Novel wind power gear box

A wind power gearbox, a new technology, applied in wind power generation, gear transmission, wind motor combination, etc., can solve the problems of internal structure impact, failure, frictional heat generation and lubrication failure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

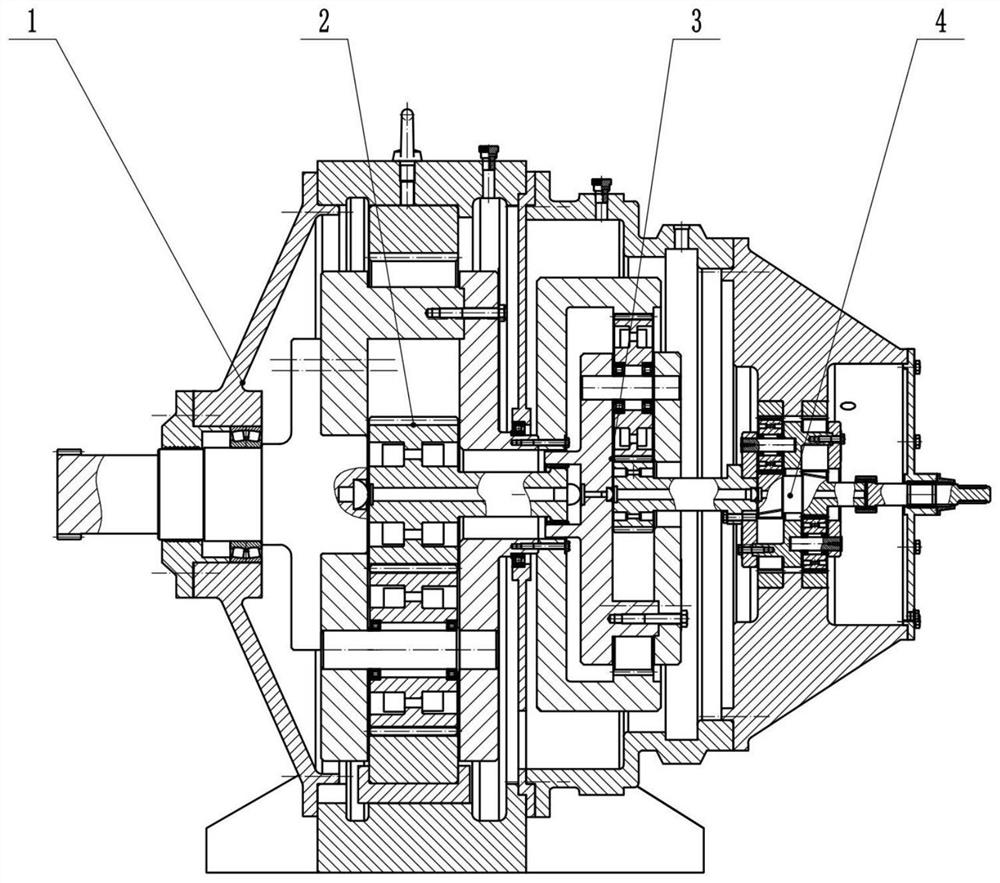

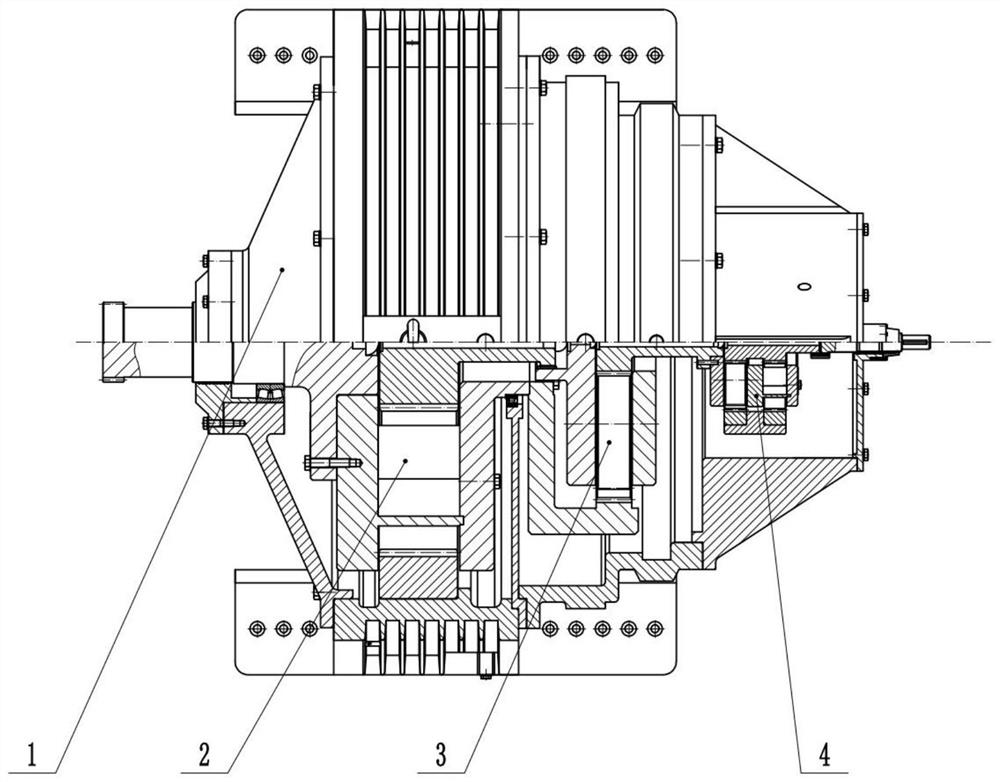

[0035] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

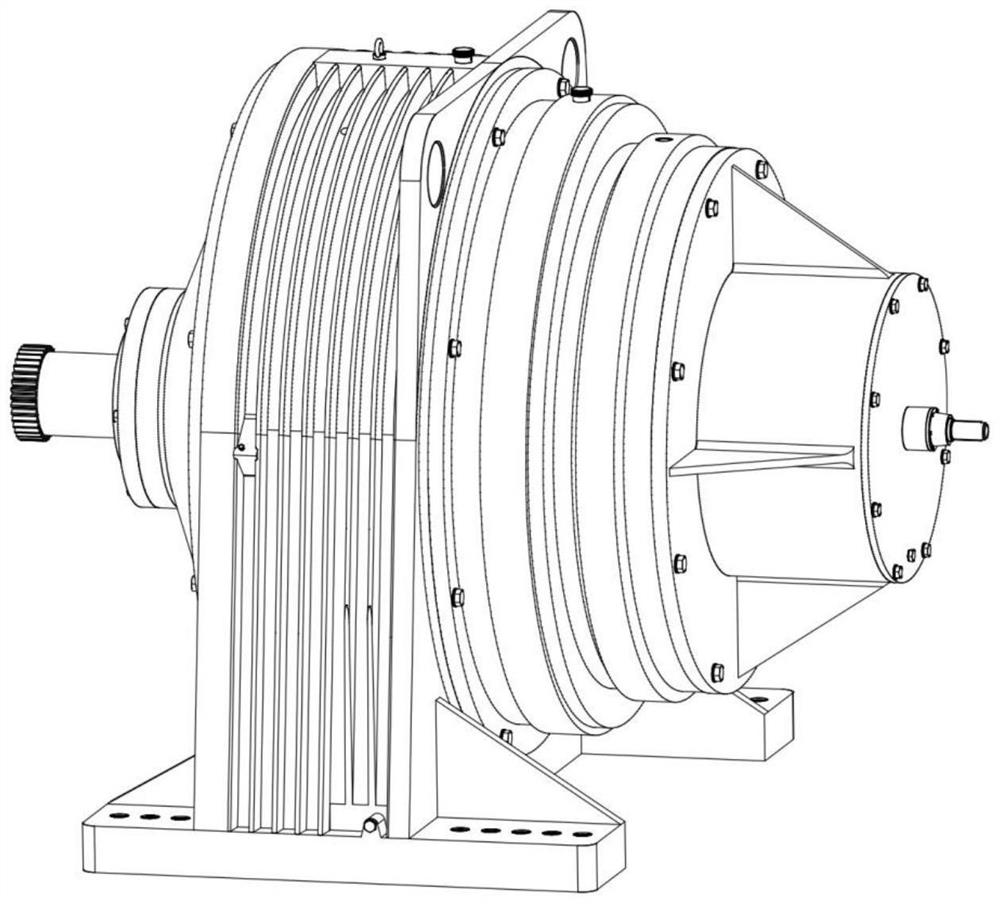

[0036] like Figure 1 to Figure 8 As shown in the figure, a new type of wind power gearbox includes a box body 1 used for supporting. The box body 1 is coaxially installed with an input end 2, an intermediate stage 3 and an output end 4, and the input end 2, the middle stage The stage 3 and the output end 4 are connected in series in sequence. The box 1 acts as the frame of the entire wind turbine gearbox, that is, supports and connects the gear train structures at all levels, and at the same time stores the lubricating oil to ensure the smooth meshing between the gears. Normal work with bearings.

[0037] The box body 1 includes an input end transparent cover 101, the input end transparent cover 101 is installed in transition fit with the input end inner hole of the input end planet carrier end cover 102 through the shaft shoulder on the inp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com