Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

57results about How to "Not easy to relax" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Iodine polarizing film manufacturing method, polaroid manufacturing method and optical laminate manufacturing method

ActiveCN1629660AReduce wrinklesReduce tensionLayered productsPolarising elementsWrinkle skinPolyvinyl alcohol

PROBLEM TO BE SOLVED: To provide a manufacturing method of polarizing film which hardly causes dyeing irregularity and permits the reduction of frequency of wrinkle generation and the reduction of tension during processes after dyeing, and to provide a polarizing plate and an optical laminate using the polarizing film. SOLUTION: In the manufacturing method of polarizing film, uniaxial stretching is performed before and / or during a process of treating a polyvinyl alcohol base film in order of swelling, iodine dyeing and borating. Prior to the borating process, the iodine dyeing is performed in dyeing baths of two steps or more and, further, uniaxial stretching is performed in dyeing baths of two steps or more. Therein, the uniaxial stretching is performed in such a manner that (1) the stretching ratio in the initial dyeing bath is set to be higher than the sum stretching ratio in dyeing baths on and after the second step or (2) the stretching ratio in the last dyeing bath is set to be higher than the sum stretching ratio in the dyeing baths prior to the last dyeing bath.

Owner:SUMITOMO CHEM CO LTD

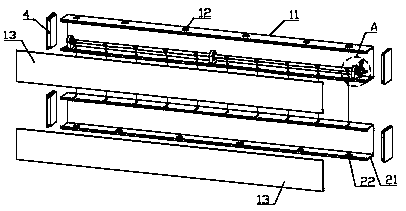

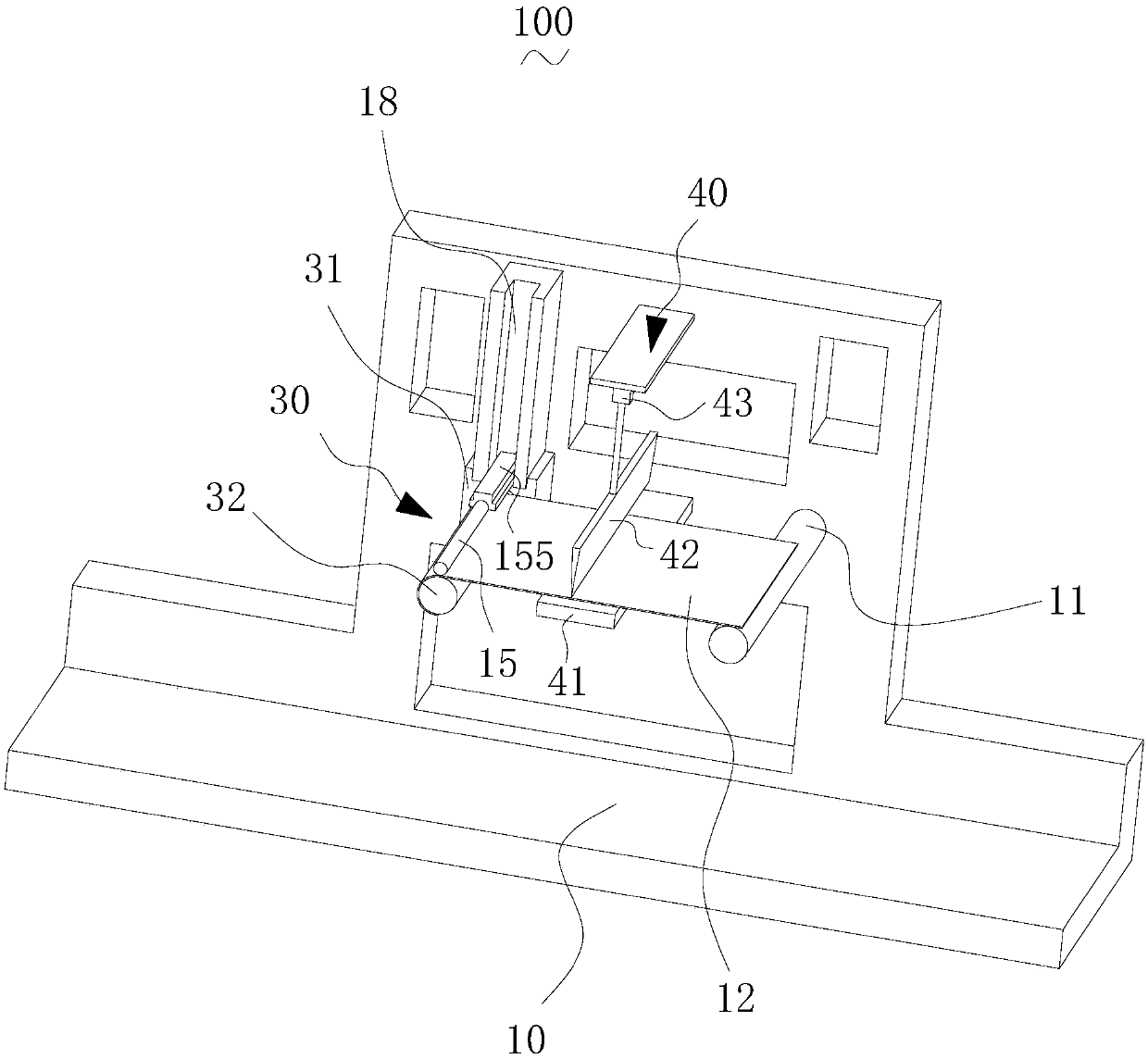

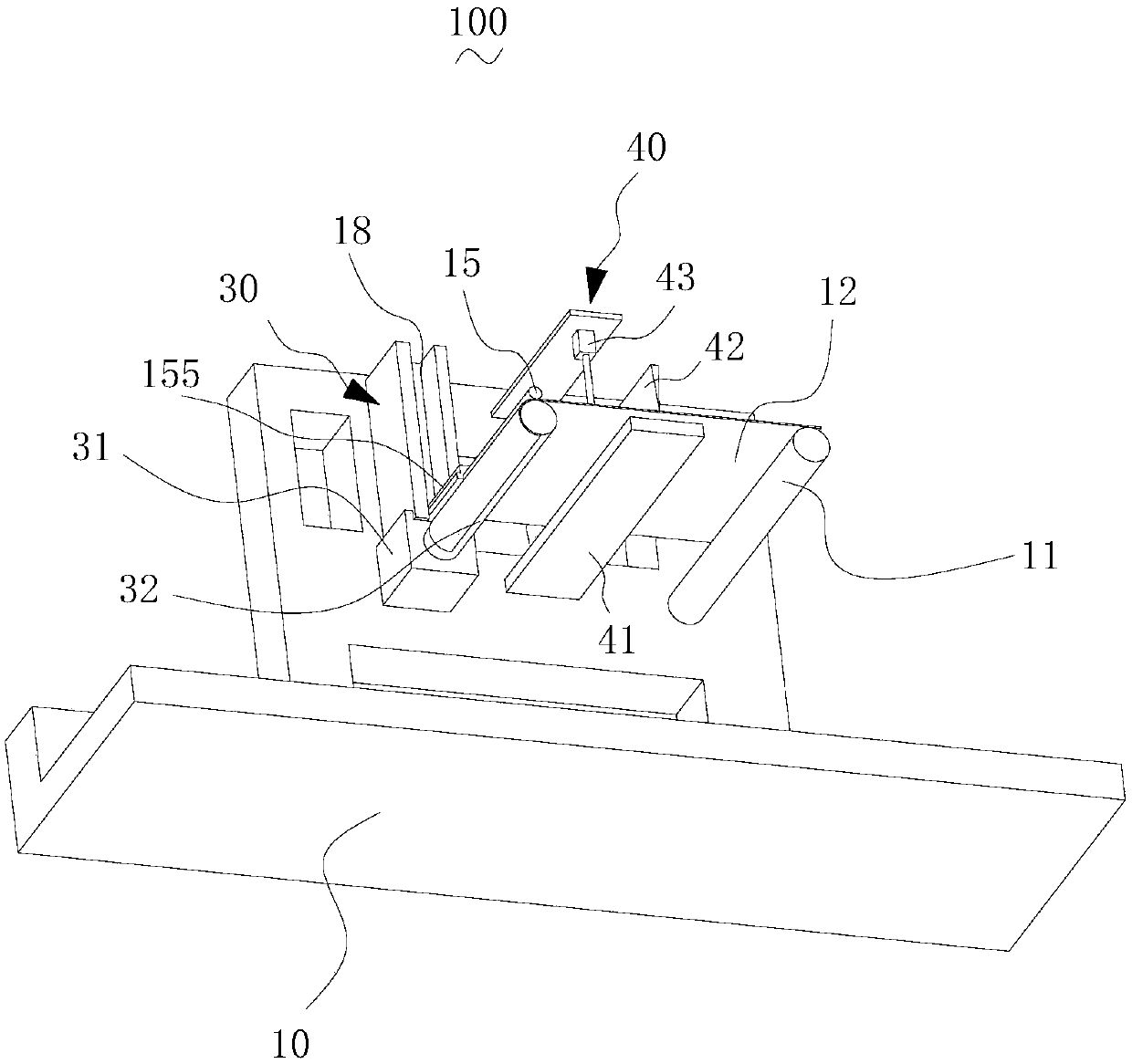

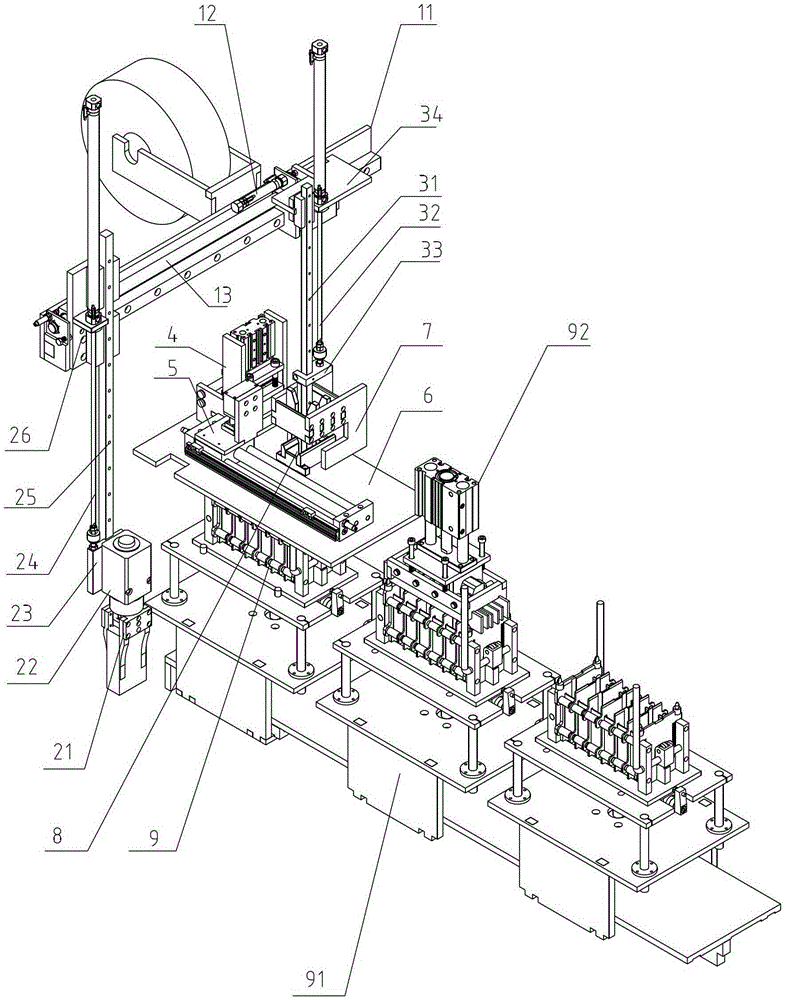

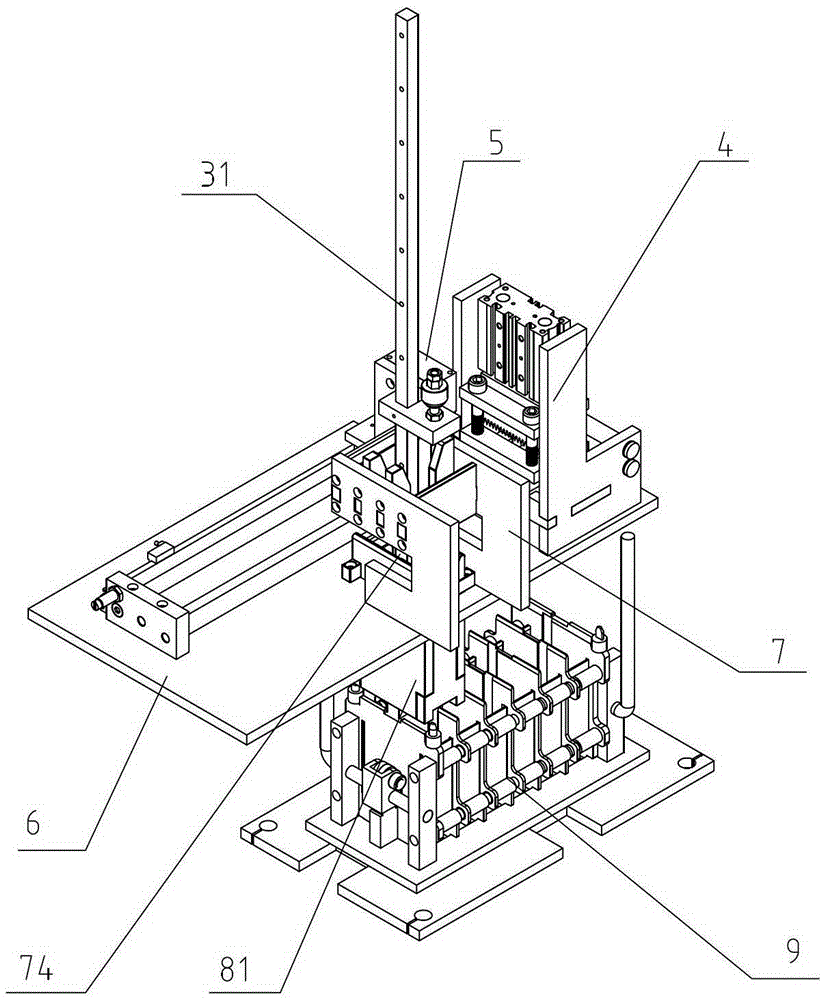

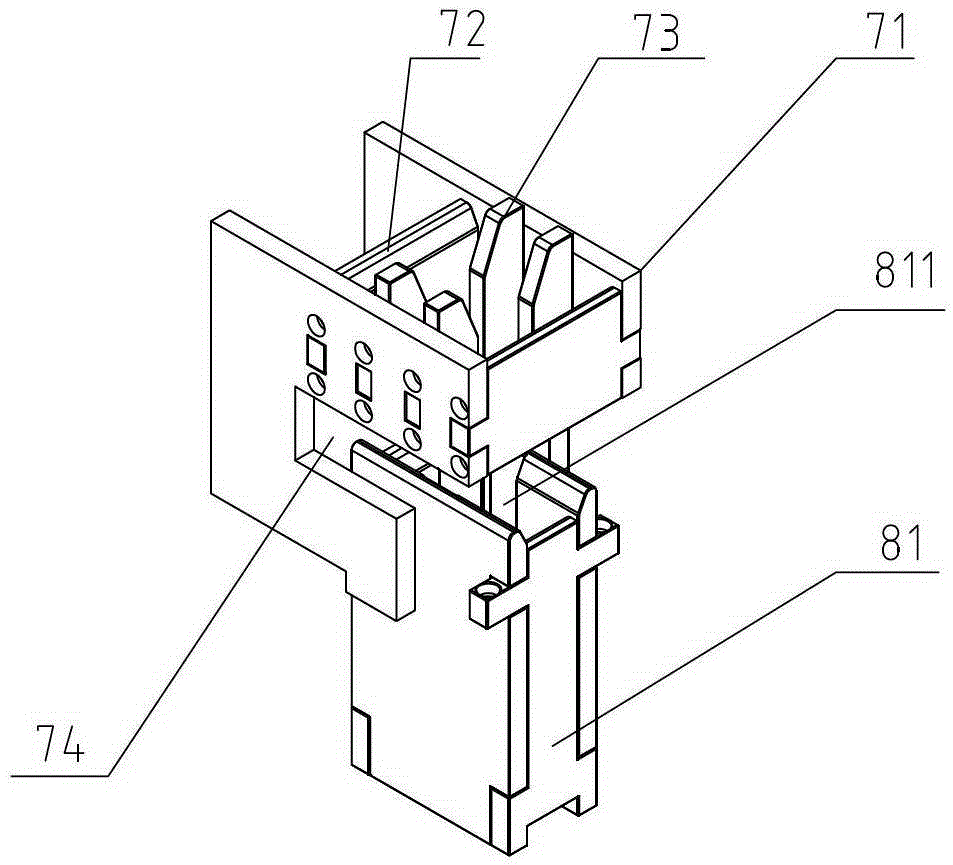

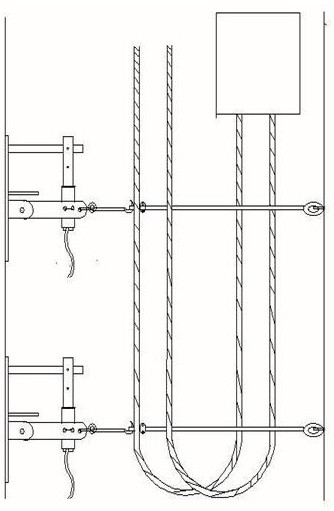

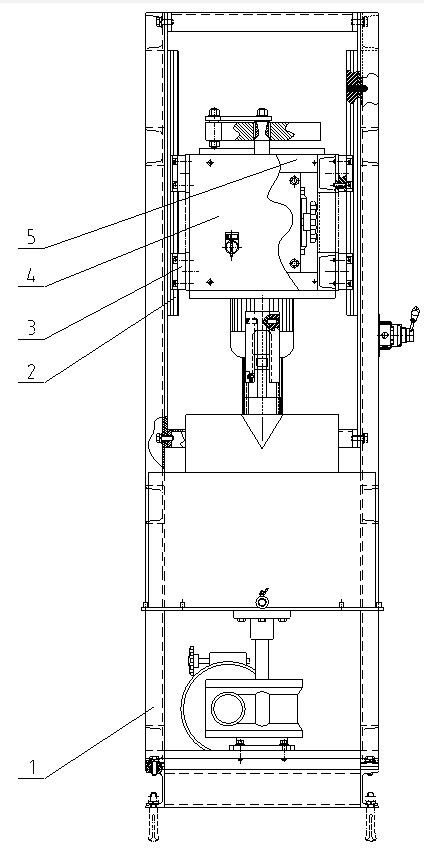

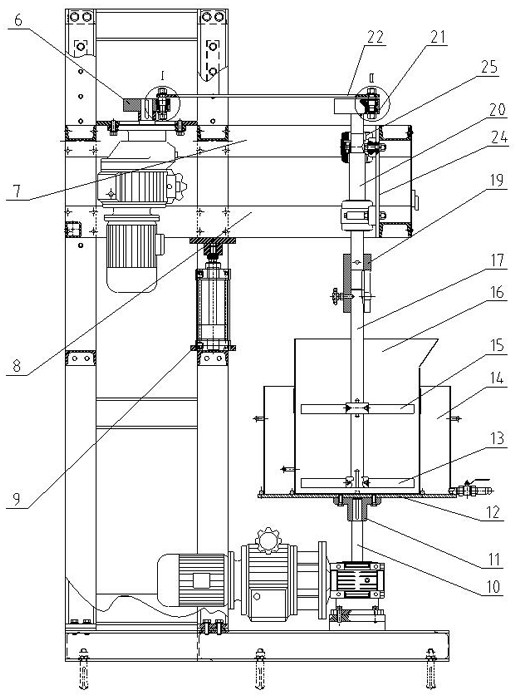

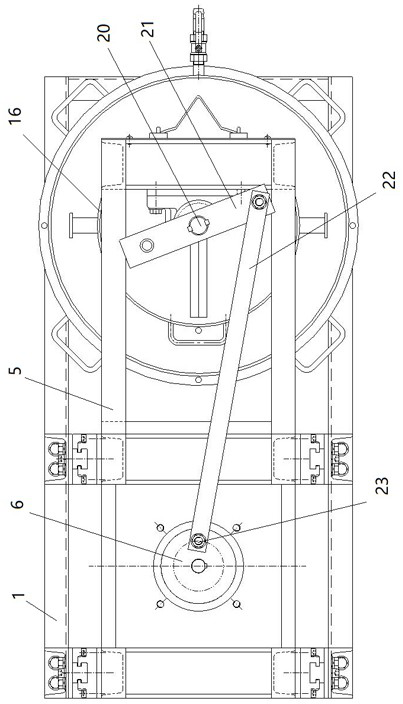

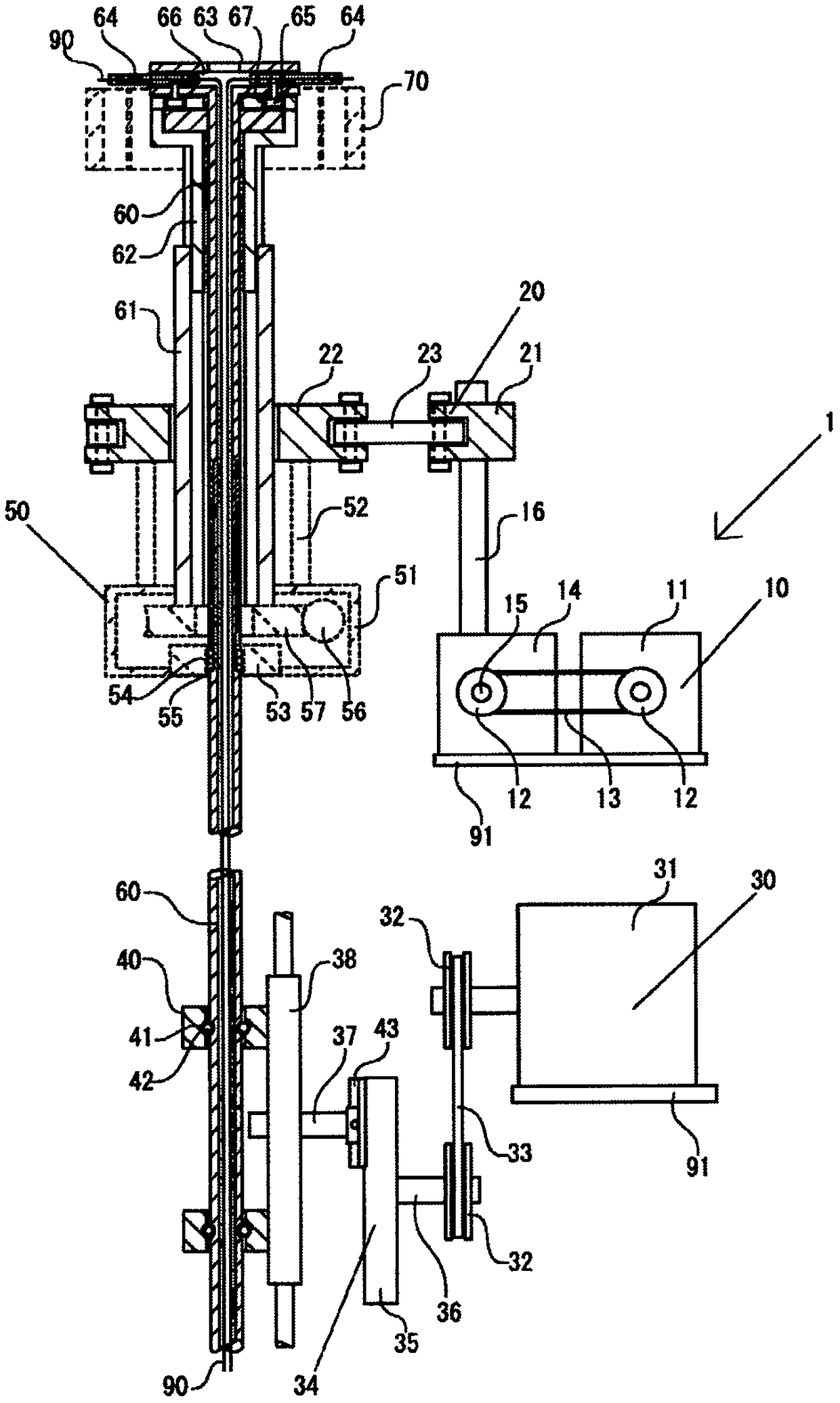

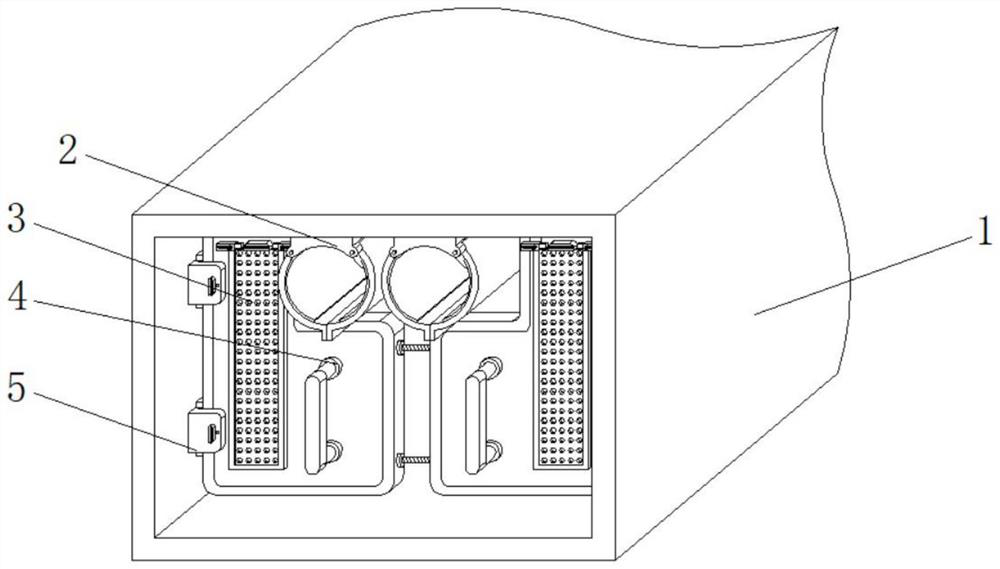

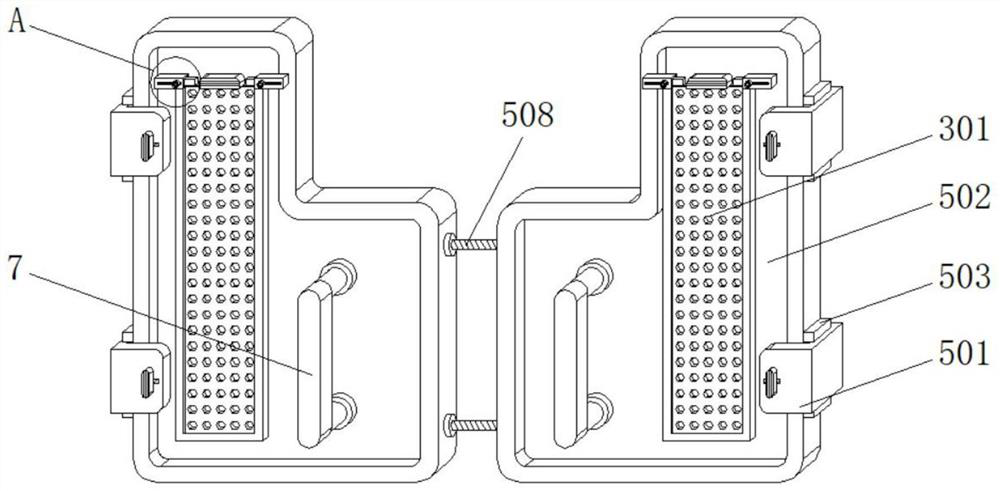

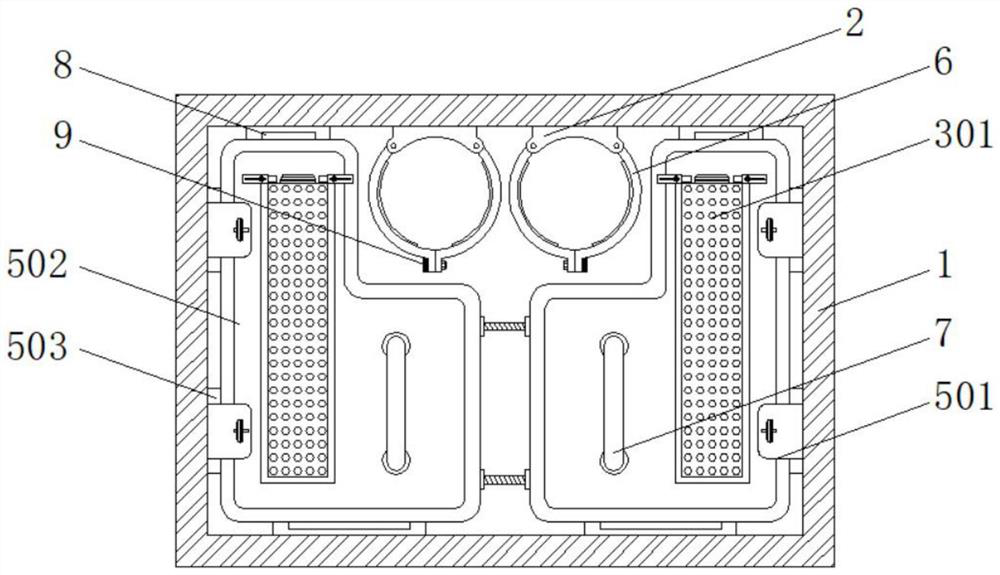

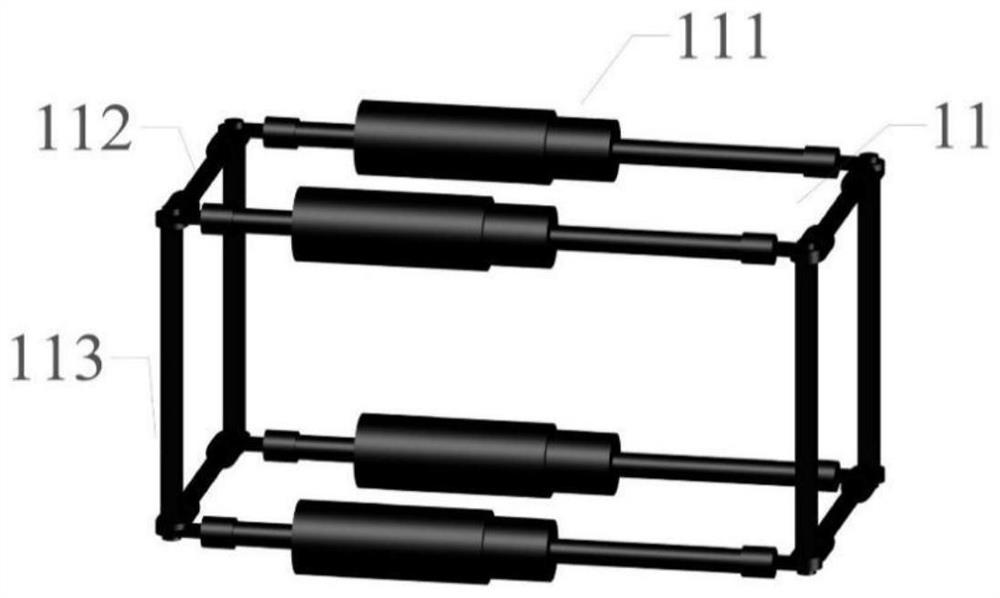

