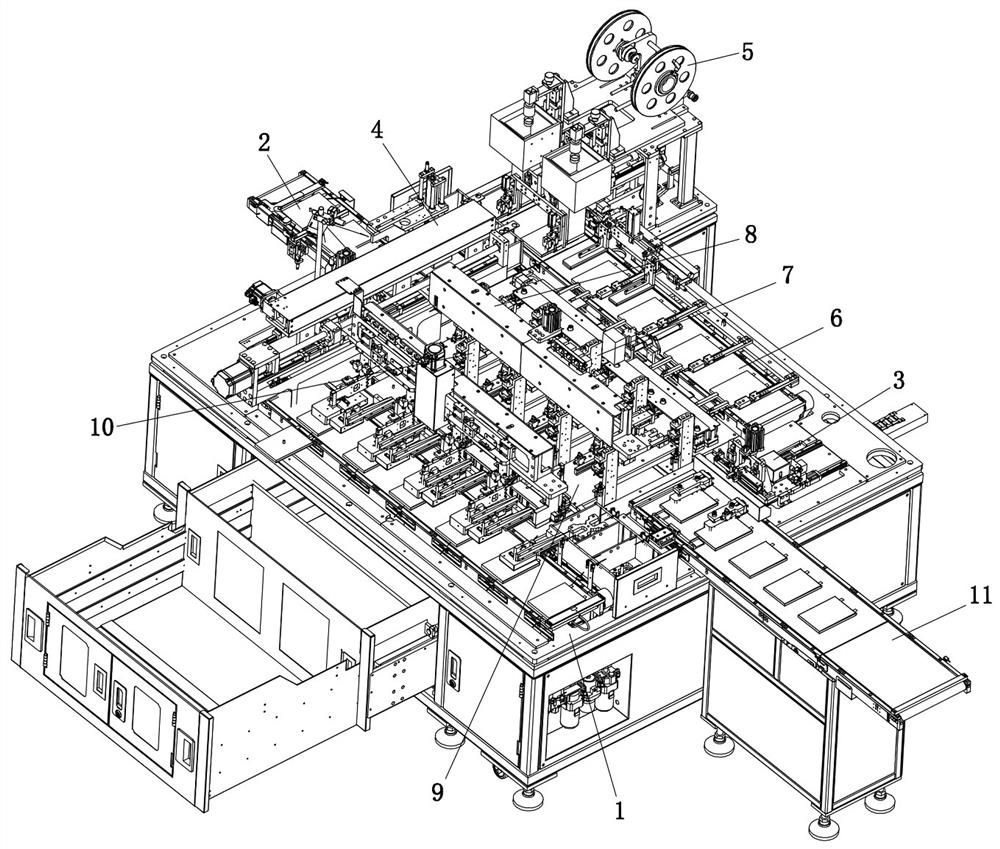

Fully-automatic enteric capsule production line

InactiveCN104546487AWon't emitProduction Process AutomationCapsule deliveryProduction lineVacuum pumping

The invention discloses a fully-automatic enteric capsule production line and belongs to the technical field of capsule production equipment. The fully-automatic enteric capsule production line comprises a platform machine, an automat, an oiling machine, a glue dipping machine, a waste material absorbing system, an upper baking channel, a lower baking channel and a main control system, wherein an air supply pipeline and an air returning pipeline are arranged on the lower baking channel at an interval; two coating machines are also arranged on the lower baking channel at an interval and are respectively arranged in separating spaces; the separating spaces are connected with a vacuum pumping device. The coating machines are arranged in the sealed separating spaces, and the vacuum pumping device absorbs volatile substances in coating liquid, so that the volatile substances are prevented from being dispersed into a workshop to cause explosion in case of open flame. A capsule produced by the fully-automatic enteric capsule production line satisfies enteric standards, the wall thickness of the capsule is uniform, and the quality of the capsule is good.

Owner:DANDONG JINWAN GRP

Unfolding and locking mechanism

ActiveCN106347632ASimple structureExpand and lock reliablyWing adjustmentsTorsion springAerospace engineering

The invention discloses an unfolding and locking mechanism, relating to the field of folding wing mechanisms and solving the problems that the existing folding wing mechanism cannot realize horizontal folding, lacks a small-size folding wing unfolding and locking mechanism and is complicated in structure and large in mass. The unfolding and locking mechanism comprises a folding wing unfolding motion mechanism and a locking device, the folding wing mechanism adopts horizontal folding and does rotation and translation motions during an unfolding process, the unfolding relies on a torsion spring as a power source, the torsion spring can provide both torque and elastic force, and the rotation and linear motion of the wing can be realized within a small space range to complete the unfolding process of the wing. A locking device adopts a spring to drive a locking pin to lock, and the locking pin limits the motion of the wing in one direction so as to realize the locking of the wing without the influence on the unfolding of the wing. The unfolding and locking mechanism is simple in structure, reliable to unfold and lock, low in cost and compact in occupation space. When an aircraft is launched after leaving away a canister, the rapid unfolding and locking of the folding wing can be realized under the interference of pneumatic resistance.

Owner:中天长光(青岛)装备科技有限公司

Three-freedom recovery exercising robot

InactiveCN100998536AImplement a rehabilitation training programEasy to implementChiropractic devicesStiltsEngineeringParallelogram

A three-freedom robot for the recovery training is composed of a rotation unit, a rotary table driven by said rotation unit, the vertical and horizontal movement mechanisms arranged on said rotary table, a parallelogram mechanism consisting of two long rods and two short rods, an extending rod connected between one long rod and the output of vertical movement mechanism, and a recovery training terminal connected to one short rod.

Owner:SOUTHEAST UNIV

Automobile interior trim plate bending device

ActiveCN108176785ARealize linear motionFast bending speedMetal-working feeding devicesPositioning devicesEngineeringPiston rod

The invention belongs to the field of automobile part machining and particularly discloses an automobile interior trim plate bending device. The automobile interior trim plate bending device comprisesa rack which is provided with a positioning part, a bending part and a conveying part; the positioning part comprises a sliding rod, a pressing plate and a base; the bending part comprises a piston barrel, a rotating shaft and a downward pressing unit, and a first rack is connected to a piston rod; a through hole is formed in the outer wall of the piston rod; the piston barrel is connected with avortex pipe; the end face of the side, away from the piston rod, of the piston barrel is provided with a gas outflow hole which is internally provided with a second gas outflow one-way valve; a firstgear engaged with the first rack is arranged on the rotating shaft; the downward pressing unit comprises a second rack connected to the rack in a sliding manner; the second rack is engaged with the first gear; a supporting rod is connected to the top of the second rack; a bending punch is connected to the supporting rod; and the conveying part comprises a belt for conveying a first roller shaft and a second roller shaft. The scheme is adopted to meet the requirements of automation to automobile interior trim plates in the automobile interior trim plate bending process.

Owner:宁波高新区新柯保汽车科技有限公司

Automatic copper strip winding and disk changing device and technology thereof

InactiveCN102942082ARealize automatic windingRealize disk changeFilament handlingLinear motionBobbin

The invention provides an automatic copper strip winding and disk changing device which comprises two sets of winding mechanisms arranged on a frame, wherein each set of winding mechanism comprises a set of bobbin, a wire spool, a squeezer and a ball screw. The automatic copper strip winding and changing technology is as follows: when winding begins, the bobbin drives the wire spool to do linear motion; when a blade at the rear part of the wire spool just excesses the copper strip, the bobbin is rotated by 90 degrees, and drives the wire spool to do reversed linear motion; then, the squeezer is started to squeeze the copper strip twisted on the blade on the rear side of the wire spool, namely finishing copper strip blocking and pressing motions; and then, the copper strip winding motion is processed; and when the copper strip is twisted till the ruled weight, the winding device stops, a guide wheel slides to the other chute to realize disk changing motion of winding.

