Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

31results about How to "Increased structural distortion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

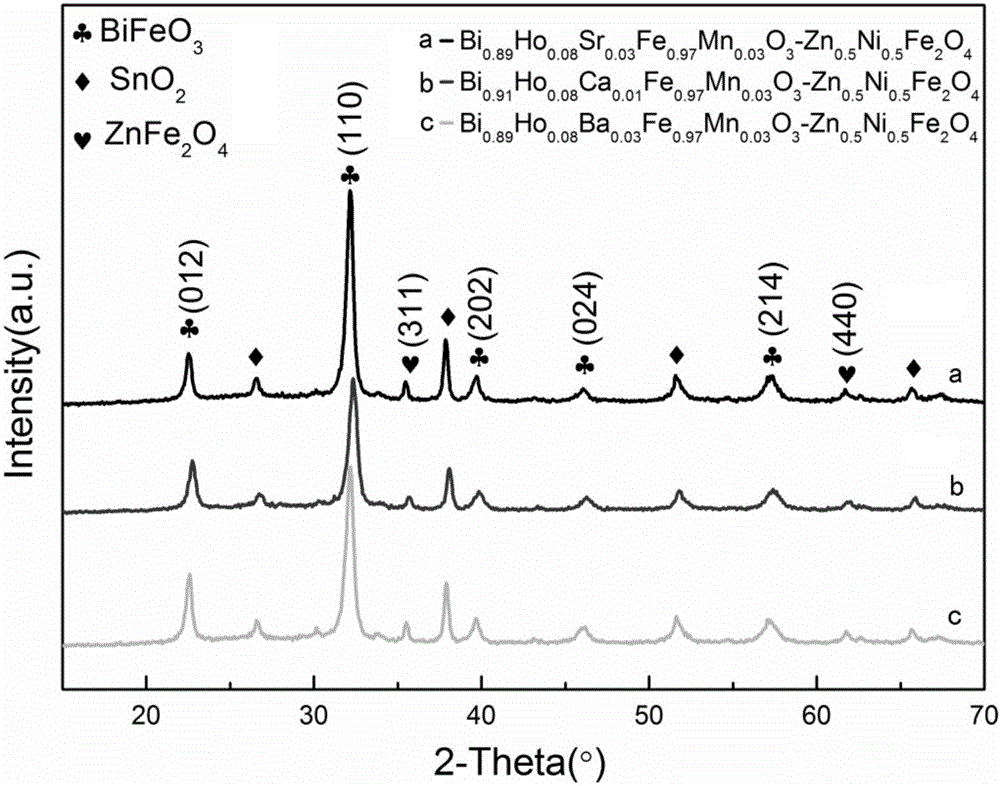

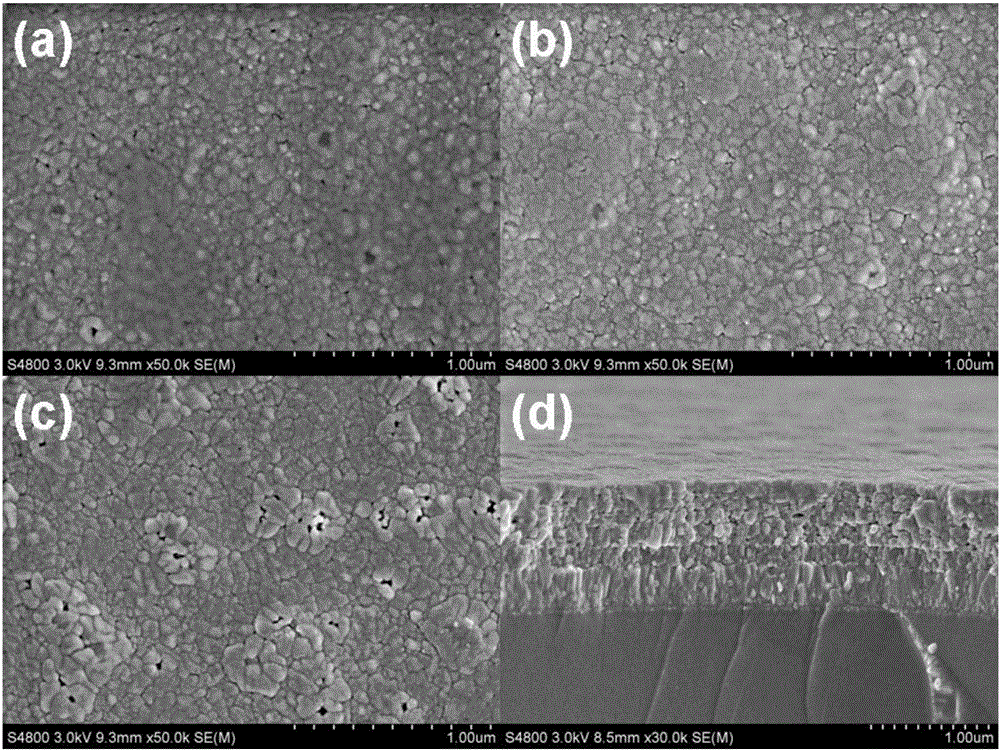

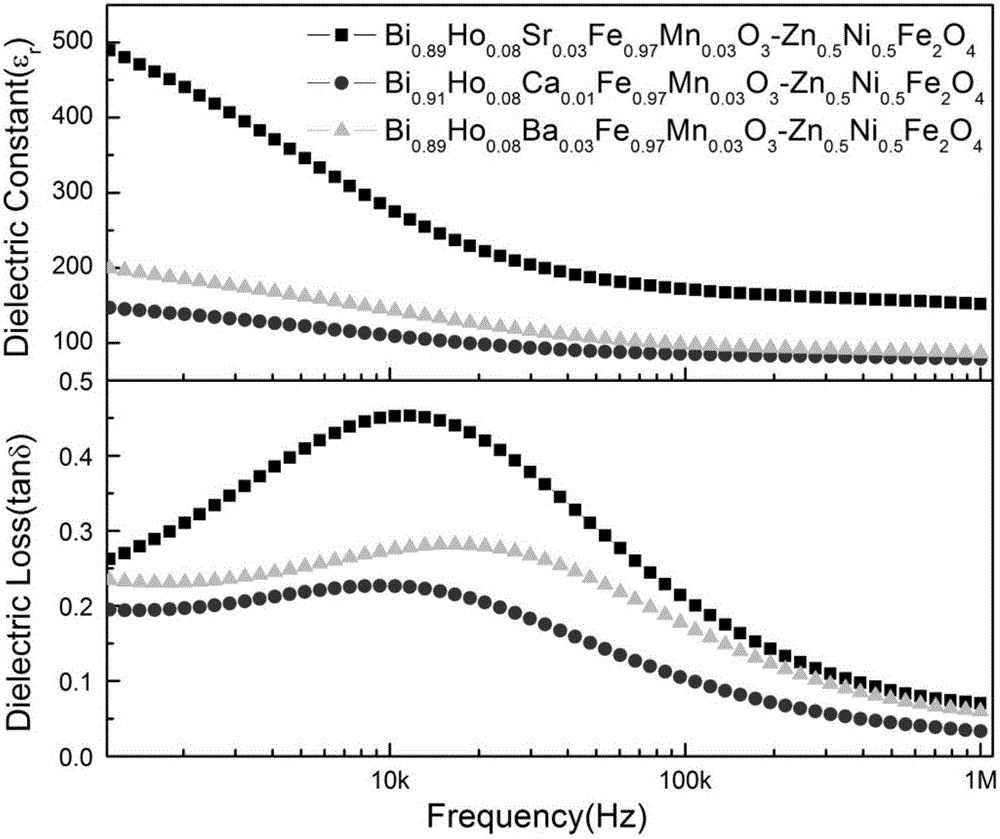

Bi0.92-xHo0.08AExFe0.97Mn0.03O3-Zn1-yNiyFe2O4 ferromagnetic composite film and preparation method thereof

InactiveCN105837196AReduce contentHigh polarizationCeramic layered productsMagnetic layerMagnetic composite

The invention provides a Bi0.92-xHo0.08AExFe0.97Mn0.03O3-Zn1-yNiyFe2O4 ferromagnetic composite film and a preparation method thereof. The ferromagnetic composite film comprises a Bi0.92-xHo0.08AExFe0.97Mn0.03O3 crystalline film and a Zn1-yNiyFe2O4 crystalline film, which are compounded together. The preparation method is as below: first respectively preparing a Zn1-yNiyFe2O4 precursor solution and a Bi0.92-xHo0.08AExFe0.97Mn0.03O3 precursor solution, wherein AE is Sr, Ca, Ba or Pb, x equals to 0.01-0.04, and y equals to 0.1-0.9; preparing a plurality of Zn1-yNiyFe2O4 films on a substrate by spin coating; and then preparing plurality of Bi0.92-xHo0.08AExFe0.97Mn0.03O3 films on the Zn1-yNiyFe2O4 films by spin coating, so as to obtain the ferromagnetic composite film. The method regulates the crystal structure of BiFeO3 by doping, and uses ferromagnetic Zn1-yNiyFe2O4 as the magnetic layer, so as to substantially increase the ferroelectric and ferromagnetic properties of the film, and effectively reduce the leakage current density of the film.

Owner:SHAANXI UNIV OF SCI & TECH

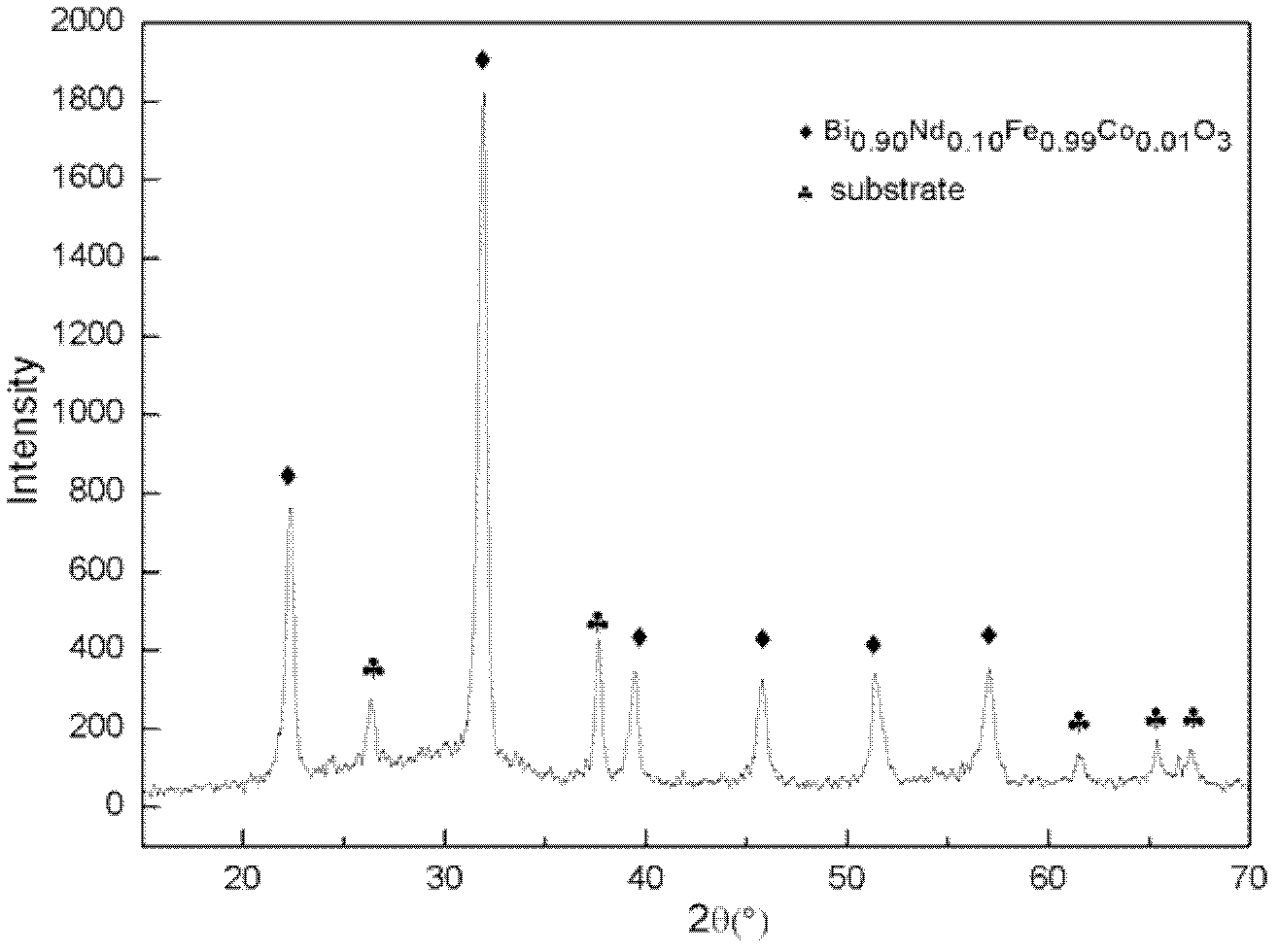

Method for preparing Nd/Co-codoped BiFeO3 film on FTO (fluorine-doped tin oxide)/glass substrate surface

InactiveCN102534588AImprove uniformityExcellent dielectric propertiesSolid/suspension decomposition chemical coatingPolymer scienceAcetic anhydride

The invention provides a method for preparing an Nd / Co-codoped BiFeO3 film on an FTO (fluorine-doped tin oxide) / glass substrate surface, which comprises the following steps: after cleaning an FTO substrate, carrying out ultraviolet irradiation, and dissolving bismuth nitrate (8% excessive), ferric nitrate, neodymium nitrate and cobalt nitrate which serve as raw materials in mixed ethylene glycol monomethyl ether and acetic anhydride in a mol ratio of 0.98:(1-x):0.1:x (x=0.01-0.05), thereby obtaining a stable BiFeO3 precursor solution of which the metallic ion concentration is 0.1-0.5mol / L; and after spin coating, drying to obtain a dry film, preannealing, naturally cooling, repeating the process above to obtain the film with expected thickness, and finally, annealing to obtain the crystalline BiFeO3 film. In the invention, the facility requests are simple, the experiment conditions can be easily achieved, the prepared film has good uniformity, the doping amount is easy to control, andthe dielectric properties of the film can be greatly enhanced by doping.

Owner:SHAANXI UNIV OF SCI & TECH

Multiferroic Bi0.96-xSr0.04RExFe0.94Mn0.04Cr0.02O3-NiFe2O4 composite film and preparation method thereof

The invention discloses a multiferroic Bi0.96-xSr0.04RExFe0.94Mn0.04Cr0.02O3-NiFe2O4 composite film and a preparation method thereof. The composite film comprises a Bi0.96-xSr0.04RExFe0.94Mn0.04Cr0.02O3 crystalline state film and a NiFe2O4 crystalline state film which are compounded together. The preparation method comprises the following steps: respectively preparing a Bi0.96-xSr0.04RExFe0.94Mn0.04Cr0.02O3 precursor solution and a NiFe2O4 precursor solution; and spinning on a substrate to prepare a multilayer NiFe2O4 film, and spinning on the NiFe2O4 film to prepare a multilayer Bi0.96-xSr0.04RExFe0.94Mn0.04Cr0.02O3 film, thereby obtaining the target product. The equipment requirement is simple, the prepared film is high in uniformity, the doping amount is easy to control, and the ferroelectric properties and ferromagnetic properties of the film are greatly improved. Meanwhile, the leakage current density of the film is effectively reduced.

Owner:SHAANXI UNIV OF SCI & TECH

Method for preparing Bi0.85Sm0.15Fe1-xCrxO3 ferroelectric film via sol-gel process

The invention discloses a method for preparing a Bi0.85Sm0.15Fe1-xCrxO3 ferroelectric film via a sol-gel process. The method is carried out by the following steps of: washing an FTO (Fluorinedoped Tin Oxide) substrate and subsequently irradiating via ultraviolet light; using bismuth nitrate, ferric nitrate, samarium nitrate and chromic nitrate as raw materials (the bismuth nitrate excesses by 5%), dissolving the above raw materials in mixed ethylene glycol monomethyl ether and acetic anhydride according to a mole ratio of 0.90: (1-x):0.15:x (x is 0.00, 0.01, 0.02 or 0.03), then adding ethanol amine to adjust a viscosity and obtain a stable BiFeO3 (bismuth ferrite) precursor solution with a metal ion concentration of 0.003-0.3mol / L; and homogenizing and subsequently obtaining a dry film, then using a layer-by-layer annealing process to obtain a crystal-state Bi0.85Sm0.15Fe1-xCrxO3 ferroelectric film. The method disclosed by the invention has the advantages of simple device requirement, easy achievement of experiment condition, good uniformity of the prepared films and easy control of the doping amount, so that the ferroelectric performance of the film is greatly enhanced.

