Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

56results about How to "Increase sugar production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

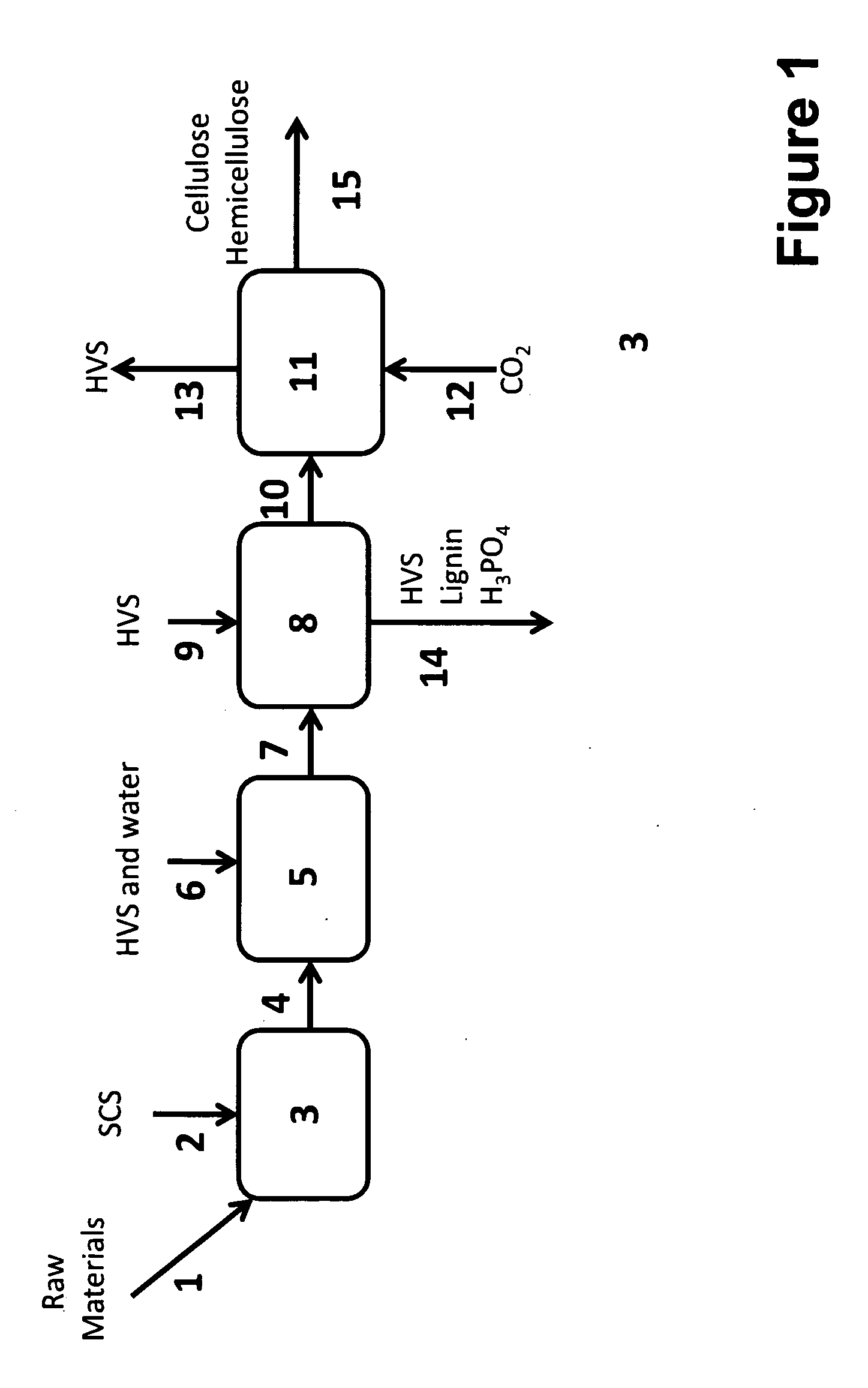

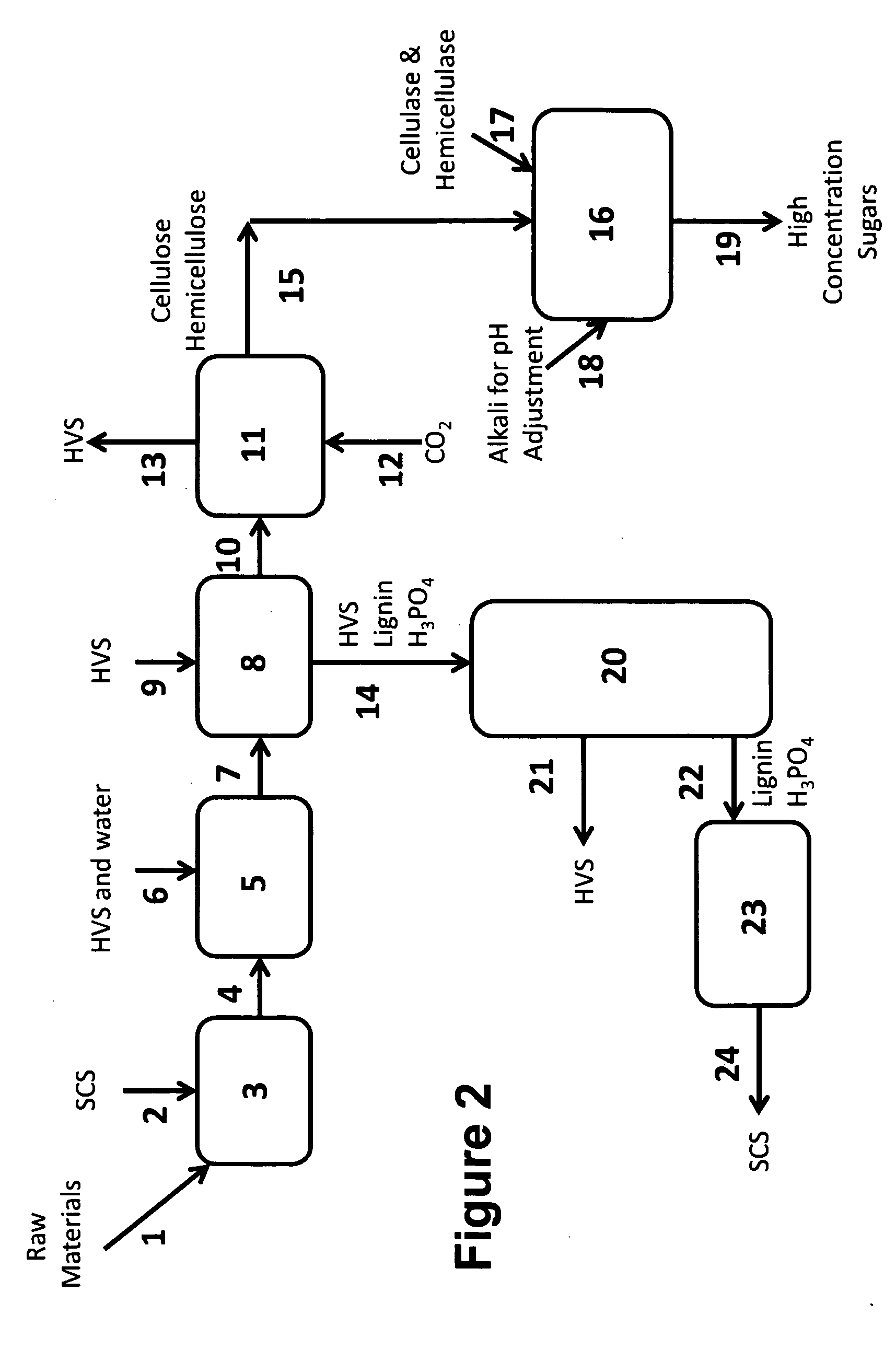

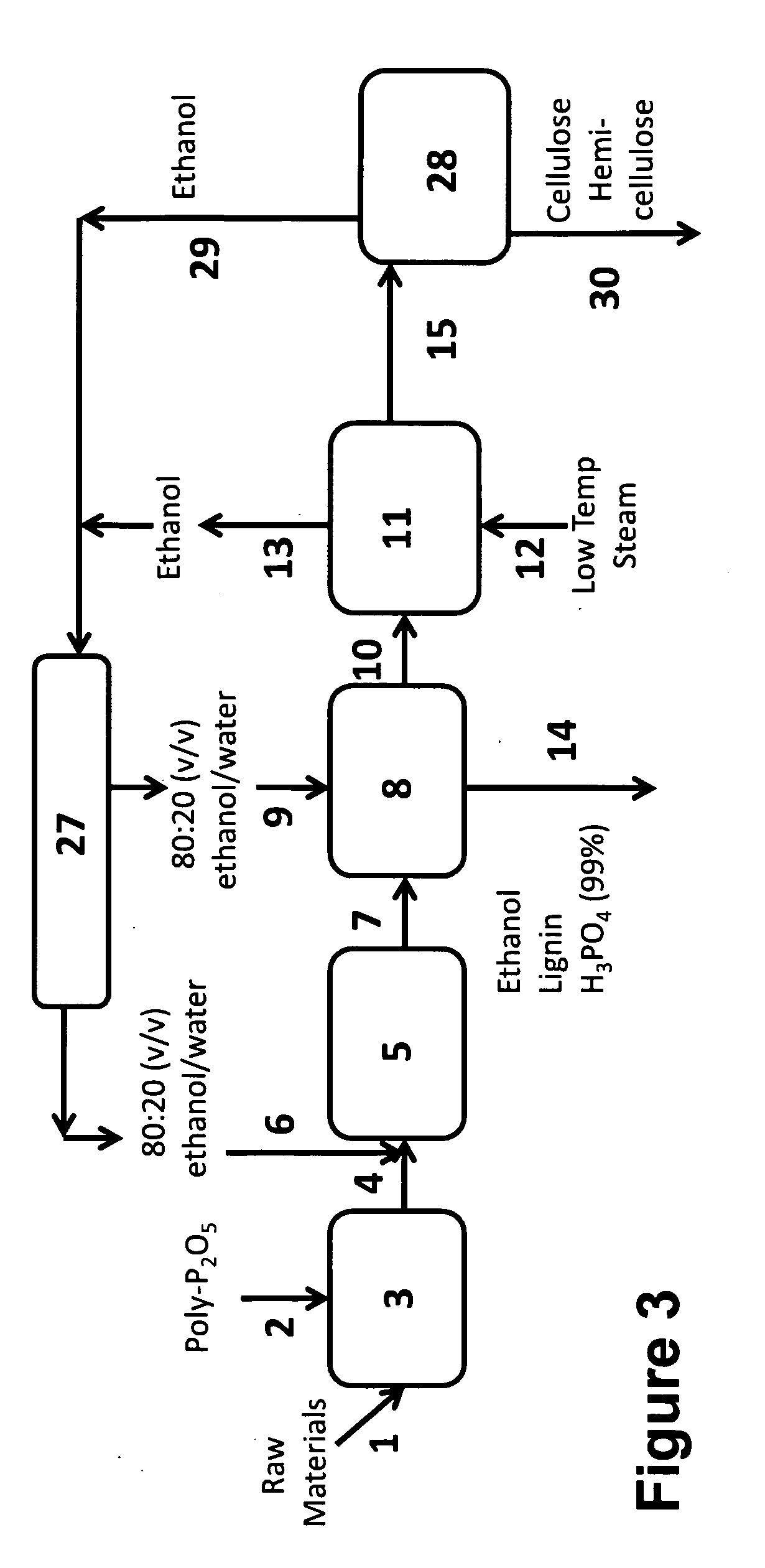

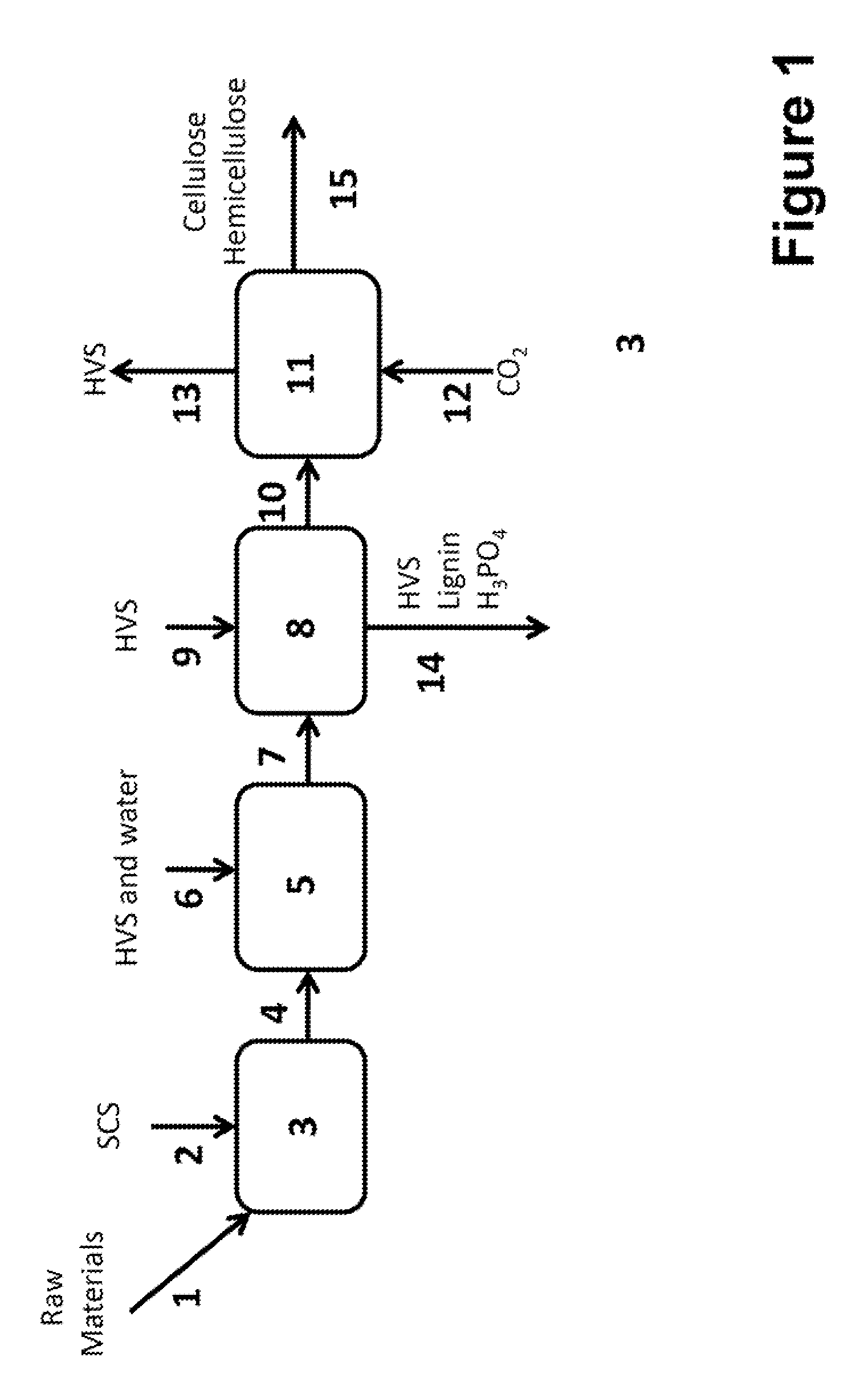

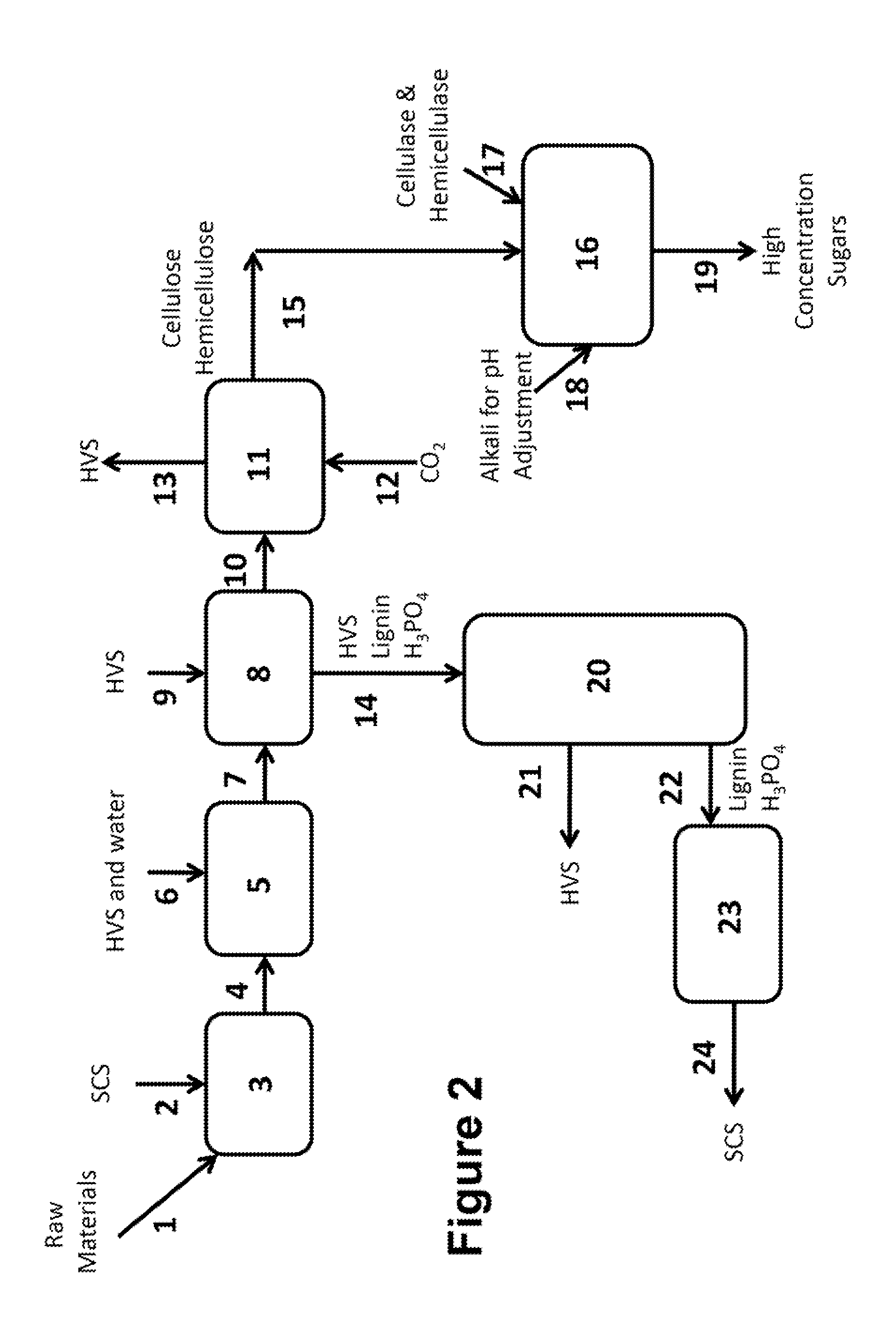

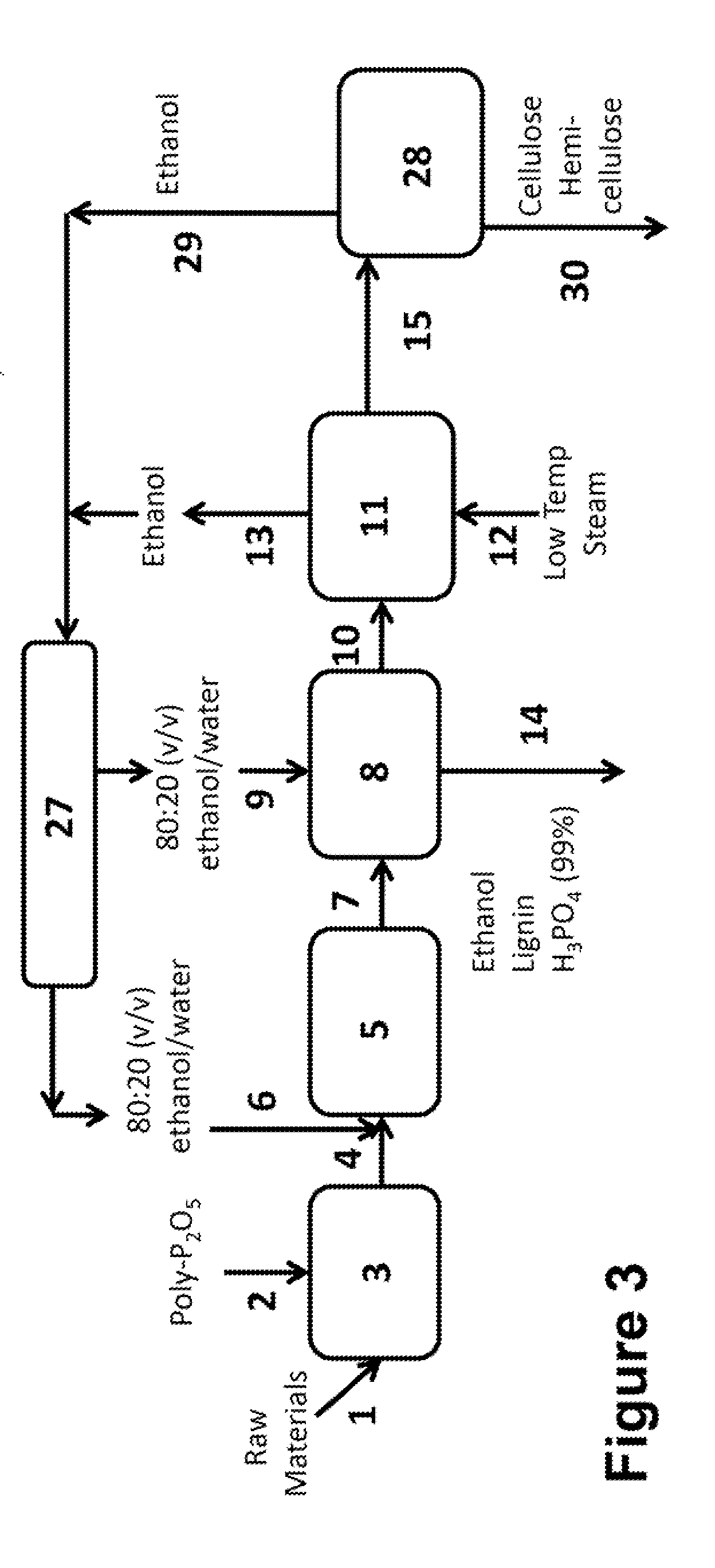

Method and apparatus for lignocellulose pretreatment using a super-cellulose-solvent and highly volatile solvents

InactiveUS20090229599A1Overcome shortcomingReduce solvent usagePressurized chemical processBiofuelsAlcoholGram

Embodiments of the present invention overcome the well-known recalcitrance of lignocellulosic biomass in an economically viable manner. A process and a system are provided for the efficient fractionation of lignocellulosic biomass into cellulose, hemicellulose, and lignin. The cellulose and hemicellulose thus obtained are highly amorphous and can be readily converted into highly concentrated mixtures of five and six carbon sugars using known methods. Typical yields of sugars exceed 100 grams of sugars per liter of sugar solution. Other products, such as alcohols, can easily be prepared according to methods of the invention. The modest process conditions and low solvent / solid ratios of some embodiments of the invention require relatively low capital and processing costs.

