Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

96results about How to "Precise weight control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

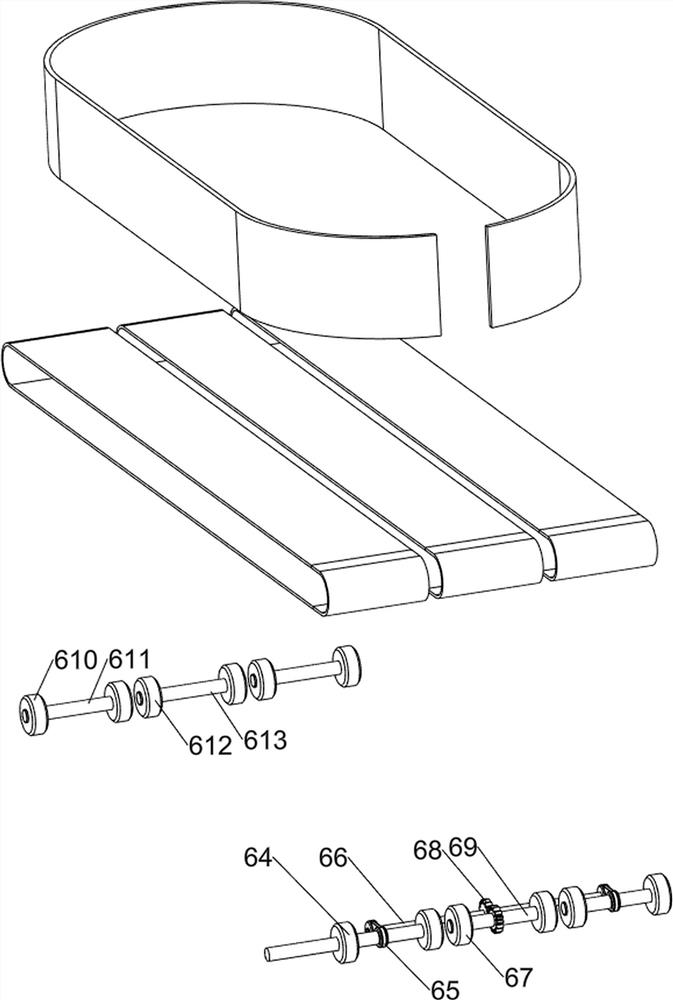

Powder coating quantifying and packing machine capable of achieving sort screening of particle sizes

The invention relates to a powder coating quantitative packaging machine that can classify and screen particle sizes, comprising a bottom plate, a conveying grinding mechanism, a screening mechanism and a quantitative mechanism are installed on the bottom plate; Above, the conveying and grinding mechanism is located above the screening mechanism, the lower end of the bottom plate is provided with a guide frame, the lower end of the bottom plate is provided with a support column, the support column is installed on the working plate, and the conveying and grinding mechanism, the screening mechanism, the quantitative mechanism, the guide The lead frame is matched to complete the quantitative packaging process of powder coating. The invention can solve the problems existing in the existing powder coating production process that need to be manually screened according to the particle size, long screening time, poor screening effect, manual packaging according to the specified weight, low quantitative packaging efficiency, and low screening efficiency. The problems of separate processing of quantitative packaging, low processing efficiency and low work efficiency can realize the functions of powder coating screening, quantitative and packaging integrated production.