Owner:JIAXING UNIV

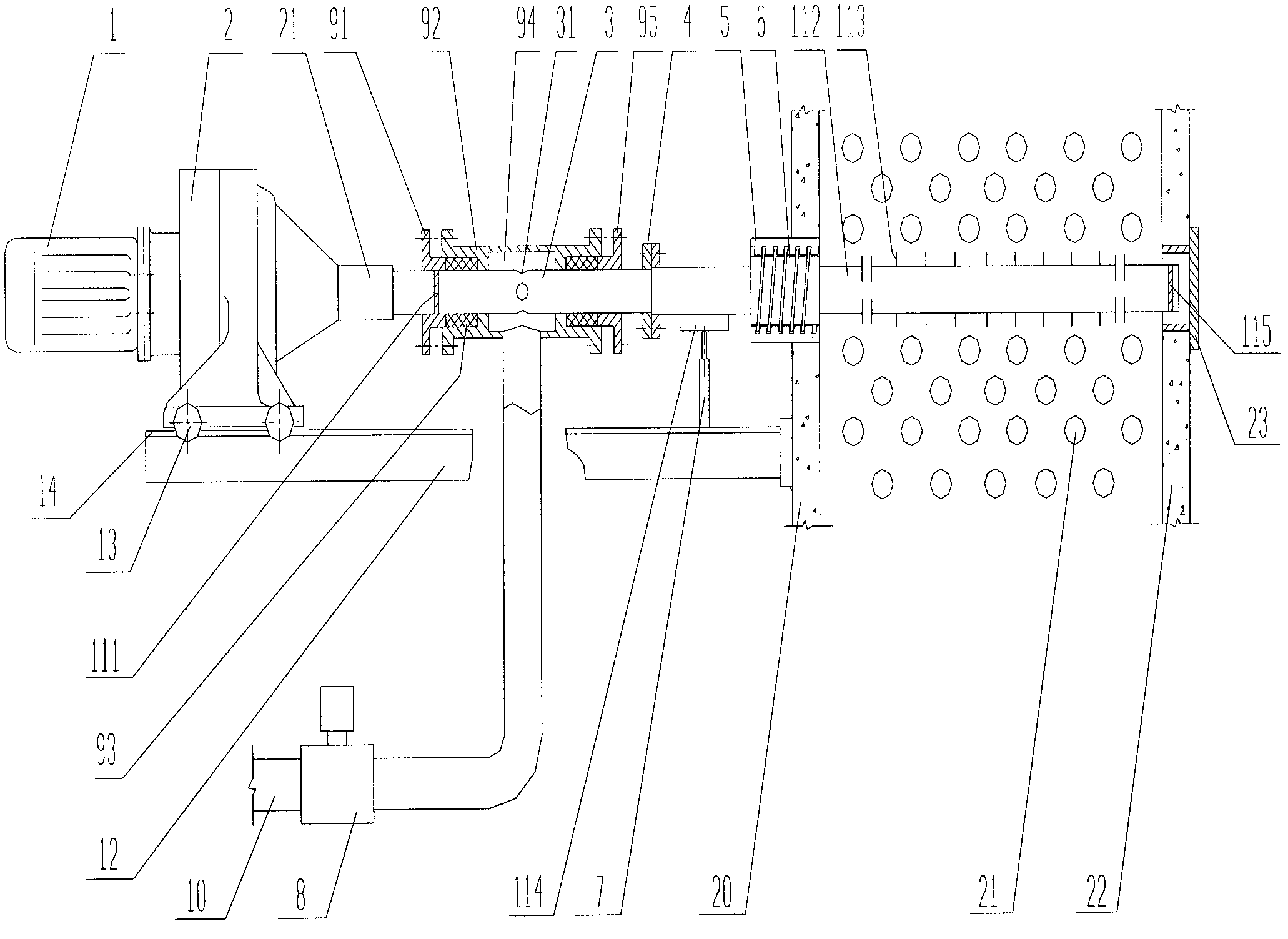

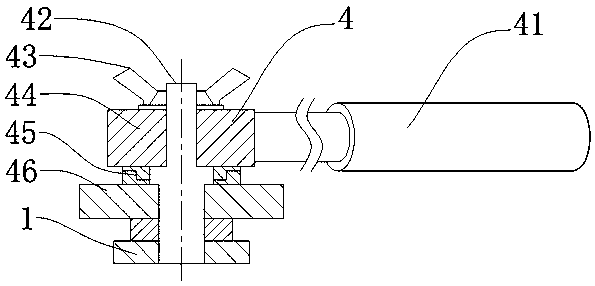

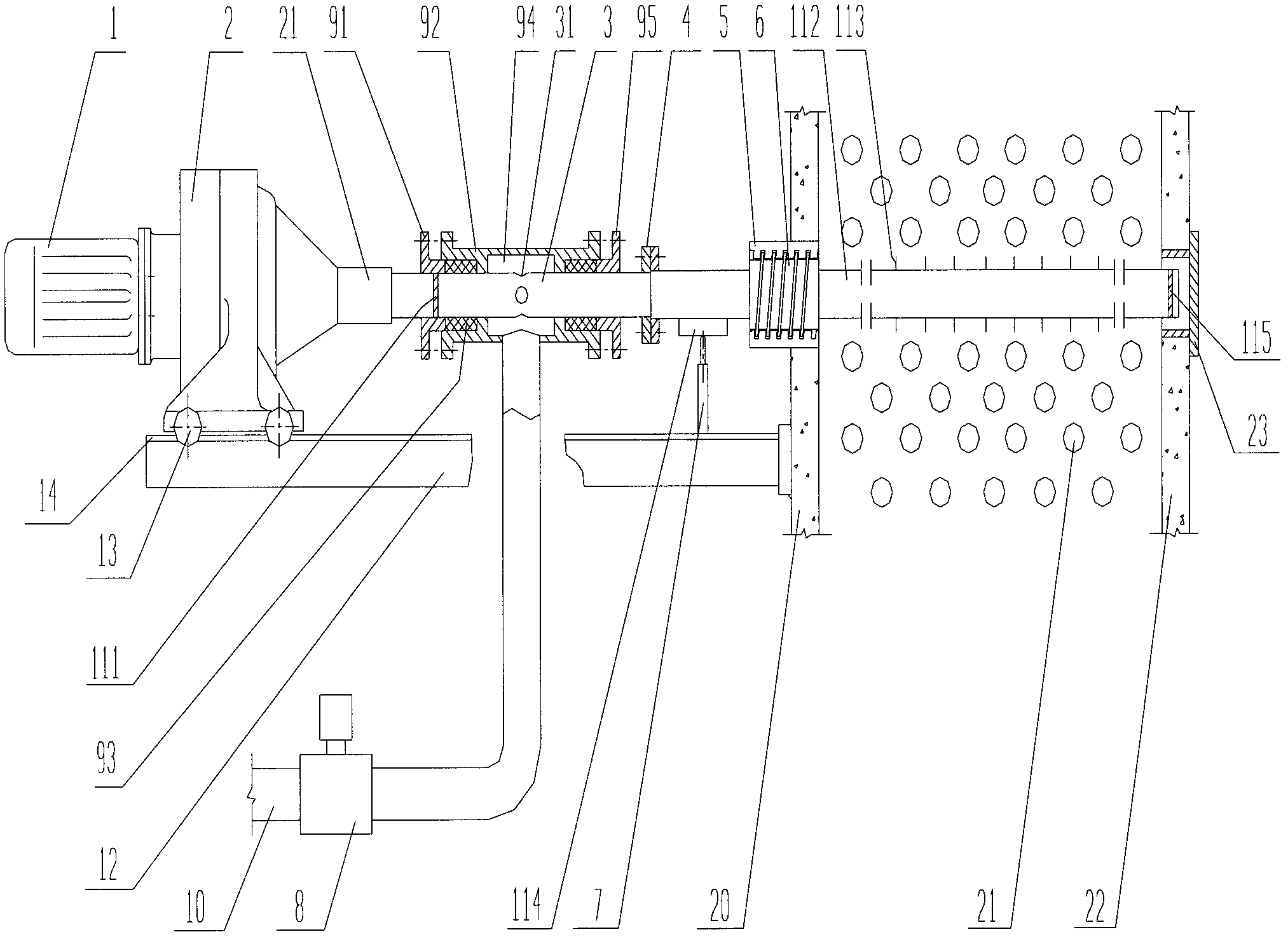

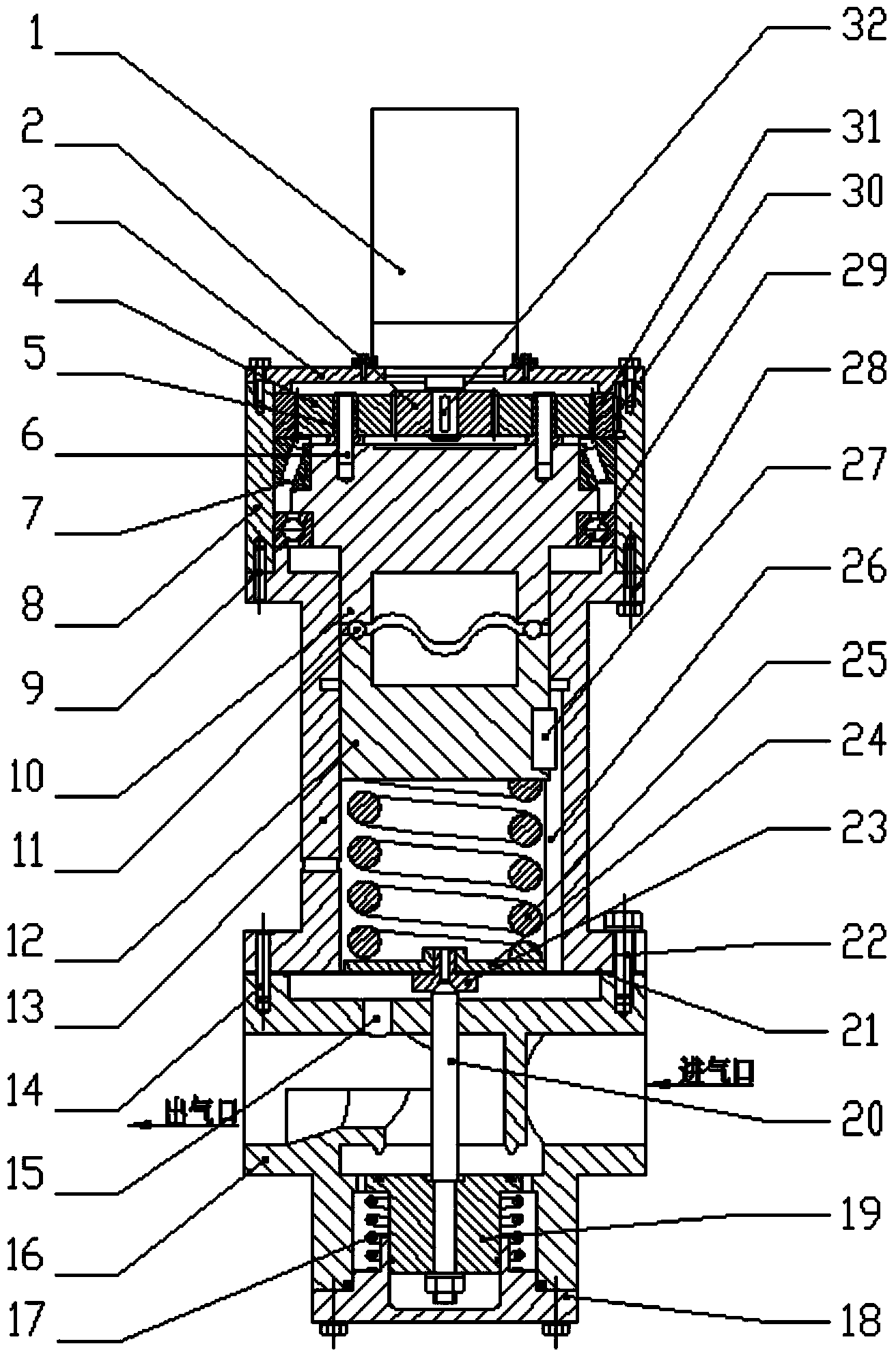

Gas soot blower

InactiveCN102809166ATo overcome only purging furnace tubeOvercome heat transferSolid removalLinear motionCoupling

The invention provides a gas soot blower which comprises a transmission system, a gas inlet system, a limit system, a feed system, a soot blowing pipe component and a bracket, wherein the limit system comprises a collision block and a limit switch; the feed system is a lead screw nut pair mechanism and comprises a hollow lead screw and a nut; one end of a gas inlet pipe of the gas inlet system is connected with a coupler of the transmission system, and the other end is connected with one end of the soot blowing pipe; the collision block is arranged on the soot blowing pipe and matched with the limit switch arranged on the bracket to jointly form the limit system; and the hollow lead screw is sleeved on the soot blowing pipe, welded into a whole with the soot blowing pipe and matched with the nut on a front furnace wall to form the lead screw nut pair mechanism. According to the gas soot blower provided by the invention, through the actions of the limit system and the feed system, the rotations of a motor are converted into rotary motions and reciprocating linear motions of a soot blowing nozzle, so that the stretching of the soot blowing nozzle is realized, a soot blowing area of the soot blowing nozzle is greatly enlarged, and the soot blowing dead angles are eliminated.

Owner:CHINA PETROLEUM & CHEM CORP +1

High-bearing and low-friction suspension type antenna unloading device

ActiveCN109515770AReduce processing difficultyReduce pipeline complexityCosmonautic condition simulationsLow frictionGravitation

The invention provides a high-bearing and low-friction suspension type antenna unloading device. The high-bearing and low-friction suspension type antenna unloading device comprises long air flotationguide rails, short air flotation guide rails, an air supply and distribution system, a double-suspension-bar suspension assembly and a bearing truss. The long air flotation guide rails are arranged on the bearing truss and driven by the air supply and distribution system to move relative to the bearing truss. The two ends of each short air flotation guide rail are arranged on the two corresponding long air flotation guide rails correspondingly, and the short air flotation guide rails are driven by the air supply and distribution system to move relative to the long air flotation guide rails. The double-suspension-bar suspension assembly is connected with the two ends of each short air flotation guide rail in a sliding mode, driven by the air supply and distribution system to move relativeto the short air flotation guide rails and used for achieving suspension of load antennas. By the adoption of the high-bearing and low-friction suspension type antenna unloading device, the long air flotation guide rails and the short air flotation guide rails are driven by the air supply and distribution system, so that linear movement of the double-suspension-bar suspension assembly in the orthogonal direction of the long guide rails is achieved. The double-suspension-bar suspension assembly is connected with satellite radar antennas, so that gravity unloading of the satellite radar antennasis achieved.