Battery packaging piece trough entering machine

ActiveCN103326058AGood effectNot easy to relaxFinal product manufactureSecondary cells manufactureWeldingEngineering

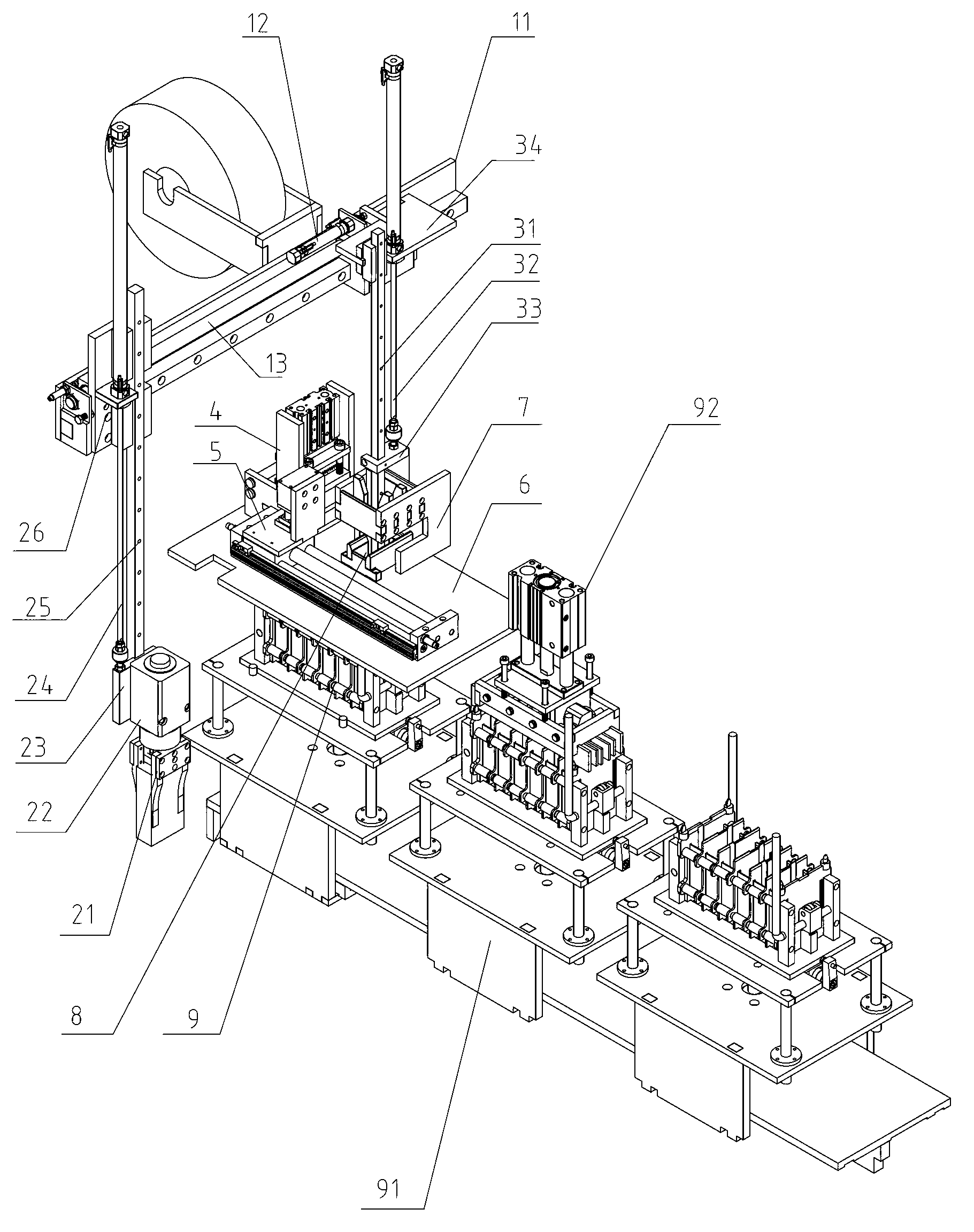

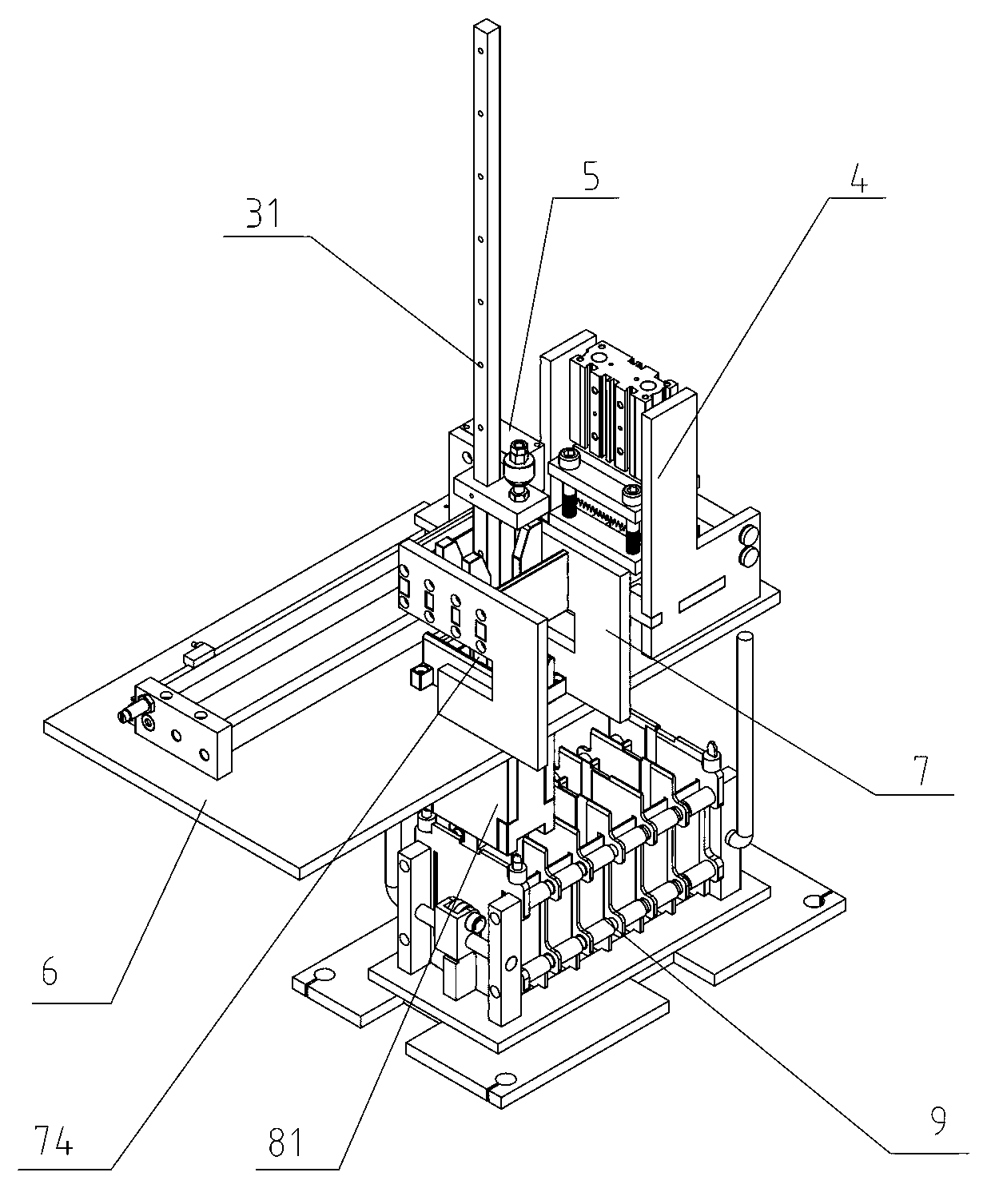

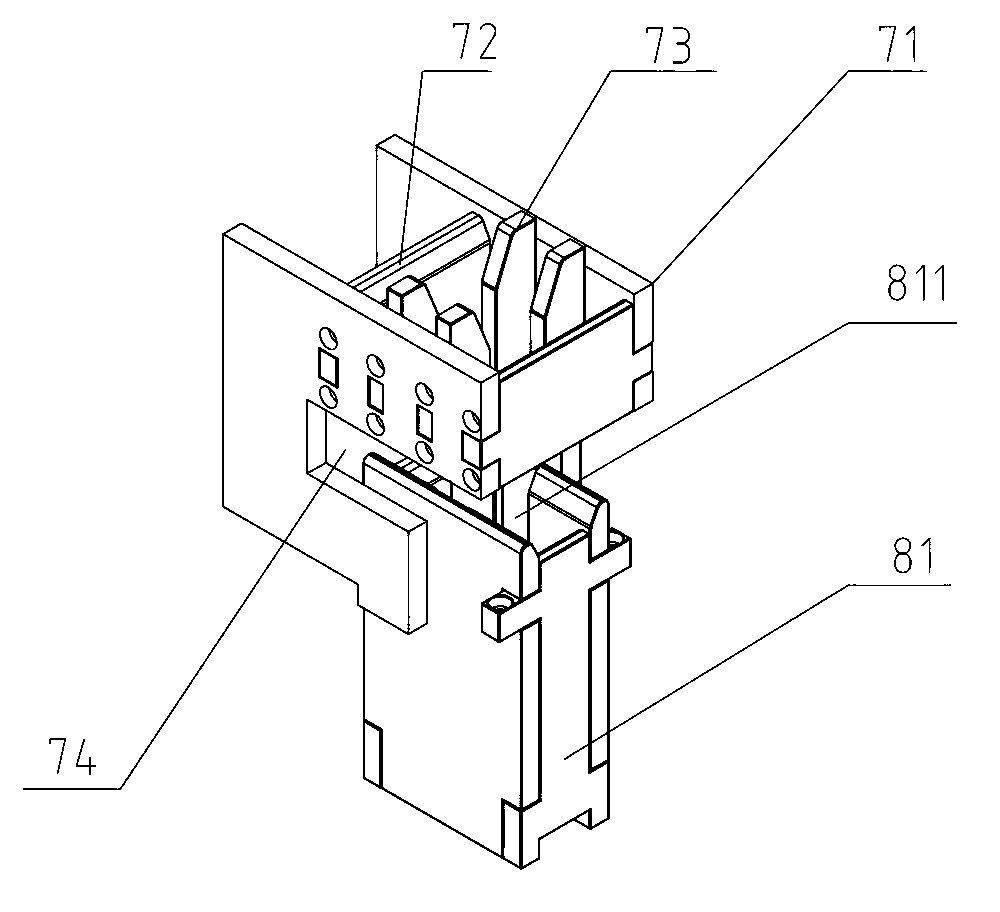

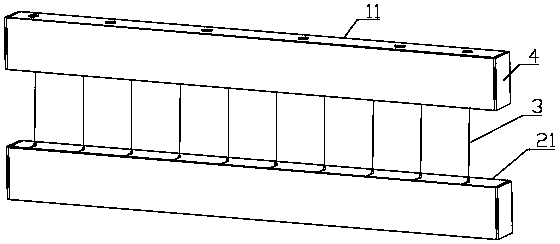

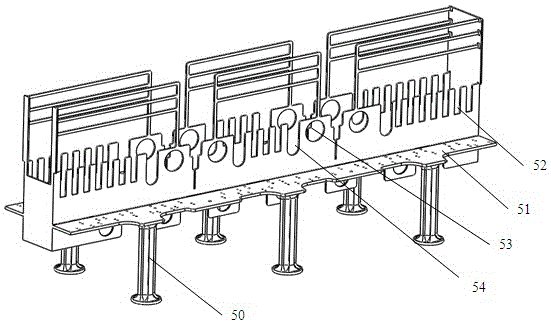

The invention discloses a battery packaging piece trough entering machine which relates to the field of battery production, and aims at solving the problems that the existing battery packaging piece trough entering machine is low in efficiency. The battery packaging piece trough entering machine comprises a feeding device, a film delivery device, a cast welding clamp and a sliding seat for driving the cast welding clamp to move transversely, wherein the film delivery device comprises a film support plate, a film cutting assembly arranged above the film support plate, and a transversely movable film taker, wherein the film support plate is provided with a film enclosing port; a feed clamping frame is arranged above the film enclosing port and is provided with an evading groove which evades the transverse movement of the film taker; the cast welding clamp is arranged just below the film enclosing port; the feeding device comprises a feed clamping arm and a push rod; the feed clamping arm can transfer a pole group to the feed clamping frame; the push rod pushes the pole group in the feed clamping frame into the cast welding clamp along the film enclosing port; by adopting the machine, film enclosing and trough entering can be achieved automatically, and as the pole group transferring and film enclosing and trough entering processes are achieved by different components, time can be fully used, and the work efficiency is improved.

Owner:湖州海悦智能科技有限公司

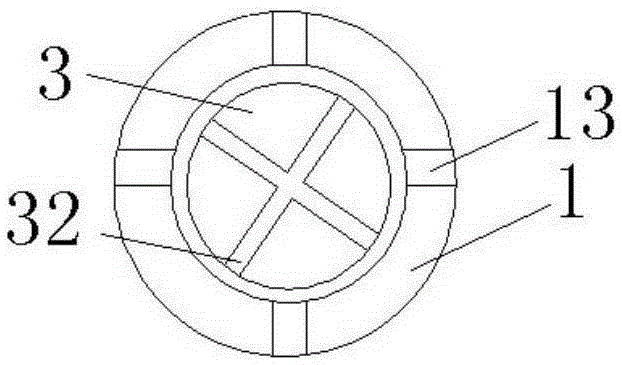

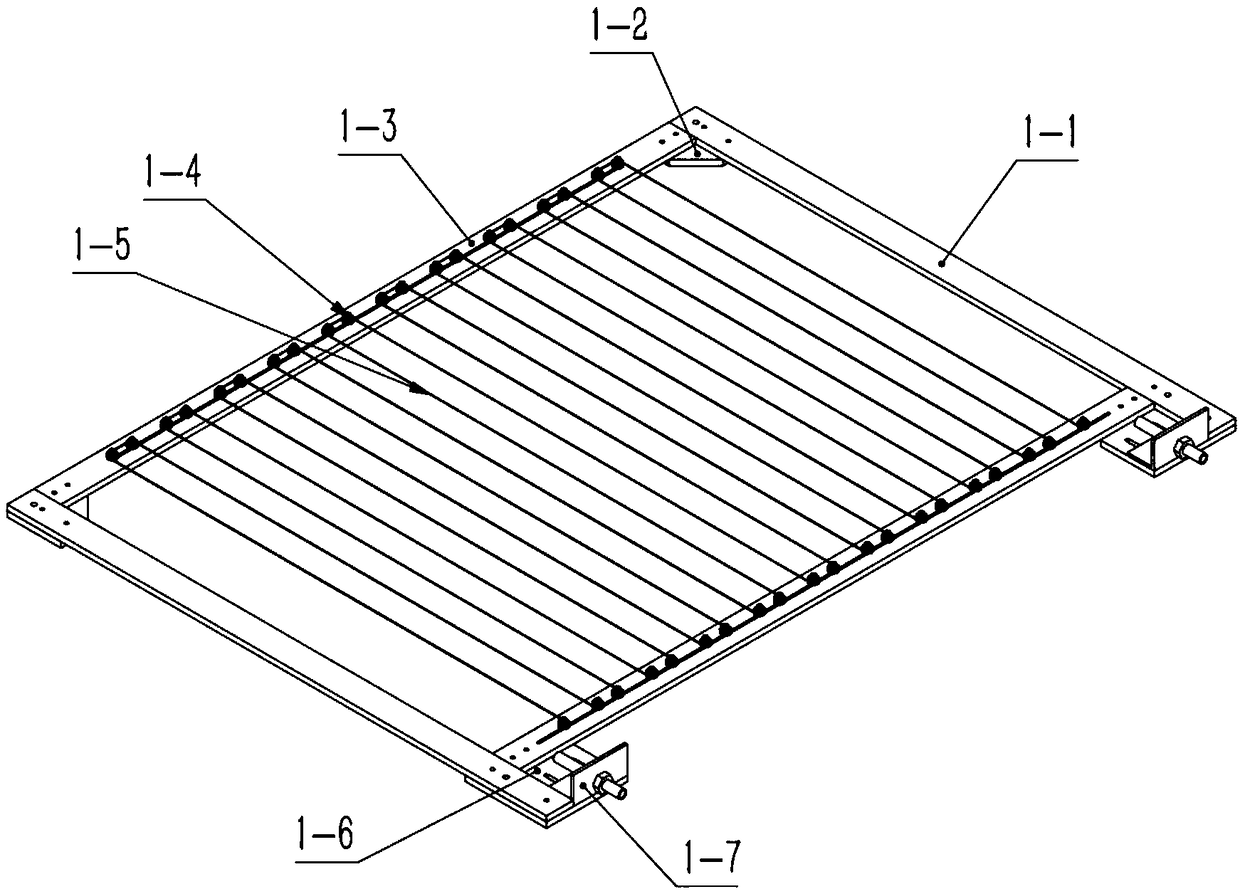

Conveniently-mounted invisible anti-theft net

InactiveCN108316837AEasy to operateImprove tightening effectFixed grillesArchitectural engineeringAnti theft

