Fracture reduction lifting needle

A needle bar and clamping part technology, applied in the field of fracture reduction and pulling needles, can solve the problems of delaying operation time, easy loosening, inconvenience to hold, etc., and achieve the effect of saving operation time, not easy to loosen, and comfortable to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

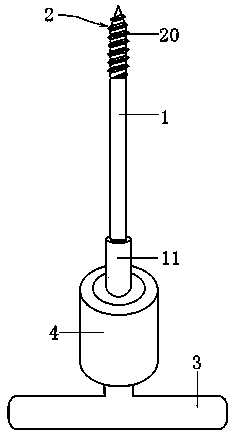

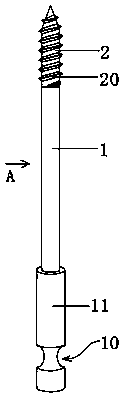

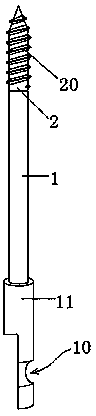

[0025] Such as figure 1 As shown, the present invention includes a needle bar 1 provided with a tip 2, the needle bar 1 is provided with a clamping part 4, one end of the clamping part 4 is provided with a jack 5 matching the tail of the needle bar 1, and the other end is provided with a handle 3, In order to facilitate handling during surgery, in this embodiment, the handle 3 is vertically connected to the clamping portion 4 , and the projection is T-shaped.

[0026] Thread 20 is provided on the needle shaft 1 at the end where tip 2 is provided. When using the lifting needle of the present invention, thread 20 can be easily drilled into the bone, and has a strong holding force, and is not easy to loosen during the reset operation. fall off. Of course, in order to increase the sharpness of the tip 2 and facilitate drilling into the bone, the tip 2 is in the shape of a triangular prism with a triangular cross-section.

[0027] Such as Figure 4 As shown, a jack 5 matching th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com