Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

49results about How to "Increase the number of teeth" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

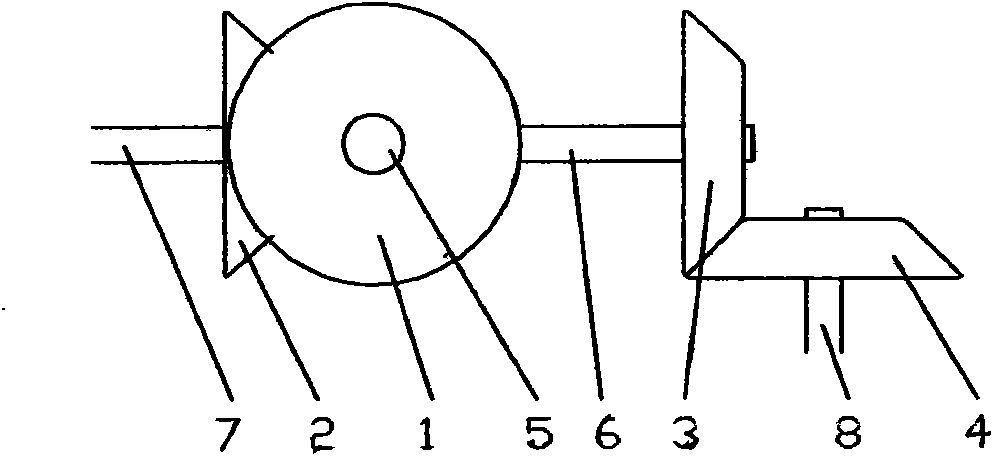

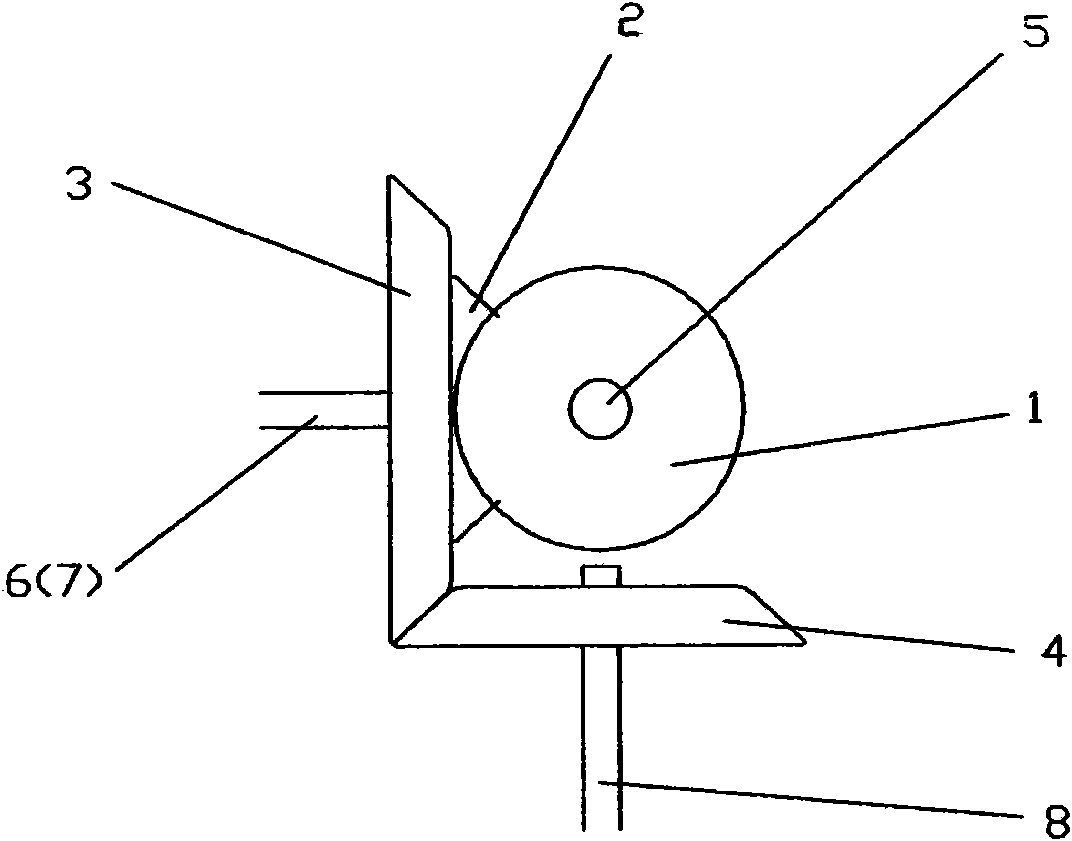

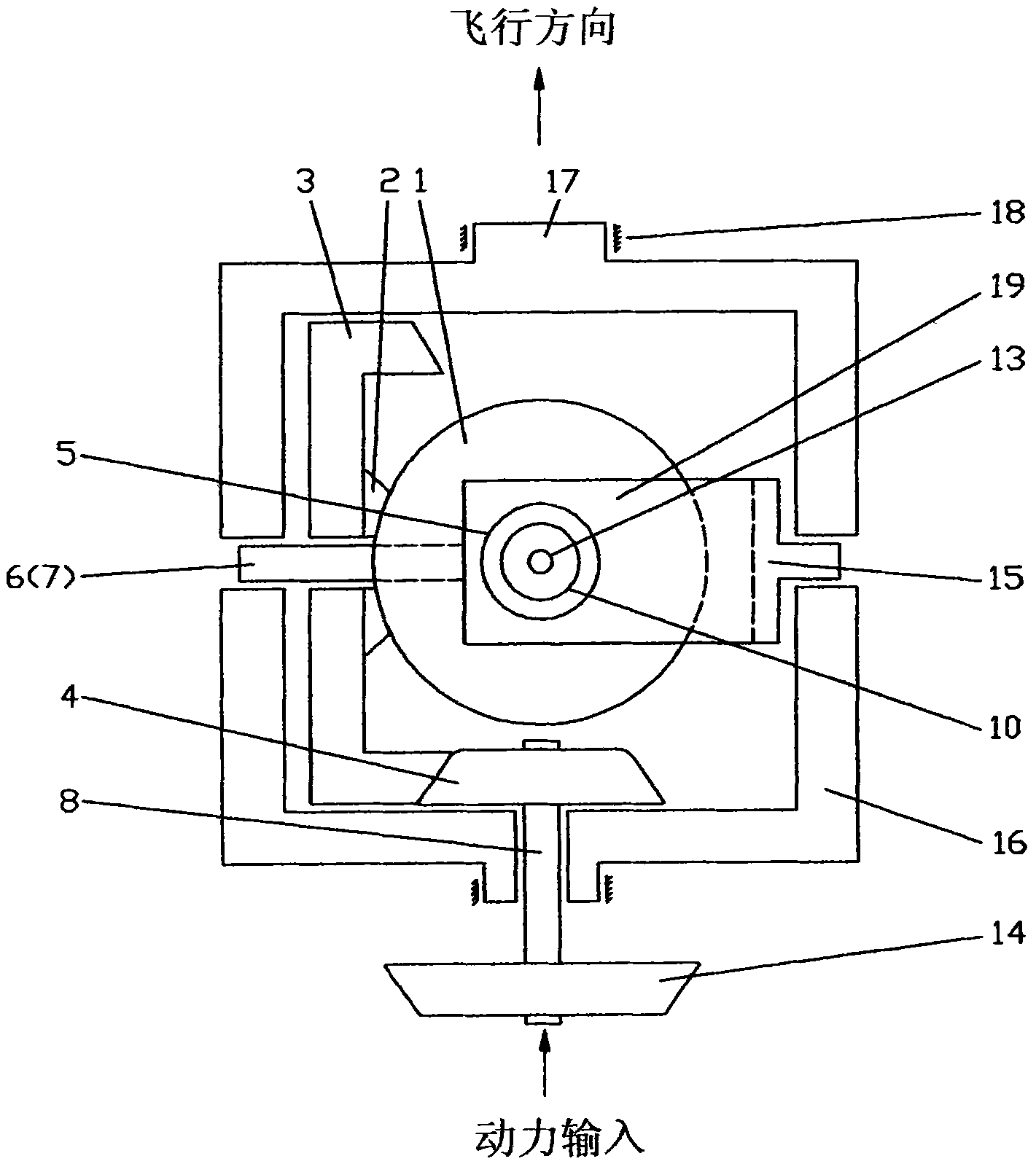

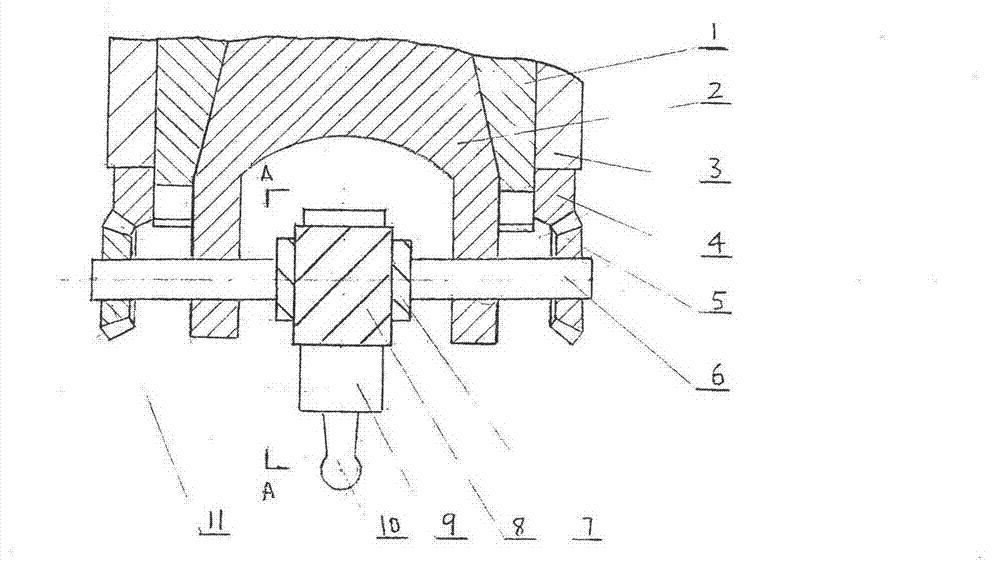

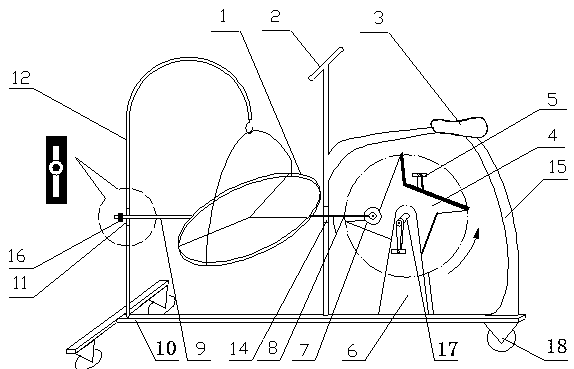

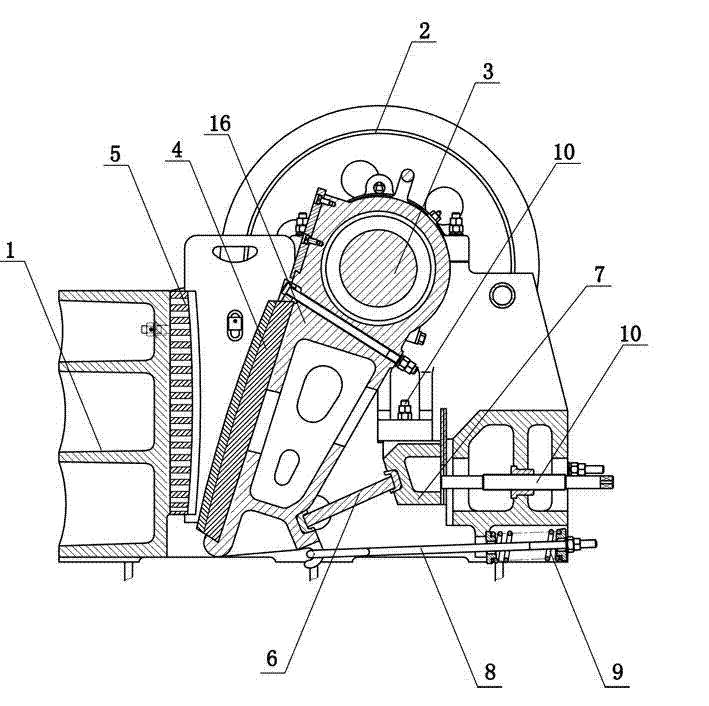

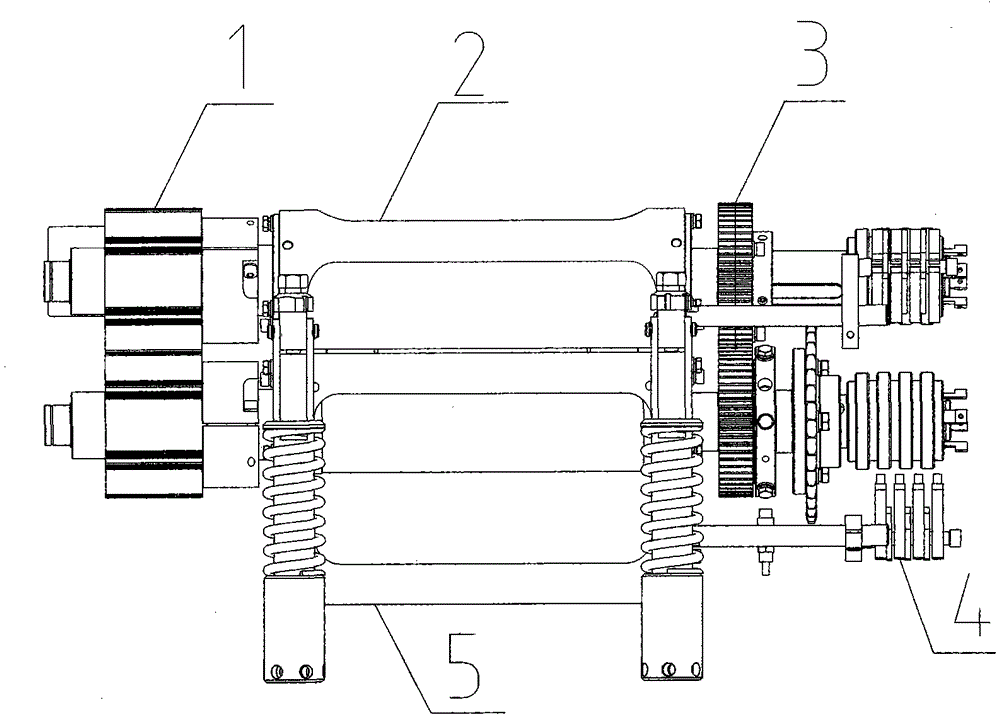

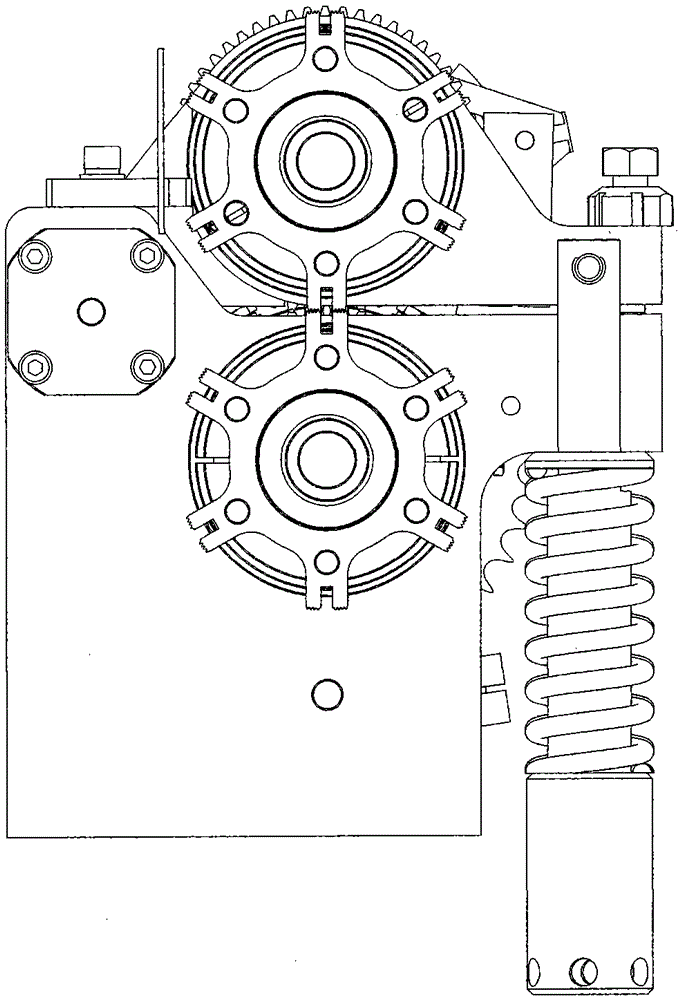

Direct inclination control rotor helicopter

InactiveCN102030105BLarge installation spaceIncrease the number of teethRotocraftPropellerHorizontal axis

Owner:林定荣

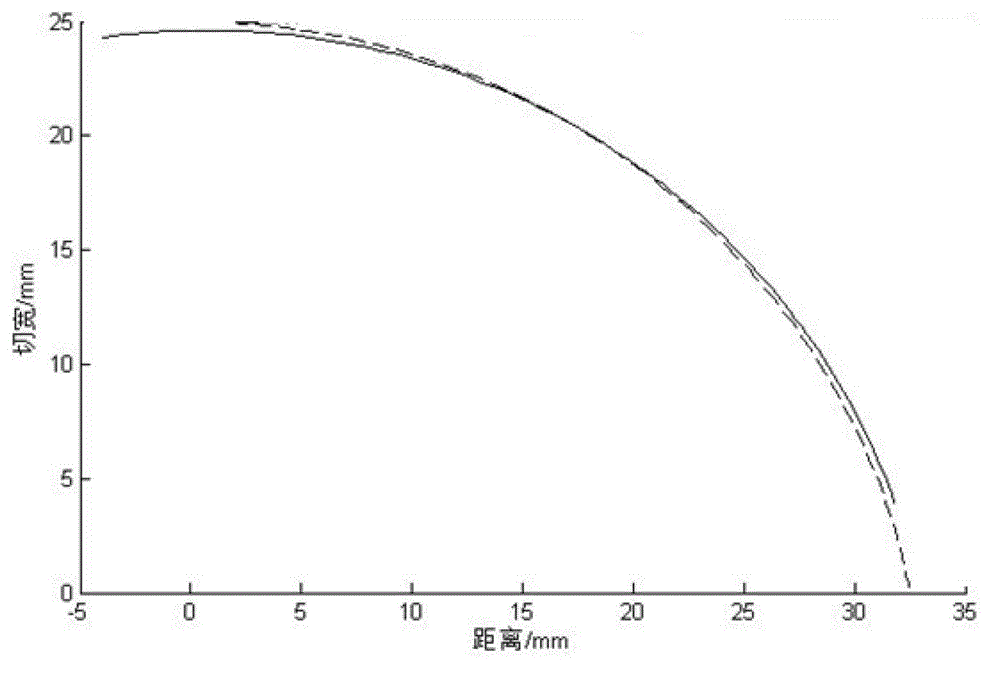

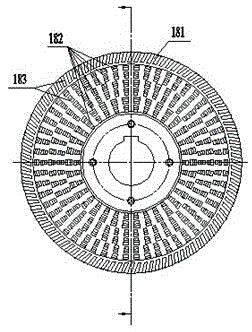

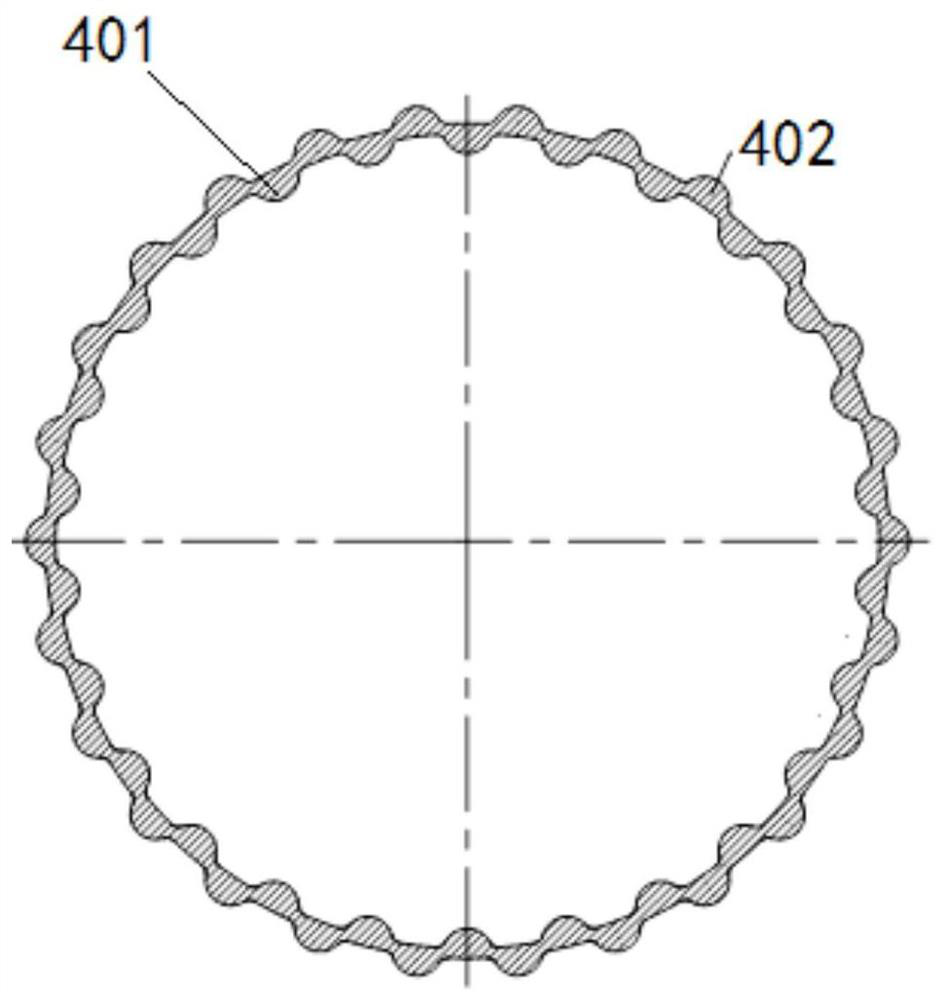

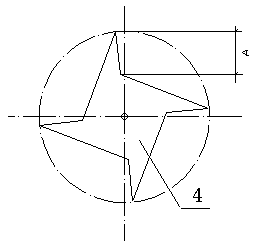

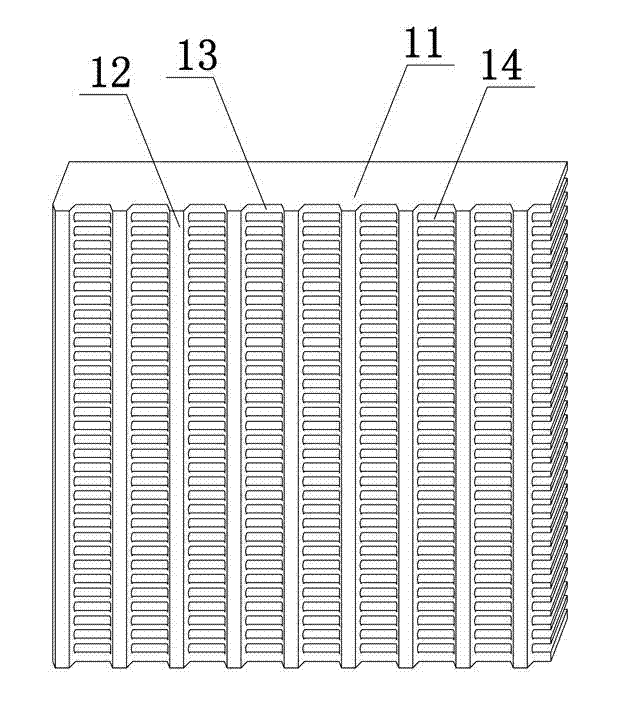

Ultra-dense tooth face milling cutter and design method thereof

The invention discloses an ultra-dense tooth face milling cutter and a design method thereof. The ultra-dense tooth face milling cutter can solve the problem that the existing milling cutter has low cutting efficiency and alow processing precision in processing on a material having high processing difficulty. In design, the number of milling teeth is used as an independent variable and according to influences of structure parameters and cutting parameters, under the premise of strength maintenance, the most appropriate number of the milling teeth of an ultra-dense tooth face milling cutter is obtained so that efficiency is improved, a loss is reduced and a processing precision is improved. The number of the milling teeth is greatly increased so that processing efficiency is greatly improved. Through appropriate decreasing of a feeding amount of each one of the milling teeth, the feeding amount adapts to the number of the ultra-dense milling teeth so that a cutting force on each one of the milling teeth is reduced, blade wear is reduced, and surface quality of a processed workpiece is improved. Under the two influences, the ultra-dense tooth face milling cutter obviously improves processing efficiency. The ultra-dense tooth face milling cutter has high cutting efficiency and precision, prolongs a milling cutter service life and reduces a processing cost.