Owner:李堂波

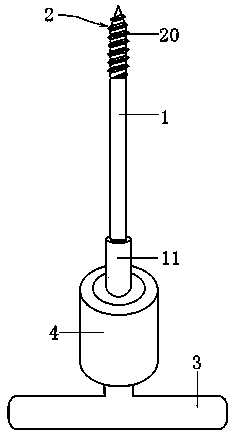

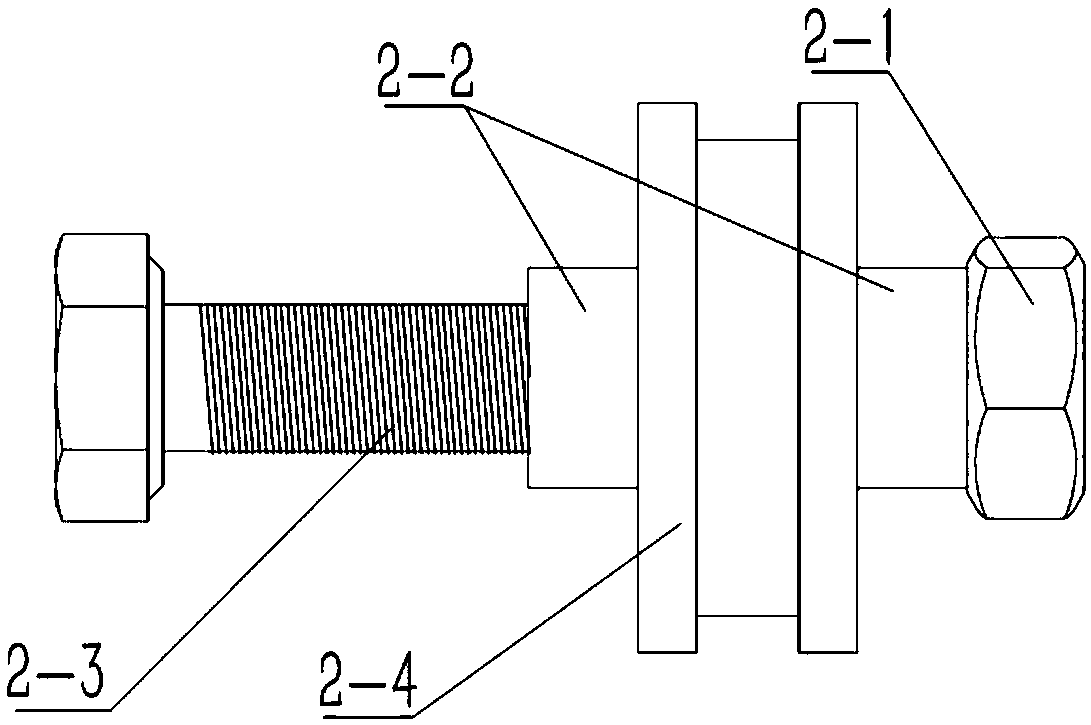

Expansion bolt

Owner:WUZHONG GUANGFU ZHENGHONG GARDENING FIELD

Multifunctional fixing device for neurosurgery department

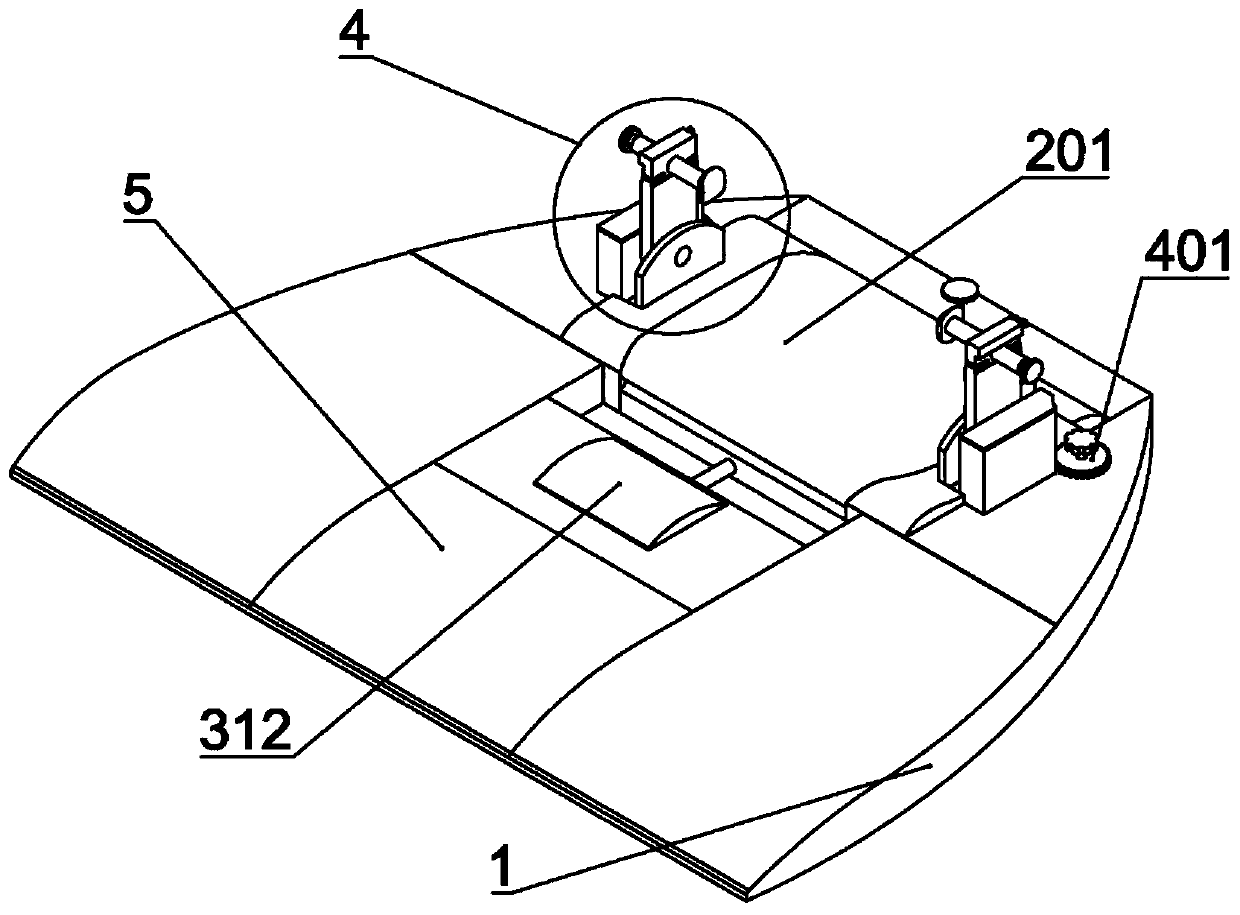

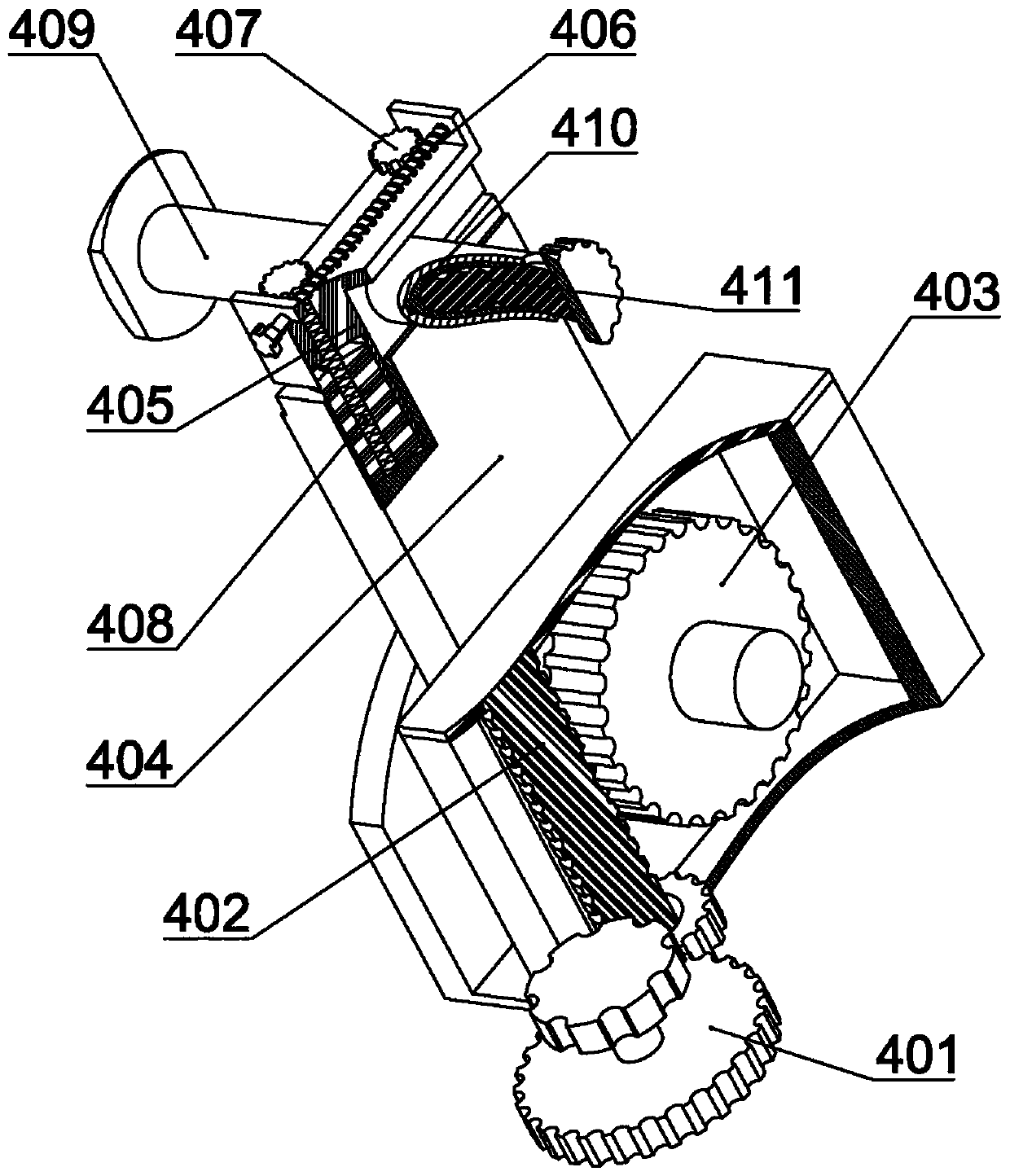

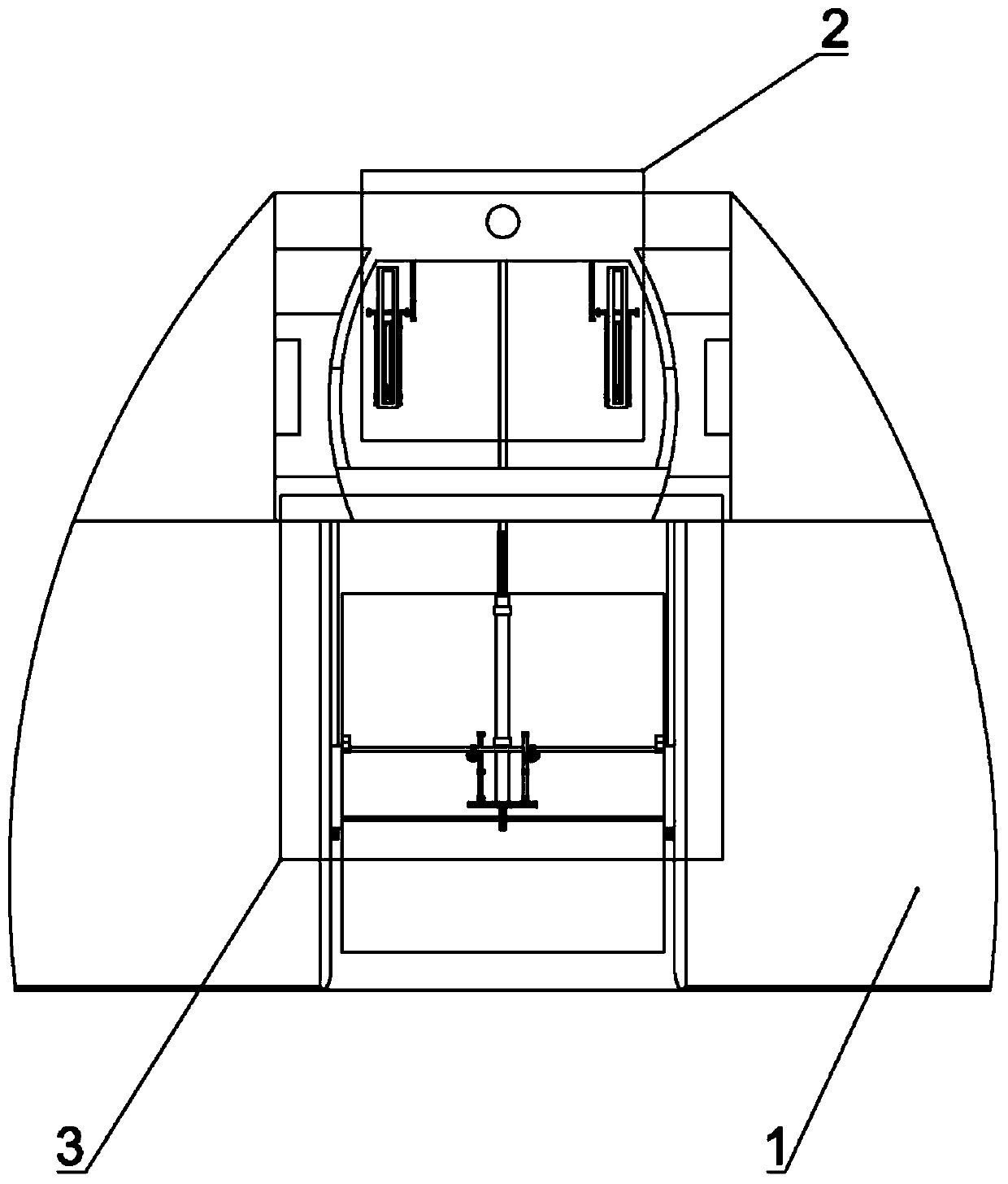

ActiveCN110292446AFixed effectImprove convenienceNursing bedsInstruments for stereotaxic surgeryNeurosurgeryEngineering

The invention belongs to the technical field of medical apparatuses and instruments, and particularly relates to a multifunctional fixing device for a neurosurgery department. The device comprises a fixing plate, and a head fixing device and a supporting device matched with the head fixing device are arranged on the fixing plate; the supporting device comprises a head supporting structure and a neck supporting structure matched with the head supporting structure; the head supporting structure comprises a head supporting plate and a head supporting transmission structure matched with the head supporting plate; the head fixing device comprises a first fixing gear rotationally connected with the fixing plate, and a multi-angle adjusting structure is connected to the first fixing gear; a supporting shell is arranged on the fixing plate, and the neck supporting structure comprises a neck supporting plate and a neck transmission structure matched with the neck supporting plate; the multi-angle adjusting structure can adjust the head fixing device according to the rotation angle of the head supporting plate, then, the head of a patient is fixed, meanwhile, the phenomenon that use is not convenient when the neck of a patient is not supported in use is avoided, and convenience and stability are improved.

