Waste recovery robot

A robot and scrap technology, applied in the direction of manipulators, road cleaning, manufacturing tools, etc., can solve the problems of not suitable for square cleaning, high noise, high cost, etc., achieve the effect of simple and effective grasping mechanism and cleaning mechanism, and improve work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

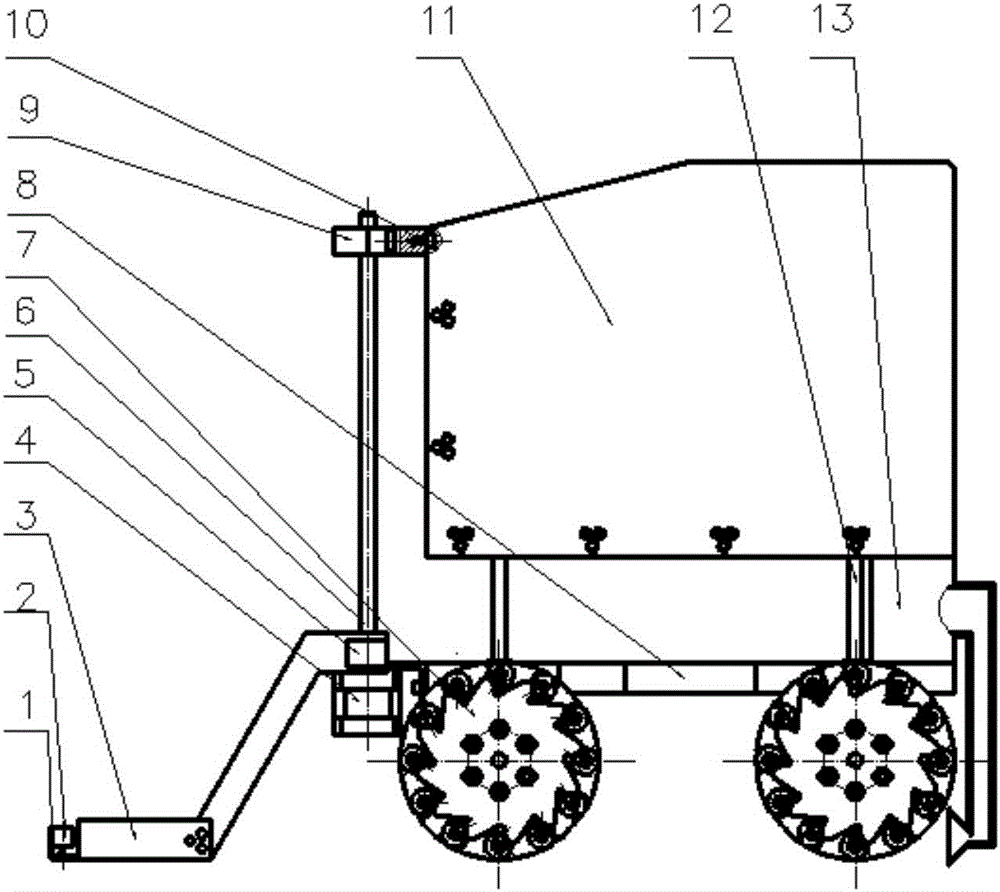

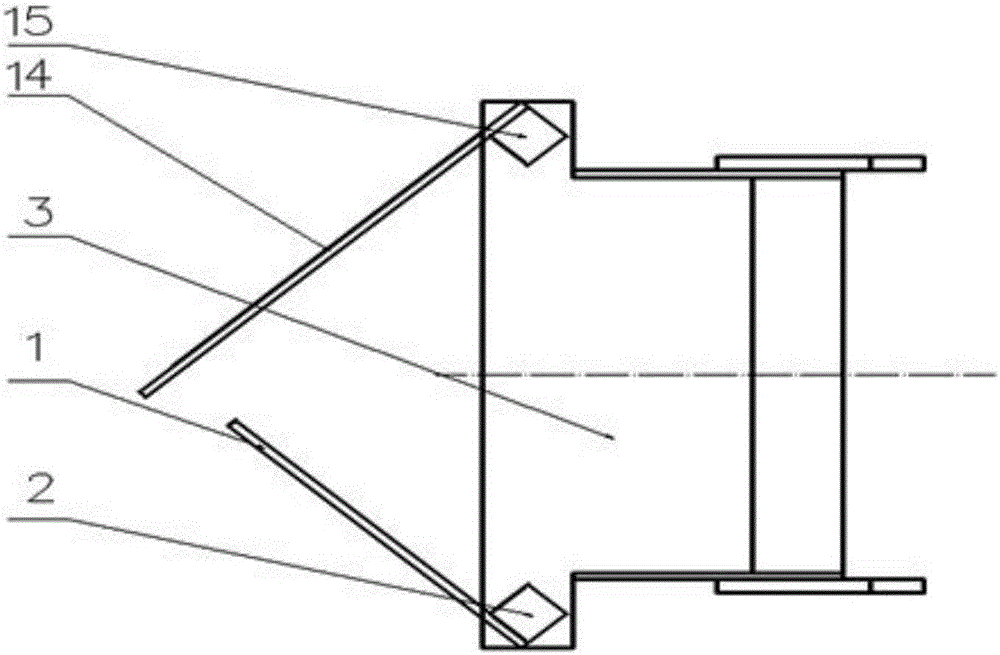

[0038] Such as figure 1 As shown, a waste recycling robot includes a cleaning mechanism, a body mechanism and a walking mechanism;