Owner:谢秋晨

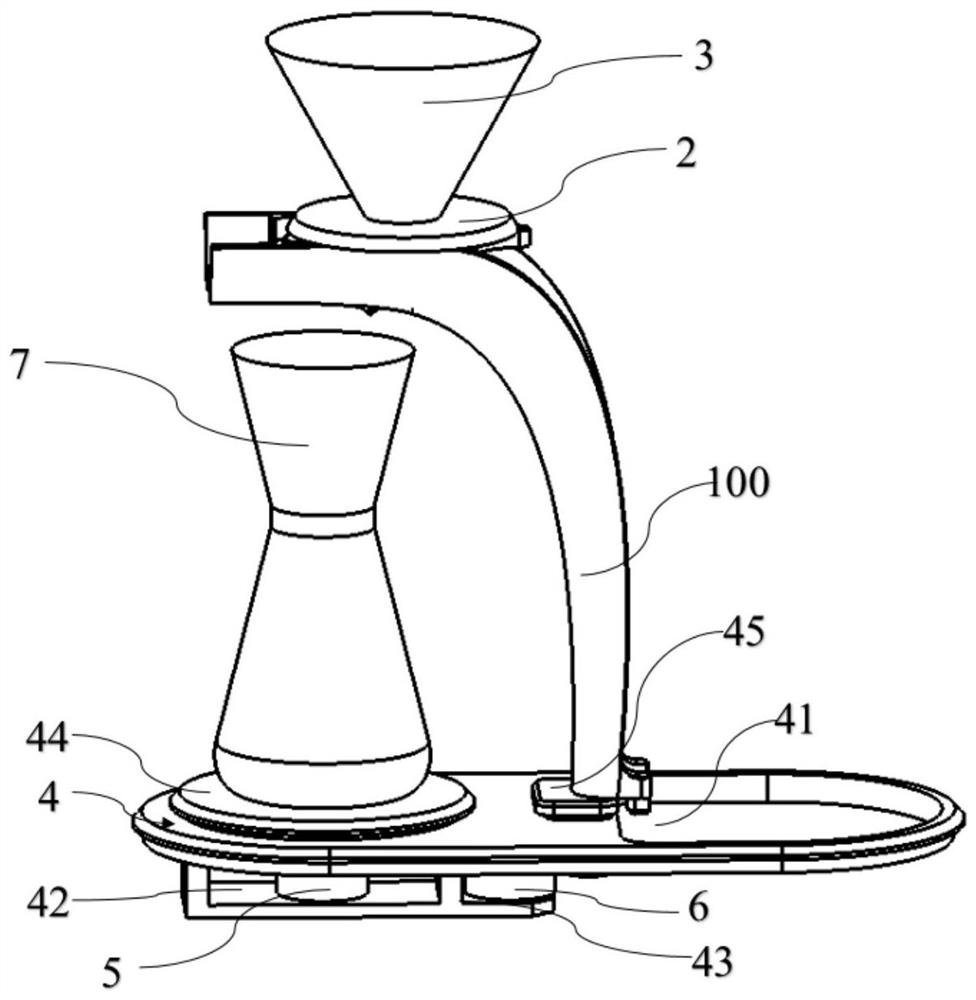

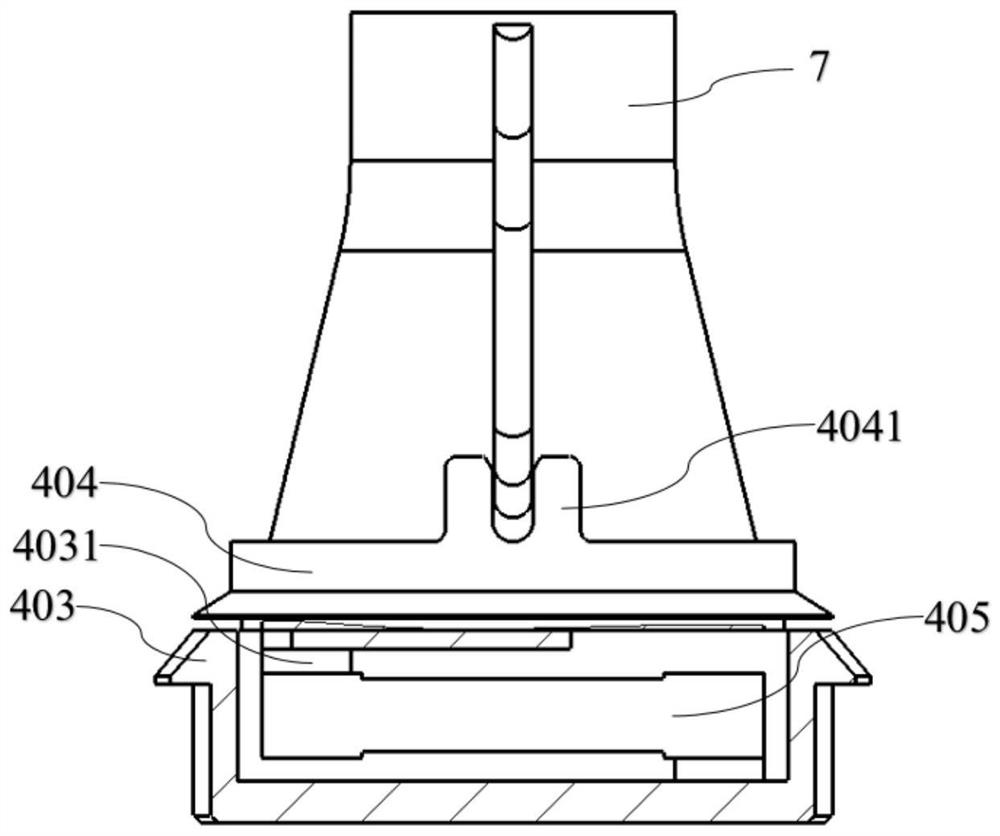

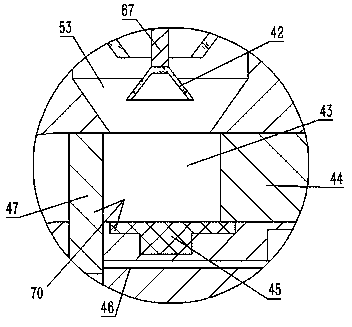

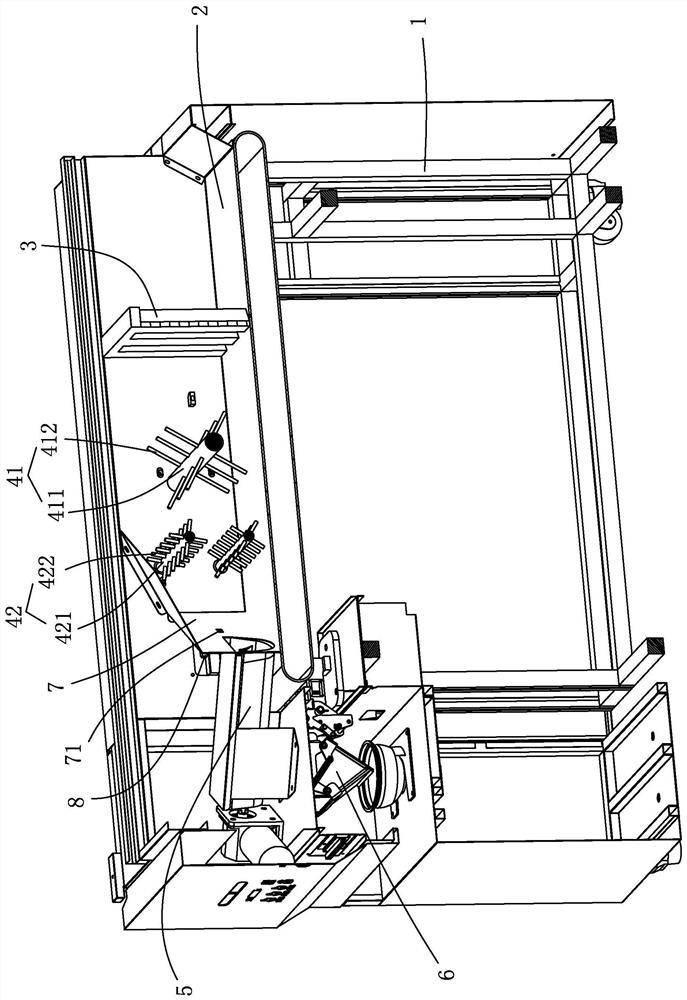

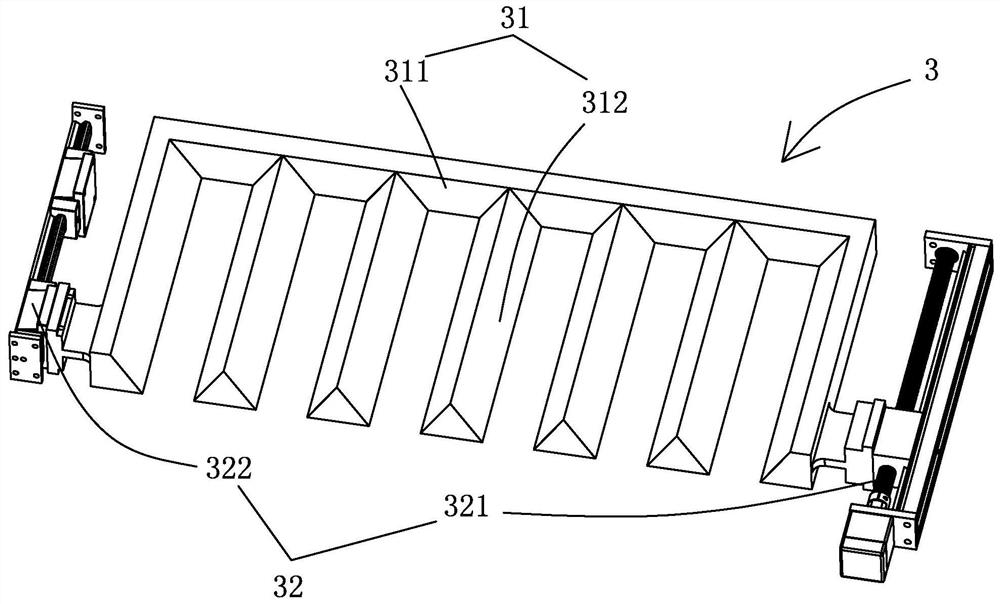

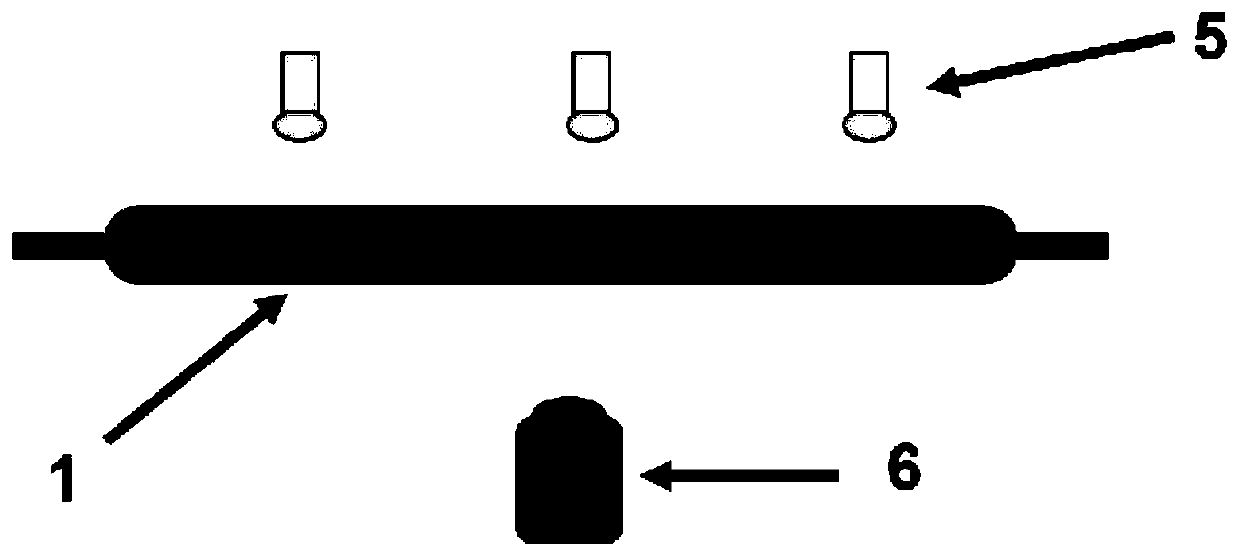

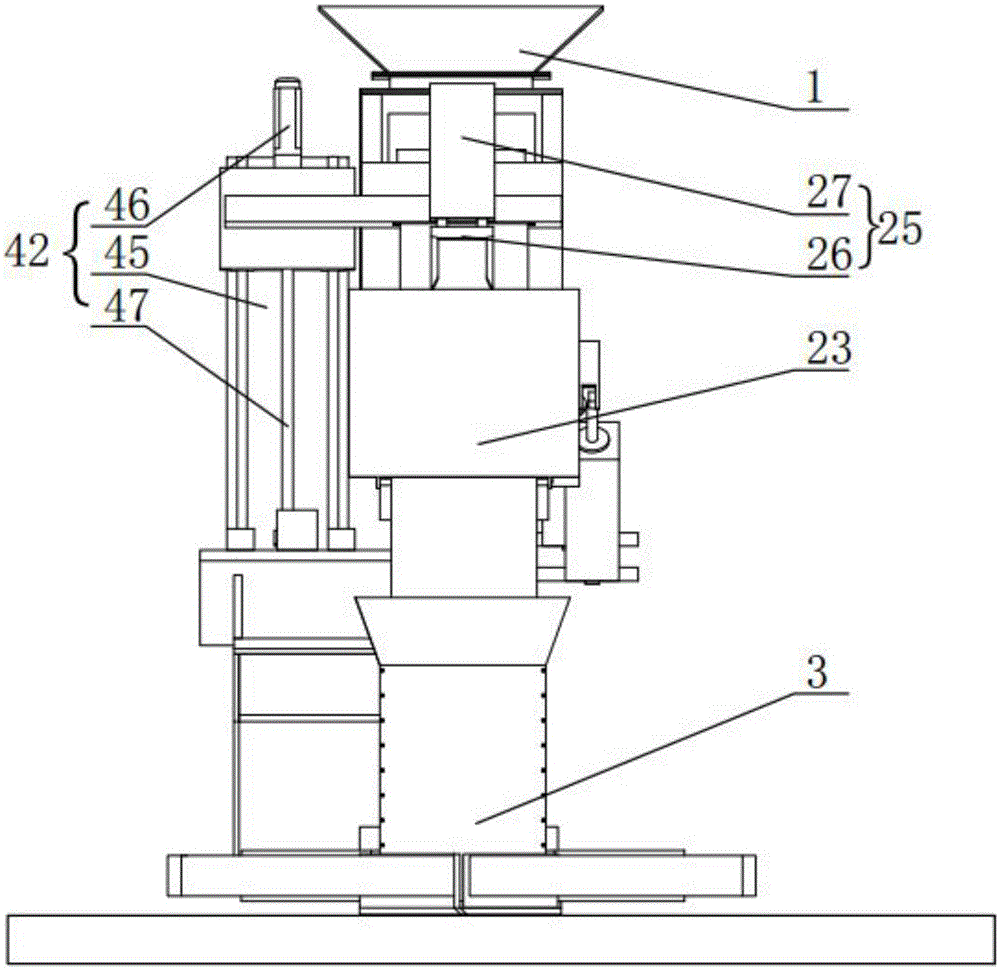

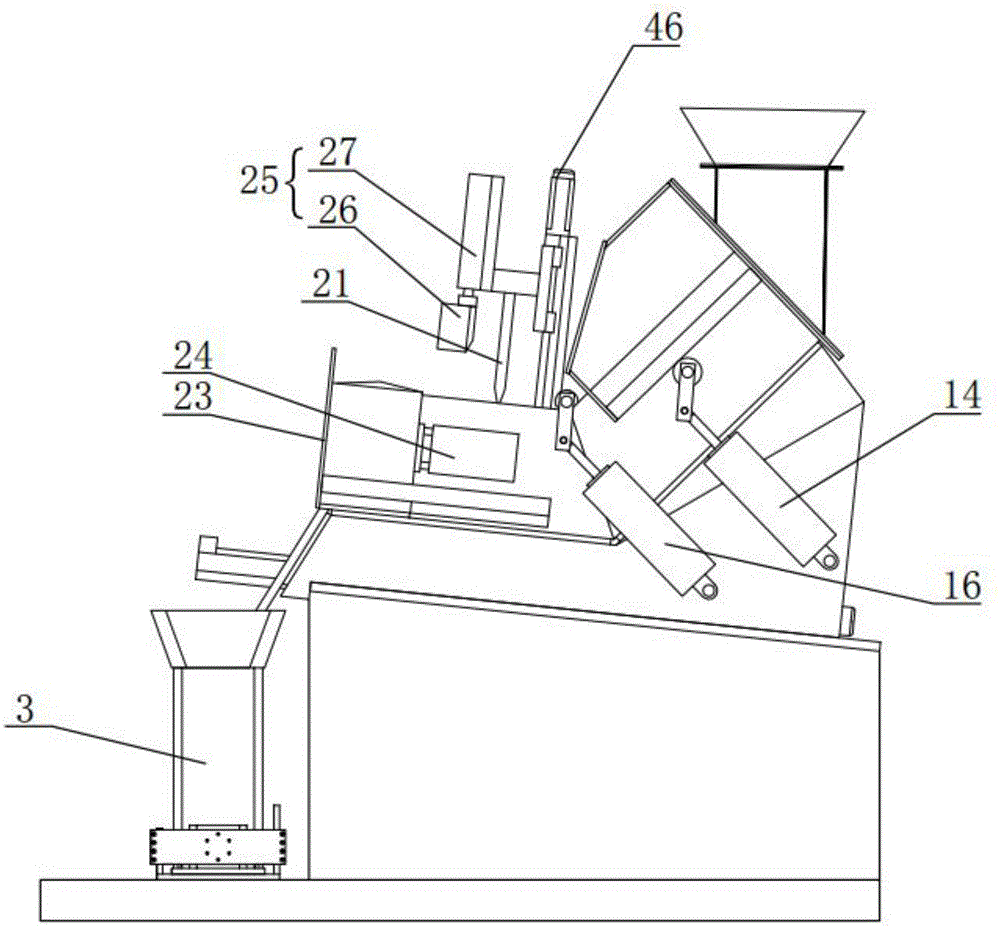

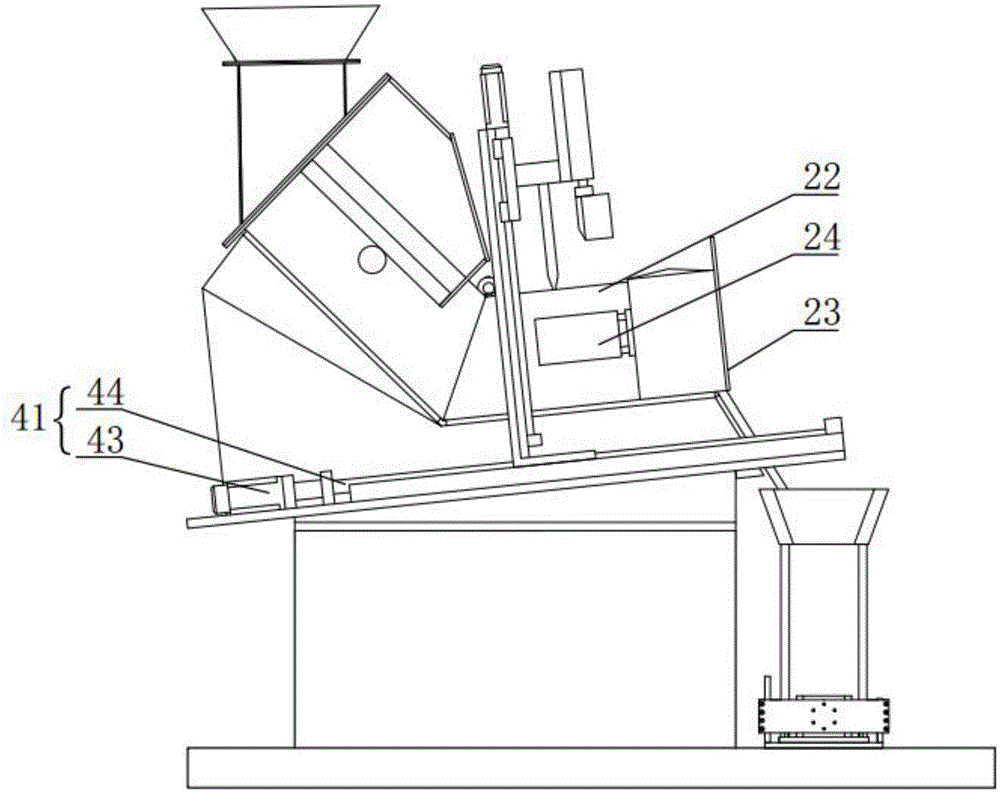

Intelligent hand-brewed coffee making equipment, control method thereof, controller and storage medium

ActiveCN112353248AFast brewing speedPrecise weight controlBeverage vesselsProcess engineeringWorkbench

The invention discloses coffee making equipment and a control method of the intelligent hand-brewed coffee making equipment. The intelligent hand-brewed coffee making equipment comprises a workbench,a water supply device, a supporting component, at least one mechanical arm and a controller, wherein the water supply device, the supporting component and the at least one mechanical arm are arrangedon the workbench, the water supply device is provided with a first weightometer, the supporting component is provided with a second weightometer used for weighing a sharing kettle, and the controllercontrols the mechanical arm to grab a filter cup from the workbench and place the filter cup on the supporting component, controls the mechanical arm to grab the sharing kettle from the workbench andplace the sharing kettle below the filter cup located on the supporting part, controls the water supply device to inject hot water into the kettle, and controls the mechanical arm to add hot water into the filter cup through the kettle based on weighing of the second weightometer so as to brew coffee powder in the filter cup. The intelligent hand-brewed coffee making equipment has the advantages of being high in coffee brewing speed, accurate in weight control and uniform in taste.