Owner:VIRGINIA TECH INTPROP INC

Method for recovering sulfuric acid from concentrated acid hydrolysate of plant cellulose material

ActiveUS8052953B2Reduce solubilityEasier the sugars precipitateSugar derivativesSugar crystallisationCelluloseOrganic solvent

Owner:CHEN PEIHAO

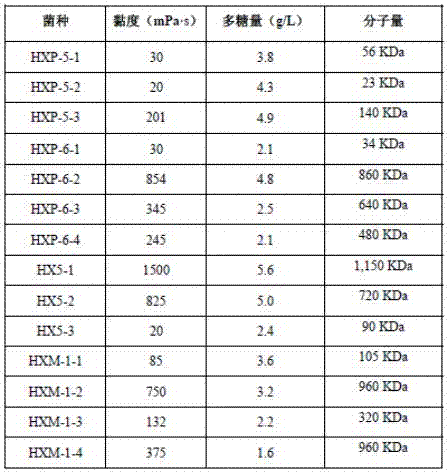

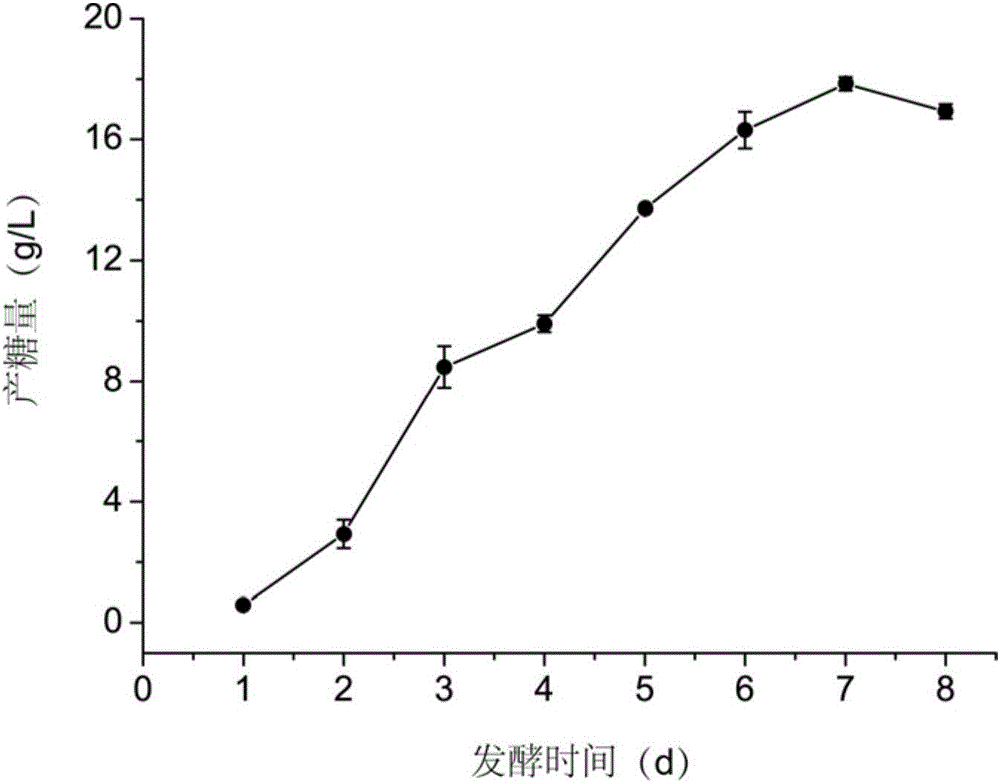

Tremella fuciformis strain and application thereof

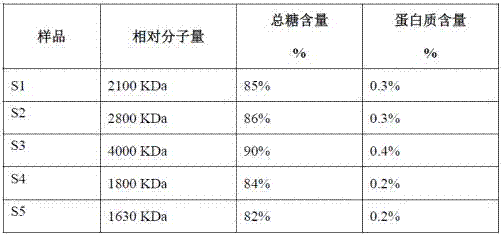

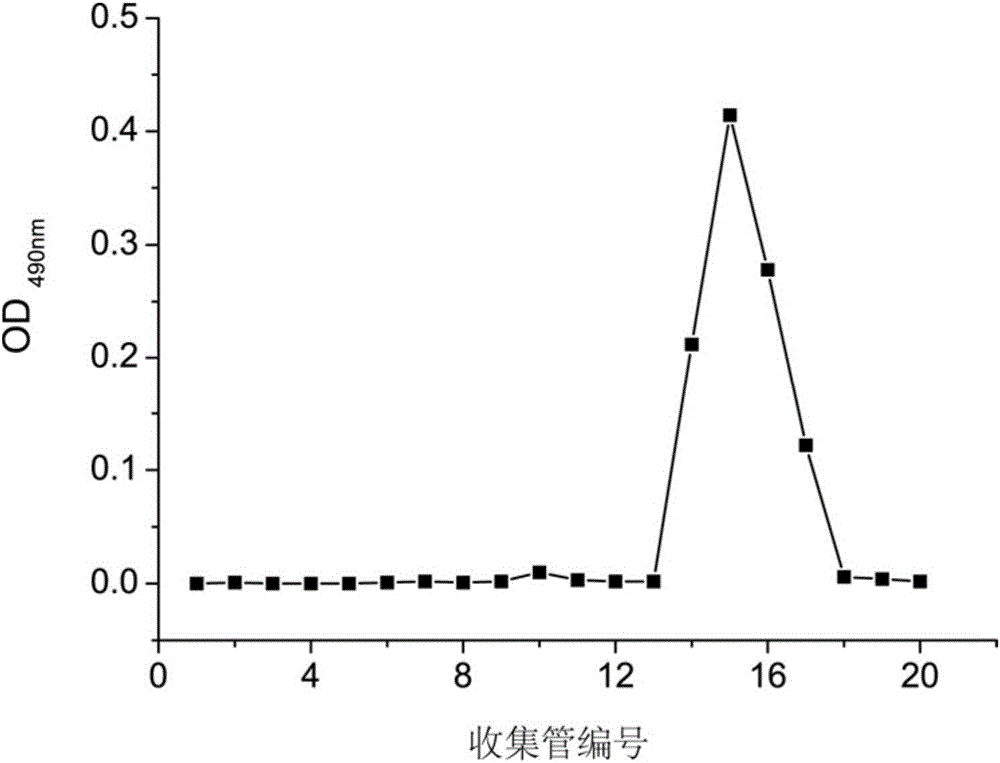

The invention discloses a tremella fuciformis spore strain HX5-1 capable of producing tremella polysaccharide in high yield. The tremella fuciformis spore strain HX5-1 is preserved in CCTCC (China Center for Type Culture Collection), and the preservation number is CCTCC M 2017271. The invention also provides a method for producing polymer tremella polysaccharide by utilizing the tremella fuciformis spore strain HX5-1 trough fermentation. A tremella polysaccharide product is obtained by adopting the steps of seed solution preparation, three-stage aerated fermentation, alcohol precipitation, decoloration, deproteinization, refining, drying and the like. According to the method provided by the invention, through the three-stage aerated fermentation, the yield of the tremella polysaccharide can be up to 18 g / L; the tremella polysaccharide product is obtained through purifying and refining, the total saccharide content is greater than 80 percent, the molecular weight is greater than 1500 KDa, the protein content is smaller than 0.5 percent, the polysaccharide content is high, the molecular weight is high, and a wide application prospect in tremella fuciformis industrial production is obtained.

Owner:BLOOMAGE BIOTECHNOLOGY CORP LTD +1

Production process of sugarcane slow release fertilizer

InactiveCN102731214AMeet the nutritional needs of growthSolve outputFertilizer mixturesRoot growthPotassium

The invention relates to a production process of a sugarcane slow release fertilizer, belonging to the technical field of fertilizers. The production process adopts a fertilizer wrapping fertilizer process to prepare a wrapped fertilizer type efficient slow release fertilizer for sugarcane, the combination of three main nutrient fertilizers of nitrogen, phosphorus and potassium is realized, and a three-element compound fertilizer is formed; according to the nutritional requirement of the growth of sugarcane, nitrogen fertilizer urea serves as a core layer, a potassium fertilizer serves as a middle layer, and a phosphorus fertilizer serves as an outer layer; and when the sugarcane slow release fertilizer serves as a base fertilizer and is applied to soil together with sugarcane seeds, the sugarcane slow release fertilizer can meet the nutritional requirement of the sugarcane for the whole life, firstly, at the growth prophase, the phosphorus fertilizer and the potassium fertilizer are released to promote the root growth and tiller of the sugarcane, and at the growth metaphase of the sugarcane, the nitrogen fertilizer of the core layer is released to promote the great growth of the sugarcane. The sugarcane slow release fertilizer is applied once when the sugarcane is planted, and the whole growing season does not need fertilization, so that the problems that the sugarcane is fertilized for many times, a lot of manpower and financial resources are consumed, and the sugarcane is low in yield and sugar content at present can be effectively solved.

Owner:GEJIU LVBAO COMPOUND FERTILIZER

Universal slow release fertilizer for sugarcane

InactiveCN103232305AImprove germination rateImprove tillering rateAgriculture gas emission reductionFertilizer mixturesNitrogenChloride

The invention relates to a universal slow release fertilizer for sugarcane, and scientifically proposes a slow release fertilizer formula, namely N:P2O5:K2O equals to 15:10:5, suitable for wide sugarcane producing areas in China according to a nitrogen, phosphorus and potassium application principle, the nutrient status of soil of the main sugarcane producing areas in China and a fertilizer requirement law of sugarcane. In the formula, the total nutrient content is 30%. The slow release fertilizer is prepared by mixing the following raw materials according to mass ratio: 310-326 kg of urea containing 46% of N, 0-82 kg of monoammonium phosphate containing 49% of P2O5 and 9% of N, 333-556 kg of calcium magnesium phosphate containing 18% of P2O5, 83kg of potassium chloride containing 60% of K2O, 8kg of a fertilizer inhibitor, 2kg of a fertilizer synergist and 25-182kg of fillers.