Owner:SHANGHAI AEROSPACE SYST ENG INST

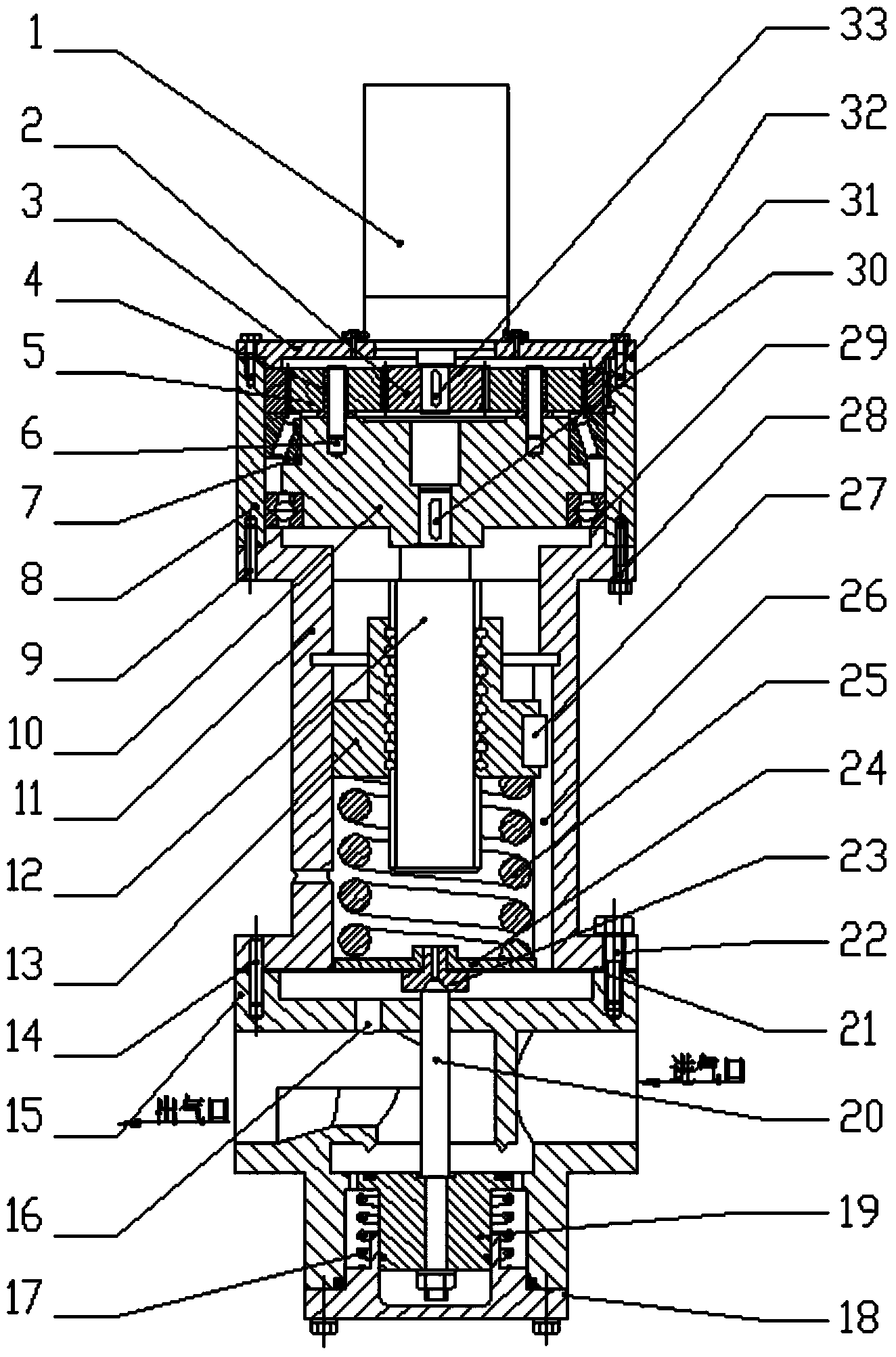

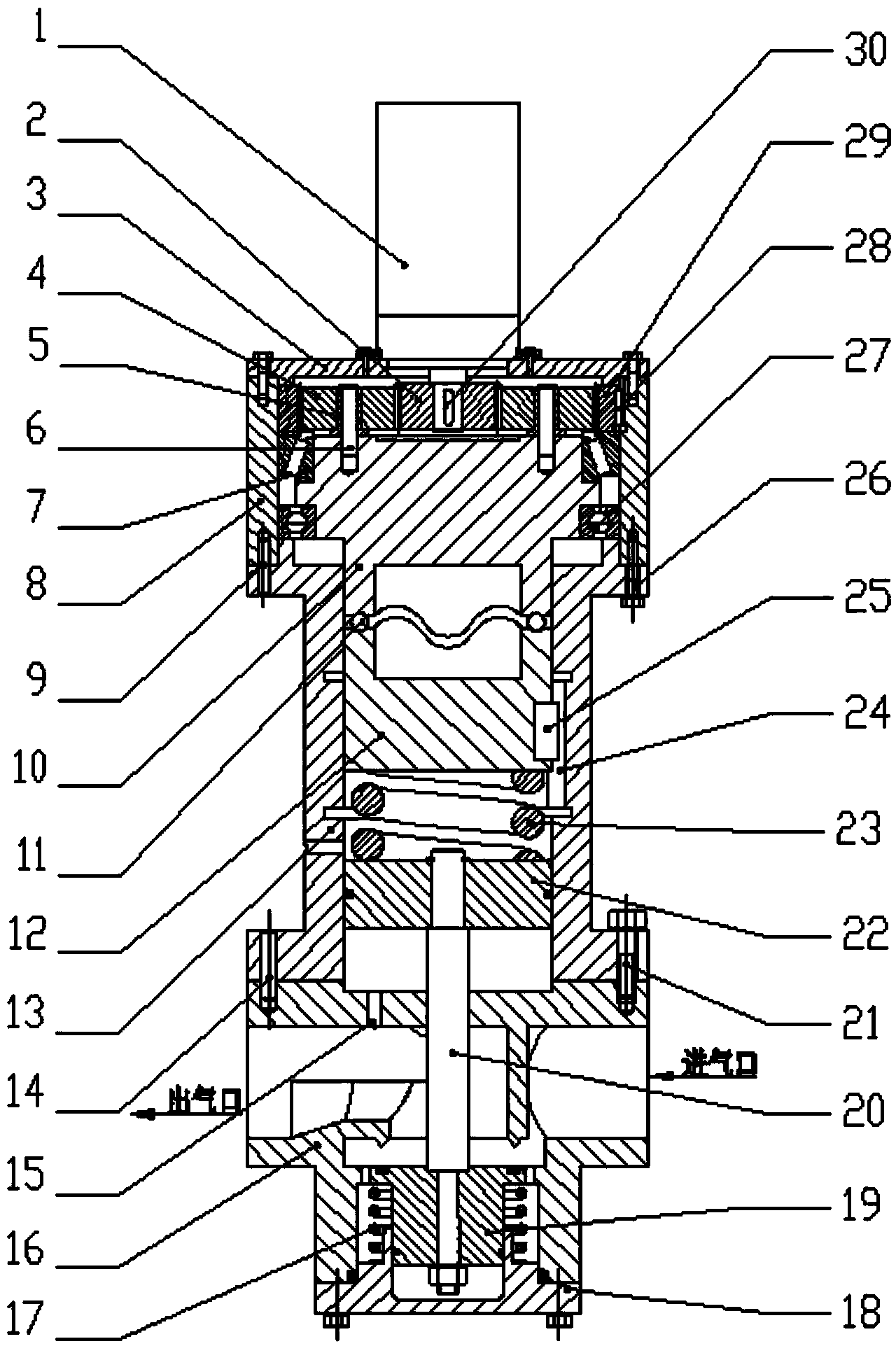

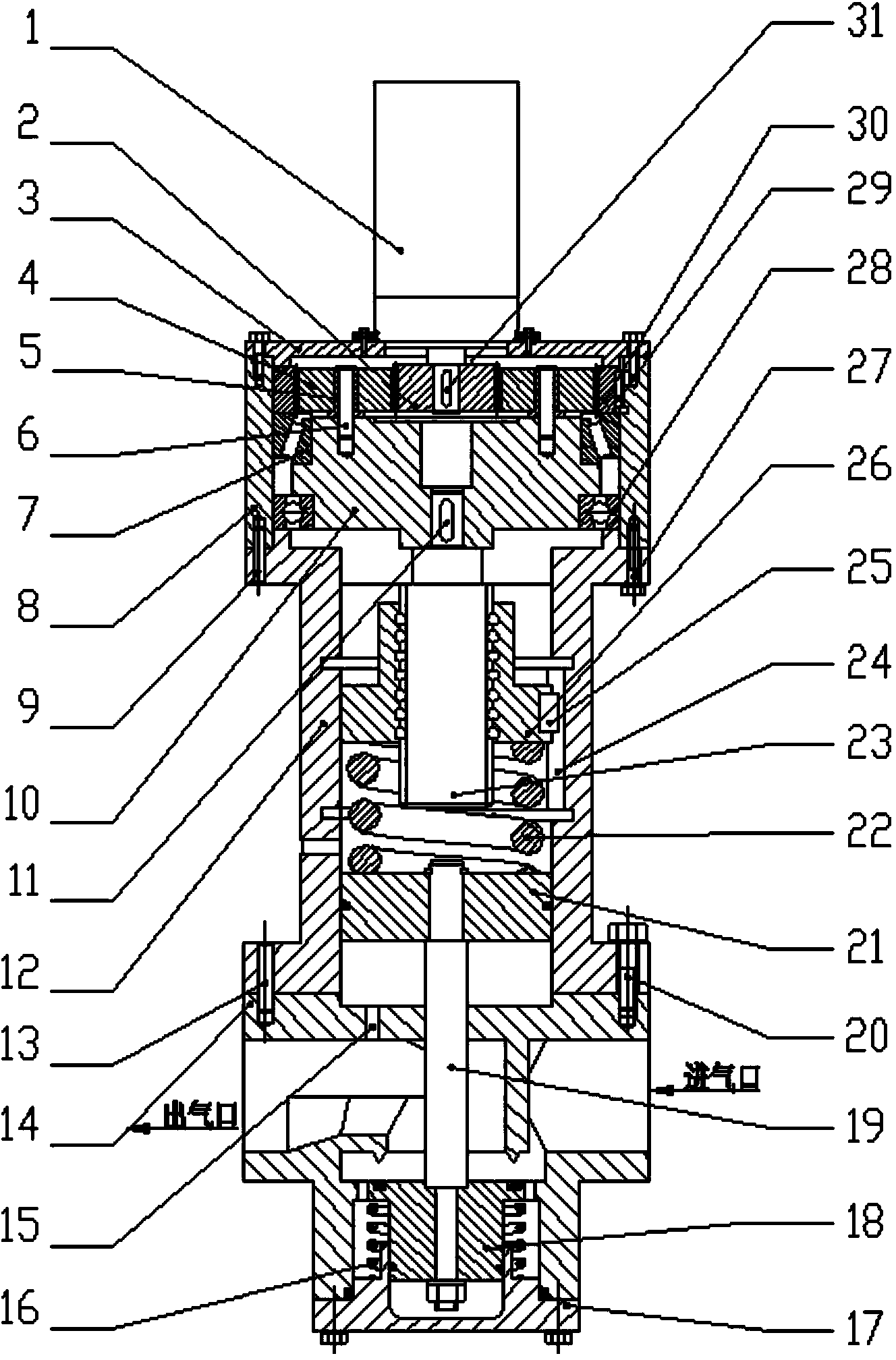

Diaphragm-type pneumatic proportional pressure reducing valve of ball screw driven by servo motor directly

InactiveCN103925400ARealize linear motionPrecise adjustment of output pressureOperating means/releasing devices for valvesEqualizing valvesLinear motionBall screw drive

The invention provides a diaphragm-type pneumatic proportional pressure reducing valve of a ball screw driven by a servo motor directly. An output shaft of the servo motor is in clearance fit with a sun gear of a planetary reducer, a planet gear of the planetary reducer is connected with a transmission block, the lower end of the transmission block is connected with the ball screw, the ball screw is matched with a lead screw nut, the lower portion of the lead screw nut is connected with a pressure adjusting spring, the lower end of the pressure adjusting spring is connected onto a spring end cover, a diaphragm is fixed between an upper valve body and a lower valve body in a compressed mode and located on the lower portion of the spring end cover, an overflow valve is installed in the middle of the spring end cover, a valve rod penetrates through the diaphragm to butt against a valve port of the overflow valve, the lower end of the valve rod is connected with a valve element, an air inlet and an air outlet are formed in the two sides of the lower valve body, an air feedback hole is formed in the lower valve body, the outer portion of the valve element is connected with a reset spring, and the valve element, the reset spring and a lower end cover are connected in a sealed mode. The servo motor directly drives the lead screw nut to compress the springs so as to achieve linear motion of the valve element, the structure is compact, transmission is stable, and dynamic control can be achieved.