Owner:XI AN JIAOTONG UNIV

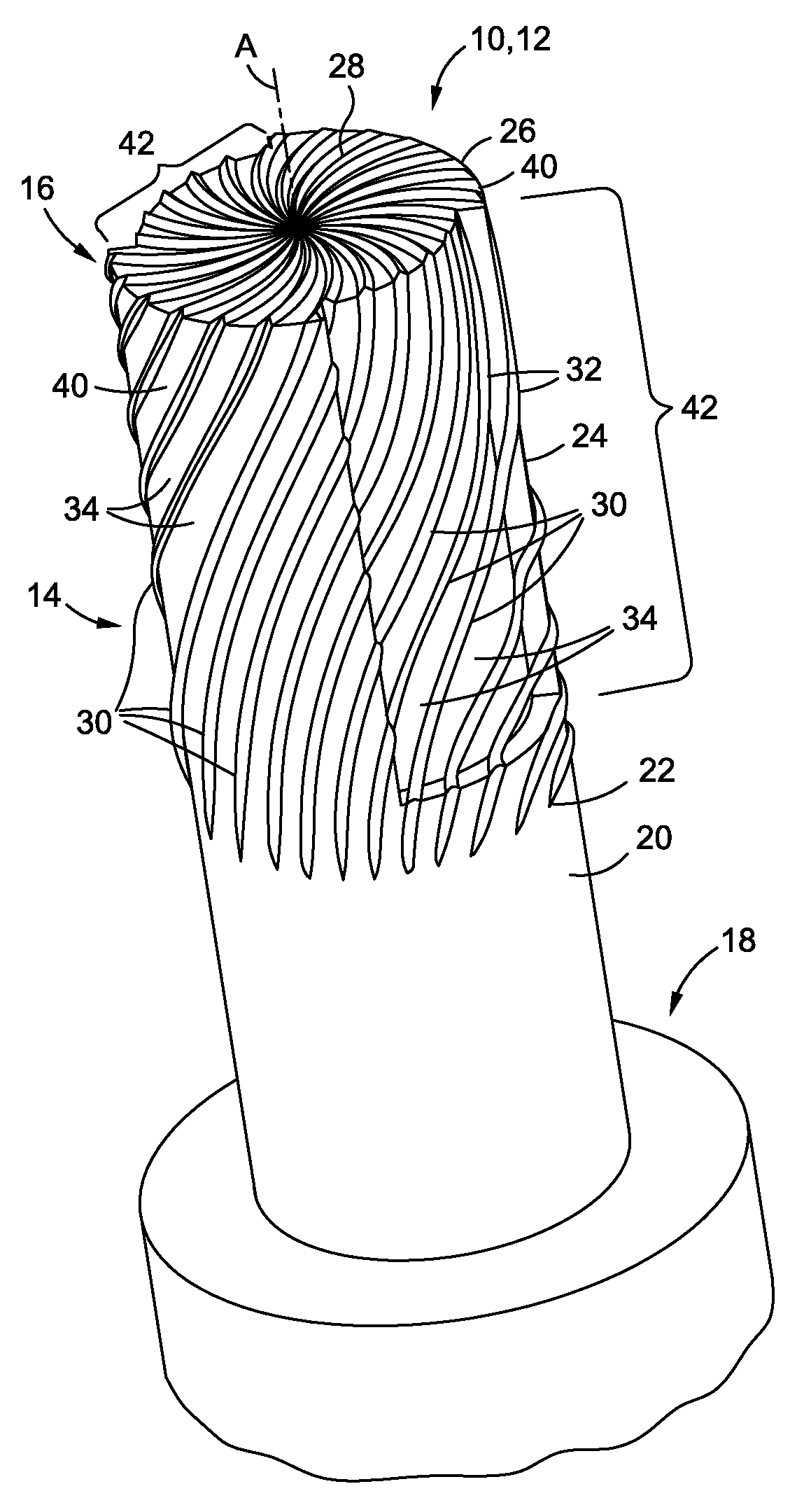

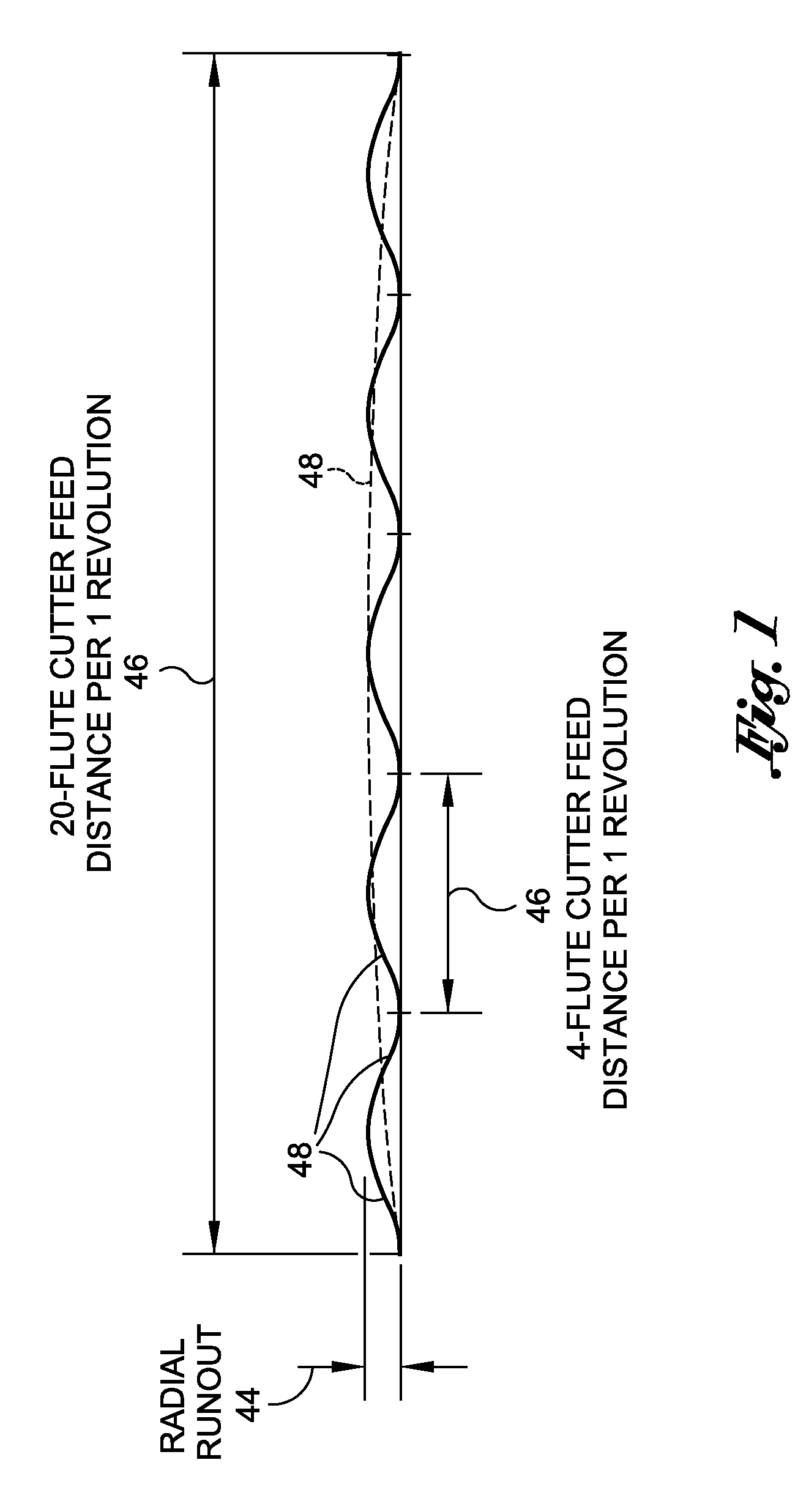

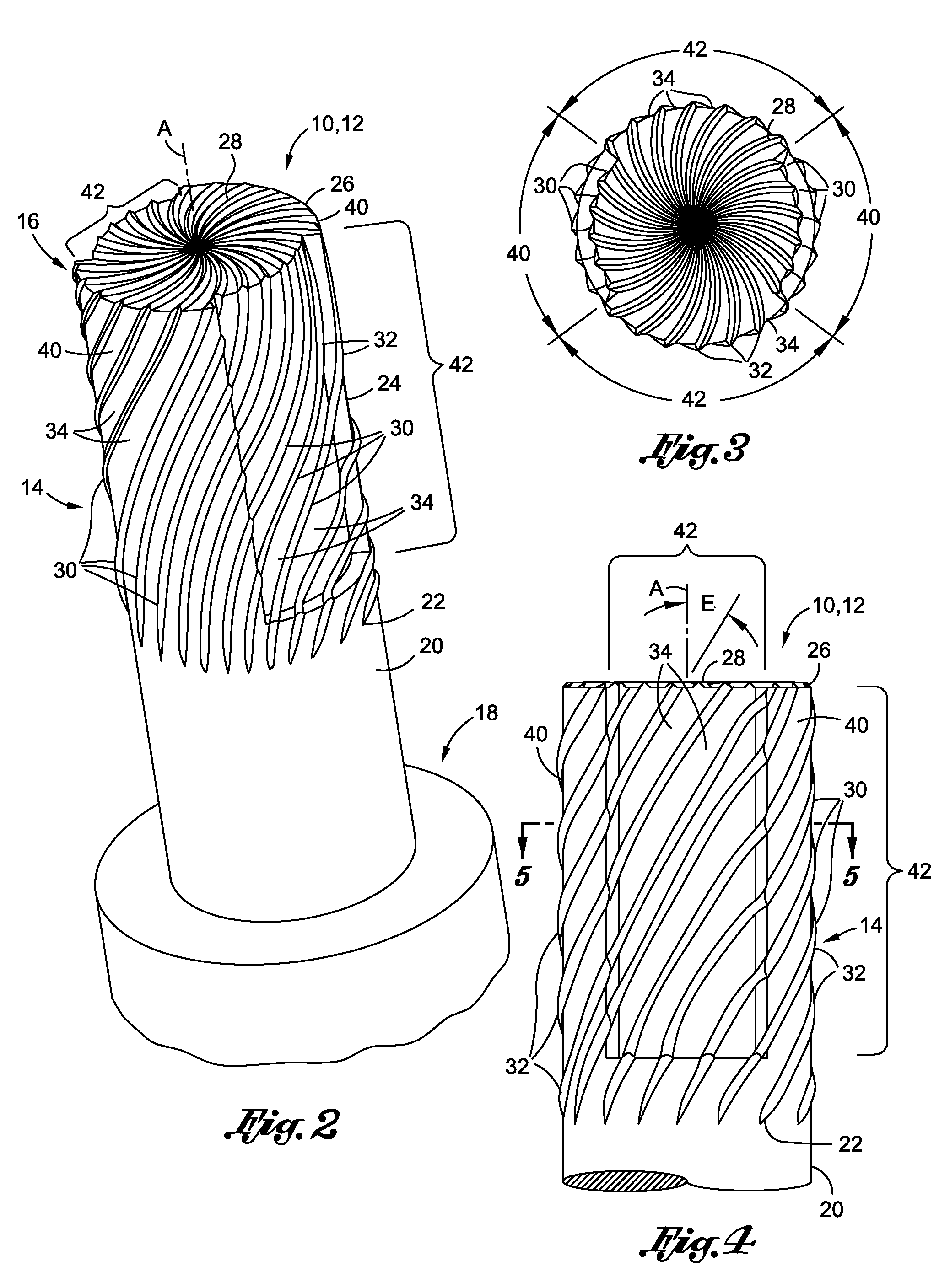

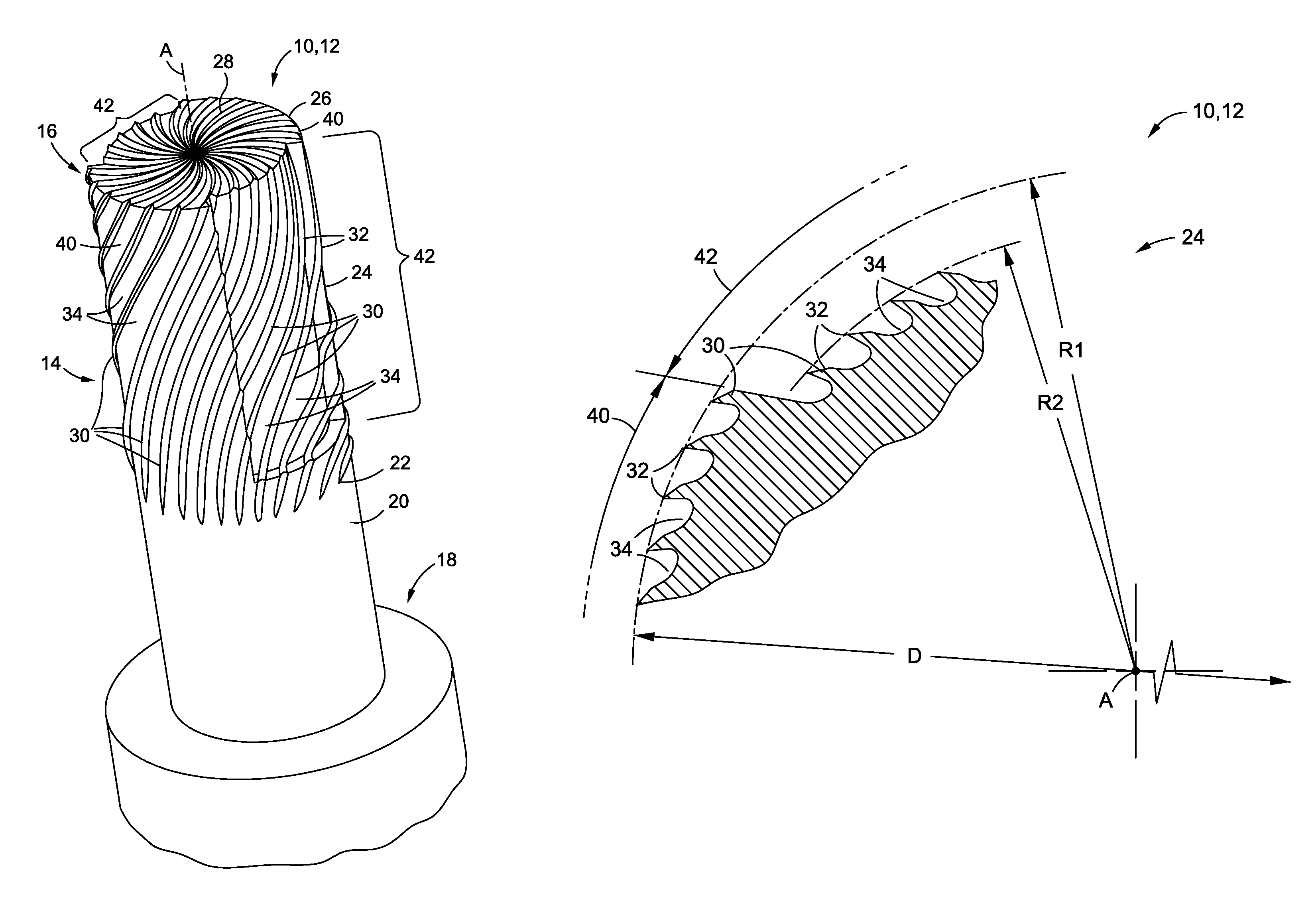

Variable diameter cutting tool

ActiveUS20090317198A1Minimize and eliminate formationIncrease the number of teethMilling cuttersShaping cuttersEngineering

A cutting tool comprises a tool body having proximal and distal ends and defining a central axis. The tool body includes a shank portion and a fluted portion. The shank portion may be configured to be rotatably engageable to a milling machine. The fluted portion may include a plurality of teeth disposed about a circumference thereof and being formed at a radius relative to the central axis. In one embodiment, the teeth may be divided into first and second tooth sections with the teeth in the second tooth section being formed at a reduced radius relative to the teeth in the first tooth section.

Owner:THE BOEING CO

Variable diameter cutting tool

ActiveUS8226334B2Minimize and eliminate formationIncrease the number of teethMilling cuttersShaping cuttersEngineering

A cutting tool includes a tool body having proximal and distal ends and defining a central axis. The tool body includes a shank portion and a fluted portion. The shank portion may be configured to be rotatably engageable to a milling machine. The fluted portion may include a plurality of teeth disposed about a circumference thereof and being formed at a radius relative to the central axis. In one embodiment, the teeth may be divided into first and second tooth sections with the teeth in the second tooth section being formed at a reduced radius relative to the teeth in the first tooth section.