Owner:云南中蔗农业科技有限责任公司 +1

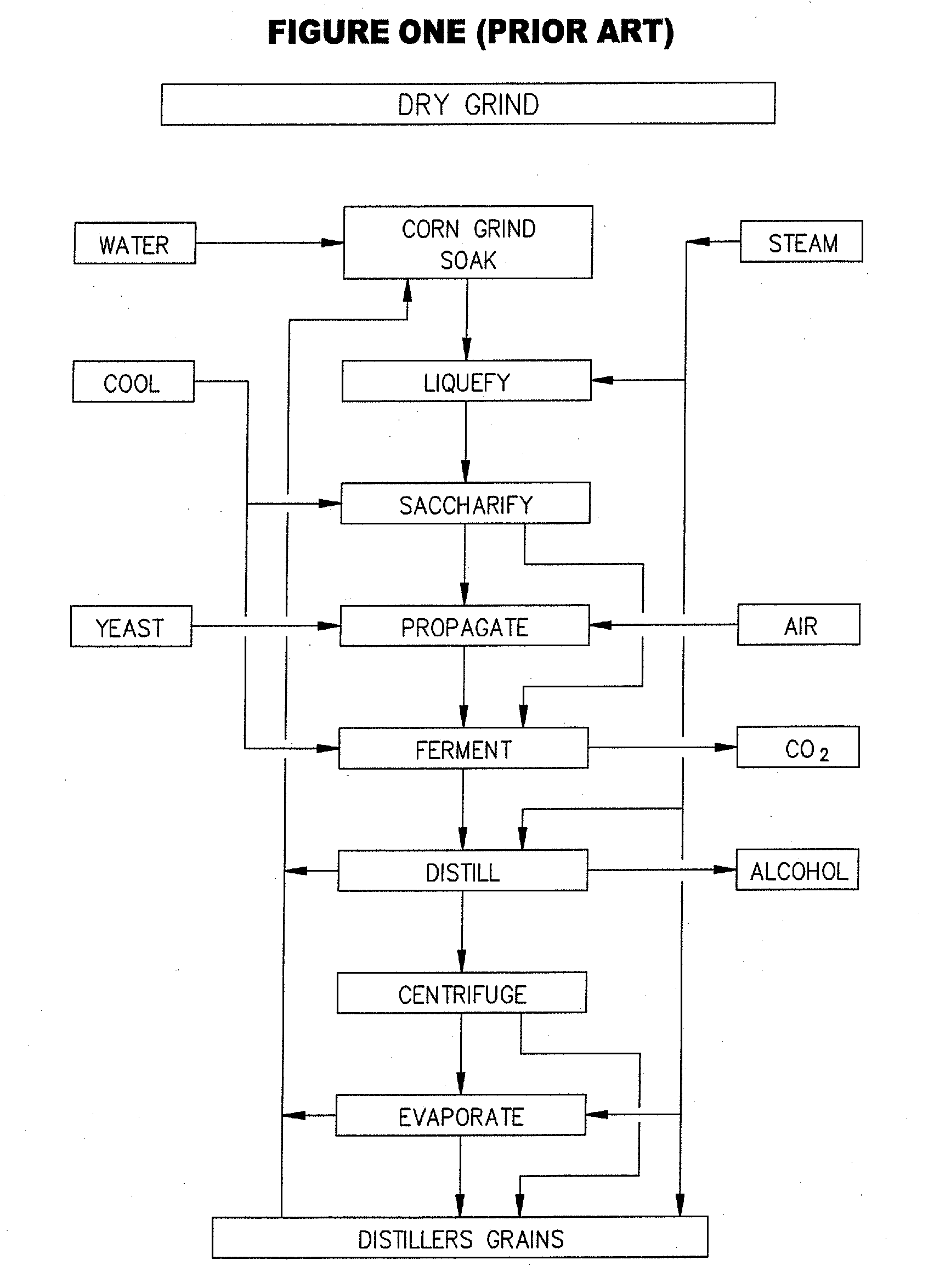

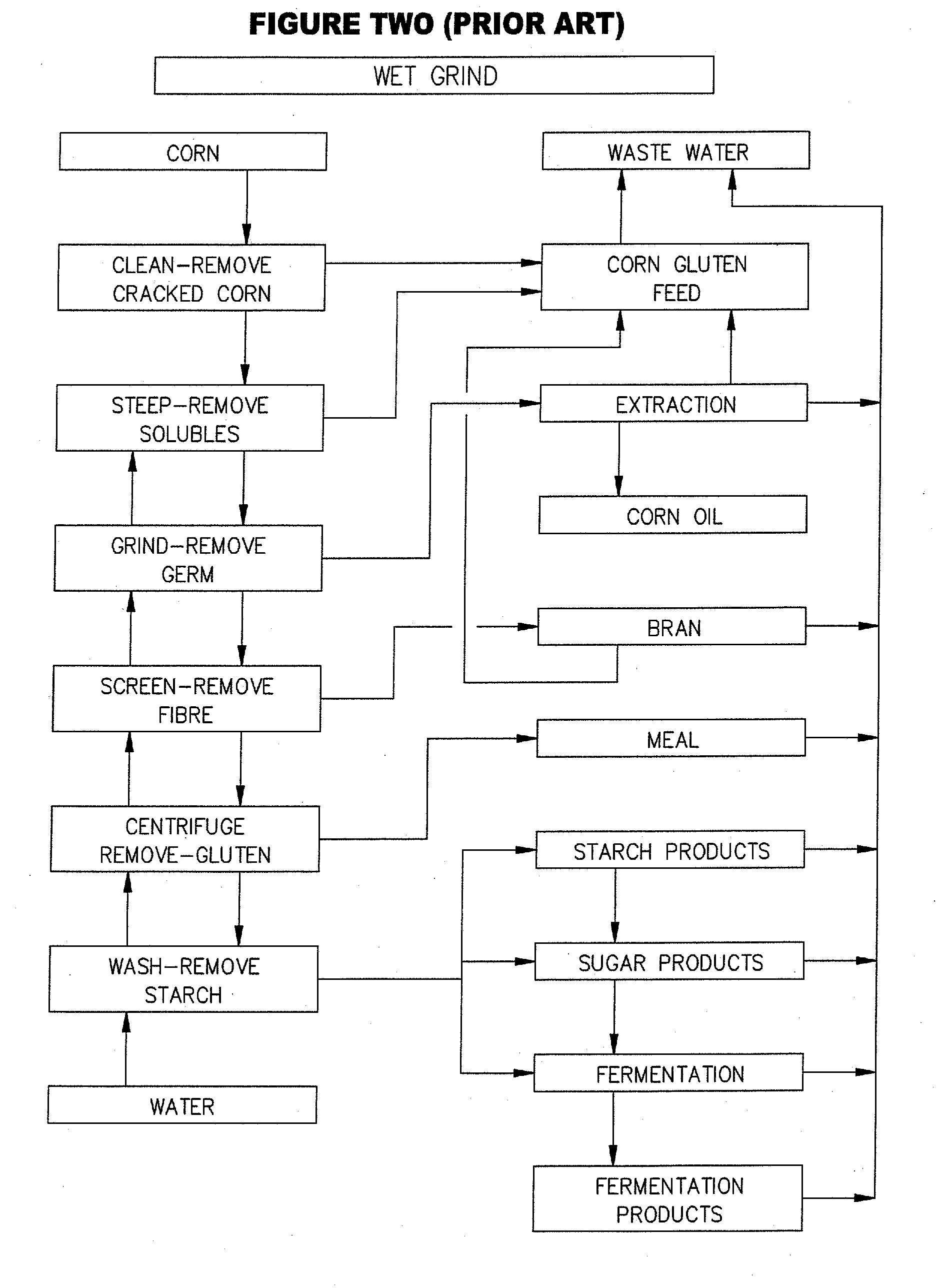

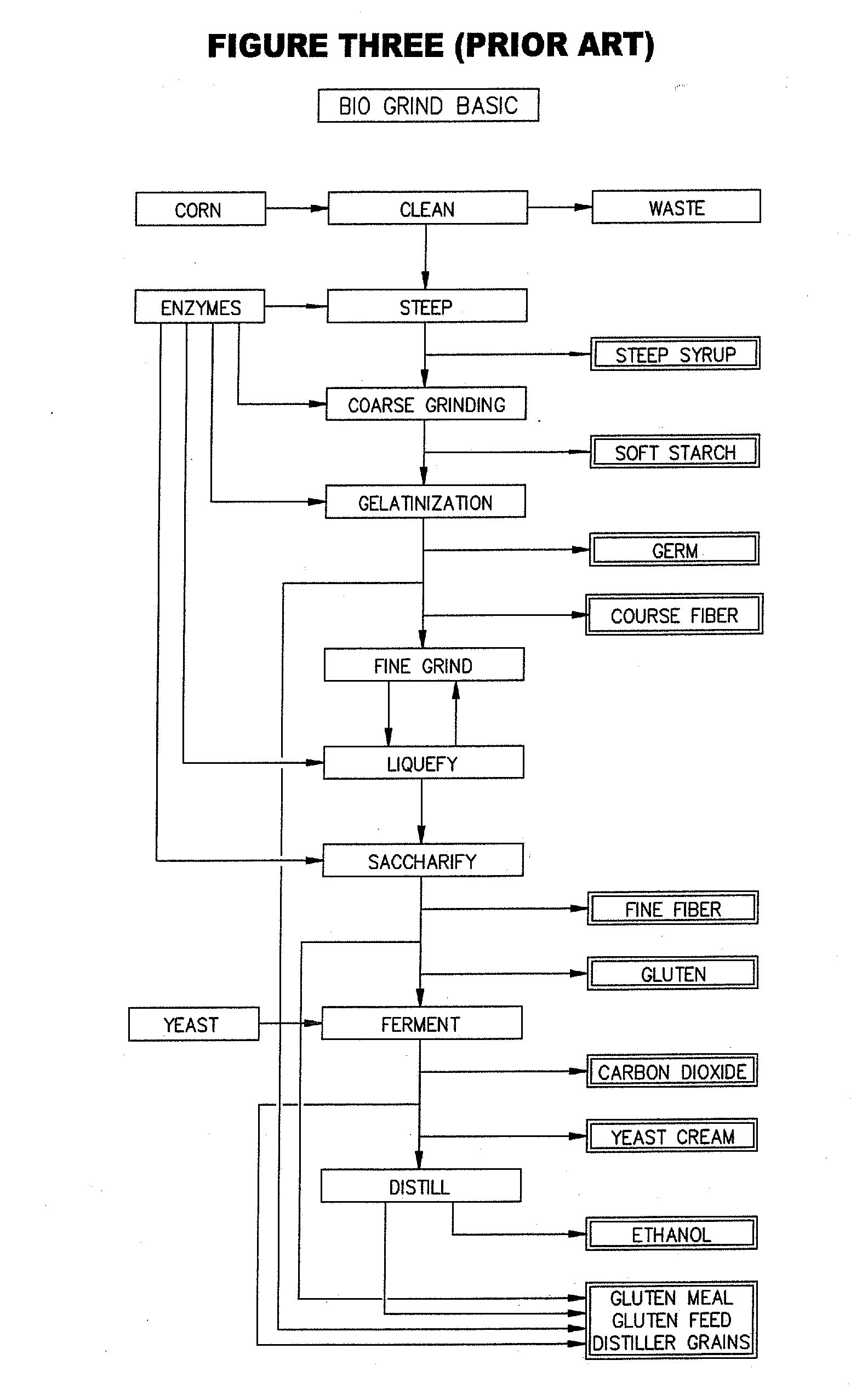

Simultaneous Food And Fuel Corn Refining

InactiveUS20140273140A1Significant improvementSpeed up the processFood processingChemical industryCelluloseEnergy products

Food grade products are given priority with a sustainable integrated corn based bio grind refining process. Premium fractions are fractionated for human foods and premium fermentable products. The balance food feedstocks are refined for animal feed with no loss of nutritional value. By-products of refining are used to produce ethanol and other energy products. There is no process waste. The integrated processes can be adapted to new continuous refineries or to optimize or retrofit one or more individual process steps. Plants located in remote growing areas can be pre-fabricated and shipped for operating of smaller plants utilizing batch and manual operation of one or more key steps or be continuous, automated, and operated simultaneous with food grade fractionated pre-ethanol process followed by cellulose processing for additional yield.

Owner:LANGHAUSER ASSOC

Method for producing microbial polysaccharide fermentation broth by using Paenibacillus mucilaginosus

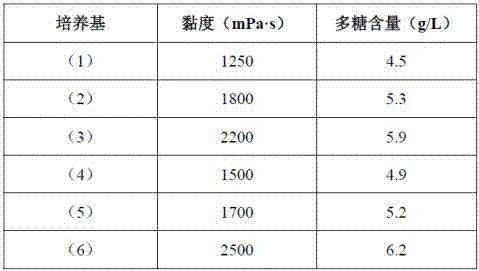

ActiveCN102952834AHigh viscosityImprove the finishMicroorganism based processesFermentationCulture mediumsBacteroides species

The present invention belongs to microbial polysaccharide fermentation, and particularly relates to a method for producing a microbial polysaccharide fermentation broth by using Paenibacillus mucilaginosus, wherein Paenibacillus mucilaginosus is inoculated in a culture medium containing a carbon source and a nitrogen source to carry out fermentation, and bacteria heat stimulation, addition of a surfactant during a fermentation process, and other manners are performed to optimize the production process. With the present invention, the problem of low yield of polysaccharides in the fermentation broth in the prior art is solved, and advantages of high polysaccharide yield in the fermentation broth, good bacterial growth, short fermentation period and the like are provided.

Owner:河北省微生物研究所有限公司

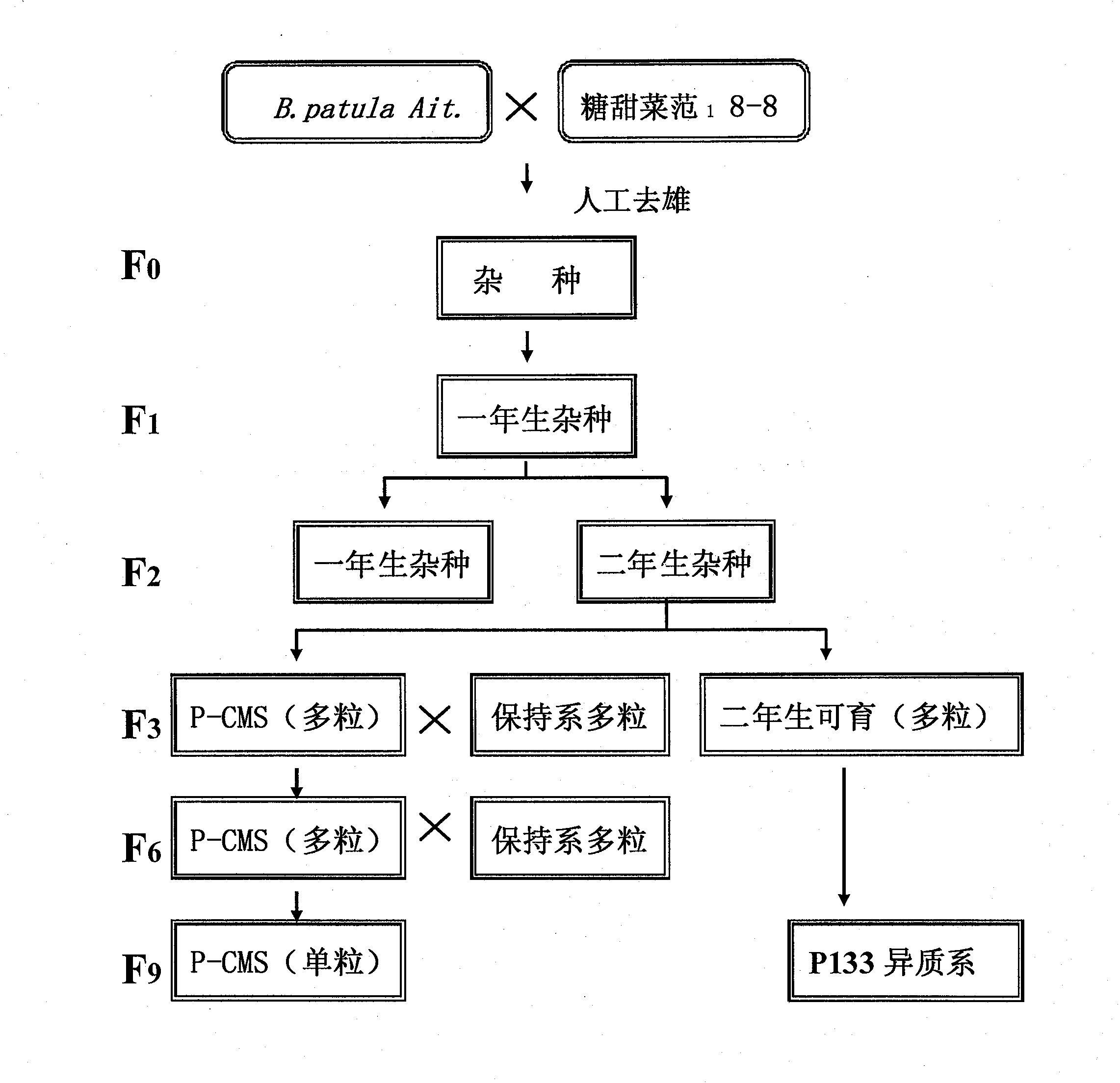

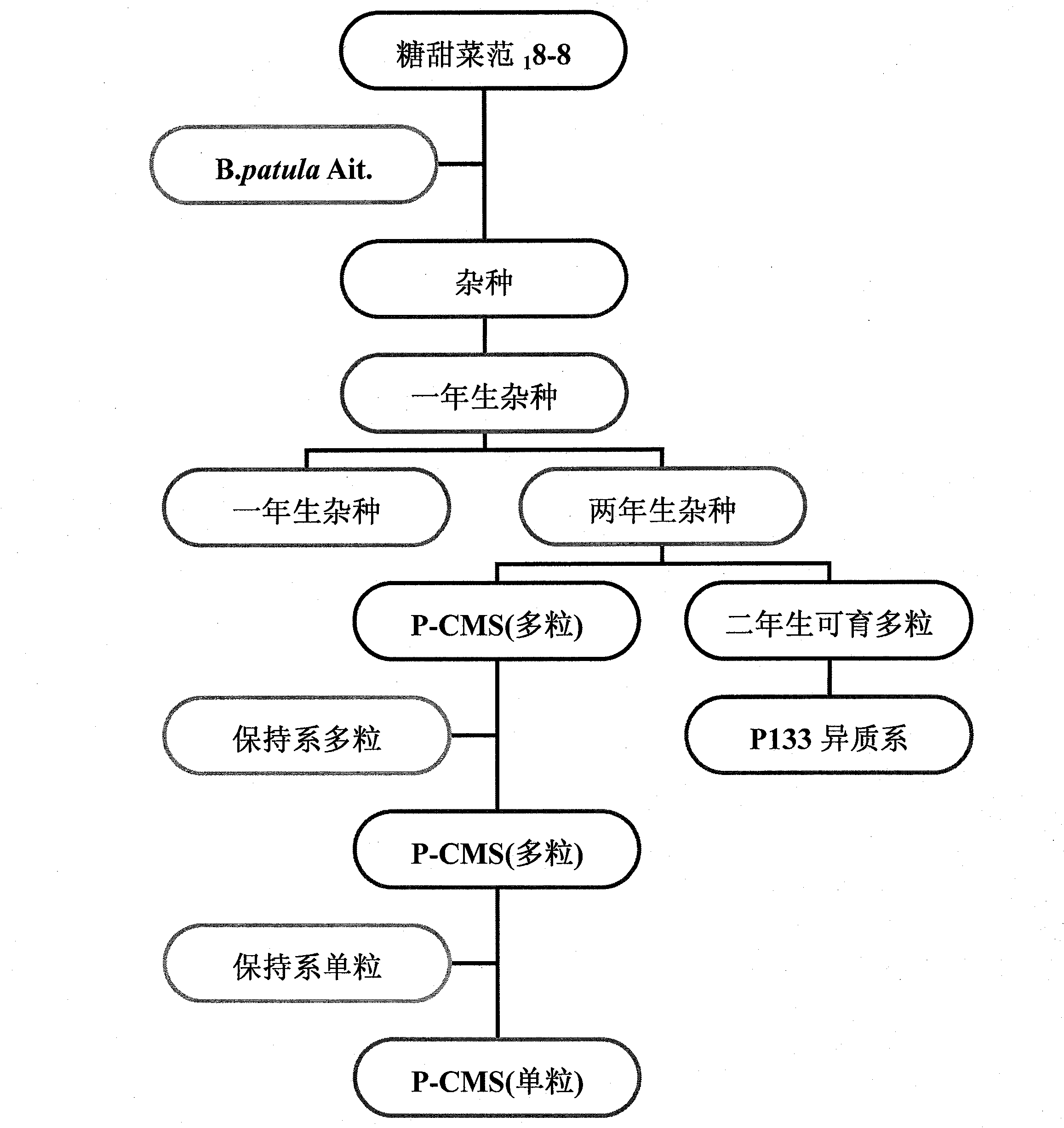

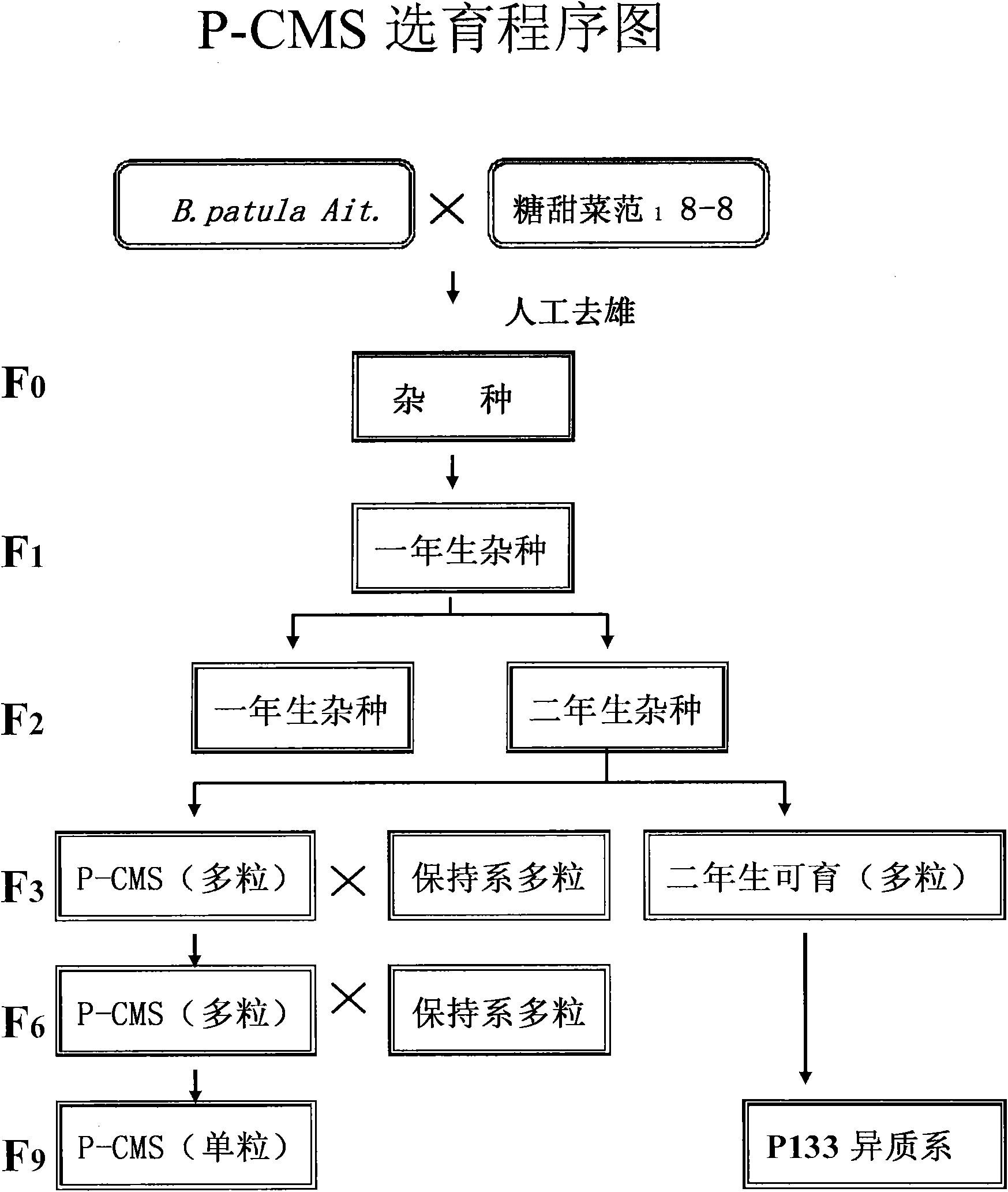

Creation of beet novel cytoplasmic male sterile (P-CMS) line

InactiveCN102461460AIncrease the sugar contentIncrease sugar productionPlant genotype modificationBiotechnologyGenetic diversity

The beet novel cytoplasmic male sterile (P-CMS) line is a male sterile line containing wild beet cytoplasm, which is obtained by separating and screening in a hybridized descendant with a core substitution and separation selection method by hybridizing wild beet seed (B.patula Ait.) with sugar beets by the Heilongjiang University. The male sterile line is cultured into a single-seed cytoplasm male sterile line with the wild beet seed B.patula Ait. cytoplasm by multiple improvements. The scientific research result can adopt the cytoplasm male sterile line with the proprietary intellectual property rights as a hybridized carrier for genetic improvement and for widening the genetic basis of the Chinese beet so as to culture and combine to obtain the new beet varieties with the excellent genetic resource. According to the implementation of the invention item, the Chinese beet seed culturing work is like a winding path along mountain ridges on the genetic basis, is not limited by others, and is improved on the genetic diversity to a large extent.

Owner:HEILONGJIANG UNIV

Special medium-concentration slow release fertilizer for sugarcanes

InactiveCN102718602AImprove germination rateImprove tillering rateFertilizer mixturesPotassiumNitrogen

The invention relates to a special medium-concentration slow release fertilizer for sugarcanes. The slow release fertilizer contains nitrogen, phosphorus and potassium according to the ratio that nitrogen: phosphorus: potassium equals 20: 10: 5. The special medium-concentration slow release fertilizer disclosed by the invention can effectively improve the emergence rate, tillering rate and plant height of the sugarcanes and significantly improve the agricultural yield and sugar yield of the sugarcanes; tests prove that the yield per unit of the sugarcanes and the sugar yield of the sugarcanes are improved; and the quality of the sugarcanes is obviously improved, and the special medium-concentration slow release fertilizer is more suitable for being applied to soil with medium-concentration fertilizers in sugarcane areas in tropical and sub-tropical regions in southern China.

Owner:SUGARCANE RES INST OF YUNNAN ACADEMY OF AGRI SCI +1

Method for recovering sulfuric acid from concentrated acid hydrolysate of plant cellulose material

ActiveUS20100284900A1Reduce solubilityEasy sugar precipitateSugar derivativesSugar crystallisationCelluloseOrganic solvent

A method for recovering sulfuric acid from concentrated acid hydrolysate of plant cellulose material is disclosed. In some of the examples, the concentrated acid hydrolysate is mixed with a liquid organic precipitant, thereby the sugars in the hydrolysate is precipitated and separated out, and the remained is sulfuric acid and an organic solvent solution. Then the organic solvent is separated by distillation or extraction, thereby obtaining the pure sulfuric acid solution. This precipitation method can recover above 90% sugars and acids with a small amount of organic precipitant, which greatly reduces the recover cost. In the other examples, the method includes: mixing the concentrated acid hydrolysate with a water-immiscible alcohol, thereby separating the sugars with a remainder of acid-alcohol solution containing sulfuric acid; contacting the acid-alcohol solution with water, thereby the sulfuric acid enters into the water phase from the organic phase; then separating the organic phase and the water phase, thereby obtaining the sulfuric acid solution. This method avoids the use of poisonous, inflammable and explosive organic solvents and also avoids the energy consumption for recovering these organic solvents, thereby greatly reducing the cost of acid recovery.

