Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

76results about How to "Less soldering steps" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

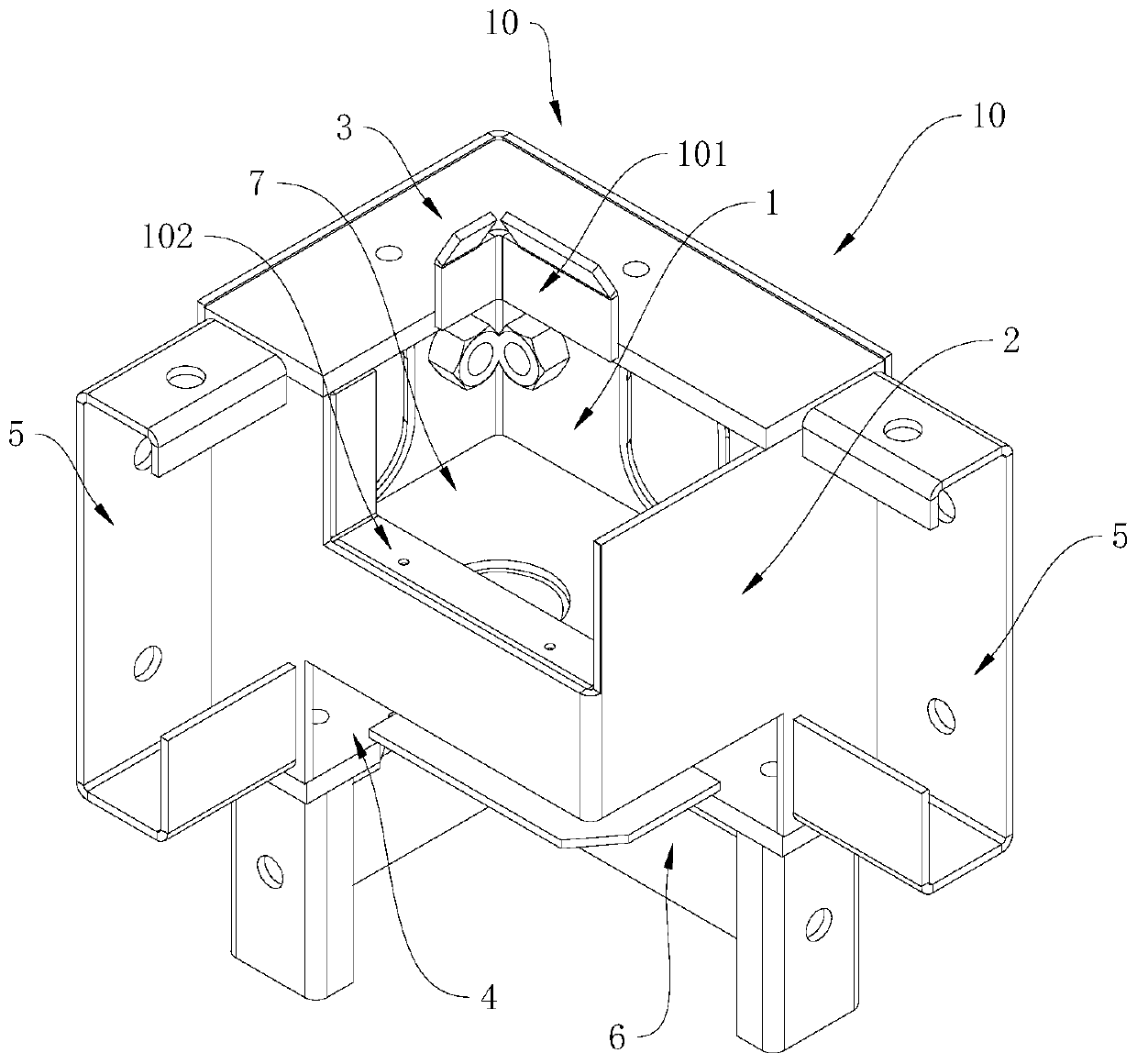

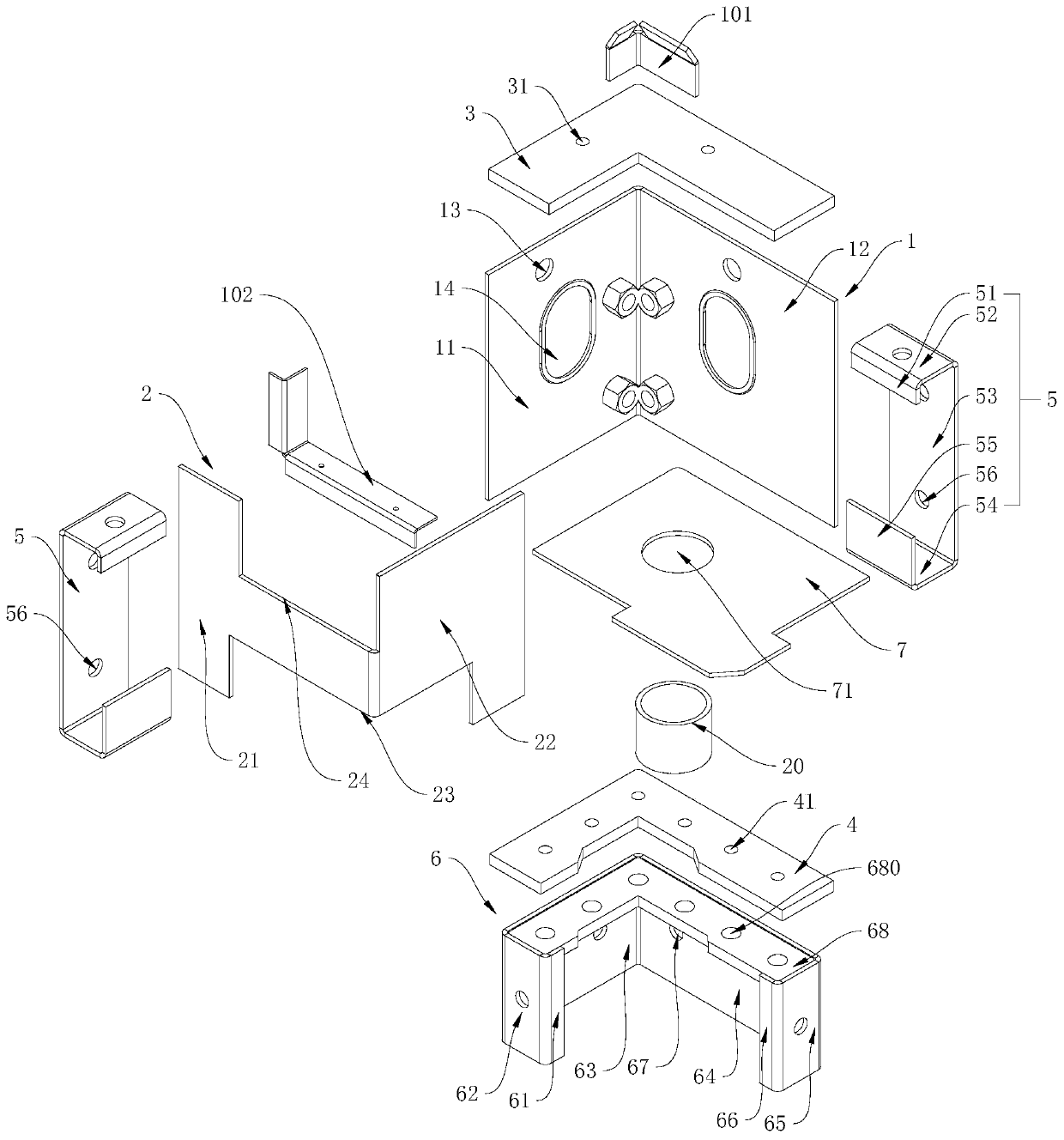

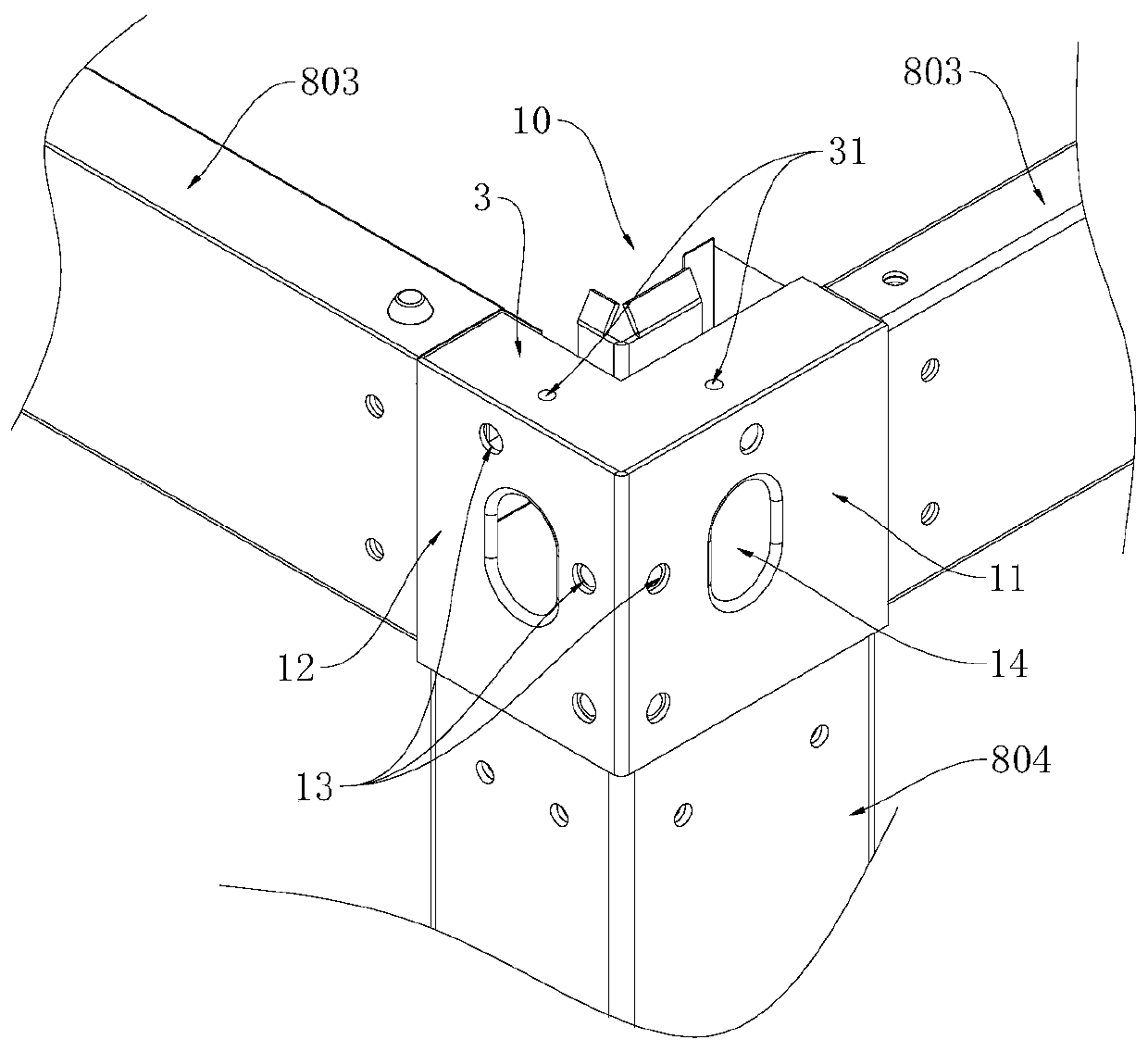

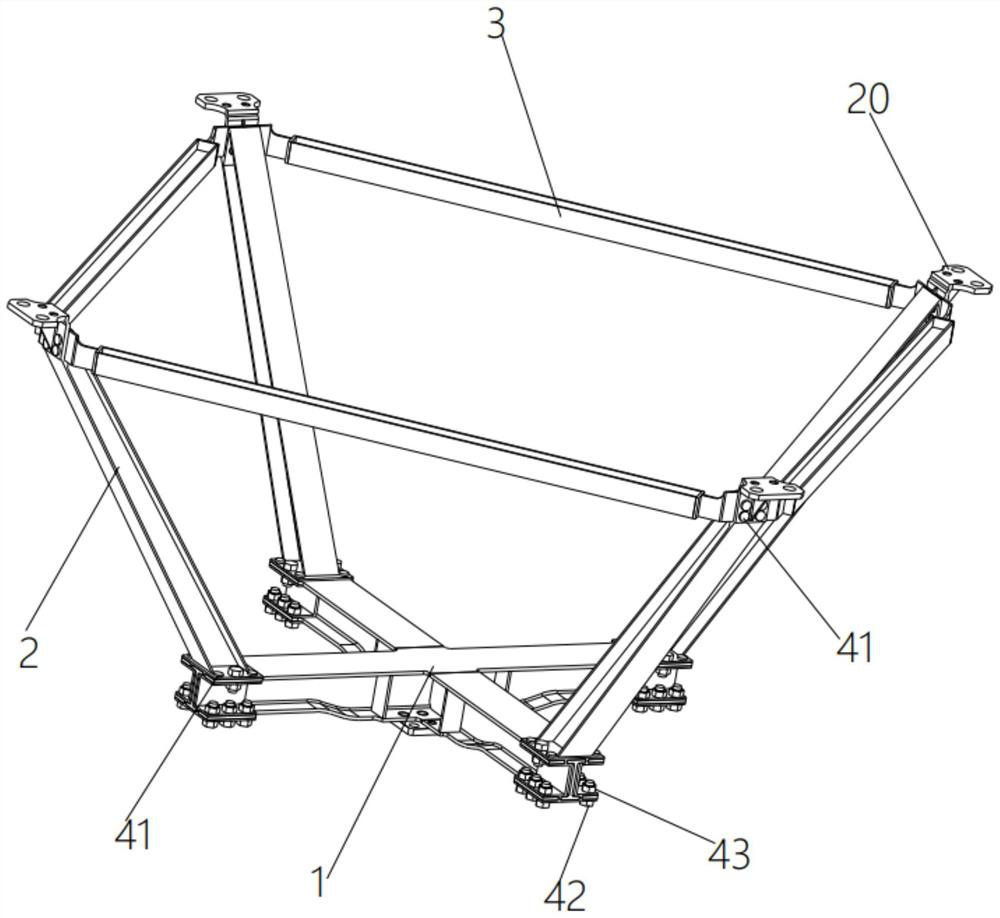

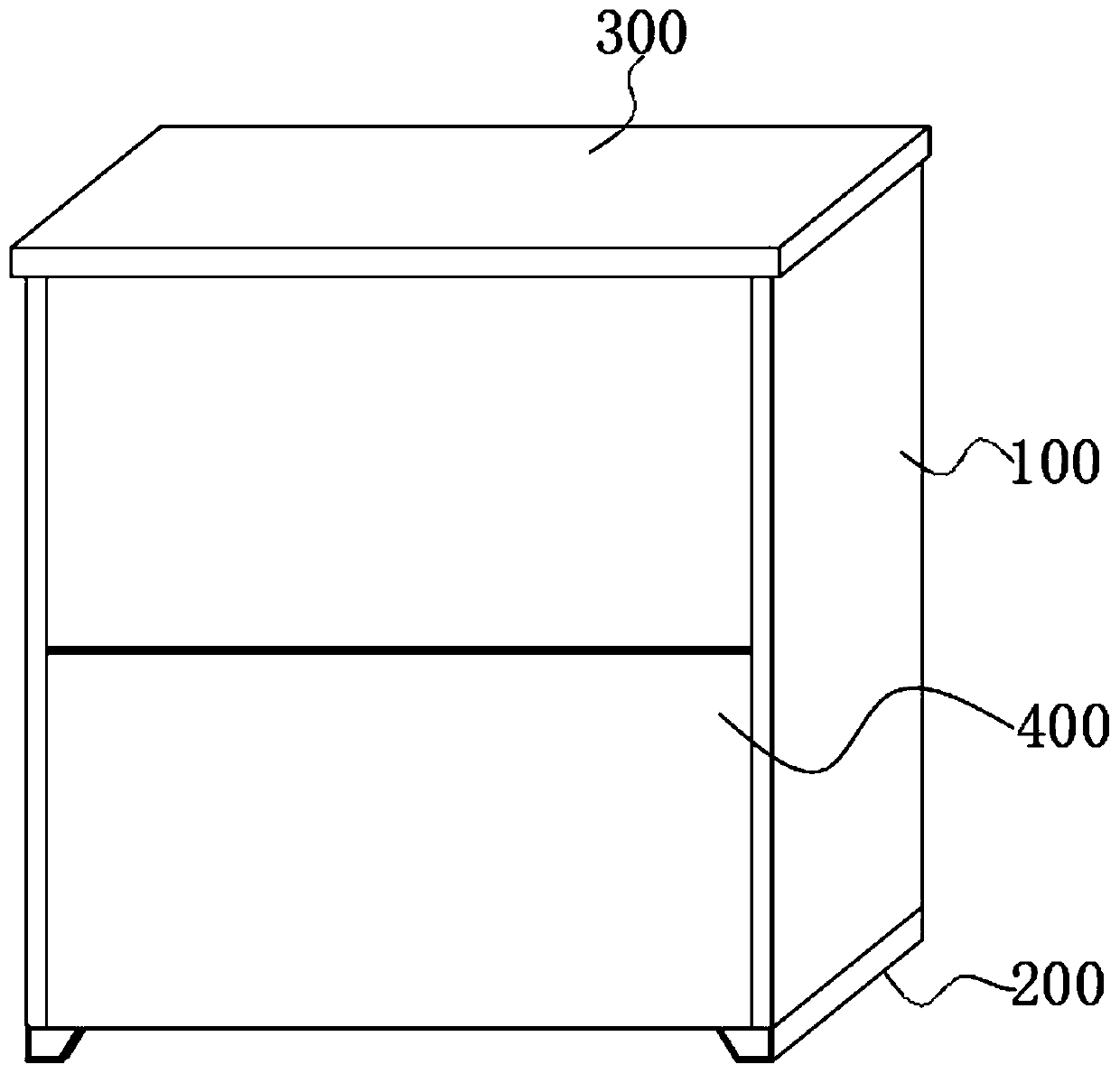

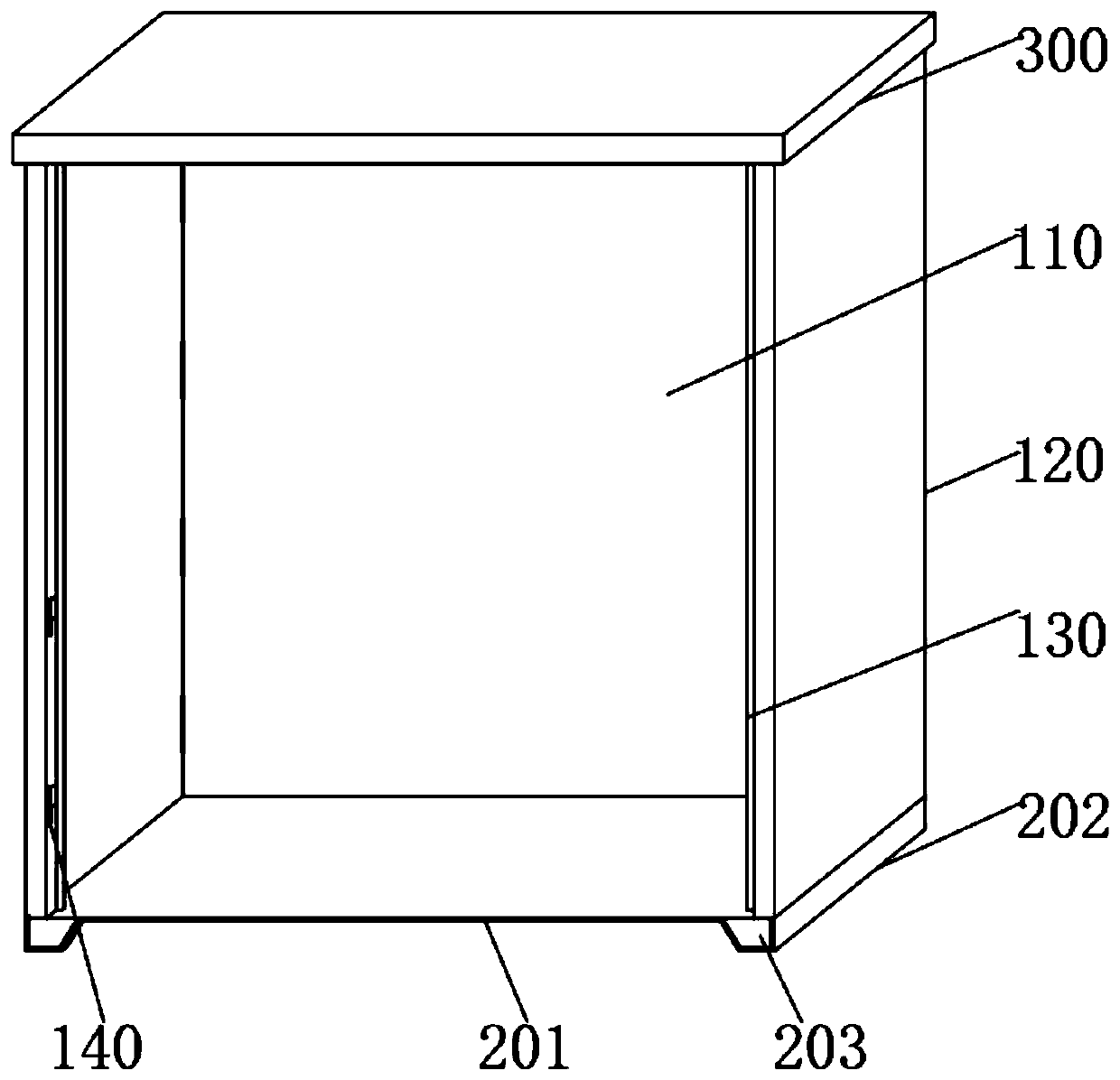

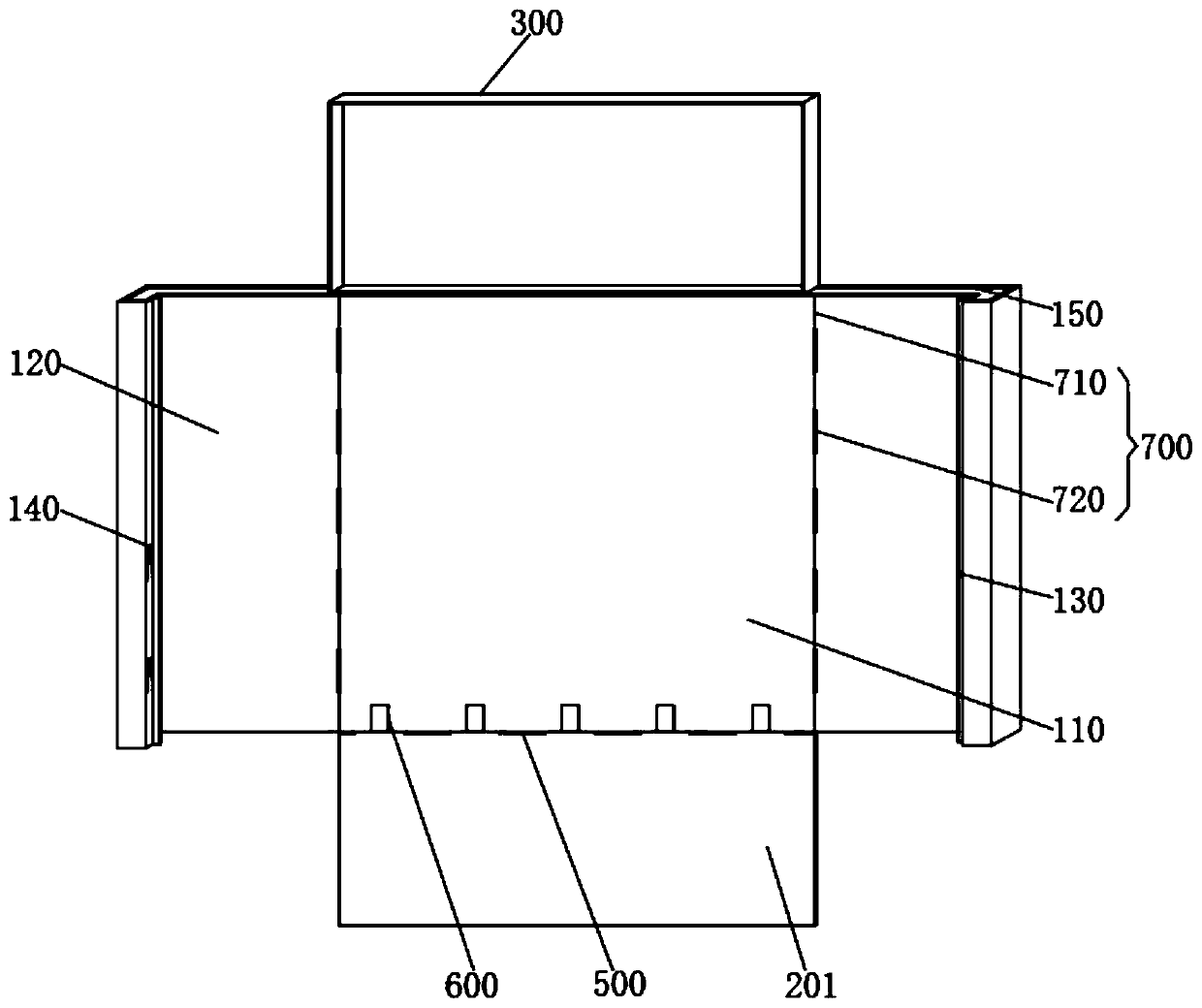

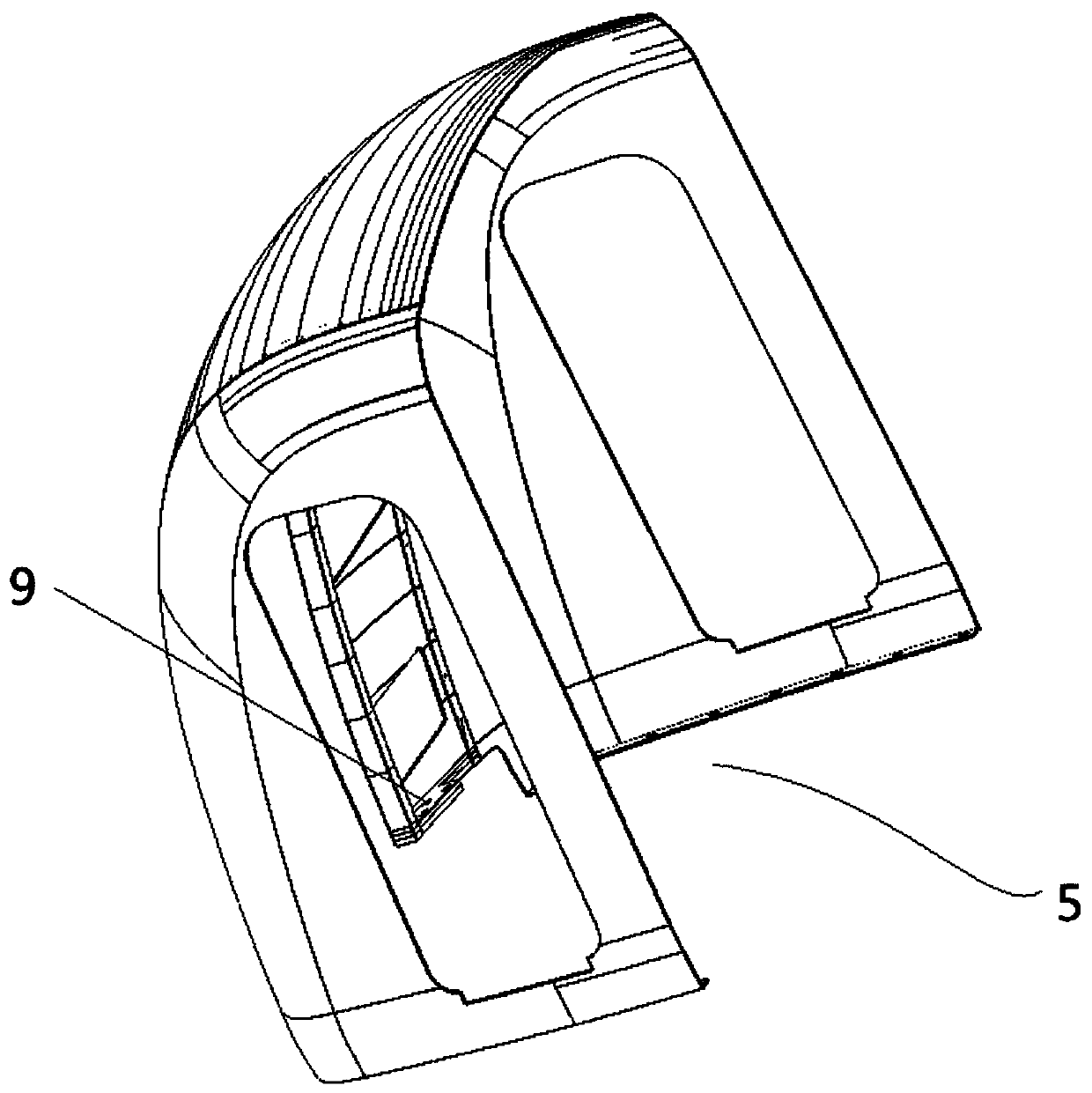

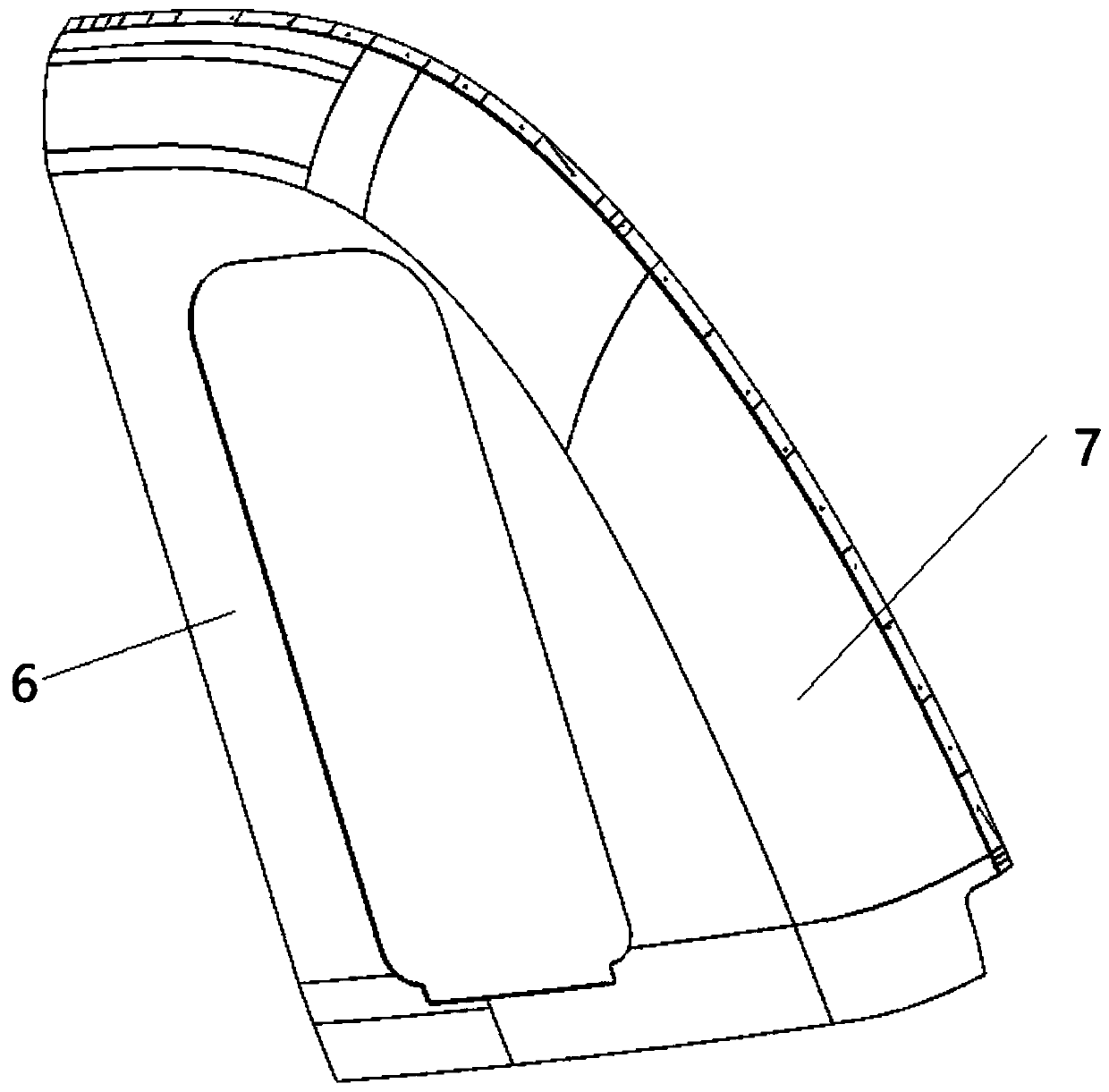

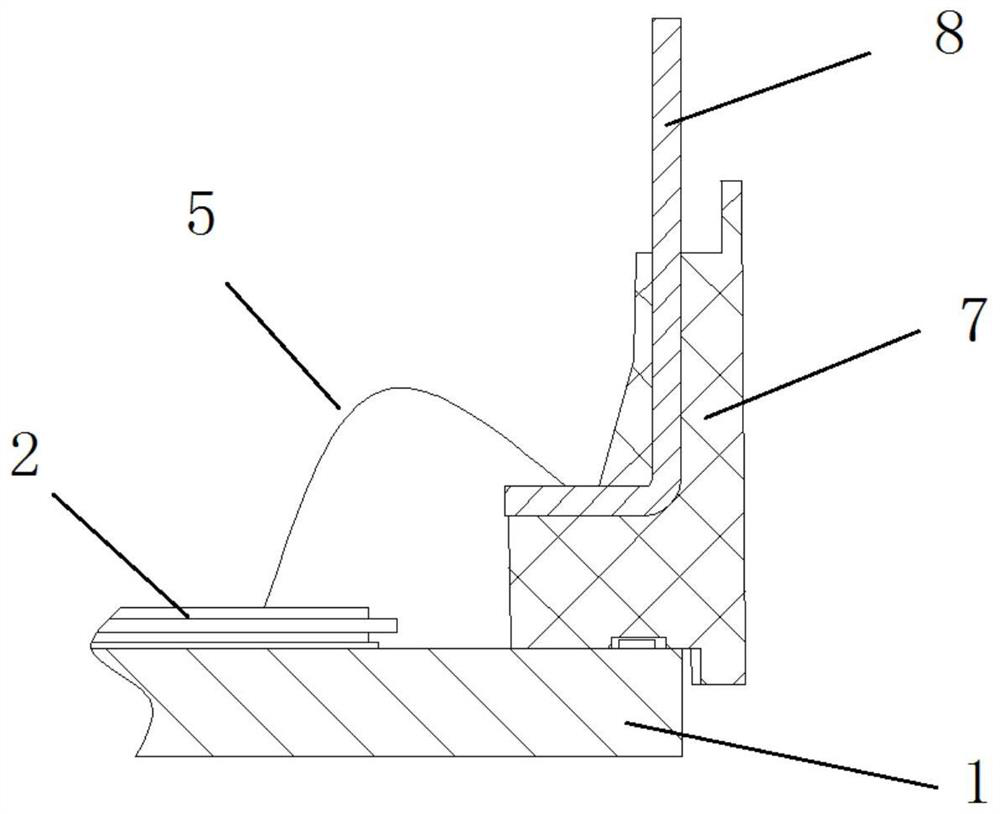

Container house corner connector and container house

PendingCN110029840AImprove stabilityImprove stress resistanceSpecial buildingBuilding constructionsEngineeringBolt connection

The invention discloses a container house corner connector and a container house, and belongs to the technical field of container houses and container house accessories. The container house corner connector includes a corner folding outer plate, a corner folding inner plate, an upper connection plate, a lower connection plate, a first groove-shaped plate, and a second groove-shaped plate, whereinthe corner folding outer