Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

41results about How to "Prevent overburning" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method of and apparatus for determining the carbon content of soils

ActiveUS20150247787A1Lose weightInhibit gas flowWeighing by removing componentChemical analysis using combustionSoil scienceOrganic matter

Owner:YEOMANS ALLAN JAMES

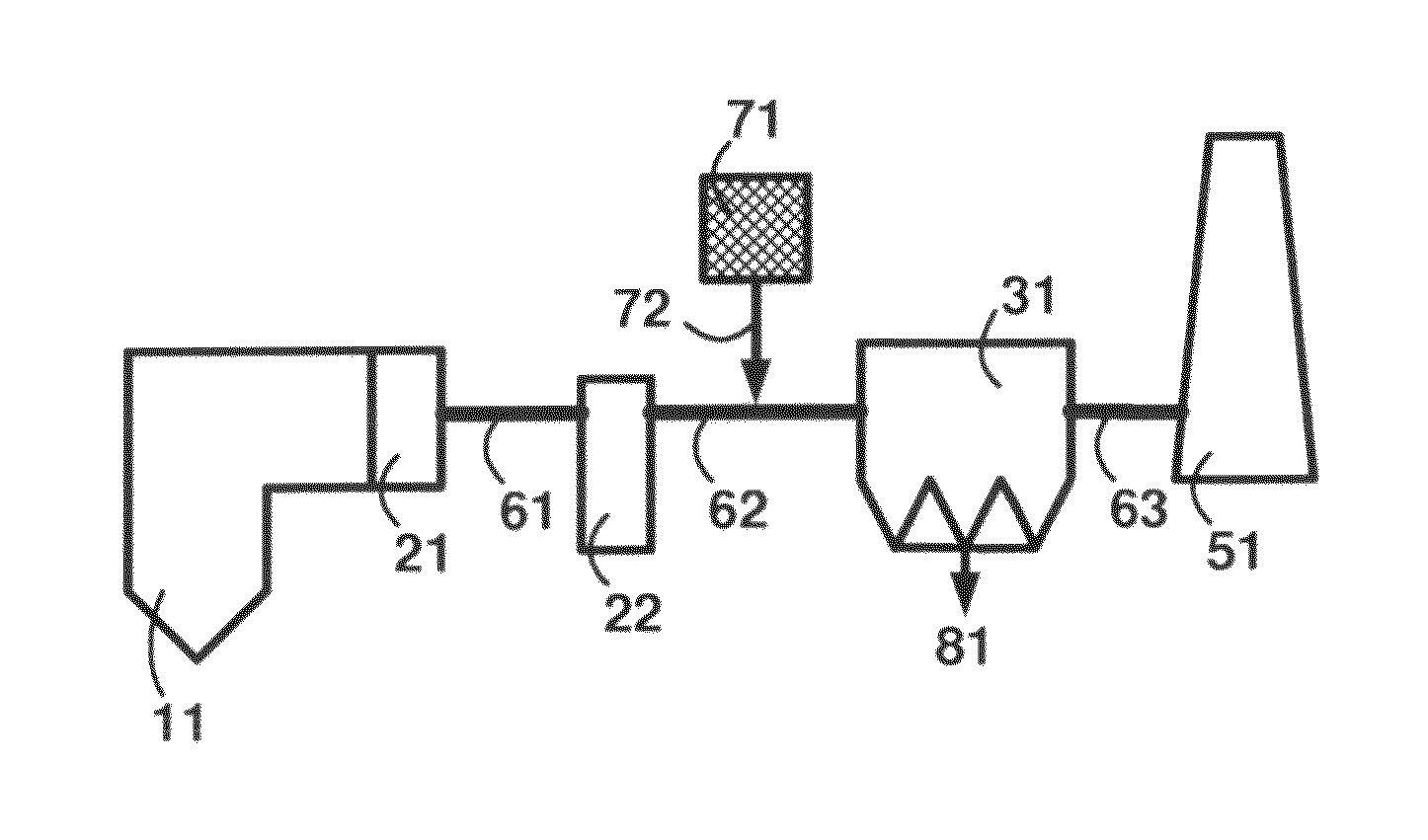

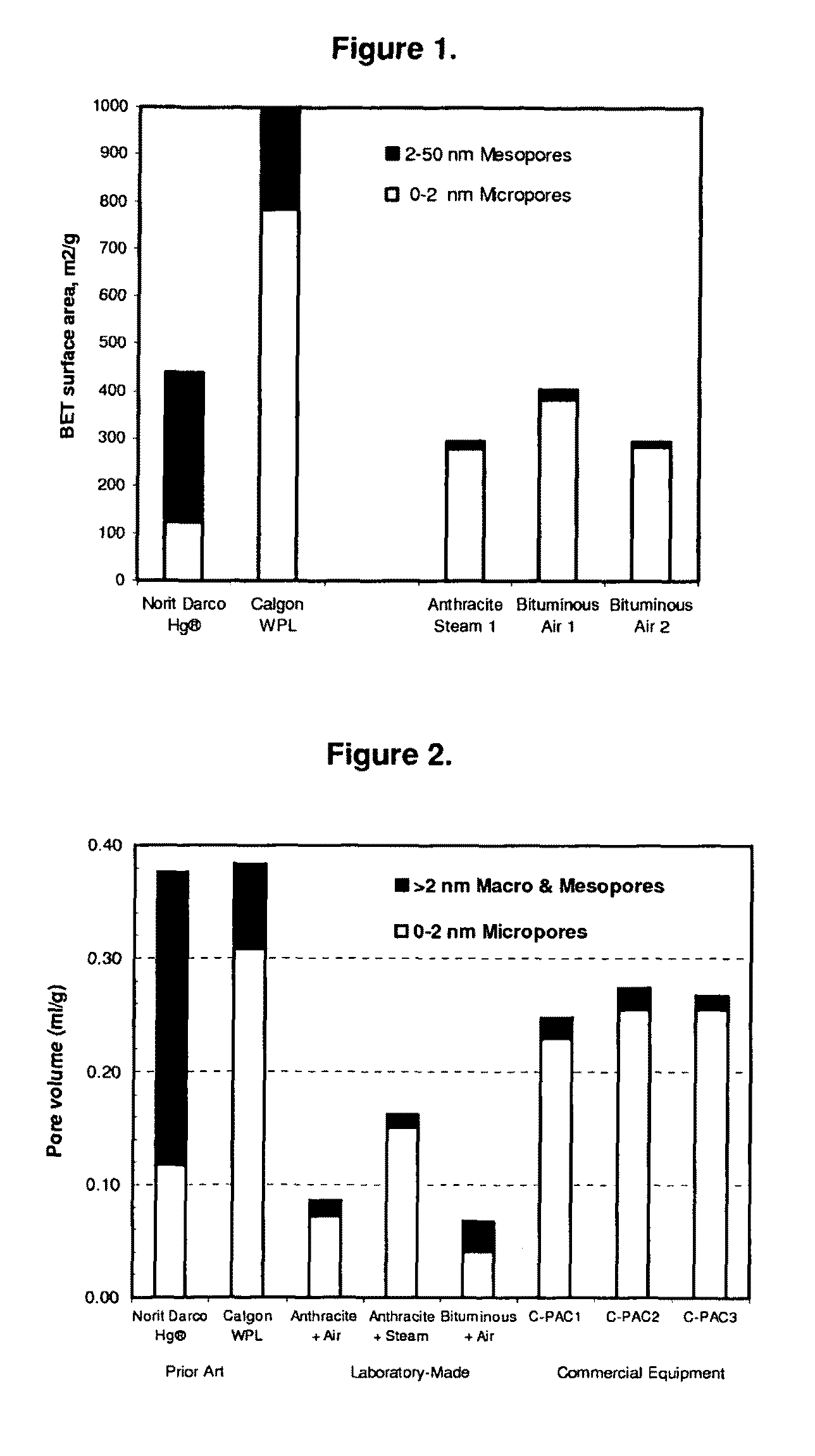

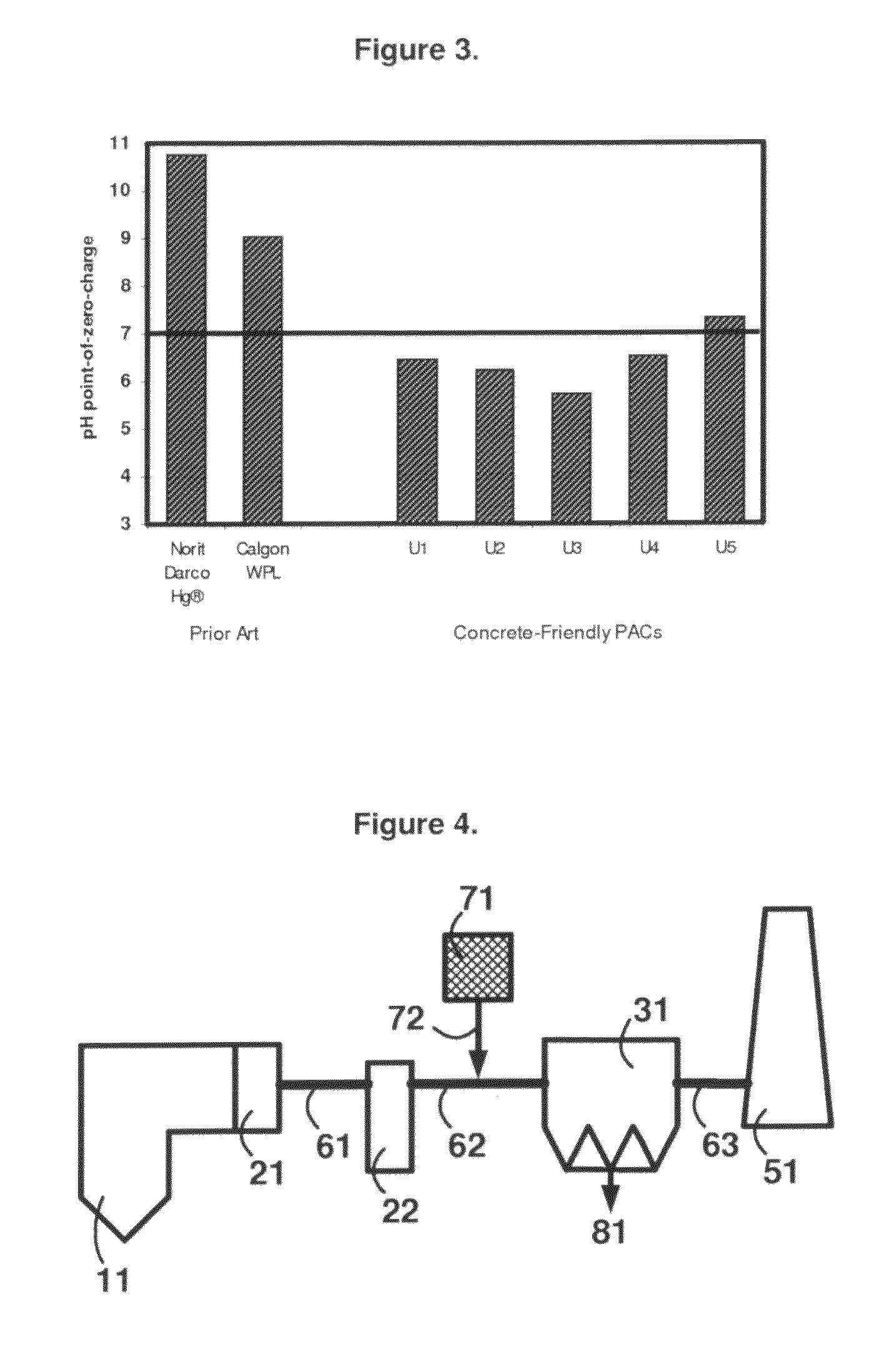

Compositions and methods to sequester flue gas mercury in concrete

ActiveUS20100212550A1Prevent overburningImprove effectivenessGas treatmentCarbon compoundsActivated carbonFlue gas

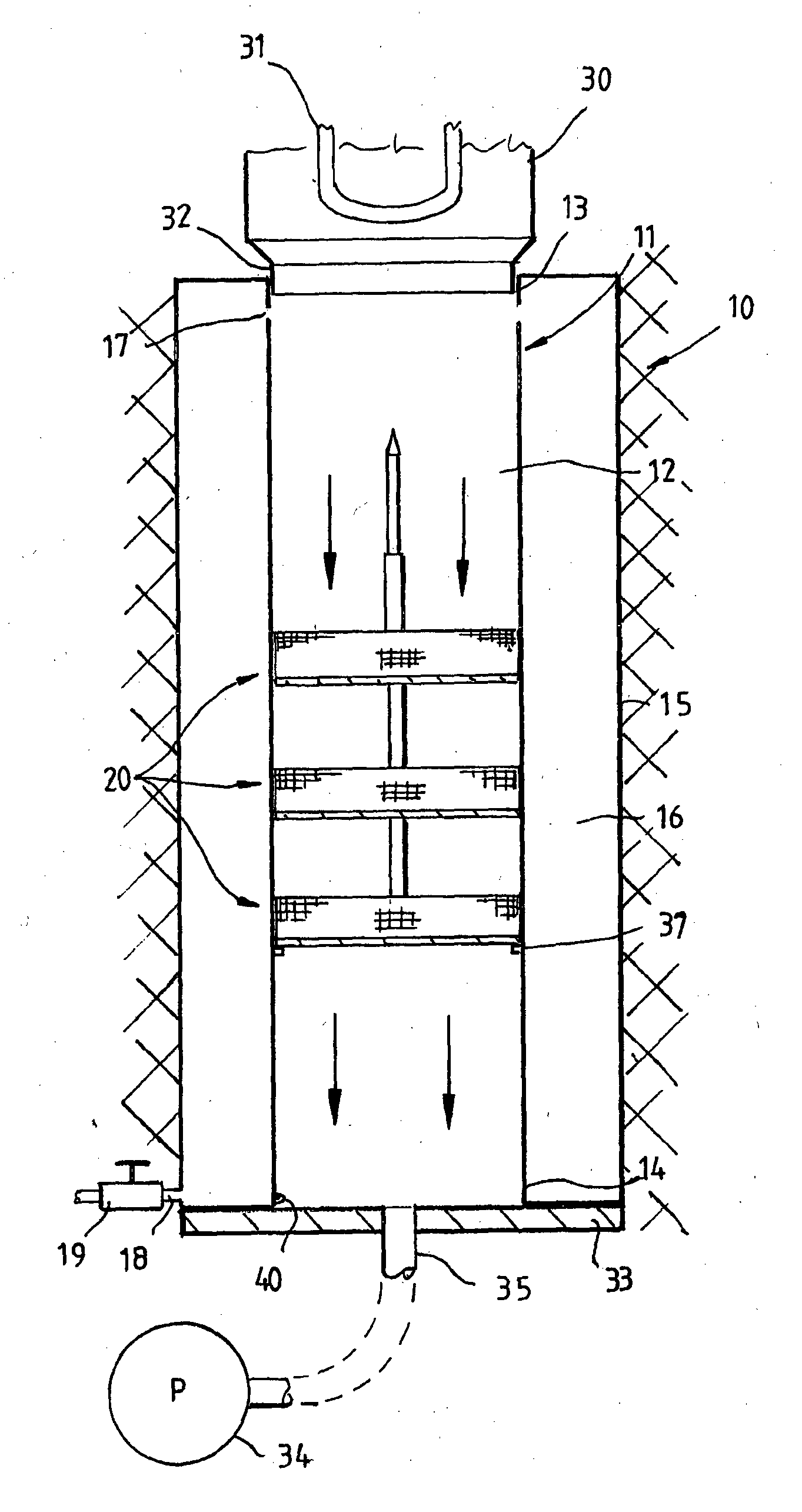

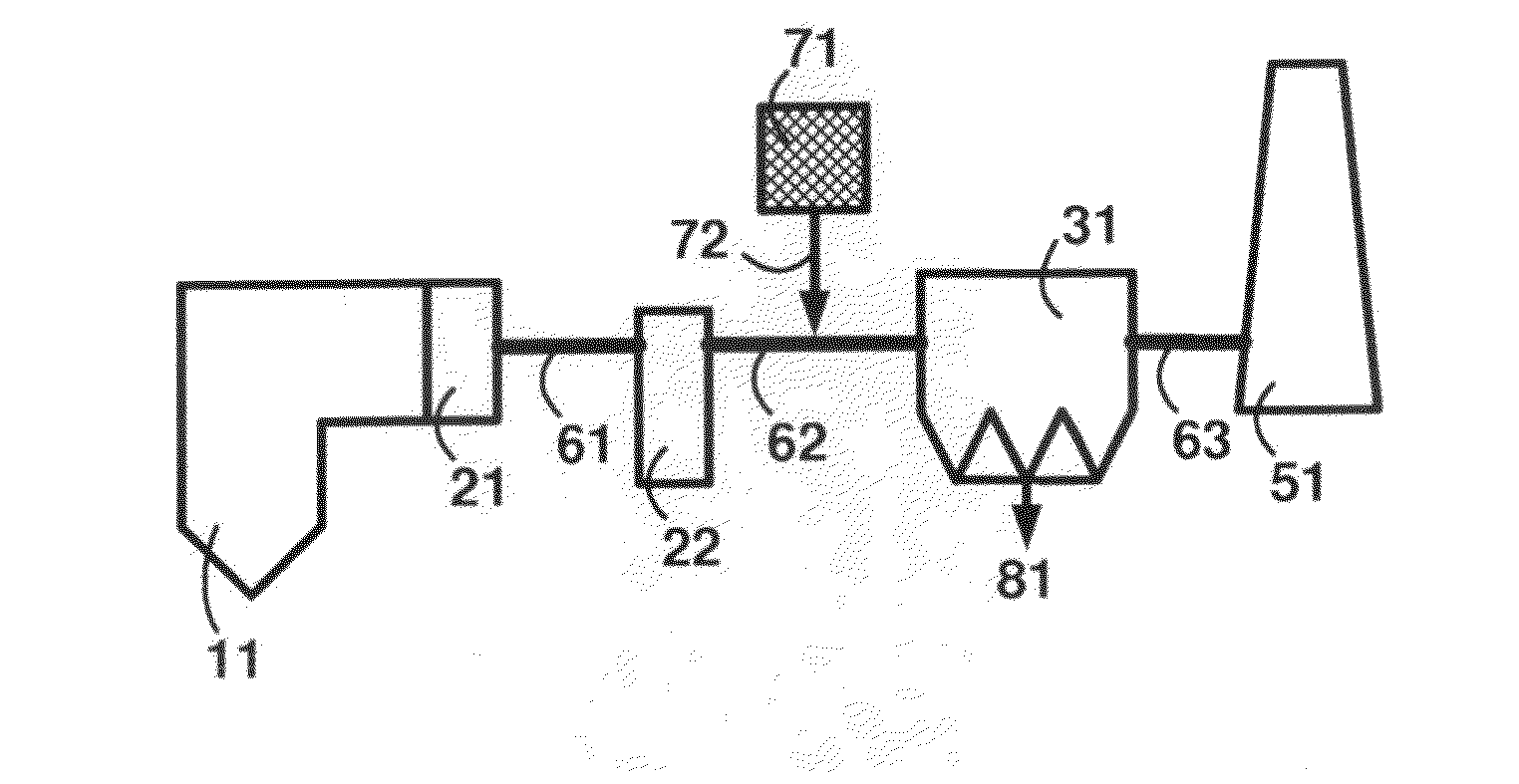

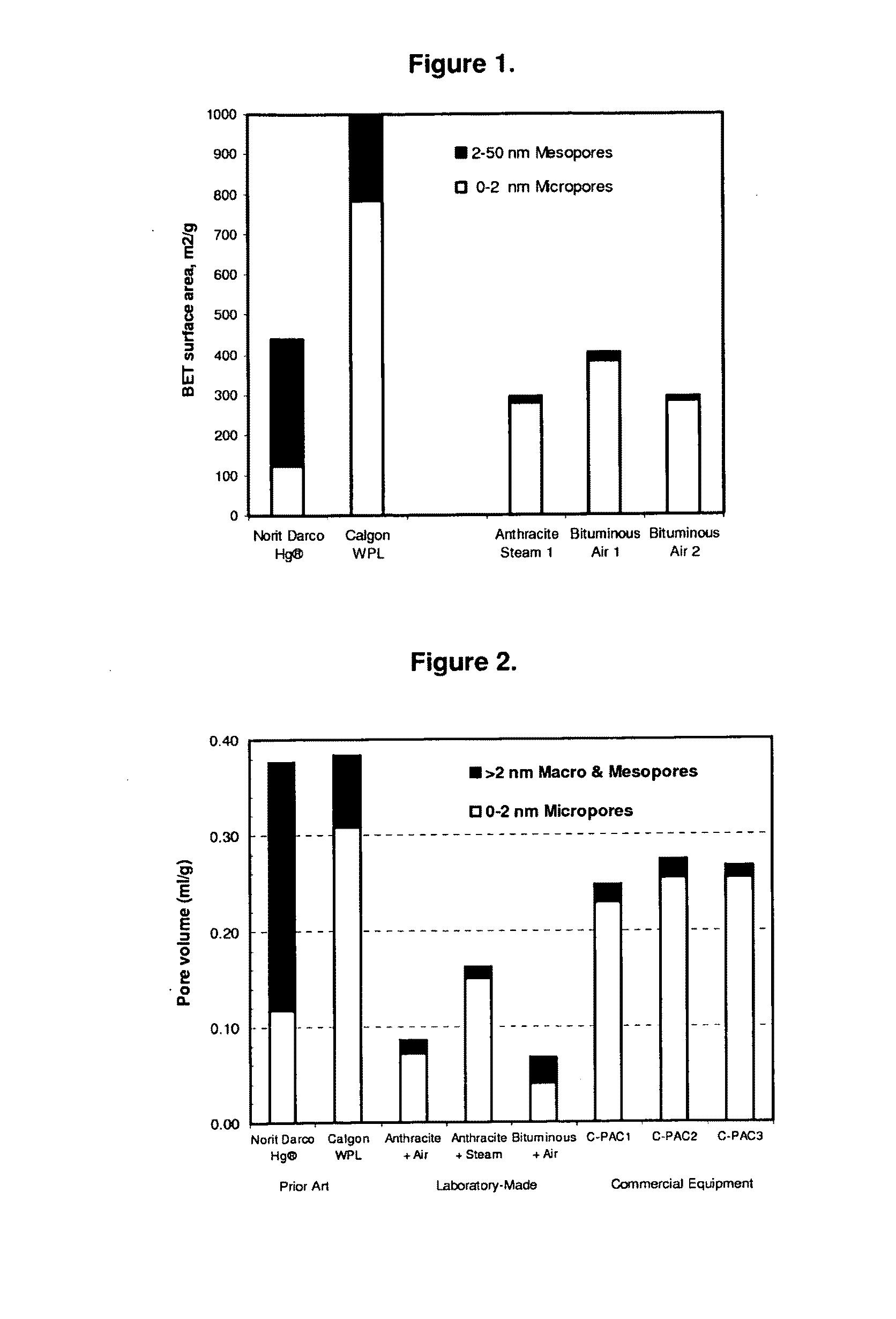

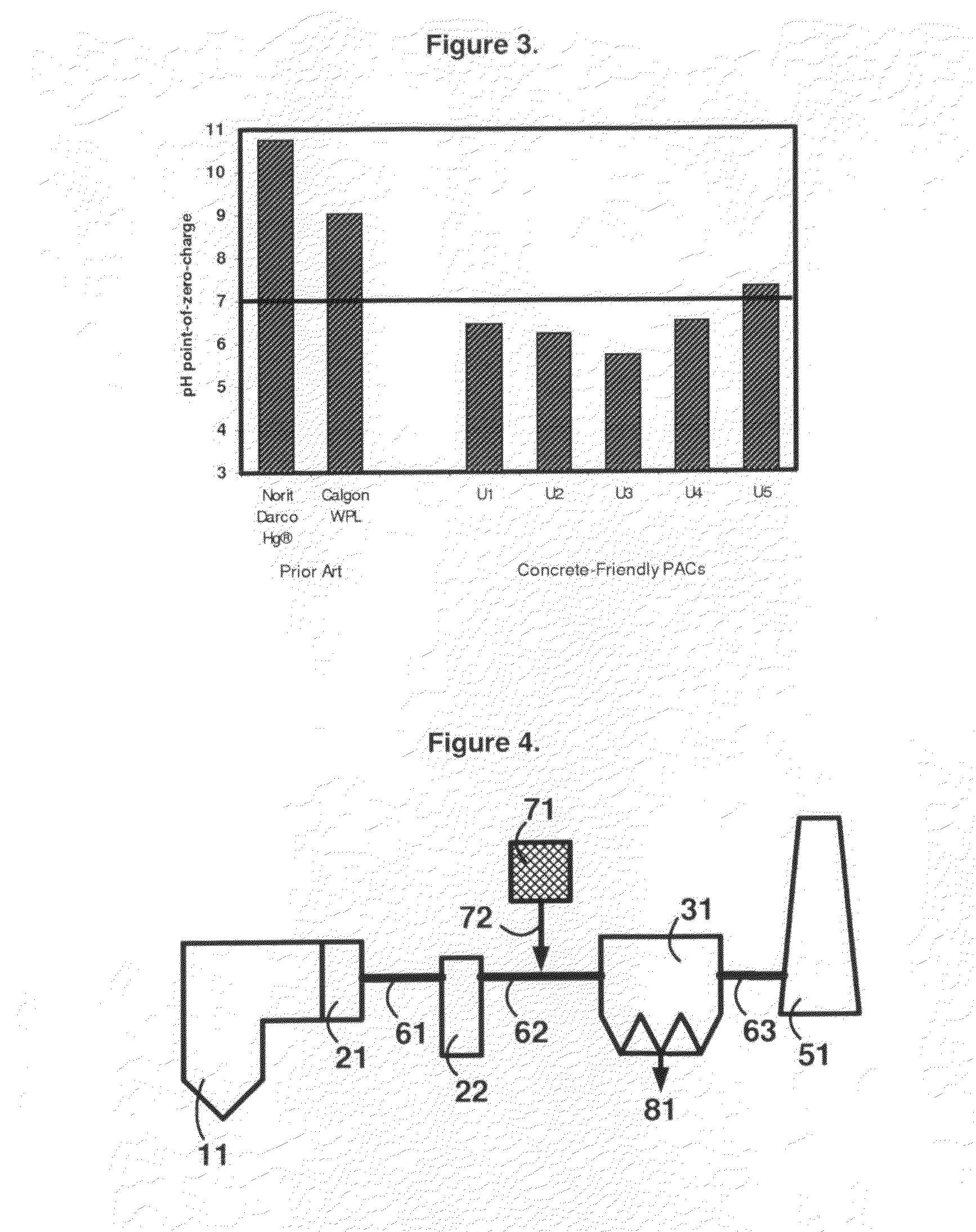

Mercury adsorbed from combustion gas by activated carbon can be sequestered in concrete containing air entraining admixtures. The activated carbon may be made by providing a carbon char made from anthracite or low-volatile bituminous coal that was devolatilized and carbonized in an oxygen-depleted environment and activating this char in the presence of steam to provide an activated carbon with an acid blue 80 index of less than about 30 milligrams per gram of carbon. The activated carbon may also be made by providing a carbon char that was devolatilized and carbonized in an oxygen-depleted environment and activating this char in the presence of oxygen to provide an activated carbon. The carbon may be injected into a combustion gas stream containing fly ash and mercury and may then be removed with fly ash from the gas stream. The resulting composition may be used as a partial substitute for cement in air-entrained concretes.