Owner:CHEN PEIHAO

Enzymolysis saccharification processing method of straw

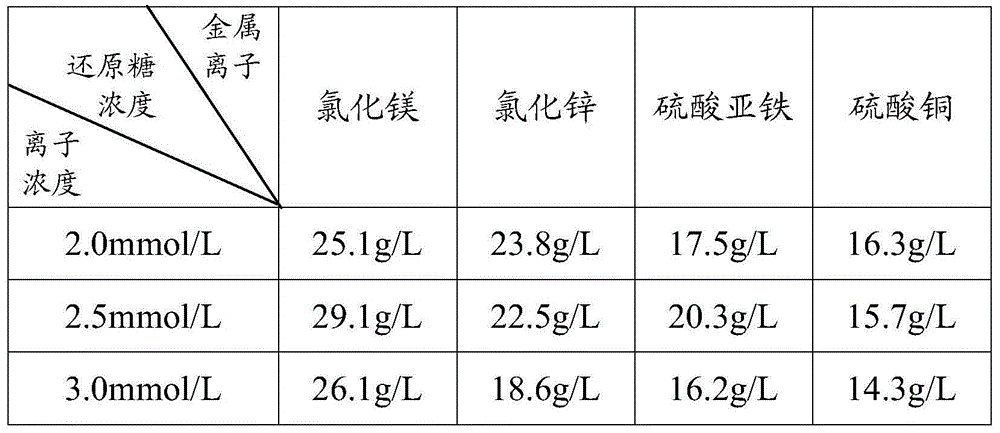

InactiveCN104561129AImprove the effect of enzymatic hydrolysis and saccharificationIncrease sugar productionBiofuelsFermentationCelluloseDistilled water

The invention discloses an enzymolysis saccharification processing method of straw. The enzymolysis saccharification processing method comprises the following steps: 1) drying straw in the sun, crushing the dried straw, and sieving the crushed straw by a sieve so as to obtain straw powder; 2) adding the straw powder in a diluted hydrochloric acid to perform an acidizing reaction, and enabling the temperature to be lowered to a room temperature when the reaction ends so as to obtain a straw serosity; 3) adding cellulose, xylanase, magnesium chloride, Twain 80 and distilled water in the straw serosity so as to obtain an enzymolysis serosity, and then performing an enzymolysis saccharification reaction. The enzymolysis saccharification processing method of straw, which is disclosed by the invention, can obviously improve the enzymolysis saccharification effect of the straw.

Owner:XINXIANG MEDICAL UNIV

Chemical fertilizer for sugarcane and preparation method thereof

InactiveCN104326783AIncrease productionIncrease sugar productionFertilizer mixturesLeavening agentNitrogen fertilizer

The invention discloses a chemical fertilizer for sugarcane and a preparation method thereof. The chemical fertilizer for sugarcane is prepared from the following ingredients in parts by mass: 10-14 parts of nitrogen fertilizer, 8-12 parts of phosphatic fertilizer, 14-18 parts of potassic fertilizer, 30-40 parts of mushroom dreg, 20-30 parts of kelp dreg, 50-60 parts of rice hull, 80-100 parts of rotten duck manure, 30-50 parts of decomposed coal, 20-40 parts of peat soil, 20-30 parts of distiller grain, 3-5 parts of leavening agent and 80-100 parts of water. The chemical fertilizer for sugarcane has simple formula, the nitrogen fertilizer, the phosphatic fertilizer and the potassic fertilizer are mixed with organic fertilizer to prepare the chemical fertilizer special for sugarcane, and the chemical fertilizer can improve the sugarcane yield and the sugar yield after being applied.

Owner:张美丽

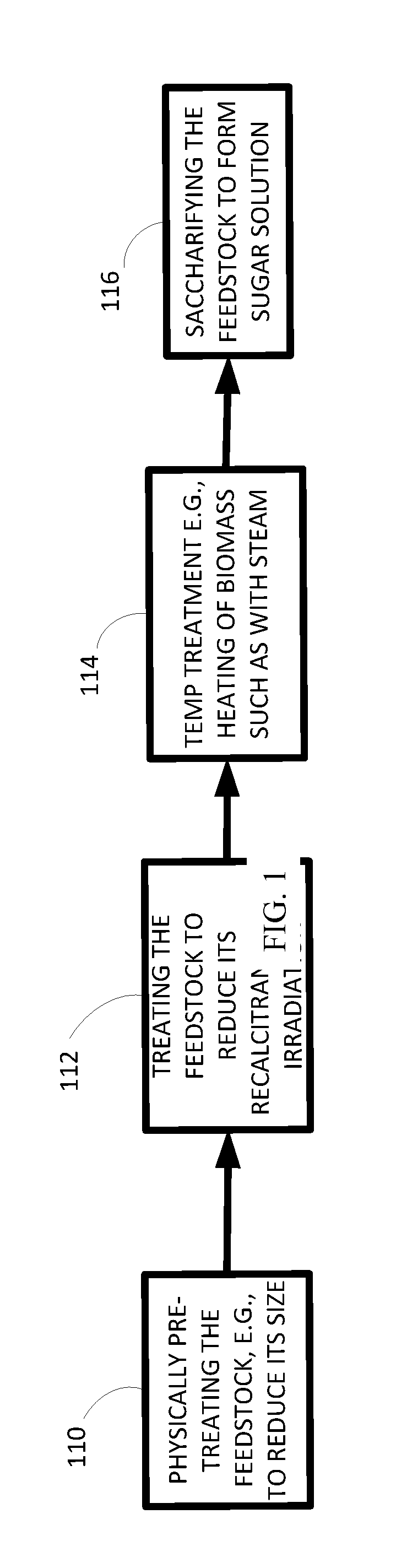

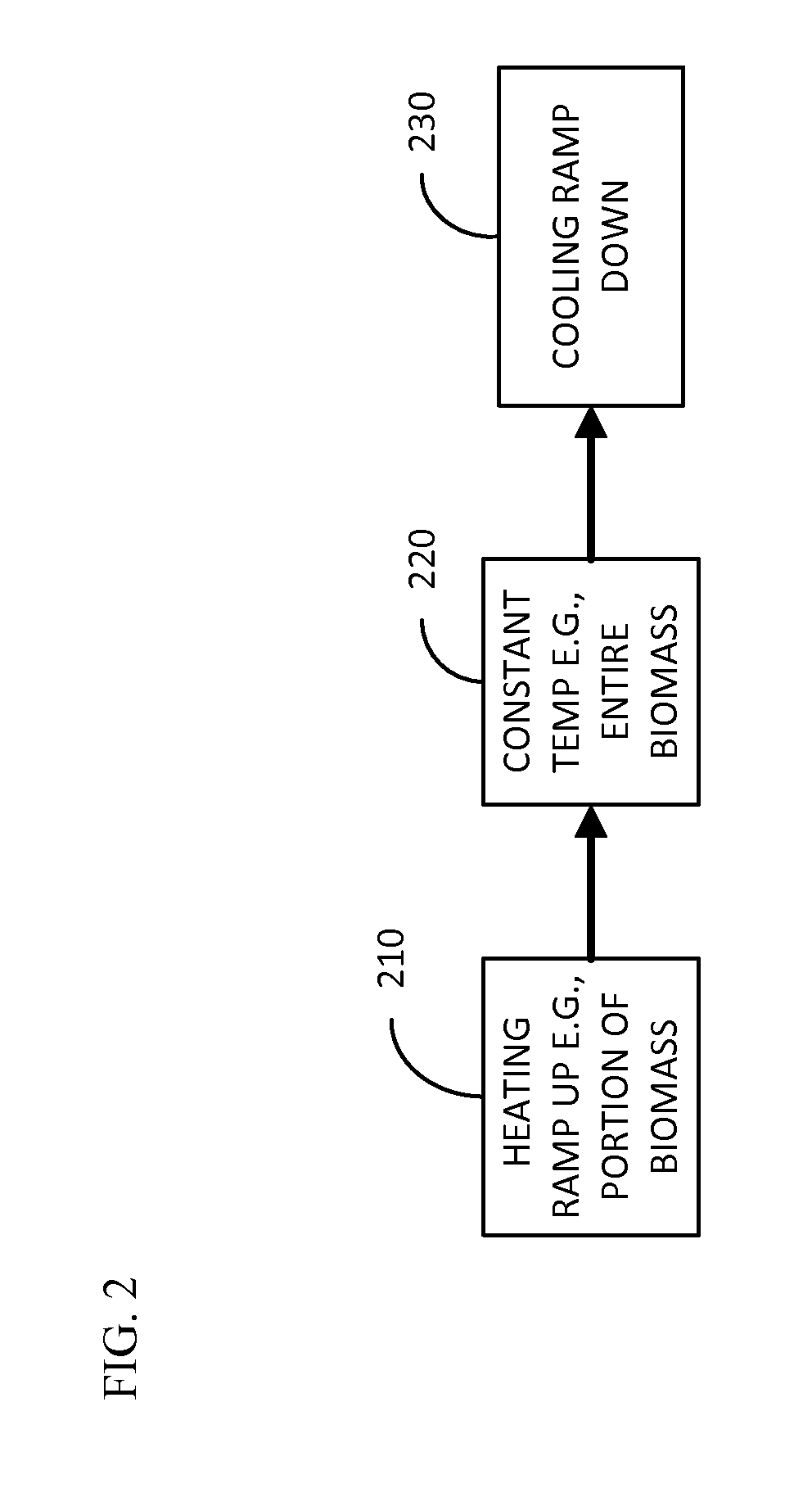

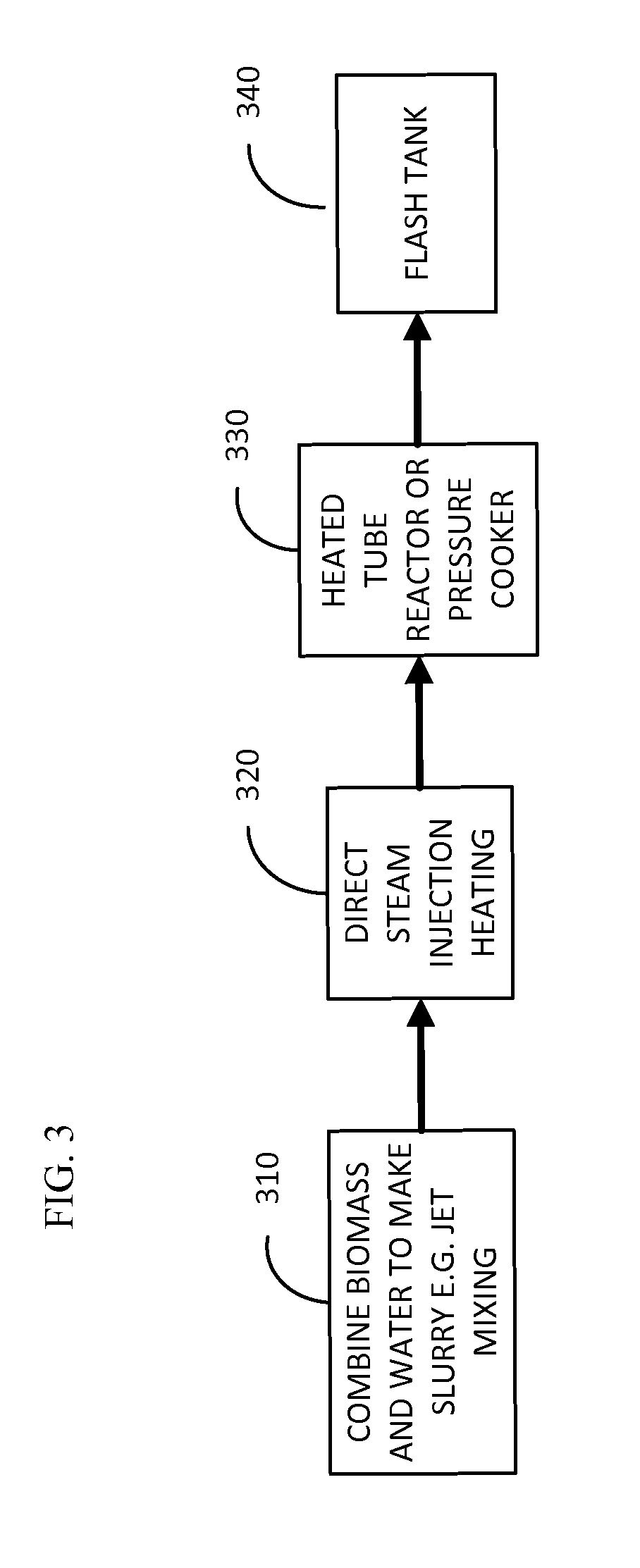

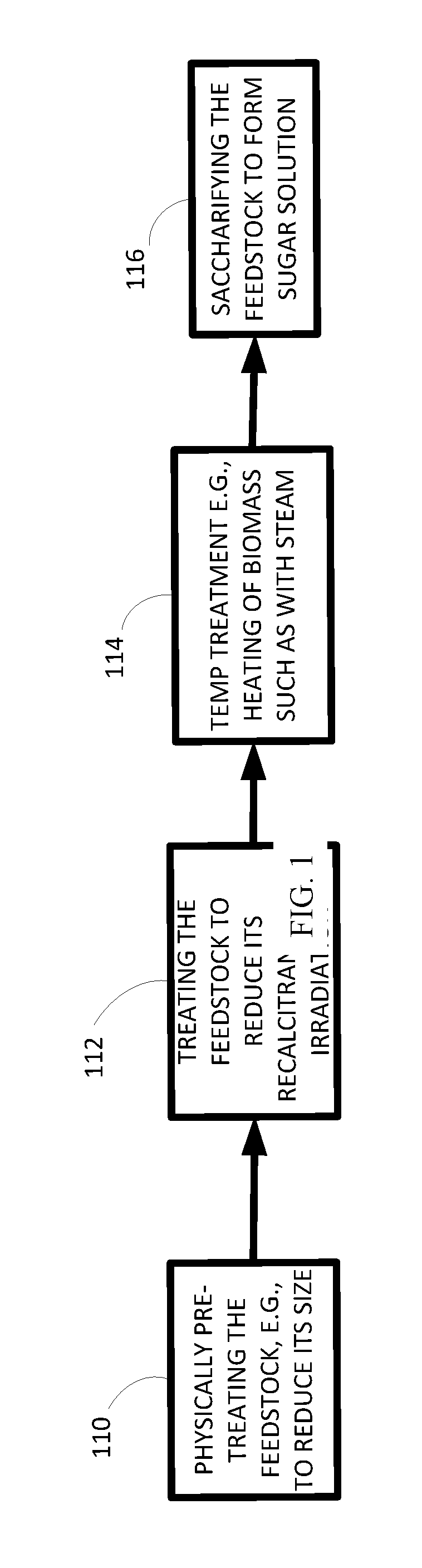

Processing biomass

InactiveUS20160017444A1Increase sugar productionImprove production yieldBiofuelsXylose productionSugar yieldBiomass

Owner:XYLECO INC

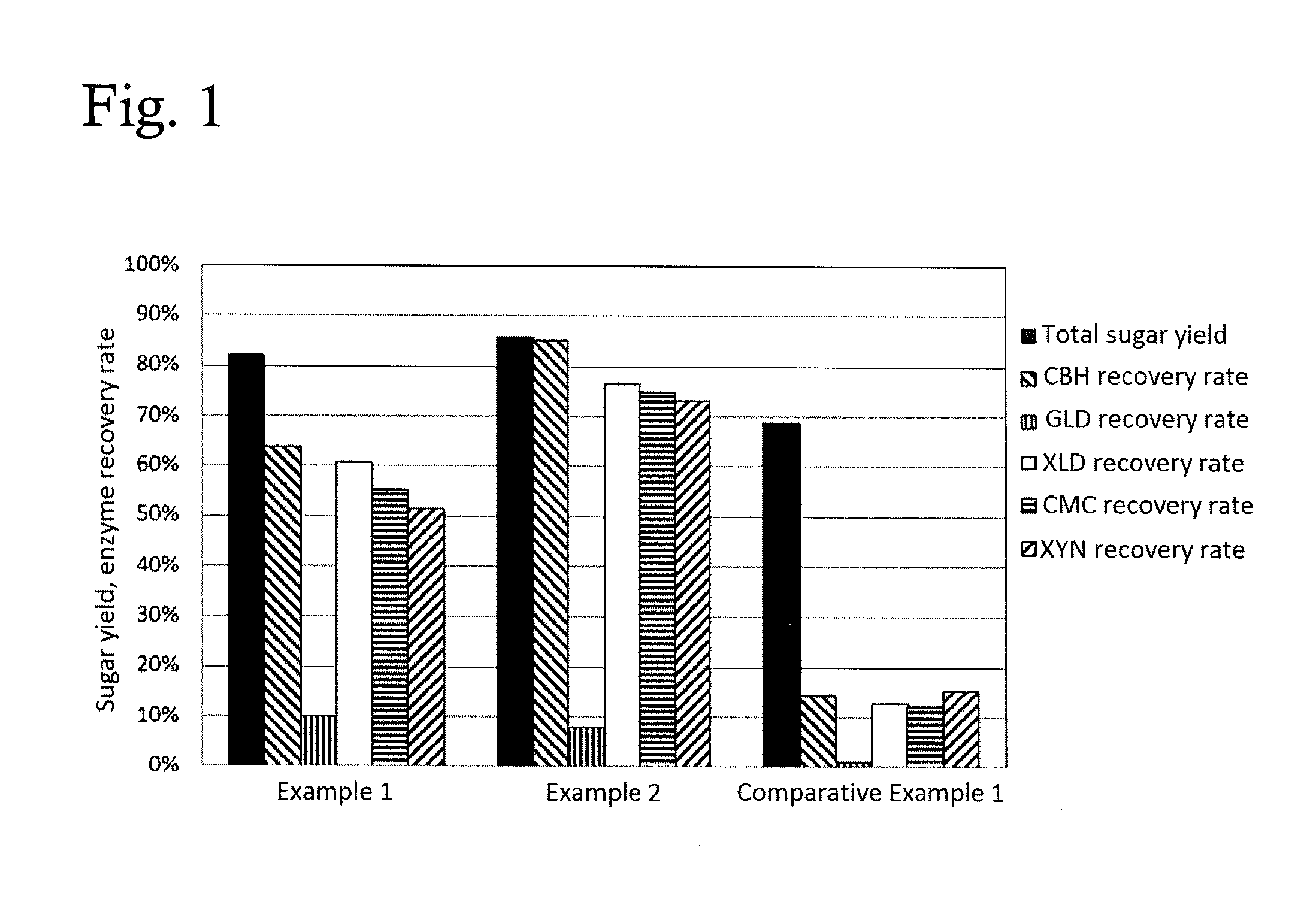

Method for saccharification of biomass

InactiveUS20150005484A1Improve fermentation effectReduce loadSugar derivativesBiofuelsCellulosePulp and paper industry

A method for saccharification of lignocellulosic biomass, the method comprising (1) a pretreatment step of impregnating lignocellulosic biomass with an aqueous alkali solution, subjecting the resultant mixture to solid-liquid separation to remove part of the aqueous alkali solution, and then performing heat treatment, and (2) a saccharification step of enzymatically degrading the lignocellulosic biomass resulting from the pretreatment step to obtain a saccharified liquid can be applied to high-lignin lignocellulosic biomass, reduce the usage of alkali and water in the pretreatment step, increase the sugar yield in the saccharification step, decrease the reaction time, reduce enzyme adsorption on a biomass residue, and improve the enzyme recovery rate.

Owner:NIPPON SHOKUBAI CO LTD

Special long-acting slow release fertilizer for sugarcane

InactiveCN103214309AMeet the nutrient needs of the growth periodReduce manufacturing costFertilizer mixturesSludgeTropics

The invention discloses a special long-acting slow release fertilizer for sugarcane. The slow release fertilizer contains nitrogen, phosphorus and potassium according to a ratio of 20:12:5. The slow release fertilizer comprises the following raw materials by mass ratio: 96-190 of ammonium dihydrogen phosphate containing 49% of P2O5 and 9% of N, 149-405 of a calcium magnesium phosphate fertilizer containing 18% of P2O5, 398-416 of urea containing 46% of N, 83 of potassium chloride containing 60% of K2O and 0-180 of a packing material. The packing material is a mixture of clay and dry lime sludge in a mass ratio of (3-7):(7-3); and the water content of the dry lime sludge is controlled to be 5%-10%. By utilizing the fertilizer, the emergence rate, tillering rate and plant height of the sugarcane can be effectively increased, the agricultural yield and sugar yield of the sugarcane are obviously improved, and tests prove that the yield per unit and the sugar yield of the sugarcane are improved; and the quality of the sugarcane is obviously improved, and the fertilizer is applicable to soil with the medium fertility in the sugarcane areas of southern tropics and subtropics in China.