plate is provided with a first panel and a second panel which are perpendicular to each other, the corner folding inner plate is provided with a third panel and a fourth panelwhich are perpendicular to each other, the side of the third panel is connected with the side of the first panel, the side of the fourth panel is connected with the side of the second panel, and thefirst panel, the second panel, the third panel and the fourth panel jointly form a four-square box-shaped structure with an upper opening and a lower opening. According to the container house corner connector and the container house, when the container house is assembled, bolt connection is adopted, welding steps are reduced, processing is simple and convenient, the structure is simple, disassembly is convenient, and the installation accuracy is high.

Owner:CHINA RAILWAY SIXTH GROUP +1

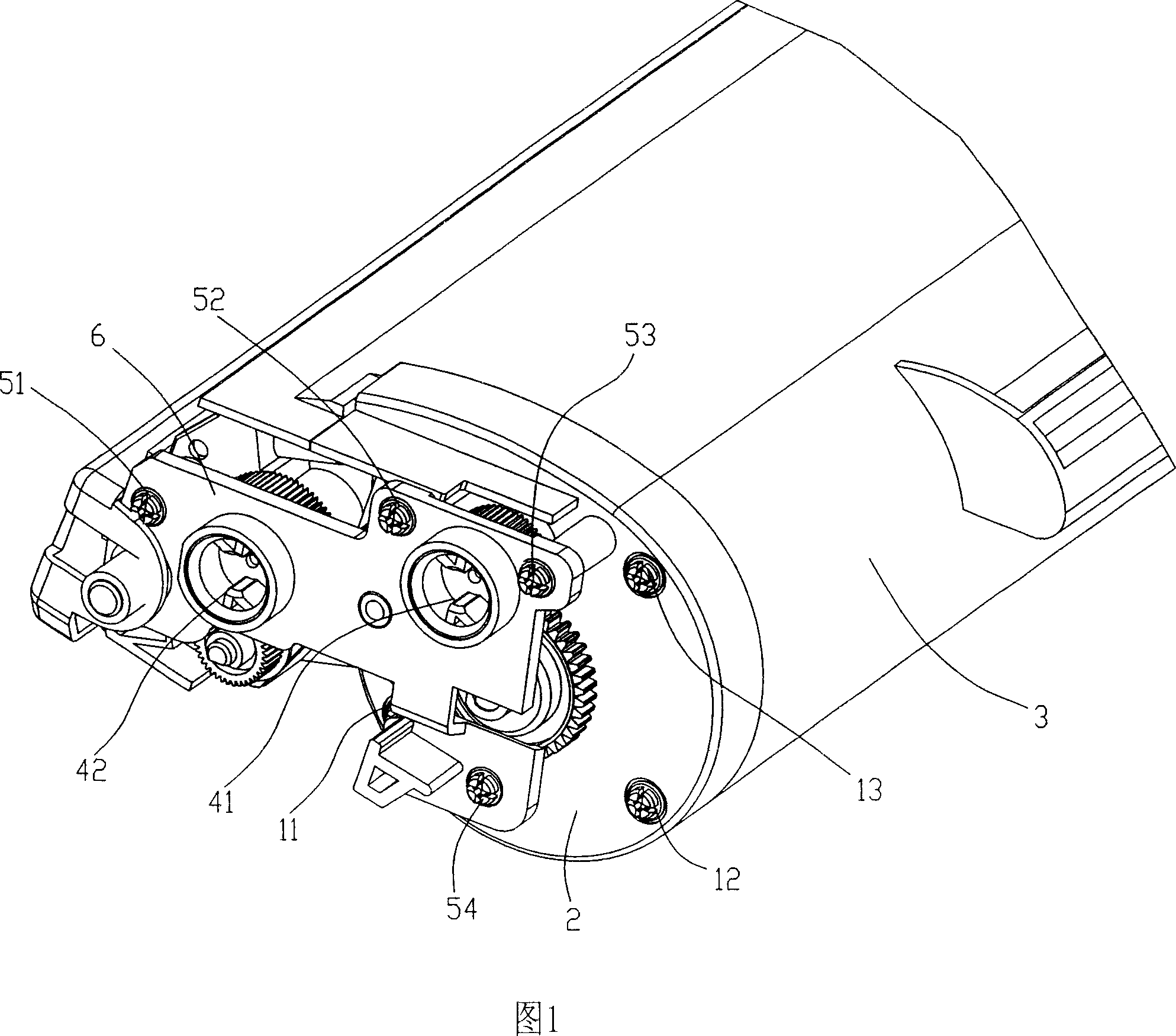

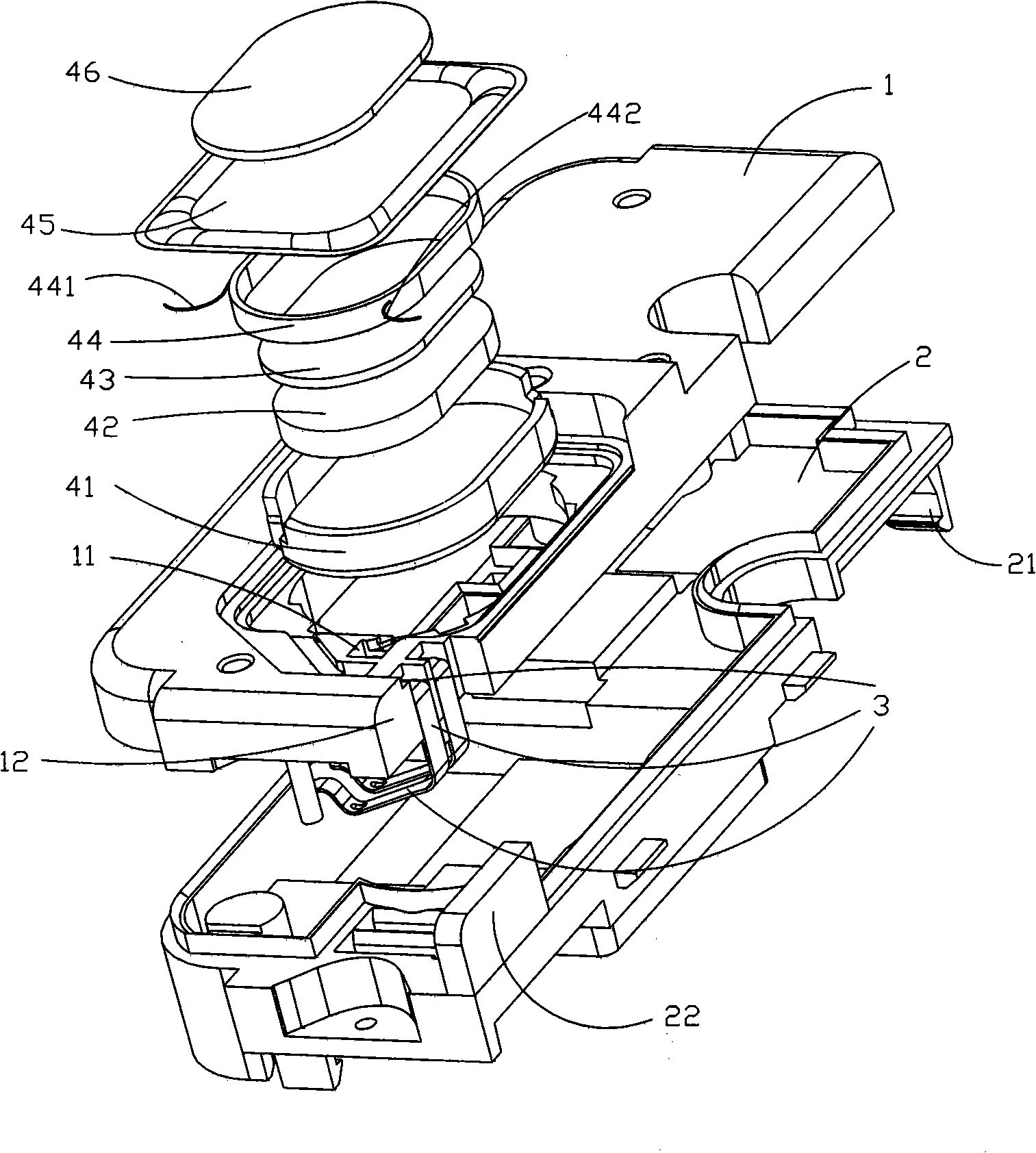

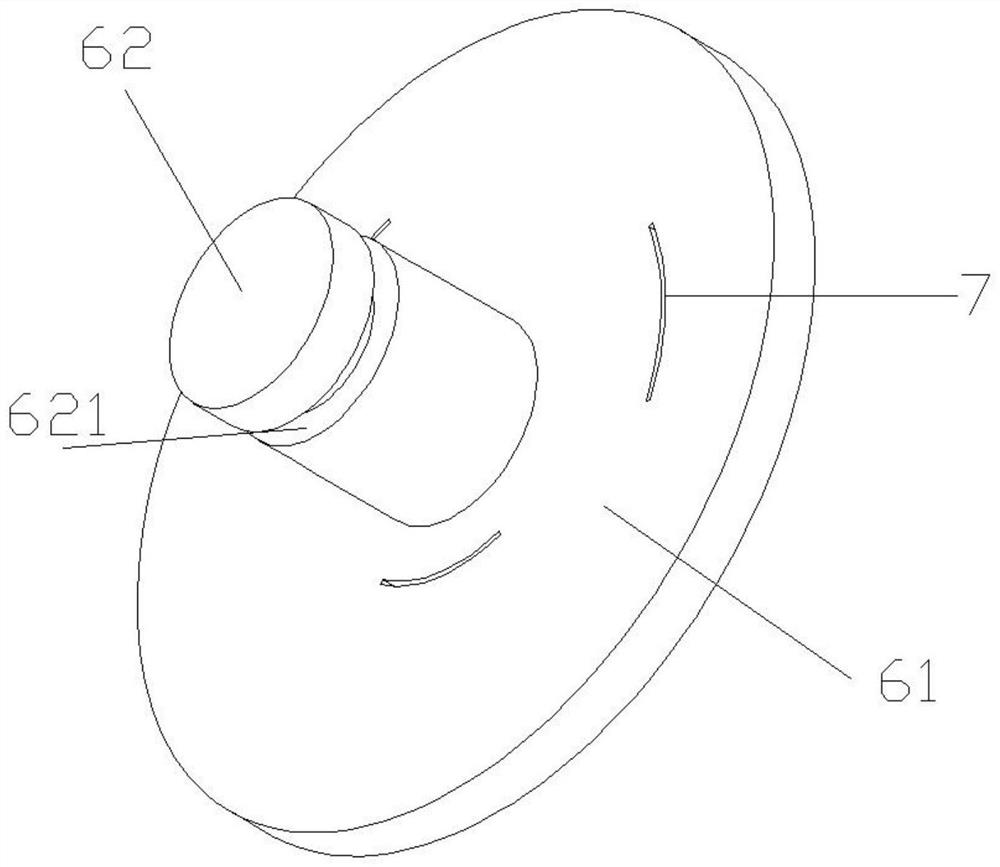

Developing box

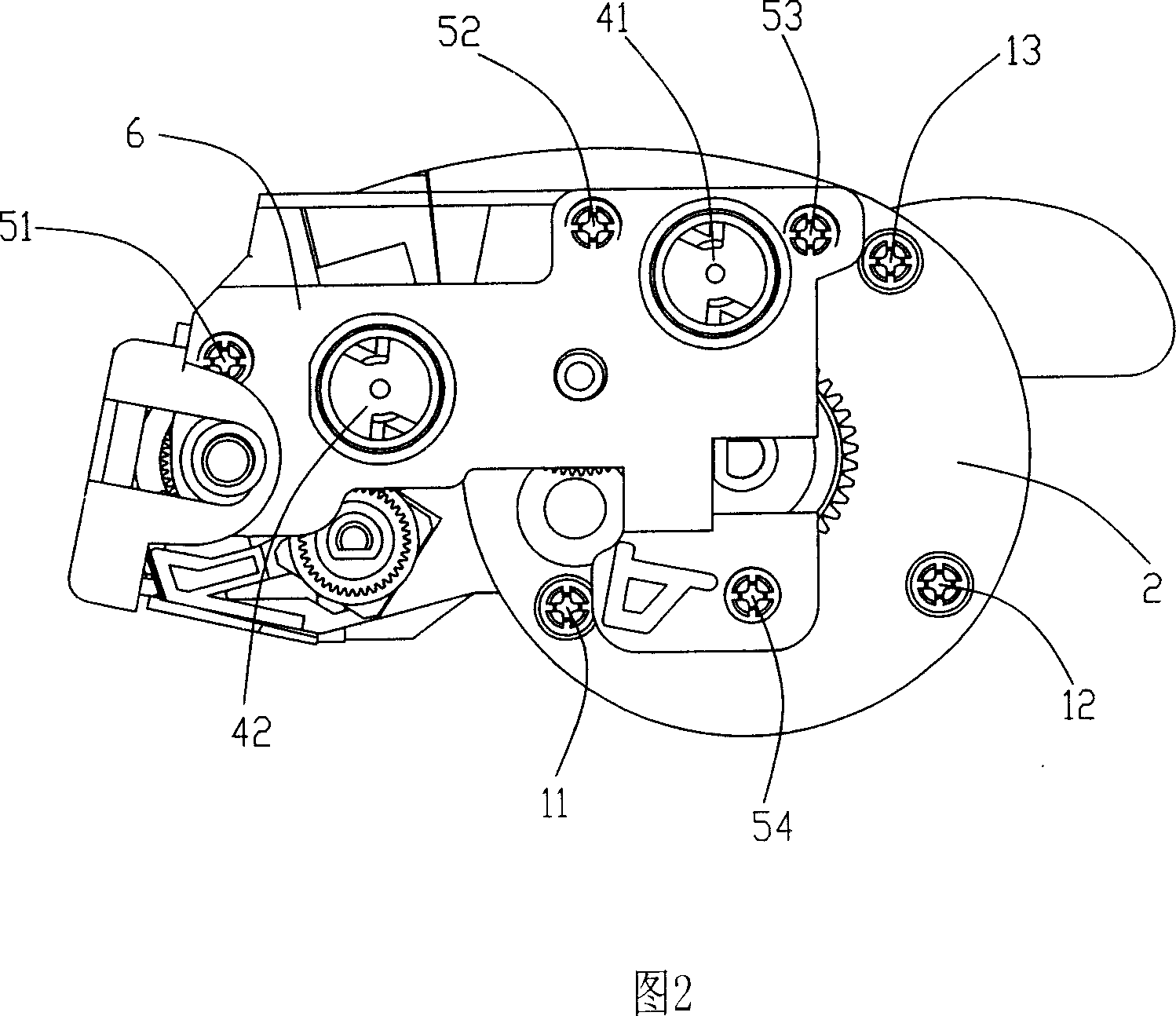

InactiveCN101021704ASimplify the assembly processSave human effortElectrographic process apparatusHuman powerMaterial resources