Owner:SHAANXI UNIV OF SCI & TECH

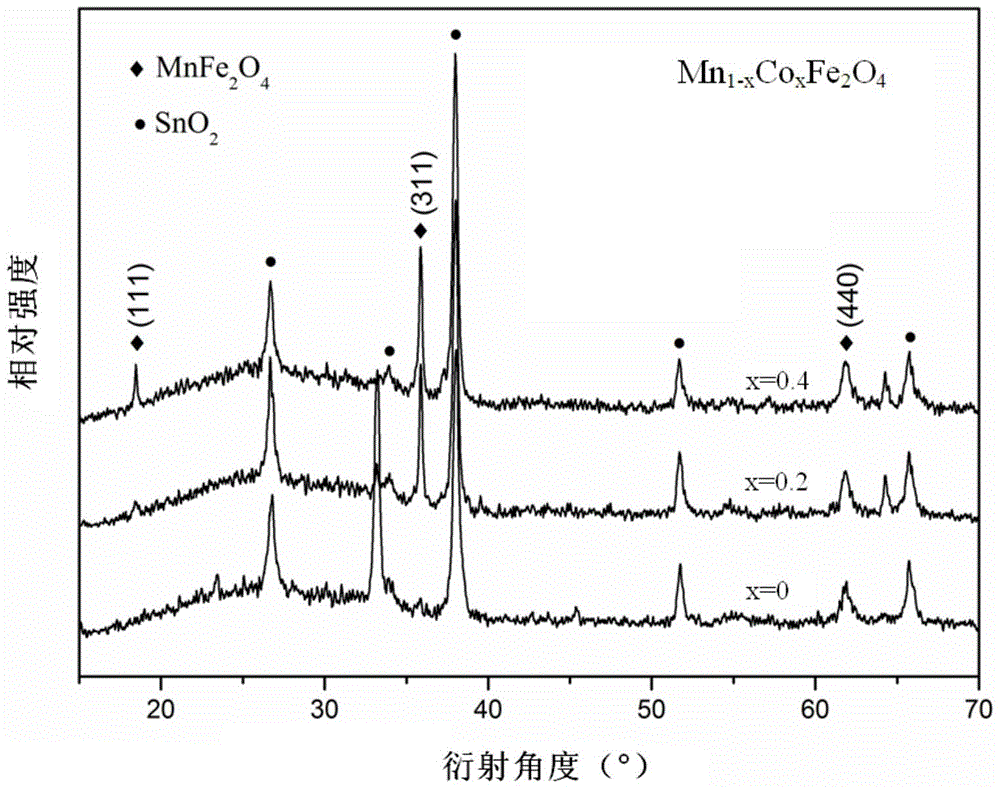

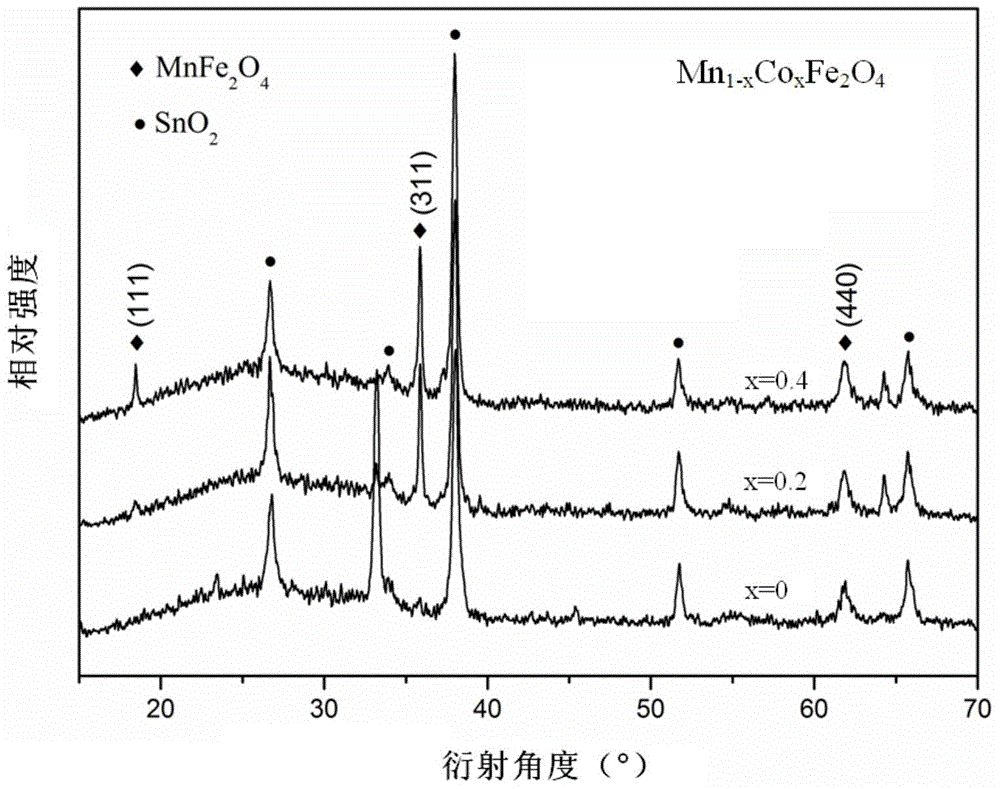

Bi0.90Er0.10Fe0.96Co0.02Mn0.02O3/Mn(1-x)CoxFe2O4 composite film and preparation method thereof

The invention provides a Bi0.90Er0.10Fe0.96Co0.02Mn0.02O3 / Mn(1-x)CoxFe2O4 composite film and a preparation method thereof. The composite film comprises a Bi0.90Er0.10Fe0.96Co0.02Mn0.02O3 crystalline-state film and a Mn(1-x)CoxFe2O4 crystalline-state film which are compounded together. The preparation method comprises the following steps: respectively preparing a Bi0.90Er0.10Fe0.96Co0.02Mn0.02O3 precursor solution and a Mn(1-x)CoxFe2O4 precursor solution; then spinning on a substrate to prepare a multi-layer Mn(1-x)CoxFe2O4 film; and spinning on the Mn(1-x)CoxFe2O4 film to prepare a multi-layer Bi0.90Er0.10Fe0.96Co0.02Mn0.02O3 film which is the target product. In the invention, the equipment requirements are simple, the prepared film has relatively good uniformity, the doping amount is easy to control, the ferroelectric property and ferromagnetic property of the film are remarkably improved, and the leak current density of the film is effectively reduced at the same time.

Owner:SHAANXI UNIV OF SCI & TECH

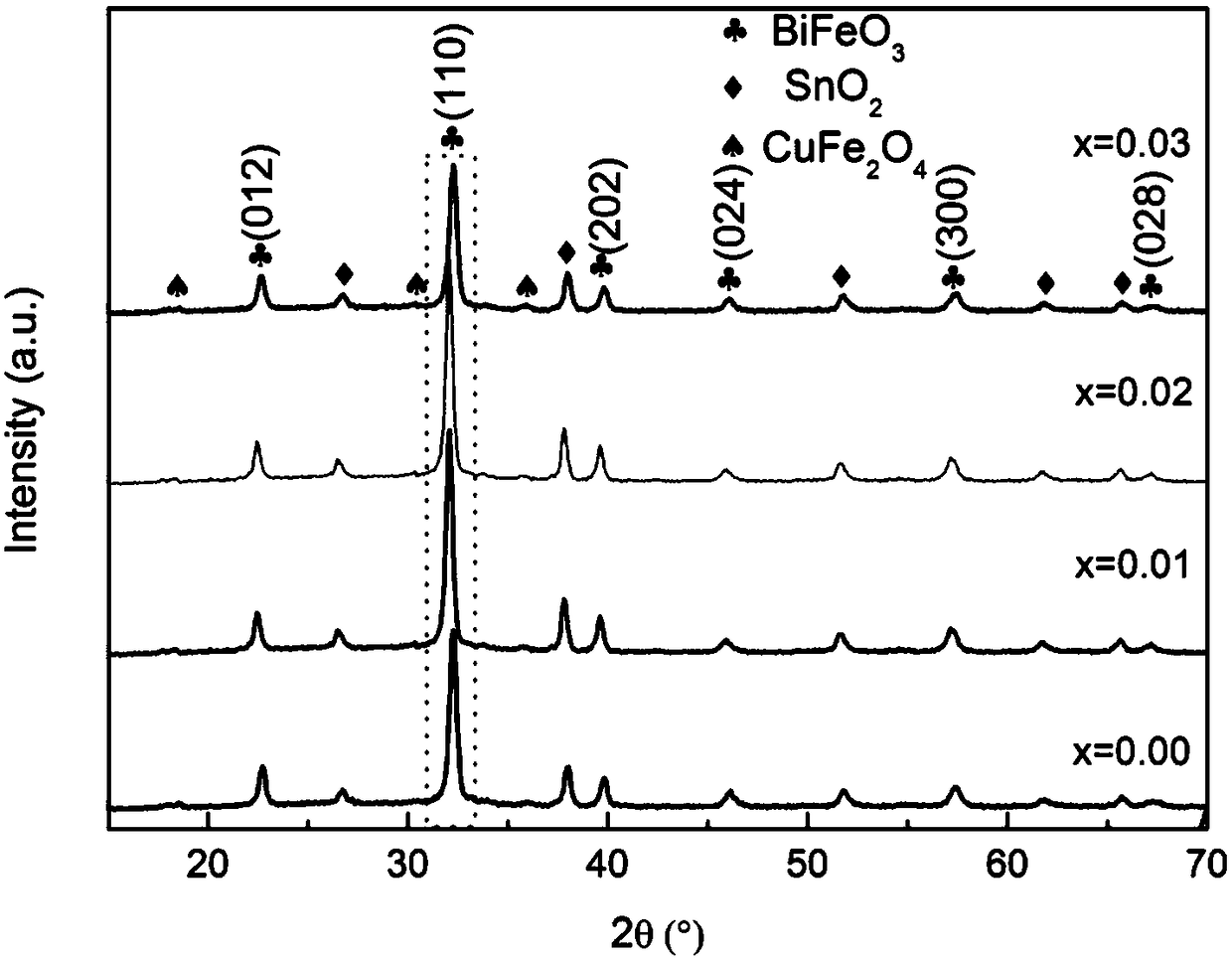

Multiferroic Bi(0.98-x)Sr0.02RExFe0.97Mn0.03O3-CuFe2O4 composite film and preparation method thereof

The invention discloses a multiferroic Bi(0.98-x)Sr0.02RExFe0.97Mn0.03O3-CuFe2O4 composite film and a preparation method thereof. The composite film comprises Bi(0.98-x)Sr0.02RExFe0.97Mn0.03O3 crystal films and CuFe2O4 crystal films which are composited together. The preparation method comprises the following steps: firstly, preparing a Bi(0.98-x)Sr0.02RExFe0.97Mn0.03O3 precursor solution and a CuFe2O4 precursor solution respectively; secondly, preparing multiple layers of CuFe2O4 films on a substrate by spin coating, and preparing multiple layers of Bi(0.98-x)Sr0.02RExFe0.97Mn0.03O3 films on the CuFe2O4 films by spin coating to obtain a target product. The equipment requirement is simple, the uniformity of the prepared film is high, the doping amount is easy to control, the ferroelectric and ferromagnetic properties of the film are improved, and the leakage current density of the film is effectively reduced.

Owner:SHAANXI UNIV OF SCI & TECH

Bi0.9Er0.1Fe1-xCoxO3 film with high ferromagnetism and ferroelectricity, and making method thereof

The invention provides a Bi0.9Er0.1Fe1-xCoxO3 film with high ferromagnetism and ferroelectricity, and a making method thereof. The method comprises the following steps: preparing a Bi0.9Er0.1Fe1-xCoxO3 precursor solution from bismuth nitrate, iron nitrate, cobalt nitrate and erbium nitrate, spin-coating a substrate with the Bi0.9Er0.1Fe1-xCoxO3 (x is 0.01-0.03) precursor solution, uniformly sizing, drying, and annealing to obtain the Bi0.9Er0.1Fe1-xCoxO3 film with high ferromagnetism and ferroelectricity. The method has the advantages of simple device requirements, easy reaching of experiment conditions, easy control of the doping amount, and great improvement of the ferromagnetism of a BiFeO3 film, and the Bi0.9Er0.1Fe1-xCoxO3 film made in the invention has the advantages of good uniformity, high magnetic intensity and high remanent polarization.

Owner:SHAANXI UNIV OF SCI & TECH

Multiferroic Bi0.83Pr0.15Sr0.02Fe0.97-xMn0.03CuxO3-CuFe2O4 composite film and preparation method thereof

ActiveCN105906221APrevent volatilizationInhibition transitionCoatingsLeakage current densityComposite film

The invention discloses a multiferroic Bi0.83Pr0.15Sr0.02Fe0.97-xMn0.03CuxO3-CuFe2O4 composite film and a preparation method thereof. The composite film comprises a Bi0.83Pr0.15Sr0.02Fe0.97-xMn0.03CuxO3 (x=0.01-0.05) crystalline film in the upper layer and a CuFe2O4 crystalline film in the lower layer. The preparation method comprises respectively preparing a Bi0.83Pr0.15Sr0.02Fe0.97-xMn0.03CuxO3 precursor solution and a CuFe2O4 precursor solution, carrying out spin-coating on a substrate with multiple CuFe2O4 films and carrying out spin-coating on the CuFe2O4 film with multiple Bi0.83Pr0.15Sr0.02Fe0.97-xMn0.03CuxO3 films to obtain the multiferroic Bi0.83Pr0.15Sr0.02Fe0.97-xMn0.03CuxO3-CuFe2O4 composite film. The preparation method has simple equipment requirements, can prepare the film with good uniformity, easily controls a doping amount, improves ferroelectric and ferromagnetic properties of the film and effectively reduces film leakage current density.

Owner:SHAANXI UNIV OF SCI & TECH

B-site Mn and Cu codoped high remanent polarization BiFeO3 film and preparation method

ActiveCN103613144AImprove multiferroic propertiesDistortionIron compoundsIonEthylene glycol monomethyl ether

The invention relates to a B-site Mn and Cu codoped high remanent polarization BiFeO3 film and a preparation method, the method comprises the following steps: dissolving bismuth nitrate, ferric nitrate, manganese acetate and cupric nitrate according to mol ratio of 1.05: [(0.92-0.98)-x]: (0.02-0.08):x in a mixed liquor of ethylene glycol monomethyl ether and acetic anhydride, then uniformly stirring to obtain a BiFeO3 precursor; wherein total metal ion concentration of the BiFeO3 precursor is 0.1-0.5mol / L, X is 0.01-0.03; performing spin coating of the BiFeO3 precursor on a FTO / glass substrate to prepare a wet membrane, baking the wet membrane to obtain a dry membrane, then annealing at 550 DEG C to obtain the crystalline state BiFeO3 film; cooling the crystalline state BiFeO3 film, and repeatedly making the crystalline state BiFeO3 film to reach a required thickness to obtain the B-site Mn and Cu codoped high remanent polarization BiFeO3 film. According to the invention, a sol gel technology is employed, the equipment requirement is simple, the film is prepared on large surface and surfaces with irregular shapes, the chemical component is accurate and controllable, and the regulation and control to its crystal structure can be carried out by codoping thereby the ferroelectric performance of the film is greatly increased.