Owner:XI AN JIAOTONG UNIV

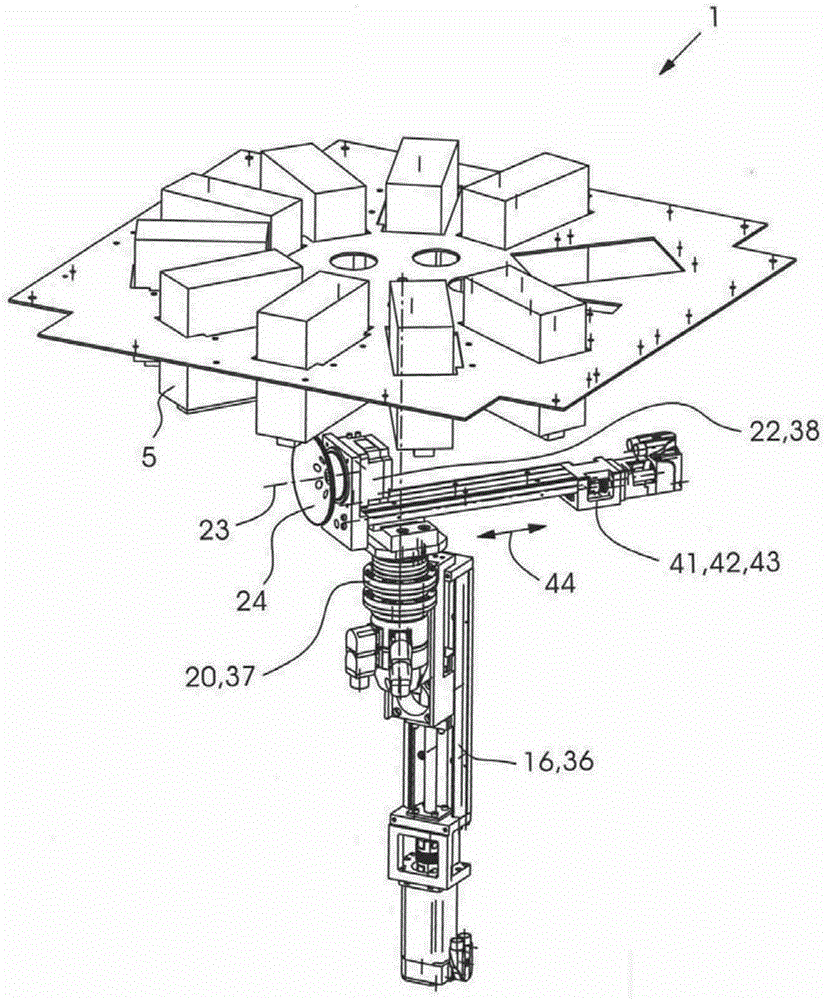

Apparatus for printing a curved surface of an object

InactiveCN104943404ARealize linear motionAchieve rotary motionTypewritersOther printing apparatusRadiant heaterControl cell

An apparatus for printing a curved surface of an object, for example a ball includes a stationary printing unit for printing the object, the printing unit including an inkjet print head producing a print on the object surface in an active region of the print head, a curing unit for curing the print, the curing unit including a radiant heater curing the print in an active region of the radiant heater, a movable holding unit for receiving the object in a receiving region, moving the object from the receiving region into the active region of the print head, moving the object in the active region of the print head during production of the print and moving the object into the active region of the curing unit, and a control unit for controlling the movements of the holding unit, the production of the print and the curing of the print.

Owner:HEIDELBERGER DRUCKMASCHINEN AG

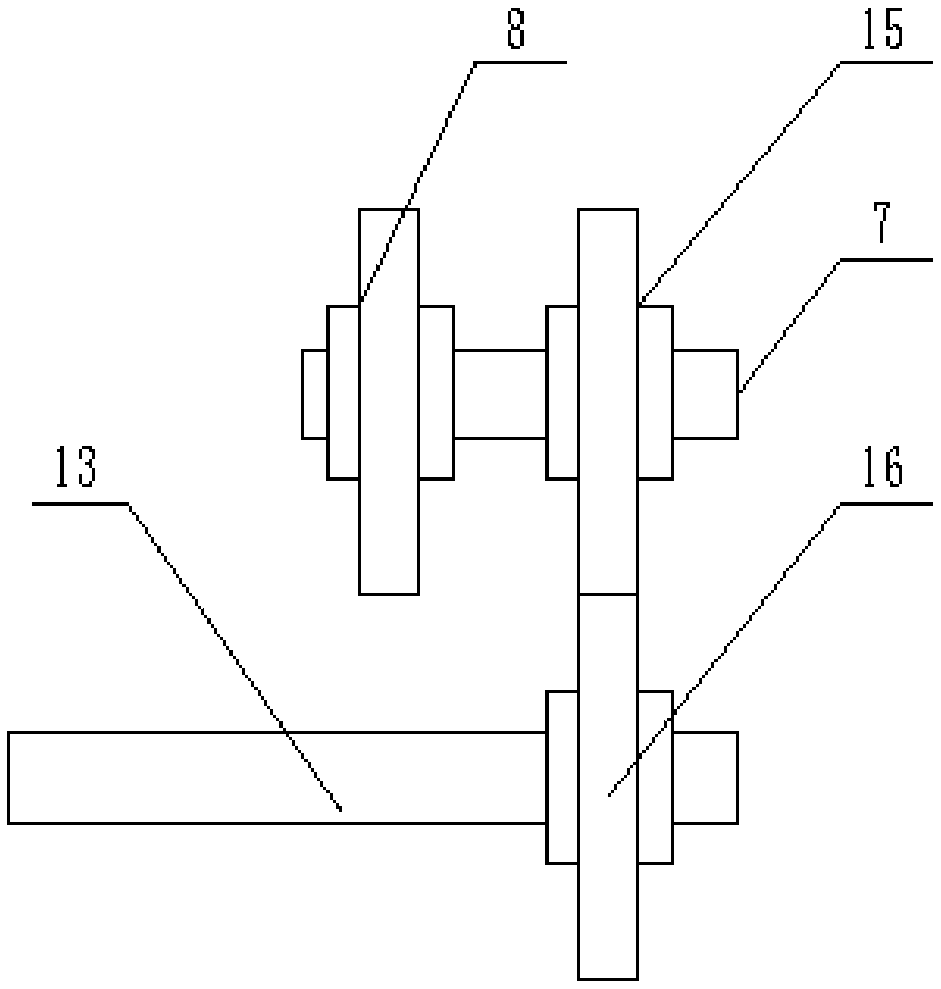

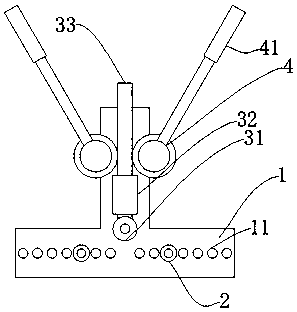

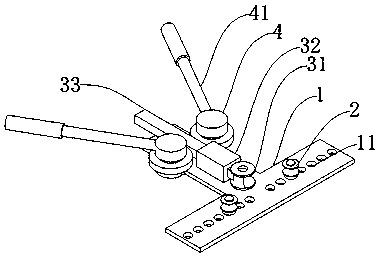

Manual cable bending machine

PendingCN107623281ASemi-mechanizedAvoid damageApparatus for overhead lines/cablesRelative motionEngineering

The invention relates to a manual cable bending machine. The manual cable bending machine is characterized by comprising a body, a bending mechanism, a feeding mechanism and driving mechanisms, wherein the bending mechanism is arranged on the body and is fixedly connected with the body, the feeding mechanism is arranged on the body and on a side surface of the bending mechanism, a bottom surface of the feeding mechanism is fixedly connected with the body, an end is fixedly connected with the bending mechanism, the driving mechanisms are arranged on the body and at two sides of the feeding mechanism, a bottom surface of each driving mechanism is fixedly connected with the body, and a middle part of each driving mechanism is in contact with the feeding mechanism. The application method comprises the steps of calculating minimum bending diameter of a cable, placing fixed rollers in through holes at appropriate positions of the body, fixedly connecting the fixed rollers, placing the cablein the bending mechanism, locking the driving mechanism, simultaneously rotating handles of the driving mechanisms by two hands, driving a gear to rotate by the driving assembly, driving a rack and apush plate to move by the gear, wherein the push plate moves relative to the two fixed roller so that the cable is bent and is plastically deformed to achieve cable bending.

Owner:STATE GRID CORP OF CHINA +1

Piston-type pneumatic proportional pressure reducing valve of edge cam driven by servo motor directly

InactiveCN103925404ARealize linear motionRealize closed-loop controlOperating means/releasing devices for valvesLinear motionProduct gas

The invention provides a piston-type pneumatic proportional pressure reducing valve of an edge cam driven by a servo motor directly. An output shaft of the serve motor is in clearance fit with a sun gear of a planetary reducer, a planet gear of the planetary reducer is connected with an upper edge cam body, the upper edge cam body is matched with a lower edge cam body, the lower portion of the lower edge cam body is connected with a pressure adjusting spring, the lower end of the pressure adjusting spring is connected onto a piston, the piston is connected with the upper end of a valve rod, the lower end of the valve rod is connected with a valve element, an air inlet and an air outlet are formed in the two sides of a lower valve body, an air feedback hole is formed in the lower valve body, the outer portion of the valve element is connected with a reset spring, and the valve element, the reset spring and a lower end cover are connected in a sealed mode. The servo motor directly drives the edge cam to compress the springs so as to achieve linear motion of the valve element, the structure is compact, transmission is stable, and dynamic control can be achieved.

Owner:XI AN JIAOTONG UNIV

In-plane buckling composite mode thin type straight line ultrasound electric motor

InactiveCN101272107ASimple designPolarization lessPiezoelectric/electrostriction/magnetostriction machinesIn planeResonance

The invention discloses an in-plane buckling compound mode thin linear ultrasonic motor which comprises a frame, an active cell, a vibration generator and a pretension mechanism. A slide seat is fixed in the frame; the active cell is movably arranged at the slide seat; the vibration generator comprises a rectangular metal elastic plate, a rectangular piezoelectric ceramic plate and a dial gear; the metal elastic plate and the piezoelectric ceramic plate are fixedly connected; the dial gear is fixedly connected with the middle position of the side surface along the length directions of the metal elastic plate and the piezoelectric ceramic plate; the dial gear is contacted with the active cell; the top surface of the vibration generator is contacted with the pretension mechanism. The motor is easy to design; the polarized subareas of the piezoelectric ceramic plate are less; the design and processing are easy. The resonance frequency of the in-plane buckling vibration tends to be consistent by changing the length-width ratios of the rectangular piezoelectric ceramic plate and the rectangular metal elastic plate, so as to generate a buckling resonance at the same frequency simultaneously; the motor has the advantage of simple and compact structure, which is thin, convenient for assembly and works reliably.

Owner:SOUTH CHINA AGRI UNIV

Multifunctional electromagnetic stirrer

Owner:BAOSHAN IRON & STEEL CO LTD

Automatic material box loading device

ActiveCN110155698AAutomate operationAchieve orderly operationConveyorsConveyor partsEngineeringMechanical engineering

The invention relates to an automatic material box loading device and belongs to the technical field of material box transporting devices. The device comprises an enclosing plate formed by mounting four rectangular plates end to end. The internal area of the enclosing plate is partitioned into a feeding position, a guide position and a positioning position from right to left in sequence. The device further comprises a bottom plate mounted at the bottom of the enclosing plate, a check mechanism used for supporting a material box, a push rod mechanism used for pushing the material box from the feeding position to the positioning position, and a guide positioning mechanism used for guiding, positioning and discharging the material box. By arranging the push rod mechanism and the guide positioning mechanism, the material box is stably conveyed to the positioning position, meanwhile, the material box can be discharged after being positioned, the whole process of guiding, positioning and discharging can be completed through a power portion only, the requirement for the precision of the power portion is lower, the time for adjusting multiple power for mutual cooperation after mounting iscompleted is saved, power is simplified, and the equipment cost is lowered.

