Container house corner connector and container house

A container house and container technology, which is applied to special buildings, small buildings, building types, etc., can solve the problems of high welding difficulty, large welding smoke, and difficult disassembly, and achieves simple processing, high installation accuracy, and easy disassembly. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032]In order to make the technical problems, technical solutions and beneficial effects to be solved by the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

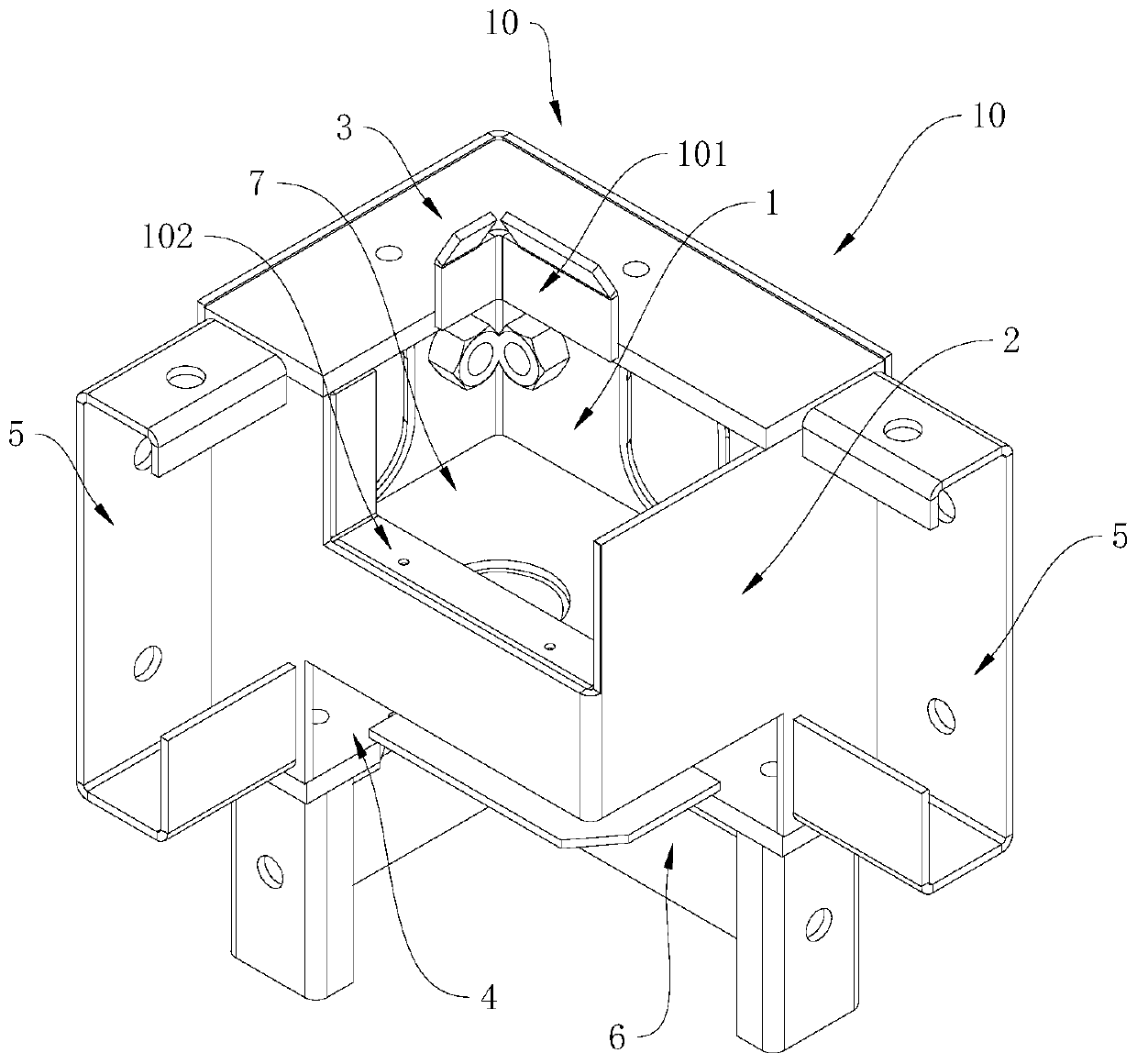

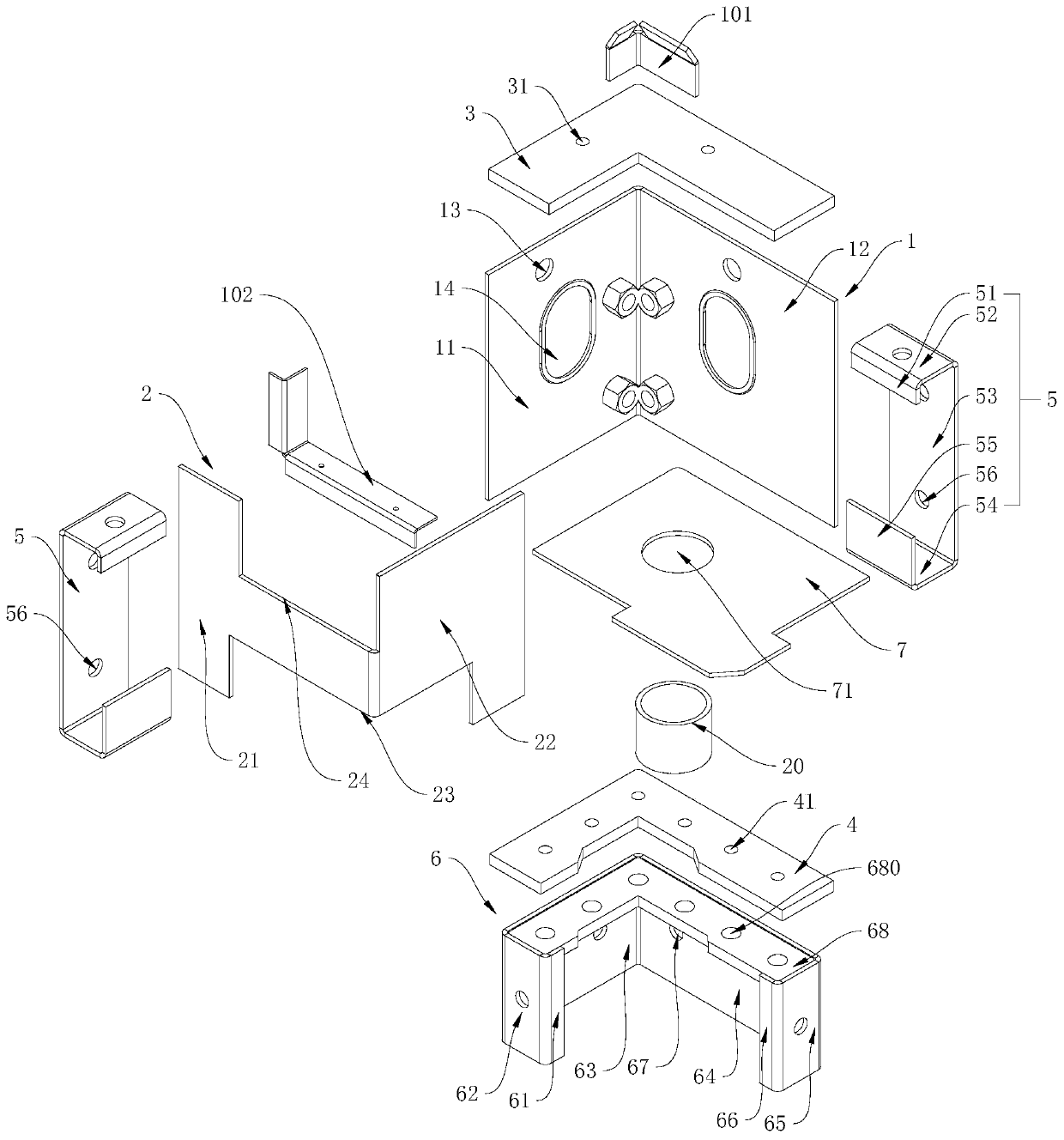

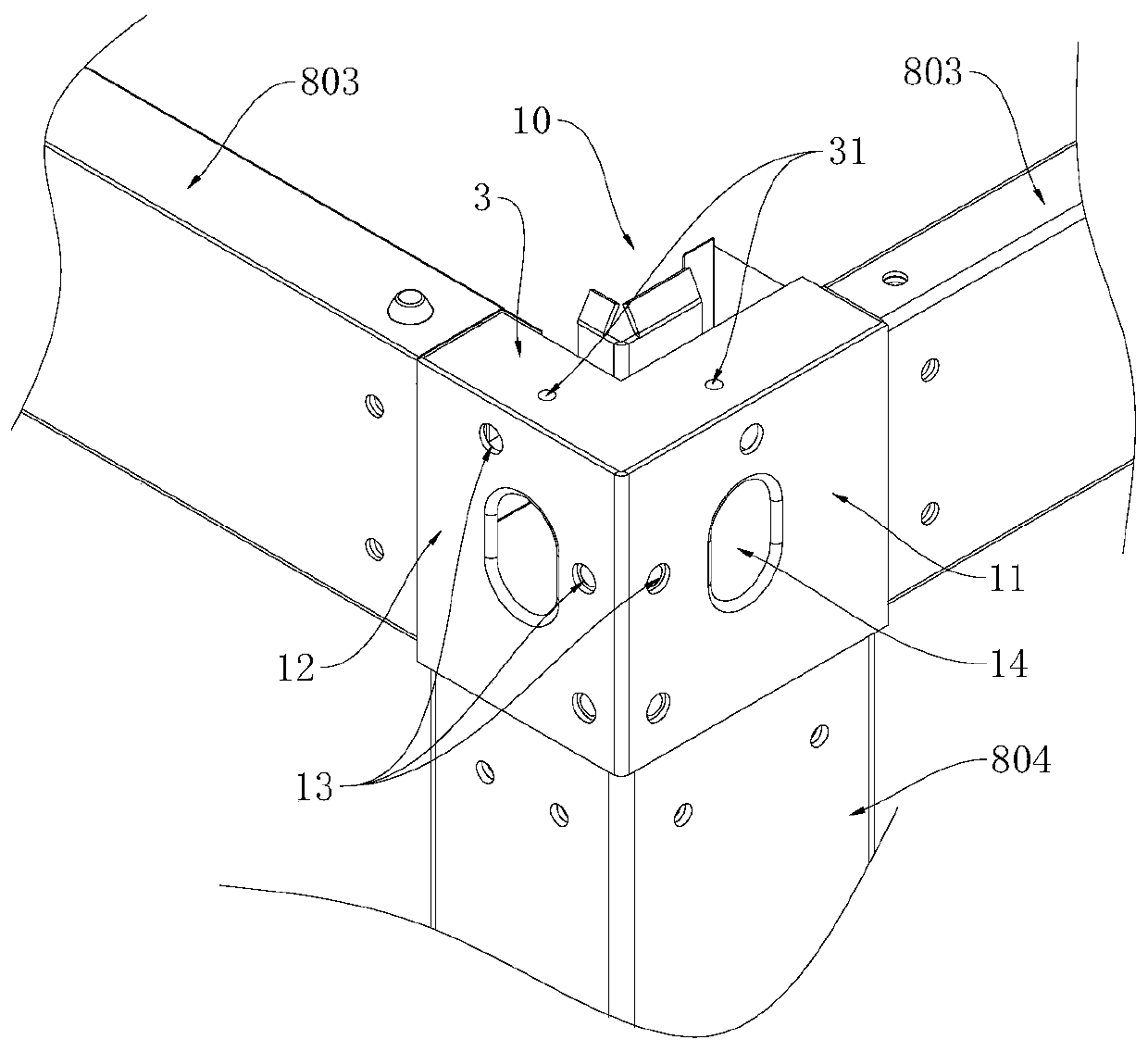

[0033] Please also refer to Figure 1 to Figure 6 , the container room corner connector provided by the present invention will now be described. The container room corner connector includes an angled outer plate 1, an angled inner plate 2, an upper connecting plate 3, a lower connecting plate 4, a first grooved plate 5 and a second grooved plate 6; the angled outer plate 1 is provided with mutual Vertical first panel 11 and second panel 12; the angled inner panel 2 is provided with a third panel 21 and a fourth panel 22 perpendicular to each other, the side of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com