Owner:THE BOEING CO

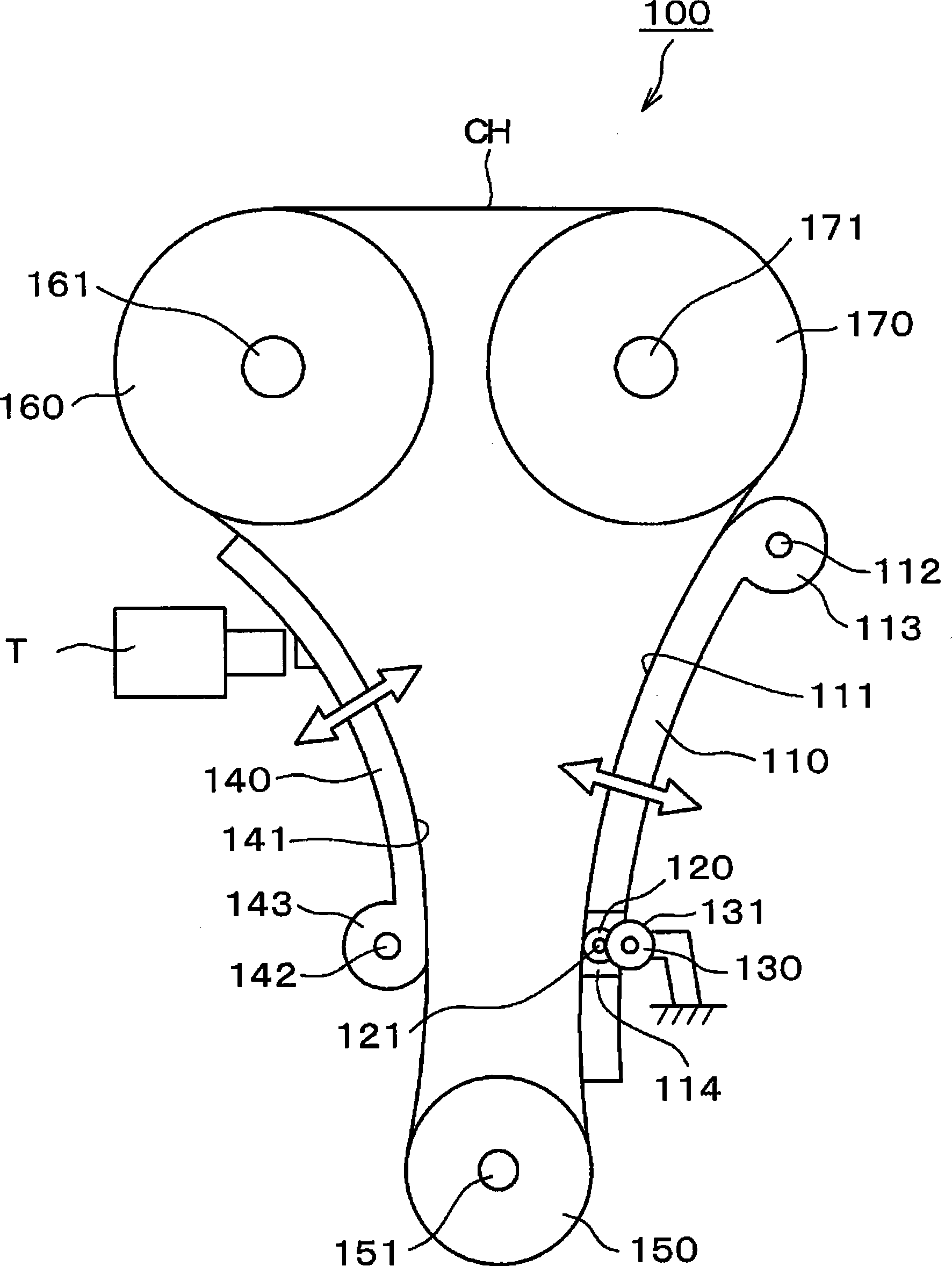

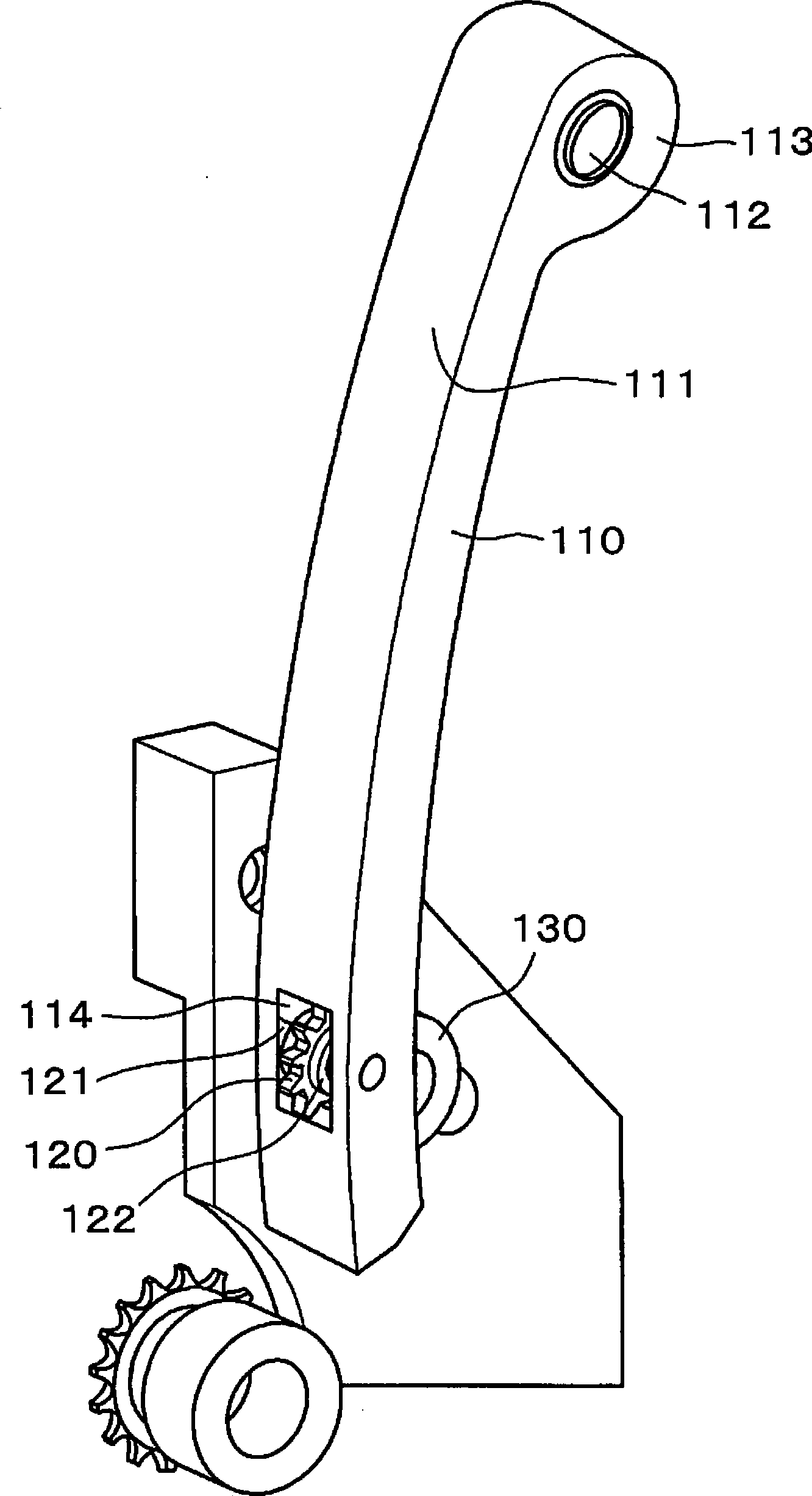

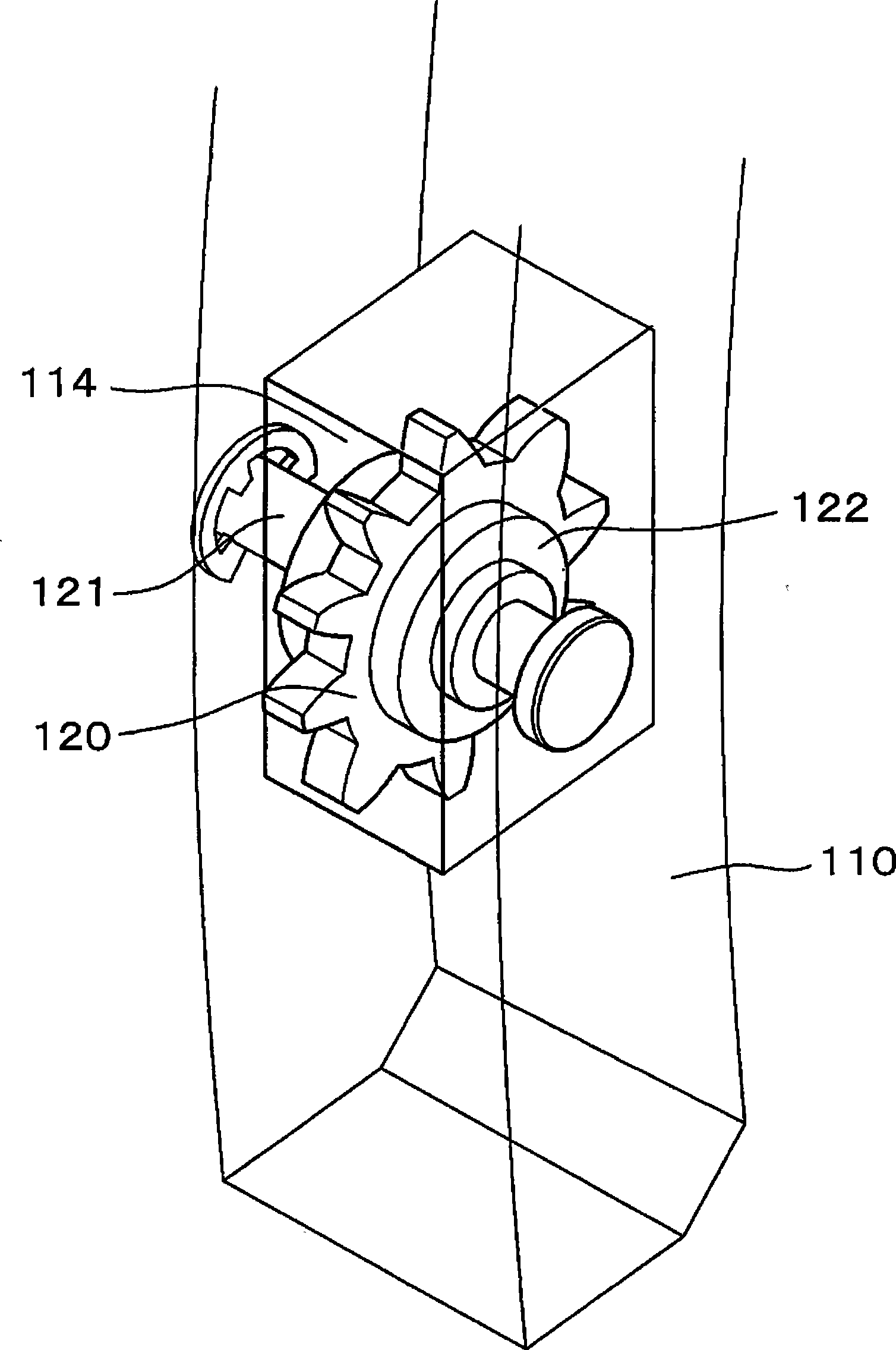

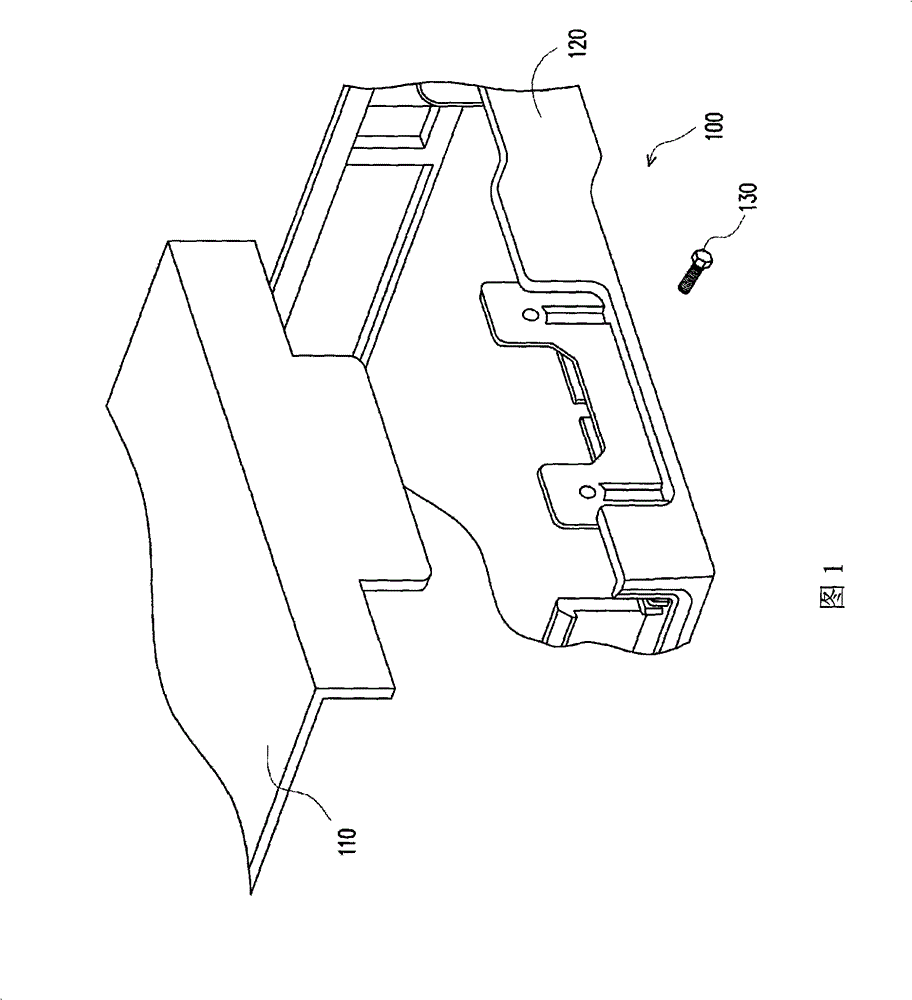

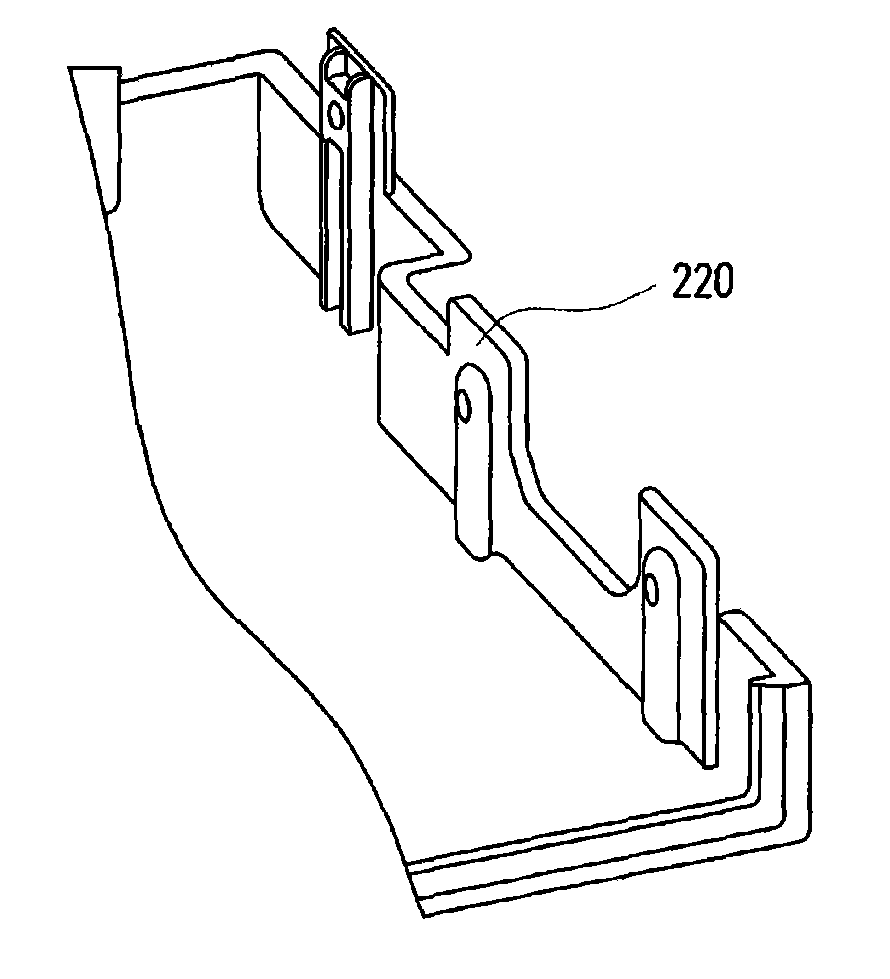

Timing chain drive unit

The invention provides a timing chain drive unit capable of reducing influence of tension changing, and realizing minature lightweighting of chain and increasing system quietness. In an engine timing chain drive(100), chain guiding pieces (110,14) are provided on the looseness side and the tension side of the chain (CH), and the chain guiding piece (110) on the tension side comprises a synchronizing sprocket (120) in fastening-rotation with the chain (CH) and the chain guiding piece (110) is set in synchronized rotation along with tension variation.

Owner:TSUBAKIMOTO CHAIN CO

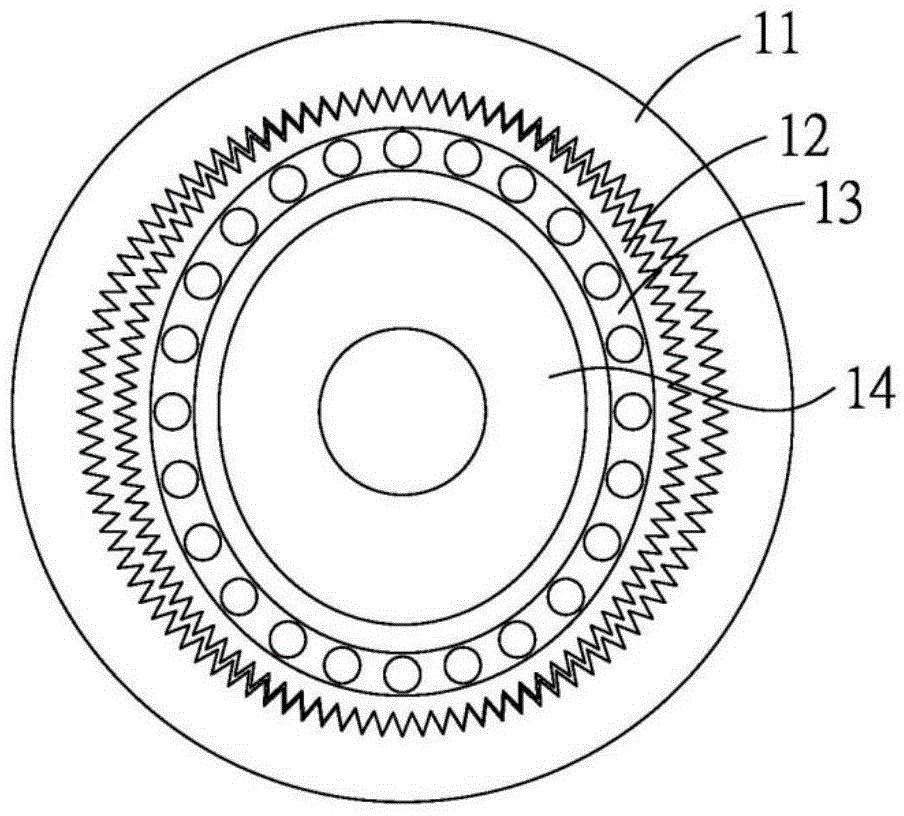

Harmonic type reducing mechanism

InactiveCN104565219AIncrease the number of teethPitch error reductionPortable liftingToothed gearingsTooth numberEngineering

The invention discloses a harmonic type reducing mechanism. The harmonic type reducing mechanism comprises an inner rigid gear with a tooth number of 2(n+1), an outer flexible gear with the tooth number of 2n, a flexible bearing and a wave generation wheel, wherein the outer flexible gear is arranged in the inner rigid gear in a penetrating manner, and the outer flexible gear has a modulus m which is identical to that of the inner rigid gear; the flexible bearing is arranged in the flexible outer bearing in a penetrating manner; the wave generation wheel is arranged in the flexible bearing in a penetrating manner. By increasing the meshed gear teeth, so that a pitch error of each tooth is reduced by average, the transmission precision is improved, the transmission torque is increased, and the flexible bearing is ensured to rotate smoothly.