Owner:盐城梦心缘鞋服有限公司

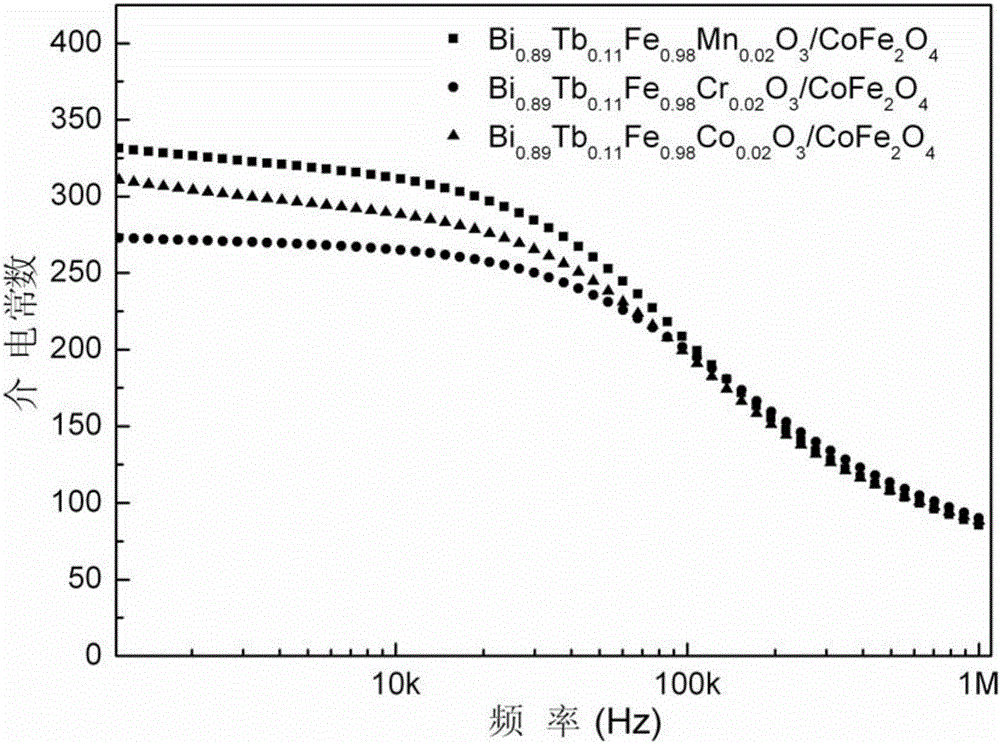

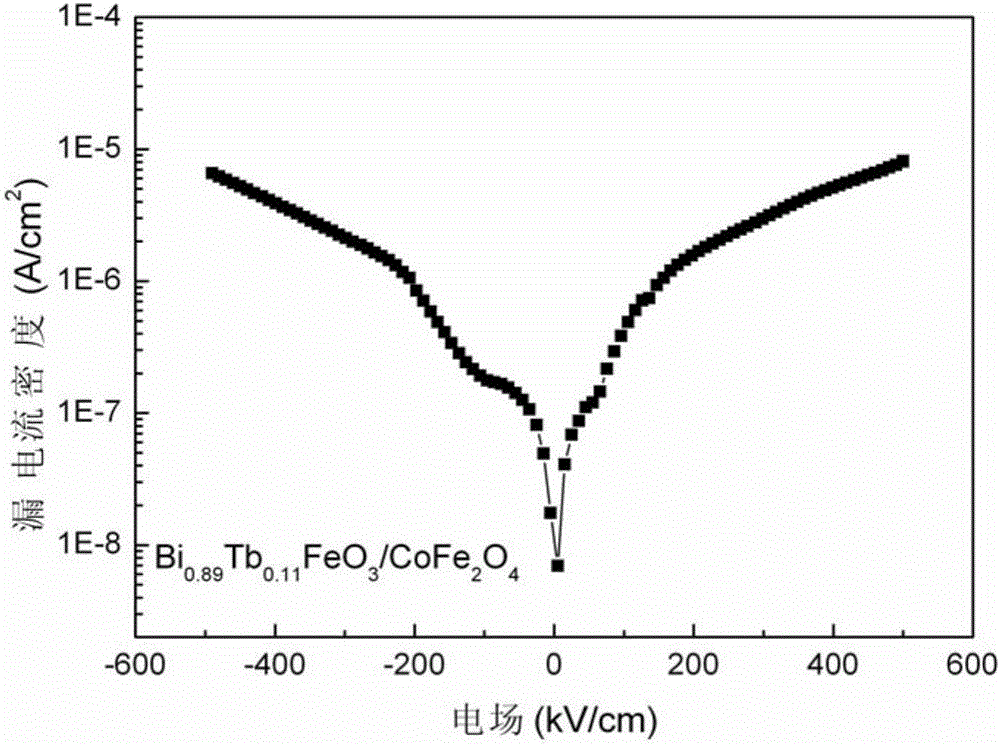

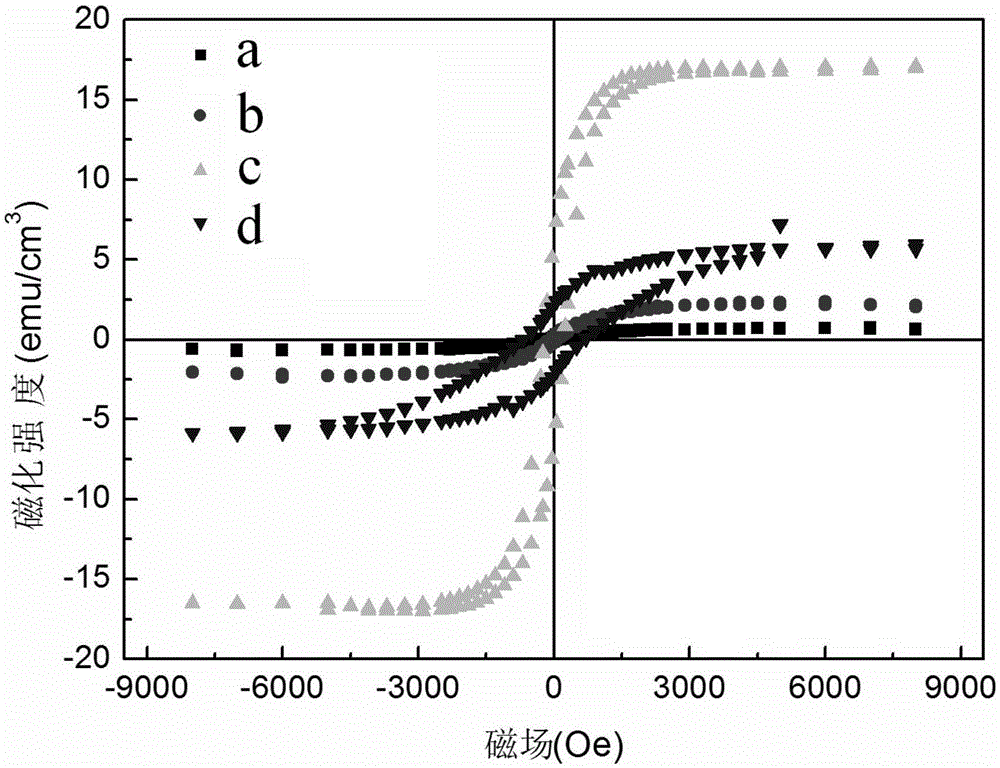

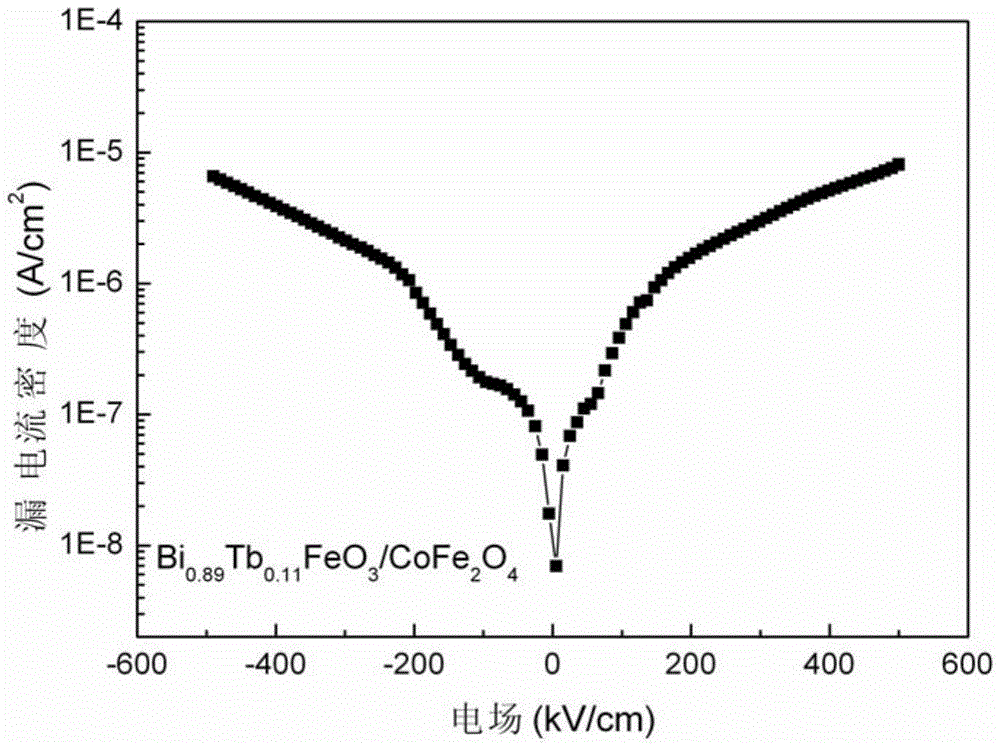

Bi1-xRExFeO3/CoFe2O4 multiferroic composite membrane and preparation method thereof

ActiveCN104538139APrecise and controllable chemical compositionSimple equipment requirementsInorganic material magnetismInductances/transformers/magnets manufactureChemistryChemical composition

The invention provides a Bi1-xRExFeO3 / CoFe2O4 multiferroic composite membrane and a preparation method thereof. The composite membrane comprises a Bi1-xRExFeO3 crystalline state membrane and a CoFe2O4 crystalline state membrane which are combined together, wherein RE is Ce, Pr, Tb, Eu or Yb, x is equal to 0.05-0.15; in the preparation, Bi1-xRExFeO3 precursor solution and CoFe2O4 precursor solution are firstly prepared respectively; and then, multi-layer CoFe2O4 membrane is prepared by spinning on a substrate, and the multi-layer Bi1-xRExFeO3 membrane is prepared by spinning on the CoFe2O4 membrane, so the target product is obtained. The facility request is simple, the homogeneity of the prepared membrane is good, the chemical composition can be accurately controlled, the doping content is easily controlled, and the ferroelectric property and ferromagnetic property of the membrane are greatly improved, so the Bi1-xRExFeO3 / CoFe2O4 multiferroic composite membrane has high residual polarization value and residual magnetization value.