The invention relates to a developing device removable from an imaging device, especially a developing box, comprising: a box body containing powder storehouse and developing device and side end cover, a developer mixing device located in the powder storehouse, a powder supply roller to supply developer to developing roller, a developing roller to develop static latent image on photosensitive body, and a limiting piece to control thickness of developer layer on the developing roller, where there is a drive bay with power receiving mouths in each roller-end gear set outside the side end cover, and it is characterized in that: the casing of the box body in the direction vertical to the side end cover is of an arc shape, the box body is integrated with the side end cover; the number of side end covers is one or two; the box body and the side end cover are connected by lockpin, locker or bolt; the number of power receiving mouths is two or more; it saves manpower, material resources and financial resources, and besides, its appearance is more beautiful; its universality is improved.

Owner:ZHUHAI SEINE TECH CO LTD

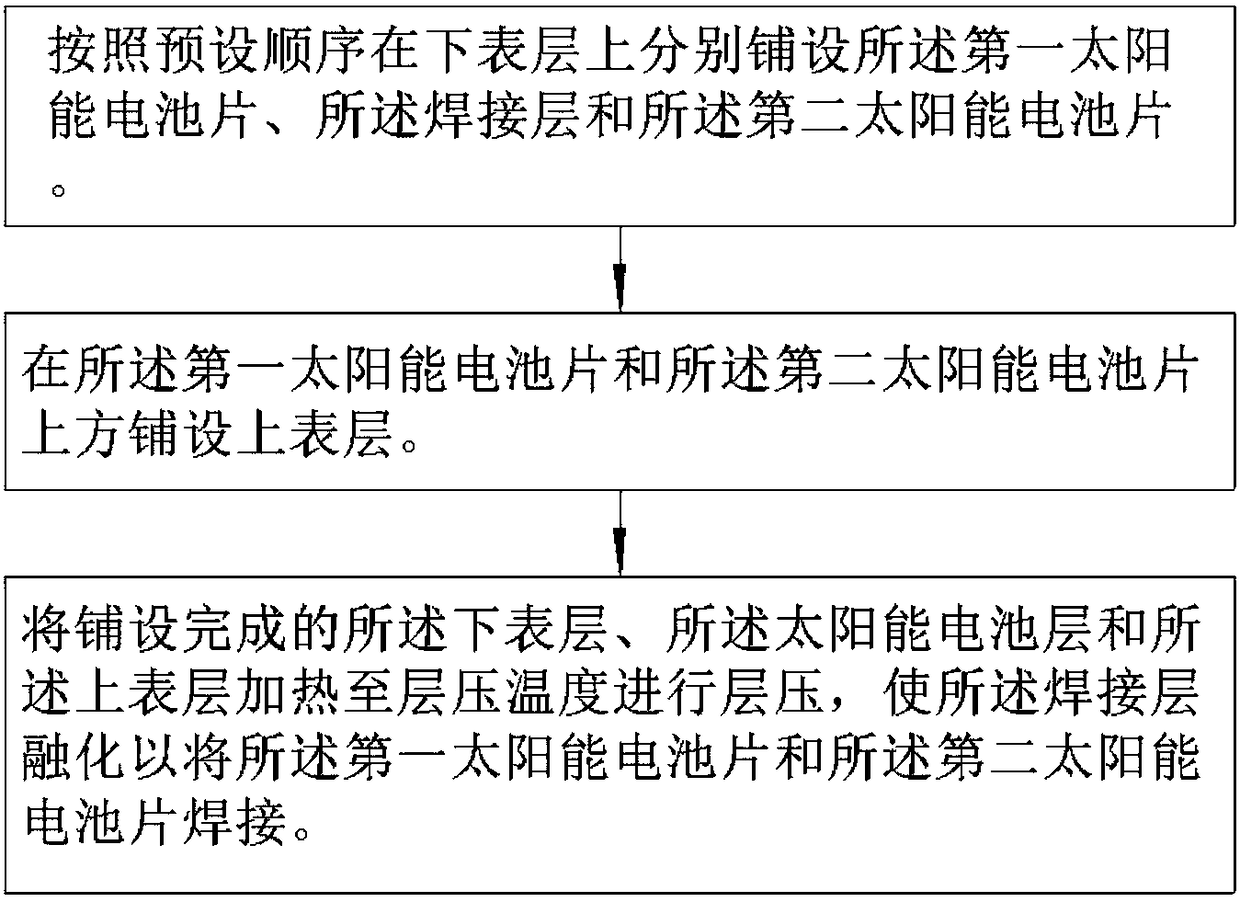

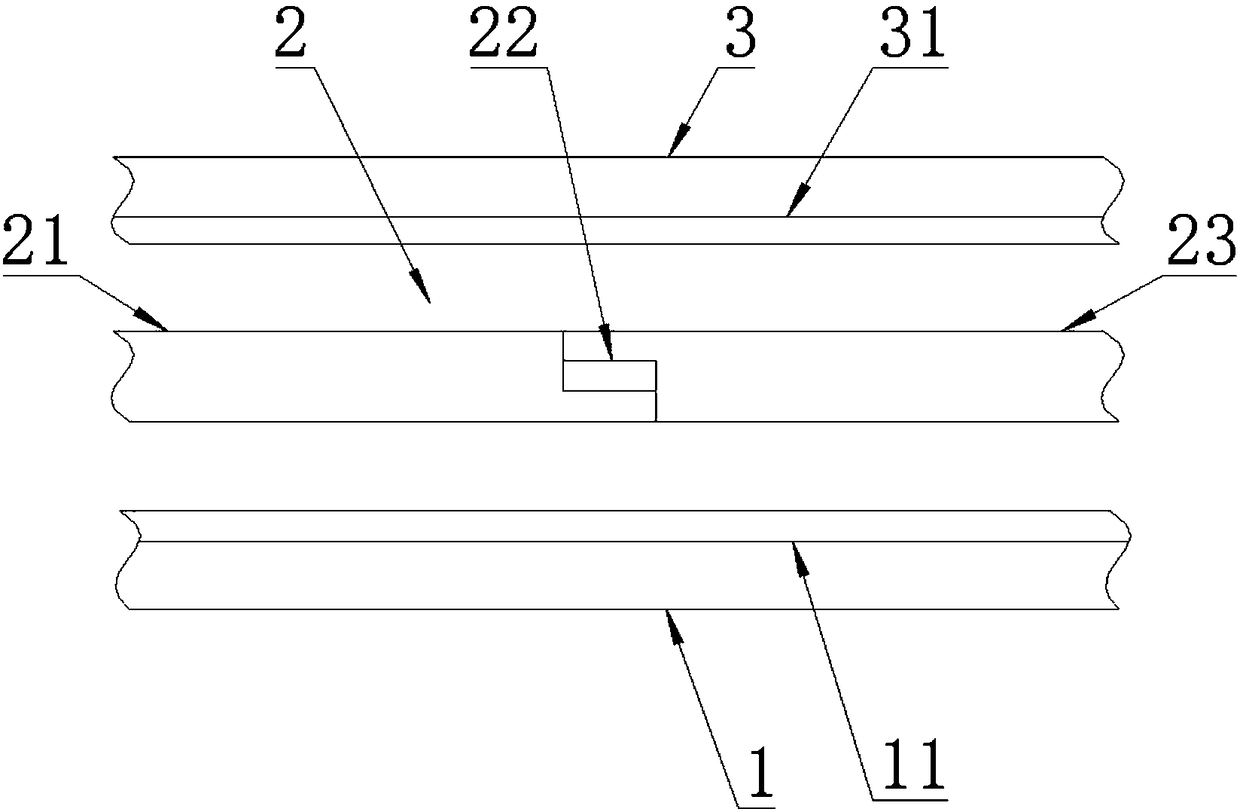

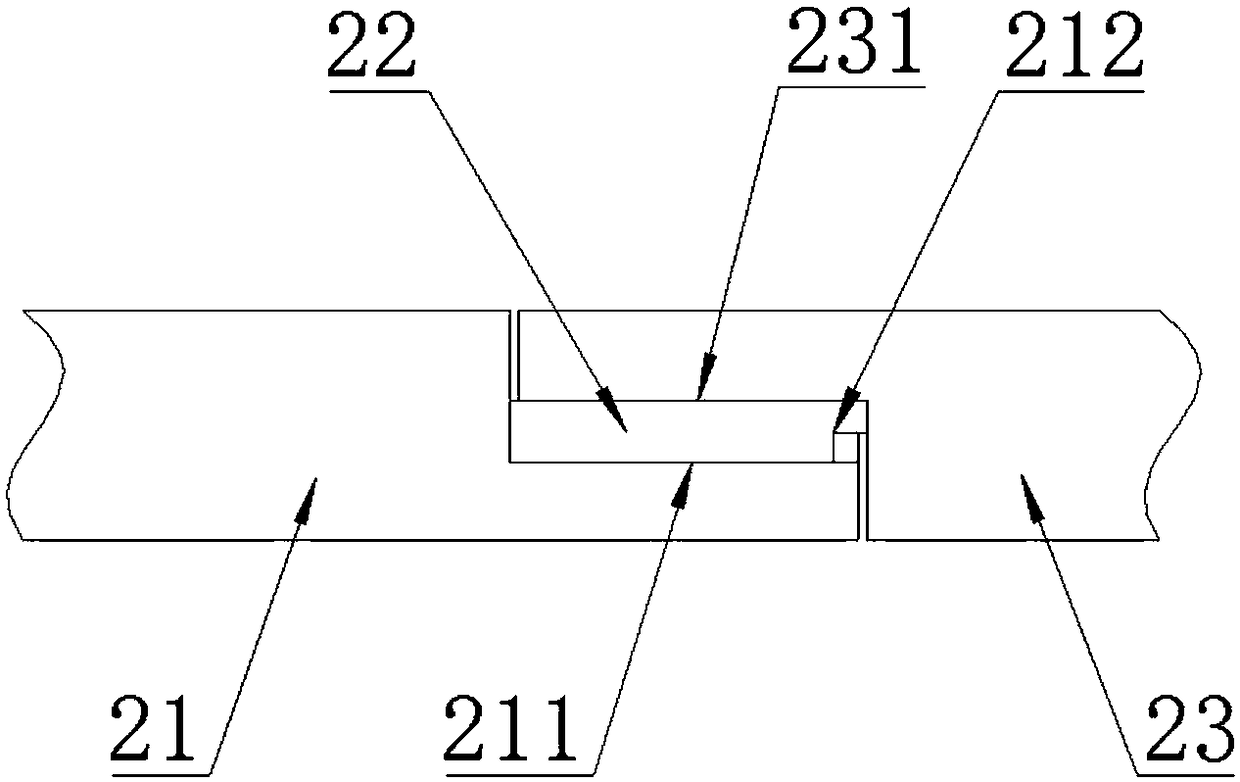

Manufacturing method of laminated tile assembly

ActiveCN108574025AAvoid damageAvoid chippingFinal product manufacturePhotovoltaic energy generationSurface layerEngineering

The invention provides a manufacturing method of a laminated tile assembly, and belongs to the field of photovoltaic power generation. The laminated tile assembly comprises a lower surface layer, a solar cell layer and an upper surface layer arranged in a laminated manner from bottom to top, the solar cell layer comprises a first solar cell, a second solar cell and a welding layer whose melting point is lower than the lamination temperature. The manufacturing method of the laminated tile assembly comprises that the first solar cell, the welding layer and the second solar cell are laid on the lower surface layer; the upper surface layer are laid on the first and second solar cells; and the laid lower surface, the solar cell layers and the upper surface layer are heated to the lamination temperature to carry out lamination, so that the welding layer is melted to weld the first and second solar cells. The welding layer is melted by heating in the lamination process, so that the first andsecond solar cells are welded, an independent welding step is omitted, technology is simplified, and the production efficiency is improved.

Owner:BAODING YITONG PV SCI & TECH

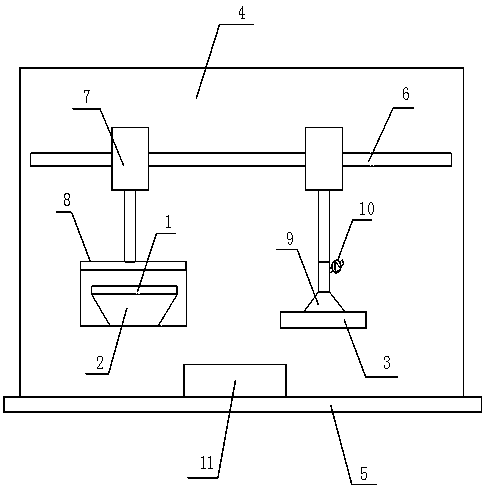

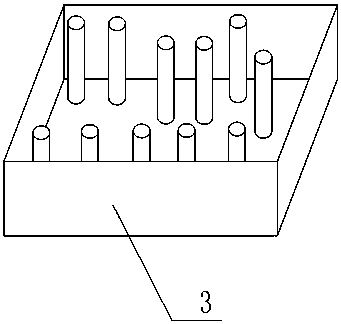

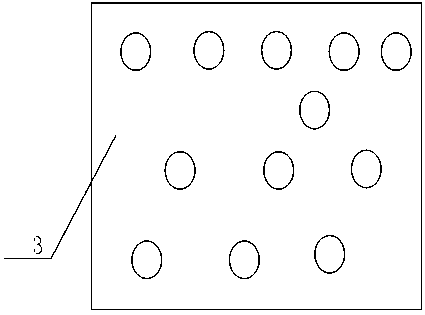

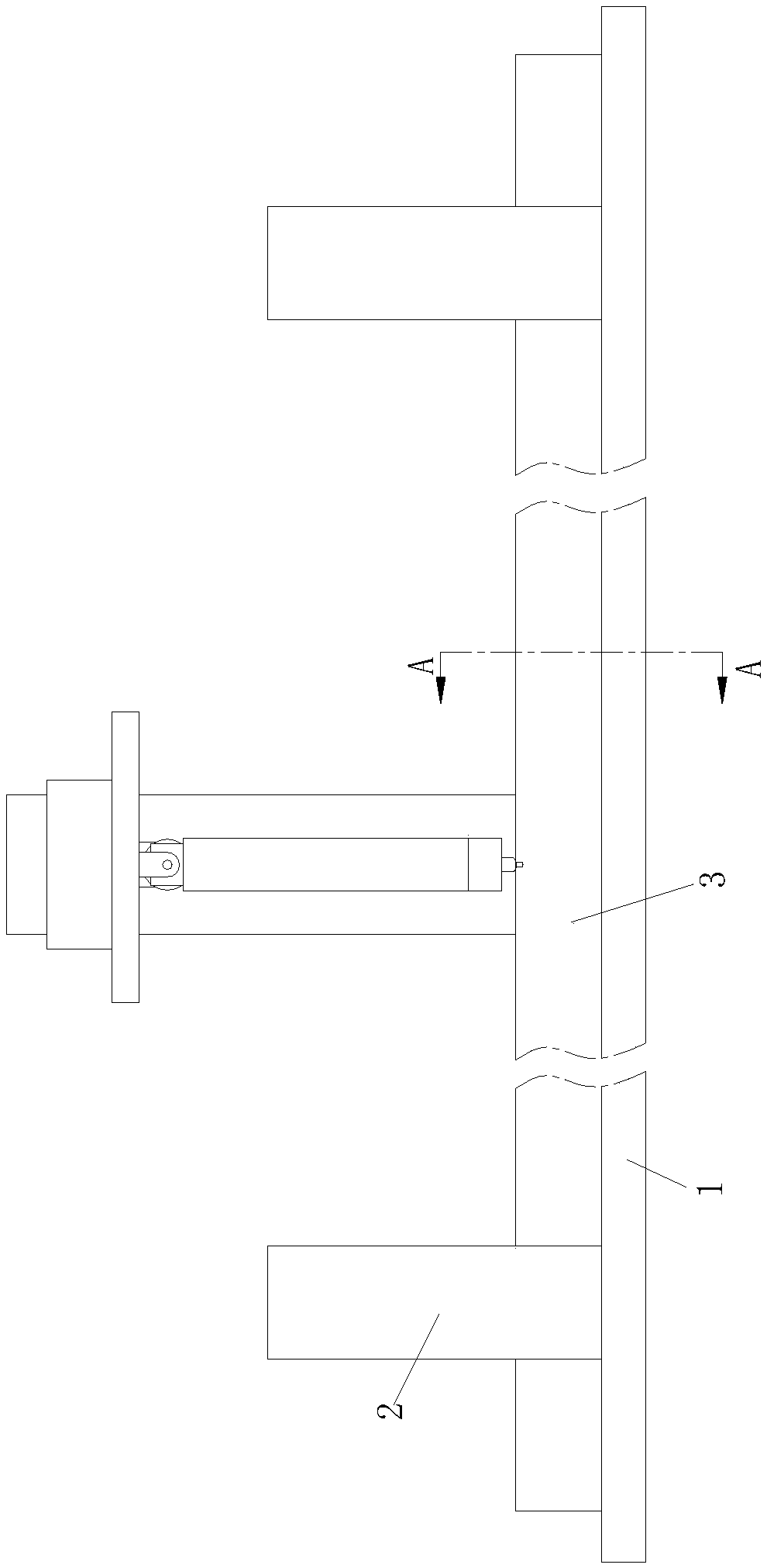

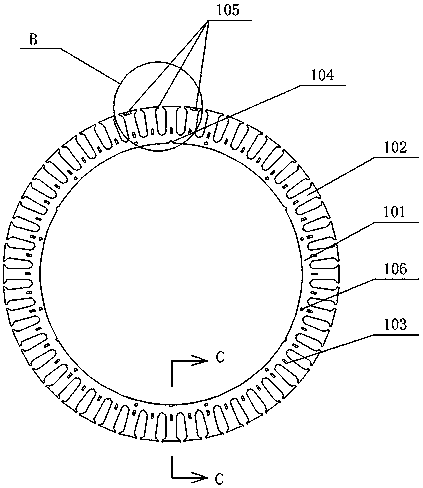

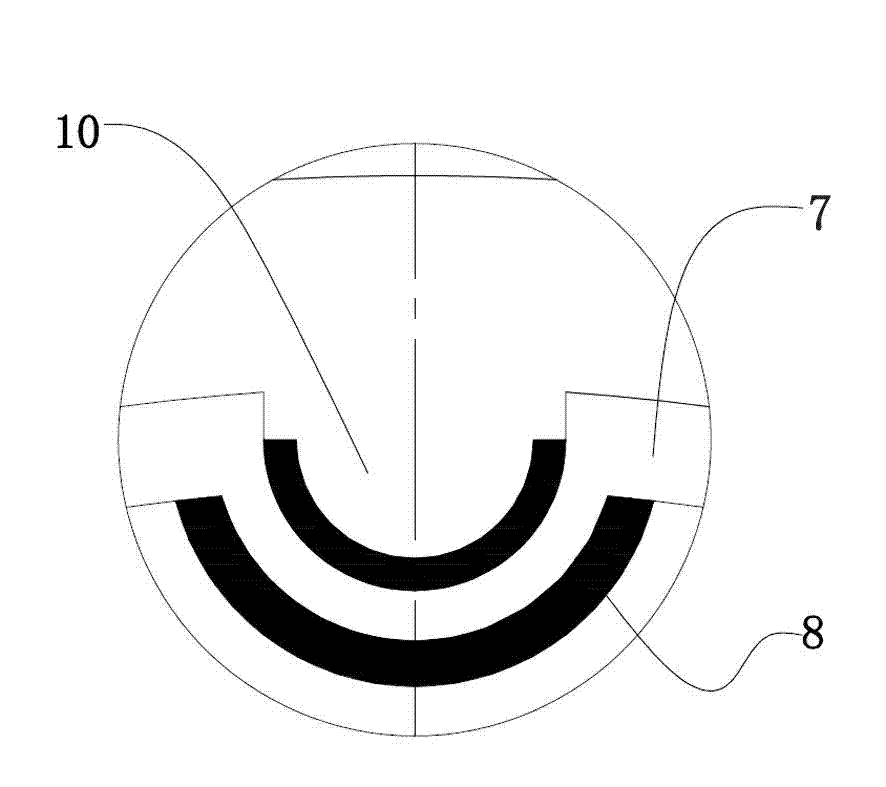

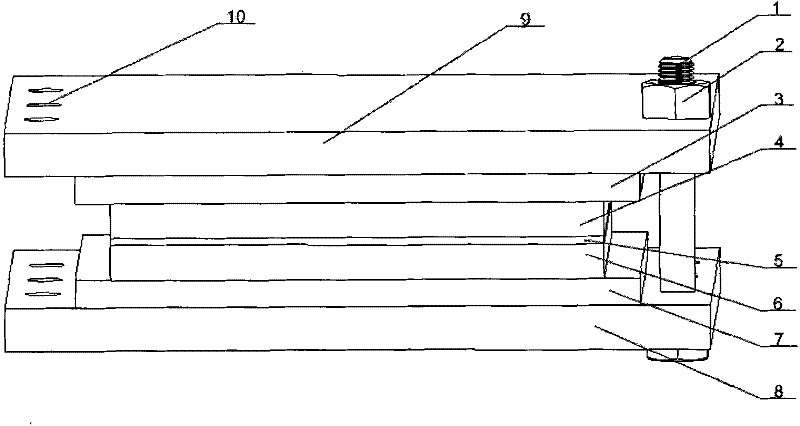

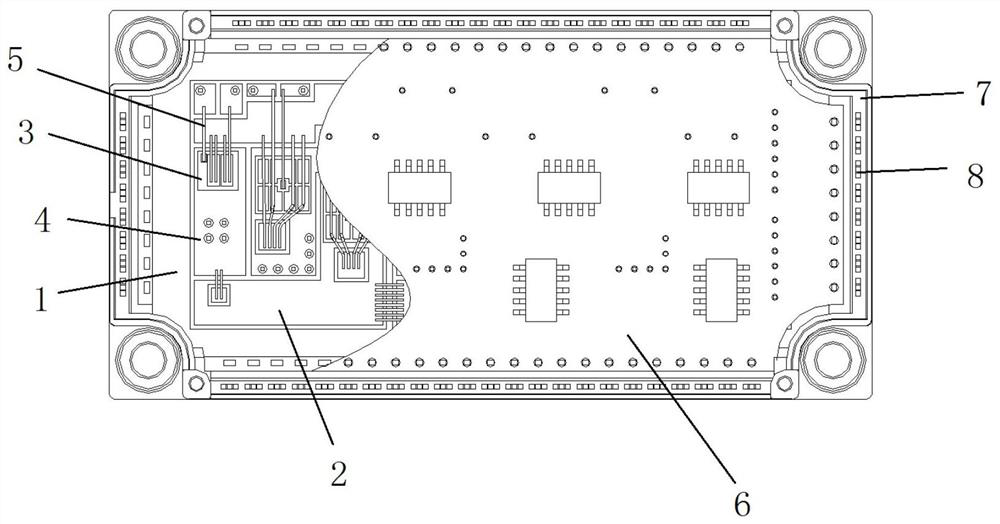

Electromagnetic pulse welding system special for PCB welding

ActiveCN109807426AGuaranteed cleanlinessLess soldering stepsHeating appliancesPrinted circuitsElectrical conductorElectromagnetic pulse

The invention discloses an electromagnetic pulse welding system special for PCB welding. The electromagnetic pulse welding system special for PCB welding comprises a bearing base used for containing ato-be-welded PCB, an electromagnetic pulse welding assembly and a shield mold. The electromagnetic pulse welding assembly comprises a pulse power source, a coil and a plate magnetic collector, and the coil is located above the plate magnetic collector and connected with the pulse power source. The electromagnetic pulse welding assembly is arranged above the bearing base through an installation frame on the bearing base; and the shield mold is used for covering the back face of the PCB and made of a non-conductor material, the whole shield mold is a box cover capable of covering a bottom opening of the PCB, multiple non-shield channels vertically penetrating through the box cover are arranged in the box cover, and the non-shield channels correspond to welding points of the back face of theto-be-welded PCB one to one.