Owner:HIWIN TECH

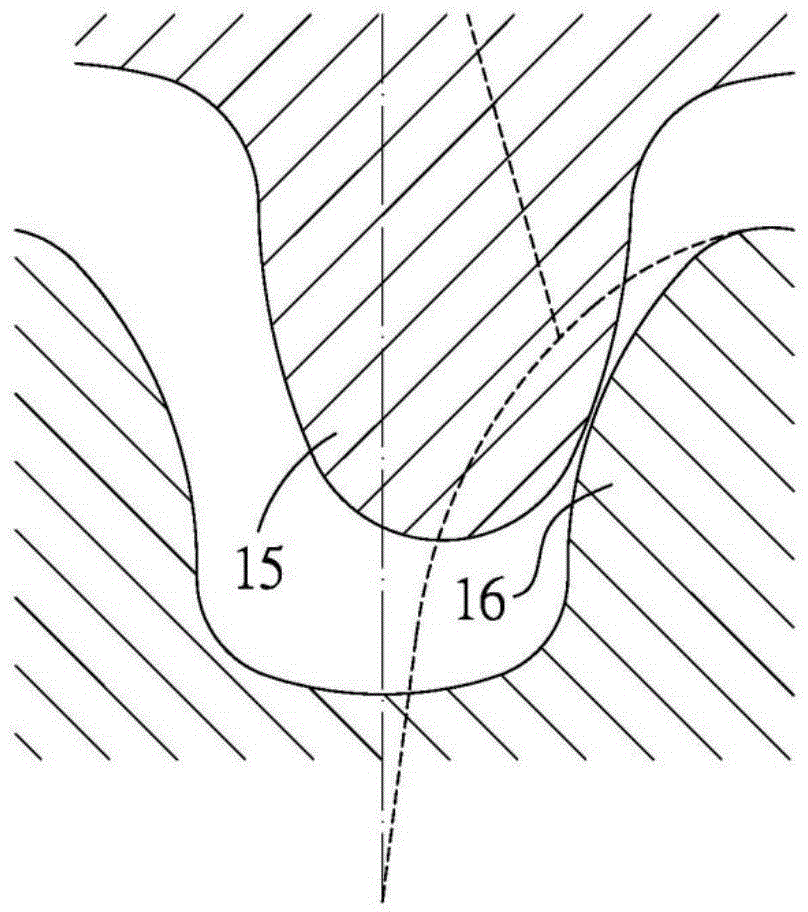

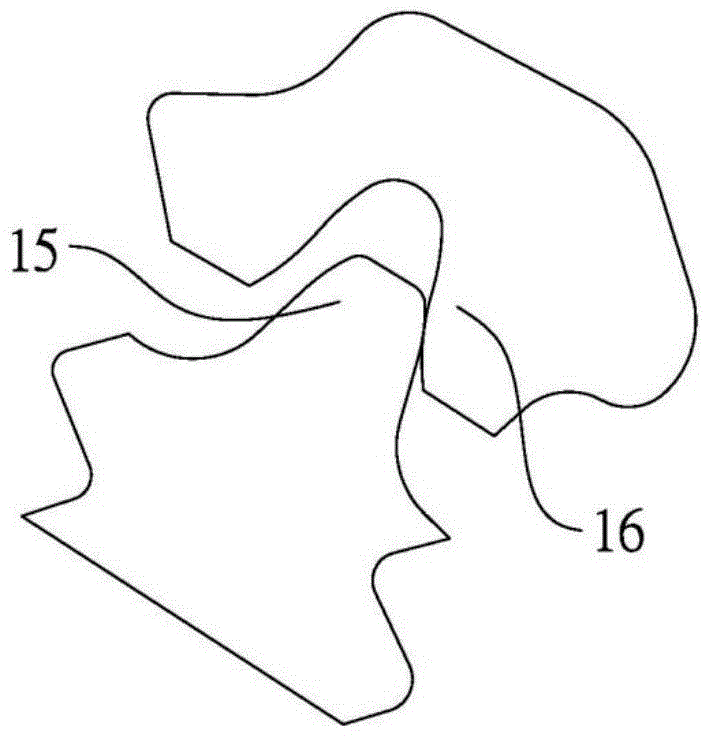

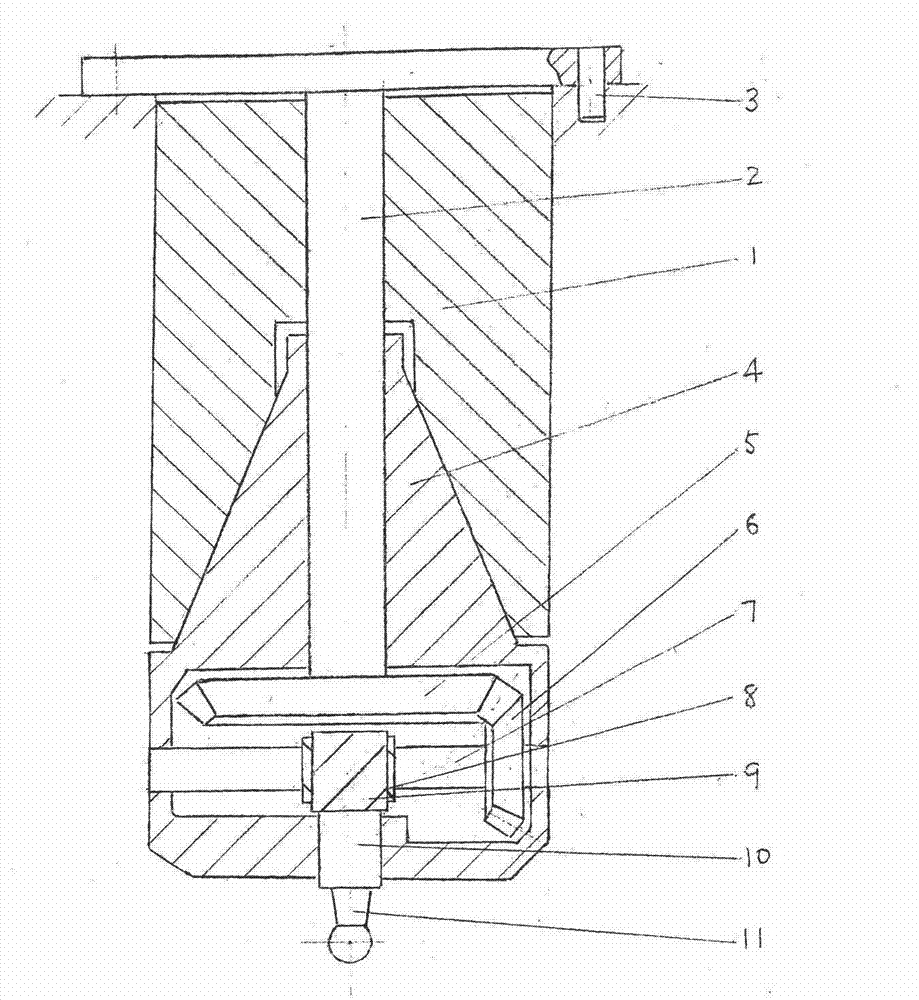

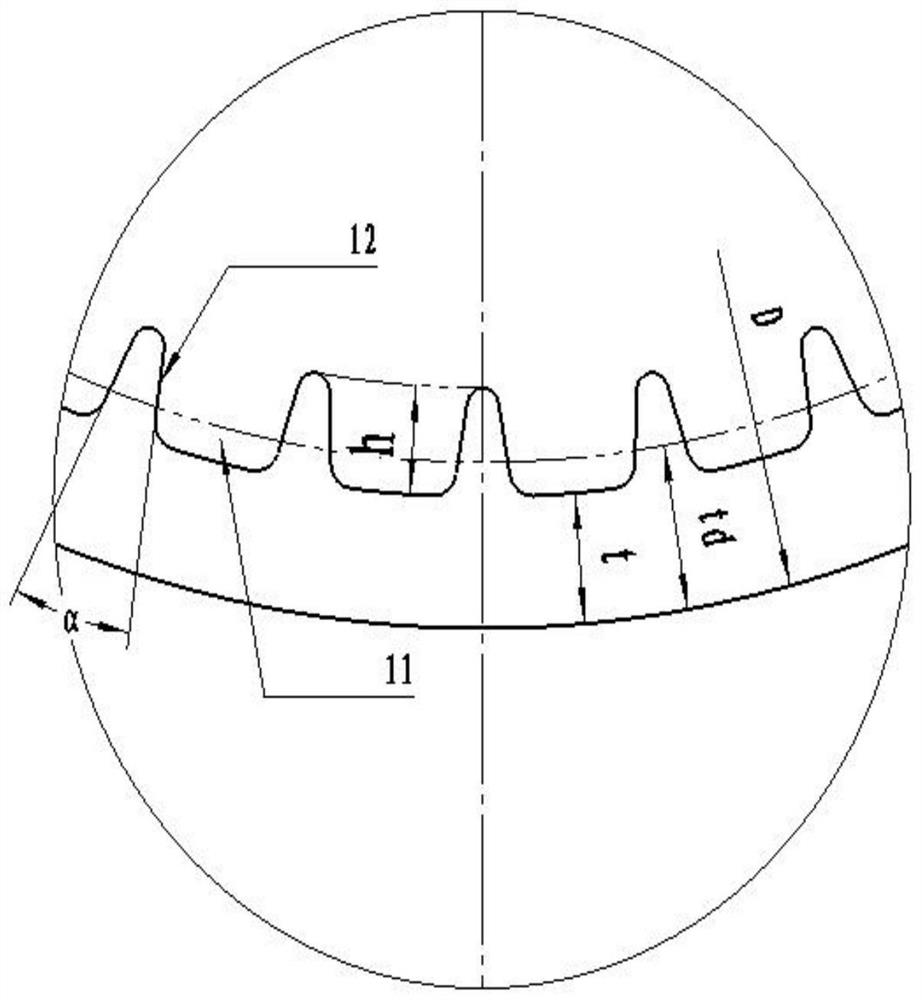

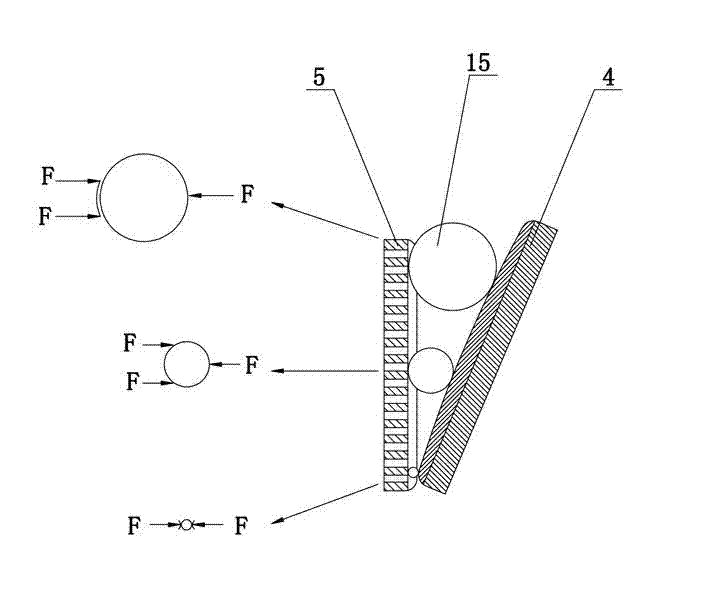

Colloid mill stator and rotor and colloid mill comprising stator and rotor

The invention discloses a colloid mill stator and rotor and a colloid mill comprising the stator and rotor, and belongs to the field of machinery. According to the colloid mill stator and rotor provided by the invention, the end surface of a stator disc and the end surface of a rotor disc are provided with concentric annular distribution toothed sections; a sluice channel is formed between adjacent toothed sections; straight teeth are arranged on the toothed section at the outermost layer of the end surface of the static disc; trapezoidal teeth are arranged on the toothed sections at the other layers of the end surface of the stator disc; the tooth height of each straight tooth is smaller than the tooth height of each trapezoidal tooth on the end surface of the stator disc; a blind groove is formed in the outer edge of the sluice channel between two adjacent straight teeth; inclined teeth are arranged on the toothed section at the outermost layer of the end surface of the rotor disc; trapezoidal teeth are arranged on the other various layers of the end surface of the rotor disc; the tooth height of each inclined tooth is smaller than the tooth height of each trapezoidal tooth of the end surface of the rotor disc; and a blind groove is formed in the inner edge of the sluice channel between two adjacent inclined teeth. The colloid mill comprising the stator and rotor disclosed by the invention is simple in structure, high in shearing efficiency and long in service life.

Owner:SHANDONG DASHAN ROAD & BRIDGE ENG

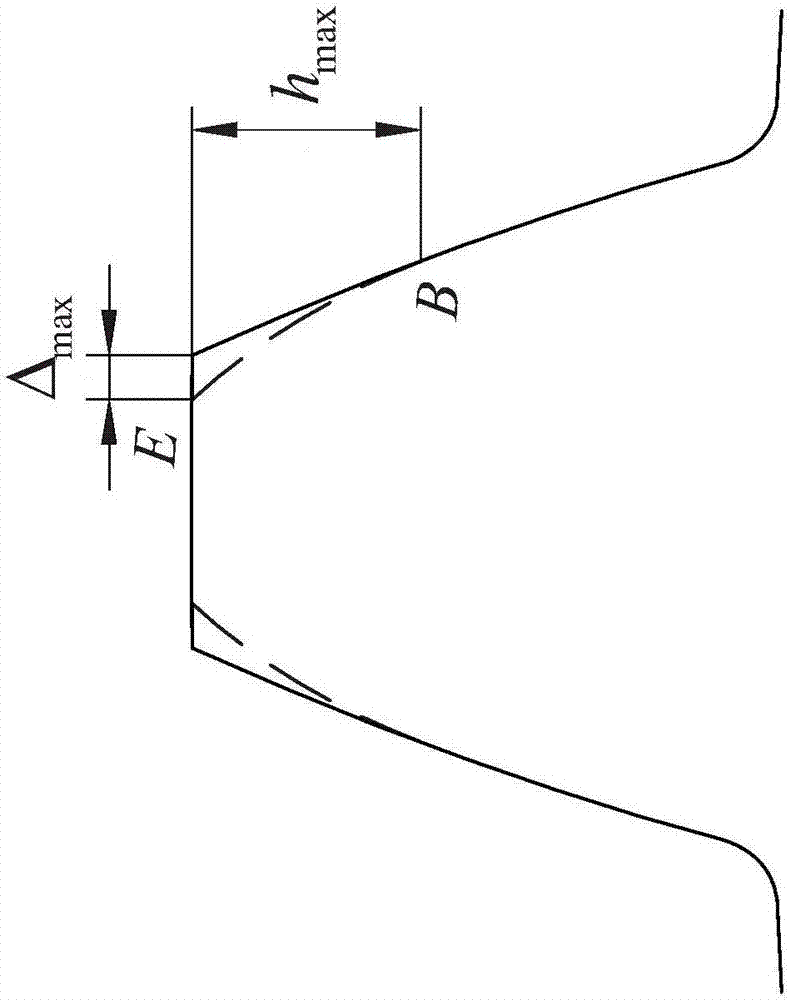

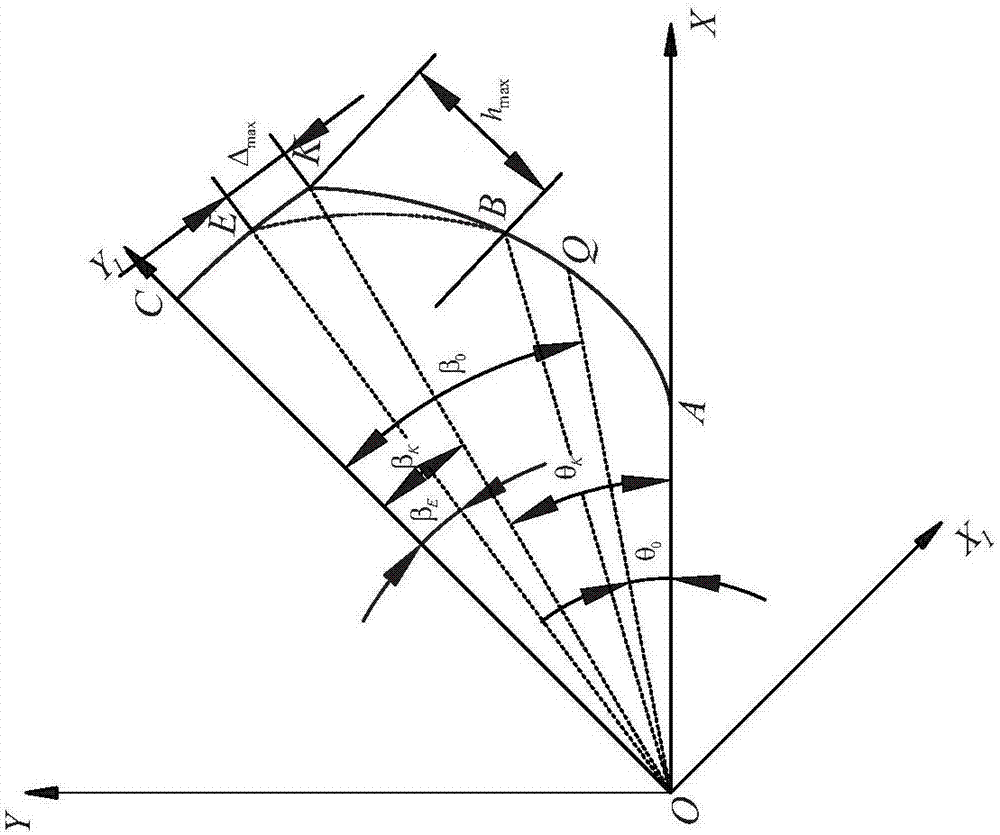

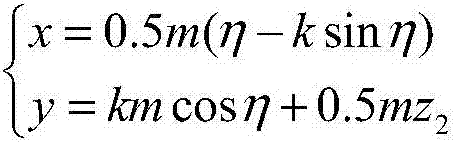

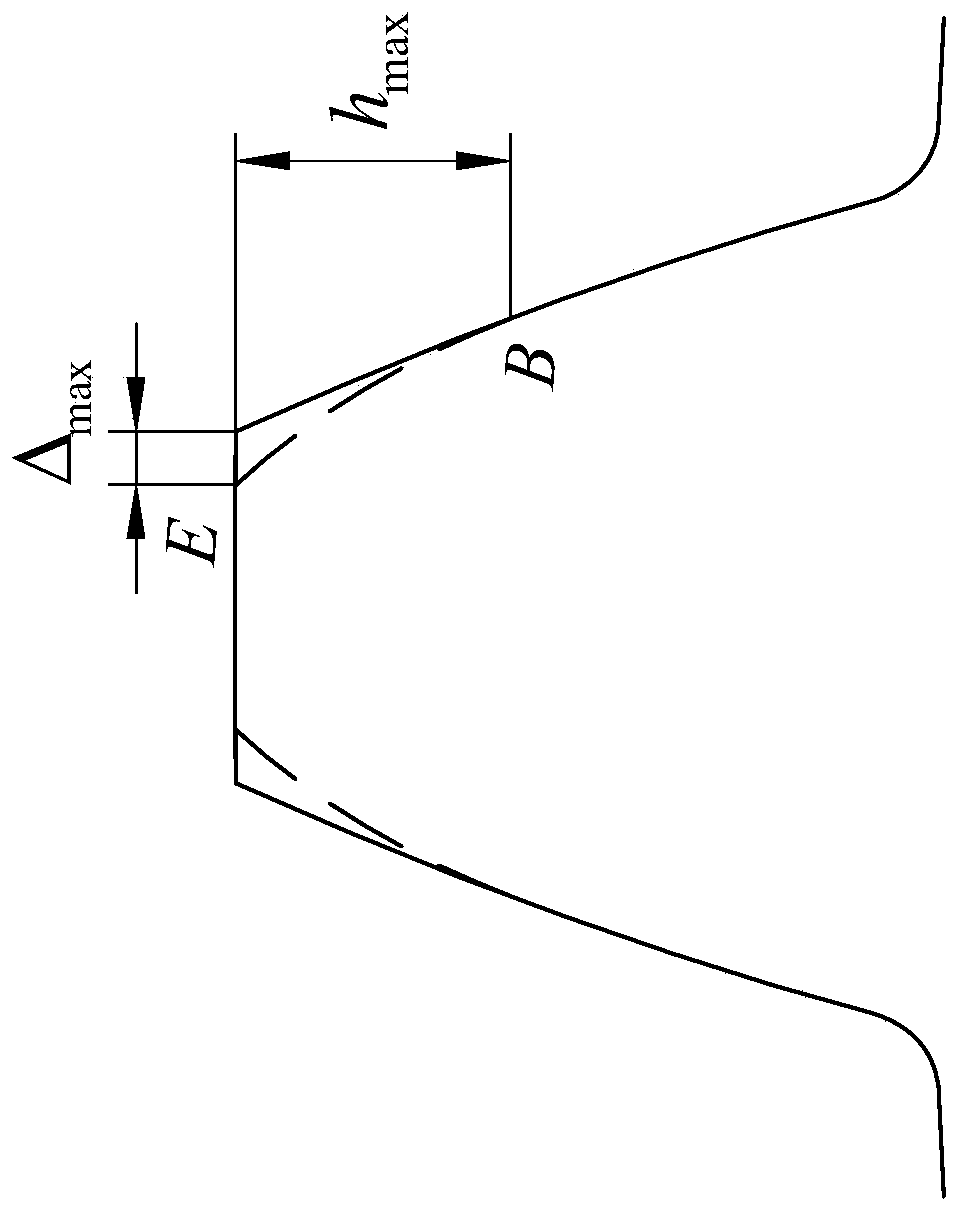

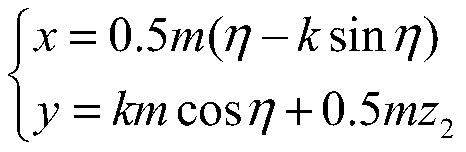

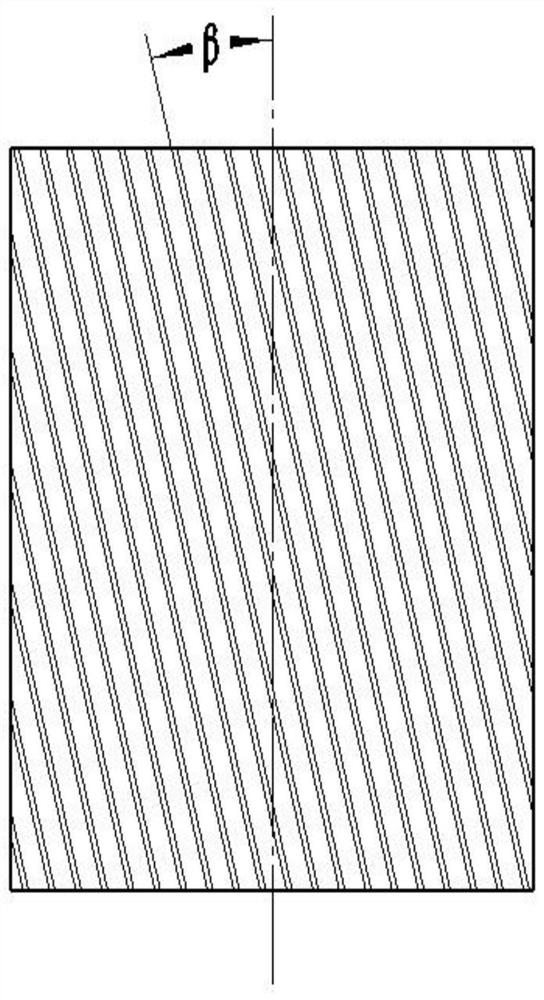

Modification method for harmonic driving involute profile

ActiveCN107882950AIncrease the number of teethSmall engagement backlashGearingPortable liftingKinematic theoryInvolute

The invention discloses a modification method for a harmonic driving involute profile. A point B serves as a point of tangency of a modification curve and a involute tooth surface. A point E serves asa point of intersection of the modification curve and an involute addendum circle. A coordinate system XOY is built with a radial OA as the abscissa axis. A coordinate system X1OY1 is built with a radial OC as the ordinate axis. After the steps of determining the coordinates of the point B and the point E in the coordinate system X1OY1 and the slope of a tangent of the involute at the point B, determining a flexible gear central point approximate movement track curvilinear equation, determining the parameter equation of the modification curve in the coordinate system X1OY1 and the like, a system of simultaneous equations is built and used for solving parameters, and the parameter equation of the modification curve in the coordinate system XOY is obtained through conversion of the coordinate system. According to the modification method, the harmonic driving involute profile is modified based on the harmonic driving kinematics theory, processing manufacturability and economy can be guaranteed, engagement performance is improved, the advantages of various harmonic tooth profiles are integrated, and the modification method can be widely applied to the technical field of harmonic gears.

Owner:国茂精密传动(常州)有限公司

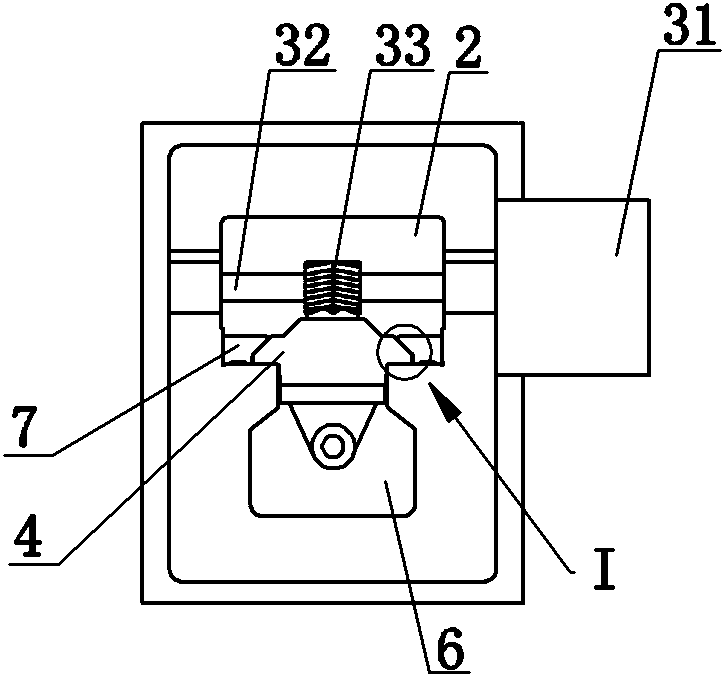

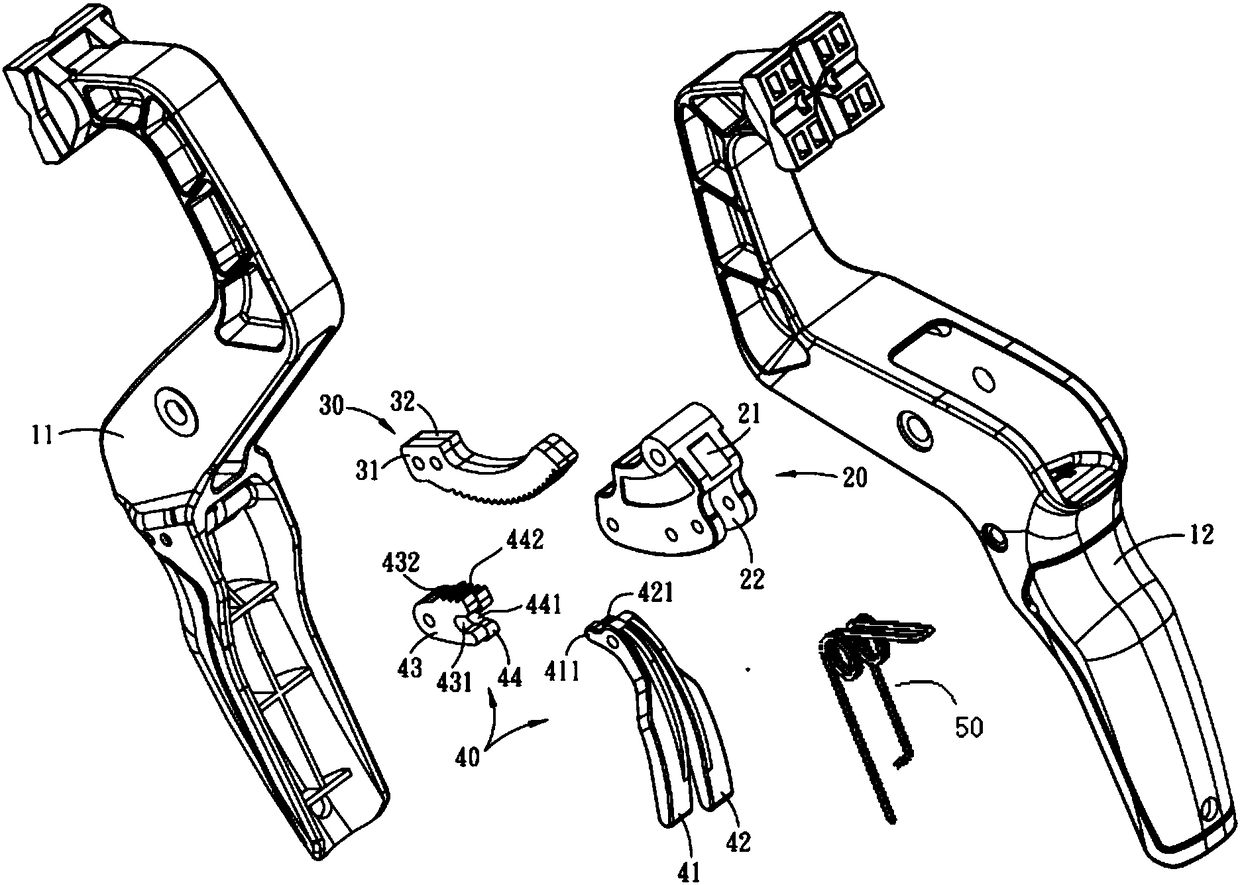

Angular adjustment accessory

InactiveCN1823656AIncrease the number of teethMany levels of switchingStoolsReclining chairsHinge angleEngineering

