Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

35results about How to "Increase load ratio" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

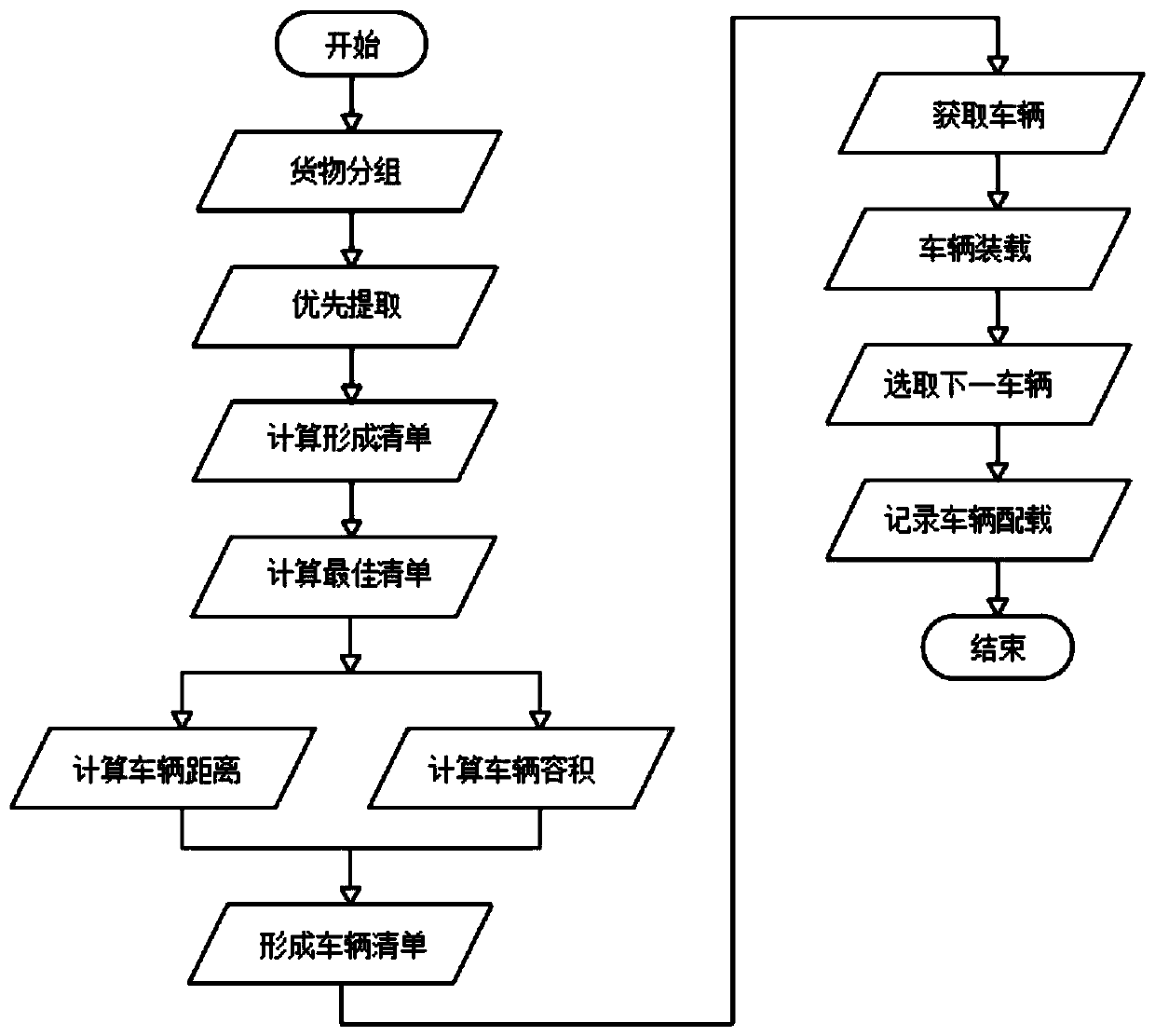

Intelligent logistics stowage scheduling method

InactiveCN110659839ANo delay in arrivalImprove loading efficiencyResourcesLogisticsLogistics managementGps navigation

The invention discloses a logistics intelligent stowage scheduling method, which comprises the following steps of S1, goods grouping: grouping to-be-loaded goodses of a current station according to agoods direction; s2, preferentially extracting: extracting goods with express item marks, and preferentially extracting a loading list; s3, calculating to form a list, comprehensively calculating volume, weight and value of goods in one direction to form a to-be-distributed list M, and permutating and combining the to-be-distributed list M; s4, calculating an optimal list; s5, calculating a vehicle distance and a vehicle volume; s6, forming a vehicle list; s7, acquiring a vehicle; s8, vehicle loading; s9, selecting a next vehicle; and S10, vehicle stowage is recorded. According to the logistics intelligent stowage scheduling method, the stowage rate and the average kilometer benefit of the single vehicle are improved by means of the positioning information of the vehicle, GPS navigation software, attributes of various goods, vehicle loads and the like, analysis of early-stage configuration data and a reasonable stowage algorithm.

Owner:杭州货天下物流科技有限公司

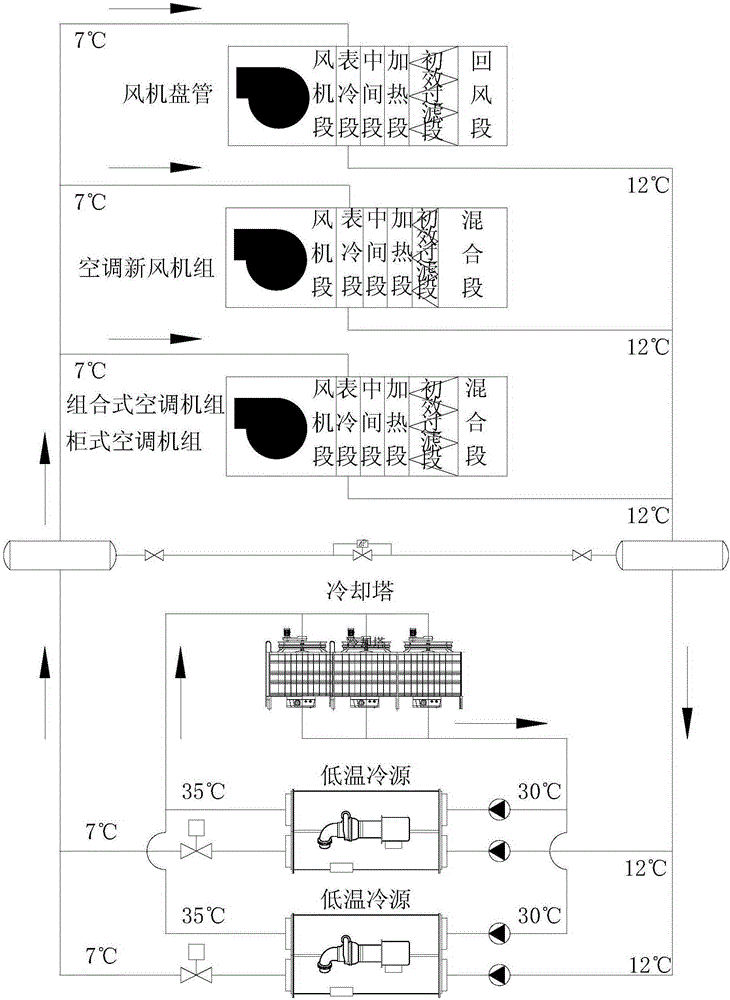

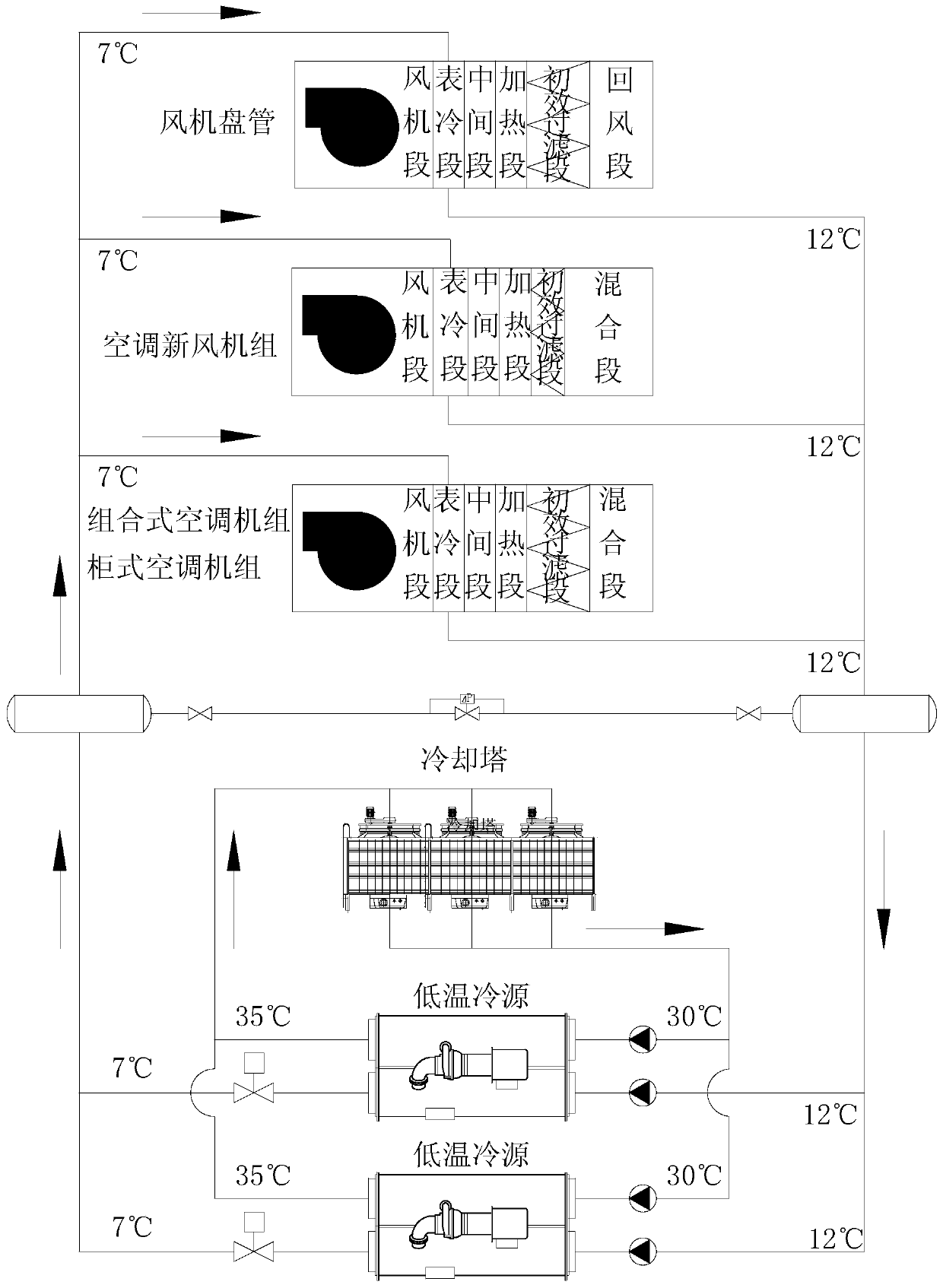

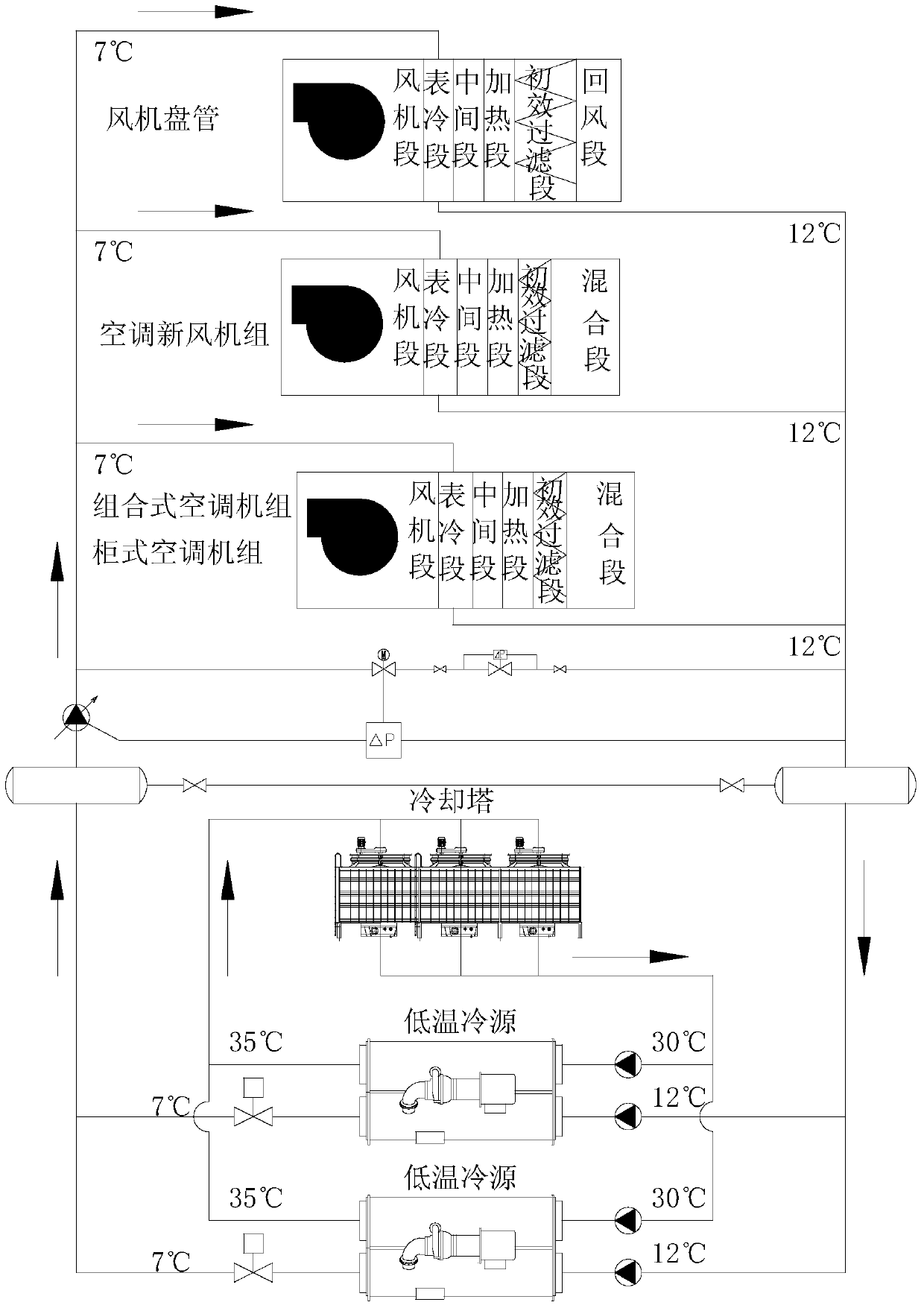

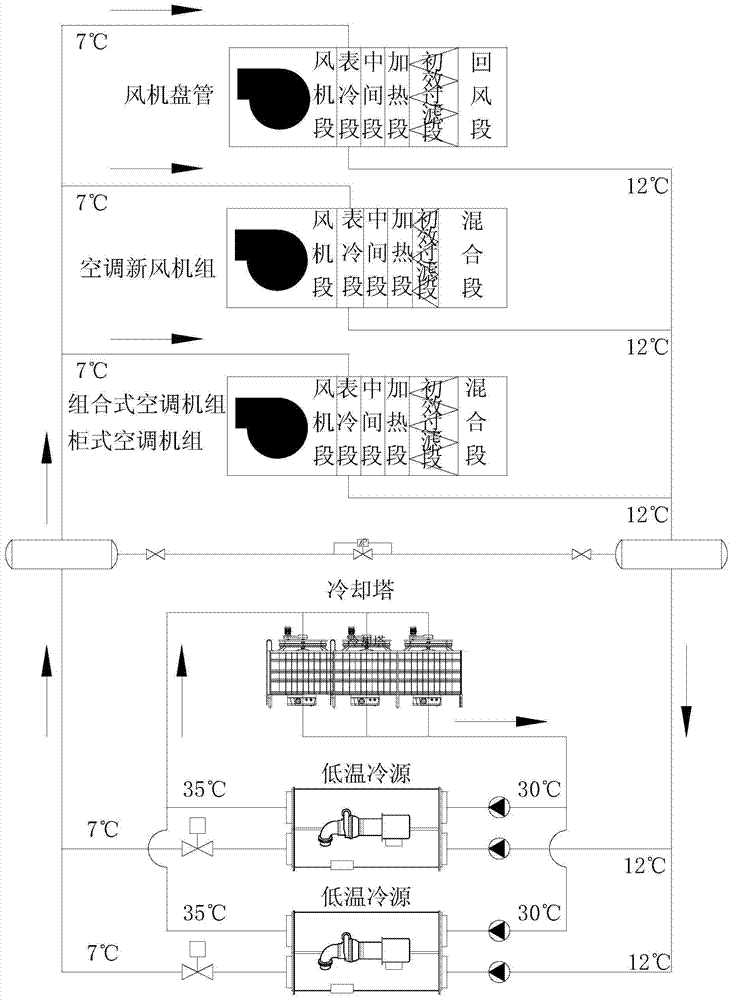

Dual-cold-source three-pipe-system air conditioner system

ActiveCN105240958AReduce energy consumptionIncrease load ratioMechanical apparatusSpace heating and ventilation safety systemsTemperature UnitWater pipe

The invention discloses a dual-cold-source three-pipe-system air conditioner system. The dual-cold-source three-pipe-system air conditioner system comprises an air conditioner terminal and a cold source system, wherein the cold source system comprises a high-temperature cold source and a low-temperature cold source; the outlet of the high-temperature cold source and the outlet of the low-temperature cold source are separately connected with a water supply pipe with a low-temperature water segregator, and the outlet of the water supply pipe is connected with the cold source inlet of the air conditioner terminal; the cold source outlet of a fan coil in the air conditioner terminal is connected with the inlet of the low-temperature cold source through a low-temperature water return pipe; a branch with a valve is arranged between the low-temperature water return pipe and the high-temperature water return pipe; the other cold source outlets of the air conditioner terminal are connected with the inlet of the high-temperature cold source through the high-temperature water return pipe; and the outlet of the high-temperature cold-source is also connected with the inlet of the low-temperature cold source. By adopting the dual-cold-source three-pipe-system air conditioner system, under the precondition that the total volume of the whole air conditioner water chilling unit is unchanged, the ratio of load borne by a high-temperature unit is improved to the greatest extent through reasonably allocating the ratios of the air conditioner load borne by the high-temperature unit and a low-temperature unit, so that the energy consumption of the cooling load of the whole air conditioner system is greatly lowered, and the air conditioner system is an energy-saving-type air conditioner system.