Owner:CHONGQING UNIVERSITY OF SCIENCE AND TECHNOLOGY

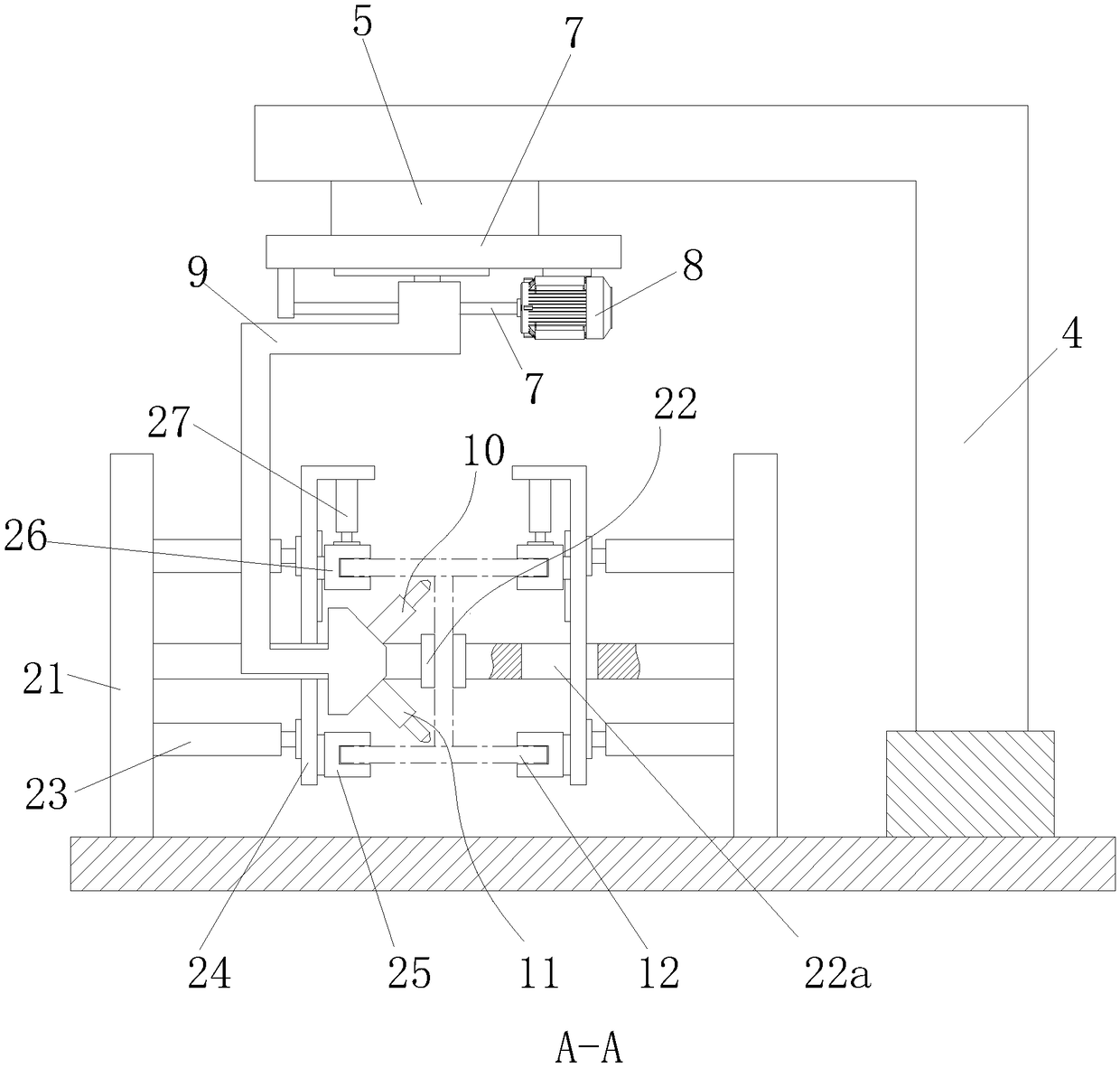

Symmetrical type welding device for H-shaped steel forming and processing

InactiveCN108788583AReasonable structural designLess soldering stepsWelding/cutting auxillary devicesAuxillary welding devicesDrive shaftEngineering

The invention relates to a symmetrical type welding device for H-shaped steel forming and processing. The symmetrical type welding device comprises a workbench, wherein the left side and the right side of the workbench are equipped with fixed mechanisms; the rear side of the workbench is equipped with a linear slide table in a length direction of the workbench; the drive end of the linear slide table is fixedly equipped with an L-shaped cantilever beam which extends out forwards; the lower side of the front end of the L-shaped cantilever beam is fixedly equipped with a rotary cylinder; the output end of the rotary cylinder is fixedly equipped with a rotary disc; a lead screw, a drive shaft and a motor connected with the lead screw are arranged on the rotary disc; a U-shaped arm which is insliding connection with the rotary disc and is provided with a backward opening is arranged on the lead screw in a matched mode; and the free end of the U-shaped arm is equipped with an inclined rearupward welding gun I, and an inclined rear downward welding gun II. The symmetrical type welding device can be used for simultaneously welding upper and lower connecting parts of steel, reduces welding steps, does not to regulate the position of the steel again by a worker, greatly reduces labor intensity, and improves production efficiency.

Owner:WUHU DINGHENG MATERIAL TECH

Portable aluminum row bending machine

The invention relates to the technical field of bending machines, in particular to a portable aluminum row bending machine. The portable aluminum row bending machine is characterized in that the portable aluminum row bending machine comprises a base, vertical racks, a hand-operated hydraulic cylinder, a bending blade and a bending blade holder, the vertical racks are arranged on the two sides of the upper portion of the base respectively, the hand-operated hydraulic cylinder is arranged in the middle of the upper portion of the base, the bending blade is arranged between the upper ends of the vertical frames, and the bending blade holder is arranged at the end of a piston rod on the upper portion of the hand-operated hydraulic cylinder. The portable aluminum row bending machine is convenient and fast to use, high in work efficiency, convenient to transport and move, easy to operate and safe to use, saves time and labor, does not need a power supply and is not affected by field conditions.

Owner:LAIAN POWER SUPPLY OF ANHUI ELECTRIC POWER CORP

Binaural U-shaped piece welding-free integrated finish machining method for thermonuclear fusion reactor

The invention relates to a machining technology of U-shaped pieces, in particular to a binaural U-shaped piece welding-free integrated finish machining method for a thermonuclear fusion reactor. The binaural U-shaped piece welding-free integrated finish machining method comprises the steps of manufacturing U-shaped blank pieces by using a forming die; carrying out first ultrasonic flaw detection on the U-shaped blank pieces after rough machining is carried out on the U-shaped blank pieces; carrying out rough machining again after heat treatment is carried out, then carrying out second ultrasonic flaw detection, picking out qualified U-shaped pieces, and carrying out a performance test by extracting samples from bodies; machining the U-shaped pieces which are qualified in the performance test into U-shaped pieces with allowance, and then manufacturing the U-shaped pieces into primary semi-finish machining U-shaped pieces by carrying out first artificial aging treatment on the U-shaped pieces; machining the primary semi-finish machining U-shaped pieces into U-shaped pieces with allowance, and then manufacturing the U-shaped pieces into secondary semi-finish machining U-shaped pieces by carrying out second artificial aging treatment on the U-shaped pieces; machining the secondary semi-finish machining U-shaped pieces into finish machining U-shaped pieces, drilling through holes in the end surfaces of side plates of the finish machining U-shaped pieces, and obtaining finished U-shaped pieces through WEDM (Wire Electrical Discharge Machining) after a metal wire is enabled to penetrate through the through holes. The binaural U-shaped piece welding-free integrated finish machining method disclosed by the invention has the advantages that the machining efficiency is high, and the product quality is good.

Owner:GUIZHOU AEROSPACE XINLI CASTINGSAND FORGINGS

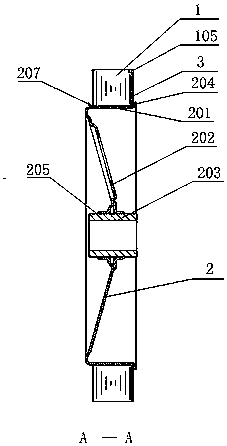

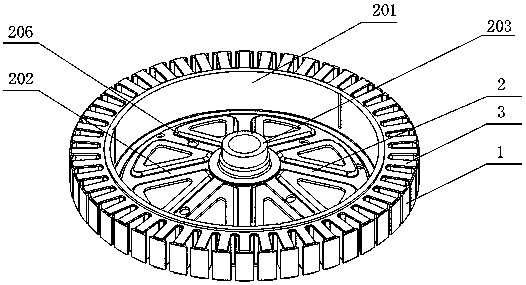

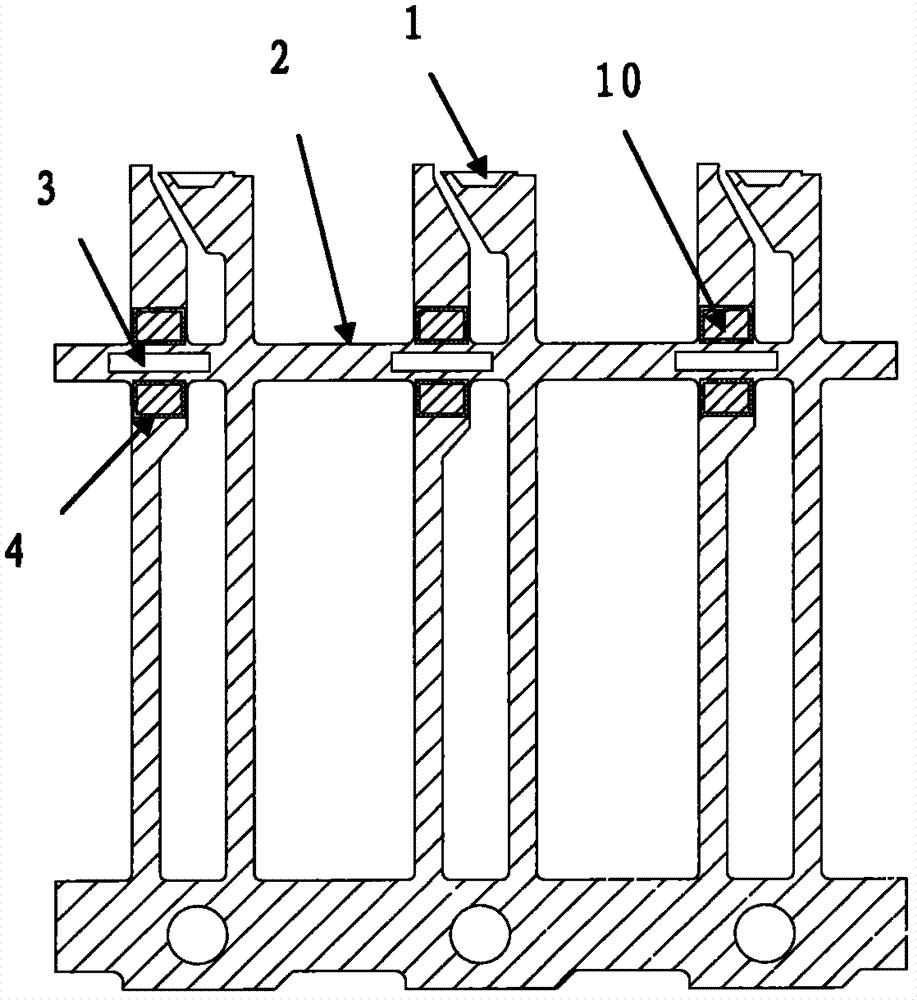

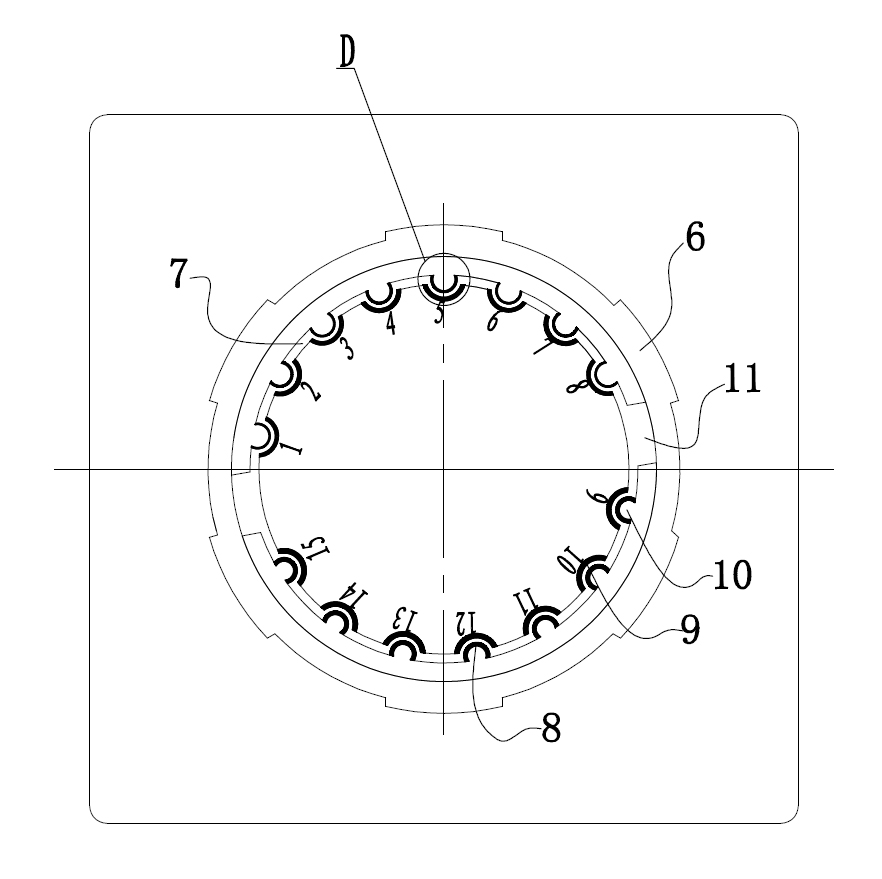

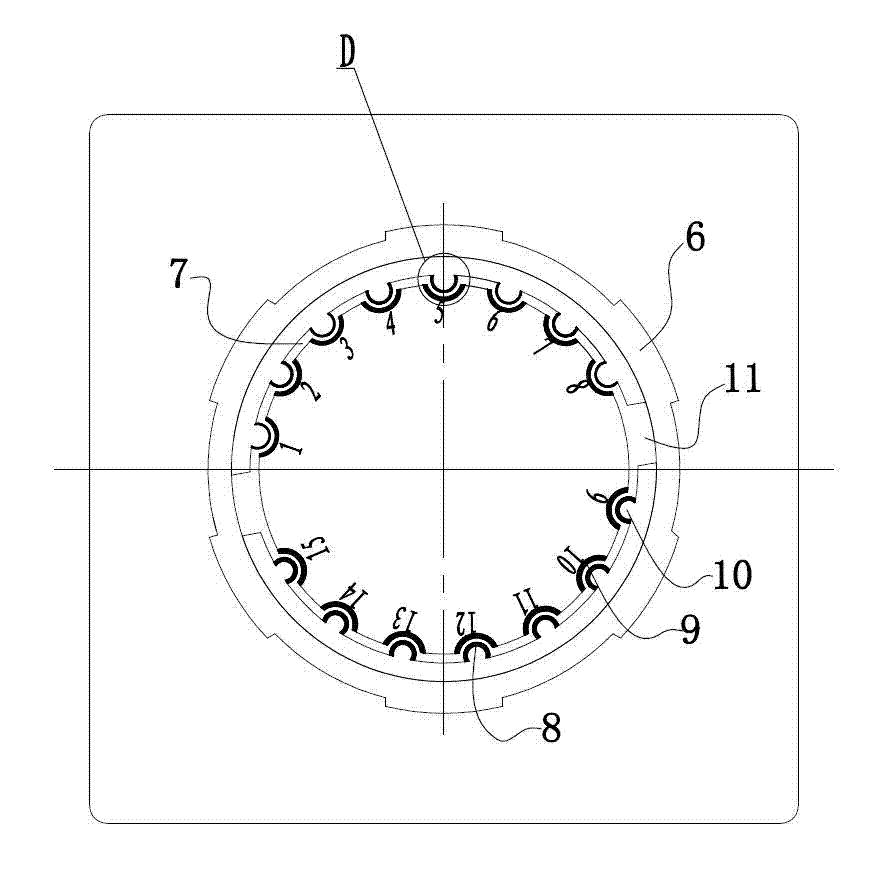

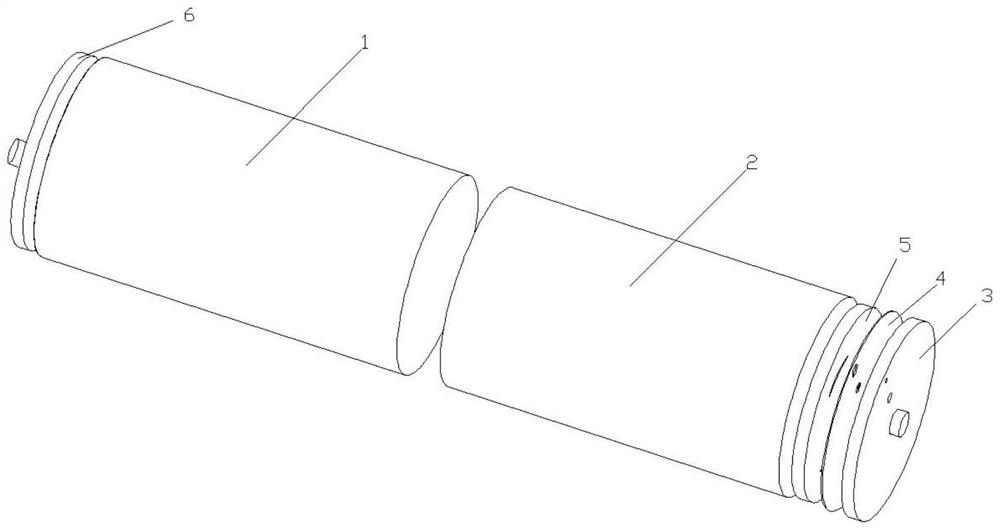

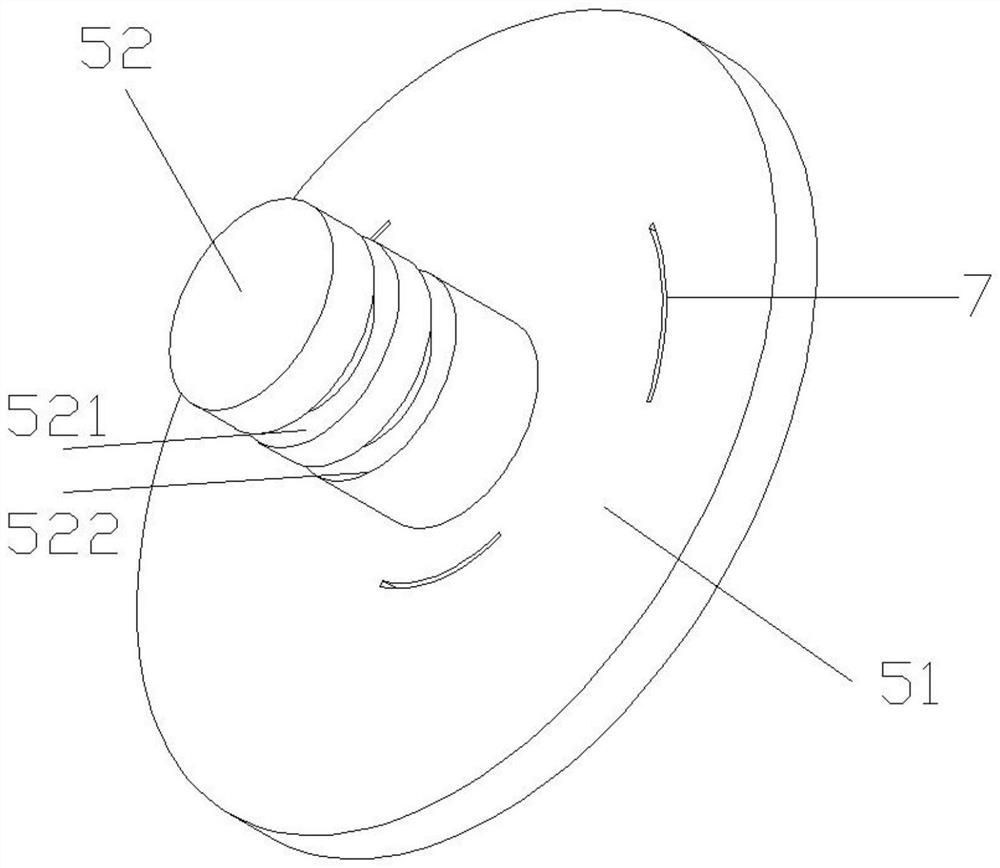

Single bracket electromobile motor stator and manufacturing method

ActiveCN110071583AImprove insulation performanceQuality improvementWindings insulation shape/form/constructionElectric machinesManufacturing technologyConductor Coil

The invention discloses a single bracket electromobile motor stator and a manufacturing method, and belongs to the technical field of motor stator manufacturing. The motor stator comprises a stator core (1) and a bracket body (2), wherein the bracket body (2) comprises a core mounting part (201), a supporting part (202) and a shaft sleeve (203); one end of the core mounting part (201) is connectedwith the supporting part (202); a flange (204) is arranged at the other end of the core mounting part (201); the shaft sleeve (203) is arranged in the center of the supporting part (202); and insulating sheets (3) are arranged on the two sides of the stator core (1). The manufacturing method comprises the steps of spinning, material cutting, notching, winding, riveting, reshaping, press mountingand fixing. According to the motor stator and the manufacturing method, the quality of a stator sheet can be improved; the efficiency of a motor can be high; the motor can operate stably; the performance of the motor can be good; and the production efficiency can be improved.