Owner:SHAANXI UNIV OF SCI & TECH

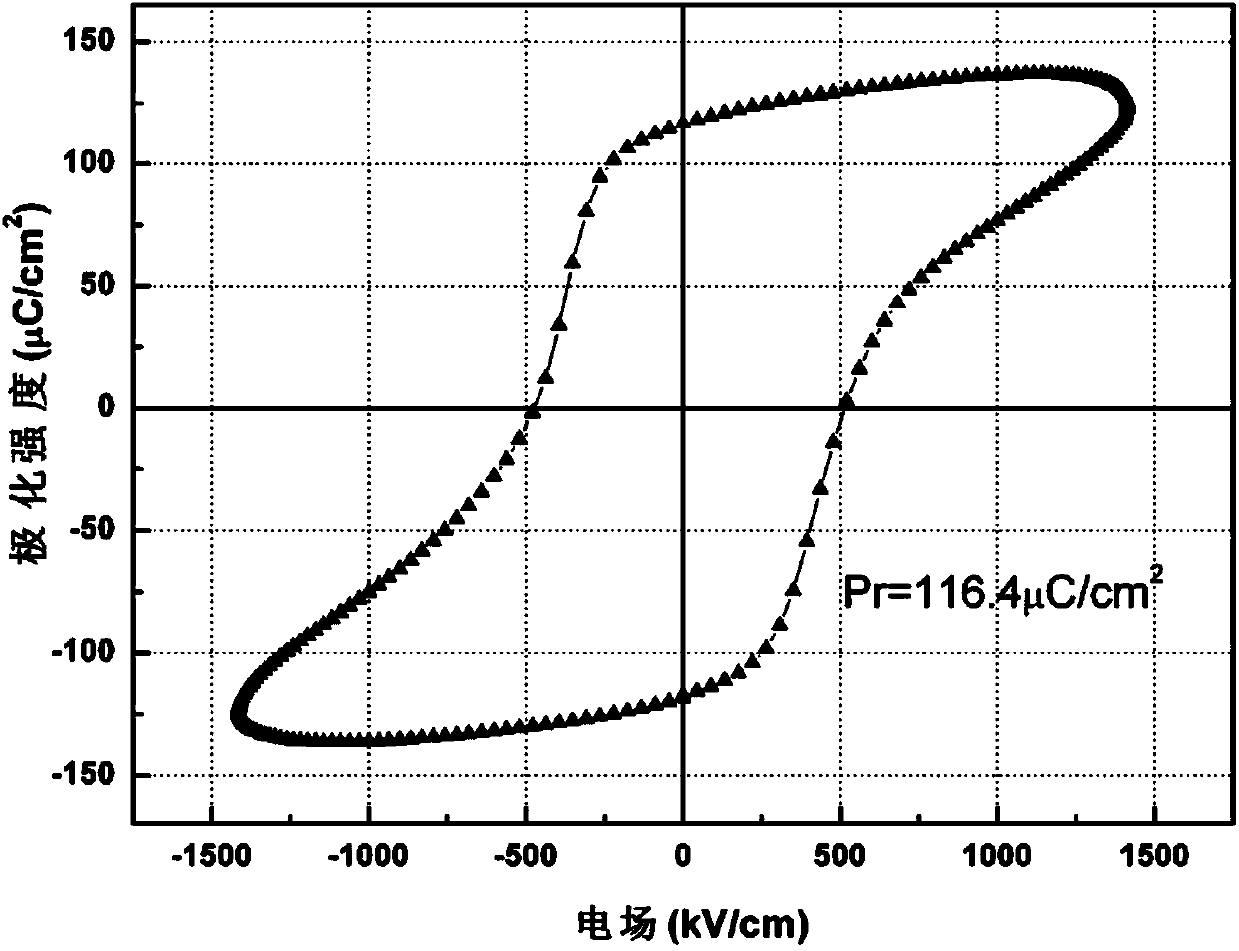

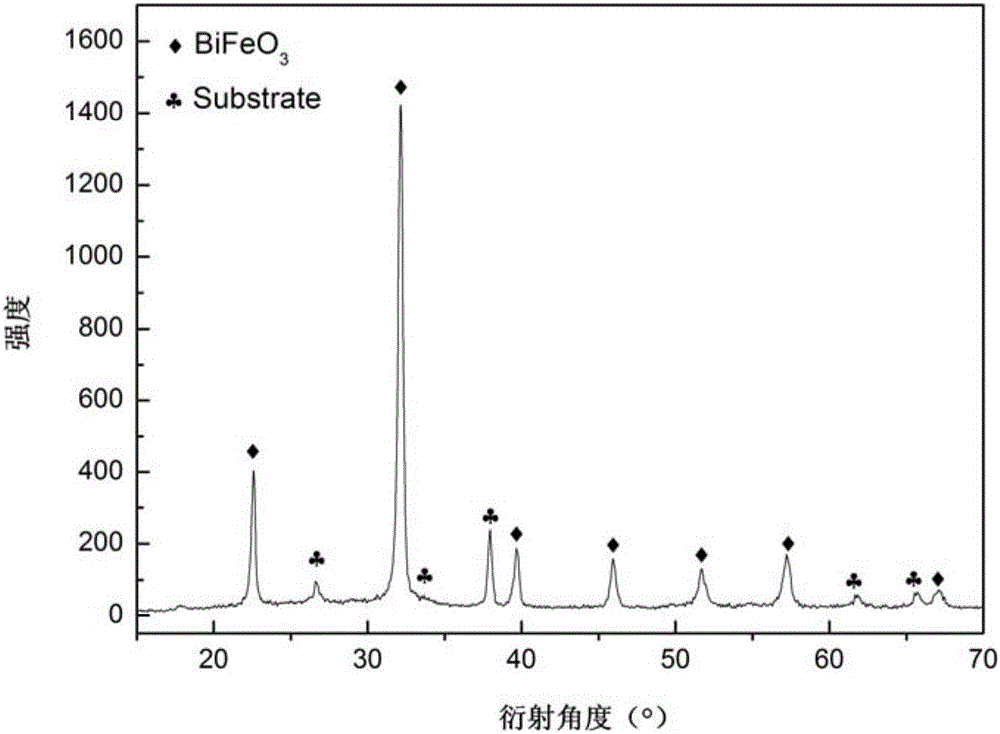

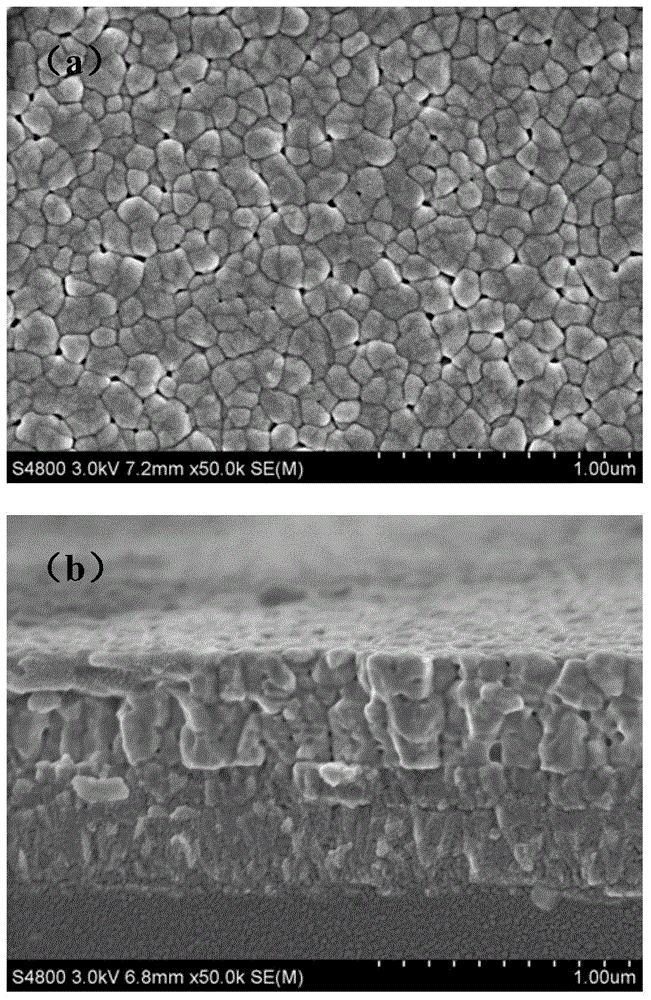

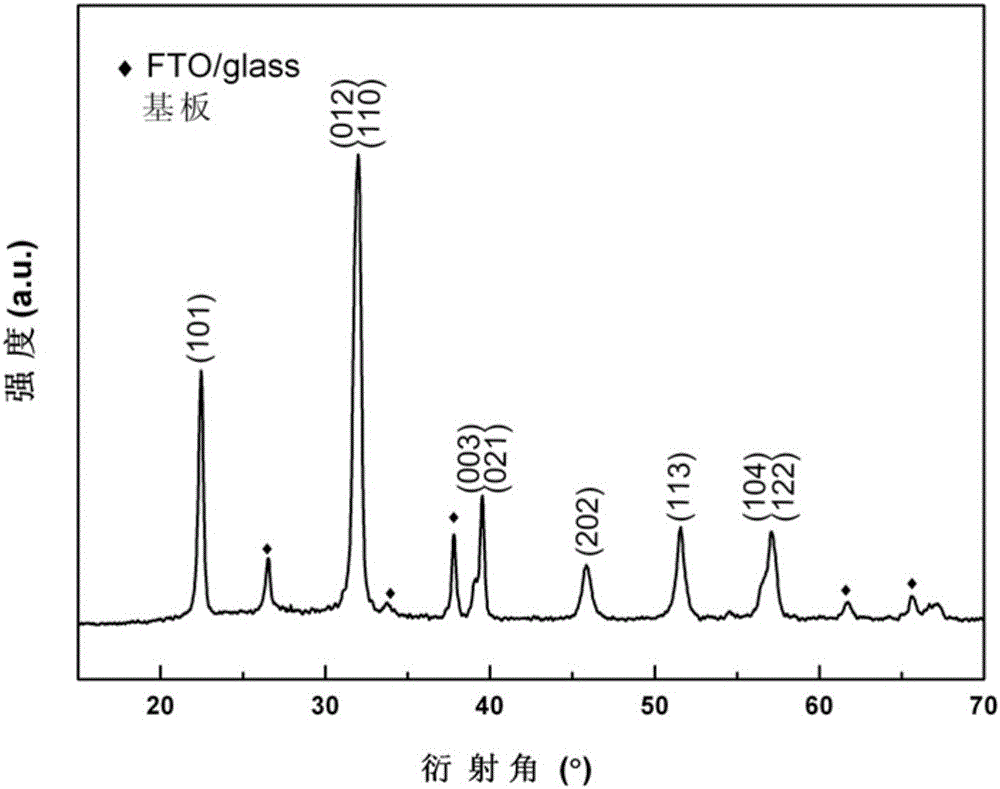

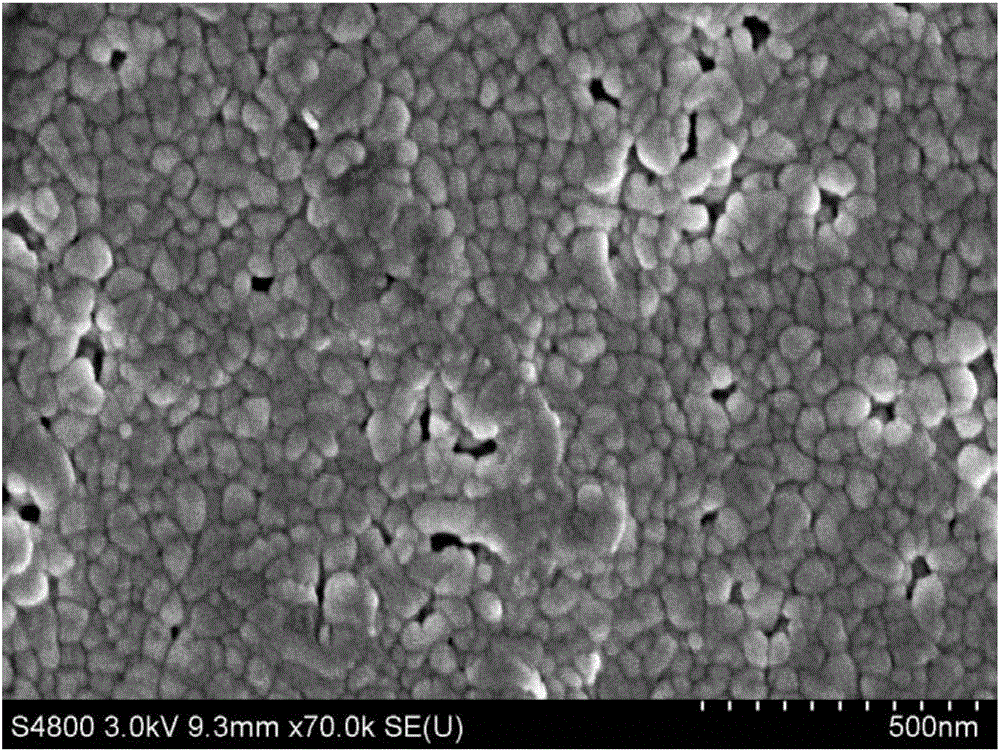

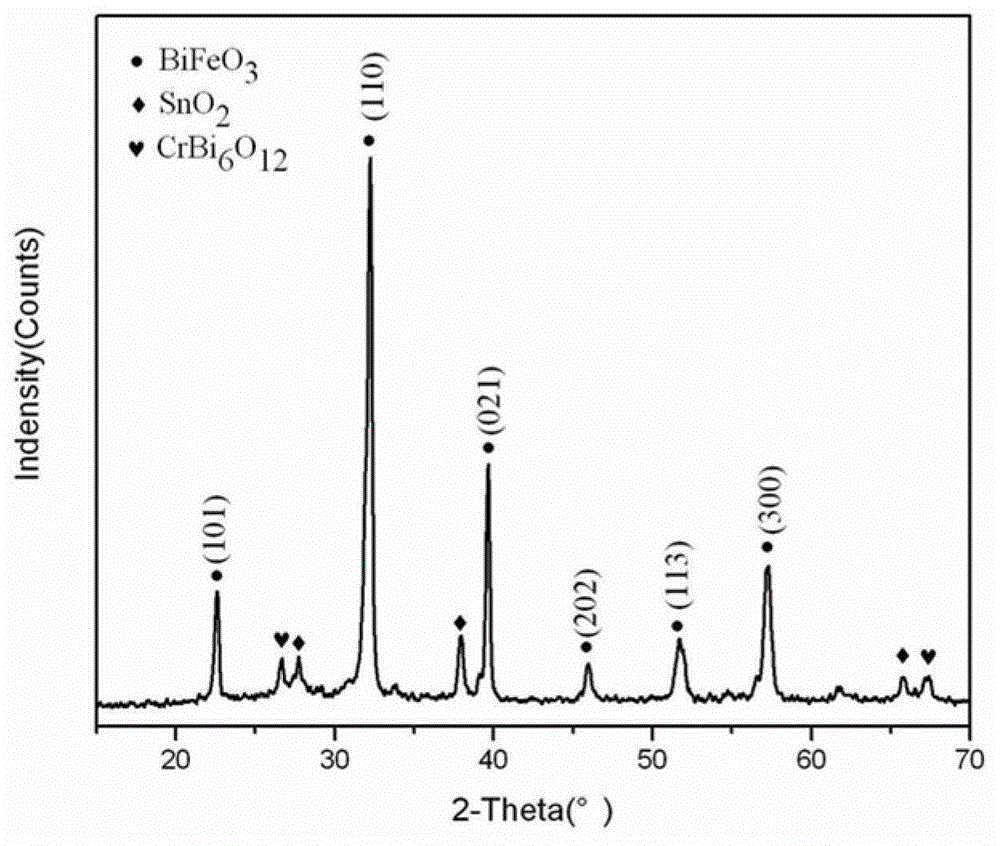

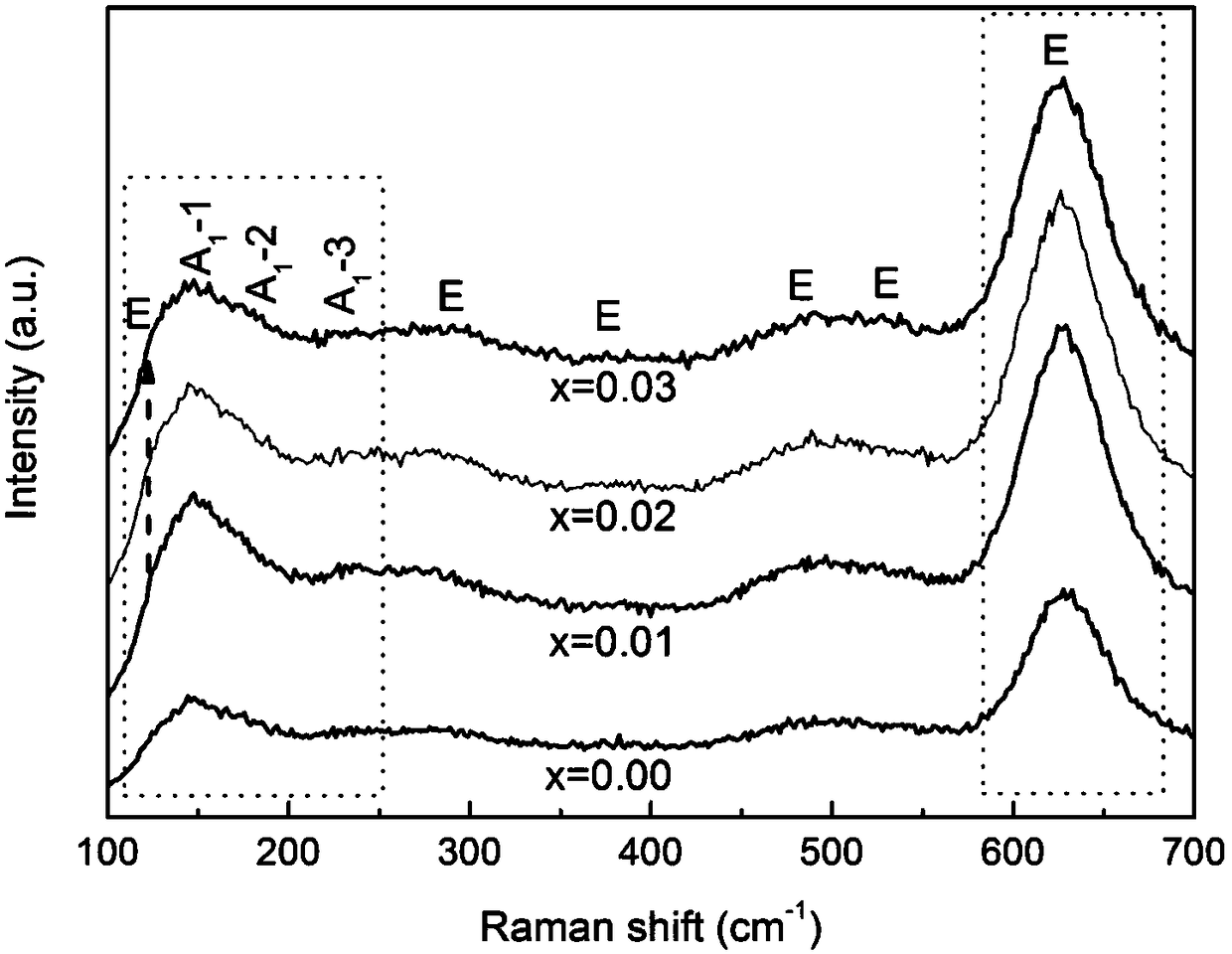

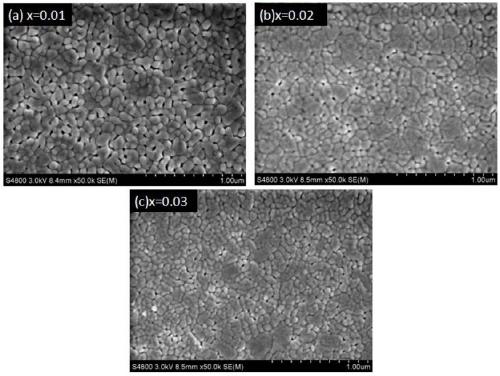

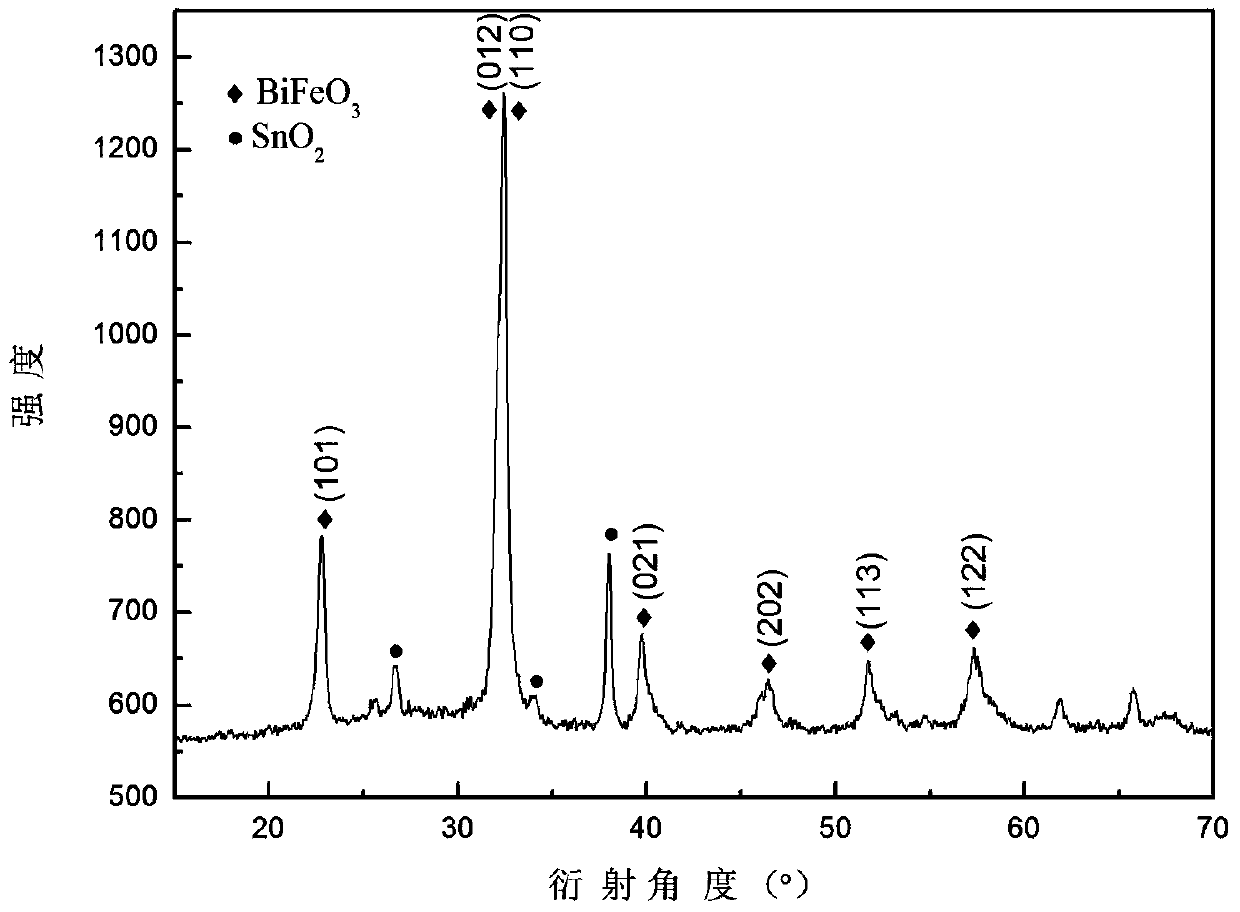

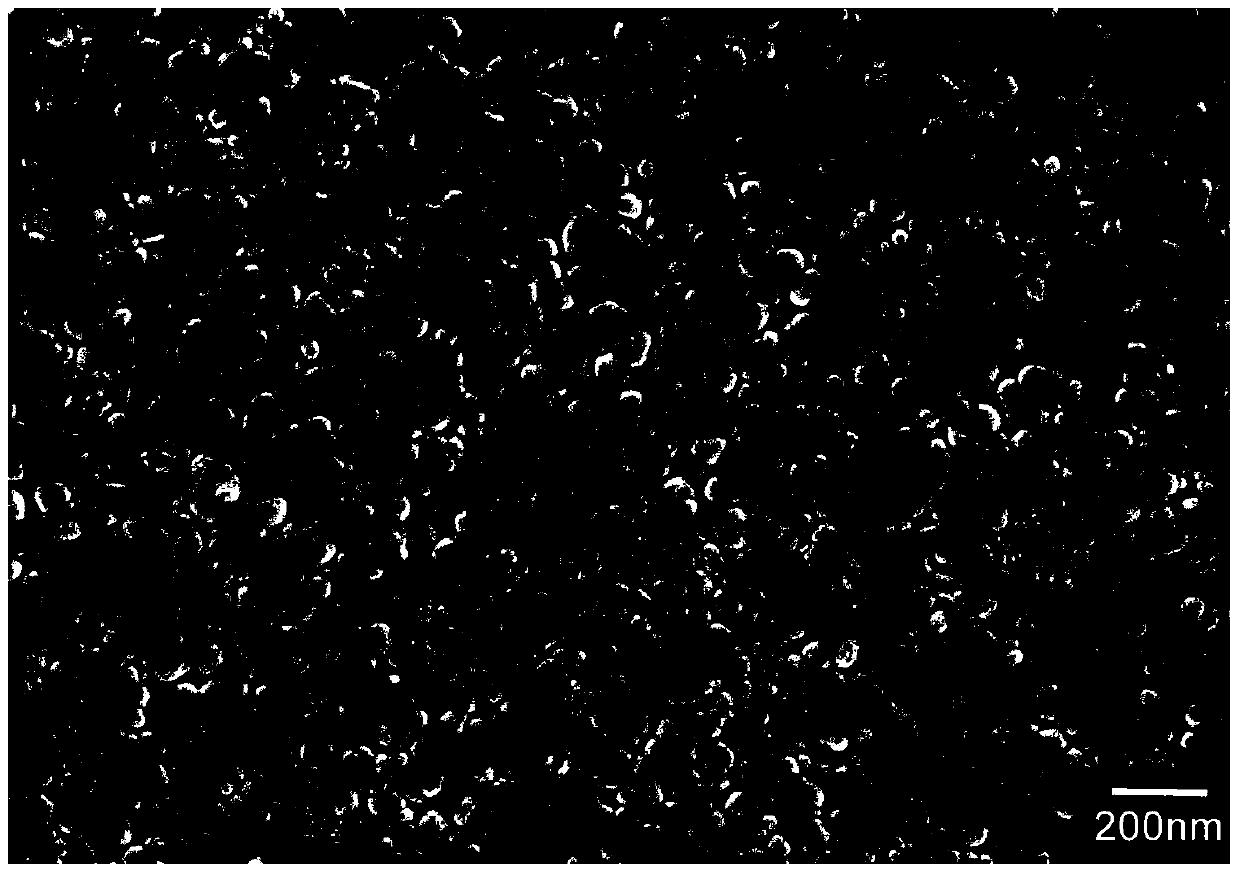

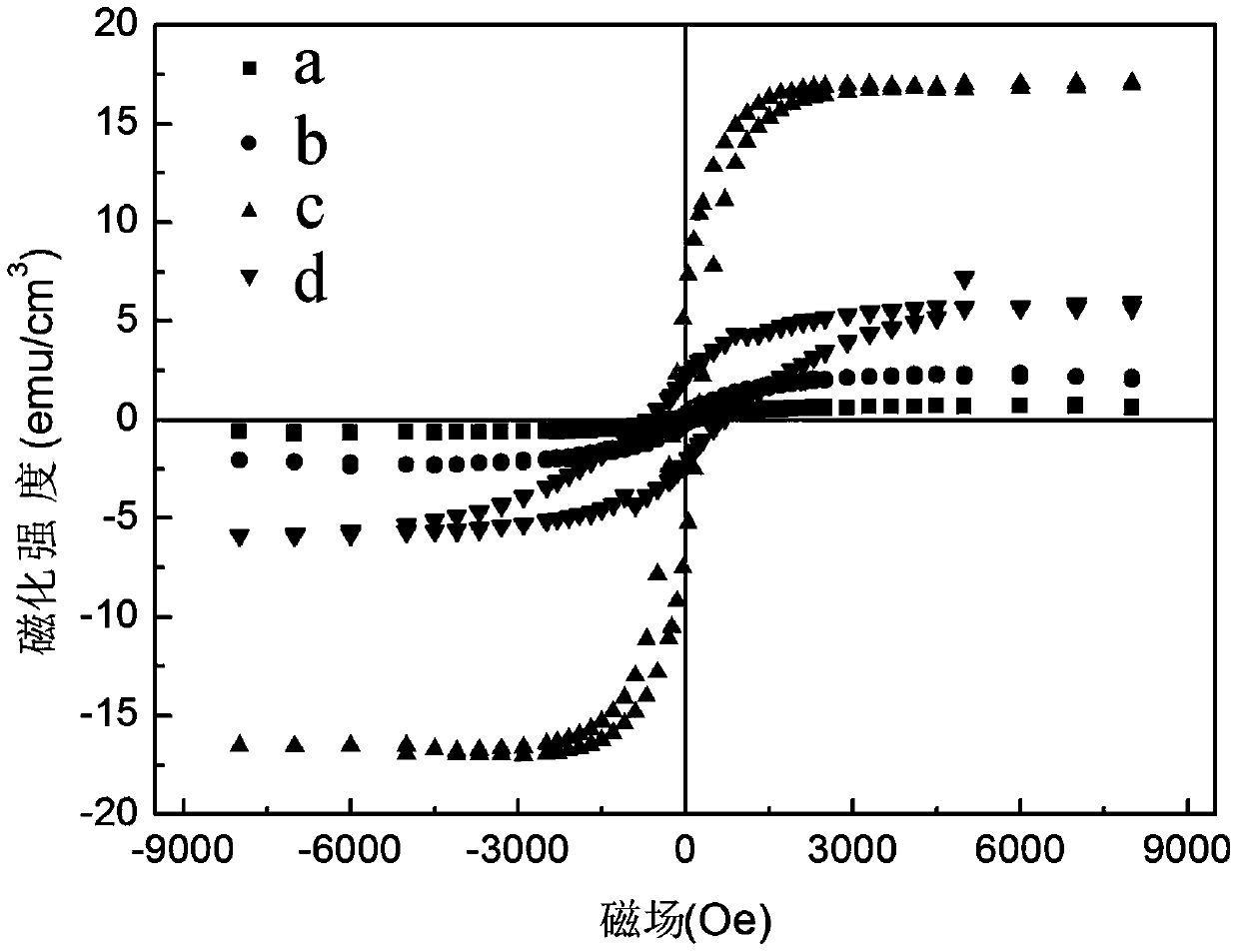

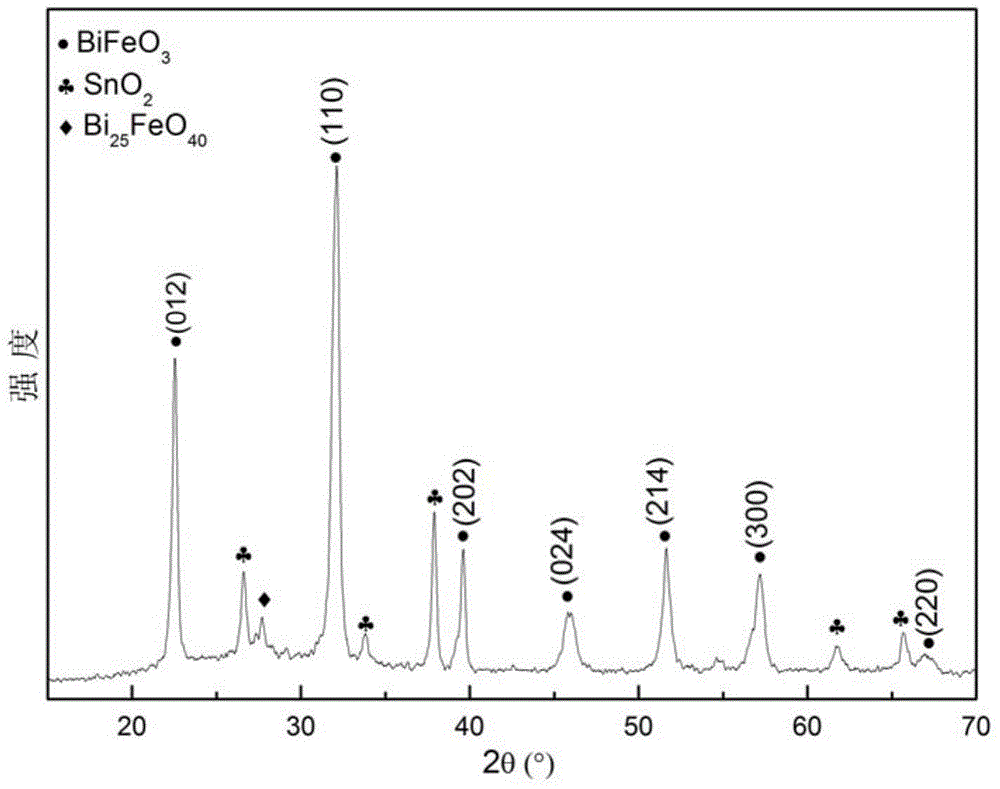

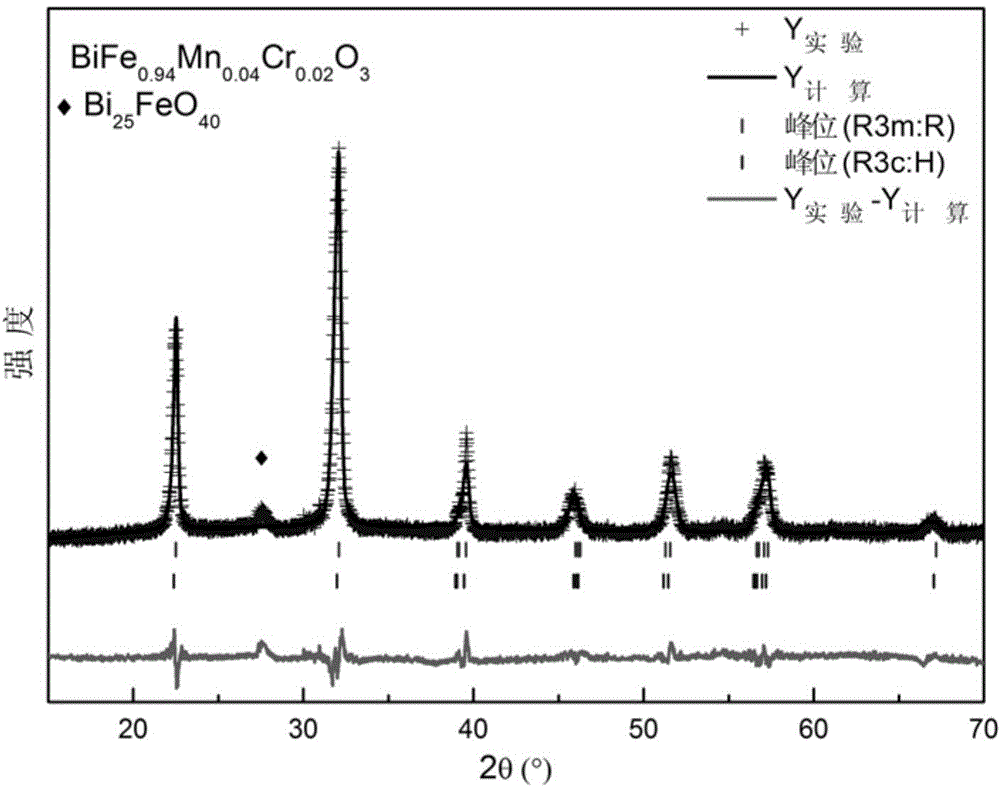

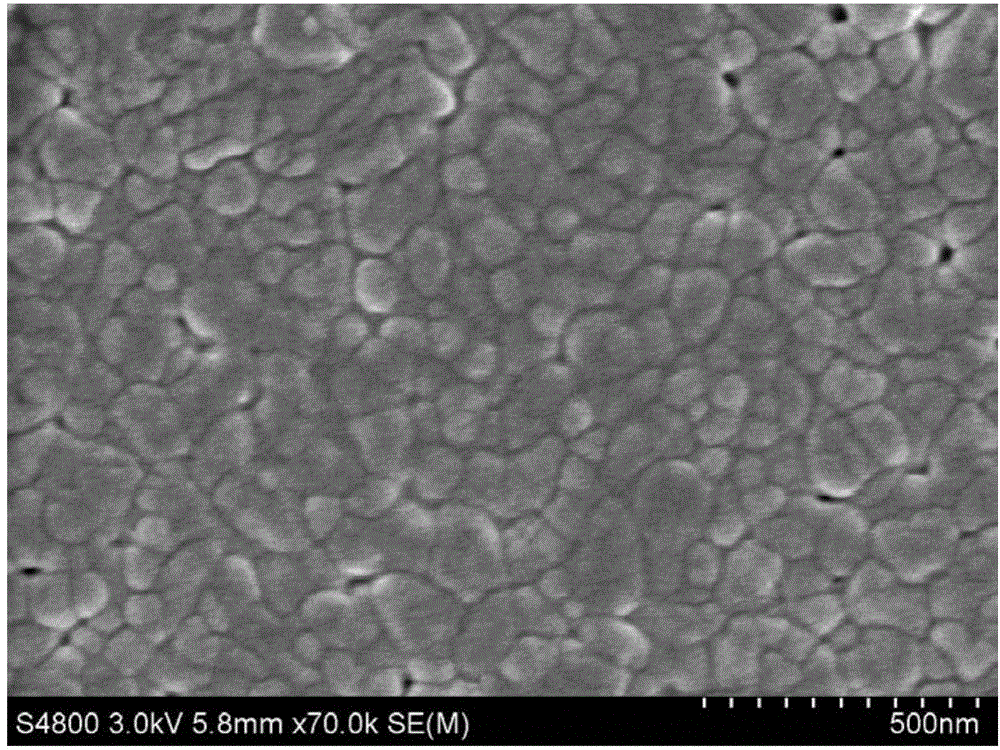

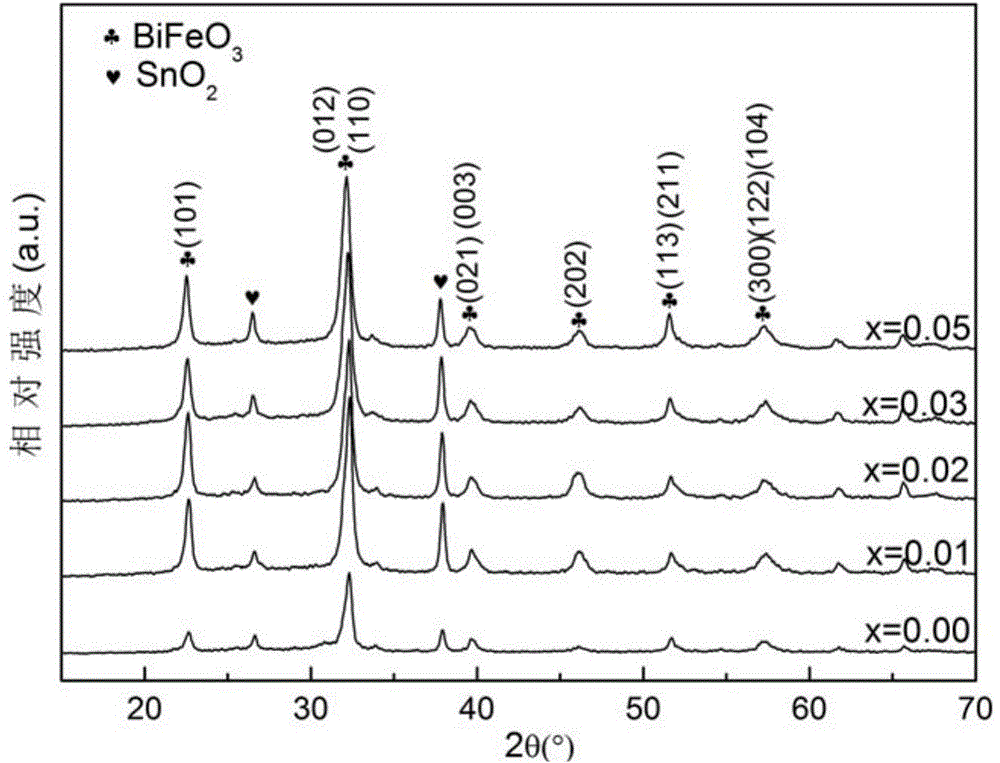