Owner:BEIJING ORION STAR TECH CO LTD

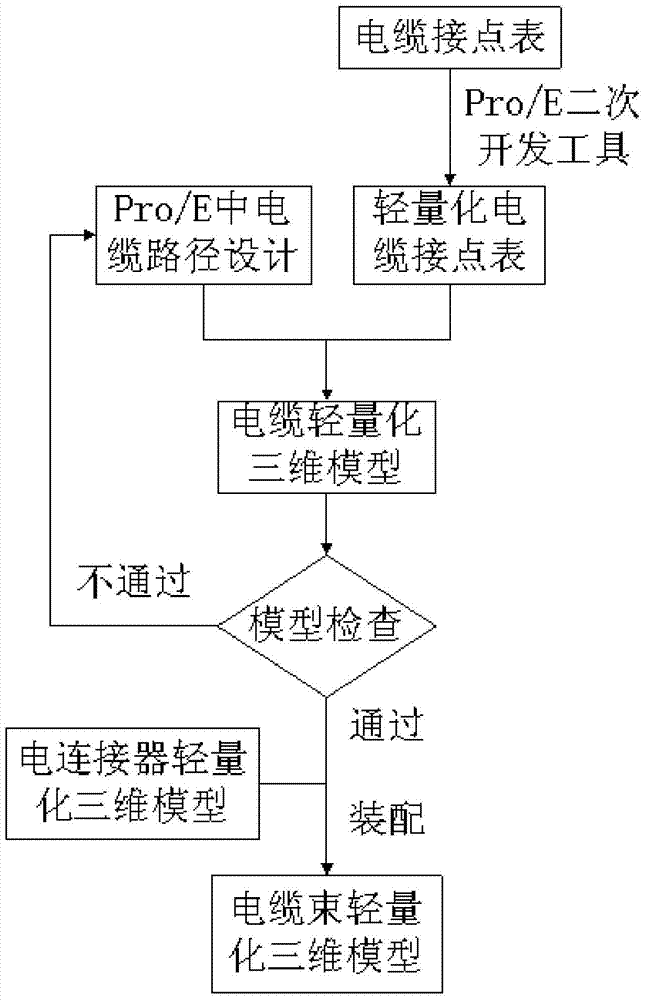

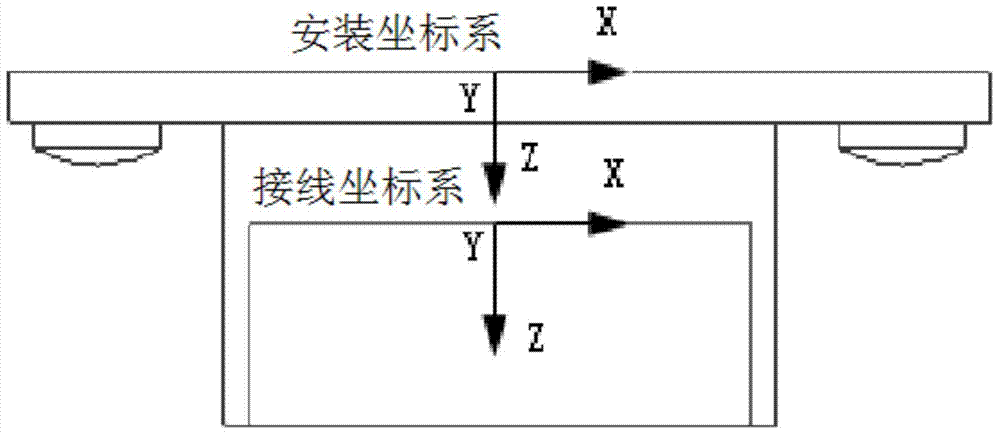

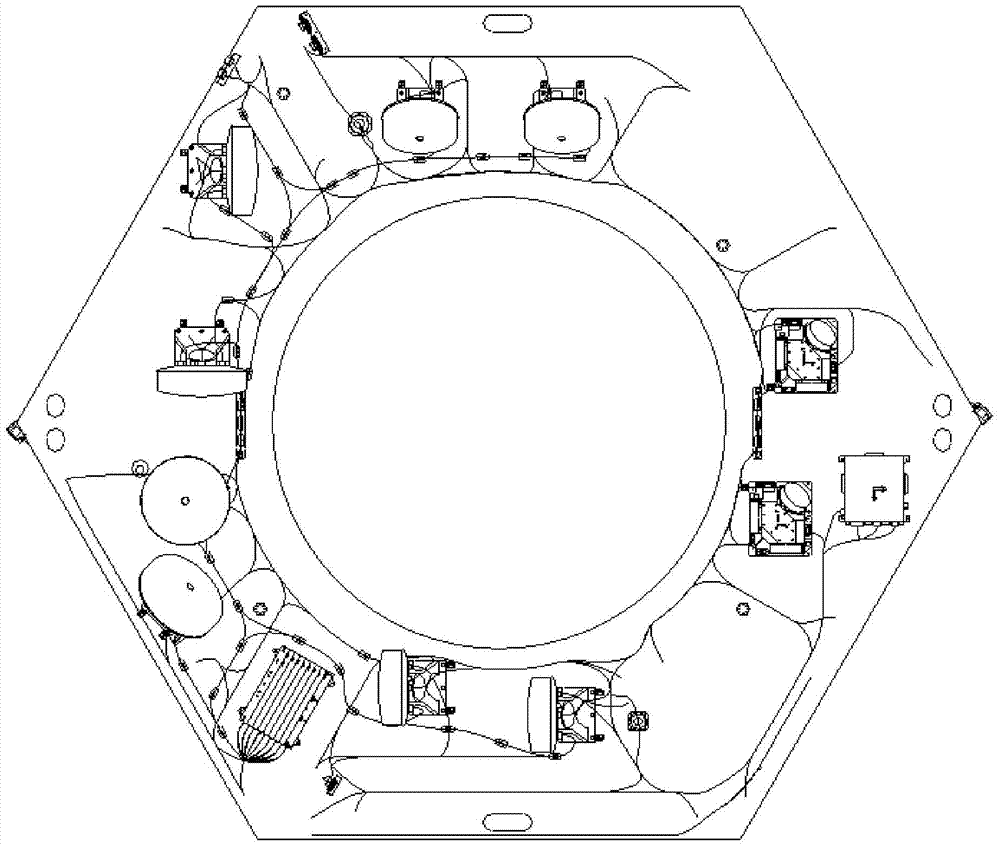

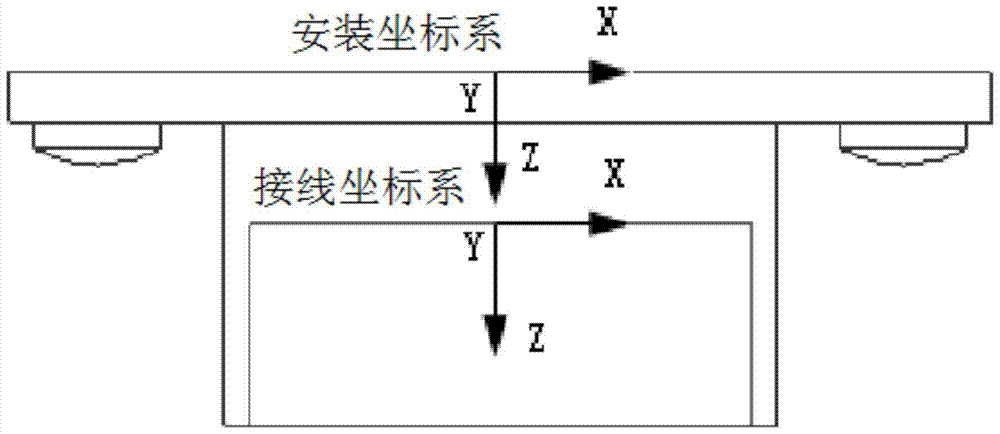

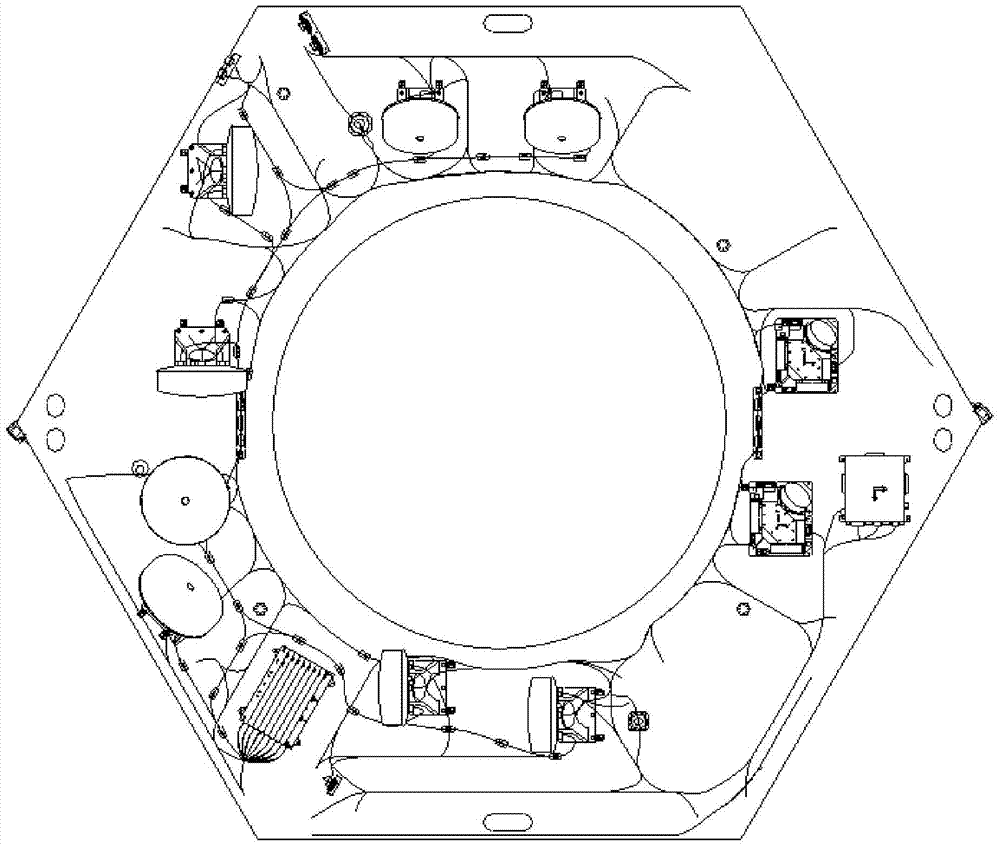

Lightweight modeling method of satellite cable

ActiveCN104268321ALow hardware performance requirementsAvoid path distortionSpecial data processing applications3D modellingPetroleum engineeringDesign technology

The invention discloses a lightweight modeling method of a satellite cable. Based on the computerized design technique and the Pro / E secondary development technology, the lightweight modeling method comprises the steps of 1, establishing a three-dimensional electrical connector lightweight model in Pro / E, 2, establishing a cable joint table in a computer system, 3, generating a lightweight cable joint table by use of a Pro / E secondary development tool, 4, designing a cable trend path in the Pro / E, 5, reading in the lightweight cable joint table in the Pro / E and creating a three-dimensional cable lightweight model, 6, performing model examination in the Pro / E, and 7, assembling the cable model and the electrical connector model in the Pro / E. The lightweight modeling method of the satellite cable has the advantages that the size of a three-dimensional cable model file can be greatly reduced, the three-dimensional modeling of the satellite cable can be improved, the length and the weight of the cable can be accurately controlled and the efficiency and the quality of the satellite cable design can be improved, based on the lightweight thought and by maintaining the major information of cable modeling and neglecting secondary and irrelevant information.

Owner:SHANGHAI SATELLITE ENG INST

PP (Polypropylene) plastic injection molding machine

The invention discloses a PP (Polypropylene) plastic injection molding machine. The PP plastic injection molding machine comprises a feeding device, a machine barrel, a screw rod, a base, a motor, a metering device and a machine head, wherein the feeding device comprises a stirring barrel and a feeding hopper; the stirring barrel is internally provided with a stirring device; an extruding screw rod is connected with the motor; the extruding screw rod comprises a core shaft, a locking nut, a flat gasket, a double-screw outer sleeve and a positioning key; double screws with the same lead are arranged outside the double-screw outer sleeve; a melt pump is arranged at a discharging end of the machine barrel; a filtering plate is arranged between the machine barrel and the melt pump; the melt pump is connected with the machine head; the metering device is arranged between the melt pump and the machine head; the machine head comprises a sleeve; a steel pipe, which is concentric with the sleeve, is arranged in the sleeve; an outer mold for extruding a material is arranged at one end of the sleeve; the steel pipe penetrates through the sleeve and the outer mold; a module sleeves outside a pipe body, located in the sleeve, of the steel pipe. The PP plastic injection molding machine is not easily blocked and the transferring amount of the injection molding machine is improved; the production efficiency is improved and the weight of a finished product can be accurately controlled.

Owner:苏州乔布注塑工业有限公司

Tea packaging machine

The invention discloses a tea packaging machine. The tea packaging machine comprises a main machine body, wherein a middle cavity is formed in the main machine body; a vibration mechanism for enablingtea to be conveyed downwards is arranged in the middle cavity; a feed hopper is arranged at the bottom of the middle cavity; a belt cavity is formed in the top wall of the middle cavity; a through groove is formed in the bottom wall of the middle cavity; a weighing cavity is formed in the bottom wall of the through groove; a weighing mechanism for weighing the tea is arranged in the weighing cavity; a crank cavity is formed in the main machine body and positioned at the right side of the weighing cavity; a small cavity is formed in the main machine body and positioned at the bottom of the crank cavity; a transmission cavity is formed on the left side of the small cavity; and a discharge port is fixedly formed in the left side of the weighing cavity. Compared with a traditional tea packaging machine, the waste of tea is reduced, and the weight of each bag of tea is accurately controlled.

Owner:湖南资兴东江狗脑贡茶业有限公司

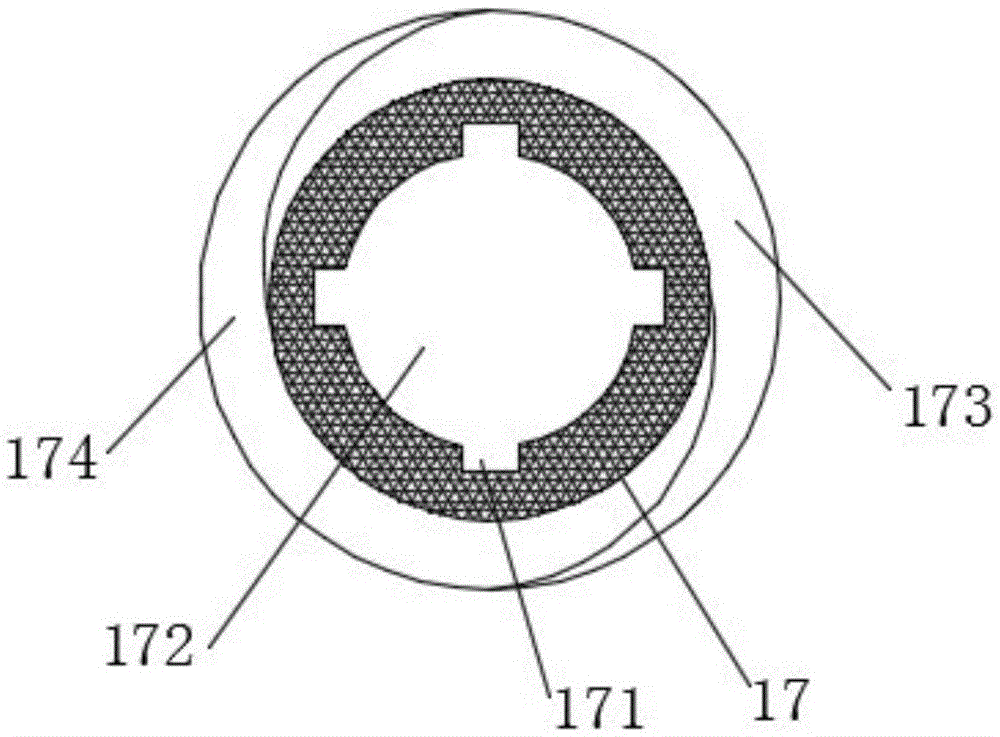

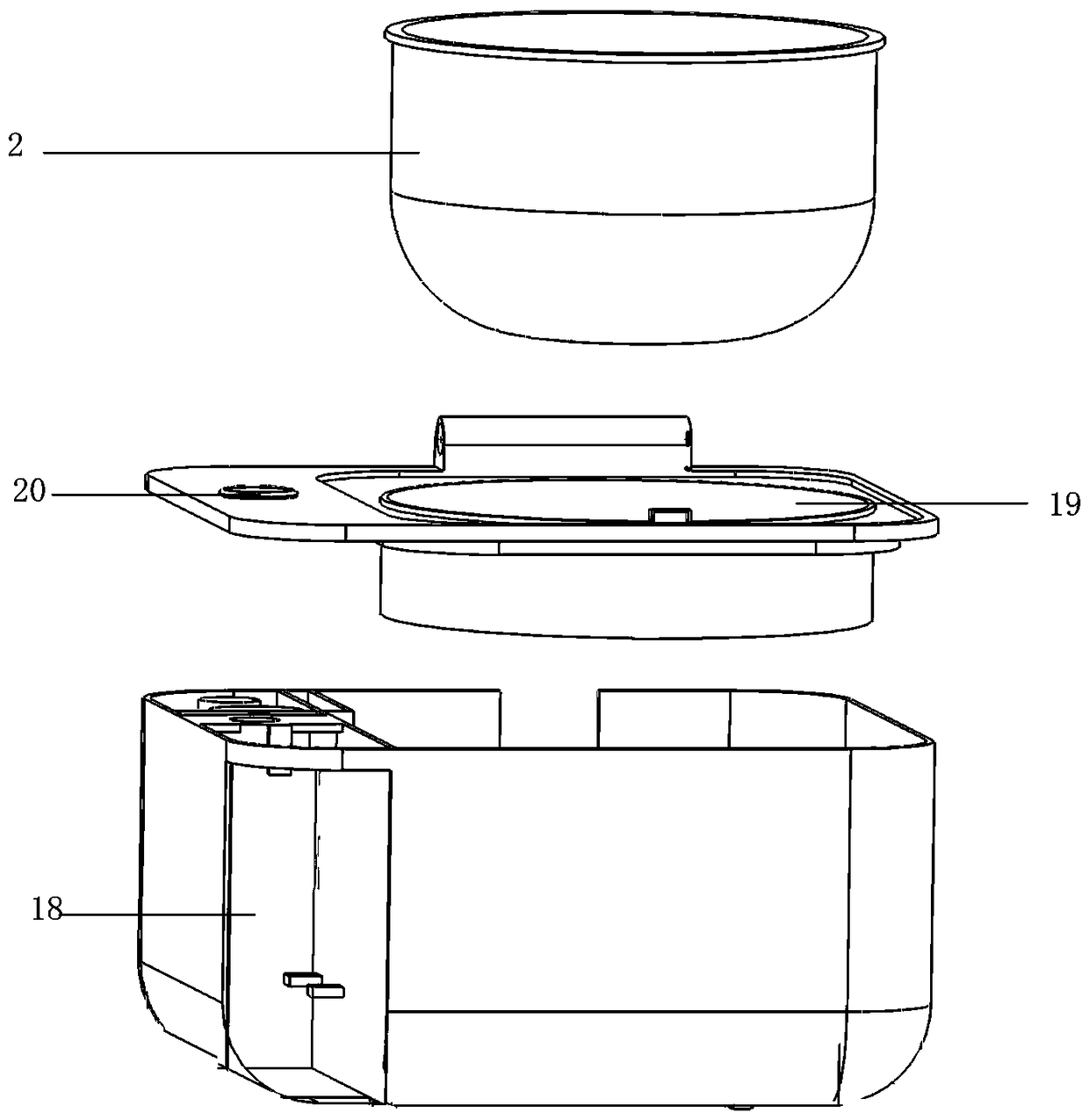

Smart rice cooker and material feeding assembly for same

InactiveCN109480637APrecise weight controlPrecise control ratioTime-controlled ignitorsCooking vessel constructionsRemote controlWater channel

The invention discloses a smart rice cooker, comprising a body with a heater at the bottom, a liner in the body, a cover on the upper side of the bod, a material feeding assembly on one side of the body, and a remote control unit. A heating area, a rotating shaft area and a water channel area are separated but cooperate mutually without interference; position of a material storage bin is adjustedthrough a rotating shaft mechanism so that automatic material feeding and automatic closing are achieved while yielding to the cover to allow the cover to close the body is realized; food materials inthe storage bin are distributed and metered automatically through an electric distributor, which is accurate in metering and simple and convenient in material distributing. The food materials can becleaned automatically through a washing box, waste water can be recovered, manual involvement is omitted, and a diversified and intelligent way for cooking rice is realized. With the material feedingassembly for the smart rice cooker, customers can remotely control material feeding and washing, water adding, start of heating and the like; as weight and proportion of food materials and water is controlled accurately, the automatic rice cooking function is achieved.