Owner:CHANGYING XINZHI TECH CO LTD

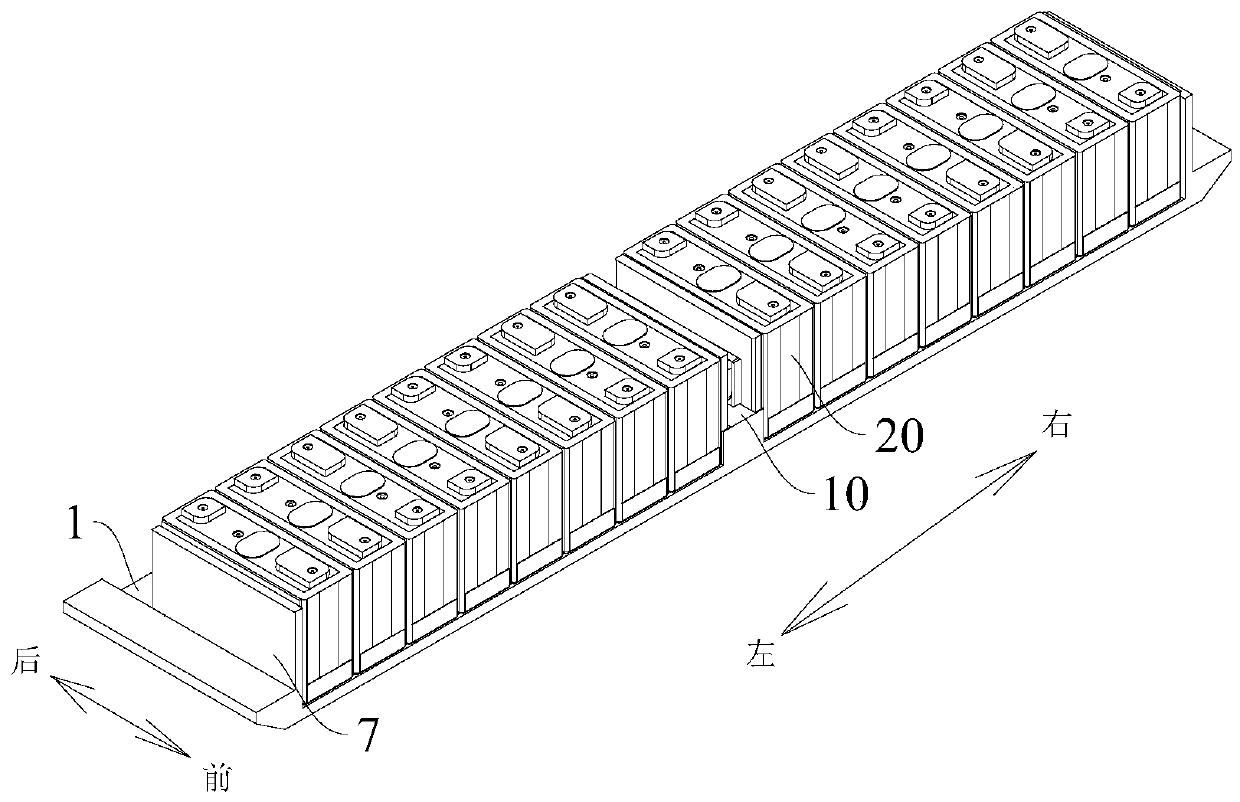

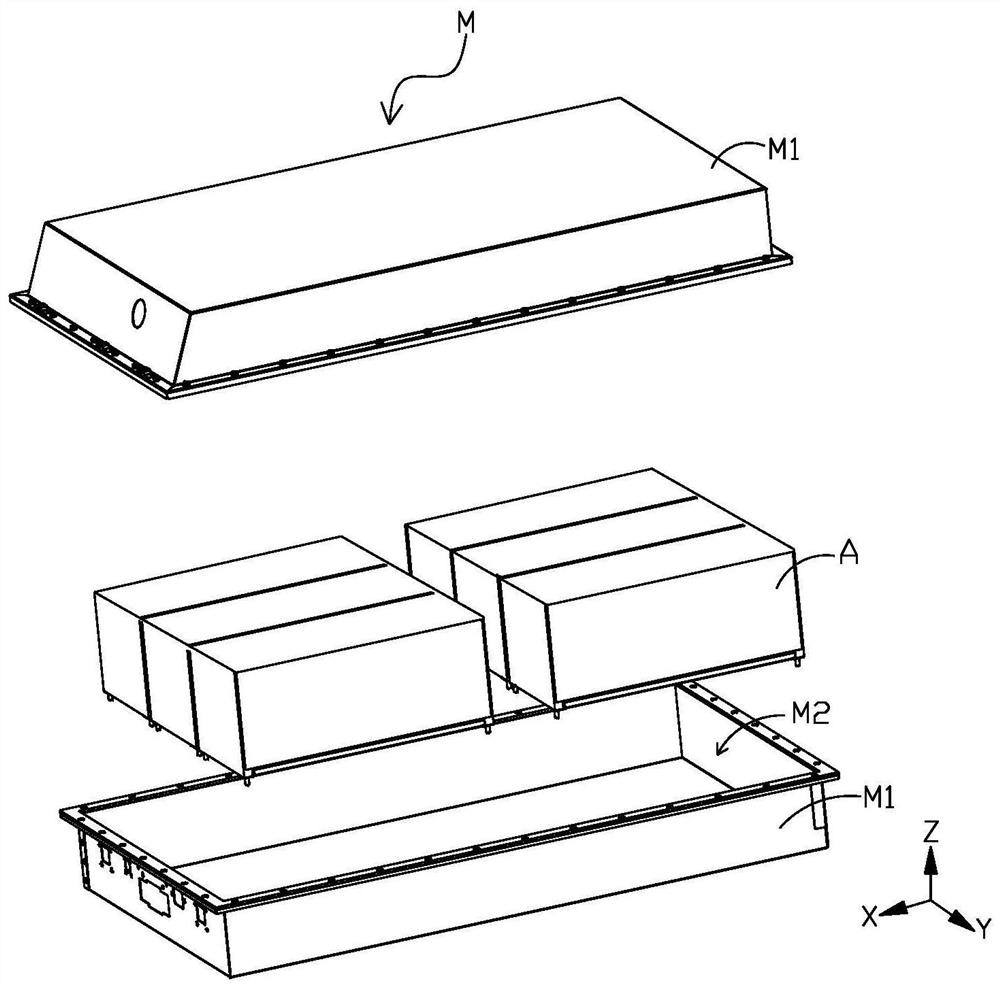

Fixing device of battery cell in battery pack and battery pack

InactiveCN109728221AReduce weightReduce processing difficultyCharging stationsCell component detailsEngineeringBattery cell

The invention provides a fixing device of a battery cell in a battery pack and a battery pack. The fixing device of the battery cell in the battery pack comprises a housing, a pressing plate and a pressing block. A fixing boss is disposed in the housing. The pressing plate is disposed on at least one side of the fixing boss. The pressing block is connected to the fixing boss. The connection matching length between the pressing block and the fixing boss is adjustable. By changing the connection matching length between the pressing block and the fixing boss, the pressing block can push the pressing plate in order that the pressing plate is pressed against the battery cell. Therefore, by the cooperation of the housing, the pressing plate and the pressing block, the battery cell in the batterypack can be pressed, the battery cell can be directly formed into the battery pack, and the side plate structure of a battery module in the battery pack can be eliminated. Thus, the weight of the battery pack is reduced. Further, a soldering step of the end plate and the side plate of the battery module can be eliminated, the process difficulty of manufacturing the battery pack can be reduced, and the assembly efficiency of the battery pack can be improved.

Owner:SVOLT ENERGY TECHNOLOGY CO LTD

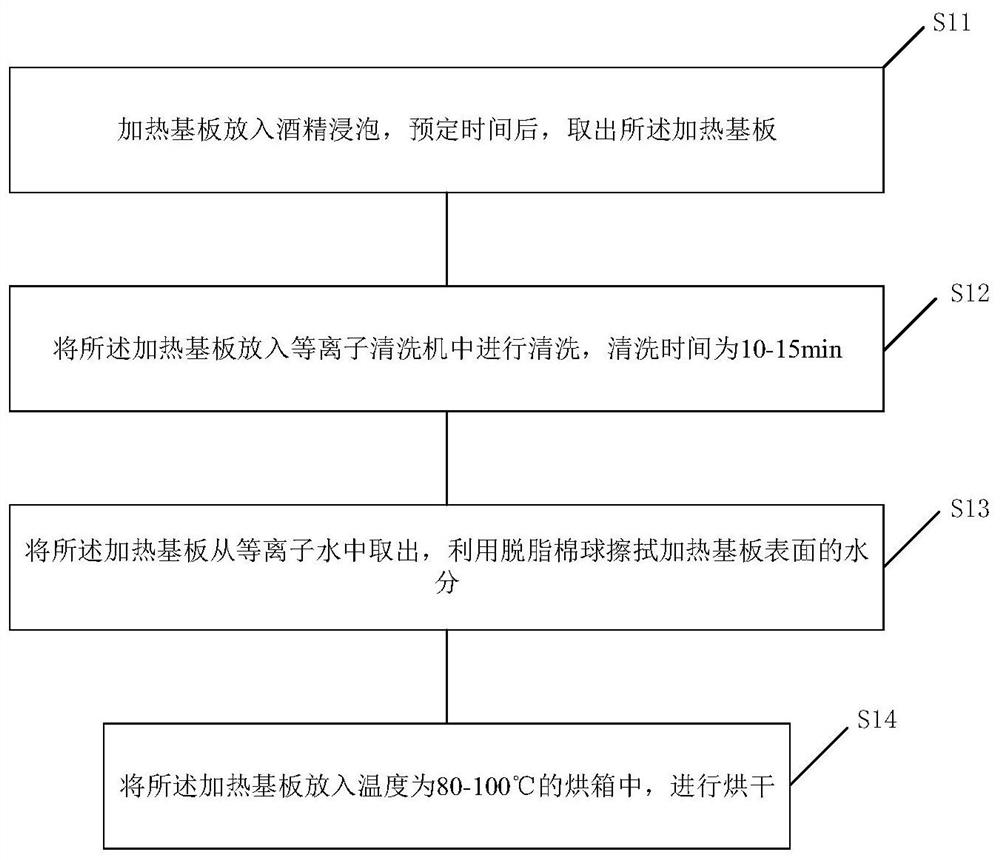

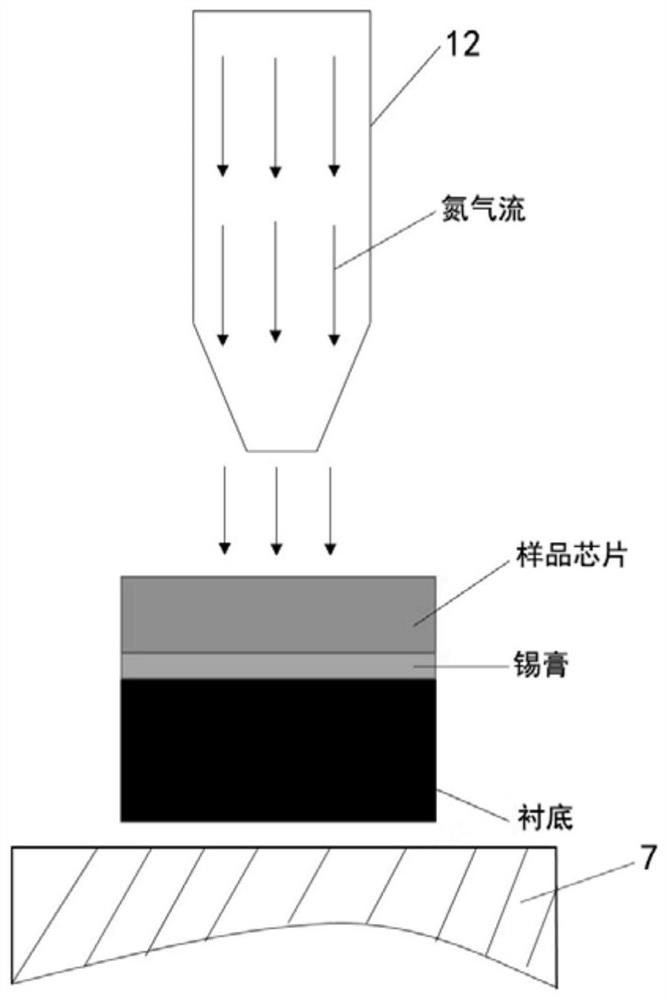

Process method for vacuum reflow eutectic welding

InactiveCN112002650AImprove welding qualityHeating up fastSemiconductor/solid-state device detailsSolid-state devicesRadiative heatingRadiant heat

The invention discloses a process method of vacuum reflow eutectic welding. The method comprises the steps of S1, taking out a heating substrate in a vacuum reflow furnace and carrying out plasma cleaning; S2, drying the heating substrate and fixing the heating substrate to a conveying device; S3, placing a sample after die bonding, and adjusting the position of a quartz air pipe; S4, setting eutectic welding parameters; and S5, carrying out welding quality inspection, wherein an improved vacuum reflow furnace is adopted for eutectic welding, the vacuum reflow furnace adopts a first heat source and a second heat source to provide heat required by sample welding, the first heat source provides hot air for heating, and the second heat source provides radiant heat. According to the invention,heat needed by eutectic welding is provided in a hot air heating mode and a radiation heating mode at the same time, the effect of rapid temperature rising can be achieved, the welding quality of a sample is improved, and the welding void ratio is reduced. The process method provided by the invention is simple to operate, high in safety, universal and suitable for production of small-batch and multi-variety products.

Owner:SHANGHAI INST OF TECH

Transducer and assembly method thereof

InactiveCN101351057AGood electrical connectionSimplify the assembly processTransducer casings/cabinets/supportsEngineeringRetaining wall

The invention discloses a transducer, which comprises a conductive terminal, a first shell and a second shell and is characterized in that the conductive terminal comprises a first conductive part, a second conductive part which is connected with the first conductive part and a third conductive part which is connected with the second conductive part; the first shell is provided with a channel and a retaining wall; the second shell is provided with a baffle plate; the first conductive part of the conductive terminal goes through the channel; the second conductive part of the conductive terminal is hung at a through groove between the baffle plate and the retaining wall; the third conductive part of the conductive terminal is exposed outside the first shell and the second shell, which realizes good electric link. The invention also discloses an assembly method of the transducer and is characterized in that the first conductive part of the conductive terminal is inserted into the channel of the first shell; the second conductive part of the conductive terminal is parallel with the retaining wall; the third conductive part of the conductive terminal is exposed outside the first shell and the second shell; therefore, the process is simplified and the cost is saved.

Owner:AAC ACOUSTIC TECH (SHENZHEN) CO LTD

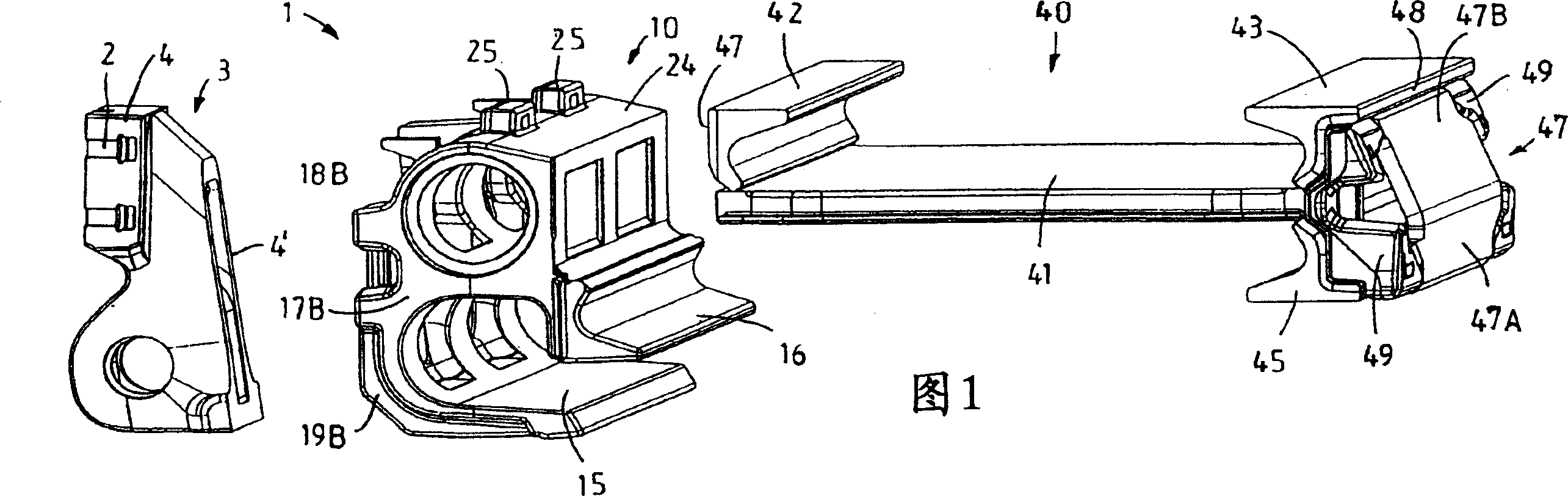

Guiding device for guiding a chain-drawn sword plane

InactiveCN1948710ALess soldering stepsEasy to wearSlitting machinesEngineeringMechanical engineering

The present invention relates to a guiding device (1) for guiding a chain-drawn sword plane which comprises a guiding element (10) consisting of a conveying shute (44) defined by the side section bar (42, 43) on the conveyor and a reversion groove (46) defined by the channel bar (16, 45) disposed at the filling side. The guiding device has an upper chain channel (12) and a lower chain channel (13) disposed with a guiding opening (14) for the planer prop. Each accommodating groove is constituted to be used to connect the clamping held for the clamping handle on the guiding element in order to connect the abutting the guiding device for guiding a chain-drawn sword plane. According to the invention, the guiding element is composed of the length extending cast for the guiding device for guiding a chain-drawn sword plane. On the cast the channel bar (16) at the filling side for each accommodating groove and / or the reversion groove and or the guiding part (16'', 15) for guiding a chain-drawn sword plane are casted as a whole.

Owner:CATERPILLER GLOBAL MINING EURO GMBH

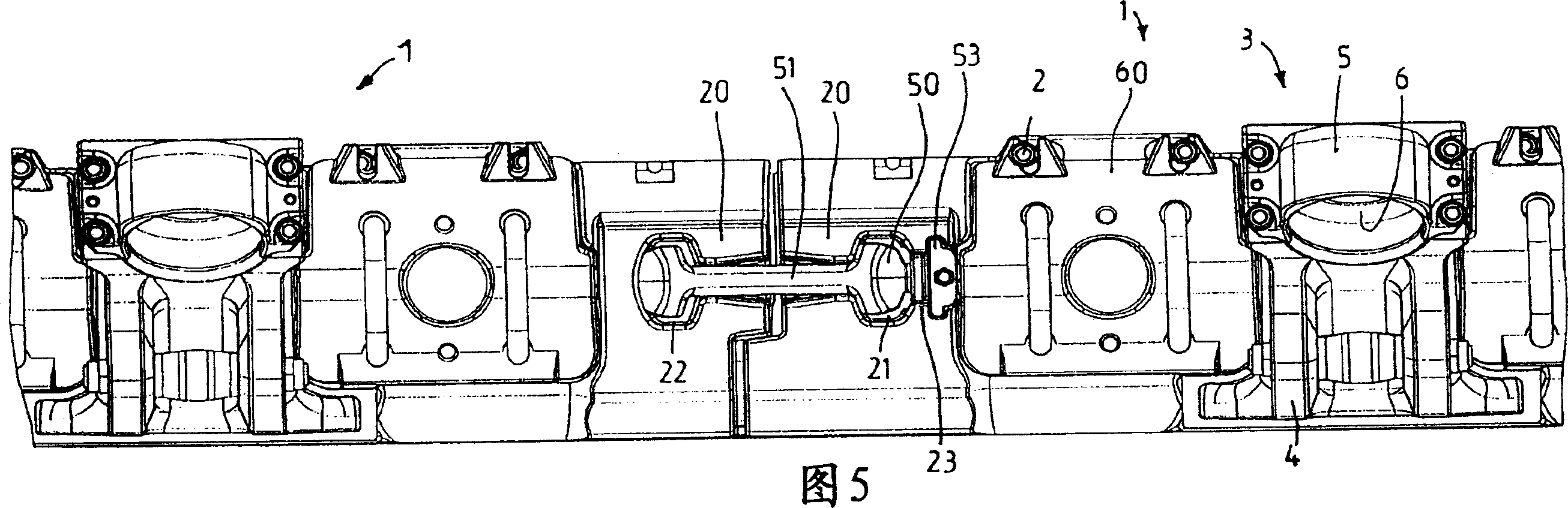

LED bracket and LED device both with SMD resistors and manufacturing method thereof

InactiveCN102769097ALess soldering stepsSave materialSolid-state devicesSemiconductor devicesEngineeringSurface mounting

The invention relates to an LED bracket and an LED device both with SMD (Surface Mounted Device) resistors and a manufacturing method thereof, and particularly relates to an LED bracket with SMD resistors. The LED bracket comprises LED bracket bodies and SMD resistors, wherein each LED bracket body is directly formed by a metal plate and comprises two electrode pins, and a broken notch for directly mounting the SMD resistor is formed on at least one electrode pin; and the SMD resistors are bonded at two ends of the broken notches of the LED bracket bodies through the SMD technique in a bridging manner. The invention further discloses an LED device with the LED bracket and manufacturing methods of both the LED bracket and the LED device. The LED device manufactured by adopting the method can be directly connected with a power cord for use; compared with the traditional manufacture process, a circuit board is not required, the welding process in welding the LED device, as well as other components, with a circuit board, is omitted; meanwhile, the materials are saved, the manufacturing time is shortened and the production efficiency is greatly improved; the manufacturing cost is lowered; and environmental pollution caused by etching in traditional circuit board production and manufacturing processes is reduced, so that environmental protection is achieved.

