Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

47results about How to "Real-time monitoring of wear and tear" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

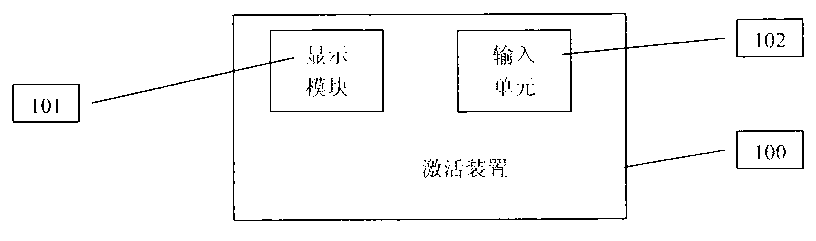

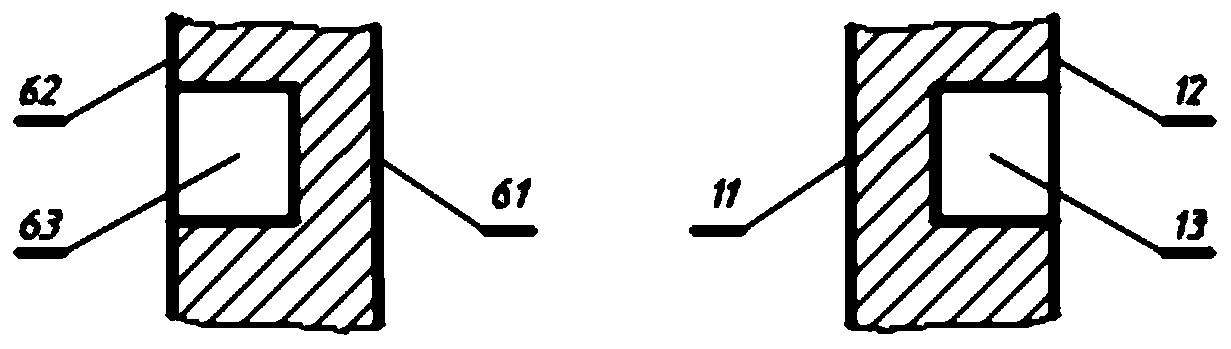

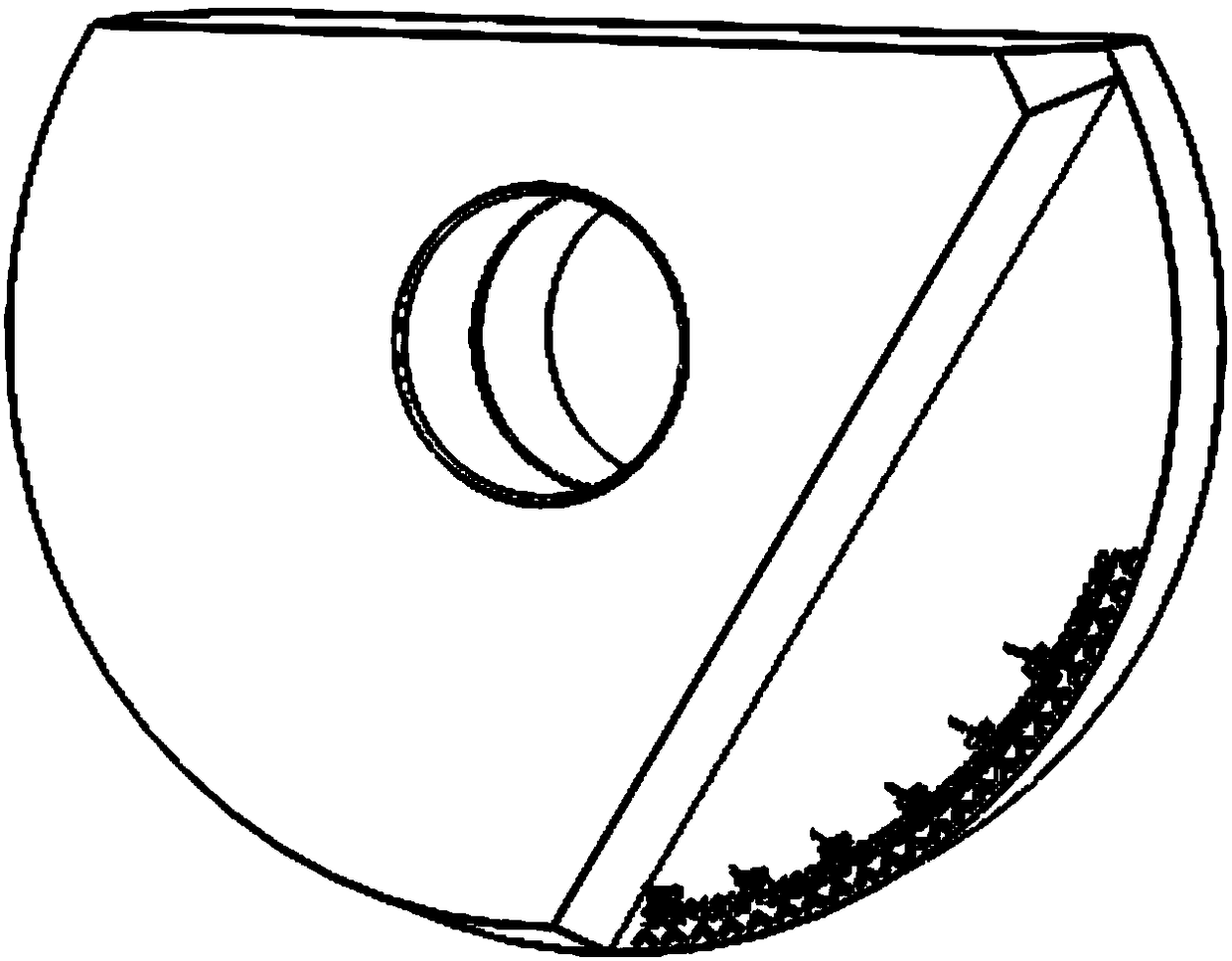

System for detecting wearing of tire based on electronic tag, and detection method thereof

InactiveCN103057361AReal-time monitoring of wear and tearImprove securitySensing record carriersTyre measurementsEngineeringBiological activation

The invention provides a system for detecting the wearing of a tire based on an electronic tag. The system comprises an activation device, a reading device, a storing device and a determining device. The determining device compares the electronic tag wearing data sent from the reading device with the electronic tag base data stored in the storing device to determine the wearing degree of the tire surface of the tire. The invention also discloses a method for detecting the wearing of the tire based on the electronic tag. The system and the method can momentarily detect the wearing condition of the tire having the electronic tag without the static state of a vehicle provided with the tire; and the determining device can determine the wearing condition of the tire in real time, pre-estimate the residual life of the tire and prompt the tire replacement, and is safe and reliable.

