Enzymolysis saccharification processing method of straw

A technology of saccharification treatment and enzymatic hydrolysis, which is applied in the fields of biofuel and fermentation, can solve the problems of increasing the difficulty of enzymatic hydrolysis, restricting direct contact with cellulose, low enzymatic hydrolysis and saccharification rate, etc. Improve the effect of enzymatic hydrolysis and saccharification, and improve the effect of enzymatic hydrolysis efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Example 1: Enzymatic hydrolysis and saccharification of straw

[0023] Sorghum stalks are dried in the sun, pulverized, and sieved with a 60-mesh sieve to obtain sorghum stalk powder. Take 10g of sorghum straw powder and add it to a conical flask, add 100mL of dilute hydrochloric acid with a mass concentration of 1.0%, then place it in a sterilized autoclave, and carry out acidification reaction at a temperature of 120°C. The sorghum stalks were taken out and cooled naturally at room temperature to obtain sorghum straw slurry.

[0024] Add 0.25 g of cellulase (2.5 g per 100 g of straw), 0.2 g of xylanase (2.0 g per 100 g of straw), 0.375 mmol of magnesium chloride (2.5 mmol / L), 1.5 mL of Tween 80 (1 %) and 50 mL of distilled water to obtain an enzymatic hydrolysis slurry with a liquid-solid ratio of 15:1, adjust the pH value to 5.0, and then place it in a water bath for enzymatic hydrolysis and saccharification reaction at 50°C for 48 hours. After the reaction is comp...

Embodiment 2

[0032] Example 2: Test of straw saccharification effect

[0033] 1. Effect of acidification reaction on straw saccharification effect

[0034] According to the enzymatic saccharification treatment method described in Example 1, sulfuric acid, sulfurous acid, formic acid, and sodium hydroxide with a mass concentration of 1.0% were used to replace the dilute hydrochloric acid used in Example 1, and the acidification reaction was carried out, and the enzymatic The concentration of reducing sugar after desaccharification treatment is shown in Table 1. The test results show that the acidification reaction with dilute hydrochloric acid has the best saccharification effect.

[0035] Table 1

[0036] sour

Dilute hydrochloric acid

NaOH

reducing sugar concentration

29.1g / L

22.5g / L

4.2g / L

18.9g / L

22.1g / L

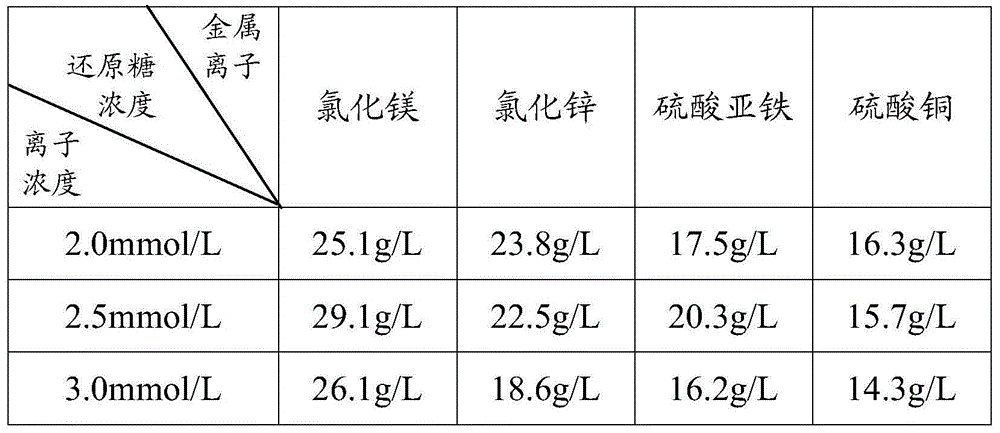

[0037]According to the enzymatic saccharification treatment method describe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com