Inspection system and inspection method of valve hall robot based on video monitoring linkage system

A linkage system and video monitoring technology, applied in the field of intelligent power transmission and transformation, can solve problems such as inability to identify abnormalities independently, limited monitoring range, and inconvenient geographical location of power transformation equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0126] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, but not as a limitation of the present invention.

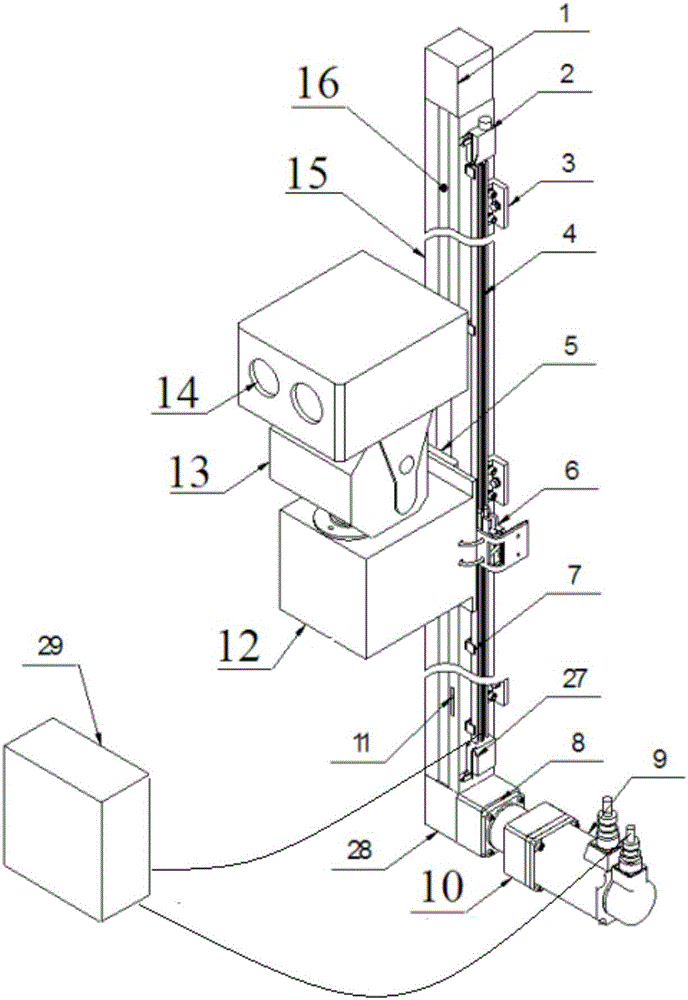

[0127] Such as figure 1 As shown, the intelligent inspection robot system for the valve hall of the converter station based on the video monitoring linkage system mainly includes a linkage analysis control host 101, a data storage server 102, a communication server 103 interacting with external systems, an inspection robot 104, and a linkage analysis robot. The wireless communication module 105 and the auxiliary fixed point monitoring subsystem 106 for controlling the communication between the host computer and the inspection robot,

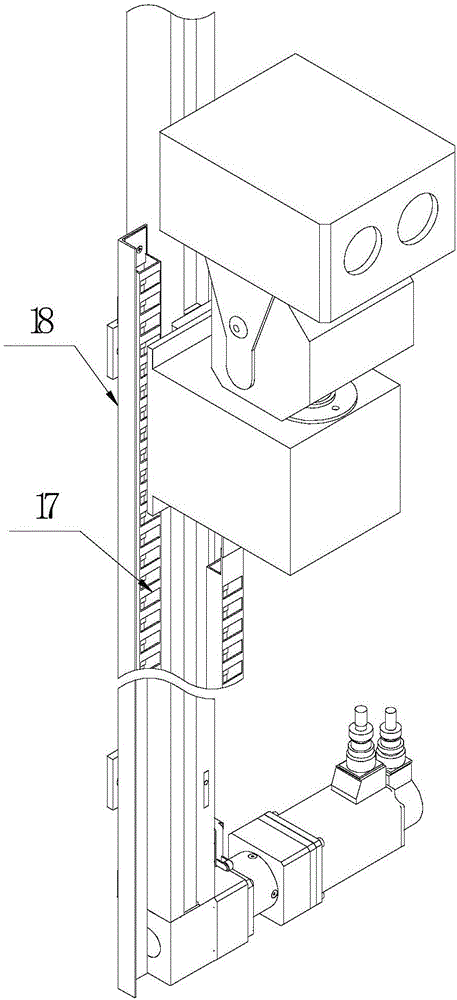

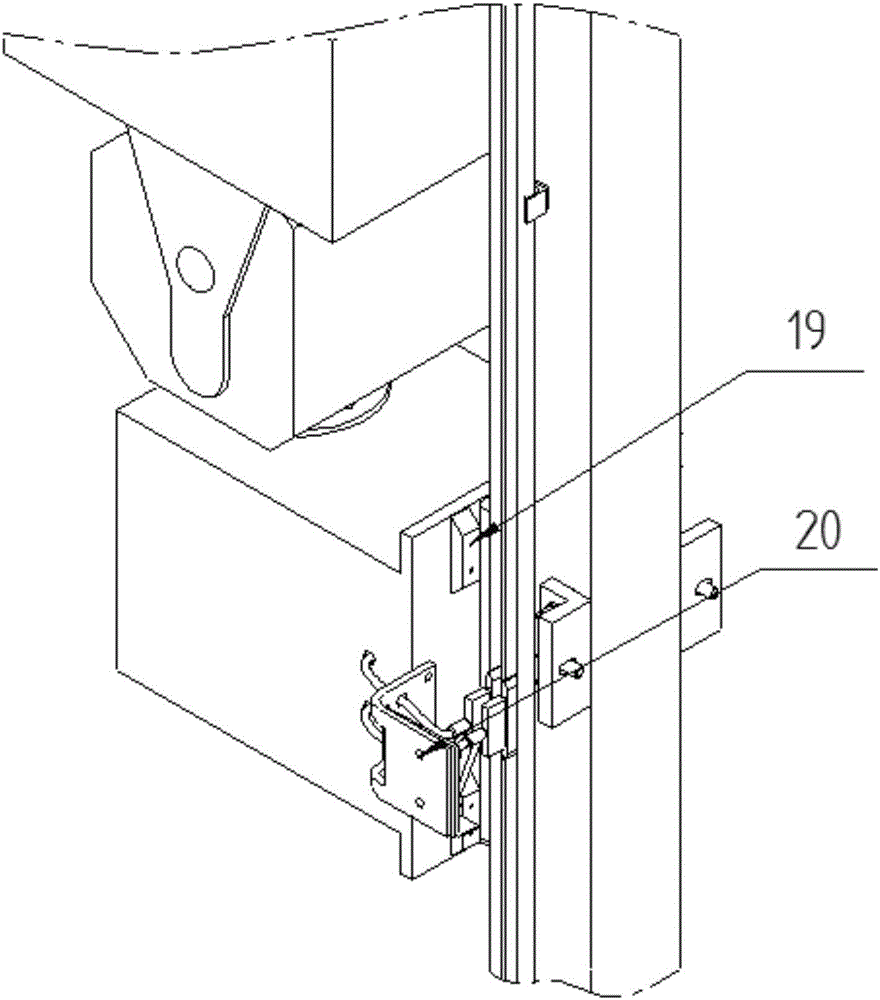

[0128] The inspection robot includes a robot terminal system 42, which communicates with the remote control system 41. The robot terminal system 42 includes a profile rail 15, which is vertically installed on the wall of the valve hall. A motion mechanis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com