Owner:杭州绿程机电有限公司

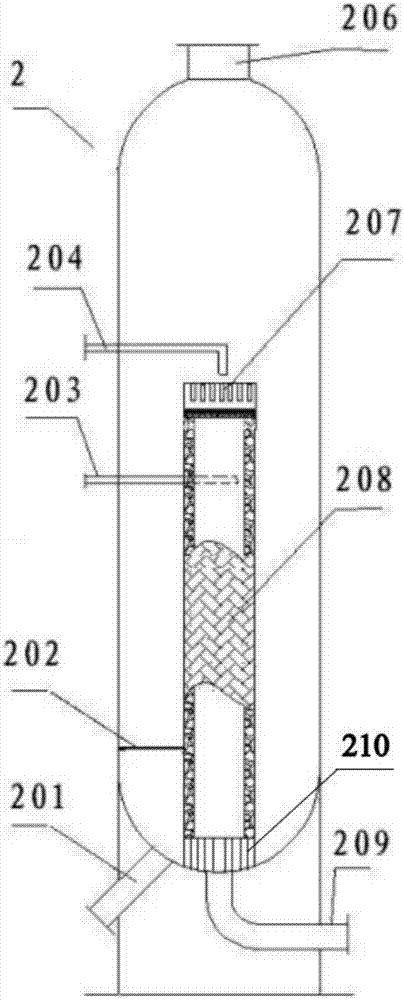

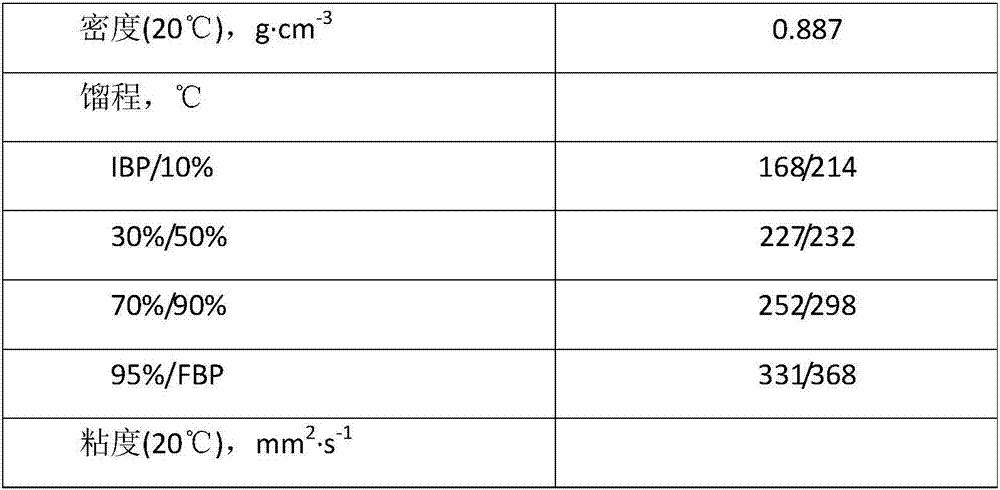

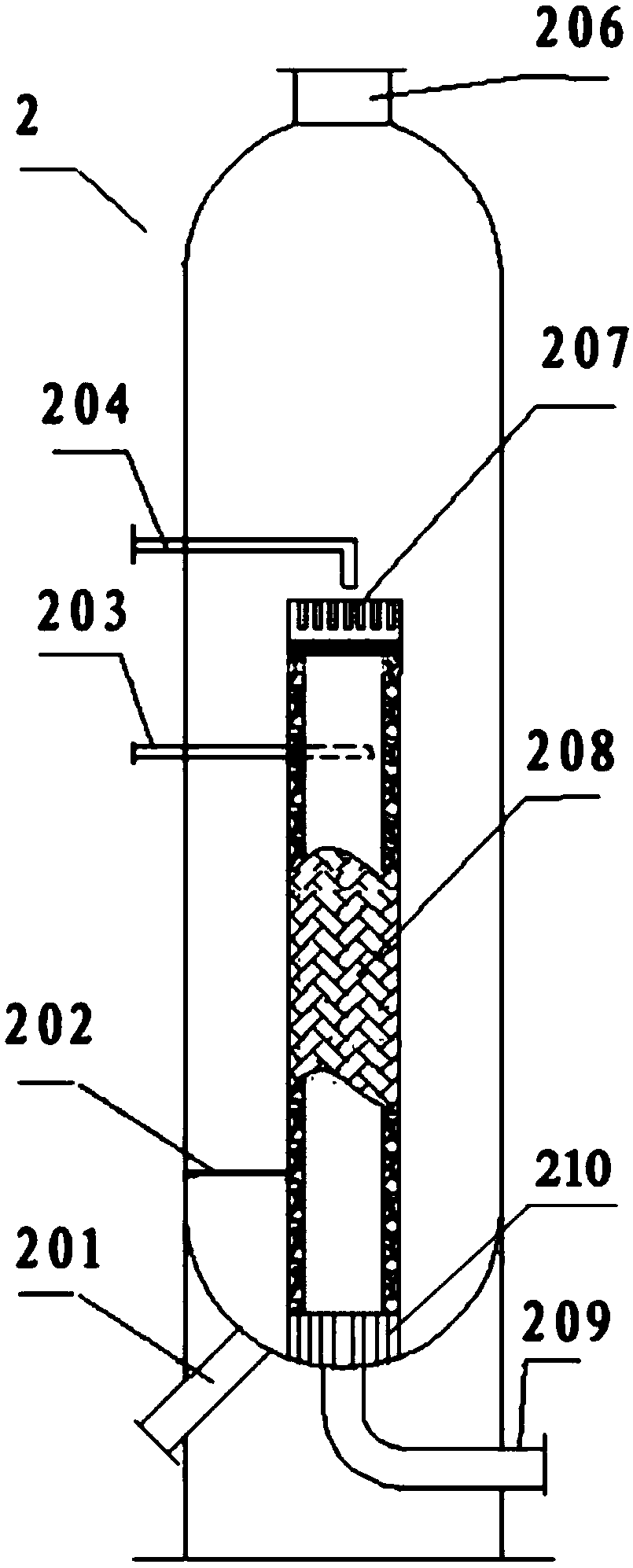

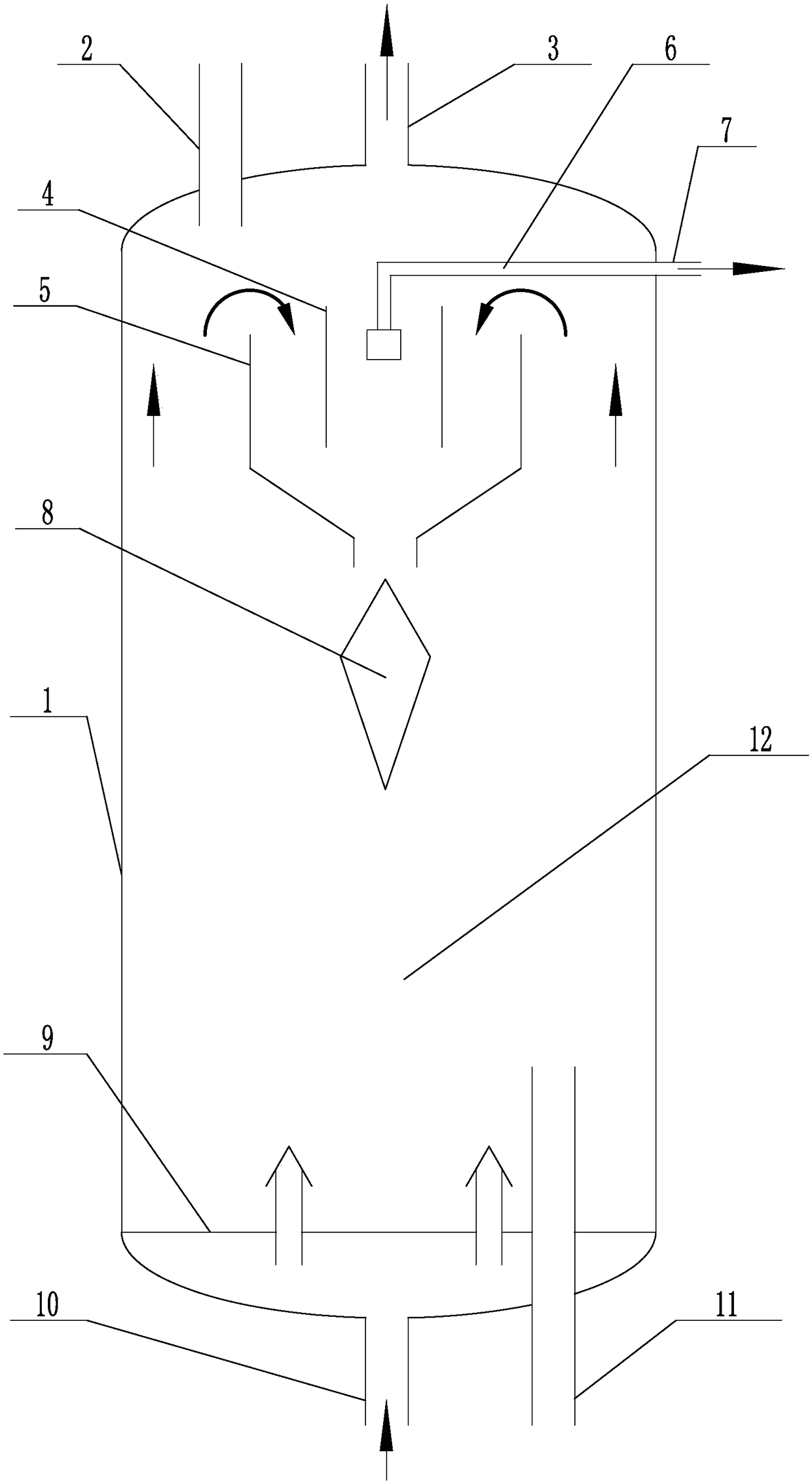

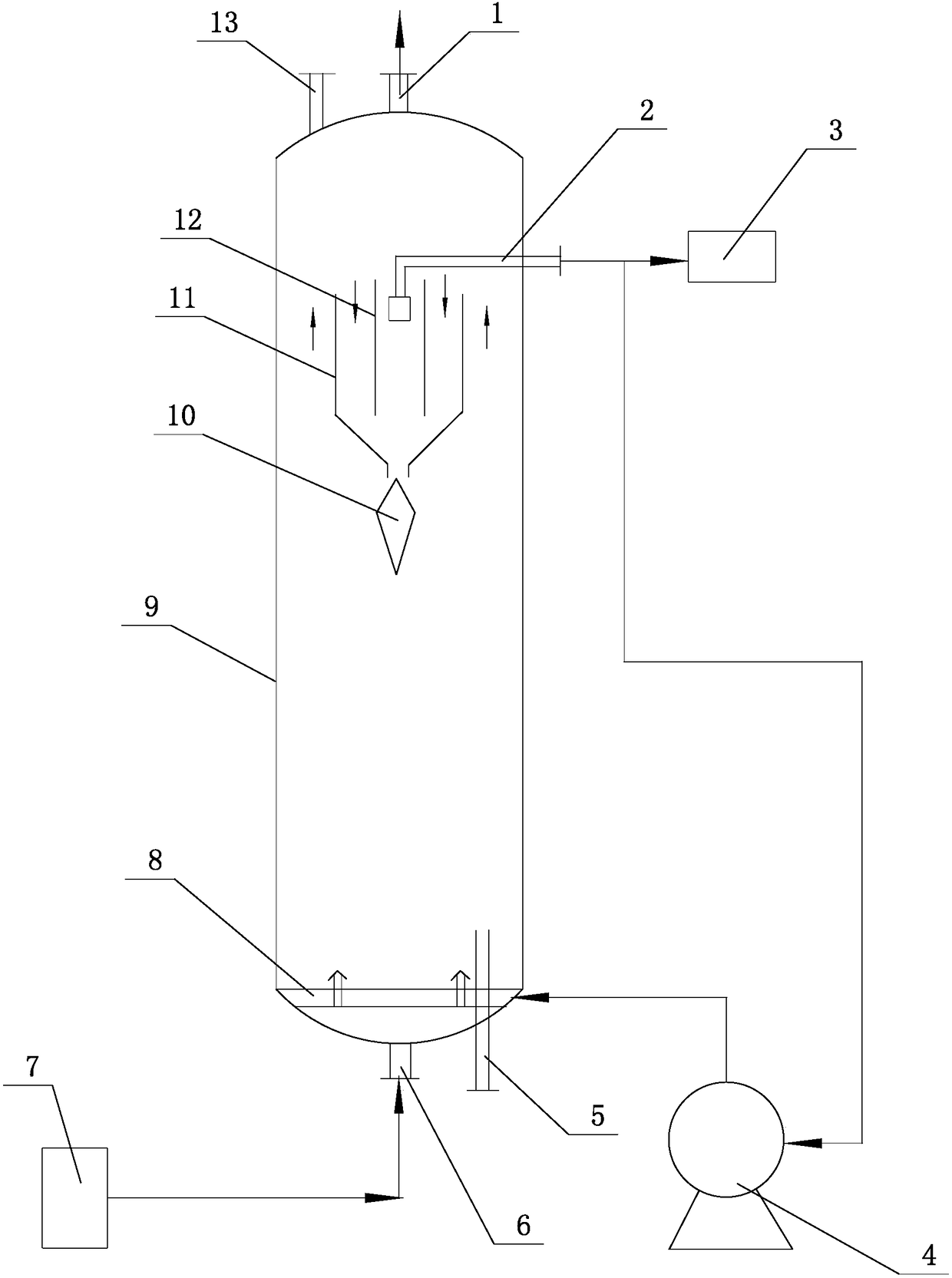

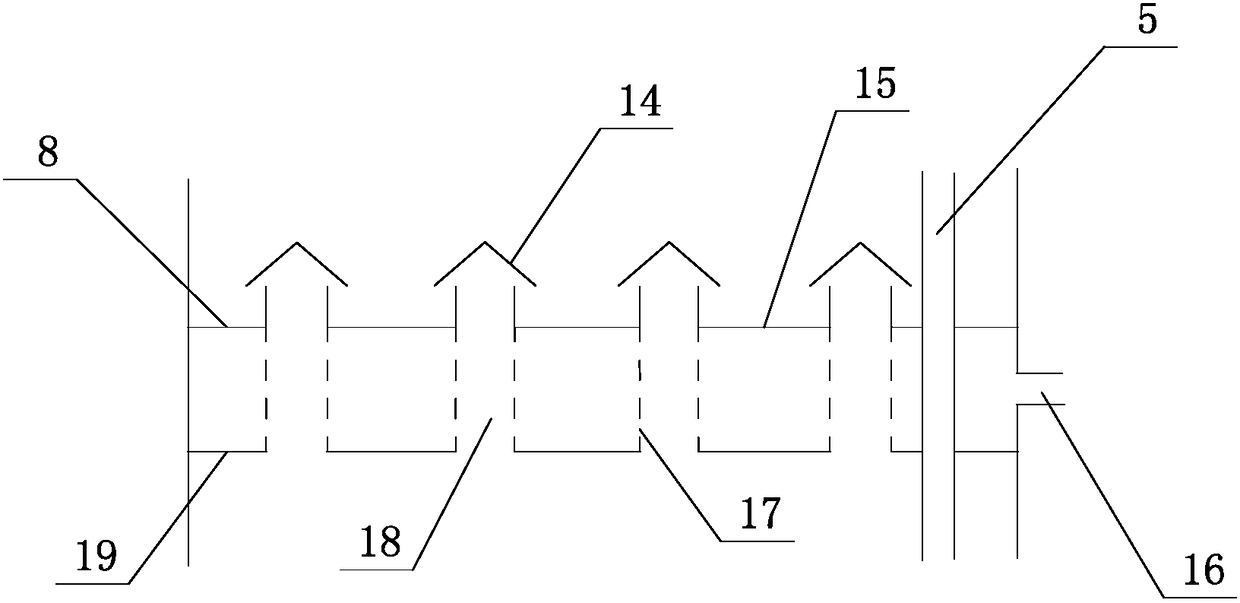

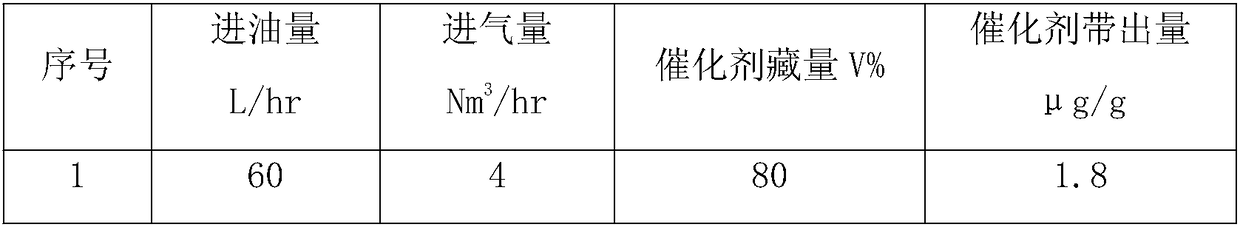

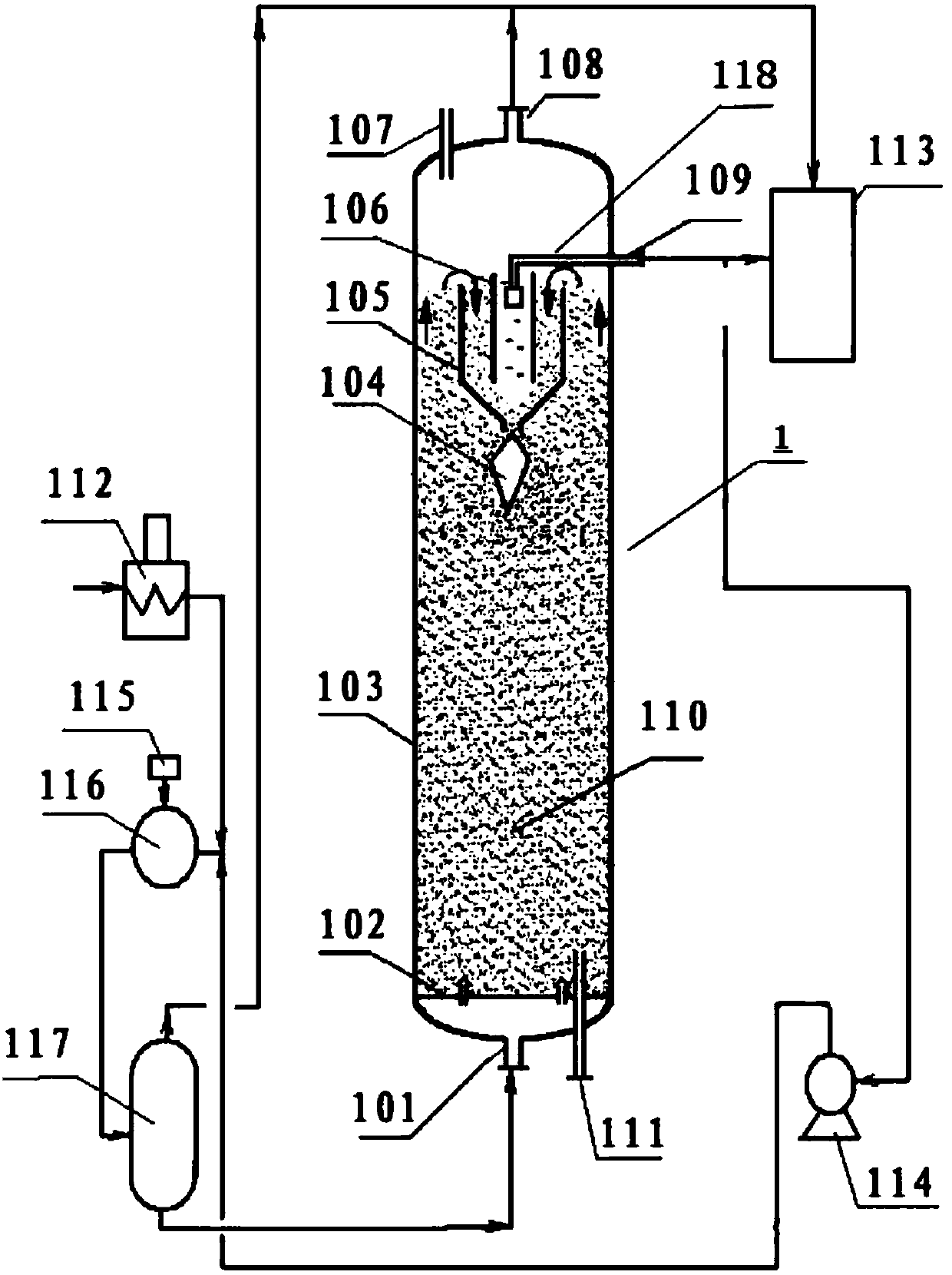

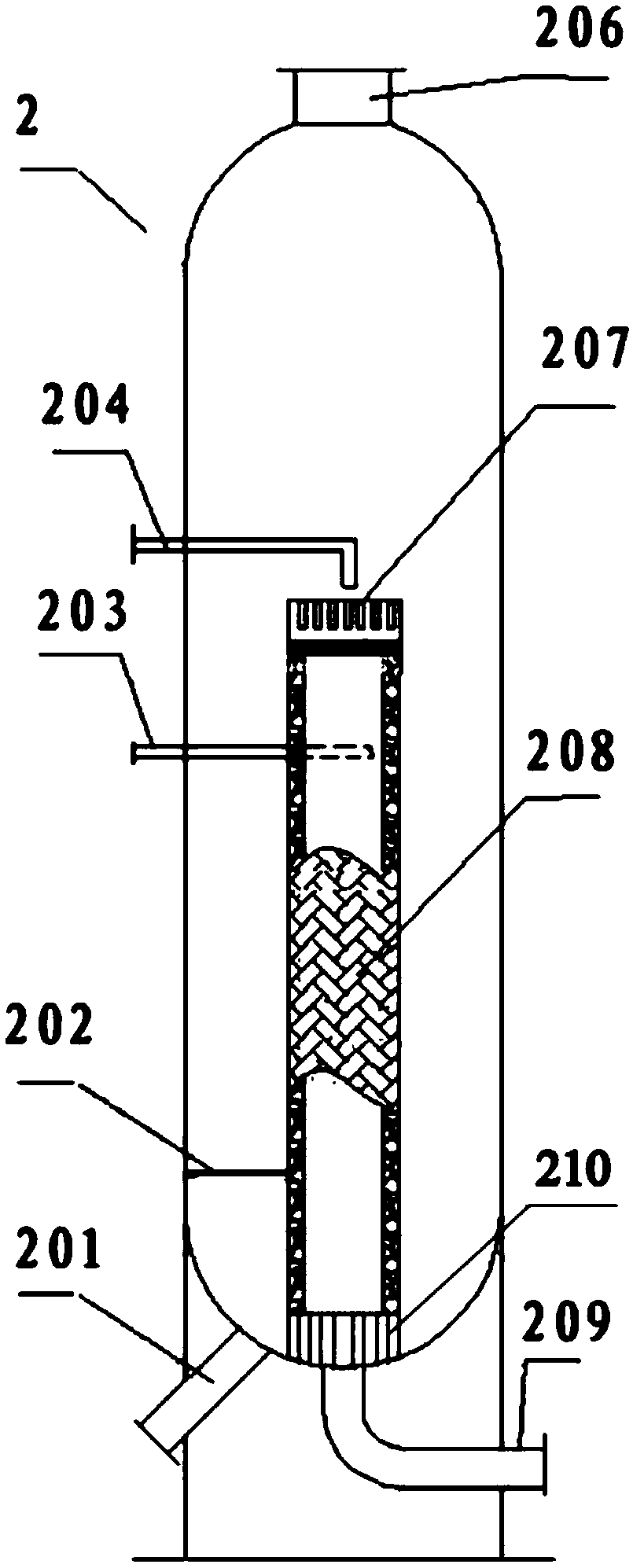

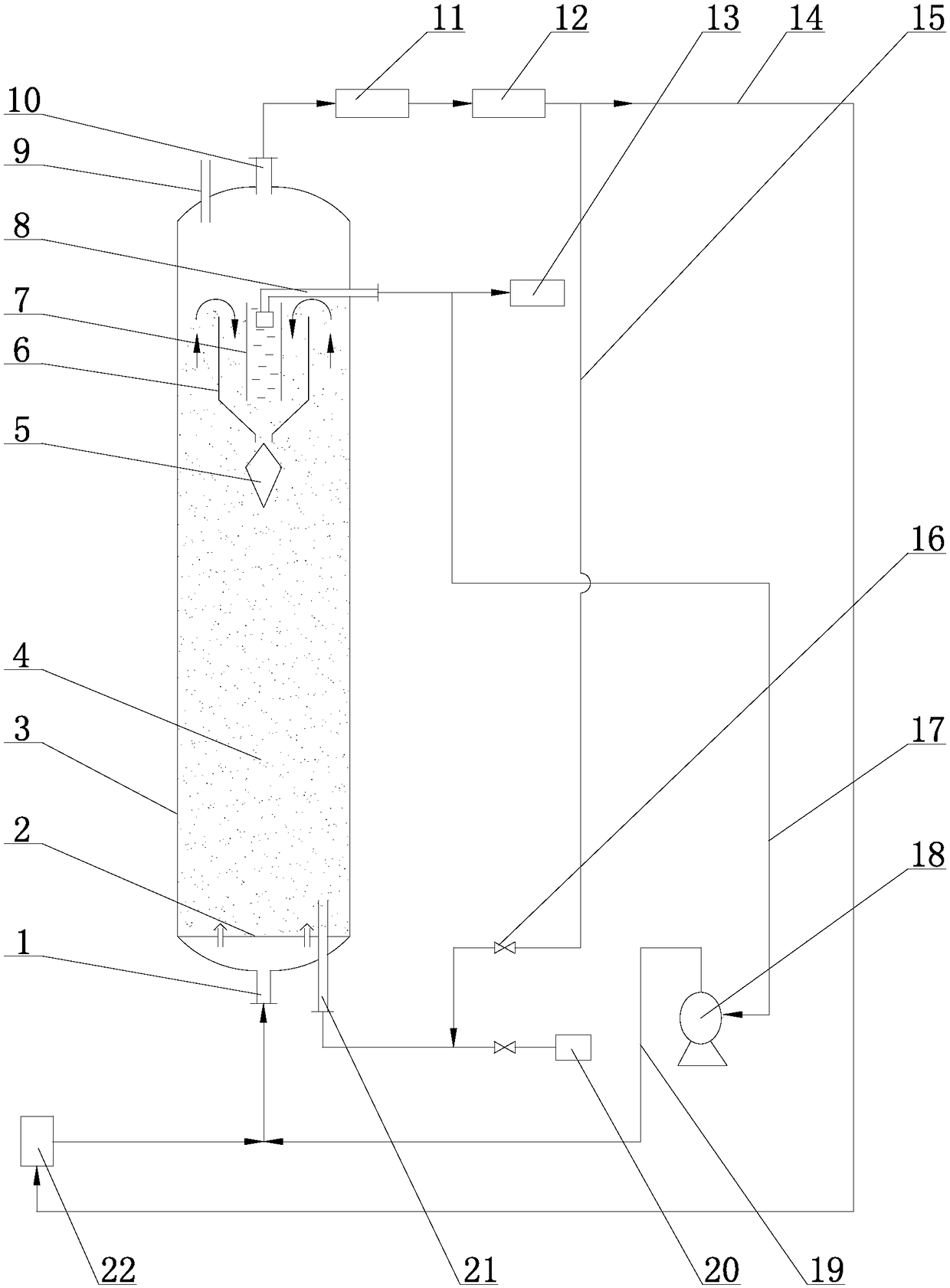

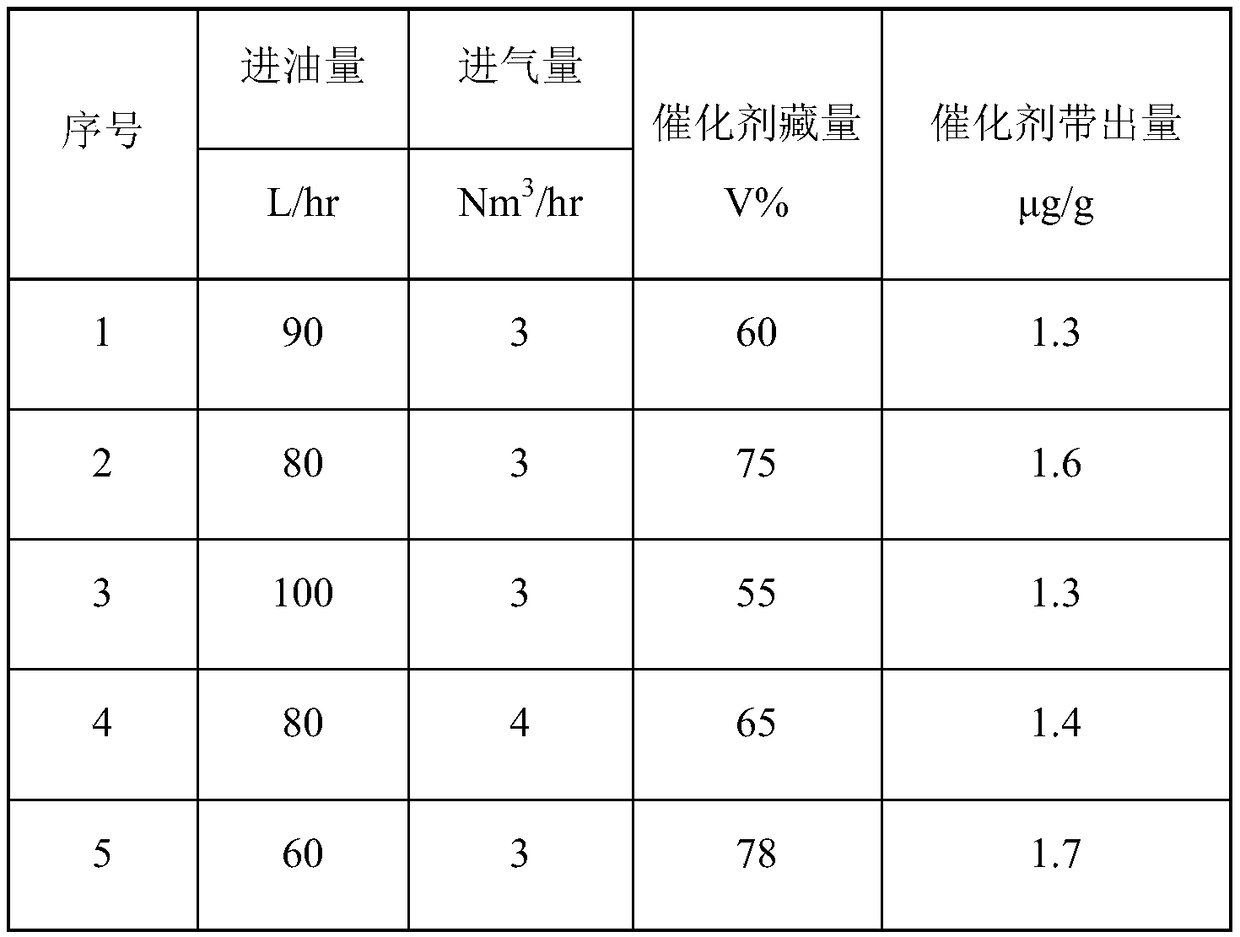

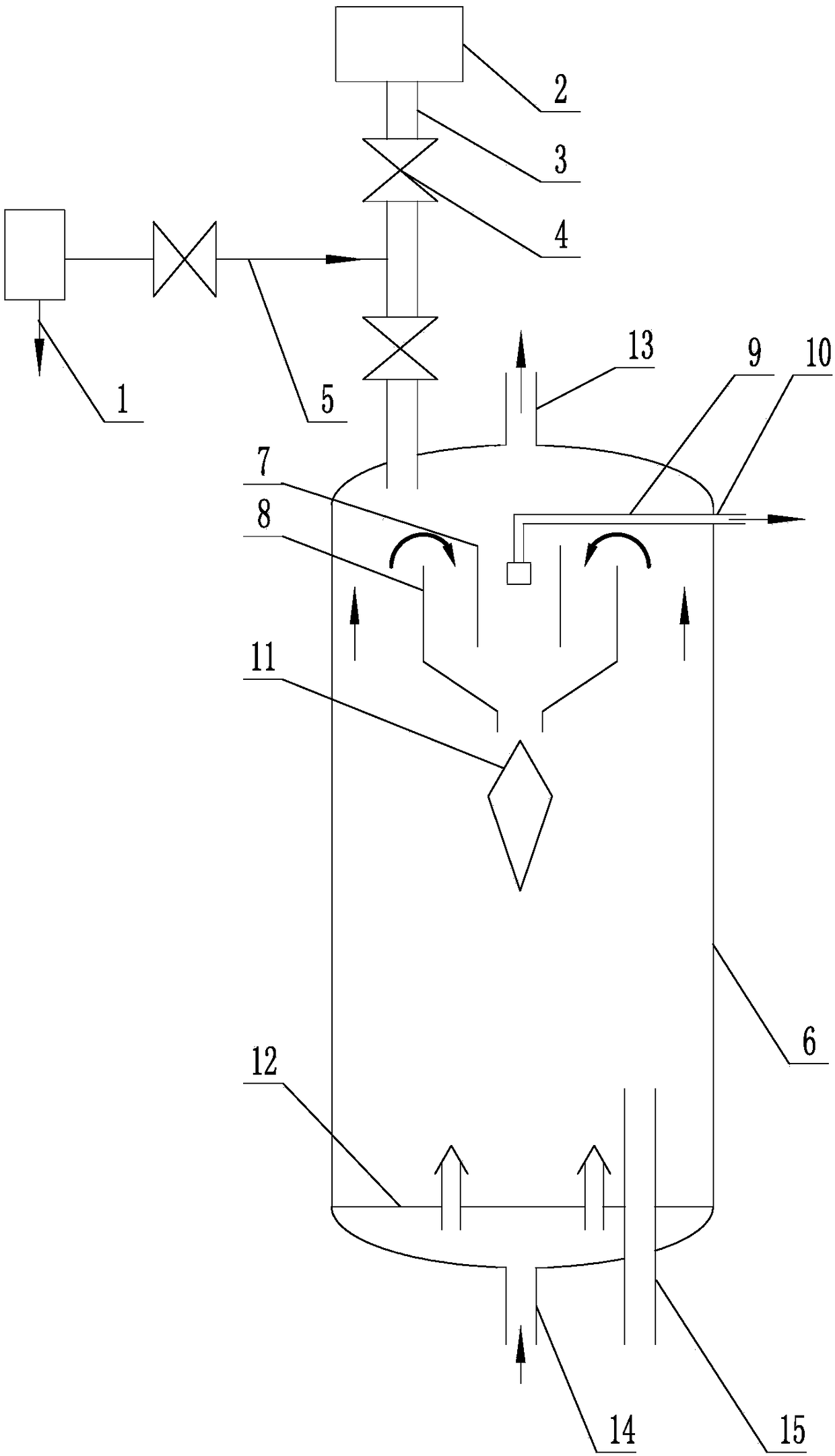

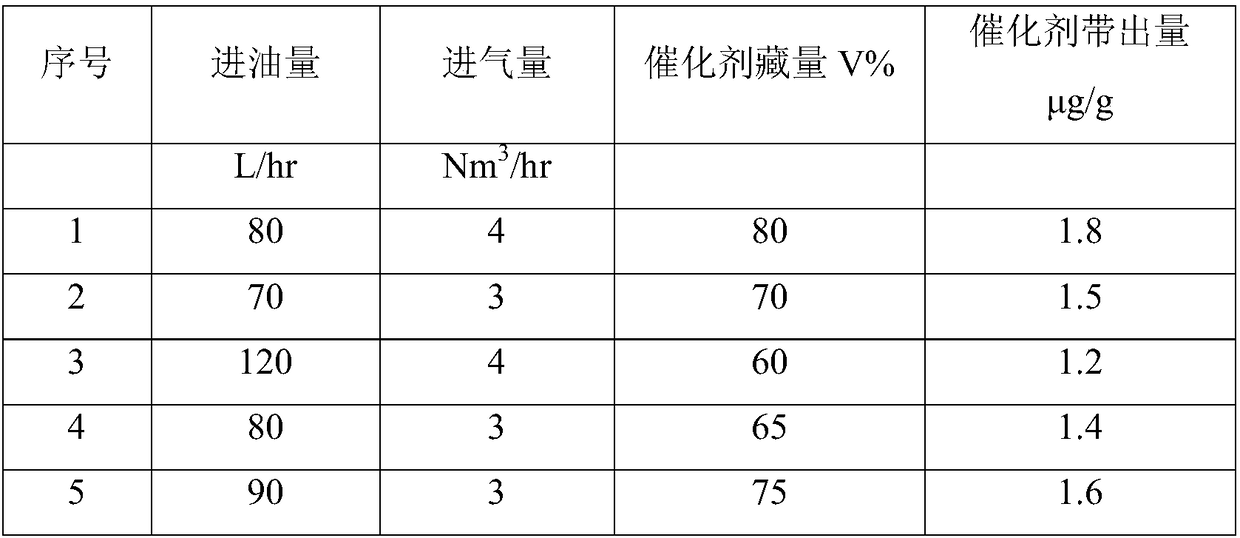

Coal tar whole-fraction fluidized bed hydrogenation method

ActiveCN107298984AIncrease profitImprove hydrogenation reaction performanceTreatment with hydrotreatment processesVapor–liquid separatorFluidized bed

The invention relates to a coal tar whole-fraction fluidized bed hydrogenation method which comprises the following steps: (1) heating coal tar whole fraction and mixing with circulation oil of a fluidized bed reactor; (2) mixing the mixture in the step (1) and hydrogen, dissolving the hydrogen, and enabling the mixture to enter a gas-liquid separator; (3) enabling a gaseous phase on the top of the gas-liquid separator in the step (2) to enter a fixed bed hydrogenation reactor from the top of the reactor, and enabling a liquid phase to enter the fluidized bed reactor from the bottom of the reactor so as to carry out a hydrogenation reaction; and (4) arranging a three-phase separator on the upper part inside the fluidized bed reactor in the step (3), discharging the gaseous phase separated from the three-phase separator from the top of the fluidized bed reactor to the fixed bed hydrogenation reactor in the step (3), and taking at least one part of the liquid phase through a circulatory system as the circulation oil in the step (1). Compared with the prior art, the method disclosed by the invention has the advantages that the steady operation problem existing in coal tar whole-fraction fluidized bed hydrogenation can be effectively solved, and the coal tar whole-fraction fluidized bed hydrogenation reaction effect is improved.