Owner:山下 直伸

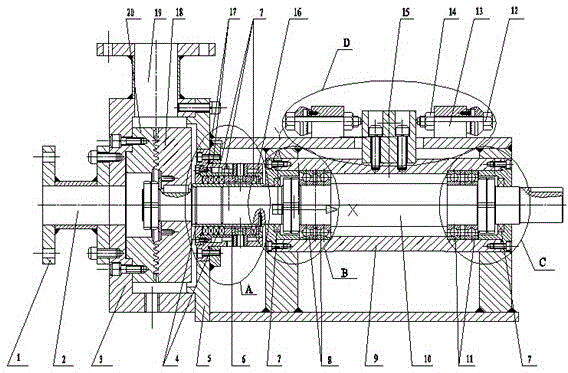

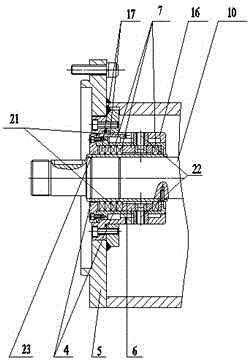

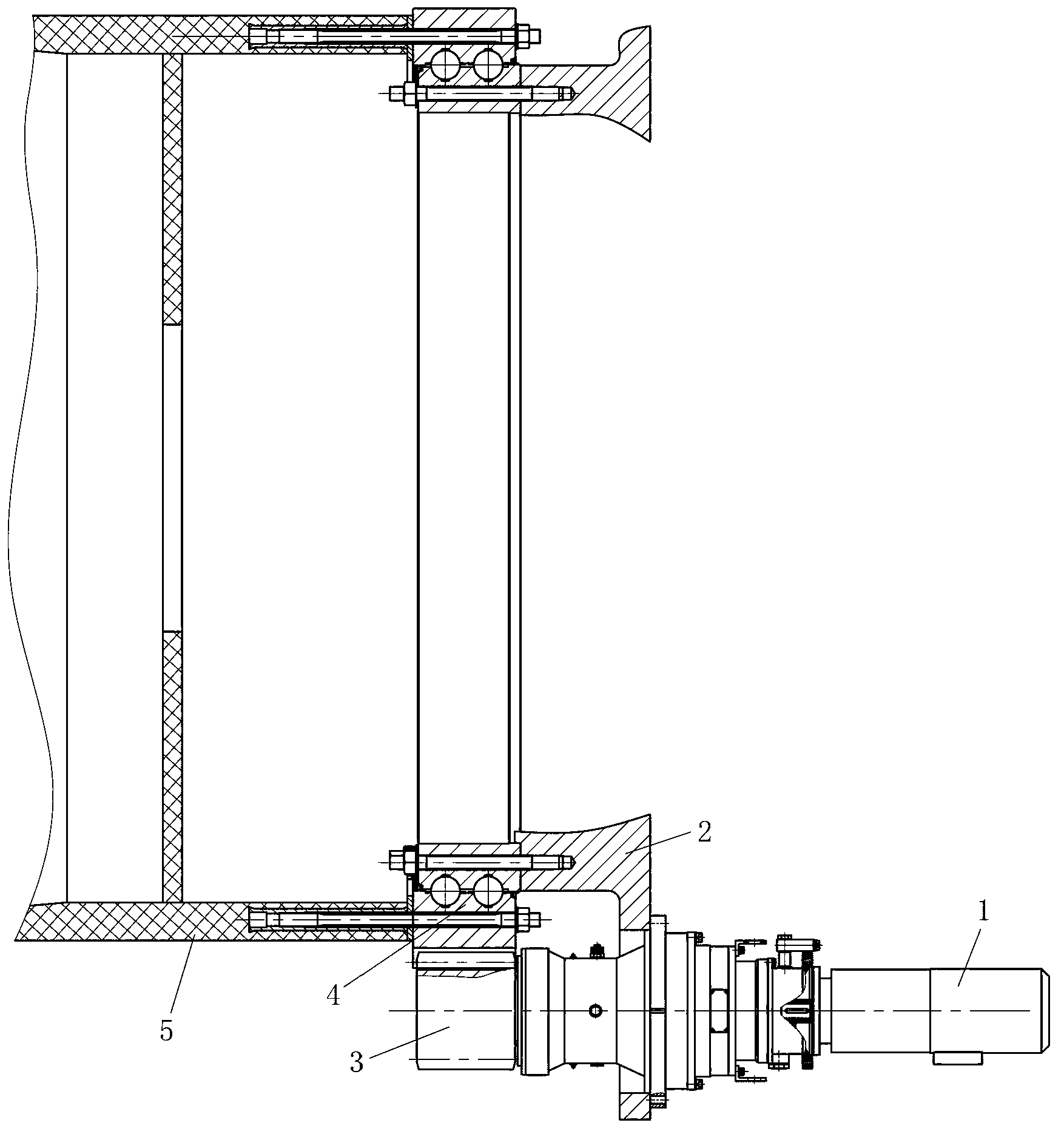

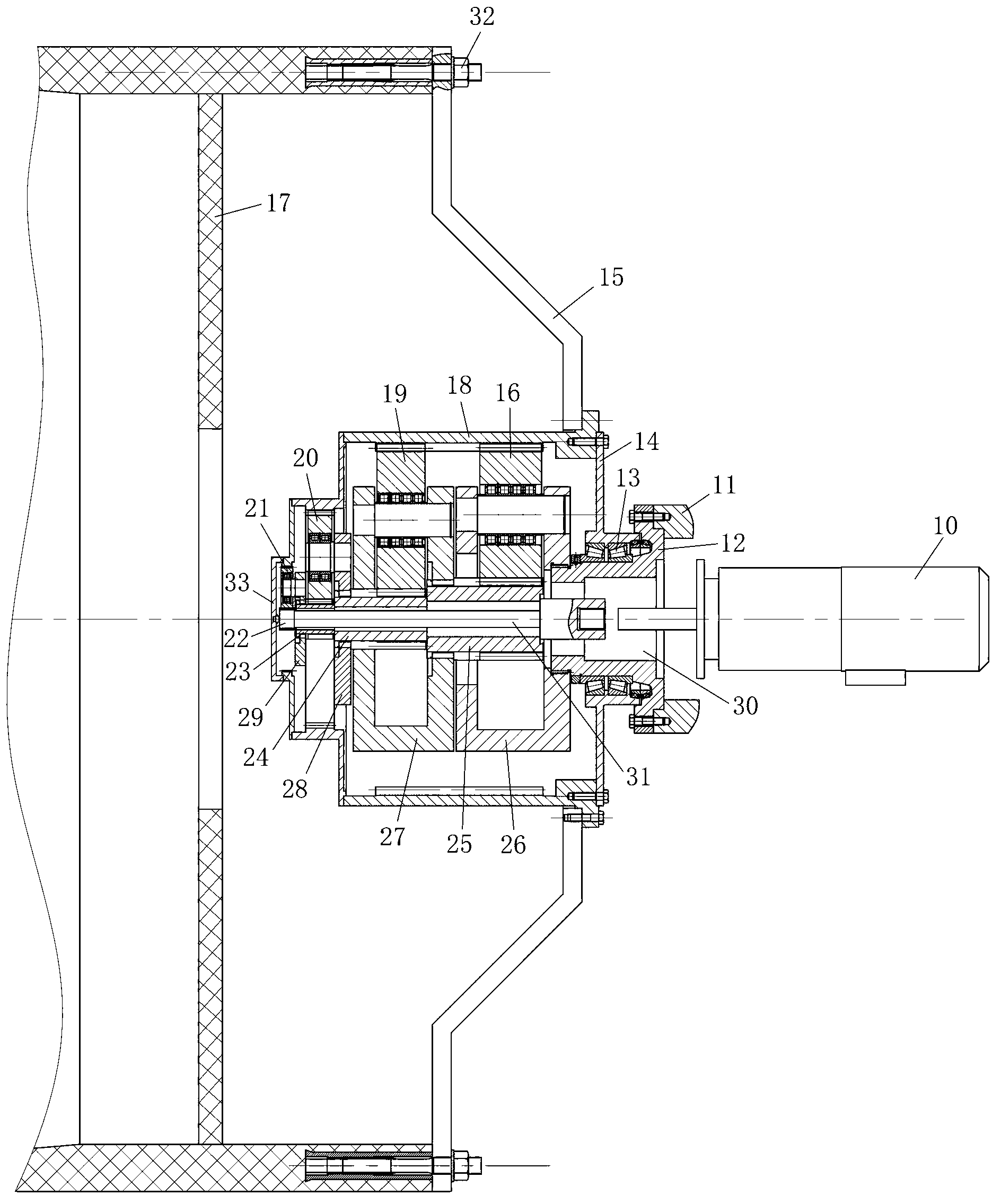

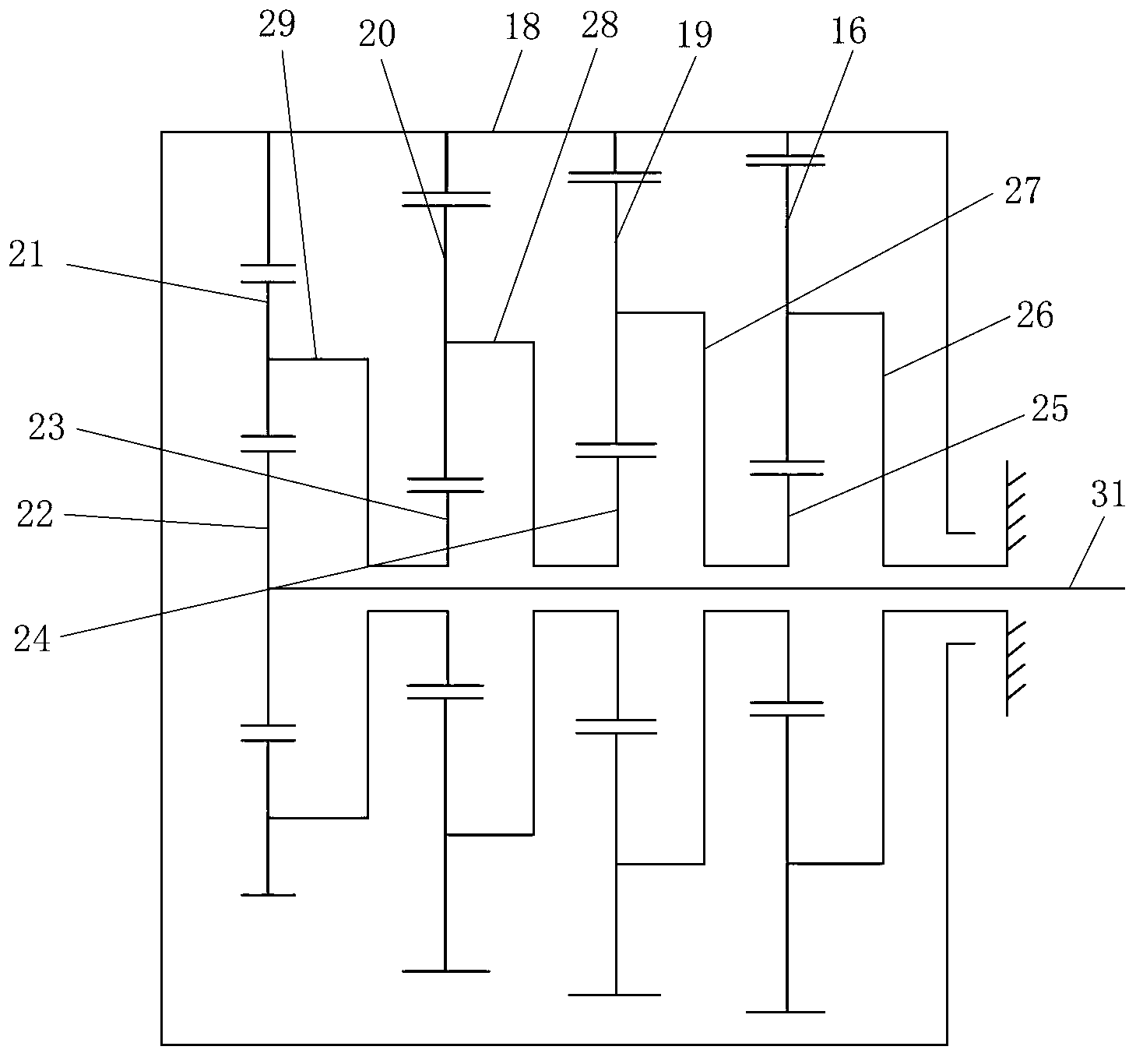

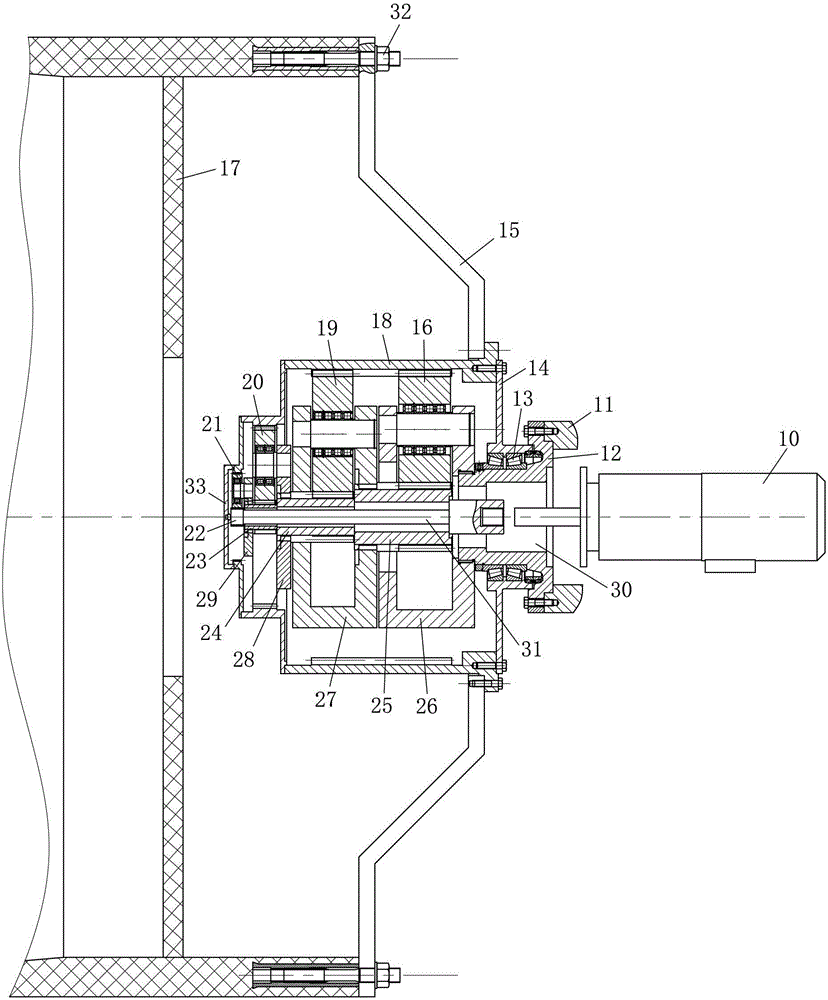

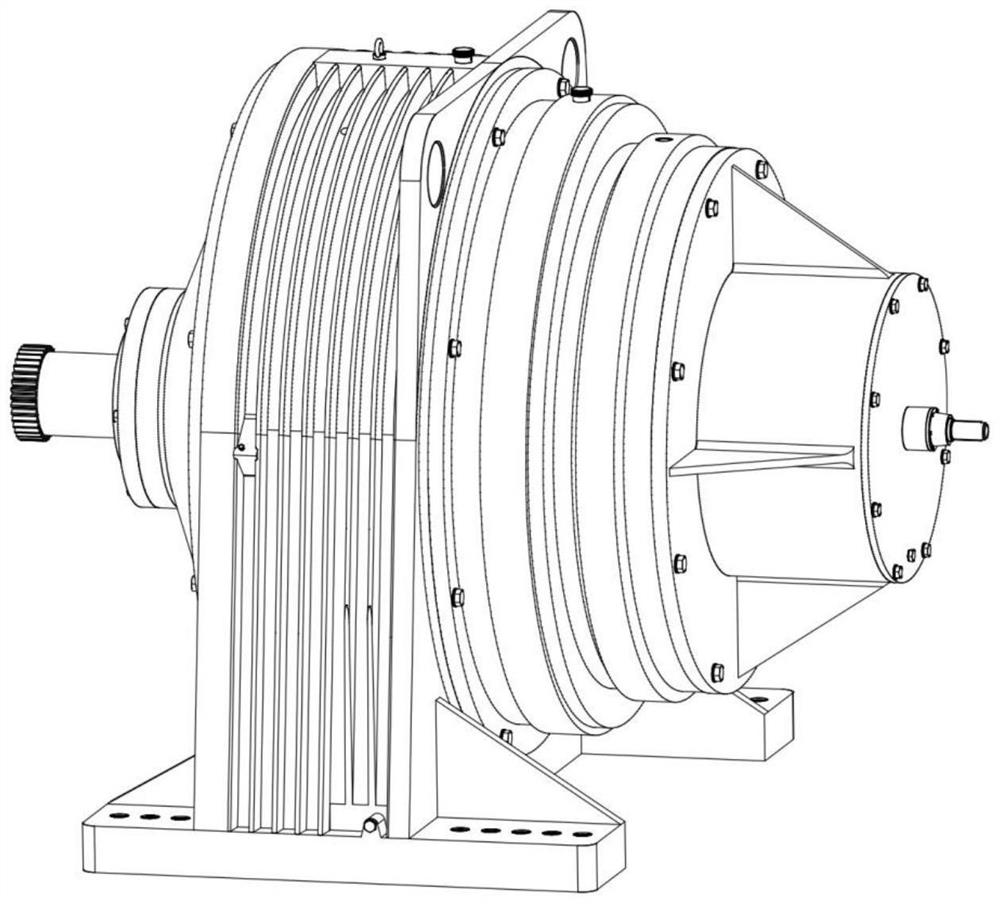

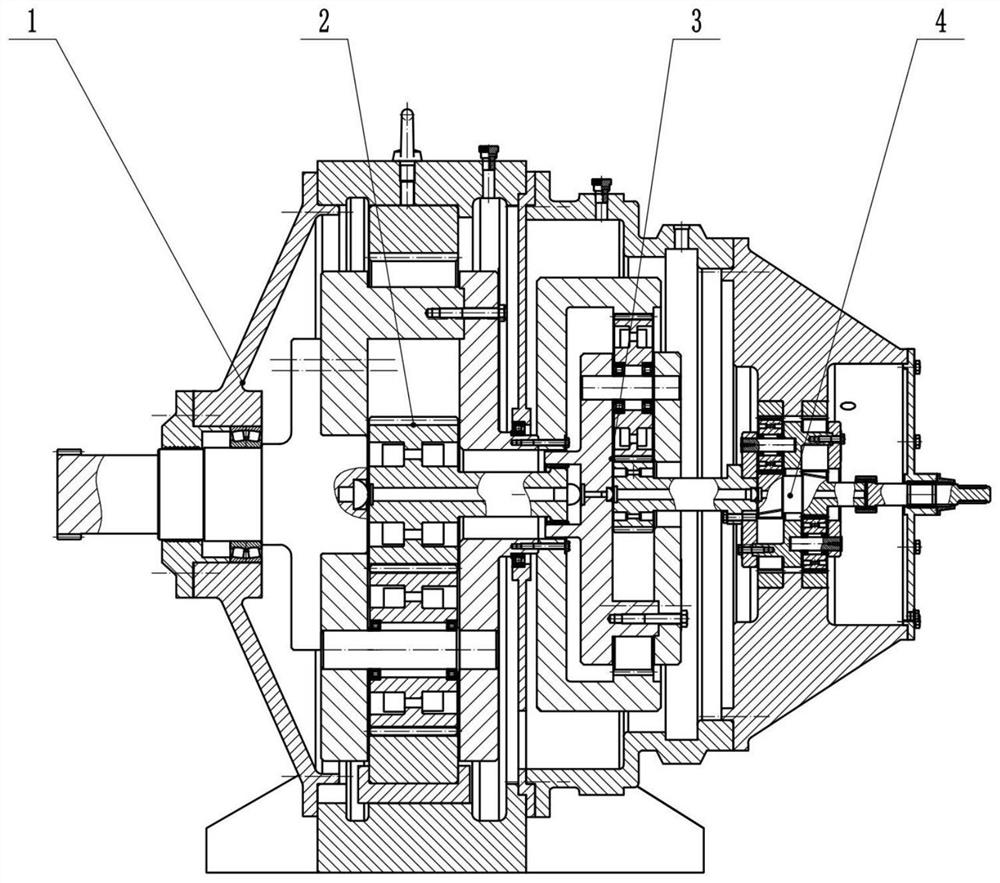

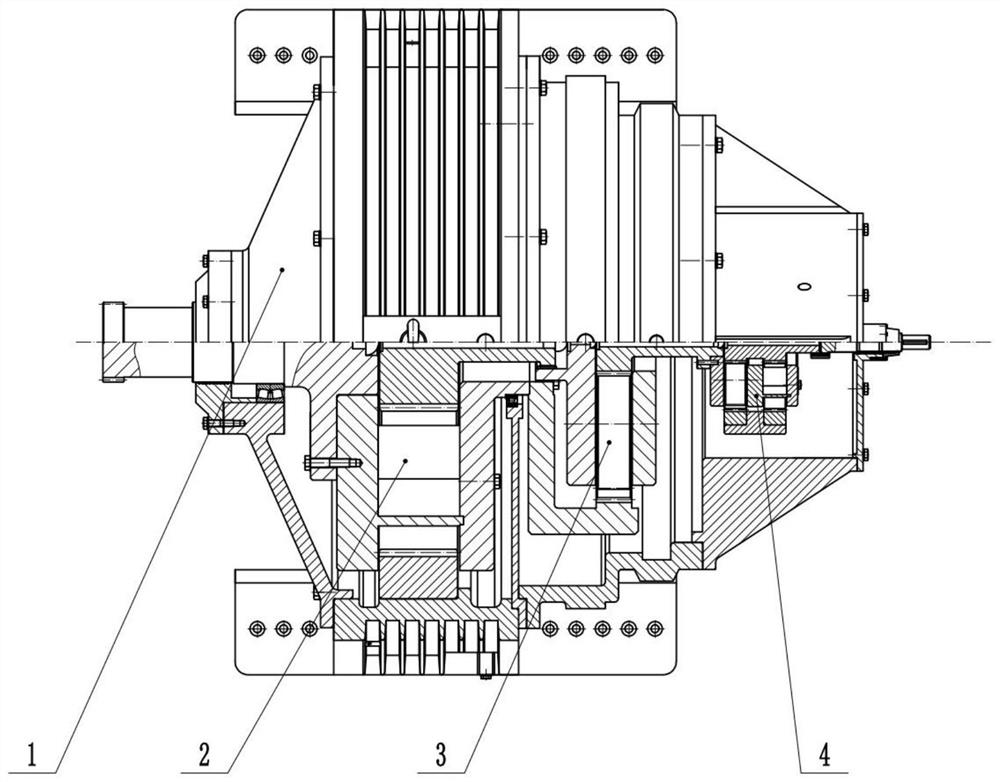

Wind generating set and variable pitch driving system thereof

ActiveCN103266988AAchieve regulationImprove reliabilityWind motor controlMachines/enginesGear driveReduction drive

The invention discloses a variable pitch driving system which is used for a wind generating set. The variable pitch driving system comprises a motor and a reducer which is connected with an output shaft of the motor, wherein the reducer comprises a planet gear transmission system which is connected with the output shaft of the motor and has multistage transmission, and the output end of the planet gear transmission system is fixedly connected with blades of the wind generating set. The closed type gear transmission is adopted in the variable pitch driving system, when the planet gear transmission system is operated, the number of meshed gears is increased, stress of the meshed gears is improved, reliability of the variable pitch driving system is improved, and the service life of the variable pitch driving system is prolonged. In addition, the planet gear transmission system is adopted in the variable pitch driving system, a variable pitch bearing is removed, and the structure of the variable pitch driving system is more compact.

Owner:BEIJING GOLDWIND SCI & CREATION WINDPOWER EQUIP CO LTD

Wind generating set and variable pitch driving system thereof

ActiveCN103266988BAchieve regulationImprove reliabilityWind motor controlMachines/enginesReduction driveReducer

The invention discloses a variable pitch driving system which is used for a wind generating set. The variable pitch driving system comprises a motor and a reducer which is connected with an output shaft of the motor, wherein the reducer comprises a planet gear transmission system which is connected with the output shaft of the motor and has multistage transmission, and the output end of the planet gear transmission system is fixedly connected with blades of the wind generating set. The closed type gear transmission is adopted in the variable pitch driving system, when the planet gear transmission system is operated, the number of meshed gears is increased, stress of the meshed gears is improved, reliability of the variable pitch driving system is improved, and the service life of the variable pitch driving system is prolonged. In addition, the planet gear transmission system is adopted in the variable pitch driving system, a variable pitch bearing is removed, and the structure of the variable pitch driving system is more compact.