Owner:毕雪松

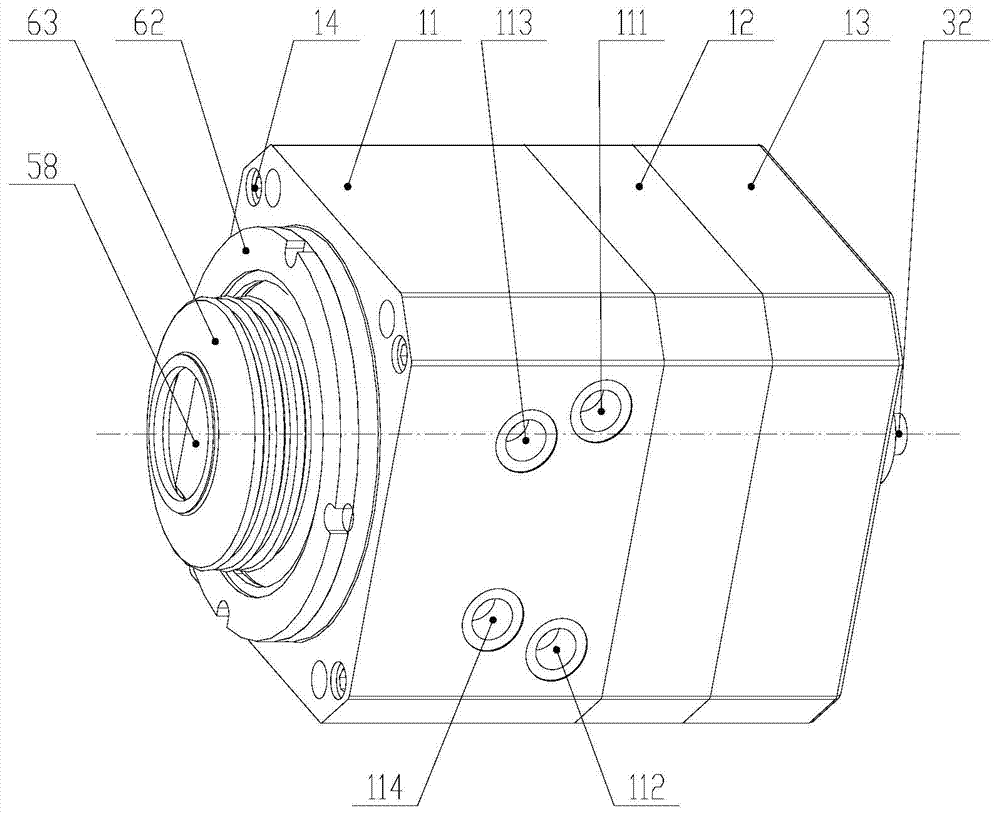

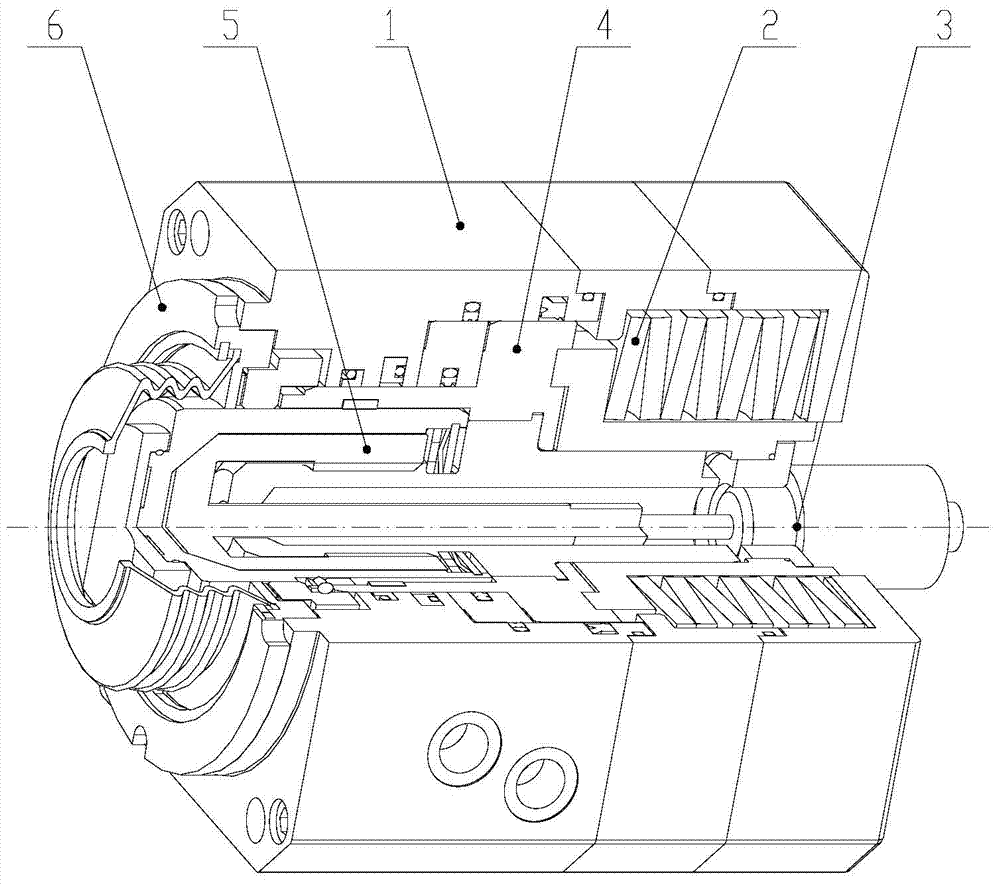

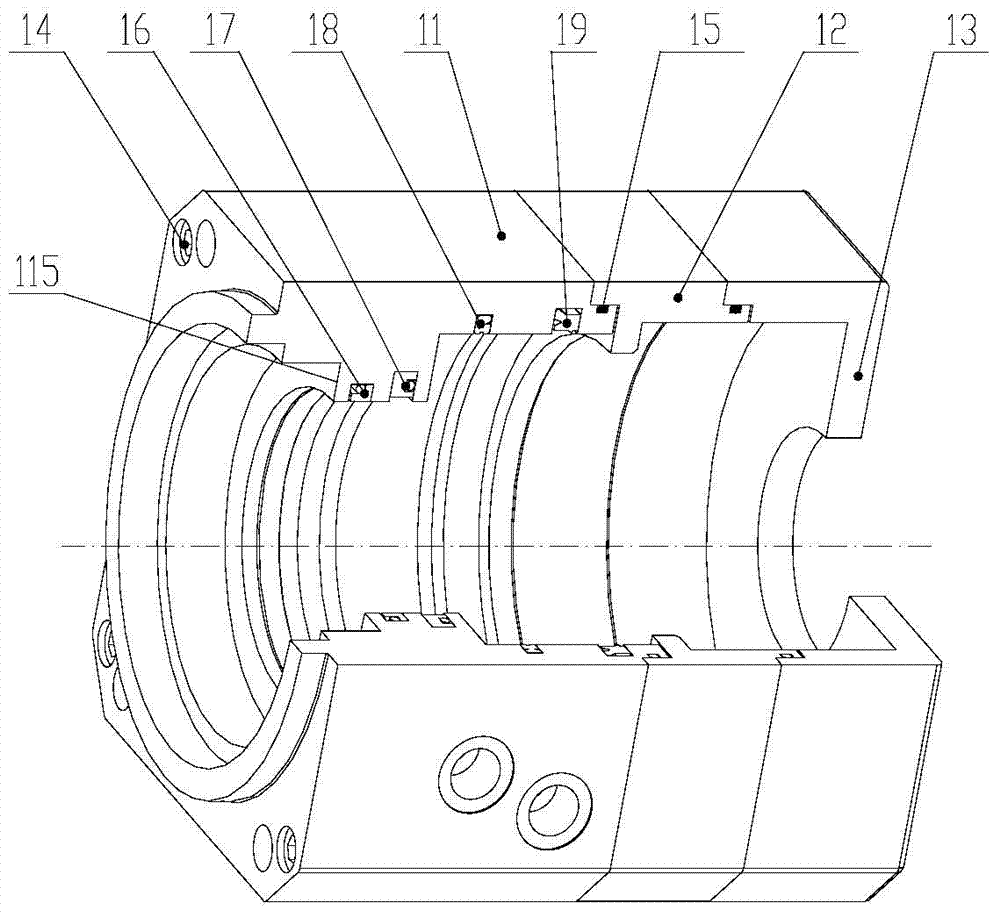

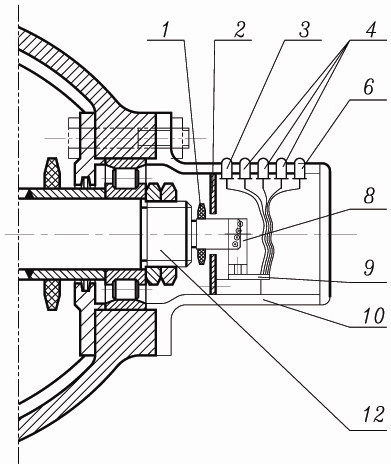

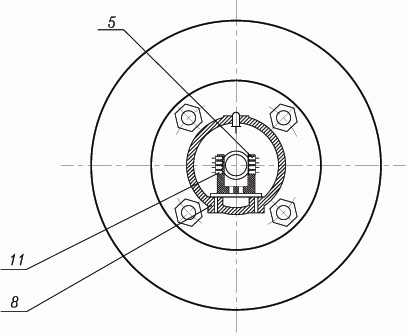

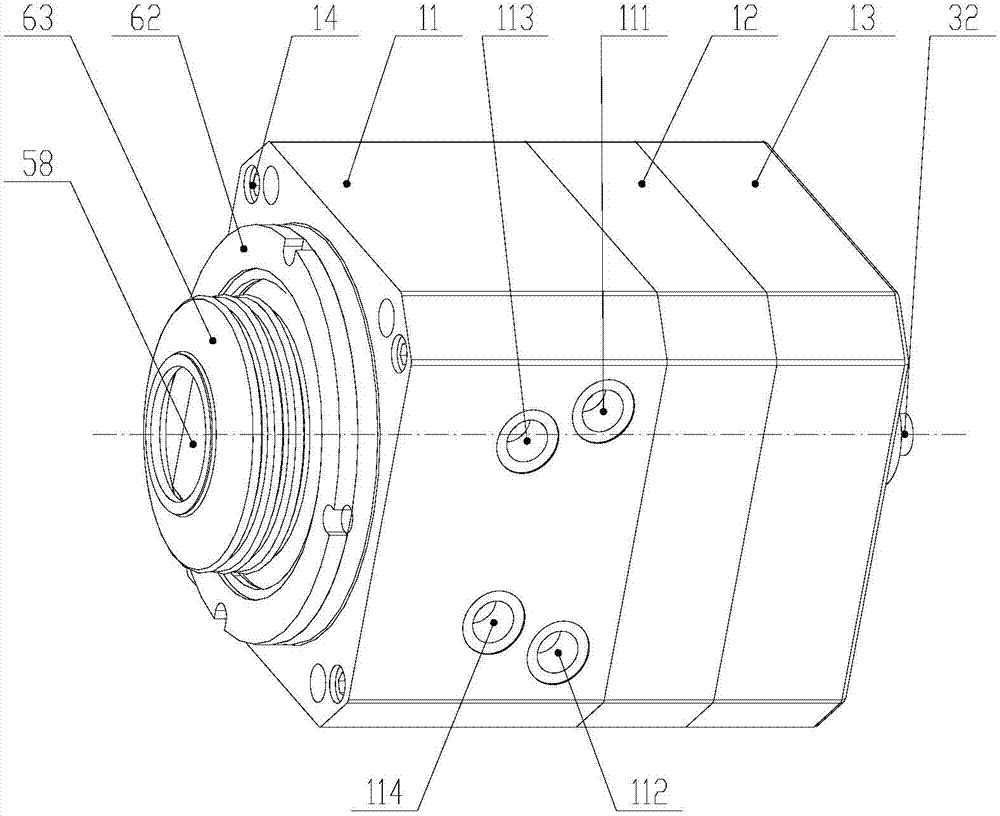

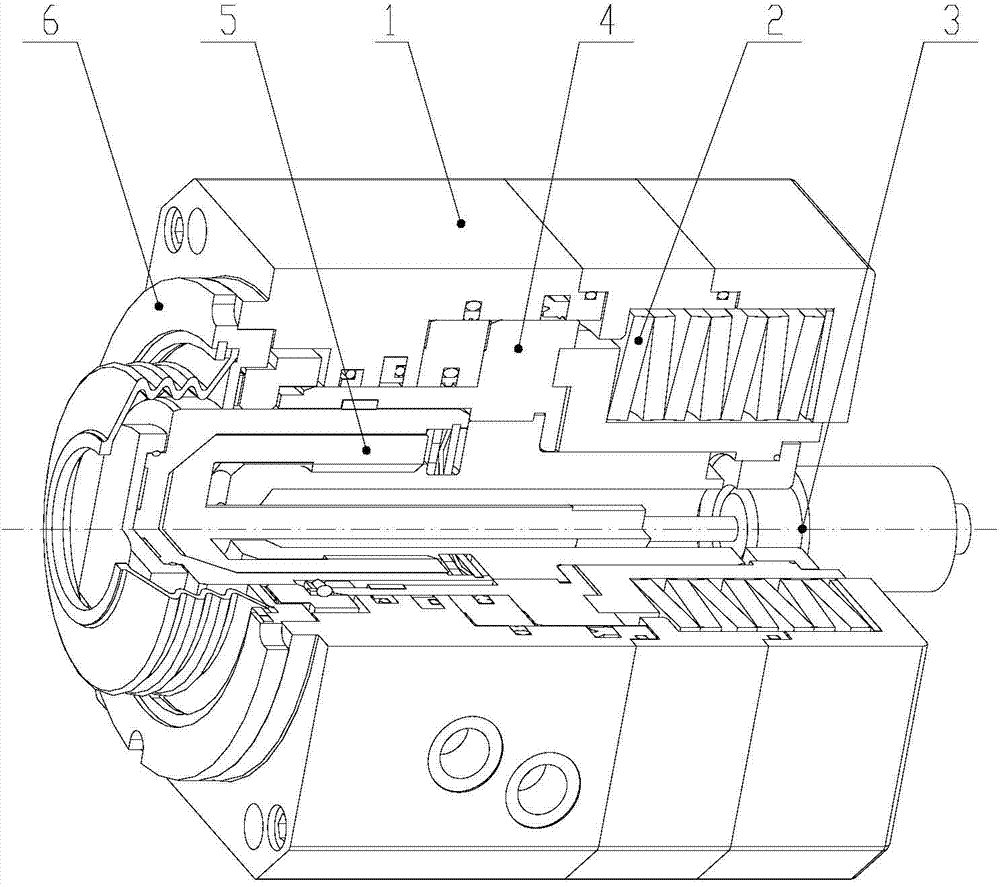

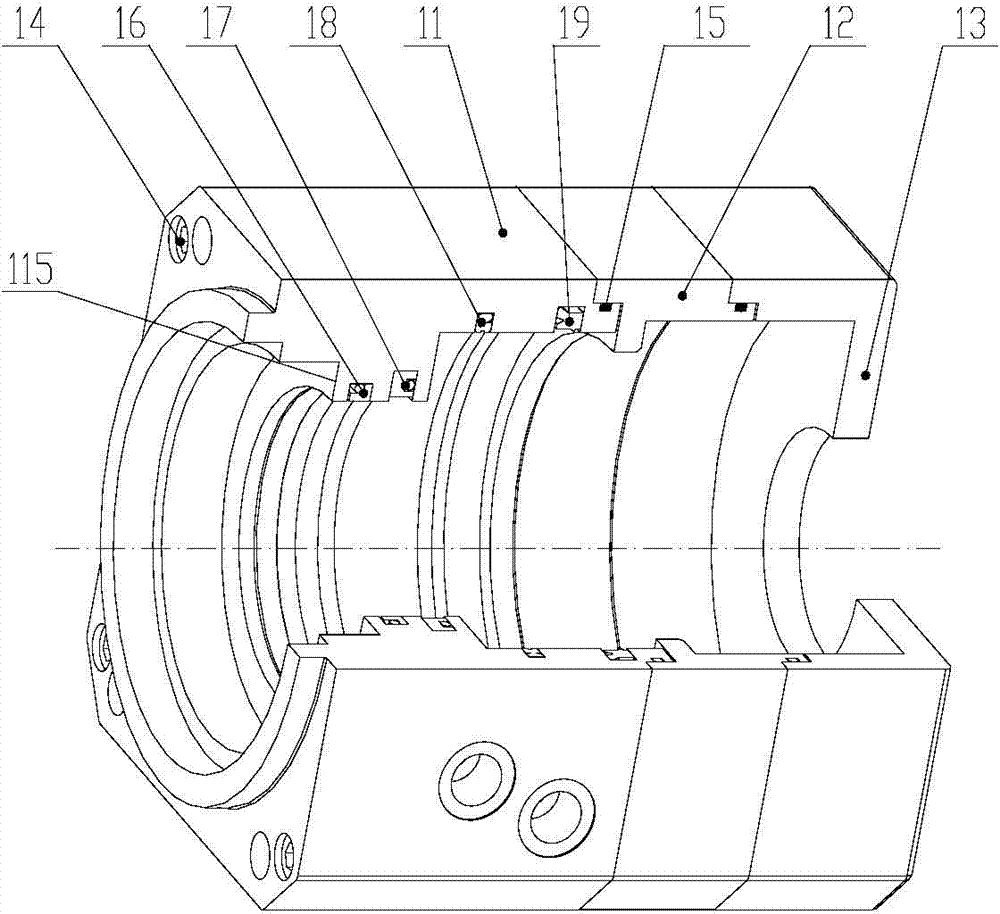

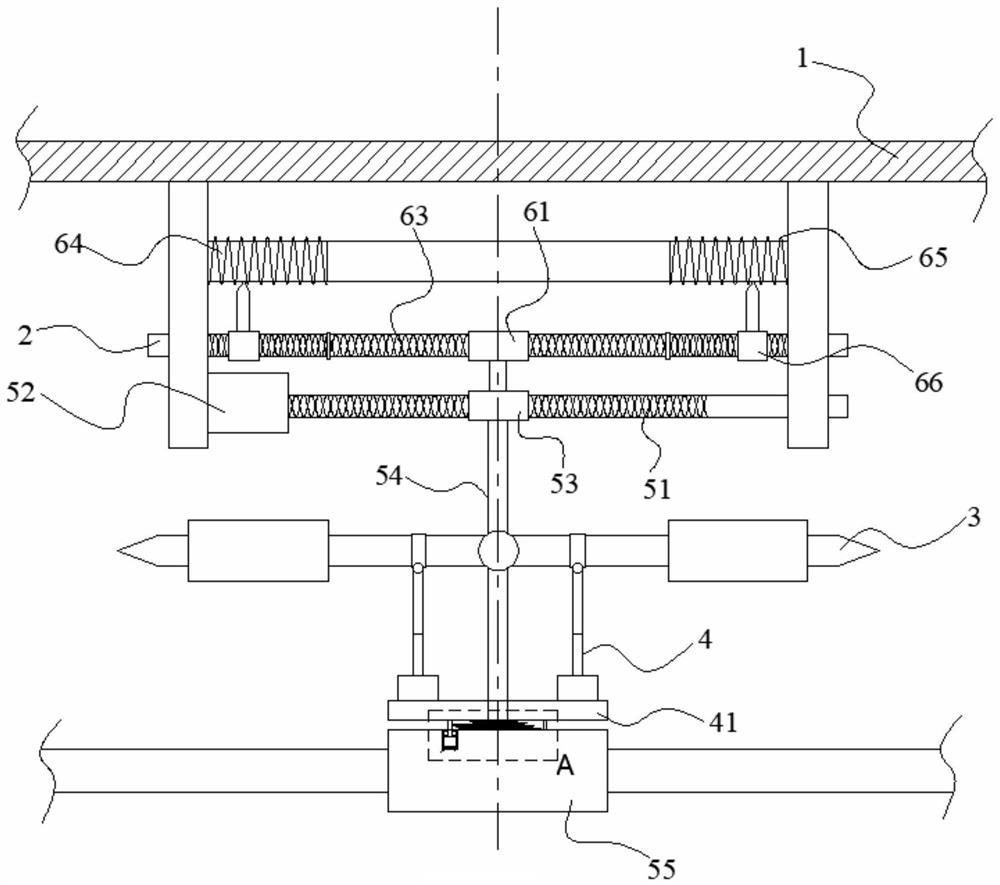

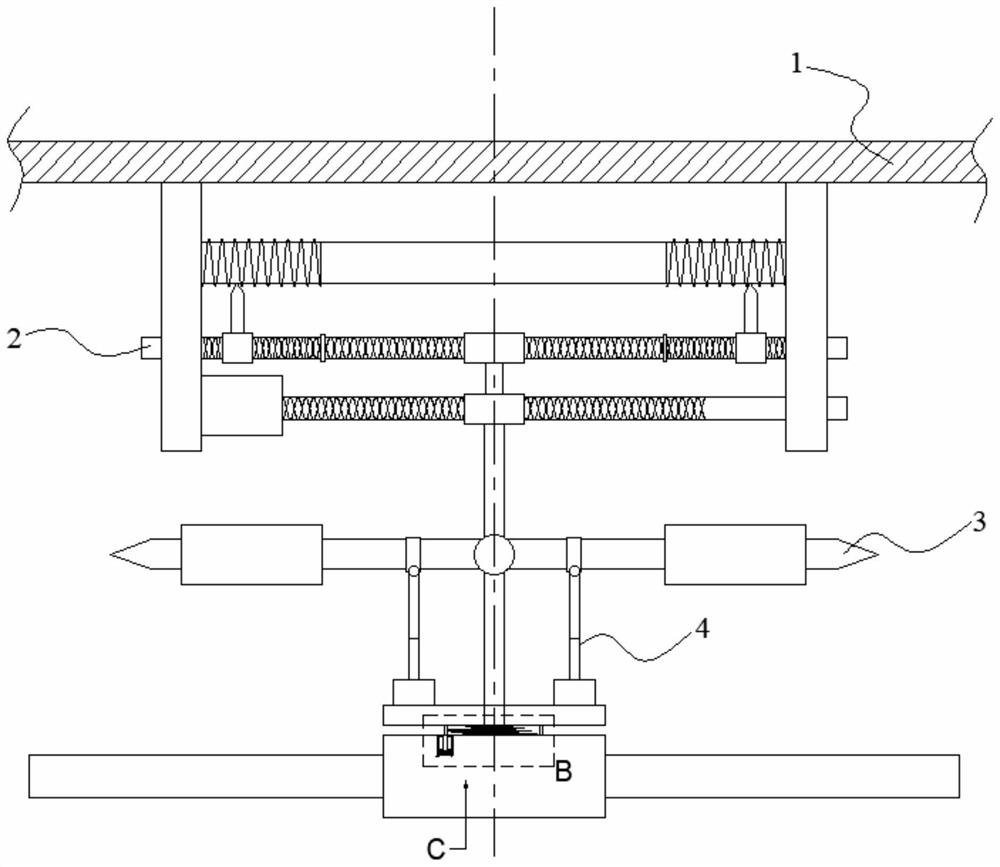

Brake cylinder of hydraulic brake device of railway vehicle

ActiveCN103486171AReal-time monitoring of working statusWith wear monitoring functionBrake actuating mechanismsSlack adjustersEngineeringMechanical engineering

The invention discloses a brake cylinder of a hydraulic brake device of a railway vehicle. The brake cylinder comprises a shell component, a disk spring assembly, an indicator assembly, a piston assembly, a push rod assembly and an end cover assembly. The push rod assembly, the piston assembly, the disk spring assembly and the indicator assembly are sequentially installed in a cylindrical hole inside the shell component from front to back, wherein the cylindrical hole is provided with a step, and the axis of the push rod assembly, the axis of the piston assembly, the axis of the disk spring assembly, and the axis of the indicator assembly are the same as the main axis of the shell component. The end cover assembly is installed on the cylindrical step at the front end of the shell component, and the axis of the end cover assembly is the same as the main axis of the shell component. Brake clearances can be automatically compensated by multiple threads. Compared with an existing brake cylinder, the brake cylinder is simple in structure, convenient to machine and assemble, few in movable parts, and high in reliability, has the friction plate and brake disc abrasion monitoring function and the automatic compensation mechanism running real-time monitoring function, and can remotely monitor the working state of the brake cylinder in real time. Manual brake loosening and adjustment can be achieved on the scene through a manual mechanical brake loosening device, and operation is conveniently and quickly conducted.

Owner:DALIAN HUARUI HEAVY IND GRP CO LTD

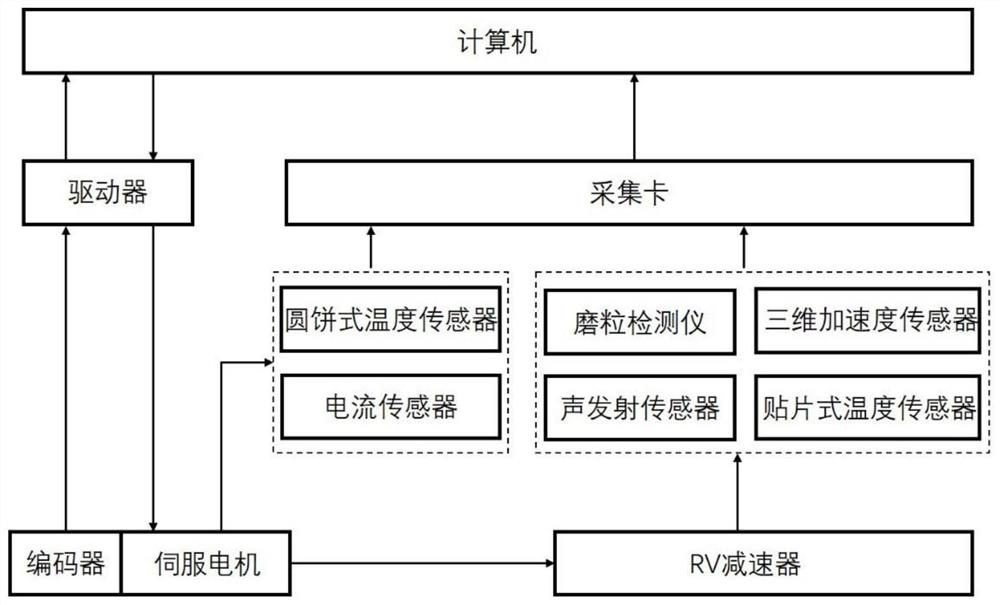

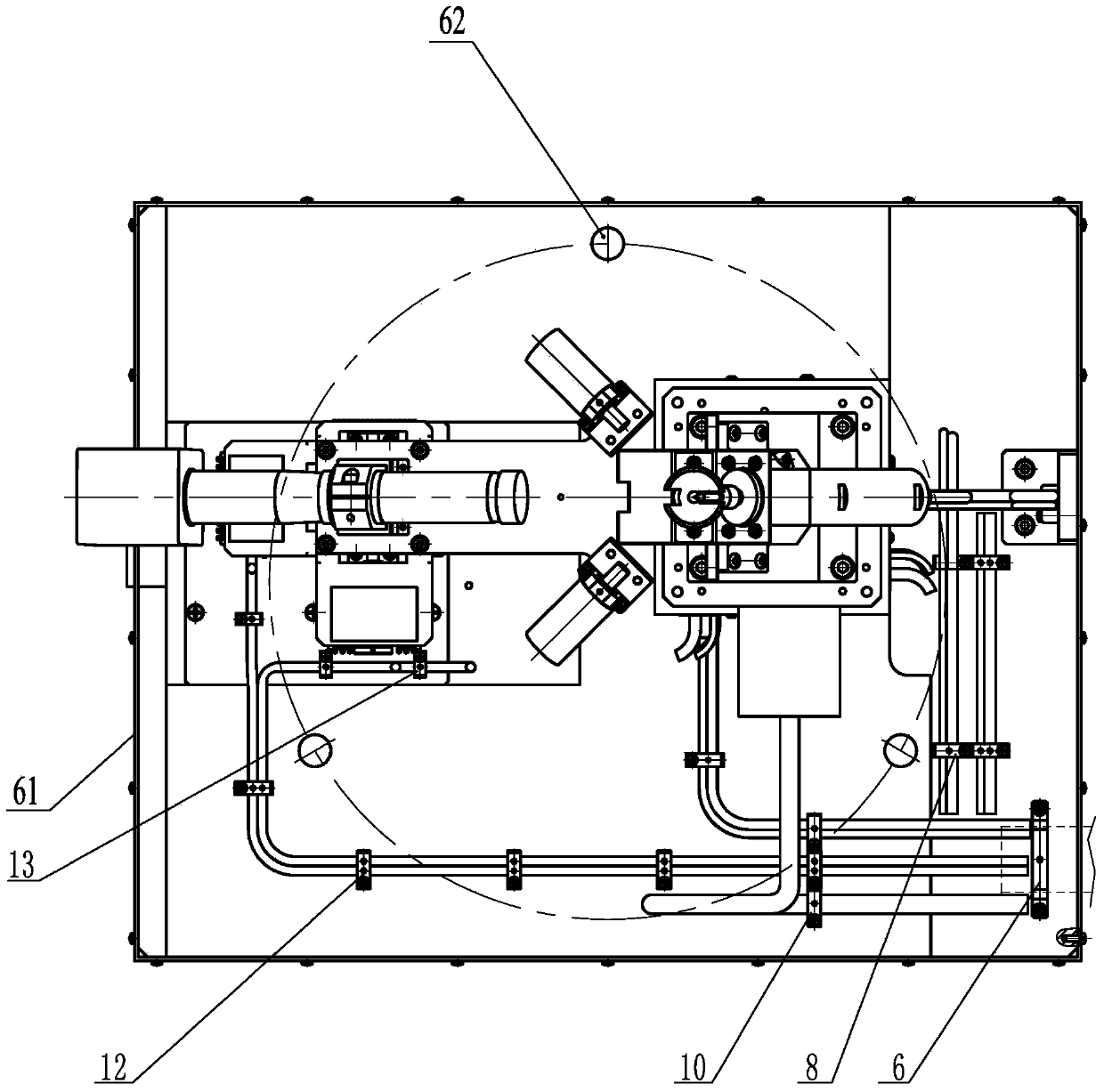

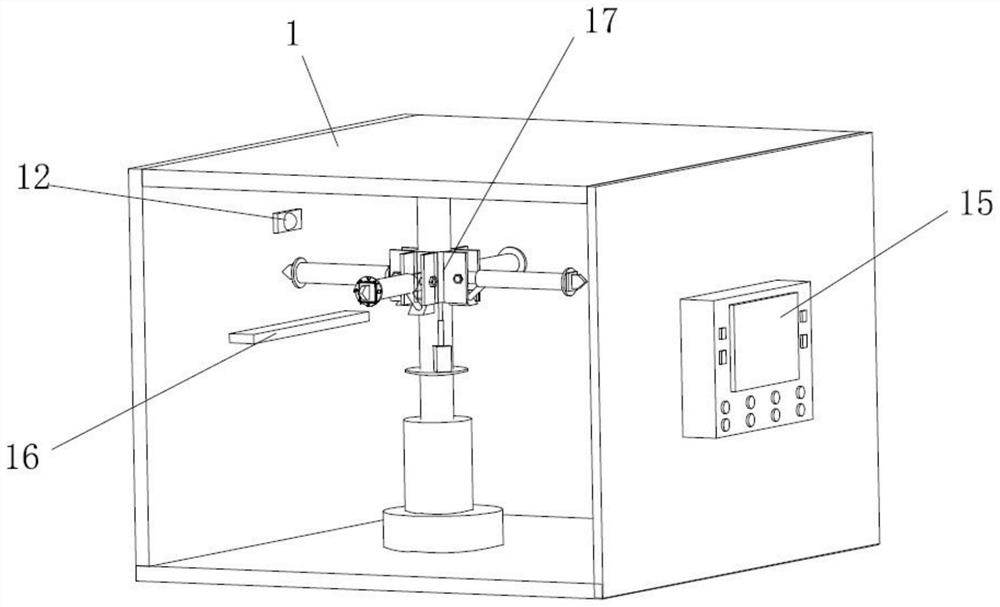

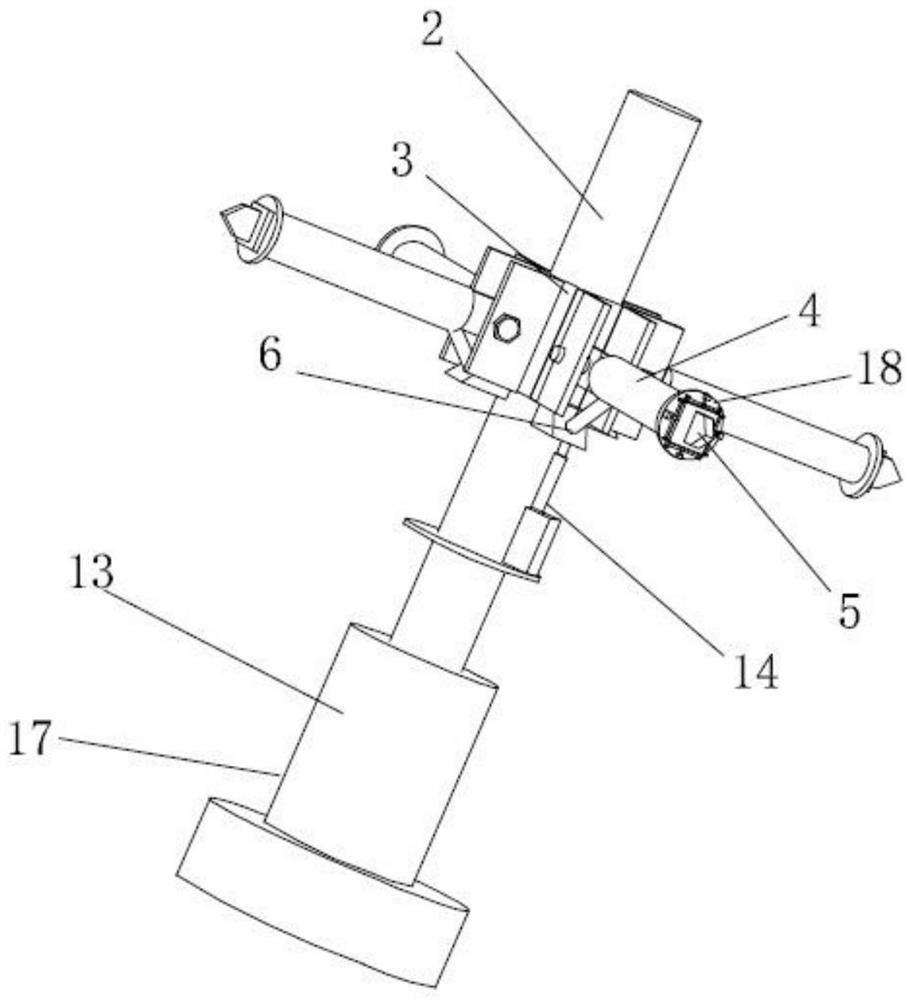

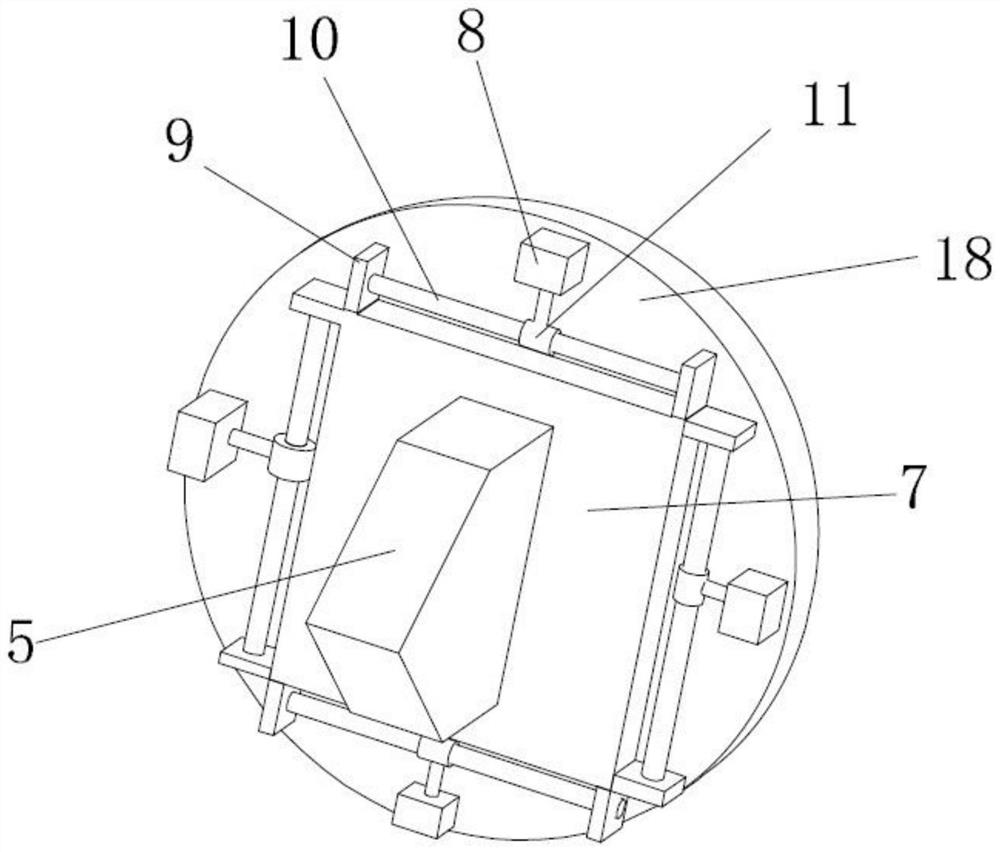

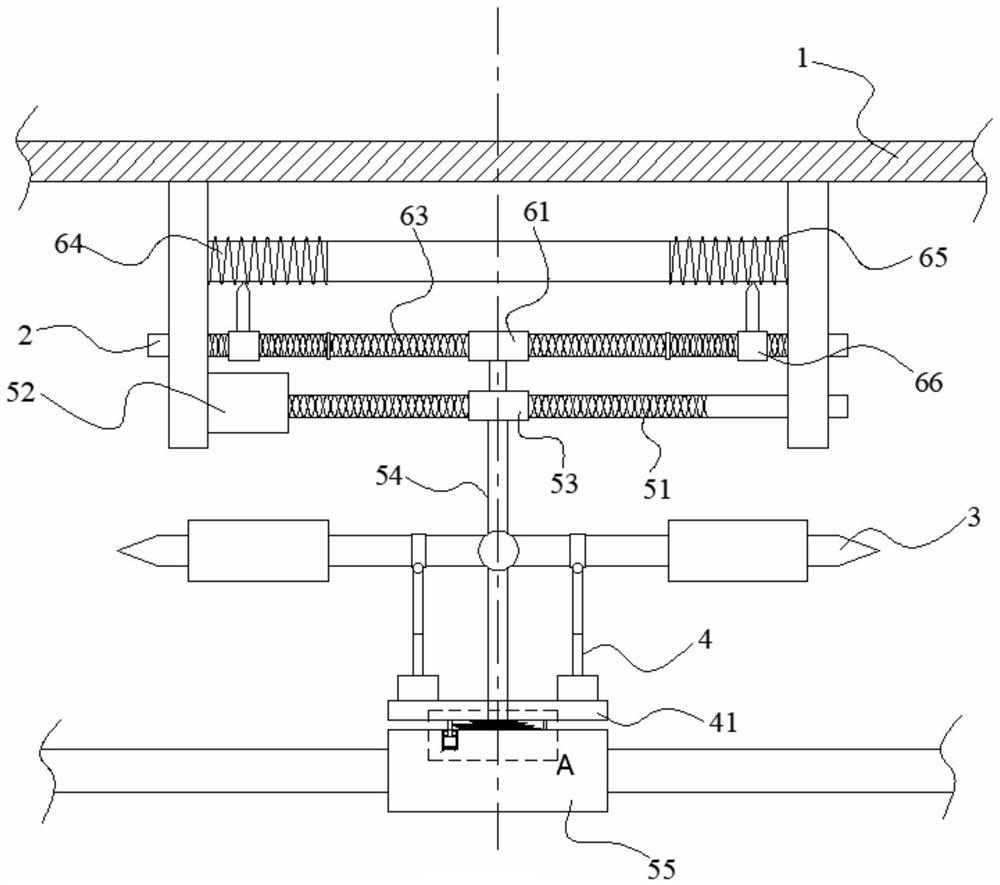

RV speed reducer performance testing device based on multi-sensor fusion

InactiveCN111795817AReduce processing difficultyReduce installation difficultyMachine gearing/transmission testingElectric machineryProcess engineering

The invention discloses an RV speed reducer performance testing device based on multi-sensor fusion. The device comprises a T-shaped groove bottom plate; an RV speed reducer is fixed to the T-shaped groove bottom plate through a speed reducer support; the RV speed reducer is connected with a servo motor through a motor flange; an output shaft of the servo motor is coaxially connected with an inputshaft of the RV speed reducer; an output shaft of the RV speed reducer is connected with the bottom end of a swing arm; a plurality of round holes are formed in the swing arm; the upper end of the swing arm is connected with a mass block; a communicated cavity is formed among the motor flange, the RV speed reducer and the swing arm, and the cavity is filled with a lubricating medium; an oil inlethole is formed in the motor flange; an oil outlet hole is formed in the swing arm; the oil inlet hole and the oil outlet hole are connected with the abrasive particle analyzer through oil pipes; an acoustic emission sensor is arranged beside the RV speed reducer; and a three-dimensional acceleration sensor and a patch type temperature sensor are mounted on the RV speed reducer. Omnibearing tracking detection can be performed on the state of the RV speed reducer in the whole life cycle, the abrasion state of the RV speed reducer is quantitatively evaluated in real time, and the performance ofthe RV speed reducer is comprehensively reflected.