Owner:YANTAI ADEKANG BIOTECHNOLOGY CO LTD

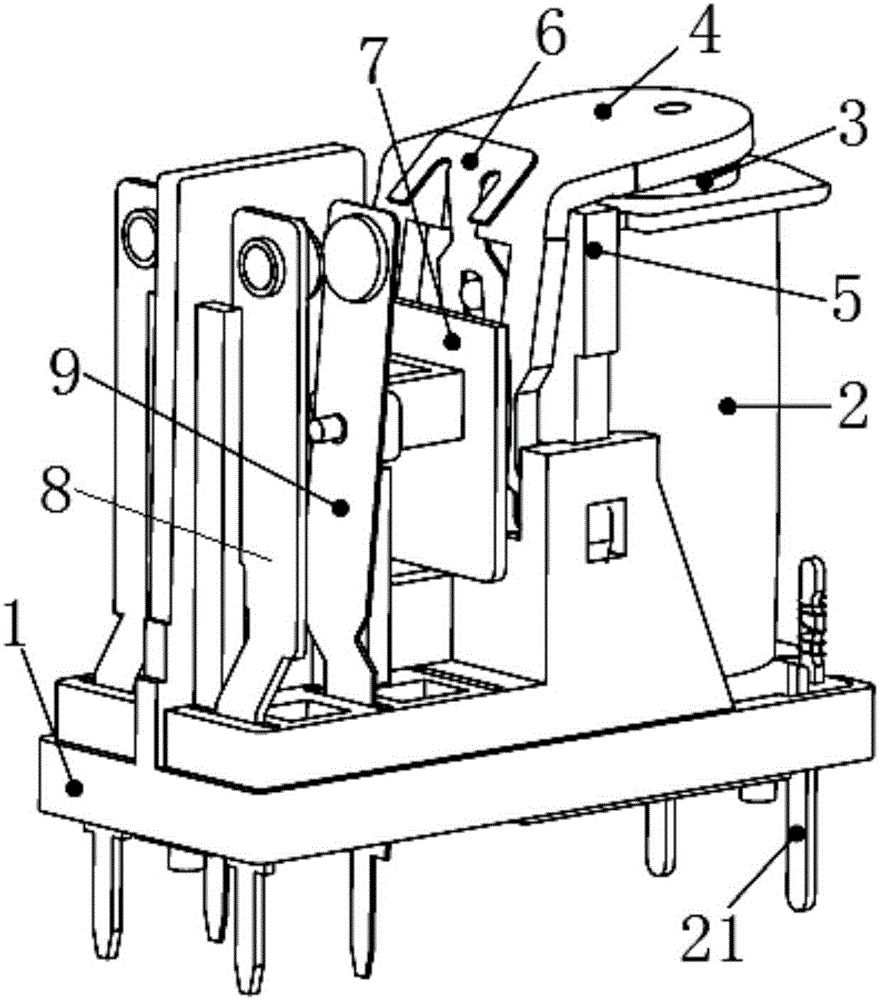

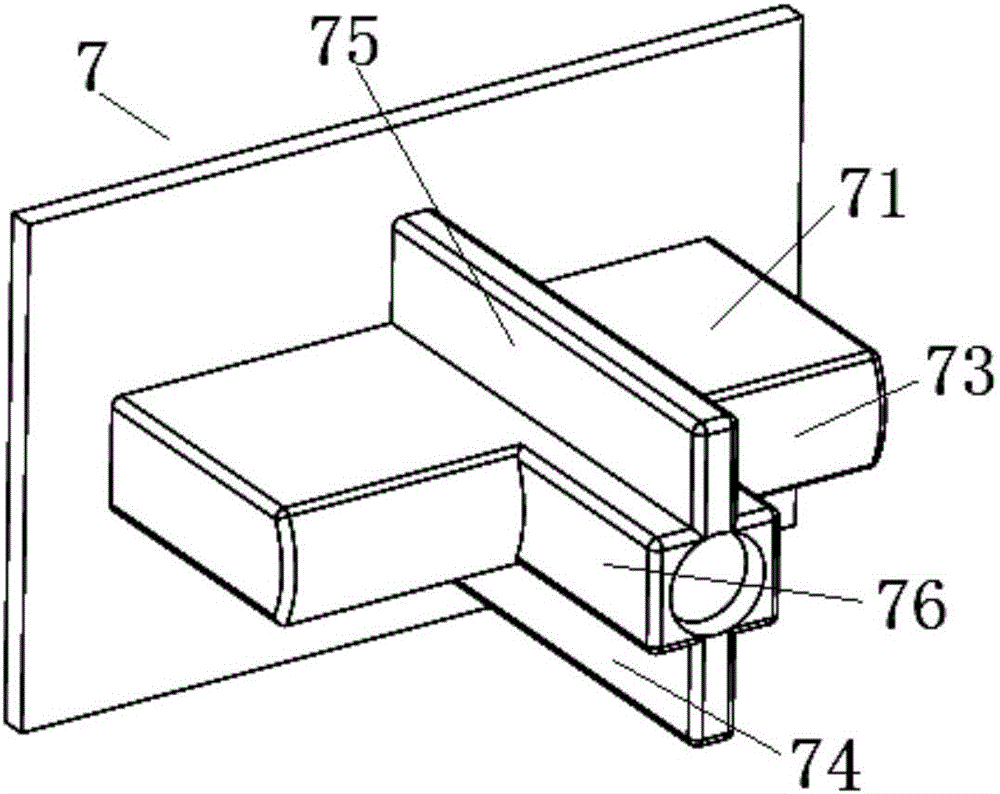

Relay push card structure and relay containing push card

ActiveCN106298370AHigh movement precisionRealize linear motionElectromagnetic relay detailsSurface structureRelay

The invention relates to a relay push card structure and a relay containing the push card. The push card comprises a push card body. An armature connecting part is arranged at one end of the push card body, and the other end of the push card body is provided with a movable-spring connecting part. The armature connecting part is a cambered-surface structure protruding outwardly. The push card is in abutted contact with the armature of the relay through the cambered surface of the armature connecting part. The relay containing the push card comprises a base, a magnetic circuit part arranged on the base and a contact part, and the push card is assembled on a base between the magnetic circuit part and the contact part. The contact coordinated face, connected with the push card, of the armature is of a plane structure.

Owner:SICHUAN HONGFA ELECTROACOUSTIC

Linear piezoelectric motor

ActiveCN107171590AReduce lossRealize linear motionPiezoelectric/electrostriction/magnetostriction machinesLinear motionLow speed

The invention relates to a linear piezoelectric motor. The linear piezoelectric motor includes a drive pre-tensioning mechanism, an output mechanism and a bearing pedestal, wherein the drive pre-tensioning mechanism includes a pair of driving vibrators on the pedestal; the pair of driving vibrators are each provided with a vibrator piezoelectric patch; the output mechanism includes an output rod; the middle part of the output rod is provided with a +-shaped framework in the axial direction; two side bars of the +- shaped framework are vibration plates; and the vibration piezoelectric patches are arranged on the vibration plates. The linear piezoelectric motor controls the bending vibration modal of the vibration plates and the driving vibrators by means of the waveform synthesis principle so as to form coordinate action between the vibration plates and the driving vibrators to realize linear motion, and does not generate sliding friction in theory, thus being less in energy loss and being high in efficiency. The operating frequency of the linear piezoelectric motor is greater than 2000Hz; the linear piezoelectric motor has high output speed and has two operating states; and the linear piezoelectric motor can realize low speed high torque output and high speed low torque output through high and low level coordination of the first and second driving vibrators.

Owner:HEFEI UNIV OF TECH

Piston-type pneumatic proportional pressure reducing valve of ball screw driven by servo motor directly

InactiveCN103925405ARealize linear motionRealize closed-loop controlOperating means/releasing devices for valvesEqualizing valvesPistonLinear motion

The invention provides a piston-type pneumatic proportional pressure reducing valve of a ball screw driven by a servo motor directly. An output shaft of the servo motor is in clearance fit with a sun gear of a planetary reducer, a planet gear of the planetary reducer is connected with a transmission block, the lower end of the transmission block is connected with the ball screw, the ball screw is matched with a lead screw nut, the lower portion of the lead screw nut is connected with a pressure adjusting spring, the lower end of the pressure adjusting spring is connected with a piston, an air inlet and an air outlet are formed in the two sides of a lower valve body, an air feedback hole is formed in the lower valve body, the outer portion of a valve element is connected with a reset spring, and the valve element, the reset spring and a lower end cover are connected in a sealed mode. The servo motor directly drives the lead screw nut to compress the springs so as to achieve linear motion of the valve element, the structure is compact, transmission is stable, and dynamic control can be achieved.

Owner:XI AN JIAOTONG UNIV

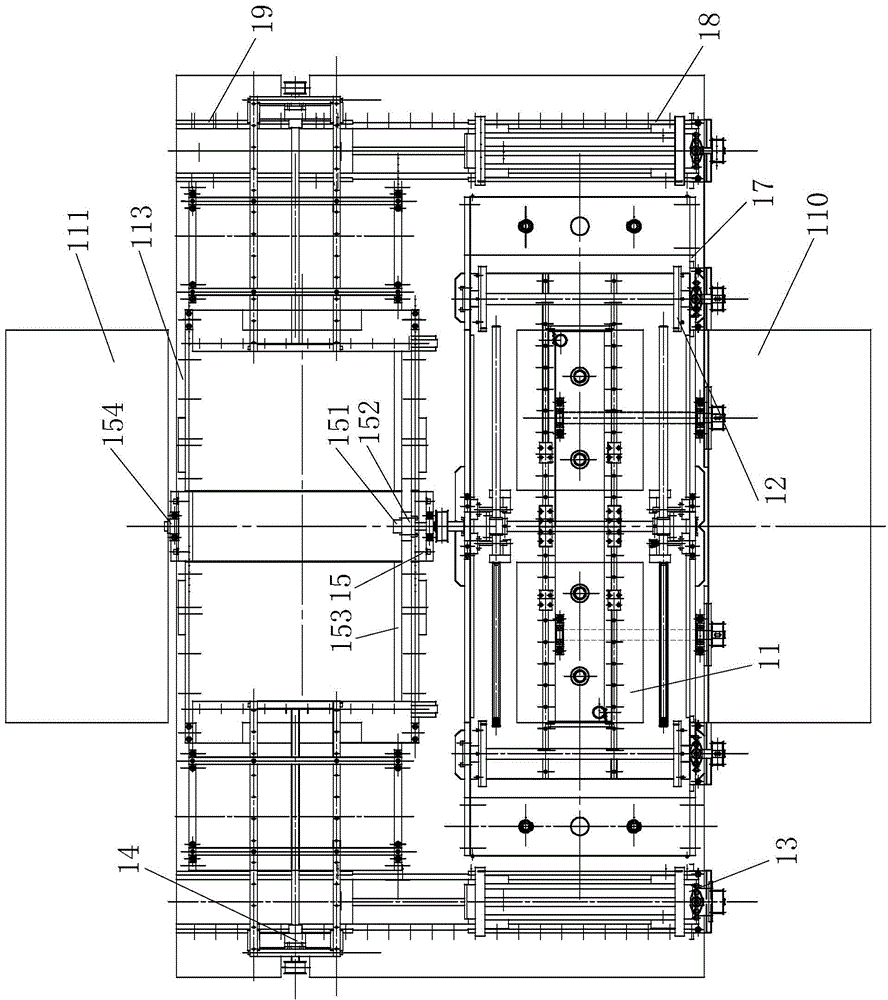

Full-automatic battery cell film tearing machine and film tearing process thereof

PendingCN112591240ASolve the auto-flip problemGuaranteed accuracyAssembling battery machinesFinal product manufactureEngineeringMechanical engineering

The invention discloses a full-automatic battery cell film tearing machine and a film tearing process thereof. The full-automatic battery cell film tearing machine comprises a feeding conveying belt,a feeding mechanism, pre-blowing mechanisms, a transfer conveying mechanism, a transfer carrying arm, a blowing and film tearing mechanism, a film tearing platform, a waste film clamping mechanism, atransfer conveying belt and a discharging conveying belt, wherein the feeding conveying belt and the discharging conveying belt are arranged at the two ends of a machine table correspondingly; the transfer conveying mechanism and the transfer conveying belt are arranged in parallel at an interval; the feeding mechanism is arranged above the feeding conveying belt and the transfer conveying mechanism in a striding mode. the at least two sets of pre-blowing mechanisms are arranged and are arranged above the feeding conveying belt at an interval; the film tearing platform is arranged between thetransfer conveying mechanism and the transfer conveying belt; the blowing and film tearing mechanism is arranged above the film tearing platform in a striding mode; the waste film clamping mechanism is arranged between the film tearing platform and the transfer conveying belt; and the transfer carrying arm is arranged above the film tearing platform in a striding mode. According to the full-automatic battery cell film tearing machine and the film tearing process thereof provided by the invention, the functions of automatic conveying, stopping and positioning, blowing and film tearing and wastefilm clamping of multiple battery cells are realized, and the problem of automatic overturning of the battery cells in previous and subsequent processes is solved.