Owner:BEIJING GOLDWIND SCI & CREATION WINDPOWER EQUIP CO LTD

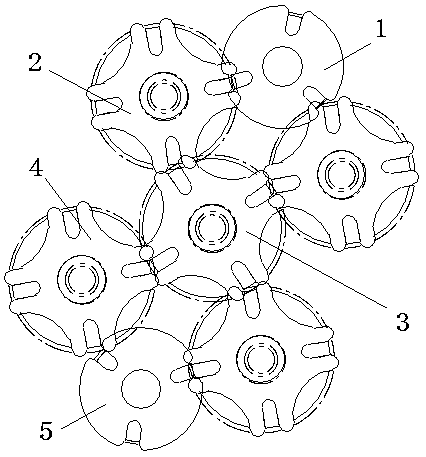

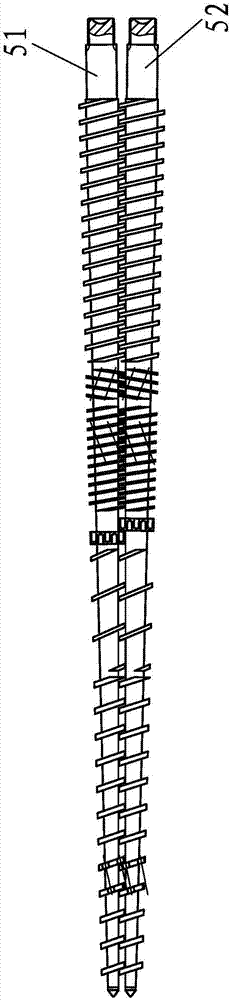

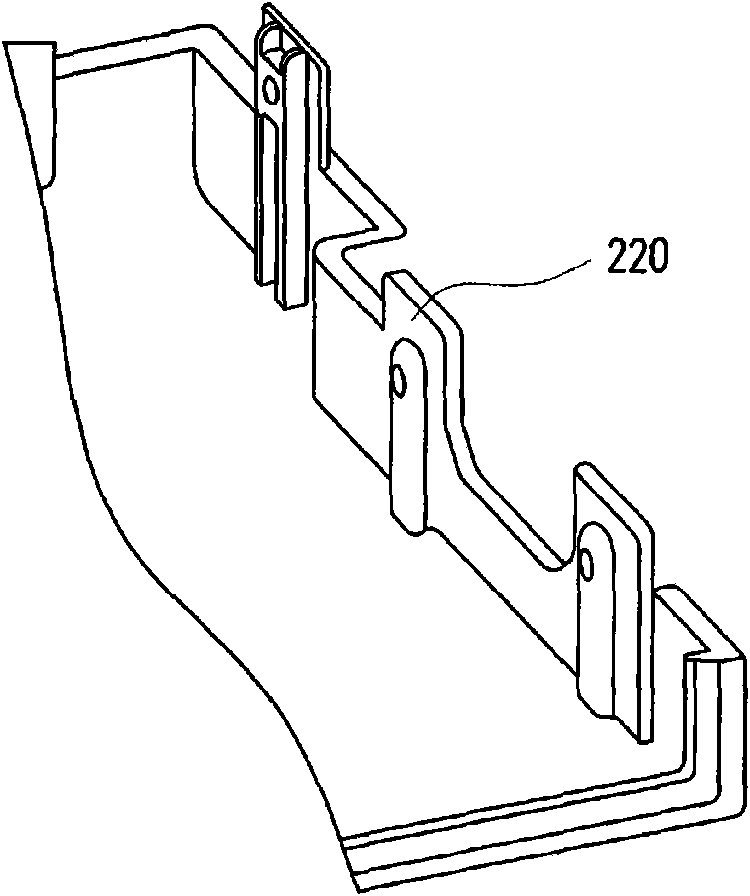

Entwined drive-cross system for national costume decoration belt knitting machine

The invention relates to an entwined drive-cross system for a national costume decoration belt knitting machine, and belongs to the national costume decoration belt knitting machine. The number of front-transition gear driving plates and rear-transition gear driving plates of the entwined drive-cross system is separate two; front-rotation gear driving plates and rear-rotation gear driving plates are separately meshed with the two front-transition gear drivings and the two rear-transition gear driving plates to form a front transmission system and a rear transmission system, an entwined weavingsystem is formed between the front transmission system and the rear transmission system through common gear driving plates meshed with each other, and adjacent drive-cross slots are aligned synchronously during operation; the rear part of a front guide rail overlaps the front part of a rear guide rail to form a common guide rail; the intersection of the front guide rail and the rear guide rail islocated on one side of the rear guide rail; and the diameter of the front guide rail at the common guide rail is larger than that of the rear guide rail. The entwined drive-cross system for the national costume decoration belt knitting machine has the advantages that the guide rail of the knitting machine has no spindle interference phenomenon, the shape of the machine is reduced, and the space is saved; the reduction of the number of teeth of a drive-cross gear increases the rotation speed of the machine, and the production volume increases with the improvement of the rotation speed of the machine; and a spindle is woven evenly smoothly, and the weaving quality is improved.

Owner:XUZHOU HENGHUI BRAIDING MACHINE

Rigid inside and outside tooth-profile-wrapped tooth reducer

Owner:ZHEJIANG HENGFENGTAI REDUCER MFG

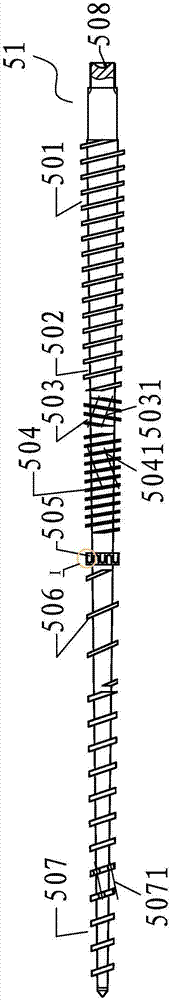

Universal tapered co-directional double-screw-rod extruder for plastic pipes and sheet materials

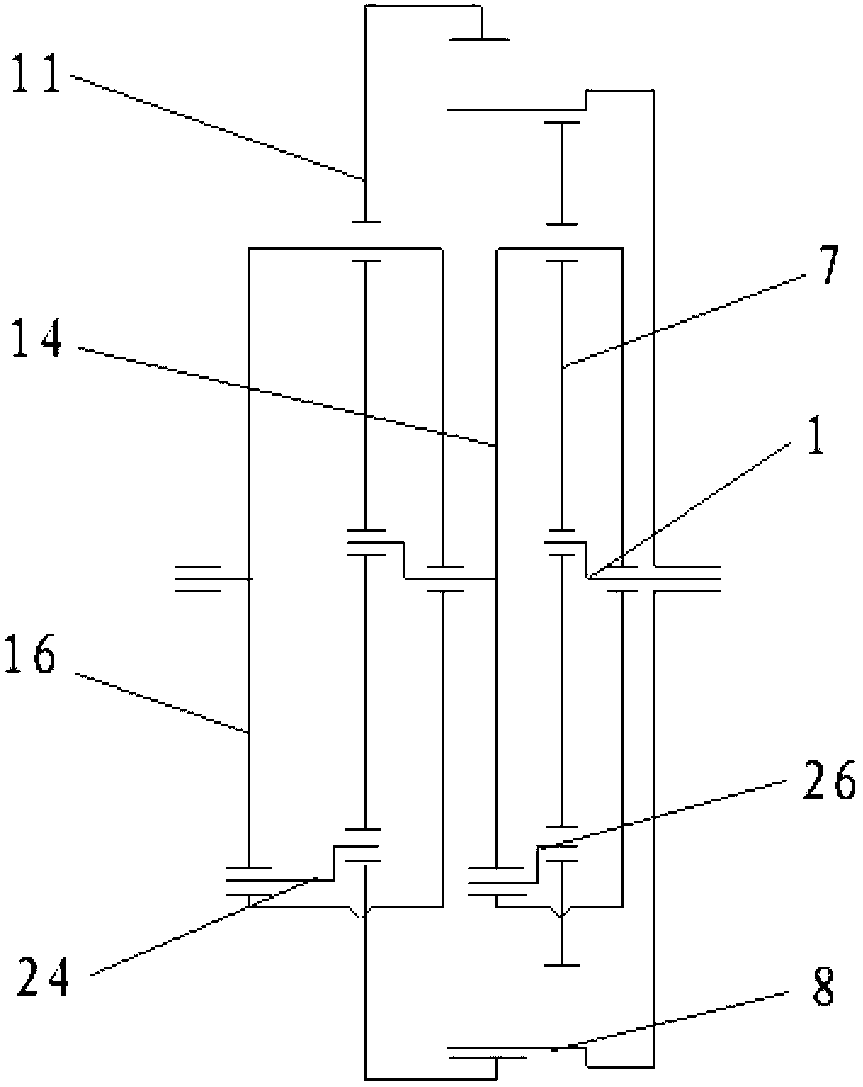

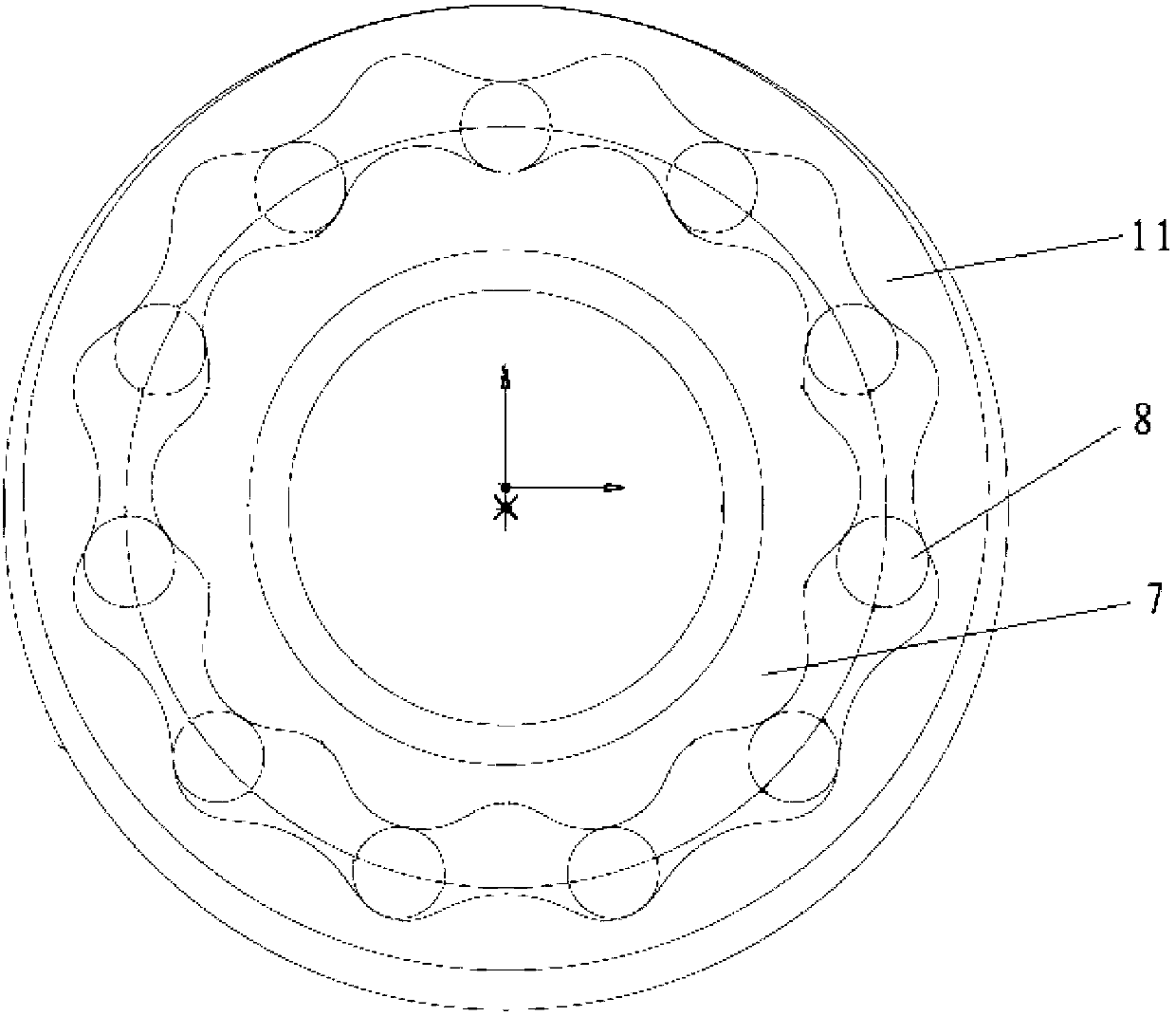

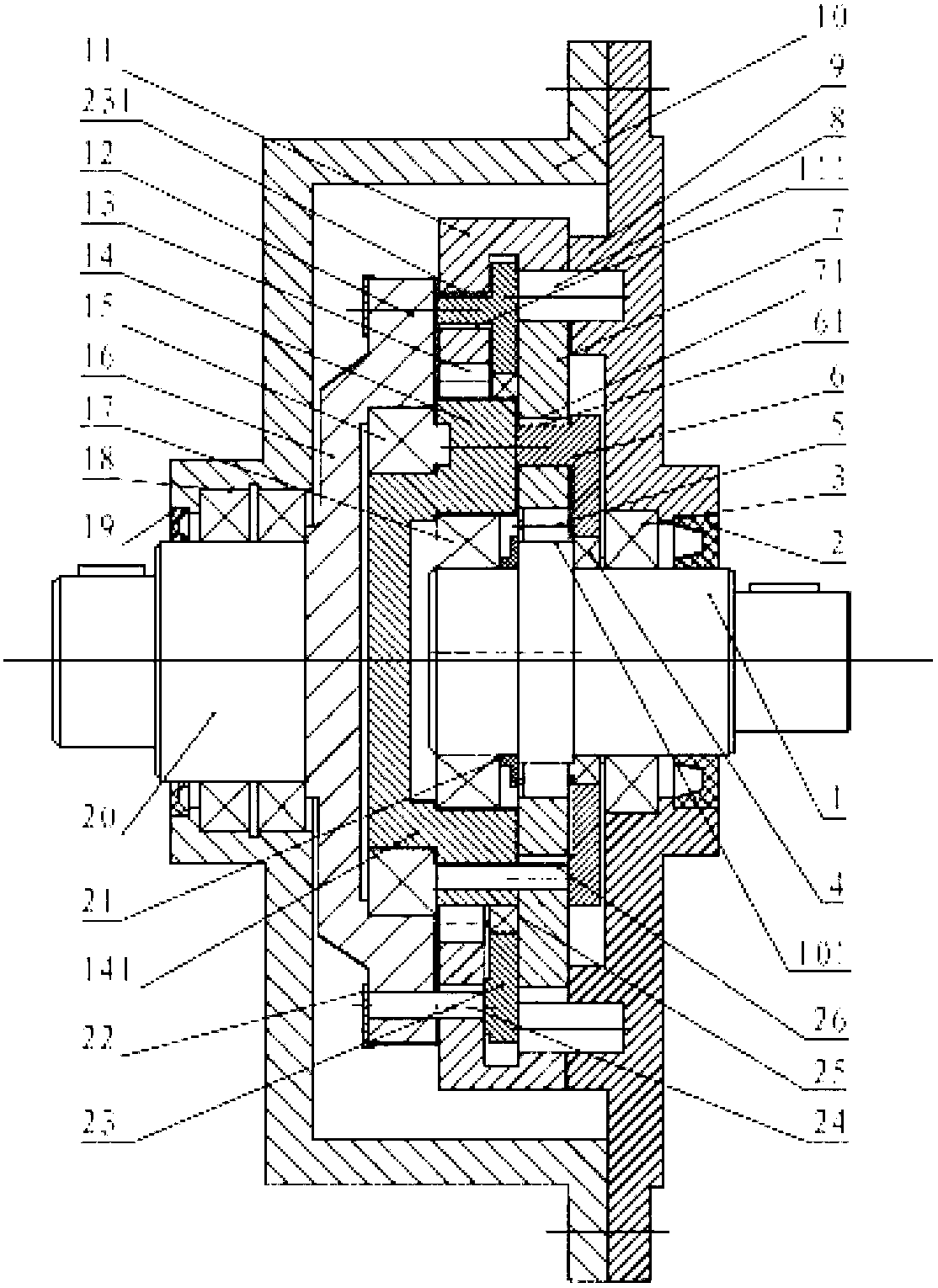

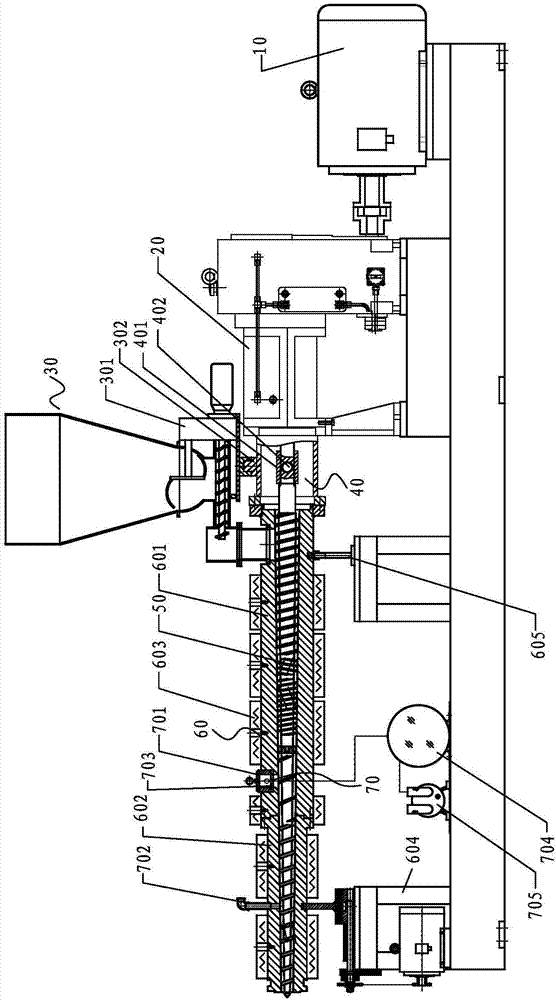

The invention discloses a universal tapered co-directional double-screw-rod extruder for plastic pipes and sheets. The universal tapered co-directional double-screw-rod extruder comprises a driving motor, a deceleration distribution box system, a feeding system, a transmission system, a tapered co-directional double-screw-rod system, an extruder barrel system and an exhaust system; and the tapered co-directional double-screw-rod system comprises a main tapered screw rod and an auxiliary tapered screw rod, the rotating directions of the main tapered screw rod and the auxiliary tapered screw rod are co-directional, and the main tapered screw rod and the auxiliary tapered screw rod are sequentially provided with feeding zones, plasticizing zones, reverse thread zones, secondary plasticizing zones, separation zones, exhaust zones and extrusion zones along the moving direction of materials. The tapered co-directional double-screw-rod extruder has the advantages that shearing heat is large, plastication is good, mixing is good, the filling ratio is high, product strength is good, the surface is bright, no discharge from an exhaust port occurs, transmission torque of the deceleration distribution box system is large, the bearing capacity is doubled, the service life is prolonged greatly, noise is small, and manufacturing is simple; according to the universal tapered co-directional double-screw-rod extruder for the plastic pipes and the sheets, and not only can the plastic sheets be extruded, but also the plastic pipes can be extruded.