Owner:XI AN JIAOTONG UNIV

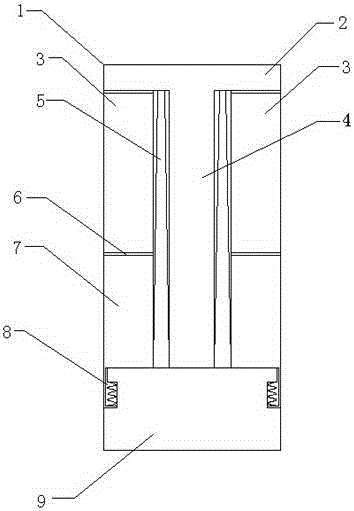

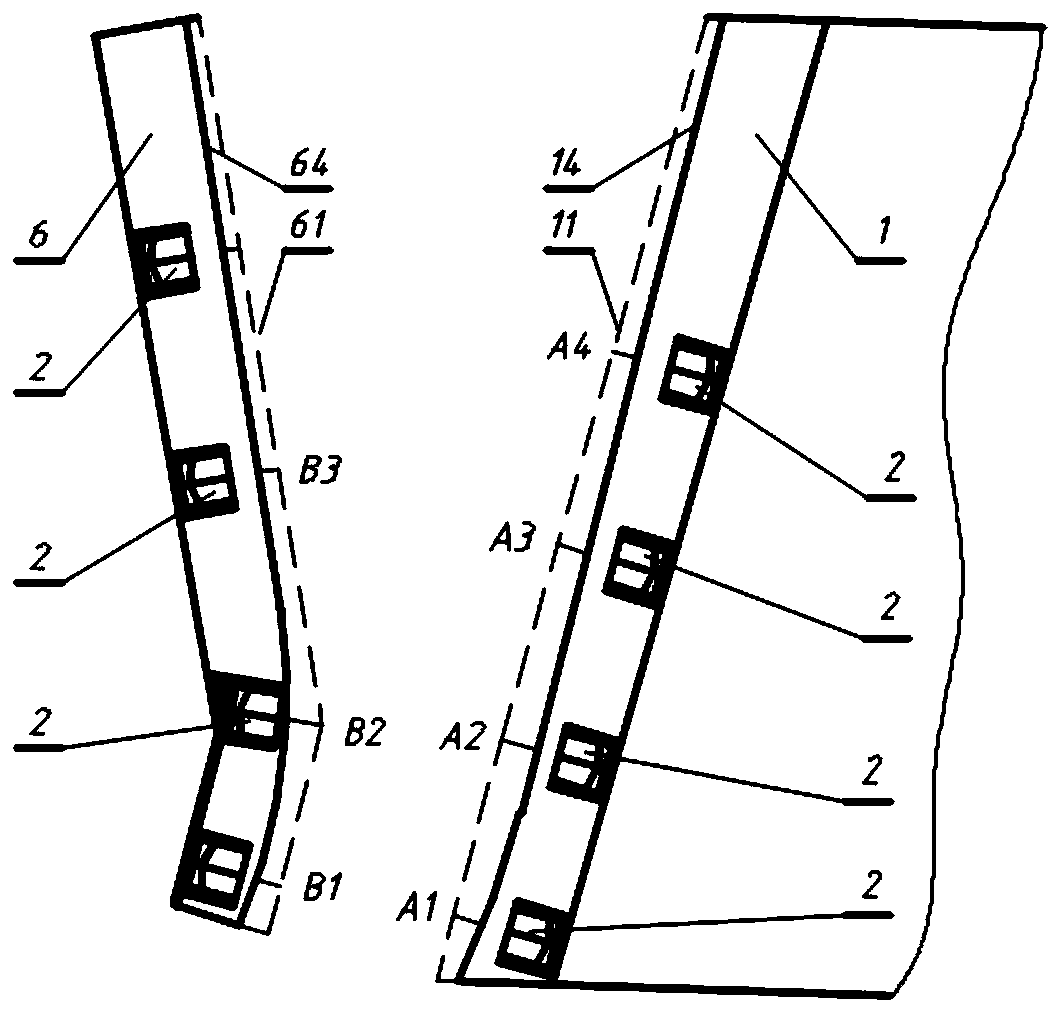

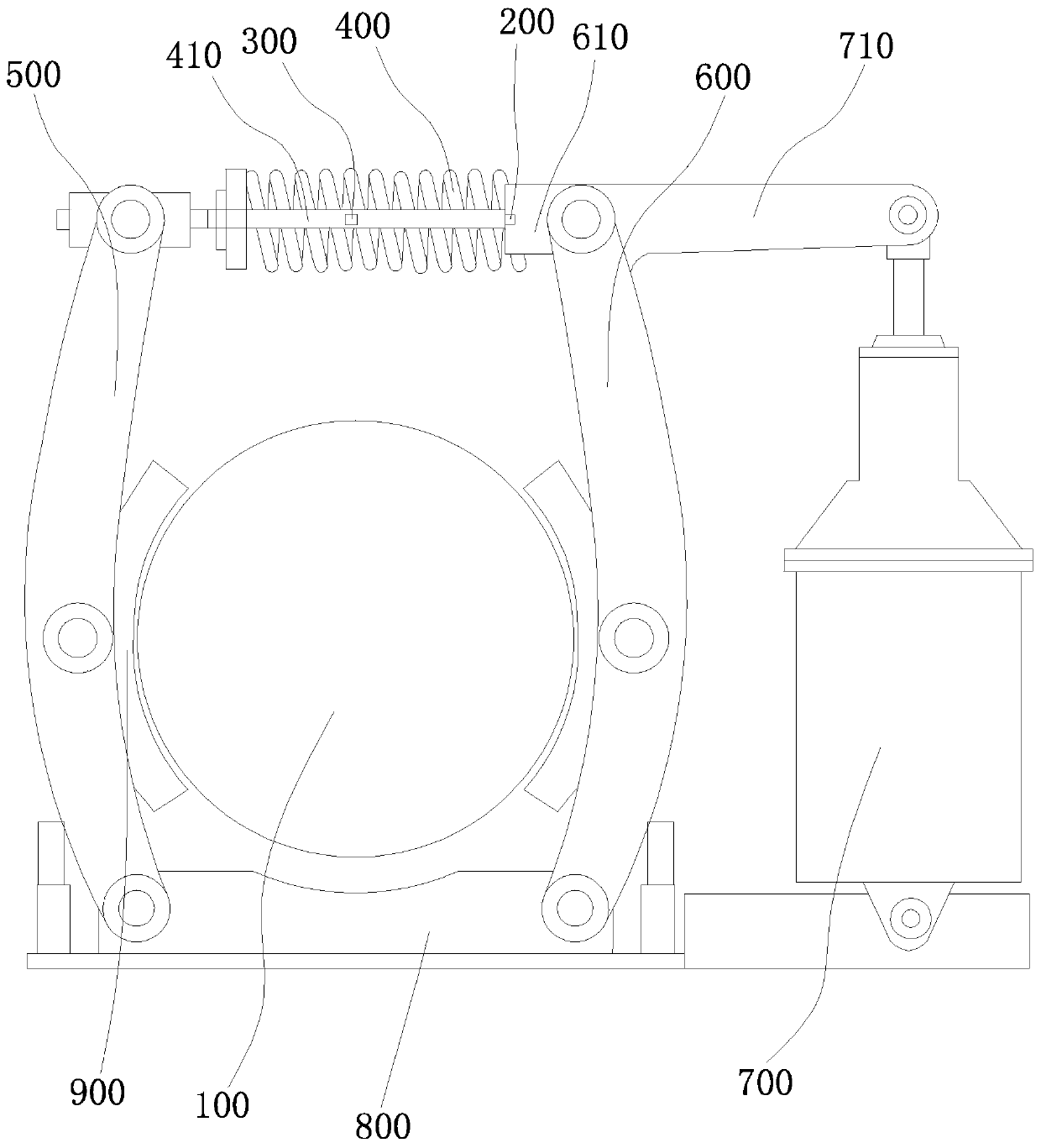

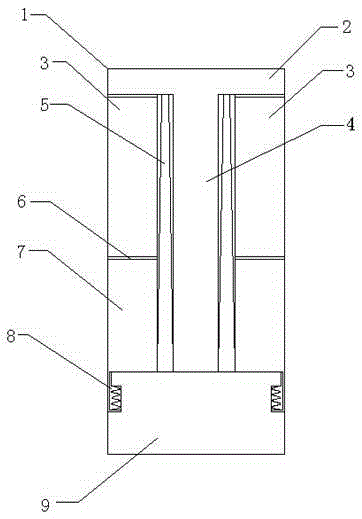

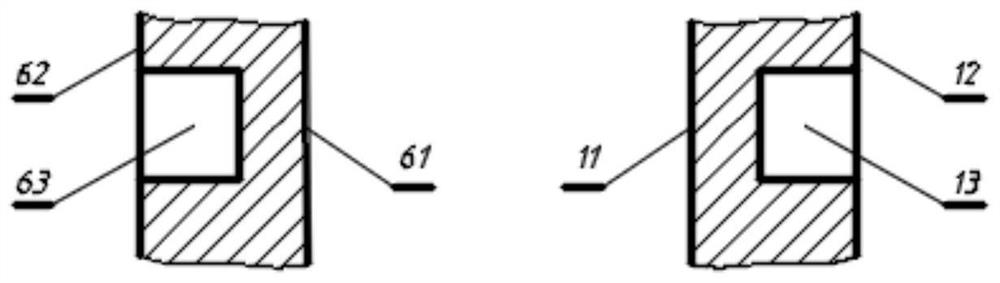

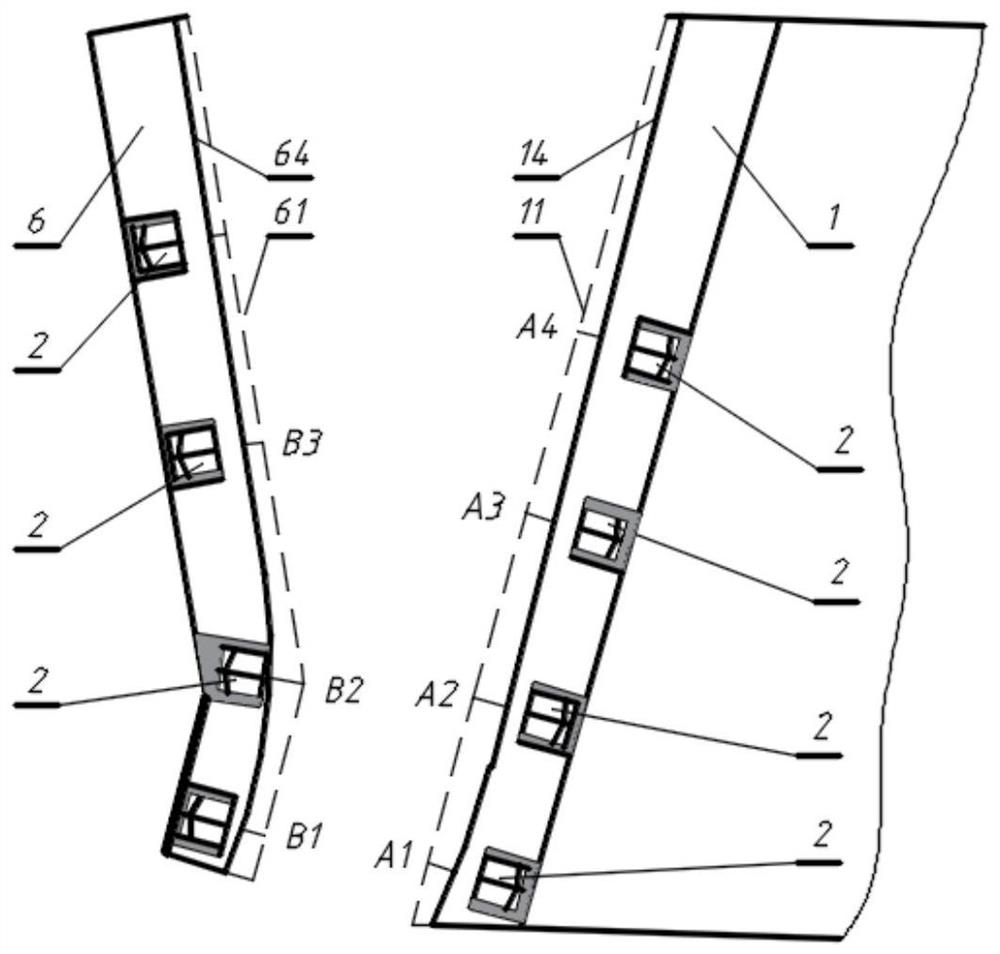

Brake block assembly used on brake and automatic detection system of brake block assembly

InactiveCN105333042ACombination structure is simple and feasibleEasy to assemble and disassembleBrake actuating mechanismsFriction liningControl engineeringStructural engineering

The invention discloses a brake block assembly used on a brake. A base frame is arranged in the brake block assembly. The base frame comprises an upper portion, a middle portion and a lower portion. Grooves are formed in the two edges of the upper portion of the base frame. Sliding guide grooves are formed in the inner walls of the two sides of each groove. Sliding blocks are installed in the grooves. The sliding blocks and the grooves are slidably connected through the sliding guide grooves. A brake block is connected to the lower portion of the base frame. Two push rods are arranged in the brake block. The brake block is elastically connected with the base frame through springs. The brake block assembly used on the brake is simple in structure, convenient to disassemble and assemble, stable and reliable in work, capable of achieving single-side braking and double-side braking, more sensitive in response, high in braking speed, and capable of achieving brake relief automatically. The invention further provides an automatic detection system and method of the brake block assembly used on the brake. By the adoption of the automatic detection system and method of the brake block assembly used on the brake, the temperature and the abrasion degree of the brake block can be monitored in real time in the traveling process of a vehicle, an alarm is given when detection data are abnormal, and the situation of brake failures is effectively avoided.

Owner:CHENGDU 90 DEGREE IND PROD DESIGN CO LTD

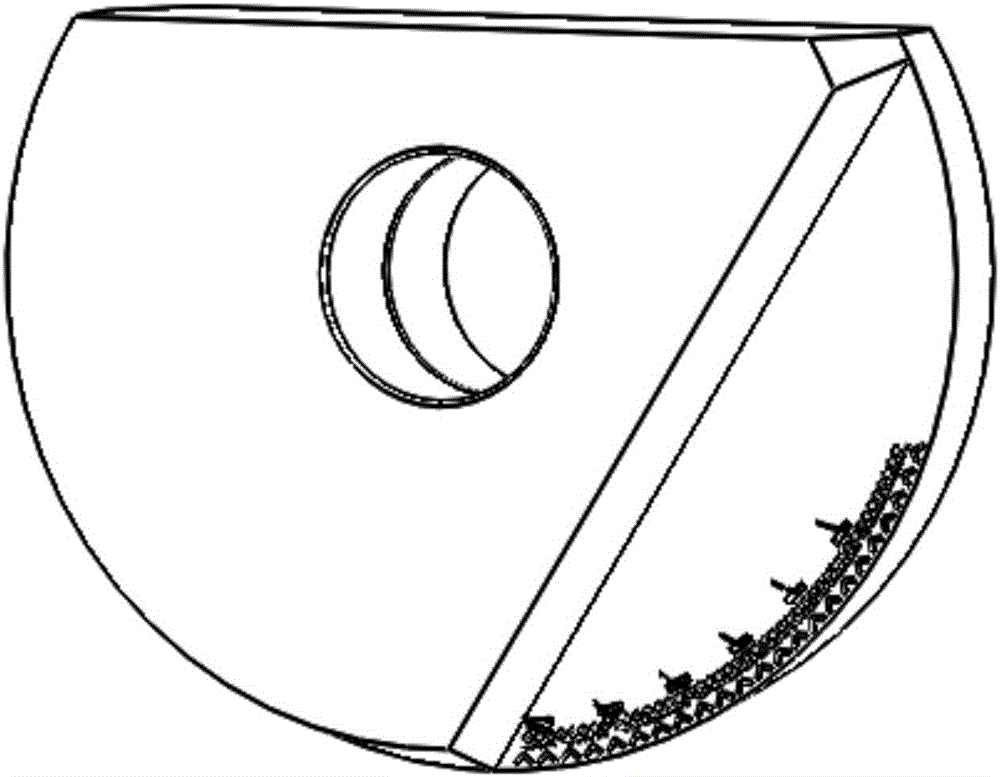

Abrasion monitoring method and structure for crushing cavity

ActiveCN110142084AMeet the measurement requirementsReal-time monitoring of wear and tearTesting/monitoring control systemsGrain treatmentsWorking lifeEngineering

The embodimentof the invention provides an abrasion monitoring method for a crushing cavity, and belongs to the technical field of monitoring of the operating state of crushing equipment. The abrasionmonitoring method for the crushing cavity comprises the steps that feedback signals having cavity characteristics of the crushing cavity and acquired on all detection nodes located at different positions of the crushing cavity are acquired, and the next step is conducted when the feedback signal meets a first preset monitoring condition; the current detection node is selected, local cavity characteristics of the crushing cavity are determined according to intra-node characteristics between the current detection node and the adjacent detection node, the feedback signal of the current detectionnode and the feedback signal of the adjacent detection node; and when the local cavity characteristics meet a second preset monitoring condition, the second step is conducted again, so that a cyclicmonitoring process is formed. According to the abrasion monitoring method for the crushing cavity, the abrasion condition of a lining plate and the structural shape changes of the crushing cavity aremonitored according to the characteristics at detection points and the local characteristics of the current detection position, the working life of the lining plate can be predicted, and conditions are created for reasonable planning of operation and maintenance of a crushing machine.