Owner:王晓晖

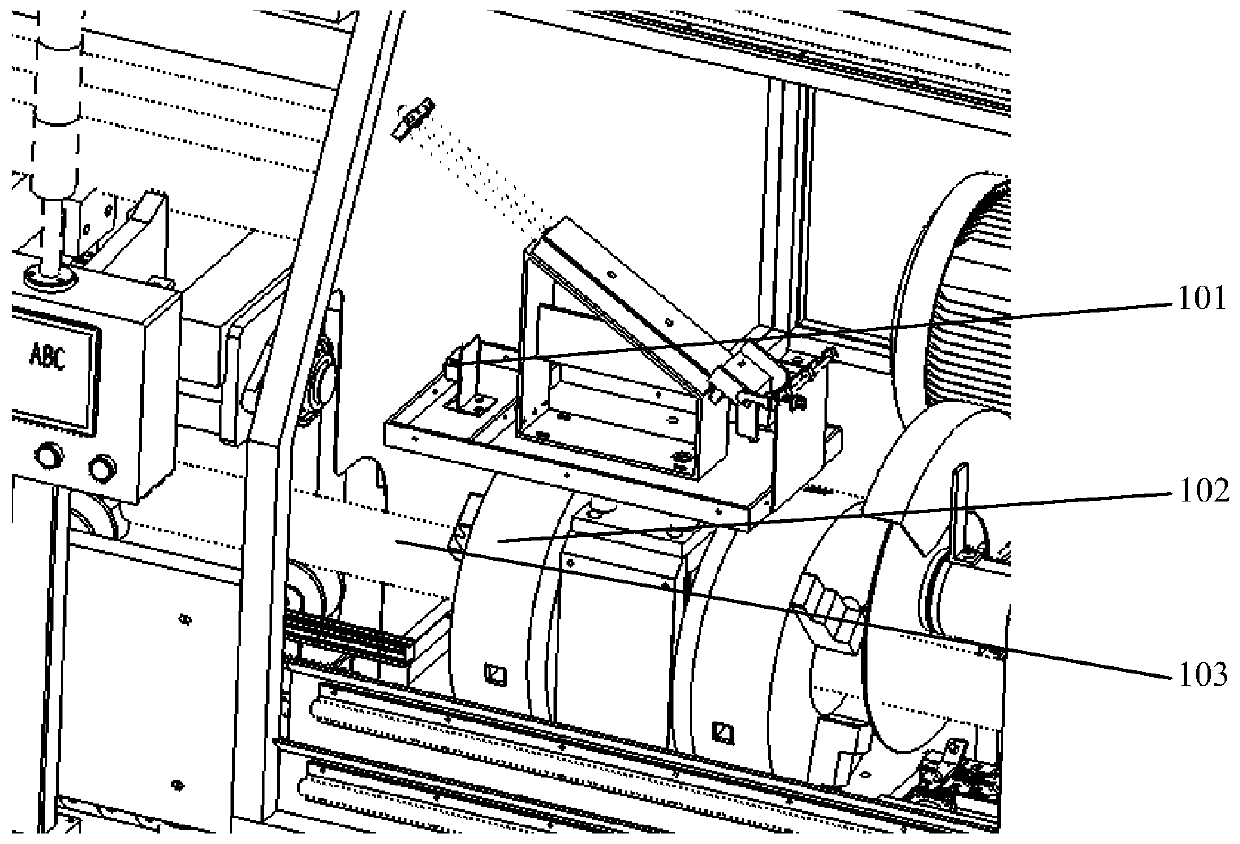

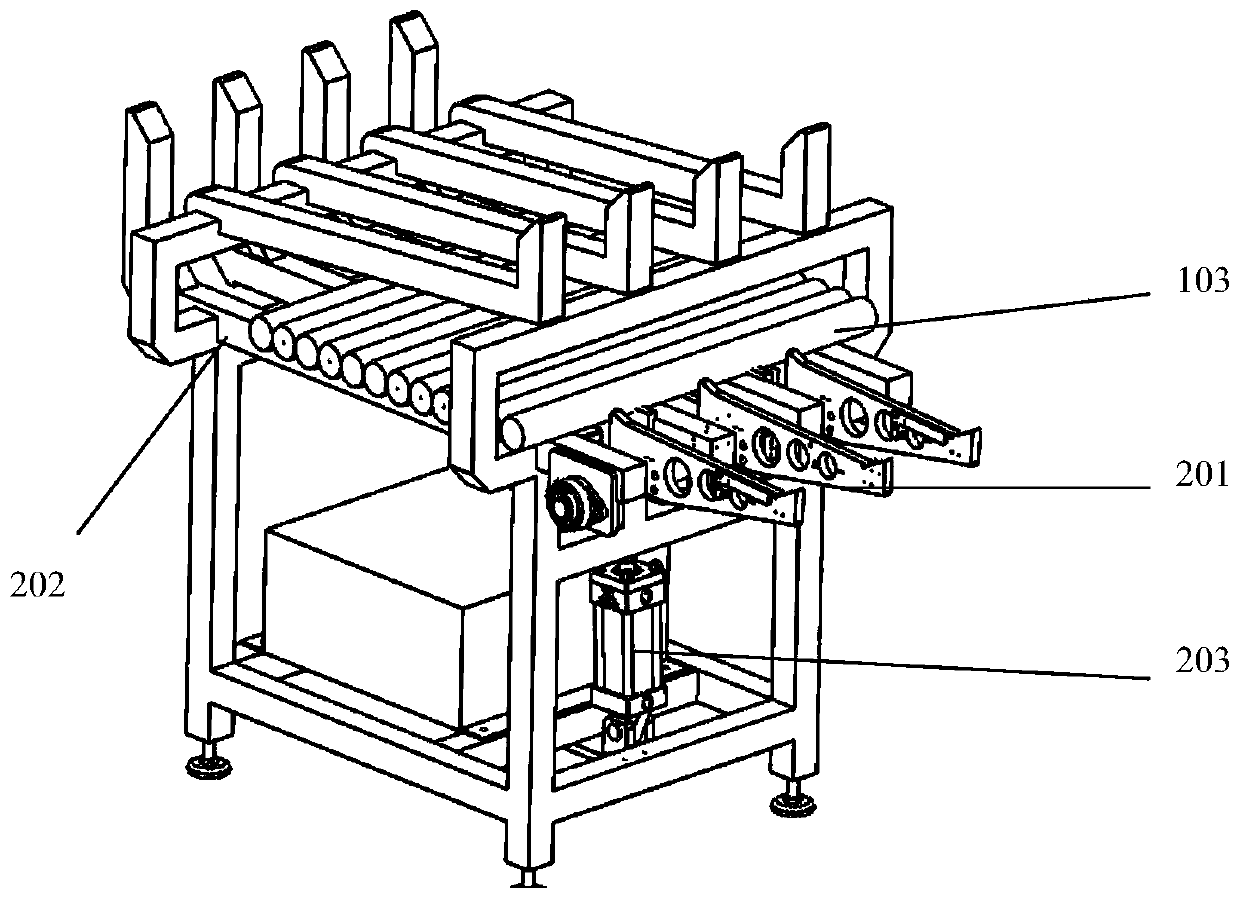

Abrasive cutting device and cutting method

PendingCN110170908APrecise weight controlGrinding feed controlGrinding machinesEngineeringCutting-plane method

The invention provides an abrasive cutting device and a cutting method. The abrasive cutting device comprises a first laser distance sensor, a master control device and an abrasive disk. The first laser distance sensor is in communication connection with the master control device. The laser distance sensor is used for acquiring the data about the outer diameter of a rod material. The master control device is used for determining the current material segment length according to the outer diameter of the rod material, the material density of the rod material and the set material segment weight.The master control device controls the abrasive disk to carry out rotary cutting on the rod material according to the determined material segment length. With the abrasive cutting device and the cutting method, the working efficiency can be improved, the labor intensity cn be reduced, and the quality of products is improved at the same time. According to the abrasive cutting device and the cuttingmethod, cutting feeding can be controlled by the cutting device quantitively, the weight of each cut material segment is accurately controlled, the weight deviation might be caused is reduced, and the requirements on the indexes of a jacking breaking device are reduced.

Owner:BEIJING BIAM ALLOYS +2

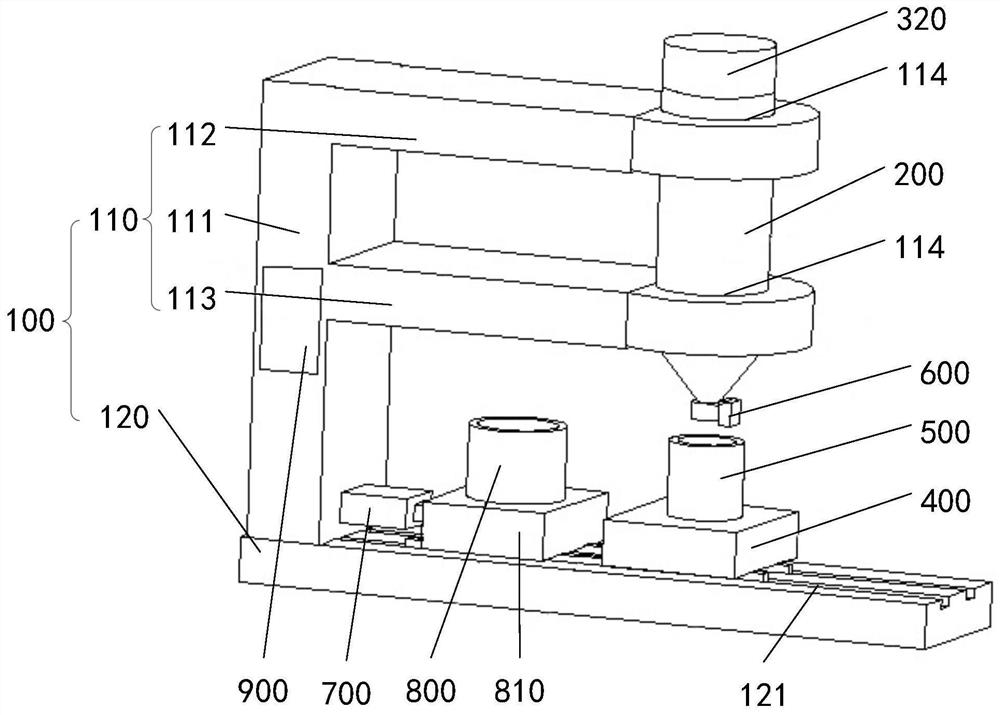

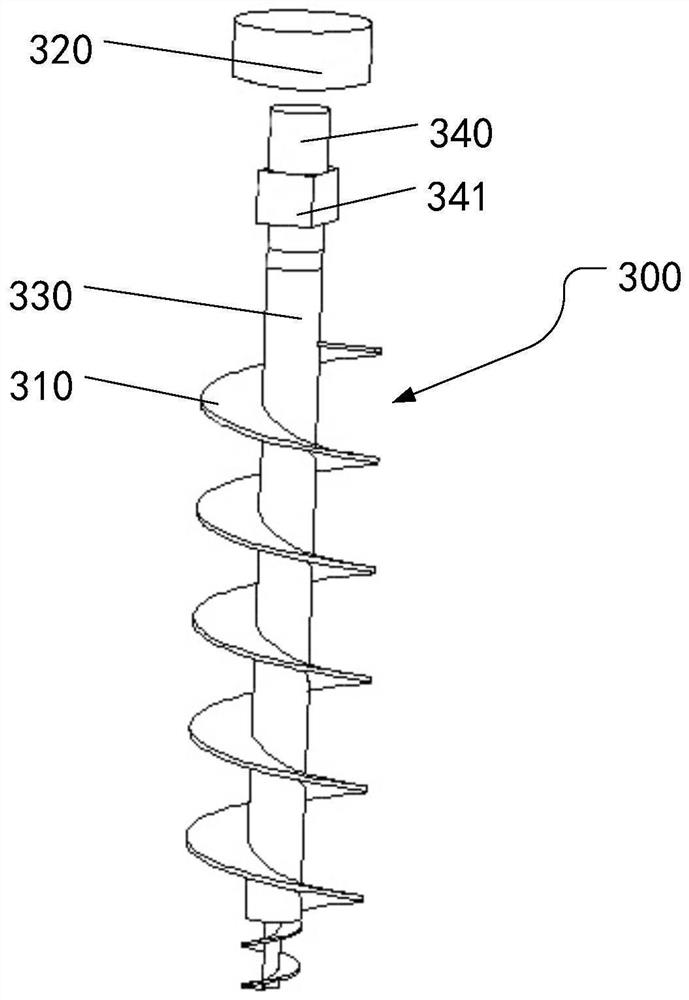

Automatic weighing device

PendingCN112577576APrecise weight controlWeight controlWeighing apparatus for materials with special property/formWeighing apparatus with automatic feed/dischargeProcess engineeringMechanical engineering

The invention discloses an automatic weighing device. The automatic weighing device comprises a rack, a sample bin, an automatic feeding mechanism, a sampling table, a weighing sensor and a sampling barrel, wherein the rack comprises a supporting arm and a base; the sample bin is fixedly connected with the supporting arm, and the sample bin is provided with a containing cavity and a discharging opening communicating with the containing cavity; the automatic feeding mechanism comprises a spiral feeding sheet; wherein the sampling table is arranged on the base, the weighing sensor is fixedly connected with the sampling table, and the sampling barrel is placed on the sampling table. According to the device, through rotation of the spiral feeding piece, tobacco shreds in the containing cavityare sent out of the discharging opening and fall into the sampling barrel, so that the trouble of manually taking in the tobacco shreds in a traditional mode is changed, and operation is easy; the weight of the tobacco shreds in the sampling barrel is obtained in real time through the weighing sensor, so that the weight of the tobacco shreds can be accurately controlled, the weight of each sampling is the same, and the reliability of data in the subsequent tobacco shred testing process is guaranteed.

Owner:CHINA TOBACCO HENAN IND

Quantitative cutting device

PendingCN108501076APrevent secondary adhesionEasy to controlMetal working apparatusEngineeringSupport plane

The invention discloses a quantitative cutting device. The device comprises a conveying mechanism for conveying an object to be cut, and a cutting mechanism for cutting the object to be cut. The device is characterized in that the cutting mechanism comprises a supporting frame, a rotatable cutter which is mounted on the supporting frame, and a driving device for supplying rotating force to the cutter, wherein the cutter is positioned above the conveying mechanism and is capable of automatically cutting the object to be cut and pushing the object to be cut to move in the conveying direction ofthe conveying mechanism during rotating. According to the device, the rotating cutter is used for cutting and pushing the object to be cut, so that a space is naturally formed between the cut object to be cut and the non-cut object to be cut, and thus the cut object to be cut can be effectively prevented from secondary adhering.

Owner:FOSHAN POLYTECHNIC

Mixed fertilizer mixing and packing integrated device

ActiveCN109094898AQuality assuranceImprove qualitySolid materialPackaging automatic controlBiochemical engineeringWork in process

The invention discloses a mixed fertilizer mixing and packing integrated device. The mixed fertilizer mixing and packing integrated device comprises a worktable. A conveying belt is arranged on the outer surface of the upper end of the worktable. Supporting legs are fixedly mounted on the outer surface of the lower end of the worktable. To sum up, the mixed fertilizer mixing and packing integrateddevice has the beneficial effects that the mixed fertilizer mixing and packing integrated device is provided with an operating window, the conveying belt and an opening and closing notch, when the device works, the working situation inside a packing box can be observed through the operating window, the problems can also be rapidly solved through the operating window when occurring in the interiorof the packing box, device operation is not affected, semi-finished products produced by the previous working procedure can be automatically conveyed to the next working procedure, and automatic integrated production is achieved; the weight of each part of chemical fertilizers can be further precisely controlled by controlling the feeding quantity, and it is guaranteed that the short weight or excessive filling is avoided; and the mixed fertilizer mixing and packing integrated device is simple in structure and convenient to use.

Owner:孙炳连

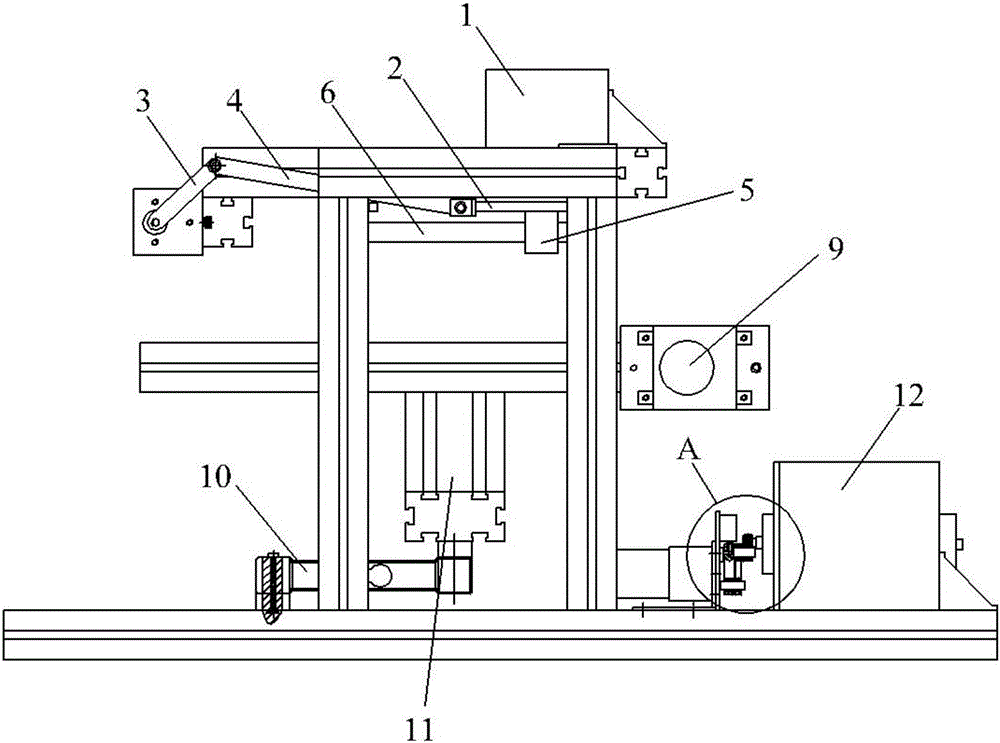

Automatic charging system

InactiveCN103350980AAvoid lostImprove work efficiencyBarrels/casks fillingAutomatic train controlAutomatic control

The invention discloses an automatic charging system. The automatic charging system comprises a reaction kettle and an automatic charging device, wherein the automatic charging device comprises an automatic scale; the automatic scale is connected with a control box; the control box is connected with a flow control device; a flow control valve is arranged in the flow control device; a weight controller is arranged in the control box; an infrared sensor is arranged at a lower port of the flow control device. The automatic charging system can control charging weight automatically and accurately, can automatically control the flow control valve, effectively guarantees the error range of weighing, reduces loss of liquid, can reduce the labor intensity through automatic control, and improves the work efficiency on a charging line.