Owner:SORBENT TECH +1

Detection apparatus

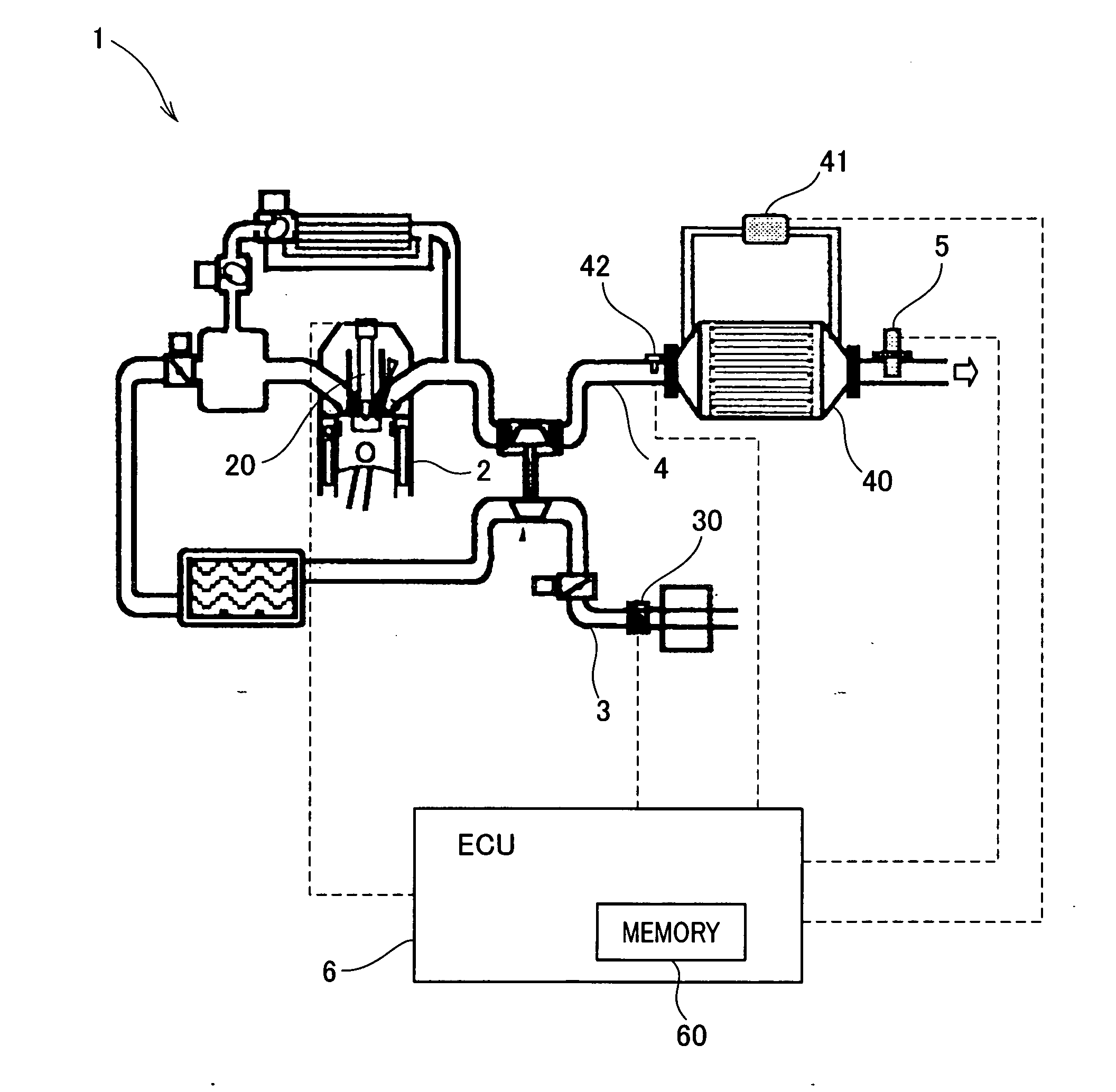

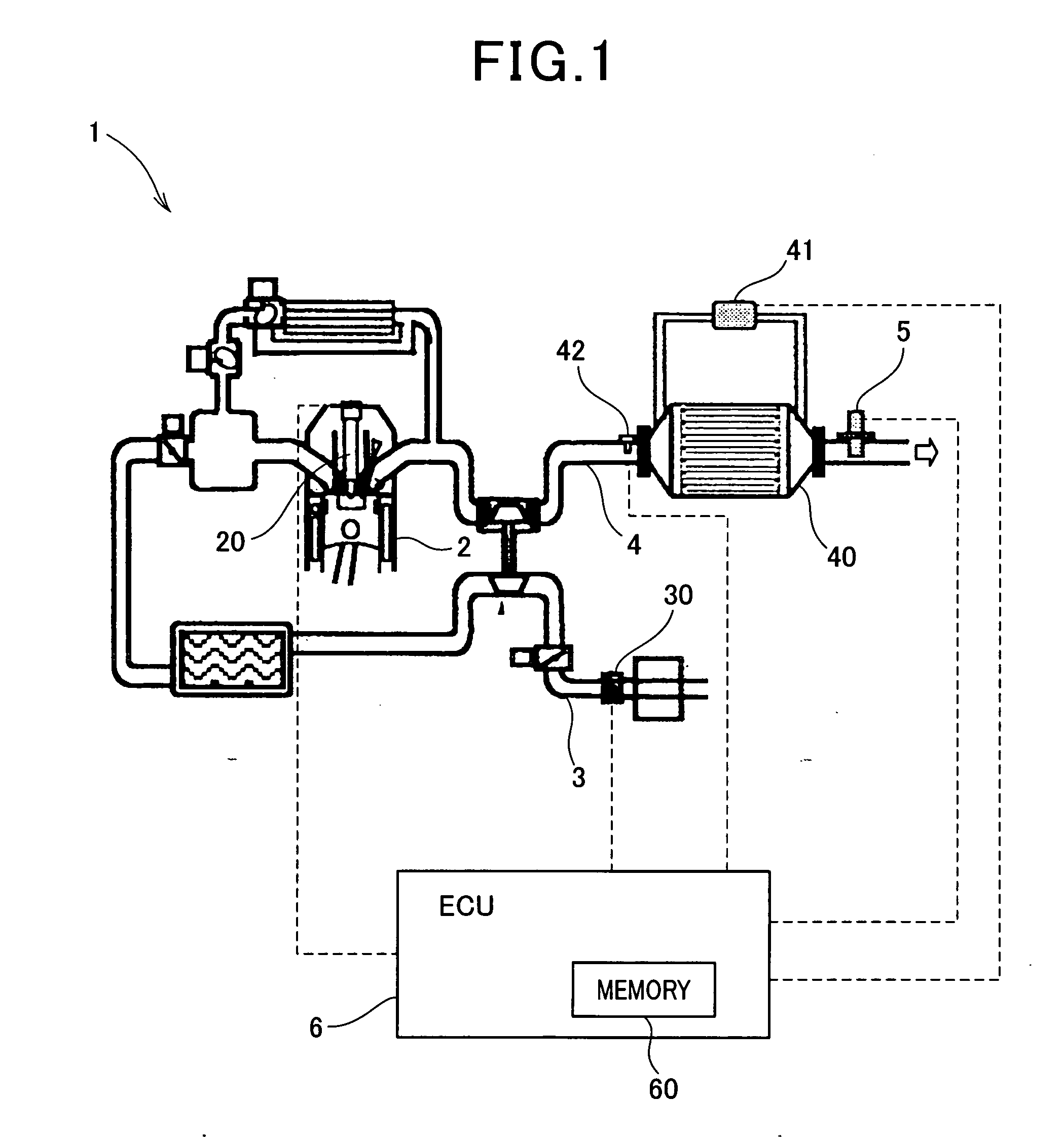

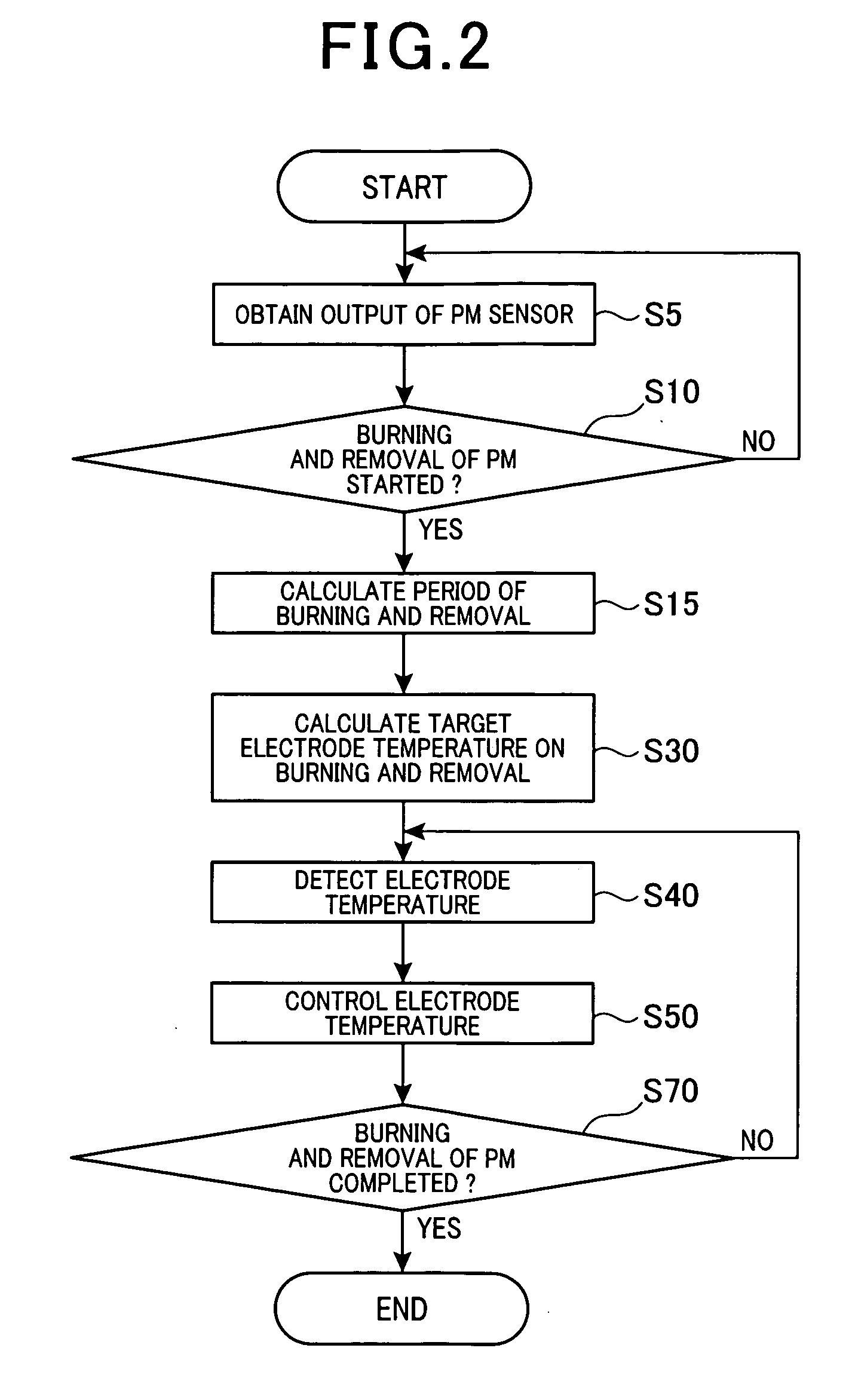

ActiveUS20120186230A1Improve accuracyKeep for a long timeElectrical controlExhaust apparatusParticulatesRegenerative process

A detection apparatus includes a detection unit, a control unit, a first setting unit, and a second setting unit. The detection unit is disposed in an exhaust path through which an exhaust gas flows, and detects a correlation value correlated with an amount of particulate matter (PM) attaching to an attachment element. The control unit controls a temperature of the attachment element to follow a target temperature while a regeneration process is performed to heat the attachment element so as to burn PM. The first setting unit sets the target temperature to be lower, as the amount of PM becomes larger. The second setting unit sets a completion timing of the regeneration process so that a period of the regeneration process becomes longer, as the amount of PM becomes larger or a temperature of the attachment element becomes lower while the regeneration process is performed.