Owner:JIANGXI UNIV OF SCI & TECH

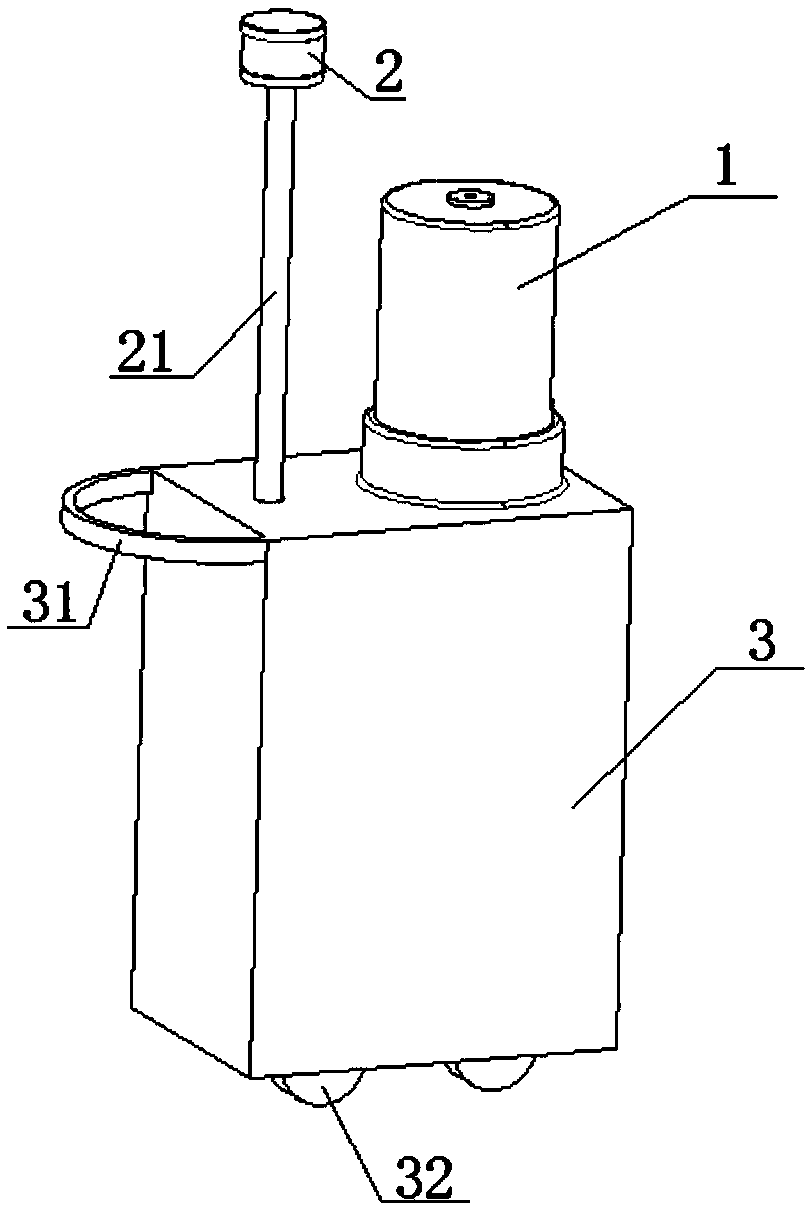

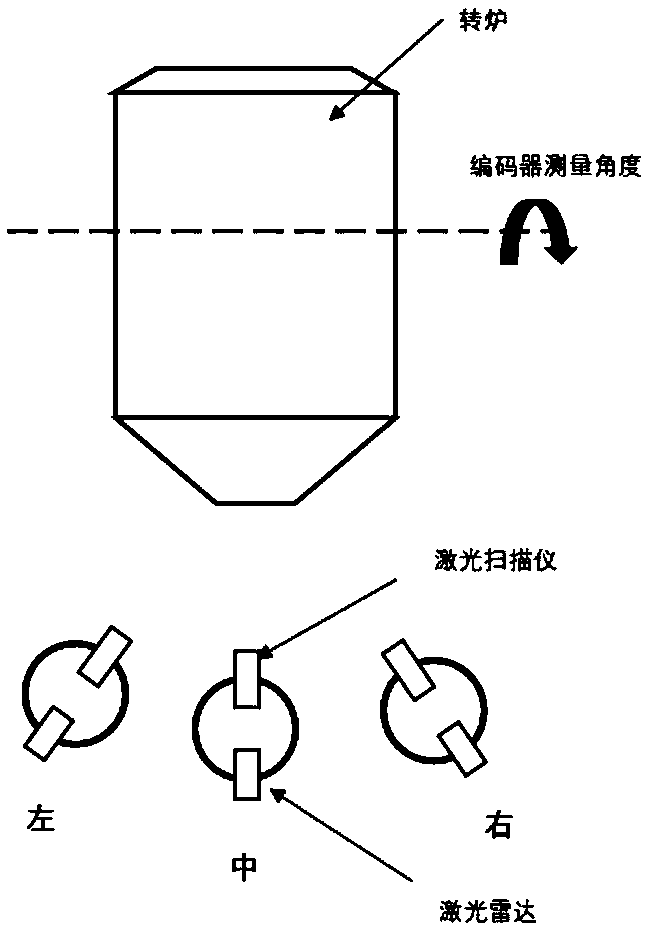

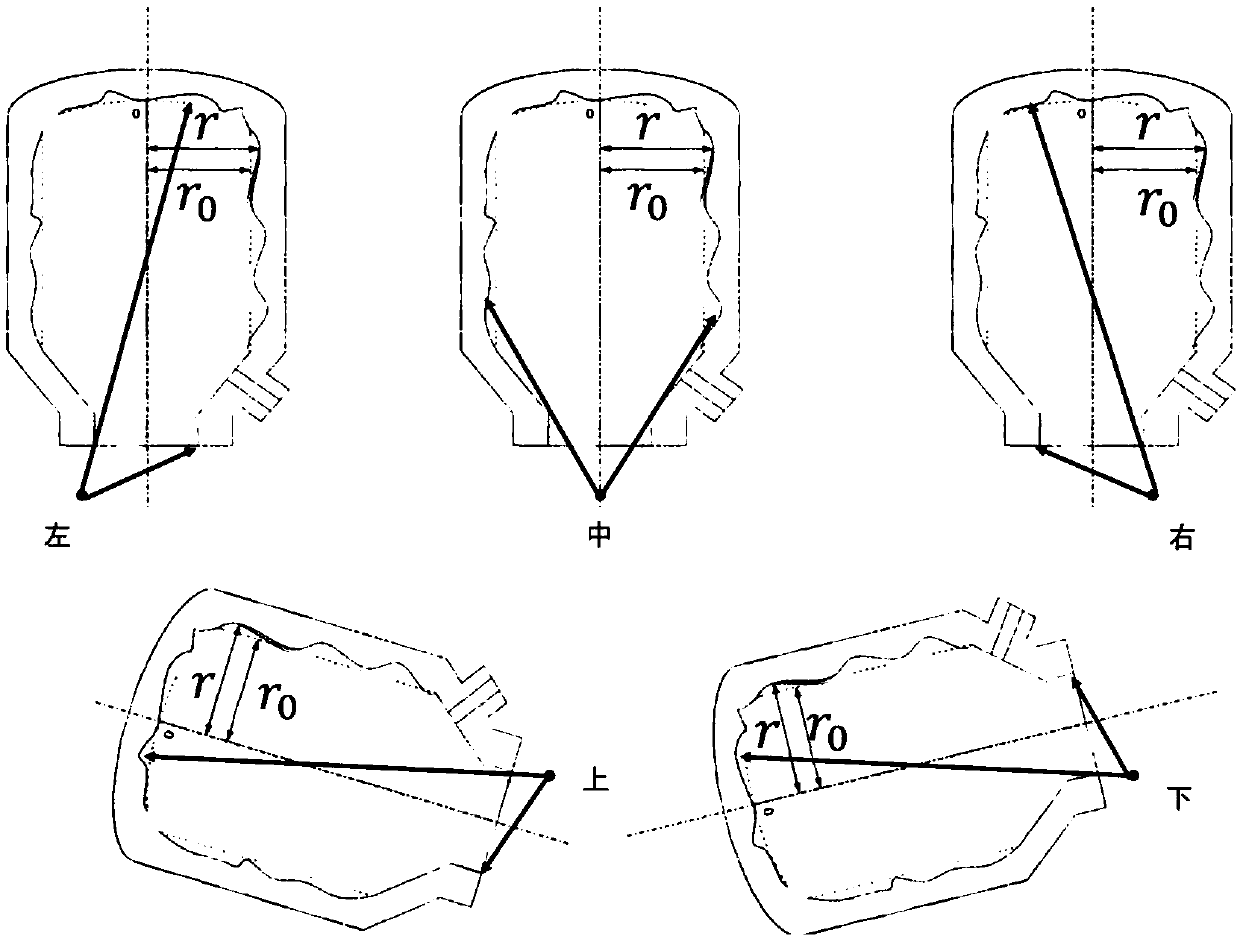

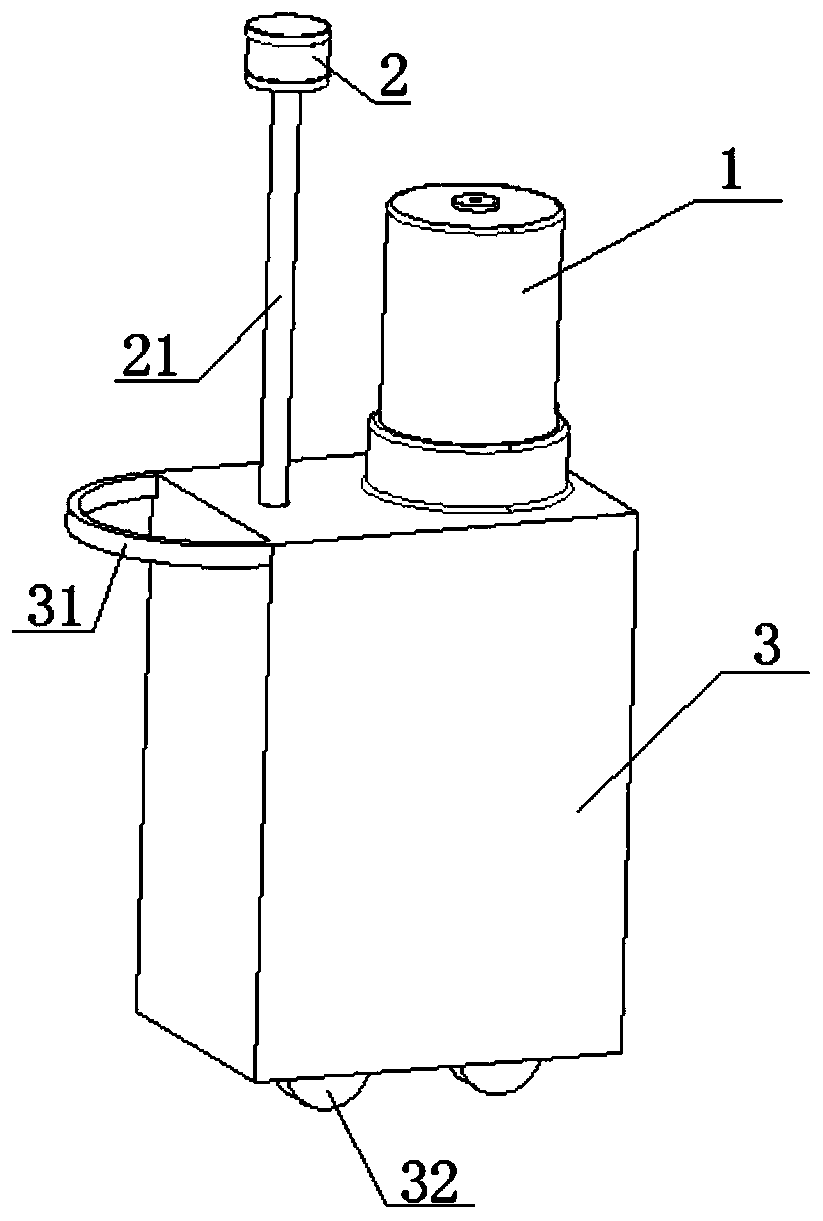

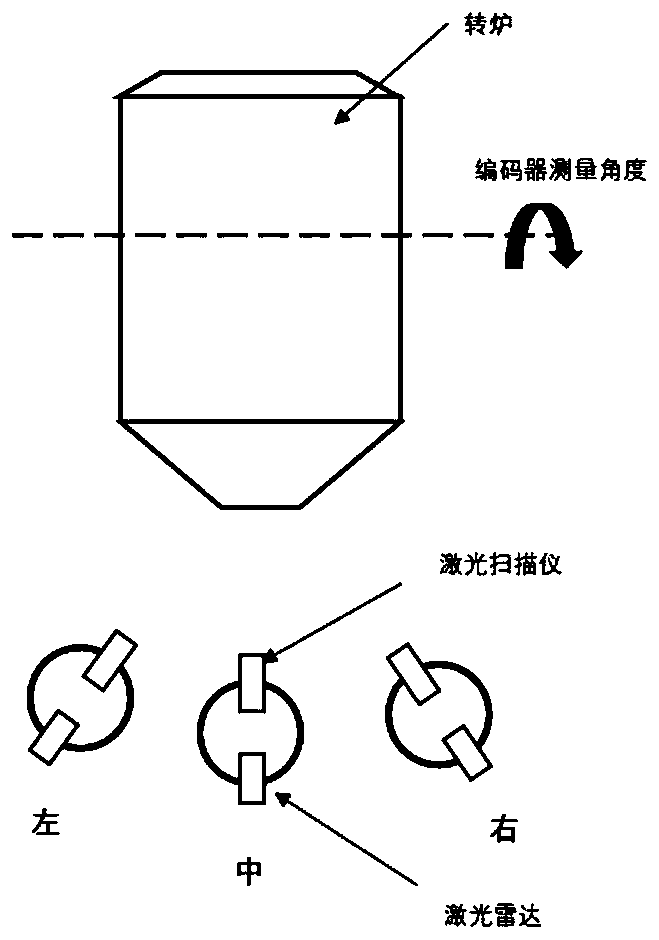

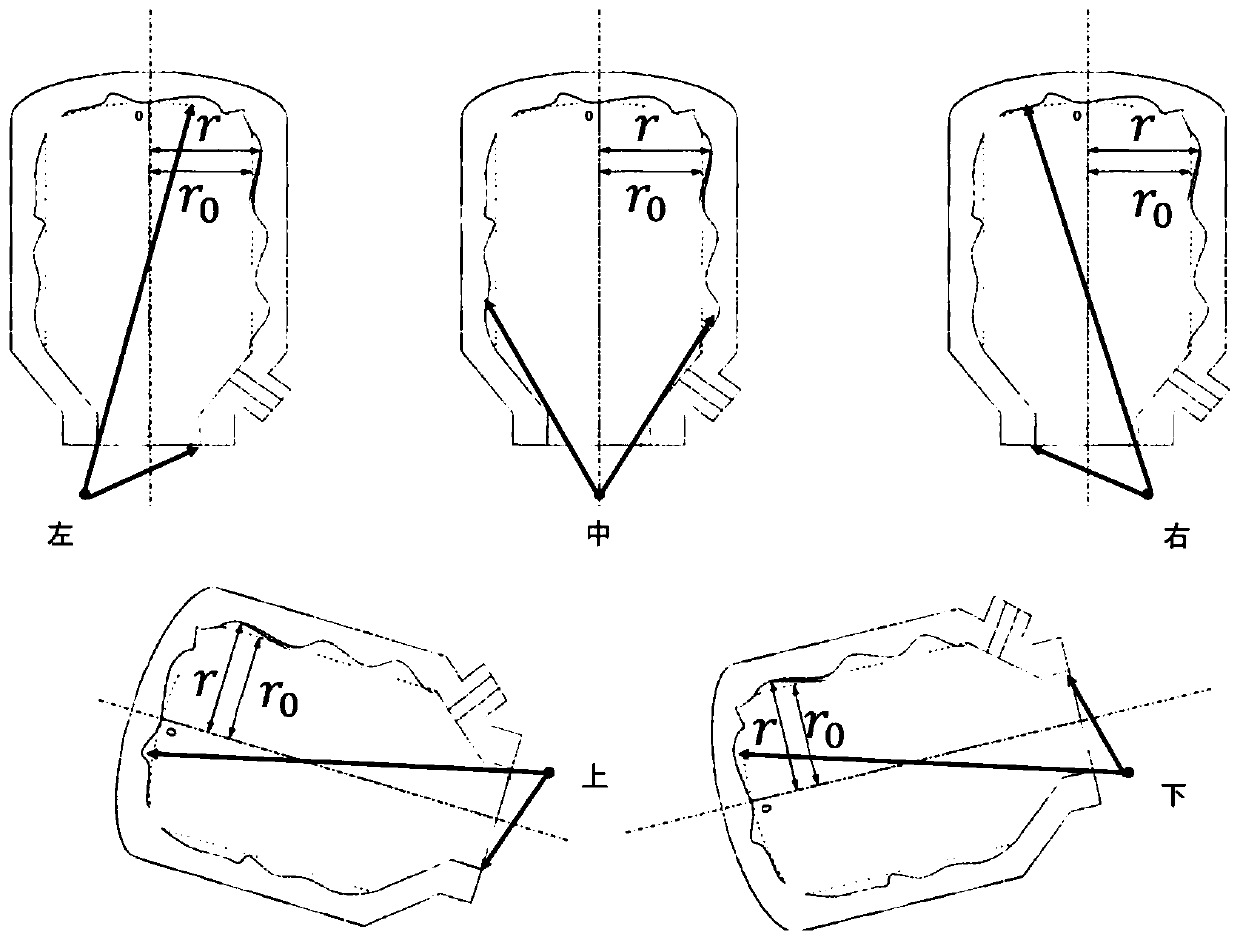

Three-dimensional measuring method and measuring device for converter furnace chamber based on three-dimensional laser radar auxiliary positioning

ActiveCN109613546ARapid positioningPrecise positioningUsing optical meansElectromagnetic wave reradiationPhysicsMeasurement device

The invention discloses a three-dimensional measuring method and measuring device for a converter furnace chamber based on three-dimensional laser radar auxiliary positioning. The measuring method andthe measuring device obtain three-dimensional point cloud of the converter furnace chamber at various angles of view by moving a three-dimensional laser scanner, at that same time, three-dimensionallaser radar scan the workshop environment of a steel mill, the relative position of the three-dimensional laser scanner in the three-dimensional space is obtained by three-dimensional laser radar, thethree-dimensional point cloud of the converter furnace chamber at various angles of view of the three-dimensional laser scanner is registered, the complete actual three-dimensional point cloud of theconverter furnace chamber is obtained by splicing, the thickness change of the converter furnace chamber is obtained by comparing with an original furnace chamber model, the wear condition of the converter furnace chamber is monitored in real time, the place of the converter needing to be repaired is indicated, whether the converter should be discarded is judged, quick and accurate positioning ofthe scanner is realized, and the measuring accuracy is improved.

Owner:ZHEJIANG UNIV

Ultra-precise three-axis association micro-milling device with micro-tool monitoring capacity

The invention provides an ultra-precise three-axis association micro-milling device with micro-tool monitoring capacity, relates to an ultra-precise three-axis association micro-milling device, and aims to solve the problem that in the prior art, no equipment for repairing micro-defects on the surfaces of large-caliber KDP crystal elements exists. A tool moving part wiring board, a tool moving part cushion block and a hand-operated lifting adjustment platform are all fixed to the upper end face of a bottom installation flat board, a tool three-axis association platform is fixed to the tool moving part cushion block, a chip collection assembly is connected with the tool three-axis association platform, a tool microscope moving platform, the hand-operated lifting adjustment platform and a microscope connecting board are sequentially connected from top to bottom, and the microscope connecting plate is connected with the upper end face of the bottom installation flat board. The ultra-precise three-axis association micro-milling device is used for repairing the micro-defects on the surfaces of the large-caliber KDP crystal elements in an ultra-precise mode.

Owner:HARBIN INST OF TECH

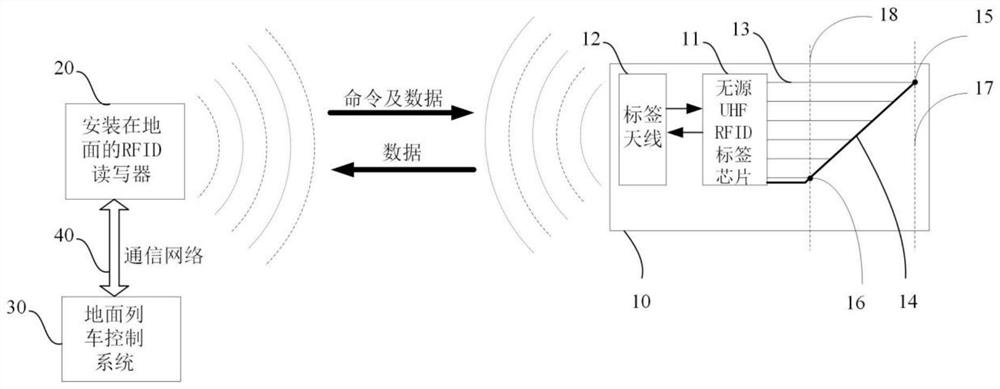

Train brake shoe abrasion detection device and method

InactiveCN112211933AReal-time monitoring of wear and tearImprove operational safetyCo-operative working arrangementsBrake typesWireless transmissionControl engineering

The invention provides a train brake shoe abrasion detection device which comprises a brake shoe abrasion detection electronic tag installed on a train brake shoe as well as an RFID reader-writer anda ground train monitoring system which are installed on the ground, wherein the brake shoe abrasion detection electronic tag detects the abrasion degree of a brake shoe friction block by detecting thechange of the thickness of the brake shoe friction block and transmits a detection result to the RFID reader-writer in a wireless transmission mode, and the RFID reader-writer is connected with the ground train monitoring system. The invention further provides a train brake shoe abrasion detection method. The train brake shoe abrasion detection system and method have the beneficial effects that the train brake shoe abrasion condition can be monitored in real time, the brake shoe with the life cycle completed is replaced in time, compared with manual visual brake shoe abrasion inspection, theefficiency of workers is improved, visual errors are prevented, automatic train brake shoe abrasion inspection management and brake shoe replacement traceability management are achieved, brake shoe waste is reduced, the train operation safety is improved, and the operation cost is reduced.

Owner:INVENGO INFORMATION TECH

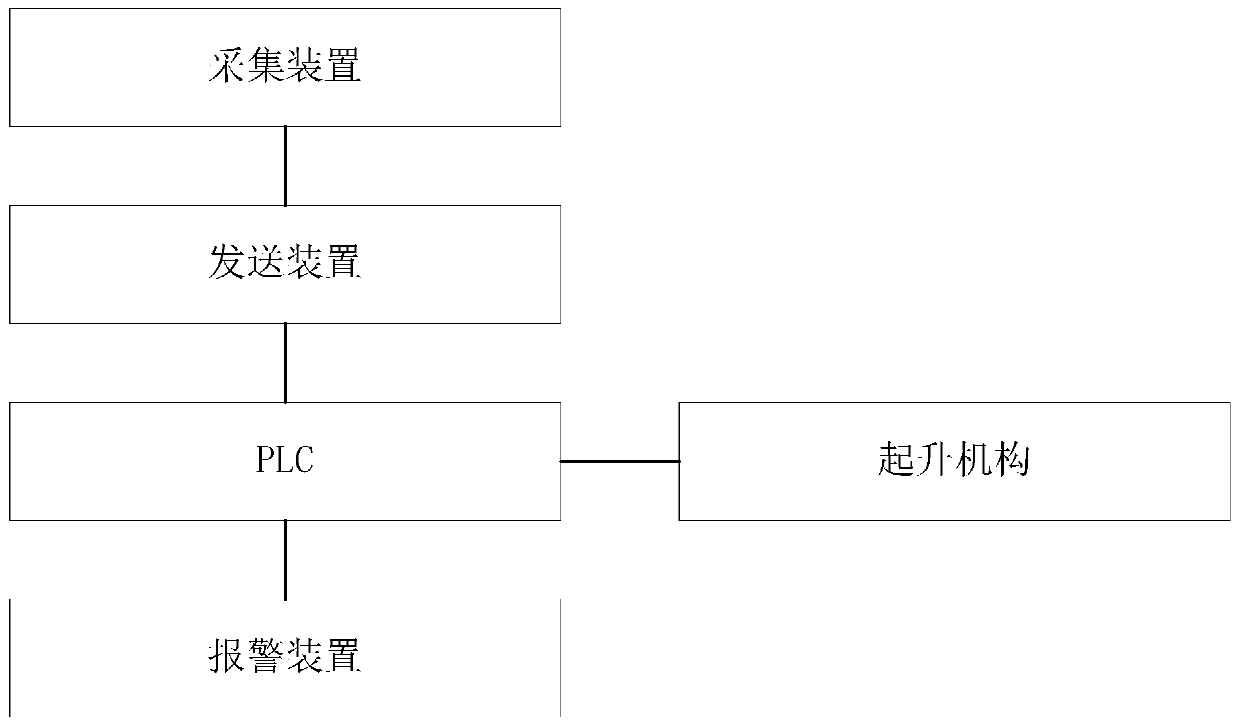

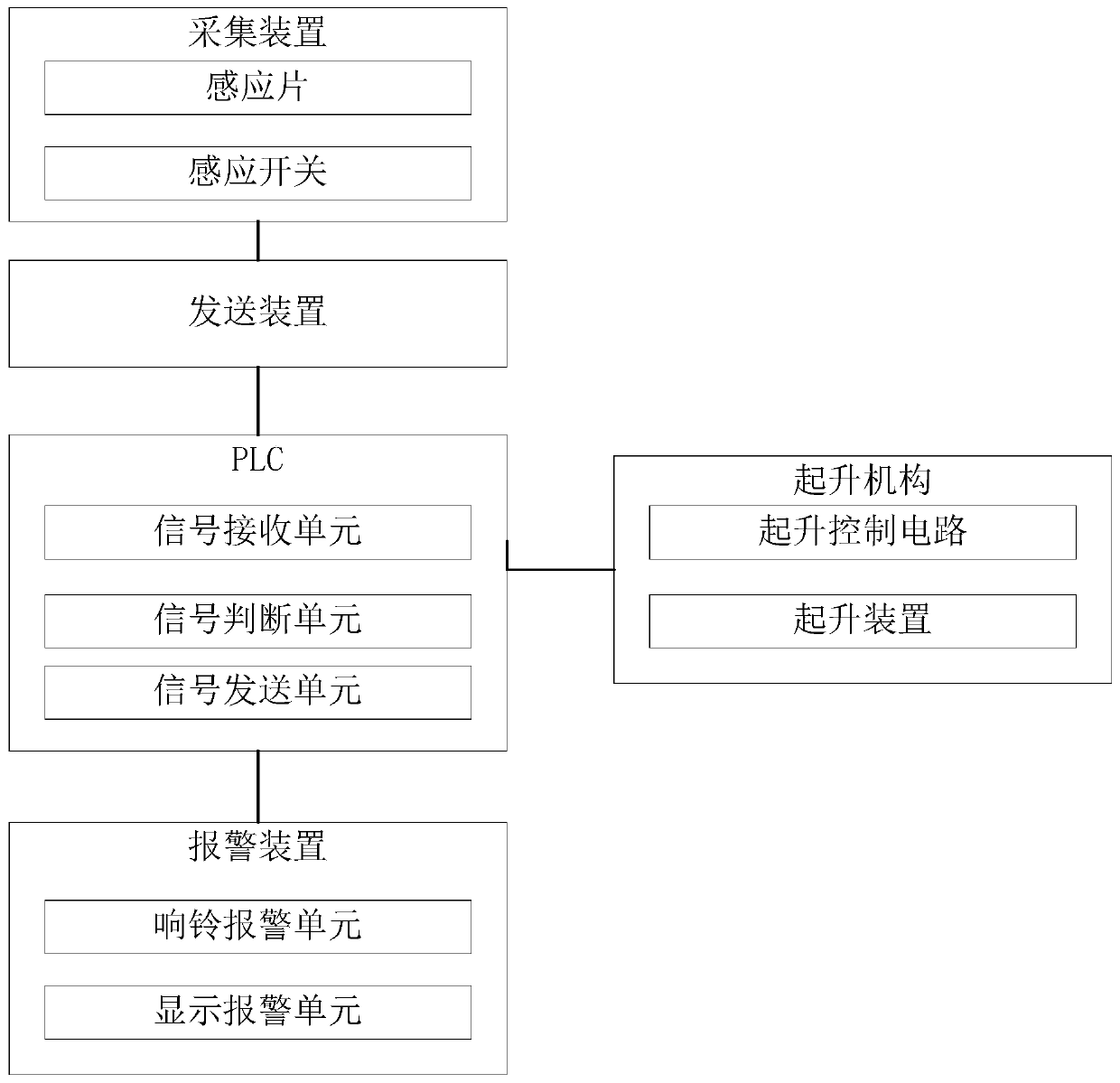

System and method for safety monitoring control of crane brake

ActiveCN110077984AEasy to useReal-time monitoring of wear and tearBrake typesHoisting equipmentsProgrammable logic controllerSafety monitoring

The invention provides a system for safety monitoring control of a crane brake, and belongs to the technical field of crane control. The system comprises a collecting device, a transmitting device, aprogrammable logic controller (PLC), a lifting mechanism and a warming device, wherein the collecting device is used for collecting the amount of compression of a brake spring during brake releasing;the transmitting device is used for transmitting the collected amount of compression of the brake spring during brake releasing, and the elongation of the brake spring during brake contracting to theprogrammable logic controller; the programmable logic controller is used for controlling the lifting mechanism to stop and lift when the amount of compression during brake contracting is equal to thesum of the limit compensation stroke and the lifting height of a push rod, and transmitting a preset warning signal to the warning device; and the warning device is used for warning when a brake pad is seriously worn. The system can monitor the wearing condition of the brake pad of the brake by collecting the amount of compression of the brake spring of the brake, can drive and stop the crane to lift according to the wearing condition of the brake pad, and reminds a worker of timely replacing the brake pad when the wearing condition of the brake pad is serious.

Owner:宁波市凹凸重工有限公司

Intelligent control method used for brake pad assembly on brake

InactiveCN105416267AExtended service lifeSimple structureBrake safety systemsEngineeringMaster controller

The invention discloses an intelligent control method used for a brake pad assembly on a brake. A pressure detection module is used for detecting a pressure value P on a side block. A temperature detection module is used for detecting a temperature value of the position where the lower end of a push rod A or a push rod B or a push rod C or a push rod D makes contact with the brake pad. A length detection module is used for detecting gap distance values, corresponding to different length detectors, between the upper end of the brake pad and the lower end of a base frame. Through inside comparison and calculation, a main controller controls a display module and an alarm module to conduct related operation. Through adoption of the intelligent control method, the temperature and abrasion degree of the brake pad can be monitored in real time during the running process of a vehicle, and when detection data are abnormal, an alarm is given. A user can be effectively reminded of the abnormal condition of the brake pad, so that the condition of braking failure is effectively avoided.

Owner:NINGBO HELI BRAKE SYST CO LTD

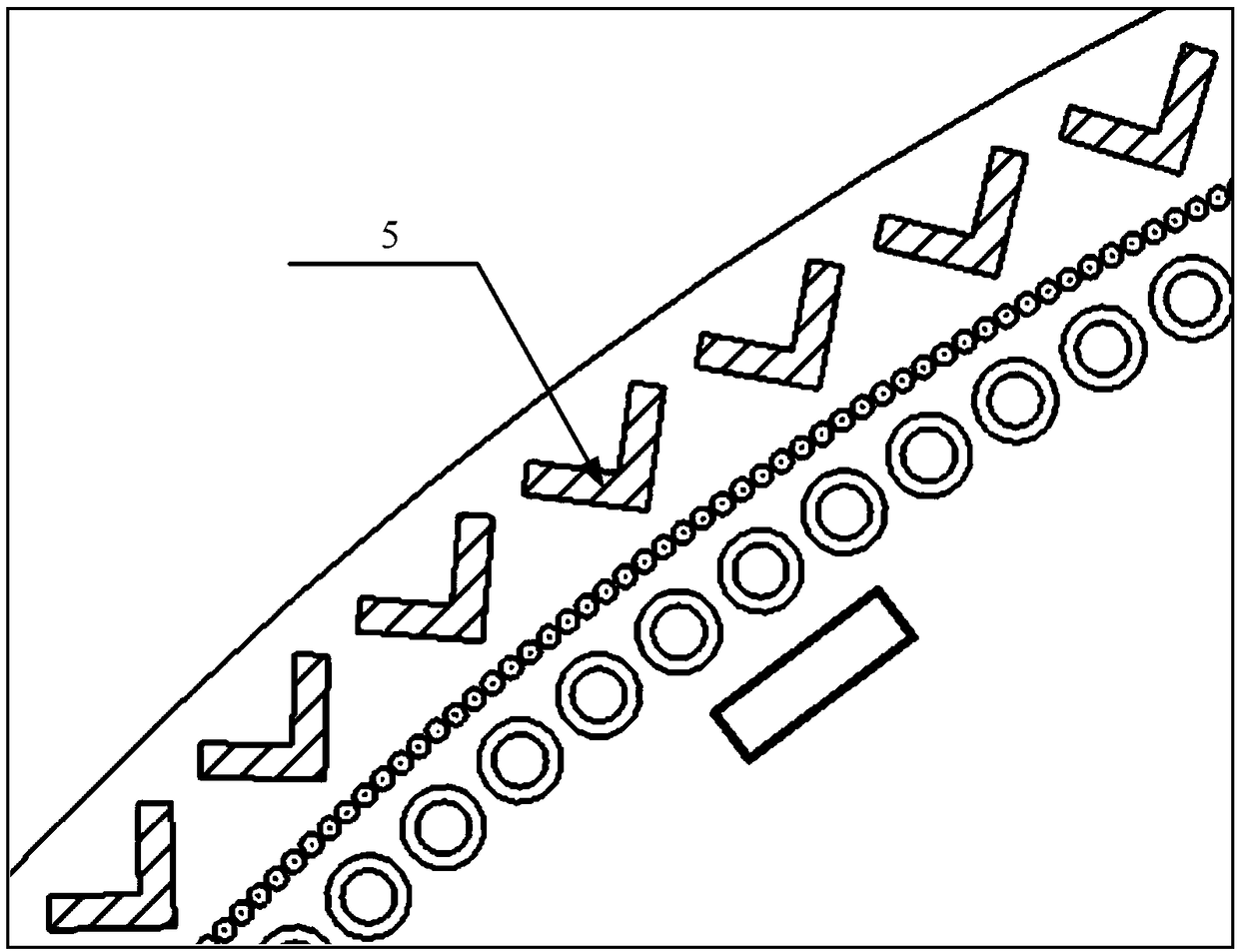

Ball-end mill with multifunctional micro-texture in titanium alloy machining

The invention provides a ball-end mill with a multifunctional micro-texture in titanium alloy machining, relates to a ball-end mill, in particular to the ball-end mill with the multifunctional micro-texture in titanium alloy processing, and aims at solving the problems of lower efficiency of processing the surface of a titanium alloy workpiece by a milling cutter,, poorer quality of the processed workpiece surface, no environmental protection in cooling and lubricating modes, untimely tool change and the like. The ball-end mill comprises a cutter head; and a blade part of the cutter head is sequentially provided with at least one arrow-shaped micro-texture, at least one sawtooth-shaped micro-texture, at least one bowl-shaped micro-texture and at least one rectangular micro-texture from outside to inside. The ball-end mill belongs to the field of machining.