Owner:云南中蔗农业科技有限责任公司 +1

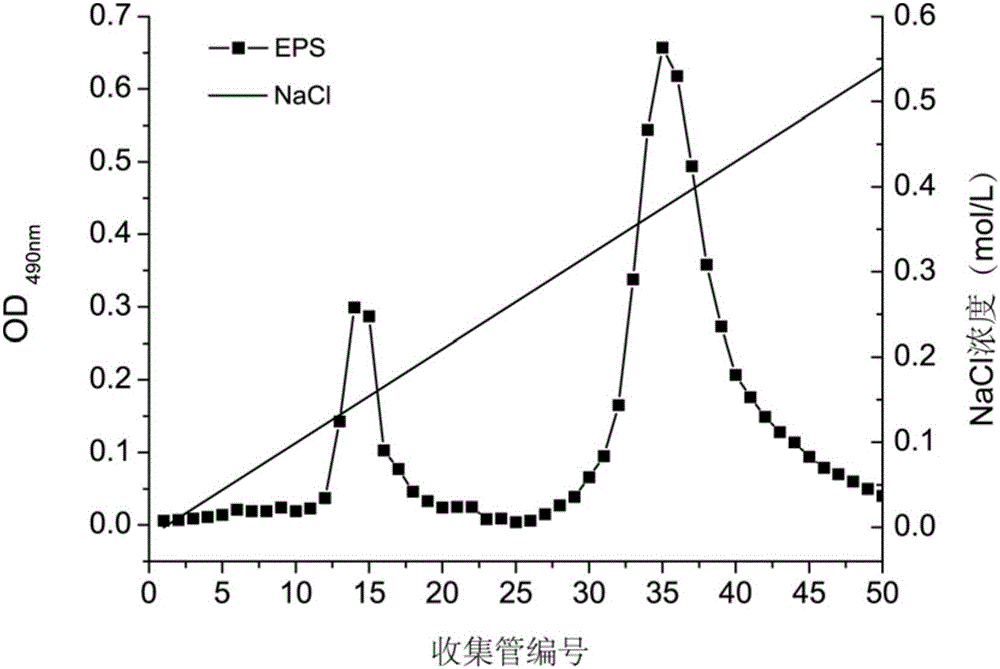

High-yield linear-chain glucan strain and glucan fermentation and production method thereof

ActiveCN108018247AImprove solubilityGood emulsifying effectBacteriaMicroorganism based processesSolubilitySucrose

The invention discloses a high-yield linear-chain glucan strain and a glucan fermentation and production method thereof. The high-yield linear-chain glucan strain is named Leuconostoc citreum N21. Thehigh-yield linear-chain glucan strain is separated from dried milk curds made by indigenous herdsmen in Xilin Gol League of Xilinhot City of Inner Mongolia, and an experiment discovers that the high-yield linear-chain glucan strain is capable of generating EPS (Exopolysaccharides) having good characteristics. The glucan fermentation and production method comprises the following steps: inoculatingthe Leuconostoc citreum N21 to an MRS basic culture medium containing 5 percent of sucrose, and culturing for 36 to 72 hours under the conditions that the pH (Potential of Hydrogen) value of an initial culture medium is 6 to 8, the temperature is 25 to 37 DEG C and the shaking speed is 0 to 170 rpm (Revolutions Per Minute), thus obtaining a fermentation solution; purifying crude polysaccharide, thus obtaining the EPS. The high-yield linear-chain glucan strain and the glucan fermentation and production method, disclosed by the invention, have the advantages of short EPS production period, highEPS yield, safety and no toxic and side effects; the EPS is higher in solubility, emulsibility and heat stability, theoretical foundation and basis are provided for industrial application, and a widecommercial application prospect is obtained.