Owner:HENAN PROVINCE HOSPITAL OF TCM THE SECOND AFFILIATED HOSPITAL OF HENAN UNIV OF TCM

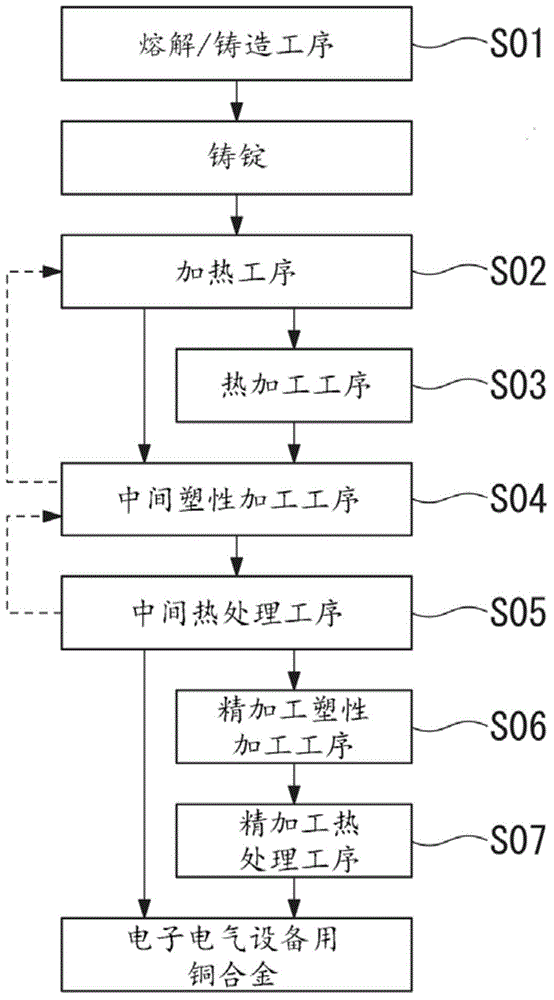

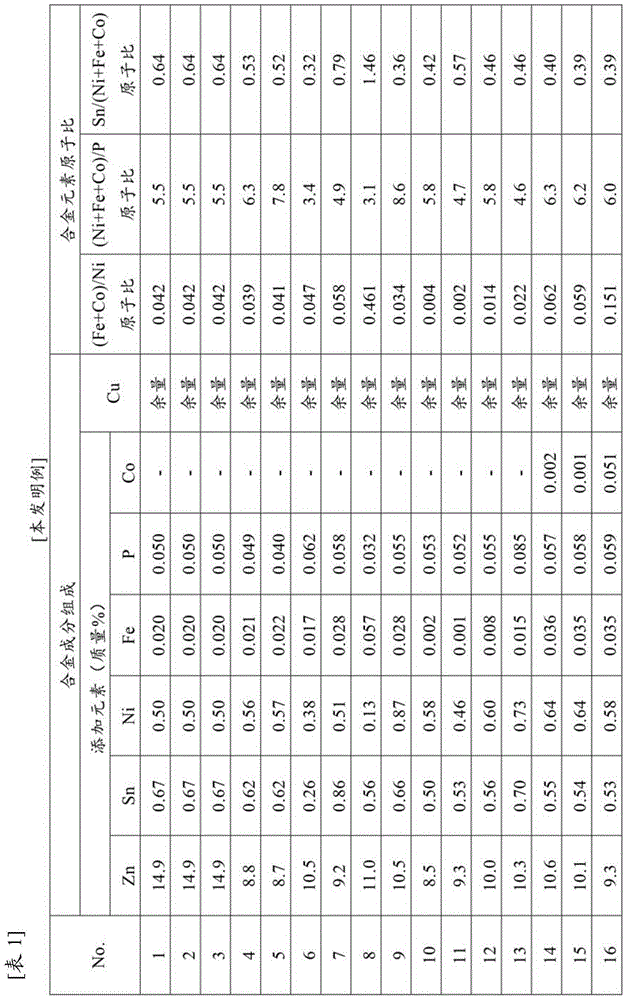

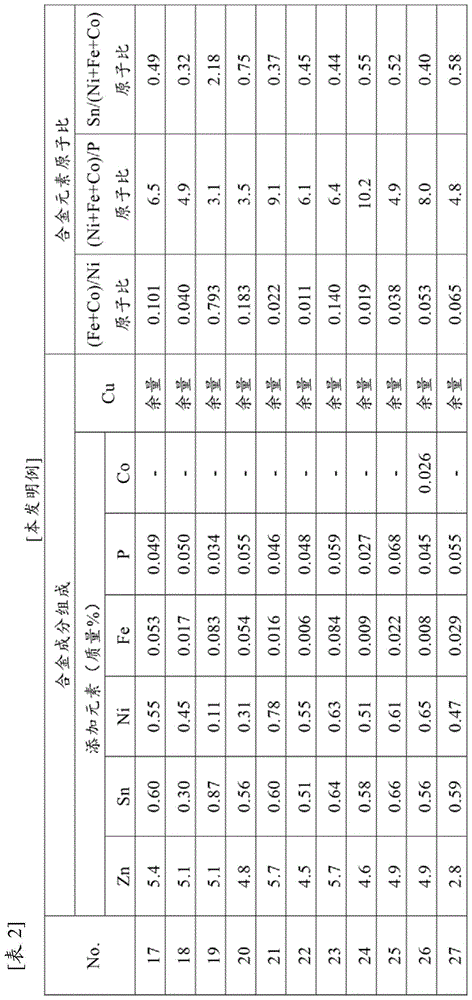

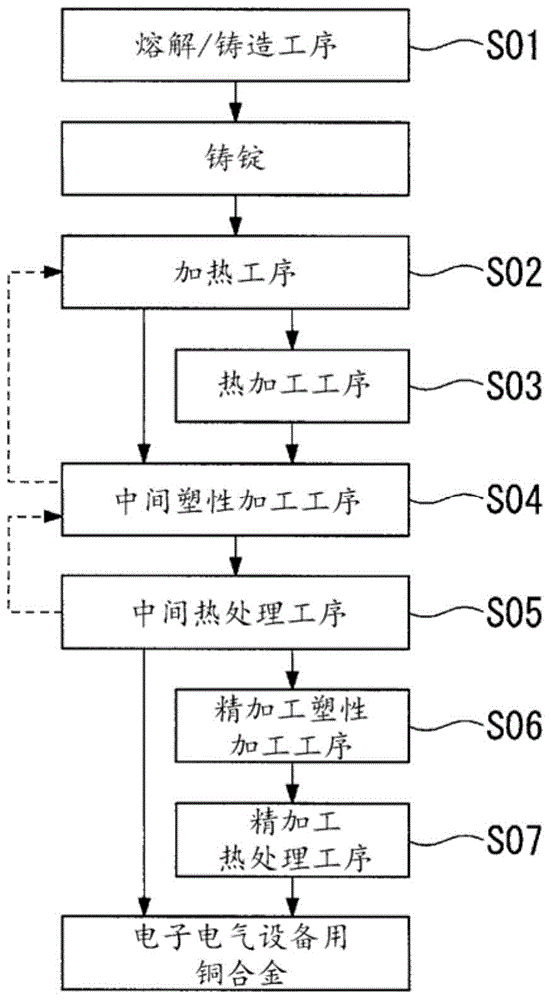

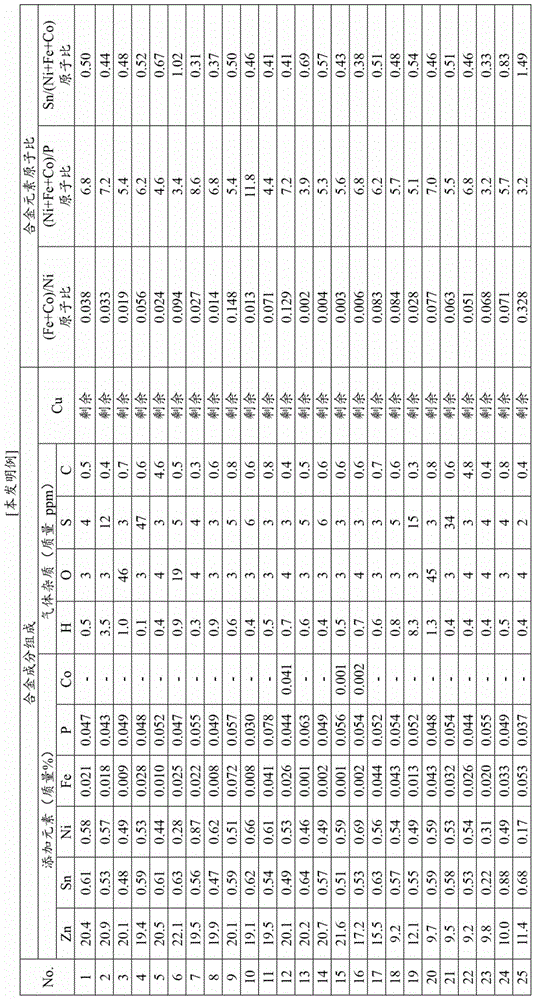

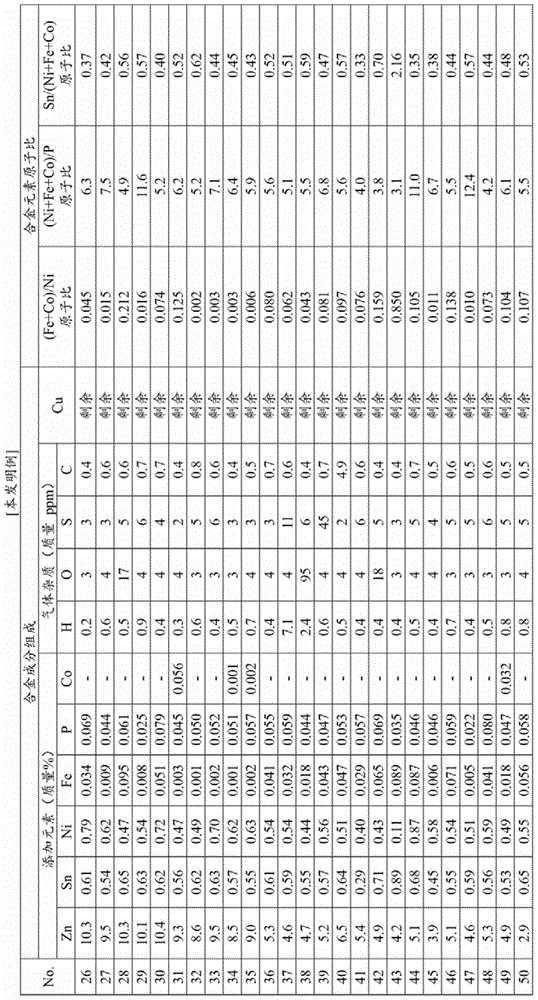

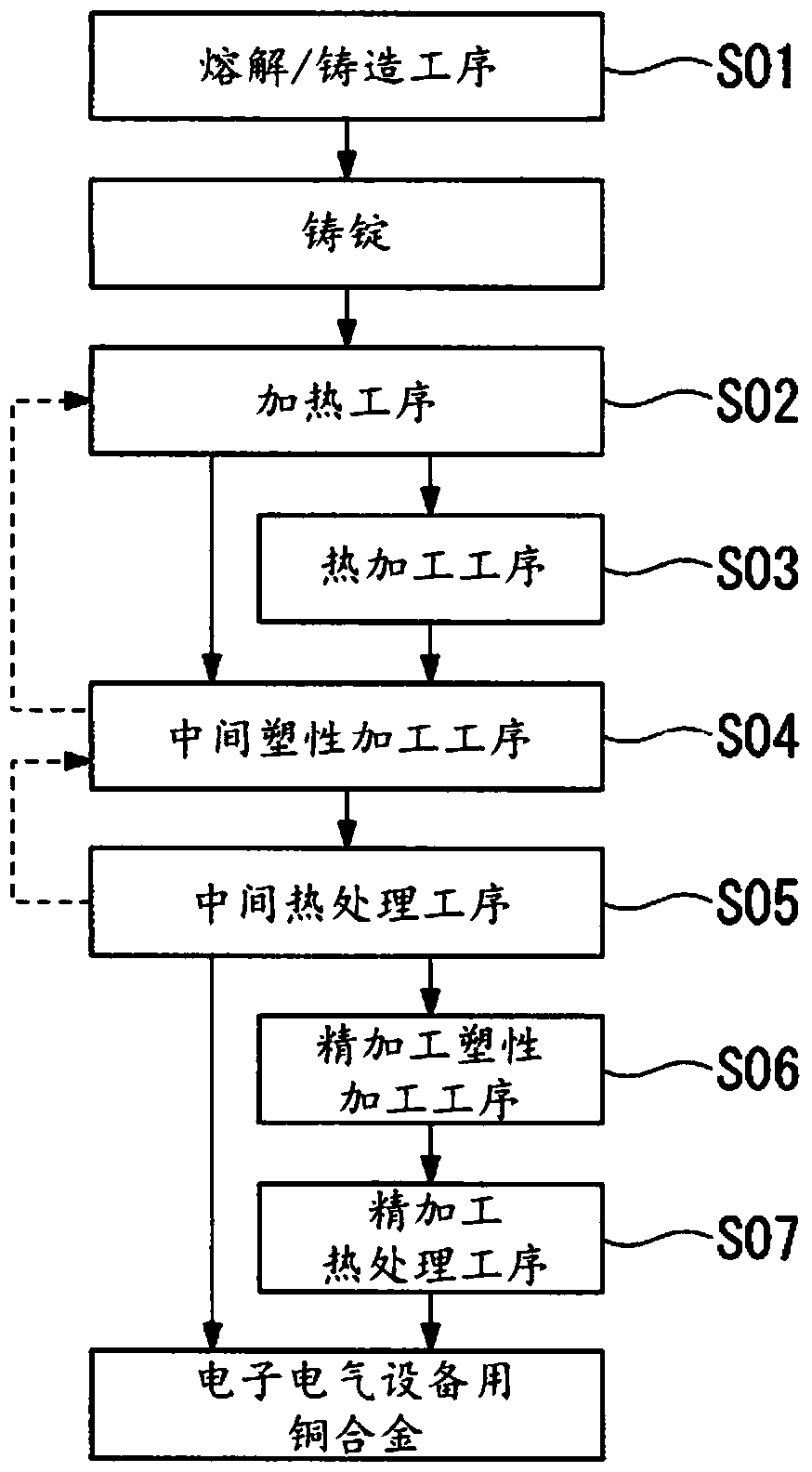

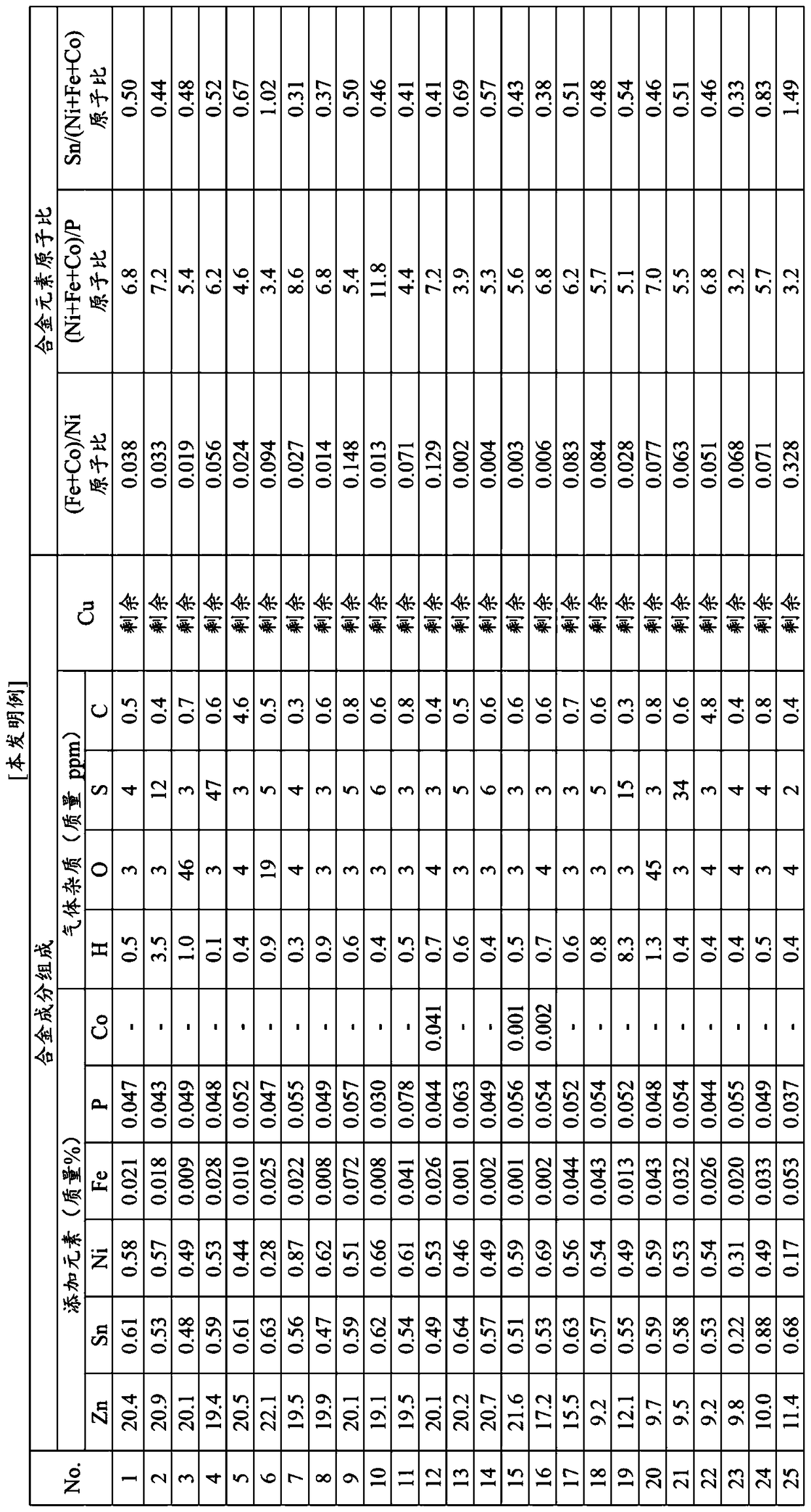

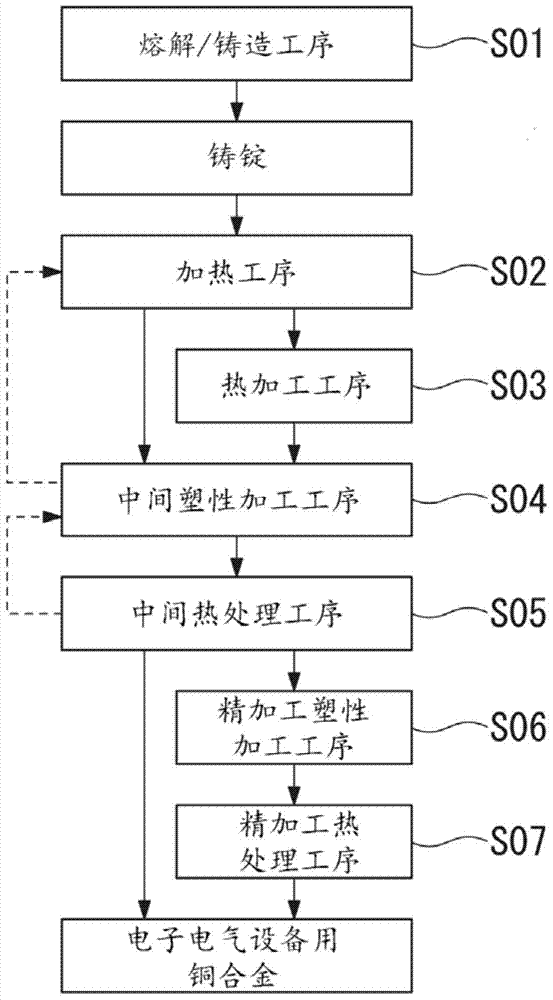

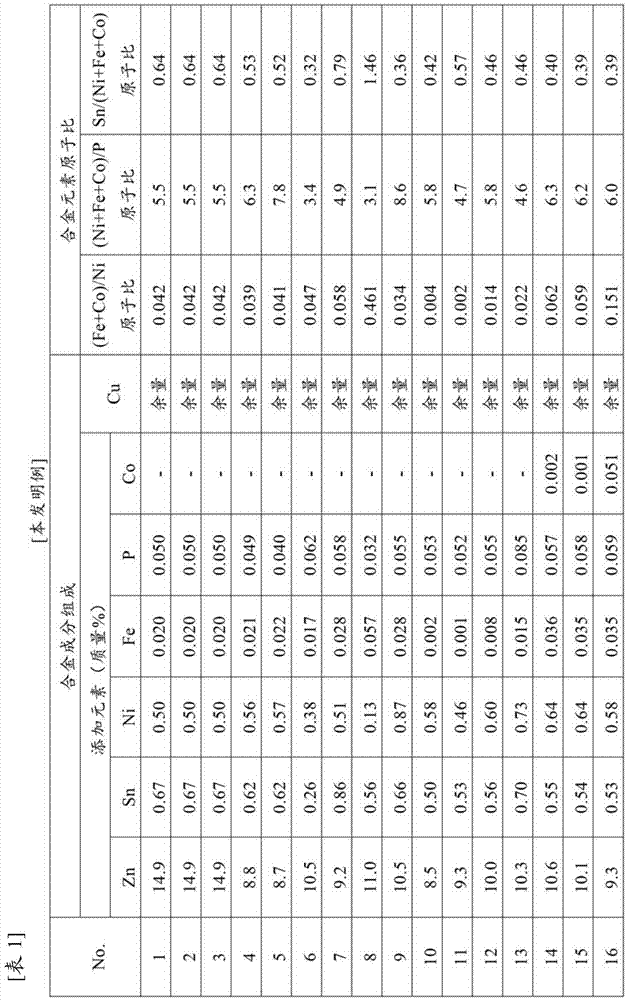

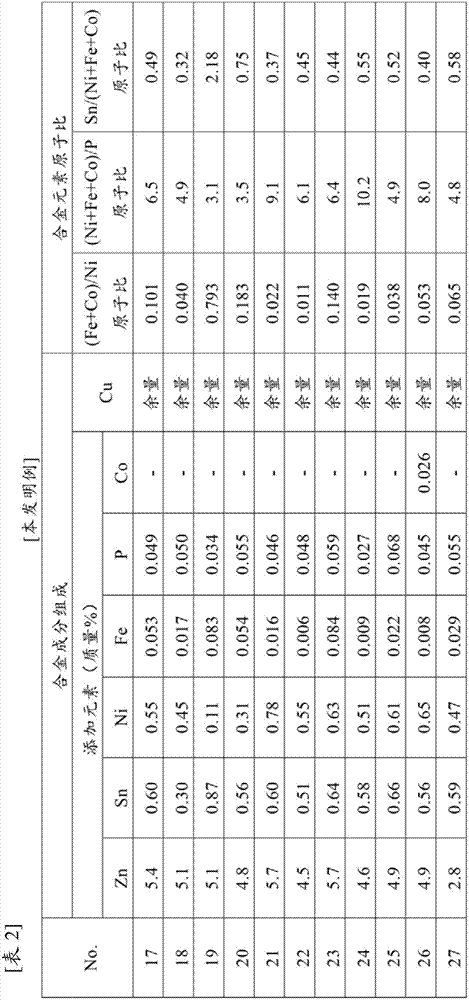

Copper alloy for electrical and electronic equipment, copper alloy thin sheet for electrical and electronic equipment, and conductive part and terminal for electrical and electronic equipment

ActiveCN104903478AExcellent bending workabilityExcellent stress relaxation resistanceHot-dipping/immersion processesSingle bars/rods/wires/strips conductorsYield ratioZinc

The present invention pertains to a copper alloy for electrical and electronic equipment, a copper alloy thin sheet for electrical and electronic equipment, and a conductive part and terminal for electrical and electronic equipment. The copper alloy for electrical and electronic equipment contains more than 2.0 mass% to 15.0 mass% of zinc, 0.10 mass% to 0.90 mass% of tin, 0.05 mass% to less than 1.00 mass% of nickel, 0.001 mass% to less than 0.100 mass% of iron, and 0.005 mass% to 0.100 mass% of phosphorus, with the remainder comprising copper and unavoidable impurities. The copper alloy satisfies 0.002 ≤ Fe / Ni < 1.500, 3.0 < (Ni + Fe) / P < 100.0, and 0.10 < Sn / (Ni + Fe) < 5.00 in terms of atomic ratios. The yield ratio (YS / TS), which is calculated from the tensile strength (TS) and 0.2% offset yield strength (YS) when a tension test is performed in a direction parallel to the rolling direction, is over 90%.

Owner:MITSUBISHI MATERIALS CORP +1

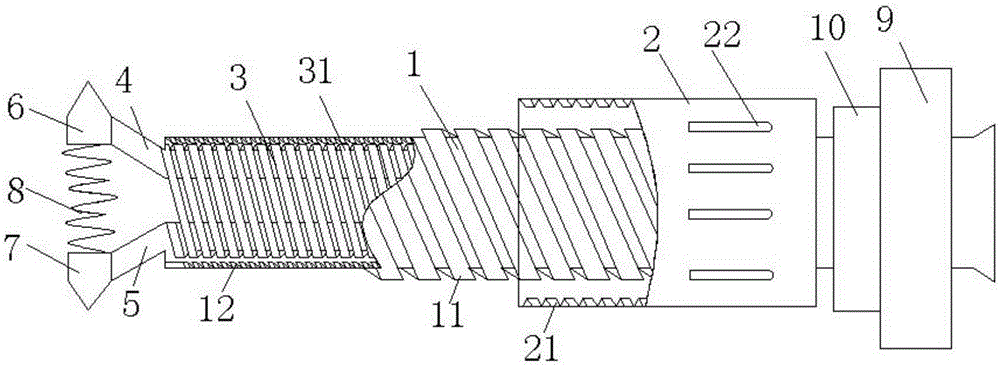

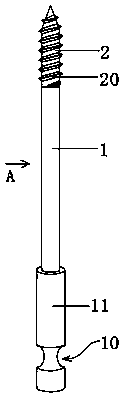

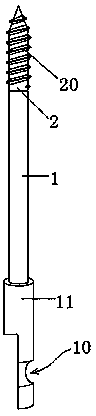

Fracture reduction lifting needle

InactiveCN103908327AImprove sharpnessShorten operation timeSurgeryFracture reductionPullout strength

The invention discloses a fracture reduction lifting needle which comprises a needle bar with a tip. The needle bar is provided with a clamping portion, an insertion hole which is matched with the tail of the needle bar is formed in one end of the clamping portion, a handle is arranged at the other end of the clamping portion, threads are arranged at the end, where the tip is arranged, of the needle bar, buckles are arranged in the insertion hole, and a clamp groove which is matched with the buckles is formed in the tail of the needle bar. The cross section of the tip is triangular. The clamping portion comprises a core bar and a sleeve, the insertion hole is formed in the core bar, the sleeve sleeves the core bar, at least two through holes which are perpendicular to the insertion hole are formed in the middle of the core bar, and the buckles are collision beads which are inlaid in the through holes. The fracture reduction lifting needle has the advantages that the tip is prismatic, is high in sharpness and can be driven into the femoral cortical bone of a patient easily, and accordingly the operation time can be saved; a needle head is provided with the threads, so that the fracture reduction lifting needle is high in pullout strength, and is not easy to loosen or fall off during reduction operation.

Owner:闫军

Copper alloy for electrical and electronic equipment, copper alloy thin sheet for electrical and electronic equipment, and conductive part and terminal for electrical and electronic equipment

ActiveCN104822854AReliable and sufficiently excellent stress relaxation resistanceHigh strengthSingle bars/rods/wires/strips conductorsConductive materialOxygenImpurity

The present invention pertains to a copper alloy for electrical and electronic equipment, a copper alloy thin sheet for electrical and electronic equipment, and a conductive part and terminal for electrical and electronic equipment. The copper alloy for electrical and electronic equipment contains more than 2.0 mass% but less than 23.0 mass% of zinc, 0.10 mass% to 0.90 mass% of tin, 0.05 mass% to less than 1.00 mass% of nickel, 0.001 mass% to less than 0.100 mass% of iron, and 0.005 mass% to 0.100 mass% of phosphorus, with the remainder comprising copper and unavoidable impurities. The copper alloy satisfies 0.002 ≤ Fe / Ni < 1.500, 3.0 < (Ni + Fe) / P < 100.0, and 0.10 < Sn / (Ni + Fe) < 5.00 in terms of atomic ratios. The content of hydrogen is not more than 10 mass ppm, the content of oxygen is not more than 100 mass ppm, the content of sulfur is not more than 50 mass ppm, and the content of carbon is not more than 10 mass ppm.

Owner:MITSUBISHI MATERIALS CORP +1

Automatic winding machine

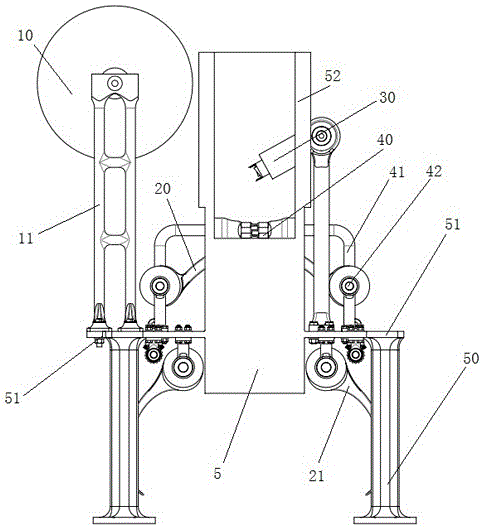

ActiveCN109534047ACoil tightlyNot easy to relaxArticle deliveryWebs handlingWinding machineEngineering

The invention relates to an automatic winding machine. The automatic winding machine comprises a support frame, a first shaft rod, a diaphragm, a winding module and a cutting module; the first shaft rod is rotationally mounted on the support frame; the diaphragm is wound on the first shaft rod; the winding module comprises a winding cylinder and a second shaft rod; the winding cylinder is mountedon the support frame; the second shaft rod is detachably connected to the winding cylinder; a free end of the diaphragm is wound on the second shaft rod; an elastic pressing body is arranged on the support frame; the diaphragm is pressed on the first shaft rod through the elastic pressing body; the cutting module comprises a bearing table, a cutter and a cutting cylinder; and the bearing table isprojected on the support frame. The automatic winding machine can wind the diaphragm more tightly.