Owner:HARBIN UNIV OF SCI & TECH

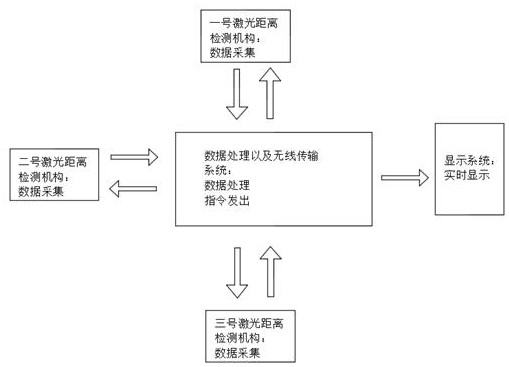

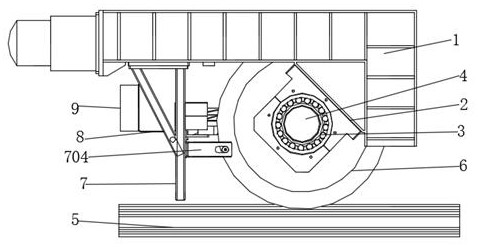

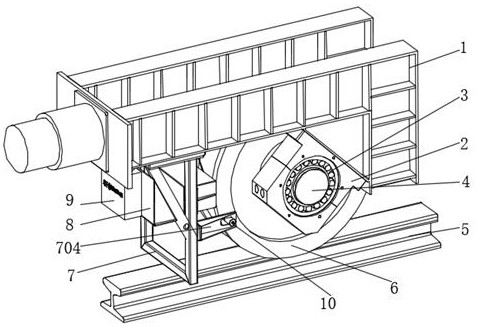

Wheel detection device and method

PendingCN112816229AReal-time monitoring of wear and tearTimely reminder for replacement and maintenanceElectromagnetic wave reradiationVehicle wheel testingDistance detectionStructural engineering

The invention discloses a wheel detection device and method, and relates to the technical field of wheel detection equipment, and the device comprises a mechanical main body, a wheel mechanism, a connection mechanism, a first laser distance detection mechanism, a second laser distance detection mechanism, and a third laser distance detection mechanism. A connecting base is connected to the two sides of one end of the bottom end, and the inner wall of the connecting base is sleeved with a bearing. By arranging a wheel body, a first limiting ring block, a second limiting ring block, a limiting rolling groove, a connecting support, a transverse rod, a connecting block, a side plate, a fixed transverse plate, a mounting base, a controller box, an alarm, the first laser distance detection mechanism, the second laser distance detection mechanism and the third laser distance detection mechanism, the abrasion condition of the wheel can be monitored in real time; when detection data reach an early warning value, a controller in the controller box can control and start the alarm, and workers can be reminded to replace and maintain the wheels in time.

Owner:博崖(上海)自动化科技有限公司

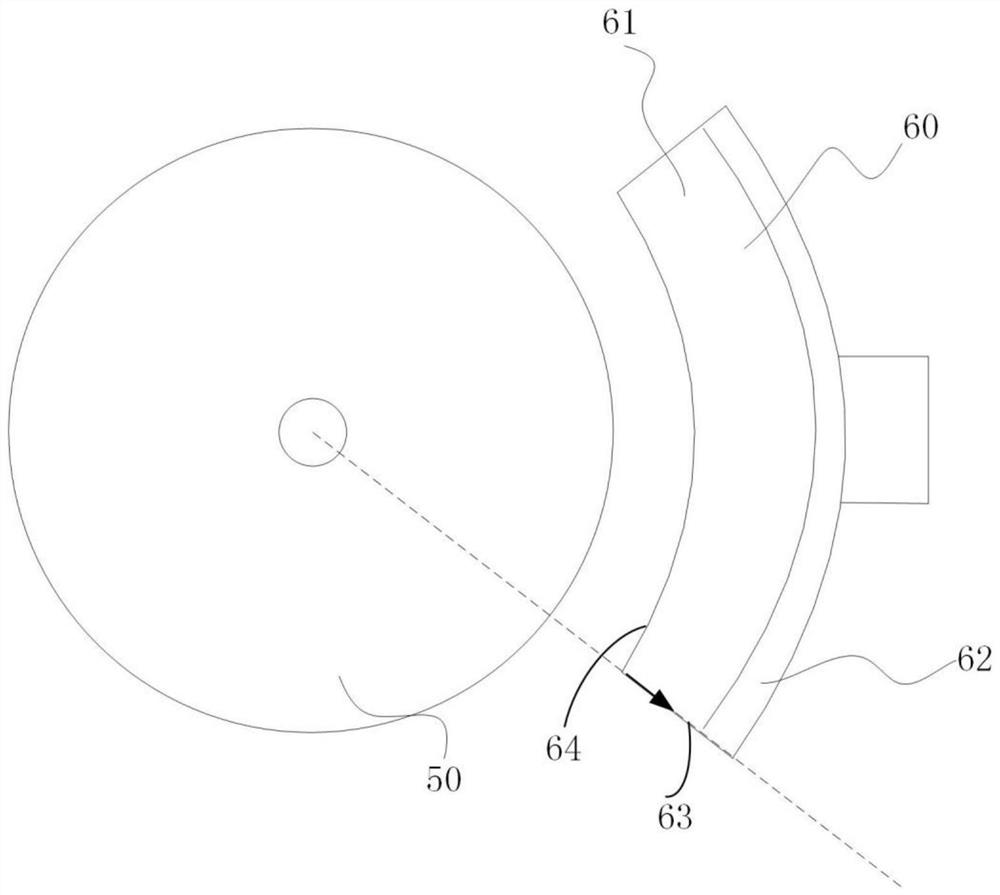

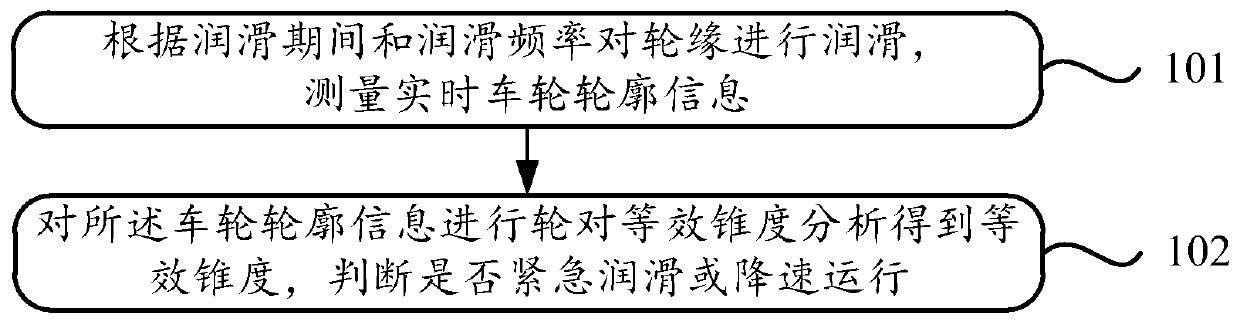

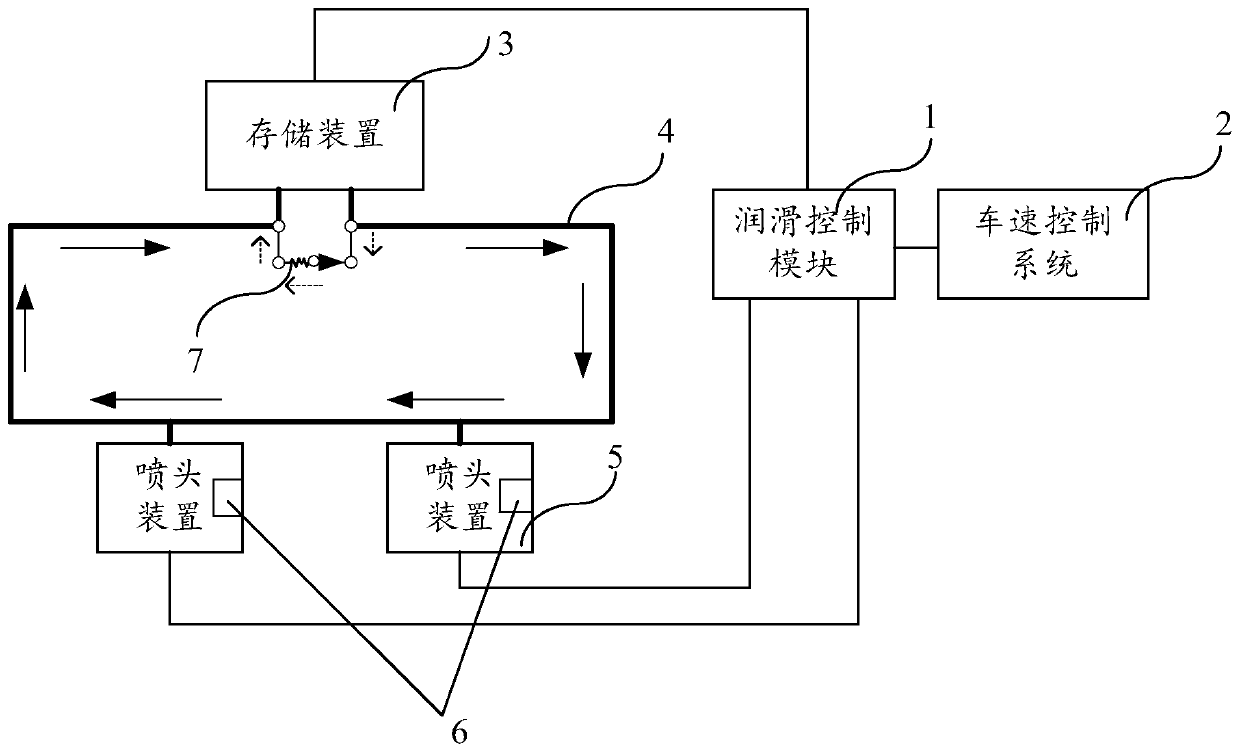

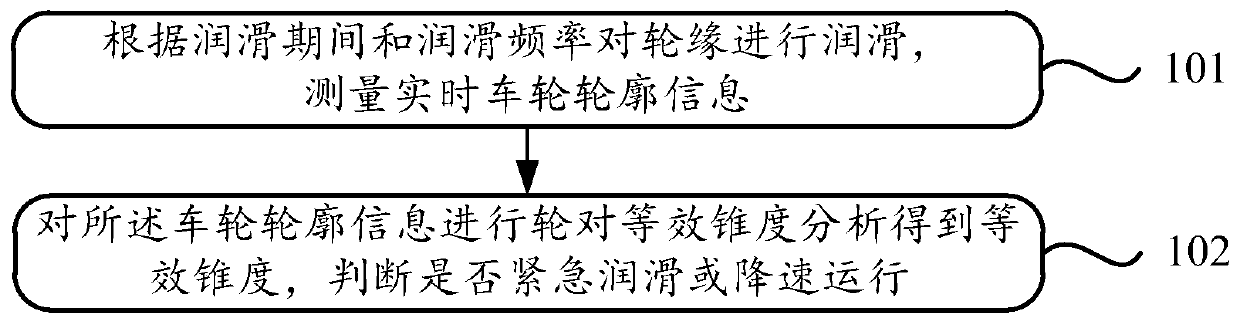

Wheel flange wear closed -loop management system and method

ActiveCN109910942AReal-time monitoring of wear and tearTimely maintenanceRail lubricationRail wetting/lubricationNoise controlMeasurement device

The invention discloses a wheel flange wear closed -loop management system and method, which solves the problems of wheel flange wear of a vehicle and untimely noise control. The method comprises thefollowing steps of lubricating a wheel flange according to a lubricating period and a lubricating frequency, and measuring real-time wheel profile information. Performing wheel set equivalent conicityanalysis on the wheel profile information to obtain the equivalent conicity, when the equivalent conicity is greater than a first threshold value, running in a speed reduction mode, and when the equivalent conicity is greater than a second threshold value but smaller than the first threshold value, performing emergent lubricating. The lubricating period is used for determining the lubricating time under a non-emergent lubricating condition, and the lubricating frequency is used for determining the number of times of lubricating within the lubricating period. The system comprises a lubricatingcontrol module for setting the lubricating frequency and the lubricating period, a lubricating system for lubricating, a laser measurement device for detecting and sending the wheel profile information, and a vehicle speed control system for performing running operation in a speed reduction mode.

Owner:北京承乾润华机电设备有限公司

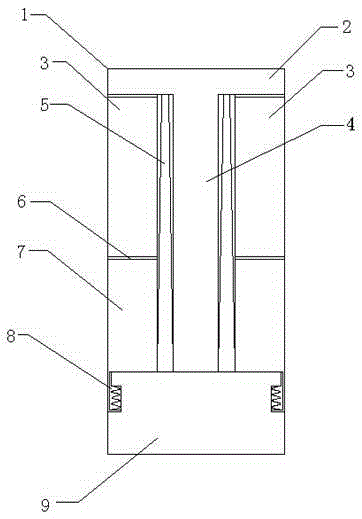

Intelligent control system and method for brake block combination on brake

InactiveCN105351411AExtended service lifeSimple structureBrake typesControl engineeringMaster controller

The invention discloses an intelligent control system and method for a brake block combination on a brake. The intelligent control system comprises a temperature detection module, a master controller, a length detection module, an alarming module, a pressure detection module and a display module. The pressure detection module detects the value P of pressure on a slider. The temperature detection module detects the value of temperature at the position, making contact with a brake block, of the lower end of a push rod A, the value of temperature at the position, making contact with the brake block, of the lower end of a push rod B, the value of temperature at the position, making contact with the brake block, of the lower end of a push rod C or the value of temperature at the position, making contact with the brake block, of the lower end of a push rod D. The length detection module detects the values of the gap distances between the portions, corresponding to different length detectors, of the upper end of the brake block and the lower end of the lower portion of a basic frame. The master controller controls the display module and the alarming module to execute relevant operation through internal comparison and calculation. By means of the intelligent control system and method, the temperature and the abrasion degree of the brake block can be monitored in real time in the driving process of a vehicle, and an alarm is given when detected data are abnormal; and a user can be effectively warned about the abnormal condition of the brake block, and the condition that braking loses efficiency is effectively avoided.

Owner:湖北省葛店开发区万联机械股份有限公司

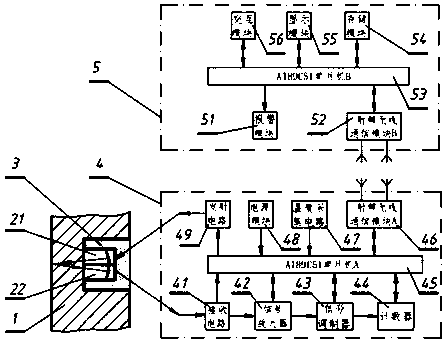

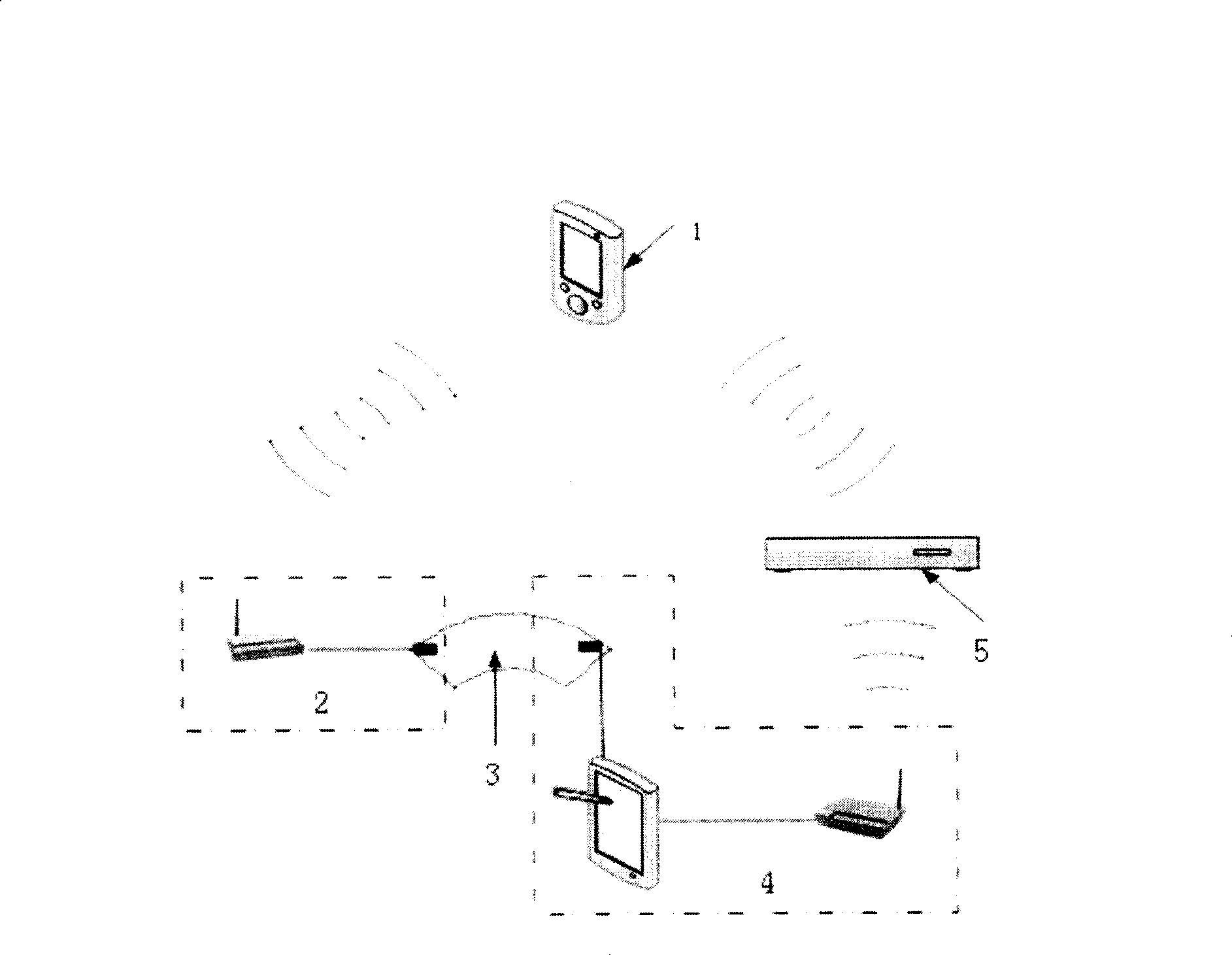

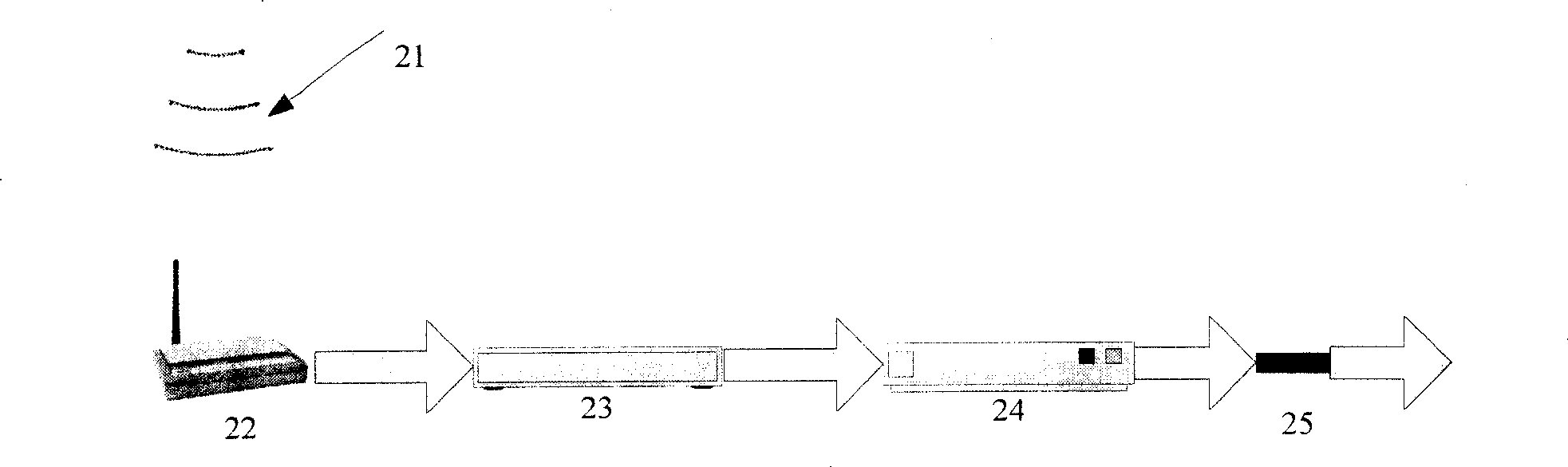

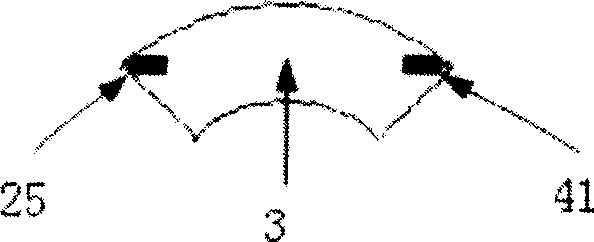

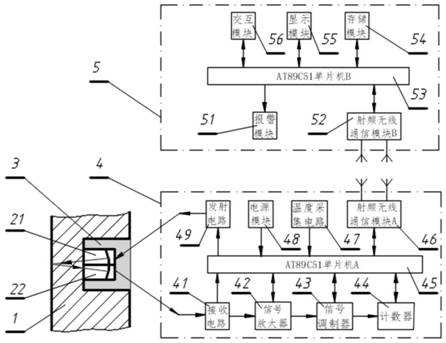

Brake friction plate abrasion degree monitoring system based on elastic wave and wireless network

InactiveCN100480533CReal-time monitoring of wear and tearImprove securityBrake typesWireless mesh networkMonitoring system

A brake friction disc attrition degree detection system based on the elastic wave and the wireless network belongs to the test engineering technology field. The invention comprises a movable wireless network terminal, an elastic wave stimulating module, an elastic wave signal receiving and transmitting module, and a vehicle computing and decision module, the movable wireless network terminal transmits a detection instruction to the elastic wave stimulating module, the elastic wave stimulating module generates a stimulating wave, an elastic wave is generated in the friction disc and transmitted to the elastic wave signal receiving and transmitting module, the elastic wave signal receiving and transmitting module digitizes the elastic wave signal and transmits the elastic wave signal to the vehicle computing and decision module, and the vehicle computing and decision module acquires the arrival time and the practical transmitting speed of the elastic wave signal, to acquire the attrition degree of the friction disc with the comparison with the database in the vehicle computing and decision module and to transmit the attrition degree to the mobile wireless network terminal. The invention detects the attrition degree of the brake friction disc and transmits the attrition degree to the driver at proper time, to enhance the security of the vehicle running.

