Laser cutting machine

A technology of laser cutting machine and rotating shaft, applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of only wet cutting, only dry cutting, and incompatibility at the same time, so as to prevent excessive burning and reduce Sewage discharge and the effect of water recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

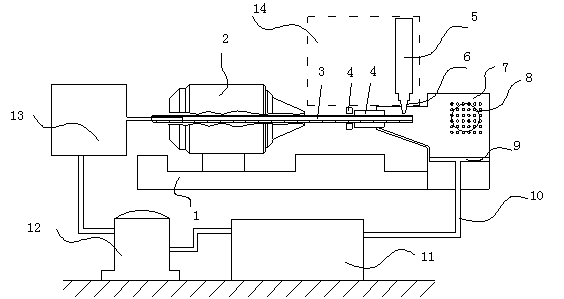

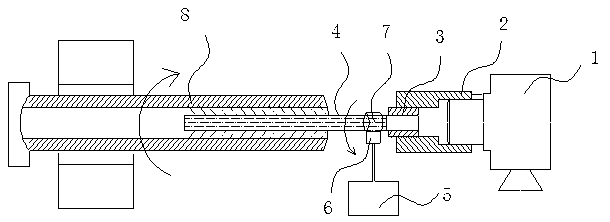

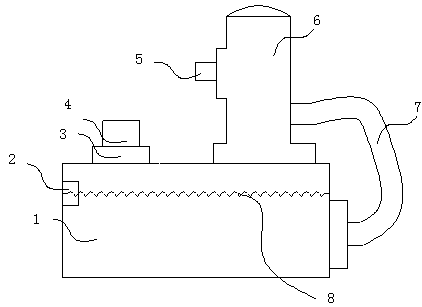

[0039] A laser cutting machine such as figure 1 As shown, it includes processing module, material receiving module, two-dimensional motion platform, dust collection module and water circulation module; The shaft 2 clamps the pipe 3 through the pipe clamp 4 and rotates at high speed, while moving along the linear shaft 2. The rotating shaft 2 is a hollow structure, and one end of the pipe 3 is placed in the rotating shaft 2; the processing module is located on the upper part of the rotating shaft 2, including the laser generator 5 and nozzle 6; the material receiving module is located below the nozzle 6 and is composed of a sealed chamber 7 and a blanking box 9. The dust collection module is composed of a vacuum cleaner and a suction pipe, and the dust collection pipe passes through the flange and the dust collection pipe on the sealed chamber 7 The installation hole 8 is connected; the water circulation module includes a water collecting pipe 10, a sewage filtering device 11, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com