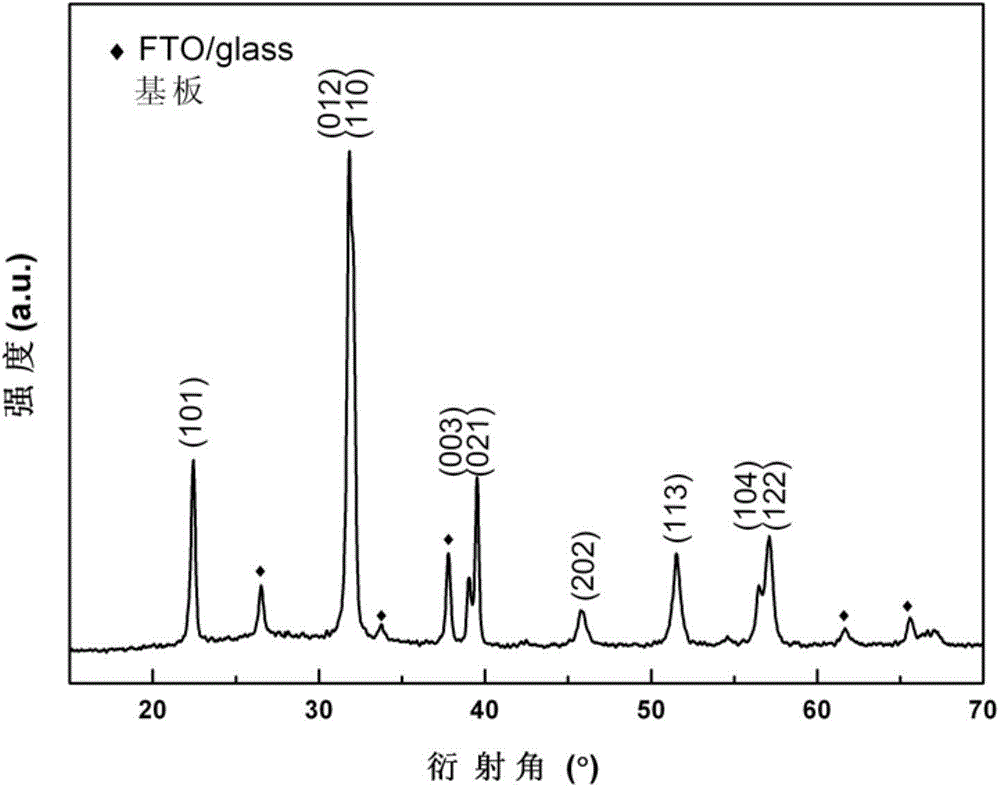

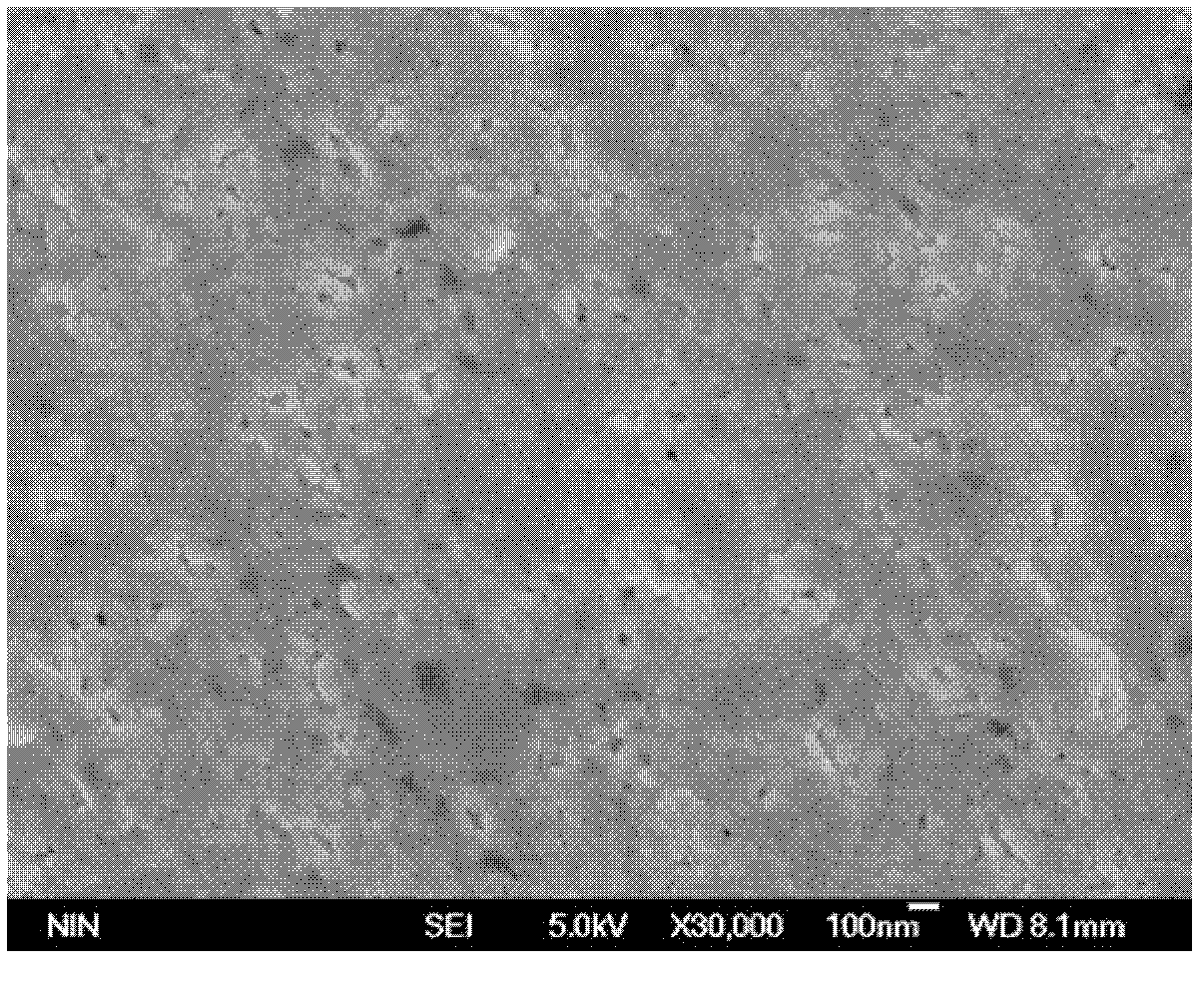

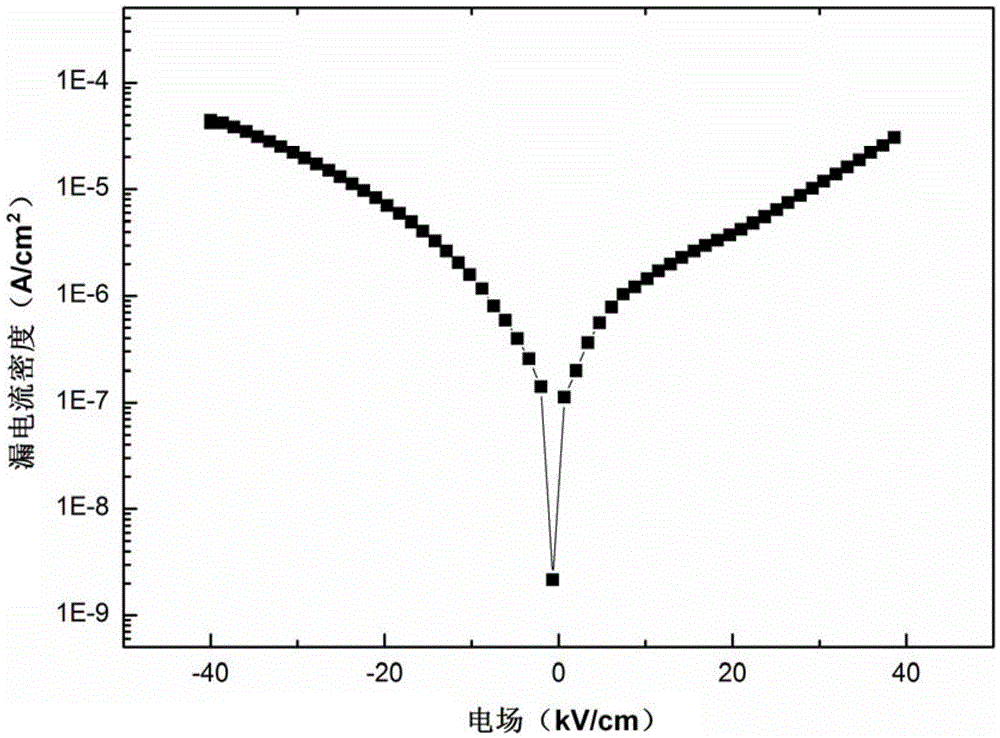

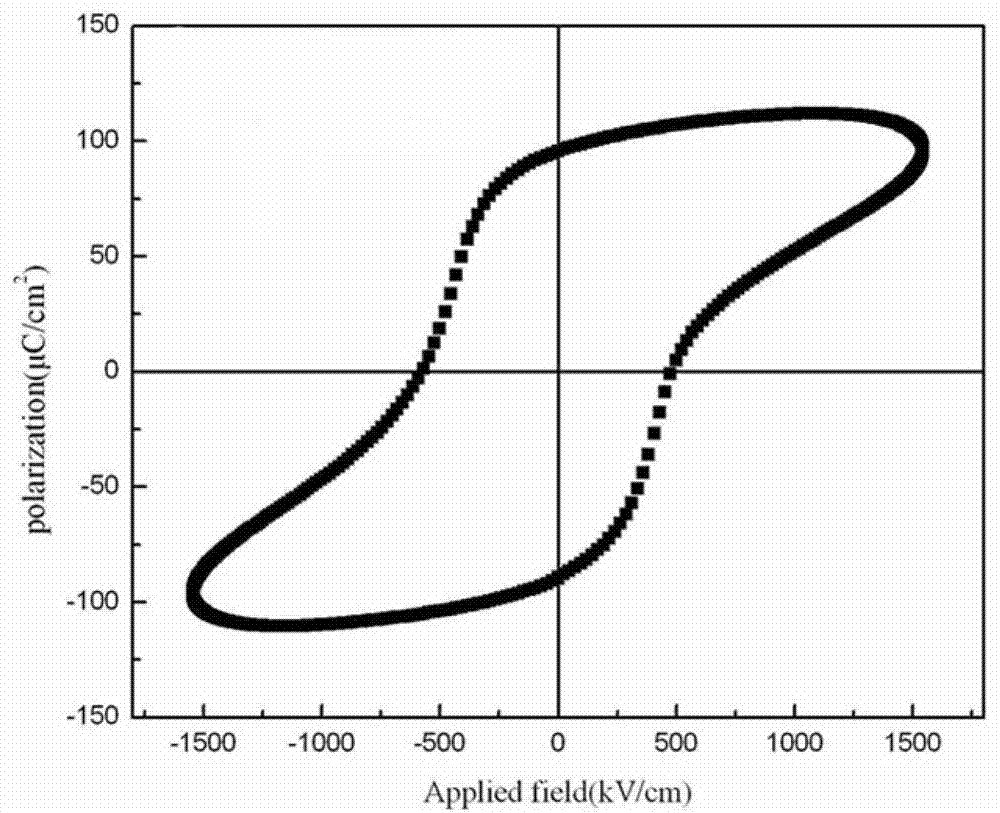

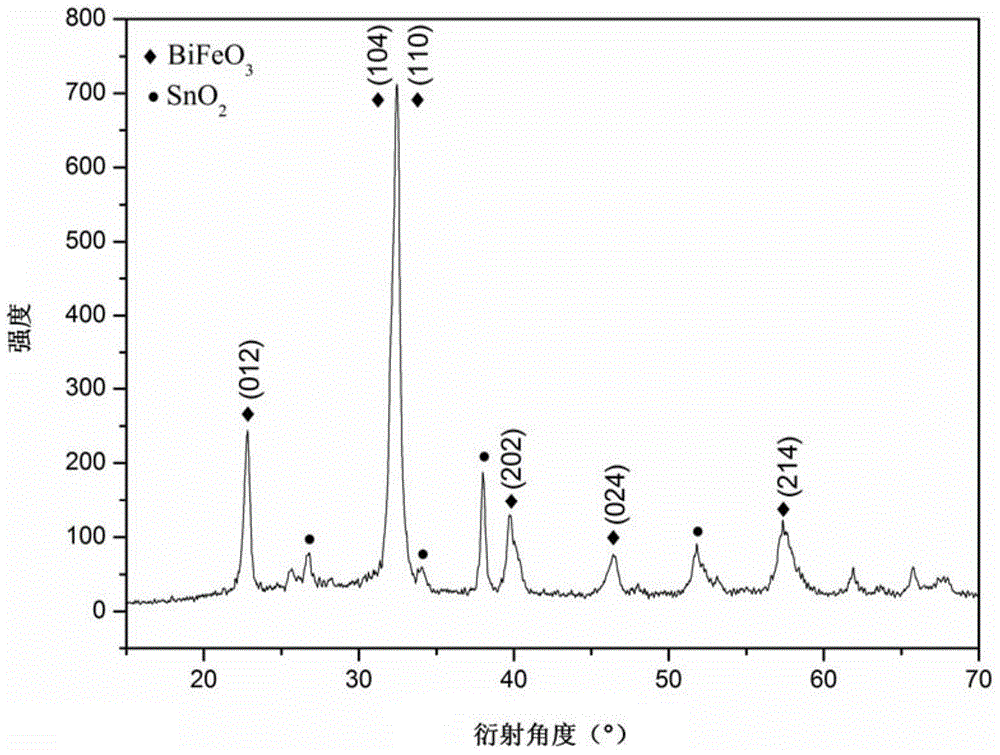

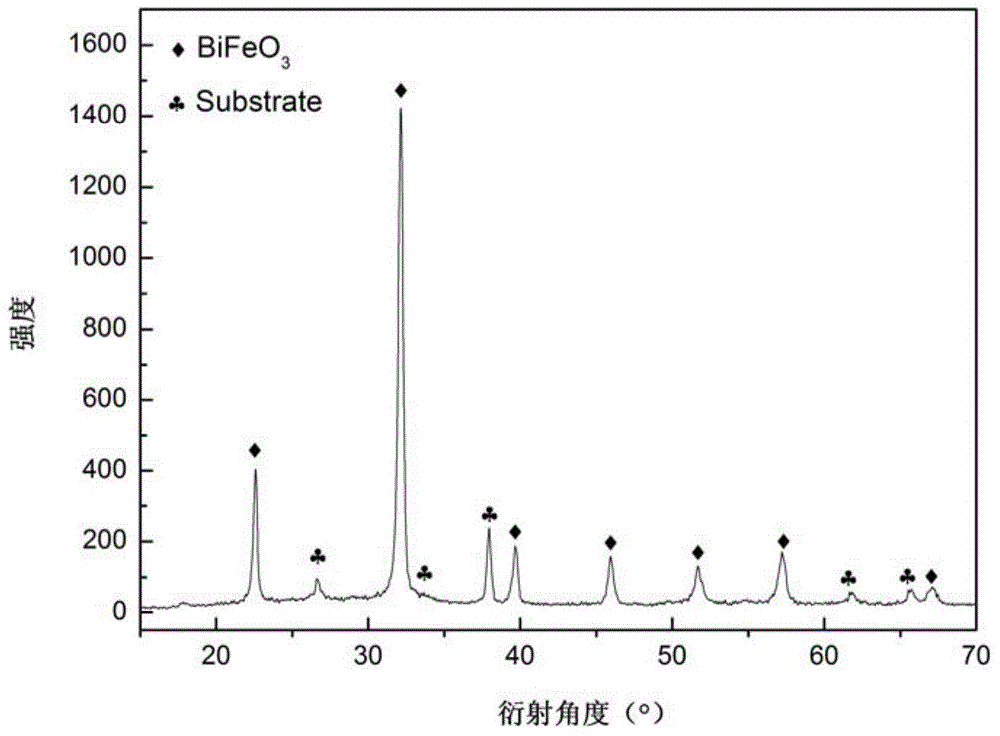

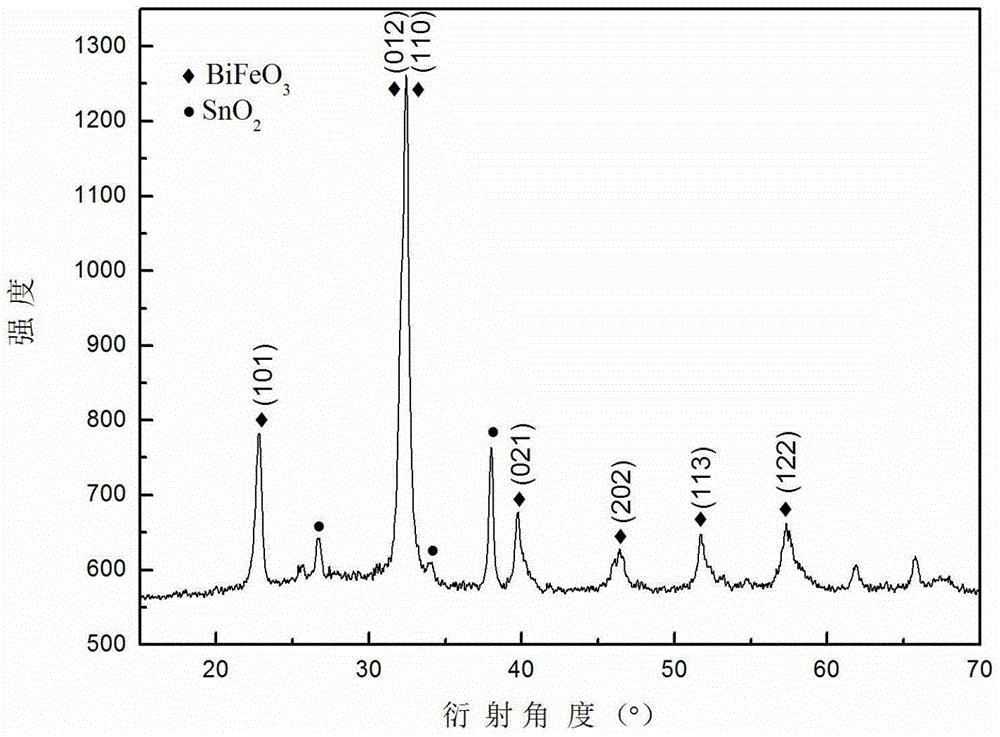

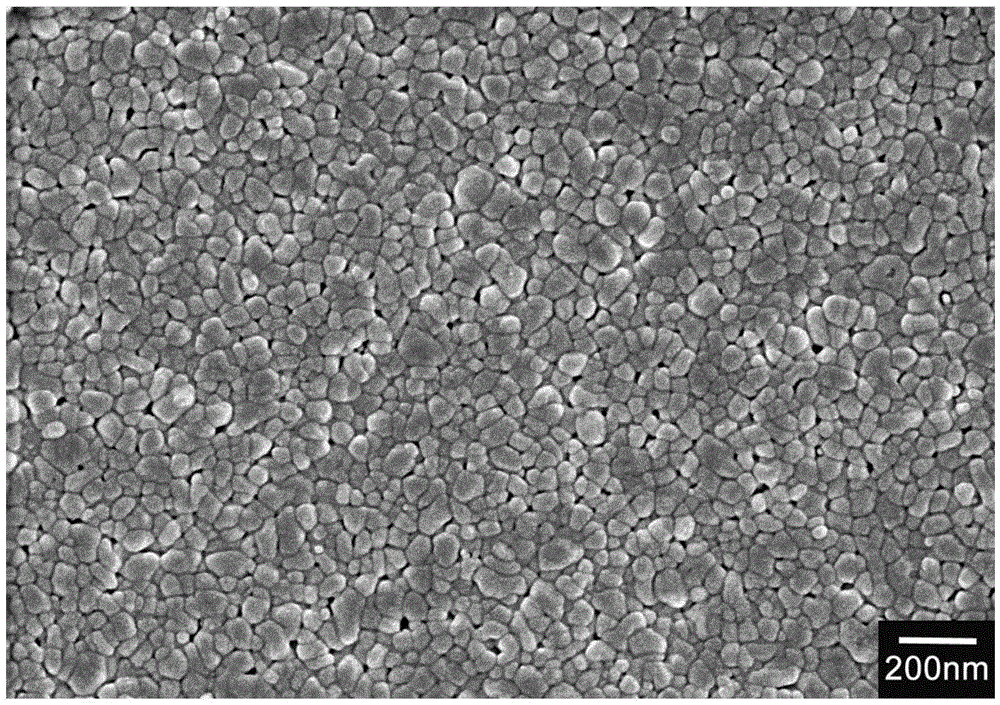

Bi[0.85-x]Pr0.15AExFe0.97Mn0.03O3 ferroelectric film and preparation method thereof

The invention provides a Bi[0.85-x]Pr0.15AExFe0.97Mn0.03O3 ferroelectric film and a preparation method thereof. The method comprises the following steps: preparing a Bi[0.85-x]Pr0.15AExFe0.97Mn0.03O3 precursor solution from bismuth nitrate, praseodymium nitrate, hydrogen nitrate AE, ferric nitrate and manganous nitrate, wherein AE is Sr, Ca or Ba, and x=0.02-0.05; spinning the precursor solution on a substrate; and then spinning, drying and annealing, so as to obtain the Bi[0.85-x]Pr0.15AExFe0.97Mn0.03O3 ferroelectric film. The Bi[0.85-x]Pr0.15AExFe0.97Mn0.03O3 ferroelectric film is simple in demands on equipment; the experiment condition is easy to achieve; the doping amount is easy to control; the ferroelectric property of the film can be greatly improved; and the prepared Bi[0.85-x]Pr0.15AExFe0.97Mn0.03O3 ferroelectric film is good in uniformity, low in leakage current, and low in coercive field, and has relatively high remanent polarization.