Owner:DENSO CORP

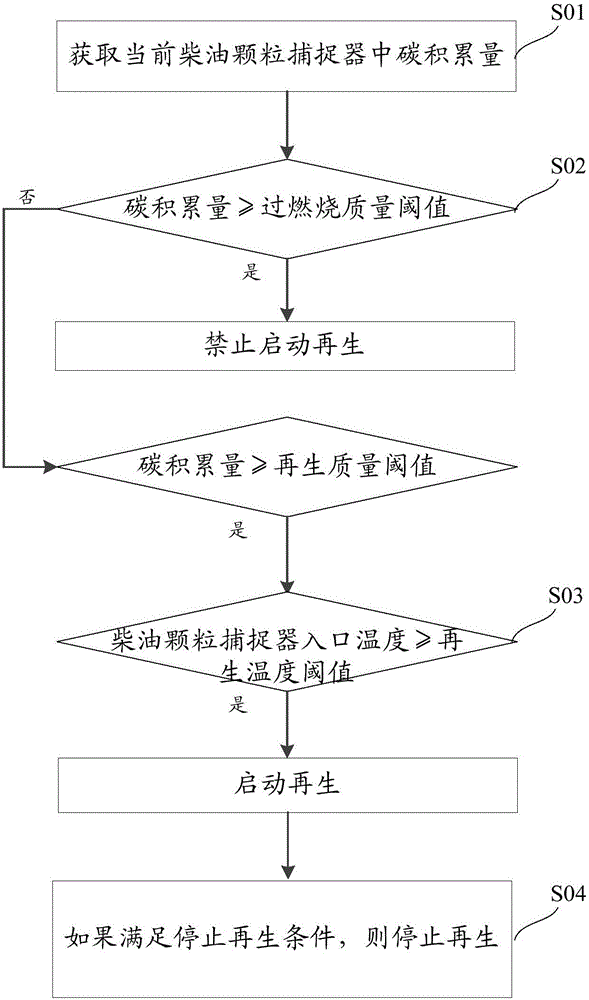

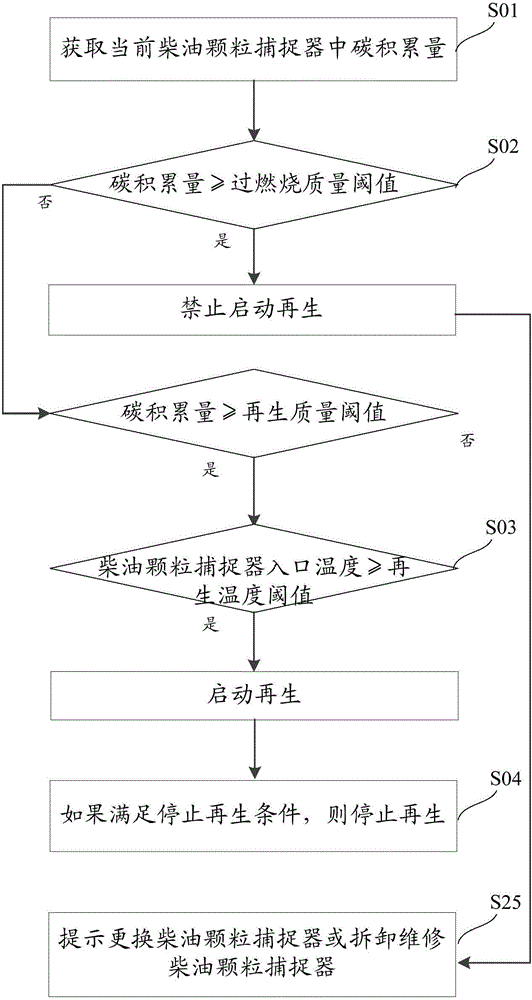

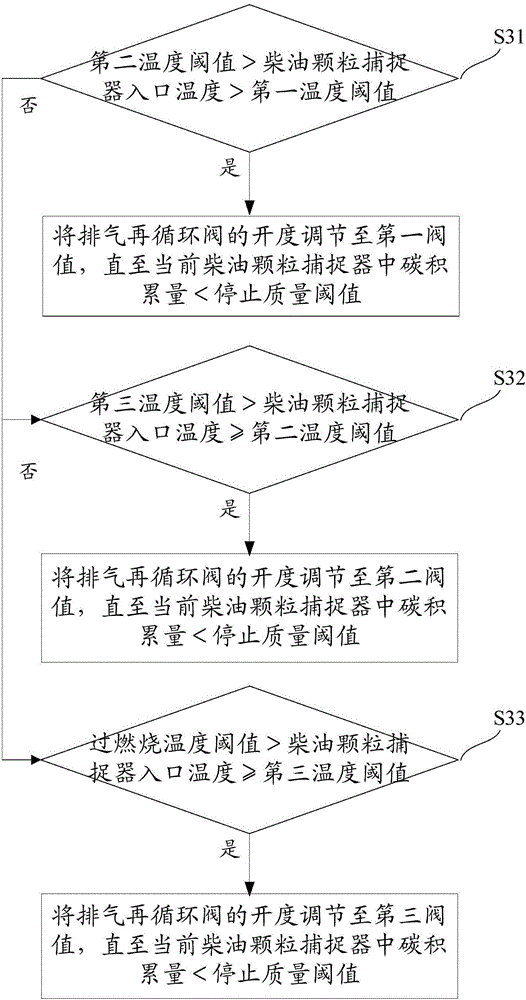

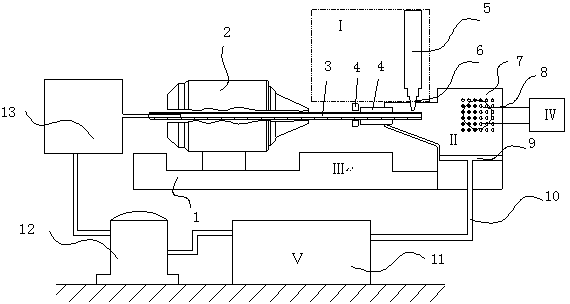

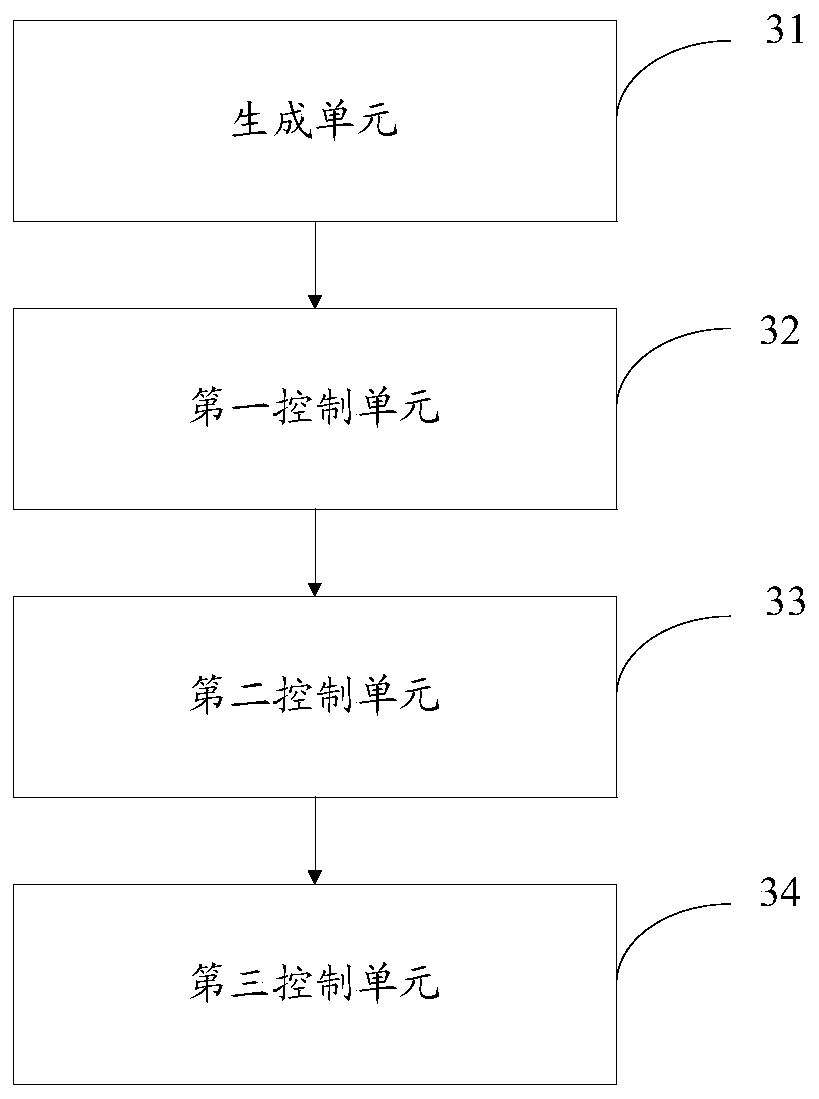

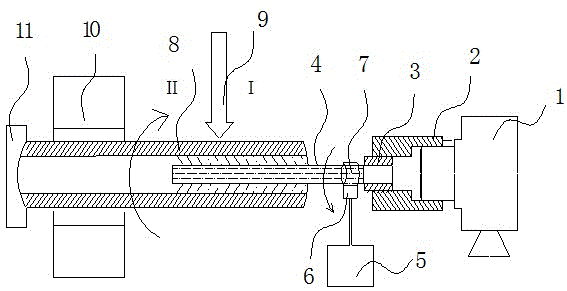

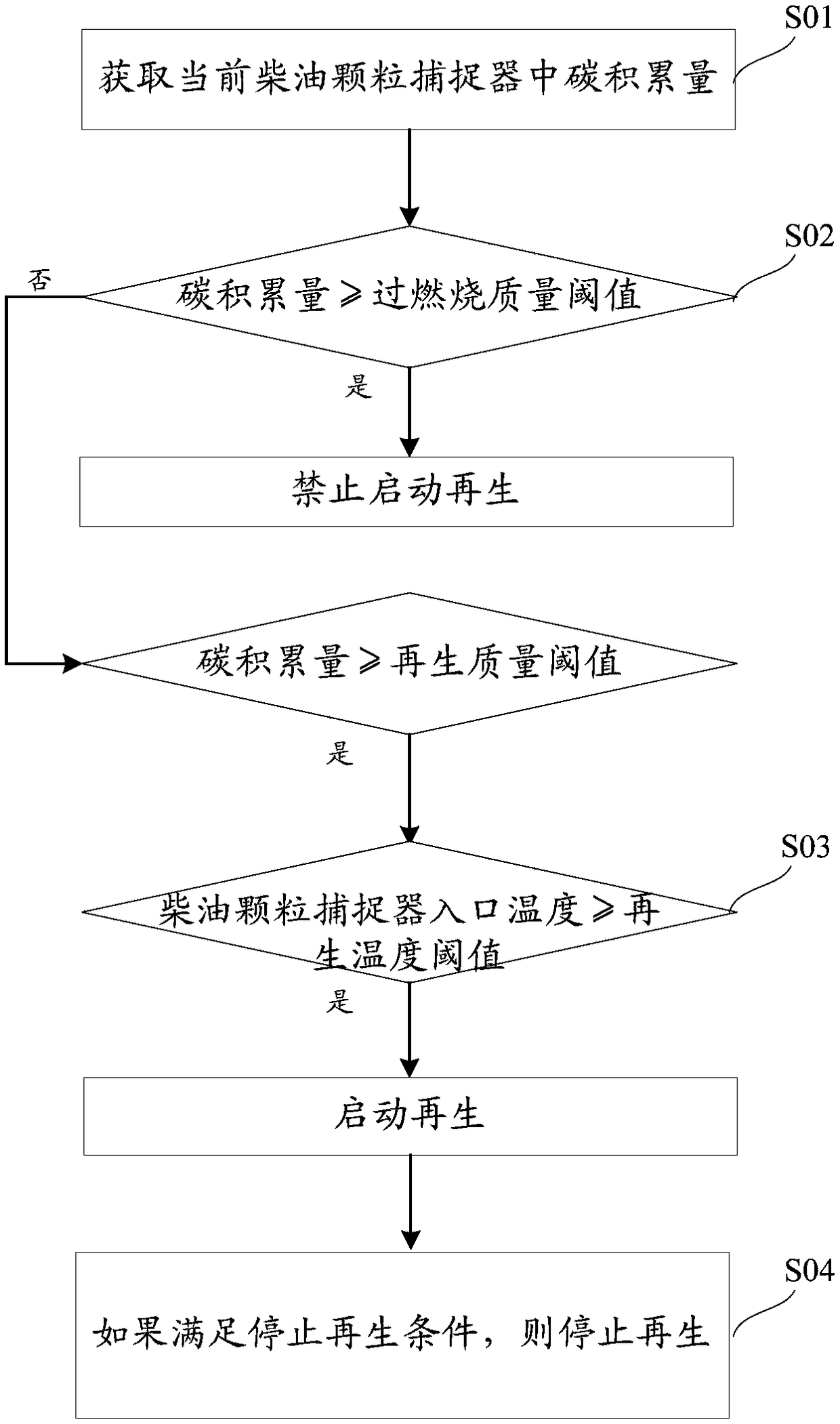

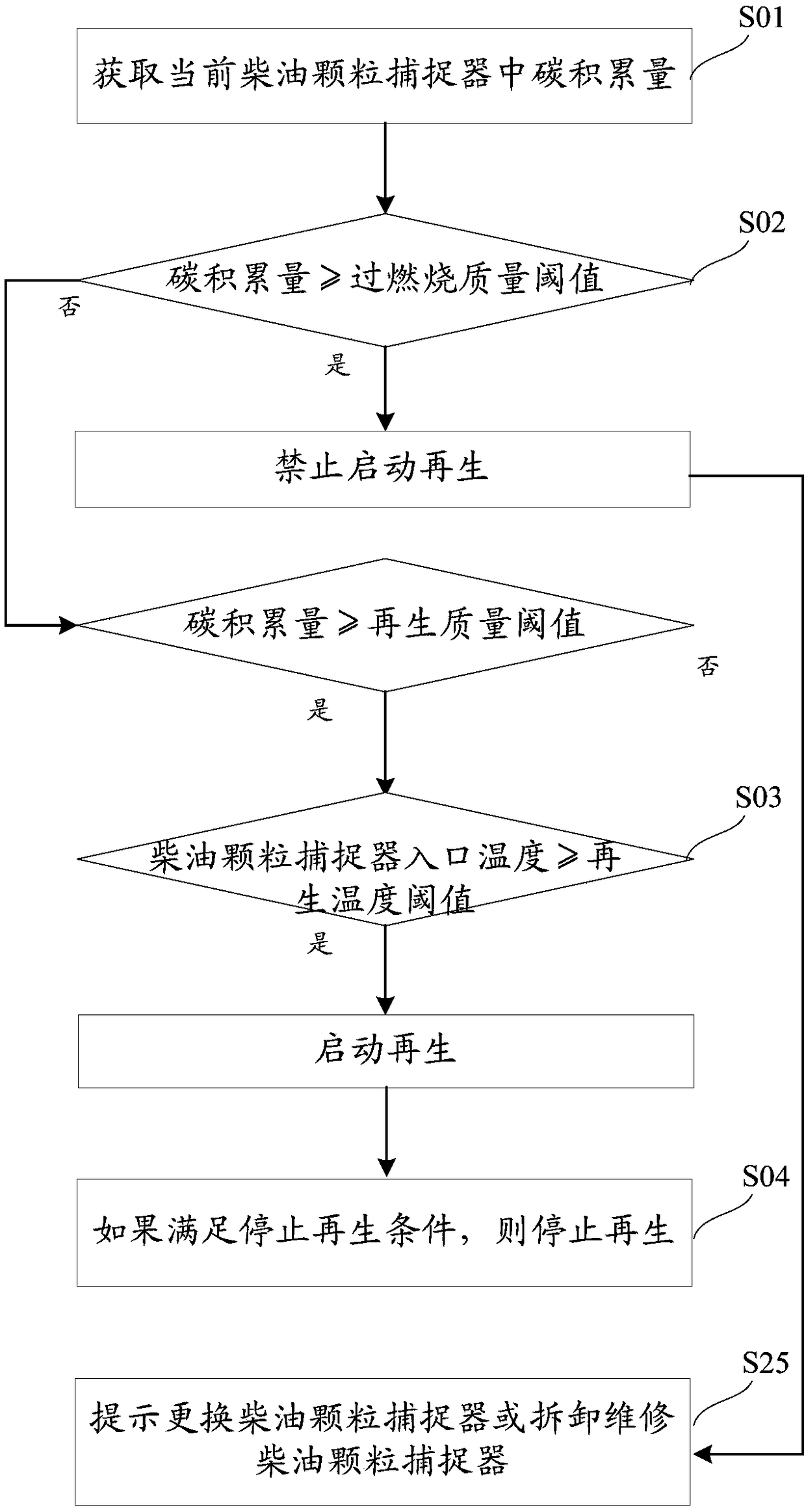

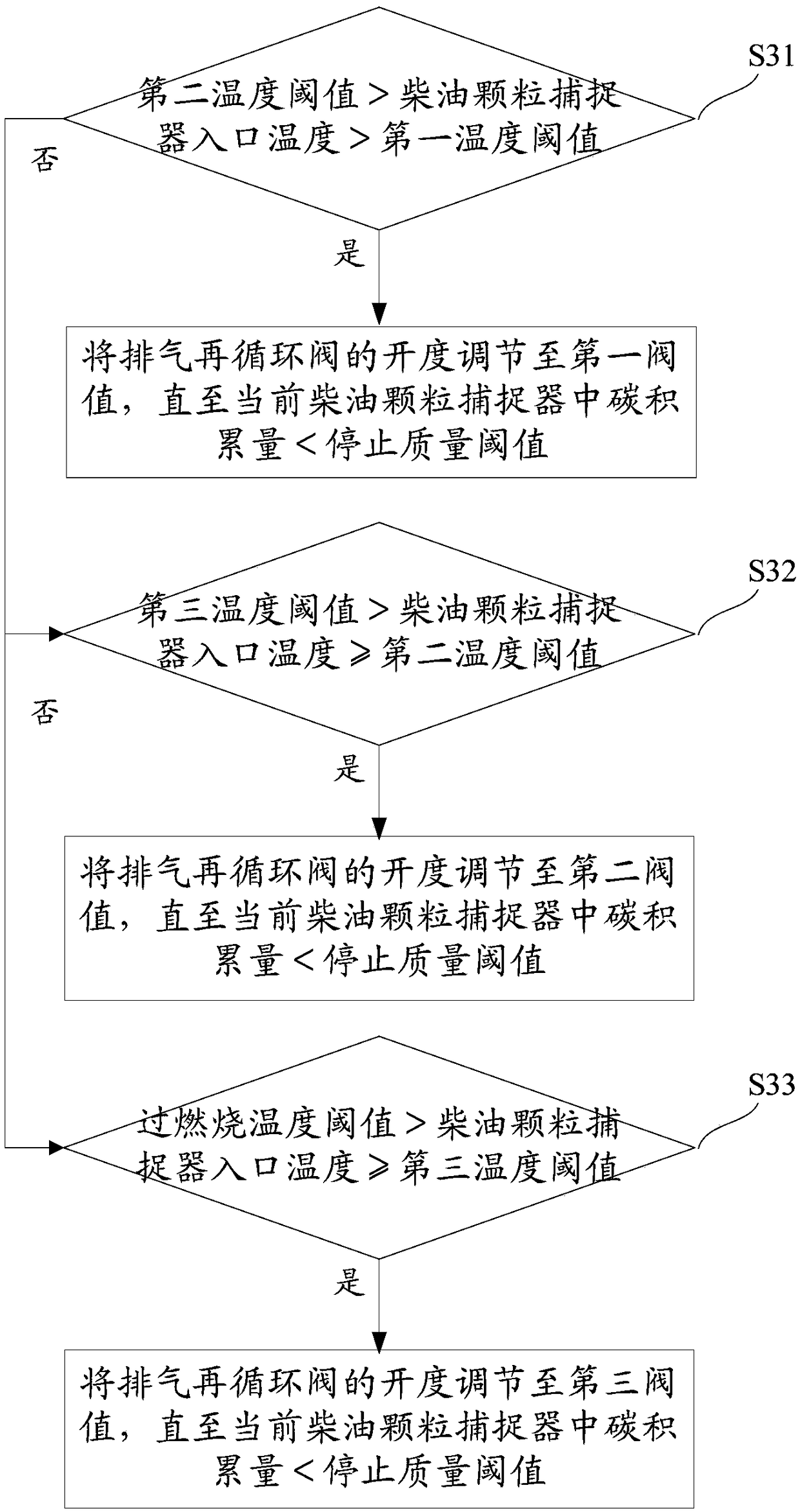

Method and system for preventing over-combustion of diesel particle catcher

ActiveCN106401720AAvoid over-burning situationsAvoid Overburning SituationsInternal combustion piston enginesExhaust apparatusCombustionLow speed

The invention discloses a method and a system for preventing over-combustion of a diesel particle catcher. The method comprises the steps that a carbon accumulation amount in the current diesel particle catcher is acquired; whether the carbon accumulation amount is larger than or equal to an over-combustion mass threshold or not is determined, and if yes, regeneration starting is forbidden; if not, whether the carbon accumulation amount is larger than or equal to a regeneration mass threshold or not is determined; when the carbon accumulation amount is larger than or equal to the regeneration mass threshold, whether the inlet temperature of the diesel particle catcher is larger than or equal to a regeneration temperature threshold or not is determined, and if yes, regeneration is started; and during a regeneration process, if a regeneration stopping condition is met, regeneration is stopped. By utilizing the method and the system, the problem of the diesel particle catcher in the prior art that over-combustion easily happens or excessive carbon particles in the diesel particle catcher cannot be effectively cleared off because a vehicle is at working conditions of idling and low-speed driving for a long term can be solved.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

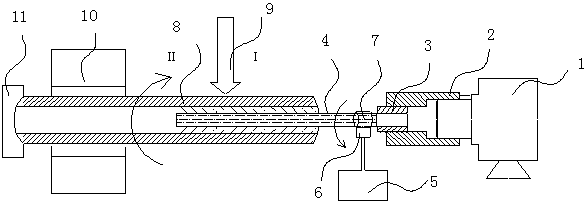

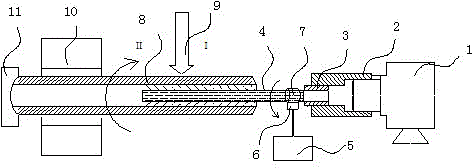

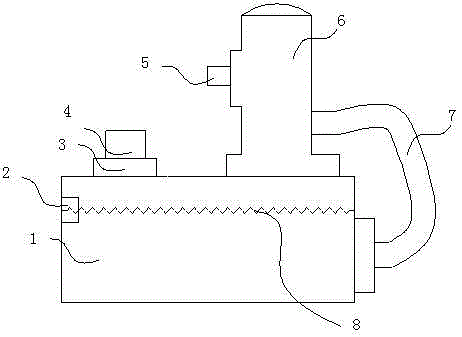

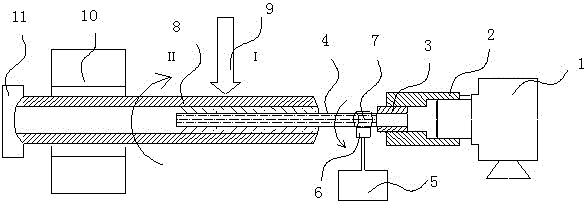

Laser cutting method

ActiveCN103212854APrevent overburningLow costLaser beam welding apparatusWater circulationLaser cutting

The invention relates to a laser cutting method which mainly solves the problems in the prior art that when a laser cutting machine processes a pipe with a small diameter, the produced heat damages parts and chips are not easily removed. The laser wet cutting method comprises the following steps that the pipe to be cut is fixedly arranged on the rotary shaft of the cutting machine, a water guiding pipe of the water guiding system of the cutting machine is inserted from one end of the thin-wall pipe to be cut, the laser cutting machine is started so that the pipe to be cut rotates, the water guiding system of the laser cutting machine is started so that the water guiding pipe rotates, the water circulation module of the laser cutting machine is started, and the cutting head of the laser cutting machine is started to cut the pipe. Due to the adoption of the technical scheme, the problems are well solved, and the laser cutting method can be used in the industrial production of laser cutting machining.

Owner:KUNSHAN THETA MICRO

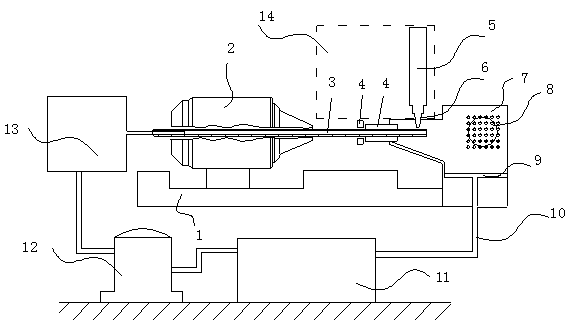

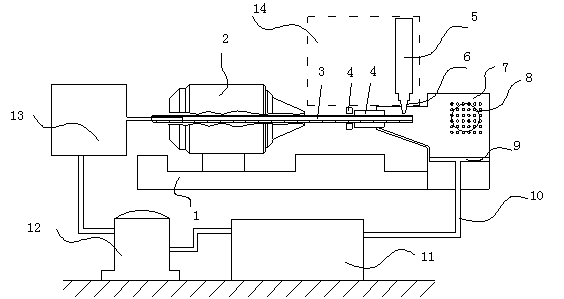

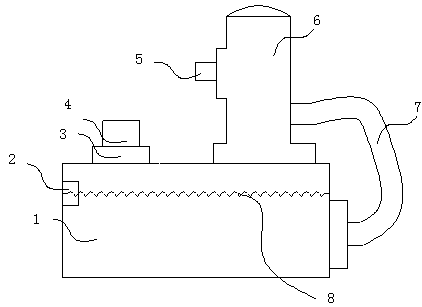

Laser cutting machine

ActiveCN103212818ASmall outer diameterAvoid wear and tearLaser beam welding apparatusLaser processingSpray nozzle

The invention relates to a laser cutting machine with a coaxial spray nozzle, and the machine mainly solves the problems in an existing thin-wall pipe laser processing technology that the laser cutting machine can only cut in a dry way or can only cut in a wet way but cannot realize the two processes simultaneously. The laser cutting machine with the coaxial spray nozzle comprises a dust suction module and a water circulation module; the dust suction module comprises a dust collector and a dust suction pipe; the dust suction pipe is connected with a dust suction pipe installation hole (8) in a sealed cavity (7) through a flange; the water circulation module comprises a water collection pipe (10), a sewage filter device (11), a pressurizing water pump (12) and a water guiding mechanism (13); one end of the water collection pipe (10) is connected with a blanking box (9), and the other end of the water collection pipe (10) is connected with the sewage filter device (11); the sewage filter device (11) is connected with the pressurizing water pump (12); the water inlet of the water guiding mechanism is connected with the pressurizing water pump (12); and a water guide pipe and a pipe (3) are inserted into a pipe to be processed. Due to the adoption of the technical scheme, the problems are well solved, and the laser cutting machine can be used in the industrial production of laser dry and wet cutting.

Owner:KUNSHAN THETA MICRO

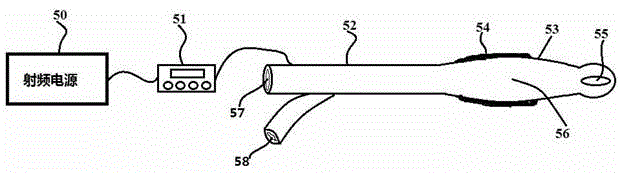

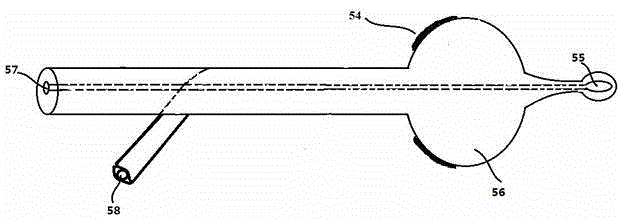

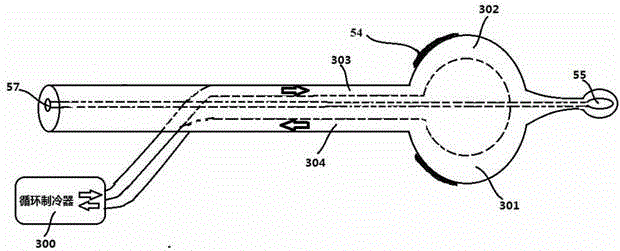

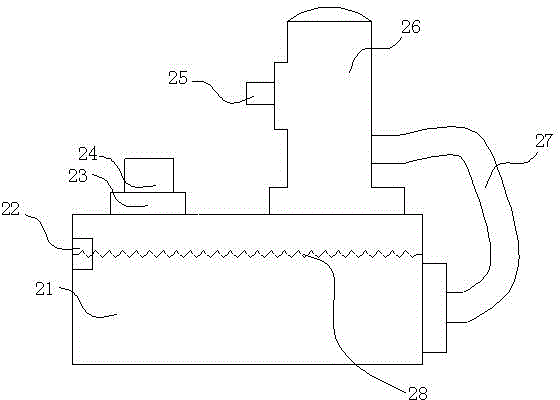

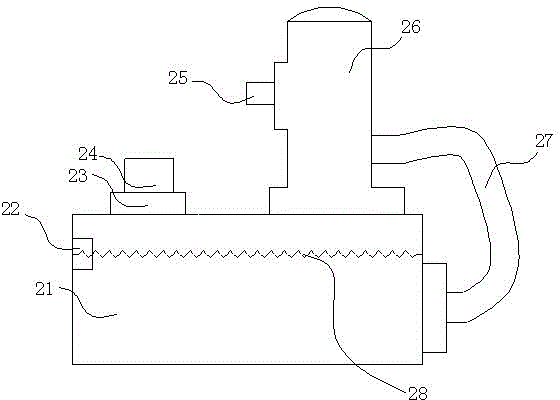

Non-invasive low-energy RF (Radio Frequency) diagnostic equipment

The invention discloses non-invasive low-energy RF (Radio Frequency) diagnostic equipment. The equipment comprises an RF power supply, an intelligent controller and a front end guide pipe; the front end guide pipe comprises a cooling system and an electrode array, wherein the electrode array is adhered to the outer surface of the cooling system and comprises at least one pair of RF bipolar electrodes, the at least one pair of RF bipolar electrodes are arranged in an annular or rectangular array, and the RF power supply applies RF power to the electrode array through the intelligent controller. The non-invasive low-energy RF diagnostic equipment has the advantages as follows: (1) the RF energy can be uniformly transmitted to a focus; (2) the skin or the surface of the inner cavity cannot be destroyed; (3) the diagnostic equipment is intelligent and likely to be operated; (4) the diagnostic equipment has a diagnostic function; and (5) the diagnostic function is convenient to process.