Owner:TIANJIN UNIV

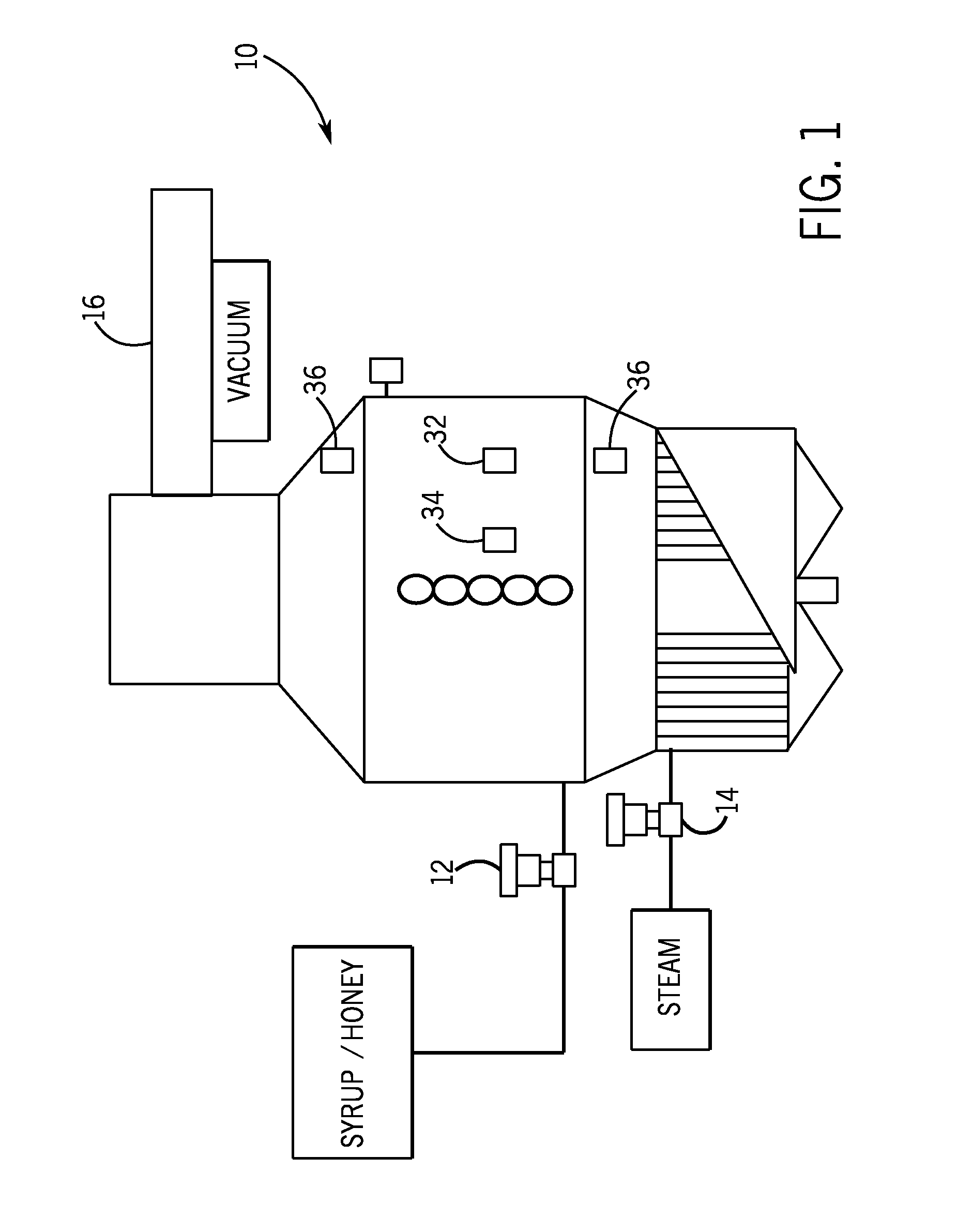

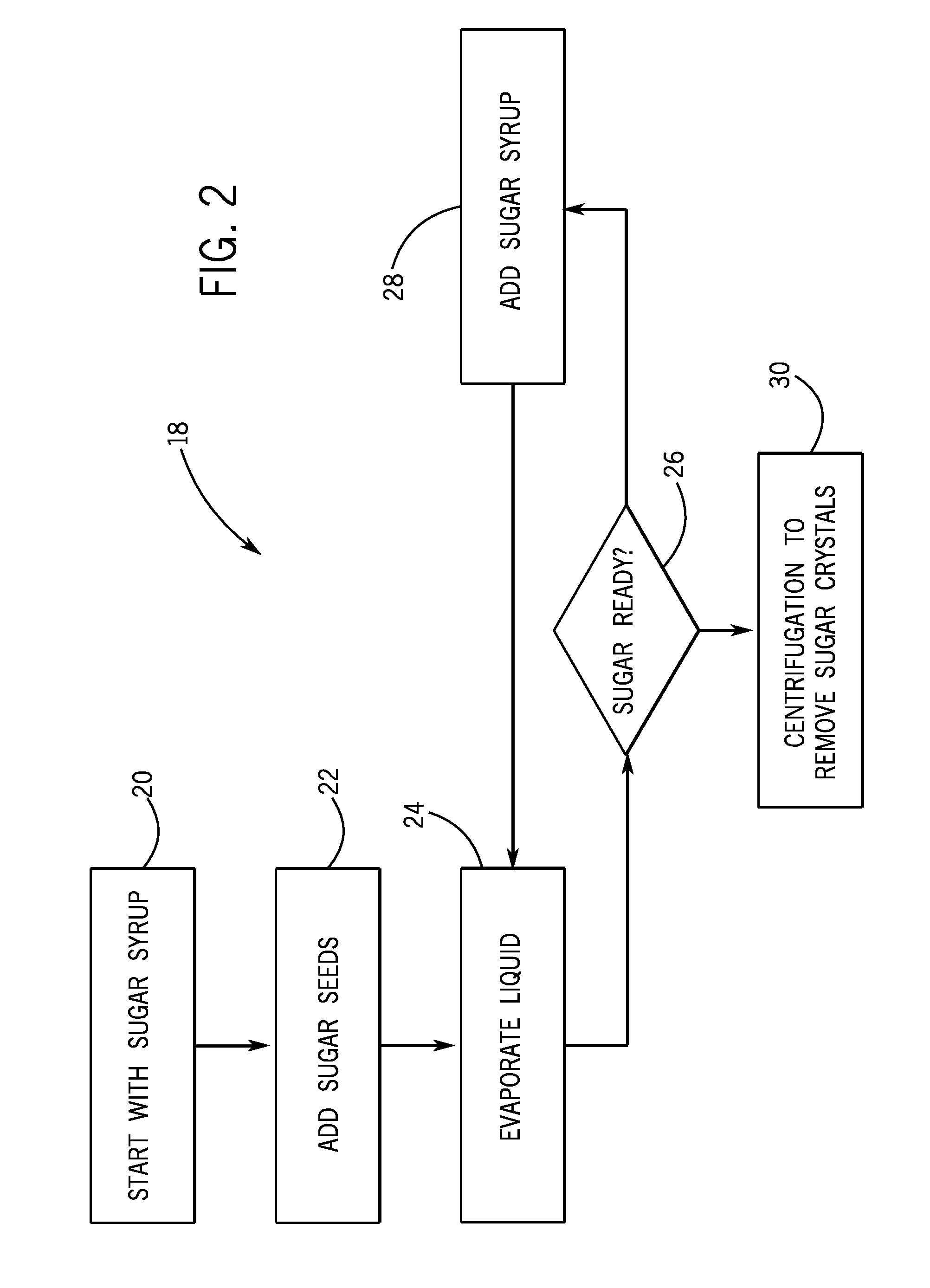

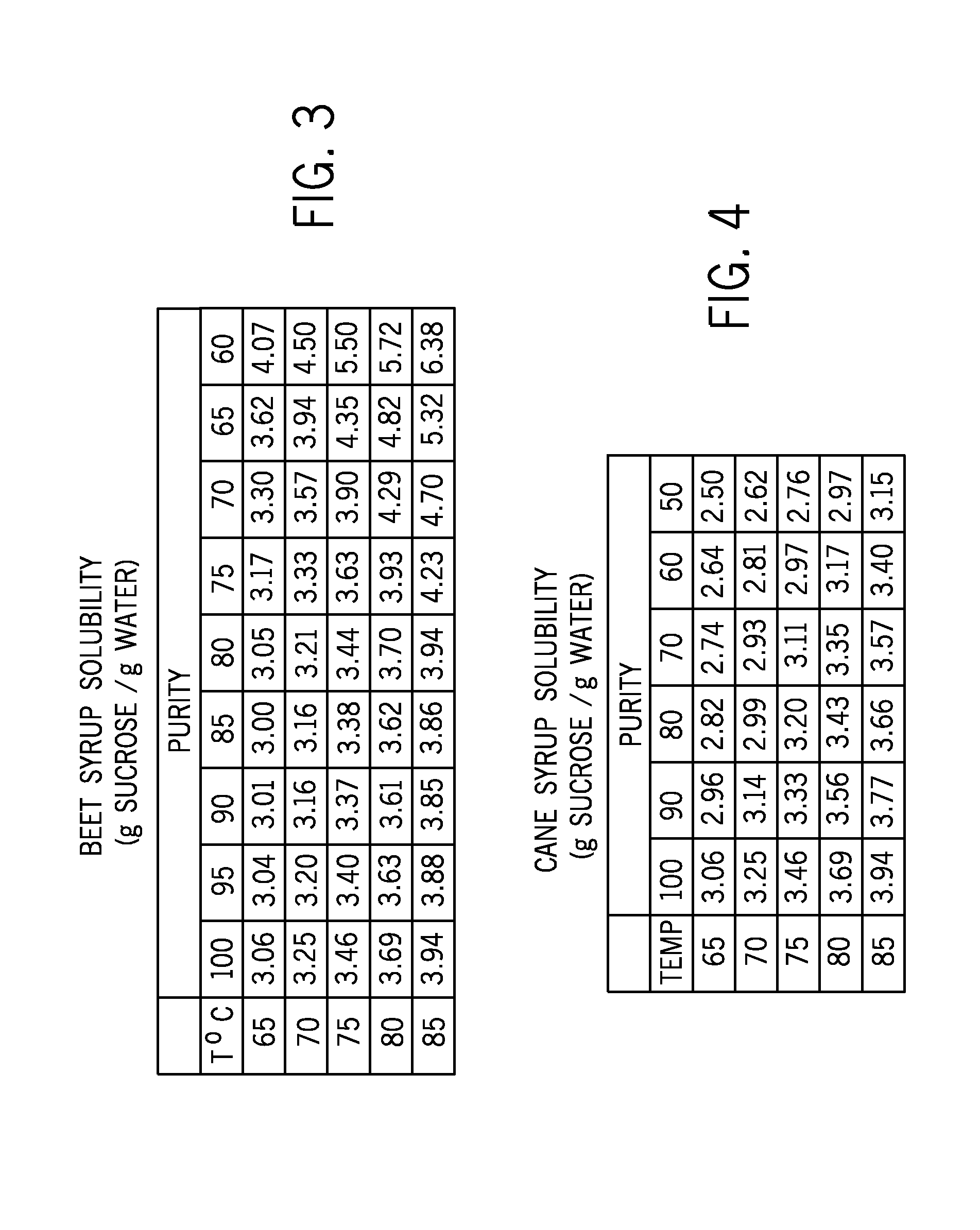

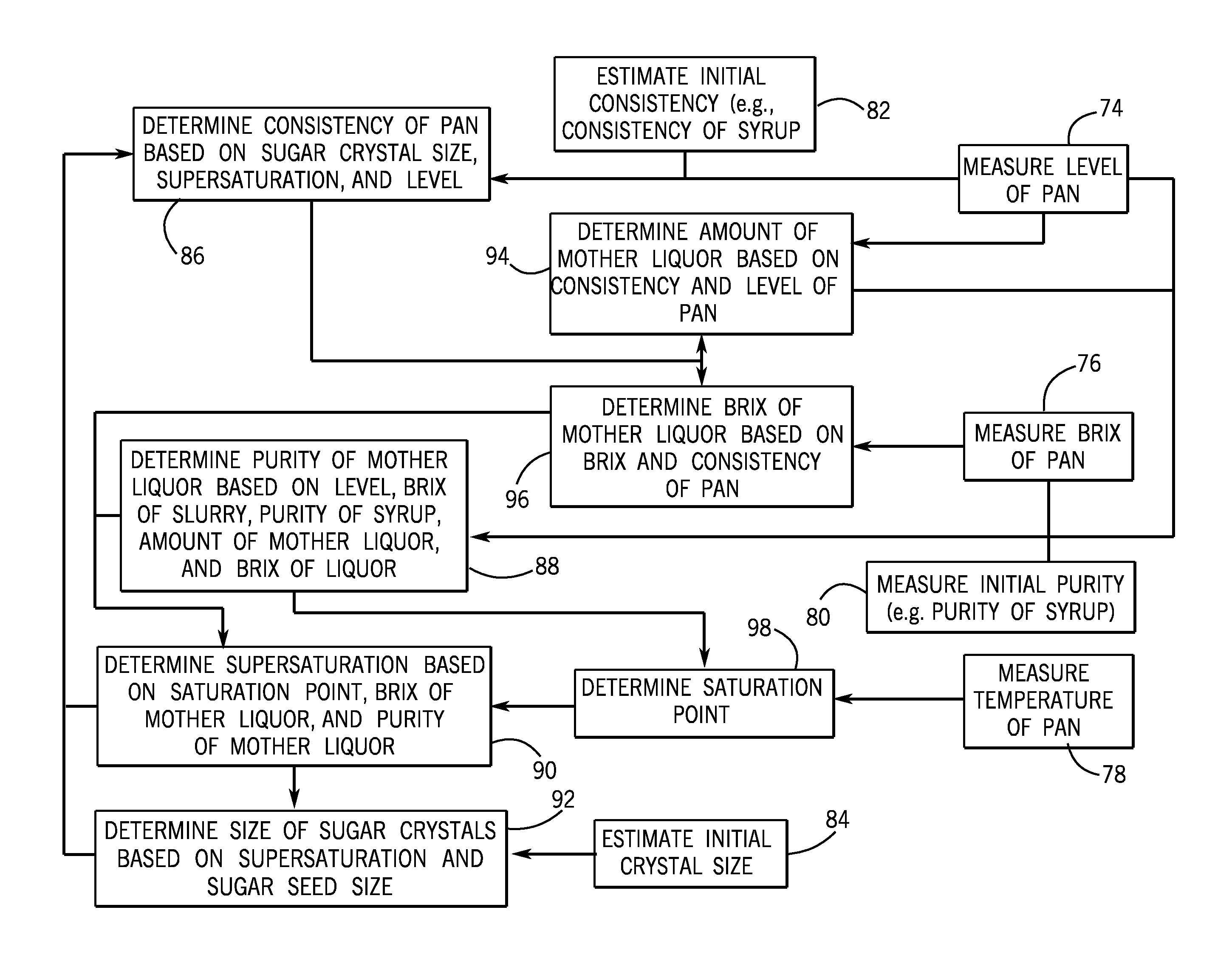

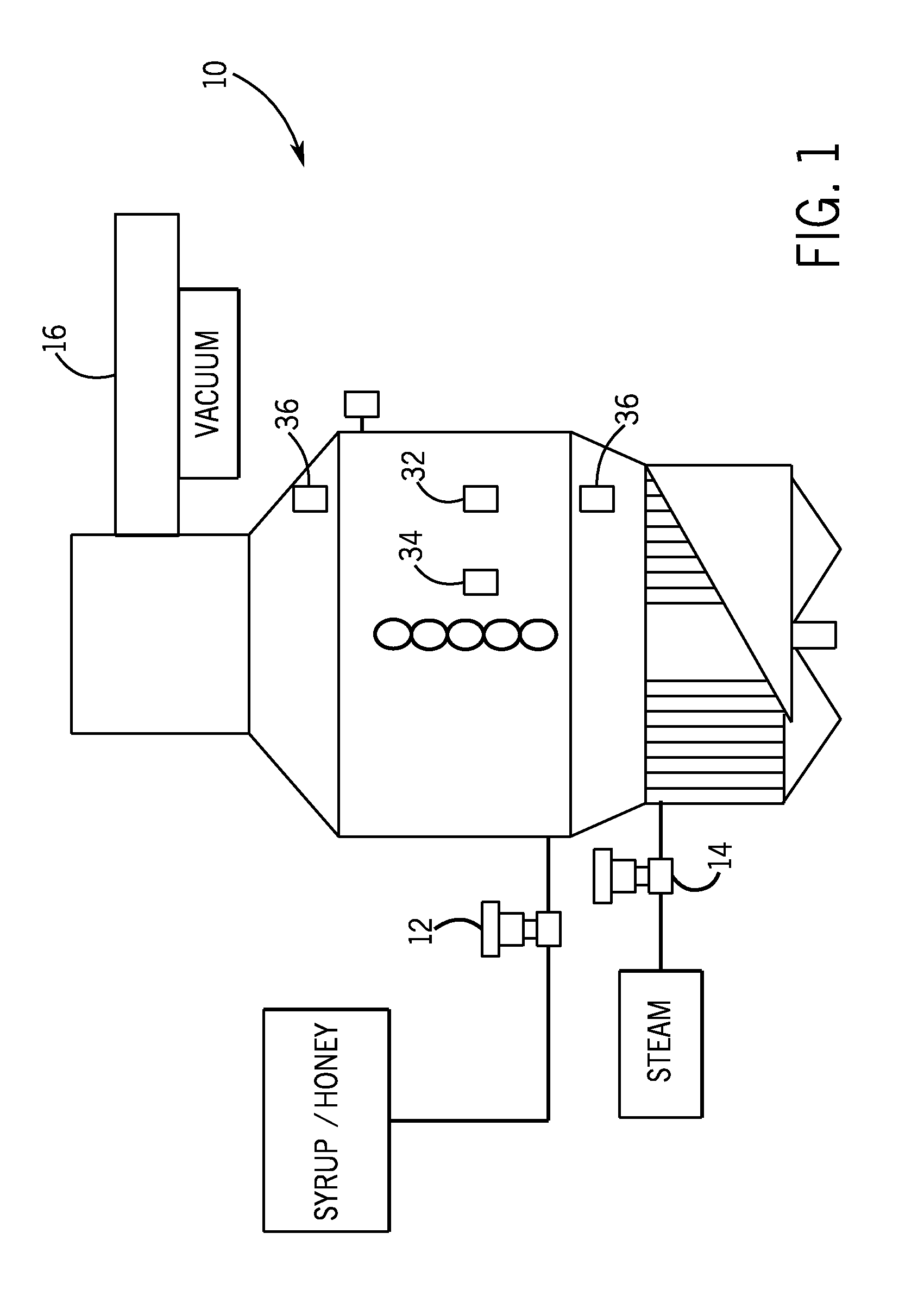

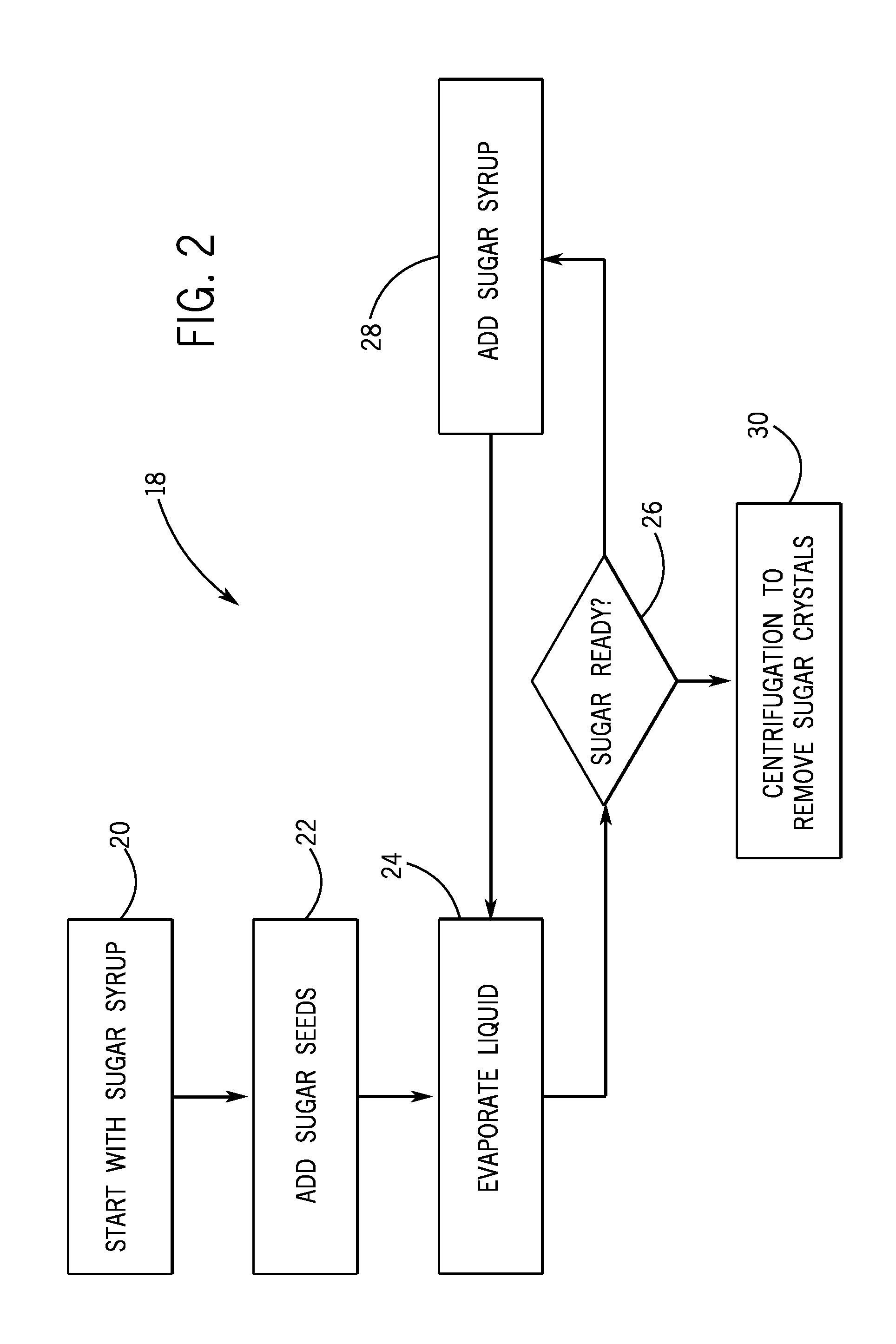

Sugar crystallization control system and method

ActiveUS20140261396A1Increase sugar productionIncreasing crystal size uniformitySugar crystallisationSolution crystallizationControl systemClosed loop

The embodiments described herein include one embodiment that provides a method for controlling sugar crystallization. The method includes, during a crystallization process, determining supersaturation of a sugar slurry of syrup and regulating influx of syrup into the sugar slurry to promote sugar crystallization in a closed-loop manner based upon the determined supersaturation.

Owner:ROCKWELL AUTOMATION TECH

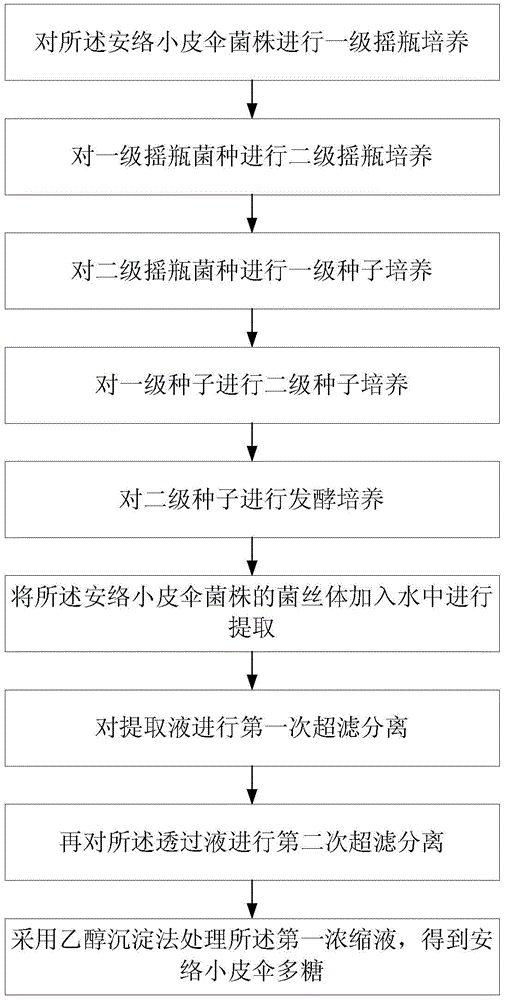

Marasmiellus androsaceus strain and application thereof

InactiveCN105462857AHigh yieldIncrease sugar productionFungiMicroorganism based processesEthanol precipitationMarasmiellus

The invention discloses a marasmiellus androsaceus strain. The preservation number of the marasmiellus androsaceus strain is CGMCC No.11734. The invention further discloses a method for applying the marasmiellus androsaceus strain in producing marasmiellus androsaceus polysaccharide. The process of hot water extraction, ultrafitration separation and ethanol precipitation is adopted, the extraction method is easy to implement, the content of marasmiellus androsaceus polysaccharide in a separated product is not lower than 60%, and the polysaccharide extraction rate is not lower than 12.3%.

Owner:西藏天虹科技股份有限责任公司

Method and apparatus for lignocellulose pretreatment using a super-cellulose-solvent and highly volatile solvents

InactiveUS20130236953A1Effectively overcome shortcomingsSpeed up the conversion processBioreactor/fermenter combinationsPressurized chemical processAlcoholGram

Embodiments of the present invention overcome the well-known recalcitrance of lignocellulosic biomass in an economically viable manner. A process and a system are provided for the efficient fractionation of lignocellulosic biomass into cellulose, hemicellulose, and lignin. The cellulose and hemicellulose thus obtained are highly amorphous and can be readily converted into highly concentrated mixtures of five and six carbon sugars using known methods. Typical yields of sugars exceed 100 grams of sugars per liter of sugar solution. Other products, such as alcohols, can easily be prepared according to methods of the invention. The modest process conditions and low solvent / solid ratios of some embodiments of the invention require relatively low capital and processing costs.