Owner:卢卡斯伟利达廊重制动器有限公司

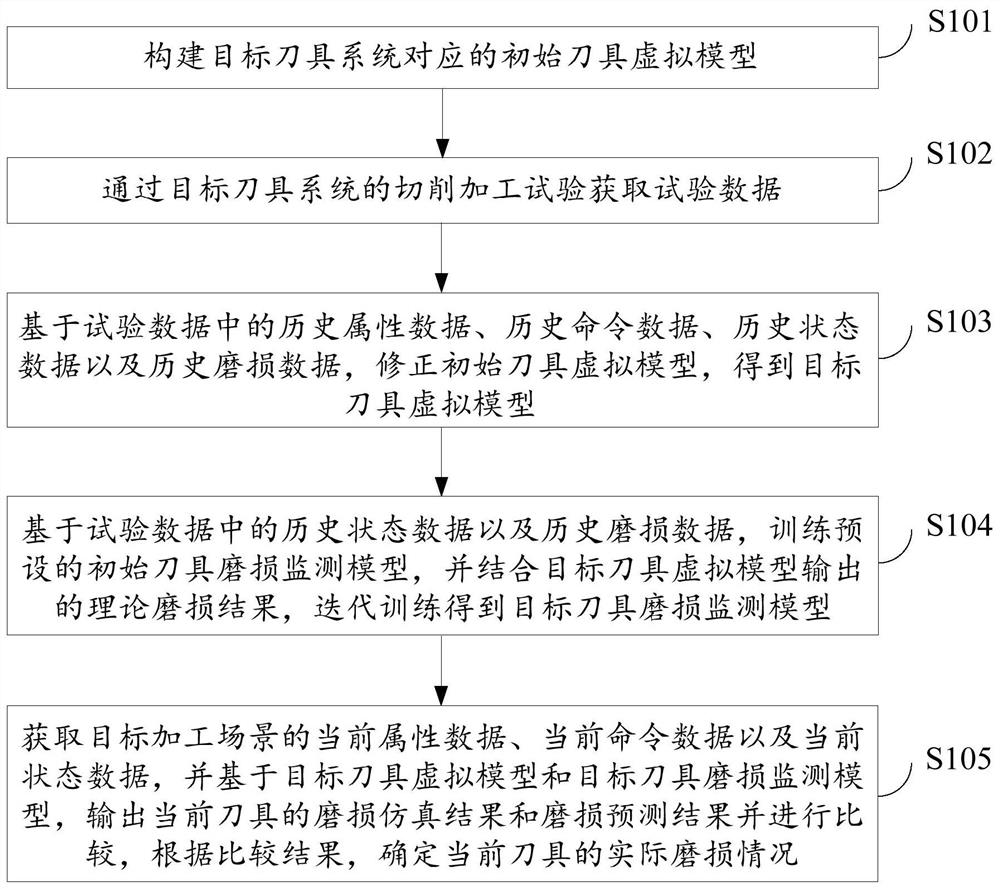

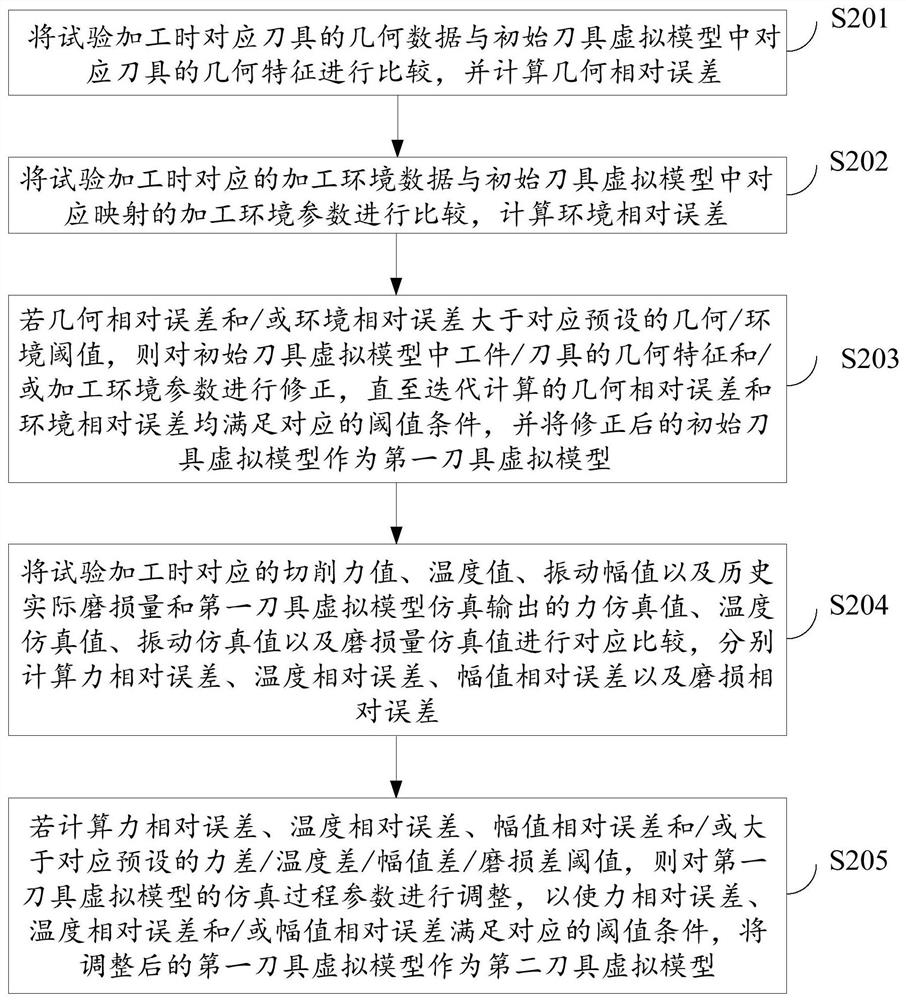

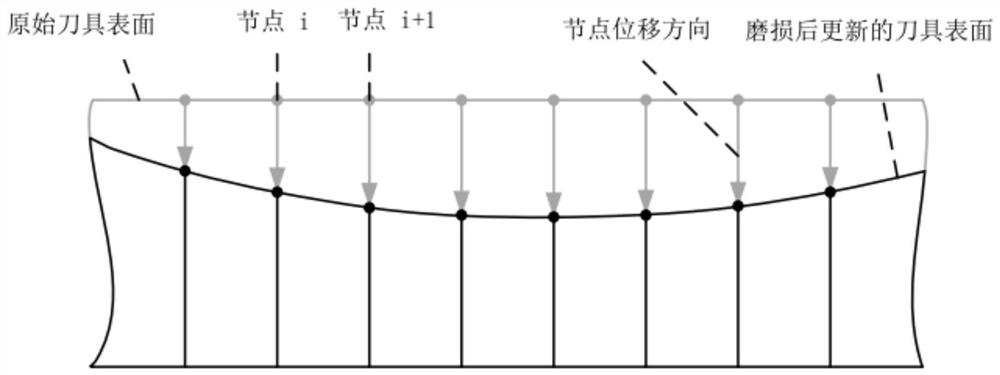

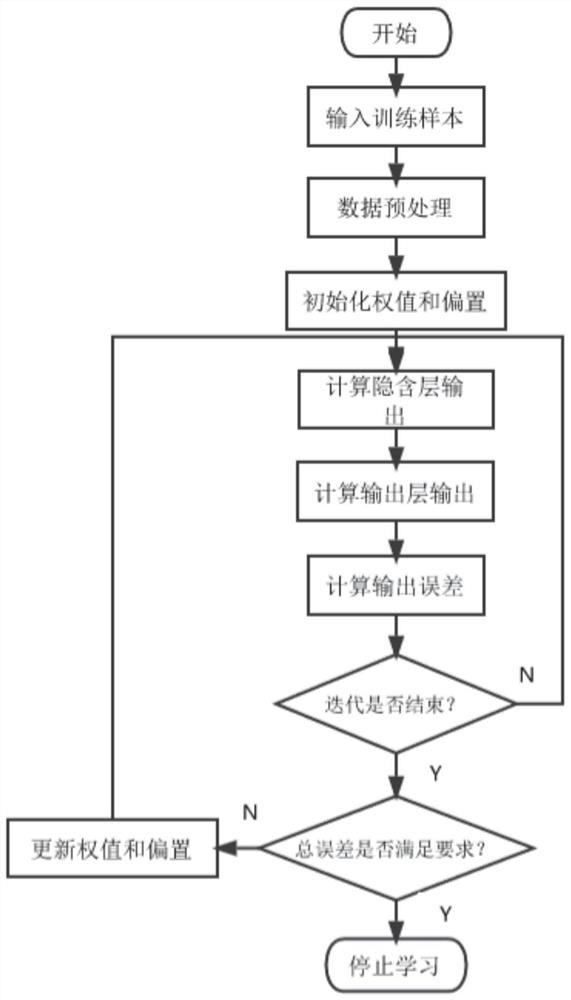

Cutter wear monitoring method and system

PendingCN113997122AReal-time monitoring of wear and tearImprove accuracyMeasurement/indication equipmentsSimulationData mining

The invention relates to a cutter wear monitoring method and system. The method comprises the following steps: constructing an initial cutter virtual model corresponding to a target cutter system; obtaining test data through a cutting machining test of the target cutter system; based on historical attribute data, historical command data, historical state data and historical wear data in the test data, correcting the initial cutter virtual model to obtain a target cutter virtual model; training a preset initial cutter wear monitoring model based on historical state data and historical wear data in the test data, and performing iterative training in combination with a theoretical wear result output by the target cutter virtual model to obtain a target cutter wear monitoring model; obtaining current attribute data, current command data and current state data of the target machining scene, and determining the actual wear condition of the current cutter based on the target cutter virtual model and the target cutter wear monitoring model. The accuracy and efficiency of cutter wear monitoring can be improved.

Owner:WUHAN UNIV OF TECH

Infrared monitoring warner of abrasion of balance disc of multi-stage pump and infrared monitoring method thereof

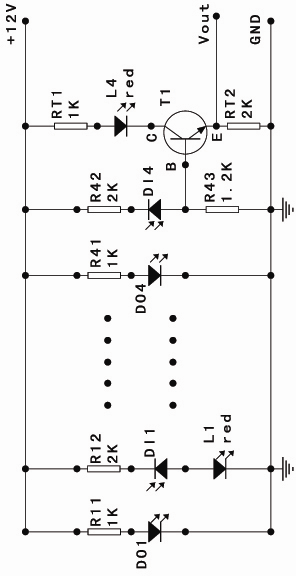

InactiveCN102052288AReal-time monitoring of wear and tearAccurate understanding of wearPump controlAlarmsCouplingSignal light

The invention discloses an infrared monitoring warner of abrasion of a balance disc of a multi-stage pump and an infrared monitoring method thereof. The infrared monitoring warner comprises a bracket arranged at the tail end of a non-motor coupling shaft end of the spindle of the multi-stage pump; a plurality of infrared emission pipes are sequentially arranged on one side of the bracket, infrared receiving pipes matched with the infrared emission pipe in a one-to-one manner are arranged on the other side, each infrared emission pipe and the infrared receiving pipe that are matched with each other form a monitoring element, the infrared emission pipes are connected to the two ends of an input power source in parallel, and the infrared receiving pipes are eclectically connected with a displacement signal light and then is connected to the two ends of the input power source in parallel. The infrared monitoring warner can display the abrasion loss of the balance disc of the multi-stage pump in real time without stopping the pump and removing the pump body, thereby avoiding the miss judgment or misjudgement to the abrasion condition of the balance disc due to experience; the infrared monitoring element has simple structure, small volume, practicability and higher detection precision and reliability.

Owner:湖南泰通能源管理股份有限公司

A brake cylinder of a rail vehicle hydraulic brake device

ActiveCN103486171BReal-time monitoring of working statusWith wear monitoring functionBrake actuating mechanismsSlack adjustersControl theoryHydraulic brake

The invention discloses a brake cylinder of a hydraulic brake device of a railway vehicle. The brake cylinder comprises a shell component, a disk spring assembly, an indicator assembly, a piston assembly, a push rod assembly and an end cover assembly. The push rod assembly, the piston assembly, the disk spring assembly and the indicator assembly are sequentially installed in a cylindrical hole inside the shell component from front to back, wherein the cylindrical hole is provided with a step, and the axis of the push rod assembly, the axis of the piston assembly, the axis of the disk spring assembly, and the axis of the indicator assembly are the same as the main axis of the shell component. The end cover assembly is installed on the cylindrical step at the front end of the shell component, and the axis of the end cover assembly is the same as the main axis of the shell component. Brake clearances can be automatically compensated by multiple threads. Compared with an existing brake cylinder, the brake cylinder is simple in structure, convenient to machine and assemble, few in movable parts, and high in reliability, has the friction plate and brake disc abrasion monitoring function and the automatic compensation mechanism running real-time monitoring function, and can remotely monitor the working state of the brake cylinder in real time. Manual brake loosening and adjustment can be achieved on the scene through a manual mechanical brake loosening device, and operation is conveniently and quickly conducted.

Owner:DALIAN HUARUI HEAVY IND GRP CO LTD

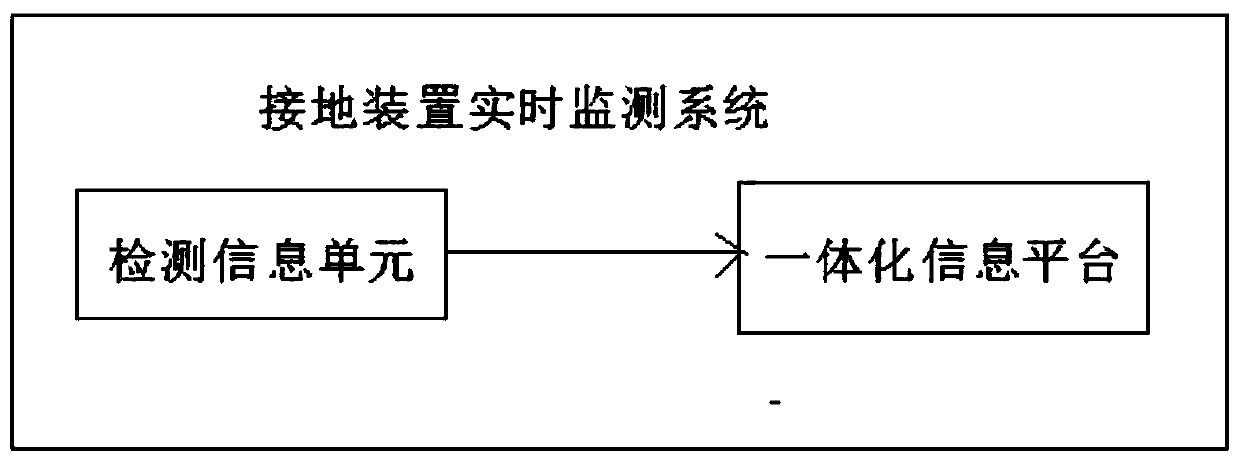

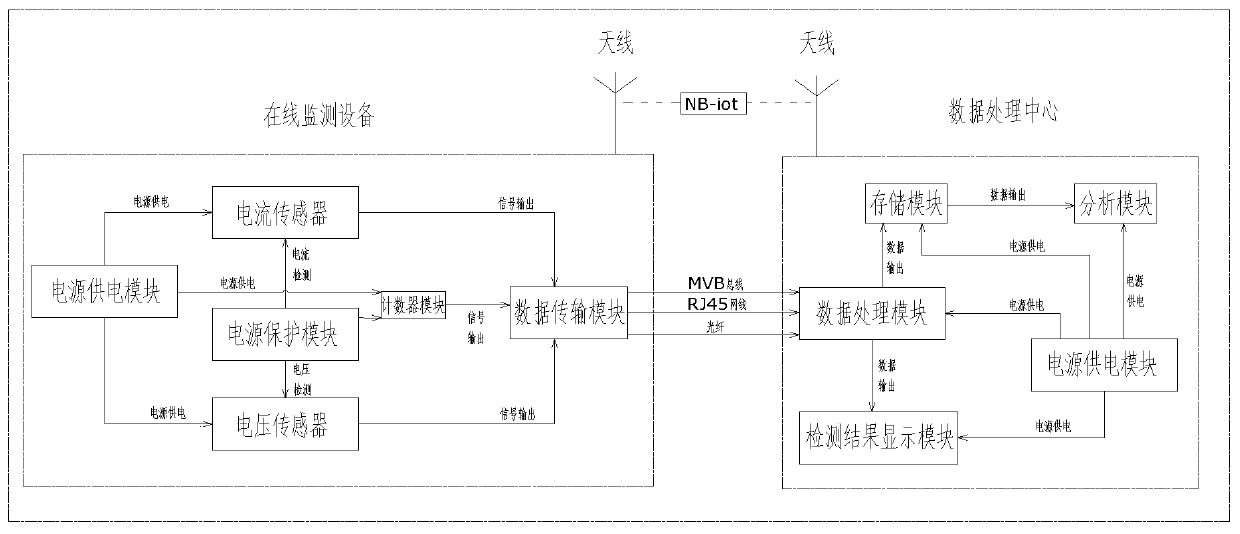

Internet-of-Things-based real-time monitoring system for grounding devices

PendingCN110412397AReal-time monitoring of wear and tearEasy and flexible installationElectrical testingMonitoring systemAcousto-optics

The present invention provides an Internet-of-Things-based real-time monitoring system for grounding devices. The operating parameters of the grounding devices are transmitted to a main control chamber. The system comprises a detection information unit and an integrated information platform; the detection information unit transmits the operation parameters to the integrated information platform; the integrated information platform checks and analyzes the obtained operation parameters through a B / S mode network, displays an analysis result through background or a display unit; if the operatingparameters of a certain set of grounding device exceed a set warning threshold value, the integrated information platform performs automatic acousto-optic warning, automatically pops up the information of the grounding device and enables early warning. With the system adopted, a reference basis can be provided for maintenance and maintenance frequency. According to the prior art, a periodic maintenance frequency and other modes are set, and as a result, excessive maintenance will be brought about, and labor cost may be increased; and machine disassembling behaviors during a maintenance processwill cause damage to a machine, and as a result, overall maintenance is disadvantaged.

Owner:陕西世翔电子科技有限公司

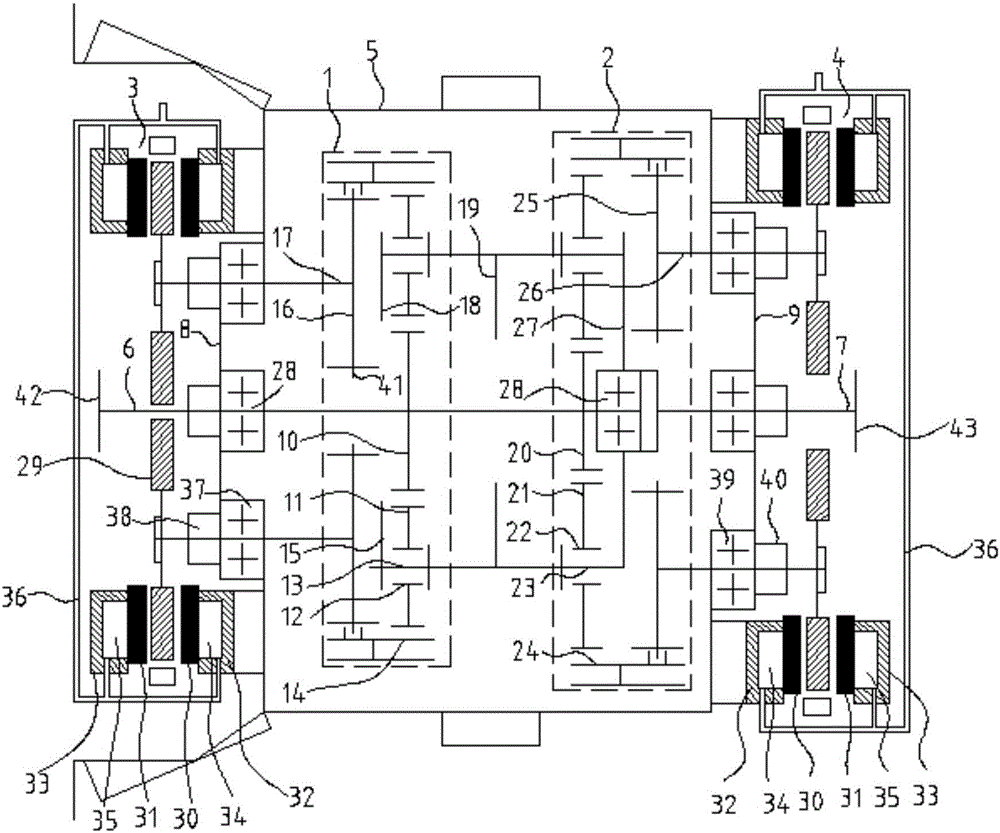

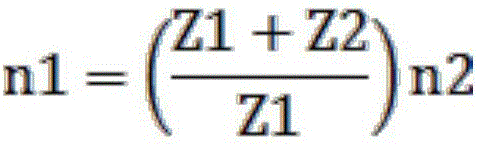

Dry friction star braking type automatic two-speed planetary speed change box

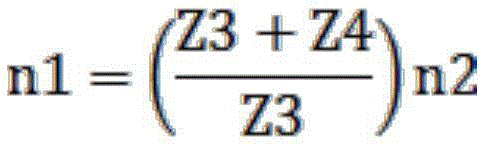

ActiveCN106641136AHigh rated speedReduced torque demandToothed gearingsTransmission elementsLow speedMoment of inertia

The invention discloses a dry friction star braking type automatic two-speed planetary speed change box. A high-speed-gear planet row and a low-speed-gear planet row of the dry friction star braking type automatic two-speed planetary speed change box are coaxially arranged in a box body. An input shaft penetrates a front end cover of the box body and is connected with the high-speed-gear planet row and the low-speed-gear planet row. An output shaft penetrates a rear end cover of the box body and is connected with the high-speed-gear planet row and the low-speed-gear planet row. Multiple high-speed-gear star brakes are evenly distributed and installed on the outer side of the front end cover of the box body with the input shaft as the center in the circumferential direction, and the high-speed-gear star brakes are connected with the high-speed-gear planet row. Multiple low-speed-gear star brakes are evenly distributed and installed on the outer side of the rear end cover of the box body with the output shaft as the center in the circumferential direction, and the low-speed-gear star brakes are connected with the low-speed-gear planet row. The dry friction star braking type automatic two-speed planetary speed change box is smaller in axial size and rotational inertia, long in service life, capable of achieving environmental adaptability, lower in cost and energy consumption, higher in transmission efficiency and reliability, and more excellent in performance.

Owner:GUANGZHOU XINYU POWER TECH CO LTD

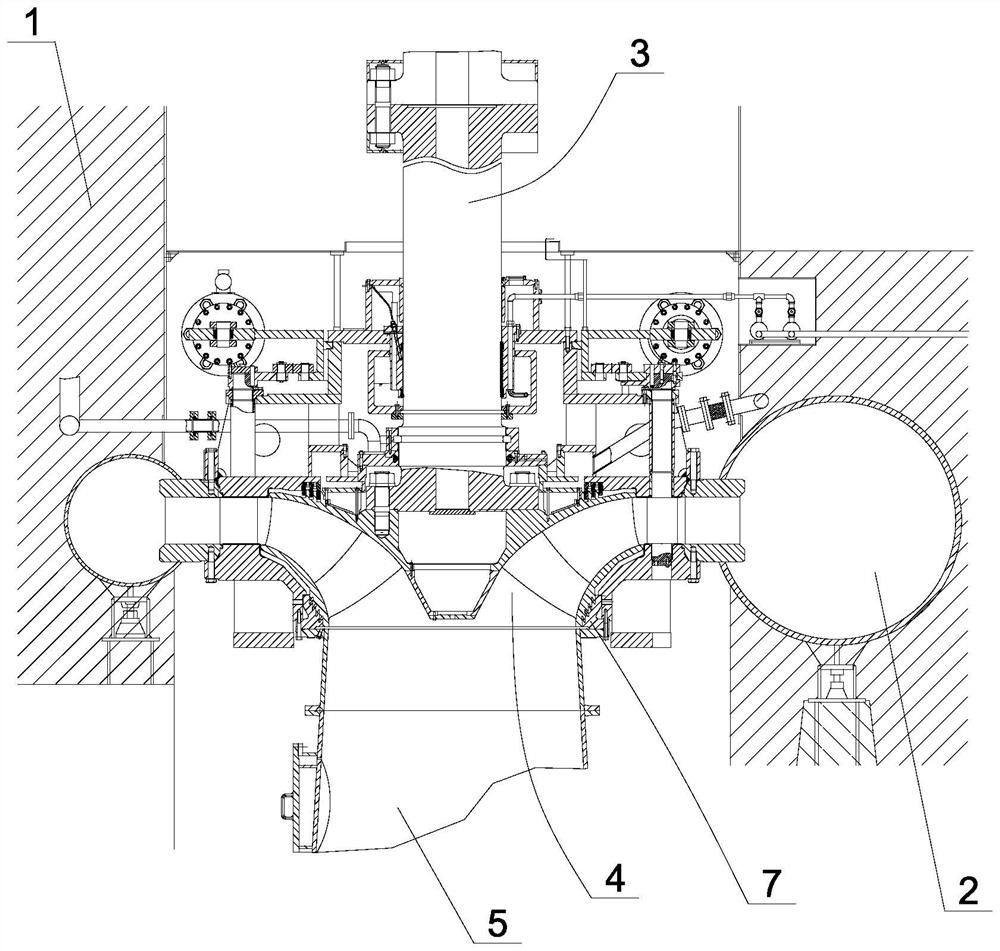

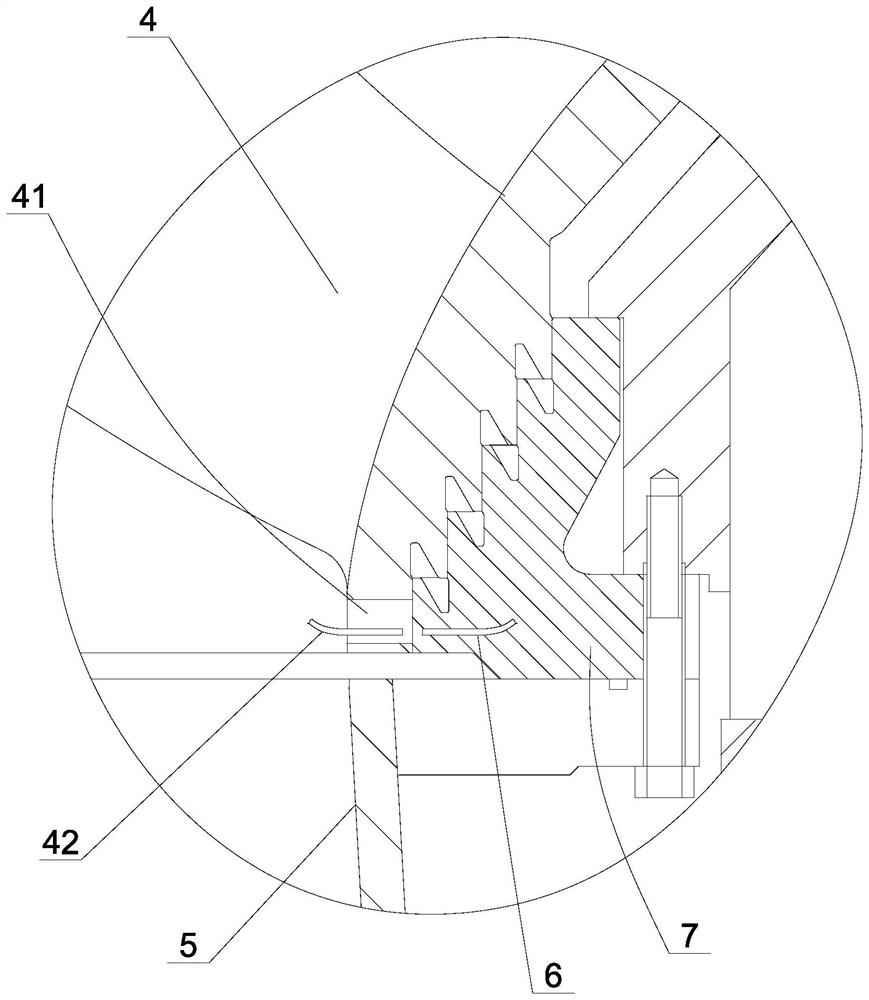

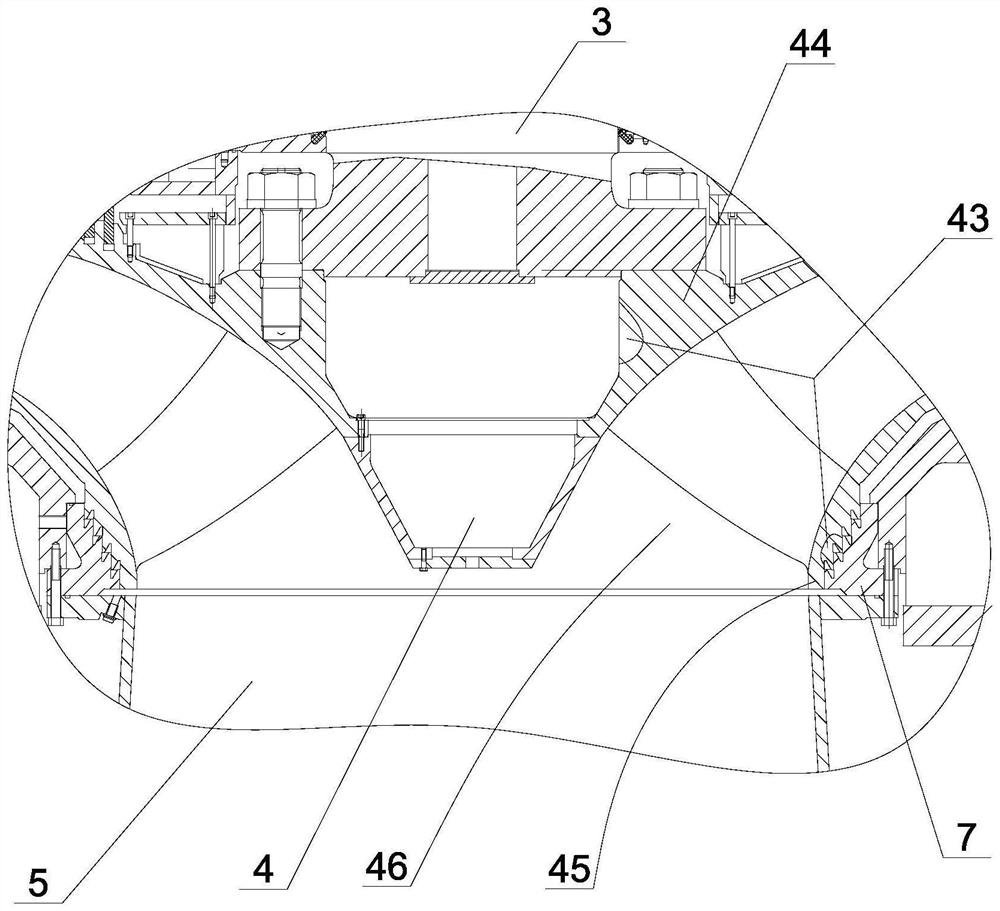

Water turbine facilitating real-time state monitoring

PendingCN114576068AReduce downtimeImprove power generation efficiencyHydro energy generationReaction enginesWater pipeElectric generator

The invention discloses a water turbine convenient for real-time state monitoring, which comprises a foundation pit, a volute positioned in the foundation pit, a vertical main shaft positioned at the center of the volute and a controller, a rotating wheel is arranged at the lower end of the main shaft, the upper end of the main shaft is connected with a rotor of a generator, and the lower end of the main shaft is connected with a motor. A rotating wheel is arranged in the volute, a tail water pipe is arranged below the rotating wheel, the water inlet end of the volute is communicated with upstream water flow through a water guide pipe, a leakage stopping ring is arranged between the rotating wheel and the volute, and a fit clearance of 1.5-2 mm is formed between the leakage stopping ring and the rotating wheel. Therefore, the water turbine can be maintained and even updated in time, normal operation of the water turbine is ensured, downtime is shortened, and power generation efficiency is improved.