Owner:安徽大松树脂有限公司

Production device for aluminum alloy baseball bar

InactiveCN104801543AAchieve Wall Thickness ControlPrecise control of wall thicknessMandrelsRollsDrive wheelAluminium alloy

The invention relates to a production device for an aluminum alloy baseballbar. The device comprises a rolling machine body, wherein the rolling machine body comprises a feeding rotating box, a feeding bed, a driving wheel and a main machine head; rollers are arranged in the main machine head; the main machine head is connected with the driving wheel through a connecting rod to form a crank sliding block mechanism; the feeding bed comprises a material propping tube and a mandrel; one end of the mandrel is connected with the feeding rotating box and while the other end of the mandrel is connected with a detachable core bar; the rollers are vertically symmetrically respectively arranged at two sides of the core bar; annular semicircular grooves are formed in outer circles of the rollers and respectively positioned in two sides of the core bar and form roller mould cavity with the core bar; the appearance curve is rolled through the rollers; the inner wall is controlled through the core bar; therefore, the wall thickness of the baseball bar can be controlled from inside and outside, and as a result, the wall thickness, weight and length of the product can be accurately controlled; the rollers and the core bars can be adjusted again according to the specification demand of the baseball bar. The device is wide in applicable scope, high in efficiency, and suitable for mass popularization.

Owner:NINGBO JIANGBEI ZHONGTONG MECHANICAL PRODN CO LTD

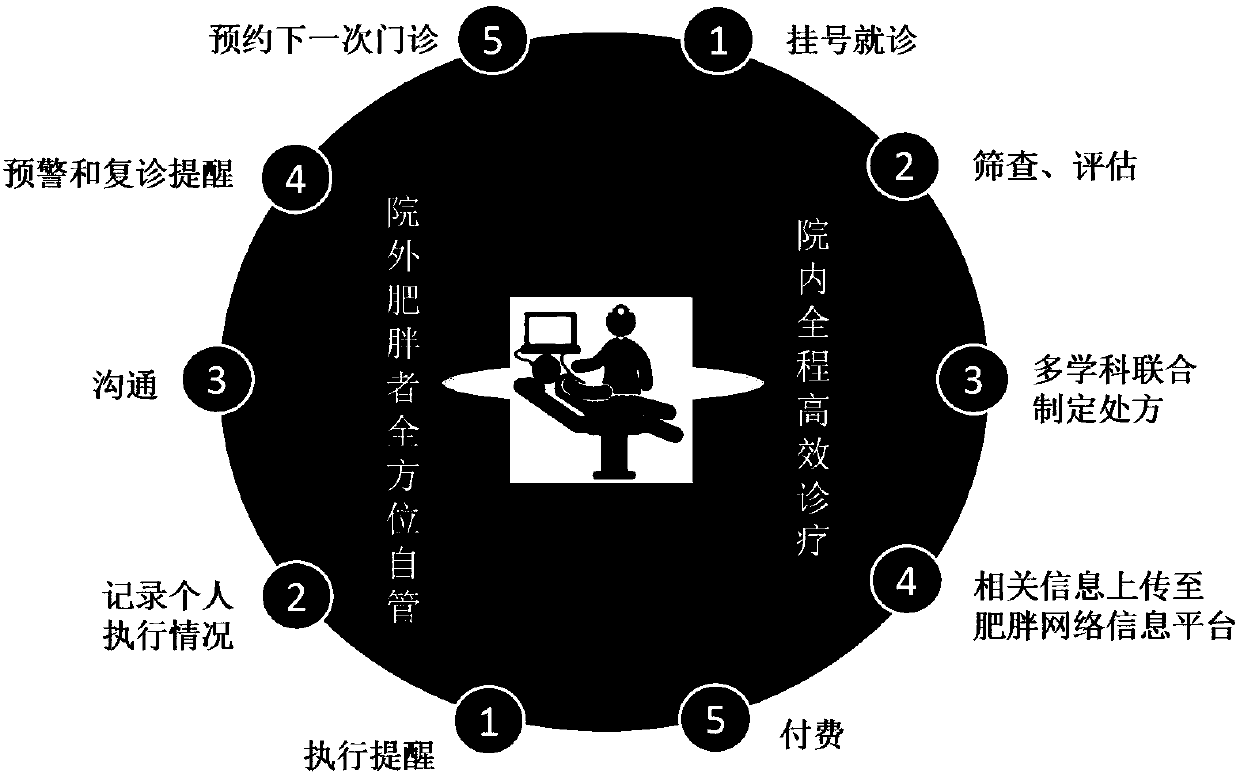

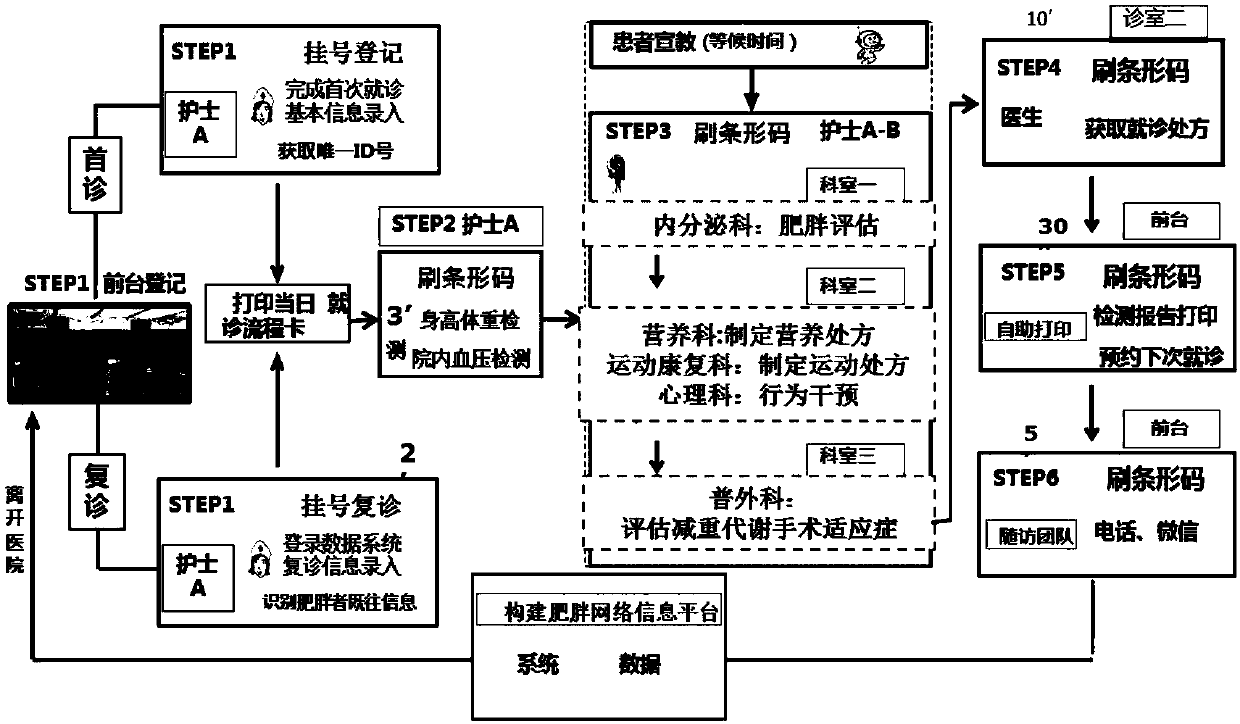

Multidisciplinary obesity intervention health management method

InactiveCN107785062AAchieve communicationIncrease weightPhysical therapies and activitiesHealth-index calculationEvaluation resultObesity

The invention discloses a multidisciplinary obesity intervention health management method. The multidisciplinary obesity intervention health management method includes the following steps that obese people are screened and evaluated, data is uploaded to an obesity network information platform, and individual electronic archives of obese people are constructed; according to the evaluation result ofobese people, a first-stage health management scheme is made through multiple-development cooperation; obese people execute the management scheme outside a hospital and upload the execution conditionthrough the network information platform in real time; the execution condition of obese people is evaluated, and whether a second-stage management scheme is executed or not is judged; obese people execute the management scheme outside the hospital and upload the execution condition; the execution condition of obese people is evaluated, and whether a third-stage management scheme is executed or not is judged; guidance after metabolism operations is provided. In the multidisciplinary obesity intervention health management method, specialist resources of multiple developments are integrated, respective responsibility and working mechanisms of members are definite, the resources are configured more reasonably, and the weight losing success rate of obese people can be increased effectively.

Owner:NANJING DRUM TOWER HOSPITAL

Adjustable sampling mechanism based on grain sampler

InactiveCN113790926ASolve the problem of inaccurate quality judgmentAccurate samplingWithdrawing sample devicesControl using feedbackAnalogue computationControl signal

The invention discloses an adjustable sampling mechanism based on a grain sampler, and relates to the technical field of grain samplers. The adjustable sampling mechanism comprises a sampling driving assembly, a sampling pipe, a negative pressure fan, a sample splitter, a collection tank, a collection box cooperation, an input control module, a sample point establishment module, a sample point analysis module and an element execution module. According to the invention, information acquisition of a grain sample, establishment of control on a three-dimensional sampling point, operation of analog calculation and generation of a first sampling control signal or a second sampling control signal are realized, and the position of a sampling pipe and the weight of the sampled grain sample are accurately controlled through generation of the first sampling control signal or the second sampling control signal; and the mechanism is more accurate in sampling, wider, deeper and more comprehensive in grain sample collection range, more accurate in subsequent detection and capable of solving the problem that the quality judgment of grain samples is not accurate enough due to the fact that traditional equipment is not accurate enough in sampling.

Owner:ANHUI KAIJIE MACHINERY MFG

Mousetrap

The invention discloses a mousetrap. A triggering mechanism of the mousetrap comprises a support rod capable of moving up and down relative to a front side plate. A box body is provided with a support locking mechanism which can rotate relative to the box body and support the support rod, a transmission rod is hinged to the front side plate and provided with a clamping position which can be clamped with a lock-clamping part on the support locking mechanism, the box body is further provided with a motor, an inhaul cable which can pull the transmission rod to rotate downward is arranged between an output shaft of the motor and the transmission rod, a reset spring for the resetting of the transmission rod by rotating upward is arranged between the transmission rod and the box body, a top cover is provided with a tread plate which moves downward after being trampled by a mouse, the tread plate and the top cover are respectively provided with conductive contact pieces which can contact to make the motor rotate with power when the thread plate moves downward, a return spring is further arranged between the tread plate and the top cover to separate the conductive contact pieces on the tread plate and on the top cover. The mousetrap has the advantages of being simple in structure, sensitive in action and good in mouse catching effect.

Owner:方鹏羽

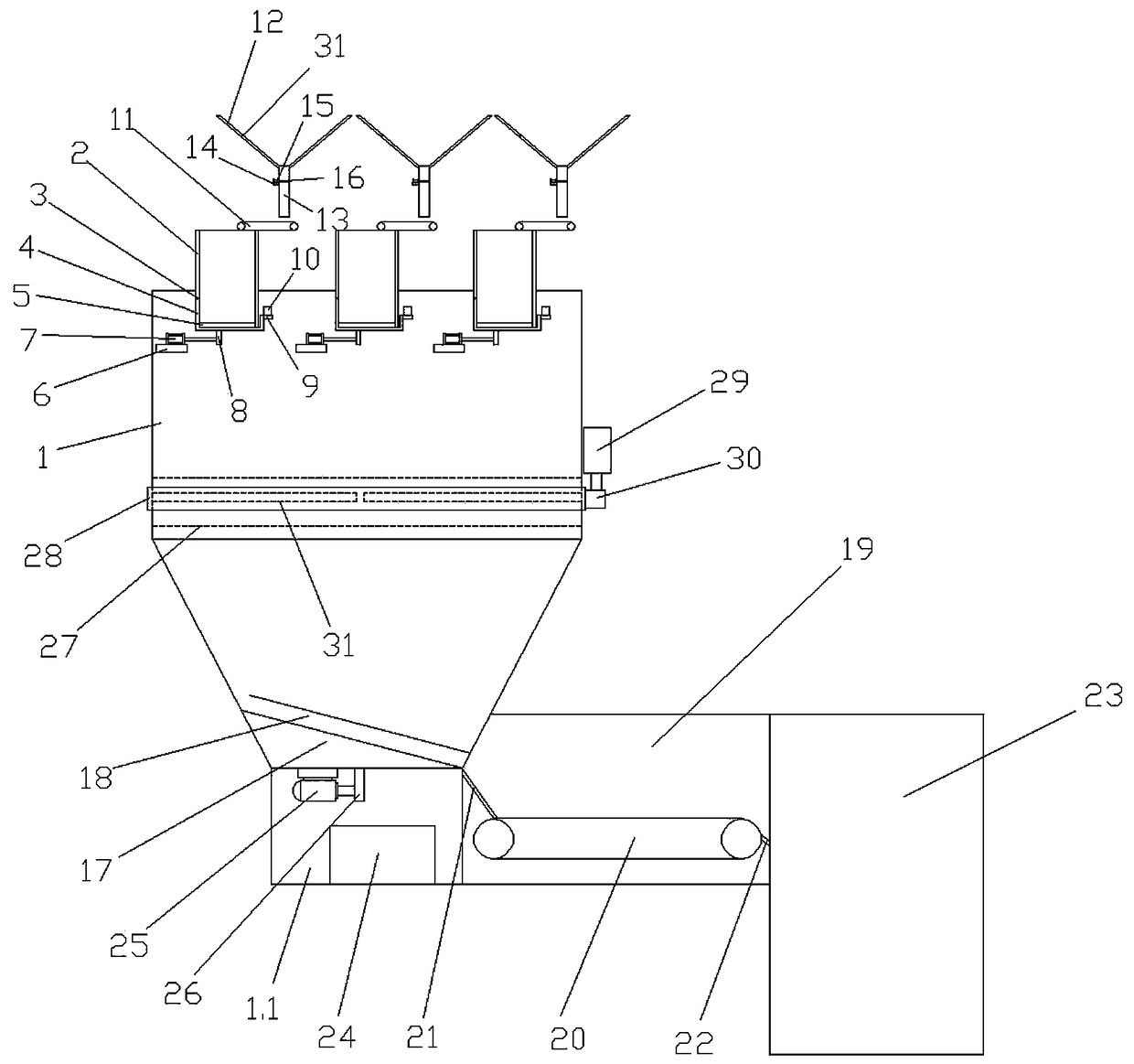

Automatic feeding internal mixer

An automatic feeding internal mixer comprises an internal mixer body. A rack is arranged above the internal mixer body. Storage bins and weighing stock bins are arranged above the rack. The storage bins are located on the sides of the weighing stock bins. The bottom faces of the storage bins are higher than the top faces of the weighing stock bins. The weighing stock bins are connected to the storage bins through conveying pipelines. The weighting bins are located above the internal mixer body. A discharging pipe is arranged at the bottom of each weighing stock bin. The discharging pipes are downwardly aligned with a top peg inlet in the internal mixer body. By the adoption of the automatic feeding internal mixer, all the raw materials are put into the storage bins by category, in the use process, the raw materials are conveyed into the weighing stock bins from the storage bins according to the quantity, and the raw materials are added to the internal mixer from the weighing stock bins after being weighed; only one working staff is needed in the whole process, and all the actions can be completed through a controller; and compared with the prior art, by the adoption of the automatic feeding internal mixer, the production efficiency of the internal mixer is improved, and the labor intensity of working staff is lowered.