Owner:杭州瑞彼加医疗科技有限公司

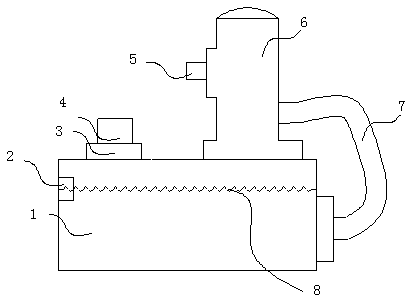

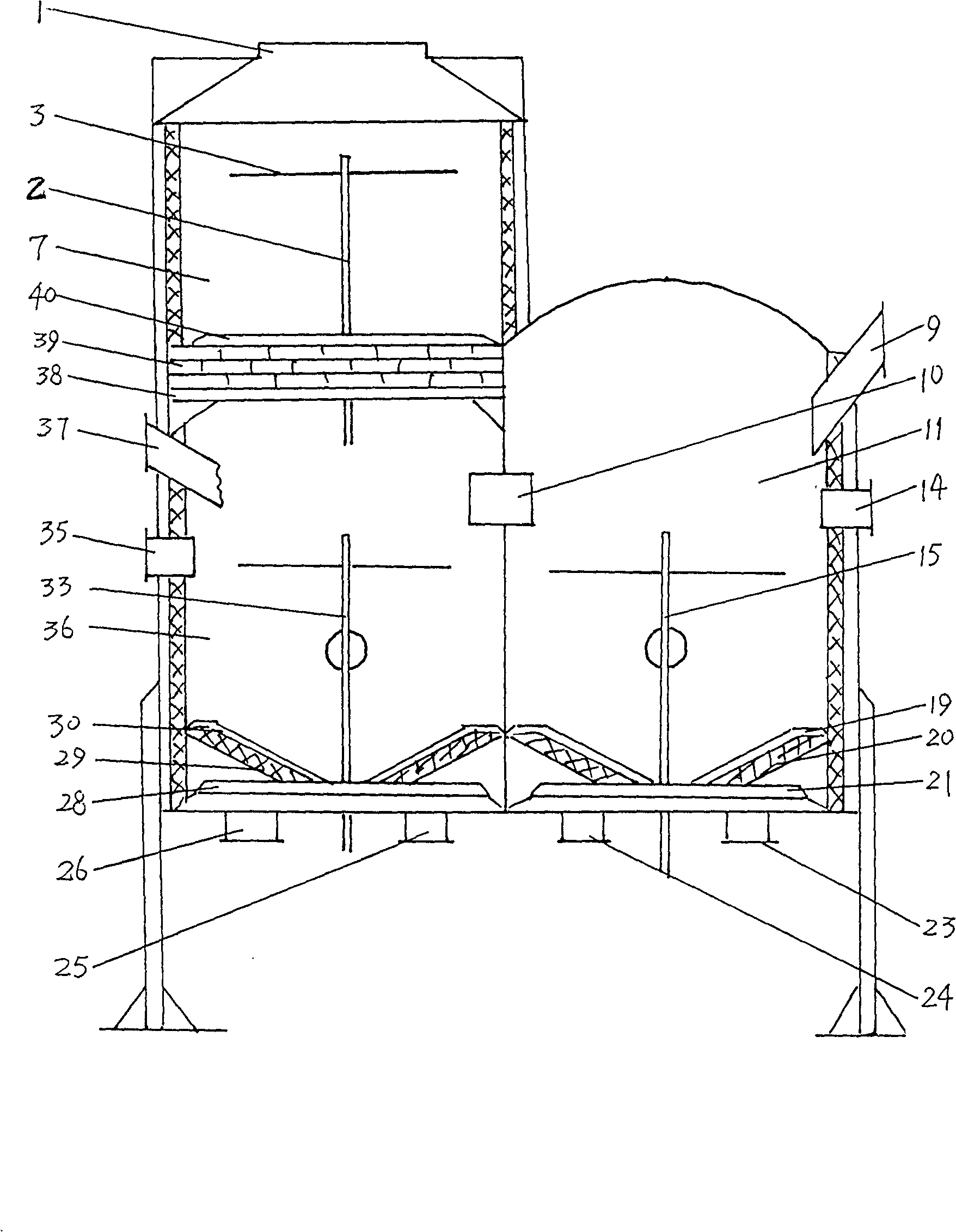

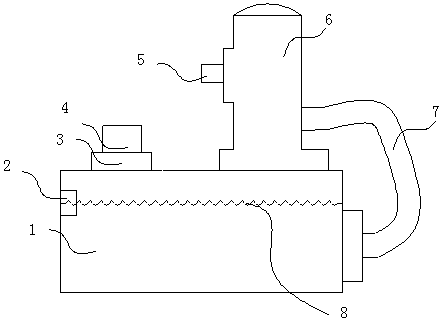

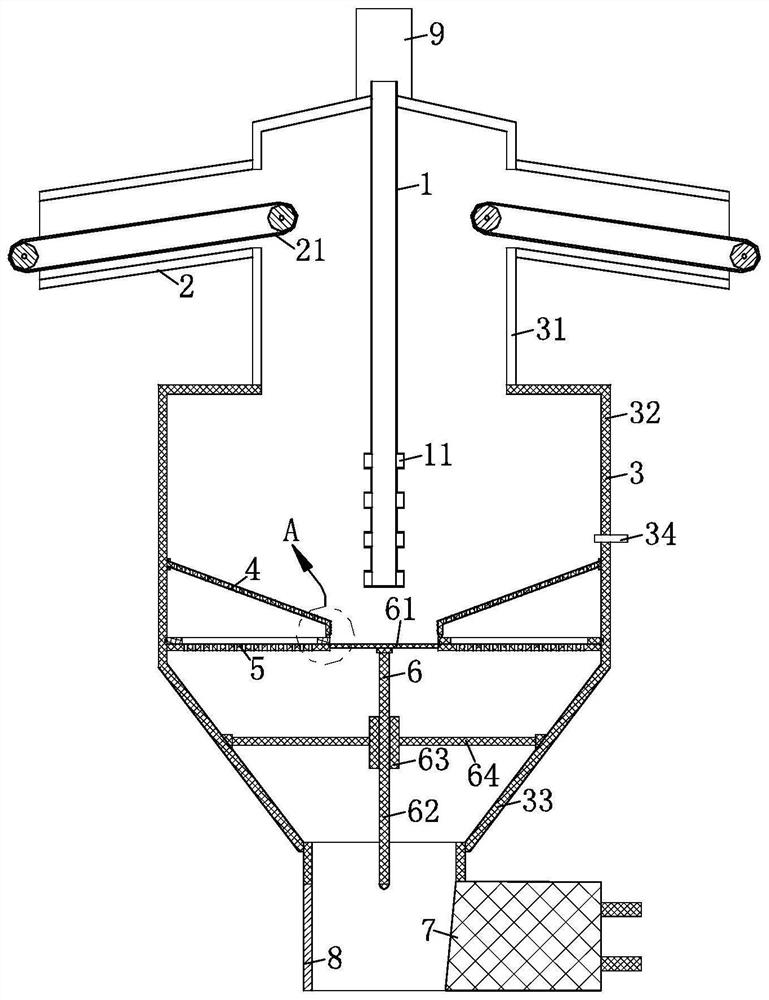

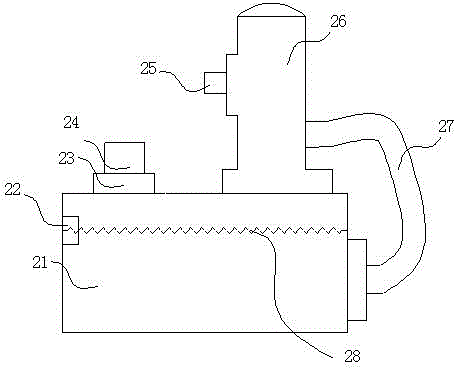

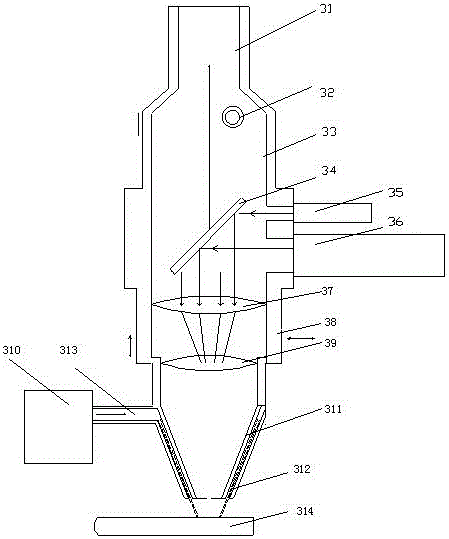

Normalizing and back run biomass gas-carbon cogeneration producer and gas-carbon cogeneration method

InactiveCN101358134AHigh strengthHigh calorific valueBiofuelsSpecial form destructive distillationBiomass carbonCombustion

The present invention relates to a forward-and-reverse-flame type producer for the coproduction of biomass gas and carbon and a relevant gas-carbon coproduction method, which belong to the technical field of energy-recycling. The producer comprises a gasification furnace and a carbonization chamber; wherein, the upper part of the gasification furnace is a reverse-flame gasification furnace chamber, and the lower part is a forward-flame gasification furnace chamber; the bottom of the reverse-flame gasification furnace chamber is communicated with the forward-flame gasification furnace chamber through a reverse flame gate; and the forward-flame gasification furnace chamber is adjacent to the carbonization chamber and is communicated with the carbonization chamber through a channel. When the producer is used, biomasses are respectively fed into the producer to be burnt, and the flammable gas produced by the reverse-flame gasification furnace chamber is mixed with the flammable gas produced by the forward-flame gasification furnace chamber through the reverse flame gate and then enters into the carbonization chamber. Finally, the flammable biomass gas passing through the carbonization chamber can be pumped out, and biomass carbon is obtained as well. The producer can increase the gasification intensity and heat value of the flammable gas and avoid overburning caused by boiling combustion, thus producing high-heat-value flammable gas meeting requirements as well as carbonized substance replacing charcoal.

Owner:赵学忠

Compositions and methods to sequester flue gas mercury in concrete

ActiveUS8420033B2Prevent overburningImprove effectivenessGas treatmentCarbon compoundsAir entrainmentOxygen

Owner:SORBENT TECH +1

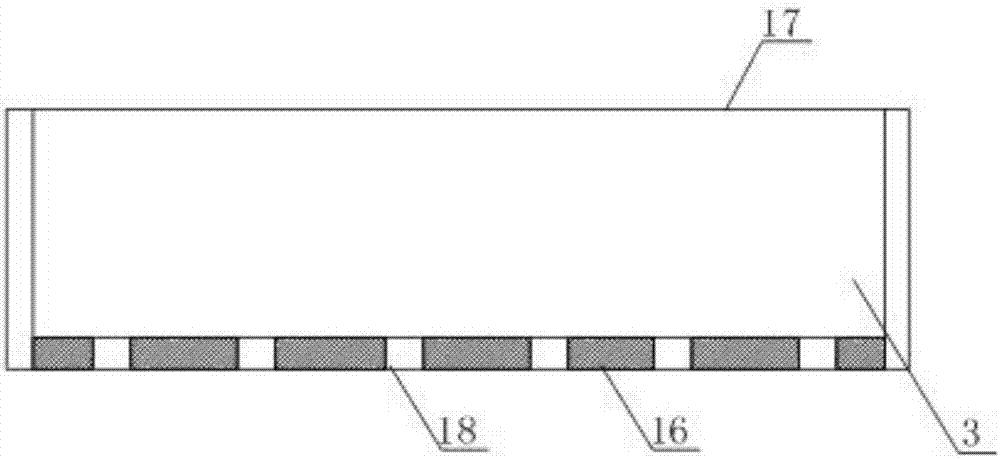

Laser cutting machine

ActiveCN103212853ASmall outer diameterAvoid wear and tearLaser beam welding apparatusLaser processingEngineering

The invention relates to a laser cutting machine which mainly solves the problems in an existing thin-wall pipe laser processing technology that the laser cutting machine can only cut in a dry way or can only cut in a wet way but cannot realize the two processes simultaneously. The laser cutting machine comprises a dust suction module and a water circulation module, wherein the dust suction module comprises a dust collector and a dust suction pipe, the dust suction pipe is connected with a dust suction pipe installation hole (8) in a sealed cavity (7) through a flange, the water circulation module comprises a water collection pipe (10), a sewage filter device (11), a pressurizing water pump (12) and a water guiding mechanism (13), one end of the water collection pipe (10) is connected with a blanking box (9) and the other end of the water collection pipe (10) is connected with the sewage filter device (11), the sewage filter device (11) is connected with the pressurizing water pump (12), the water inlet of the water guiding mechanism is connected with the pressurizing water pump (12), and a water guide pipe and a pipe (3) are inserted into a pipe to be processed. Due to the adoption of the technical scheme, the problems are well solved, and the laser cutting machine can be used in the industrial production of laser dry and wet cutting.

Owner:KUNSHAN THETA MICRO

Processing method for laser wet cutting of thin-wall pipes

ActiveCN103212820AOvercome unstable water supplyCompact structureLaser beam welding apparatusEngineeringLaser cutting

The invention relates to a processing method for laser wet cutting of thin-wall pipes and mainly solves the problems of difficult removal of scraps and heat damage to parts caused by heat generated in the machining process of micro-small-diameter pipes by a laser cutting machine in the prior art. In order to better solve the problems, the processing method for the laser wet cutting comprises the steps of sealing one end of a to-be-cut thin-wall pipe and fixing at a position close to the sealing end by a clamp jacket of the laser cutting machine; inserting a water guide pipe of a water guide system from the other end of the to-be-cut tin-wall pipe; starting the laser cutting machine to enable the to-be-cut pipe to rotate at high speed; starting a front-mounted spraying water guide system of the laser cutting machine to enable the water guide pipe to rotate; starting an automatic water supply system of the front-mounted spraying water guide system to enable high-pressure water to spray out from the water spraying port of the water guide pipe so as to act on a to-be-cut position of the thin-wall pipe; and starting a cutting head of the laser cutting machine to cut the thin-wall pipe. The processing method for the laser wet cutting of the thin-wall pipes can be used in the industrial production of a laser wet cutting process.

Owner:KUNSHAN THETA MICRO

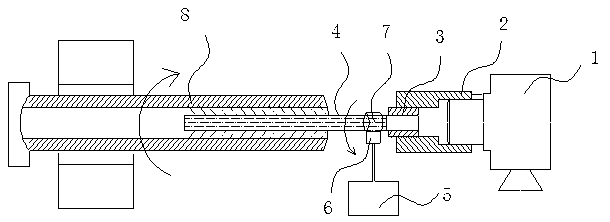

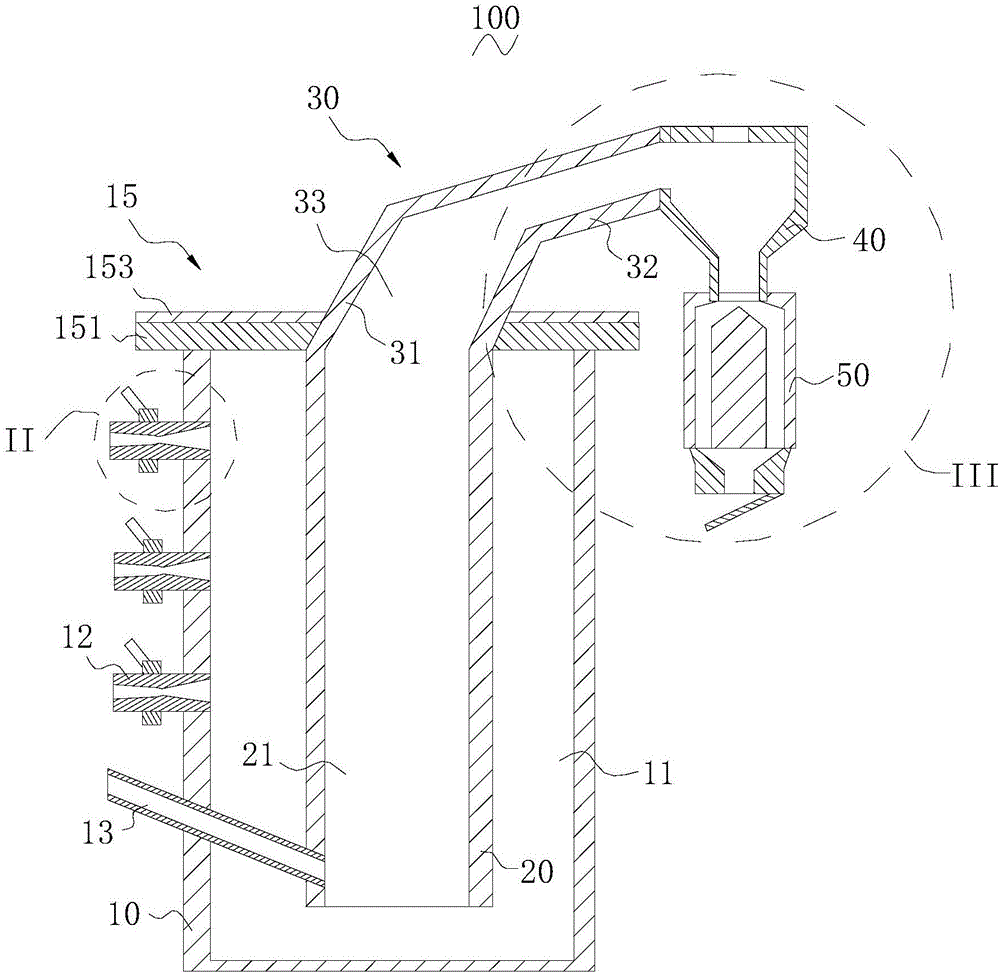

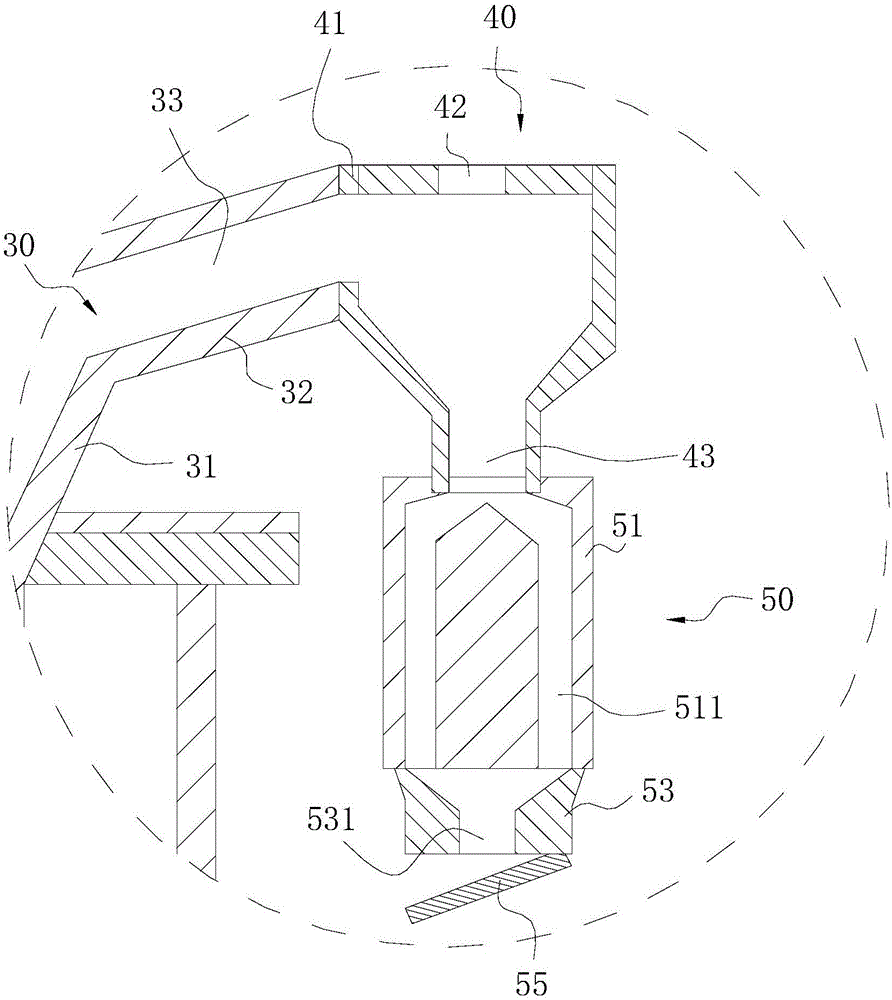

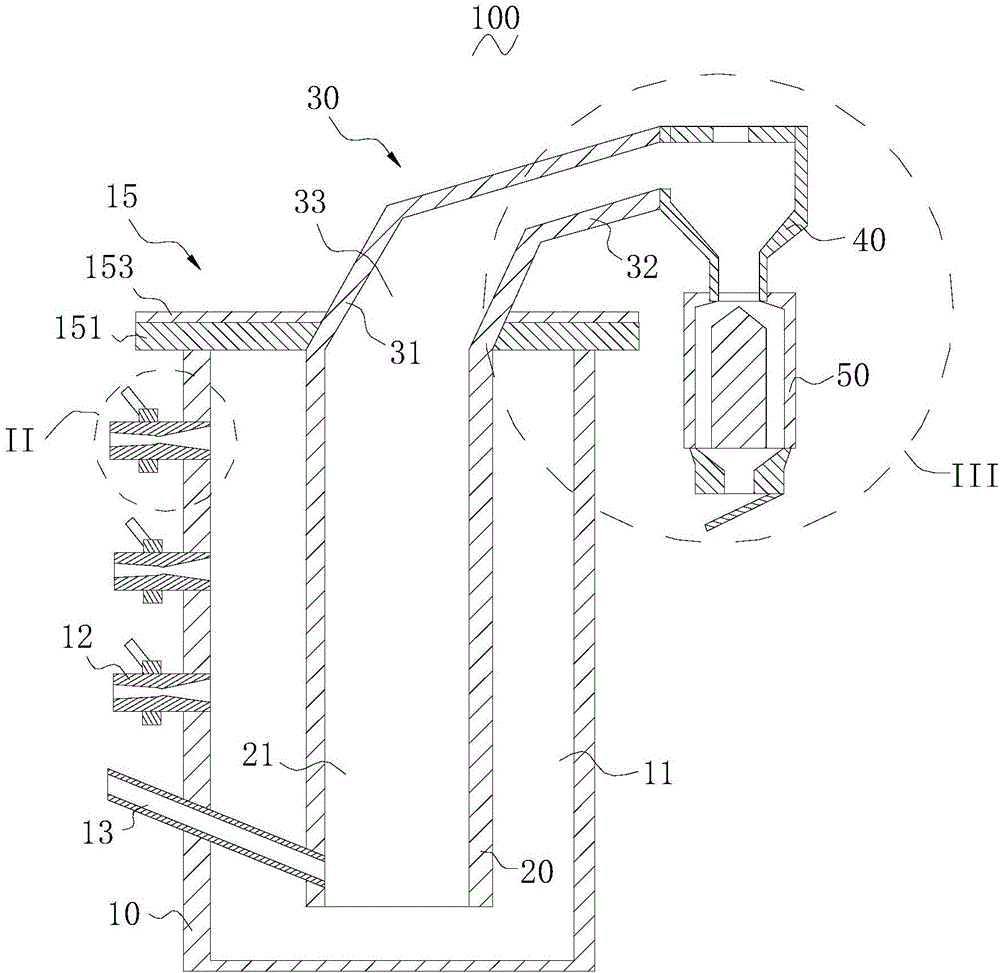

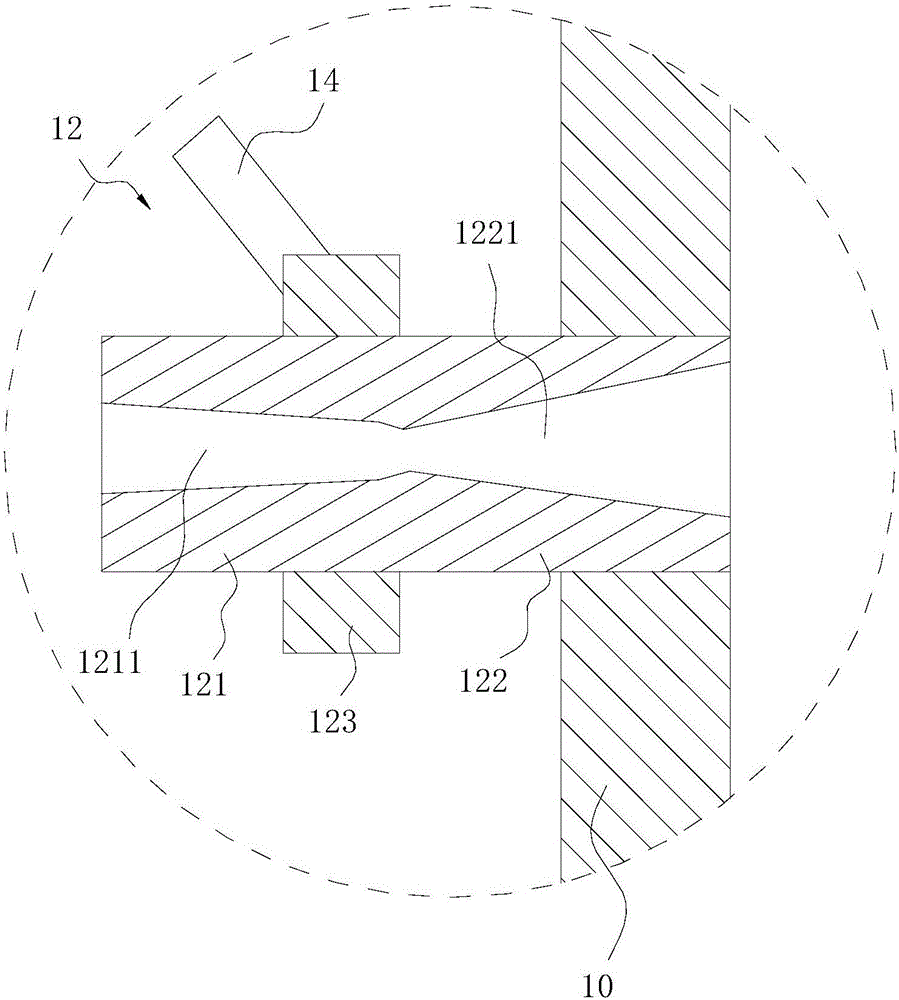

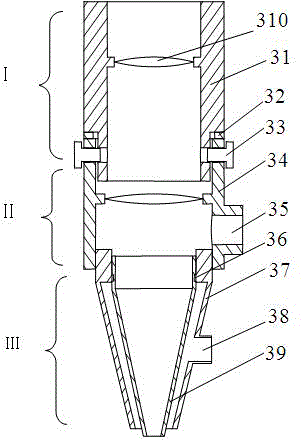

Laser cutting machine comprising front spraying and water guiding structure

ActiveCN103212803APrevent overburningReduce pollutionLaser beam welding apparatusCouplingSpray nozzle

The invention relates to a laser cutting machine comprising a front spraying structure and a coaxial type nozzle, mainly solving the problems that during the process of machining a tube with a miniature diameter by a laser cutting machine in the prior art, thermal damage is brought to a spare part by generated heat, and scraps are not easily cleaned. The invention adopts the technical scheme that the laser cutting machine comprises the coaxial spray nozzle and a front water guiding system, wherein the motor (1) of the front water guiding system is connected with a water guiding pipe (4) through a coupling (2) and a bushing (3), one end of the bushing (3) is arranged in the coupling (2), the other end of the bushing (3) is connected with the water guiding pipe (4) in a sealing way, a water inlet (6) is arranged on the end of the water guiding pipe (4) close to the bushing (3), the water inlet (6) is connected with the sealed bearing (7) of an automatic water supply system (5), the outer diameter of the water guiding pipe (4) is smaller than the inner diameter of a to-be-processed tube (8), and the end,, far away from the bushing (3), of the water guiding pipe (4) is embedded into the inside of the to-be-processed tube. According to the invention, the problems are better solved, and the laser cutting machine can be applied to the industrial production of laser wet cutting processing.

