Laser cutting method

A laser processing method and laser cutting technology, applied in laser welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of difficult removal of debris, thermal damage of parts, etc., and achieve low cost, reduce sewage discharge, and reduce pollution. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

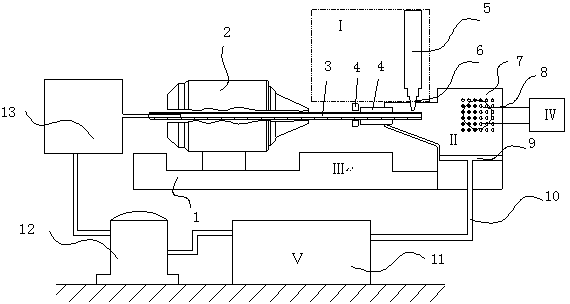

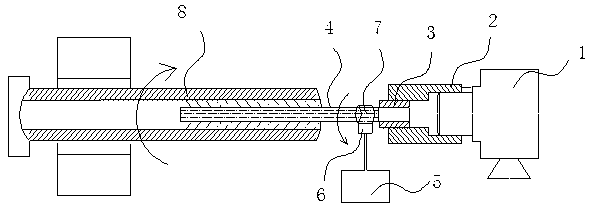

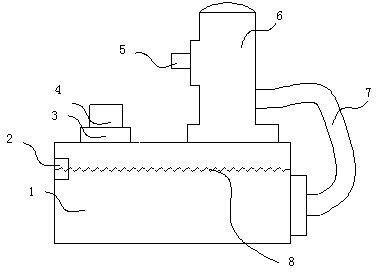

[0054] This embodiment provides a laser cutting processing method, which includes the following steps: fixing the pipe to be cut on the rotating shaft of the cutting machine; Insert; start the rotating shaft of the laser cutting machine to rotate the pipe to be cut; start the water guide system of the laser cutting machine to rotate the water pipe; start the water circulation module of the laser cutting machine; start the cutting head of the laser cutting machine to cut the pipe; among them, The laser cutting machine, such as figure 1 As shown, it includes coaxial water jet module I, material receiving module II, two-dimensional motion platform III, dust collection module IV and water circulation module V; two-dimensional motion platform III includes linear axis 1 and rotary axis 2, and rotary axis 2 is installed On the slide rail of the linear shaft 1, the rotating shaft 2 clamps the pipe 3 through the pipe clamp 4 and rotates at high speed, and at the same time moves along t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com