Owner:VIRGINIA TECH INTPROP INC

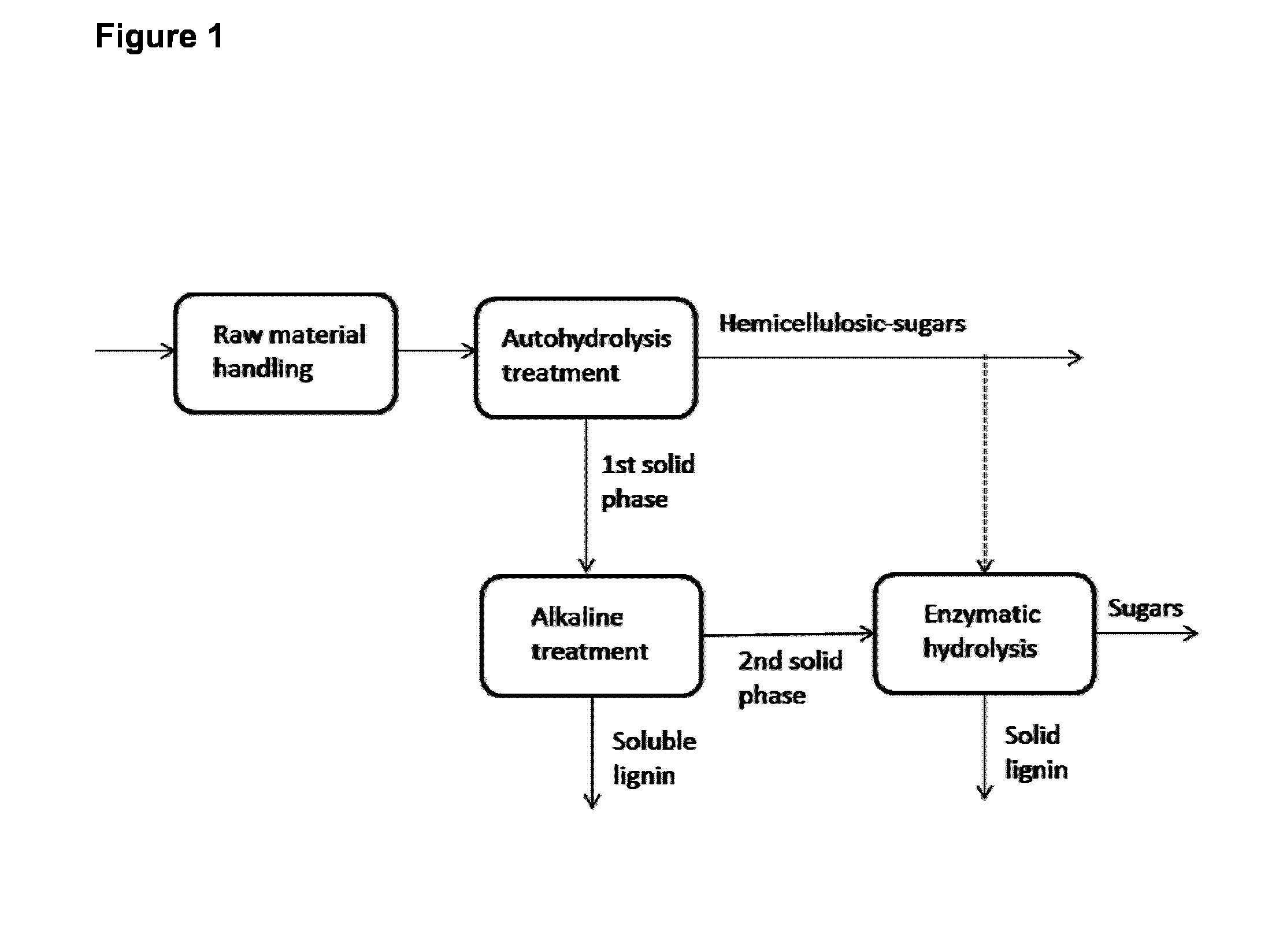

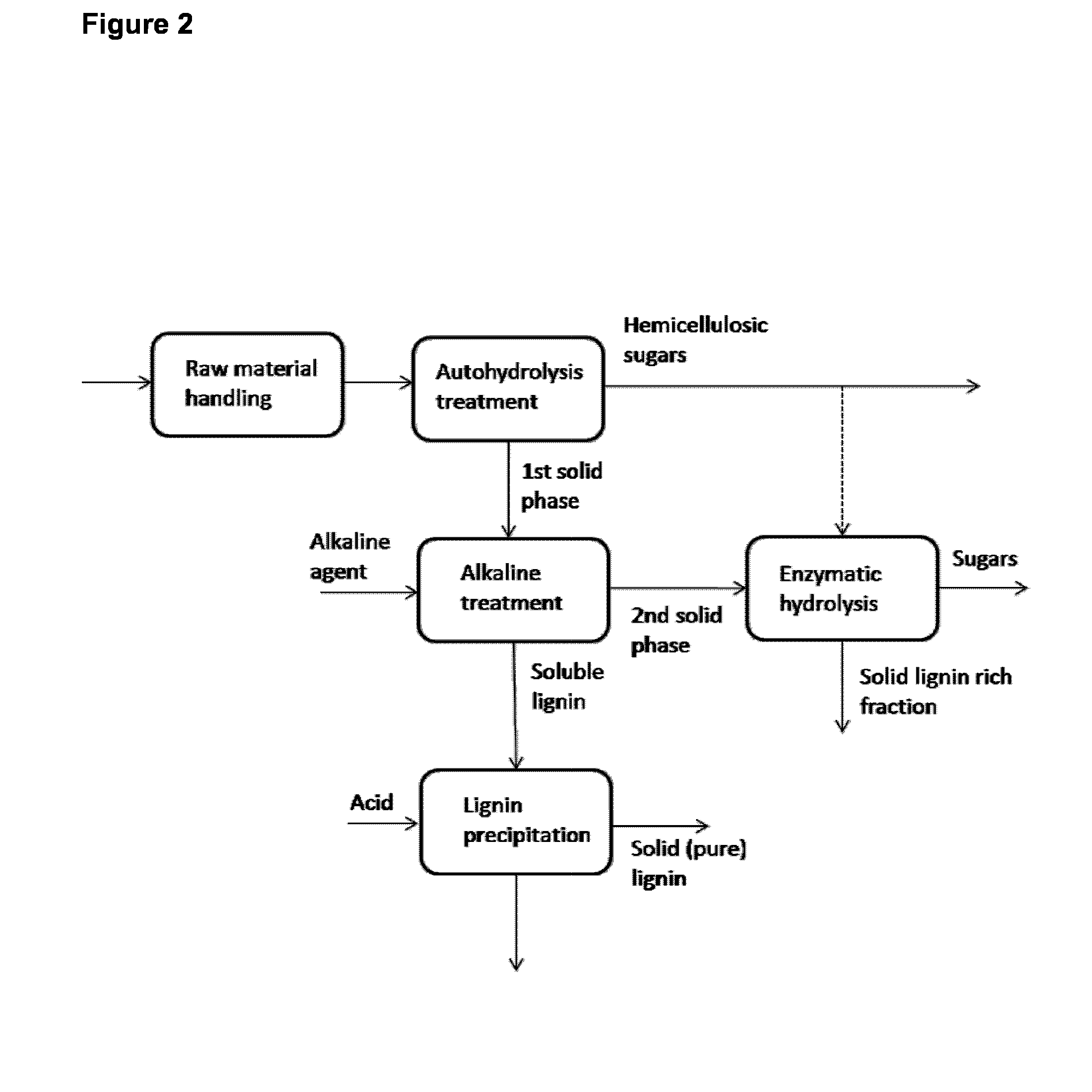

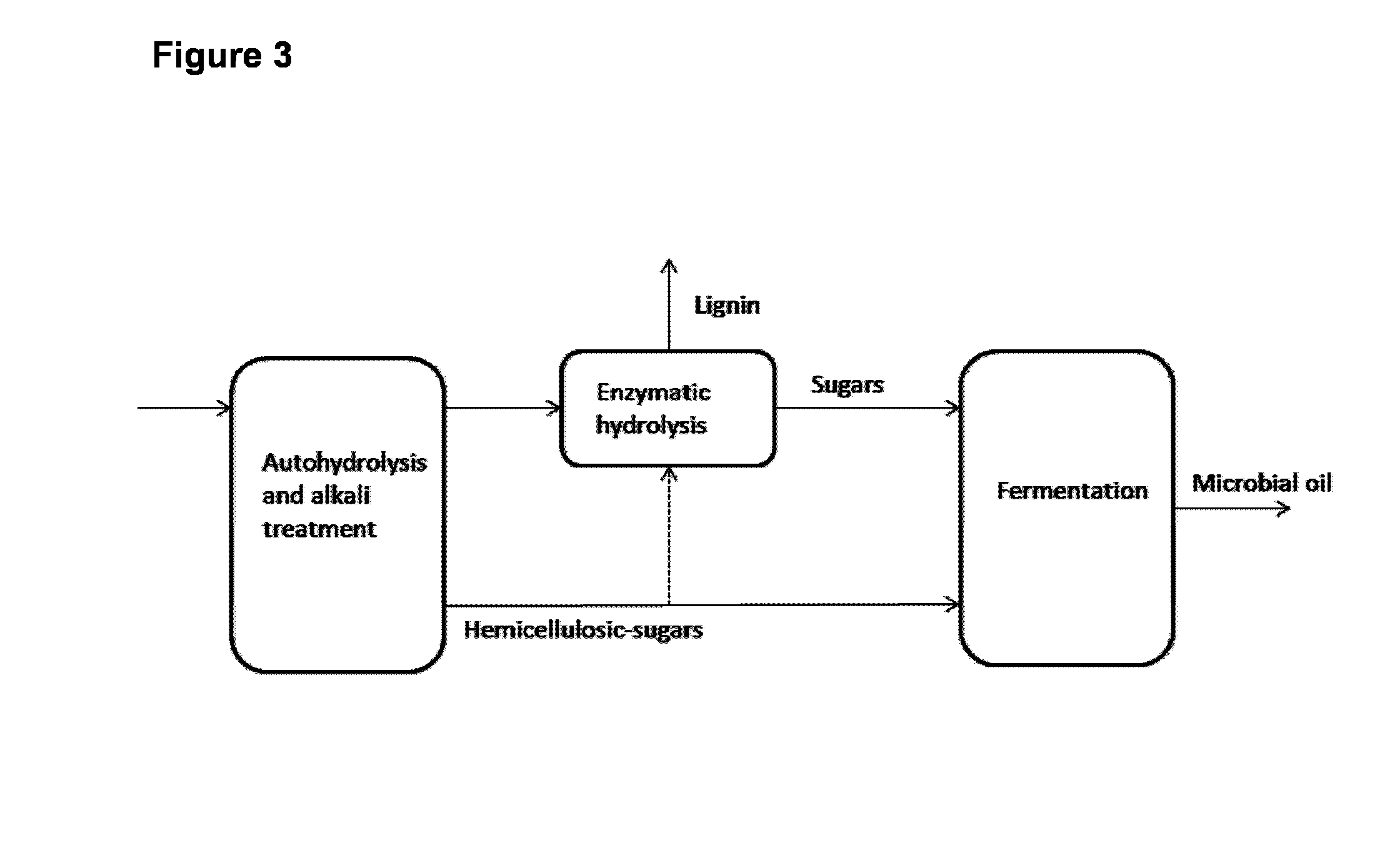

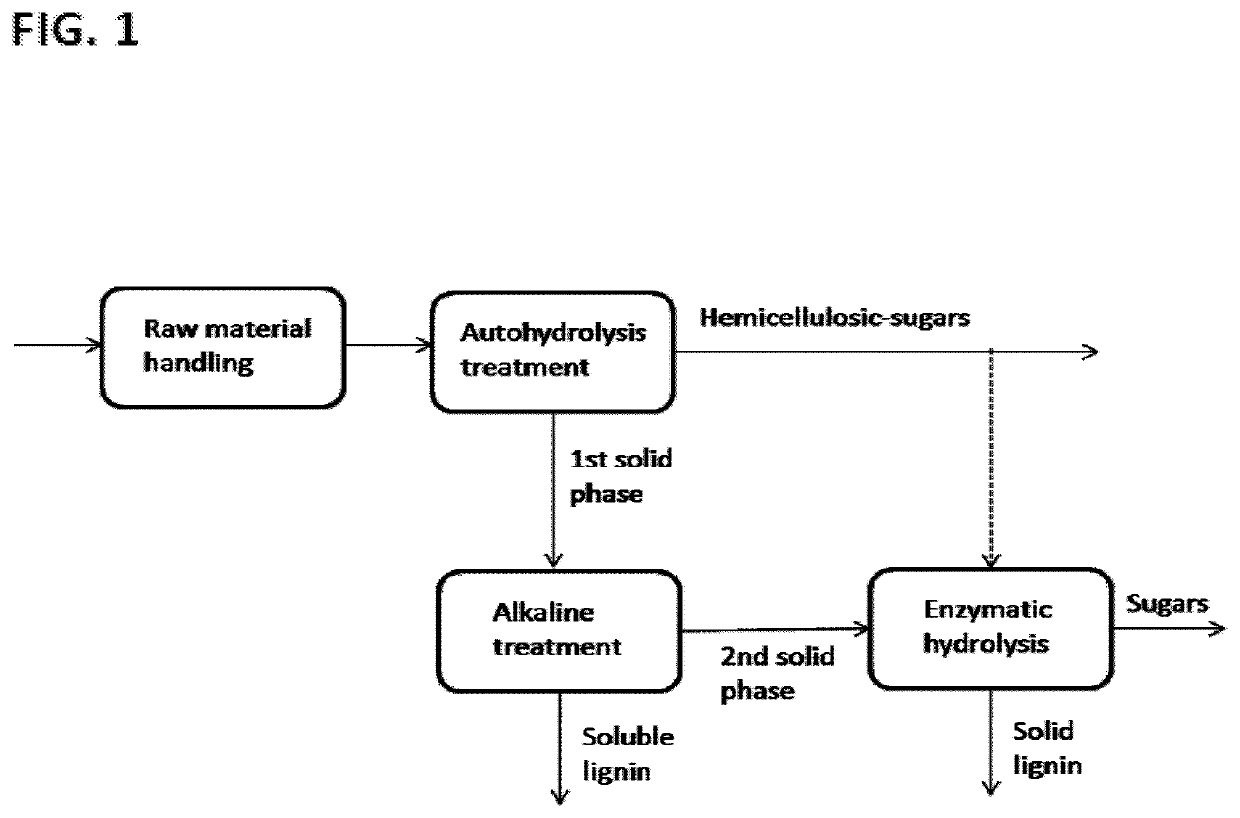

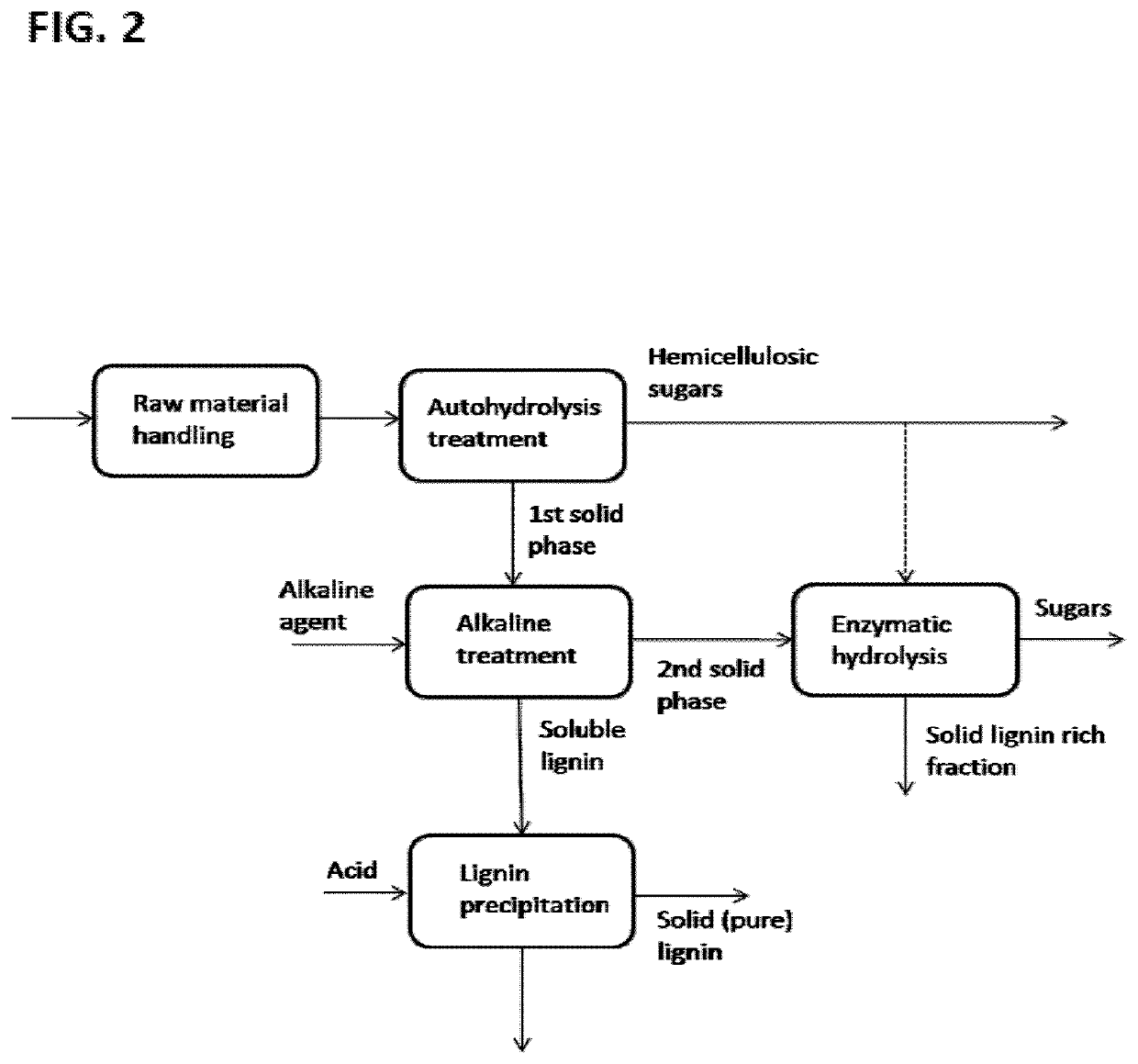

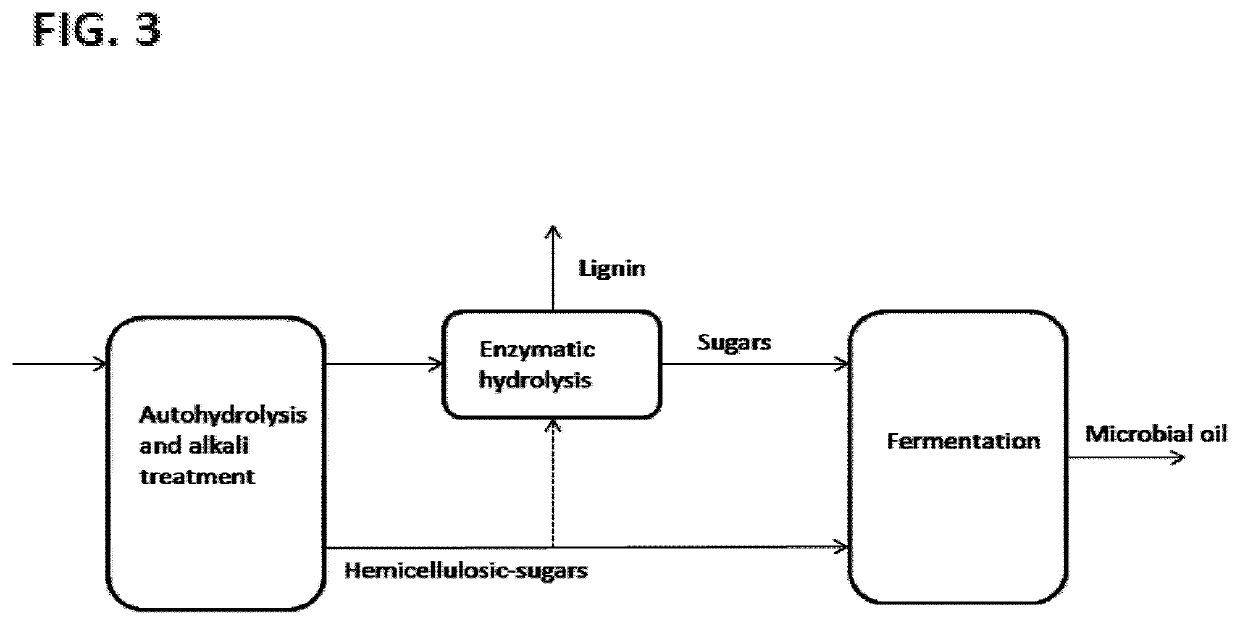

Method of processing lignocellulosic material using an alkaline delignification agent

ActiveUS20160312259A1Increase sugar productionImprove efficiencyBiofuelsFermentationCelluloseHydrolysate

The present invention relates to a method for obtaining sugar and lignin fractions from lignocellulosic materials and to a method for producing fermentation products using the sugars obtained from the lignocellulose. In particular, the present invention relates to a method for improving the sugar yield in the enzymatic hydrolysate by introducing a pre-treatment step of hydrothermal hydrolysis and an alkaline delignification step.

Owner:NESTE OIL OY

Sugar crystallization control system and method

ActiveUS9309576B2Increase sugar productionGood size uniformitySugar crystallisationSolution crystallizationControl systemClosed loop

The embodiments described herein include one embodiment that provides a method for controlling sugar crystallization. The method includes, during a crystallization process, determining supersaturation of a sugar slurry of syrup and regulating influx of syrup into the sugar slurry to promote sugar crystallization in a closed-loop manner based upon the determined supersaturation.

Owner:ROCKWELL AUTOMATION TECH

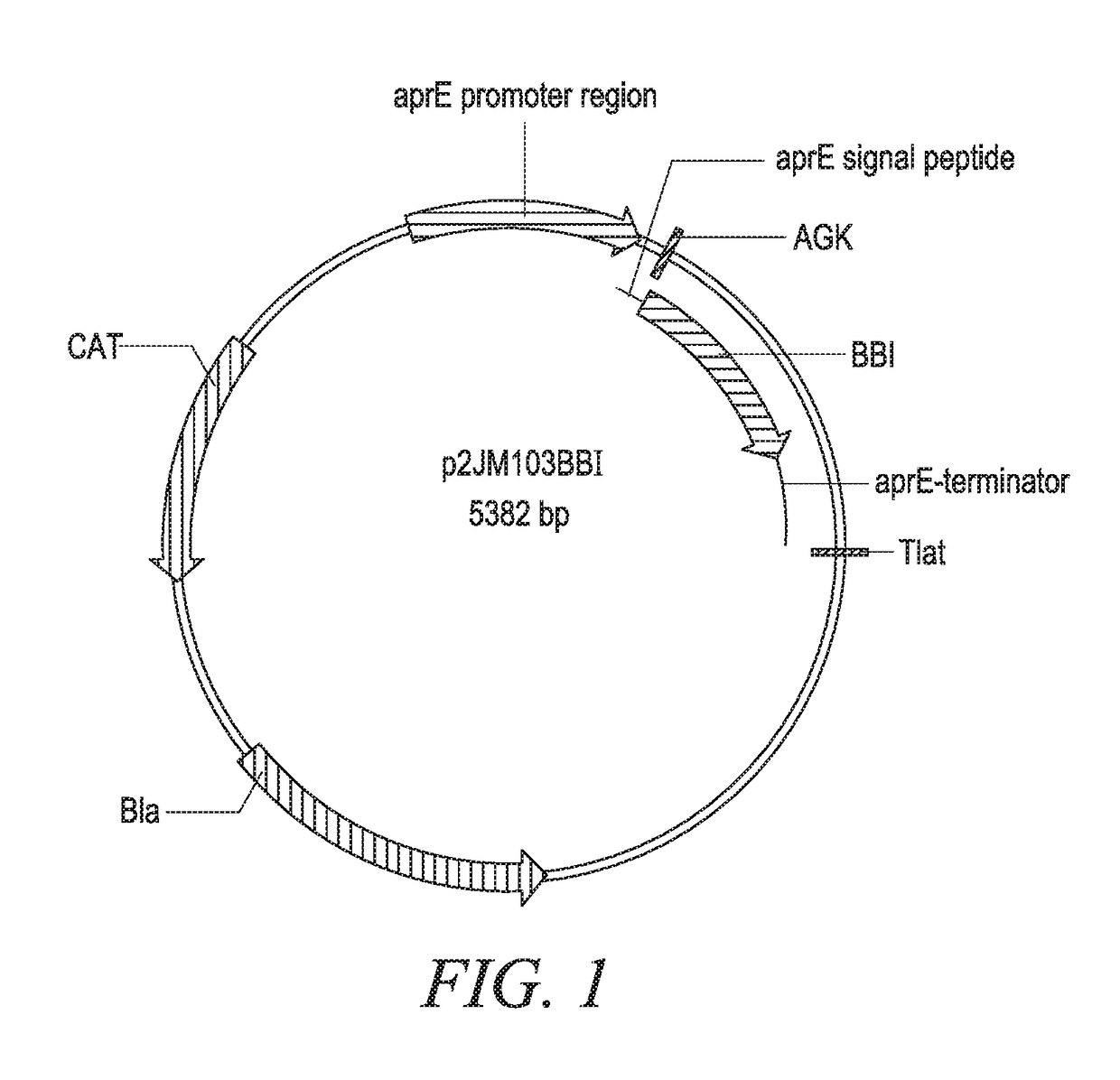

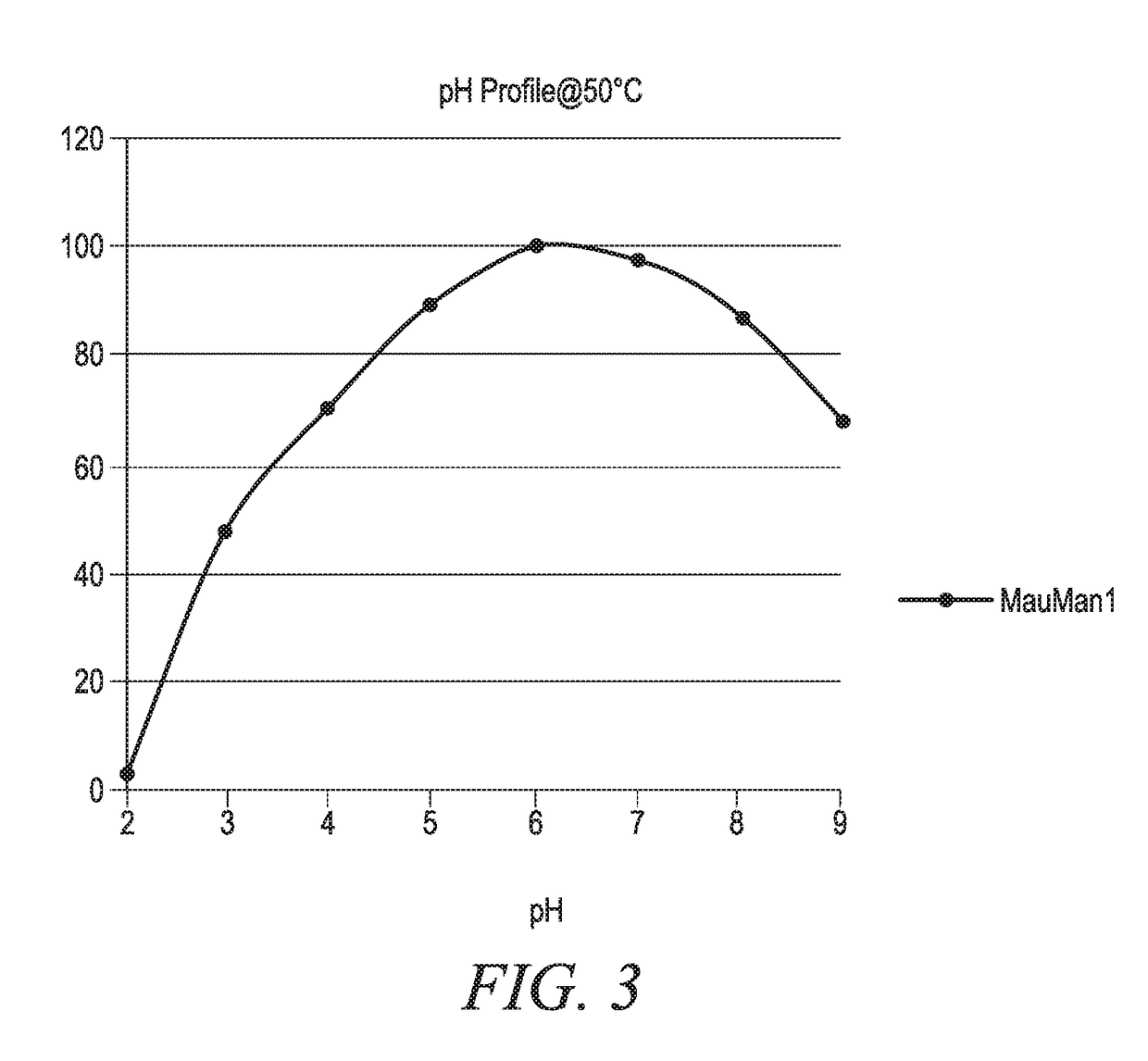

Compositions comprising beta mannanase and methods of use

InactiveUS20170211052A1Reduce capacityIncrease capacityFermentationGlycosylasesGalactoglucomannanLignocellulosic biomass

The present compositions and methods relate to a beta-mannanase from Mahella australiensis, polynucleotides encoding the beta-mannanase, and methods of make and / or use thereof. Formulations containing the beta-mannanase are suitable for use in hydrolyzing lignocellulosic biomass substrates, especially those comprising a measurable level of galactoglucomannan (GGM) and / or glucomannan (GM).

Owner:DANISCO US INC

Efficient sugarcane slow release fertilizer capable of promoting sugar accumulation and preparation method of efficient sugarcane slow release fertilizer

InactiveCN106431681AGood sustained release effectFull of nutritionCalcareous fertilisersAnimal corpse fertilisersFertilizerParaffin wax

The invention discloses an efficient sugarcane slow release fertilizer capable of promoting sugar accumulation. The efficient sugarcane slow release fertilizer comprises the following components in parts by weight: sunflower oil, paraffin wax, calcium peroxide, nano-white carbon black, bagasse, furfural residue, edible starch residue, fructose, lentinan microspheres, active dry yeast powder, selenium-enriched nutrient energy elements, choline chloride, aloe gel, persimmon flavonoids, xanthan gum, polyethylene glycol, hydroxypropylcellulose, 200-300-mesh coconut shell activated carbon and the like. The slow release fertilizer for cultivating sugarcanes can be prepared by coating a fermentation main material with coated liquid capable of dynamically releasing nutrients, so that the slow release effect is good, the nutrients are rich, the fertilizer efficiency is stable, the action time of the fertilizer efficiency is long, the emergence rate and plant heights of the sugarcanes can be effectively increased, and the agricultural yield and sugar yield of the sugarcanes can be remarkably increased; and added exogenous choline chloride can be transported upwards along fiber tube bundles after being absorbed by the roots of the sugarcanes so as to promote the photosynthesis of the sugarcanes, so that the synthesis and accumulation of sugar in the sugarcanes is promoted, and the efficient cultivation of the sugarcanes is promoted.

Owner:HEFEI SIFANG PHOSPHATE COMPOUND FERTILIZER

Sugarcane fertilizer

InactiveCN107759297AImprove disease resistancePromote growthCalcareous fertilisersExcrement fertilisersDiseaseContinuous cropping

The invention relates to a sugarcane fertilizer. The sugarcane fertilizer is prepared from, by weight, 25-35 parts of livestock excrement, 18-25 parts of urea, 15-20 parts of limestone powder, 14-16 parts of fishbone dust, 10-13 parts of crop straw powder, 5-7 parts of amino acid, 1.2-3 parts of titanium fertilizer, 1.5-3 parts of anti-freezing agent and 1.5-3 parts of anti-continuous-cropping agent. The sugarcane fertilizer is reasonable in preparation of adopted composition, can improve the soil structuredness, improves the soil fertility, improves the absorption capacity of sugarcane to fertilizer, improves the disease resistance capacity of the sugarcane, effectively promotes growth of the sugarcane and improves the sugar yield of the sugarcane.