Owner:KUNSHAN THETA MICRO

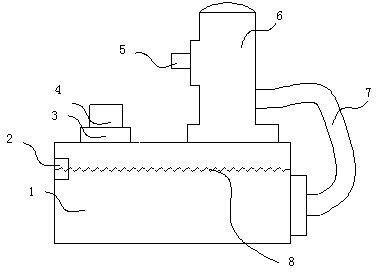

Environment-friendly barbecue equipment which helps coal to be combusted

The invention records an environment-friendly barbecue equipment for combustion-supporting coal, which includes a car body and a combustion-supporting chamber, a heating chamber, a transition area, and a smoke collection hood arranged on the car body in sequence from bottom to top. A smoke exhaust pipe is connected to the smoke collecting hood, and a blower fan is arranged outside the combustion-supporting chamber. The air outlet of the blower fan is connected with a U-shaped pipe. The upper pipe of the U-shaped pipe is fixed on the side wall of the heating chamber, and the lower pipe of the U-shaped pipe A plurality of air outlets are uniformly opened on the tube, an oxygen supply machine is connected to the upper tube of the U-shaped tube, a rotating shaft is arranged in the combustion chamber, and a paddle is arranged on the rotating shaft; the lower end of the heating chamber is a coal burning layer, and the upper end is a In the grill, a plurality of combustion-supporting holes are provided on the coal-burning layer. In the present invention, the combustion-supporting air in the upper pipe can be heated and then sent to the combustion-supporting chamber, and the hot combustion-supporting air will directly contact the coal through the combustion-supporting hole. For the cooler combustion-supporting air, the combustion-supporting effect is better and the energy utilization rate is lower. high.

Owner:弘毅天承知识产权股份有限公司

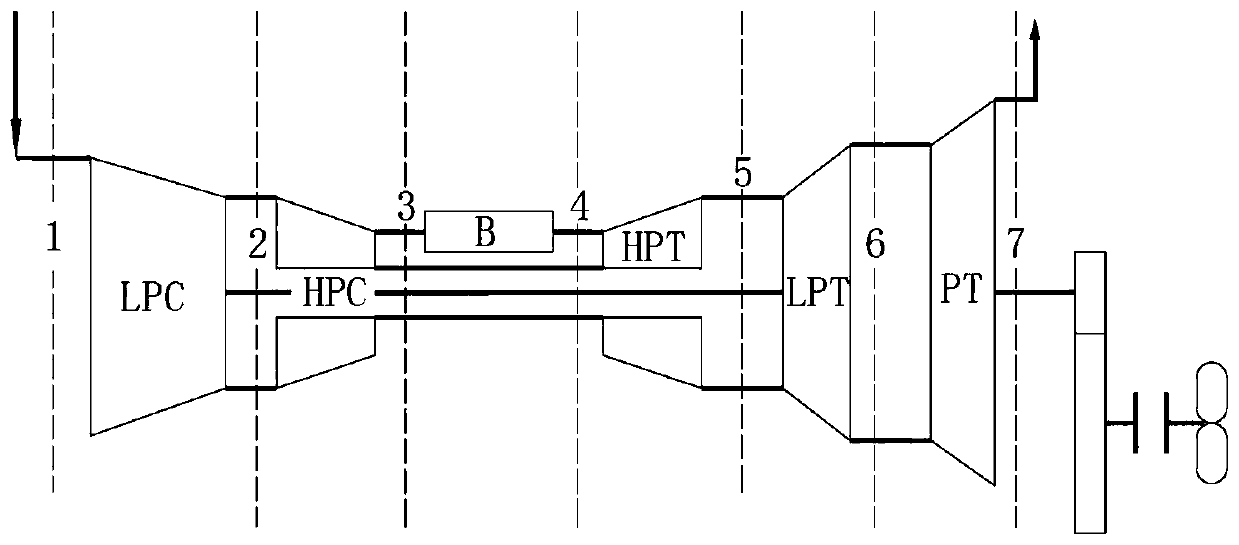

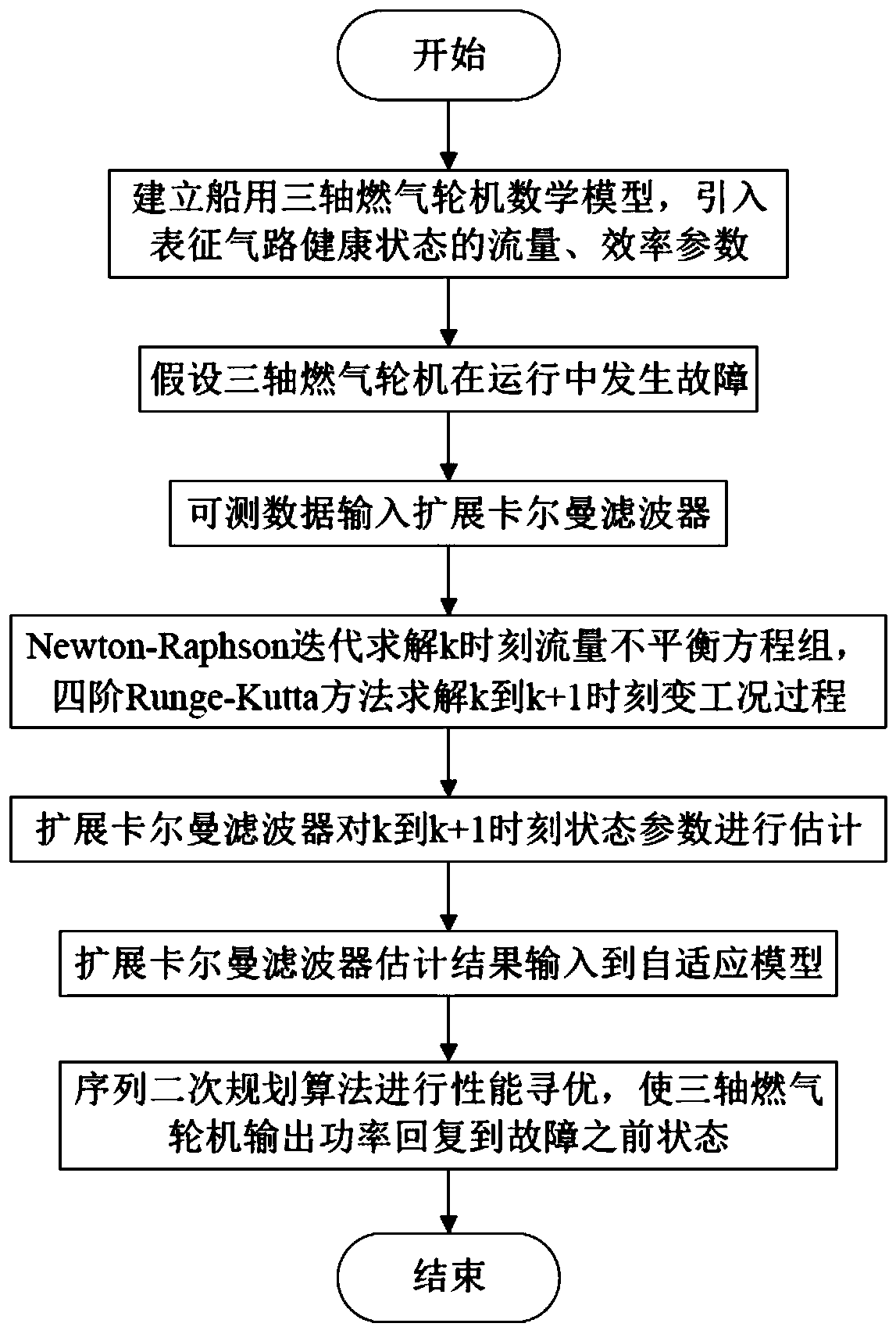

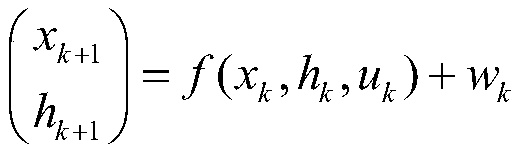

Marine gas turbine parameter estimation and performance optimization method based on extended Kalman filtering

ActiveCN111077778AStable output powerSafe and stable operationSustainable transportationAdaptive controlMathematical modelControl engineering

The invention aims at providing a marine gas turbine parameter estimation and performance optimization method based on extended Kalman filtering. The marine gas turbine parameter estimation and performance optimization method comprises the following steps: establishing a three-axis gas turbine mathematical model; estimating the gas path state of the marine three-axis gas turbine by adopting an extended Kalman filtering method and utilizing the output of observable data of the marine three-axis gas turbine with the gas path fault in the operation process; adopting a Newton-Raphson iteration method to solve the pressure ratio, the flow and the efficiency characteristic of each part of the three-axis gas turbine under the variable working condition, and adopting a Runge-Kutta method to solvethe variable working condition dynamic process of the three-axis gas turbine; and establishing a performance optimization model by adopting a sequential quadratic programming algorithm, and solving anoptimal steady-state working point for keeping the output power of the marine gas turbine stable. According to the method, when the marine three-axis gas turbine has a gas path fault, the gas path health state can be accurately estimated, and parameter optimization is carried out. The method for solving the nonlinear dynamic system is wide in application range and also has reference significancewhen other systems are applied to Kalman filtering.