Owner:PUYANG HENGXIN RUBBER & PLASTIC

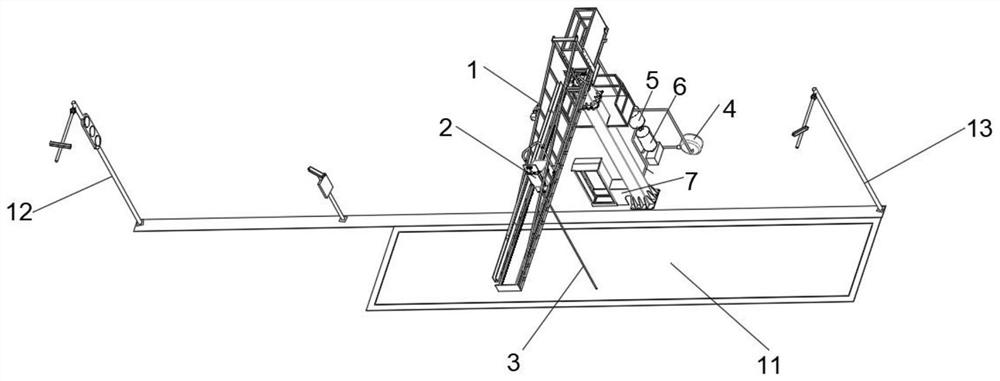

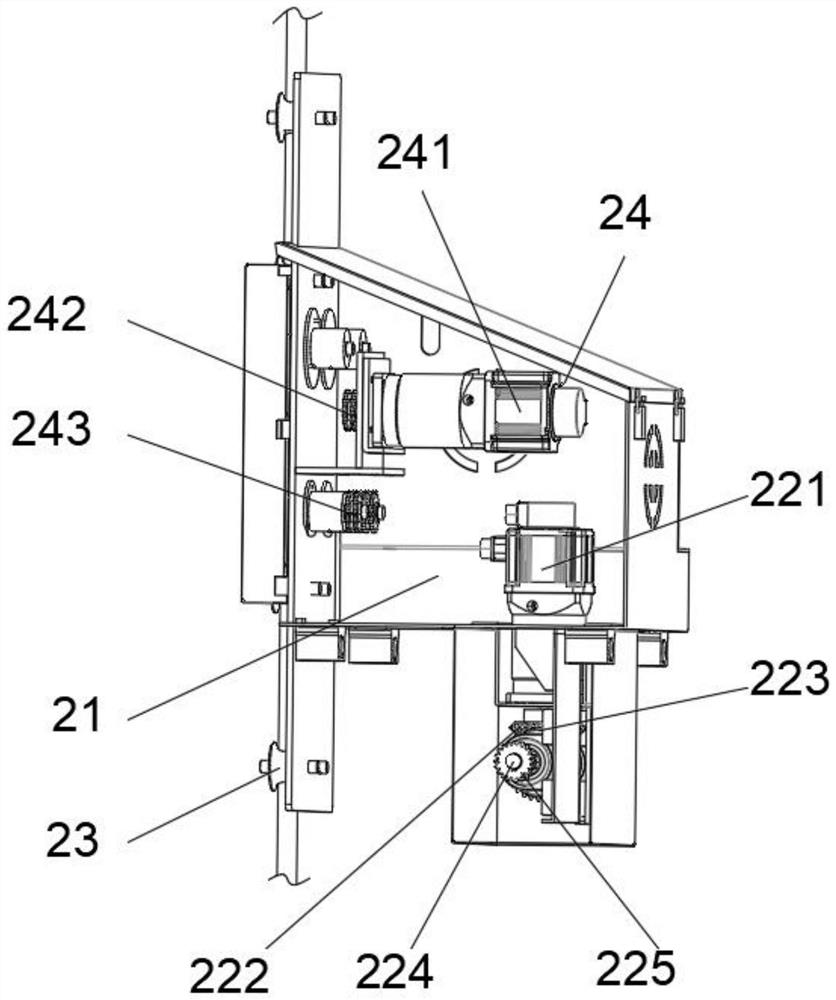

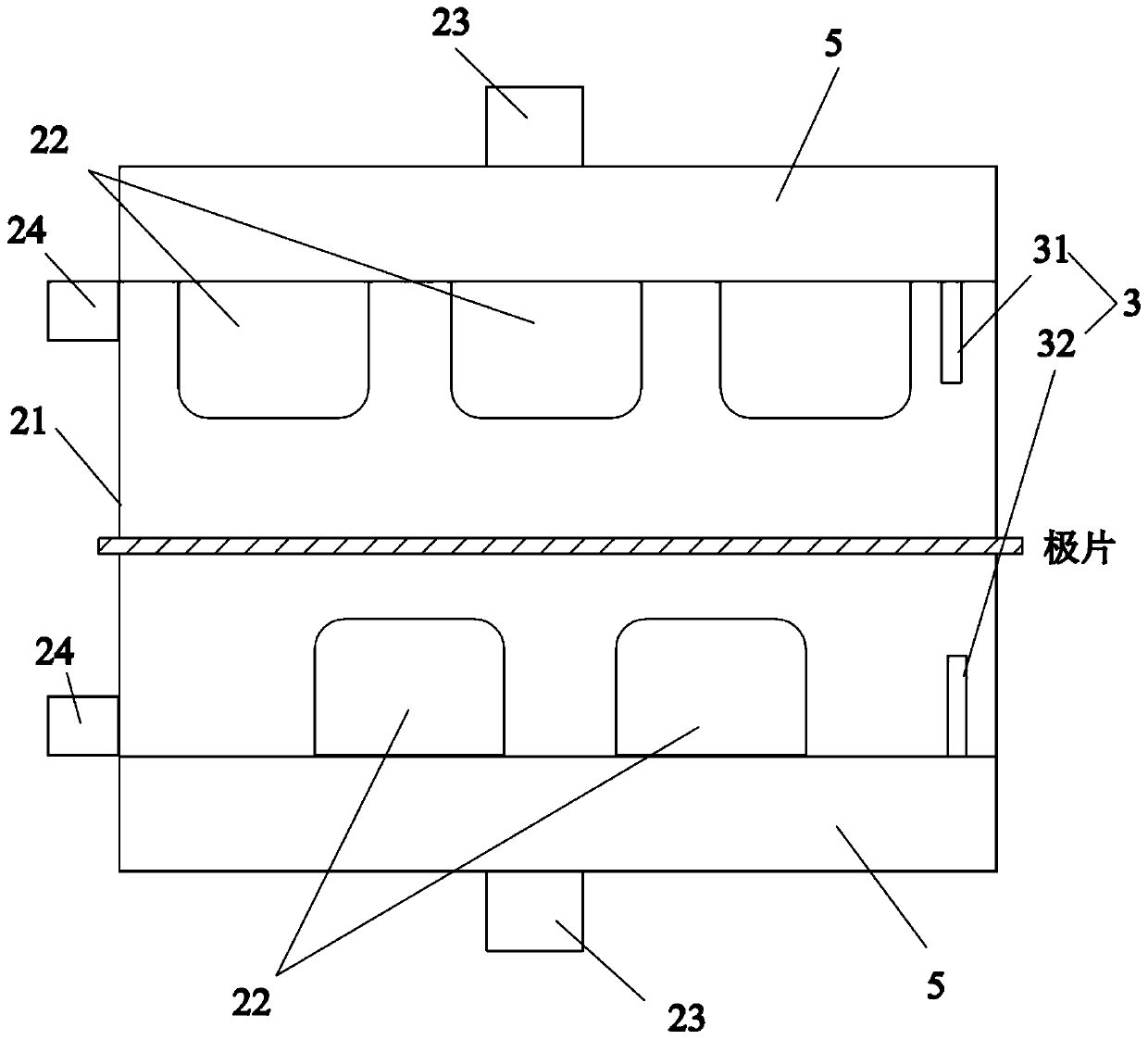

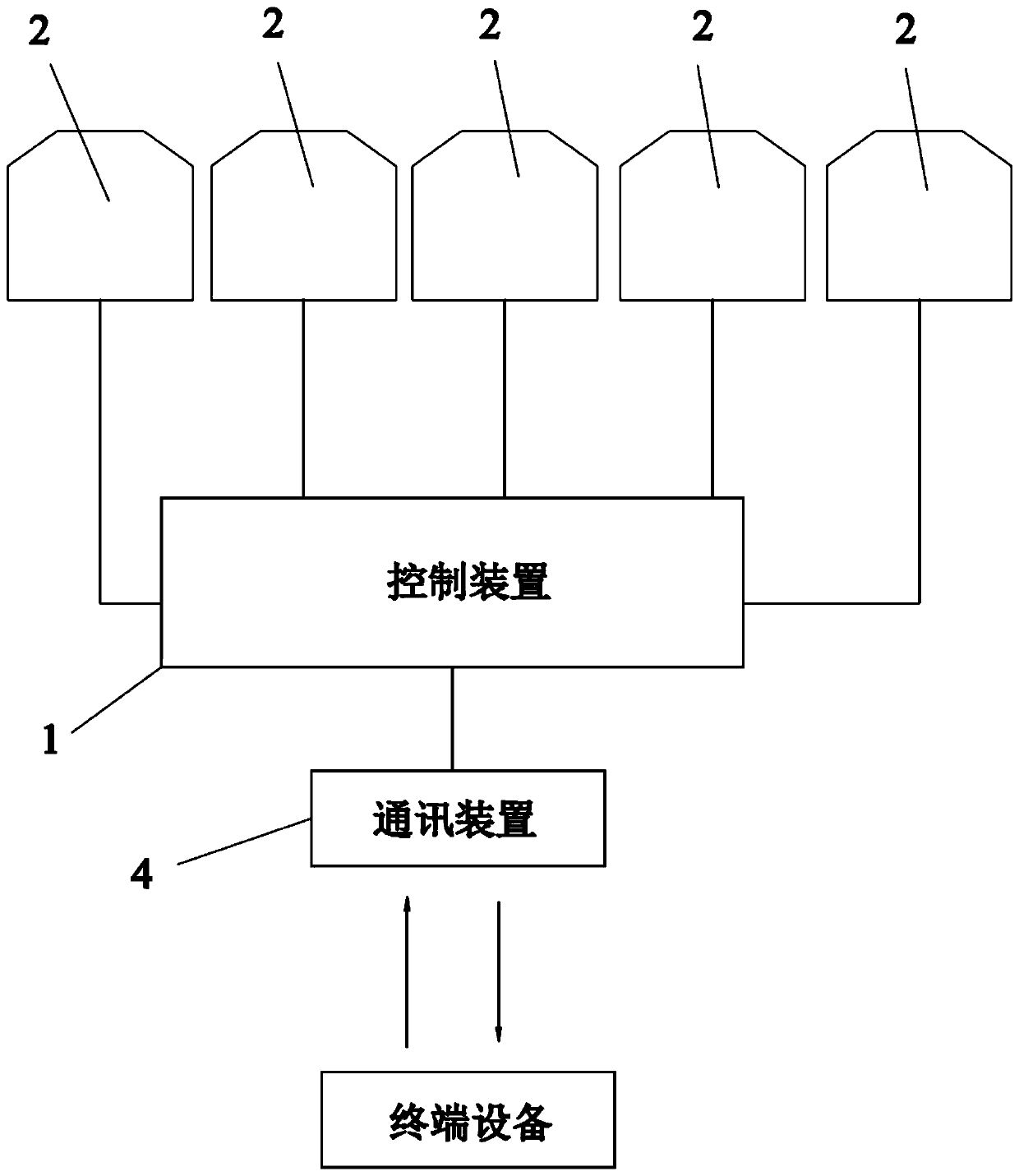

Intelligent drying system for battery pole pieces and intelligent drying method for pole pieces

InactiveCN110385244AAccurately control the drying ratePrecise weight controlPretreated surfacesCoatingsEngineeringPole piece

The invention belongs to the technical field of battery production and manufacturing, and particularly relates to an intelligent drying system for battery pole pieces. The intelligent drying system for the battery pole pieces comprises a control device and a plurality of pole piece drying boxes, the plurality of pole piece drying boxes are arranged in the movement direction of the pole pieces, each pole piece drying box is provided with a weight detection device, the pole piece drying boxes and the weight detection devices are all in communication connection with the control device, the weightdetection devices are used for detecting the weight of the pole pieces and feeding back the weight of the pole pieces to the control device, the control device is used for receiving weight signals fed back by the weight detection devices and controlling the pole piece drying boxes. According to the intelligent drying system for the battery pole pieces, the weight of the pole pieces can be monitored in real time so that the drying speed of the pole pieces can be controlled, closed-loop control of pole piece drying can be further realized, the stability of the pole pieces can be improved, and then the quality of the pole pieces is improved. In addition, the invention further discloses an intelligent drying method for the battery pole pieces.

Owner:JIANGSU ZENIO NEW ENERGY BATTERY TECH CO LTD

Full-automatic meal distribution machine

PendingCN112278750AEffectively loosenMeet the needs of usePackagingWeighing apparatus with automatic feed/dischargeAgricultural scienceRice dishes

The invention provides a full-automatic meal distribution machine relating to the technical field of meal distribution machines. The full-automatic meal distribution machine comprises a rack, whereina food material conveying device is arranged on the rack; and a rice block cutting mechanism and a rice loosening mechanism are sequentially arranged at the upper part of the food material conveying device in the conveying direction. According to the full-automatic meal distribution machine provided by the invention, when the food material conveying device conveys rice, lumped rice can be effectively loosened through the cutting effect of the rice block cutting mechanism and the loosening effect of the rice loosening mechanism, and the full-automatic meal distribution machine can convenientlycarry out subsequent meal distribution operation, therefore, regardless of rice species, sticky rice or refrigerated lumped rice, the full-automatic meal distribution machine can be suitable for mealdistribution operation, and the use requirements of users are effectively met.