Owner:上海竣铭化工工程设计有限公司

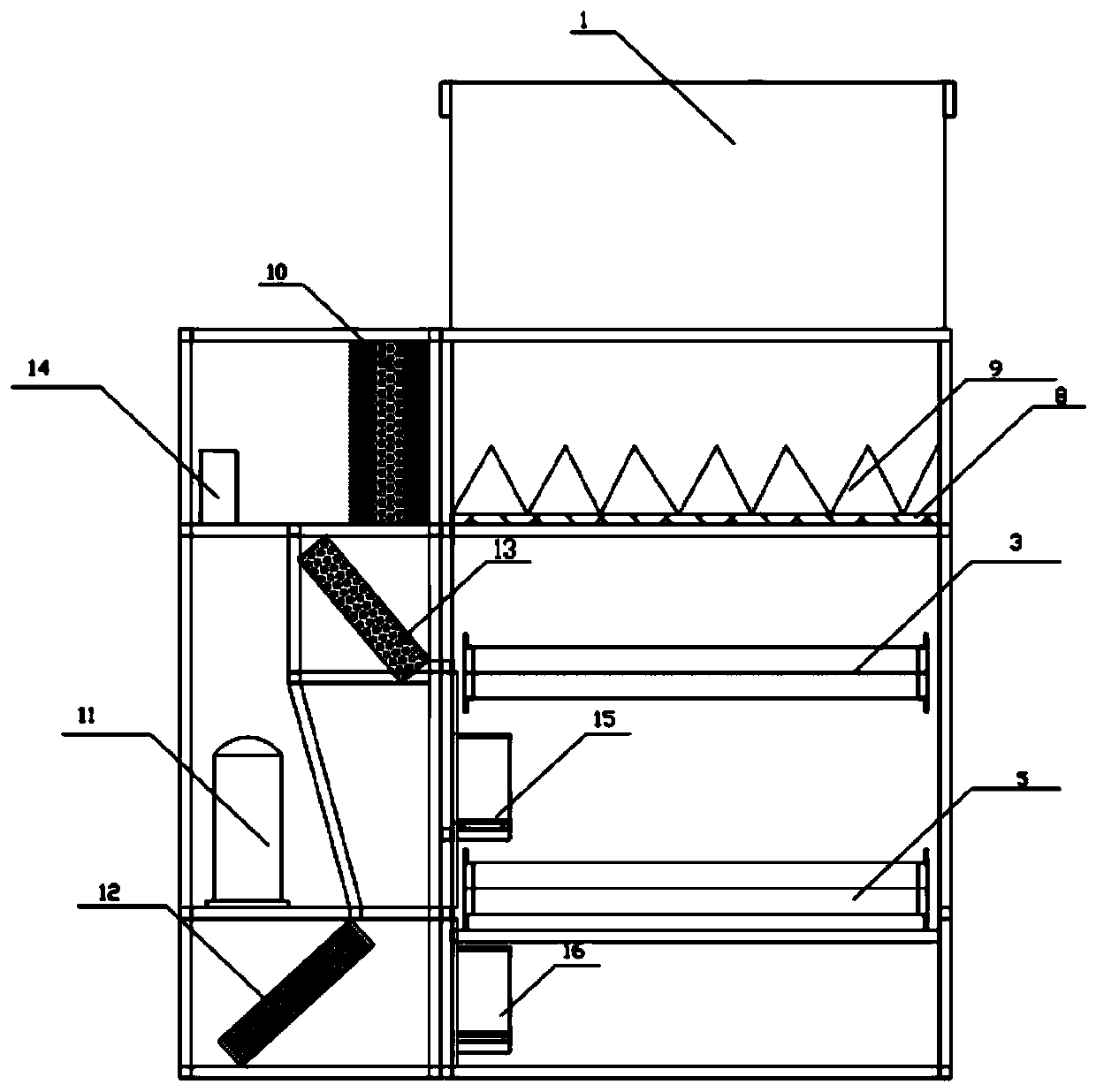

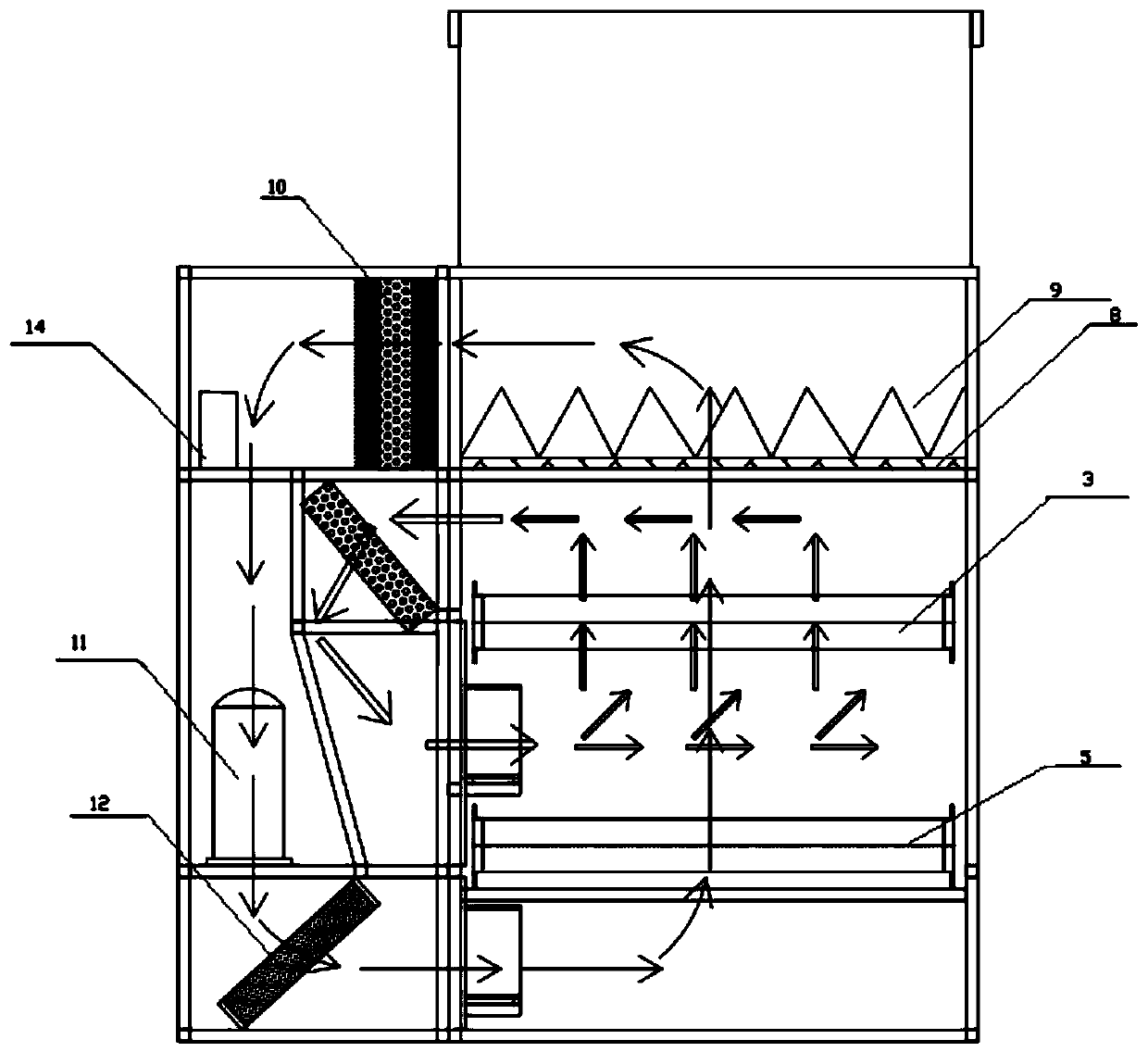

Sludge low-temperature heat pump drying equipment

PendingCN110127984AReduce loadIncrease load ratioSludge treatment by de-watering/drying/thickeningHeat pumpsSludgeAir filter

The invention relates to sludge low-temperature heat pump drying equipment, which comprises a sludge drying chamber, wherein a sludge feeding and distributing device is arranged above one side of thesludge drying chamber; a heat pump system chamber is arranged at one side of the sludge drying chamber; a heat pump system is arranged in the heat pump system chamber; the sludge feeding and distributing device comprises a sludge feeding hopper and a sludge distributing machine which are arranged from top to bottom; the sludge drying chamber is provided with a sludge inlet; the distributing machine is connected with the sludge inlet; a sludge outlet is arranged at the bottom of the sludge drying chamber; and an air filtering device is arranged at the upper part of the sludge drying chamber. Aplurality of layers of conveyor mesh belts are arranged in the middle of the sludge drying chamber, a discharging device is arranged below the lowermost conveyor mesh belt, the discharging device is connected with the sludge outlet, an auxiliary fan is arranged between any two adjacent layers of conveyor mesh belts, and a plurality of main fans are arranged at the bottom of the sludge drying chamber. The sludge low-temperature heat pump drying equipment has the advantages of low drying energy consumption, no secondary pollution, high safety performance, compact structure and small occupied area.