Owner:SHAANXI UNIV OF SCI & TECH

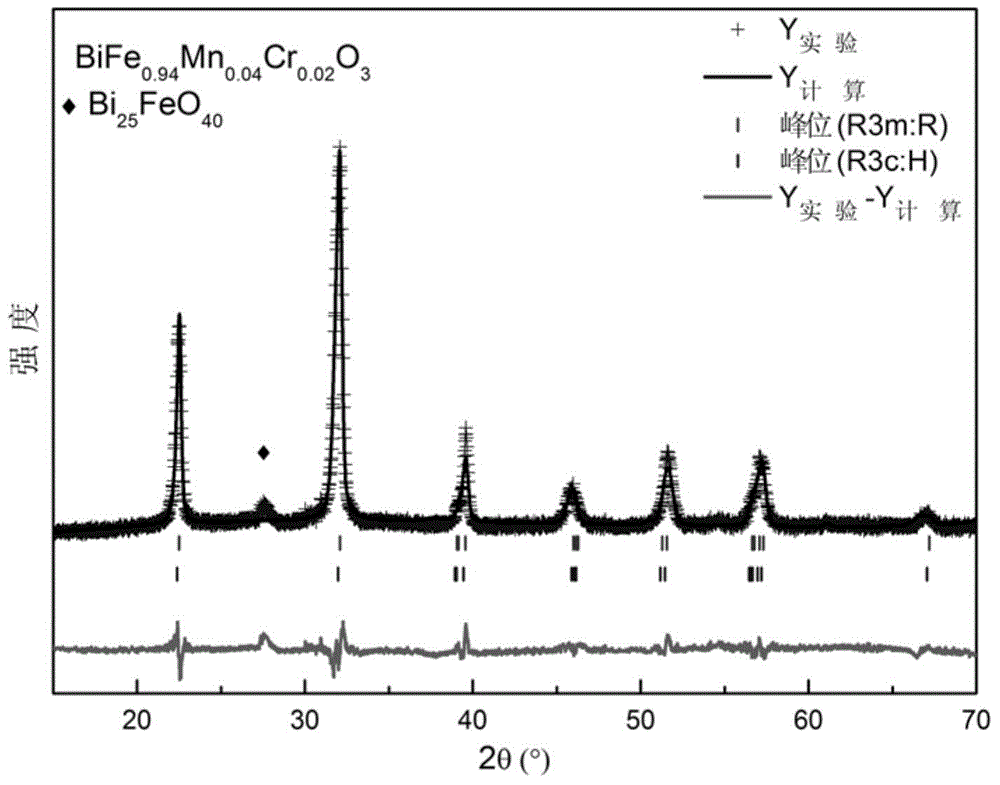

BiFe0.96-yMn0.04CryO3 ferroelectric film with high remanent polarization and high dielectric constant and preparation method thereof

ActiveCN103601249AIncreased polarizationImprove surface topographyIron compoundsAcetic anhydrideUltimate tensile strength

The invention relates to a BiFe0.96-yMn0.04CryO3 ferroelectric film with high remanent polarization and high dielectric constant and a preparation method thereof. The method comprises the steps of mixing bismuth nitrate, ferric nitrate, manganese acetate and chromic nitrate according to the mole ratio of 1.05: (0.96-y): 0.04: y, then, dissolving a mixture into mixed ethylene glycol monomethyl ether, and then, adding acetic anhydride, so as to obtain a BiFe0.96-yMn0.04CryO3 precursor solution with the metal ion concentration of 0.003-0.3mol / L; uniformly dispensing the BiFe0.96-yMn0.04CryO3 precursor solution on a FTO / glass substrate, of which the surface reaches atomic cleanliness, by adopting a spin-coating method, so as to prepare a film, then, drying to obtain a dry film, and then, adopting a layer-by-layer annealing process, thereby obtaining the crystalline BiFe0.96-yMn0.04CryO3 film. The method has the advantages that the requirements for equipment are simple, the experimental conditions are easily met, the prepared film is relatively good in uniformity and easy in doped amount control, and the ferroelectric properties and dielectric properties of the film can be improved greatly.

Owner:SHAANXI UNIV OF SCI & TECH

B-site Mn and Ni co-doped high-remanent-polarization BiFeO3 film and preparation method thereof

ActiveCN103626236AImprove multiferroic propertiesPromote productionIron compoundsMANGANESE ACETATEAcetic anhydride

The invention discloses a B-site Mn and Ni co-doped high-remanent-polarization BiFeO3 film and a preparation method thereof. The preparation method comprises the following steps: dissolving bismuth nitrate, ferric nitrate, manganese acetate and nickel acetate according to a molar ratio of 1.05:[(0.92-0.98)-x]:(0.02-0.08):x in a mixed solution of ethylene glycol monomethyl ether and acetic anhydride, uniformly stirring to obtain a BiFeO3 precursor solution, wherein the total metal ion concentration in the BiFeO3 precursor solution is 0.1-0.5mol / L, and x is equal to 0.01 to 0.03; spin coating the BiFeO3 precursor solution on a FTO / glass substrate to prepare a wet film, baking the wet film to obtain a dried film, annealing at the temperature of 550 DEG C for 8-13 minutes, thus obtaining a crystalline state BiFeO3 film; repeatedly operating until the BiFeO3 film reaches the needed thickness after the crystalline state BiFeO3 film is cooled, thus obtaining the B-site Mn and Ni co-doped high-remanent polarization BiFeO3 film. According to the method, a sol-gel process is adopted, the equipment requirement is simple, the method is suitable for preparing films on large surfaces and out-of-shape surfaces, the chemical constituents are accurately controlled, and the crystal structure is regulated through co-doping, so that the ferroelectric properties of the film are greatly improved.

Owner:SHAANXI UNIV OF SCI & TECH

a bi 1‑x re x fe 1‑y tm y o 3 /cofe 2 o 4 Multiferroic composite film and preparation method thereof

ActiveCN104575907BImprove ferroelectric propertiesReduce volatilityInorganic material magnetismInductances/transformers/magnets manufactureComposite filmNanotechnology

The invention provides a Bi1-xRExFe1-yTMyO3 / CoFe2O4 multiferroic composite film and a preparation method thereof. The composite film comprises a Bi1-xRExFe1-yTMyO3 crystalline film and a CoFe2O4 crystalline film which are compounded together. The preparation comprises the following steps: firstly preparing Bi1-xRExFe1-yTMyO3 precursor solution and CoFe2O4 precursor solution respectively; then spin-coating to prepare a plurality of layers of CoFe2O4 films on a substrate; next preparing a plurality of layers of Bi1-xRExFe1-yTMyO3 films on the CoFe2O4 films through spin coating to obtain a target product. The equipment requirement is simple, the prepared film is good in uniformity, chemical components are accurate and controllable, the doping content is easy to control, and the ferroelectric property and the ferromagnetic property of the film are greatly improved, and the film has high residual polarization value and residual magnetization value.

Owner:SHAANXI UNIV OF SCI & TECH

a multiferroic bi 0.98‑x sr 0.02 re x fe 0.97 mn 0.03 o 3 ‑cufe 2 o 4 Composite film and preparation method thereof

ActiveCN104478235BHigh polarizationEnhanced macroscopic magnetismCoatingsMultilayer membraneLeakage current density

The invention discloses a multiferroic Bi(0.98-x)Sr0.02RExFe0.97Mn0.03O3-CuFe2O4 composite film and a preparation method thereof. The composite film comprises Bi(0.98-x)Sr0.02RExFe0.97Mn0.03O3 crystal films and CuFe2O4 crystal films which are composited together. The preparation method comprises the following steps: firstly, preparing a Bi(0.98-x)Sr0.02RExFe0.97Mn0.03O3 precursor solution and a CuFe2O4 precursor solution respectively; secondly, preparing multiple layers of CuFe2O4 films on a substrate by spin coating, and preparing multiple layers of Bi(0.98-x)Sr0.02RExFe0.97Mn0.03O3 films on the CuFe2O4 films by spin coating to obtain a target product. The equipment requirement is simple, the uniformity of the prepared film is high, the doping amount is easy to control, the ferroelectric and ferromagnetic properties of the film are improved, and the leakage current density of the film is effectively reduced.

Owner:SHAANXI UNIV OF SCI & TECH

a laminated bife 0.97-x mn 0.03 tm x o 3 /cofe 2 o 4 Multiferroic composite film and preparation method thereof

ActiveCN104476832BImprove multiferroic propertiesHigh saturation magnetizationLaminationLamination apparatusComposite filmNanotechnology

The invention provides a laminated BiFe(0.97-x)Mn0.03TMxO3 / CoFe2O4 multiferroic composite film and a preparation method thereof. The composite film comprises a BiFe(0.97-x)Mn0.03TMxO3 / CoFe2O4 crystallized film and a CoFe2O4 crystallized film which are compounded together. The preparation method comprises the following steps of firstly, preparing a BiFe(0.97-x)Mn0.03TMxO3 / CoFe2O4 precursor solution and a CoFe2O4 precursor solution respectively; and then carrying out spin coating on a substrate to prepare a multi-layer CoFe2O4 film, and then carrying out spin coating on the CoFe2O4 film so as to prepare a multi-layer BiFe(0.97-x)Mn0.03TMxO3 / CoFe2O4 film, thereby obtaining the target product. According to the invention, the equipment requirement is simple; the prepared film is good in uniformity; chemical components are accurate and controllable; the doped amount is easy to control; the ferroelectric properties and the ferromagnetic property of a film are improved greatly, so that the film has high residual polarization value and a residual magnetization value.

Owner:SHAANXI UNIV OF SCI & TECH

A bifeo3 thin film with high remnant polarization intensity co-doped with b-site mn and ni and its preparation method

ActiveCN103626236BImprove multiferroic propertiesPromote productionIron compoundsMANGANESE ACETATEAcetic anhydride

The invention discloses a B-site Mn and Ni co-doped high-remanent-polarization BiFeO3 film and a preparation method thereof. The preparation method comprises the following steps: dissolving bismuth nitrate, ferric nitrate, manganese acetate and nickel acetate according to a molar ratio of 1.05:[(0.92-0.98)-x]:(0.02-0.08):x in a mixed solution of ethylene glycol monomethyl ether and acetic anhydride, uniformly stirring to obtain a BiFeO3 precursor solution, wherein the total metal ion concentration in the BiFeO3 precursor solution is 0.1-0.5mol / L, and x is equal to 0.01 to 0.03; spin coating the BiFeO3 precursor solution on a FTO / glass substrate to prepare a wet film, baking the wet film to obtain a dried film, annealing at the temperature of 550 DEG C for 8-13 minutes, thus obtaining a crystalline state BiFeO3 film; repeatedly operating until the BiFeO3 film reaches the needed thickness after the crystalline state BiFeO3 film is cooled, thus obtaining the B-site Mn and Ni co-doped high-remanent polarization BiFeO3 film. According to the method, a sol-gel process is adopted, the equipment requirement is simple, the method is suitable for preparing films on large surfaces and out-of-shape surfaces, the chemical constituents are accurately controlled, and the crystal structure is regulated through co-doping, so that the ferroelectric properties of the film are greatly improved.

Owner:SHAANXI UNIV OF SCI & TECH

Method for preparing BiFe1-xCrxO3 ferroelectric film by using sol-gel method

ActiveCN103121836BImprove ferroelectric propertiesIncreased structural distortionAcetic oxideCHROMIC NITRATE

Owner:盐城青墩津邦水务有限公司

a bi 1‑x re x feo 3 /cofe 2 o 4 Multiferroic composite film and preparation method thereof

ActiveCN104538139BImprove multiferroic propertiesReduce volatilityInorganic material magnetismInductances/transformers/magnets manufactureCrystallographyMultilayer membrane

The invention provides a Bi1-xRExFeO3 / CoFe2O4 multiferroic composite membrane and a preparation method thereof. The composite membrane comprises a Bi1-xRExFeO3 crystalline state membrane and a CoFe2O4 crystalline state membrane which are combined together, wherein RE is Ce, Pr, Tb, Eu or Yb, x is equal to 0.05-0.15; in the preparation, Bi1-xRExFeO3 precursor solution and CoFe2O4 precursor solution are firstly prepared respectively; and then, multi-layer CoFe2O4 membrane is prepared by spinning on a substrate, and the multi-layer Bi1-xRExFeO3 membrane is prepared by spinning on the CoFe2O4 membrane, so the target product is obtained. The facility request is simple, the homogeneity of the prepared membrane is good, the chemical composition can be accurately controlled, the doping content is easily controlled, and the ferroelectric property and ferromagnetic property of the membrane are greatly improved, so the Bi1-xRExFeO3 / CoFe2O4 multiferroic composite membrane has high residual polarization value and residual magnetization value.

Owner:SHAANXI UNIV OF SCI & TECH

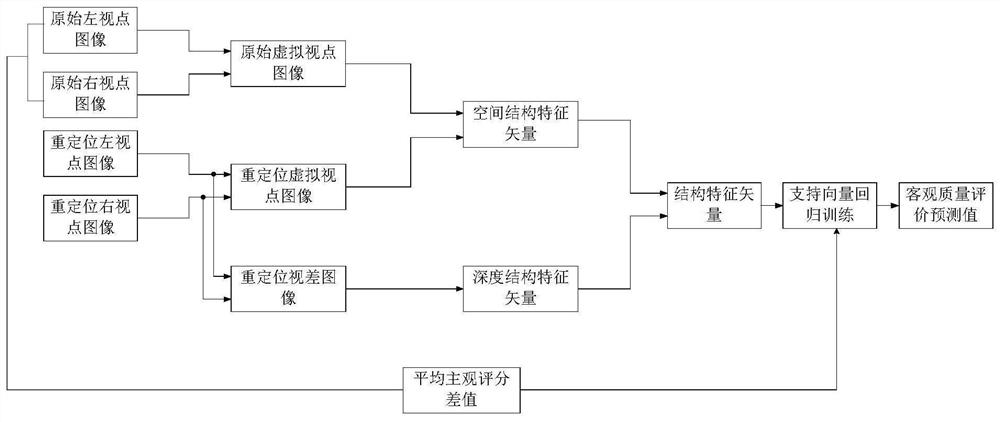

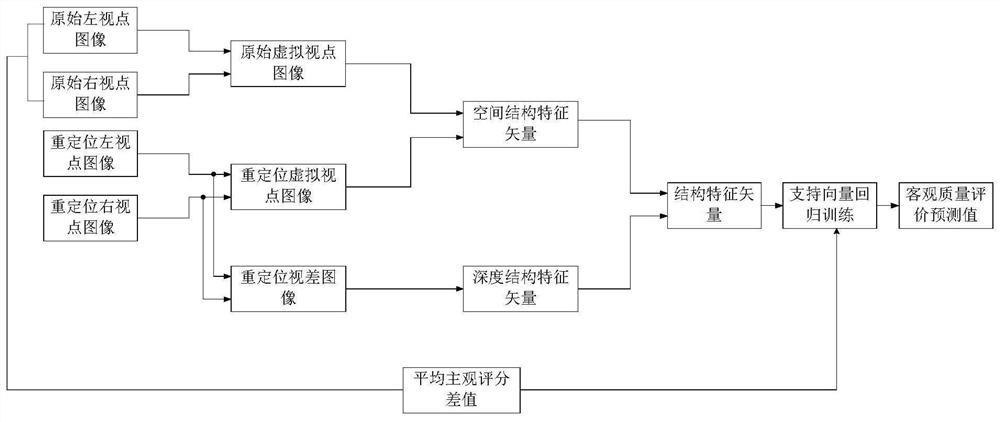

A Quality Evaluation Method of Relocation Stereo Image Based on Structural Features

ActiveCN112770105BReflect structural distortionIncreased Structural DistortionTelevision systemsSteroscopic systemsParallaxEvaluation result

The invention discloses a method for evaluating the quality of a relocated stereoscopic image based on structural features, which calculates the local information preservation feature of the relocated virtual viewpoint image, the forward information loss of the original virtual viewpoint image, and the reconstruction from the original virtual viewpoint image. The backward information loss of the virtual view point image is obtained, the spatial structure feature vector of the repositioned virtual view point image is obtained, and all the disparity images between the left and right view point images of the repositioned stereo image are calculated. The parallax amplitude features of the pixels belonging to the cross parallax area and the relative width features of all the pixels belonging to the occlusion area are obtained to obtain the depth structure feature vector, and finally the structure feature vector of the repositioned stereo image is obtained; The feature vector is trained to obtain the support vector regression training model; the advantage is that the correlation between the objective evaluation result and the subjective perception of the human eye is improved.