Owner:DEA GENERAL AVIATION HLDG CO LTD

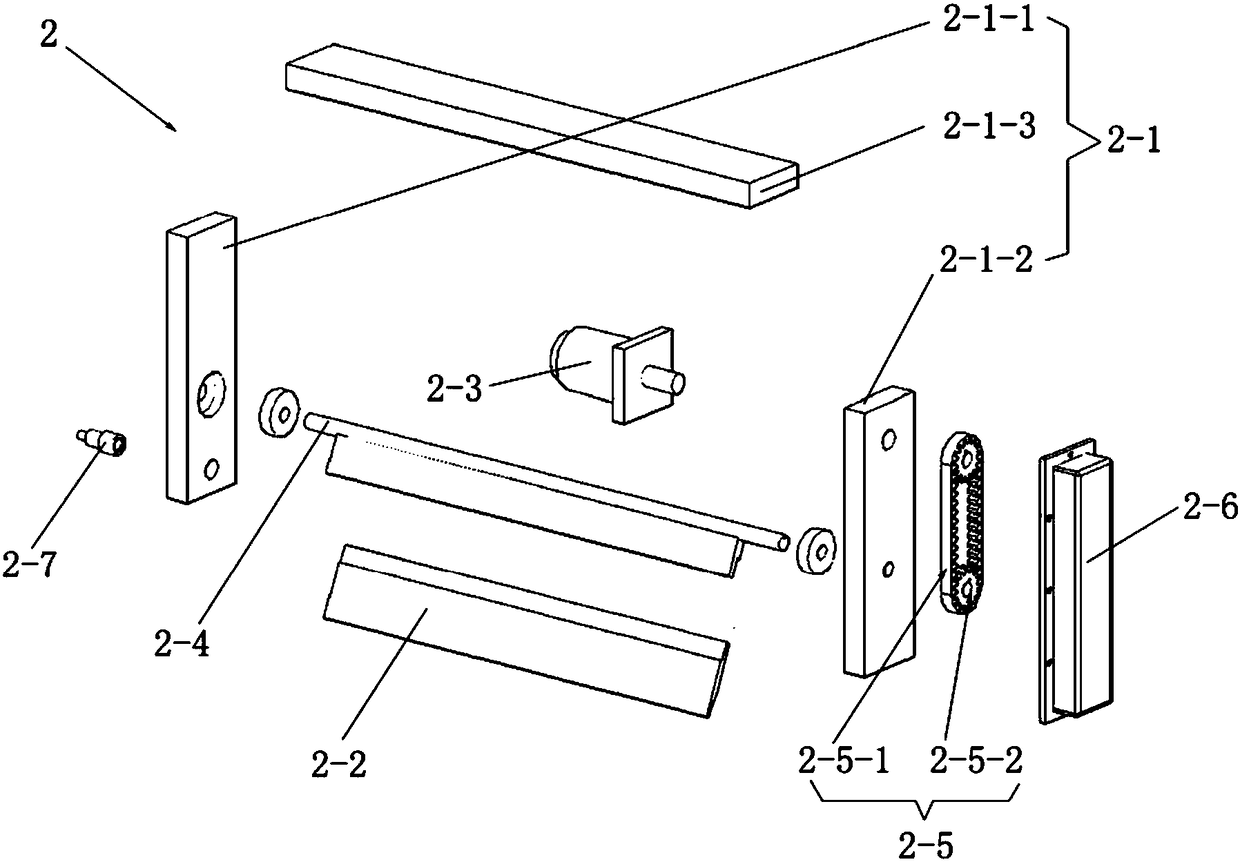

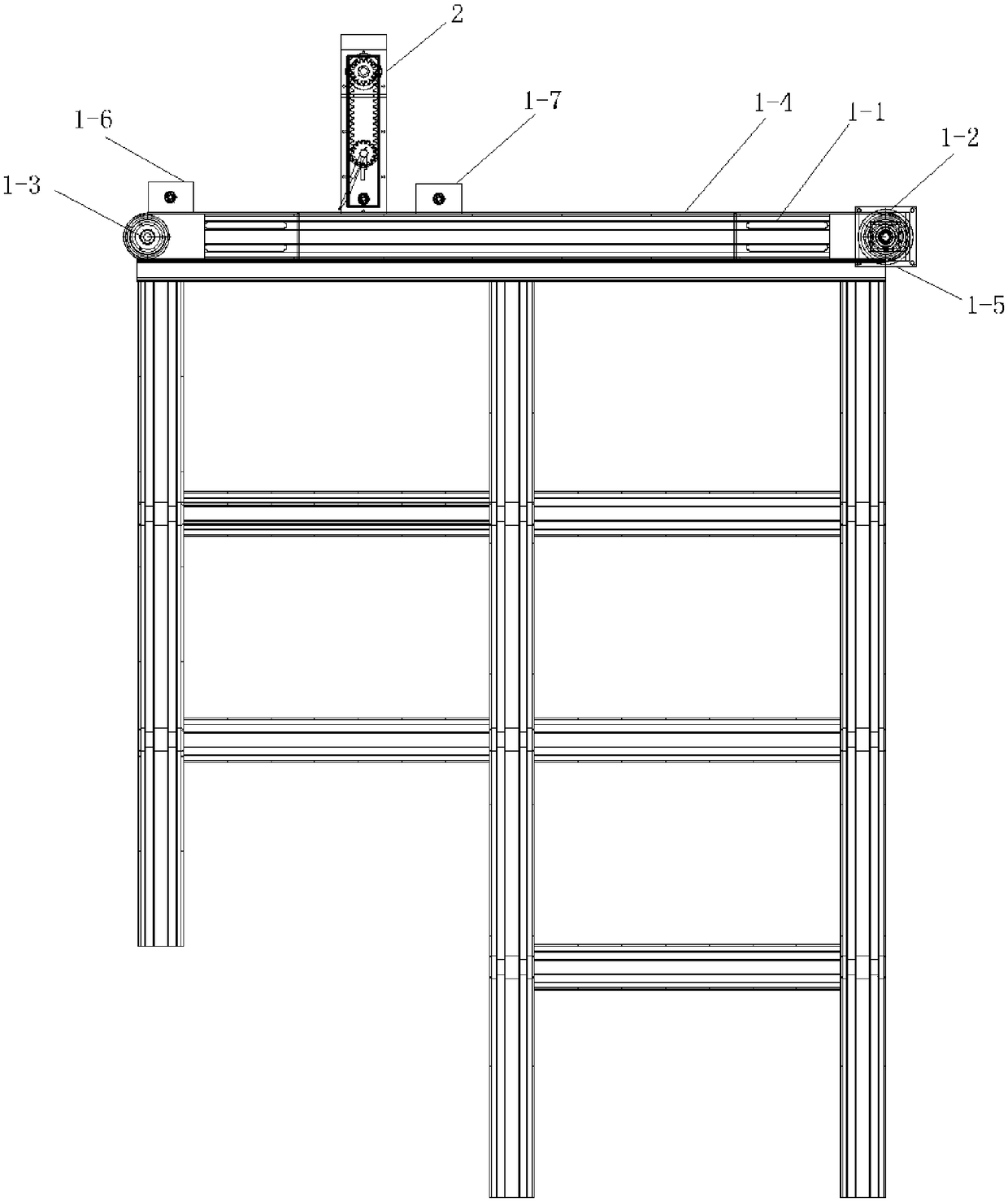

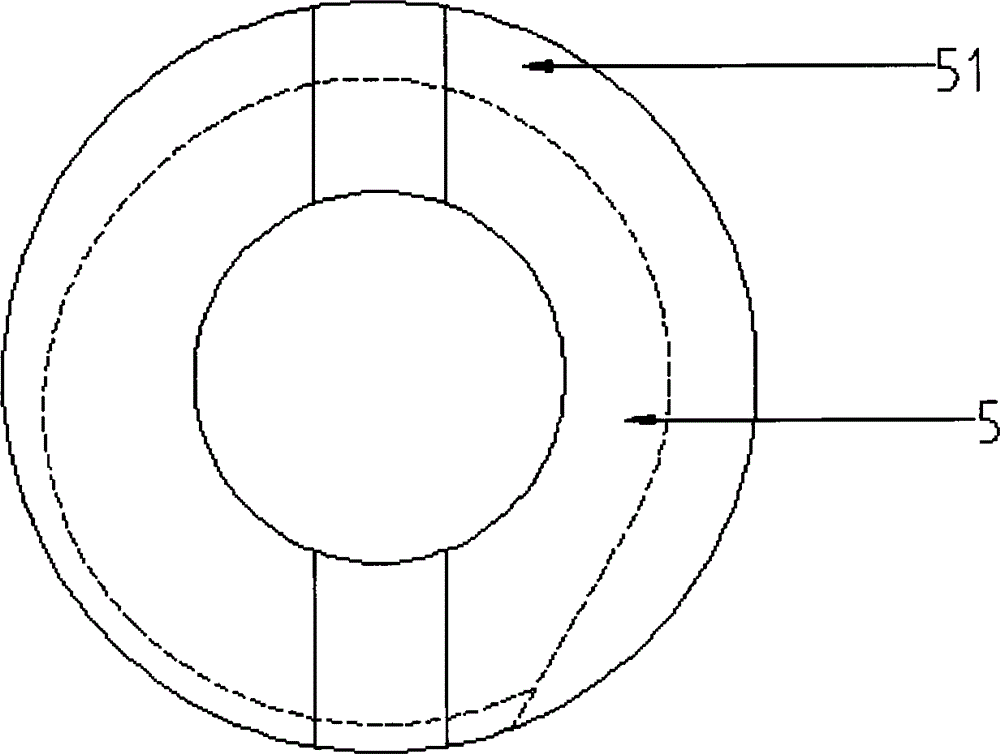

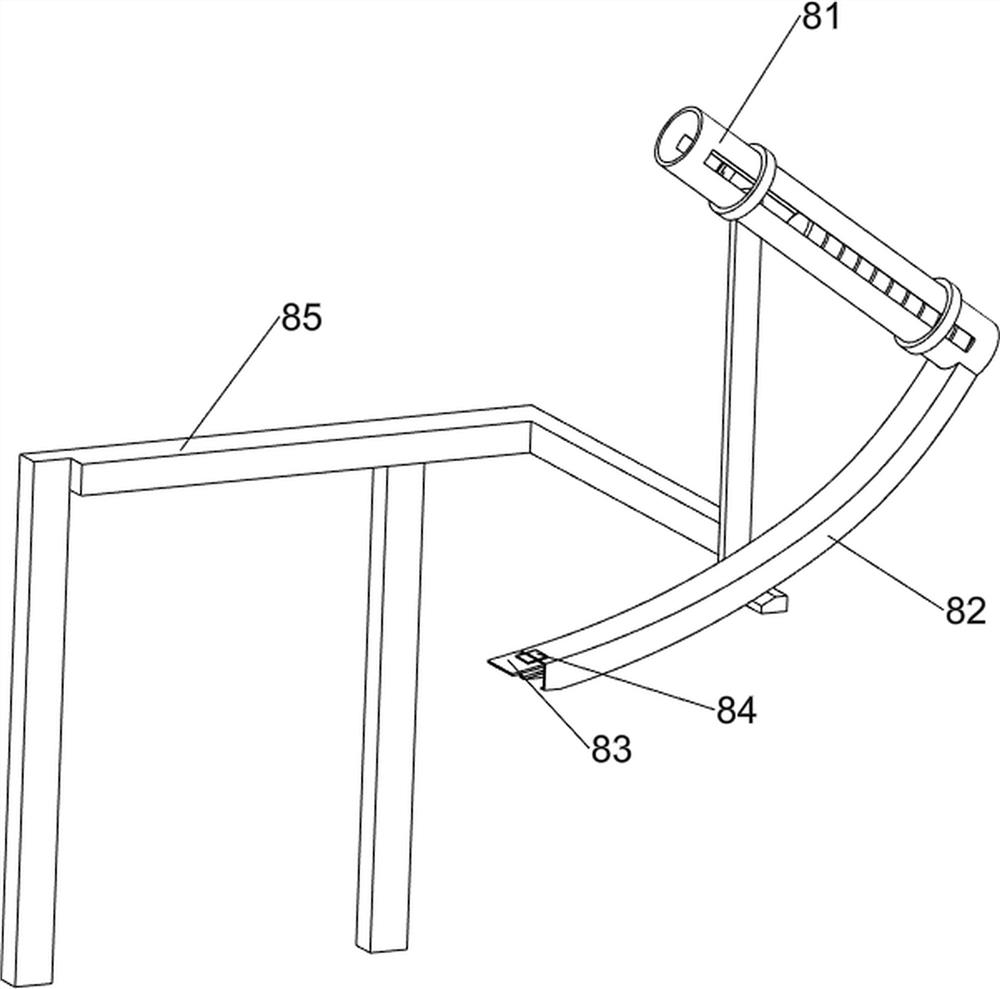

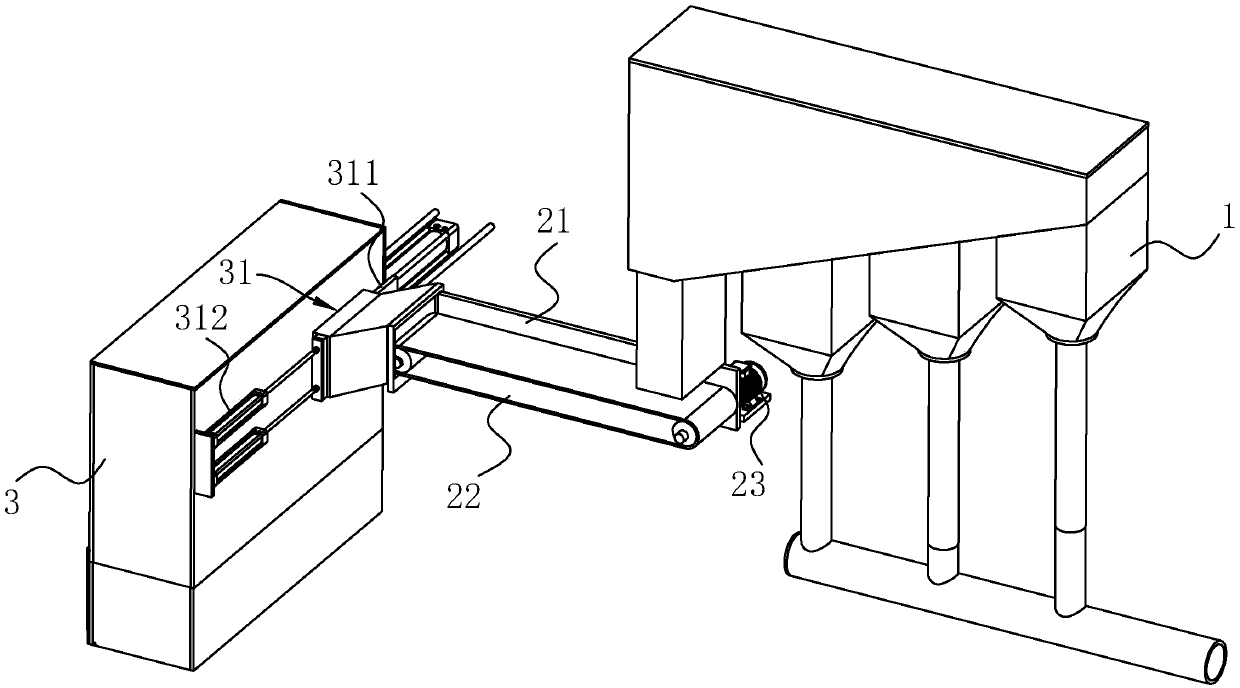

Intelligent control system and method for manufacturing optical fiber prefabricated rod by using OVD (optical variable device)

InactiveCN110526573AImprove intelligent productionPromote OVD method to prepare optical fiber preform to realize intelligent productionGlass making apparatusEngineeringOptical variable device

The invention discloses an intelligent control system and a method for manufacturing an optical fiber prefabricated rod by using an OVD (optical variable device) and relates to the field of optical fiber manufacturing. The intelligent control system comprises a support device, at least one blowtorch, a diameter measuring device and a control device, wherein the support device is used for clampinga core rod to be processed; a weighing sensor is arranged on the support device; the weighing sensor is used for measuring the weight of a loosened body on the core rod in real time; the at least oneblowtorch is arranged on the support device; the diameter measuring device is used for measuring the outer diameter of the loosened body in real time; and the control device is used for receiving weight data transmitted from the weighing sensor and outer diameter data transmitted from the diameter measuring device, and used for adjusting the flow of the blowtorch according to the weight data and the outer diameter data, and thus the outer diameter and the density of the loosened body are both within preset ranges. By adopting the intelligent control system, the outer diameter size, the weightand the density of the loosened body can be precisely controlled.

Owner:FENGHUO COMM SCI & TECH CO LTD +1

Powdery admixture accurate weighing device

ActiveCN110260957AHigh precisionPrecise unloadingWeighing apparatus for materials with special property/formFrequency conversionEngineering

The invention relates to a powdery admixture accurate weighing device. The powdery admixture accurate weighing device comprises a weighing hopper, a weighing sensor, a bracket, a flexible steel wire rope, a weighing meter and a blanking device, wherein the weighing hopper is fixed on the bracket; the weighing sensor is arranged at the contact portion of the weighing hopper and the bracket, the bracket is suspended below the weighing meter through the flexible steel wire rope, and the blanking device is arranged in the weighing hopper; by adopting the suspension structure and the sandwich type composite damping structure of the bracket, the influence of vibration on the weighing precision of the admixture can be effectively avoided; by arranging two sets of weighing devices with different precisions and sensitivities, high-efficiency feeding and high-precision discharging can be achieved; by adopting a turn buckle to connect the weighing meter and the bracket, the weighing hopper can be quickly leveled, the weighing sensor is adopted to match with a feeding frequency conversion spiral machine and a discharge spiral ribbon to accurately control the weight of the discharge, and a rotating blade is adopted to stir powder in the weighing hopper to make blanking smooth.

Owner:ZHENGZHOU SANHE HYDRAULIC MACHINERY +4

Lightweight Modeling Method for Satellite Cable

ActiveCN104268321BLow hardware performance requirementsAvoid path distortionSpecial data processing applications3D modellingEngineeringPetroleum engineering

The invention discloses a lightweight modeling method of a satellite cable. Based on the computerized design technique and the Pro / E secondary development technology, the lightweight modeling method comprises the steps of 1, establishing a three-dimensional electrical connector lightweight model in Pro / E, 2, establishing a cable joint table in a computer system, 3, generating a lightweight cable joint table by use of a Pro / E secondary development tool, 4, designing a cable trend path in the Pro / E, 5, reading in the lightweight cable joint table in the Pro / E and creating a three-dimensional cable lightweight model, 6, performing model examination in the Pro / E, and 7, assembling the cable model and the electrical connector model in the Pro / E. The lightweight modeling method of the satellite cable has the advantages that the size of a three-dimensional cable model file can be greatly reduced, the three-dimensional modeling of the satellite cable can be improved, the length and the weight of the cable can be accurately controlled and the efficiency and the quality of the satellite cable design can be improved, based on the lightweight thought and by maintaining the major information of cable modeling and neglecting secondary and irrelevant information.

