Method for testing mechanical property of superhard diamond film

A technology of diamond film and testing method, which is applied in the field of measurement and evaluation of mechanical properties of superhard diamond film, can solve the problems of inability to quantitatively characterize the bonding force between diamond film and substrate, inaccurate test results, poor test repeatability, etc., and achieve improvement The effect of fixed load indentation method, promotion of popularization and application, and reduction of test cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The tests carried out are all tested on the domestic MFT-5000 micron indentation tester, and the machine indenter is replaced with a synthetic diamond indenter.

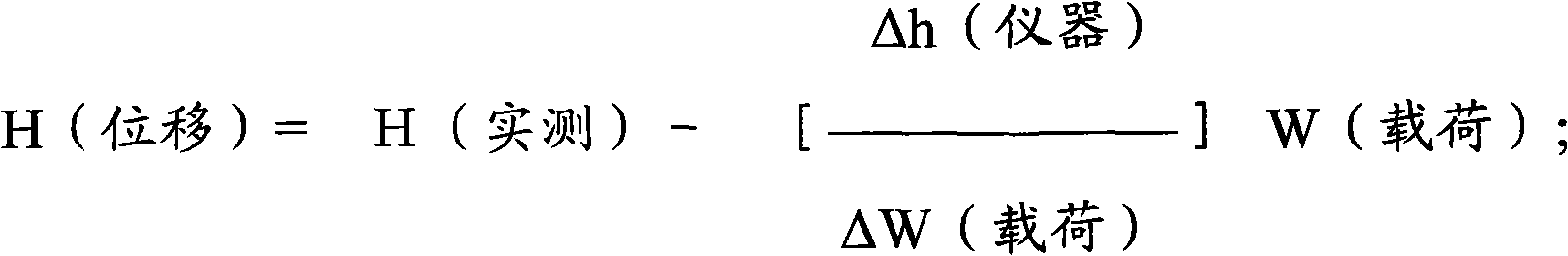

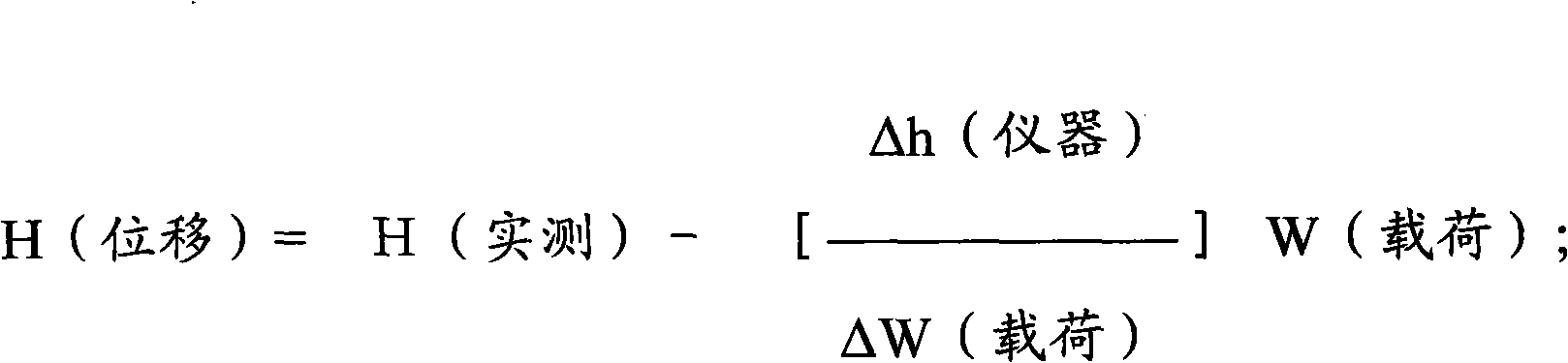

[0029] Such as figure 1 As shown, the micron indentation tester includes a main frame, on which a sample stage is arranged, and the sample to be tested is placed and fixed on the sample stage; above the sample is a load loading mechanism, and the load loading mechanism is connected continuously Loading motor, the load loading mechanism is provided with an artificial diamond indenter that applies a continuous load, the load loading mechanism is connected with a displacement sensor, a loading sensor and an acoustic emission sensor, and the displacement sensor, the loading sensor and the acoustic emission sensor pass through a signal amplifier It is connected with a computer, the displacement sensor is connected with a depth sensor moving motor, and the computer is connected with a control converter, and the cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com