Laser cutting machine with pre-spray water guide structure

A technology of laser cutting machine and water guide mechanism, applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of difficult removal of debris and thermal damage of parts, so as to improve processing quality and avoid thermal damage and burning , reducing the effect of the heat-affected zone

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

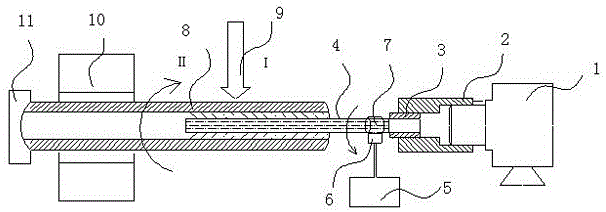

[0030] This example provides a laser cutting machine, such as figure 1 As shown, it includes a coaxial water jet device 9, a fixture 10, a sealing plug 11 and a pre-spray water-guiding mechanism, the pre-spray water-guiding mechanism contains an automatic water supply system; the pre-spray water-guiding mechanism, Including motor 1, coupling 2, bushing 3, water guide pipe 4, automatic water supply system 5 and water inlet 1-6, motor 1 is connected with shaft coupling 2, bushing 3 and water guide pipe 4, and one end of bushing 3 is located in the joint In the shaft device 2, the other end is in sealing connection with the aqueduct 4, and the end of the aqueduct 4 near the bushing 3 has a water inlet-6, and the water inlet-6 is connected with the automatic water supply system 5 sealed bearing 7, and the outer diameter of the aqueduct 4 is smaller than that to be The inner diameter of the pipe material 8 is processed, and the end of the water guide pipe 4 away from the bushing 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com