Owner:SHANGHAI SATELLITE ENG INST

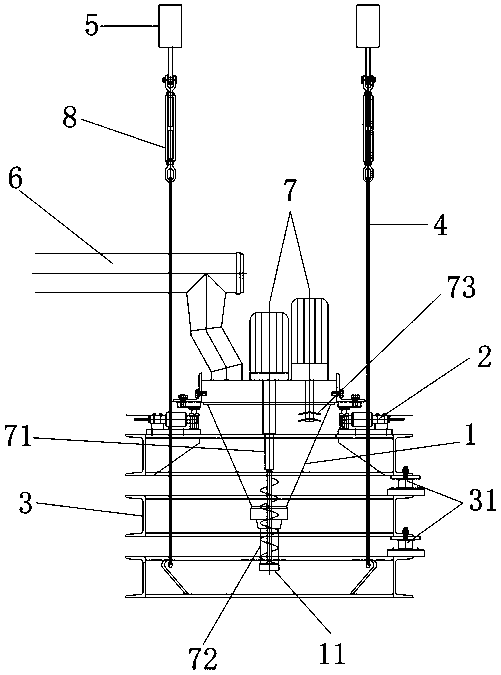

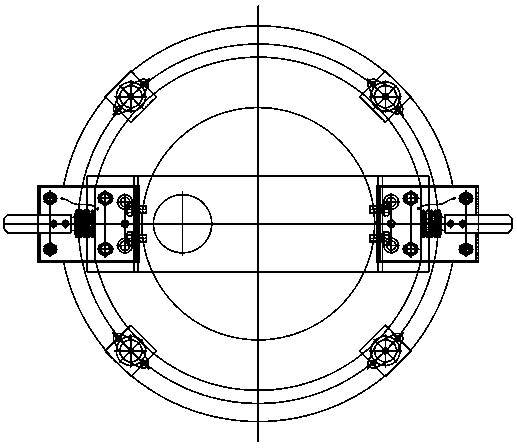

Filtering and weighing integrated reaction kettle

InactiveCN106732253APrecise weight controlNo splashProcess control/regulationChemical/physical/physico-chemical stationary reactorsFiltrationProcess engineering

The invention relates to a filtering and weighing integrated reaction kettle. The filtering and weighing integrated reaction kettle comprises a kettle body and a weighing device arranged at the top of the kettle body, wherein a kettle cover is arranged at the top of the kettle body, and a manhole, a feed port and a thermometer well are arranged on the kettle cover; the thermometer well extends into the kettle body, the upper end is fixed on the kettle cover, a thermometer is arranged in the thermometer well, and a discharge port is formed in the bottom of the kettle body; a stirring device is arranged in the kettle body; a mounting support frame is arranged at the bottom of the kettle body. According to the filtering and weighing integrated reaction kettle, weight of fed materials can be accurately controlled when the materials are fed into the reaction kettle, the structure is simple, and the cost is low; meanwhile, with the arrangement of a filtrate sieve plate and a filtering device, the reaction kettle is completely sealed for filtering, no liquid is splashed, the filtration is thorough, and the safety of an operating worker is guaranteed.

Owner:浙江晨诺高分子材料有限公司

Weight control method for braided fabric

The invention relates to the technical field of textile and discloses a weight control method for a braided fabric. The control method has the following advantages that 1, according to the method, a standard sheet is divided into a plurality of segments and is used as a modeling reference, and thus, a plurality of segmented linear control densities can be realized and a sweater sheet woven by the weight control method is uniform in density and is comfortable to wear; 2, by adopting the method, an operator does not need to have rich weaving experience and a common worker can attend a weaving machine by simple training, so that labor cost is reduced; 3, due to adoption of segmented control and real-time monitoring on the weight, generation of waste sheets is reduced and yield is obviously promoted, so that by adopting the method, the qualified rate of woven sweaters is also greatly improved; 4, by adopting the method, accurate control on the density and the weight can be implemented and the aim of saving yarns also can be fulfilled.

Owner:DONGGUAN DINGHONG ELECTRONICS TECH CO LTD

Automatic liquid shampoo canning device

PendingCN113213408ASave time on capping and pressingImprove capping and pressing efficiencyBottle-handling machinesLiquid bottlingProcess engineeringManufacturing engineering

The invention relates to a canning device, in particular to an automatic liquid shampoo canning device. The invention aims to provide the automatic liquid shampoo canning device which is simple and convenient to operate, short in spent time, high in efficiency, standard in operation and capable of avoiding bacteria breeding in the canning process. According to the technical scheme, the automatic liquid shampoo canning device comprises a machine frame, a conveying mechanism, materials and a material extruding mechanism; the machine frame is arranged on one portion of a bottom plate; the transportation mechanism is arranged on the bottom plate; the materials are placed on the conveying mechanism; and the material extruding mechanism is arranged on the machine frame. Through cooperation of a capping mechanism and a compaction mechanism, automatic capping of the materials can be achieved, meanwhile, bottle caps are automatically compacted, and the manual capping and compaction time can be saved.

Owner:张真桂

Automatic material weighing and agitating device for bubble blowing machine for glassware

InactiveCN108261961APrecise deliveryPrecisely control the ratioRotating receptacle mixersTransportation and packagingEngineeringMechanical engineering

The invention discloses an automatic material weighing and agitating device for a bubble blowing machine for glassware. The automatic material weighing and agitating device comprises a material mixinghopper, wherein the material mixing hopper is provided with one group of weighing hoppers; discharge holes in the lower sides of the weighing hoppers are connected with end covers in a hinging manner; the end covers are connected with attraction plates; one group of electromagnets is also mounted in the material mixing hopper; the electromagnets all correspondingly attract the corresponding attraction plates; a first air cylinder is connected below each weighing hopper; the first air cylinders are connected with push plates; the push plates correspondingly cooperate with the end covers; weighing scales are mounted in the end covers; the upper sides of the weighing hoppers are provided with feed conveying belts; feed hoppers are correspondingly arranged above the feed conveying belts; thebottom of the material mixing hopper is provided with a discharge hole; the outer side of the discharge hole is provided with a material guide box; the material guide box is correspondingly cooperatively connected with an agitating device. The automatic material weighing and agitating device has the advantages that the device can be used for weighing and feeding various raw materials respectively,and is used for accurately controlling the feed quantity of each raw material, accurately controlling the mixing proportion of the raw materials and conveying the raw materials to the agitating device to carry out agitation through a material conveying device, and the work efficiency is improved.

Owner:蚌埠冠平机械有限公司

Method for manufacturing table tennis bat

The invention relates to a method for manufacturing a table tennis bat and aims to provide a method for manufacturing the table tennis bat with fiber material so as to improve the performance of the table tennis bat. The steps sequentially included in the method are as follows: the closed end of a fiber long tube is wound in a bat-shaped first cut piece made of two pieces of the fiber material; one end of a second nylon tube is closed and inserted at the connecting part of the first cut piece and a bat handle, and is covered by a second cut piece made of the fiber material to form the handle. The open ends of the fiber long tube and the second nylon tube are arranged at the outer end of the handle of the pre-profiling bat, the pre-profiling bat is placed in a forming mold of the table tennis bat and sequentially passes through preheating, inflating for the pre-profiling bat from the open end, heating and setting, and cutting for the open ends of the fiber long tube and the second nylon tube arranged outside the bat handle and the tail end of the handle, thereby obtaining the full-fiber table tennis bat through integrated molding. The table tennis bat has high strength, difficult deterioration and stable performance.

Owner:张爱莲

Waste residue cleaning system for waste incineration electricity generation

ActiveCN109592450AWeight controlControl amountLoading/unloadingSolid removalControl circuitIncineration

The invention discloses a waste residue cleaning system for waste incineration electricity generation and belongs to the field of waste incineration electricity generation. The key points of the technical scheme of the system include that the system comprises an incinerator, a conveying device, a residue pit and a transporting vehicle; the bottom of the incinerator communicates with the conveyingdevice; the end, away from the incinerator, of the conveying device is connected with the residue pit; the transporting vehicle can be connected with the other end of the residue pit; a first loadingplate, a second loading plate and a discharging plate are arranged in the residue pit in a stepped shape in sequence; a second push assembly used for pushing waste residue on the second loading plateto the discharging plate is connected to the second loading plate, and a second control circuit used for controlling the second push assembly is arranged on the second loading plate; and the second control circuit can be used for controlling the second push assembly to push waste on the second loading plate to the discharging plate. By means of the waste residue cleaning system provided by the invention, the problem that outward discharging of the waste residue in a residue pit is not up to standard is solved, and the temperature when the waste residue is discharged outwards can be accuratelycontrolled by arranging a temperature sensor in the residue pit.

Owner:上海金山环境再生能源有限公司

Underground coal bunker weighing system

InactiveCN106044265AFully automatedPrecise weight controlConveyorsControl devices for conveyorsDischarge efficiencyCoal

The invention belongs to the technical field of underground coal bunker transportation equipment and specifically relates to an underground coal bunker weighing system. The underground coal bunker weighing system comprises a rack, a coal feed hopper, a transportation device, a weighing device and a coal discharge hopper, wherein the coal feed hopper is fixed at the upper side of the rack; the transportation device can slightly move in the vertical direction of the rack and is arranged right under an outlet of the coal feed hopper; the weighing device is connected with the transportation device through supports; and the coal discharge hopper is arranged below the outlet end in the operating direction of the transportation device. The underground coal bunker weighing system can accurately control the weight of transported coal, realizes automation of a coal loading and unloading process, saves labor cost and meanwhile avoids potential safety hazards; the coal discharge direction of the coal discharge hopper of the system is adjustable, thereby adapting to coal receiving devices in different positions and being in favor of improving the coal discharge efficiency; and the underground coal bunker weighing system is simple in device, is convenient to operate and is suitable for popularization and use in a large range.

Owner:杭州市萧山区高级技工学校

Accurate feeding mechanism

ActiveCN105016092APrecise weight controlPrecise and smooth dischargeLoading/unloadingEngineeringButt joint

The invention relates to an accurate feeding mechanism for powdery refractory materials. The accurate feeding mechanism is connected with a weighing mechanism in a butt joint manner, wherein the weighting mechanism is used for measuring the weight of materials. The feeding mechanism comprises a stacking assembly used for stacking the materials and smoothly conveying out the stacked materials, and a scraping assembly used for accurately scraping in the materials conveyed out by the stacking assembly. The scraping assembly is provided with a first scraper which can be inserted in the materials to scrap the materials, and the depth of the portion, inserted in the materials, of the first scraper can be adjusted. According to the accurate feeding mechanism, the powdery materials are scraped in the weighing mechanism to be weighed through the first scraper; when the materials are placed in the weighing mechanism, the situation that the materials are blocked in a stock bin because the materials cake is avoided; and the depth of the portion, inserted in the materials, of the first scraper can be adjusted, and therefore the weight of the materials placed in the weighing mechanism can be accurately controlled.

Owner:无锡乔尼威尔铁路设备科技有限公司

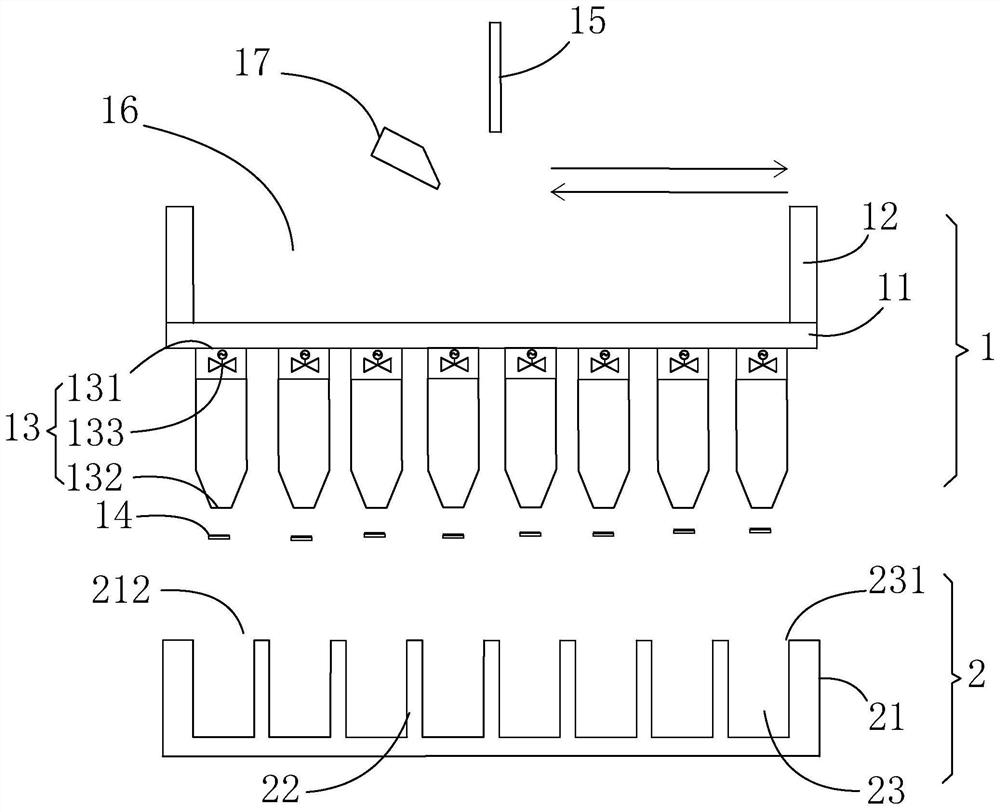

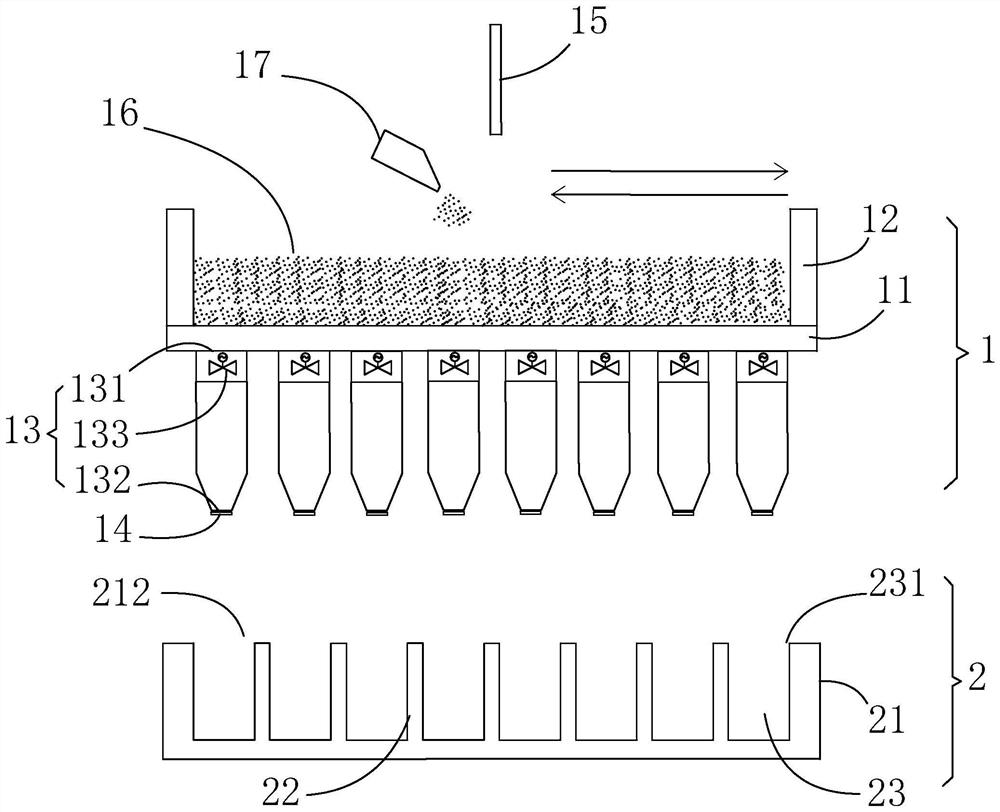

Powder distribution device, powder distribution method of powder distribution device and manufacturing method of NdFeB thin-sheet magnet

PendingCN111968814AReduce reunionPrecise weight controlInductances/transformers/magnets manufactureMagnetic materialsMechanical engineeringThin sheet

The invention provides a powder distribution device, which comprises a powder distributor and a mold used in cooperation with the powder distributor, wherein the powder distributor comprises a bottomplate, a side wall connected with the bottom plate and used for forming a containing cavity with the bottom plate, a powder sweeping plate, at least two funnels in butt joint with the side, deviatingfrom the containing cavity, of the bottom plate, and powder distribution valves arranged between the inlets of the funnels and through holes corresponding to the funnels and capable of being opened and closed, through holes which are uniformly distributed and penetrate through the bottom plate are formed in the bottom plate, the powder distributor further comprises weighing devices which are in one-to-one correspondence with the funnels, and the mold comprises a mold body with a containing space and a partition plate dividing the containing space into at least two mold cavities. The powder distribution method comprises the procedures of powder weighing, powder pouring, powder distribution and mold closing. According to the powder distribution device, powder agglomeration can be reduced; and the weighing device is arranged, so that the weight value of the powder filled in each mold cavity can be accurately controlled, and the filling amount of the powder in each mold cavity is consistent so as to realize batch uniform filling and powder distribution of the magnets.

Owner:AAC TECH NANJING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com