Owner:王定锋

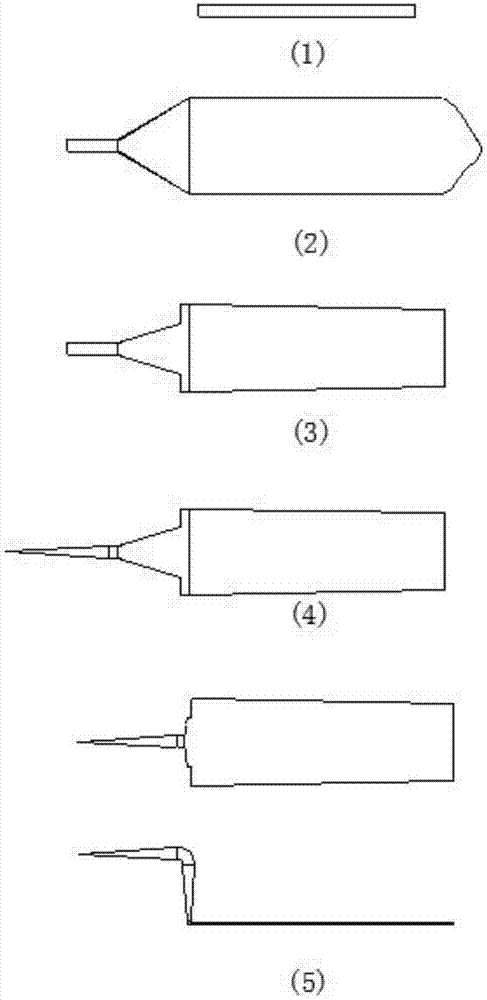

Aerial plug

ActiveCN102082343AReduce labor intensityLower requirementEngagement/disengagement of coupling partsCoupling contact membersAviationDip soldering

The invention relates to a solderless aerial plug used for machine riveting, which aims at overcoming the defects of poor soldering and unsoldering easily because of the fixed soldering manner between a metal contact pin used in the plug and a lead wire in the prior art. The aerial plug comprises an insulating body and a metal contact pin arranged inside the body; one end part of the body is provided with an annular groove; the outer wall of the annular groove is provided with a notch; the outer wall of the annular groove is connected with a nut; the end part of the metal contact pin is in a fork structure; the horn of fork corresponds to the annular groove; and the horn of fork is respectively fixed on the inner side of the outer wall of the annular groove and the outer side of the inner wall of the annular groove. The annular groove with an opening is arranged at the end part of the body; the metal contact pin is fixed in the annular groove; the outer wall of the annular groove is fixed through a tightened nut; the outer wall of the annular groove is extruded and deformed inwards; the distance between the two forks of the metal contact pin becomes smaller so as to tighten the lead wire and completely realize mechanical tightening; and therefore, the step of soldering is eliminated, the working procedure is simpler, the operation is simple, the labor intensity of workers is decreased, and the requirement for workers is also decreased.

Owner:ZHEJIANG XINLI ELECTRIC APPLIANCE TECH CO LTD

Integrated forming process for support and plate body of plastering plate

The invention relates to a process for integrally forming a plasterboard with a gray knife and a plate body, comprising the following steps: (1) blanking the steel material into a single steel blank; (2) rolling one end of the steel blank into a block (3) take the obtained plate to form the dimensions of the horizontal connection between the bracket and the plate body to obtain the first semi-finished product; (4) forge the tail of the first semi-finished product with a forging press The shape of the bracket is used to obtain the second semi-finished product; (5) the middle part of the second semi-finished product is formed and bent by a press to obtain the third semi-finished product; (6) the surface of the third semi-finished product is post-processed; (7) the third semi-finished product is Just install the handle on the bracket. The beneficial effects of the present invention are: the bracket and the board are integrally formed, eliminating the steps of welding, forging and stamping in the traditional process, reducing the steps of processing, reducing the difficulty of processing, reducing the cost and waste of resources, and improving the strength of the bracket and the board. Body connection strength, this product is easy to clean and recycle after use, prolonging the service life of the product.

Owner:重庆市大足区君治五金工具有限公司

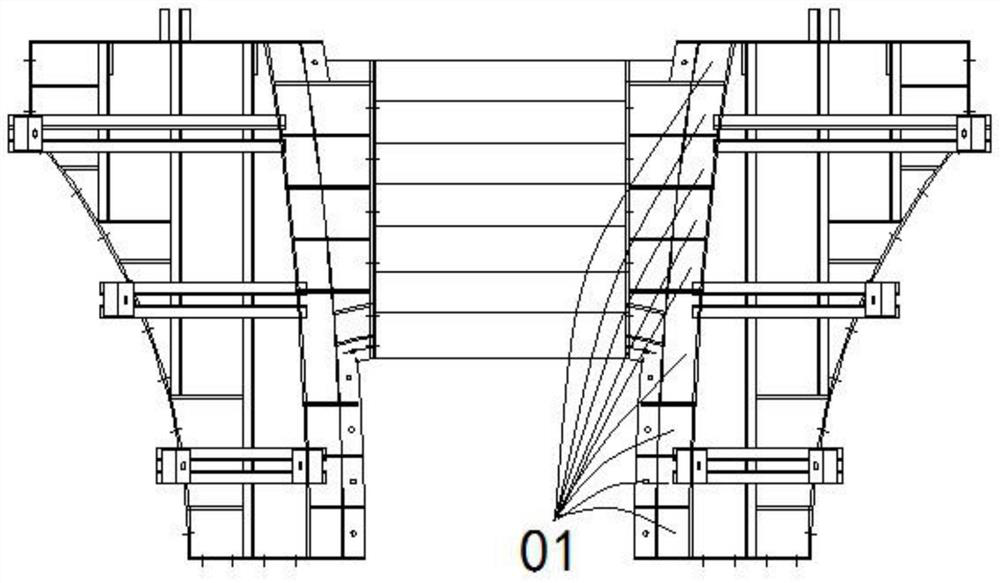

A construction process of the curved surface of a vase-shaped pier-column mold for a bridge

The invention discloses a construction process for the curved surface of a bridge vase-shaped pier mold, which is characterized in that it includes the following steps: (1), rolling: rolling a flat steel plate into a cylindrical steel plate through rolling equipment; (2) ), welding: the cylindrical steel plate obtained in the rounding step is seamed into a steel pipe; (3), rounding: the steel pipe obtained in the welding step is processed into a curved steel pipe through a rounding machine; (4), cutting: the rounded The curved steel pipe obtained in the step is cut into a curved strip curved panel along its bending axis; (5), welding: the curved strip curved panel obtained in the cutting step is welded as a curved surface position on the steel formwork; the bridge vase-shaped pier In the construction process of the curved surface of the column mold, the curved steel pipe is cut into curved strip-shaped curved panels, and the strip-shaped curved panels are used to replace the multiple small curved panels welded from bottom to top in the prior art, reducing nonlinear welding The tedious process improves the construction efficiency.

Owner:HUBEI SHIRUIDA HEAVY ENG MACHINERY +1

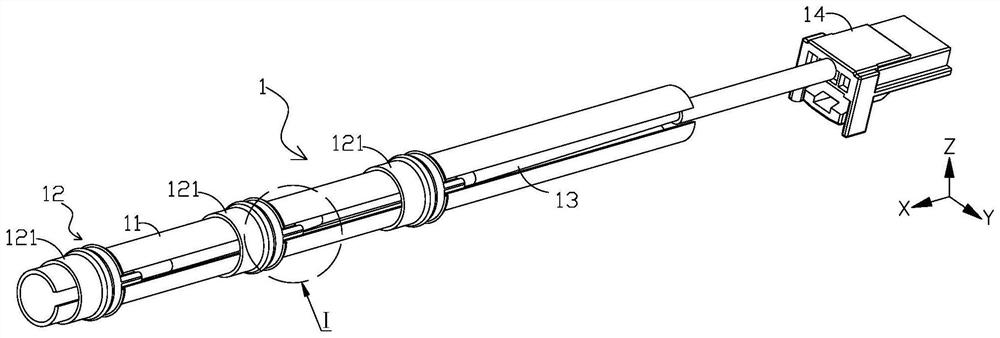

Sampling component, battery module, battery pack and device

ActiveCN112310566ALess soldering stepsReduce processing difficultyCell component detailsElectrical batteryControl theory

The invention relates to a sampling component, a battery module, a battery pack and a device. The sampling component can comprise a body part, a sampling terminal and a sampling wire, the sampling terminal is provided with a main body part, the main body part sleeves the body part, and the sampling wire is electrically connected with the sampling terminal. As the main body part sleeves the body part, when the sampling component penetrates through the connecting piece and / or the electrode terminal of the battery module, the sampling terminal can be abutted against and electrically connected with the connecting piece and / or the electrode terminal through the main body part, so that the sampling wire can be electrically connected with the battery module, the step of welding the sampling component and the battery module can be omitted, and the processing difficulty is reduced; and the production efficiency is enhanced.

Owner:CONTEMPORARY AMPEREX TECH CO

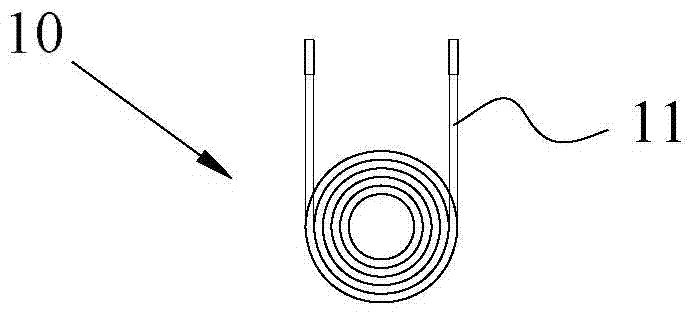

Manufacturing method of surface mount coil inductor

ActiveCN103578731AThe production process is simpleLow manufacturing costInductances/transformers/magnets manufactureFixed signal inductancesInductorEngineering

The invention discloses a manufacturing method of a surface mount coil inductor. The manufacturing method comprises the following steps of: providing a coil and a baseband, and fixing at least one terminal wire of the coil on the baseband; encapsulating the coil by an encapsulation process, so that the terminal wires of the coil are exposed to the outside of an encapsulation shell; reserving the partial length of the terminal wire outside the encapsulation shell, cutting off the remaining length of the terminal wire outside the encapsulation shell, and taking out the encapsulation shell outside which the terminal wire is cut off, so that the encapsulation shell is separated from the baseband; bending the wire terminal outside the encapsulation shell separated from the baseband in the same or opposite direction, so that the terminal wire is bonded to the bottom and / or the side of the encapsulation shell to form a coil inductor. The manufacturing method provided by the invention has the advantages of stable electrical connection performance, simple manufacturing process, low manufacturing cost and the like.

Owner:SHIN YUAN ELECTRONICS PROD KUNSHAN

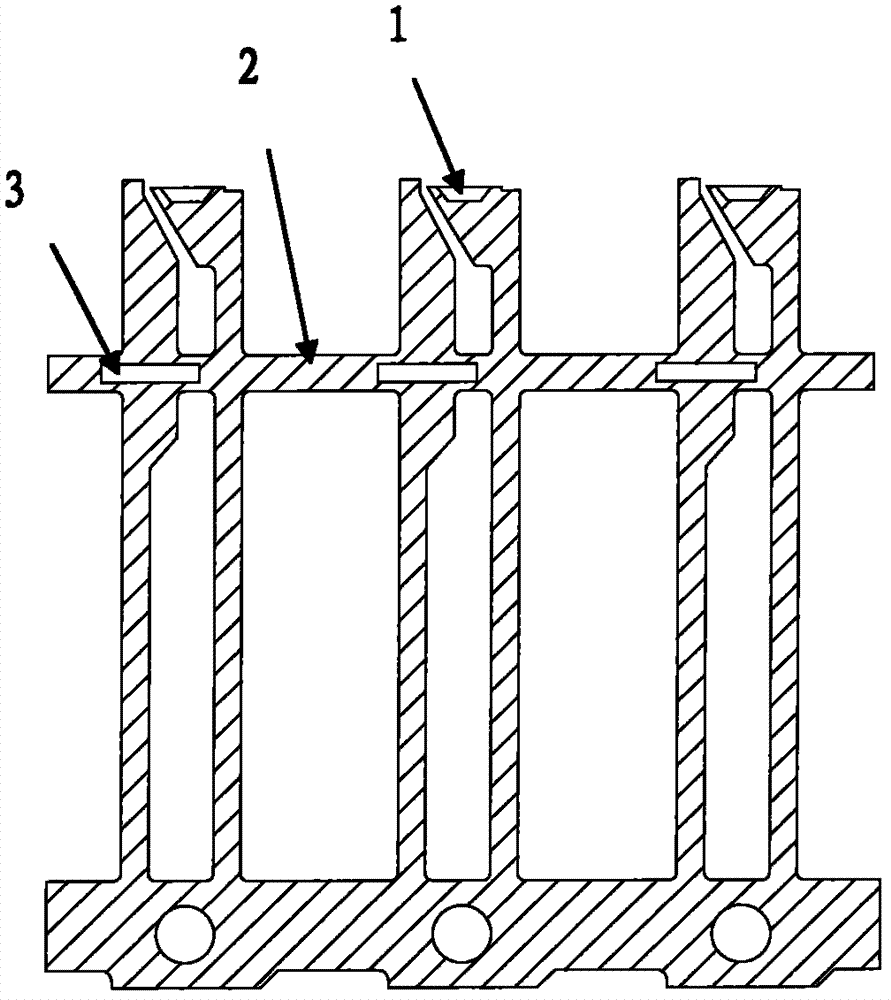

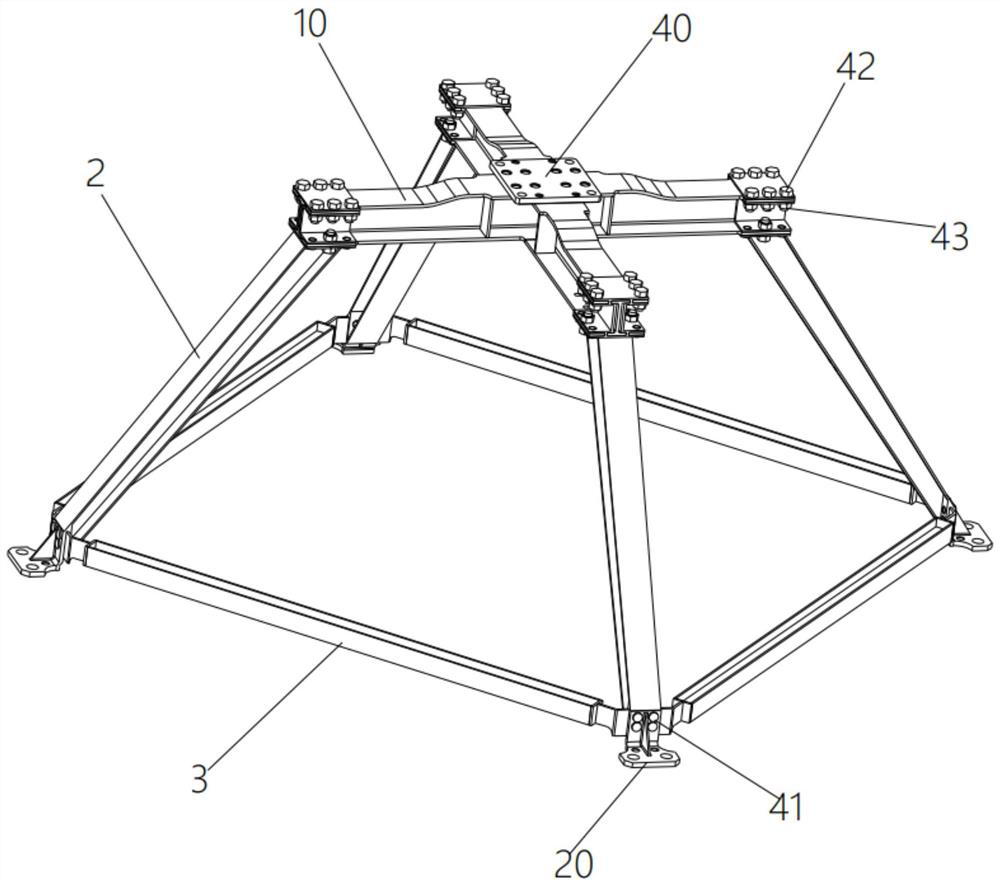

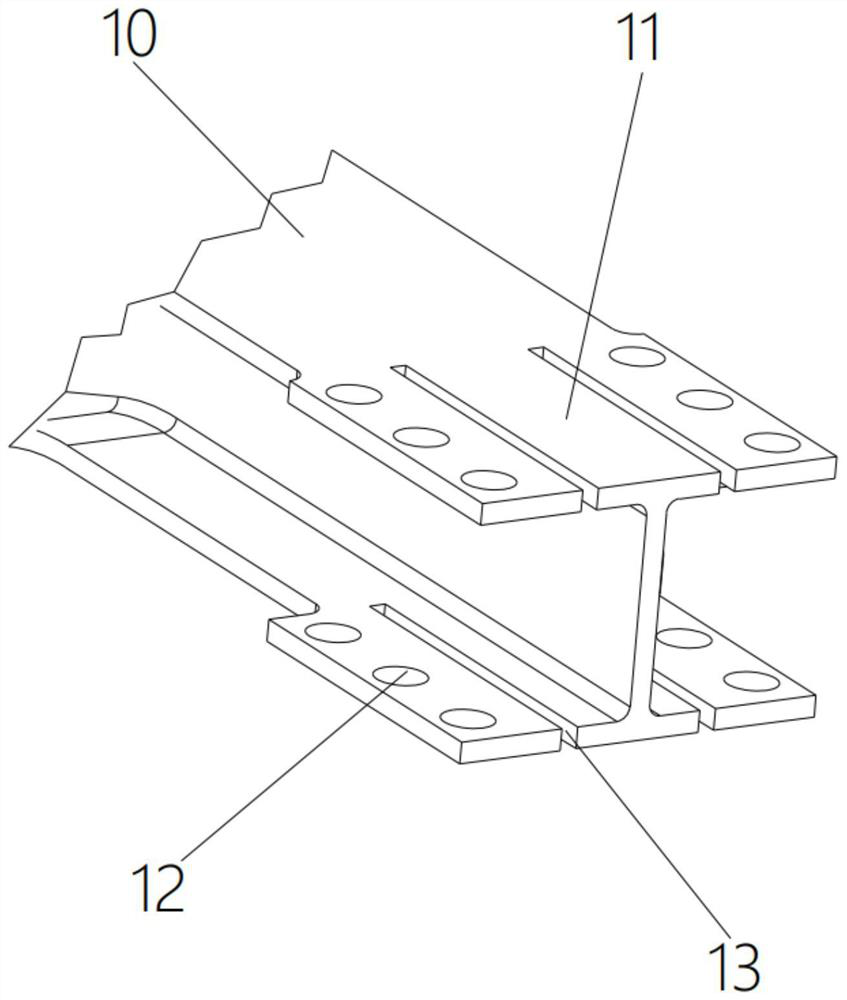

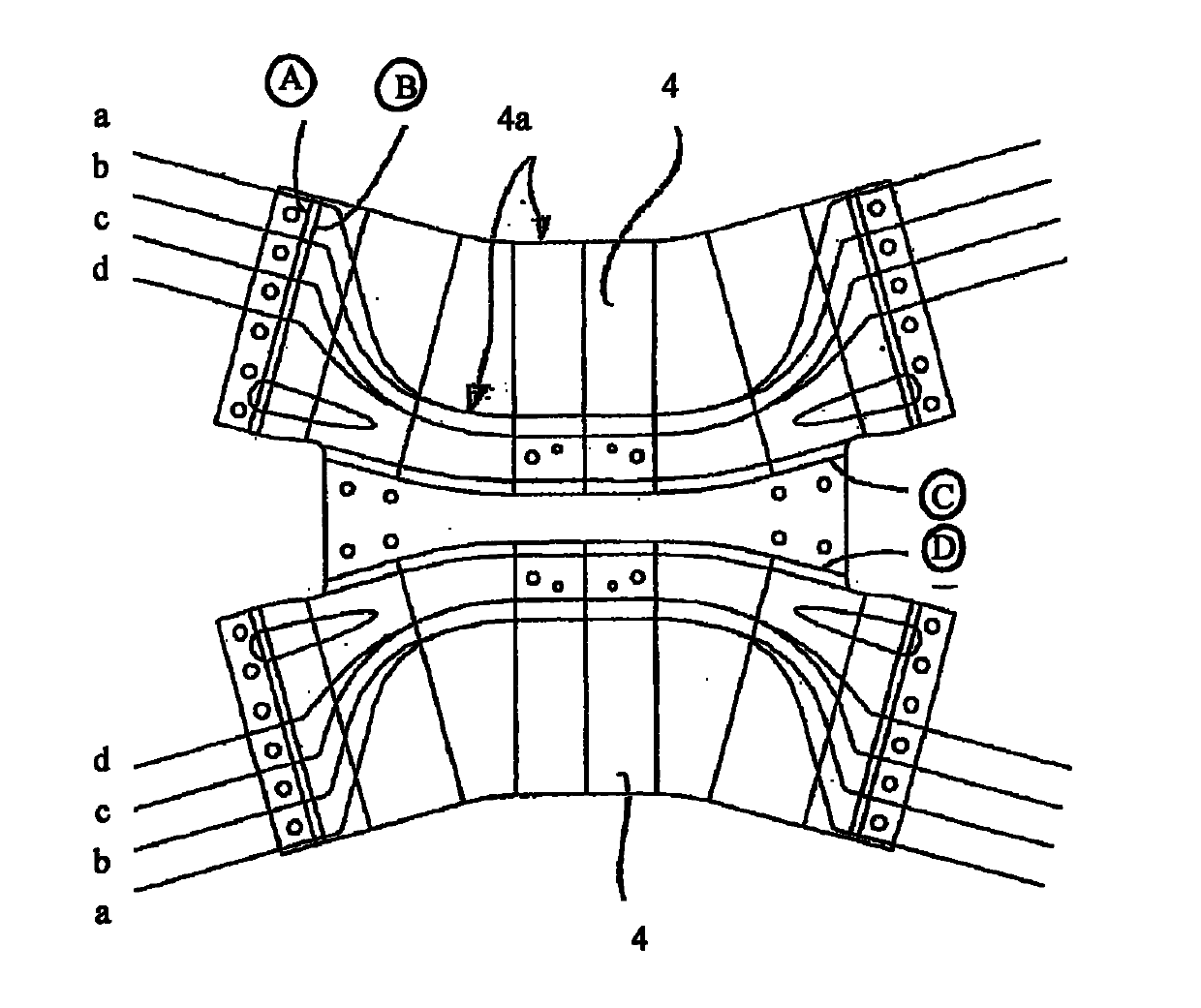

Mortise and tenon type machine frame used for liquid rocket engine

PendingCN112727638APrevent looseningReduce distortionRod connectionsRocket engine plantsMortise and tenonShaped beam

The invention discloses a mortise and tenon type machine frame used for a liquid rocket engine. The mortise and tenon type machine frame used for the liquid rocket engine comprises a cross-shaped beam, force bearing beams and cross beams, mortise and tenon plugs are arranged at four ends of the cross-shaped beam; the number of the force bearing beams is four, the lower ends of the force bearing beams are provided with mortise and tenon sockets which are inserted into the mortise and tenon plugs, the upper ends of the force bearing beams are provided with two mortise and tenon insertion grooves; and the number of the cross beams is four, the cross beams are arranged between every two adjacent force bearing beams, and the two ends of each cross beam are each provided with a mortise and tenon insertion piece inserted into the corresponding mortise and tenon insertion groove. The four force bearing beams are inserted and fixed to the four ends of the cross-shaped beam respectively through insertion of the mortise and tenon plugs and the mortise and tenon sockets, the four cross beams are inserted and fixed between every two adjacent force bearing beams respectively through insertion of the mortise and tenon insertion pieces and the mortise and tenon insertion grooves, and therefore assembly of the cross-shaped beam, the force bearing beams and the cross beams is achieved, and the whole machine frame is formed, the welding steps are reduced, the deformation of the machine frame is small, the machining quality is improved, meanwhile, stress concentration does not occur, and the reliability of the machine frame in the using process can be improved.