Owner:SHENZHEN XING GRAIN AUTOMATION CO LTD

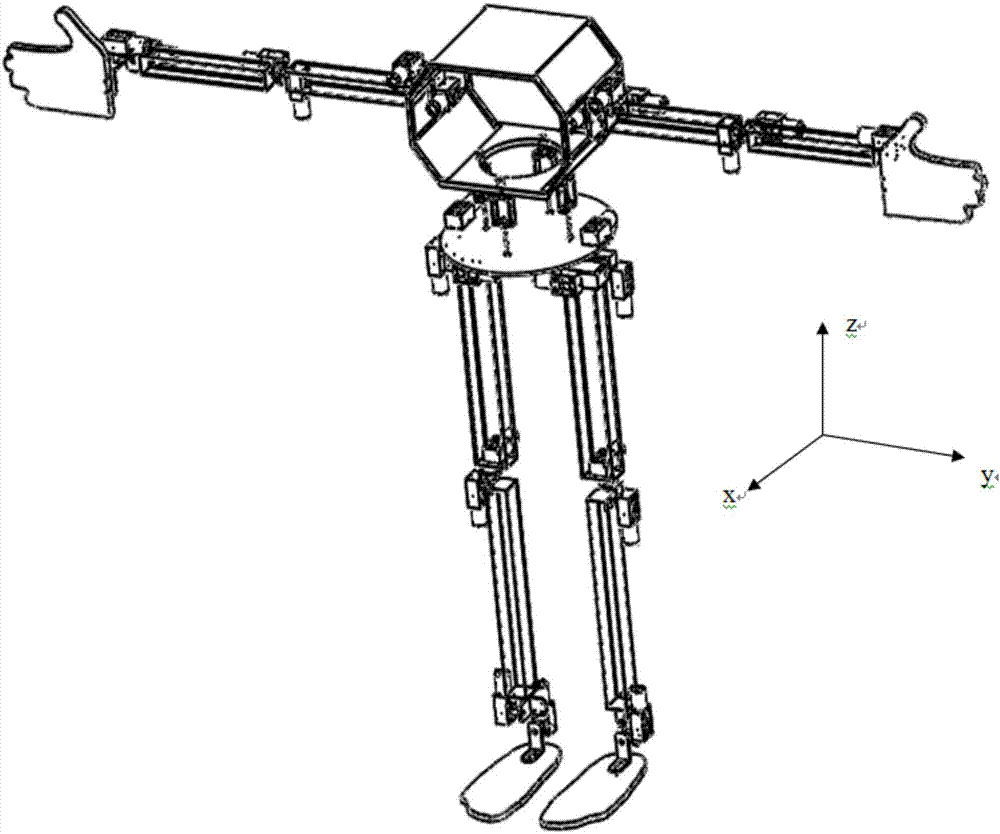

Motor-driven humanoid robot

InactiveCN107972063AHeavy loadRealize self-lockingProgramme-controlled manipulatorJointsKnee JointEngineering

The invention discloses a motor-driven humanoid robot. According to the motor-driven humanoid robot, shoulder joints, elbow joints, wrist joints, a waist joint, hip joints, knee joints and ankle joints are driven to move by a worm gear motor and a lead screw gear motor, and the function of completely simulating human movement can be achieved; and the shoulder joints of the designed motor-driven humanoid robot have three degrees of freedom, the elbow joints have two degrees of freedom, the wrist joints have two degrees of freedom, the waist joint has three degrees of freedom, the hip joints have three degrees of freedom, the knee joints have two degrees of freedom, the ankle joints have two degrees of freedom, and meanwhile, the cyclovergence movement of ulnae and fibulae can be realized. The motor-driven humanoid robot is driven by the worm gear motor and the lead screw gear motor and has the advantages of being compact in structure, high in bearing capacity, capable of achieving the self-locking function and capable of being used for teaching and demonstration.