Owner:ZHEJIANG SCI-TECH UNIV +1

3D measurement method and measurement device of converter furnace cavity based on 3D lidar-assisted positioning

ActiveCN109613546BRapid positioningPrecise positioningUsing optical meansElectromagnetic wave reradiationScannerPoint cloud

The invention discloses a three-dimensional measuring method and measuring device for a converter furnace chamber based on three-dimensional laser radar auxiliary positioning. The measuring method andthe measuring device obtain three-dimensional point cloud of the converter furnace chamber at various angles of view by moving a three-dimensional laser scanner, at that same time, three-dimensionallaser radar scan the workshop environment of a steel mill, the relative position of the three-dimensional laser scanner in the three-dimensional space is obtained by three-dimensional laser radar, thethree-dimensional point cloud of the converter furnace chamber at various angles of view of the three-dimensional laser scanner is registered, the complete actual three-dimensional point cloud of theconverter furnace chamber is obtained by splicing, the thickness change of the converter furnace chamber is obtained by comparing with an original furnace chamber model, the wear condition of the converter furnace chamber is monitored in real time, the place of the converter needing to be repaired is indicated, whether the converter should be discarded is judged, quick and accurate positioning ofthe scanner is realized, and the measuring accuracy is improved.

Owner:ZHEJIANG UNIV

Double turret turning center with high precision and stable angle control

ActiveCN112658302BBalanced sliding connectionAvoid machining errorsMeasurement/indication equipmentsFeeding apparatusControl engineeringControl theory

The invention discloses a double-turret turning center with high-precision and stable angle control, which includes a frame, an angle control mechanism, a tool feeding mechanism and a tool. The tool feeding mechanism is assembled on the frame, and one end of the tool feeding mechanism is fixed to the frame. connection, the other end of the knife feed mechanism is slidingly connected with the frame, the end of the knife away from the active end is connected with the knife feed mechanism, one end of the angle control mechanism is set at the end of the knife away from the active end, and the other end of the angle control mechanism is connected to the The feeding mechanism is fixedly connected. The invention provides a double-turret turning center with high-precision and stable angle control, which can achieve the effect of highly accurate control of the required angle adjustment while ensuring the stability of the angle adjustment process; For batch type workpieces, the tool wear can be monitored in real time according to the adjustment of the displacement difference during the tool feeding process, and the main and standby tools can be switched in time to ensure the smooth progress of the entire turning process.

Owner:JIANGSU BOSUNMAN IND EQUIP

Turning center

PendingCN114734270AEasy to replaceImprove processing effectBio-organic fraction processingMeasurement/indication equipmentsStructural engineeringIndustrial engineering

The invention discloses a turning center, and relates to the technical field of numerical control turning centers, the turning center comprises a shell, the turning center is arranged on the inner side of the shell, the turning center comprises a center shaft, a connecting sleeve, a connecting shaft, a machining cutter, a first air cylinder and an adjusting mechanism, a machining station is arranged on the inner side of the shell, and the center shaft is arranged on the machining station; the upper end of the center shaft is rotatably connected with the inner wall of the upper side of the shell, the outer edge of the center shaft is sleeved with a connecting sleeve, a plurality of connecting shafts are arranged on the outer edge of the connecting sleeve, an adjusting mechanism is arranged at the end, away from the connecting sleeve, of each connecting shaft, a machining cutter is arranged on each adjusting mechanism, and a plurality of first air cylinders are arranged on the outer edge of the connecting sleeve. Each first air cylinder is connected with the corresponding connecting shaft. According to the device, the position of the machining cutter in the vertical direction can be adjusted, the position of the machining cutter can be controlled to be adjusted in the horizontal direction and the vertical direction, the machining cutter can be controlled to conduct arc-shaped displacement, and multi-directional adjustment and machining angle control over the machining cutter can be conveniently achieved.

Owner:常州汎亚液压机器有限公司

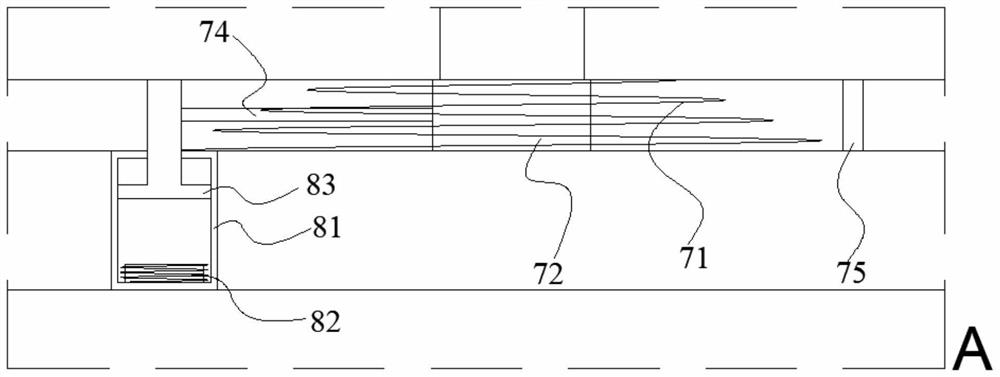

A lubricating device and lubricating method for edge trimming disc shears

InactiveCN110090995BReal-time monitoring of wear and tearAvoid the problem of poor processing effectShearing machinesMaintainance and safety accessoriesCircular discControl engineering

The invention discloses a lubricating device and a lubricating method for edge trimming disc scissors. The lubricating device includes a support frame arranged on the machine body and located at the upper end of the disc scissors. The support frame is provided with auxiliary boxes and industrial camera; the auxiliary box is equipped with a controller and an electromagnetic oiler; the oil inlet end of the electromagnetic oiler is connected to the lubricating oil pipeline; the oil outlet end of the electromagnetic oiler is connected to the lubricating parts; the industrial camera and the electromagnetic oiler connected to the controller respectively. The invention can monitor the wear degree of the disc shear blade in real time, and perform automatic lubrication according to the wear degree, avoiding the problem of poor processing effect caused by the passivation of the disc shear blade, and effectively improving work efficiency and yield. The alarm device of the present invention can give an alarm prompt to the disc scissors that have not been lubricated in time, so as to avoid the leakage of lubrication caused by the failure of the lubricating parts.

Owner:SICHUAN UNIV

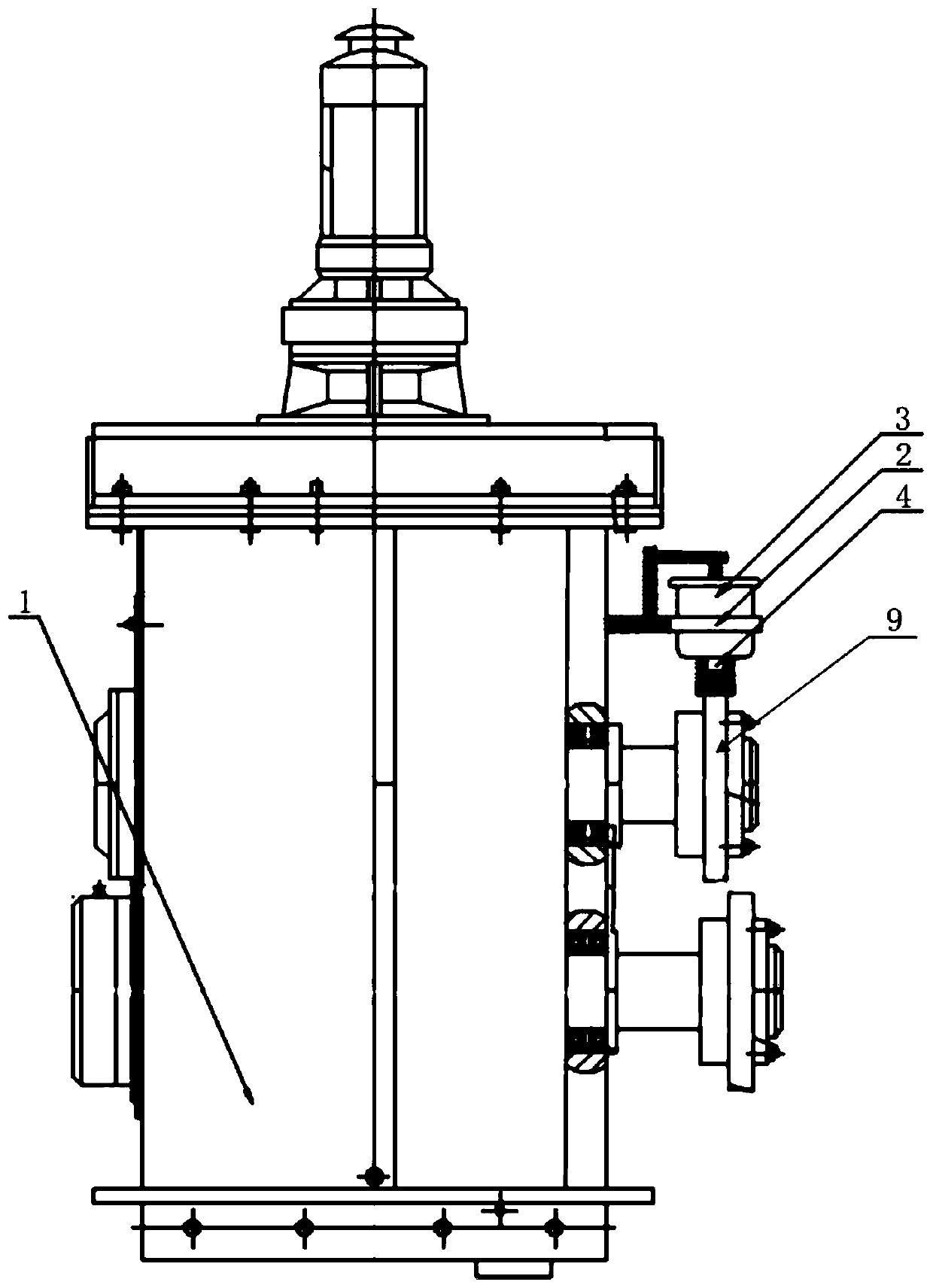

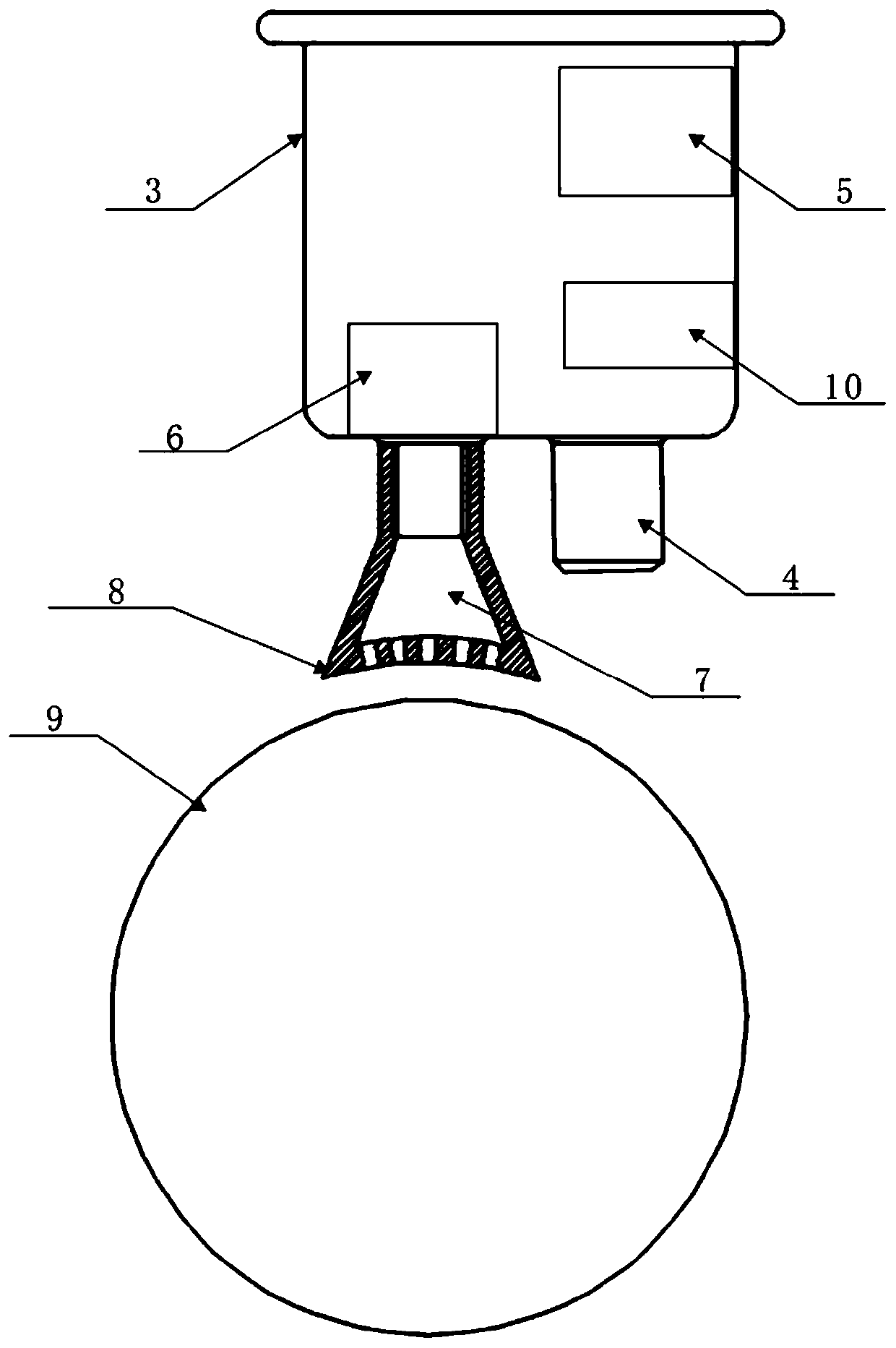

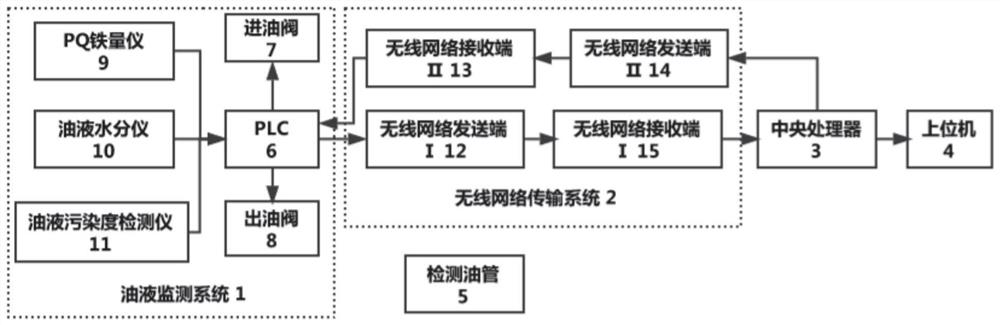

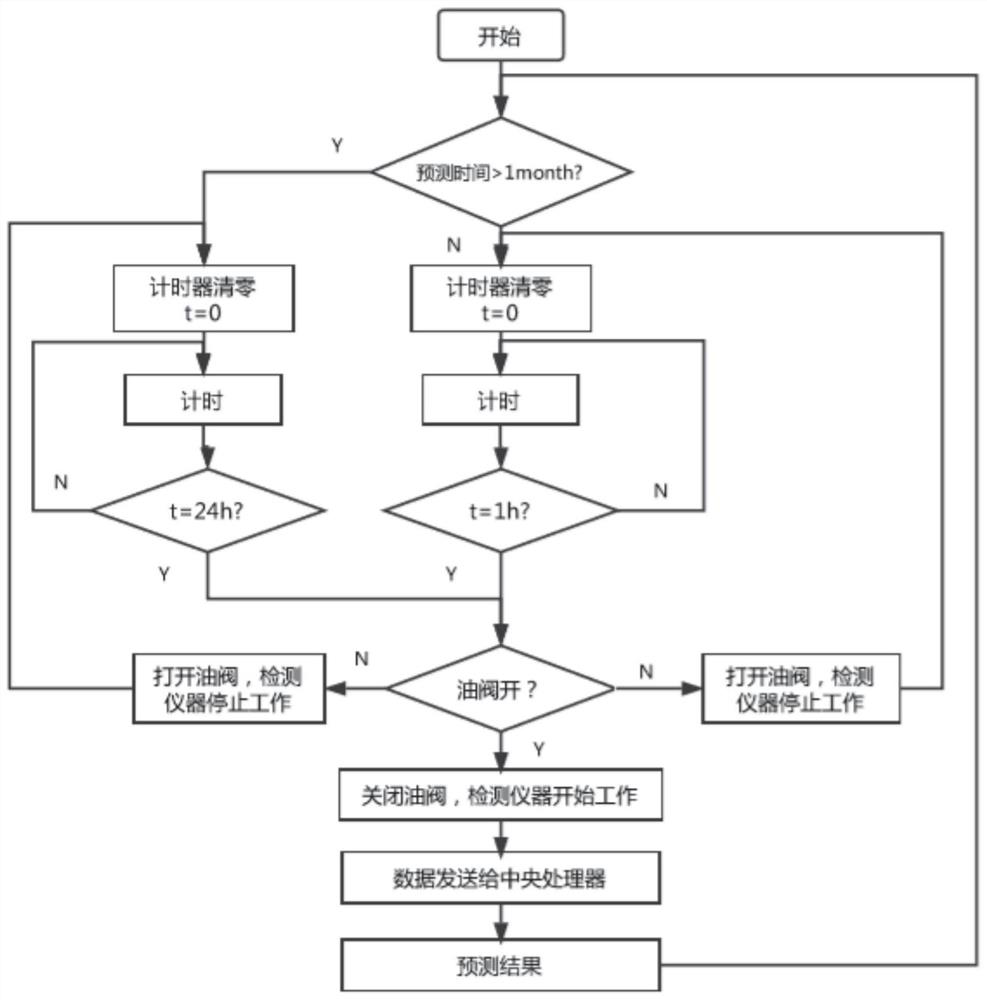

An online control system and control method for lubricating oil in a wind turbine gearbox

ActiveCN108843778BIncreased wear and tearReal-time monitoring of wear and tearGear lubrication/coolingGear wheelOil quality

The invention discloses an online control system and a control method for lubricating oil of a wind power generator gearbox, belonging to the field of wind power generation. The system includes an oil monitoring system, a wireless network transmission system, a central processing unit, a host computer, and a detection oil pipe. The oil monitoring system monitors and detects the PQ value, oil moisture content and oil pollution degree in the oil pipe, and sends the collected data to the central processing unit through the wireless network transmission system, and predicts and analyzes in the central processing unit, and then The machine displays the degree of gear wear, whether the filter element and lubricating oil need to be replaced, and the scrapping time of the filter element and lubricating oil. The invention combines the oil monitoring system, the wireless network transmission system, the central processing unit, and the upper computer to realize the on-line monitoring and oil quality prediction of the fine filter system, and replace the filter element and lubricating oil on time according to the oil quality prediction results. Maximize the use of filter elements and lubricating oil, save costs and save resources.

Owner:KUNMING UNIV OF SCI & TECH

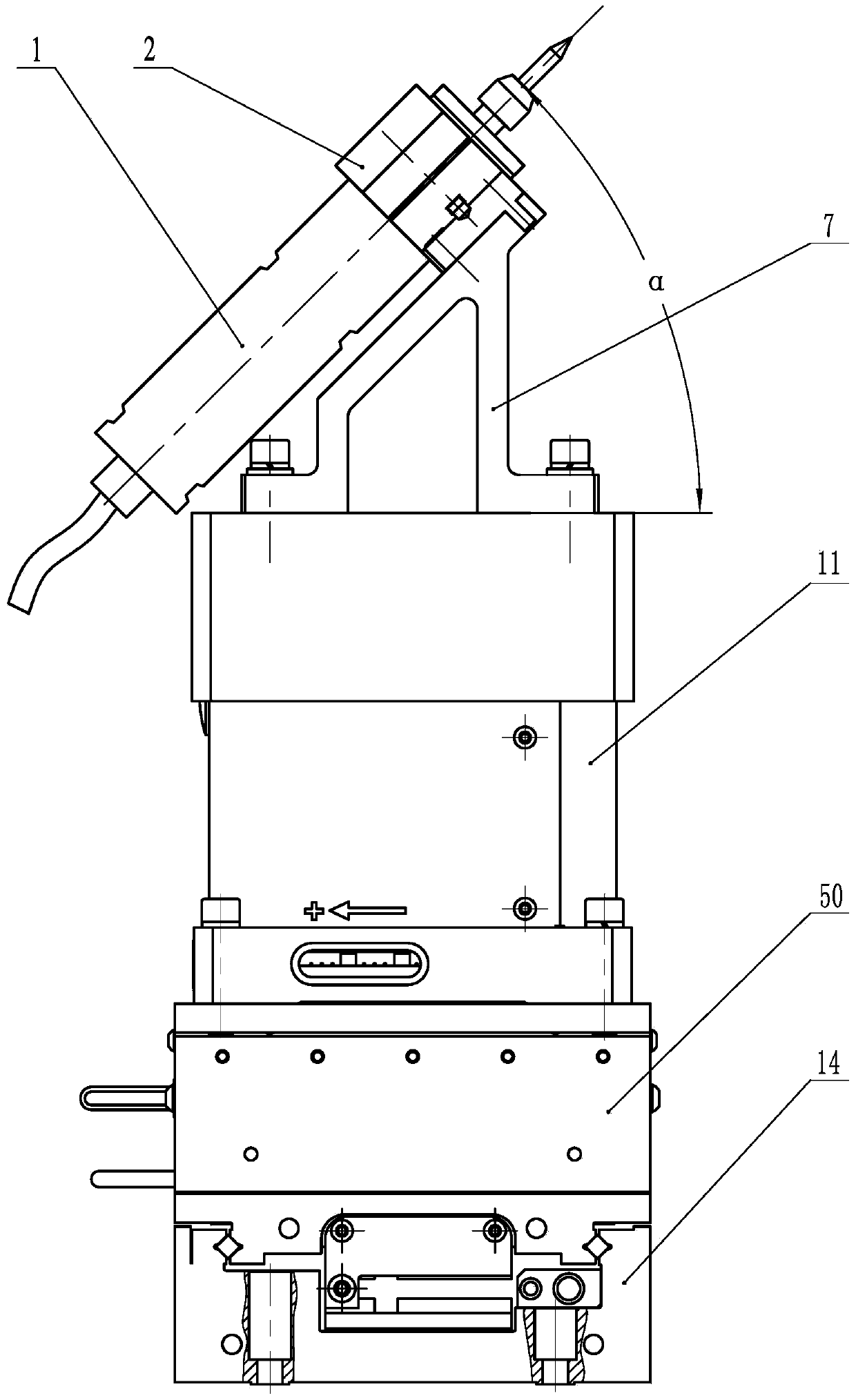

Double-cutter-tower turning center with high-precision stable angle control

ActiveCN112658302AAvoid machining errorsReal-time monitoring of wear and tearMeasurement/indication equipmentsFeeding apparatusControl engineeringControl theory

The invention discloses a double-cutter-tower turning center with high-precision stable angle control. The double-cutter-tower turning center with high-precision stable angle control comprises a rack, an angle control mechanism, a tool feeding mechanism and a tool, the tool feeding mechanism is assembled on the rack, one end of the tool feeding mechanism is fixedly connected with the rack, the other end of the tool feeding mechanism is in sliding connection with the rack, the end, away from the acting end, of the tool is connected with the tool feeding mechanism, one end of the angle control mechanism penetrates through the end, away from the acting end, of the tool, and the other end of the angle control mechanism is fixedly connected with the tool feeding mechanism. According to the double-cutter-tower turning center with high-precision stable angle control, the stability in the angle adjusting process can be guaranteed, and meanwhile the effect of highly accurately controlling the angle needing to be adjusted is achieved. Besides, a spare tool is arranged, when workpieces of the same batch and model are machined, the abrasion condition of the tool can be monitored in real time according to the adjustment displacement difference in the tool feeding process, the main tool and the spare tool are switched in time, and it is guaranteed that the whole turning process is conducted smoothly.