Owner:北京中科宇航技术有限公司

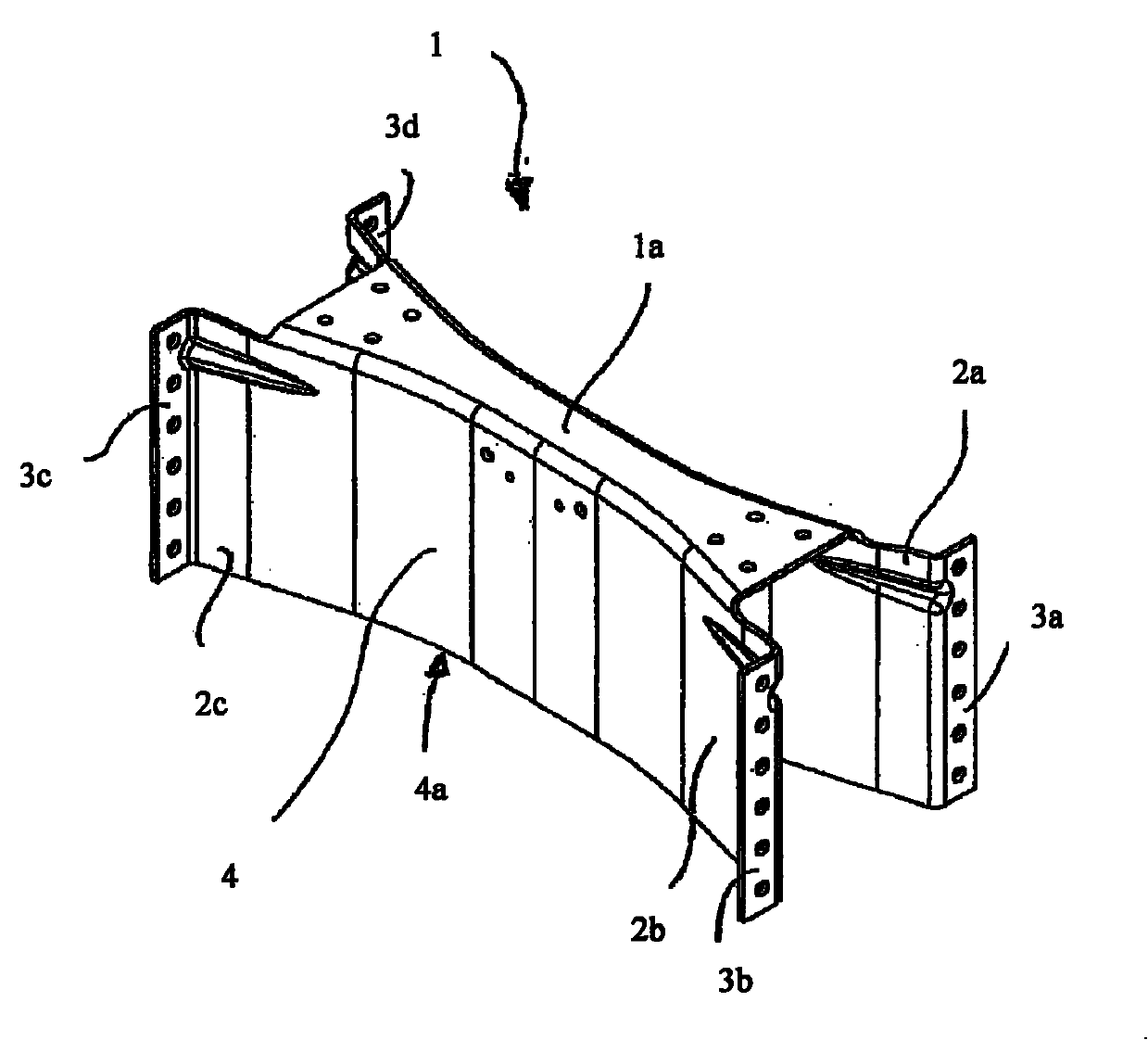

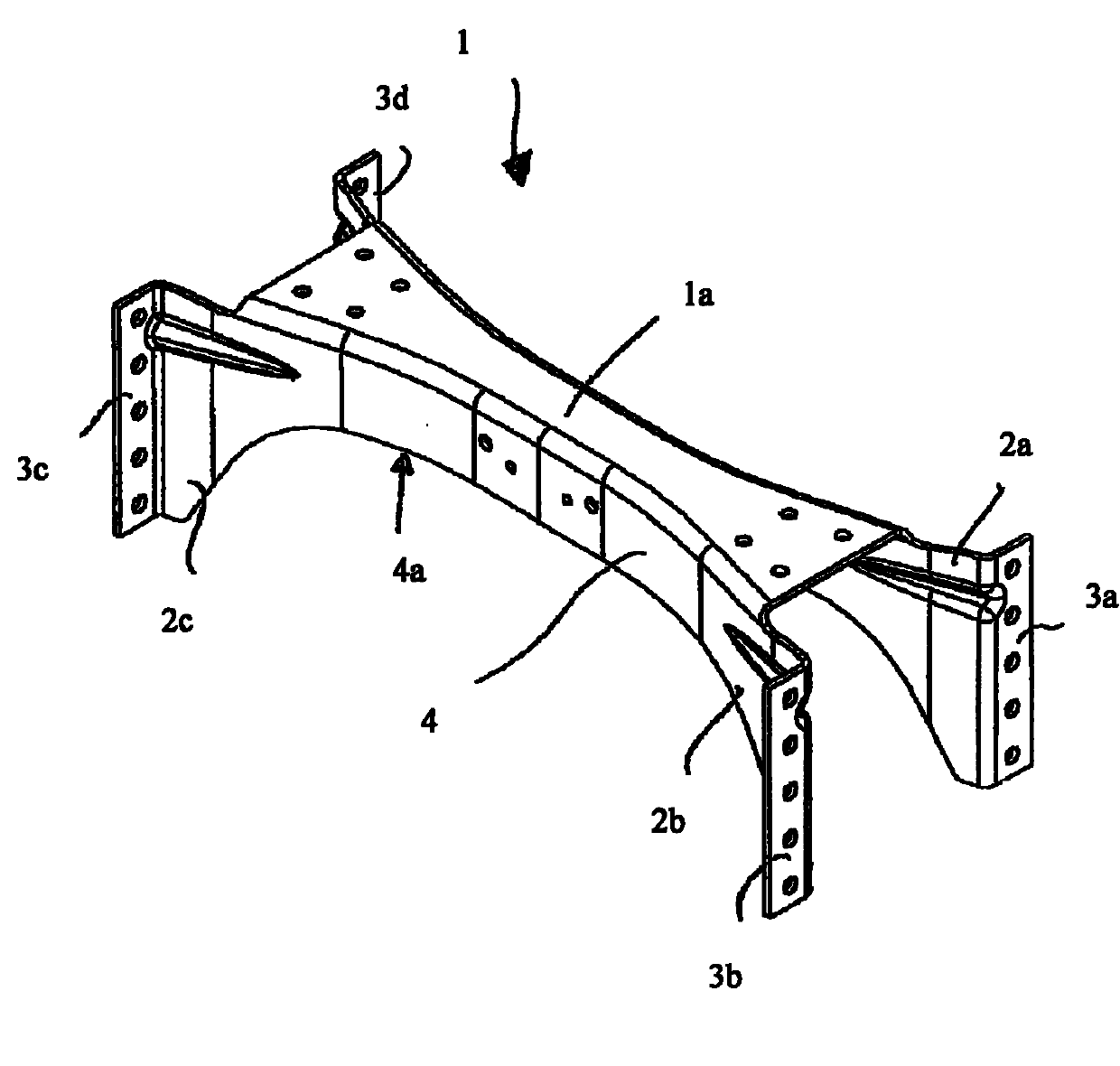

Method for obtaining a stiffening cross member for a vehicle frame and cross member obtained with such method

ActiveCN102026865ALess soldering stepsReduce manufacturing process stepsUnderstructuresVehicle frameWork in process

This invention relates to a method for obtaining a stiffening cross member for a vehicle frame, in particular heavy vehicles, the cross member obtained with such method, and also a vehicle frame comprising such cross member. The method according to this invention allows to obtain a cross member made of a single piece, and to obtain cross members having different profiles and dimensions according to what is required, using the same semi-finished product.

Owner:IVECO SPA

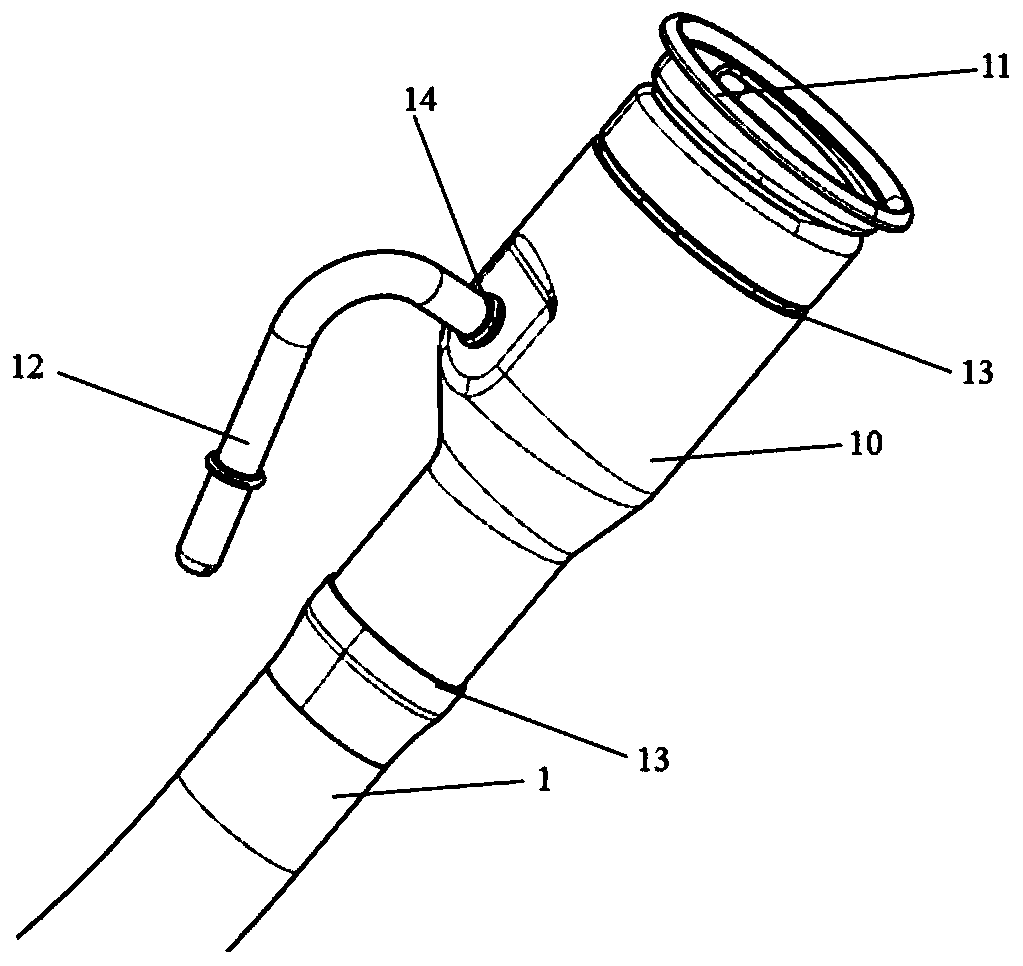

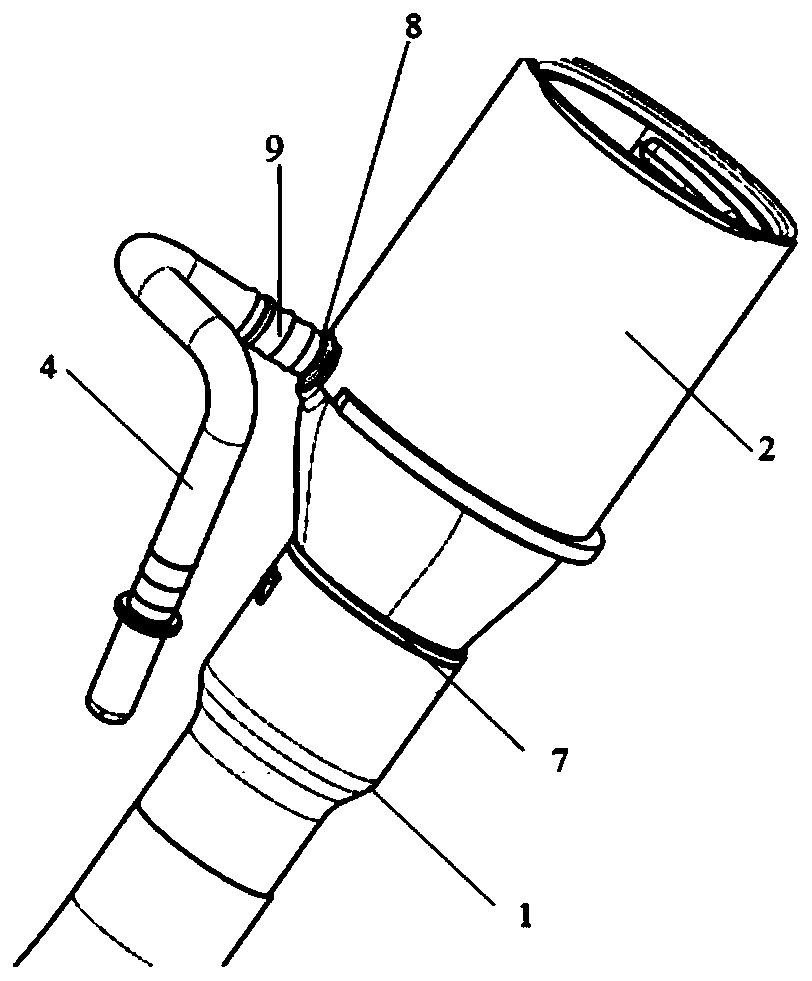

Metal oil filling pipe for assembling plastic oil pipe head

The invention discloses a metal oil filling pipe for assembling a plastic oil pipe head. The metal oil filling pipe for assembling the plastic oil pipe head comprises a metal oil filling pipe main pipe and a plastic oil pipe head part; the metal oil filling pipe main pipe and the plastic oil pipe head part are connected together in an assembling mode and are connected in a sealing mode through sealing pieces; and one side of the plastic oil pipe head part is connected with an air return pipe in an assembling mode. According to the metal oil filling pipe for assembling the plastic oil pipe head, the plastic oil pipe head part and the metal oil filling pipe main pipe can be assembled and connected together by means of plugging, sleeving or buckling and the like, the plastic oil pipe head part and the metal oil filling pipe main pipe are detachably connected, the plastic oil pipe head part is used for replacing a traditional stainless steel or low carbon steel oil pipe head flaring or necking reducing part, an assembly connection mode is used for replacing a traditional welding connection mode, meanwhile, the sealing pieces such as sealing rings or sealing gaskets and the like are used at connection positions for sealing, the structure is simple, the efficiency is high, the sealing performance is good, the integral weight is greatly reduced, at least three metal welding steps arereduced, the production and investment costs are obviously reduced, artificial errors do not exist basically, and the standardization degree of parts is high.

Owner:戴胜汽车科技(苏州)有限公司

Aerial plug

ActiveCN102082343BNo interferenceReduce labor intensityEngagement/disengagement of coupling partsCoupling contact membersAviationDip soldering

The invention relates to a solderless aerial plug used for machine riveting, which aims at overcoming the defects of poor soldering and unsoldering easily because of the fixed soldering manner between a metal contact pin used in the plug and a lead wire in the prior art. The aerial plug comprises an insulating body and a metal contact pin arranged inside the body; one end part of the body is provided with an annular groove; the outer wall of the annular groove is provided with a notch; the outer wall of the annular groove is connected with a nut; the end part of the metal contact pin is in a fork structure; the horn of fork corresponds to the annular groove; and the horn of fork is respectively fixed on the inner side of the outer wall of the annular groove and the outer side of the innerwall of the annular groove. The annular groove with an opening is arranged at the end part of the body; the metal contact pin is fixed in the annular groove; the outer wall of the annular groove is fixed through a tightened nut; the outer wall of the annular groove is extruded and deformed inwards; the distance between the two forks of the metal contact pin becomes smaller so as to tighten the lead wire and completely realize mechanical tightening; and therefore, the step of soldering is eliminated, the working procedure is simpler, the operation is simple, the labor intensity of workers is decreased, and the requirement for workers is also decreased.

Owner:ZHEJIANG XINLI ELECTRIC APPLIANCE TECH CO LTD

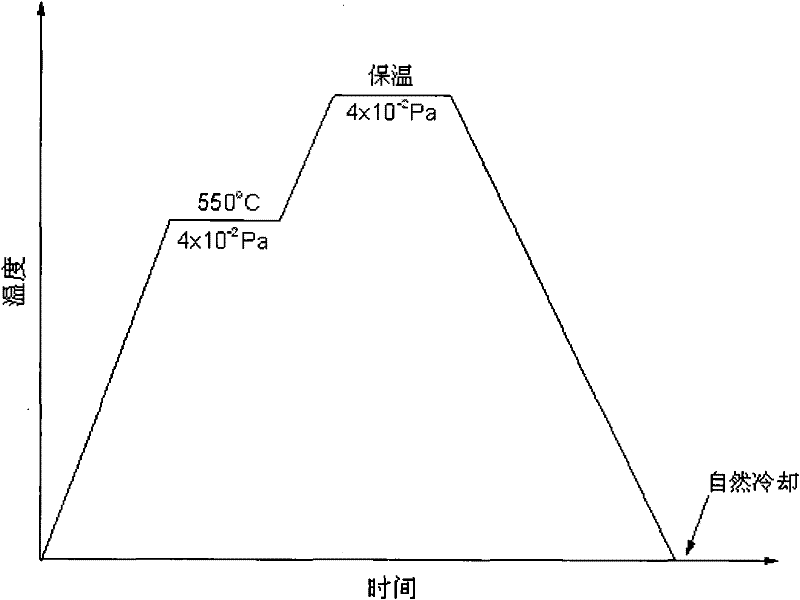

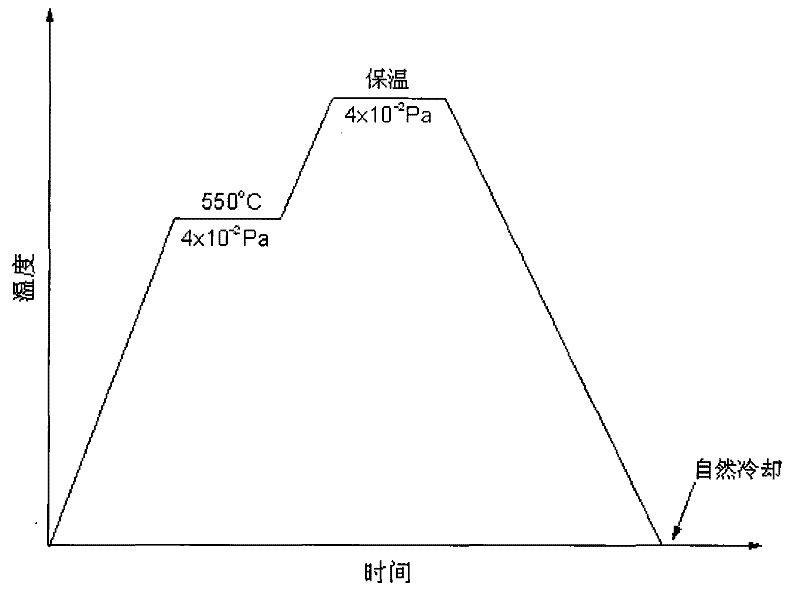

Glass and metal vacuum brazing technique

The invention relates to a glass and metal vacuum brazing technique which has the advantages of simple operation, low cost and good economic effect. The technique has the technical scheme of comprising the steps of: 1) carrying out surface treatment on glass and metal workpieces; and 2) putting the treated welding workpieces into a vacuum brazing furnace, and vacuumizing and heating for vacuum brazing. The technique is characterized in that the step 1) comprises: carrying out roughening and cleaning treatment on the surface of glass; carrying out surface purification and smooth finish treatment on the metal workpieces; and carrying out chemical plating treatment on the surface of glass.

Owner:NANJING UNIV OF TECH

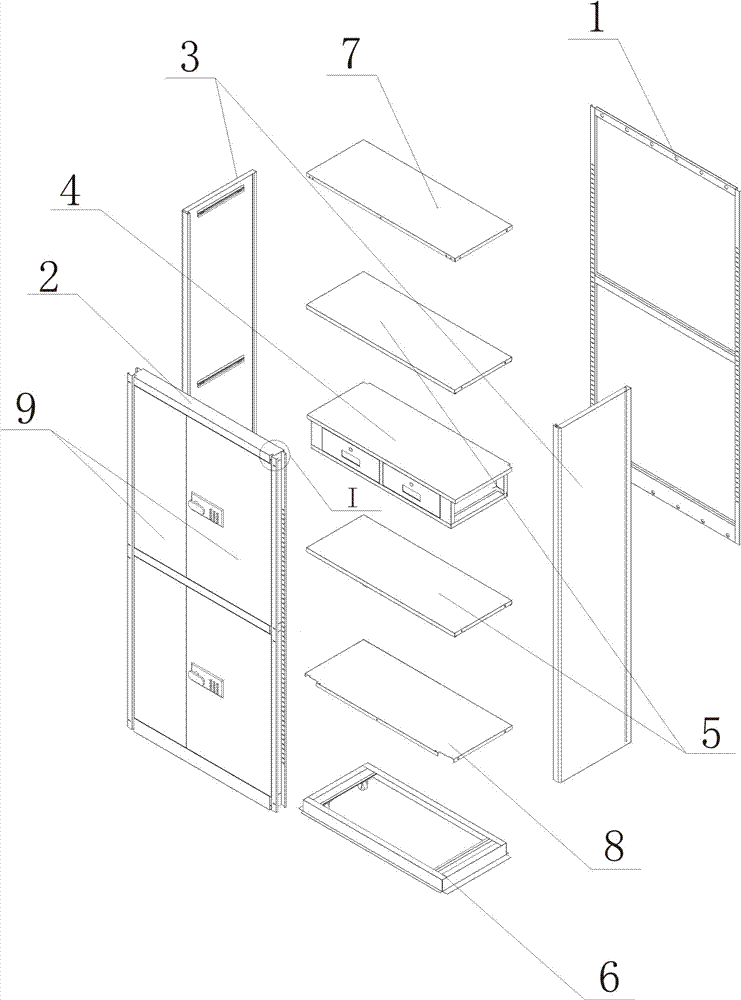

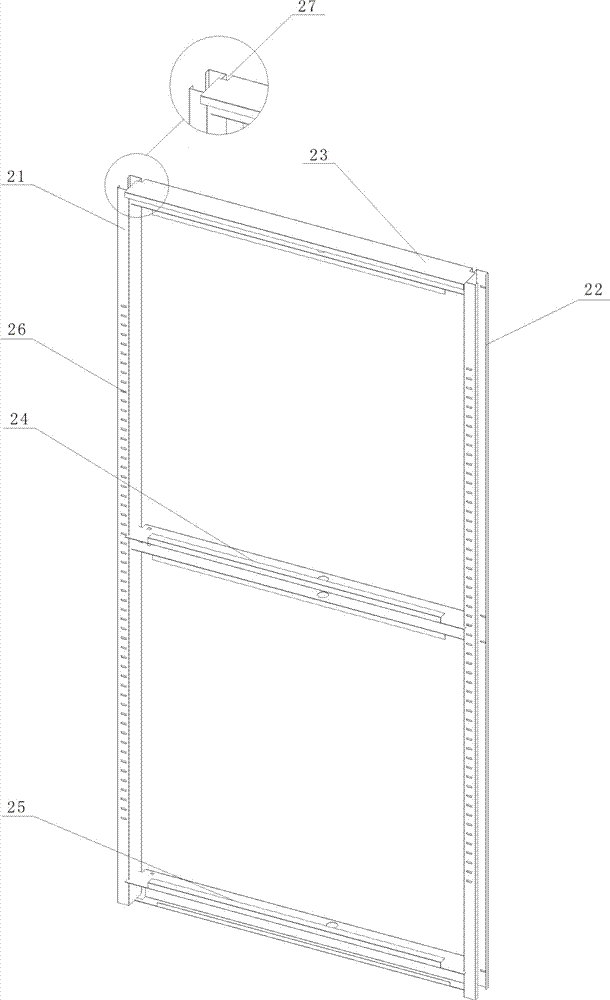

Detachable type prying-resistant confidential cabinet

ActiveCN107440348ASimple structureEasy to assembleBook cabinetsStructural engineeringMechanical engineering

The invention discloses a detachable type prying-resistant confidential cabinet which comprises a rear frame, a front frame, two side plates, a drawer device and a base. The detachable type prying-resistant confidential cabinet has the advantages that the detachable type prying-resistant confidential cabinet is simple in integral structure and easy to produce and assemble; space wastage in carrying procedures can be effectively reduced, and the detachable type prying-resistant confidential cabinet is convenient to transport; the detachable type prying-resistant confidential cabinet can be accurately and firmly assembled, can be quickly assembled in service sites and can be conveniently used in the service sites, and welding steps can be reduced.