Owner:四川天润德环境工程有限公司

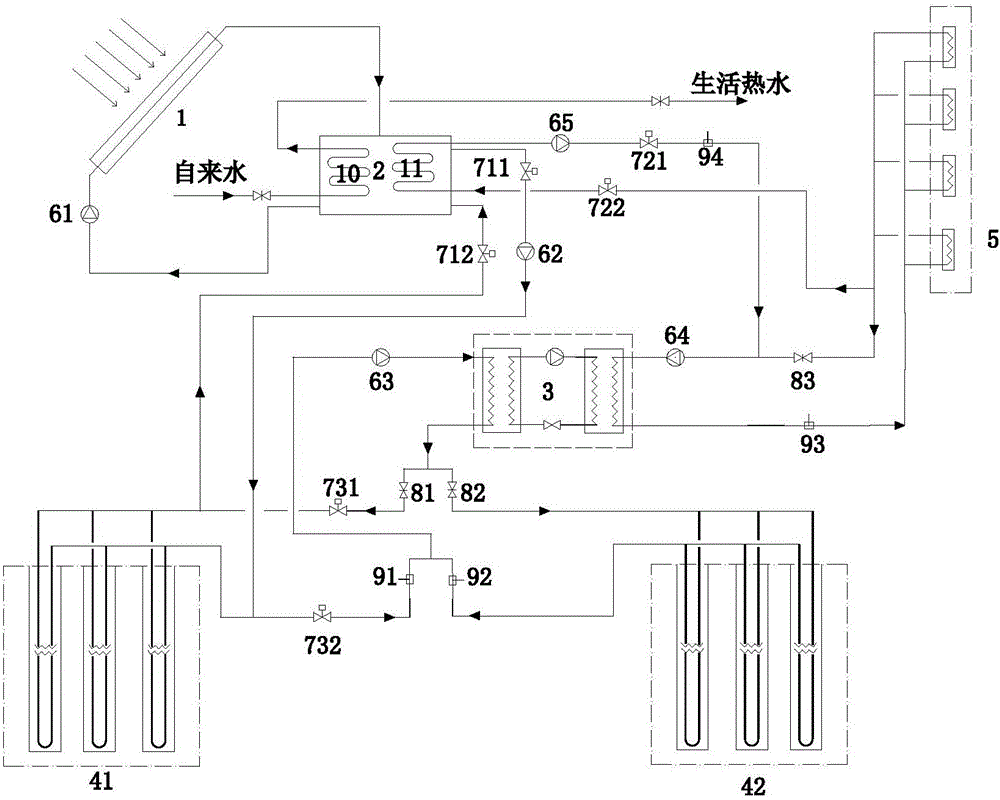

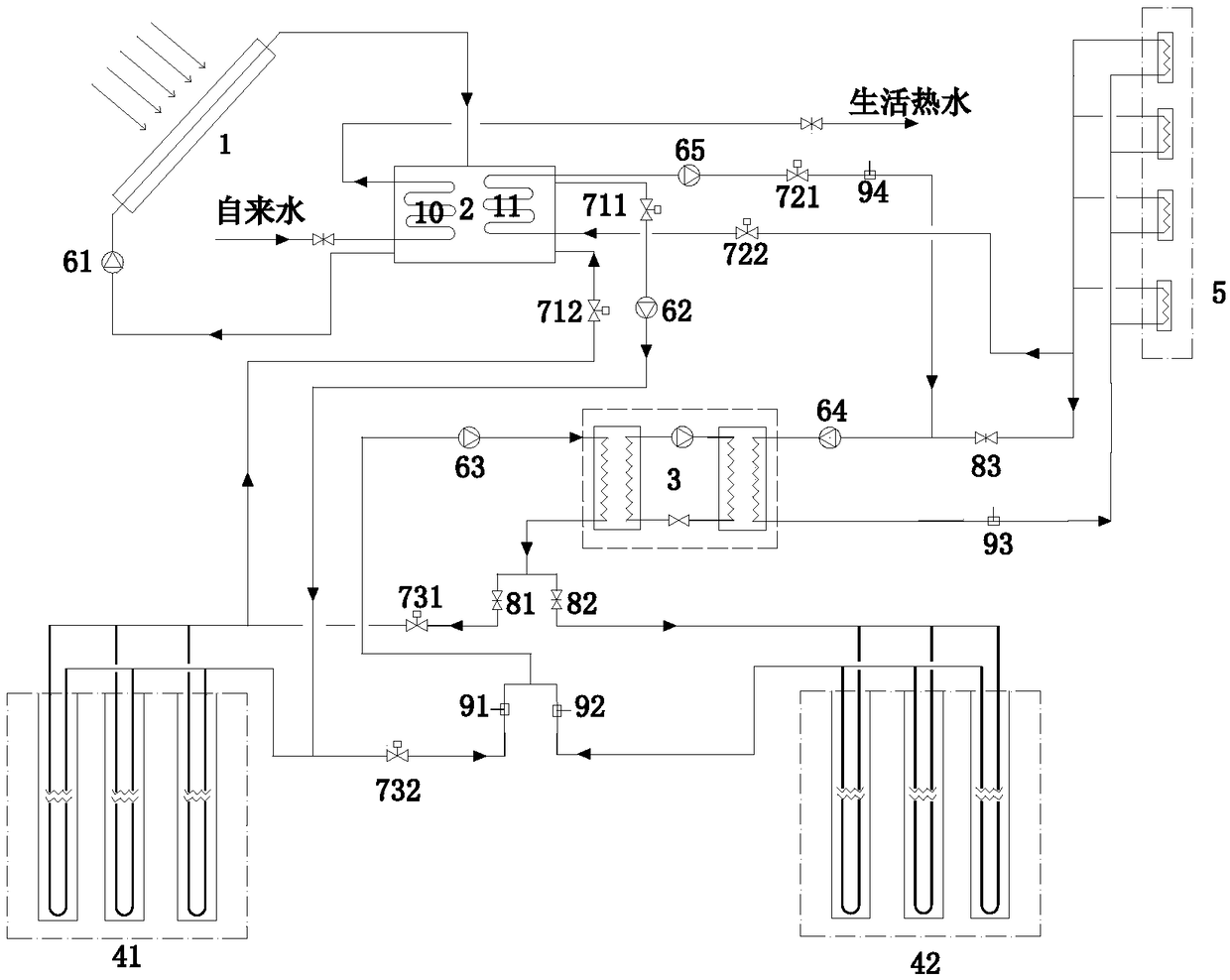

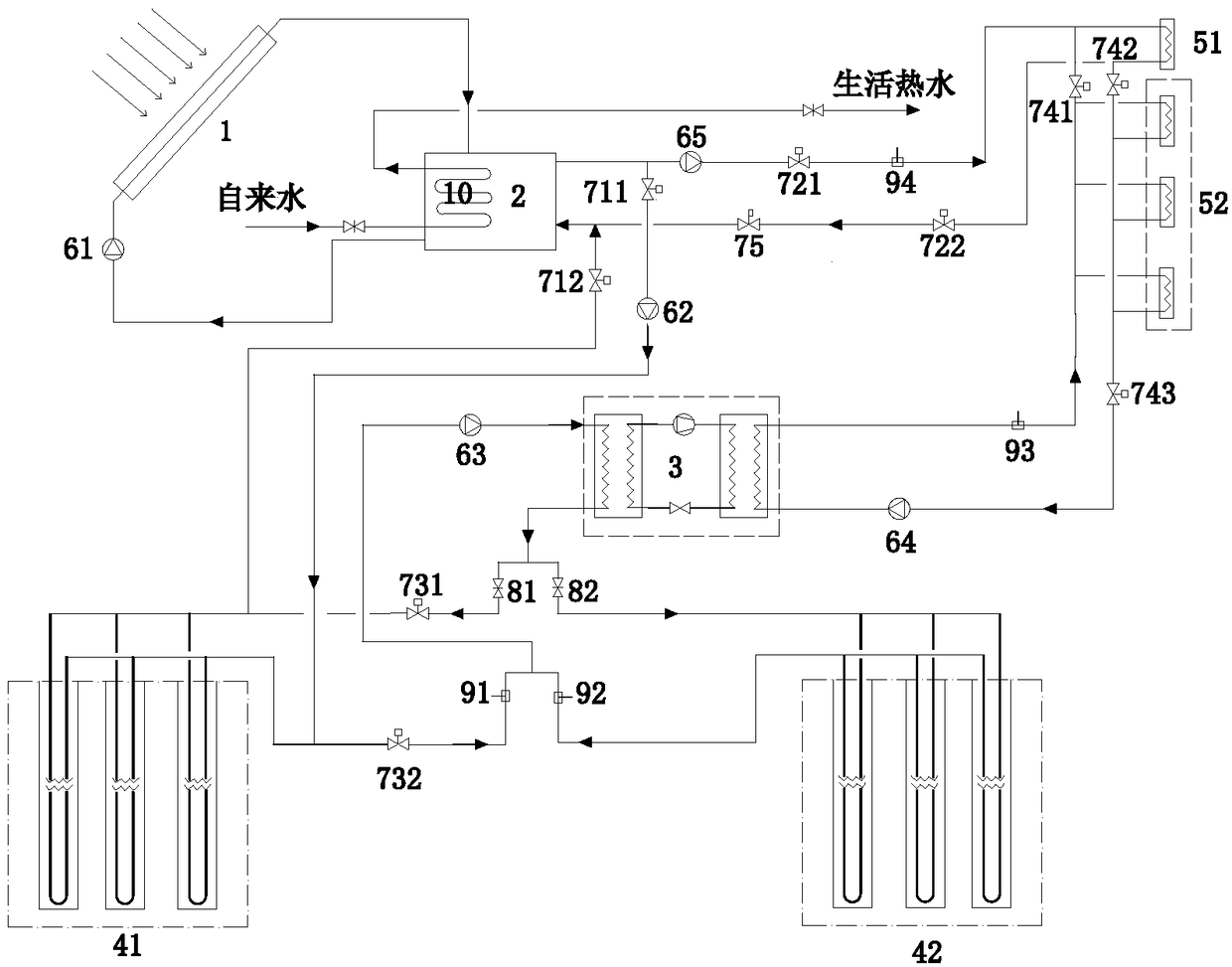

Solar energy-ground source heat pump coupling type energy supply system provided with two buried pipe groups

ActiveCN106196714AAchieve thermal balanceSolve solar heat storage across seasonsSolar heating energyHeat pumpsCouplingEnergy supply

The invention relates to a solar energy-ground source heat pump coupling type energy supply system provided with two buried pipe groups. The solar energy-ground source heat pump coupling type energy supply system provided with the two buried pipe groups is characterized in that the energy supply system comprises a solar heat collector, a heat-storage water tank, a ground source heat pump unit, the first buried pipe group, the second buried pipe group, a building tail end device, a heat-collection circulating water pump, a heat-storage circulating water pump, a ground source side circulating water pump, a first heat-storage control valve, a second heat-storage control valve, a first ground source side control valve, a second ground source side control valve, a first pipe group flow regulation valve, a second pipe group flow regulation valve, a first pipe group heat meter and a second group pipe heat meter; the solar heat collector is sequentially connected with the heat-storage water tank and the heat-collection circulating water pump through pipelines, namely a heat collection cycle is formed, and hot water generated by solar energy is collected; and the hot water outflow end of the heat-storage water tank is sequentially connected with the first heat-storage control valve, the heat-storage circulating water pump, the first buried pipe group, the second heat-storage control valve and the backflow end of the heat-storage water tank through pipelines, so that a heat storage cycle is formed.

Owner:河北泓宇能源科技有限公司

Solar-ground source heat pump coupled energy supply system and operating method thereof

ActiveCN106369872AAchieve thermal balanceSolve solar heat storage across seasonsHeating fuelHeat pumpsOperation modeSoil temperature

The invention relates to a solar-ground source heat pump coupled energy supply system and an operating method thereof. A large unit, a small unit and solar hot water are adopted to supply heat to a building, the two units are interconnected and intercommunicated at the tail end and ground source side of the building, the heat is supplied to the building under various modes by using two ground source heat pump systems and the solar hot water according to an actual thermal load requirement, the operation mode of the system is optimized under the condition of ensuring that the soil temperatures of the ground source heat pumps are balanced, and efficient operation for cooling in summer and heating in winter is realized. When bearing an extremely low heat supply load within a relatively long period of time, the heat supply requirement of the building is met through supplying heat by solar-assisted ground source heat pumps and directly supplying heat by solar energy; and when bearing a normal heat supply load, the heat supply requirement of the building is met by using a pure ground source heat pump unit.