Owner:四川佰纳川超声波设备有限公司

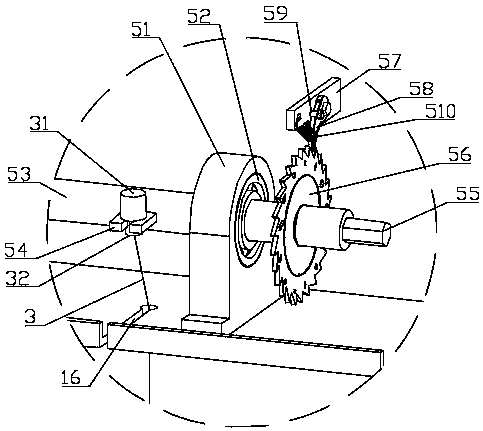

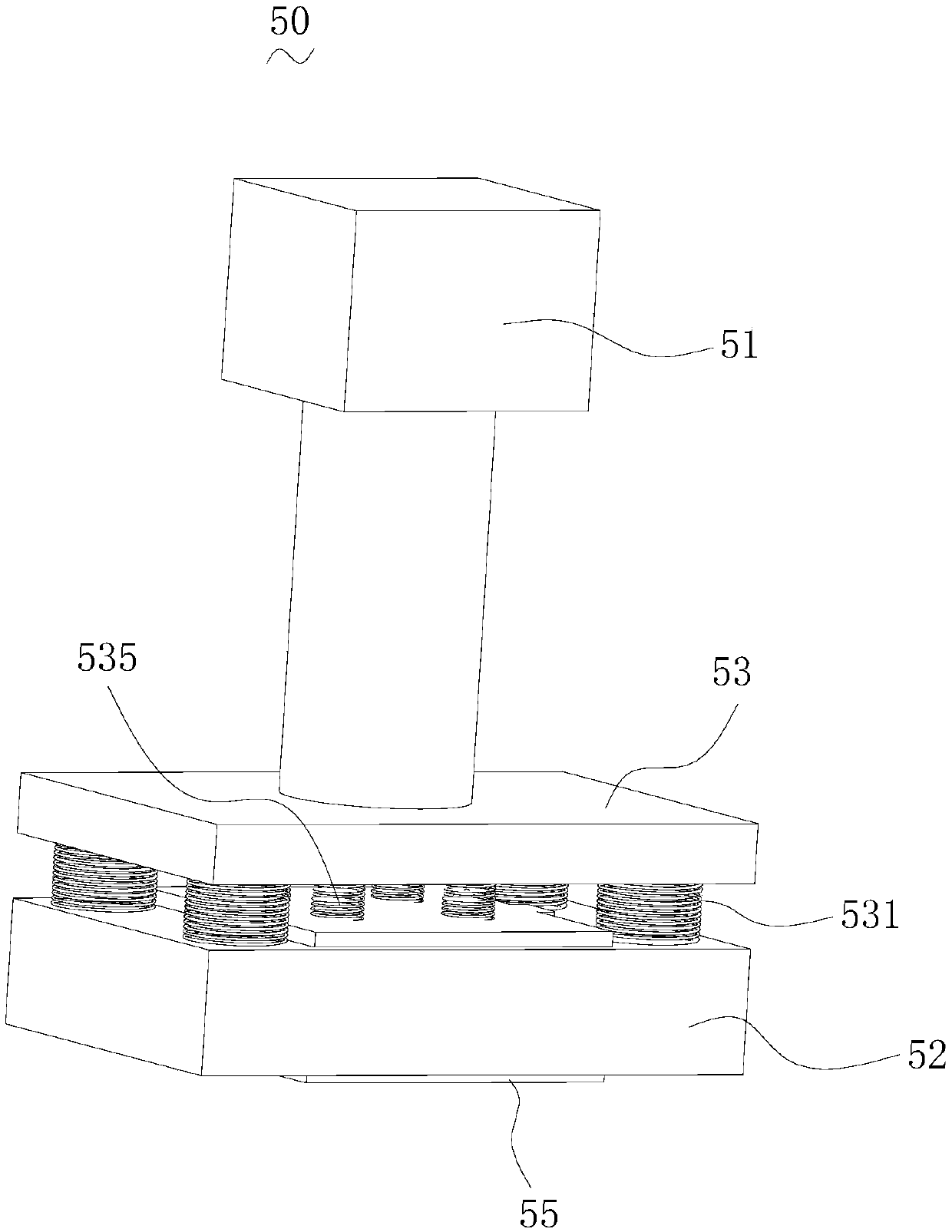

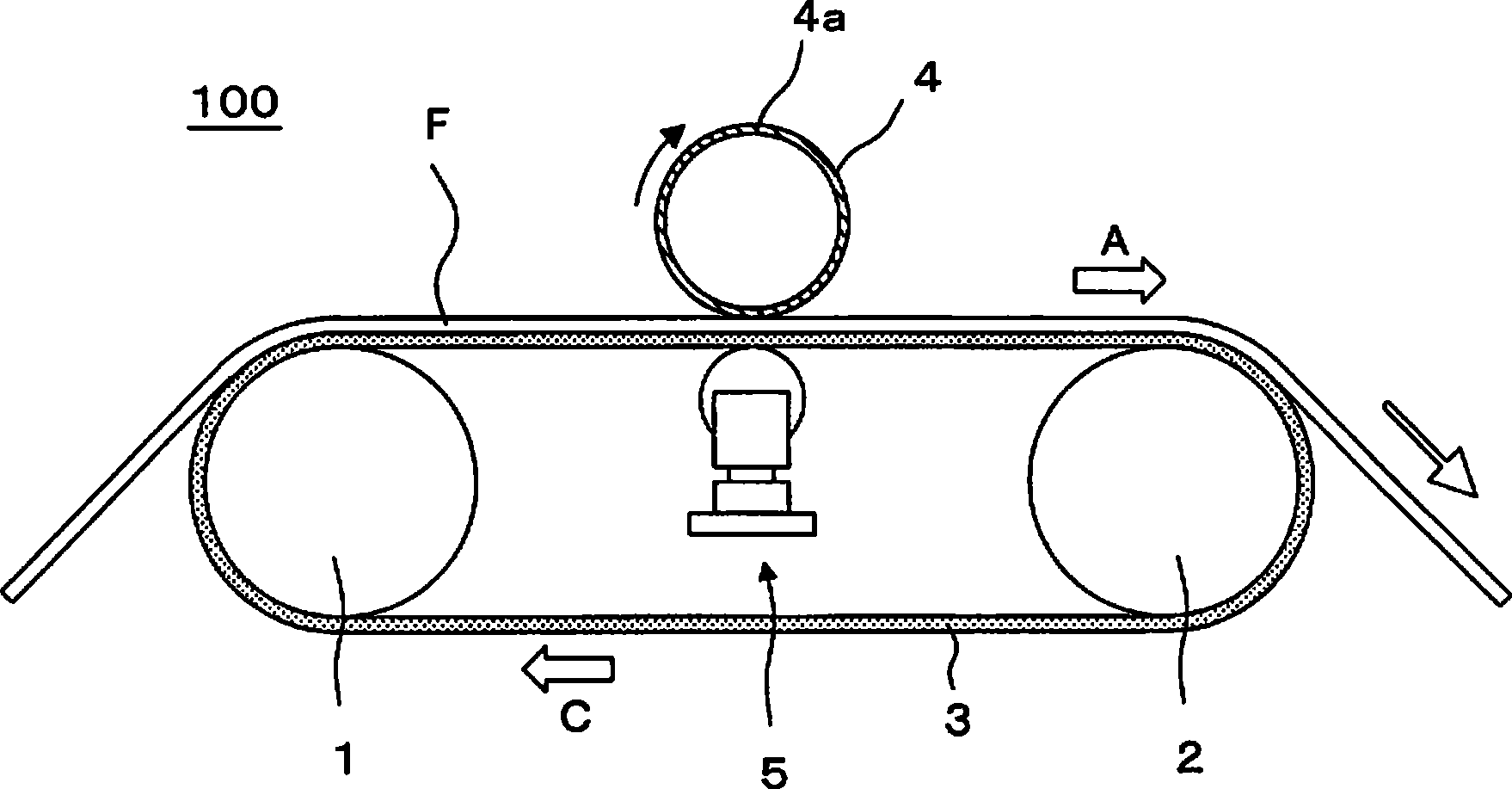

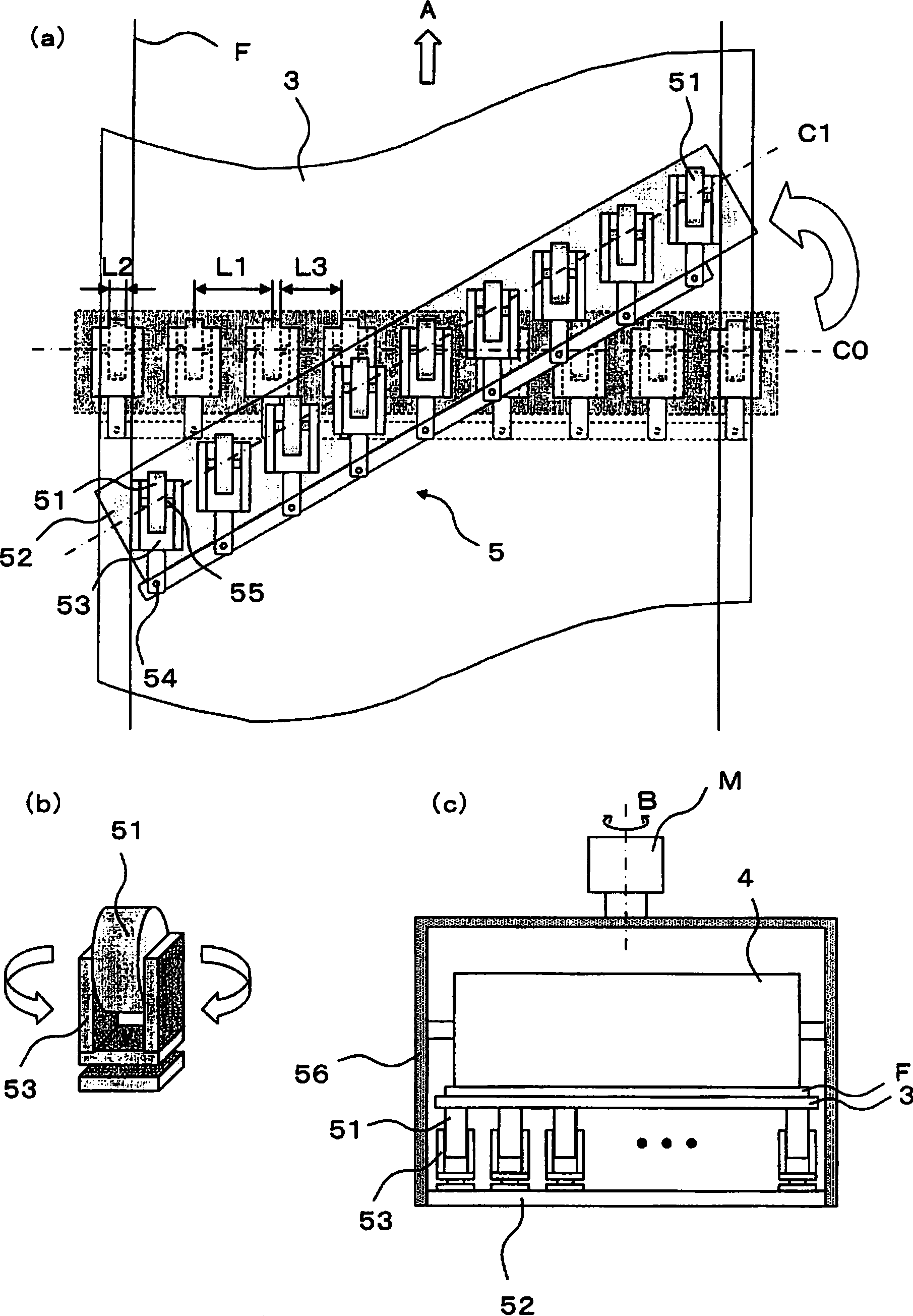

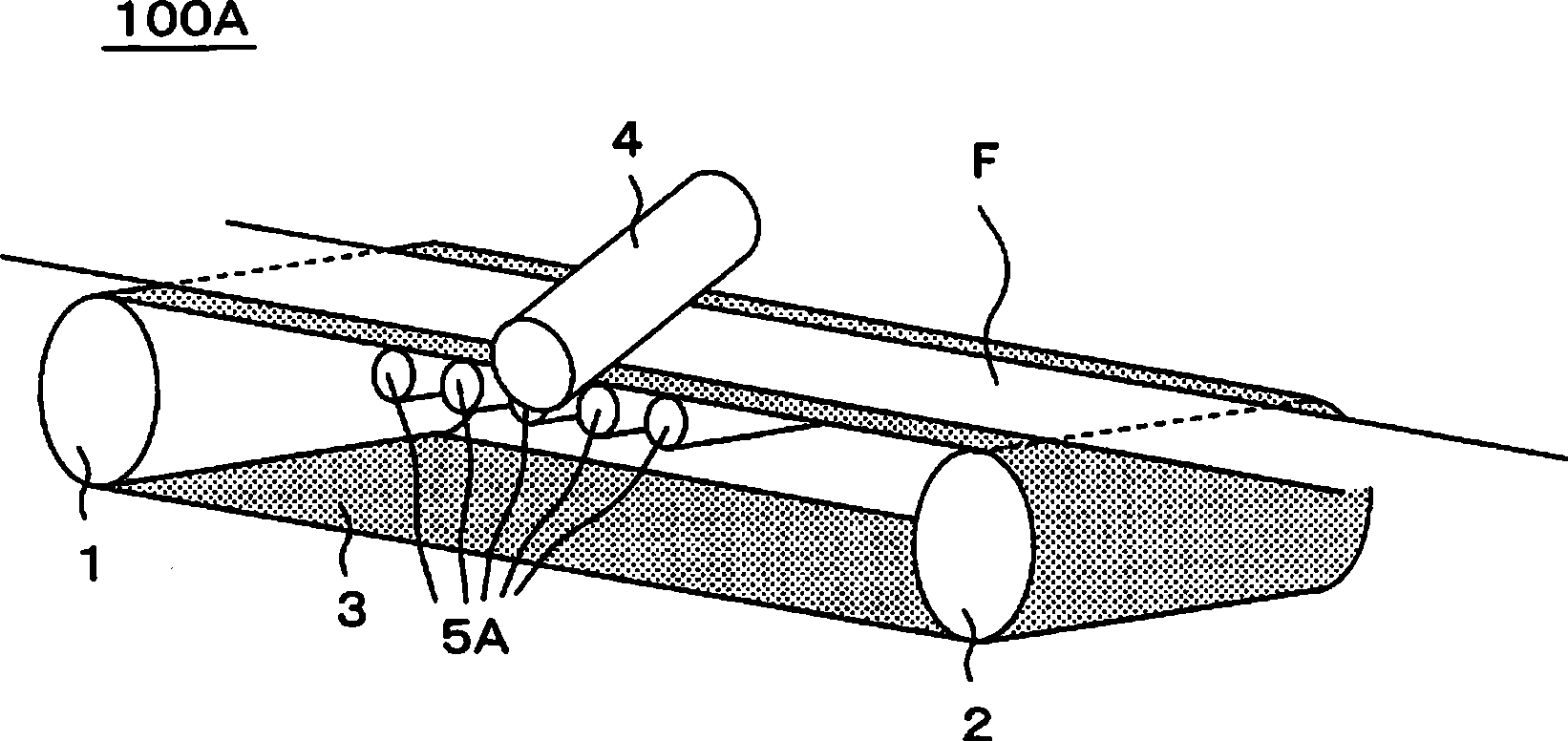

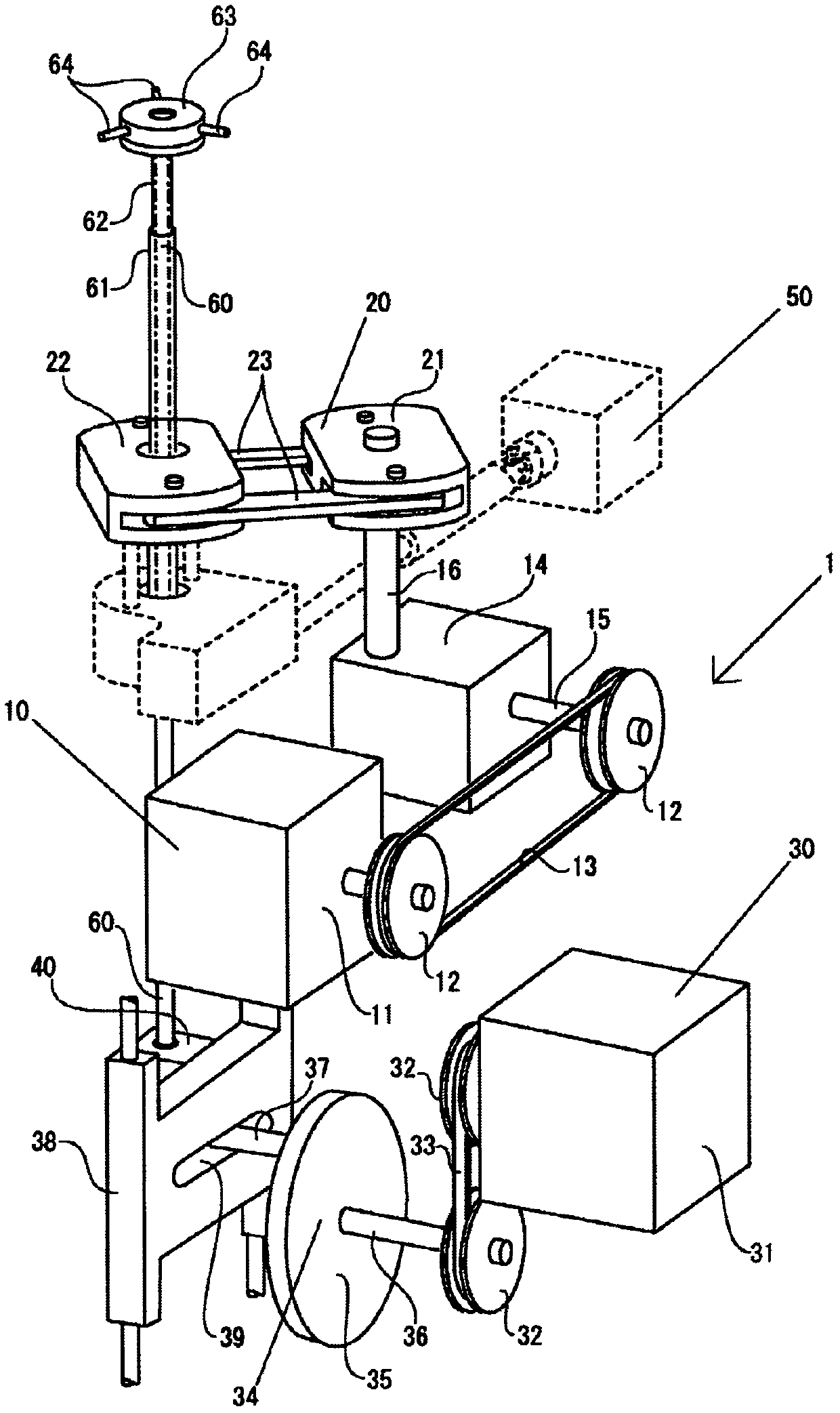

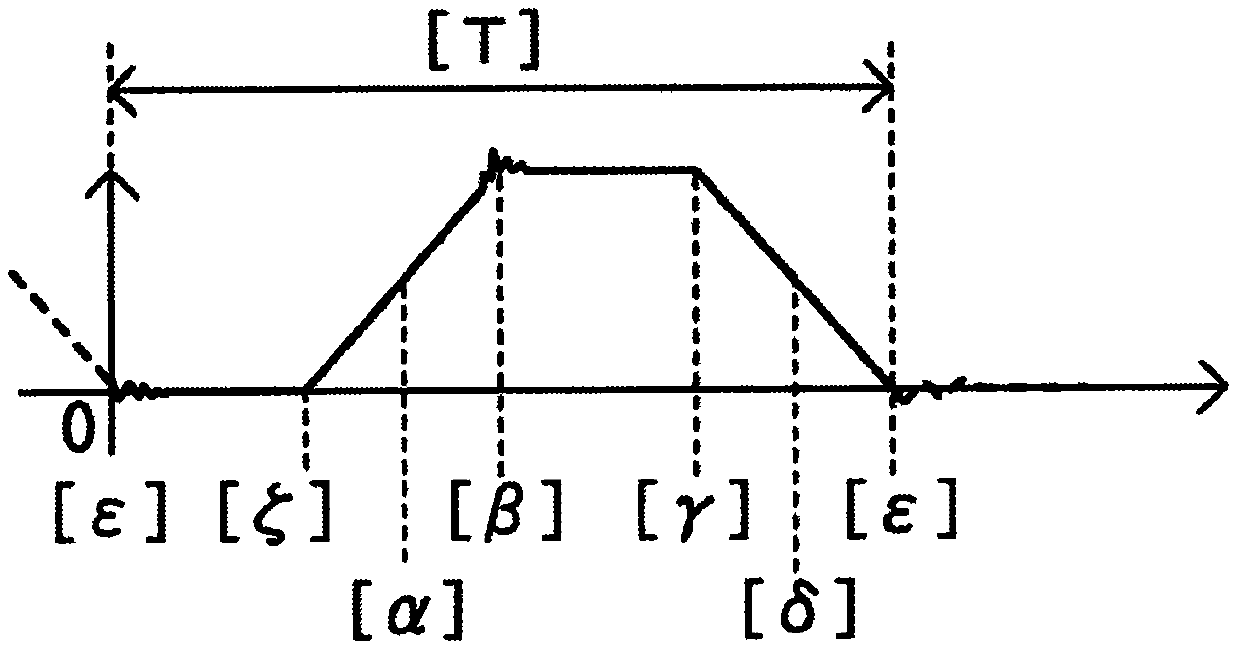

Manufacturing method of optical film

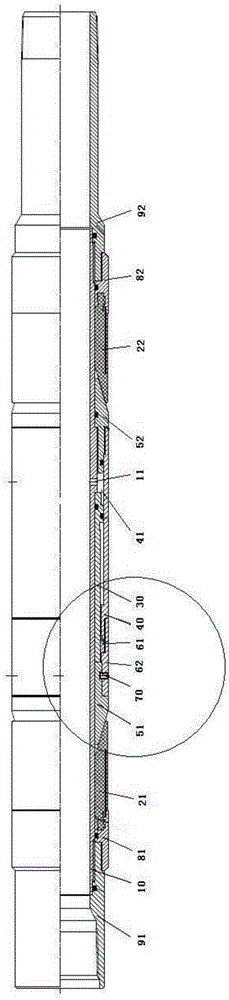

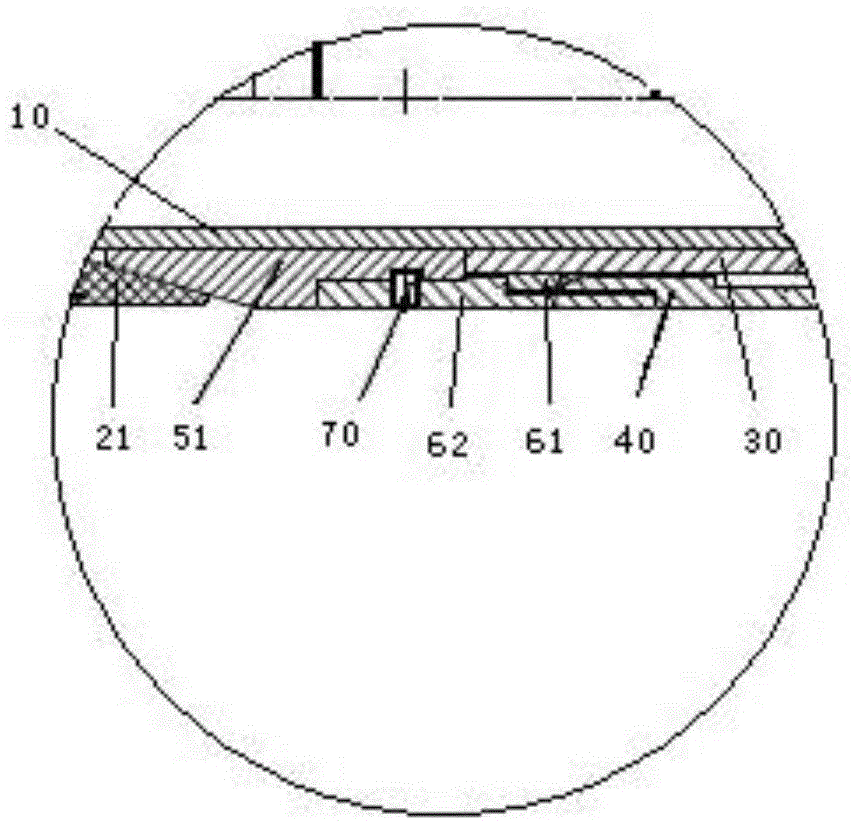

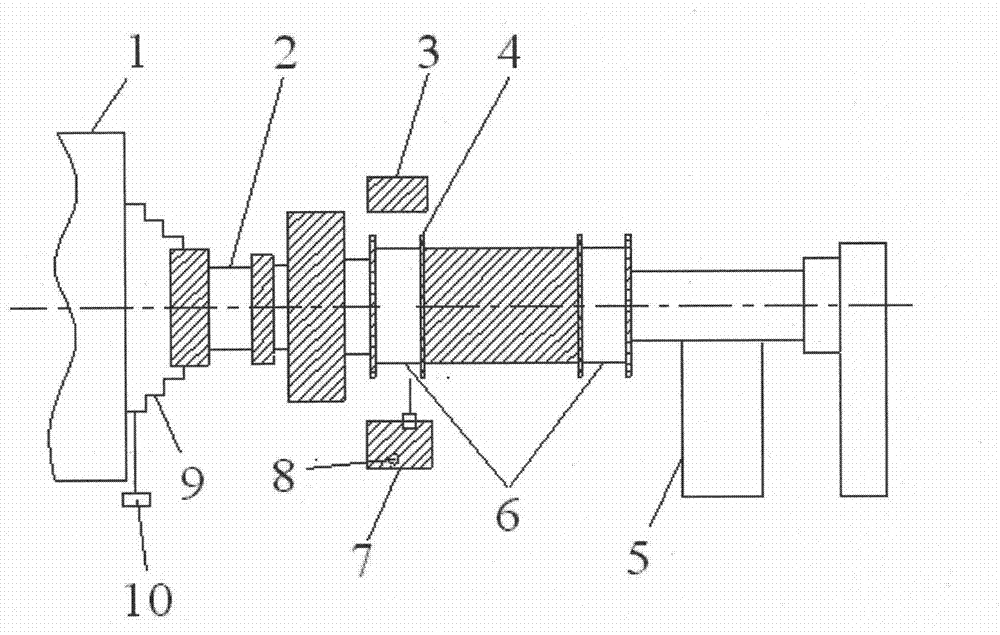

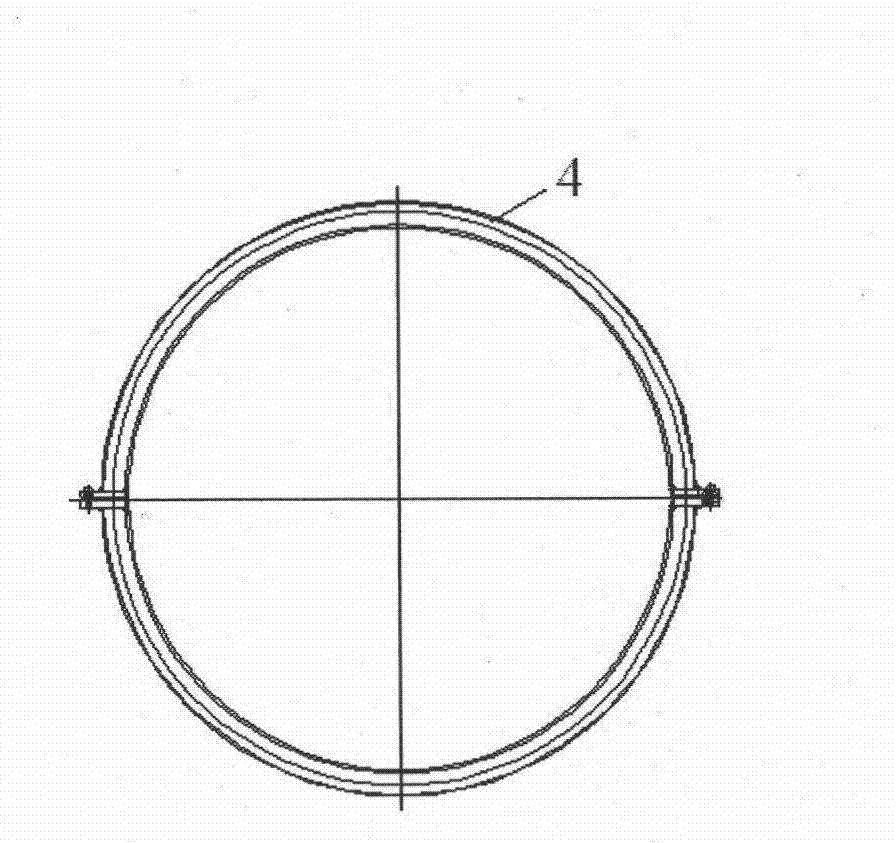

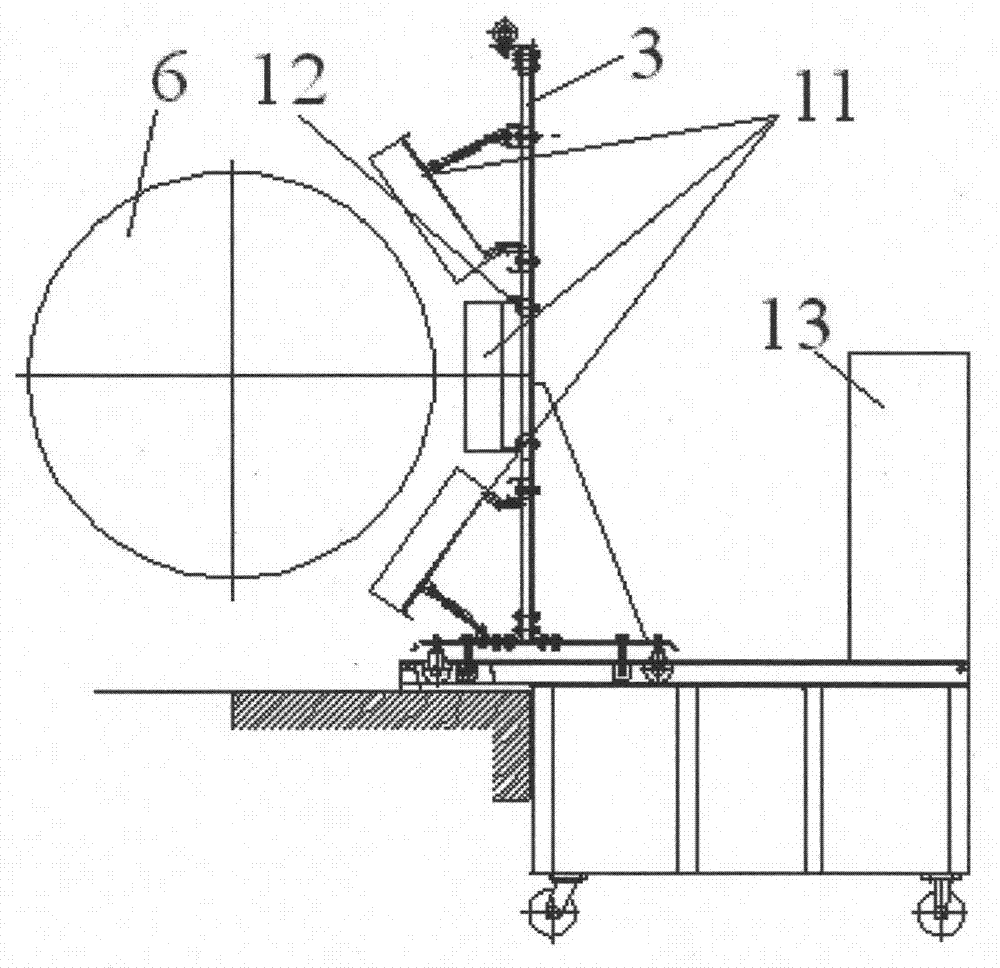

InactiveCN101460874ANot easy to relaxUniform optical propertiesPolarising elementsNon-linear opticsLiquid crystallinePlastic film

A method of manufacturing an optical film has a rubbing step for rubbing the surface of a long plastic film (F) by a rubbing roll (4) around which a napped fabric is wound, an application step for applying liquid crystalline molecules to the surface of the film having passed the rubbing step, and a fixation step for fixing the applied liquid crystalline molecules. The rubbing step has a backup roll mechanism (5) for supporting and conveying the film by the use of a conveyor belt (3) that has a metal surface and supporting the lower surface of the conveyor belt. The backup roll mechanism has backup rolls (51) individually rotated in the moving direction of the conveyor belt. The backup rolls are disposed immediately beneath the rubbing roll, along a straight line substantially in parallel with the rotating axis of the rubbing roll.