Owner:曾绍珍

Method of processing lignocellulosic material using an alkaline delignification agent

ActiveUS10604777B2Increase sugar productionImprove efficiencyBiofuelsFermentationCelluloseHydrolysate

The present disclosure relates to a method for obtaining sugar and lignin fractions from lignocellulosic materials and to a method for producing fermentation products using the sugars obtained from the lignocellulose. The present disclosure relates to a method for improving the sugar yield in the enzymatic hydrolysate by introducing a pre-treatment step of hydrothermal hydrolysis and an alkaline delignification step.

Owner:NESTE OIL OY

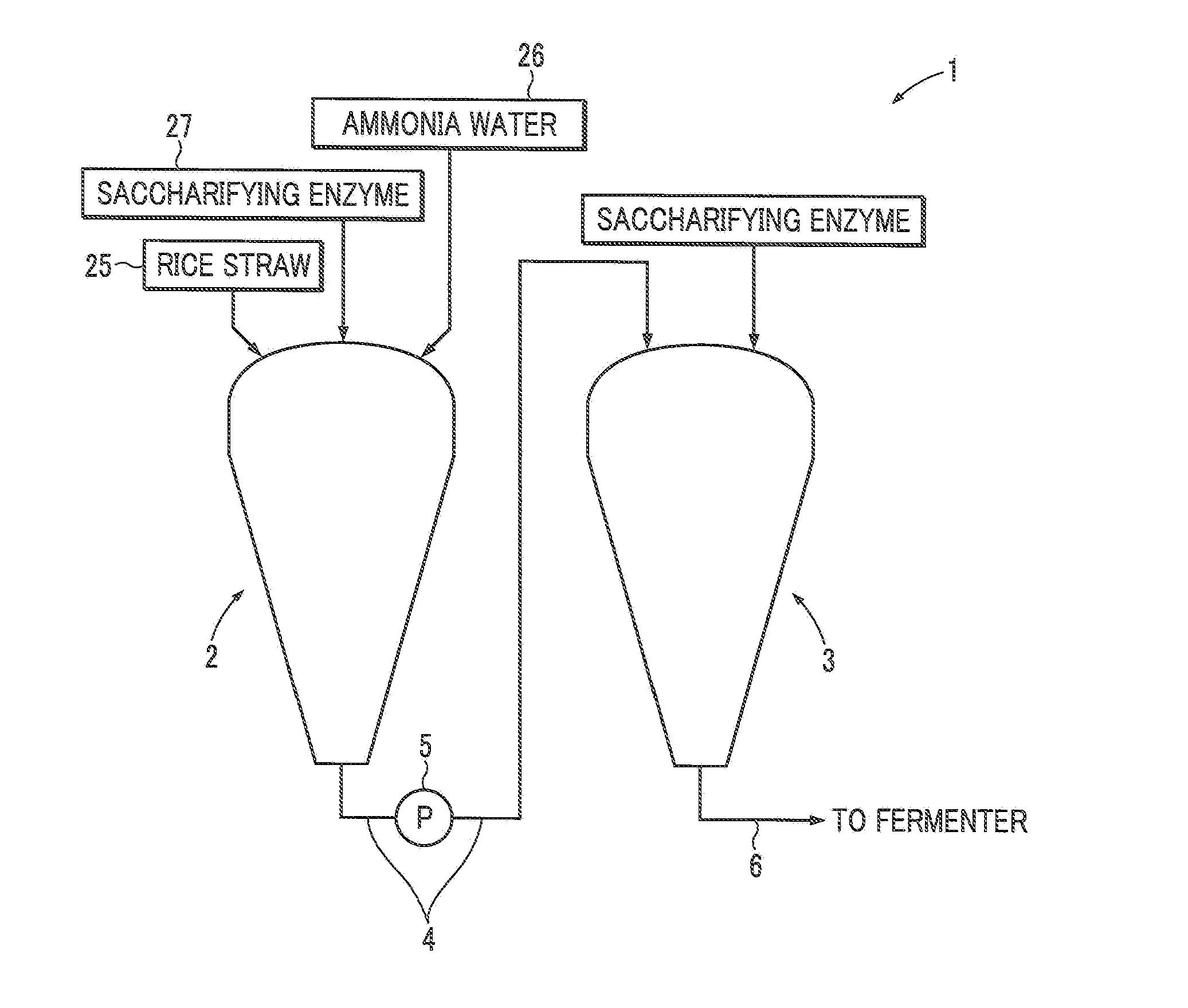

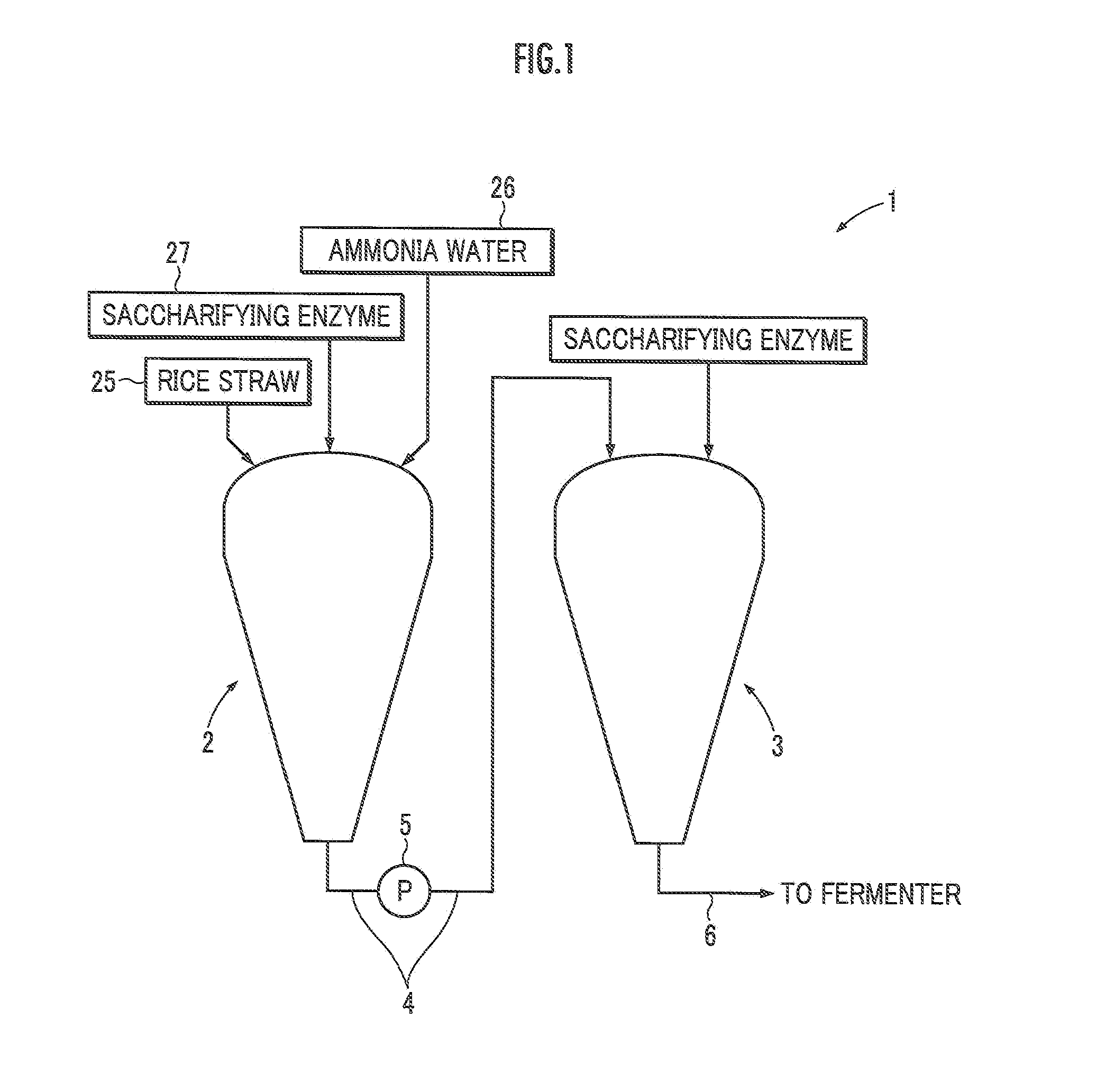

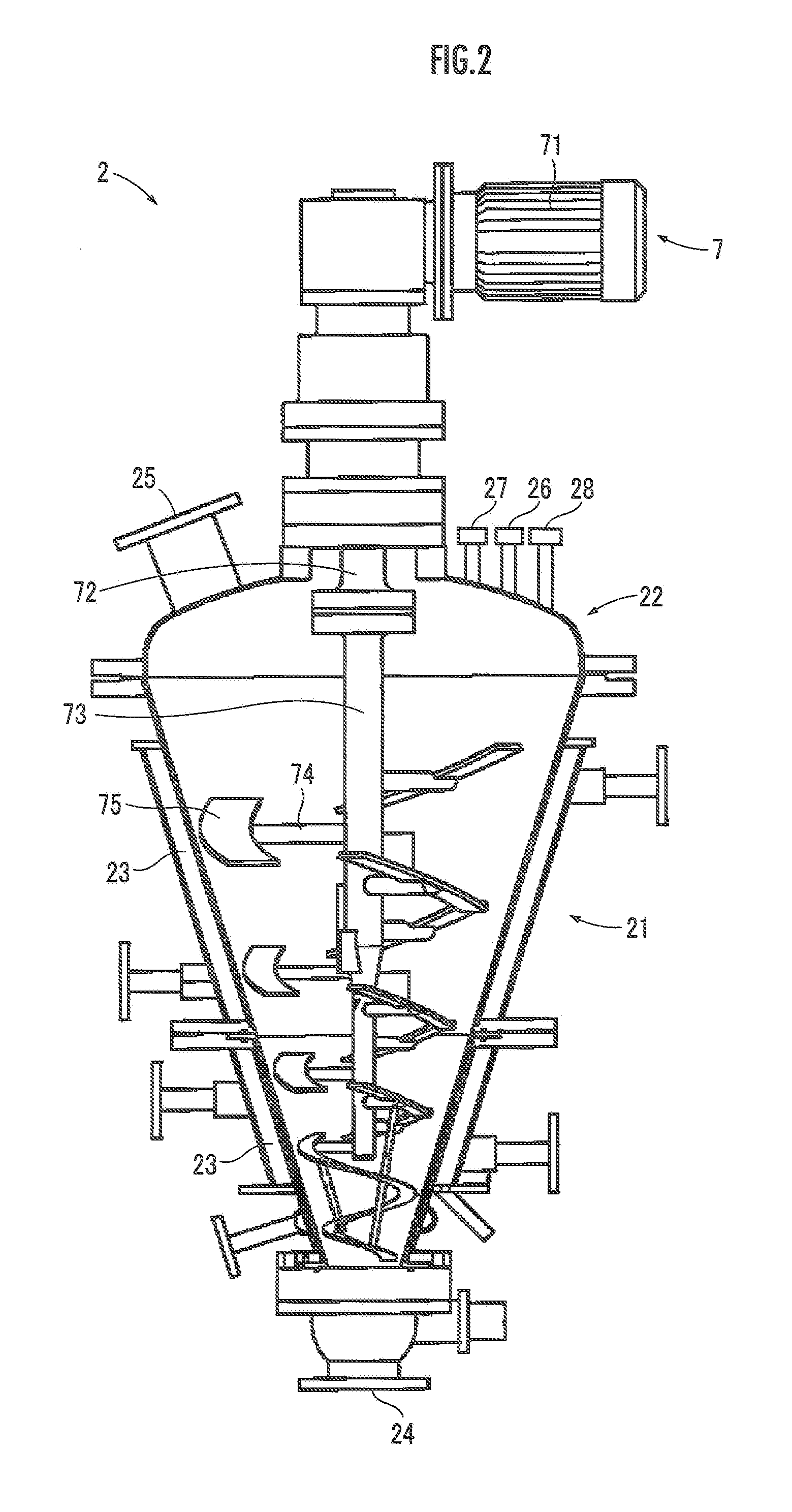

Method for treating lignocellulosic biomass

It is intended to provide a method for treating lignocellulosic biomass, which can reliably show the completion of the course by which pretreated lignocellulosic biomass is rendered flowable and thus transportable. The method for treating lignocellulosic biomass comprises a first saccharification step of saccharifying pretreated lignocellulosic biomass with stirring using a stirring unit 7 to obtain a first saccharification product that is flowable and thus transportable and a second saccharification step of obtaining a second saccharification product from the first saccharification product, wherein the rate of change dW / dt of power W required for the stirring in the stirring unit 7 versus stirring time t falls below a predetermined value, after which the first saccharification product is transported under non-air-contact conditions from the first saccharification step to the second saccharification step.

Owner:HONDA MOTOR CO LTD

A kind of arctic marine bacterium and its application

ActiveCN103937707BIncrease sugar productionLess researchBacteriaMicroorganism based processesBacteroidesNon toxicity

The invention relates to a polaribacter sp. and an application. Luojia Mountain in Wuchang district, Wuhan, China, and the preservation number is CCTCC No. M2013437. The bacterial strain can secrete a lot of polaribacter sp extracellular polysaccharide. The polysaccharide has good rheology property, is capable of absorbing moisture, preserving moisture, removing activity of organic free radical, hydroxyl radical and oxyradical, and has the characteristics of non toxicity and no stimulation.

Owner:SHANDONG UNIV

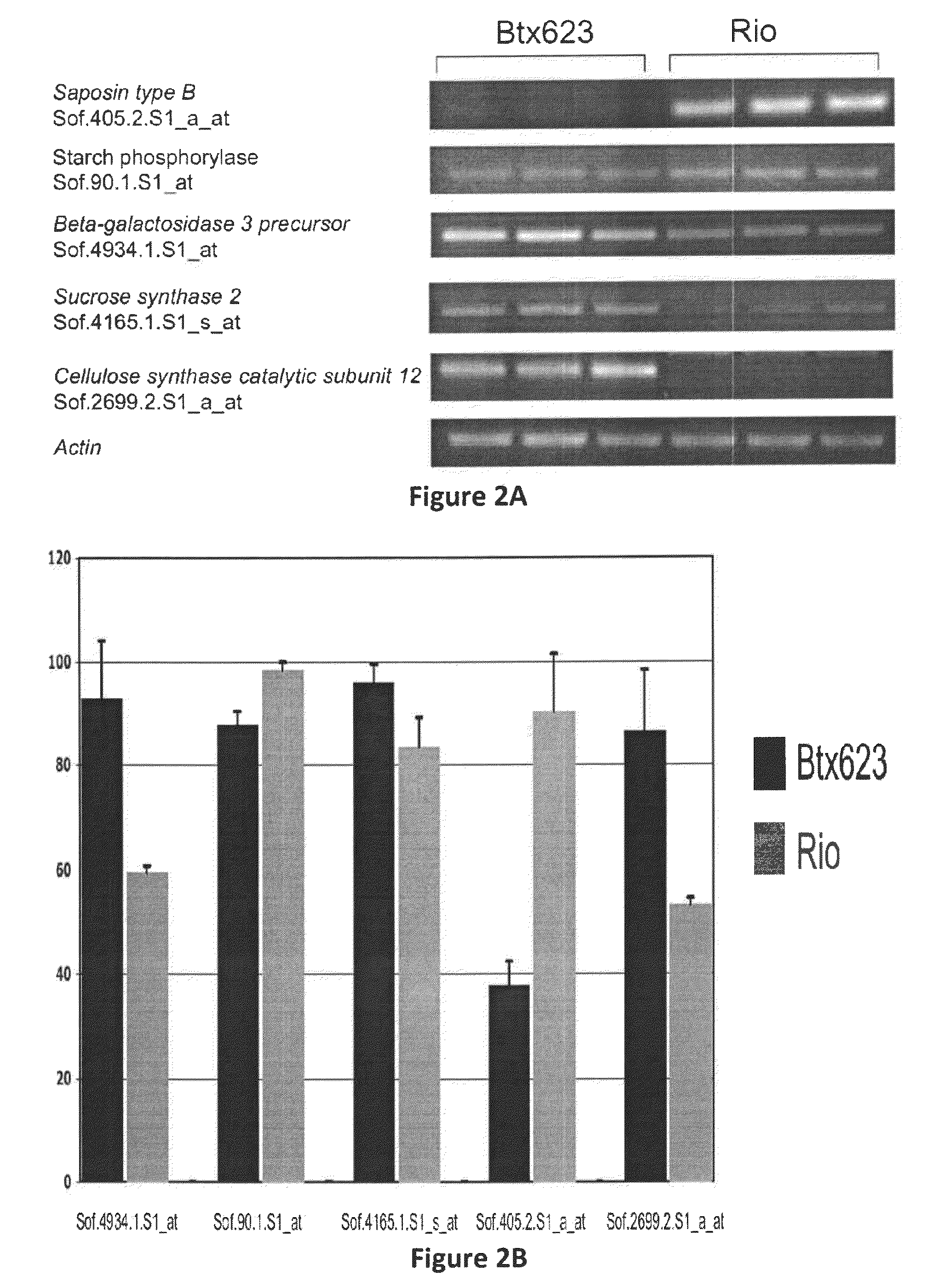

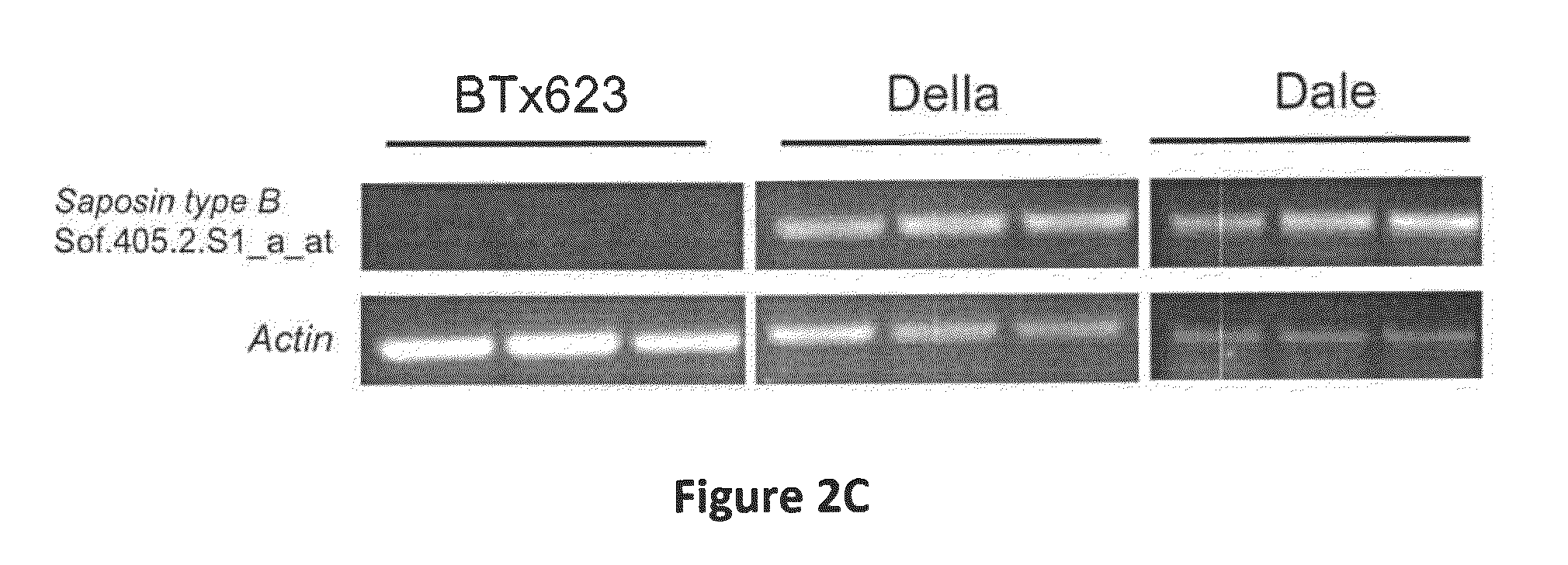

Compositions and Methods for Biofuel Crops

InactiveUS20150218571A1Low costEnhanced C4 photosynthesisSugar derivativesMicrobiological testing/measurementCelluloseBiotechnology

Owner:RUTGERS THE STATE UNIV

Processing biomass

InactiveUS20170159077A1High yieldIncrease sugar productionBiofuelsXylose productionSugar yieldBiomass

Owner:XYLECO INC

Special enhancement fertilizer for sugarcane

InactiveCN103172471AIncrease productionIncrease sugar productionFertilizer mixturesDiammonium phosphateChemistry

The invention discloses a special enhancement fertilizer for sugarcane and a preparation method. The special enhancement fertilizer for sugarcane is characterized by being formed by mixing urea, diammonium phosphate, potassium nitrate, calcium superphosphate, potassium sulfate and an additive according to a certain proportion. The components are mixed according to a certain proportion and then subjected to granulation, drying and granulation by special fertilizer production equipment to finally form a finished product.

Owner:陕西中助达信商贸有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com