Method for preparing Bi0.85Sm0.15Fe1-xCrxO3 ferroelectric film via sol-gel process

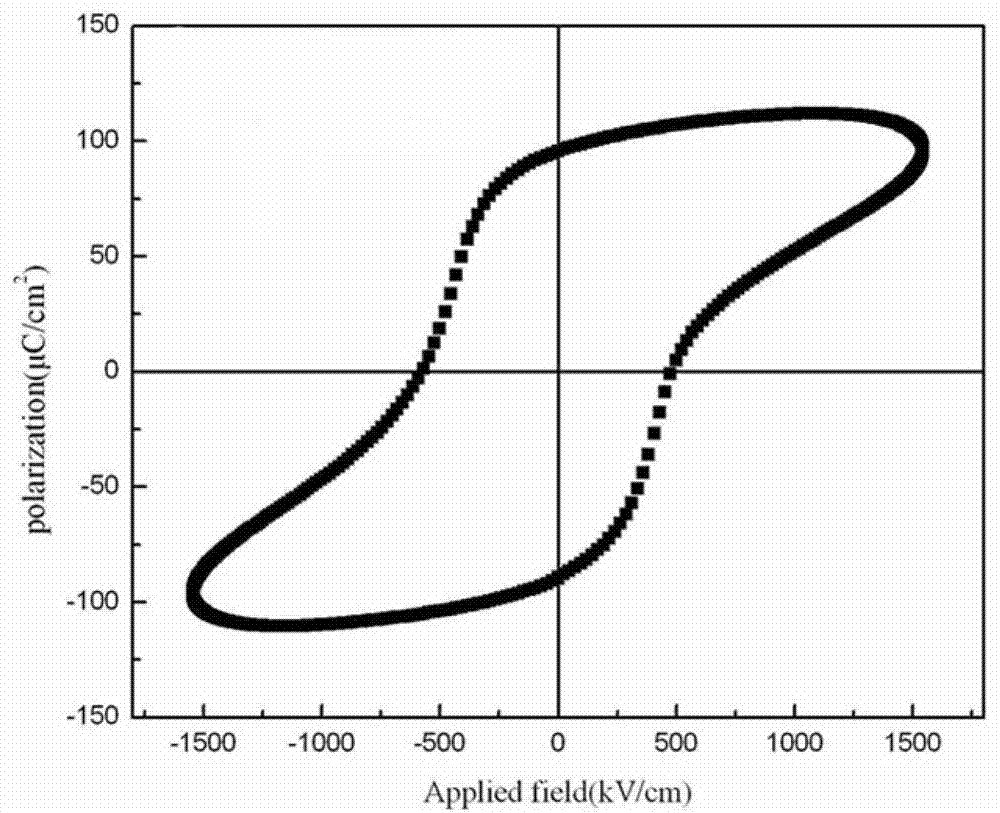

A bi0.85sm0.15fe1-xcrxo3, ferroelectric thin film technology, applied in the field of functional materials, can solve the problems of large leakage conductance of pure phase BiFeO3, inability to obtain saturated electric hysteresis loop, limit practical application, etc., achieve chemical composition Precise and controllable, increased number of flips, improved ferroelectricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Step 1: Select the FTO / glass substrate as the substrate, place the cut FTO substrate in detergent, acetone, and ethanol in sequence for ultrasonic cleaning, rinse the substrate with a large amount of distilled water after each ultrasonic cleaning for 10 minutes, and finally dry it with nitrogen.

[0031] Step 2: Bake the FTO / glass substrate in a 60°C oven for 5 minutes, take it out and let it stand at room temperature.

[0032] Step 3: Place the clean FTO / glass substrate in a UV irradiator for 40 minutes to make the surface of the substrate reach "atomic cleanliness".

[0033] Step 4: Bi(NO 3 ) 3 ·5H 2 O, Fe(NO 3 ) 3 9H 2 O, Sm(NO 3 ) 3 ·6H 2 O and Cr(NO 3 ) 3 9H 2 O was dissolved in a mixture of ethylene glycol methyl ether and acetic anhydride at a molar ratio of 0.90:1.00:0.15:0.00, and then adding ethanolamine to the mixture to adjust the viscosity. After magnetic stirring for 3 hours, the metal ion concentration was 0.003mol / L. The stable Bi 0.85 SM 0...

Embodiment 2

[0038] Step 1: Select the FTO / glass substrate as the substrate, place the cut FTO substrate in detergent, acetone, and ethanol in sequence for ultrasonic cleaning, rinse the substrate with a large amount of distilled water after each ultrasonic cleaning for 10 minutes, and finally dry it with nitrogen.

[0039] Step 2: Bake the FTO / glass substrate in a 60°C oven for 5 minutes, take it out and let it stand at room temperature.

[0040] Step 3: Place the clean FTO / glass substrate in a UV irradiator for 40 minutes to make the surface of the substrate reach "atomic cleanliness".

[0041] Step 4: Bi(NO 3 ) 3 ·5H 2 O, Fe(NO 3 ) 3 9H 2 O, Sm(NO 3 ) 3 ·6H 2 O and Cr(NO 3 ) 3 9H 2 O is dissolved in the mixed solution of ethylene glycol methyl ether and acetic anhydride at a molar ratio of 0.90:0.99:0.15:0.01, and then ethanolamine is added to the mixed solution to adjust the viscosity. After magnetic stirring for 3 hours, a metal ion concentration of 0.3mol / L is obtained. S...

Embodiment 3

[0046] Step 1: Select the FTO / glass substrate as the substrate, place the cut FTO substrate in detergent,

[0047] Ultrasonic cleaning in acetone and ethanol, rinse the substrate with a large amount of distilled water after each ultrasonic cleaning for 10 minutes, and finally blow dry with nitrogen.

[0048] Step 2: Bake the FTO / glass substrate in a 60°C oven for 5 minutes, take it out and let it stand at room temperature.

[0049] Step 3: Place the clean FTO / glass substrate in a UV irradiator for 40 minutes to make the surface of the substrate reach "atomic cleanliness".

[0050] Step 4: Bi(NO 3 ) 3 ·5H 2 O, Fe(NO 3 ) 3 9H 2 O, Sm(NO 3 ) 3 ·6H 2 O and Cr(NO 3 ) 3 9H 2 O is dissolved in the mixture of ethylene glycol methyl ether and acetic anhydride at a molar ratio of 0.90:0.98:0.15:0.02, and then adding ethanolamine to the mixture to adjust the viscosity. After magnetic stirring for 3 hours, the metal ion concentration is 0.01mol / L. The stable Bi 0.85 SM 0.15...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Saturation polarization | aaaaa | aaaaa |

| Remanent polarization | aaaaa | aaaaa |

| Coercive field | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com