Owner:NITTO DENKO CORP

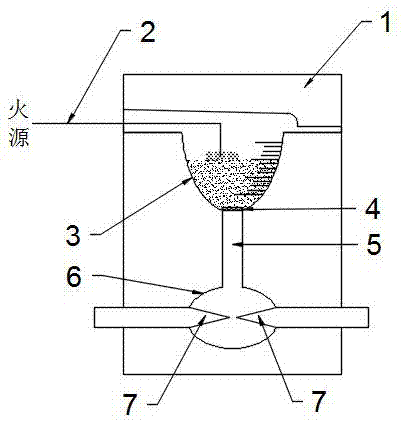

Heat-released welding method of ground lead in Amazon rainforest

ActiveCN107322157AHot melt welding operation safetyEfficient fusion welding operationAlumino-thermic welding apparatusExothermic weldingCotton gauze

The invention relates to a heat-released welding method of a ground lead in the Amazon rainforest. The heat-released welding method comprises the following steps that to-be-welded heads at the butt joint positions of the ground lead are peeled into a cone with the conical angle being alpha through an arc peeling pincer; the to-be-welded heads of the ground lead are bundled up through an iron wire to be dried; cotton gauze is used for wiping the to-be-welded heads until an oxide layer is removed and metallic luster is completely exposed out; the to-be-welded heads are placed into a die welding chamber to enable a to-be-formed welding head to right face an outlet in the center of a die flow guide groove; a die and the to-be-welded heads are heated; the whole die is heated after the die is closed; a supporting sheet of the die is placed at the bottom of a heat melting chamber; an appropriate amount of welding powder is poured into the heat melting chamber with scale marks, a small amount of pyrophoric powder is scattered, one end of an igniting cable is inserted into the pyrophoric powder, the other end of the igniting cable is led out of the die, and the part, out of the die, of the igniting cable is ignited after a die cover is buckled; and cooling is carried out for 30 s to 50 s after welding is completed, the die is opened, the welding head is taken out to be cleaned and inspected, and antiseptic paint is sprayed to the welding head after the welding head is qualified.

Owner:POWERCHINA SEPCO1 ELECTRIC POWER CONSTR CO LTD

A kind of slotting machine for battery packs

ActiveCN103326058BGood effectNot easy to relaxFinal product manufactureSecondary cells manufactureState of artMembrane configuration

The invention discloses a battery wrapping slotting machine, which relates to the field of storage battery production and solves the technical problem that the efficiency of the wrapping slotting machine in the prior art is too low. The wrapping slotting machine provided by the invention includes a feeding device, a film feeding device, casting and welding jig, and a sliding seat that drives the casting and welding jig to move laterally. The film feeding device includes a film support plate, a film cutting component arranged above the film support plate, and a film taking part that can move laterally. The film support plate is provided with a film There is a clipping rack above the coating port and an avoidance groove for avoiding the lateral movement of the film parts on the clipping frame. A casting and welding fixture is set directly below the coating port. The feeding device includes a pole group that can be transferred to the clipping The clamping arm of the rack and the push rod that pushes the pole group in the clamping rack into the casting and welding fixture along the coating opening; through this device, the automatic coating and slotting are completed, and the transfer of the pole group and coating into the slot The process is completed by different parts, which can make full use of time and improve work efficiency.

Owner:湖州海悦智能科技有限公司

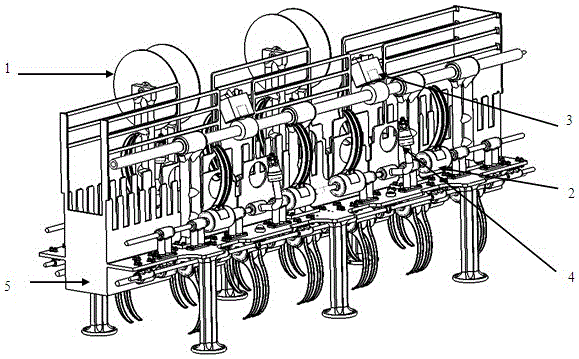

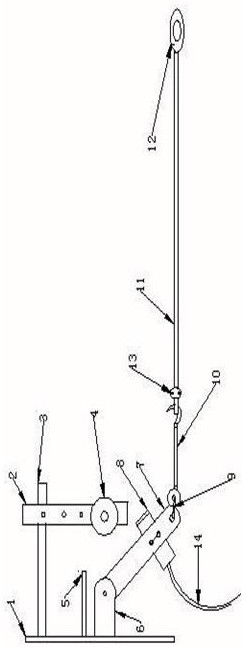

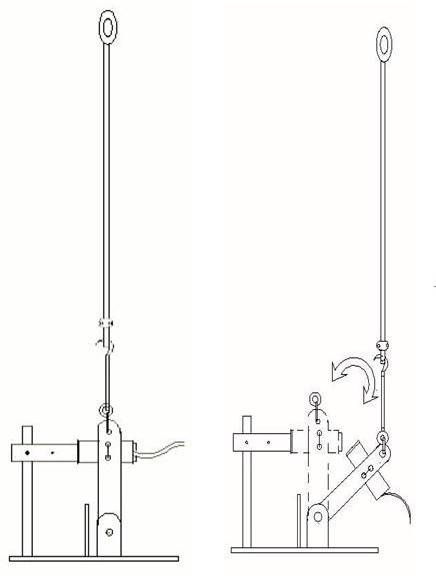

Inegration type bundling device for Jujun grass and bundling method thereof

The invention relates to an integration type bundling device for Jujun grass and a bundling method thereof. The device comprises supporting vertical seats, wherein a bottom-and-top through straw box is arranged on the supporting vertical seats; two sides of the central part of the straw box extend outward and are each provided with a supporting side plate used for supporting mechanisms; the upper and lower parts of two supporting side plates of the straw box are respectively provided with a plurality of first slots and second slots which are used for passing of compression claws and supporting claws of a compression supporting mechanism; more than one through-hole used for passing of a rope-clamping body in a knotting mechanism are arranged between the first slots at intervals; and the upper sides of the two supporting side plates are also symmetrically fixedly provided with knotting mechanisms. Meanwhile, the device also comprises a rope conveying mechanism and a cutting-clamping mechanism, wherein the rope conveying mechanism is fixedly arranged on the upper side of the supporting side plate located at one side of a side plate of the straw box; and the cutting-clamping mechanism is fixedly arranged on the upper side of the supporting side plate located at the other side of the side plate of the straw box in lateral separation. The invention has the following beneficial effects: the device is simple and compact in structure, is stable and reliable to operate, has good working efficiency and sustainability, and has greatly-improved bundling efficiency.

Owner:FUJIAN AGRI & FORESTRY UNIV

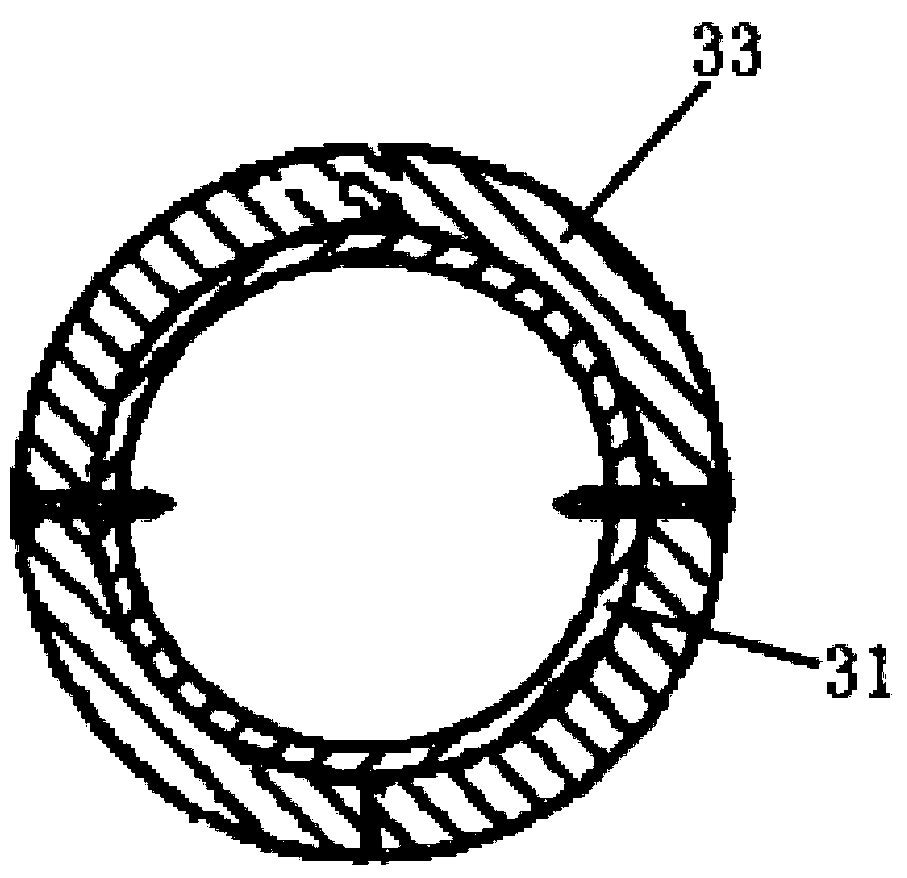

Packer

The invention provides a packer. The packer comprises a central pipe, a first packer element, a second packer element, a first packer element pushing part, a second packer element pushing part and a sleeve, wherein the first packer element and the second packer element are axially fixed on the outer wall of the central pipe at an interval; the first packer element pushing part is mounted on the central pipe in a sleeving manner and is in butted connection with the first packer element; the second packer element pushing part is mounted on the central pipe in a sleeving manner and is in butted connection with the second packer element; the sleeve is mounted on the outer side of the central pipe in a sleeving manner and located between the first packer element and the second packer element, and a sealed driving cavity is formed among the first packer element pushing part, the second packer element pushing part and the sleeve; an overflowing hole for communicating a central inner cavity and the driving cavity is formed in the central pipe. When the packer is in operation, the first packer element and the second packer element expand simultaneously under the action of hydraulic pressure of the driving cavity, two seal points are formed between the packer and the inner wall of a to-be-sealed pipe, the expansion ratio of the packer elements is high, and the packer elements are not prone to loosening; the packer has the bidirectional pressure-bearing capacity, can be better suitable for the irregular open hole wall and has a sealing effect more reliably.

Owner:PETROCHINA CO LTD

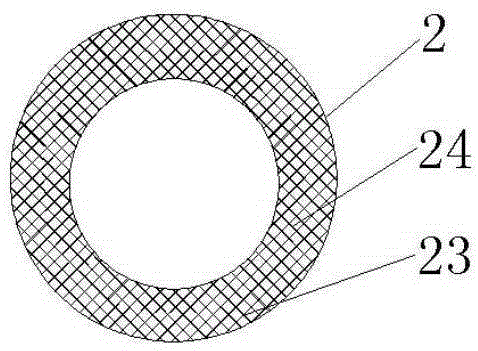

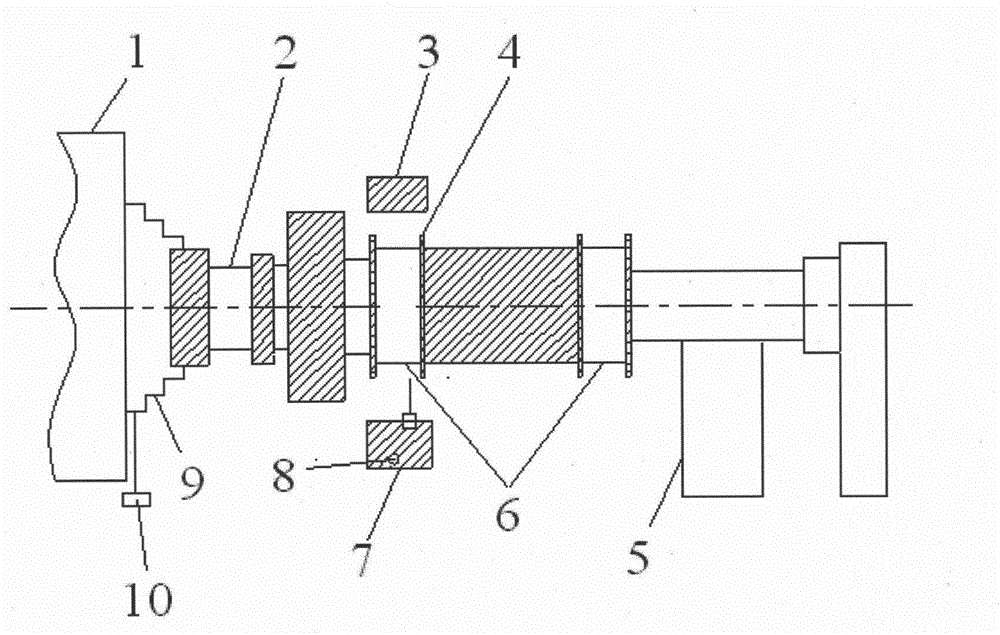

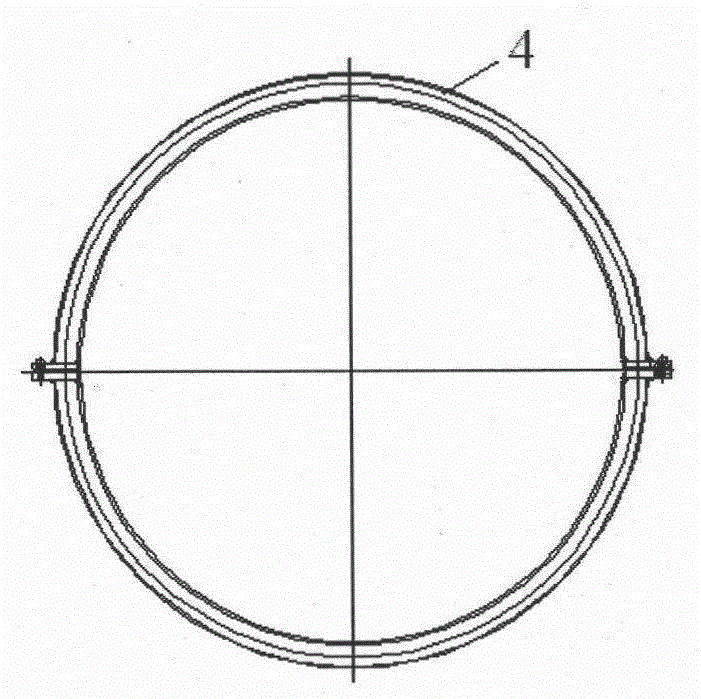

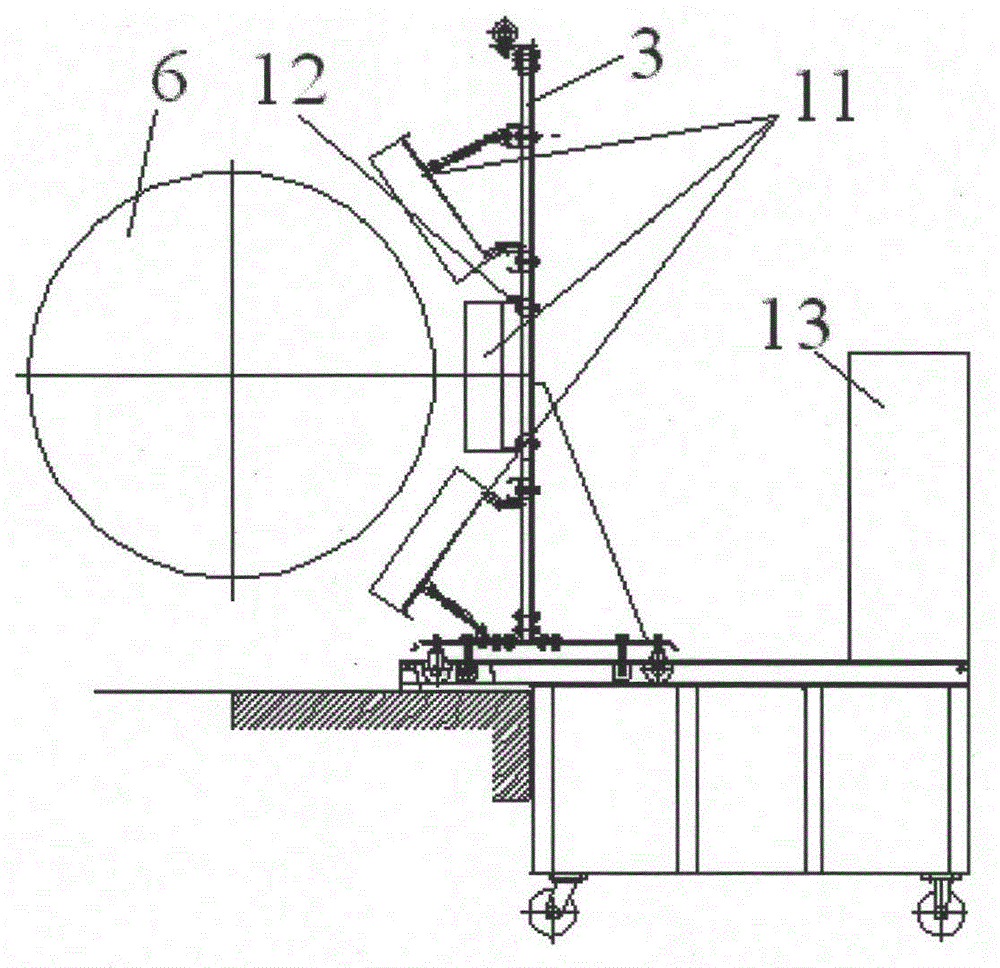

Method for arranging non-weft band hoop on end portion of armature of brushless exciter

ActiveCN103036373AIncrease the heating areaImprove adhesionWindingsManufacturing dynamo-electric machinesEngineeringMachine tool

The invention provides a method for arranging a non-weft band hoop on the end portion of an armature of a brushless exciter. The method for arranging the non-weft band hoop on the end portion of the armature of the brushless exciter is characterized by comprising the steps that a rotating shaft is hung on a hoop arranging machine tool firstly, and hoop arranging tools are arranged in place; then a non-weft band is heated through a heating device, a tensioning device is started, and a counting device records the number of arranged hoops; and at last, after curing of the non-weft band hoop, the outer diameter of the non-weft band hoop can be controlled by strengthening or releasing curing shrinkage to meet requirements. The method for arranging the non-weft band hoop on the end portion of the armature of the brushless exciter overcomes the defects existing in the prior art, and can effectively improve the quality of the arrangement of the non-weft band hoop on the end portion of the armature of the brushless exciter. Moreover, after the curing, the non-weft band hoop is attractive and tidy.

Owner:SHANGHAI ELECTRIC POWER GENERATION EQUIPMENT CO LTD

Preparation method of special-shaped section wire titanium alloy spring

The invention relates to a preparation method of a titanium alloy spring made of a wire with a specially-shaped section and belongs to the technical field of springs. The spring is formed by winding of the titanium alloy wire with the specially-shaped section; the titanium alloy wire comprises the components in percentage by mass as follows: 2-4 of Al, 6-10 of V, 4-8 of Cr, 2-6 of Mo, 2-6 of Zr, 0.1-0.3 of Fe, 0.03-0.15 of Si and the balance of Ti. The section of the titanium alloy spring wire can be rectangular, square, orthohexagonal or oval. The titanium alloy wire wound into the spring is prepared with forging, pressing and hot rolling technologies, the wire is subjected to solution treatment before being wound into the spring, and a finished product of the spring is subjected to aging and strengthening treatment. A titanium alloy which is used for preparing the spring can play a weight reduction role, and meanwhile, the titanium alloy has the good corrosion resistance and the long fatigue life in an ocean environment. With the adoption of the wire with the specially-shaped section, the section area can be increased under the condition that specifications of wires are similar, so that the rigidity of the spring is improved, and the usage requirement of the titanium alloy spring under the high workload can be met.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