Owner:河北泓宇能源科技有限公司

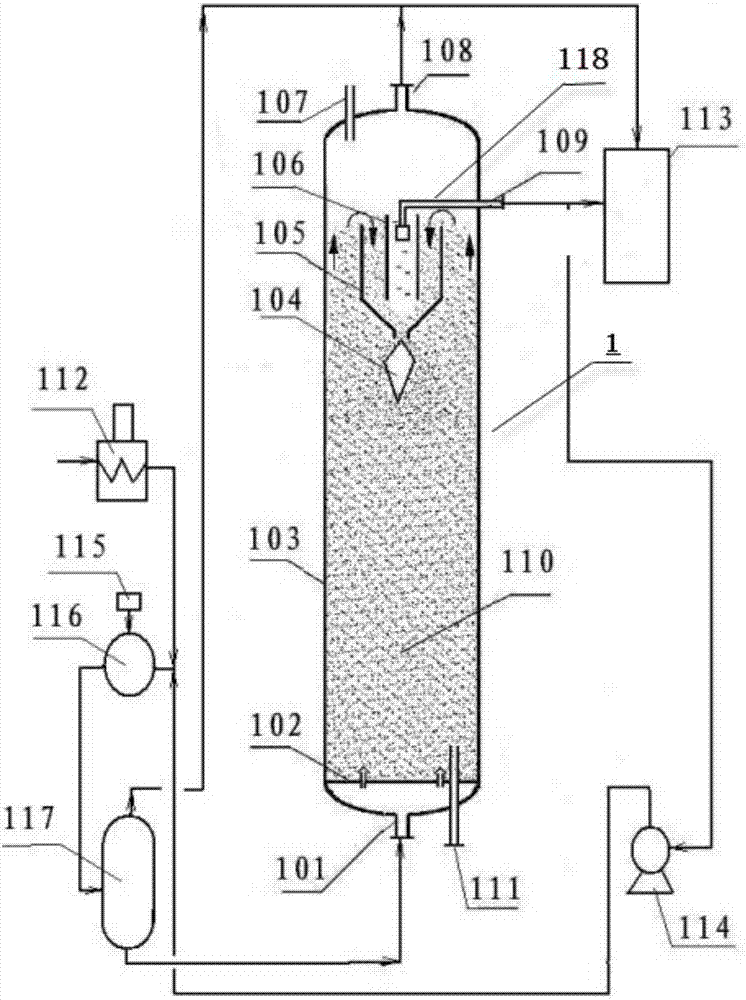

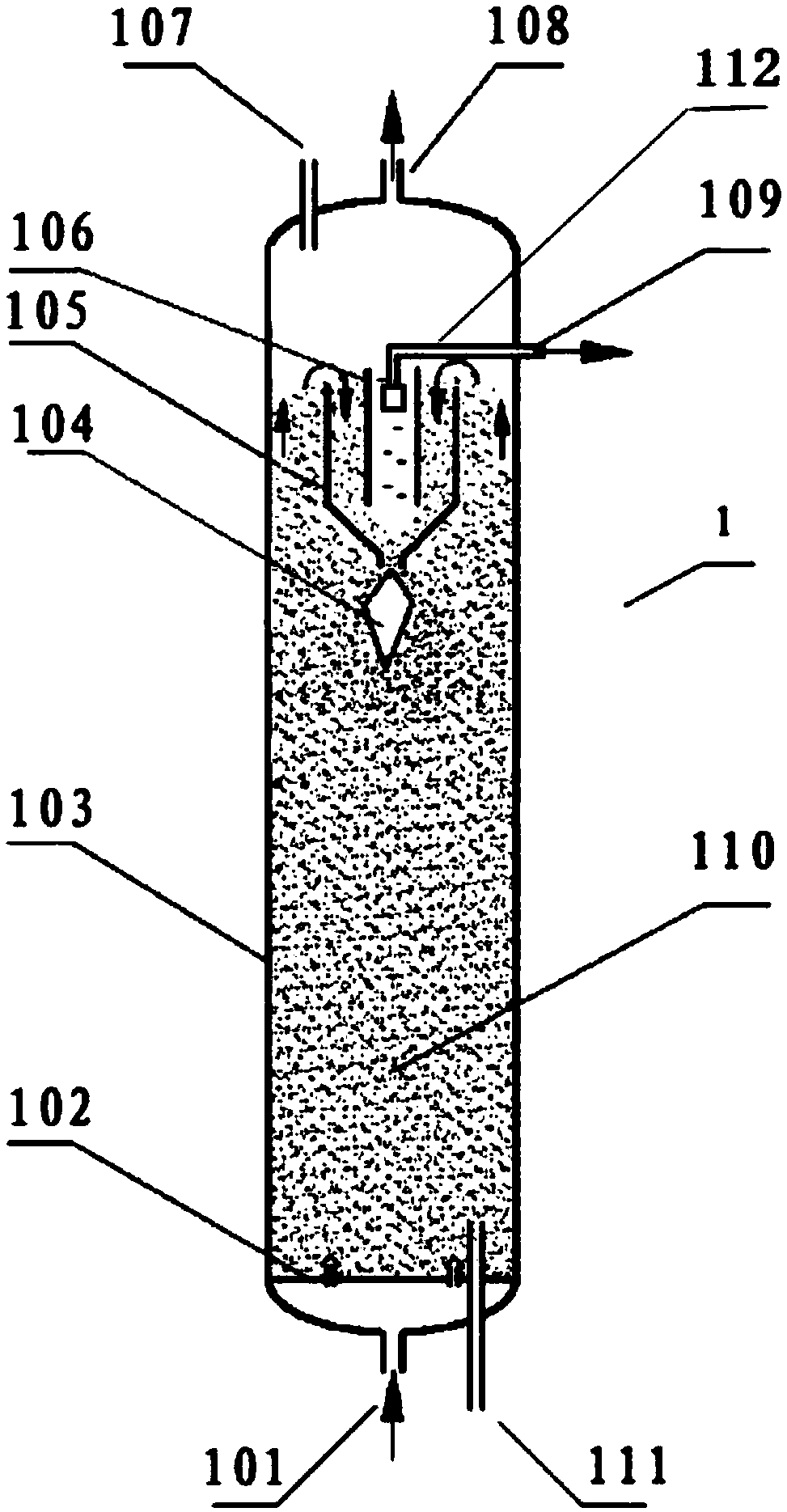

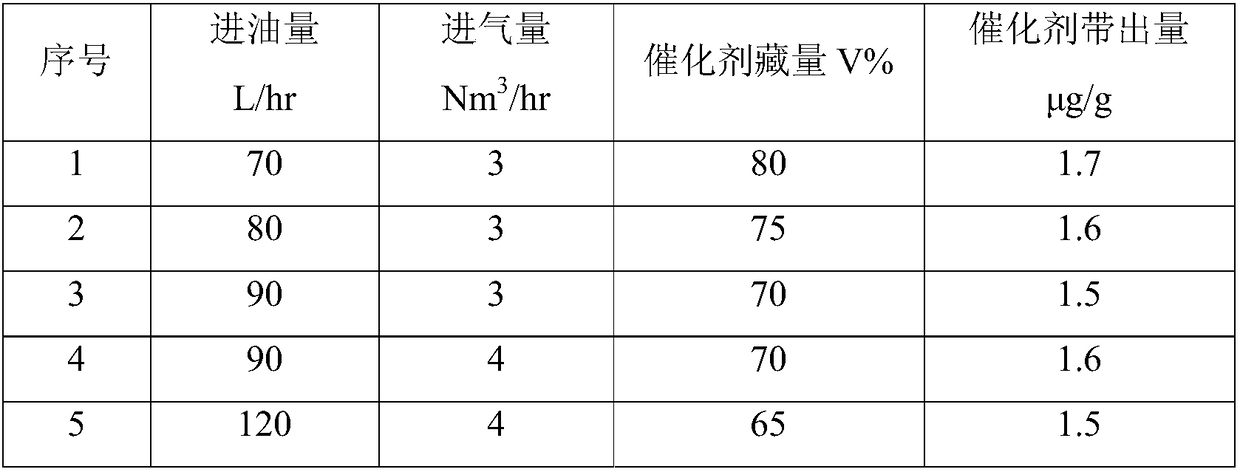

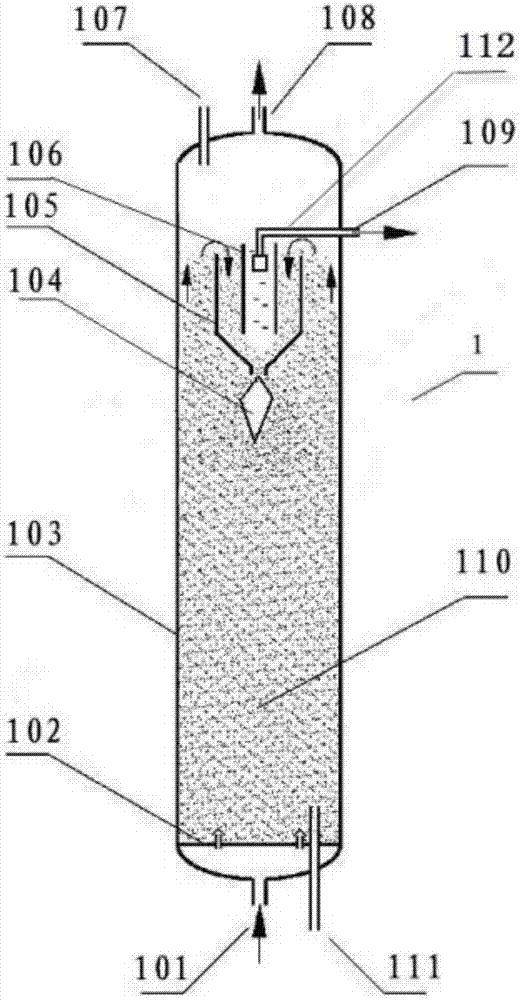

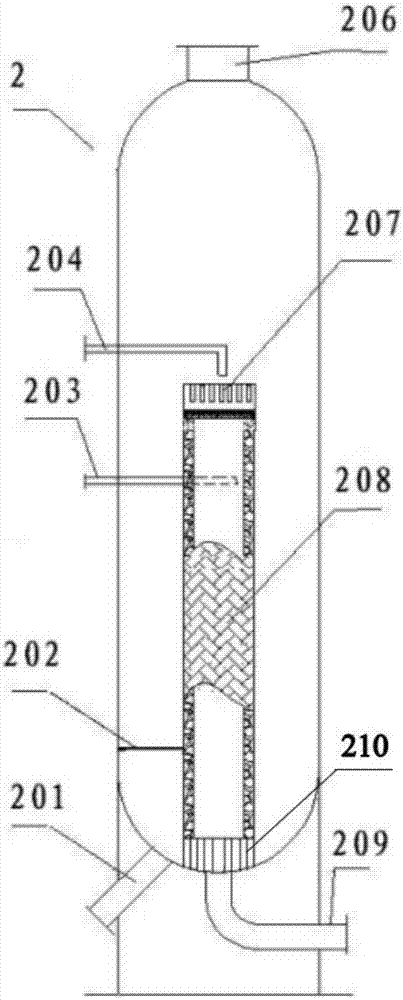

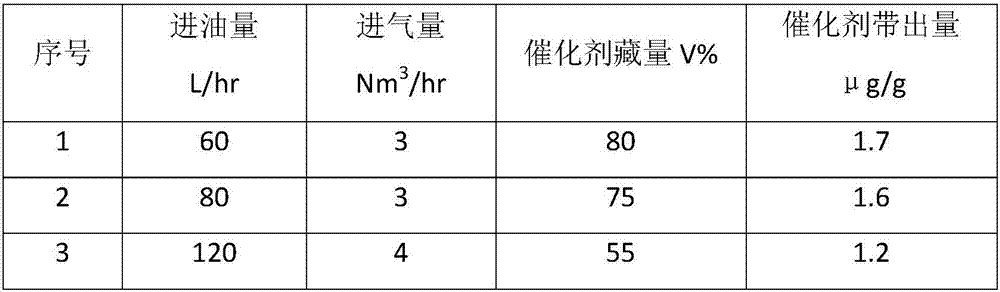

A kind of fluidized bed hydrogenation reaction system and fluidized bed hydrogenation method

ActiveCN107297186BEasy to separateSolve the resistanceChemical/physical processesHydrogenation reactionFluidized bed

The invention relates to a fluidized bed hydrogenation reaction system, which comprises a fluidized bed reactor, wherein the fluidized bed reactor comprises a reactor barrel; a three-phase separator is arranged at the upper part of the reactor barrel and comprises an inner barrel and an outer barrel; openings are formed in the upper ends and the lower ends of the inner barrel and the outer barrel; the opening in the upper end of the outer barrel is lower than that of the inner barrel and the opening in the lower end of the outer barrel is lower than that of the inner barrel; the inner barrel is a straight barrel segment; the straight barrel segment is arranged at the upper part of the outer barrel and a frustum-shaped contraction segment is arranged at the lower part; the opening in the lower end of the contraction segment is the opening in the lower end of the outer barrel; and a gap is arranged between the opening in the lower end of the inner barrel and the outer barrel contraction segment, so that a material passes through the gap. The fluidized bed hydrogenation reaction system is adopted by the fluidized bed hydrogenation method, so that the utilization rate (namely the catalyst inventory in the reactor) of the reactor is further improved, and the hydrogenation reaction effect can be further improved.

Owner:上海竣铭化工工程设计有限公司

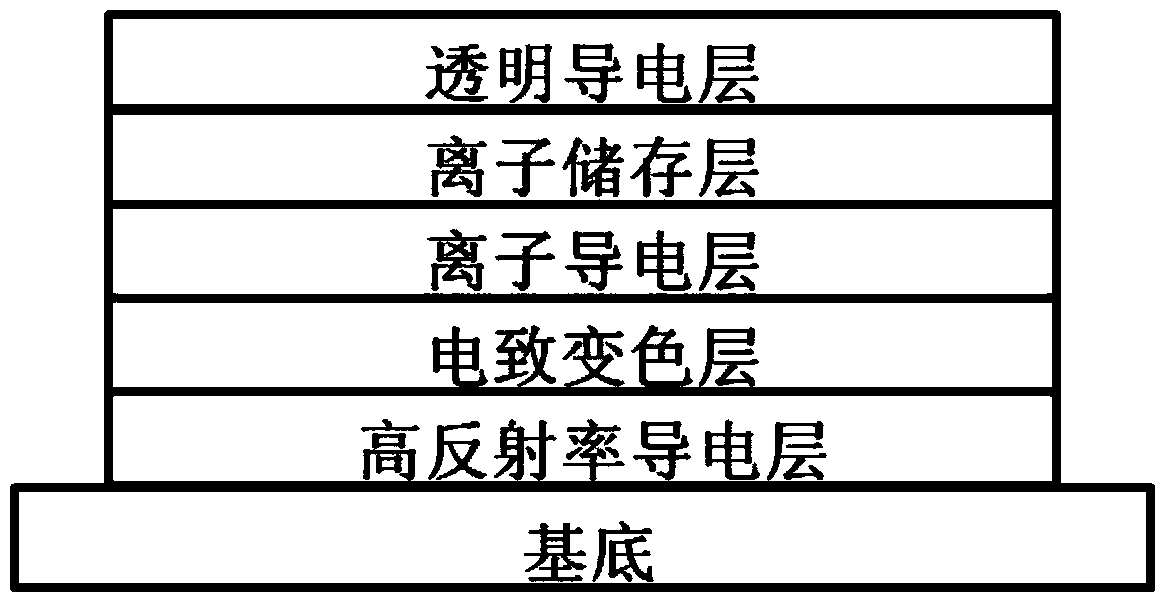

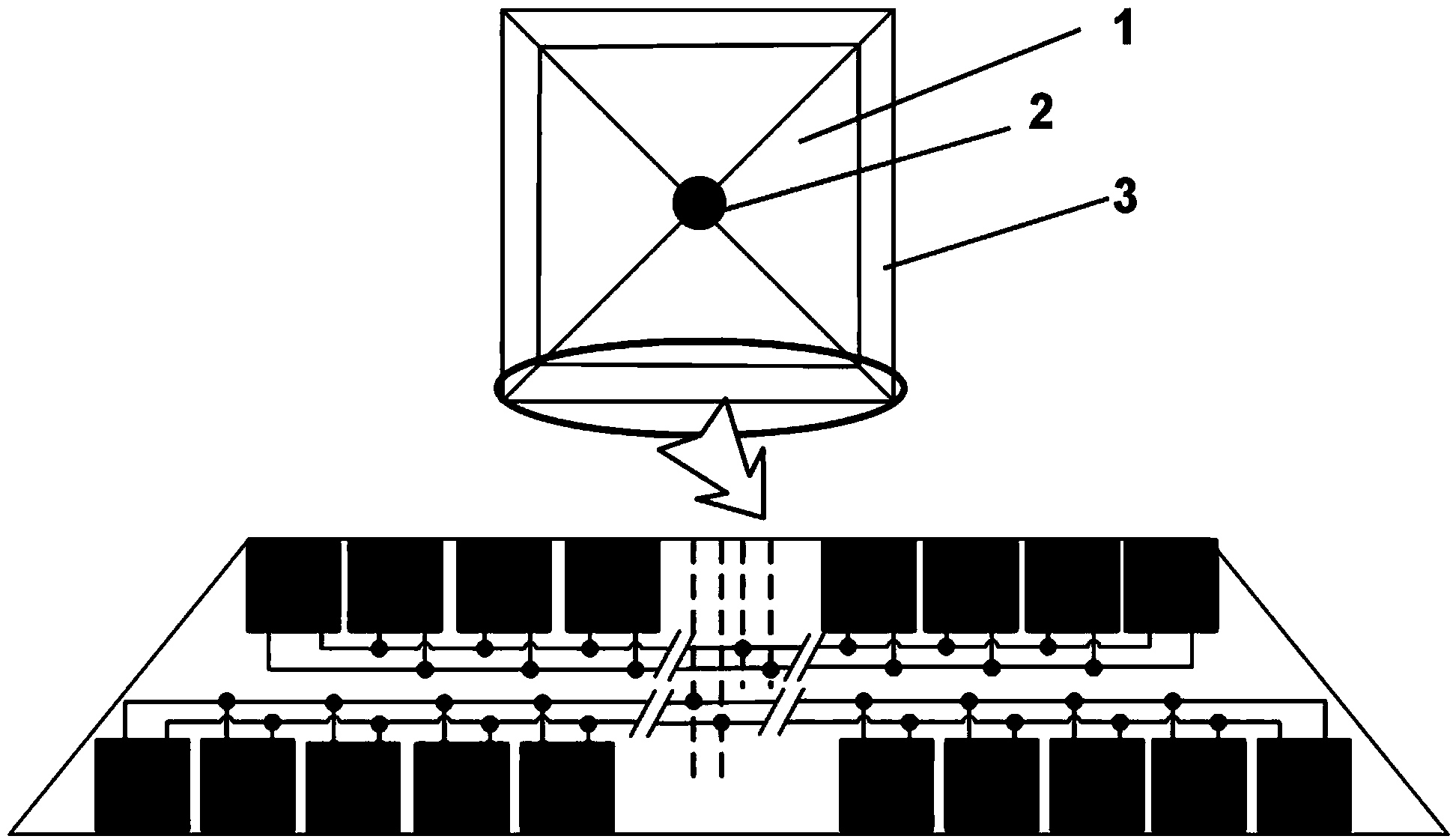

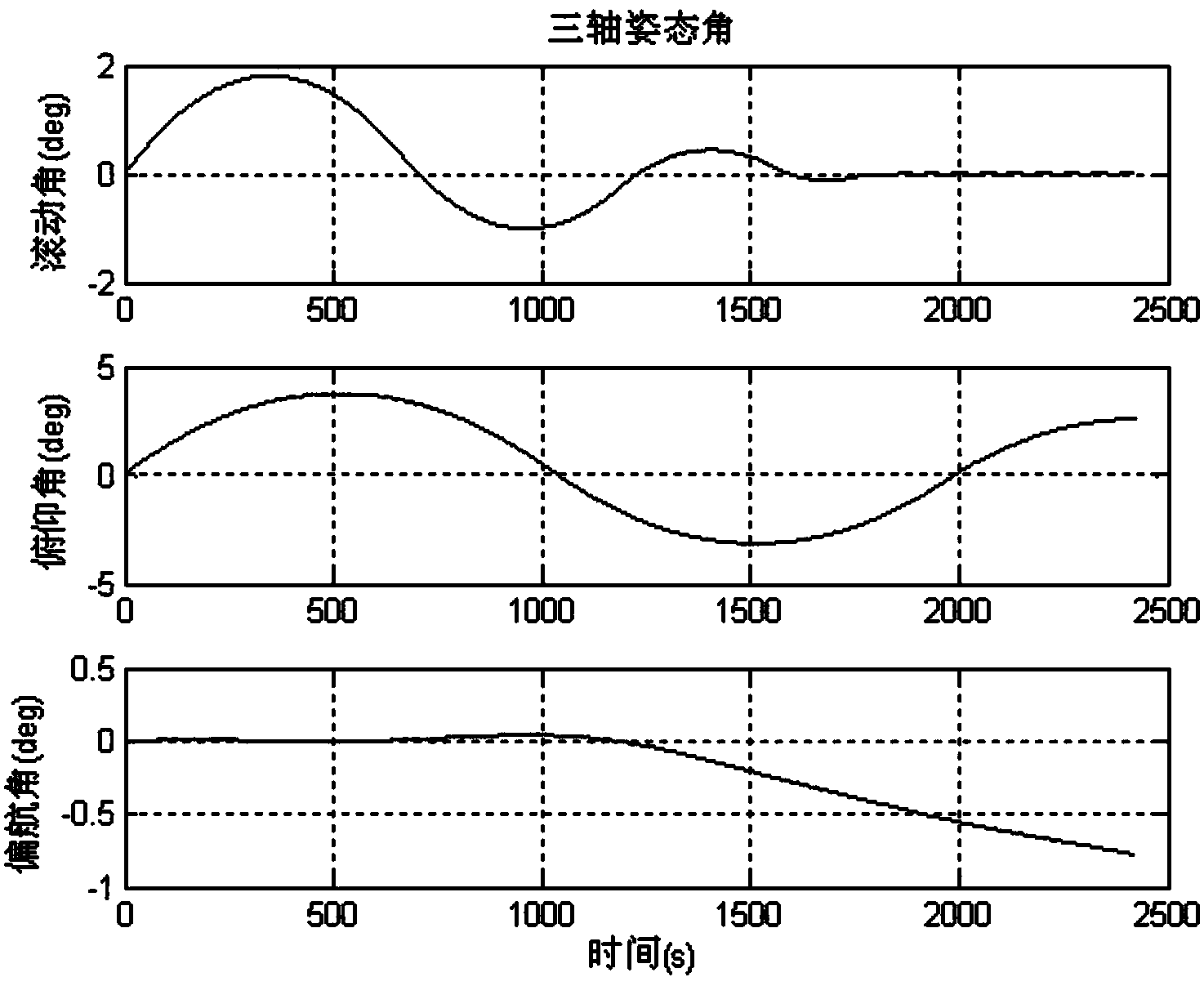

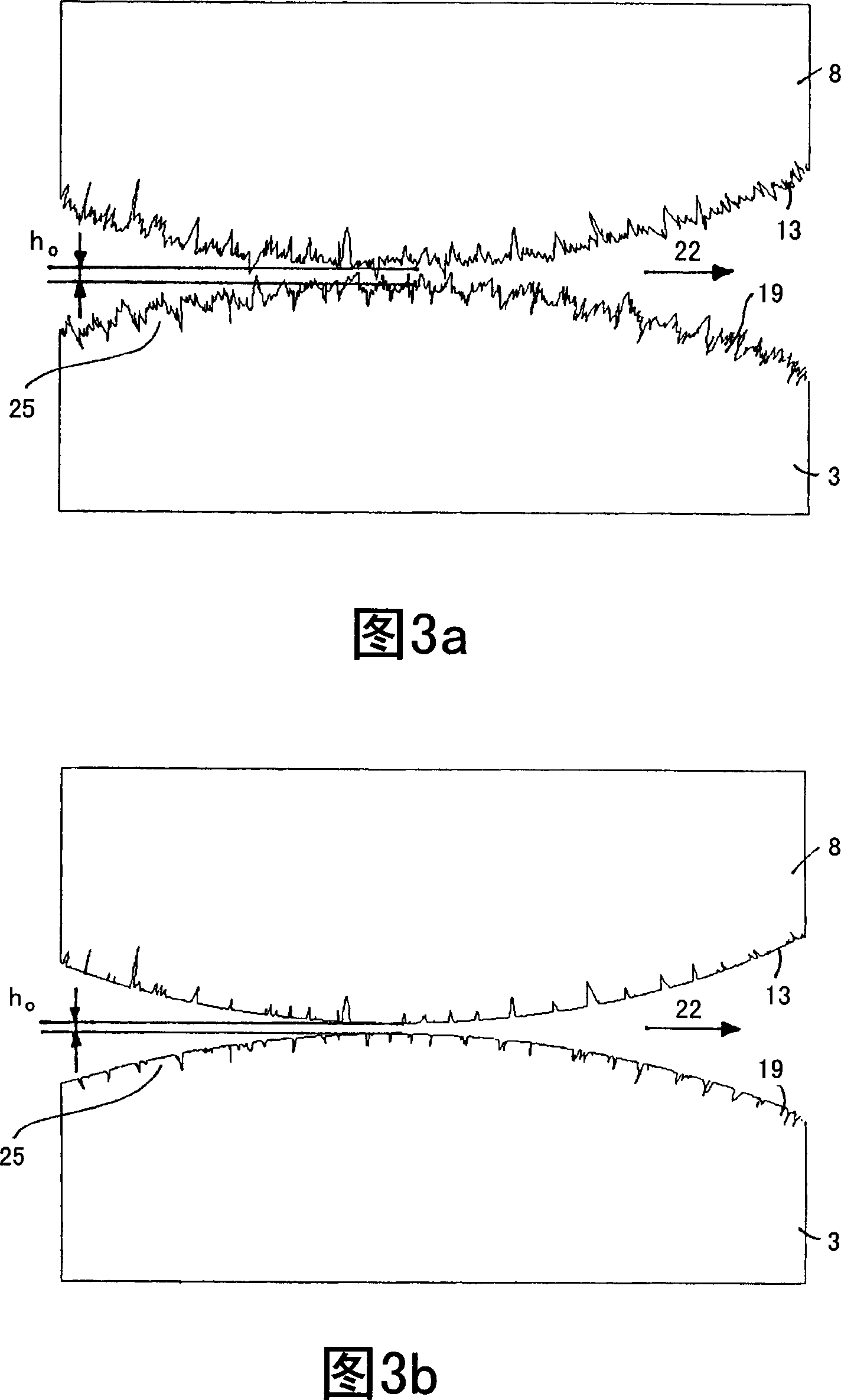

Attitude control method for solar sail spacecraft

InactiveCN104340380AReduce weightImprove performanceSpacecraft guiding apparatusSolar sailAttitude control

The invention discloses an attitude control method for a solar sail spacecraft, which can realize attitude control over the spacecraft. According to the method, a variable-reflectivity flexible thin-film device is pasted to the outer edge area of the upper surface of the solar sail of the spacecraft, and the reflectivity of the variable-reflectivity flexible thin-film device is changed by controlling the voltage of the variable-reflectivity flexible thin-film device so as to change the light pressure on the surface of the solar sail of the spacecraft to generate a differential moment, and further realize attitude control over the spacecraft. An attitude controller is the thin-film device and can be integrated with the solar sail spacecraft more easily to improve the integration level and the reliability of the solar sail. In addition, the attitude controller has a light weight, can greatly reduce the weight of the spacecraft, increases the load ratio and greatly improves the solar sail attitude control performance. With no mechanical structure, the attitude controller has high reliability.

Owner:LANZHOU INST OF PHYSICS CHINESE ACADEMY OF SPACE TECH

Steelmaking method for increasing ratio for scrap steel to enter furnace

InactiveCN108004369AIncrease the loading ratioHigh speedupManufacturing convertersProcess efficiency improvementSteelmakingMulti method

The invention discloses a steelmaking method for increasing ratio for scrap steel to enter a furnace. The steelmaking method for increasing the ratio for the scrap steel to enter the furnace includesthe steps of material adding, blowing and tapping, wherein before material adding, a device is transformed, the volume of a scrap steel bucket is increased by 4-6 cubic meters; a crown block for adding the scrap steel works in a speed decreasing manner, and a magnetic disk of the crown block is in an oval shape; the scrap steel and iron blocks are adopted as raw materials, the scrap steel comprises scrap steel pressed blocks and scrap steel spray rim charge, the scrap steel pressed blocks are placed on the inner side of the scrap steel bucket, and are sequentially arranged, and the scrap steelspray rim charge is used for gap filling; before tapping of a mixed iron furnace, firstly the scrap steel pressed blocks and the scrap steel spray rim charge are added into ladle; the scrap steel pressed blocks in the ladle are baked, and it is guaranteed that the tapping temperature is in balance; and the adding amount of the iron blocks is 45-65 kg / t, and the adding amount of the scrap steel is45-55 kg / t. According to the steelmaking method for increasing the ratio for the scrap steel to enter the furnace, the adding proportion of self-produced scrap steel and scrap steel purchased from the outside is increased in a multi-means and multi-method manner. According to the steelmaking method for increasing the ratio for the scrap steel to enter the furnace, on the premise that the steelmaking quality is guaranteed, the scrap steel charging proportion is increased, and therefore the scrap steel ratio is increased, consumption is reduced, cost is reduced, and benefits are increased.

