Abrasion monitoring method and structure for crushing cavity

A crushing cavity and cavity shape technology, applied in testing/monitoring control systems, instruments, control/regulation systems, etc., can solve the problems of inability to update and predict the dynamic usage of the crusher, high wear rate, inability to replace or maintain the liner, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0136] A service node for monitoring a crushing chamber comprising:

[0137] The calculation device is used to calculate the change characteristics of the feedback signal of each detection node at different positions in the crushing cavity, and has the characteristics according to the relationship between the change characteristics of the feedback signal and the preset monitoring conditions and the characteristics of the feedback signal and the distance between adjacent detection nodes. The function of judging whether the crushing cavity is worn by the formed local characteristics of the cavity shape, selectively outputting a driving signal to each detection node, and receiving a feedback signal having the cavity shape characteristic of the crushing cavity of each detection node.

[0138] A detection node for monitoring a crushing cavity, comprising: a transmitter that receives a ranging signal transmitted by a service node, generates a ranging pulse from the ranging signal, an...

Embodiment 2

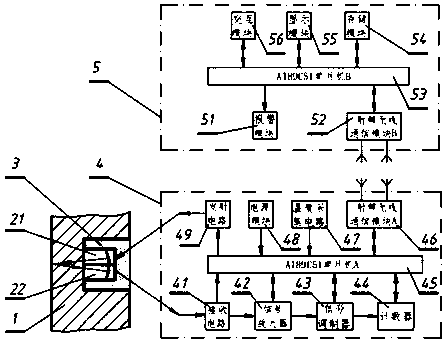

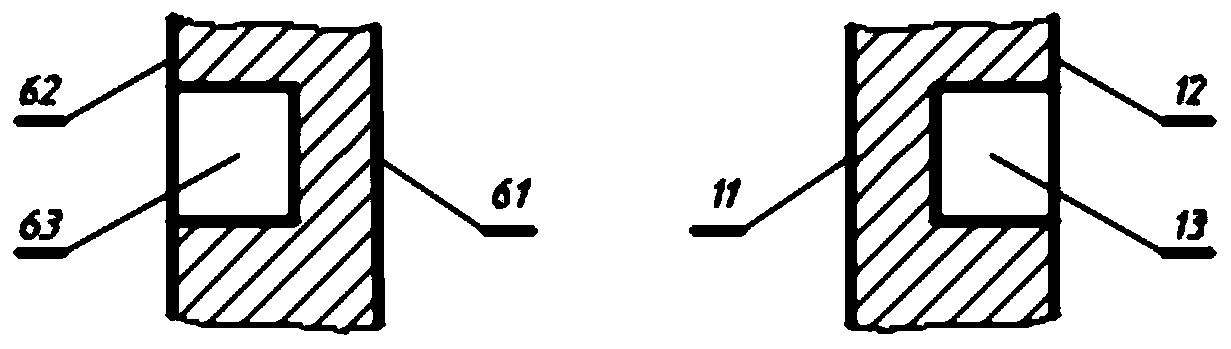

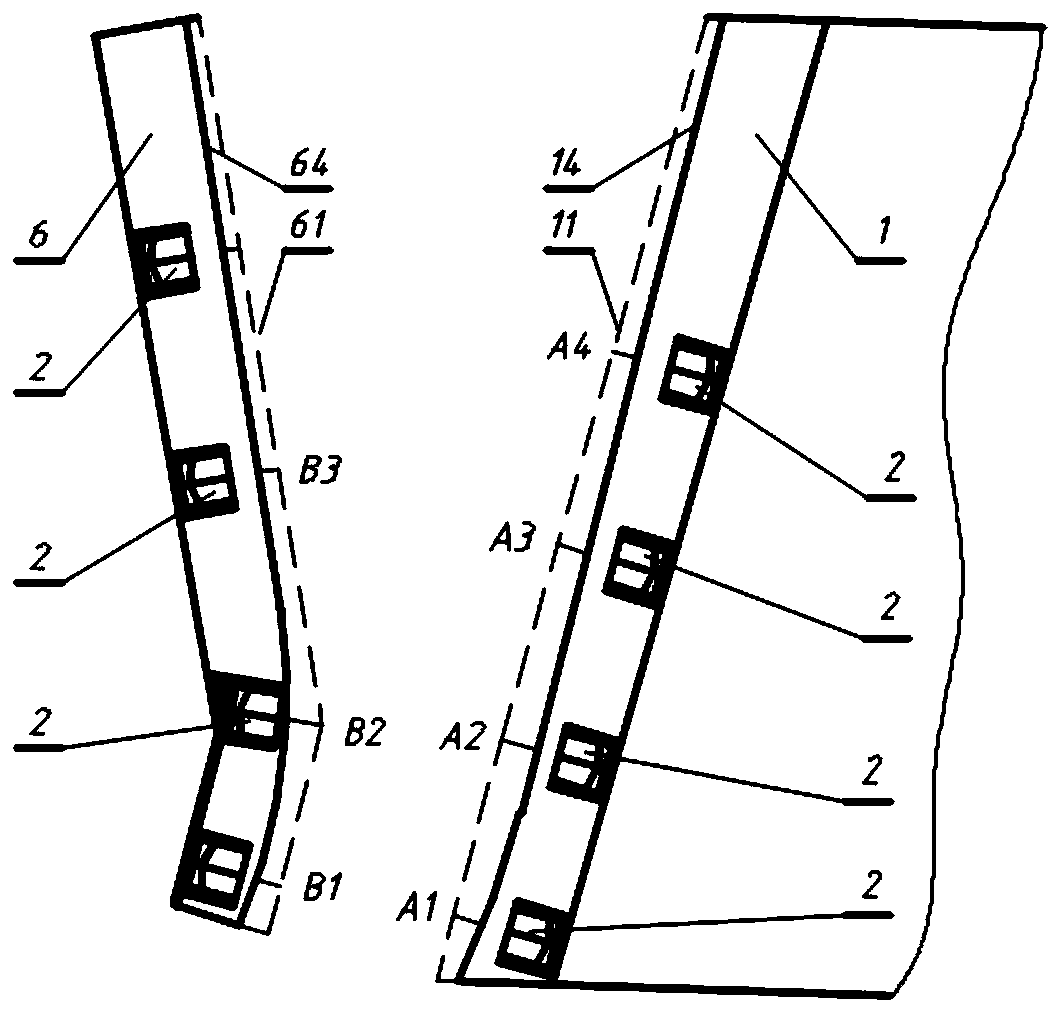

[0159] Based on Example 1, such as figure 1 As shown, the present invention discloses an intelligent liner, including a movable cone liner 1 , a fixed cone liner 6 , an ultrasonic ranging sensor 2 , a coupling agent 3 , an ultrasonic ranging and transmission module 4 and a host computer 5 . The ultrasonic ranging sensor 2 is composed of a transmitting chip 21 and a receiving chip 22. The ultrasonic ranging sensor 2 is installed in the blind hole 13 on the side of the non-working surface of the lining plate 1, and in the blind hole 1 of the lining plate 1 13 is filled with coupling agent 3 between the ultrasonic distance measuring sensor 2, the transmitting chip 21 of the ultrasonic ranging sensor 2 is connected with the transmitting circuit 49 of the ultrasonic ranging and transmission module 4, and the ultrasonic ranging sensor 2 The receiving chip 22 is connected to the receiving circuit 41 of the ultrasonic ranging and transmission module 4, and the host computer 5 is conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com