Method for preparing BiFe1-xCrxO3 ferroelectric film by using sol-gel method

A ferroelectric thin film and gel method technology, applied in the field of functional materials, can solve the problems of large leakage conductance of pure-phase BiFeO, inability to obtain a saturated hysteresis loop, limiting practical applications, etc., so that the doping amount can be precisely controlled, Increased structural distortion and enhanced ferroelectricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Step 1: Bi(NO 3 ) 3 ·5H 2 O, Fe(NO 3 ) 3 9H 2 O and Cr(NO 3 ) 3 9H 2 O was dissolved in a mixture of ethylene glycol methyl ether, acetic anhydride and ethanolamine at a molar ratio of 1.05:1.00:0.00, and after magnetic stirring for 3 hours, stable BiFeO with a metal ion concentration of 0.003 mol / L was obtained. 3 Precursor solution, wherein the volume ratio of ethylene glycol methyl ether, acetic anhydride and ethanolamine is 14:5:1.

[0027] Step 2: Spin-coat BiFeO on FTO / glass substrate by spin-coating method 3 Thin films were prepared from the precursor solution, and the layer-by-layer annealing process was used to obtain crystalline BiFeO 3 film.

[0028] Step 3: In Crystalline BiFeO 3 Preparation of 0.502mm thin film surface by ion sputtering 2 Au electrode, and then 300 ℃ for 20min for electrode annealing treatment.

[0029] Determination of BiFeO by XRD 3 Phase composition and structure of thin films, determined by FE-SEM for BiFeO 3 Microscopic ...

Embodiment 2

[0031] Step 1: Bi(NO 3 ) 3 ·5H 2 O, Fe(NO 3 ) 3 9H 2 O, and Cr(NO 3 ) 3 9H 2 O was dissolved in a mixture of ethylene glycol methyl ether, acetic anhydride and ethanolamine at a molar ratio of 1.05:0.99:0.01, and after magnetic stirring for 3 hours, a stable BiFe with a metal ion concentration of 0.3mol / L was obtained. 0.99 Cr 0.01 o 3 Precursor solution, wherein the volume ratio of ethylene glycol methyl ether, acetic anhydride and ethanolamine is 14:5:1.

[0032] Step 2: Spin-coat BiFe on FTO / glass substrate by spin-coating method 0.99 Cr 0.01 o 3 Thin films were prepared from the precursor solution, and the layer-by-layer annealing process was used to obtain crystalline Cr-doped BiFe 0.99 Cr 0.01 o 3 film.

[0033] Step 3: BiFe in Crystalline State 0.99 Cr 0.01 o 3 Preparation of 0.502mm thin film surface by ion sputtering 2 Au electrode, and then 300 ℃ for 20min for electrode annealing treatment.

[0034] Determination of BiFe by XRD 0.99 Cr 0.01 o ...

Embodiment 3

[0036] Step 1: Bi(NO 3 ) 3 ·5H 2 O, Fe(NO 3 ) 3 9H 2 O, and Cr(NO 3 ) 3 9H 2 O was dissolved in a mixture of ethylene glycol methyl ether, acetic anhydride and ethanolamine at a molar ratio of 1.05:0.98:0.02, and after magnetic stirring for 3 hours, a stable BiFe with a metal ion concentration of 0.1mol / L was obtained. 0.98 Cr 0.02 o 3 Precursor solution, wherein the volume ratio of ethylene glycol methyl ether, acetic anhydride and ethanolamine is 14:5:1.

[0037] Step 2: Spin-coat BiFe on FTO / glass substrate by spin-coating method 0.98 Cr 0.02 o 3 Thin films were prepared from the precursor solution, and the layer-by-layer annealing process was used to obtain crystalline Cr-doped BiFe 0.98 Cr 0.02 o 3 film.

[0038] Step 3: BiFe in Crystalline State 0.98 Cr 0.02 o 3 Preparation of 0.502mm thin film surface by ion sputtering 2 Au electrode, and then 300 ° C for 20 min for electrode annealing treatment.

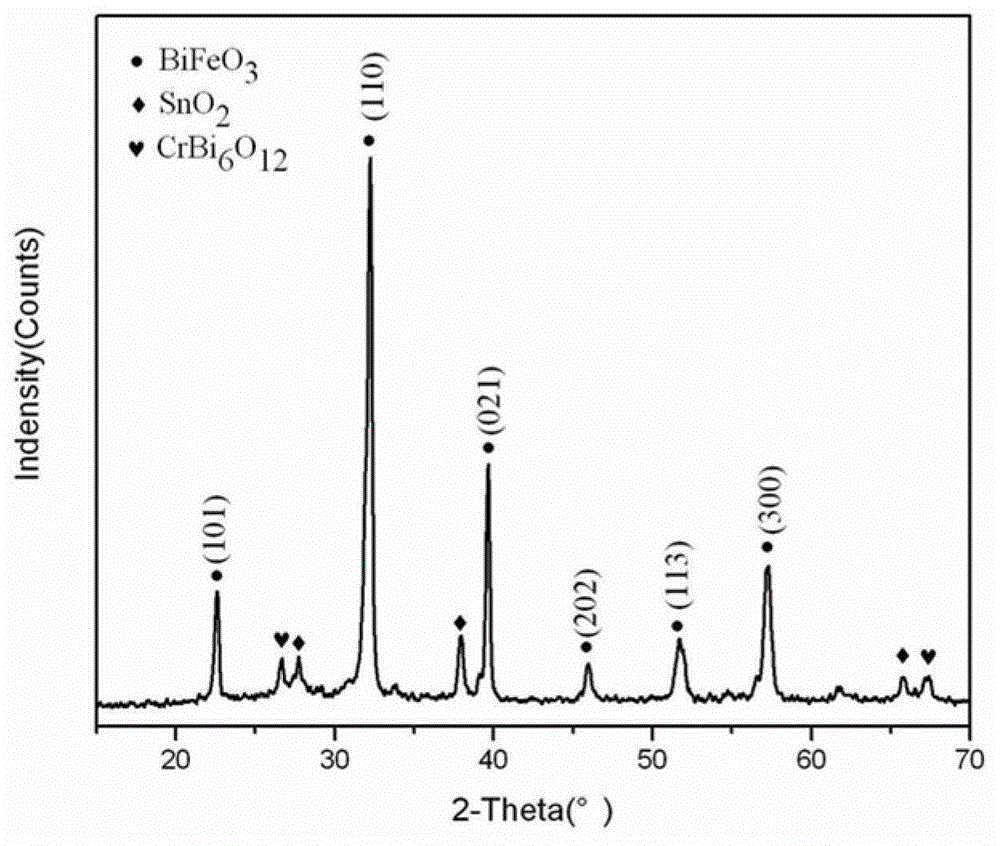

[0039] see figure 1 As shown, the BiFe was determi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| saturated polarization | aaaaa | aaaaa |

| remanent polarization | aaaaa | aaaaa |

| saturated polarization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com