Owner:JIANGSU BOSUNMAN IND EQUIP

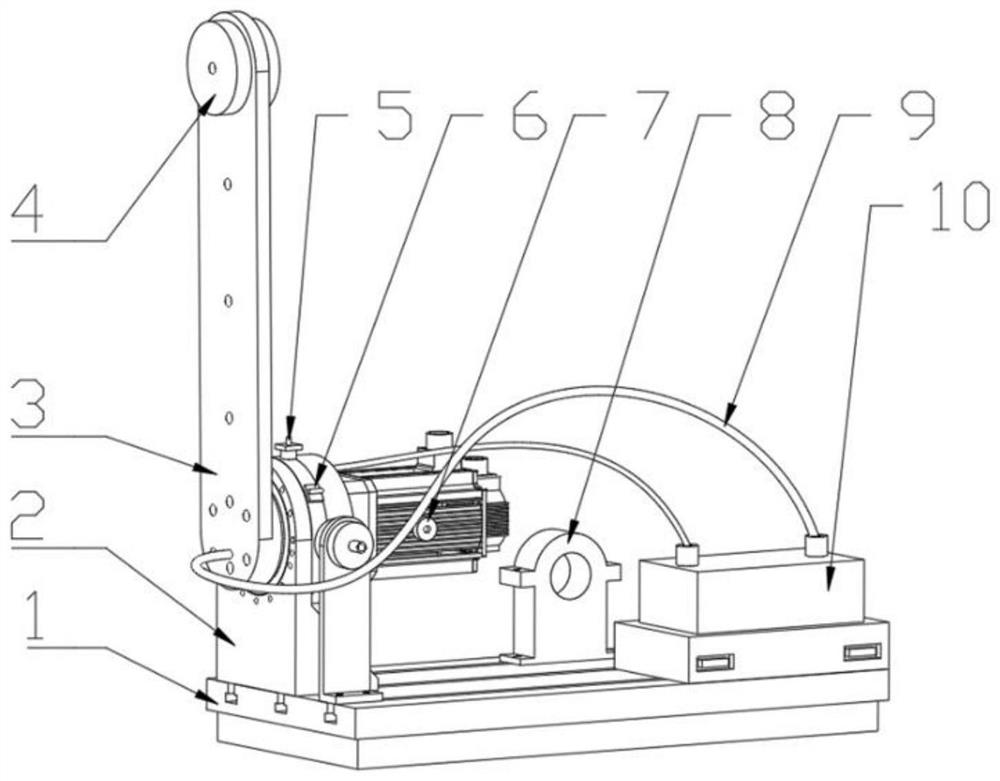

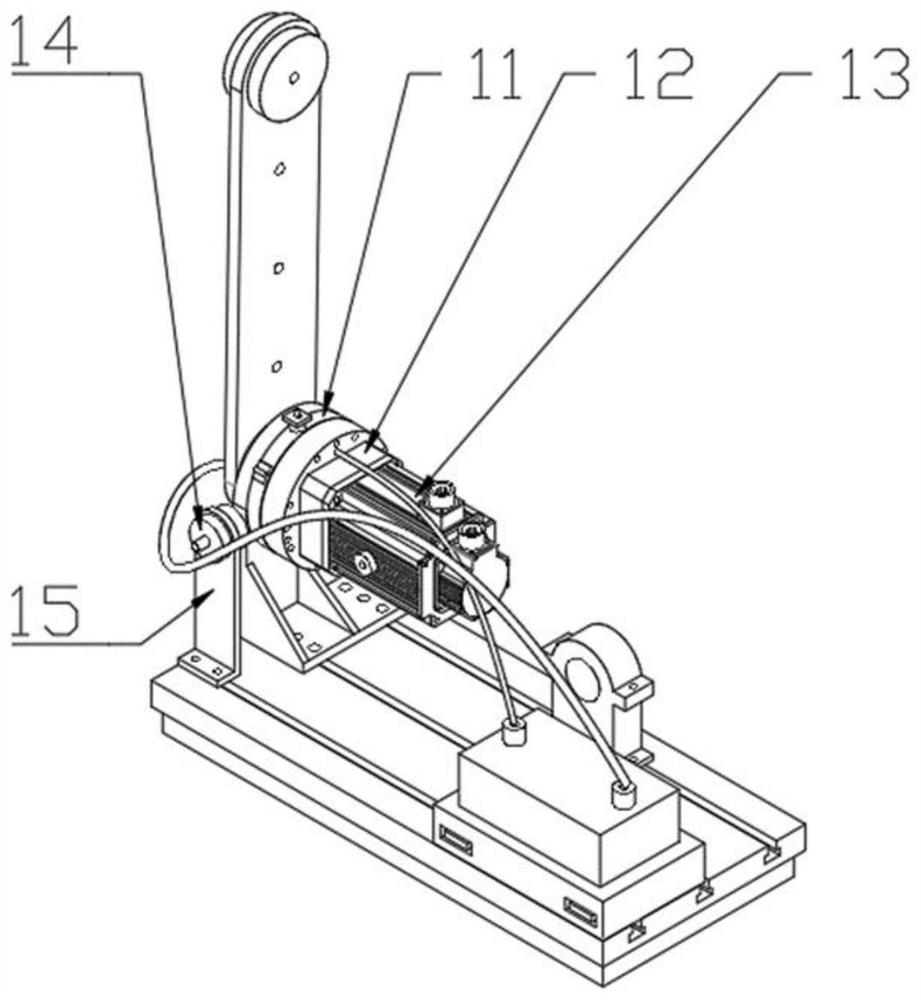

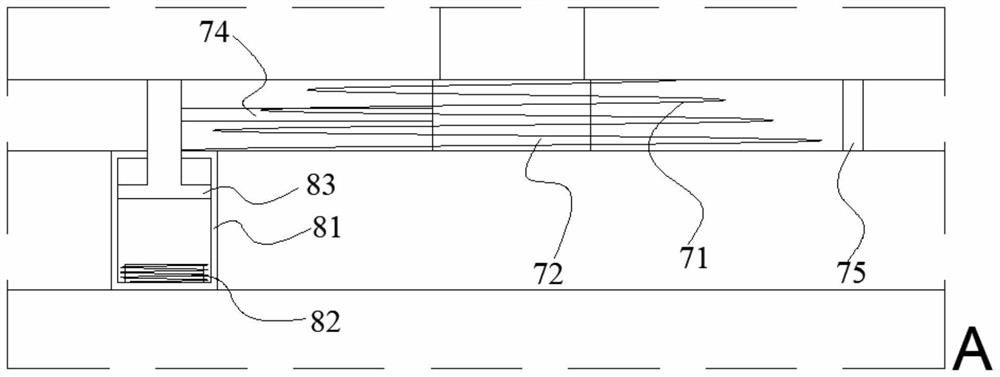

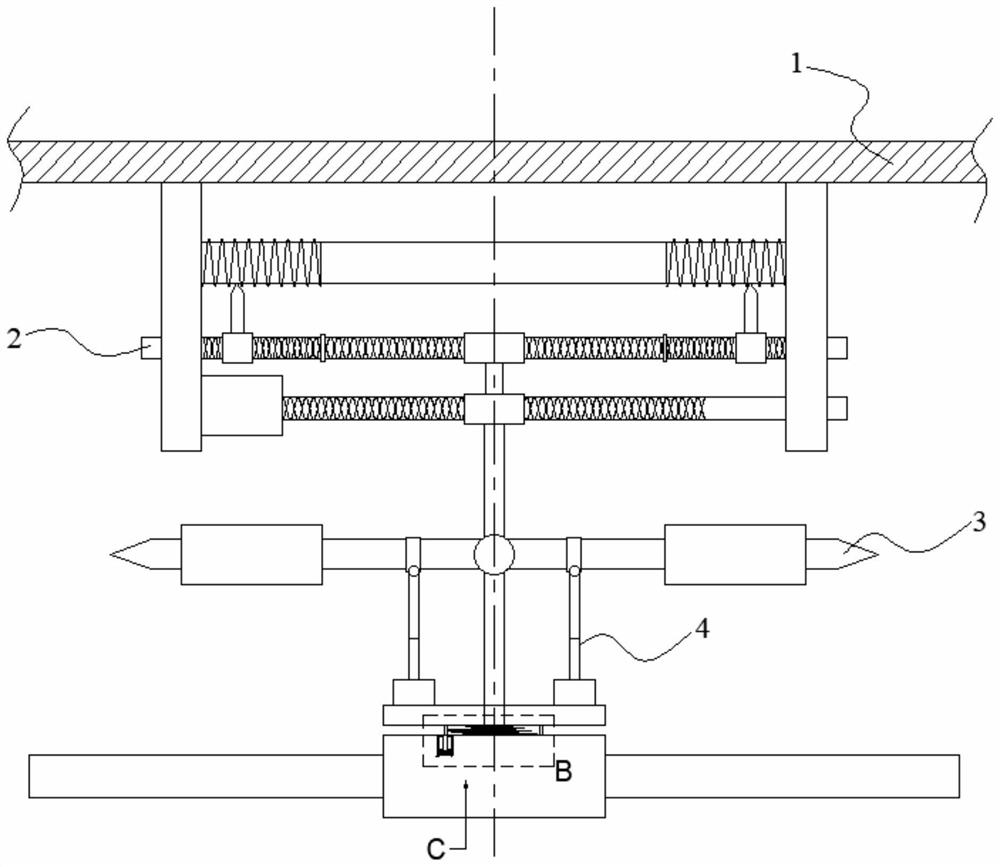

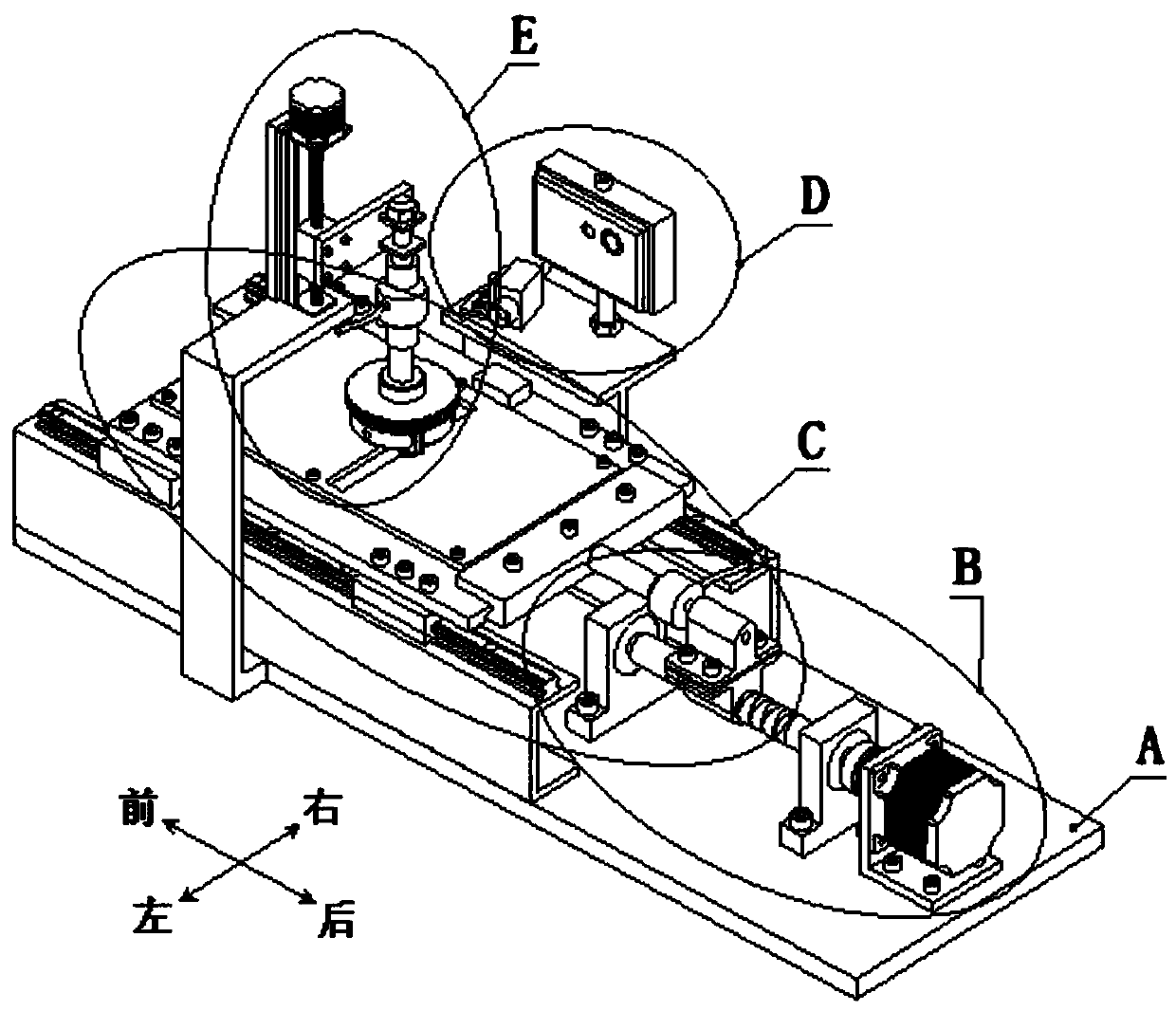

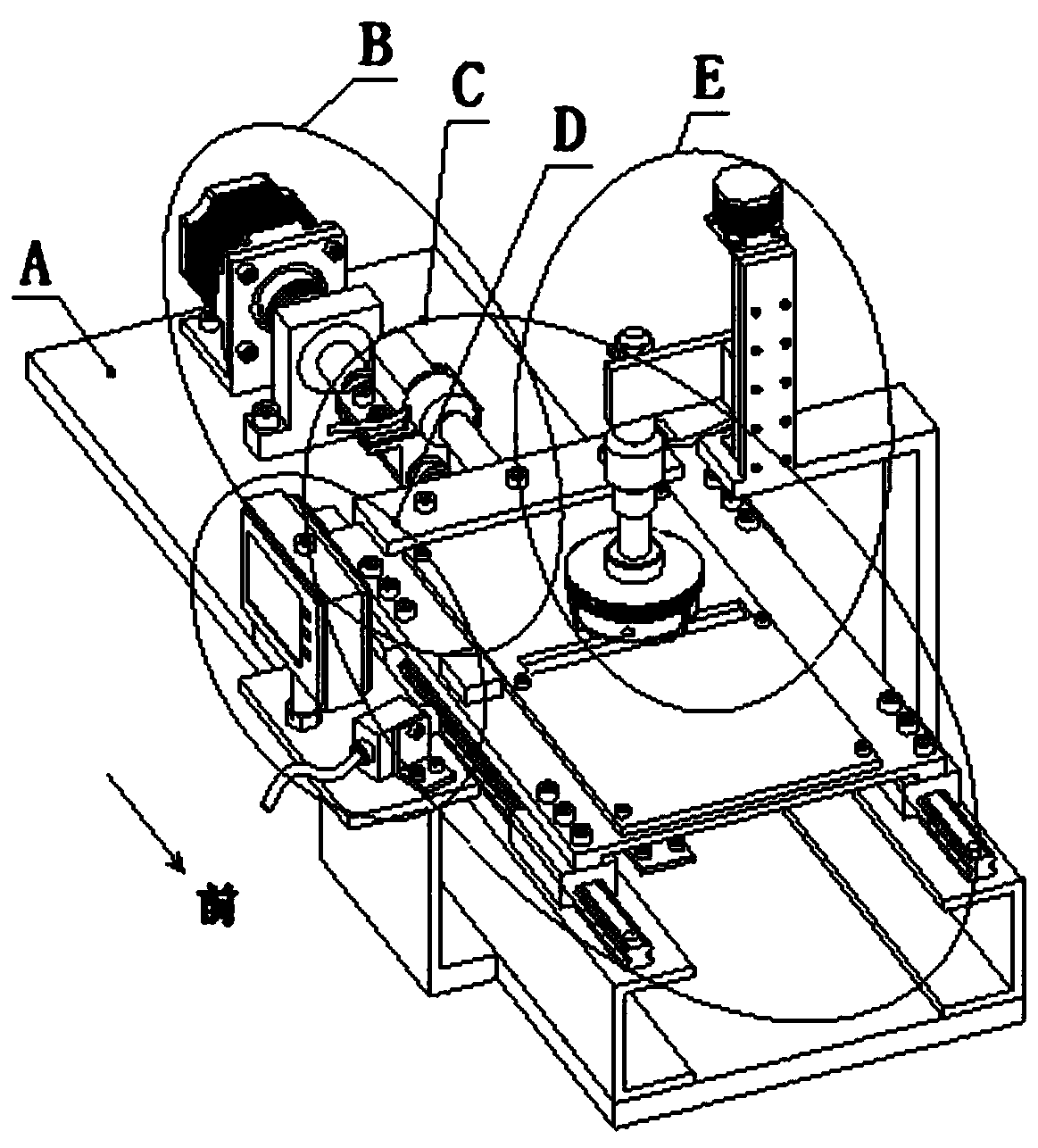

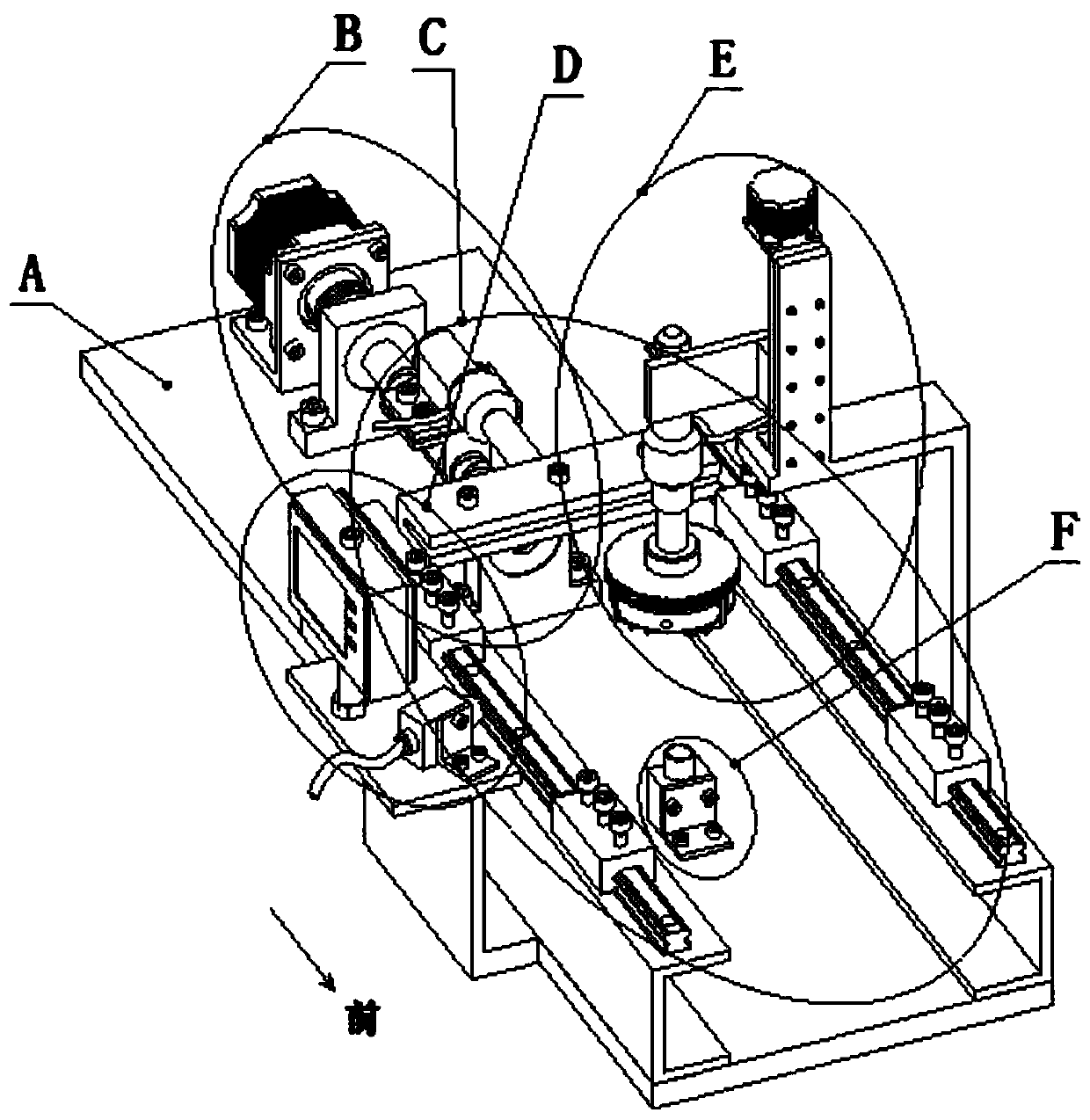

Reciprocating type mechanical friction interface in-situ information acquisition device

PendingCN110726664AReal-time monitoring of friction mechanical propertiesReal-time monitoring featuresRadiation pyrometryUsing mechanical meansElectric machineryForce sensor

The invention provides a reciprocating type mechanical friction interface in-situ information acquisition device, and belongs to the technical field of mechanical friction detection. A reciprocating screw driving method is adopted, and the running speed is stable in the whole process. Since an experimental table is in a reciprocating mode, the speed of points of the friction of a sample to be measured is consistent; a method that a force sensor and acceleration sensor compensate each other is used, so that the precision of a friction force measurement result is very high; a pressure loading mechanism is controlled by a motor screw module, and the force sensor is used for real-time feedback. Before the experiment, the weight of a chuck on the lower part of the force sensor, the sample and the like is eliminated, so accurate loading is achieved. Different friction plates are replaced, so that the friction mechanical characteristics, wear conditions, the temperature and stress change of different sample bodies can be quickly and accurately monitored in real time and detected.

Owner:JILIN UNIV

A ball-end milling cutter with multifunctional micro-woven structure in titanium alloy machining

The invention provides a ball-end mill with a multifunctional micro-texture in titanium alloy machining, relates to a ball-end mill, in particular to the ball-end mill with the multifunctional micro-texture in titanium alloy processing, and aims at solving the problems of lower efficiency of processing the surface of a titanium alloy workpiece by a milling cutter,, poorer quality of the processed workpiece surface, no environmental protection in cooling and lubricating modes, untimely tool change and the like. The ball-end mill comprises a cutter head; and a blade part of the cutter head is sequentially provided with at least one arrow-shaped micro-texture, at least one sawtooth-shaped micro-texture, at least one bowl-shaped micro-texture and at least one rectangular micro-texture from outside to inside. The ball-end mill belongs to the field of machining.

Owner:HARBIN UNIV OF SCI & TECH

Crushing cavity wear monitoring method

ActiveCN110142084BMeet the measurement requirementsReal-time monitoring of wear and tearTesting/monitoring control systemsGrain treatmentsWorking lifeControl engineering

An embodiment of the present invention provides a crushing cavity wear monitoring method, which belongs to the technical field of crushing equipment operation status monitoring. The crushing cavity wear monitoring method includes: obtaining feedback signals having cavity shape characteristics of the crushing cavity at each detection node at different positions of the crushing cavity, and proceeding to the next step when the feedback signals meet the first preset monitoring condition; Select the current detection node, and determine the crushing cavity’s size based on the distance between the current detection node and the adjacent detection node, the feedback signal corresponding to the current detection node, and the feedback signal corresponding to the adjacent detection node. Local characteristics of the cavity shape; when the wear rate corresponding to the local characteristics of the cavity shape satisfies the second preset monitoring condition, jump to the second step to form a cyclic monitoring process. The invention monitors the wear condition of the lining plate and the change of the structural shape of the crushing cavity by detecting the characteristics at the position and the current detection local area characteristics, can predict the working life of the lining plate and create conditions for reasonably formulating the operation and maintenance plan of the crusher.

Owner:JIANGXI UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com