Output measuring system for medical ultrasonic equipment

A technology of ultrasonic equipment and measurement system, which is applied in the direction of measuring ultrasonic/sonic/infrasonic waves, measuring devices, instruments, etc., and can solve problems such as backward technology, incapable of precise orientation and positioning, and outdated functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

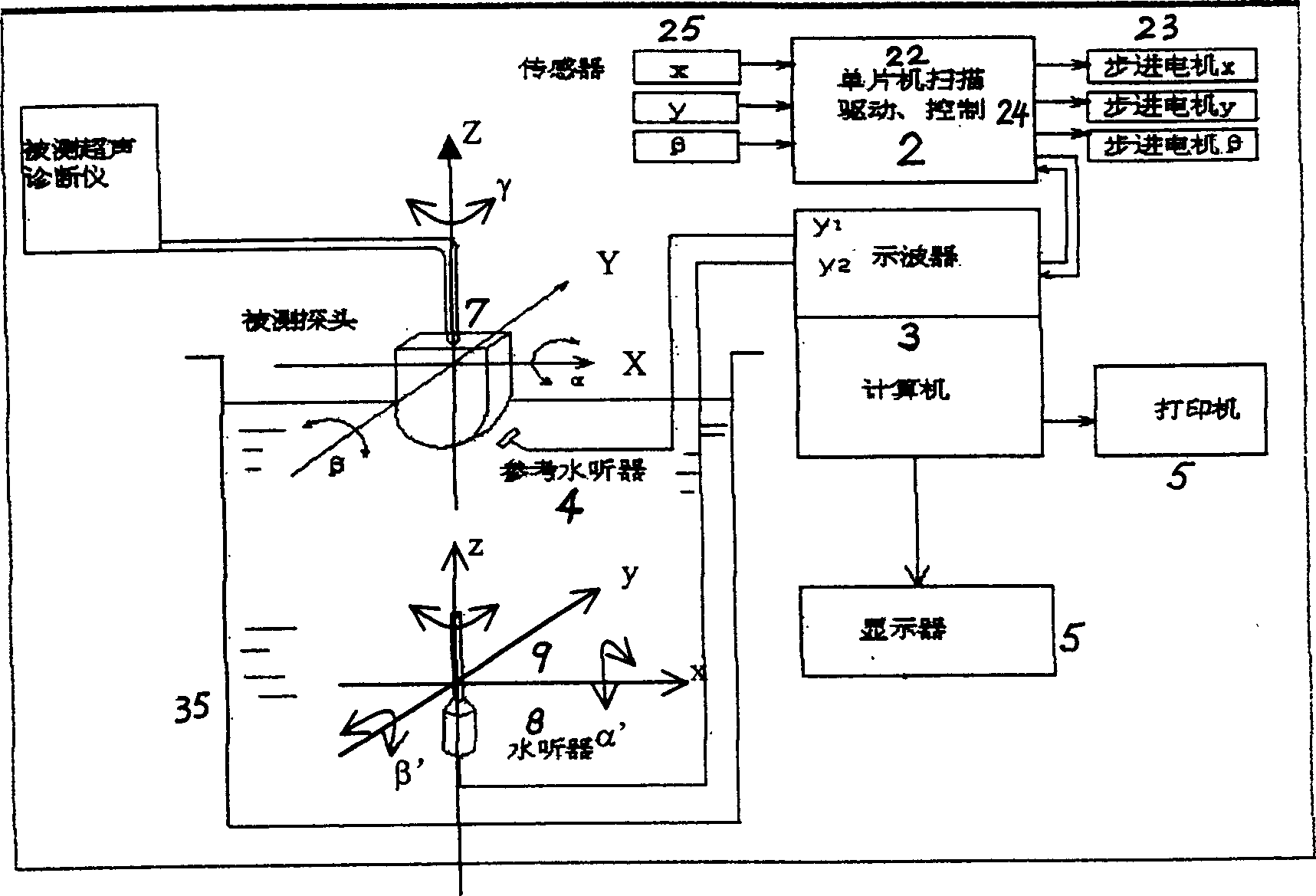

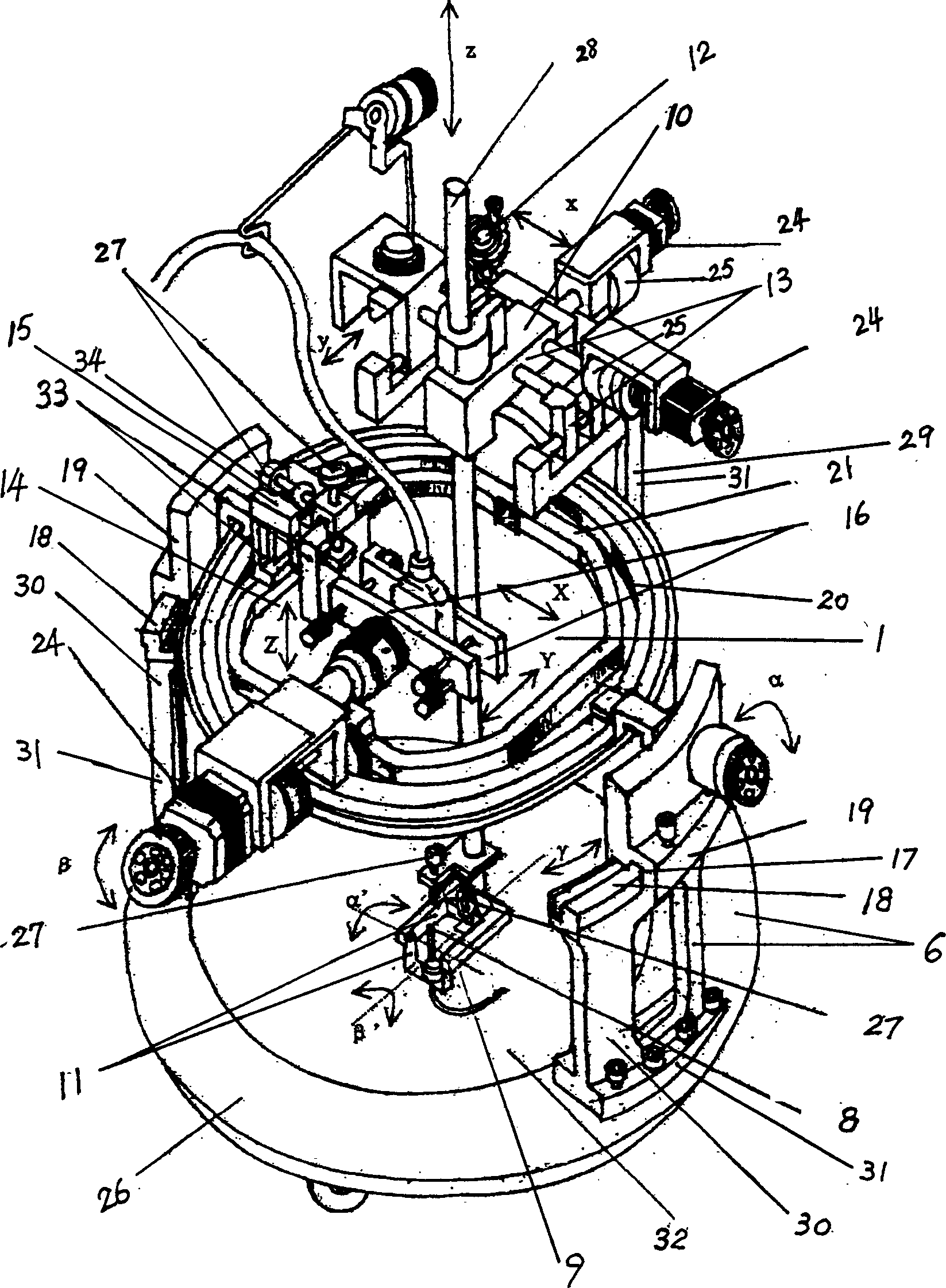

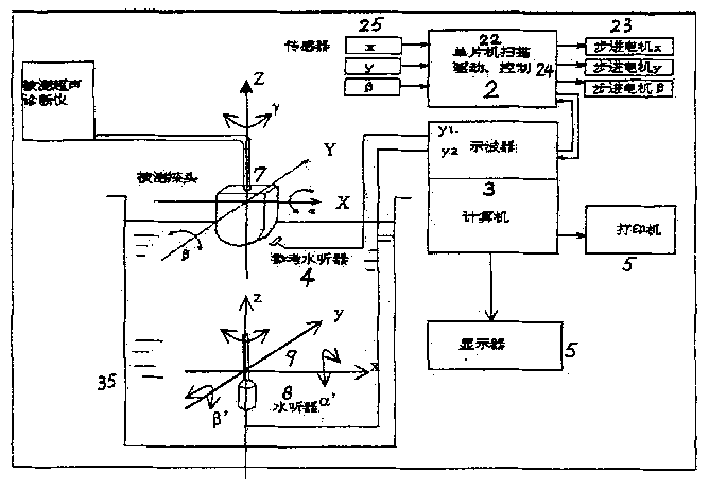

[0028] Such as figure 1 and figure 2 As shown, the present invention includes: the measured probe with 11 degrees of freedom and the two-way coordinate precision orientation and positioning system 1 of the hydrophone, the three-dimensional sound field scanning stepper motor drive and control system 2, the storage oscilloscope-computer system 3, the measurement The hydrophone and the reference hydrophone 4, the auxiliary equipment 5, and the mechanical frame 6 are connected as follows: the measuring hydrophone and the reference hydrophone 4 are fixed on the measured probe with 11 degrees of freedom and the measuring water through a fixture. On the two-way coordinate precision orientation and positioning system 1 of the earphone, the cables of the measuring hydrophone and the reference hydrophone 4 are directly connected to the signal input end of the storage oscilloscope-computer system 3, and the three-dimensional sound field scanning stepper motor drive and control system 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com