Owner:舟山盈科塑料机械有限公司 +1

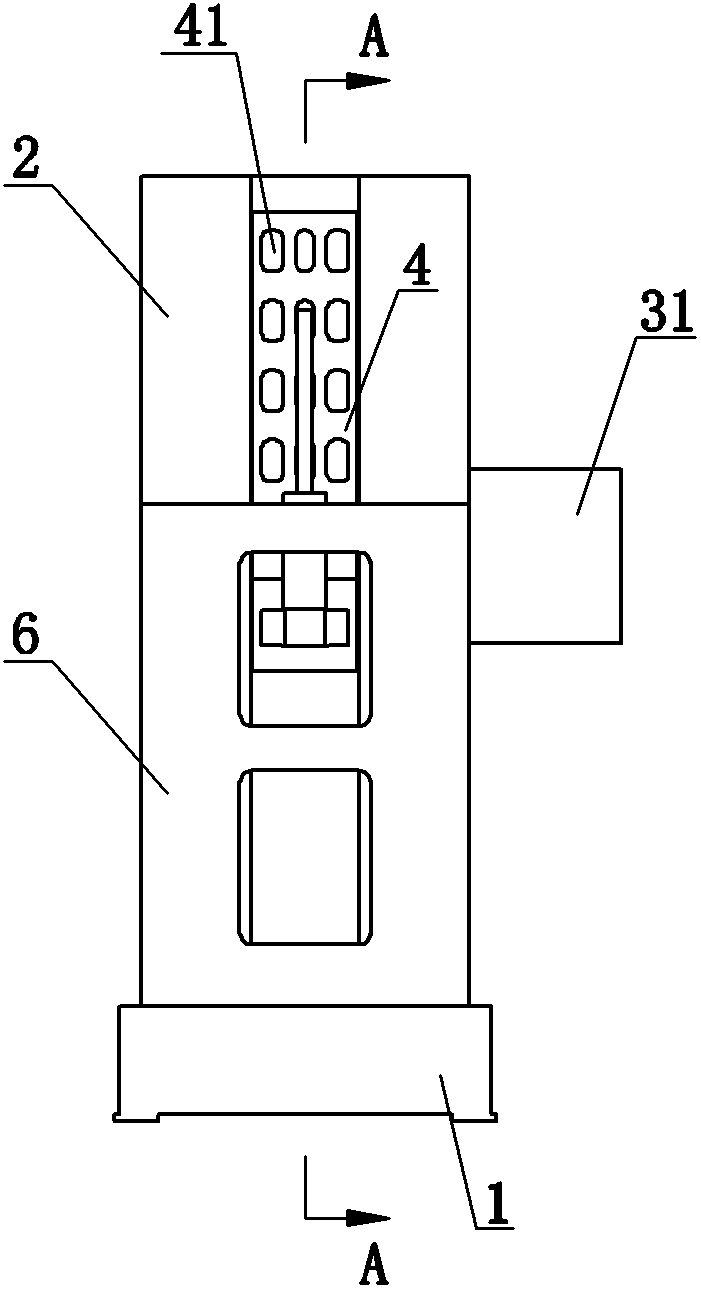

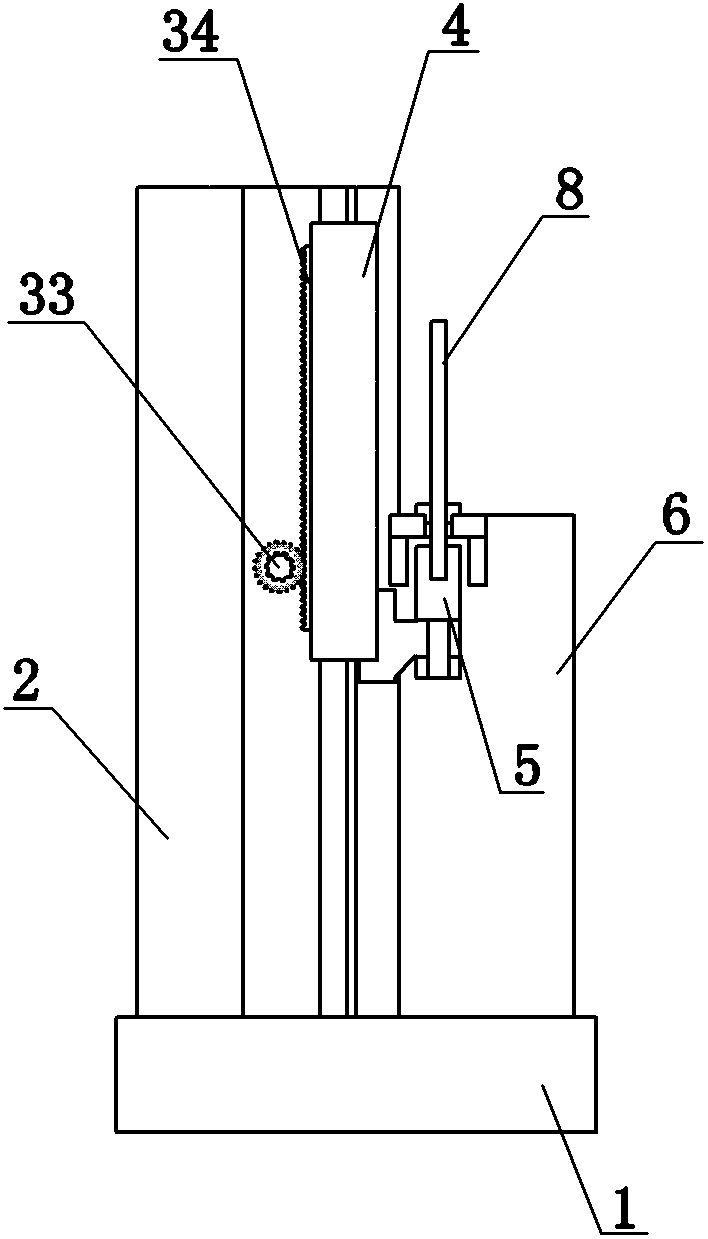

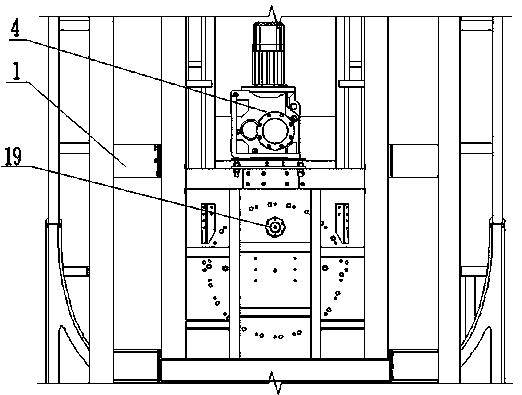

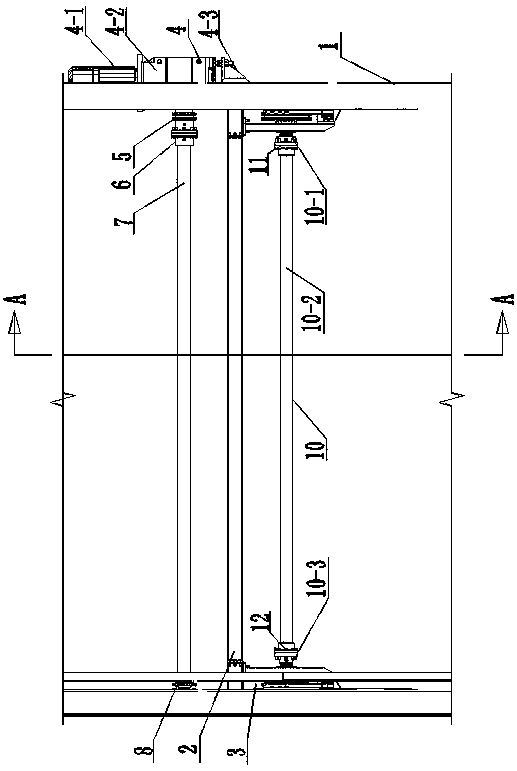

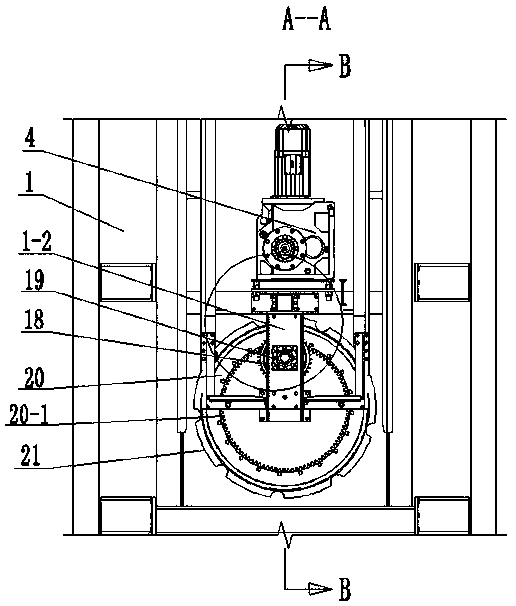

Heavy gear transmission vertical broaching machine tool

InactiveCN102554363ASimple transmissionShorten maintenance timeFeeding apparatusLarge fixed membersGear transmissionMachining process

The invention discloses a heavy gear transmission vertical broaching machine tool. The heavy gear transmission vertical broaching machine tool comprises a base and a machine tool body, wherein the machine tool body is fixed on the base; a guide rail extending in the vertical direction is arranged on the machine tool body; a main slide carriage driven by a power device and linearly moving in a reciprocating way is arranged within the guide rail; the power device comprises an electric motor and a driving shaft; the driving shaft is connected to an output end of the electric motor; a driving gear is arranged on the driving shaft; a driving rack adaptive to the driving gear is fixed on the main slide carriage; a clamping device for fixing a broaching tool is arranged on the main slide carriage; the heavy gear transmission vertical broaching machine tool also comprises a workbench arranged on the base; and a fixing device for fixing a workpiece is arranged on the workbench. The heavy gear transmission vertical broaching machine tool disclosed by the invention has the advantages of simple transmission mode and convenience for mounting and is very suitable for broaching heavy and large-sized workpieces; the bearing capacity of the broaching machine tool can be effectively enhanced so that the transmission is stable and the error generated in the machining process is largely reduced; and the fault source can be accurately figured out in time after the fault occurs so that the maintenance time is reduced.

Owner:CHAGYI LIHUI BROACHING MACHINE MAFACTURE

Novel wind power gear box

PendingCN114718994AReduce volumeReduce hysteresis problemGear lubrication/coolingToothed gearingsGear wheelCoupling

A novel wind power gear box belongs to the technical field of mechanical gear boxes and comprises a box body for supporting, and an input end, an intermediate stage and an output end are mounted in the box body and sequentially connected. Therefore, the structure can effectively reduce the return difference problem of the planetary gear train caused by manufacturing and mounting errors, so that the processing and mounting requirements on high-speed components can be properly reduced by utilizing the structure; the reliability of a design object is improved, so that the design object can be suitable for a power generation occasion with MW-level power; by means of the structure, axial force can be counteracted, the axial force on the shaft is reduced, the joint of the shaft can be fixed through the elastic check ring and connected with the gear coupling, meanwhile, the most beneficial floating uniform load mode is achieved, and the adverse effect of unbalance loading on reliability is reduced.

Owner:NORTHEASTERN UNIV

Cycloid flexible gear speed reducer

PendingCN113153982ACompact structureIncrease the number of teethToothed gearingsReduction driveGear wheel

The invention provides a cycloid flexible gear speed reducer, relates to the technical field of mechanical transmission, and aims to optimize the structure of the cycloid flexible gear speed reducer to a certain extent so as to reduce the size and machining difficulty of a whole speed reducing mechanism. The cycloid flexible gear speed reducer comprises a shell, an input assembly, a speed reduction flexible gear and an output assembly. The input assembly, the speed reduction flexible gear and the output assembly are all arranged in the shell. The input assembly comprises an eccentric shaft and a main gear, and an eccentric section of the eccentric shaft is connected with the main gear; the speed reduction flexible gear comprises an outer tooth part and an inner tooth part, the outer tooth part and the inner tooth part are distributed in the circumferential direction of the speed reduction flexible gear, a meshing part is formed in the shell in the circumferential direction of the shell, the inner tooth part is meshed with the main gear, and the outer tooth part is meshed with the meshing part; and the output assembly is connected with the main gear so as to rotate along with the main gear.

Owner:南京南传智能技术有限公司

A hub-ratchet combination structure

InactiveCN106895091AShorten the interlocking pitchSmall spacingHubsFreewheel clutchesTooth numberEngineering

The invention provides a hub-ratchet combination structure comprising a hub base, a linkage ring, a sleeve base and a ratchet tooth group. Linkage teeth of the linkage ring are characterized by a great tooth number and a small pitch, and the number of the teeth can reach up to 155 at most. Each pawl member of the ratchet tooth group is provided with meshing teeth with a small pitch corresponding to the linkage teeth. The sliding distance of the meshing teeth on the tooth ends of the linkage teeth can be effectively reduced and further the spacing distance of meshing linkage of the ratchet tooth group and the linkage ring can be shortened, so that the state of meshing linkage can be reached quickly, the pedaling gaps can be reduced, the definiteness of riding and pedaling can be improved greatly and the safety is improved.

Owner:CHOSEN

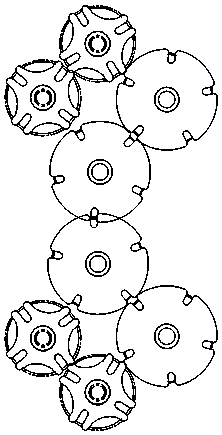

Double-chain double-shaft gear bearing transmission structure of three-dimensional garage chain shifting plate

PendingCN111395834AIncrease the diameterIncrease the number of teethRolling contact bearingsBearing componentsGear wheelDrive shaft

The invention relates to a vertical circulation type three-dimensional garage, in particular to a double-chain double-shaft gear bearing transmission structure of a three-dimensional garage chain shifting plate. The structure comprises a front rack, a rear rack, the chain shifting plate and a transmission shaft, an output shaft of a driving device is provided with a first chain wheel, the output shaft is connected with one end of a driving shaft through a first coupler, a second chain wheel is mounted at the other end of the driving shaft, the driving shaft is connected with the rear rack through a first bearing seat, and the driving shaft is parallel to the transmission shaft; a third chain wheel and a fourth chain wheel which are arranged on the transmission shaft are respectively transmitted with the first chain wheel and the second chain wheel through a transmission chain, the two ends of the transmission shaft are respectively provided with gears, the gears are engaged with an inner gear ring of an inner gear type slewing bearing, the inner end face of the inner gear ring is provided with the chain shifting plate, and the outer ring of the inner gear type slewing bearing is respectively fixedly connected with the front rack and the rear rack. According to the structure, the inner gear type slewing bearing is adopted, so that the diameter and the number of teeth of the chain shifting plate are increased, the sliding of a roller of a lifting chain in the chain shifting plate is reduced, and the service life of the chain shifting plate is prolonged.

Owner:唐山宝乐智能科技股份有限公司

A Modification Method of Involute Tooth Profile in Harmonic Drive

ActiveCN107882950BIncrease the number of teethSmall engagement backlashGearingPortable liftingKinematic theoryGear wheel

The invention discloses a modification method for a harmonic driving involute profile. A point B serves as a point of tangency of a modification curve and a involute tooth surface. A point E serves asa point of intersection of the modification curve and an involute addendum circle. A coordinate system XOY is built with a radial OA as the abscissa axis. A coordinate system X1OY1 is built with a radial OC as the ordinate axis. After the steps of determining the coordinates of the point B and the point E in the coordinate system X1OY1 and the slope of a tangent of the involute at the point B, determining a flexible gear central point approximate movement track curvilinear equation, determining the parameter equation of the modification curve in the coordinate system X1OY1 and the like, a system of simultaneous equations is built and used for solving parameters, and the parameter equation of the modification curve in the coordinate system XOY is obtained through conversion of the coordinate system. According to the modification method, the harmonic driving involute profile is modified based on the harmonic driving kinematics theory, processing manufacturability and economy can be guaranteed, engagement performance is improved, the advantages of various harmonic tooth profiles are integrated, and the modification method can be widely applied to the technical field of harmonic gears.

Owner:国茂精密传动(常州)有限公司

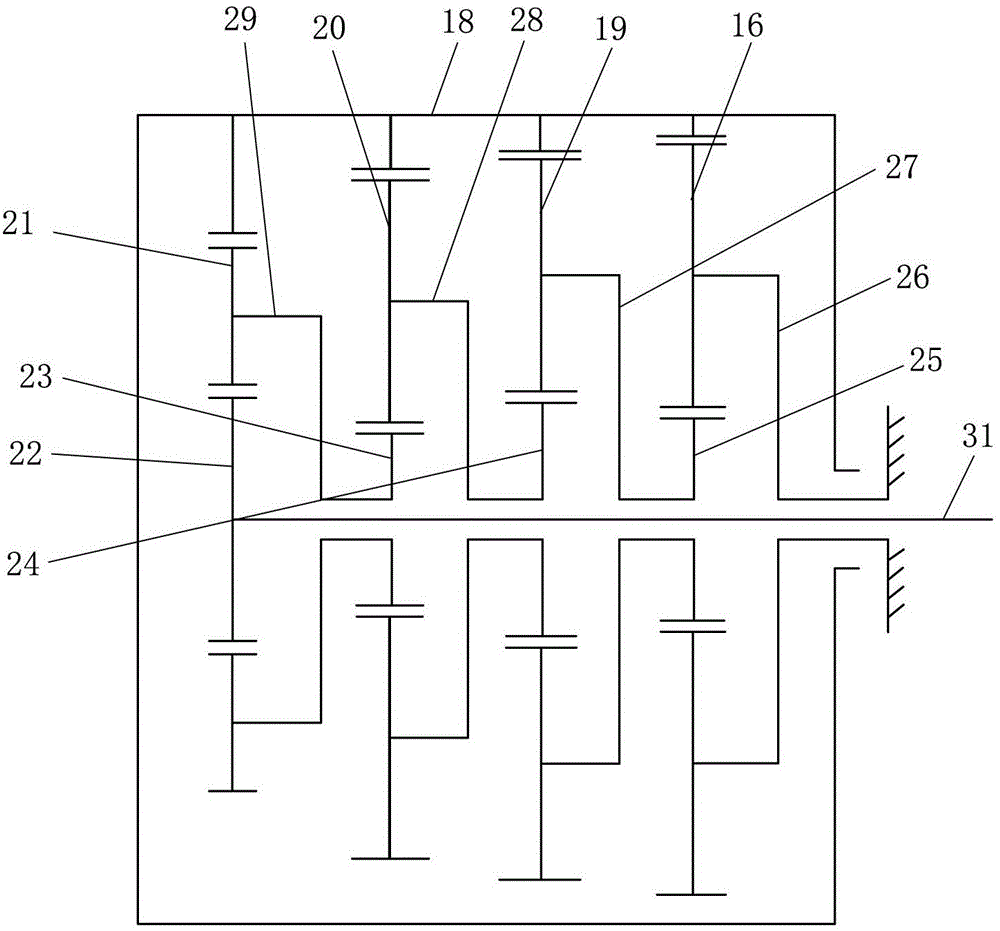

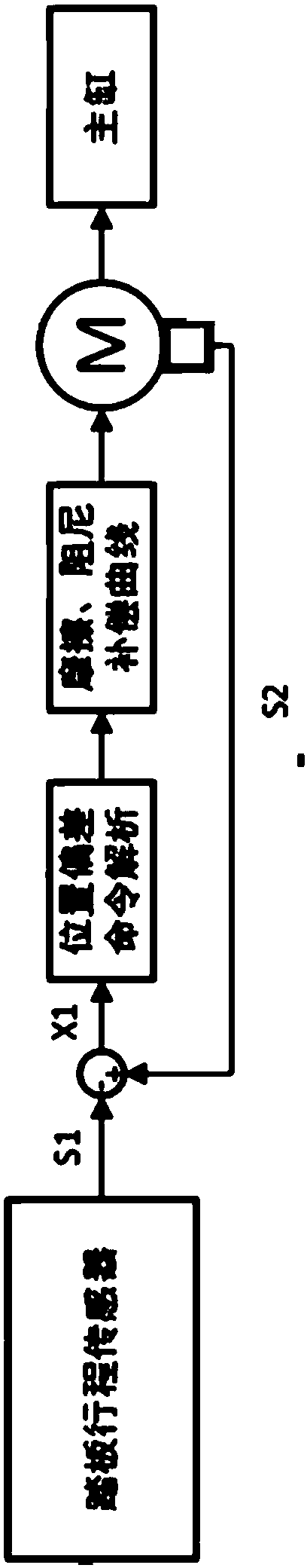

Electric power-assisted braking system

ActiveCN109849885AReduce assembly linksLow costBraking action transmissionElectric power systemBall screw

The invention provides an electric power-assisted braking system that comprises a power booster outer shell; a power assisting sleeve is arranged in the power booster outer shell; one end of a brake pedal push rod penetrates into one end of the power booster outer shell and is hinged to one end of a booster push rod. The booster push rod is installed at one end of the power assisting sleeve and can move in the power assisting sleeve; a motion conversion mechanism is mounted outside the booster push rod, is connected with a motor and used for realizing conversion from rotation to translation ofthe motor. According to the electric power-assisted braking system, conversion from rotation to translation of the motor is achieved through a gear reduction mechanism, and then a transmission targetis achieved through a hollow ball screw mechanism. By reducing the number of teeth of a pinion and increasing the number of teeth of a bull gear, the meshing frequency of the gears is reduced, meanwhile, the linear speed of the ball screw is reduced, and the NVH performance is improved.

Owner:SHANGHAI HUIZHONG AUTOMOTIVE MFG

Efficient cutting device of ball-end milling cutter

InactiveCN102825313AMature manufacturing technologyImprove processing qualityMilling equipment detailsMilling cutterGear wheel

A mechanical transmission device is capable of enhancing the cutting property of a ball-end milling cutter, and comprises a driving shaft, an intermediate shaft, a plurality of gears (cylindrical gear, internal gear, bevel gear, spiral gear), a driven shaft and a milling cutter; the driving shaft and the driven shaft form an included angle; when a main shaft is driven to rotate by a power source, the main shaft drives the driven shaft to rotate around the main shaft by the gears and rotates around the axis. The centre of the ball-end is corrected by a scale or by other methods, so as to be arranged on the centre line of the main shaft. The method is simple and convenient. Therefore, the centre part of the ball-end milling cutter does not participate in cutting due to the fact that the centre part is likely to tip and wear. The part of the end face of the ball-end milling cutter which does not participate in cutting is increased along with the increment of included angle between the driving shaft and the driven shaft. The centre of the ball-end milling cutter is avoided from tipping, thereby enhancing the wearing resistance of the cutter, fastening the cutter feeding speed, and improving the cutting efficiency.

Owner:邵枫

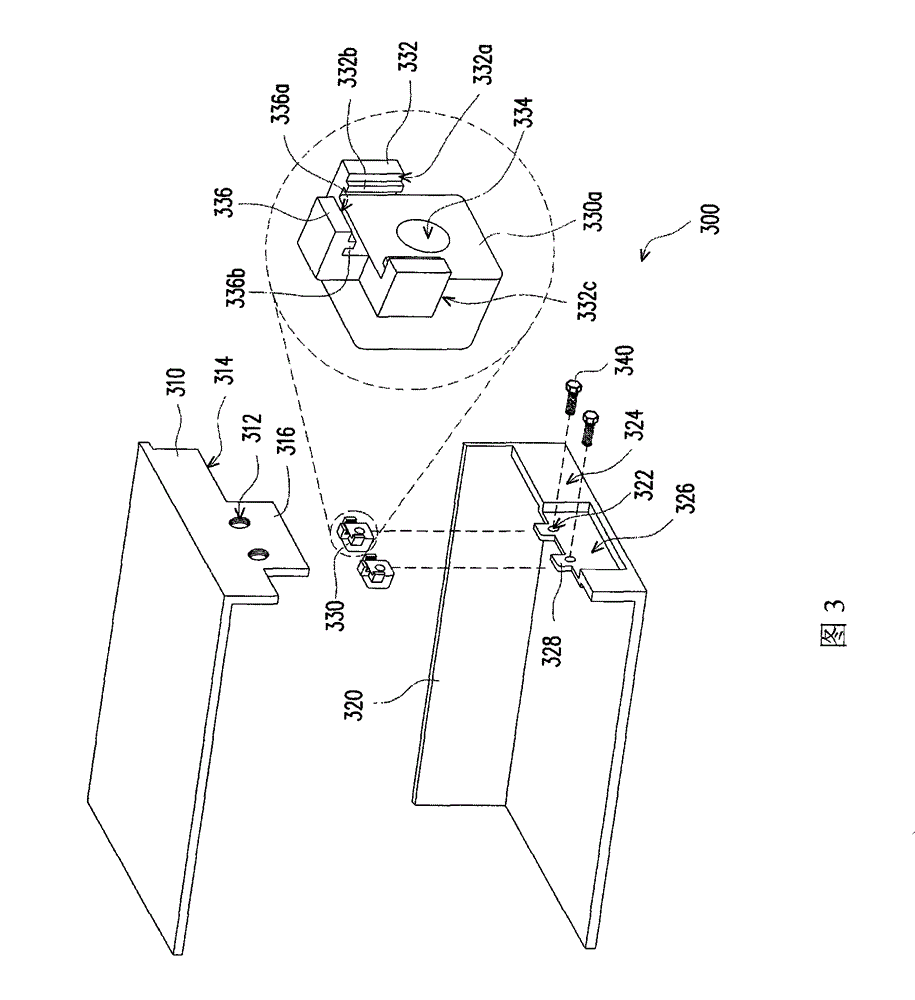

Electronic device

ActiveCN101778544AIncrease the number of teethImprove assembly stabilityElectrical apparatus casings/cabinets/drawersEngineeringMechanical engineering

The invention relates to an electronic device which comprises a first casing, a second casing, a plurality of assembly pieces and a plurality of locking pieces, wherein the first casing is provided with at least one first combining part; the second casing is provided with at least one second combining part; each assembly piece is provided with a plurality of assembly parts and a locking part, wherein the assembly parts are combined with the second casing for fixing the assembly pieces on the second casing; and when being used for assembling the first casing and the second casing, the locking pieces penetrate through the first combining part and the second combining part correspondingly superposed and are locked in the locking parts.

