Fully-automatic enteric capsule production line

An enteric-coated capsule and production line technology, applied in the field of automatic enteric-coated capsule production line, can solve problems such as harm to the human body, unsealed factory buildings, etc., and achieve the effects of good quality, good product quality, and automatic production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

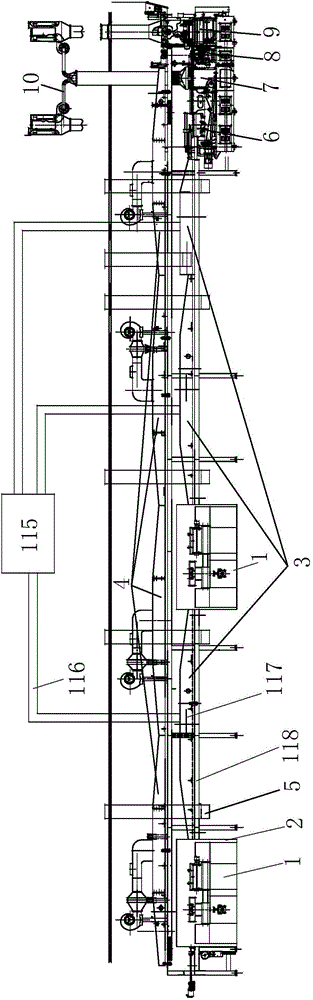

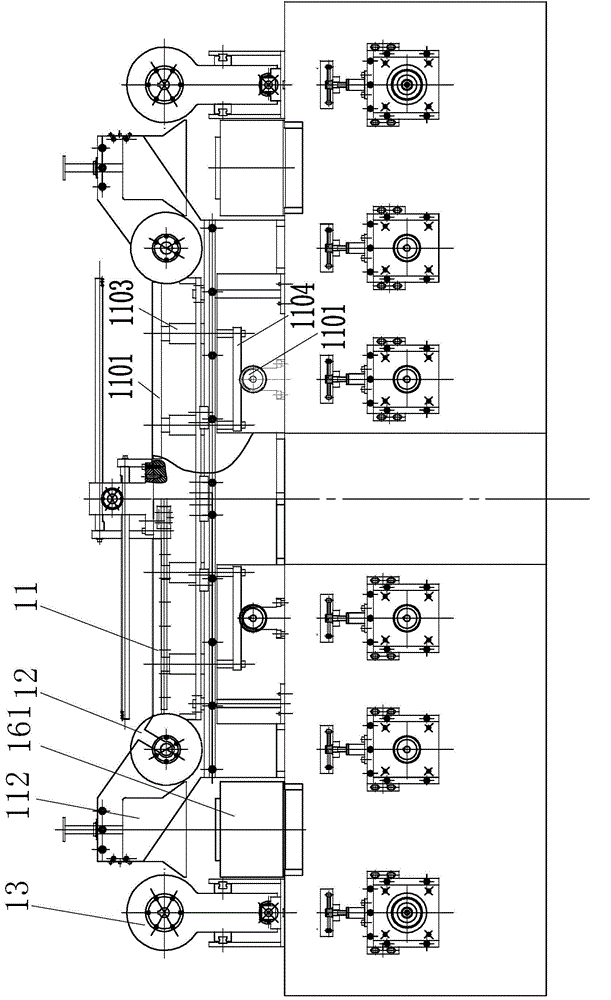

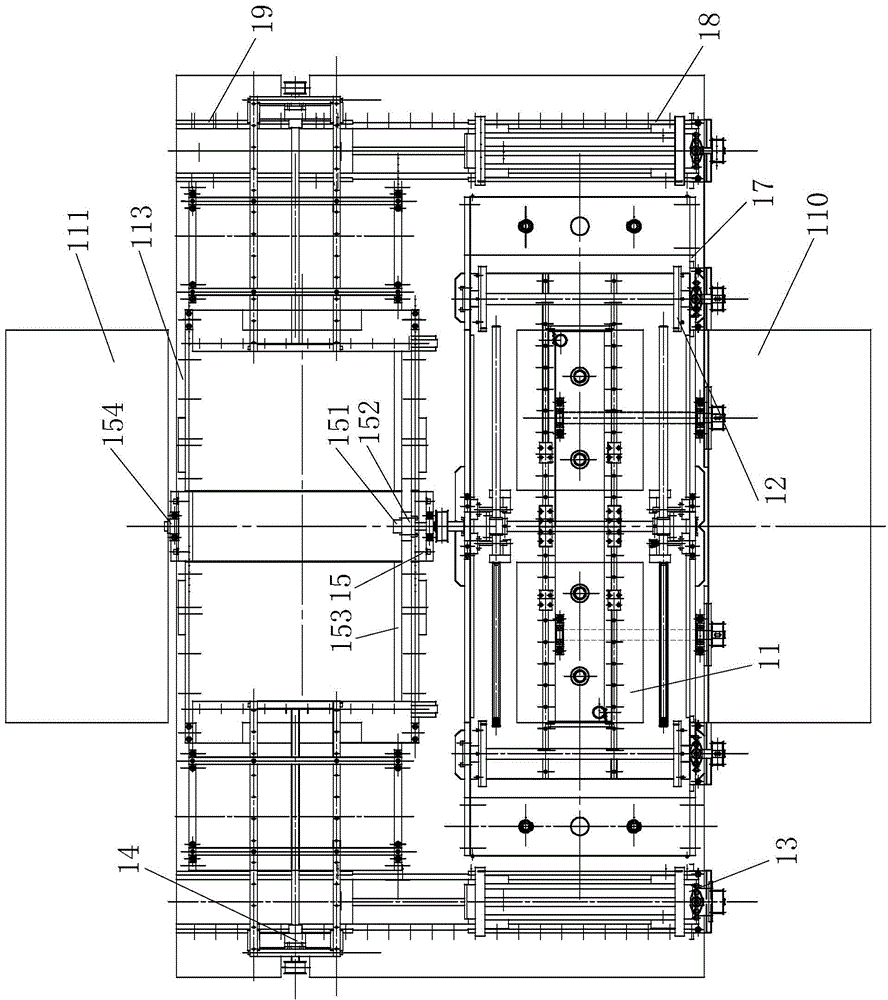

[0050] Example: such as figure 1 , figure 2 As shown, the present invention comprises a platform machine 6, an automatic machine 7, an oiler 8, a glue dipping machine 9, a waste suction system 10, an upper drying tunnel 4, a lower drying tunnel 3, a tail platform and a main control system. On the road 3, the air supply duct 116 and the return air duct 5 are arranged at intervals, and two coating machines are also arranged at intervals on the lower drying tunnel 3. The first coating machine 1 is arranged at the front end of the tail platform, and the first coating machine 1 is arranged at the front end of the tail platform. Two coating machines 1 ' are arranged between the first coating machine 1 and the platform machine 6, and the two coating machines are placed in the isolation room 2 respectively, and the isolation room 2 is connected with a vacuum device to prevent coating The coating liquid granule volatilizes and explodes in the room, and the isolation room 2 has an ent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com