Owner:JIAXING UNIV

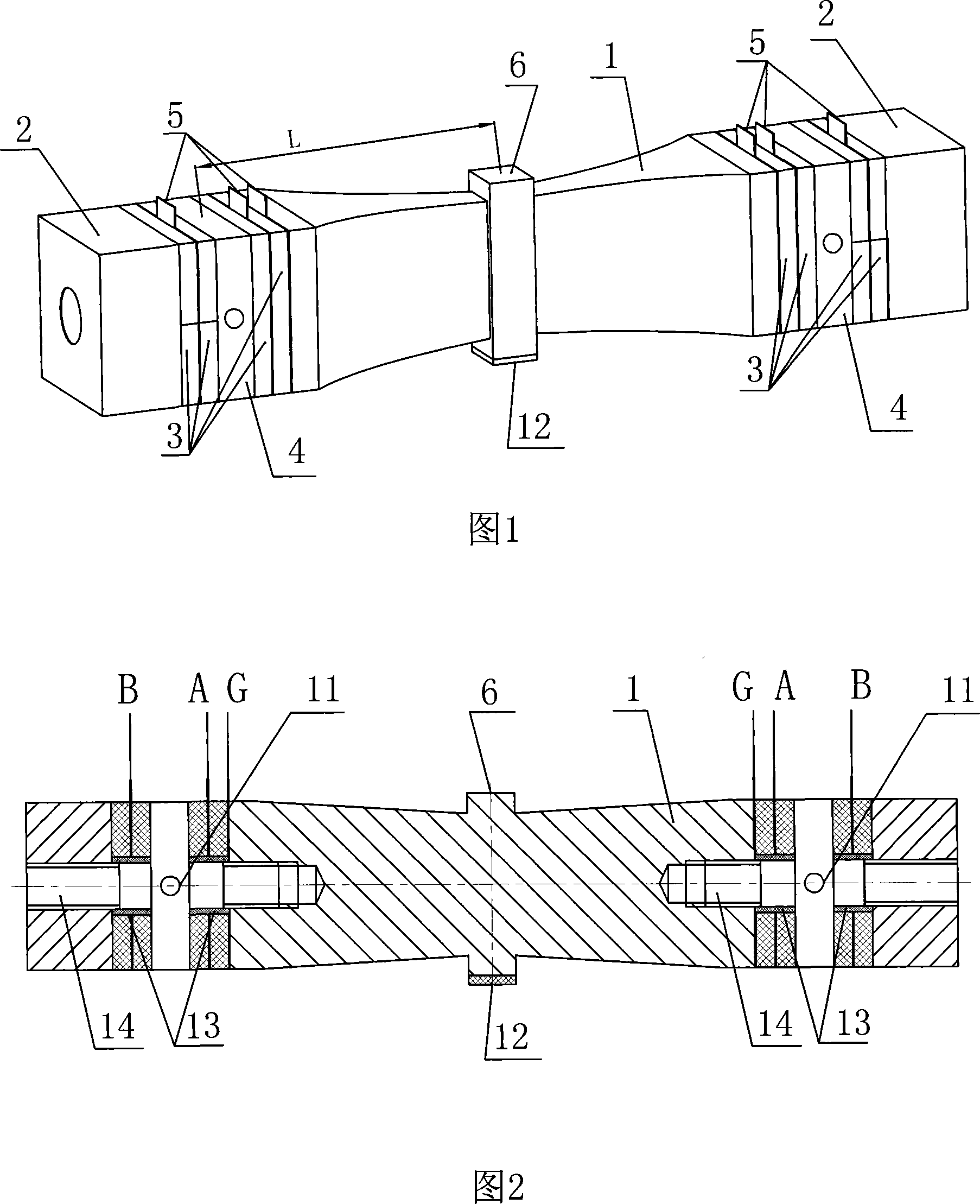

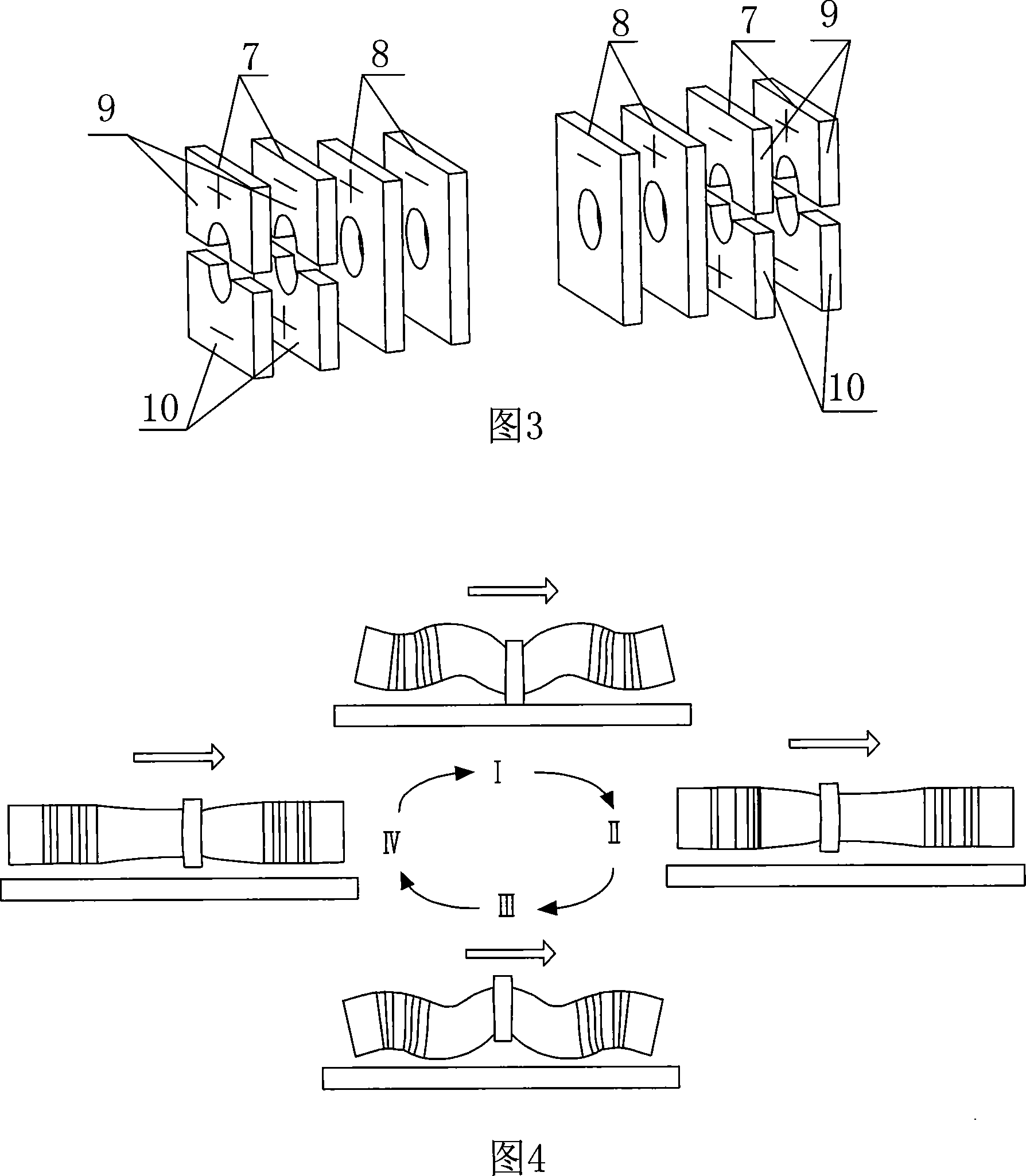

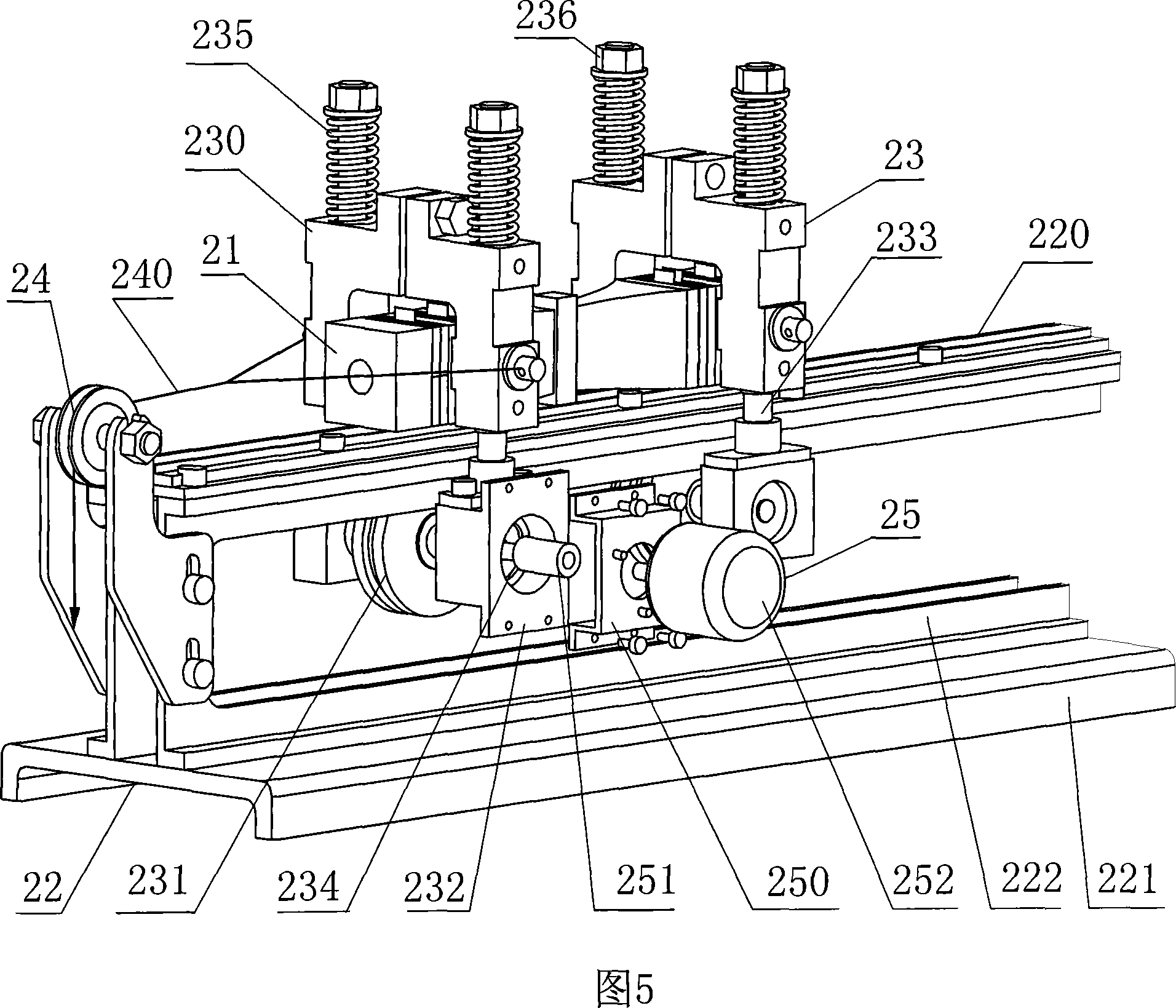

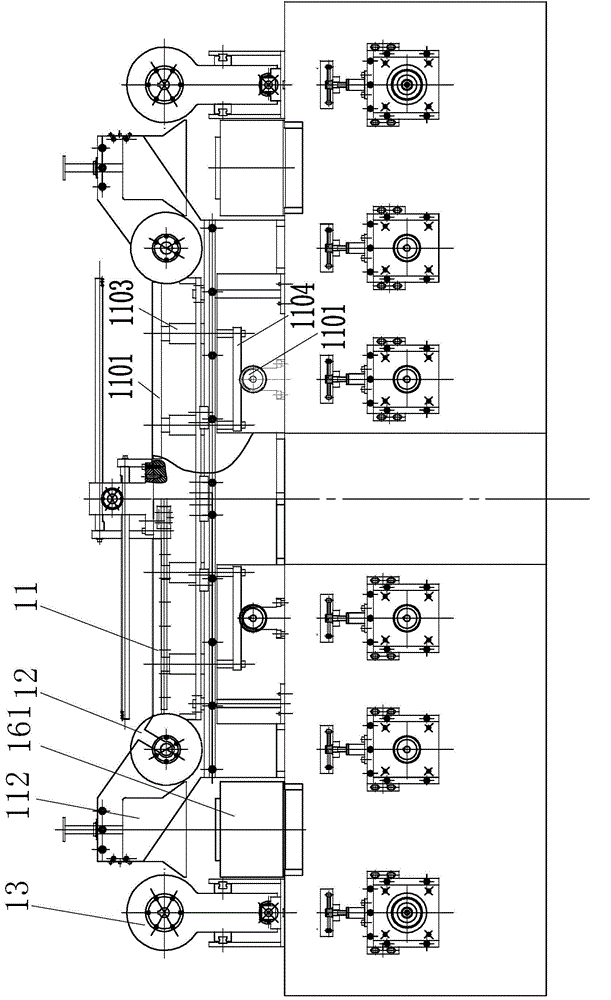

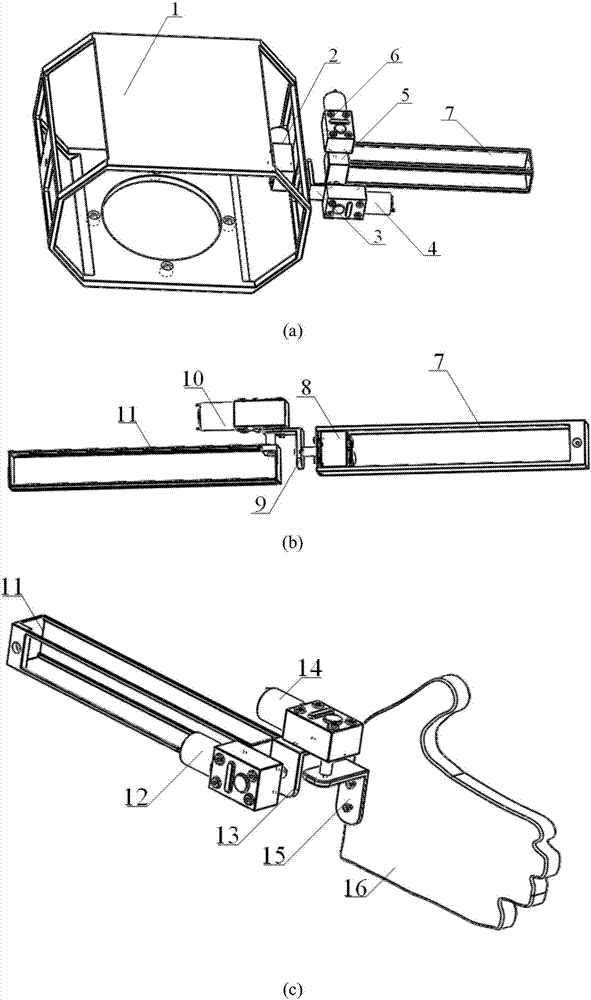

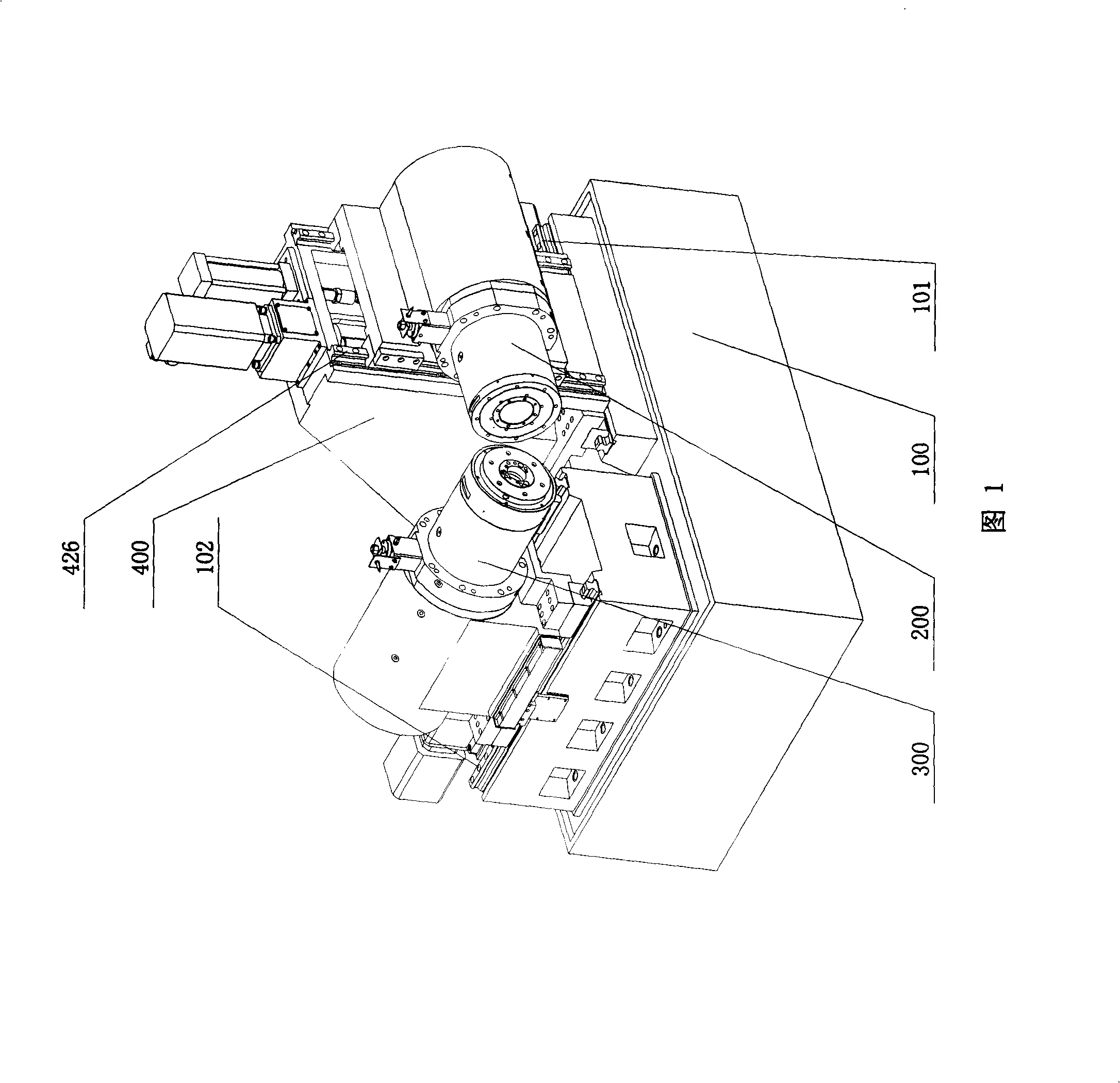

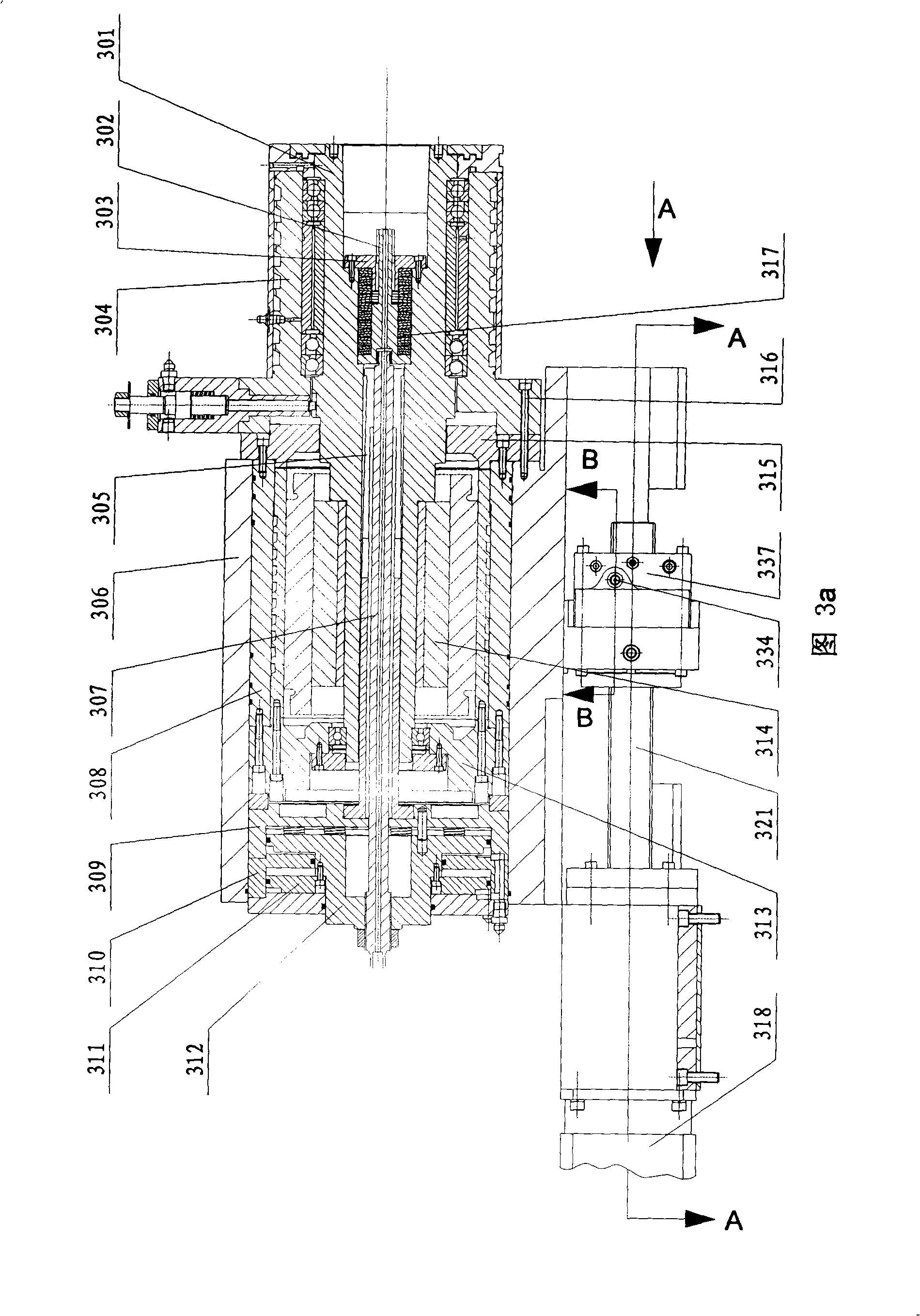

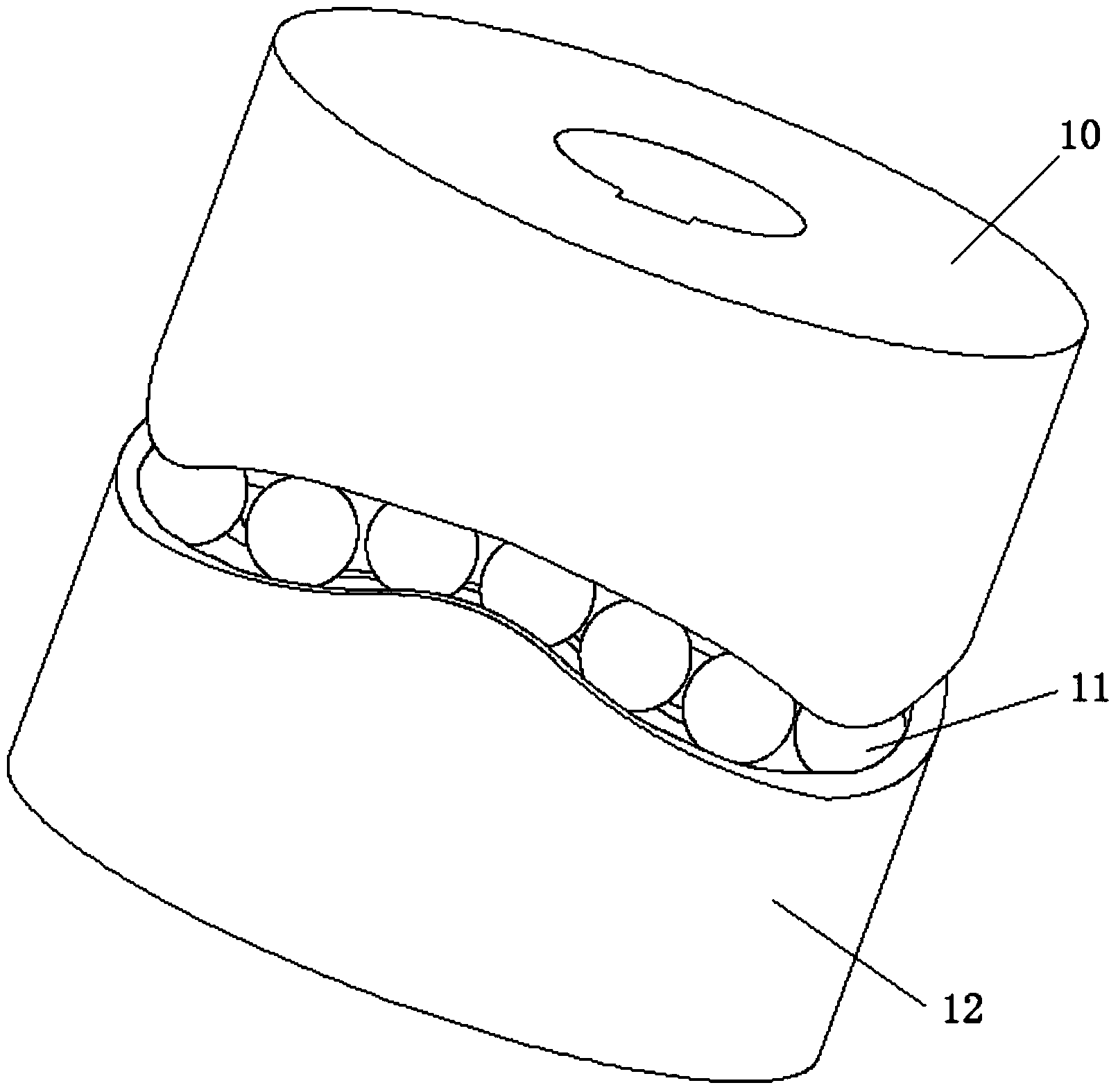

Numerical control machine for lapping spiral bevel gear

ActiveCN101406975ASolve automatic tooth recognitionResolve AutomeshLarge fixed membersGear teethGear wheelEngineering

The invention discloses a numerical control spiral bevel gear lapping machine, which comprises a bed piece, an upright post, a driving headstock, a driven headstock, and a numerical control system, wherein the bed piece is provided with a driving guide rail and a driven guide rail, the upright post is arranged on the driving guide rail, and an automatic moving mechanism is arranged between the bottom of the upright post and the bed piece; the driving headstock is laterally suspended at the side surface of the upright post, and the bottom of the driving headstock is provided with an automatic moving mechanism; the driven headstock is arranged on the driven guide rail on the bed piece, and an automatic moving mechanism is arranged between the bottom of the driven headstock and the bed piece; the driving headstock and the driven headstock are provided with a driving spindle and a driven spindle respectively, and inner holes of the driving spindle and the driven spindle are provided with a driving gear and a driven gear respectively. The numerical control spiral bevel gear lapping machine has the advantages that the numerical control spiral bevel gear lapping machine has a compact structure, ensures that an operator can furthest approach workpieces, automatically recognizes teeth and adjusts the mounting distance and the side clearance of a bevel gear pair, adopts an electric spindle technology to realize the zero transmission of the revolution of the two spindles and improve the speed and maintain the dynamic stability at high speed, and has high production efficiency.

Owner:通用技术集团天津第一机床有限公司

Gas soot blower

InactiveCN103148491ATo overcome only purging furnace tubeOvercome heat transferSolid removalLinear motionCoupling

The invention provides a gas soot blower which comprises a transmission system, a gas inlet system, a limit system, a feed system, a soot blowing pipe component and a bracket, wherein the limit system comprises a collision block and a limit switch; the feed system is a lead screw nut pair mechanism and comprises a hollow lead screw and a nut; one end of a gas inlet pipe of the gas inlet system is connected with a coupler of the transmission system, and the other end of the gas inlet pipe of the gas inlet system is connected with one end of the soot blowing pipe; the collision block is arranged on the soot blowing pipe and matched with the limit switch arranged on the bracket to jointly form the limit system; and the hollow lead screw is sleeved on the soot blowing pipe, welded into a whole with the soot