Diaphragm-type pneumatic proportional pressure reducing valve of ball screw driven by servo motor directly

A servo motor and ball screw technology, applied in valve details, safety valves, balance valves, etc., can solve the problems of insensitivity, poor dynamic and static performance, and low performance, and achieve the effect of high transmission efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

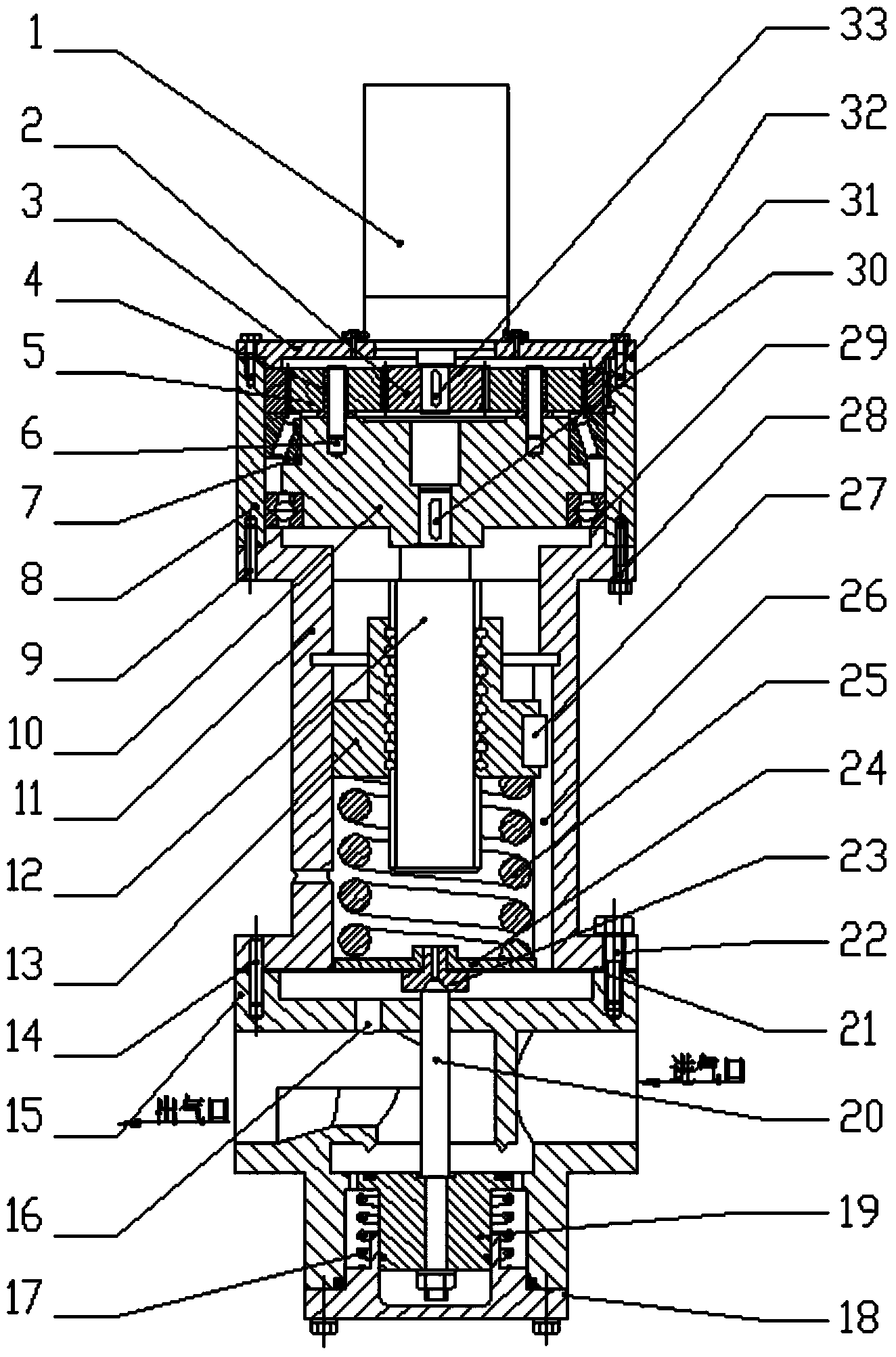

[0011] The present invention will be further described in detail below in conjunction with the accompanying drawings.

[0012] Referring to the accompanying drawings, a diaphragm type pneumatic proportional pressure reducing valve directly driven by a servo motor includes a housing 8, the servo motor 1 is fixed on the upper end cover 3 connected to the top of the housing 8, and the output shaft of the servo motor 1 is connected to the planetary deceleration The sun gear 2 of the planetary reducer is fitted with a gap through the first key 33, and the planetary gear 5 of the planetary reducer is connected with the transmission block 10 through the bushing 4 and the pin shaft 6 to drive the transmission block 10 to rotate. The outer ring and the inner ring of the tapered roller bearing 7 Positioned by the ring gear 32 and the transmission block 10 respectively, the outer ring and the inner ring of the deep groove ball bearing 29 are respectively positioned by the upper valve body...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com