Owner:XINXING DUCTILE IRON PIPES CO LTD

Fluidized bed hydrogenated reactor and fluidized bed hydrogenating method

InactiveCN108148621AEasy to separateSolve the resistanceTreatment with moving solid particlesEarth's rotationHydrogenation reaction

The invention belongs to the technical field of hydrogenation, and particularly relates to a fluidized bed hydrogenated reactor and a fluidized bed hydrogenating method. The fluidized bed hydrogenatedreactor comprises a shell, wherein a catalyst adding opening and a gas outlet are formed in the top of the shell; a three-phase separator is arranged on the upper portion of the inside of the shell and comprises two concentric barrels with different inner diameters, namely an inner barrel and an outer barrel; a flow guiding body is arranged below an opening of the lower end of the outer barrel; the shape of the flow guiding body is in the shape of a spindle with the small upper and lower ends and the large middle; a distributing plate is arranged on the lower portion of the inside of the shell; and a material inlet and a catalyst discharging opening are formed in the bottom of the shell. While the capacity utilization ratio of the reactor is improved, a catalyst lean-phase zone is reducedor cancelled, the hydrogenation reaction effect is improved, and the problem that the reaction effect is affected due to uneven distribution of catalysts caused by earth rotation is solved.

Owner:上海竣铭化工工程设计有限公司

Fluidized bed hydrogenation reaction system and fluidized bed hydrogenation method

ActiveCN107297186AEasy to separateSolve the resistanceChemical/physical processesHydrogenation reactionFluidized bed

The invention relates to a fluidized bed hydrogenation reaction system, which comprises a fluidized bed reactor, wherein the fluidized bed reactor comprises a reactor barrel; a three-phase separator is arranged at the upper part of the reactor barrel and comprises an inner barrel and an outer barrel; openings are formed in the upper ends and the lower ends of the inner barrel and the outer barrel; the opening in the upper end of the outer barrel is lower than that of the inner barrel and the opening in the lower end of the outer barrel is lower than that of the inner barrel; the inner barrel is a straight barrel segment; the straight barrel segment is arranged at the upper part of the outer barrel and a frustum-shaped contraction segment is arranged at the lower part; the opening in the lower end of the contraction segment is the opening in the lower end of the outer barrel; and a gap is arranged between the opening in the lower end of the inner barrel and the outer barrel contraction segment, so that a material passes through the gap. The fluidized bed hydrogenation reaction system is adopted by the fluidized bed hydrogenation method, so that the utilization rate (namely the catalyst inventory in the reactor) of the reactor is further improved, and the hydrogenation reaction effect can be further improved.

Owner:上海竣铭化工工程设计有限公司

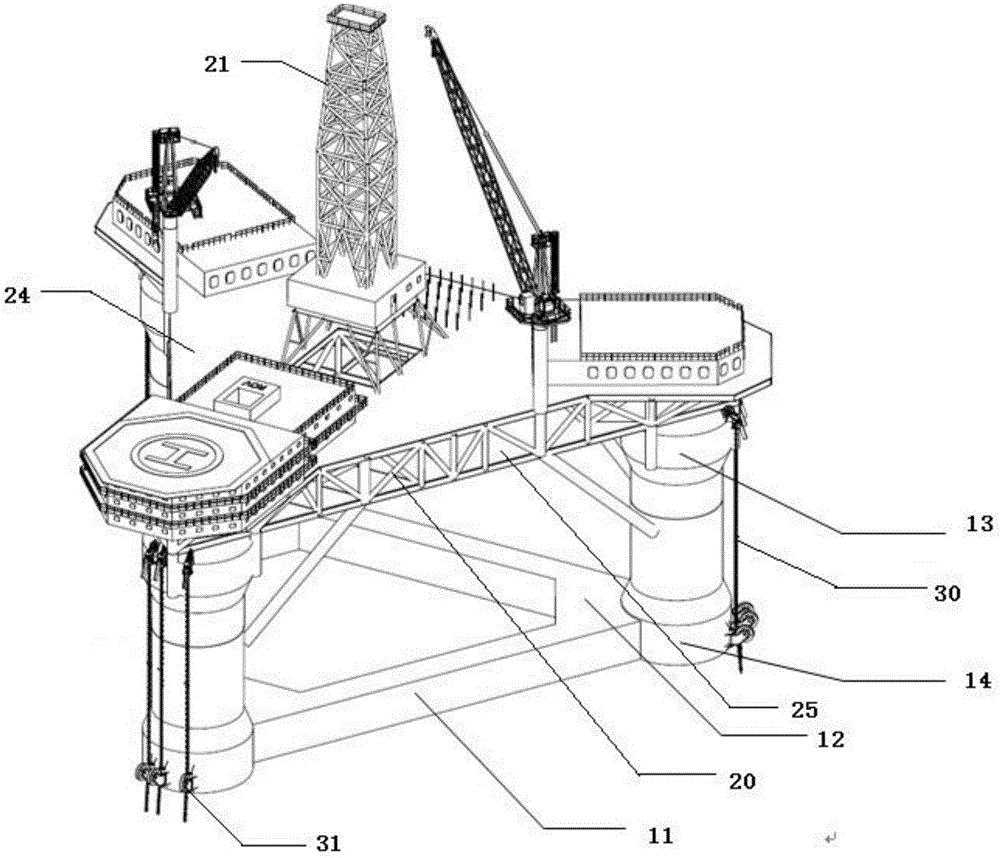

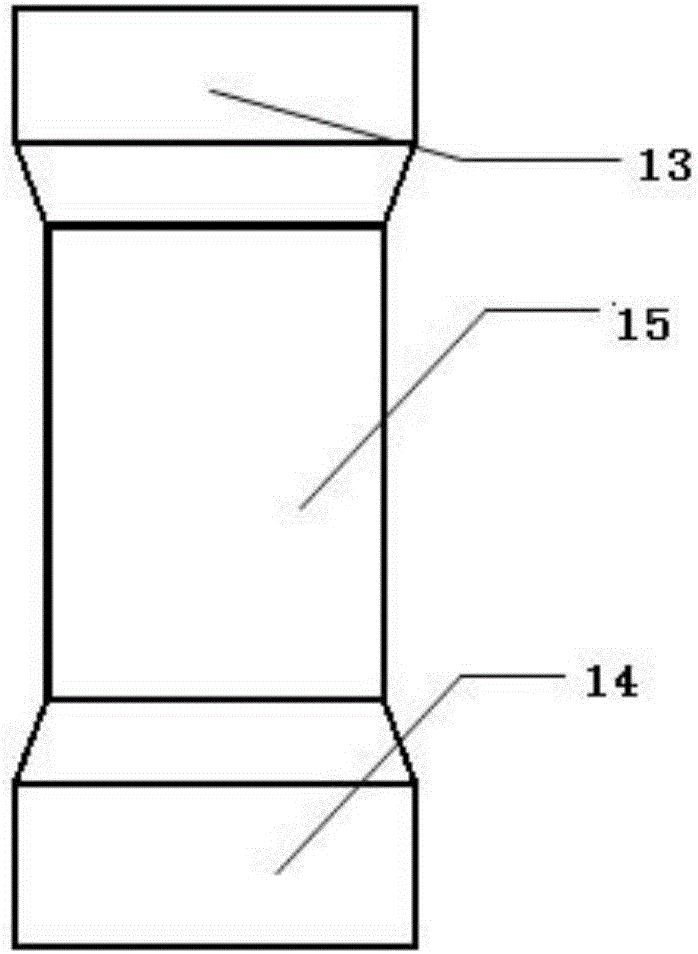

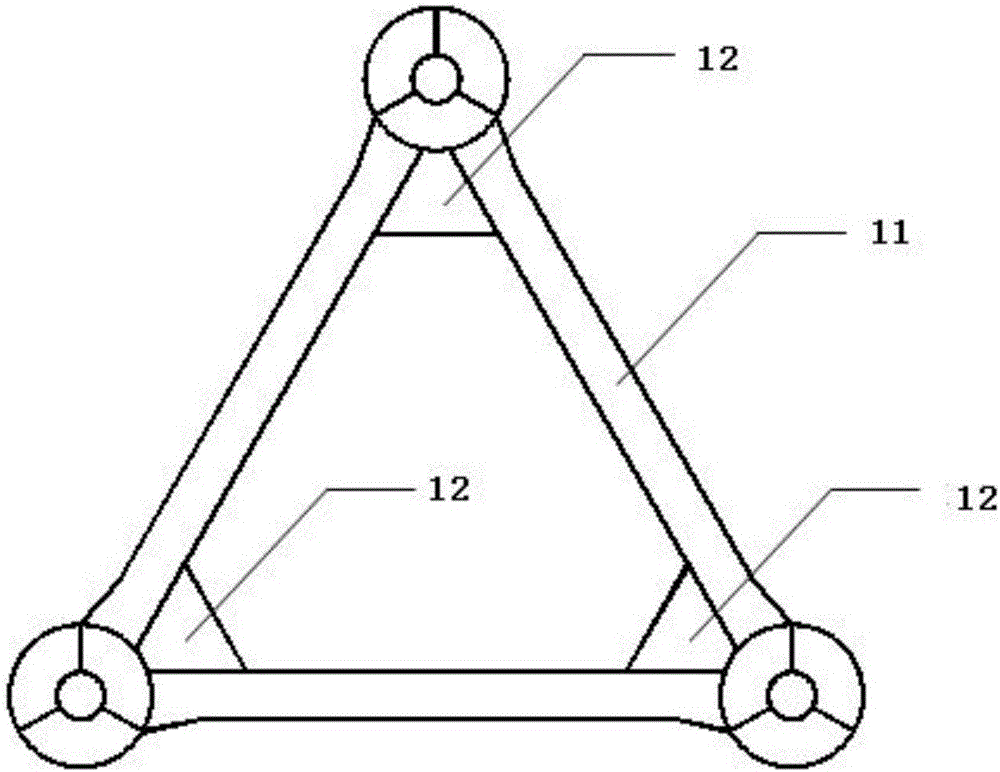

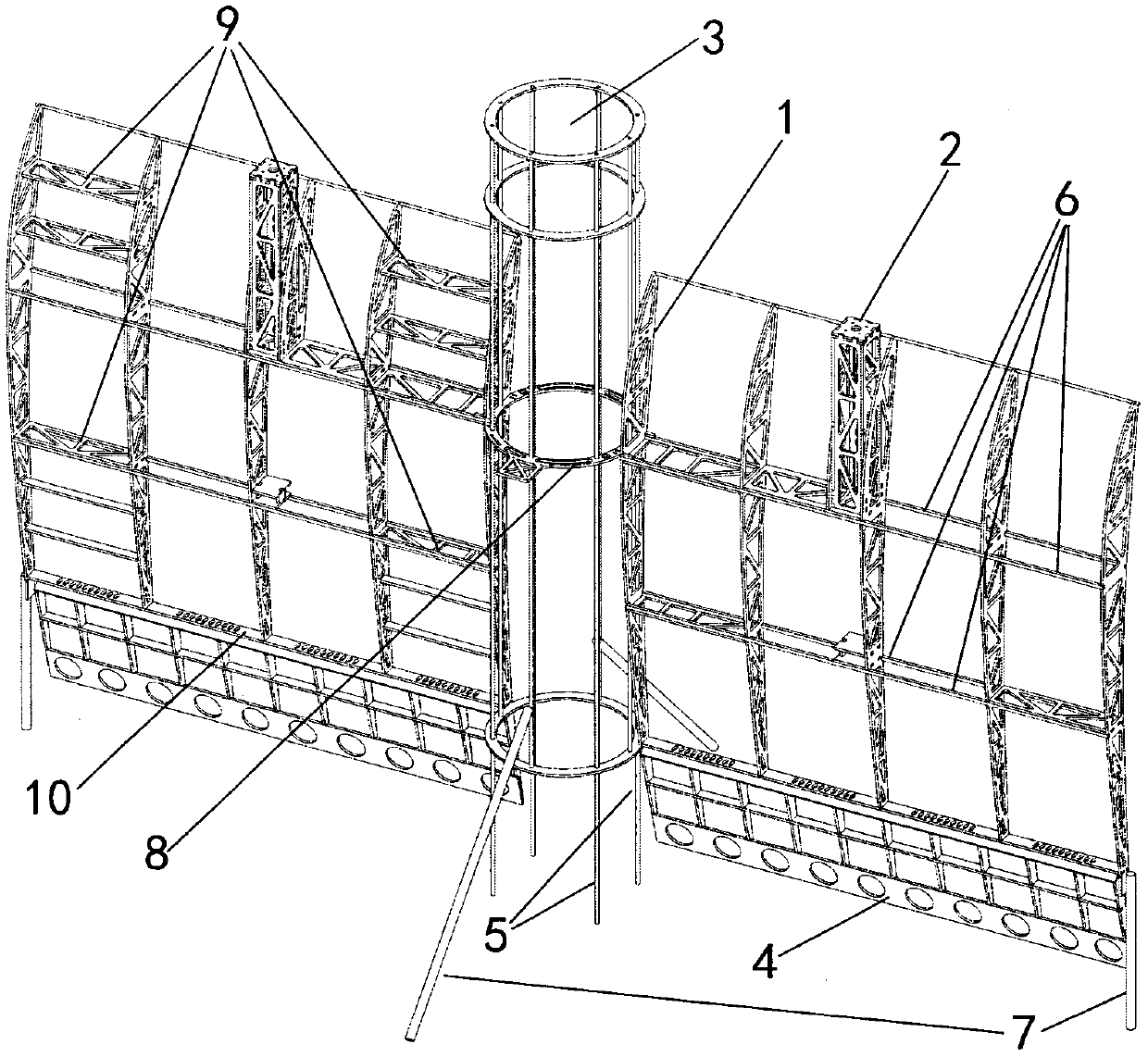

High-effective-load-ratio light semi-submersible type production platform

ActiveCN106114774AImprove economySuitable for a wide range of water depthsWaterborne vesselsFloating buildingsMarine engineeringLoad ratio

The invention discloses a high-effective-load-ratio light semi-submersible type production platform which comprises three rectangular buoyancy tanks connected end to end, three uprights connected with the rectangular buoyancy tanks and spaced from one another, a truss arranged at the upper ends of the three uprights and a deck arranged on the truss. The three rectangular buoyancy tanks form an integrated triangular structure with a triangular hole formed in the middle portion. Each rectangular buoyancy tank and the corresponding upright are of a sealed hollow structure. Each upright is arranged on the outer side of the connecting position of the corresponding two adjacent rectangular buoyancy tanks. A web-shaped angular cabin is arranged at the position, located at the connecting position of every two adjacent rectangular buoyancy tanks, in the triangular hole. By the adoption of the platform, three-upright platform floating bodies are adopted, so that the load ratio is effectively increased; the economical efficiency of the semi-submersible type production platform is improved, and cost can be saved for medium-deep water marginal oil-gas field development; and the semi-submersible type production platform is wide in applicable water depth range, small in displacement, good in mobility and suitable for conducting drilling and production operation under the severe sea environment conditions of the South China Sea and the like.

Owner:CHINA NAT OFFSHORE OIL CORP +1

Boiling bed reactor

ActiveCN108067169AEasy to separateSolve the resistanceHydrocarbon oils refiningChemical/physical processesThree-phaseEngineering

The invention relates to the technical field of boiling beds, in particular to a boiling bed reactor. The boiling bed reactor comprises a reactor cylinder, a three-phase separator is arranged at the upper side inside the reactor cylinder, a gas-liquid distributor is arranged at the lower side inside the reactor cylinder and comprises a material distributing pipe, an upper tray and a lower tray, the upper tray and the lower tray form a dual-layer tray structure, gaps are formed by the upper tray and the lower tray, the material distributing pipe penetrates through the upper tray and the lower tray, a hood is arranged at an upper end opening of the material distributing pipe, a pipe wall opened hole is formed in the portion, between the upper tray and the lower tray, of the material distributing pipe, and a circulating oil reactor inlet is further formed between the upper tray and the lower tray. By means of the boiling bed reactor, a solid catalyst which is separated from the three-phase separator is settled in the radial center area of the reactor and flows back into the reactor, the problem that when the three-phase separator is filled with a large dosage of catalyst, the settlingand backflow resistance of the catalyst is large is solved, and it is guaranteed that the three-phase separator still has a good separating effect when filled with a large dosage of catalyst.

Owner:上海竣铭化工工程设计有限公司

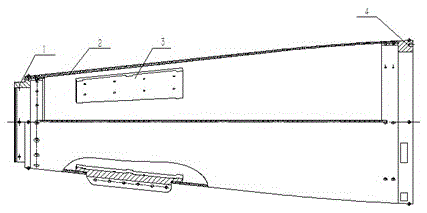

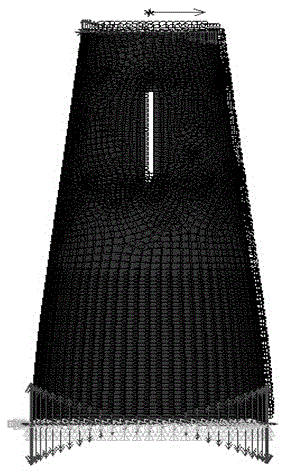

Cabin of conical rotary body structure and manufacturing method of cabin

InactiveCN105466288AReduce structural weightIncrease load ratioCartridge ammunitionGlass fiberElement analysis

The invention relates to a cabin of a conical rotary body structure and a manufacturing method of the cabin. The cabin comprises a front connecting frame and a rear connecting frame. A cone is connected between the front connecting frame and the rear connecting frame and provided with a front wing seat. The cone comprises a glass fiber layer, a carbon fiber layer, an aramid fiber layer, an ultra-high molecular weight polyethylene fiber layer and a basalt fiber layer, and resin layers are connected between the layers. The manufacturing method of the cabin comprises the steps that the structural sizes of the front connecting frame, the rear connecting frame and the cone are determined; finite element analysis calculation of the cone is carried out, and the structure of the cone is determined; the cone is formed, fiber winding materials of the cone are subjected to layering forming, and then post curing, appearance size machining, demolding and nondestructive testing are carried out; a fixture is manufactured; the front connecting frame and rear connecting frame at the two ends and the cone are assembled together on the fixture; and the cabin is inspected. The cabin has the beneficial effects of being light and high in loading ratio, manufacturing cost is reduced, and the wide application range of composites in the field of air ammunition is widened.

Owner:江西长江化工有限责任公司

A kind of coal tar full-fraction ebullating bed hydrogenation method

ActiveCN107298984BIncrease profitImprove hydrogenation reaction performanceTreatment with hydrotreatment processesCoal tar distillateVapor–liquid separator

Owner:上海竣铭化工工程设计有限公司

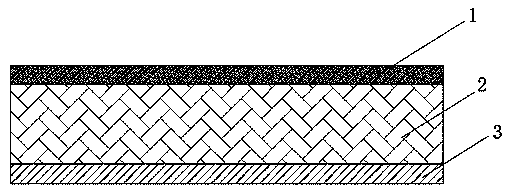

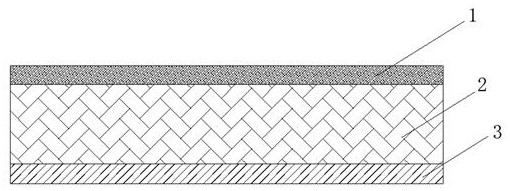

High-strength lightweight multi-layered carbon fiber special-shaped bulkhead plate

The invention discloses a high-strength lightweight multi-layered carbon fiber special-shaped bulkhead plate. The bulkhead plate sequentially comprises an outer mask plate, a structural foam sandwichand an inner mask plate from outside to inside; the outer mask plate, the structural foam sandwich and the inner mask plate are embedded into resin for bonding through an adhesive or vacuum introduction method; the outer mask plate is formed by laminated adhesive pressing of at least four layers of carbon fiber cloth; the inner mask plate is formed by laminated adhesive pressing of at least two layers of carbon fiber cloth; the edges of all the layers of carbon fiber cloth of the outer mask plate and the inner mask plate are overlapped and adhesively pressed with one another. The bulkhead plate manufactured by adopting the layering design has the advantages of corrosion resistance, high load ratio, low density and low weight; the layering design is simple in structure and strong in maneuverability.

Owner:衡阳泰豪通信车辆有限公司

Boiling bed hydrogenation reaction system and boiling bed hydrogenation process method

PendingCN108144556ASolve easy cokingEasy to operateHydrocarbon oil crackingHydrocarbon oils refiningHydrogenation reactionHydrogenation process

The invention belongs to the technical field of hydrogenation, and particularly relates to a boiling bed hydrogenation reaction system and a boiling bed hydrogenation process method. On one hand, theproblem of coking of parts of pipelines caused by intermittent operation of a catalyst discharge system can be effectively solved. On the other hand, the use ratio of a reactor can be further increased (namely, reserve of catalysts in the reactor is improved), hydrogenation reaction effects are further improved, operating stability of the system is improved, and particularly, stable boiling stateof the catalysts can be maintained in start, in stop and under unusual service conditions.