blowing pipe and matched with the nut on a front furnace wall to form the lead screw nut pair mechanism. According to the gas soot blower provided by the invention, through the actions of the limit system and the feed system, the rotations of a motor are converted into rotary motions and reciprocating linear motions of a soot blowing nozzle, so that the stretching of the soot blowing nozzle is realized, a soot blowing area of the soot blowing nozzle is greatly enlarged, and soot blowing dead angles are eliminated.

Owner:CHINA PETROLEUM & CHEM CORP +1

Multiple sporting state spherical robot

The invention discloses a multi-kinetic spherical robot, which comprises two hemispherical shells and a spiral expansion mechanism that drives the two hemispherical shells to expand or close. The spiral expansion mechanism includes a fixed bracket, a drive assembly and two sets of expansion assemblies. , the driving assembly is installed in the middle of the fixed bracket, and two sets of telescopic assemblies are respectively installed at both ends of the fixed bracket. motor. The multi-motion spherical robot has three motion forms of ball state, two-wheel state and bouncing, is easy to carry, transport and release, and can move in various complex terrain environments.

Owner:NAT UNIV OF DEFENSE TECH

Diaphragm-type pneumatic proportional pressure reducing valve of edge cam driven by servo motor directly

InactiveCN103925399ARealize linear motionRealize closed-loop controlOperating means/releasing devices for valvesEqualizing valvesLinear motionReducer

The invention provides a diaphragm-type pneumatic proportional pressure reducing valve of an edge cam driven by a servo motor directly. An output shaft of the serve motor is in clearance fit with a sun gear of a planetary reducer, a planet gear of the planetary reducer is connected with an upper edge cam body, the upper edge cam body is matched with a lower edge cam body, the lower portion of the lower edge cam body is connected with a pressure adjusting spring, the lower end of the pressure adjusting spring is connected onto a spring end cover, a diaphragm is fixed between an upper valve body and a lower valve body in a compressed mode and located on the lower portion of the spring end cover, an overflow valve is installed in the middle of the spring end cover, a valve rod penetrates through the diaphragm to butt against a valve port of the overflow valve, the lower end of the valve rod is connected with a valve element, an air inlet and an air outlet are formed in the two sides of a lower valve body, an air feedback hole is formed in the lower valve body, the outer portion of the valve element is connected with a reset spring, and the valve element, the reset spring and a lower end cover are connected in a sealed mode. The servo motor directly drives the edge cam to compress the springs so as to achieve linear motion of the valve element, the structure is compact, transmission is stable, and dynamic control can be achieved.

Owner:XI AN JIAOTONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com