Owner:HARBIN ENG UNIV

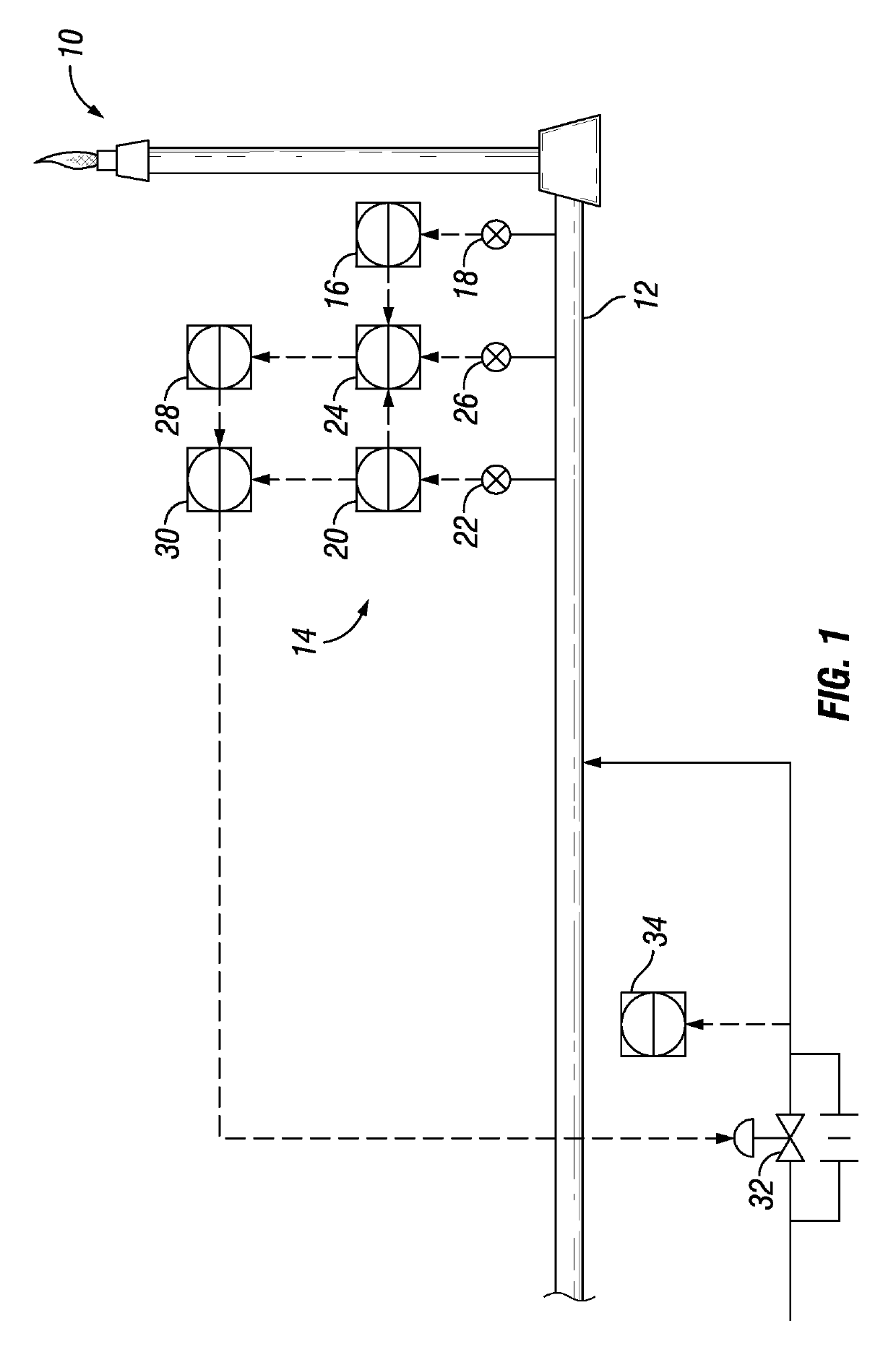

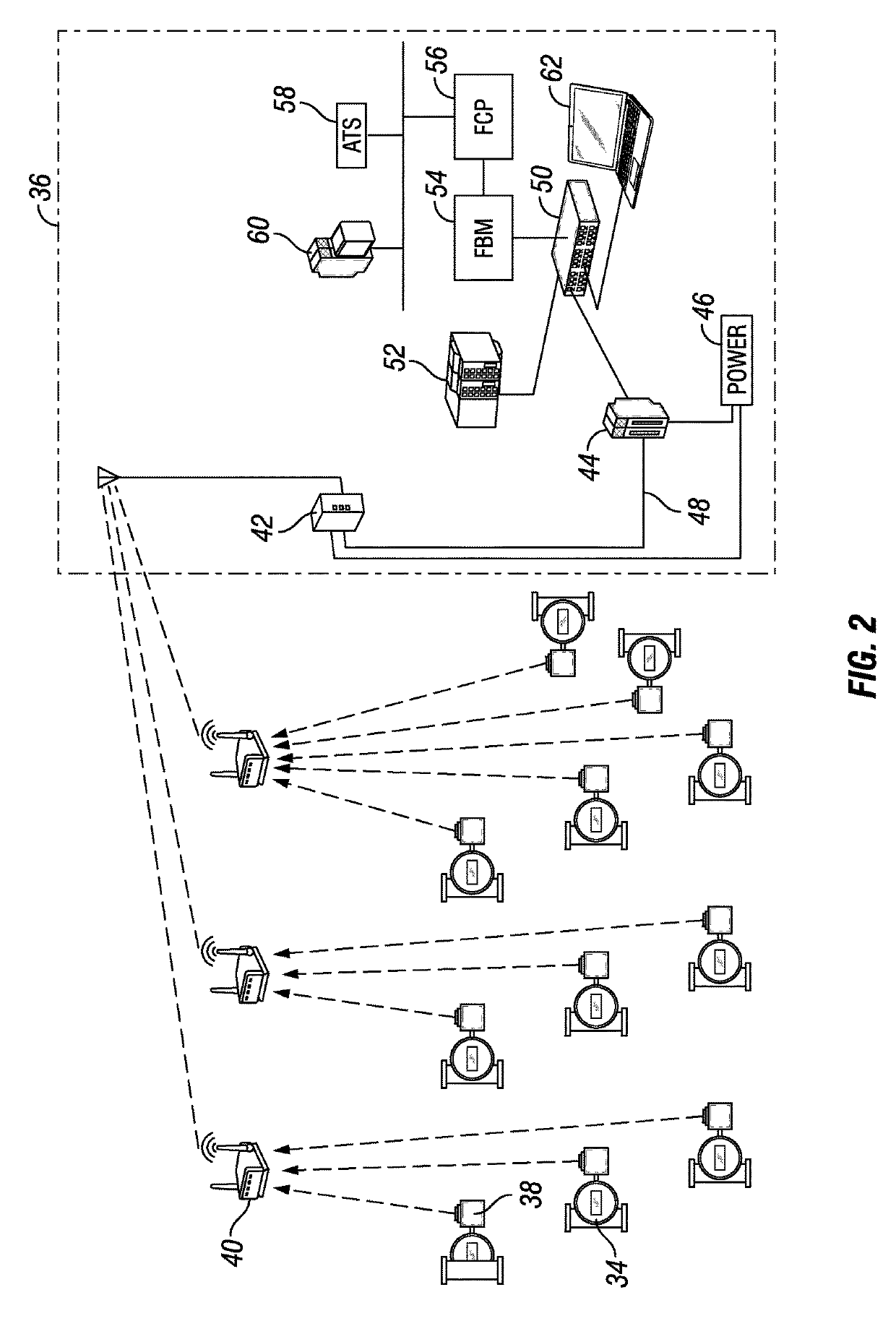

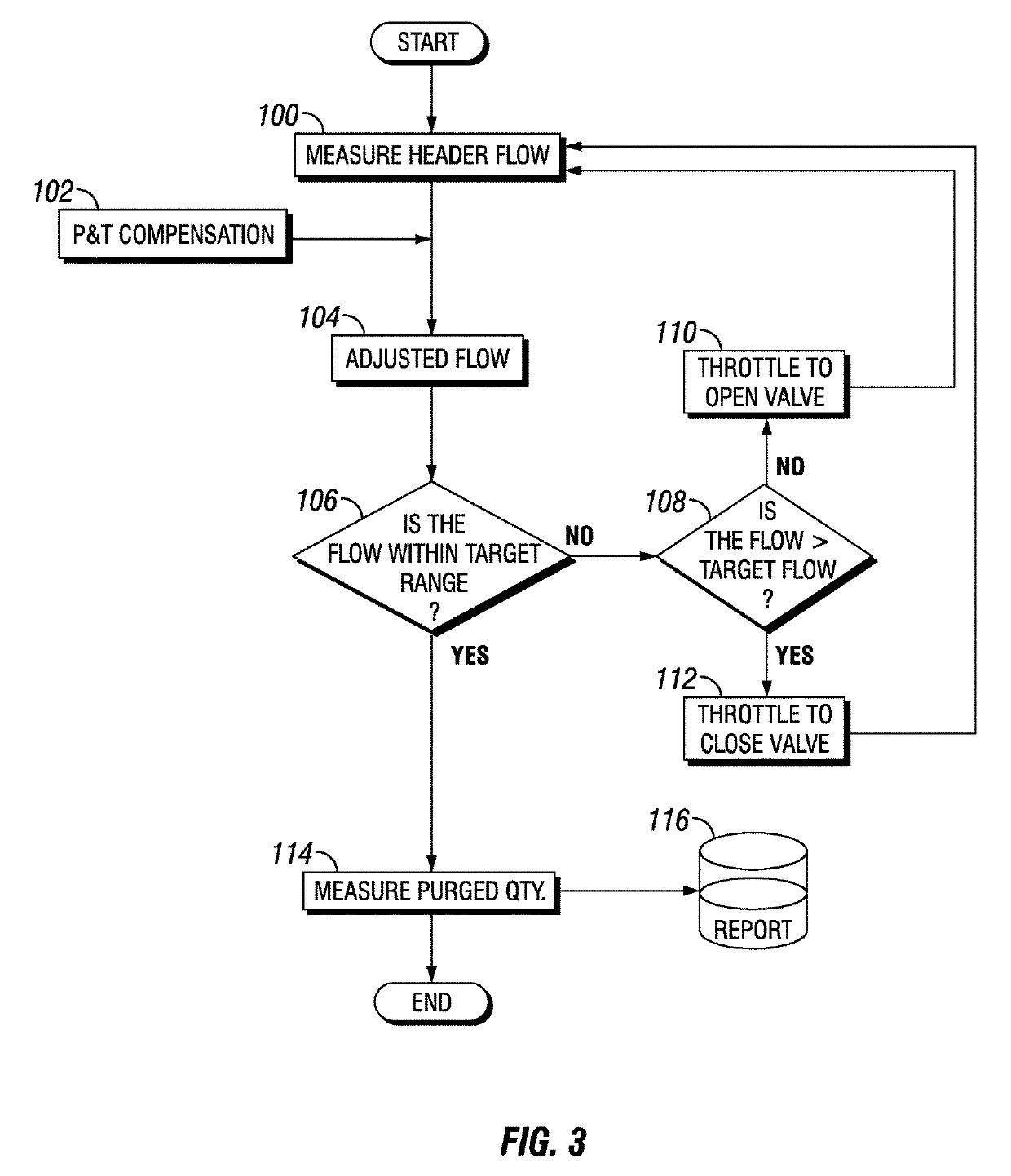

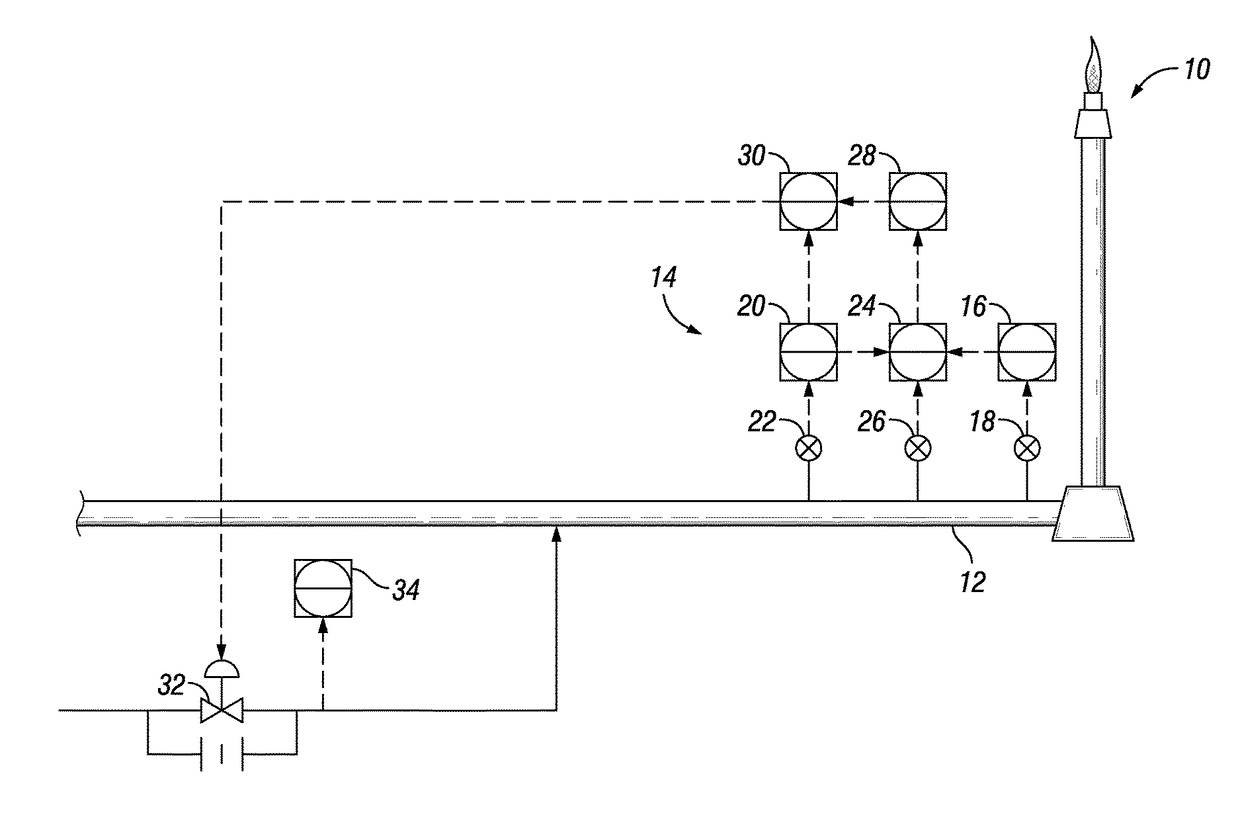

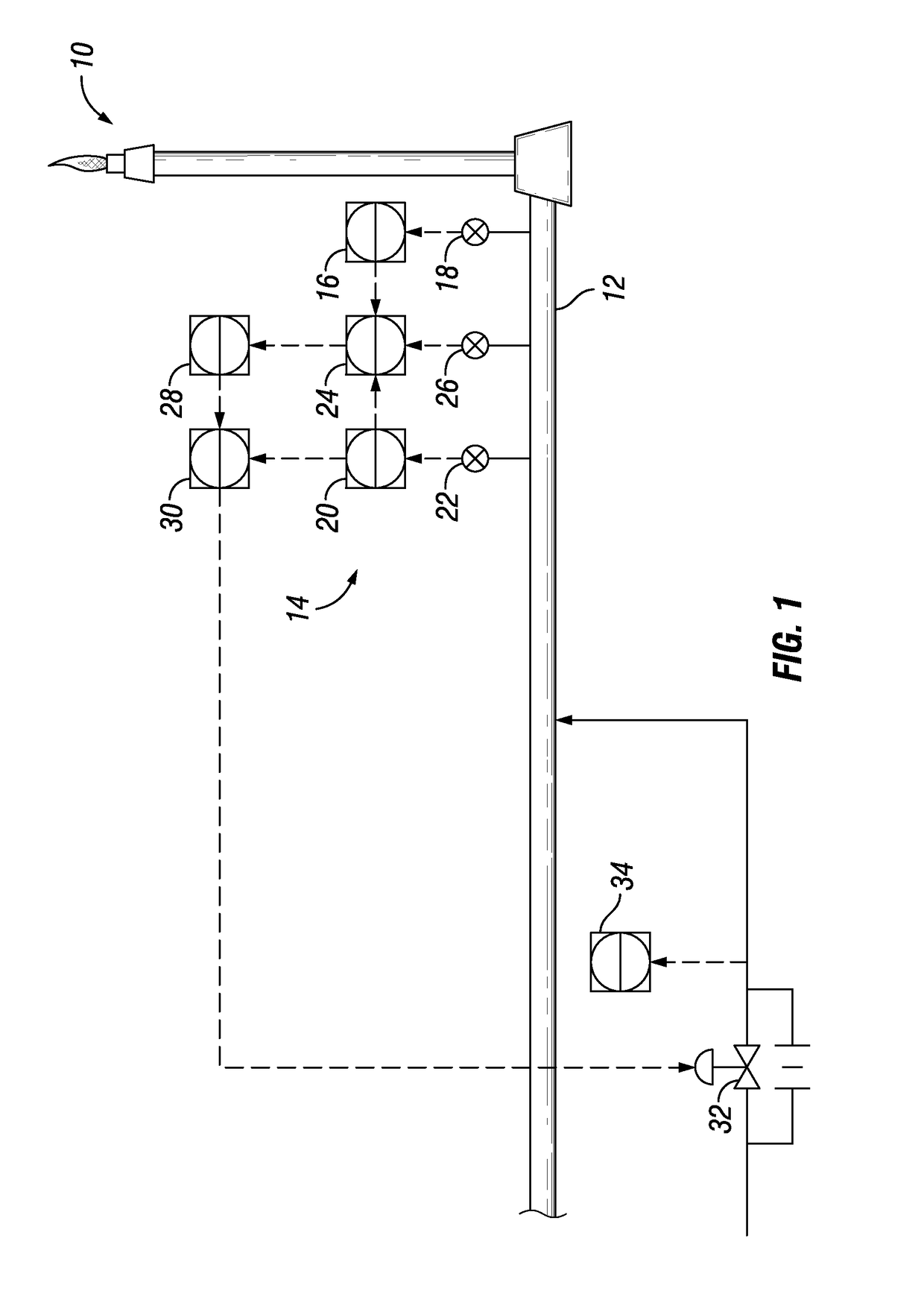

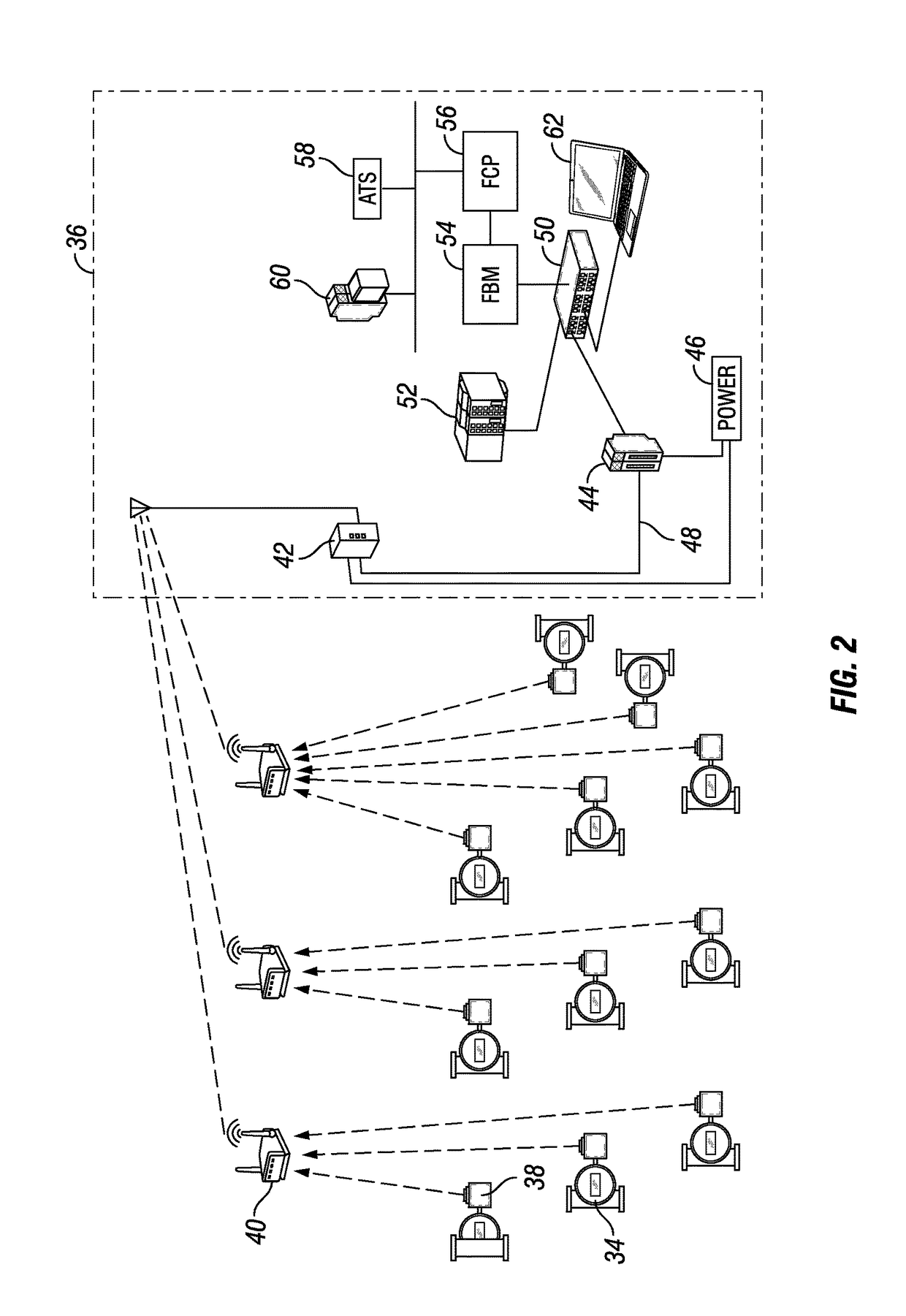

Systems and methods for monitoring and optimizing flare purge gas with a wireless rotameter

ActiveUS10343195B2Adequate purgingPrevent overburningHollow article cleaningVolume indication and recording devicesWireless transmissionControl system

A method for optimizing purge gas of a flare system includes measuring a flow of flare fluids within a flare system to obtain a measured flow value. The flow of the flare fluids is compared to a target flow to obtain a difference between the flow of the flare fluids and the target flow. A control valve is operated to amend a flow of purge gas and the steps of measuring a flow of flare fluids and comparing the flow of the flare fluids to the target flow are repeated until the flow of the purge gas is within a target range. A value of the flow of purge gas is measured and transmitted wirelessly to a control system.

Owner:SAUDI ARABIAN OIL CO

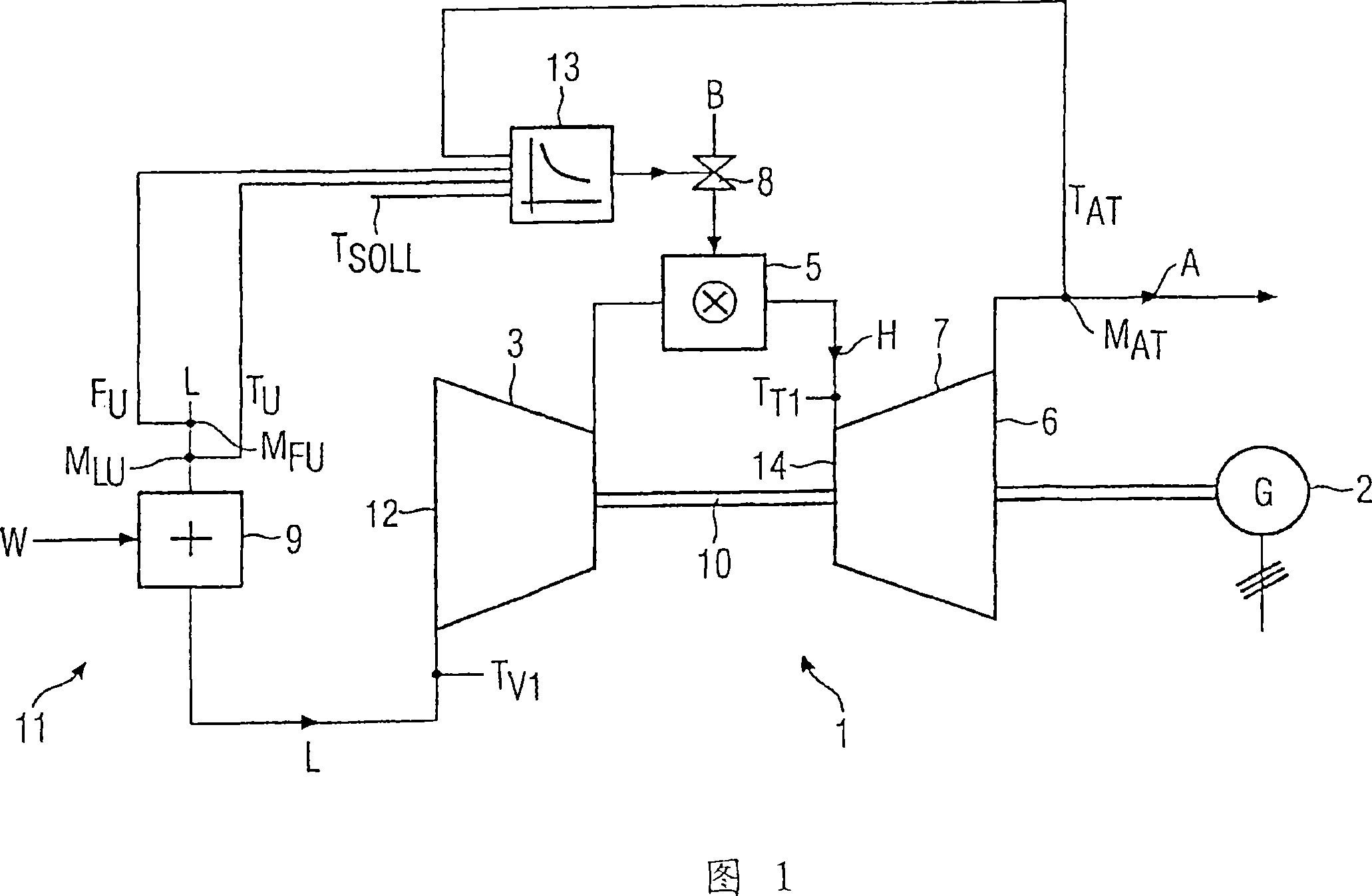

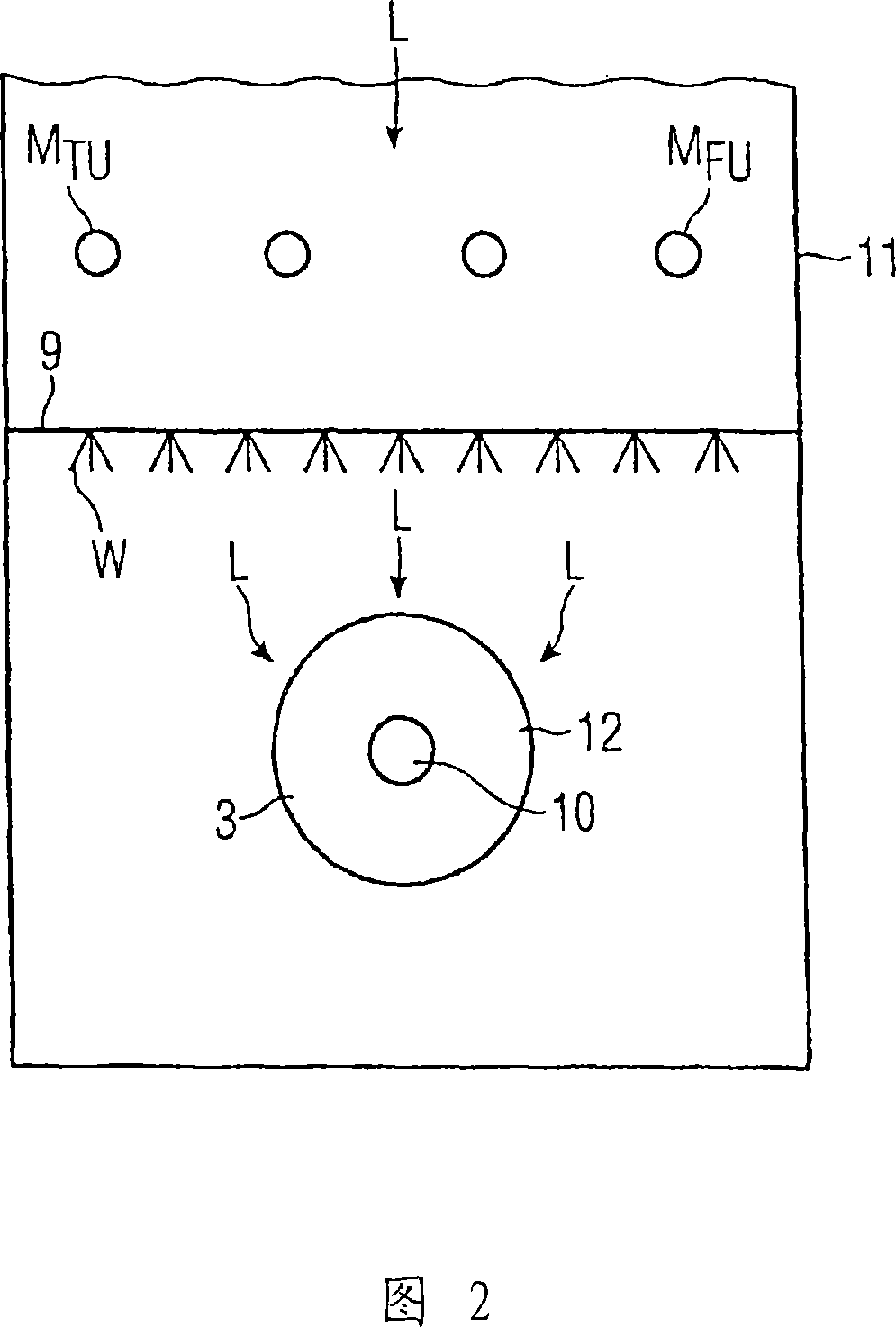

Regulation of the temperature of hot gas of a gas turbine

ActiveCN101230801AImprove protectionHumidity is accurately calculatedEngine fuctionsGas turbine plantsCombustion chamberControl system

The invention relates to a device for regulating the hot flue gas temperature of a gas turbine (1), in particular a stationary gas turbine for power generation, which gas turbine has a gas turbine for injecting a liquid (W) into a gas stream which can be compressed by a compressor. An injection device (9) into the air flow (L) sucked by the machine (3), with the help of which a combustion medium (B) can be burned in a downstream combustion chamber (5) to form hot flue gases (H), the hot flue gas expands and performs work when flowing through the downstream turbine section (7), and the gas turbine has a temperature measuring device for detecting the temperature of the air flow (L) before the compressor (3) ( MTU), wherein the hot flue gas temperature is adjusted by the amount of combustion medium, in order to provide a regulating means to increase the service life of components exposed to hot flue gas during wet compression operation, the invention proposes that the temperature measurement A device (MTU) is arranged before the injection device (9) and uses the measured temperature (TU) to calculate the temperature (TV1) of the air flow (L) at the inlet (12) of the compressor (3) ).