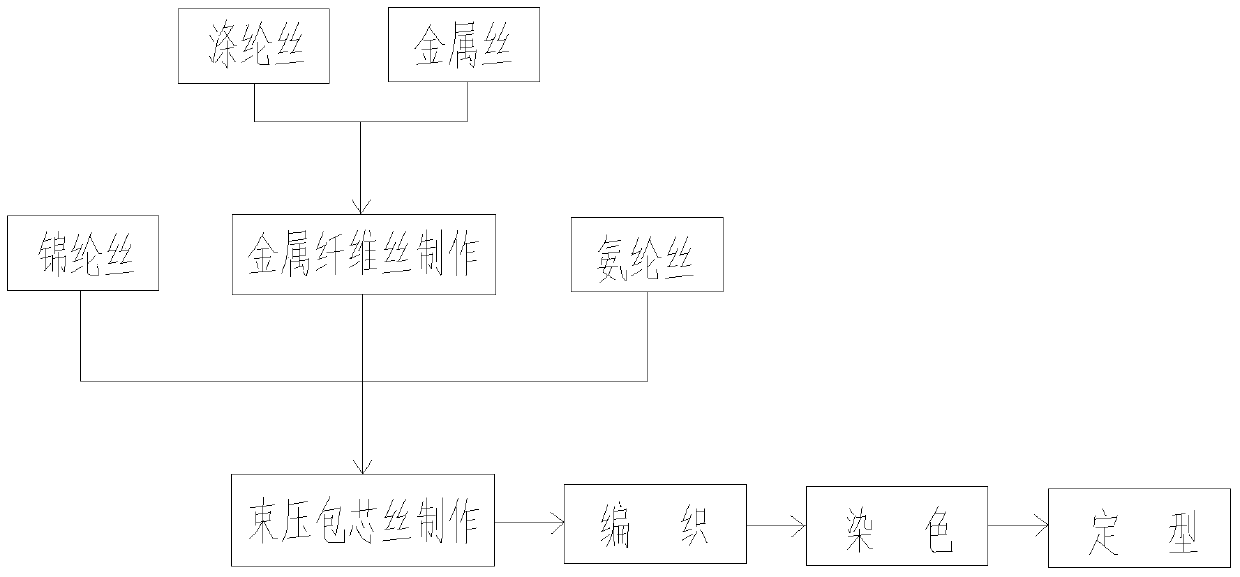

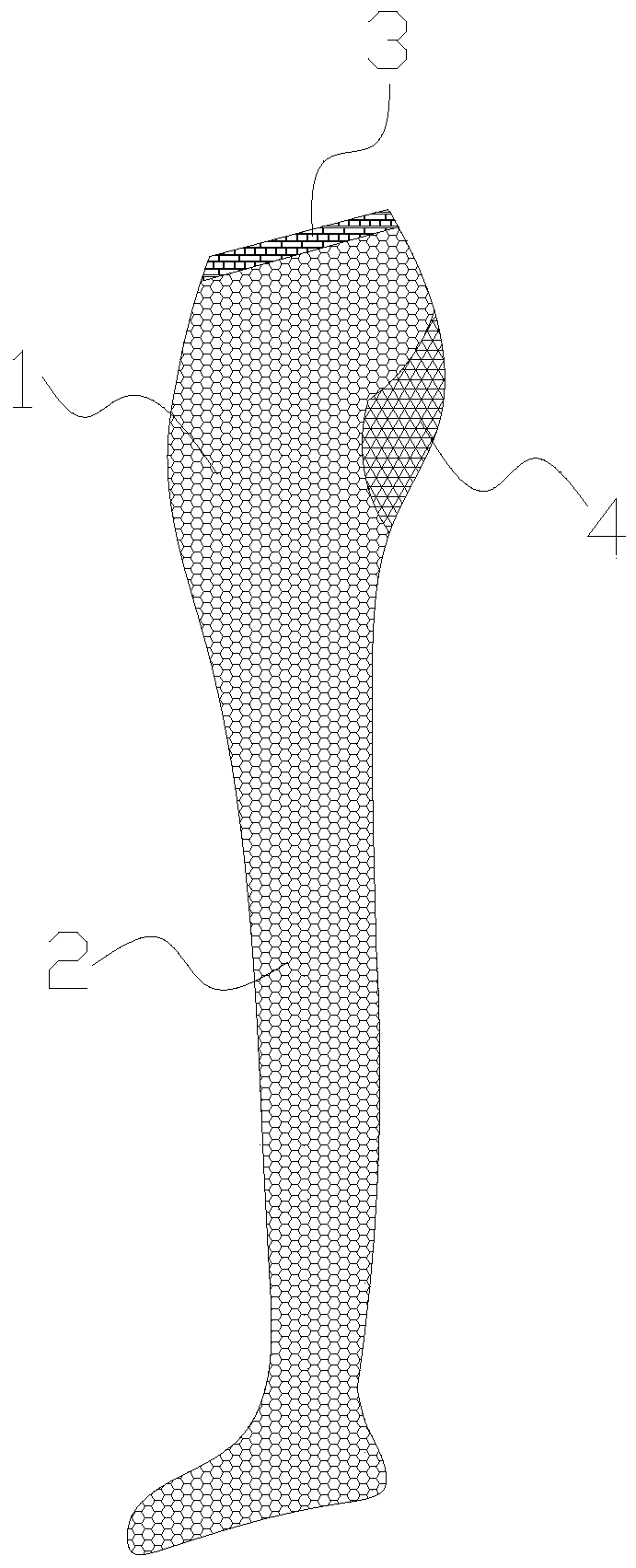

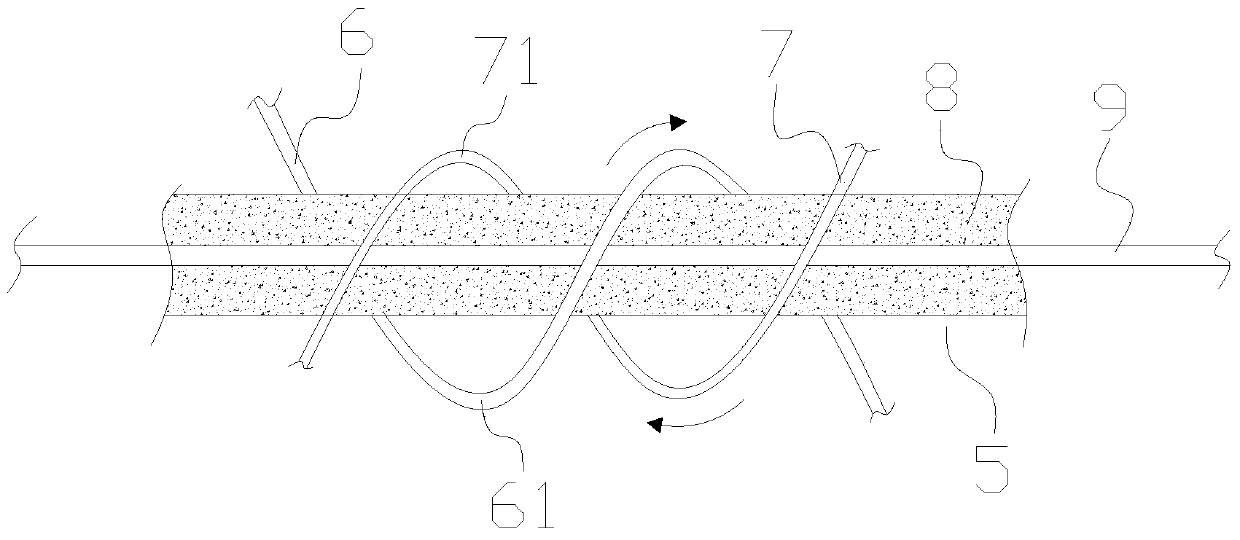

A kind of knitting process of steel wire pantyhose

ActiveCN105586702BNot easy to slipGood butt lifting and shaping effectSucessive textile treatmentsWeft knittingThighYarn

The invention discloses a knitting technology for a steel wire panty-hose. The panty-hose comprises a pants body which is integrally knitted corresponding to a human waist-hip part, and a hose body corresponding to a human leg-foot part. The pants body is provided with a high-elastic compaction portion on the position corresponding to the low hip of a human hip. The high-elastic compaction portion is from the joining position of thighs and the hip, and ends at the highest point of hip bulge. The high-elastic compaction portion is spun on the inner surface of the pants body. Chinlon and wrap yarns are used to knit 1x1 eyelet stitch for the integrated panty-hose. The high-elastic compaction portion is formed by metal fibers used as inner yarns, and nylon yarns and spandwx which are used as cladding yarns to wrap on the metal fibers. The nylon yarns and spandwx wrap on the metal fibers in positive and negative directions. The knitting technology comprises five steps of manufacturing metal fibers, manufacturing compaction core-spun silk, weaving, dyeing, and shaping. Since the steel wire panty-hose produced by the knitting technology is provided with the high-elastic compaction portion on the position corresponding to the human hip, the panty-hose has very good hip lifting effect.

Owner:浙江宝娜斯袜业有限公司

A mine hoist tail rope monitoring device

ActiveCN111847190BAvoid damageAccurate detection and monitoringElectric switchesElevatorsFailure rateEngineering

The invention relates to a mine hoist tail rope monitoring device, which is characterized in that the monitoring device includes a detection switch bracket, a magnetic control switch, a steel wire rope assembly and a double switch series switchable control circuit, the magnetic control switch, the steel wire rope assembly and The double-switch series switchable control circuits are all set on the detection switch bracket; this technical solution solves many defects in the above-mentioned traditional technology, reduces the failure rate, improves work efficiency, and reduces the difficulty of maintenance.

Owner:NANJING MEISHAN METALLURGY DEV

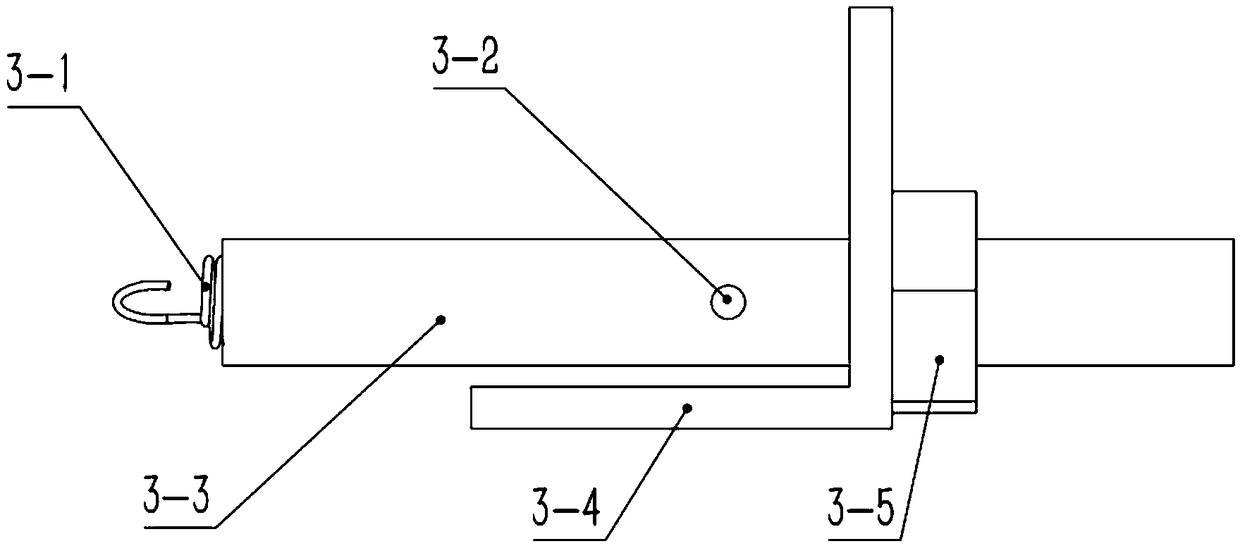

A wire electrode fixing device

ActiveCN107317222BReduce frictionAlleviate the problem of uneven tightness distributionCorona dischargeStatic frictionFriction force

The invention discloses a linear electrode fixing device. The linear electrode fixing device comprises a main body support frame, a resistance conversion module and an automatic stringing module, wherein the resistance conversion module is used for converting a static friction force generated by an electrode tightly attached onto a fixing frame at a corner to a sliding friction force between a pulley body and a bearing, the friction force between a linear electrode and the fixed frame is substantially reduced, and the problem that tightness of the linear electrode in the whole electrode fixing frame is not uniform in distribution is greatly solved; moreover, the resistance conversion module can slide in a sliding groove so as to adjust distance between lines, and the adaptability of electrode fixing frame is effectively improved; and by employing the automatic stringing module to apply a continuously-adjustable tension force onto a tail end of the linear electrode, the tightness of the linear electrode can be automatically adjusted, so that the linear electrode is difficult to loosen with time, and the discharge stability of the linear electrode is improved.

Owner:HUAZHONG UNIV OF SCI & TECH

Resin stirrer with stable lifting device

PendingCN113524477ARealize lifting operationImprove controllabilityMechanical engineeringComposite material

The invention discloses a resin stirrer with a stable lifting device. The resin stirrer comprises a main frame of the stirrer, a stirring shaft mechanism, a stirring barrel mechanism, a lifting mechanism and a rotating mechanism, wherein the stirring shaft mechanism is arranged on the main frame, and the stirring barrel mechanism is arranged on the side surface of the main frame; the stirring shaft mechanism is arranged on the lifting mechanism; the stirring barrel mechanism is arranged below the stirring shaft mechanism and on the rotating mechanism; and the stirring shaft mechanism is matched with the stirring barrel mechanism. According to the resin stirrer, the controllability is high, and the lifting action is smooth; the weight is light, the cost is low, looseness is not prone to occurring, the service life is long, and disassembly and maintenance are convenient; and multi-direction and multi-angle staggered stirring is achieved, stirring is sufficient, the period is short, and the effect is good.

Owner:TANGSHAN HEXIANG INDAL

Copper alloys for electrical and electronic equipment, copper alloy sheets for electrical and electronic equipment, conductive components and terminals for electrical and electronic equipment

ActiveCN104822854BRealize thin wallNot easy to relaxSingle bars/rods/wires/strips conductorsConductive materialMetallurgyImpurity

The present invention relates to a copper alloy for electrical and electronic equipment, a copper alloy sheet for electrical and electronic equipment, a conductive element and a terminal for electrical and electronic equipment. Zn from 0.10 mass % to 0.90 mass % Sn, 0.05 mass % to less than 1.00 mass % Ni, 0.001 mass % to less than 0.100 mass % Fe, 0.005 mass % to 0.100 mass % P , the rest is composed of Cu and unavoidable impurities, and in terms of atomic ratio, it satisfies 0.002≤Fe / Ni<1.500, 3.0<(Ni+Fe) / P<100.0, 0.10<Sn / (Ni+Fe)<5.0 , and the H content is 10 mass ppm or less, the O content is 100 mass ppm or less, the S content is 50 mass ppm or less, and the C content is 10 mass ppm or less.

Owner:MITSUBISHI MATERIALS CORP +1

Iodine polarizing film manufacturing method, polaroid manufacturing method and optical laminate manufacturing method

ActiveCN100437162CReduce wrinklesReduce tensionLayered productsPolarising elementsWrinkle skinPolyvinyl alcohol

The invention is aimed to provide a manufacturing method of polarizing film which hardly causes dyeing irregularity and permits the reduction of frequency of wrinkle generation and the reduction of tension during processes after dyeing, and to provide a polarizing plate and an optical laminate using the polarizing film. In the manufacturing method of polarizing film, uniaxial stretching is performed before and / or during a process of treating a polyvinyl alcohol base film in order of swelling, iodine dyeing and borating. Prior to the borating process, the iodine dyeing is performed in dyeing baths of two steps or more and, further, uniaxial stretching is performed in dyeing baths of two steps or more. Therein, the uniaxial stretching is performed in such a manner that (1) the stretching ratio in the initial dyeing bath is set to be higher than the sum stretching ratio in dyeing baths on and after the second step or (2) the stretching ratio in the last dyeing bath is set to be higher than the sum stretching ratio in the dyeing baths prior to the last dyeing bath.

Owner:SUMITOMO CHEM CO LTD

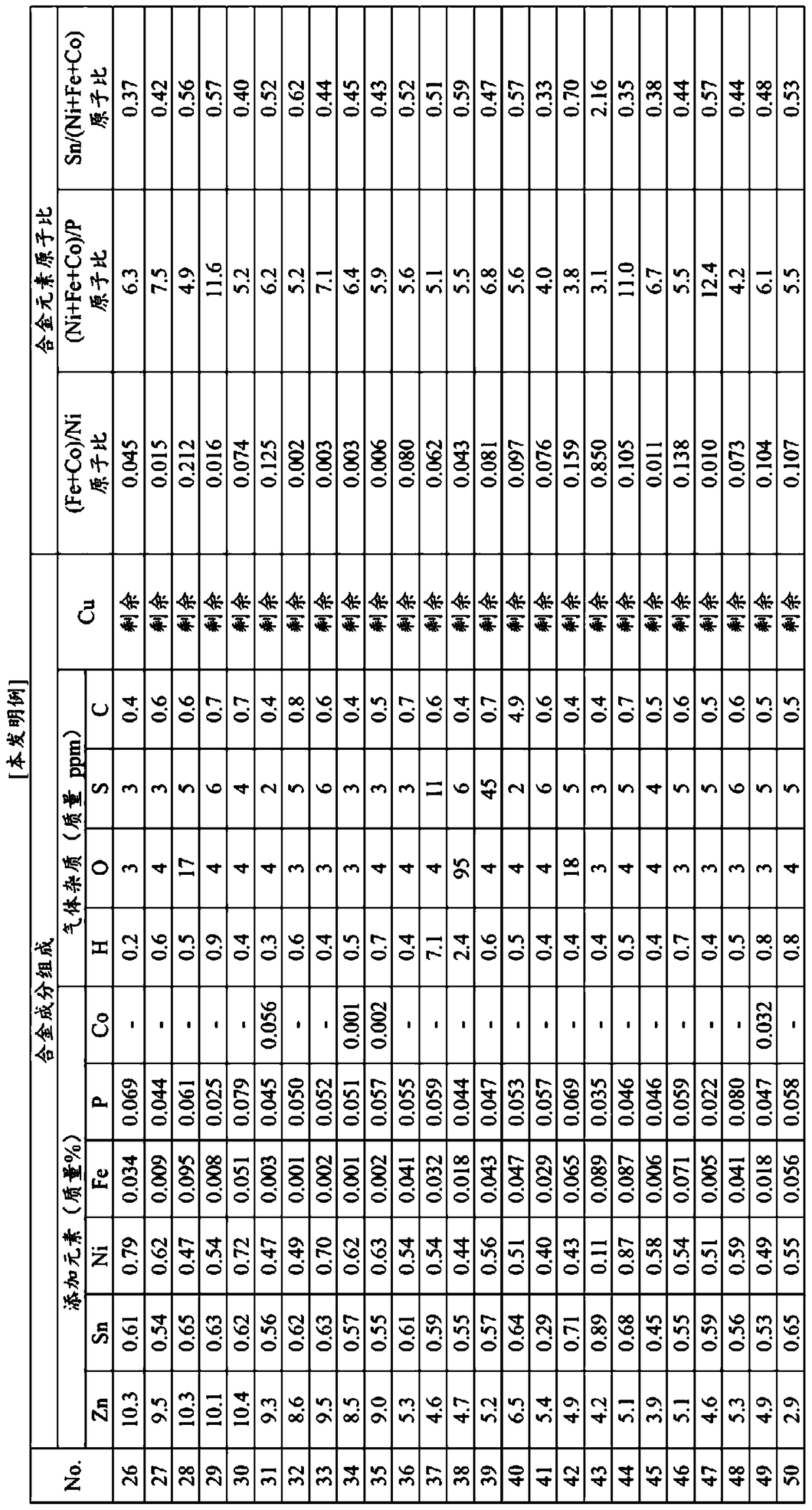

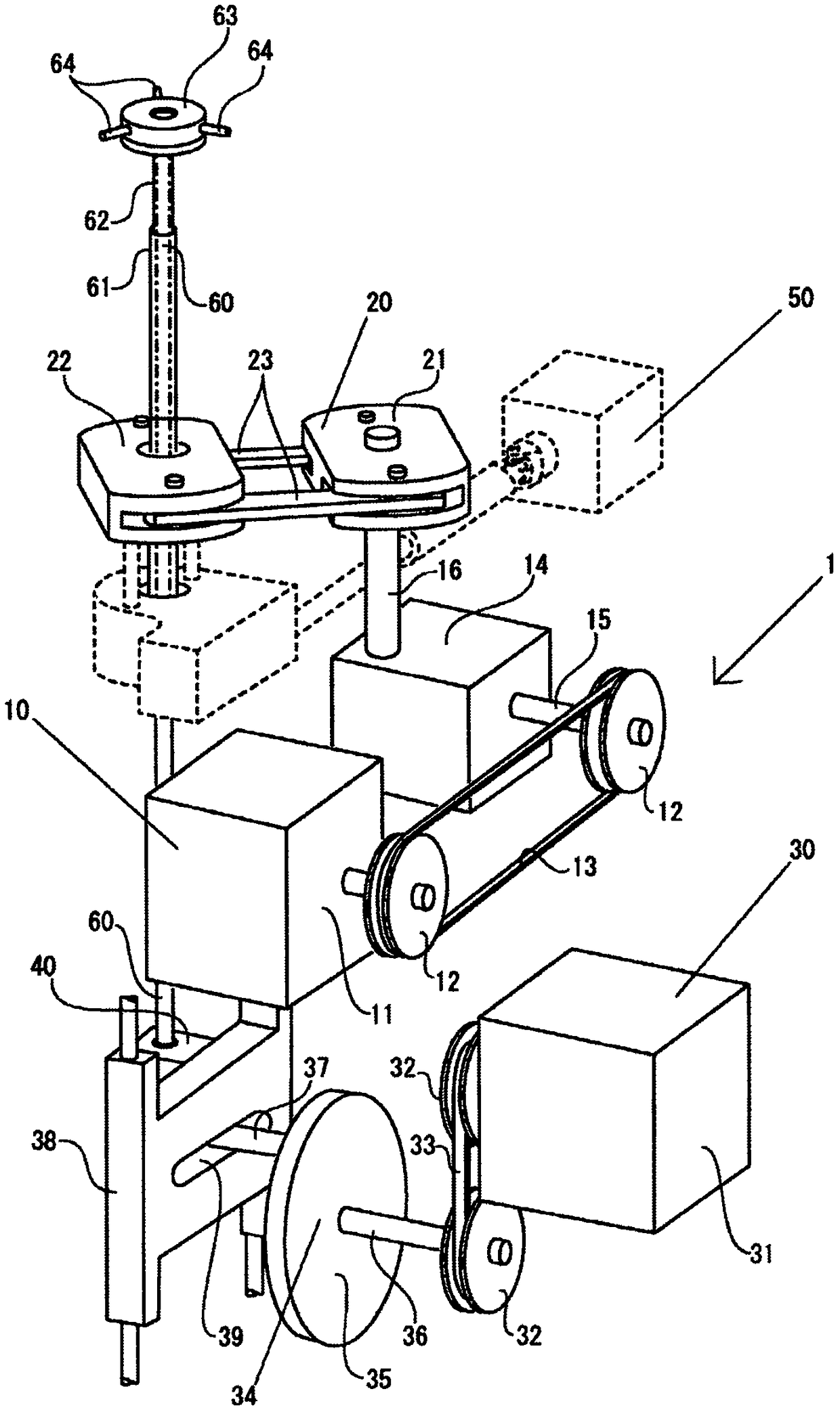

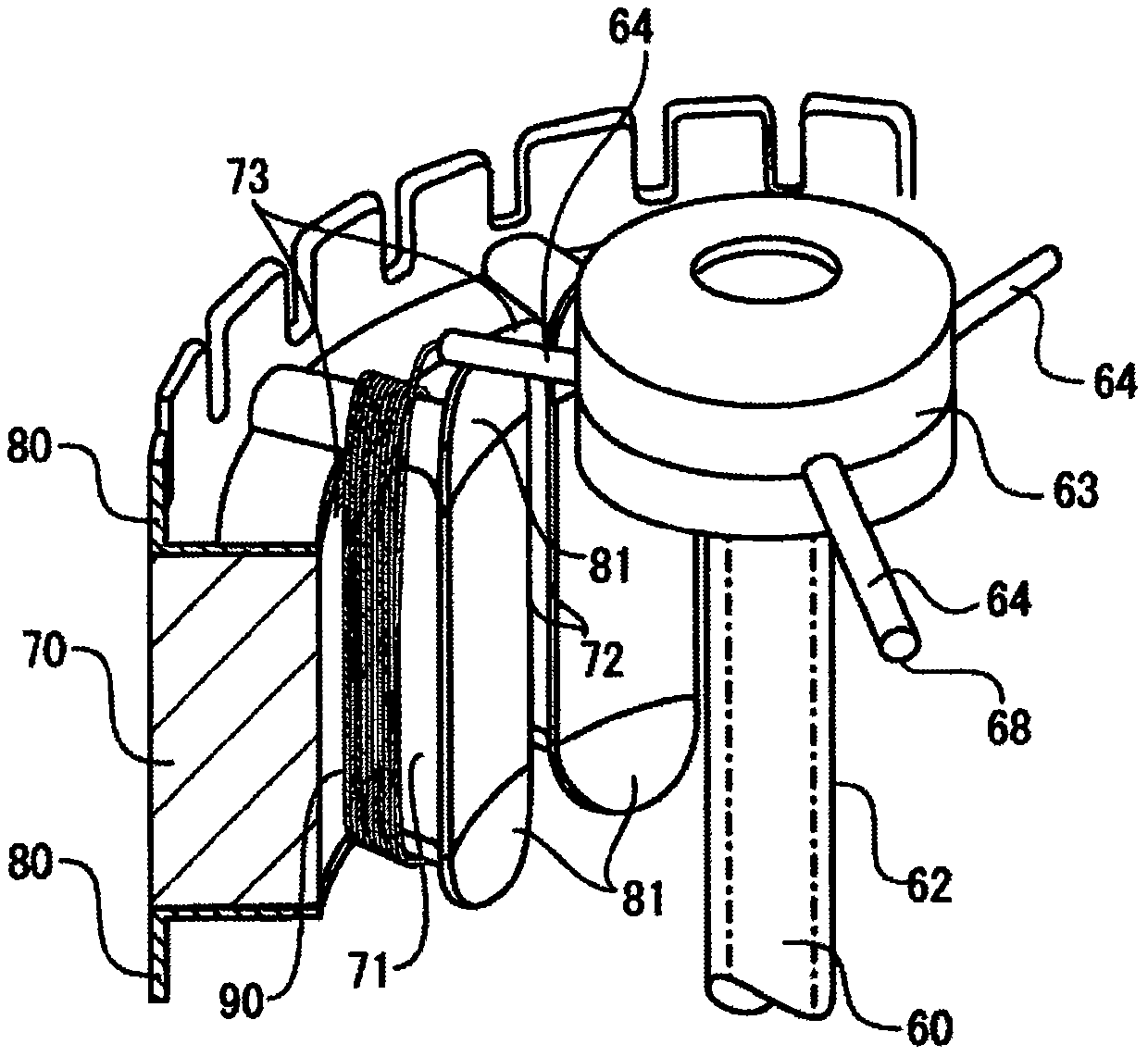

Needle circling means and winding machine

ActiveCN109075676AImprove alignment accuracyIncreased durabilityManufacturing dynamo-electric machinesWinding machineLinear motion

The invention provides a needle circling means and a series winding-type winding machine that comprises said needle circling means, wherein winding can be performed at a high speed, a coil wire that has been wound has high alignment accuracy, and when an insulator of a different shape is used, the trajectory of a needle can be changed without rearranging the winding machine. A servo motor for linear motion and a servo motor for oscillating motion are made to rotate only in one direction, and each servo motor is fixed to a base in an independent manner. Additionally, a circling trajectory control means controls the speed of the rotational motion of each servo motor and allows the circling trajectory of a tip of a needle to be changed.