Owner:上海竣铭化工工程设计有限公司

Low-speed aircraft capable of vertically taking off and landing

InactiveCN110861766AAvoid restrictionsReduce weightSpars/stringersVertical landing/take-off aircraftsAviationFiber

The invention discloses a low-speed aircraft capable of vertically taking off and landing, and the aircraft is a small high efficiency aircraft capable of vertically taking off and landing based on 2032cjc wing section. The structure is composed of wings, ailerons, engine mounting seats, square carbon rods, round carbon rods, a loading cylinder, a landing gear structure and an aircraft electroniccontrol circuit. In structural design, a rectangular large-wing-surface aero-pneumatic layout is adopted for the aircraft and can ensure that the aircraft has a larger lifting force source in the process of ultra-low-speed heavy-load cruising flight so as to ensure the stability of the heavy-load flight. The main structure of an airframe is a wooden airframe and the loading cylinder formed by combining carbon fiber boards and carbon fiber pipes, the control circuit is integrally installed on the middle carbon fiber board of the airframe, the stability of a low-speed heavy-load cruising stagecan be greatly enhanced through the rectangular large-wing-surface aero-pneumatic layout design of the aircraft, the mission efficiency of the aircraft can be effectively improved, and the aircraft has good maneuverability when flying at a low speed.