Owner:SIEMENS ENERGY GLOBAL GMBH CO & KG

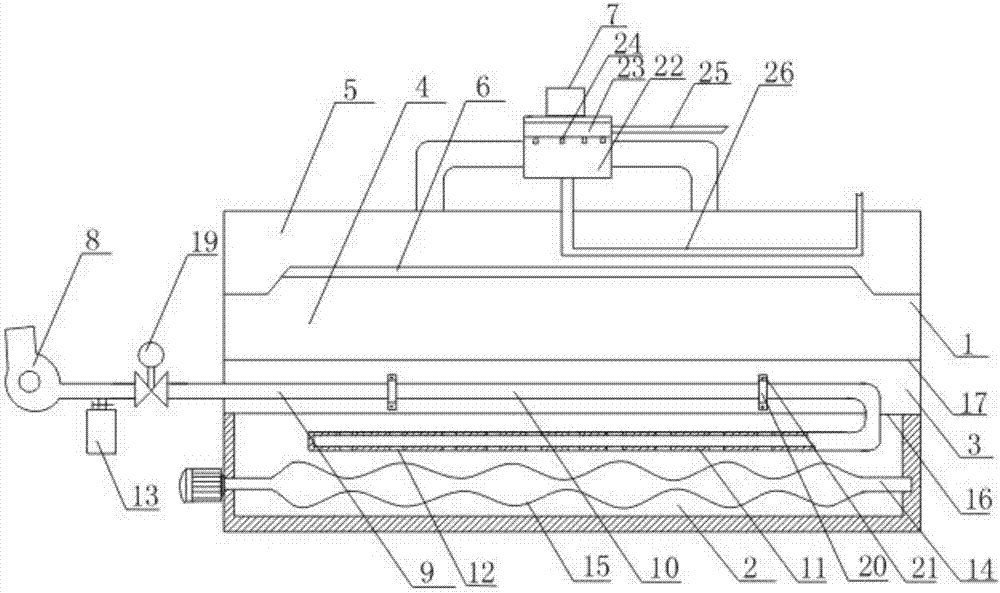

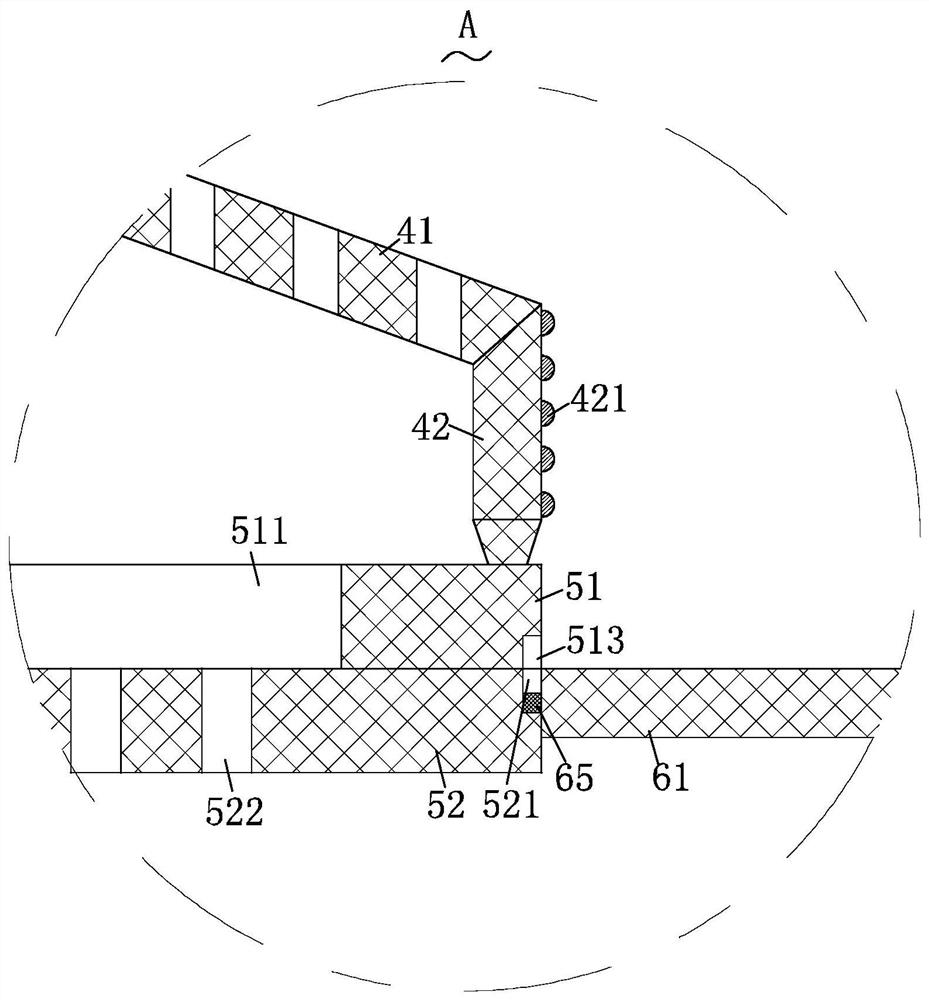

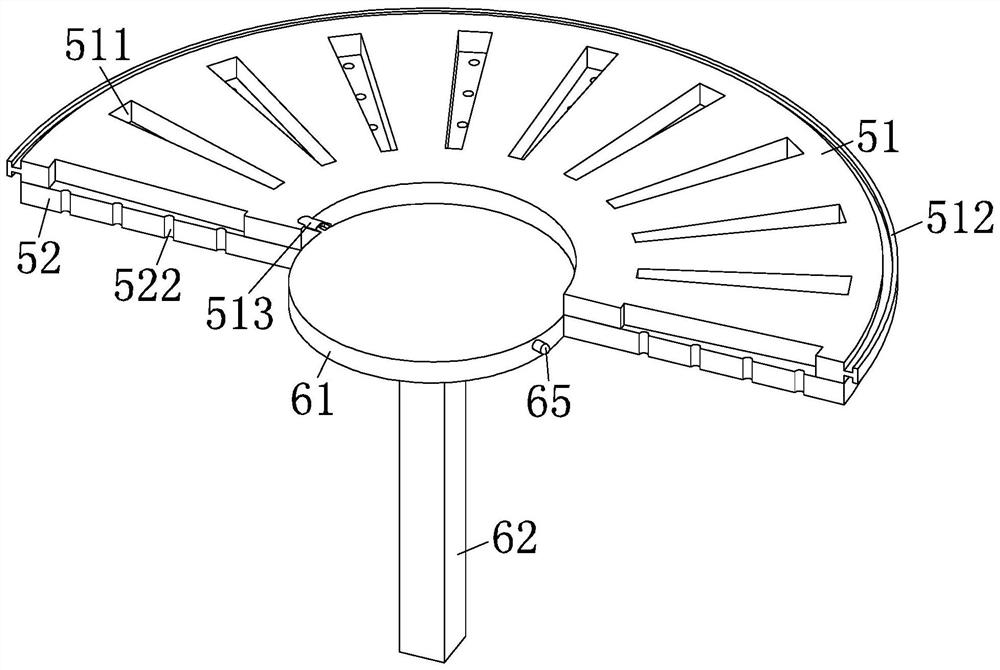

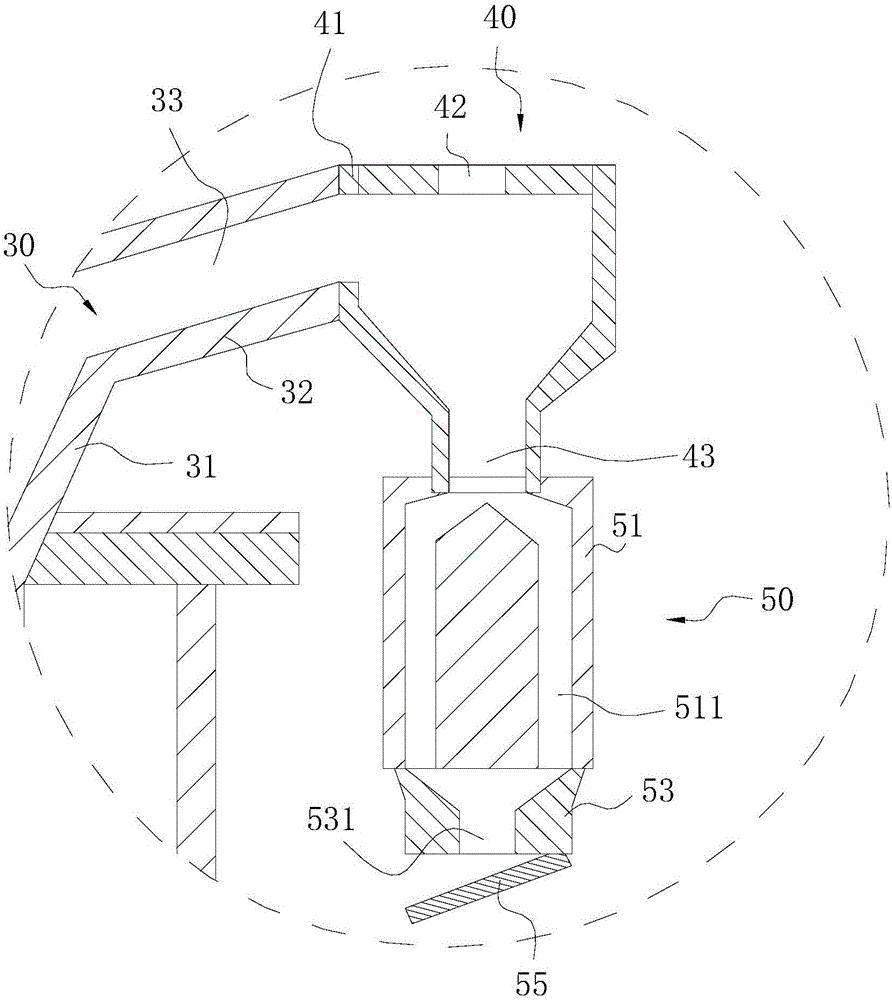

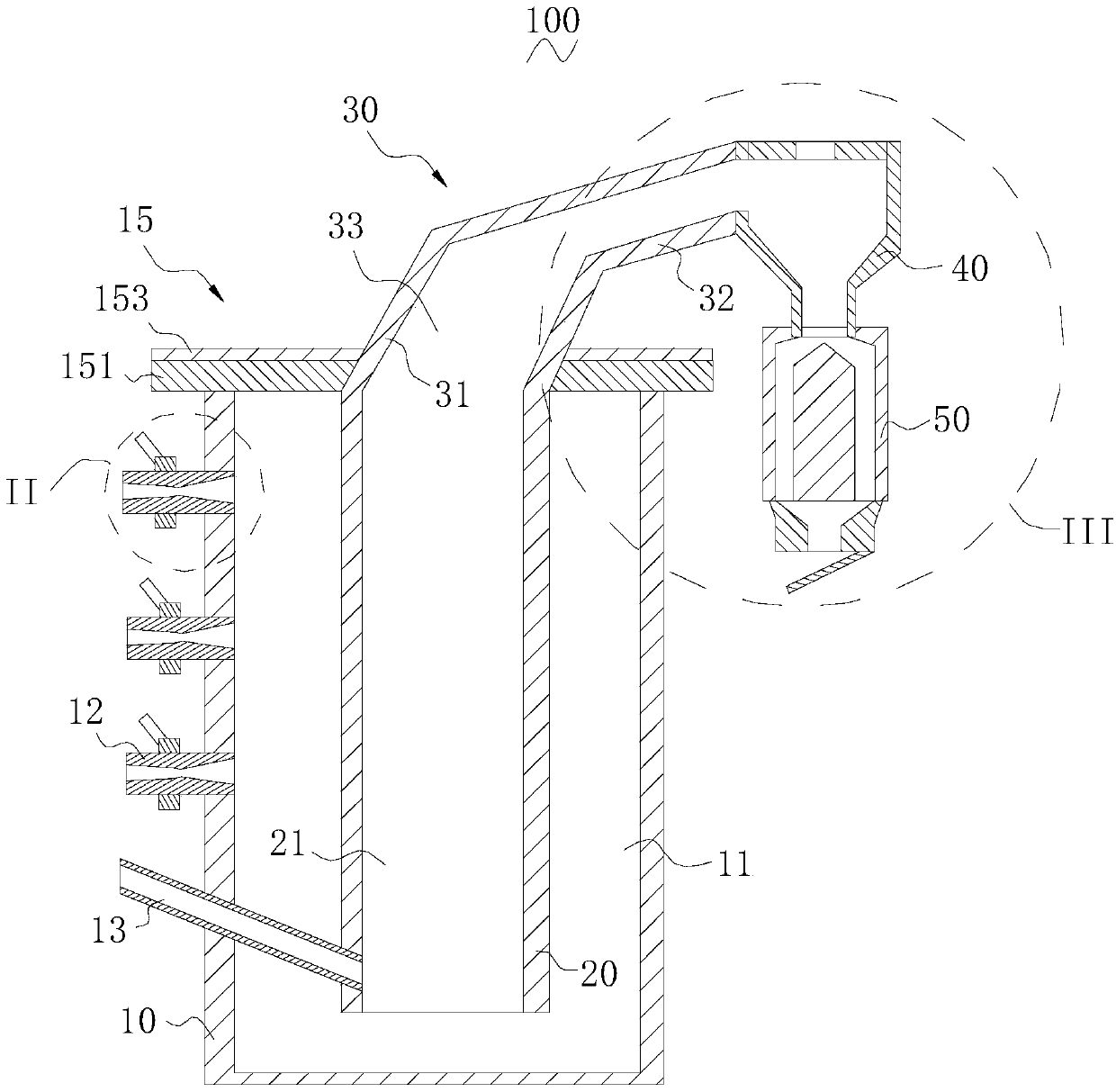

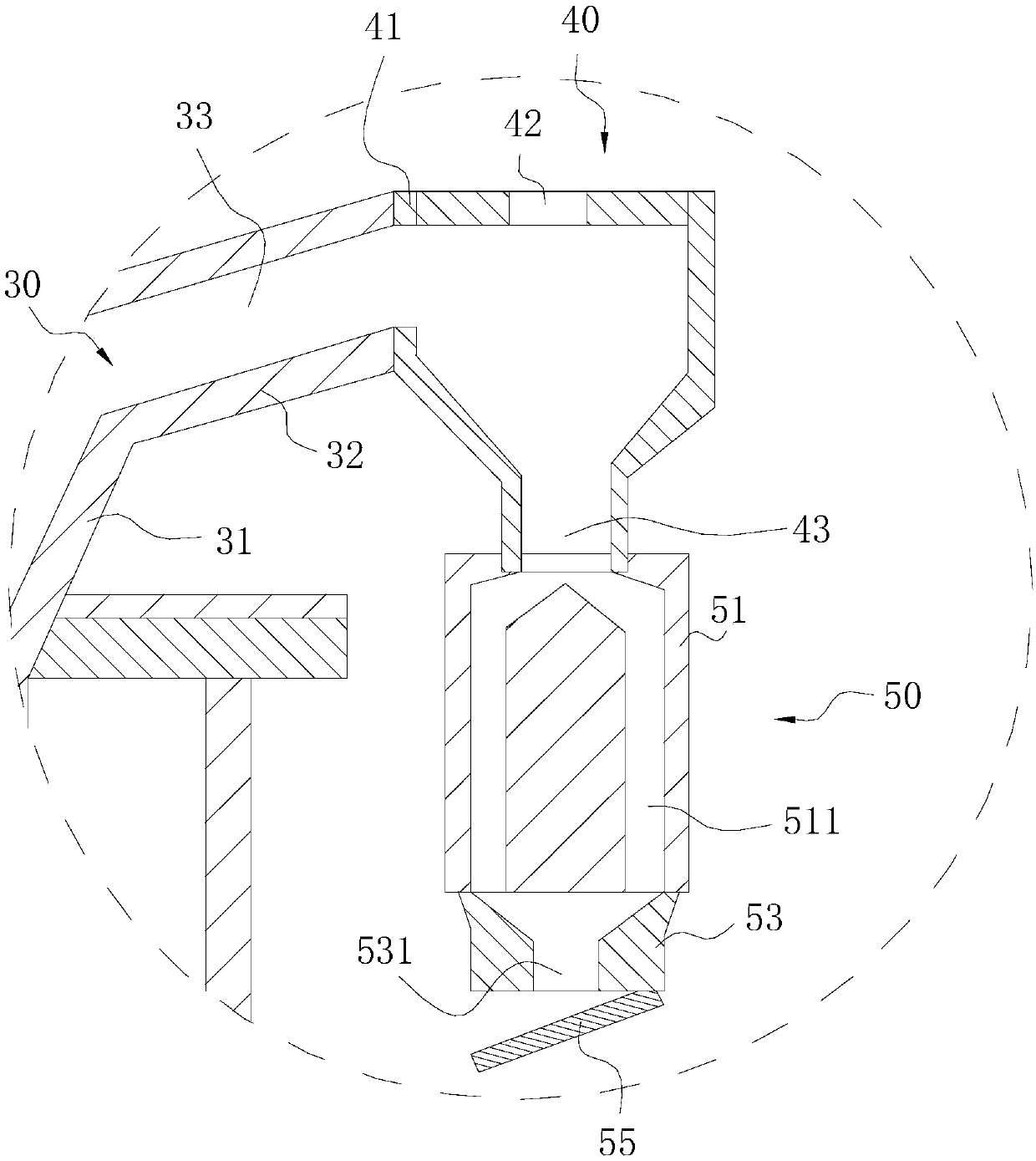

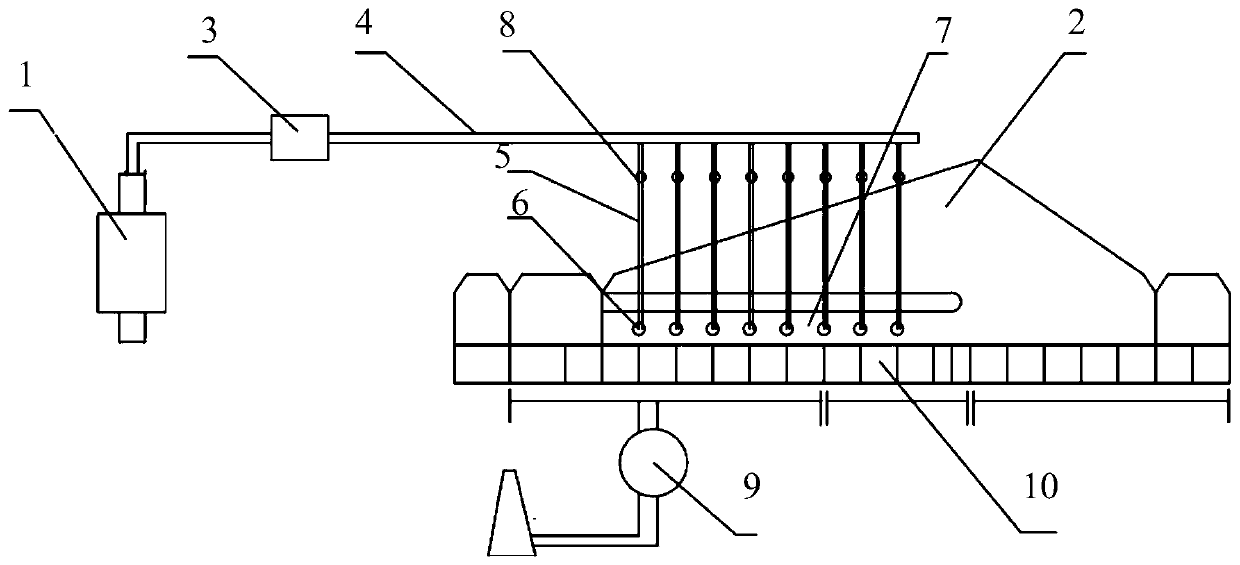

Calcining equipment

ActiveCN106440798AImprove combustion efficiencyPrevent overburningFluidised-bed furnacesCombustion chamberHeat conducting

The invention relates to calcining equipment. The calcining equipment comprises a combustion barrel, a calcining barrel, a discharge pipe, a solid-liquid separation barrel and an unloading part. A hearth is formed in the calcining barrel, the calcining barrel is sleeved with the combustion barrel, and an annular combustion chamber is formed between the combustion barrel and the calcining barrel. A feed pipe and multiple combustion nozzles are arranged on the combustion barrel, the solid-liquid separation barrel is arranged at the end of the discharge pipe, and the unloading part is arranged on the solid-liquid separation barrel. The extension direction of the combustion nozzles is vertical to that of the combustion barrel, combustion supporting air pipes are arranged on the combustion nozzles and inclined relative to the combustion nozzles, and each combustion nozzle comprises a guiding part and a connecting part connected with the guiding part. The calcining equipment can avoid excessive combustion, and is high in heat conducting efficiency, and fuel can be conveniently guided in.

Owner:DEMETER SUZHOU ELECTRONICS ENVIRONMENTAL MATERIALS CO LTD

Systems and methods for monitoring and optimizing flare purge gas with a wireless rotameter

ActiveUS20170361363A1Adequate purgingPrevent overburningHollow article cleaningVolume/mass flow by dynamic fluid flow effectControl systemEngineering

A method for optimizing purge gas of a flare system includes measuring a flow of flare fluids within a flare system to obtain a measured flow value. The flow of the flare fluids is compared to a target flow to obtain a difference between the flow of the flare fluids and the target flow. A control valve is operated to amend a flow of purge gas and the steps of measuring a flow of flare fluids and comparing the flow of the flare fluids to the target flow are repeated until the flow of the purge gas is within a target range. A value of the flow of purge gas is measured and transmitted wirelessly to a control system.

Owner:SAUDI ARABIAN OIL CO

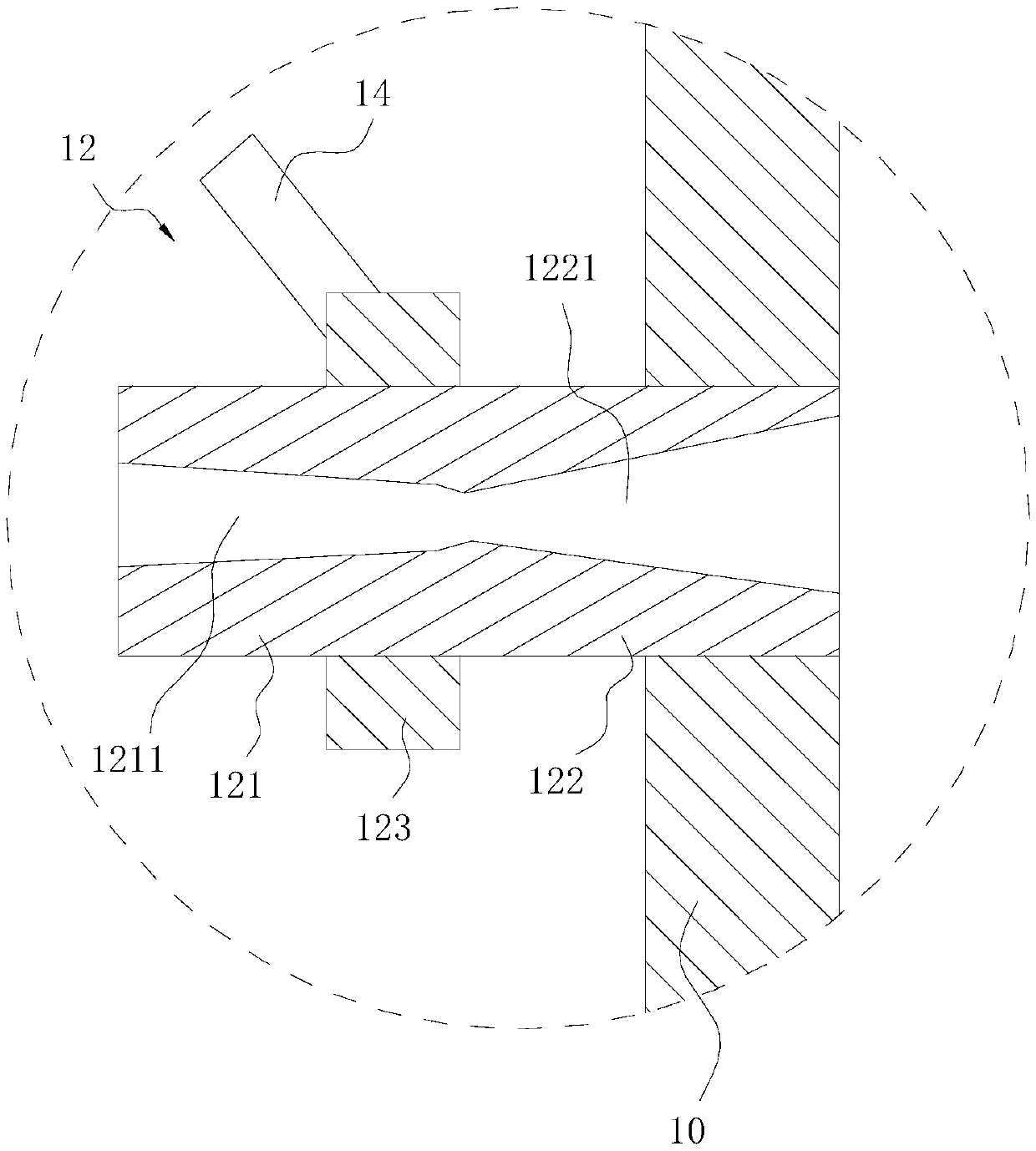

Internal heating type coking furnace for briquette coal cracking

InactiveCN112430467AImprove product qualityReduce contact areaSpecial form destructive distillationThermodynamicsCombustion

The invention relates to the technical field of industrial production equipment, in particular to an internal heating type coking furnace for briquette coal cracking, which comprises a preheating zone, a combustion zone and a maturation zone, wherein an ash filtering mechanism and an ash leaking mechanism are arranged on the inner side wall of the joint of the combustion zone and the maturation zone, and a sealing cover mechanism is arranged in the middle of the ash leaking mechanism. In working, the sealing cover mechanism moves upwards, briquetted briquette coal accumulated on the sealing cover mechanism and the ash filtering mechanism falls into the maturation zone, the ash leaking mechanism can be closed while the sealing cover mechanism moves upwards, so that ash formed by combustionof newly added pulverized coal cannot be mixed into coke in the maturation zone, the coke outlet door is closed, the coke pusher moves rightwards, when the coke pusher moves to a certain position, thecoke pusher does not abut against the bottom end of the cover sealing mechanism any more, the cover sealing mechanism drives the ash leaking mechanism to be opened in the downward moving process, ashaccumulated on the ash leaking mechanism falls onto coke in the maturation zone, the contact area between the coke in the maturation zone and air is reduced, excessive combustion is prevented, and resource waste is reduced.

Owner:内蒙古蓝色火宴科技环保股份公司

Calcinator

ActiveCN106482519AEasy to separatePrevent overburningCharge treatment typeFurnace typesCombustion chamberCalcination

The invention relates to a calcinator. The calcinator comprises a burning cylinder, a calcination cylinder, a discharge pipe, a solid-liquid separation cylinder and an unloading piece. A furnace chamber is formed in the calcination cylinder, the burning cylinder is arranged on the outer side of the calcinations cylinder in a sleeving mode, and an annular burning chamber is formed between the burning cylinder and the calcination cylinder; a feed pipe and a plurality of burning nozzles are arranged on the burning cylinder, the solid-liquid separation cylinder is arranged at the end of the discharge pipe, and the unloading piece is arranged on the solid-liquid separation cylinder; a connecting end is arranged on the side wall of the solid-liquid separation cylinder and connected to the end of the discharge pipe, a smoke hole and a discharge hole are formed in the two ends of the solid-liquid separation cylinder correspondingly, and the discharge hole communicates with the smoke hole; and a discharge cavity is formed in the discharge piece, the discharge cavity communicates with the discharge hole, and the discharge cavity is an annular cavity. According to the calcinator, over burning is avoided, heat conduction efficiency is high, and unloading is facilitated.

Owner:DEMETER SUZHOU ELECTRONICS ENVIRONMENTAL MATERIALS CO LTD

cautery device

ActiveCN106482518BEasy to exportPrevent overburningFluidised-bed furnacesCombustion chamberEngineering

The invention relates to a burning device which comprises a combustion cylinder, a calcination cylinder, a discharging pipe, a solid-liquid separation cylinder and a discharging piece. A furnace chamber is formed in the calcination cylinder; the outer side of the calcination cylinder is sleeved with the combustion cylinder; an annular combustion chamber is formed between the combustion cylinder and the calcination cylinder; a feeding pipe and a plurality of burners are arranged on the combustion cylinder; the solid-liquid separation cylinder is arranged at the end of the discharging pipe; and the discharging piece is arranged on the solid-liquid separation cylinder. The discharging pipe comprises a solid joint part and a guiding part which are connected with each other, the solid joint part is connected to the calcination cylinder, the guiding part is arranged in an inclined mode relative to the solid joint part, and a discharging channel is formed in the discharging pipe. The burning device has the beneficial effects that excessive burning is avoided, the efficiency of heat conduction is high and calcined materials are conveniently guided out.