Owner:洛阳花冠办公家具有限公司

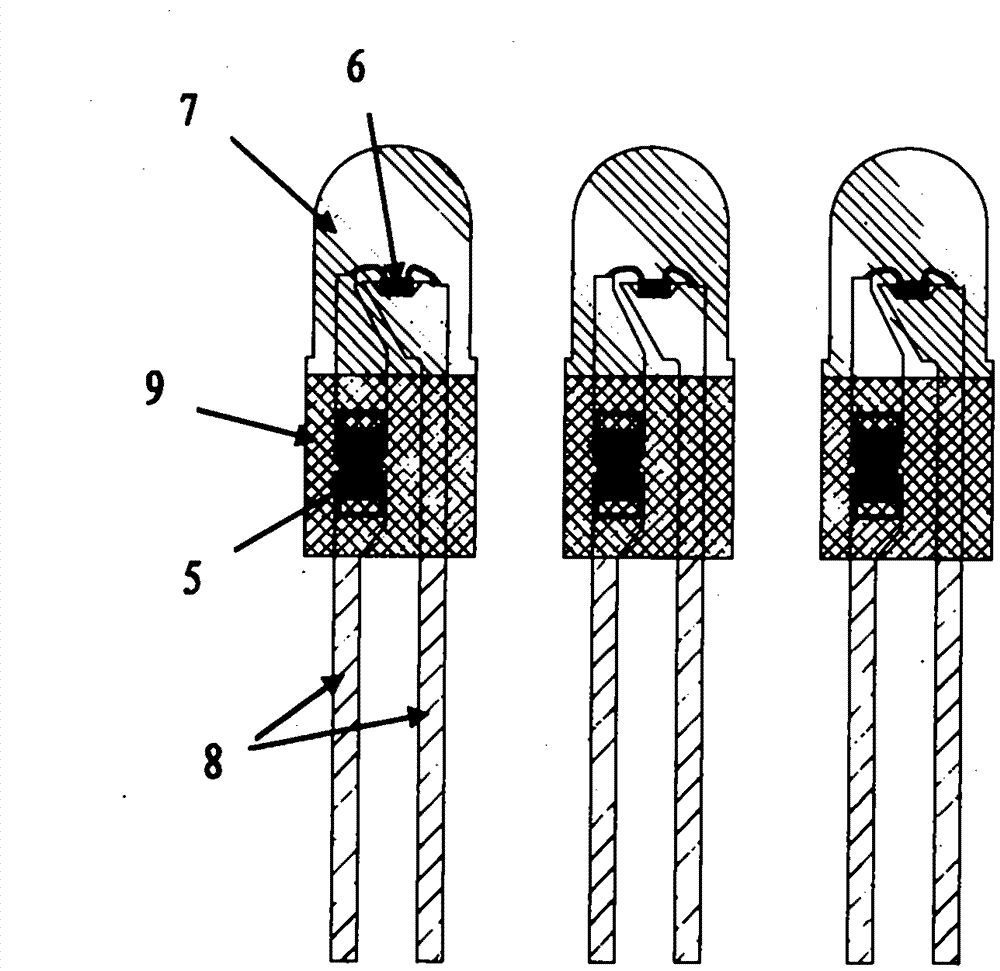

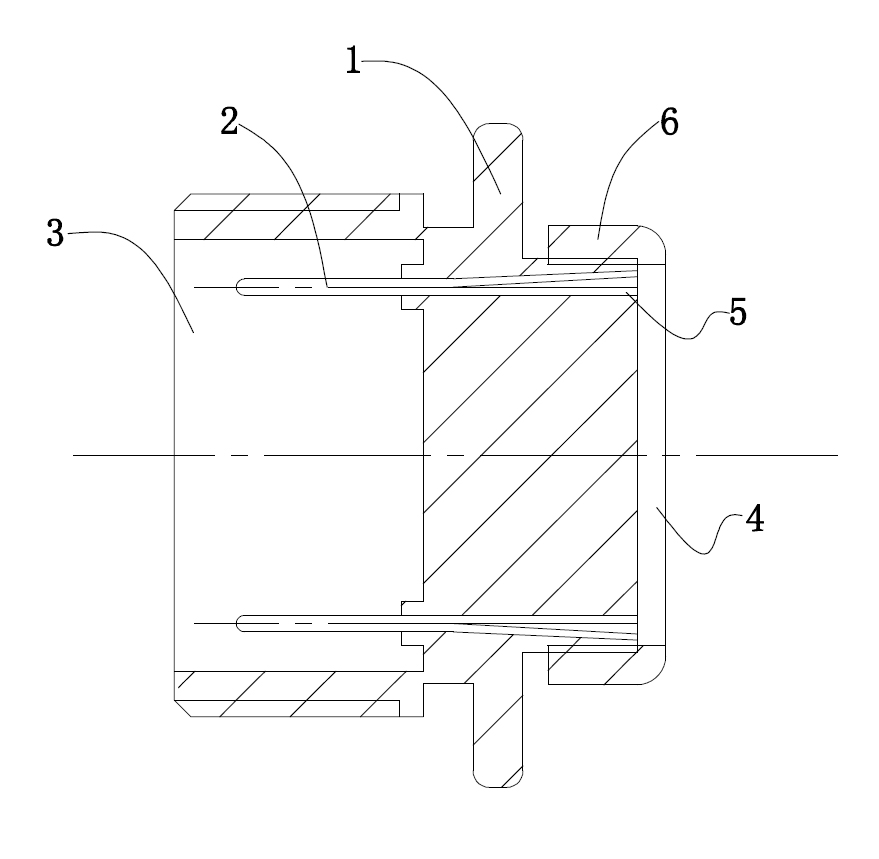

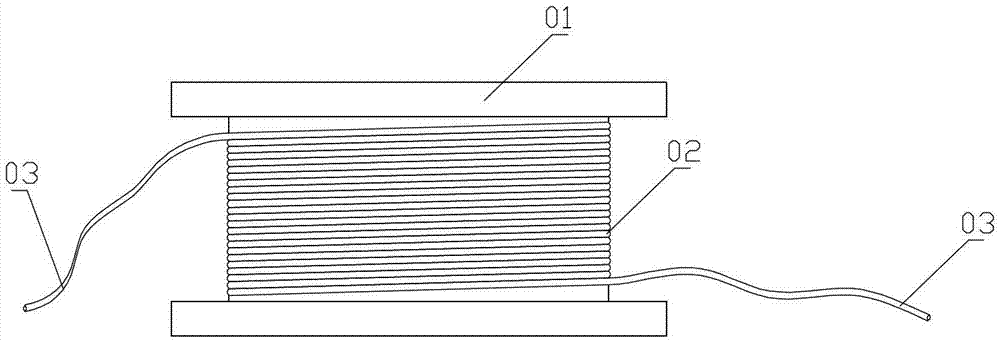

Contactor coil

The invention relates to a contactor coil, which at least comprises a winding unit. The winding unit comprises a framework (1) and an enamelled wire (2), and the enamelled wire (2) is twined on the framework (1). The contactor coil is characterized in that an insulating layer (3) sealing the enamelled wire (2) covers outside the enamelled wire (2), and both a starting thread end and an ending thread end of the enamelled wire (2) are provided with a wiring structure stretching out of the insulating layer. The invention provides a contactor coil which can prevent water and vibration, causes low work noise, hardly leaks electricity, and has small spatial arrangement limitation when in use.

Owner:NINGBO ZHONGCE E T ELECTRONICS

Folding-type fire extinguisher box

PendingCN110694203AThere will be no deformationSmall footprintFire rescueEngineeringStructural engineering

The invention relates to a folding-type fire extinguisher box which includes a box body, a base fixedly connected to the bottom of the box body, a top cover sleeving the top of the box body and a boxdoor sleeving the box body. The box body includes a back plate. An entire plate is cut by means of laser cutting and bending, and the fire extinguisher box is formed by bending treatment, so that thesteps of cutting plates according to size of different part and welding the plate into a whole during machining of an existing product are reduced. The folding-type fire extinguisher box has the advantages that during transportation, the fire extinguisher box can be unfolded into an integral plate, the area occupied by the box body during transportation is reduced, the transportation volume is increased, the integral plate is not deformed when being pressed, even if the deformation occurs, the plate can still be spliced into the box body through treatment, the reject rate and damage rate are reduced, carrying is convenient, the convenience of online sales and delivery is realized, and the subsequent assembly is very convenient.

Owner:安徽向阳消防安全科技有限公司

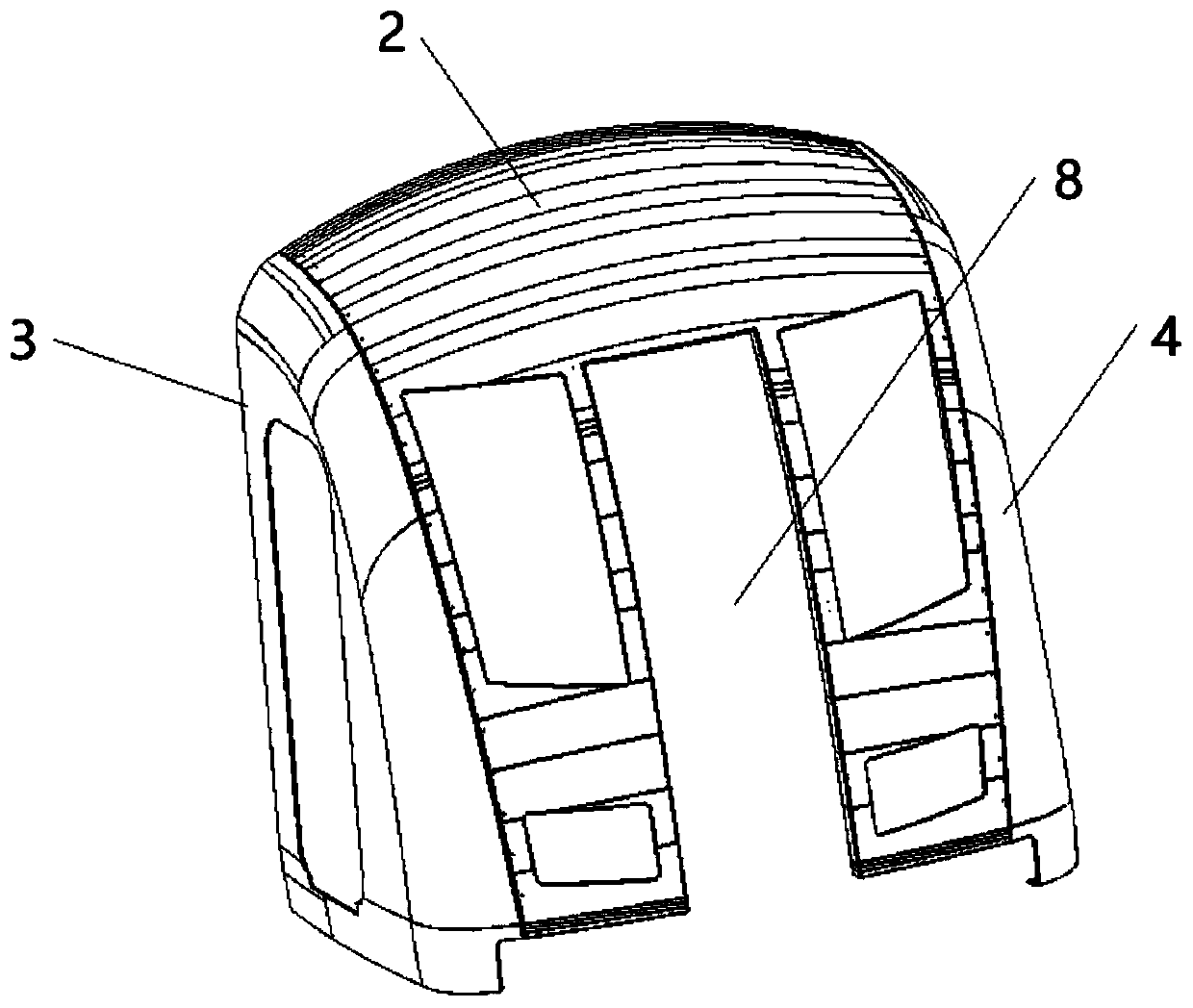

Cab hood structure, railway vehicle and production process

PendingCN111532297AReduce manufacturing costReduce scrap rateDoor arrangementAxle-box lubricationPolymer adhesiveMechanical engineering

The invention relates to the technical field of vehicle engineering, and particularly relates to a cab hood structure, a railway vehicle and a production process. The hood structure comprises at leasttwo hood plates, the hood plates are made of resin at least, any two adjacent hood plates are connected at least through an adhesive, and the adhesive is a high-molecular polymer adhesive; and a hoodis defined by all the hood plates, and the hood is provided with at least one hood cavity with an opening. In the cab hood structure, the hood structure is divided into at least two hood plates; thetwo hood plates are formed in a split manner; when the hood is fixed, the high-molecular polymer adhesive is used as the adhesive to bond and fix two adjacent hood plates; safety performance can reacha safety performance standard required when the cab hood is applied to the rail for fixed installation and actual use, and an effect that the safety performance is the same as that required when theintegrally-formed hood plate is applied to the rail for fixed installation and actual use is achieved.

Owner:北京天亿万赛轻量化材料有限公司

Lithium battery and assembly method

PendingCN114824435AFirmly connectedAccurate connectionAssembling battery machinesLi-accumulatorsInternal resistanceElectric current flow

The lithium battery comprises a shell, a battery cell, a positive electrode cover plate, a positive electrode insulating sheet, a positive electrode current collecting structure and a negative electrode current collecting structure, the shell is a hollow cylindrical tube, the positive electrode end is open, the negative electrode end is closed, an assembly through hole A is formed in the center of the surface of the negative electrode end, the positive electrode cover plate is installed on the positive electrode current collecting structure, and the positive electrode insulating sheet is installed on the battery cell. The positive electrode insulation sheet is installed on the positive electrode current collecting structure and located between the positive electrode cover plate and the positive electrode current collecting structure, the battery cell positive electrode face is welded to the positive electrode current collecting structure, the battery cell negative electrode face is welded to the negative electrode current collecting structure, and the negative electrode current collecting structure is connected with the shell negative electrode end through an assembly through hole A. The invention has the beneficial effects that the current collecting columns are arranged on the current collecting plates, so that the connection between the current collecting columns and the current collecting plates is enhanced, the internal resistance of the battery is further reduced, and the current is increased; and the insulating sheet and the cover plate are directly mounted on the current collecting column, so that the welding steps are reduced, and the technological process is simplified.

Owner:英能基(成都)科技有限公司

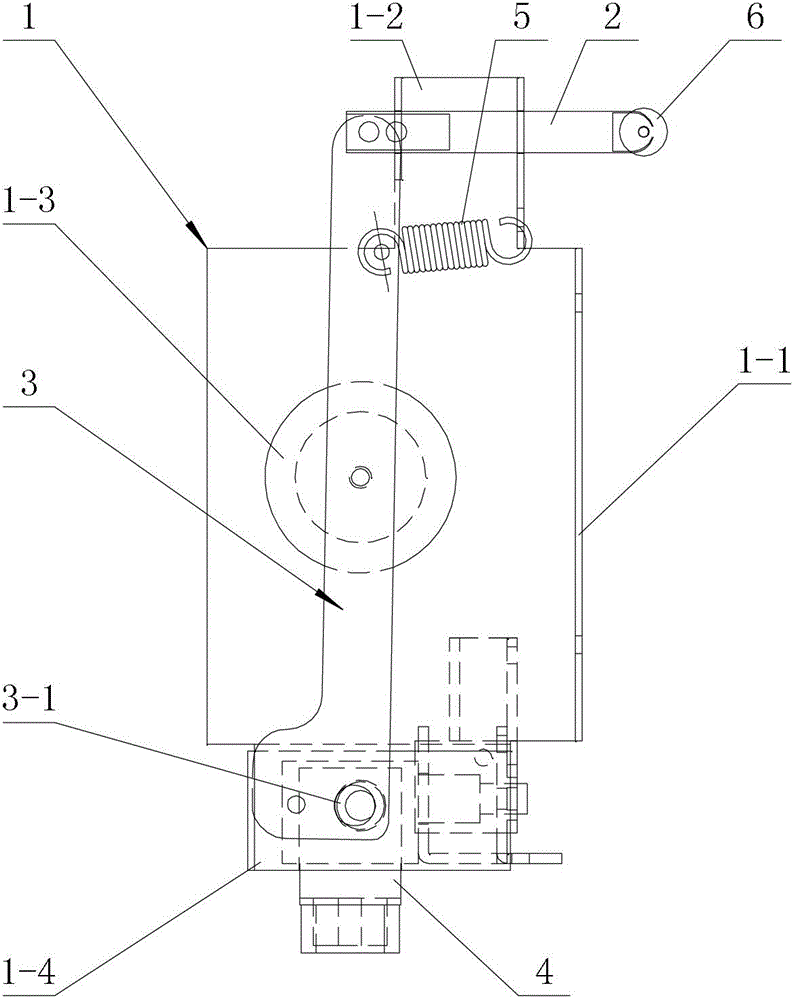

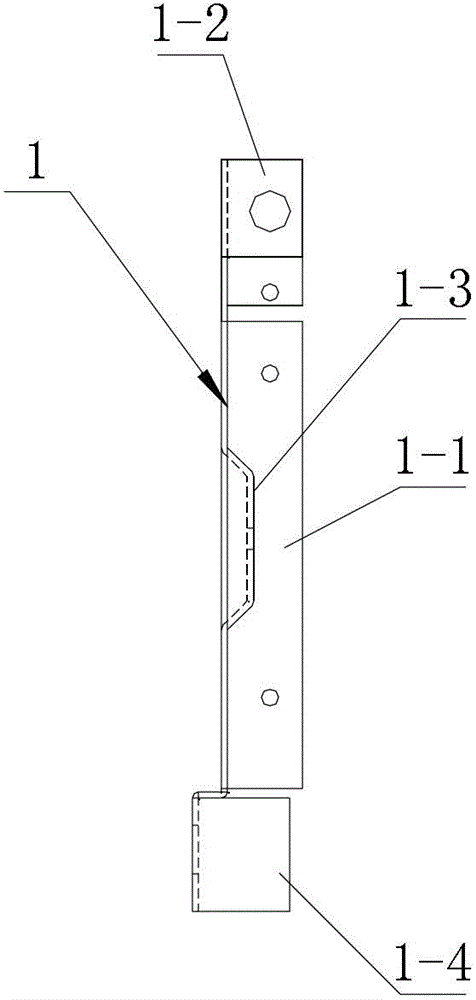

Breaker interlocking mechanism

InactiveCN103066519AAvoid lossSimplified quantitySwitchgear with withdrawable carriageEngineeringCircuit breaker

The invention relates to a breaker interlocking mechanism which comprises a locking rod, a interlocking driver plate, a lock body with a locking dog and a reset spring. One end of the interlocking driver plate is hinged with one end of a locking rod, the other end of the interlocking driver plate is provided with a lock hole matched with the locking dog of the lock body, and the reset spring is connected with the interlocking driver plate. The breaker interlocking mechanism is characterized by comprising a linkage body which is of an integrated structure formed by bending a steel plate, and a fixed portion, a lock rod installing portion, a protruding portion and a lock body fixing portion are arranged on the linkage body, wherein the fixed portion is used for being connected with a handcart, the lock rod installing portion is used for installing the lock rod, the protruding portion is used for being hinged with the interlocking driver plate, the lock body fixing portion is used for installing the lock body, and the reset spring is connected with the lock rod installing portion. The breaker interlocking mechanism has the advantages of being simple in structure, convenient to assemble, low in cost, delicate and attractive in appearance, and low-carbon and environment-friendly in an assembling process.

Owner:TIANJIN JIUAN GRP

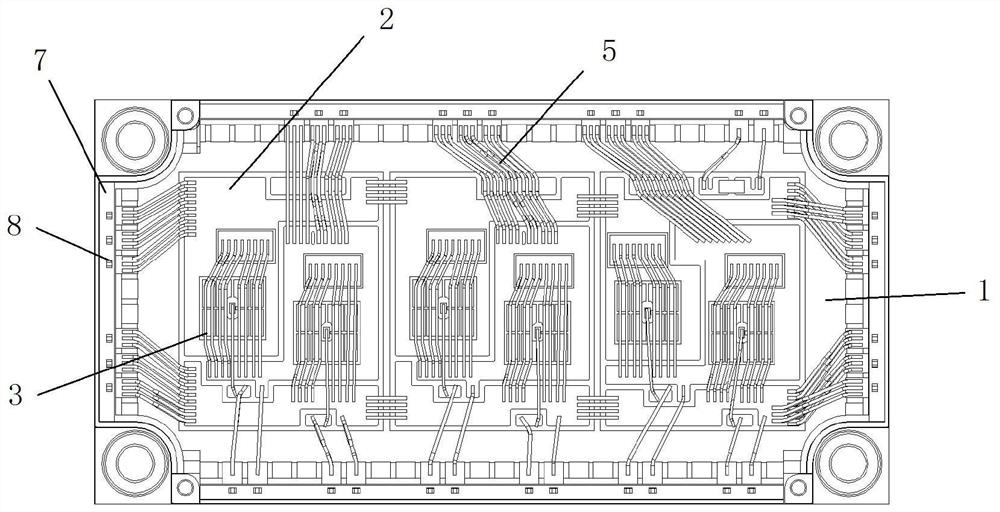

IPM power module with compact structure

PendingCN111863763ASimple structureReduce processing difficultySemiconductor/solid-state device detailsSolid-state devicesLogic cellHemt circuits

The invention discloses a compact-structure IPM power module, and the module comprises an insulating substrate disposed on a bottom plate, and the insulating substrate is provided with a power circuit. The module further comprises a control circuit board positioned above the insulating substrate and a shell fixed on the bottom plate, terminals are arranged on the periphery of the shell, the tail parts of the terminals are inserted into connecting holes correspondingly formed in the periphery of the control circuit board, and the control circuit board are fixed and electrically connected; meanwhile, the head parts of the terminals extend out of the shell to be electrically connected with an external circuit; and the control circuit board is electrically connected with the insulating substrate through needle-shaped electrodes. According to the IPM power module with the compact structure, the PCB with an integrated control and evaluation logic unit is added, and the PCB is supported and fixed only by the terminals, so that the shell structure is simplified, and the process difficulty is reduced. The single insulating substrate forms an electrical loop, electrical performance testing can be carried out, defective chips are screened out in advance and replaced, the failure and scrapping of the whole module are avoided, and the cost is reduced.

Owner:YANGZHOU GUOYANG ELECTRONICS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com