Owner:ASUSTEK COMPUTER INC

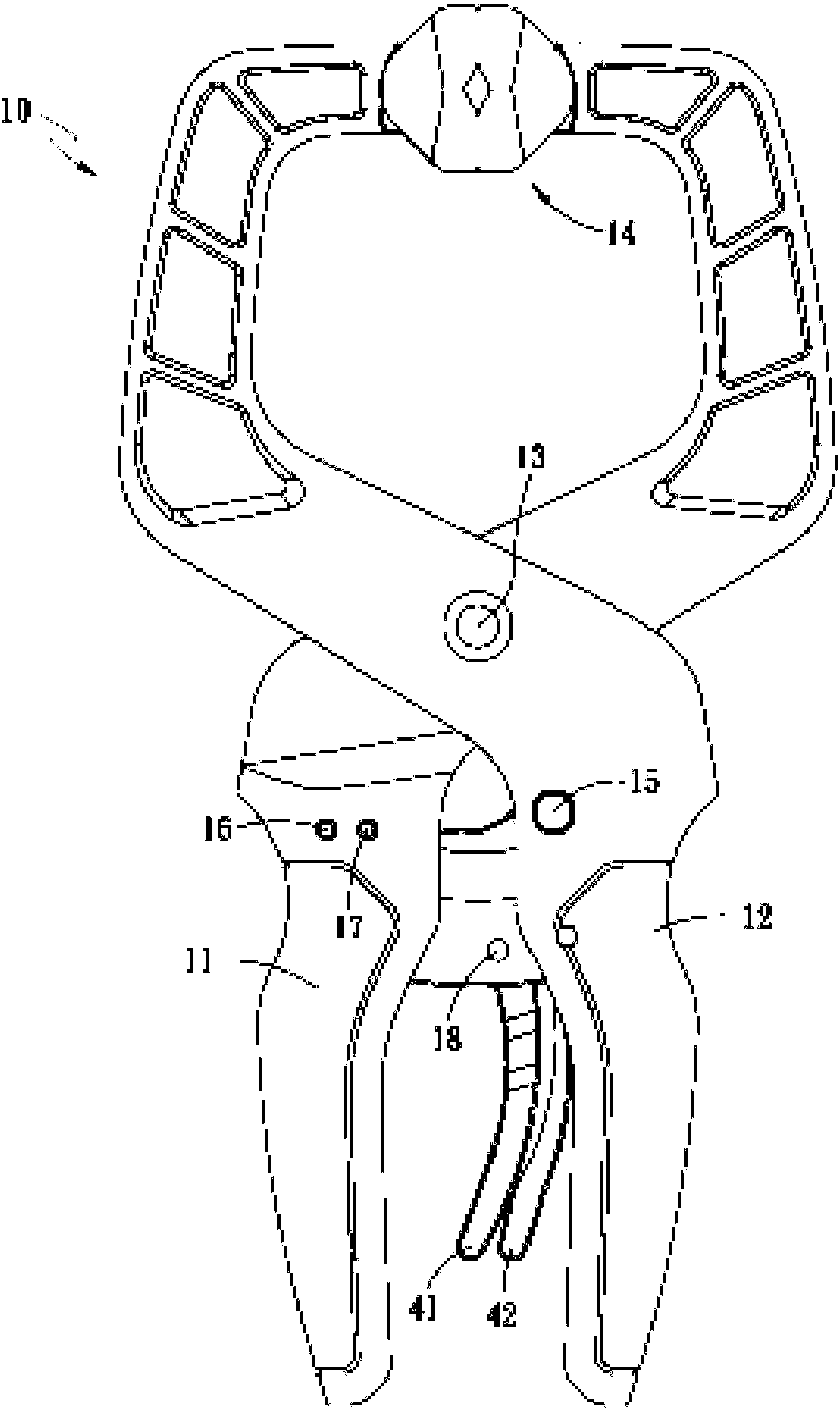

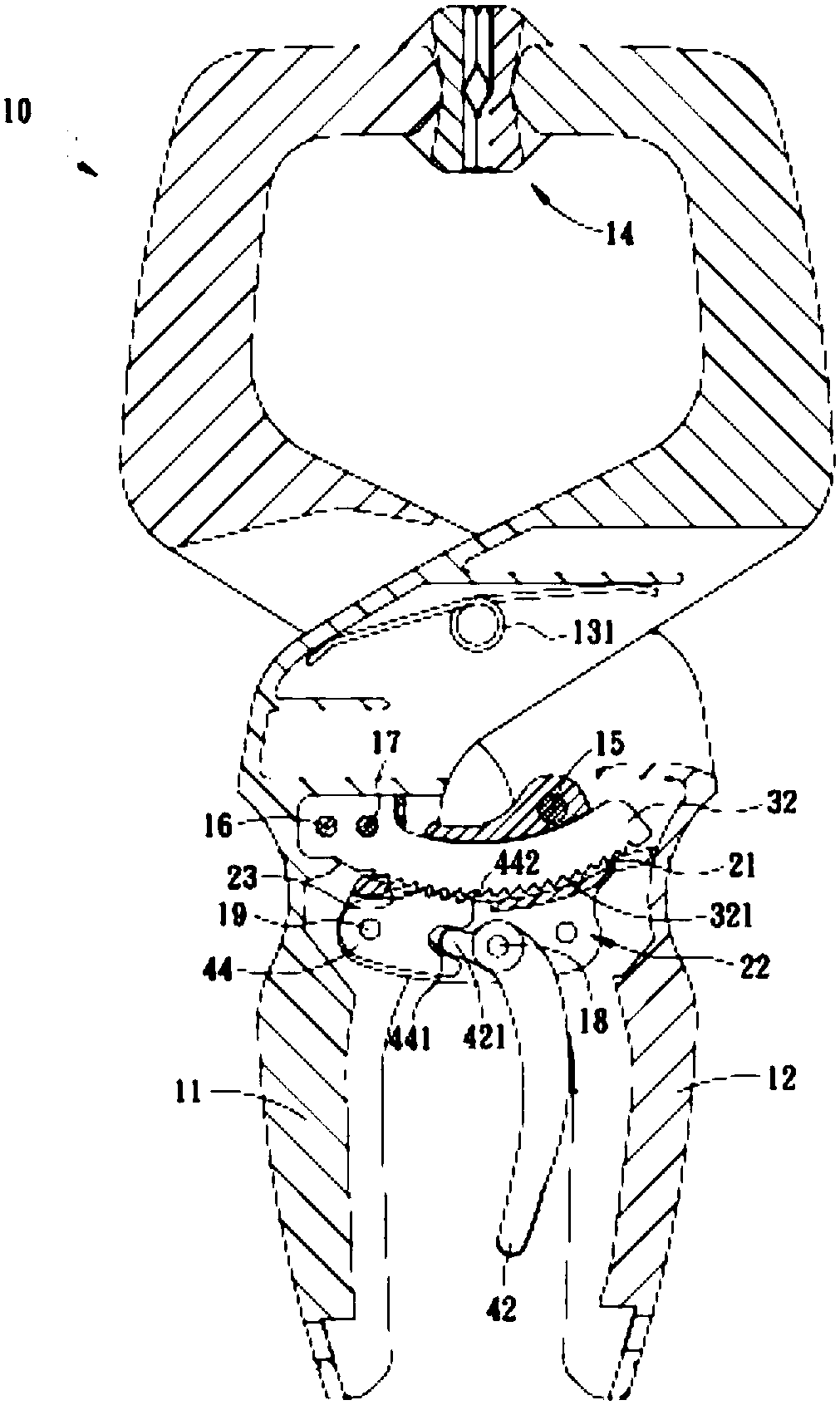

Ratchet mechanism with staggered locking and releasing functions and ratchet wheel clamp

PendingCN108262699AIncreased engagement areaGuaranteed structural strengthPliersEngineeringMechanical engineering

The invention discloses a ratchet wheel clamp. The ratchet wheel clamp comprises that a first clamping arm and a second clamping arm are mutually pivoted to be opened or closed relative to each otherthrough a connecting shaft, and a ratchet component, a swinging component and a control component are arranged between the first clamping arm and the second clamping arm; the ratchet component is provided with a plurality of first ratchets and a plurality of second ratchets which are arranged side by side and are staggered with one another; the swinging component and the ratchet component are relatively far away from or close to each other by taking the connecting shaft as a rotating axis; a clamping part of the control component is provided with at least a first pawl and at least a second pawl, a pulling part of the control component is used for shifting the clamping part to move; when the clamping part moves to a meshing position, the first pawl and the second pawl are correspondingly meshed with the corresponding the first ratchets and the second ratchets; and when the clamping part moves to a release position, the first pawl and the second pawl are correspondingly far away from thecorresponding first ratchets and the second ratchets. Through the design of ratchets which is arranged in a staggered mode, the ratchet shape cannot be reduced, so that the structural strength is increased, and the overall clamping force is greatly enhanced.

Owner:HANGZHOU GREAT STAR TOOLS +1

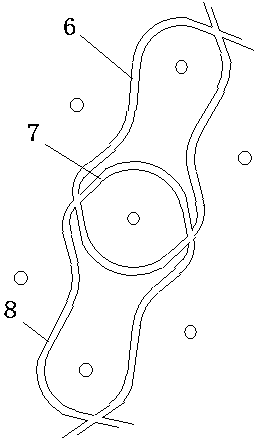

Small-outer-diameter grooved copper pipe and production method thereof

PendingCN112696951AIncrease the number of teethReduce widthIndirect heat exchangersHeat exchange apparatusSpinningPipe

The invention relates to the technical field of heat pipes, in particular to a small-outer-diameter grooved copper pipe and a production method thereof. The small-outer-diameter grooved copper pipe comprises a copper pipe body, the inner wall of the copper pipe body is provided with a plurality of grooves in the circumferential direction, and the grooves are spirally formed in the length direction of the copper pipe body. According to the small-outer-diameter grooved copper pipe and the production method thereof, a high-speed liquid-filled spinning method and a multi-tooth core head are adopted to make metal on the inner wall of a copper pipe base pipe subjected to continuous plastic forming to form the micro grooves. Under the pressure action of the multi-tooth core head and a spinning ball, the metal on the inner wall surface is subjected to plastic deformation after complex plastic flow, so that the final inner wall surface micro grooves are formed. By optimizing the tooth profile design of the drawing core head, the bottom width of grooved pipe internal teeth is reduced, the number of the groove internal teeth is increased, and therefore the small-outer-diameter multi-groove copper pipe for heat pipes is obtained.

Owner:广东龙丰精密铜管有限公司

Pedal type screening device

PendingCN109174624AIncrease the number of teethAdjustable sizeSievingScreeningRest frameMechanical engineering

The invention discloses a pedal type screening device. The device comprises a base, a sieve, an arm-rest frame, a ratchet wheel, two pedals and a seat. The arm-rest frame is arranged in the middle ofthe base. A supporting hanging rod is arranged at the front end of the base. Guide grooves are formed in the arm-rest frame and the supporting hanging rod correspondingly. A sieve bracket is hung on the supporting hanging rod. The sieve is arranged on the sieve bracket. A guide rod is arranged at the front end of the sieve bracket, and a push rod is arranged at the rear end of the sieve bracket. The front portion of the guide rod is located in the guide groove formed in the supporting hanging rod, the push rod is located in the guide groove formed in the arm-rest frame, and the rear segment ofthe push rod is in sliding connection with the ratchet wheel. A seat frame is arranged at the rear end of the base. The seat is mounted on the seat frame. Two ratchet wheel seats are arranged on theportion, behind the arm-rest frame, of the base. An axletree is mounted on the upper portions of the two ratchet wheel seats. The two pedals are mounted at the two ends of the axletree in a 180-degreeintersecting mode, and the ratchet wheel is fixed to the middle of the axletree and located between the two ratchet wheel seats. The pedal type screening device adopts a riding mode to replace pure manual oscillating and can be used for both laboratory soil sample screening and peasant household grain screening, the labor intensity is relieved, and the working efficiency is improved.

Owner:张靖宜

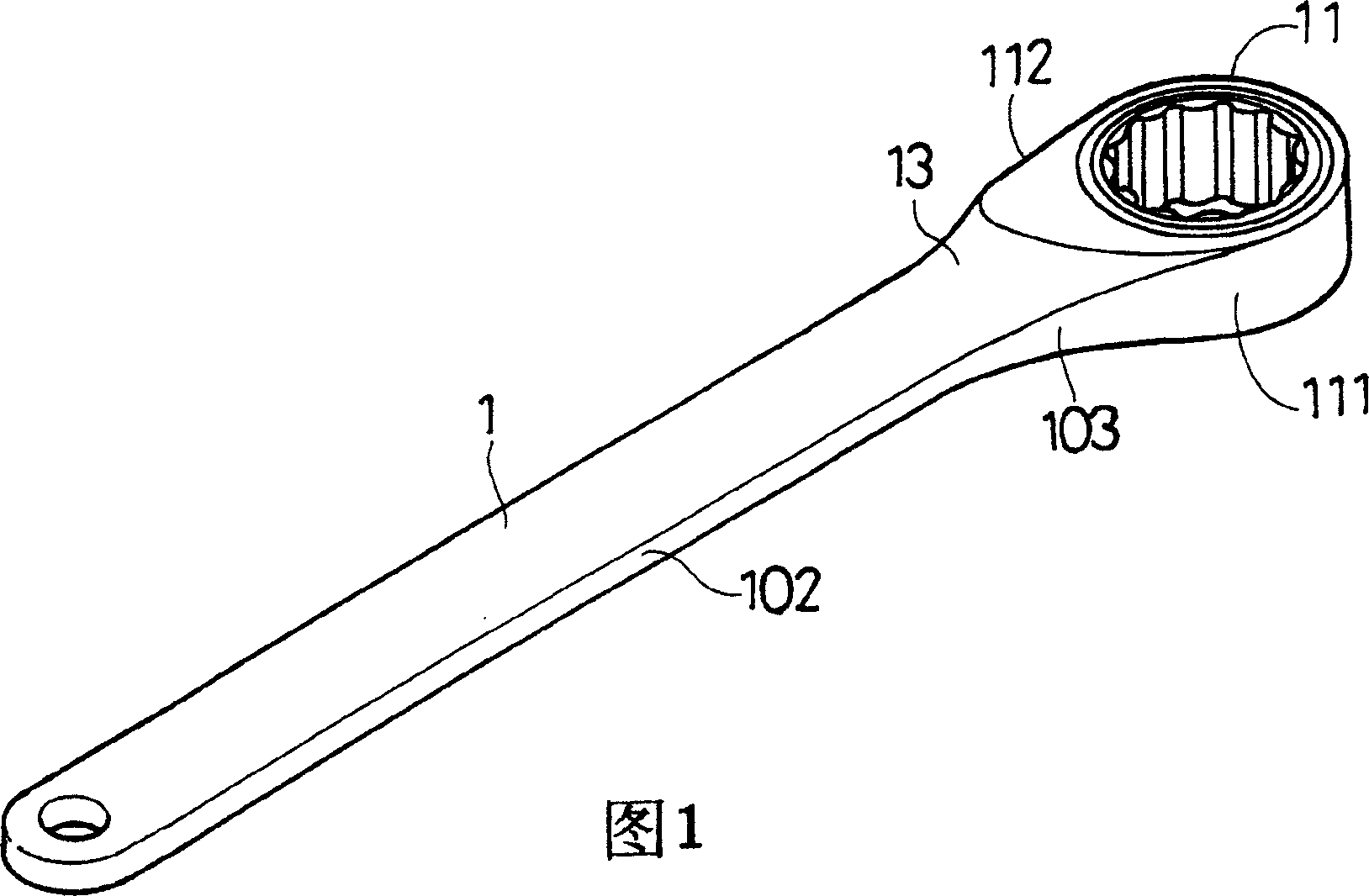

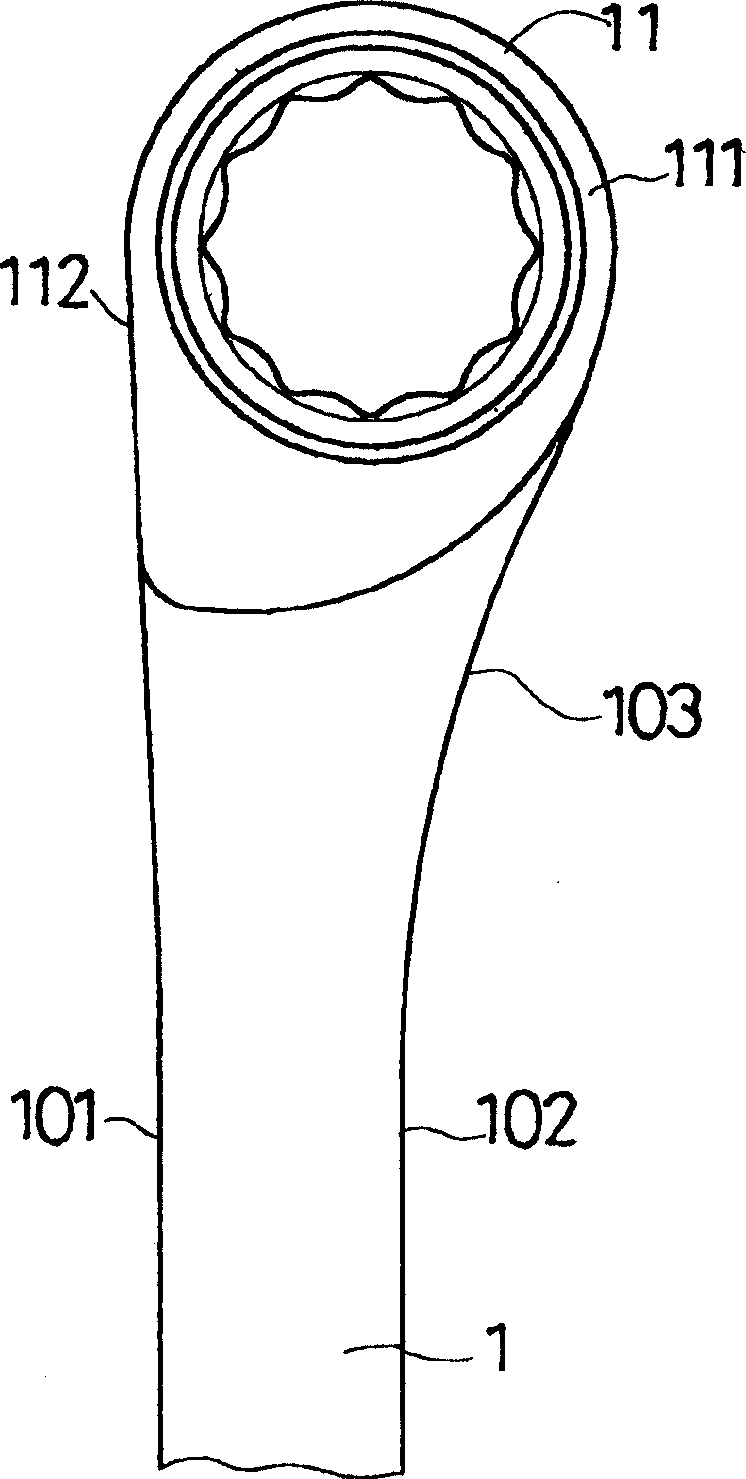

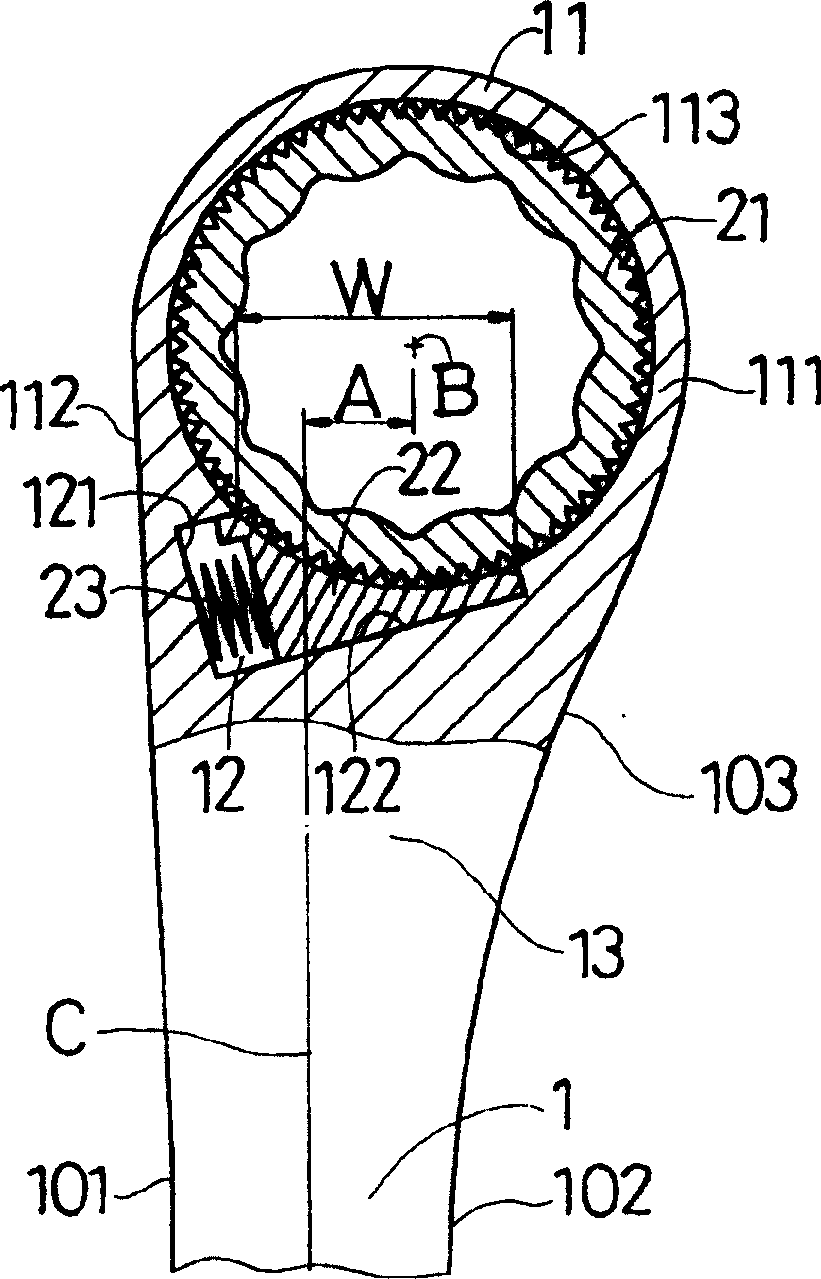

Improved ratchet ring spanner

An improved ratchet double offset ring wrench has a handle with a hand at its one end. THe head has a slot for setting a ratchet wheel, and there is one holding trough for arranging a ratchet block which is pushed elastically to mesh with the ratchet wheel normally. There is a spacing between the center of the head and the central line of the handle, and the head has a bulged part at one side of the central line. The present invention has easy-to-identify driving direction of the ratchet machanism, and the ratchet mechanism can bear relatively high twisting force.

Owner:魏宏因

Electronic device

ActiveCN101778544BIncrease the number of teethImprove assembly stabilityElectrical apparatus casings/cabinets/drawersEngineeringMechanical engineering

The invention relates to an electronic device which comprises a first casing, a second casing, a plurality of assembly pieces and a plurality of locking pieces, wherein the first casing is provided with at least one first combining part; the second casing is provided with at least one second combining part; each assembly piece is provided with a plurality of assembly parts and a locking part, wherein the assembly parts are combined with the second casing for fixing the assembly pieces on the second casing; and when being used for assembling the first casing and the second casing, the locking pieces penetrate through the first combining part and the second combining part correspondingly superposed and are locked in the locking parts.

Owner:ASUSTEK COMPUTER INC

Jaw breaker with tooth profile self modification breaking pair

Owner:ZHEJIANG SHENGDA MACHINERY

An external candy packaging machine horizontal seal upper and lower cutting knife device

The invention discloses an external horizontal sealing upper-and-down cutter device for a candy wrapping machine. The device comprises a horizontal sealing upper seat, a horizontal sealing lower seat, horizontal sealing upper-and-down cutters, transmission gears and conducting rings; two horizontal sealing upper-and-down cutters are respectively arranged at the same sides of the horizontal sealing upper seat and the horizontal sealing lower seat by transmission shafts; the horizontal sealing upper seat is arranged at the upper part of the horizontal sealing lower seat by a connecting shaft; two transmission gears are respectively arranged at the other sides of the horizontal sealing upper seat and the horizontal sealing lower seat; the transmission gears are arranged on the transmission shafts; and two conducting rings are respectively arranged at the positions on the horizontal sealing upper seat and the horizontal sealing lower seat, which are at the same sides with the transmission gears. According to the invention, the horizontal sealing upper-and-down cutters are arranged externally, so that the complex process of internal assembling is avoided; the sizes of the horizontal sealing upper-and-down cutters and the number of cutter teeth on the horizontal sealing upper-and-down cutters are increased, so that the rotating speed of the machine can be reduced when the production speed is not reduced, and thus, service life of the horizontal sealing upper-and-down cutters and the conducting rings is prolonged; and the horizontal sealing upper-and-down cutters are arranged externally, so that difficulty in repair is also reduced.

Owner:台州硕邦机械有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com