Owner:NINGBO UNIV

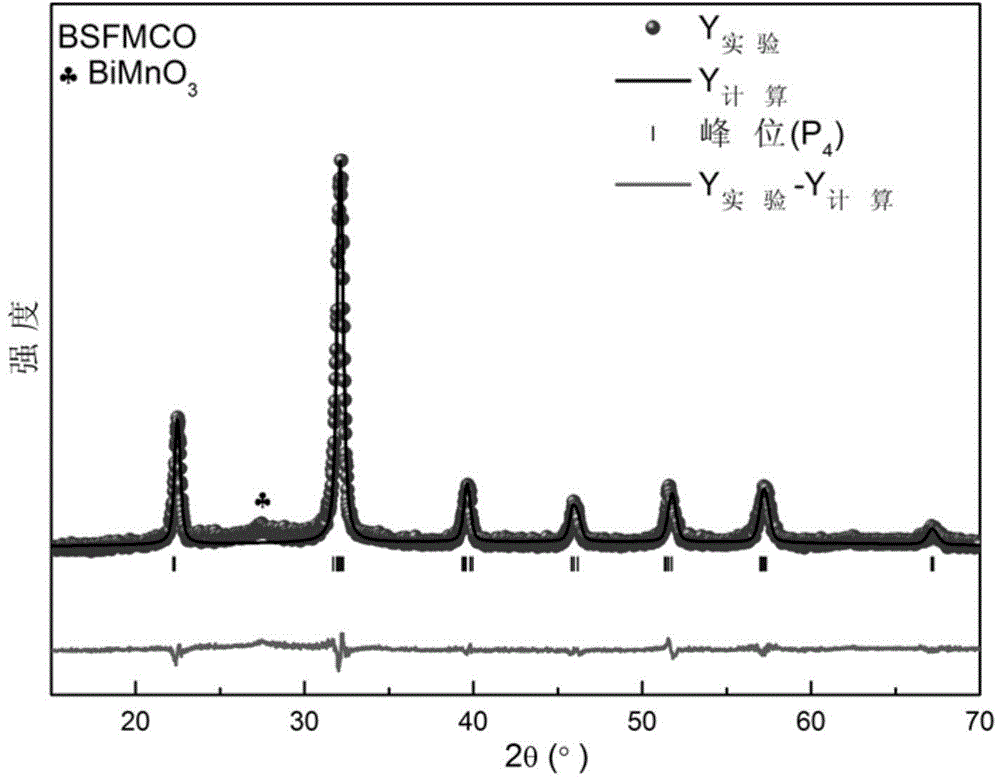

a multiferroic bi 0.96‑x sr 0.04 re x fe 0.94 mn 0.04 cr 0.02 o 3 ‑nife 2 o 4 Composite film and preparation method thereof

ActiveCN104445996BToxic volatilizationIncreased structural distortionLeakage current densityMultiferroics

The invention discloses a multiferroic Bi0.96-xSr0.04RExFe0.94Mn0.04Cr0.02O3-NiFe2O4 composite film and a preparation method thereof. The composite film comprises a Bi0.96-xSr0.04RExFe0.94Mn0.04Cr0.02O3 crystalline state film and a NiFe2O4 crystalline state film which are compounded together. The preparation method comprises the following steps: respectively preparing a Bi0.96-xSr0.04RExFe0.94Mn0.04Cr0.02O3 precursor solution and a NiFe2O4 precursor solution; and spinning on a substrate to prepare a multilayer NiFe2O4 film, and spinning on the NiFe2O4 film to prepare a multilayer Bi0.96-xSr0.04RExFe0.94Mn0.04Cr0.02O3 film, thereby obtaining the target product. The equipment requirement is simple, the prepared film is high in uniformity, the doping amount is easy to control, and the ferroelectric properties and ferromagnetic properties of the film are greatly improved. Meanwhile, the leakage current density of the film is effectively reduced.

Owner:SHAANXI UNIV OF SCI & TECH

Bi1-xSmxFe0.94Mn0.04Cr0.02O3 ferroelectric film with high remanent polarization and low leakage current density and preparation method thereof

ActiveCN103601247BAvoid breakingReduce surface defectsIron compoundsMANGANESE ACETATEAcetic anhydride

The invention relates to a Bi1-xSmxFe0.94Mn0.04Cr0.02O3 ferroelectric film with high remanent polarization and low leakage current density and a preparation method thereof. The method comprises the steps of dissolving bismuth nitrate, ferric nitrate, samarium nitrate, manganese acetate and chromic nitrate into mixed ethylene glycol monomethyl ether according to the mole ratio of (1.05-x): x: 0.94: 0.04: 0.02, then, adding acetic anhydride, and adding ethanolamine to adjust viscosity, so as to obtain a Bi1-xSmxFe0.94Mn0.04Cr0.02O3 precursor solution with the metal ion concentration of 0.003-0.3mol / L; uniformly dispensing the Bi1-xSmxFe0.94Mn0.04Cr0.02O3 precursor solution on a FTO / glass substrate, of which the surface reaches atomic cleanliness, by adopting a spin-coating method, so as to prepare a film, then, drying to obtain a dry film, and then, adopting a layer-by-layer annealing process, thereby obtaining the Bi1-xSmxFe0.94Mn0.04Cr0.02O3 film. The method has the advantages that the requirements for equipment are simple, the experimental conditions are easily met, the prepared film is relatively good in uniformity and easy in doped amount control, the remanent polarization of the film is increased greatly, and the leakage current density of the film is reduced effectively.

Owner:盐城市鹤业实业投资有限公司

A multiferroic bi0.83pr0.15sr0.02fe0.97-xmn0.03cuxo3-cufe2o4 composite film and its preparation method

ActiveCN105906221BPrevent volatilizationInhibition transitionCoatingsLeakage current densityComposite film

The invention discloses a multiferroic Bi0.83Pr0.15Sr0.02Fe0.97-xMn0.03CuxO3-CuFe2O4 composite film and a preparation method thereof. The composite film comprises a Bi0.83Pr0.15Sr0.02Fe0.97-xMn0.03CuxO3 (x=0.01-0.05) crystalline film in the upper layer and a CuFe2O4 crystalline film in the lower layer. The preparation method comprises respectively preparing a Bi0.83Pr0.15Sr0.02Fe0.97-xMn0.03CuxO3 precursor solution and a CuFe2O4 precursor solution, carrying out spin-coating on a substrate with multiple CuFe2O4 films and carrying out spin-coating on the CuFe2O4 film with multiple Bi0.83Pr0.15Sr0.02Fe0.97-xMn0.03CuxO3 films to obtain the multiferroic Bi0.83Pr0.15Sr0.02Fe0.97-xMn0.03CuxO3-CuFe2O4 composite film. The preparation method has simple equipment requirements, can prepare the film with good uniformity, easily controls a doping amount, improves ferroelectric and ferromagnetic properties of the film and effectively reduces film leakage current density.

Owner:SHAANXI UNIV OF SCI & TECH

A bi with high ferromagnetic and ferroelectric properties 0.9 er 0.1 fe 1‑x co x o 3 Thin film and its preparation method

The invention provides a Bi0.9Er0.1Fe1-xCoxO3 film with high ferromagnetism and ferroelectricity, and a making method thereof. The method comprises the following steps: preparing a Bi0.9Er0.1Fe1-xCoxO3 precursor solution from bismuth nitrate, iron nitrate, cobalt nitrate and erbium nitrate, spin-coating a substrate with the Bi0.9Er0.1Fe1-xCoxO3 (x is 0.01-0.03) precursor solution, uniformly sizing, drying, and annealing to obtain the Bi0.9Er0.1Fe1-xCoxO3 film with high ferromagnetism and ferroelectricity. The method has the advantages of simple device requirements, easy reaching of experiment conditions, easy control of the doping amount, and great improvement of the ferromagnetism of a BiFeO3 film, and the Bi0.9Er0.1Fe1-xCoxO3 film made in the invention has the advantages of good uniformity, high magnetic intensity and high remanent polarization.

Owner:SHAANXI UNIV OF SCI & TECH

A kind of high remnant polarization and high dielectric constant bife0.96-ymn0.04cryo3 ferroelectric thin film and preparation method thereof

ActiveCN103601249BIncreased polarizationImprove surface topographyIron compoundsMANGANESE ACETATEAcetic anhydride

Owner:SHAANXI UNIV OF SCI & TECH

Bi0.90Ho0.10Fe1-XMnXO3 ferroelectric film with high remanent polarization and preparation method thereof

ActiveCN103708562BImprove insulation performanceReduce generationIron compoundsAcetic acidMANGANESE ACETATE

The invention relates to a Bi0.90Ho0.10Fe1-xMnXO3 ferroelectric film with high remanent polarization and a preparation method thereof, wherein x is equal to 0.01-0.05, and the film is of a distorted perovskite structure, has a diamond crystal system and has good uniformity, remanent polarization of 78-108 muC / cm<2>, and a dielectric constant of 196.2-271.8. The preparation method comprises the steps of dissolving bismuth nitrate, ferric nitrate, holmium nitrate and manganese acetate in a mixture prepared by mixing ethylene glycol monomethyl ether and acetic anhydride to obtain a precursor solution; spin-coating the precursor solution on a substrate, coating glue evenly, then baking to obtain a dry film, then annealing to obtain a Bi0.90Ho0.10Fe1-xMnXO3 film, and repeatedly spin-coating the precursor solution, baking and annealing to achieve the required film thickness to obtain the film. According to the Bi0.90Ho0.10Fe1-xMnXO3 ferroelectric film with high remanent polarization and the preparation method thereof, the requirements for equipment are simple, the doping amount is easy to control, and the ferroelectric properties of the BiFeO3 film can be greatly improved.

Owner:SHAANXI UNIV OF SCI & TECH

a bi 0.90 er 0.10 fe 0.96 co 0.02 mn 0.02 o 3 /mn 1-x co x fe 2 o 4 Composite film and preparation method thereof

The invention provides a Bi0.90Er0.10Fe0.96Co0.02Mn0.02O3 / Mn(1-x)CoxFe2O4 composite film and a preparation method thereof. The composite film comprises a Bi0.90Er0.10Fe0.96Co0.02Mn0.02O3 crystalline-state film and a Mn(1-x)CoxFe2O4 crystalline-state film which are compounded together. The preparation method comprises the following steps: respectively preparing a Bi0.90Er0.10Fe0.96Co0.02Mn0.02O3 precursor solution and a Mn(1-x)CoxFe2O4 precursor solution; then spinning on a substrate to prepare a multi-layer Mn(1-x)CoxFe2O4 film; and spinning on the Mn(1-x)CoxFe2O4 film to prepare a multi-layer Bi0.90Er0.10Fe0.96Co0.02Mn0.02O3 film which is the target product. In the invention, the equipment requirements are simple, the prepared film has relatively good uniformity, the doping amount is easy to control, the ferroelectric property and ferromagnetic property of the film are remarkably improved, and the leak current density of the film is effectively reduced at the same time.

Owner:SHAANXI UNIV OF SCI & TECH

B-site Mn and Cu codoped high remanent polarization BiFeO3 film and preparation method

ActiveCN103613144BImprove multiferroic propertiesPromote productionFrom gel stateMANGANESE ACETATEAcetic anhydride

The invention relates to a B-site Mn and Cu codoped high remanent polarization BiFeO3 film and a preparation method, the method comprises the following steps: dissolving bismuth nitrate, ferric nitrate, manganese acetate and cupric nitrate according to mol ratio of 1.05: [(0.92-0.98)-x]: (0.02-0.08):x in a mixed liquor of ethylene glycol monomethyl ether and acetic anhydride, then uniformly stirring to obtain a BiFeO3 precursor; wherein total metal ion concentration of the BiFeO3 precursor is 0.1-0.5mol / L, X is 0.01-0.03; performing spin coating of the BiFeO3 precursor on a FTO / glass substrate to prepare a wet membrane, baking the wet membrane to obtain a dry membrane, then annealing at 550 DEG C to obtain the crystalline state BiFeO3 film; cooling the crystalline state BiFeO3 film, and repeatedly making the crystalline state BiFeO3 film to reach a required thickness to obtain the B-site Mn and Cu codoped high remanent polarization BiFeO3 film. According to the invention, a sol gel technology is employed, the equipment requirement is simple, the film is prepared on large surface and surfaces with irregular shapes, the chemical component is accurate and controllable, and the regulation and control to its crystal structure can be carried out by codoping thereby the ferroelectric performance of the film is greatly increased.

Owner:盐城梦心缘鞋服有限公司

a bi 0.85‑x pr 0.15 ae x fe 0.97 mn 0.03 o 3 Ferroelectric thin film and preparation method thereof

The invention provides a Bi[0.85-x]Pr0.15AExFe0.97Mn0.03O3 ferroelectric film and a preparation method thereof. The method comprises the following steps: preparing a Bi[0.85-x]Pr0.15AExFe0.97Mn0.03O3 precursor solution from bismuth nitrate, praseodymium nitrate, hydrogen nitrate AE, ferric nitrate and manganous nitrate, wherein AE is Sr, Ca or Ba, and x=0.02-0.05; spinning the precursor solution on a substrate; and then spinning, drying and annealing, so as to obtain the Bi[0.85-x]Pr0.15AExFe0.97Mn0.03O3 ferroelectric film. The Bi[0.85-x]Pr0.15AExFe0.97Mn0.03O3 ferroelectric film is simple in demands on equipment; the experiment condition is easy to achieve; the doping amount is easy to control; the ferroelectric property of the film can be greatly improved; and the prepared Bi[0.85-x]Pr0.15AExFe0.97Mn0.03O3 ferroelectric film is good in uniformity, low in leakage current, and low in coercive field, and has relatively high remanent polarization.

Owner:SHAANXI UNIV OF SCI & TECH

Relocation stereo image quality evaluation method based on structural features

ActiveCN112770105AReflect structural distortionIncreased Structural DistortionTelevision systemsSteroscopic systemsParallaxFeature vector

The invention discloses a relocation three-dimensional image quality evaluation method based on structural features, which comprises the following steps of: calculating local information retention features of a relocation virtual viewpoint image, forward information loss of an original virtual viewpoint image and backward information loss of a virtual viewpoint image reconstructed from the original virtual viewpoint image; obtaining a spatial structure characteristic vector of the relocated virtual viewpoint image; calculating parallax amplitude characteristics of all pixel points belonging to a matching region, a visual comfort region and a cross parallax region and relative width characteristics of all pixel points belonging to a shielding region in a parallax image between a left viewpoint image and a right viewpoint image of the repositioned stereo image to obtain a depth structure characteristic vector; and finally obtaining a structural feature vector of the relocated stereo image; then training all the structural feature vectors by using support vector regression to obtain a support vector regression training model; the method has the advantage that the correlation between an objective evaluation result and human eye subjective perception is improved.

Owner:NINGBO UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![Bi[0.85-x]Pr0.15AExFe0.97Mn0.03O3 ferroelectric film and preparation method thereof Bi[0.85-x]Pr0.15AExFe0.97Mn0.03O3 ferroelectric film and preparation method thereof](https://images-eureka-patsnap-com.libproxy1.nus.edu.sg/patent_img/d33c2ba5-ceec-44cc-a709-6bfddffa1e71/HDA0000631192430000011.PNG)

![Bi[0.85-x]Pr0.15AExFe0.97Mn0.03O3 ferroelectric film and preparation method thereof Bi[0.85-x]Pr0.15AExFe0.97Mn0.03O3 ferroelectric film and preparation method thereof](https://images-eureka-patsnap-com.libproxy1.nus.edu.sg/patent_img/d33c2ba5-ceec-44cc-a709-6bfddffa1e71/HDA0000631192430000012.PNG)

![Bi[0.85-x]Pr0.15AExFe0.97Mn0.03O3 ferroelectric film and preparation method thereof Bi[0.85-x]Pr0.15AExFe0.97Mn0.03O3 ferroelectric film and preparation method thereof](https://images-eureka-patsnap-com.libproxy1.nus.edu.sg/patent_img/d33c2ba5-ceec-44cc-a709-6bfddffa1e71/HDA0000631192430000021.PNG)