Owner:ETEC

Fabricated building drainage piping shaft

PendingCN114250949AImprove securityAvoid falling objectsPipe supportsSound proofingPipingFloor level

The invention relates to the technical field of assembly type building piping shafts, and discloses an assembly type building drainage piping shaft which comprises a piping shaft body, blocking structures are arranged on the two sides of the inner wall of the piping shaft body correspondingly, and each blocking structure comprises a limiting clamp, a blocking plate, a positioning block, a pushing block, a rotating shaft, a blocking block, a clamping block and a connecting rope. The fabricated building drainage piping shaft is provided with the blocking structure, the blocking structure can install the blocking plate in a gap of the piping shaft through cooperation between the limiting clamp and the blocking plate, the blocking plate can shield the narrow and through piping shaft to a certain degree, and the blocking plate is arranged in the gap of the piping shaft. In this way, the safety degree can be improved at ordinary times or when workers maintain and overhaul the drainage pipeline, objects falling from high altitudes can be prevented, and it can also be prevented that tools fall accidentally during operation of the workers, fall from a high-floor pipeline shaft to a low floor, and drainage pipes of other floors are damaged in the falling process.

Owner:赵小燕

Method for arranging non-weft band hoop on end portion of armature of brushless exciter

ActiveCN103036373BIncrease the heating areaImprove adhesionWindingsManufacturing dynamo-electric machinesEngineeringMachine tool

The invention provides a method for arranging a non-weft band hoop on the end portion of an armature of a brushless exciter. The method for arranging the non-weft band hoop on the end portion of the armature of the brushless exciter is characterized by comprising the steps that a rotating shaft is hung on a hoop arranging machine tool firstly, and hoop arranging tools are arranged in place; then a non-weft band is heated through a heating device, a tensioning device is started, and a counting device records the number of arranged hoops; and at last, after curing of the non-weft band hoop, the outer diameter of the non-weft band hoop can be controlled by strengthening or releasing curing shrinkage to meet requirements. The method for arranging the non-weft band hoop on the end portion of the armature of the brushless exciter overcomes the defects existing in the prior art, and can effectively improve the quality of the arrangement of the non-weft band hoop on the end portion of the armature of the brushless exciter. Moreover, after the curing, the non-weft band hoop is attractive and tidy.

Owner:SHANGHAI ELECTRIC POWER GENERATION EQUIPMENT CO LTD

Copper alloys for electrical and electronic equipment, copper alloy sheets for electrical and electronic equipment, conductive components and terminals for electrical and electronic equipment

ActiveCN104903478BNot easy to relaxExcellent yield strength-bending balanceHot-dipping/immersion processesSingle bars/rods/wires/strips conductorsMetallurgyYield ratio

The present invention relates to a copper alloy for electric and electronic device, a copper alloy sheet for electric and electronic device, a conductive component for electric and electronic device, and a terminal. The copper alloy for electric and electronic device includes more than 2.0 mass% to 15.0 mass% of Zn; 0.10 mass% to 0.90 mass% of Sn; 0.05 mass% to less than 1.00 mass% of Ni; 0.001 mass% to less than 0.100 mass% of Fe; 0.005 mass% to 0.100 mass% of P; and a remainder comprising Cu and unavoidable impurities, in which 0.002‰¤Fe / Ni<1.500, 3.0<(Ni+Fe) / P<100.0, and 0.10<Sn / (Ni+Fe)<5.00 were satisfied by atomic ratio, and a yield ratio YS / TS is more than 90% which is calculated from a strength TS and a 0.2% yield strength YS when a tensile test is performed in a direction parallel to a rolling direction.

Owner:MITSUBISHI MATERIALS CORP +1

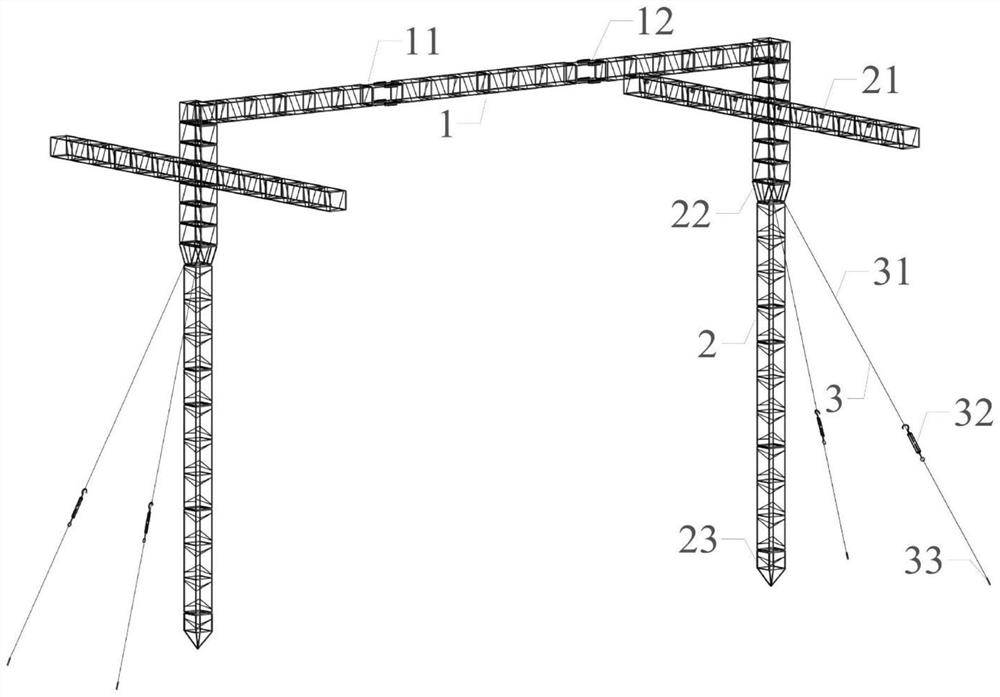

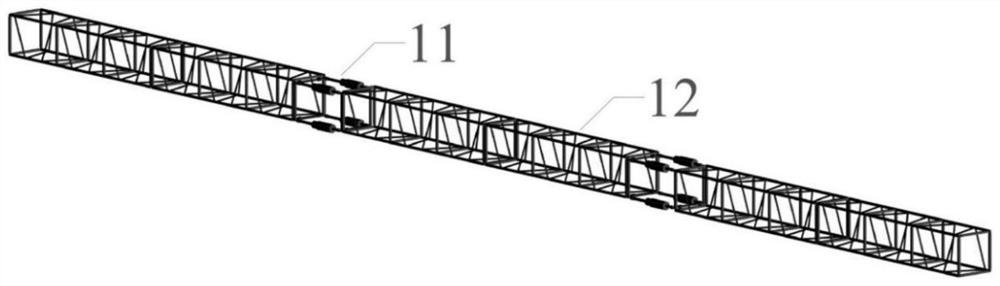

Blocking tower for construction of power transmission line crossing high-speed railway and construction method

The invention discloses a blocking tower for construction of a power transmission line crossing a high-speed railway and a construction method. The blocking tower comprises a pair of towers, a lattice type connecting frame and an inhaul cable, wherein each tower comprises a tower supporting column and a cross arm perpendicular to the tower supporting column; a net pulling connecting piece is arranged in each cross arm and used for being connected with a net pulling rope; each tower supporting column and each cross arm are formed by detachably assembling prefabricated truss modules; the lattice type connecting frame is connected and installed between two towers, and the lattice type connecting frame comprises a prefabricated truss module and a prefabricated damper module which are connected together in series; and the inhaul cable comprises an inhaul cable line, a turn buckle and a nonlinear spring, the initial end of the inhaul cable line is connected into the tower supporting columns, and the tail end of the inhaul cable line is connected with the nonlinear spring and anchored to the ground. The blocking tower is simple in structure, easy to manufacture, convenient to transport due to prefabricated assembly, quick to mount, easy to dismount, capable of being recycled and saving cost, efficient in construction, capable of shortening the construction period, high in safety and high in economy.

Owner:国网江苏省电力有限公司建设分公司

Needle loop assembly and winding machine

InactiveCN109075676BImprove alignment accuracyIncreased durabilityManufacturing dynamo-electric machinesWinding machineEngineering

[Problem] To provide a needle circling means and a series winding-type winding machine that comprises said needle circling means, wherein winding can be performed at a high speed, a coil wire that has been wound has high alignment accuracy, and when an insulator of a different shape is used, the trajectory of a needle can be changed without rearranging the winding machine. [Solution] This servo motor for linear motion and this servo motor for oscillating motion are made to rotate only in one direction, and each servo motor is fixed to a base in an independent manner. Additionally, a circling trajectory control means controls the speed of the rotational motion of each servo motor and allows the circling trajectory of a tip of a needle to be changed.

Owner:ETEC

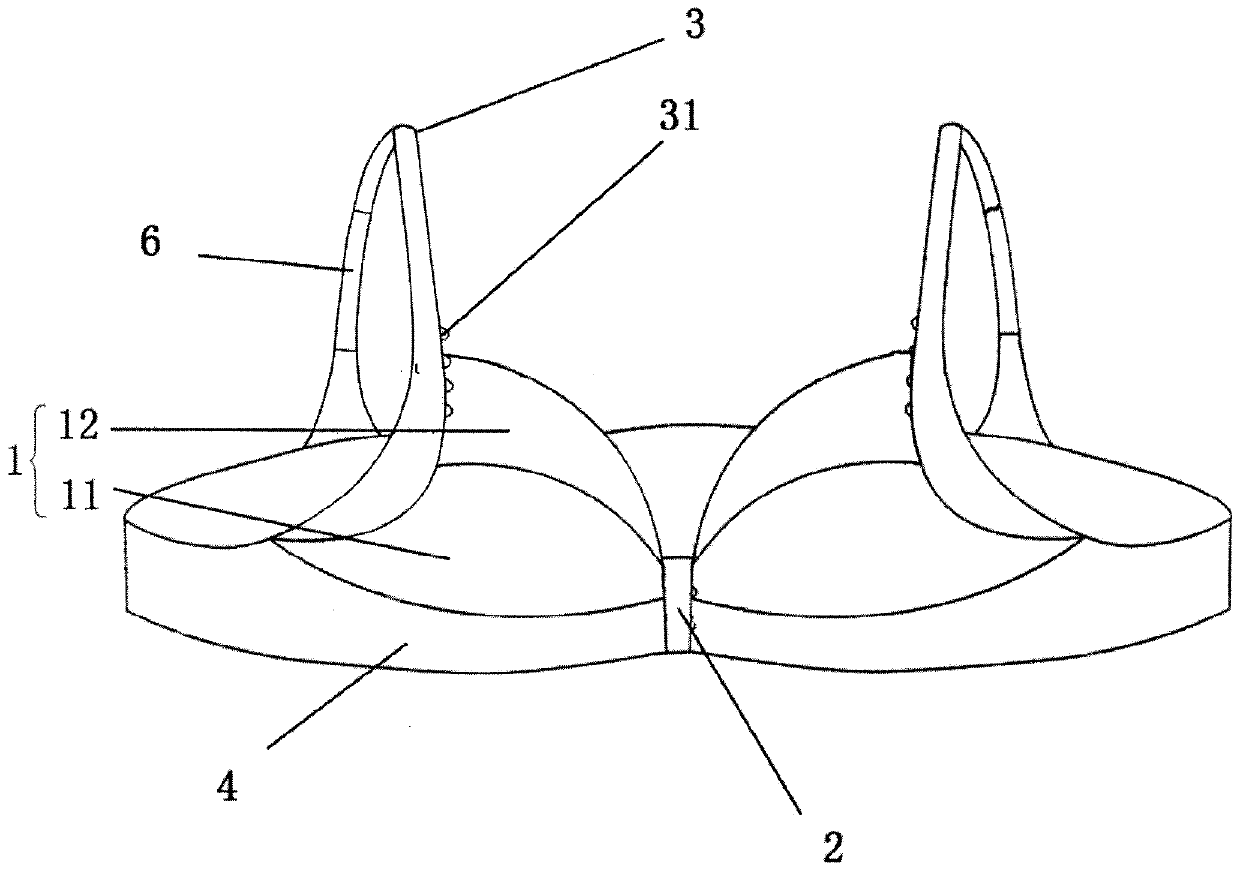

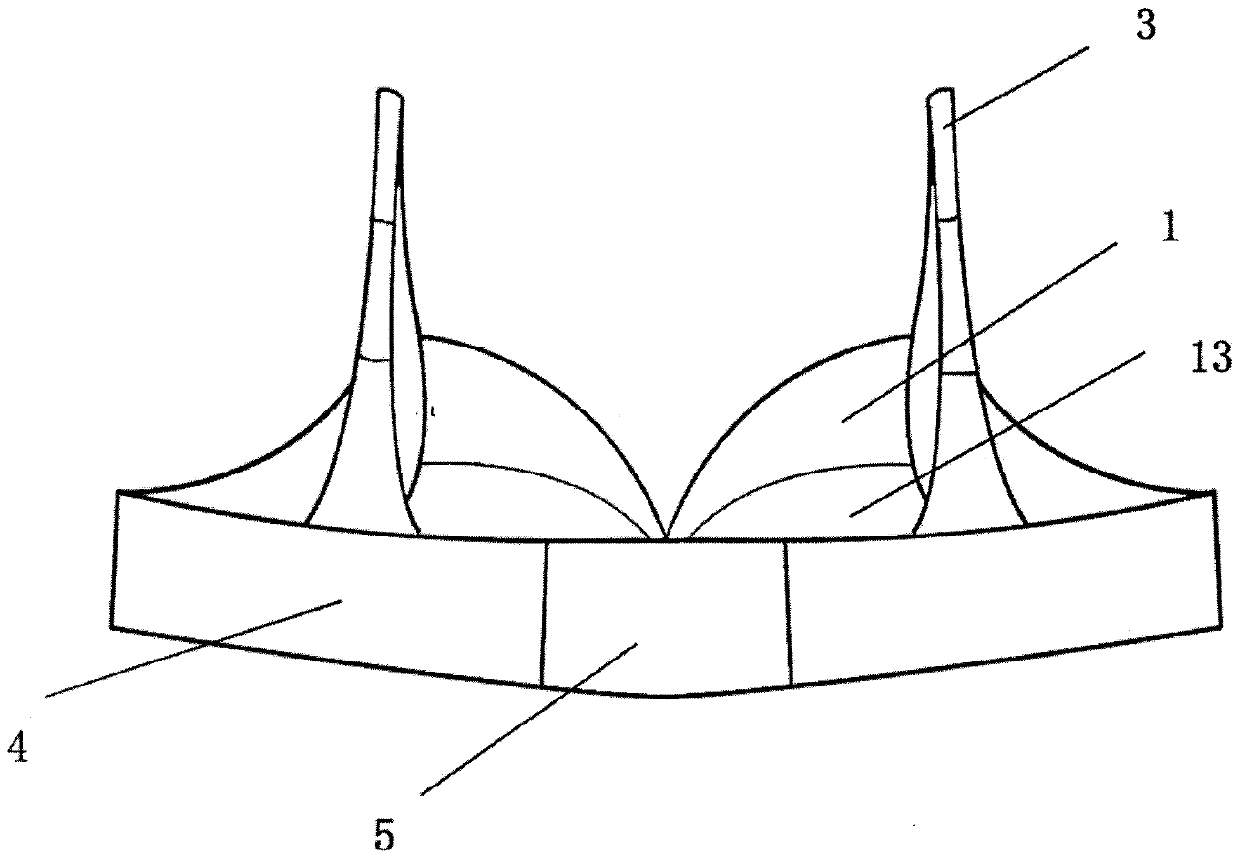

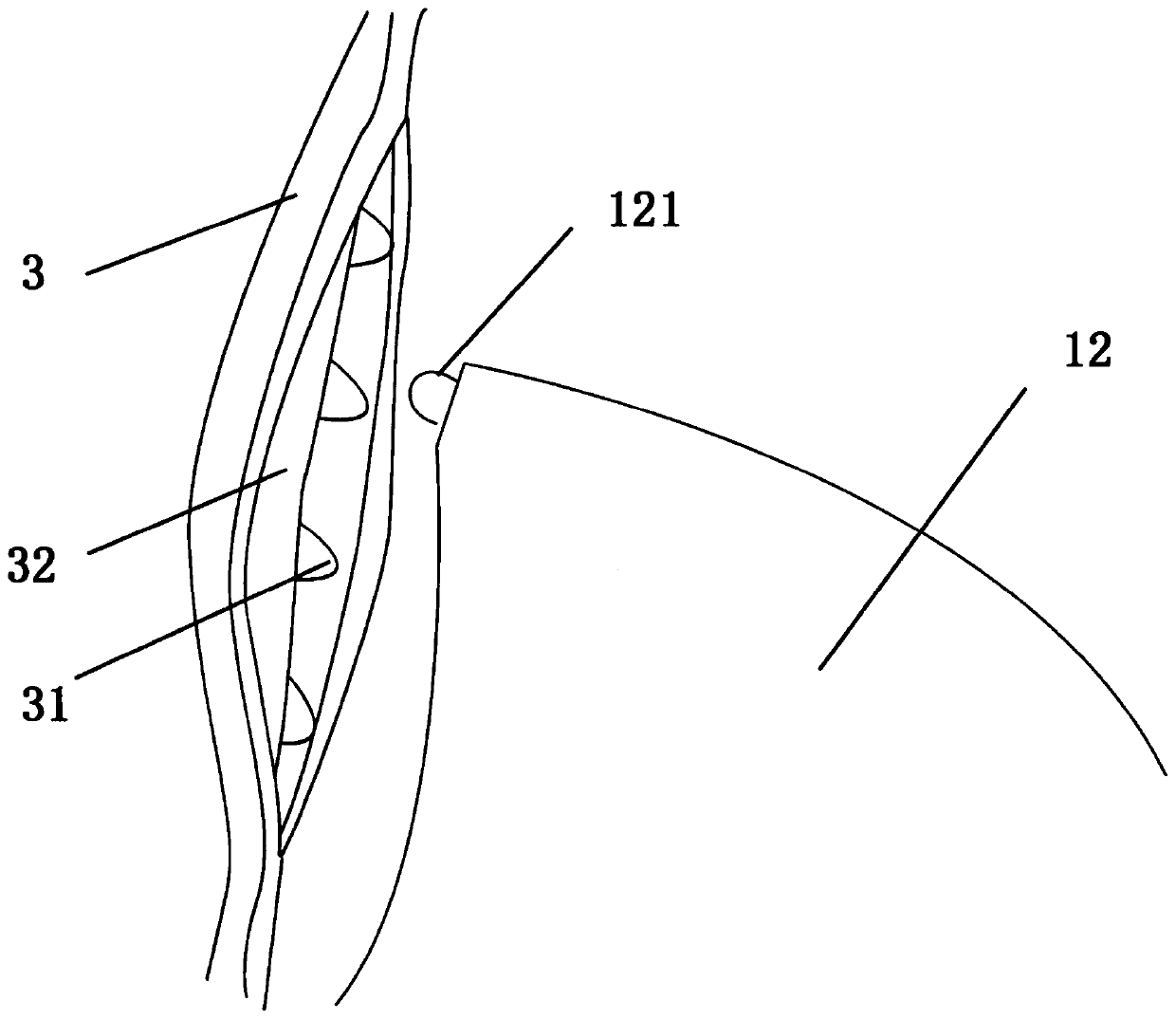

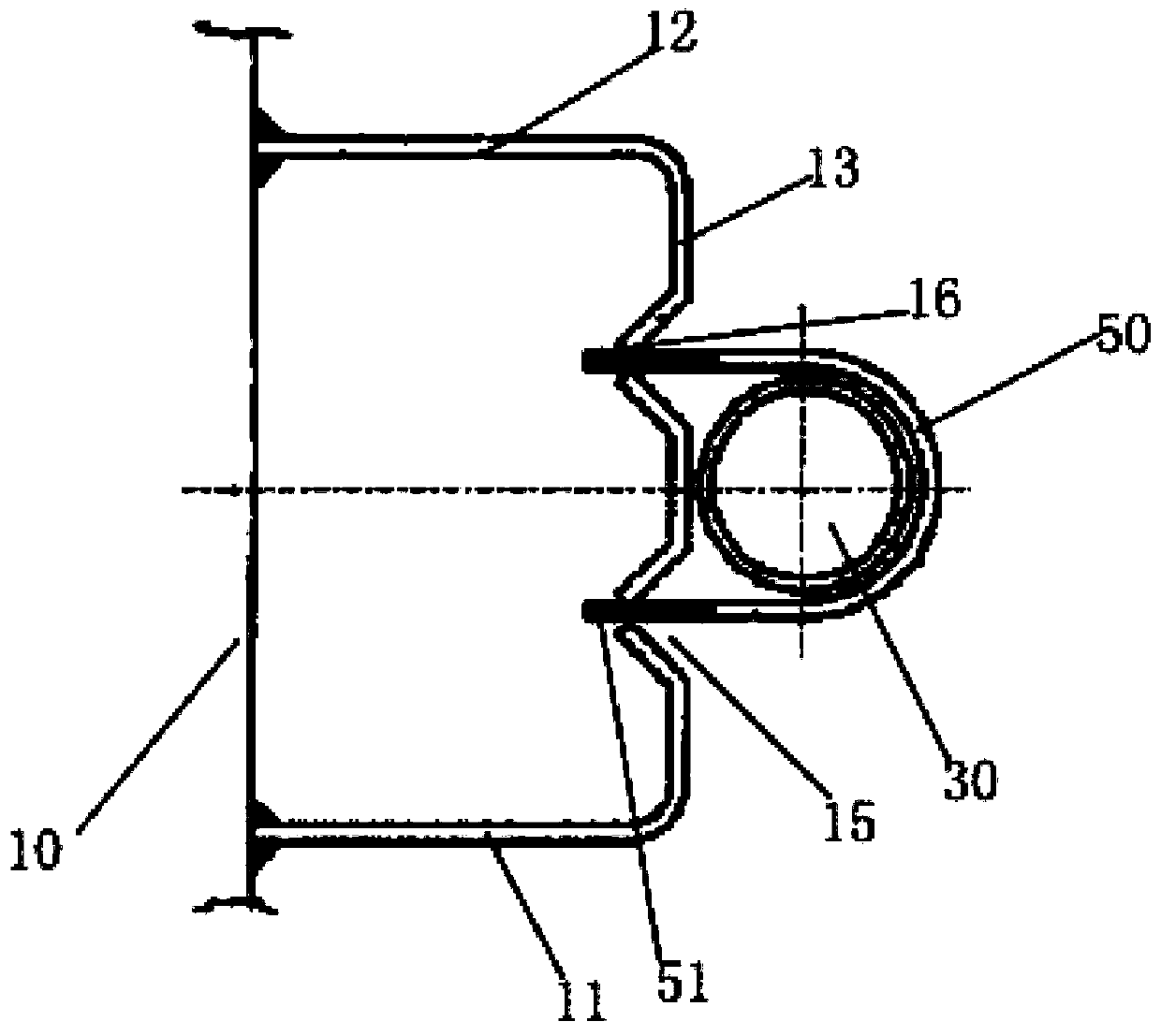

Bra for girls at age of puberty

InactiveCN110680028AFit soft and comfortableImprove perspirationBrassieresPhysical medicine and rehabilitationEngineering

The invention provides a bra for girls at the age of puberty, and belongs to the technical field of underwear. The bra includes cups, a connecting body used for connecting the cups, shoulder straps extending upward from outer side edges of the cups, lower supporters arranged at the bottoms of the cups, and adjusting belts. The cups include lower cup bodies and upper cup bodies, one side of each upper cup body close to the shoulder straps is provided with round hooks, and side edges of the shoulder straps corresponding to the upper cup bodies are provided with a plurality of upper cup connecting rings used for being matched and connected to the round hooks; and one side of each shoulder strap towards the upper cup bodies forms a gap, the upper cup connecting rings are embedded in the gaps,and the adjusting belts are arranged at the positions of the lower supporters corresponding to the back of a wearer. The bra has the advantages that the wearer can choose the appropriate upper cup connecting rings according to the chest shape to enable the chests to be well covered by the cups, and through the upper cup connecting rings, the size of the cups can be adjusted with the slow change ofthe chests during the age of puberty; by adding the adjusting belts on the lower supporters, the lower supporters can be suitable for a variety of lower bust sizes with good fit; and the shoulder straps are fitted with elastic straps and can be flexibly adjusted according to the body shape of the wearer so as to increase the comfort degree.

Owner:CHANGSHU INSTITUTE OF TECHNOLOGY

fence

ActiveCN106939565BEasy to assembleFirmly assembledRoadway safety arrangementsStructural engineeringEngineering

The invention provides a protective fence. The protective fence comprises a plurality of vertical columns which are arrayed side by side at intervals, and transverse rods arranged on the vertical columns, wherein a connecting part is arranged at one side of the top of each vertical column; each connecting part comprises two horizontal sections which horizontally extend outward from the corresponding vertical column and are arranged at interval, and a vertical section connected between the two horizontal sections; the middle part of each vertical section is inward concave to from an annular groove; two through holes are formed in each annular groove; the transverse rods are fixed to the connecting parts of all the vertical columns through U-shaped screws; the hole diameter of the through holes in the grooves is less than the screw diameter of the U-shaped screws; two thread ends of each U-shaped screw penetrate into the through holes of the corresponding groove; the transverse rods penetrate into the U-shaped screws and are fixed. According to the protective fence provided by the invention, the transverse rods are mounted on the connecting parts of the vertical columns through the U-shaped screws; the protective fence is convenient and rapid to assemble on site, and is conveniently assembled on a narrow road when a vehicle drives; the protective fence is firm and stable to assemble and is not easy to loose.

Owner:枣庄瑞衡建筑工程有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com