Automatic material box loading device

An automatic loading and material box technology, applied in transportation and packaging, conveyors, conveyor objects, etc., can solve the problems of high cost, high accuracy requirements, low transportation efficiency, etc., to reduce equipment costs and low accuracy requirements. , the effect of streamlining power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

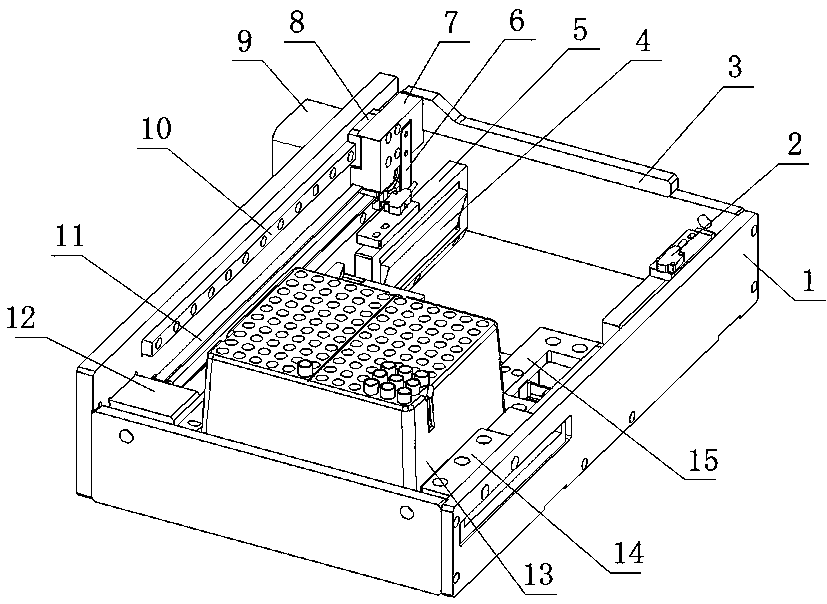

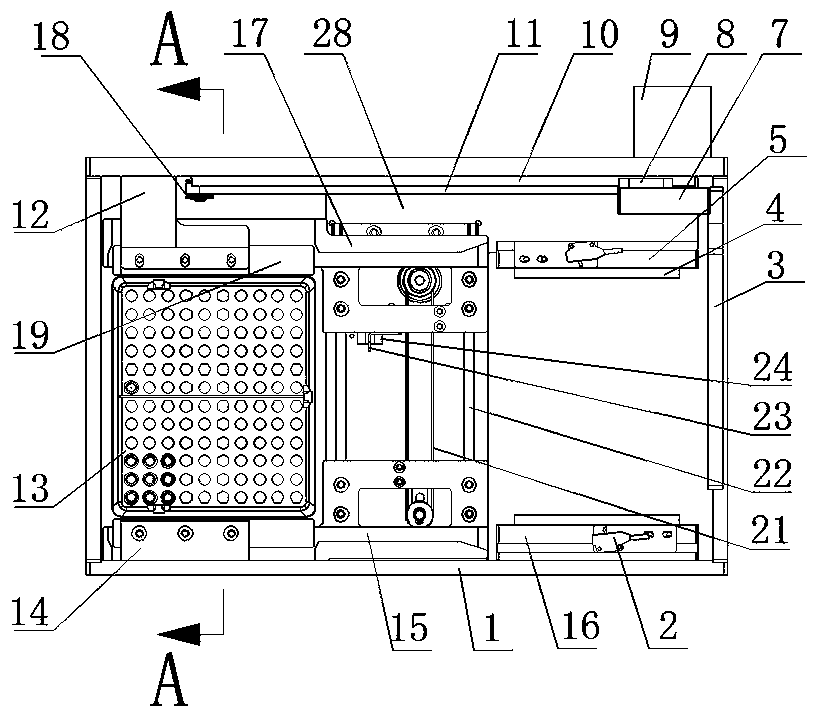

[0043] The principles and features of the present invention will be described below with reference to the accompanying drawings. The examples are only used to explain the present invention, but not to limit the scope of the present invention.

[0044] like Figure 1-3 As shown in the figure, an automatic loading device for a material box includes an enclosure 1 formed by four rectangular plates installed end to end. The inner area of the enclosure 1 is sequentially divided into a feeding position, a guiding position and a positioning position from right to left. It also includes a bottom plate 28 installed at the bottom of the enclosure 1, a non-return mechanism used to support the material box 13, a push rod mechanism used to push the material box 13 from the feeding position to the positioning position, and the material box 13. 13. Guiding and positioning mechanism for guiding, positioning and discharging;

[0045] like Figure 9-13 As shown in the figure, the non-return...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com