Owner:DEMETER SUZHOU ELECTRONICS ENVIRONMENTAL MATERIALS CO LTD

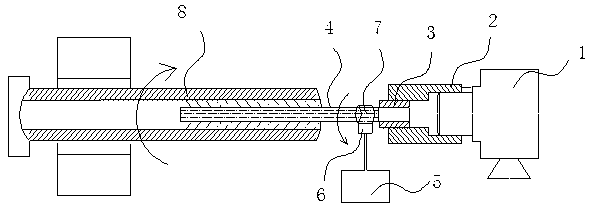

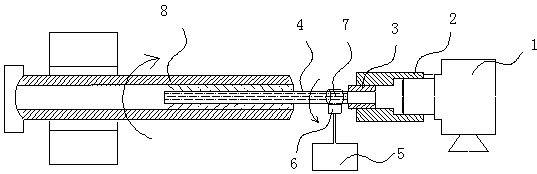

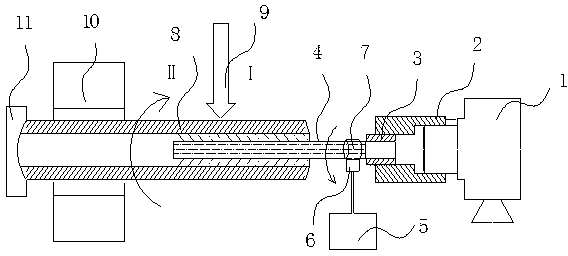

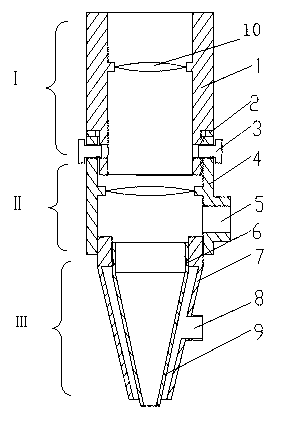

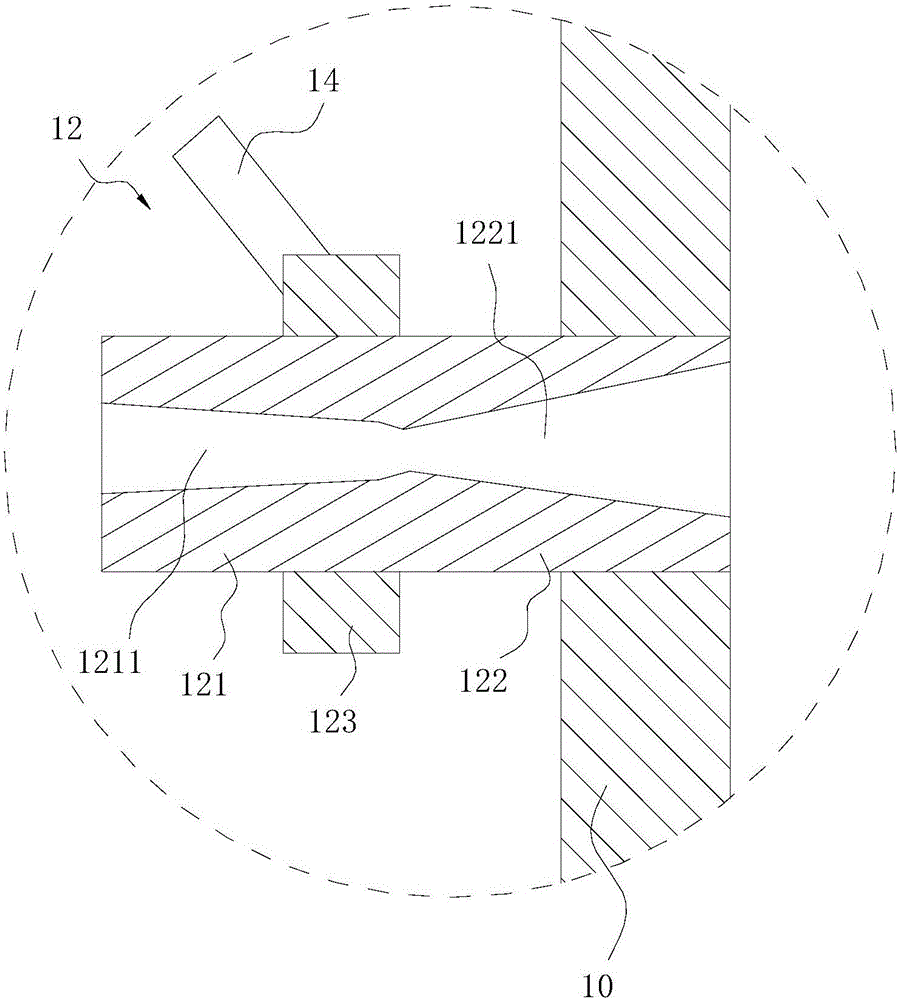

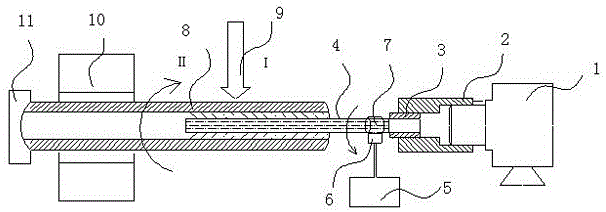

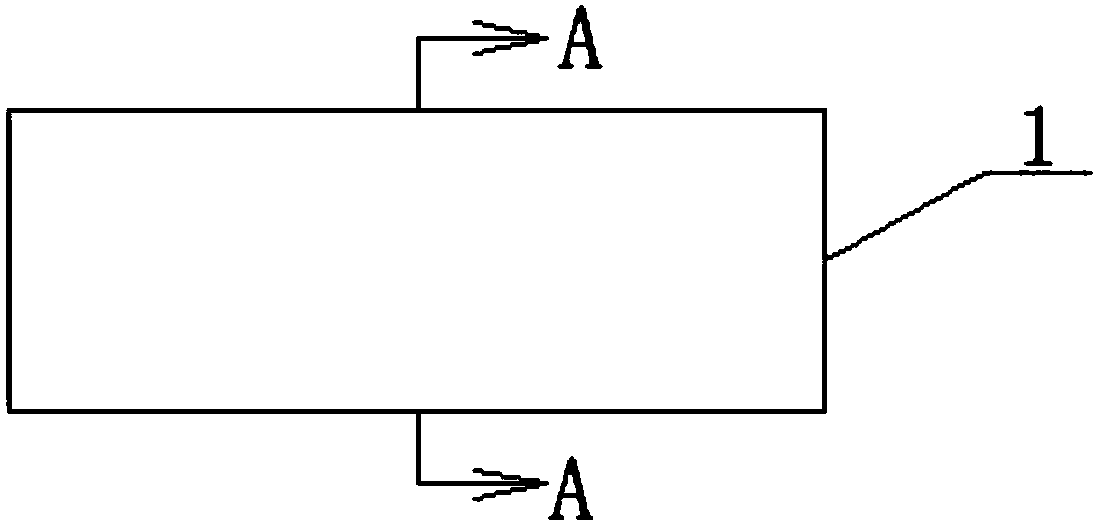

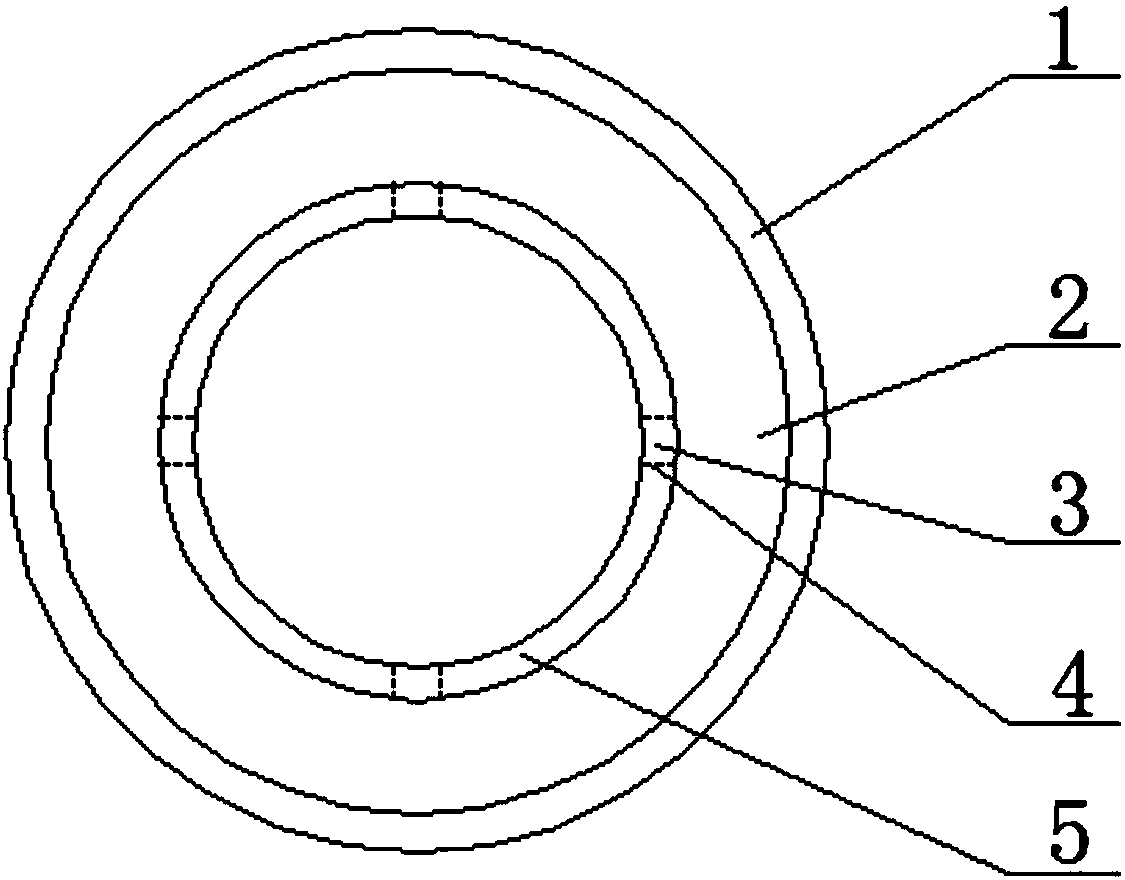

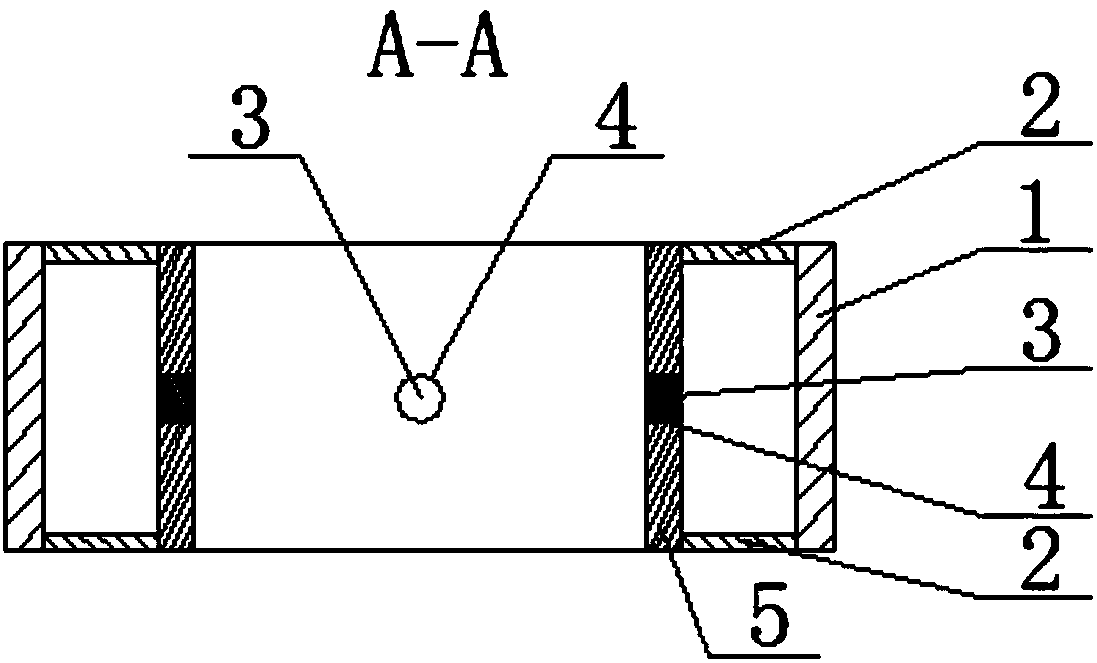

Pre-spray water guiding mechanism for laser wet cutting

ActiveCN103212804BPrevent overburningReduce pollutionLaser beam welding apparatusCouplingEngineering

The invention relates to a front-end spray water guiding mechanism in laser wet cutting machining, and the mechanism mainly solves the problems in the prior art that when laser is used for processing a pipe with a small diameter, the produced heat damages parts and chips are not easily removed. The front-end spray water guiding mechanism comprises a motor (1), a coupler (2), a lining (3), a water guiding pipe (4), an automatic water supply system (5) and a water inlet (6), the motor (1) is connected with the water guiding pipe (4) through the coupler (2) and the lining (3), one end of the lining (3) is arranged in the coupler (2) and the other end of the lining (3) is in sealed connection with the water guiding pipe (4), one end of the water guiding pipe (4) which is close to the lining (3) is provided with the water inlet (6), the water inlet (6) and the automatic water supply system (5) are connected through a seal bearing (7), the outer diameter of the water guiding pipe (4) is less than the inner diameter of a pipe (8) to be processed, and the end of the water guiding pipe (4) which is far from the lining (3) is inserted into the pipe to be processed. Due to the adoption of the technical scheme, the problems are well solved, and the front-end spray water guiding mechanism in laser wet cutting machining can be used in the industrial production of laser wet cutting machining.

Owner:KUNSHAN THETA MICRO

Conductive paste and solar cell using the same

InactiveUS20200295206A1Improve photovoltaic conversion efficiencySave troubleNon-conductive material with dispersed conductive materialPhotovoltaic energy generationAl powderPhotovoltaic industry

A conductive paste composed of an aluminum powder, an organic carrier consisting of an organic solvent and resin or cellulose, a glass powder, and a lead oxide. A total content of the glass powder and the lead oxide is from about 1.0 to 6.0 wt % of the conductive paste; and a content of the lead oxide is from about 0.5 to 3.0 wt % of the conductive paste. The conductive paste contains specific percentages of glass powder and lead oxide and can be used in manufacturing solar cells, and the solar cells so manufactured can have increased photovoltaic conversion efficiency without the need of using any expensive laser drilling apparatus, large plant space and any precision-alignment printing machine. With these advantages, the conductive paste is able to promote photovoltaic industry upgrading.

Owner:PANCOLOR INK

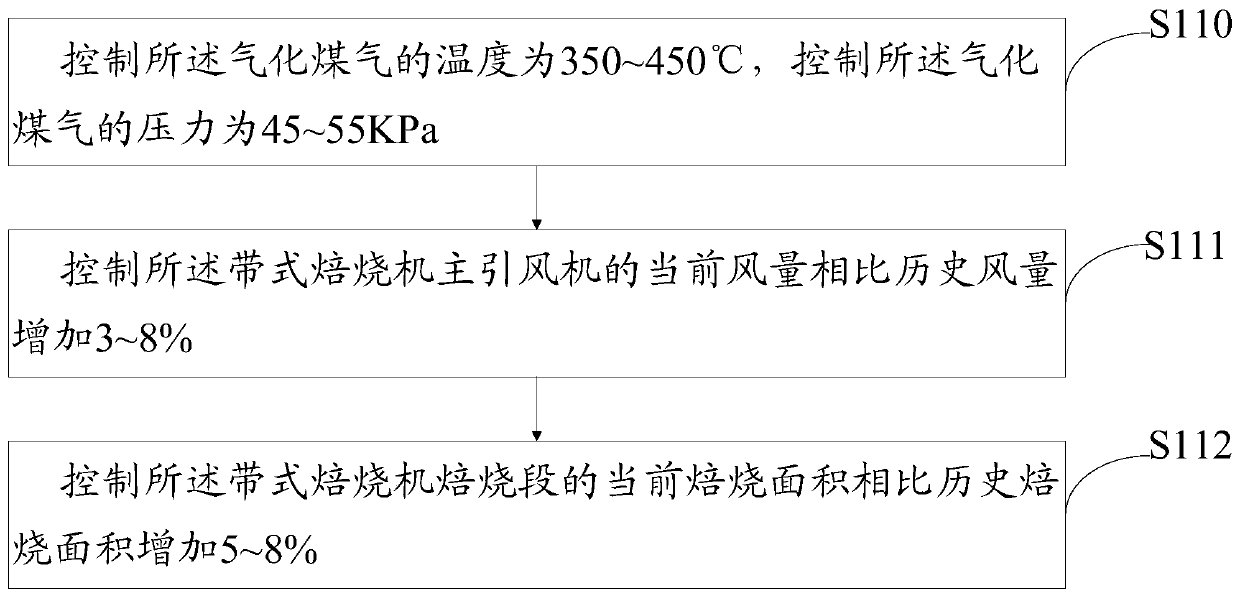

Method and device for producing pellet ores

The invention provides a method and a device for producing pellet ores. The method comprises the following steps of: controlling the temperature of gasified gas to be 350-450 DEG C and controlling thepressure of the gasified gas to be 45-55 KPa; controlling the current air volume of a main draught fan of a belt type roasting machine to be increased by 3% to 8% than a history air volume; and controlling the current roasting area of a roasting section of the belt type roasting machine to be increased by 5% to 8% than a history roasting area. Therefore, the temperature of the gasified gas is controlled to be 350-450 DEG C in order to guarantee the temperature required by combustion of the pellet ores; the pressure of the gasified gas is controlled to be 45-55 KPa in order to guarantee the flowing speed of the gasified gas; the combustion value of the gasified gas is low, so the combustion value of the gasified gas is increased by increasing the air volume so as to guarantee a heat transfer effect; the roasting area is increased by 5% to 8% so that the speed, flowing through a material layer, of the flue gas of the gasified gas is regulated to be in a proper range; and by the above-mentioned comprehensive optimization, the quality of the pellet ores can be finally guaranteed when the belt type roasting machine is used for producing the pellet ores by using coal or a low-heat-valuefuel.

Owner:SHOUGANG CORPORATION

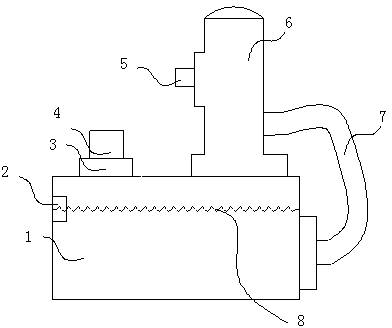

Wet Laser Cutting Machine

ActiveCN103212821BPrevent overburningReduce pollutionLaser beam welding apparatusCouplingLaser cutting

The invention relates to a laser cutting machine, which mainly solves the problem of the prior art that the heat damage on parts is caused by the generated heat and chips are difficultly removed when a pipe with small pipe diameter is processed by the laser cutting machine. The laser cutting machine adopts the technical scheme that the laser cutting machine comprises a cutting head and a front water guide system, wherein a motor (1) of the front water guide system is connected with a water guide pipe (4) through a coupling (2) and a bushing (3), one end of the bushing (3) is positioned in the coupling (2), the other end of the bushing (3) is in sealed connection with the water guide pipe (4), one end, near the bushing (3), of the water guide pipe (4) is provided with a water inlet (6), the water inlet (6) is connected with a sealing bearing (7) of an automatic water supply system (5), the outer diameter of the water guide pipe (4) is smaller than the inner diameter of a pipe (8) to be processed, and the end, away from the bushing (3), of the water guide pipe (4) is inserted into the pipe to be processed. The problems are well solved, and the laser cutting machine can be widely applied to the industrial production of laser wet cutting processing.

Owner:KUNSHAN THETA MICRO

A method and system for preventing over-combustion of a diesel particulate filter

ActiveCN106401720BAvoid over-burning situationsAvoid Overburning SituationsInternal combustion piston enginesExhaust apparatusCombustionLow speed

The invention discloses a method and a system for preventing over-combustion of a diesel particle catcher. The method comprises the steps that a carbon accumulation amount in the current diesel particle catcher is acquired; whether the carbon accumulation amount is larger than or equal to an over-combustion mass threshold or not is determined, and if yes, regeneration starting is forbidden; if not, whether the carbon accumulation amount is larger than or equal to a regeneration mass threshold or not is determined; when the carbon accumulation amount is larger than or equal to the regeneration mass threshold, whether the inlet temperature of the diesel particle catcher is larger than or equal to a regeneration temperature threshold or not is determined, and if yes, regeneration is started; and during a regeneration process, if a regeneration stopping condition is met, regeneration is stopped. By utilizing the method and the system, the problem of the diesel particle catcher in the prior art that over-combustion easily happens or excessive carbon particles in the diesel particle catcher cannot be effectively cleared off because a vehicle is at working conditions of idling and low-speed driving for a long term can be solved.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

Laser cutting machine with pre-spray water guide structure

ActiveCN103212805BPrevent overburningReduce pollutionLaser beam welding apparatusCouplingLaser cutting

The invention relates to a laser cutting machine, mainly solving the problems that during the process of machining a tube with a miniature diameter by a laser cutting machine in the prior art, thermal damage is brought to a spare part by generated heat, and scraps are not easily cleaned. The invention adopts the technical scheme that the laser cutting machine comprises a coaxial water jet-flowing device system and a front water guiding system, wherein the motor (1) of the front water guiding system is connected with a water guiding pipe (4) through a coupling (2) and a bushing (3), one end of the bushing (3) is arranged in the coupling (2), the other end of the bushing (3) is connected with the water guiding pipe (4) in a sealing way, a water inlet (6) is arranged on the end of the water guiding pipe (4) close to the bushing (3), the water inlet (6) is connected with the sealed bearing (7) of an automatic water supply system (5), the outer diameter of the water guiding pipe (4) is smaller than the inner diameter of a to-be-processed tube (8), and the end, far away from the bushing (3), of the water guiding pipe (4) is embedded into the inside of the to-be-processed tube. According to the invention, the problems are better solved, and the laser cutting machine can be applied to the industrial production of laser wet cutting processing.

Owner:KUNSHAN THETA MICRO

Healthy protective ring for cigarette

The invention relates to the technical field of automatic cigarette extinguishment, in particular to a healthy protective ring for a cigarette. The healthy protective ring includes a shell, sealing plates, paraffin blocks, paraffin holes and an inner wall; the shell is a hollow cylinder body with two transparent ends; the inner wall is a hollow cylinder body with two transparent ends; the two endsof the shell are both connected and sealed with the two ends of the inner wall through the sealing plates; the paraffin holes running through the inner wall are formed in the middle of the inner wall; water is contained in a space defined by the shell, the inner wall and the sealing plates; the paraffin blocks are positioned in the paraffin holes and seal the water in the space defined by the shell, the inner wall and the sealing plates. According to the healthy protective ring for the cigarette, by adopting a liquid water design, when the paraffin blocks are melted by the high temperature ofthe cigarette, liquid water overflows from the paraffin holes to extinguish the cigarette. The protective ring can prevent excessive combustion when people smoke, correspondingly people are preventedfrom sucking a great quantity of cancerogenic substances generated by combustion of cigarette holders, and harm caused by smoking to the human body is reduced.

Owner:石佳敏

Laser wet cutting processing method

ActiveCN103212852BPrevent overburningReduce pollutionLaser beam welding apparatusEngineeringLaser cutting

The invention relates to a laser wet cutting machining method which mainly solves the problems in the prior art that when a laser cutting machine processes a pipe with a small diameter, the produced heat damages parts and chips are not easily removed. The laser wet cutting method comprises the following steps that the pipe to be cut is fixedly arranged on the rotary shaft of the cutting machine, a water guiding pipe of the water guiding system of the cutting machine is inserted from one end of the thin-wall pipe to be cut, the laser cutting machine is started so that the pipe to be cut rotates, the water guiding system of the laser cutting machine is started so that the water guiding pipe rotates, the water circulation module of the laser cutting machine is started, and the cutting head of the laser cutting machine is started to cut the pipe. Due to the adoption of the technical scheme, the problems are well solved, and the laser cutting machining method can be used in the industrial production of laser wet cutting machining.

Owner:KUNSHAN THETA MICRO

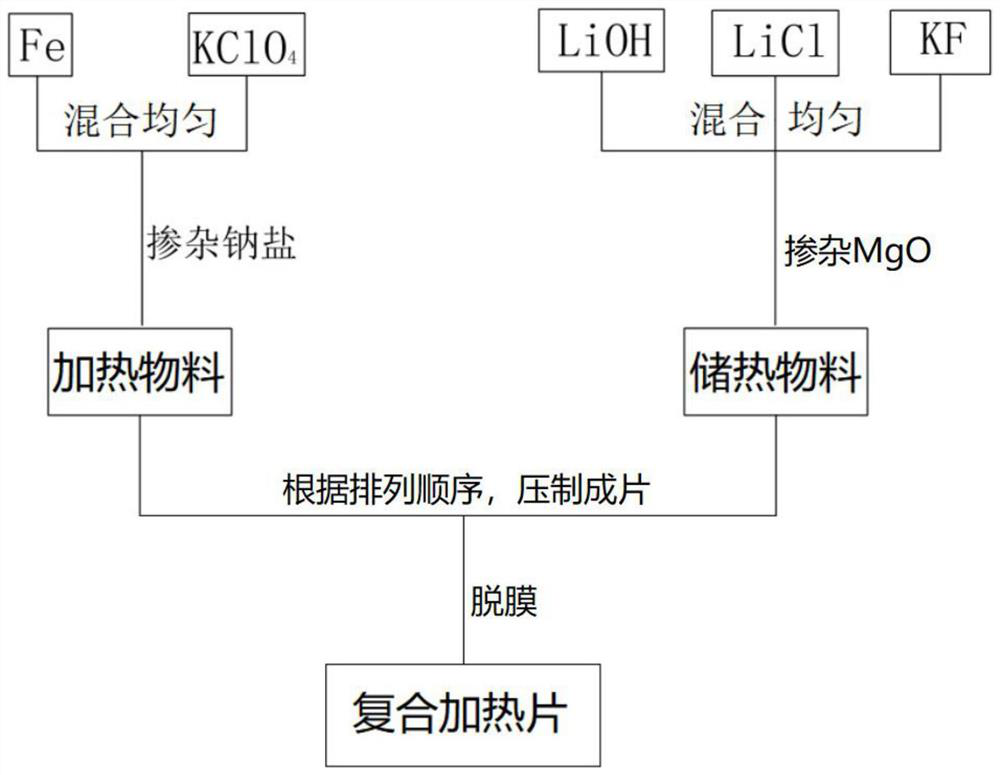

Preparation method and application of a composite heating sheet for thermal battery

ActiveCN110890565BGuaranteed to work long hoursGuaranteed to workDeferred-action cellsPrimary cell maintainance/servicingElectrical batteryHeat storage material

The invention discloses a preparation method of a composite heating sheet for a thermal battery, the composite heating sheet is prepared from a heating material and a heat storage material, and the preparation method comprises the following steps: weighing Fe powder and KClO4 powder in proportion, uniformly stirring, adding a sodium salt, uniformly mixing, and sieving to obtain the heating material; the preparation method comprises the following steps: weighing LiOH, LiCl and KF powder in proportion, uniformly stirring, adding MgO powder, uniformly mixing, and sieving to obtain a heat storagematerial; and sequentially putting the heating material and the heat storage material into a mold, applying pressure to mold the powder, and demolding to obtain the composite heating sheet. Accordingto the composite heating sheet of the thermal battery, the sodium salt is added into the heating material, and active substances in the heating material can be effectively dispersed in the presence ofthe sodium salt, so that overburning of the heating material is prevented, the heat release time of the heating material is prolonged, and the thermal battery can work for a long time.

Owner:GUIZHOU MEILING POWER SUPPLY CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com