[0039] Described vehicle body structure comprises dustbin 11 and chassis 8, and described dustbin 11 is supported below described chassis 8 by support rod 12; Described running mechanism comprises wheel coupling and four wheels 7, and described four wheels 7 are respectively symmetrically installed on both sides of the chassis 8 through the wheel couplings to drive the body mechanism to walk, and the top of the dustbin 11 is provided with an opening;

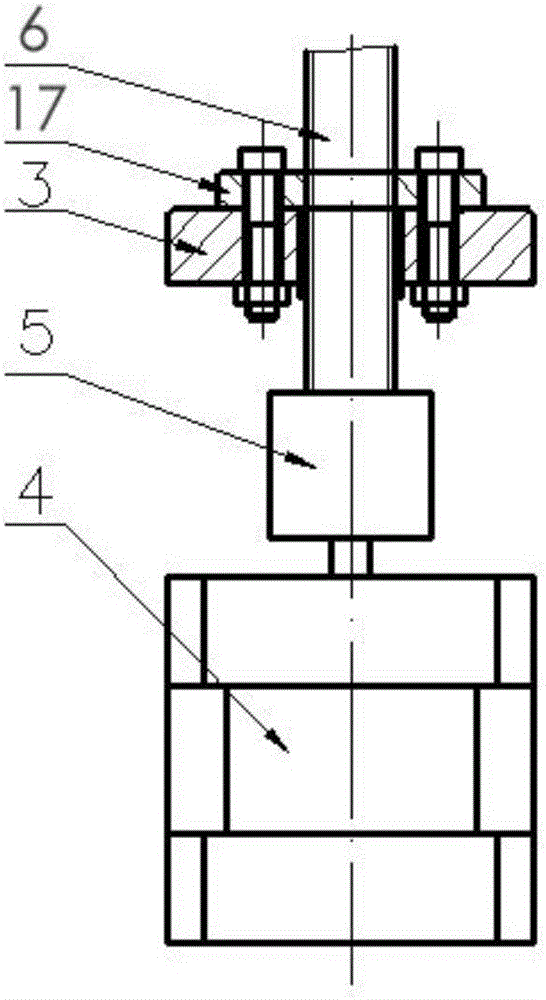

[0040] The cleaning mechanism includes a screw mandrel 6, a dust suction device 13 for sucking paper scraps and a grabbing device for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com