Relay push card structure and relay containing push card

A technology for pushing cards and relays, applied in the direction of relays, electromagnetic relays, detailed information of electromagnetic relays, etc., can solve problems such as poor practicability, poor stability and reliability, and affect the stability and reliability of relays, so as to achieve reliable assembly and improve movement The effect of precision, stability and reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

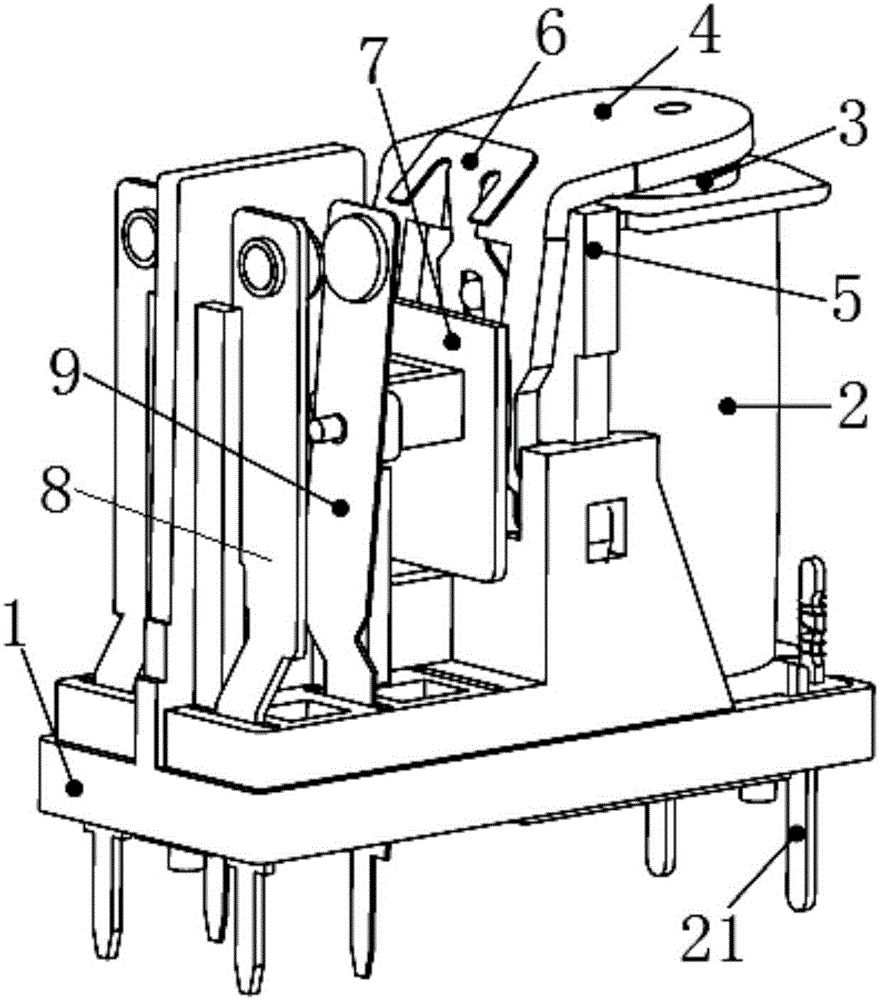

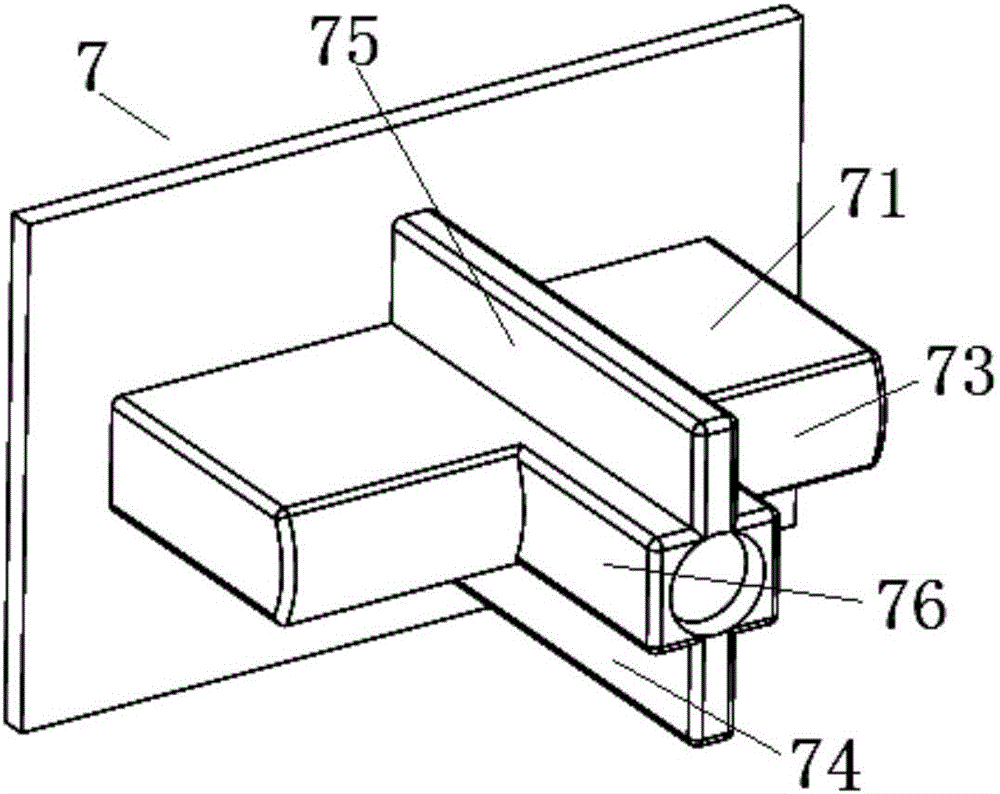

[0034] see figure 2 and image 3 As shown, the present invention is a push card structure applied to a push card relay, and the push card 7 has a push card body 71 with a plate-shaped structure. One end of the push card body 71 has an armature connection portion 72, and the other end has a moving spring connection portion 73, and a limit structure for linear displacement is provided on the push card body 71 near the armature connection portion 72, that is, the limit structure is The plate-shaped structure extends from the periphery of the push card body 71 . If the push card body 71 is the axial direction, the position-limiting structure is a plate-shaped structure formed in the radial direction of the push card body 71 .

[0035] The armature connection part 72 of the push card 7 is an outwardly convex arc surface structure, that is, the armature connection part 72 is an arch shape in the upper and lower directions of the end surface of the push card body 71, and the arc of...

Embodiment 2

[0039] The invention is a push card structure applied to a push card type relay, and the push card has a plate-shaped push card body. One end of the push card body has an armature connecting portion, and the other end has a moving spring connecting portion, and a linear displacement limiting structure is provided on the pushing card body near the armature connecting portion, that is, the limiting structure is a plate-shaped structure. The periphery of the push card body extends out. If the push card body is the axial direction, the position-limiting structure is a plate-shaped structure formed in the radial direction of the push card body.

[0040] The armature connection part of the push card is an outwardly convex arc surface structure, that is, the armature connection part is an arch shape in the upper and lower directions of the end surface of the push card body, and the arc of the arch can be specified according to the specific product. During use, the push card abuts aga...

Embodiment 3

[0044] The other content of this embodiment is the same as that of Embodiment 1 or 2, except that the linear sliding structure on the push card is formed in a linear chute (of course, it must be aligned with The structure on the relay base matches), specifically, the push card body at the rear of the limit structure is provided with a linear upper chute and a lower chute, and the upper chute is formed on the top surface of the push card body in a concave manner. The sliding groove is concavely formed on the bottom surface of the push card body.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com