Owner:夏开心

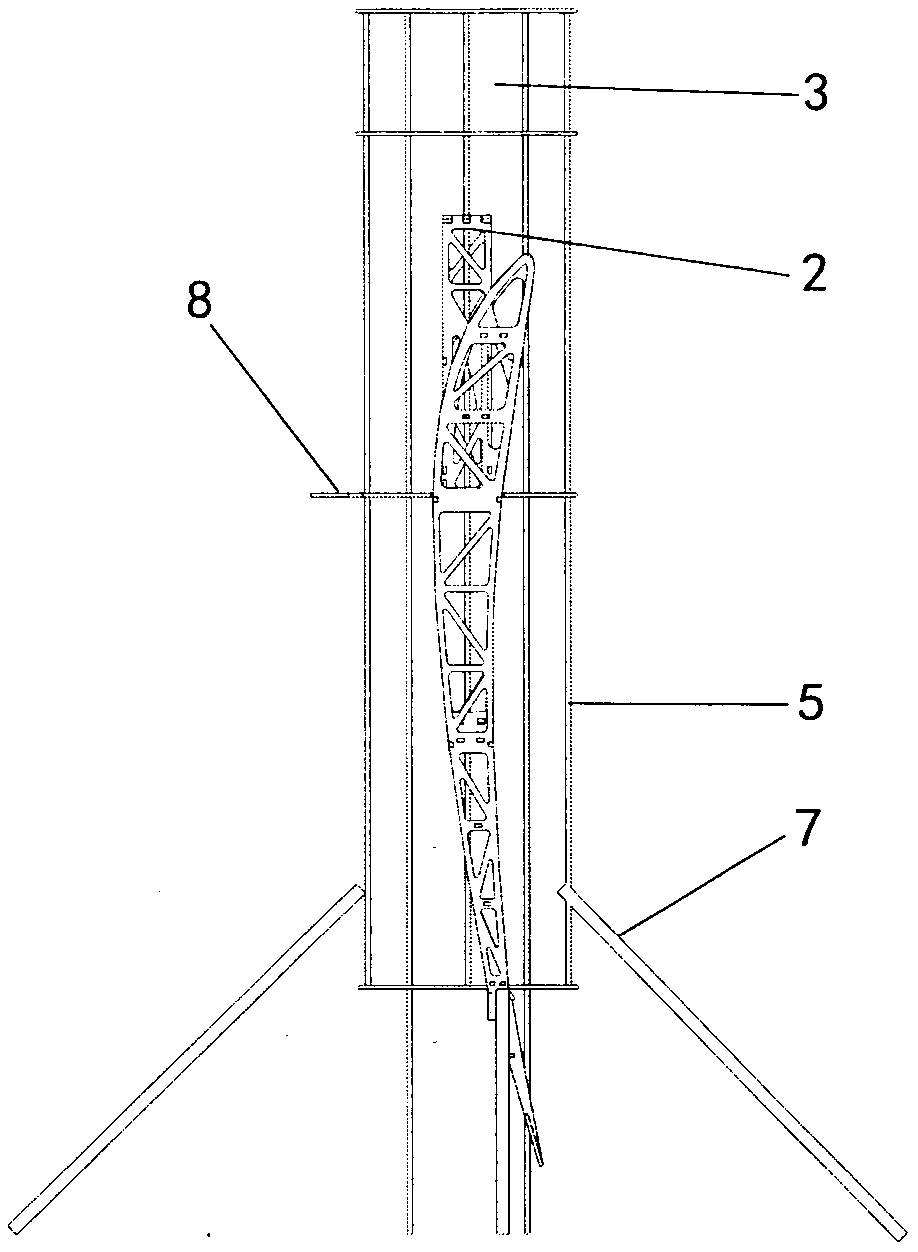

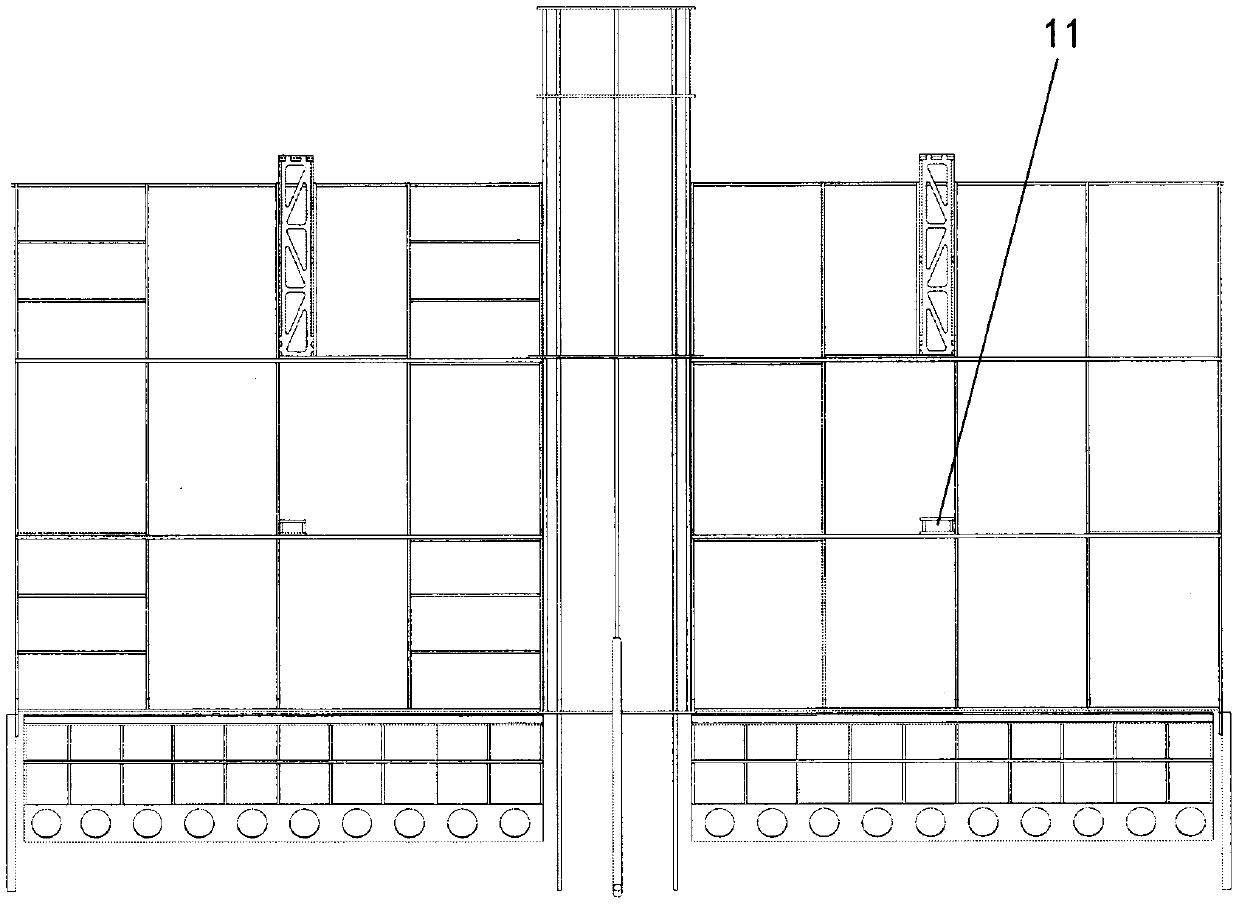

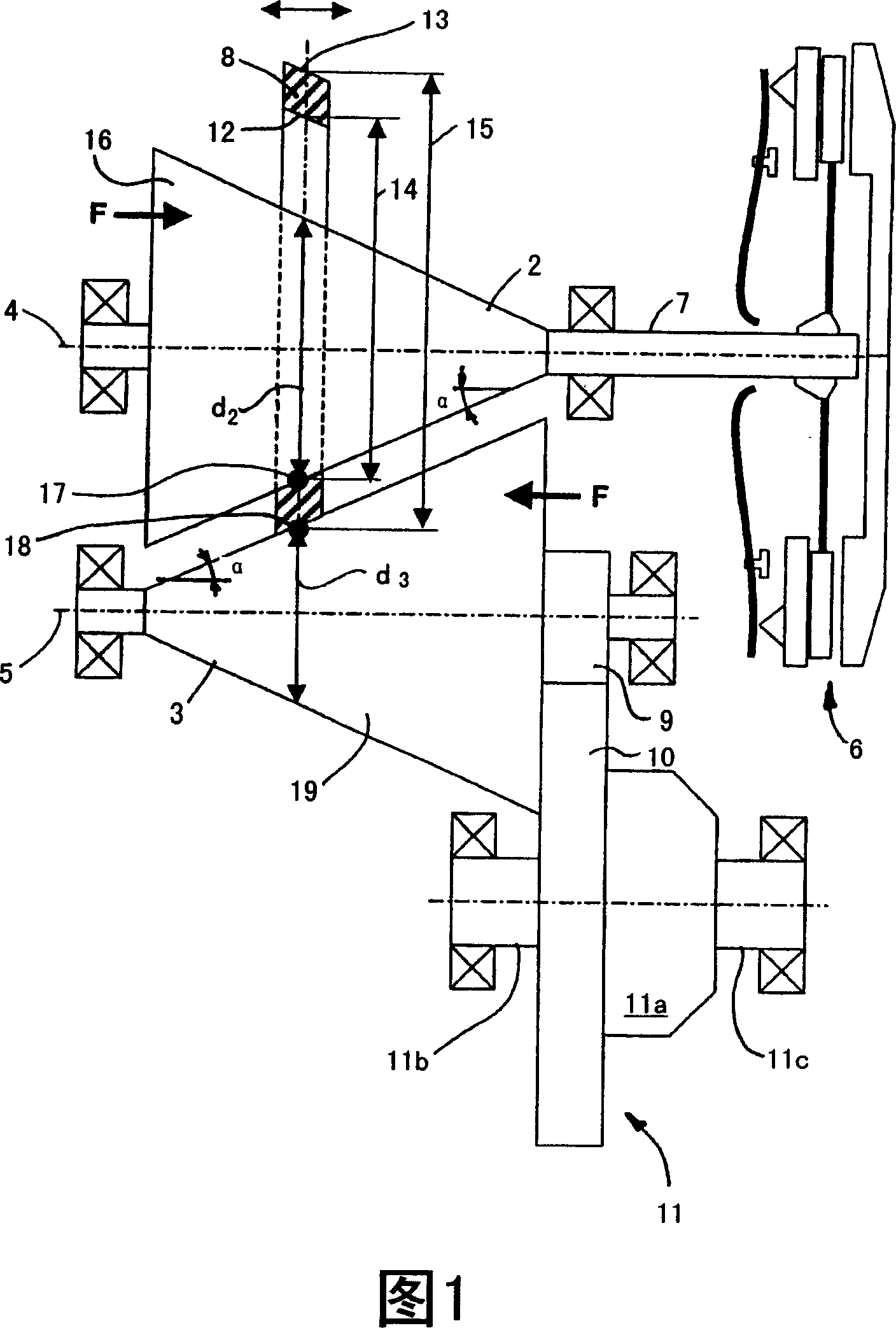

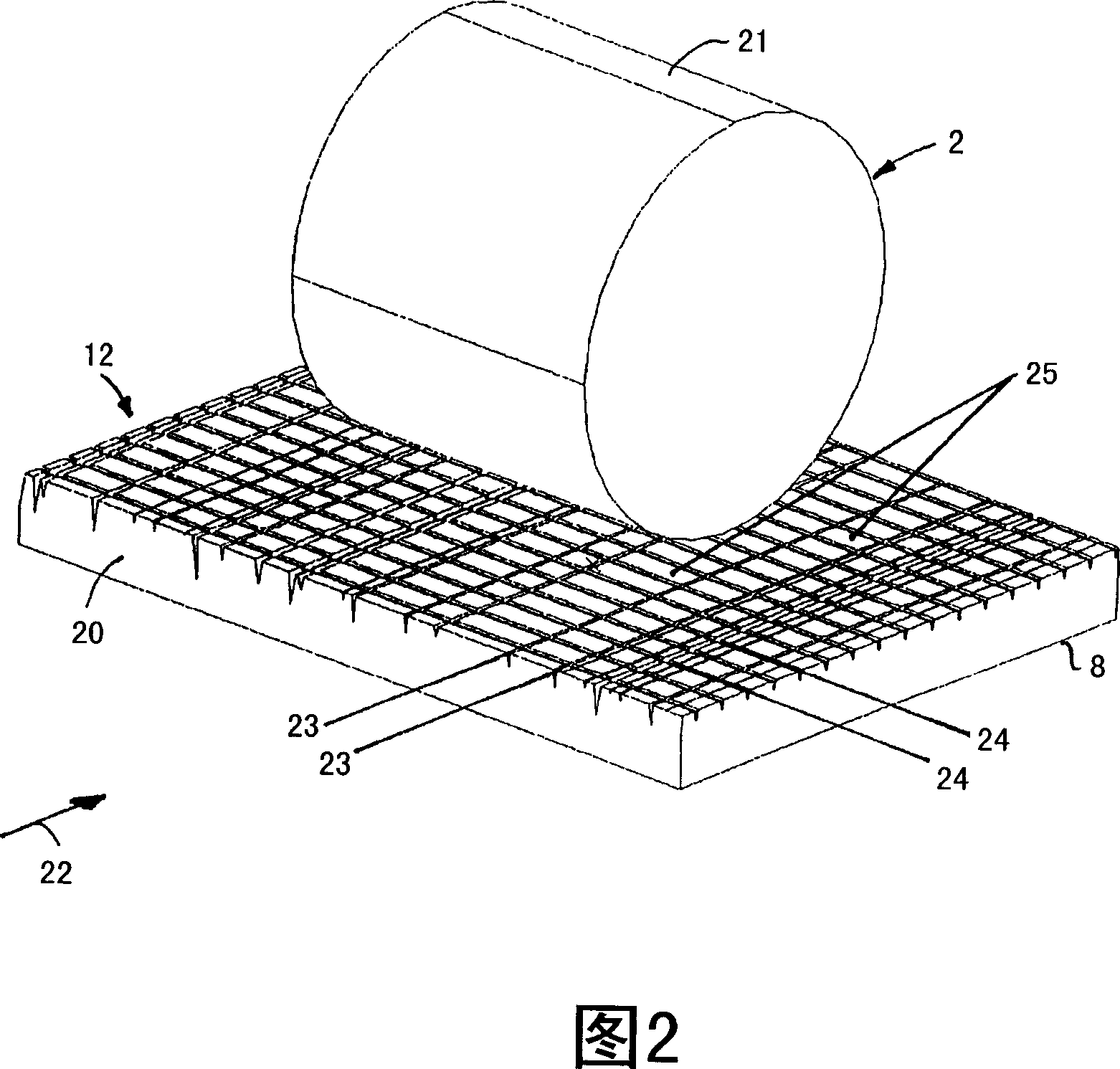

Taper ring transmission with surface optimization of contact region

Owner:GETRAG FORD TRANSMISSIONS GMBH

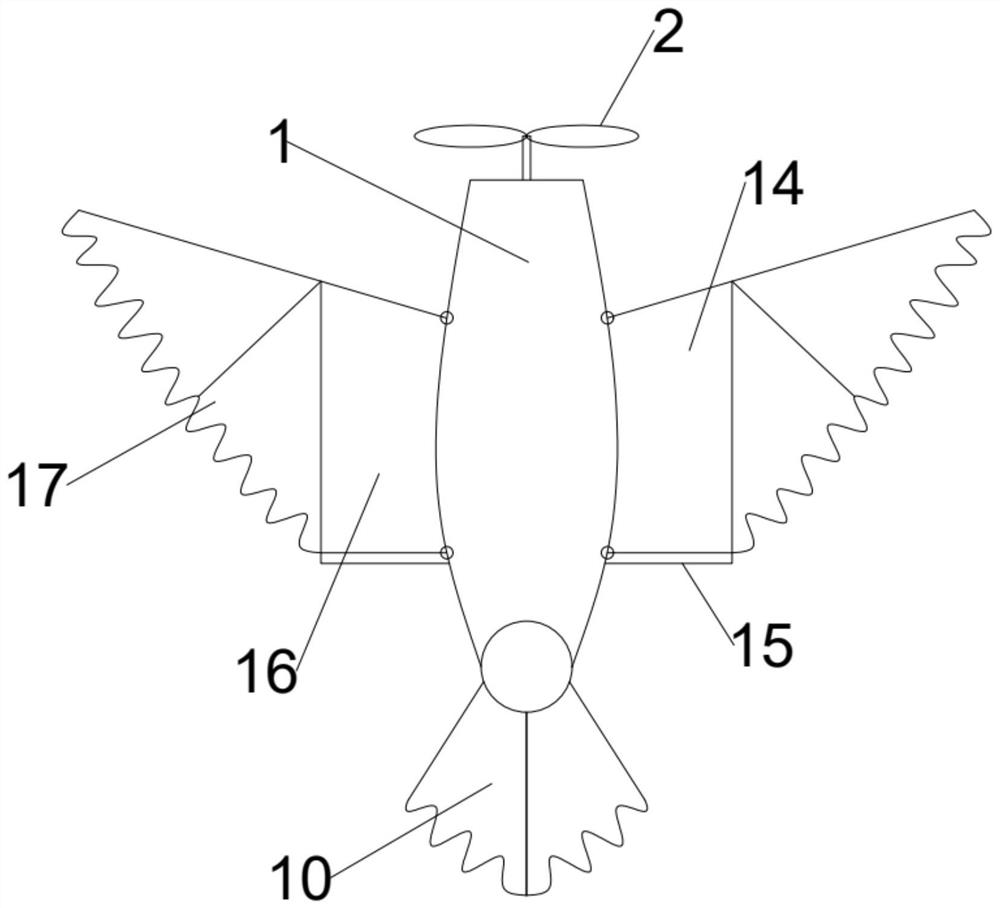

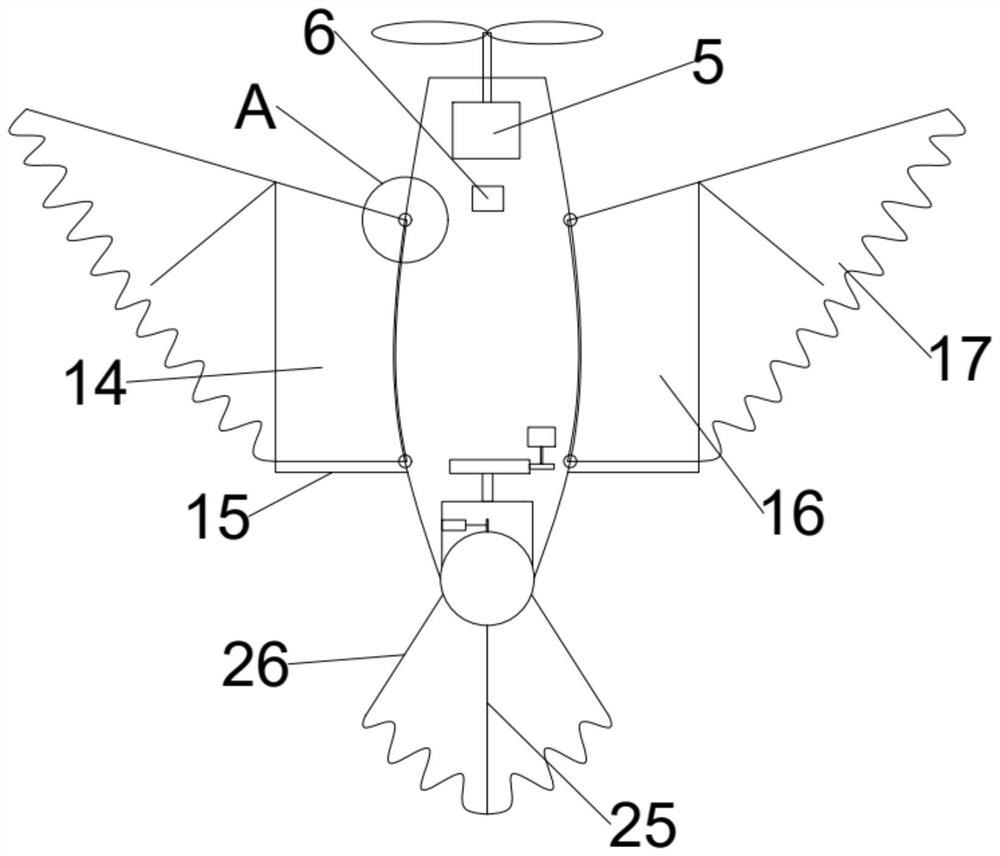

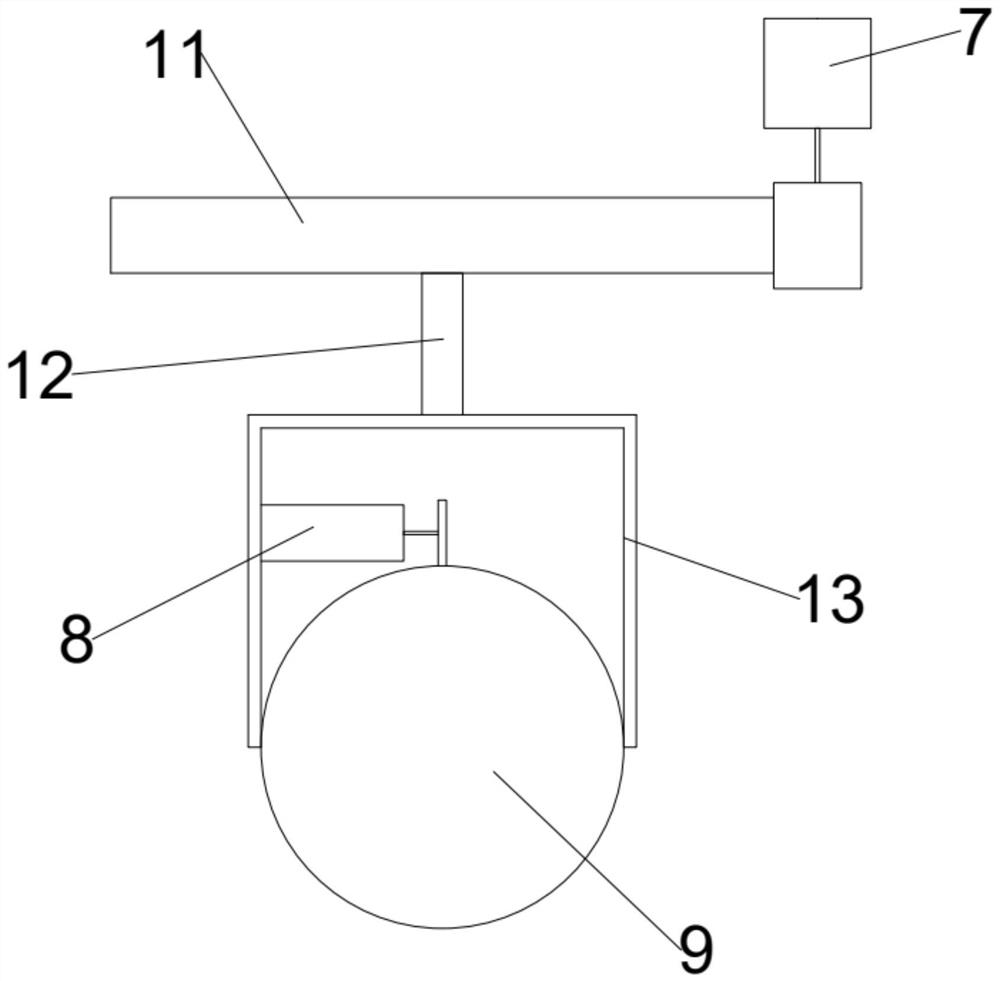

Bionic unmanned aerial vehicle

PendingCN113148153AReduce volumeSmall bodyAircraft stabilisationWing shapesGear wheelElectric machinery

The invention discloses a bionic unmanned aerial vehicle which is characterized in that propellers are arranged at the front end of a fuselage, wings are symmetrically arranged about two sides of the fuselage, and a tail is arranged at the rear part of the fuselage; clamping strips are symmetrically arranged on the two sides of the fuselage, buckles are arranged on the front portions and the rear portions of the clamping strips, and the wings are connected with the fuselage through the buckles and the clamping strips. A power motor, a battery and a direction control device are arranged in the machine body, the first servo motor is in gear connection with the transmission device, and the second servo motor is arranged on the transmission device and connected with the machine tail gear. The tail comprises a balance ball and an empennage, the balance ball is in gear connection with the second servo motor, the transmission device is rotationally connected with the balance ball, and the empennage is inserted into the balance ball; a sweepforward large-area wingspan structure is adopted, and the long-time hang capacity can be obtained with small power; the wings are all covered with nano-coating thin cloth, the fuselage is light, and the load ratio is increased; the auxiliary wings and the tail wings imitate a bat body structure and are independently controlled by two servo motors.

Owner:王益民

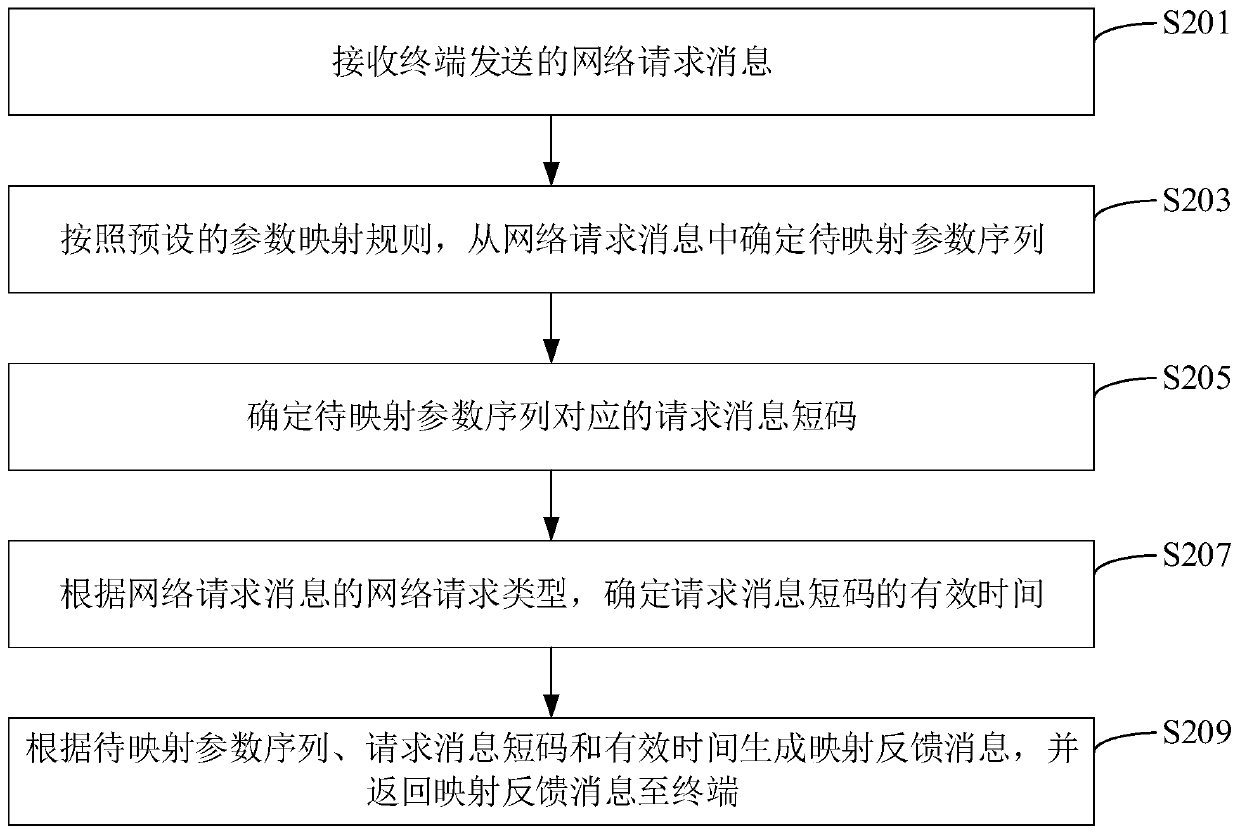

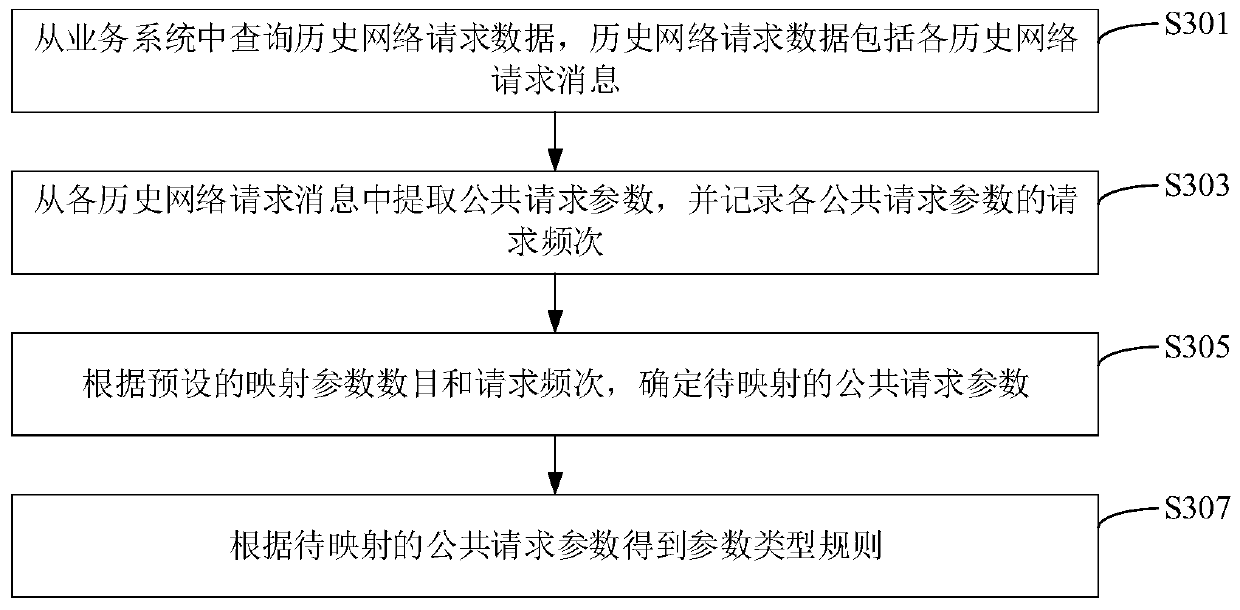

Network request processing method and device, computer equipment and storage medium

PendingCN110113390AImprove processing efficiencyIncrease load ratioTransmissionValid timeComputer equipment

The invention relates to a network request processing method and device, computer equipment and a storage medium. The method relates to a service process optimization technology and comprises the following steps: receiving a network request message sent by a terminal; determining a to-be-mapped parameter sequence from the network request message according to a preset parameter mapping rule; determining a request message short code corresponding to the to-be-mapped parameter sequence; determining the valid time of the short code of the request message according to the network request type of the network request message; and generating a mapping feedback message according to the to-be-mapped parameter sequence, the request message short code and the valid time, and returning the mapping feedback message to the terminal. By adopting the method, the processing efficiency of the network request message can be improved.

Owner:ONE CONNECT SMART TECH CO LTD SHENZHEN

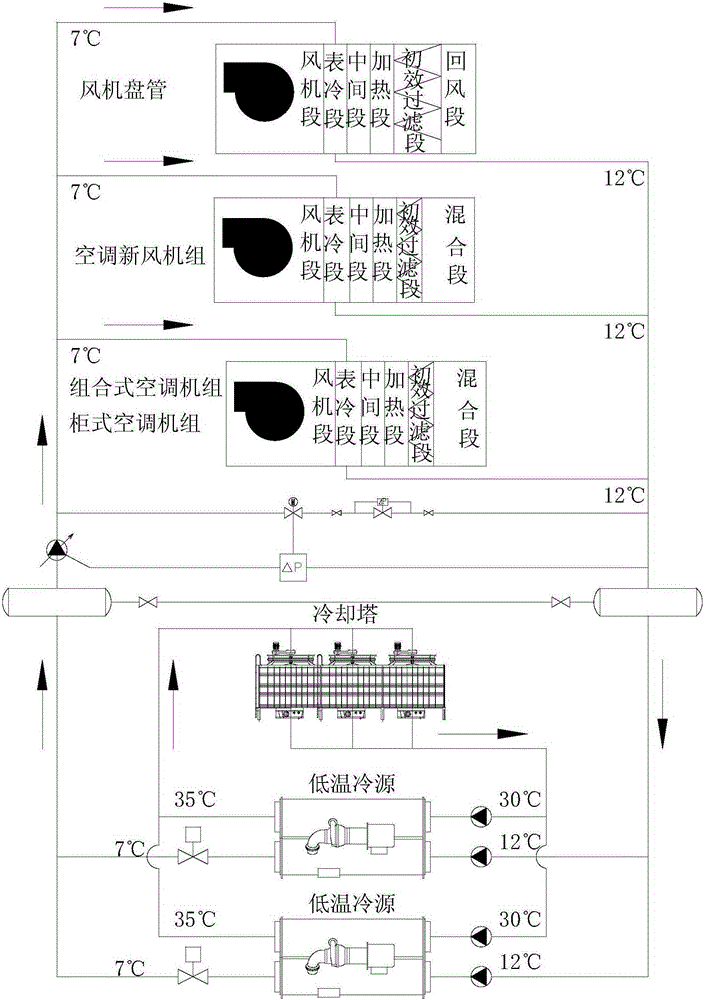

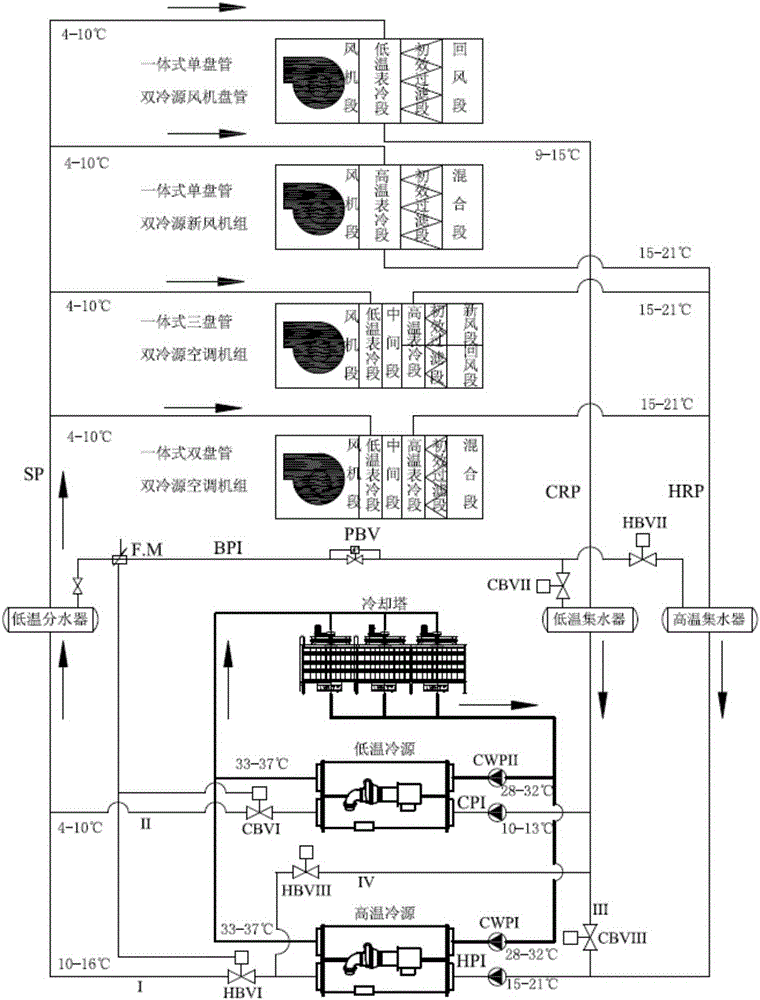

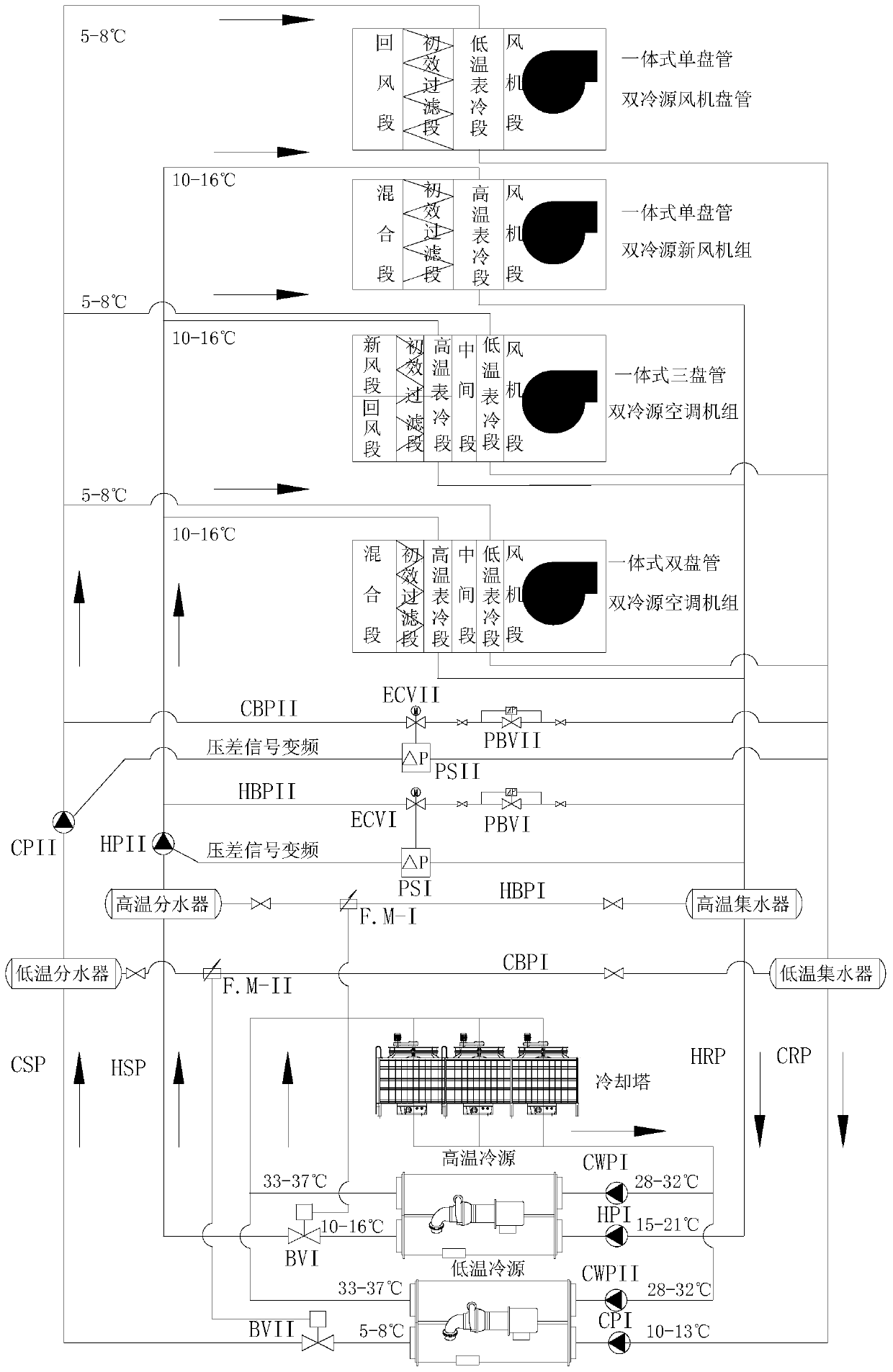

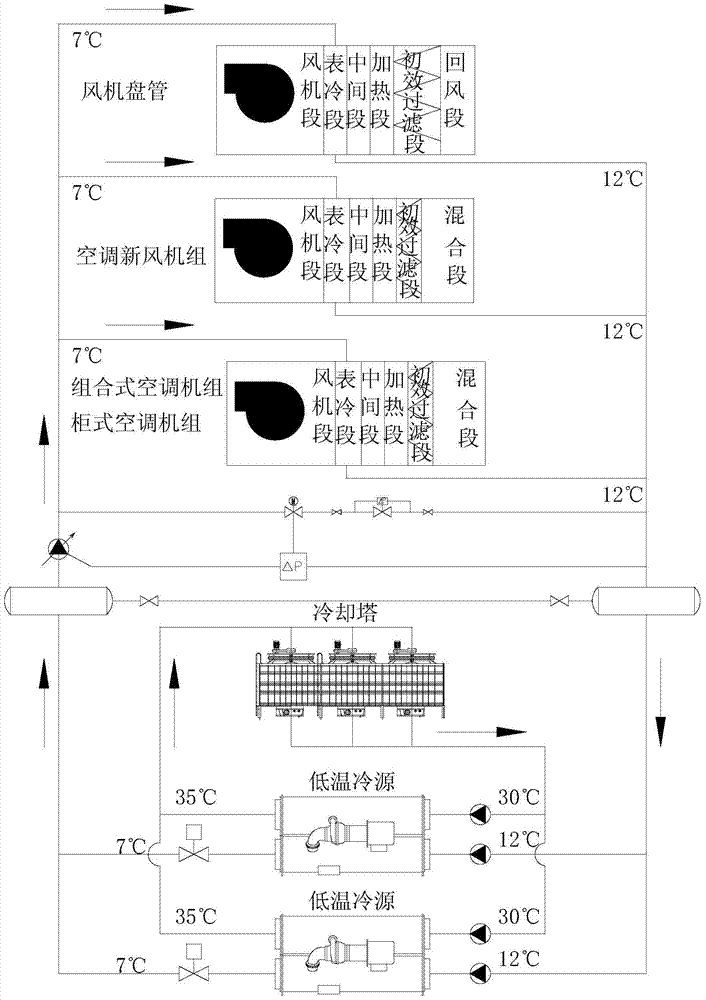

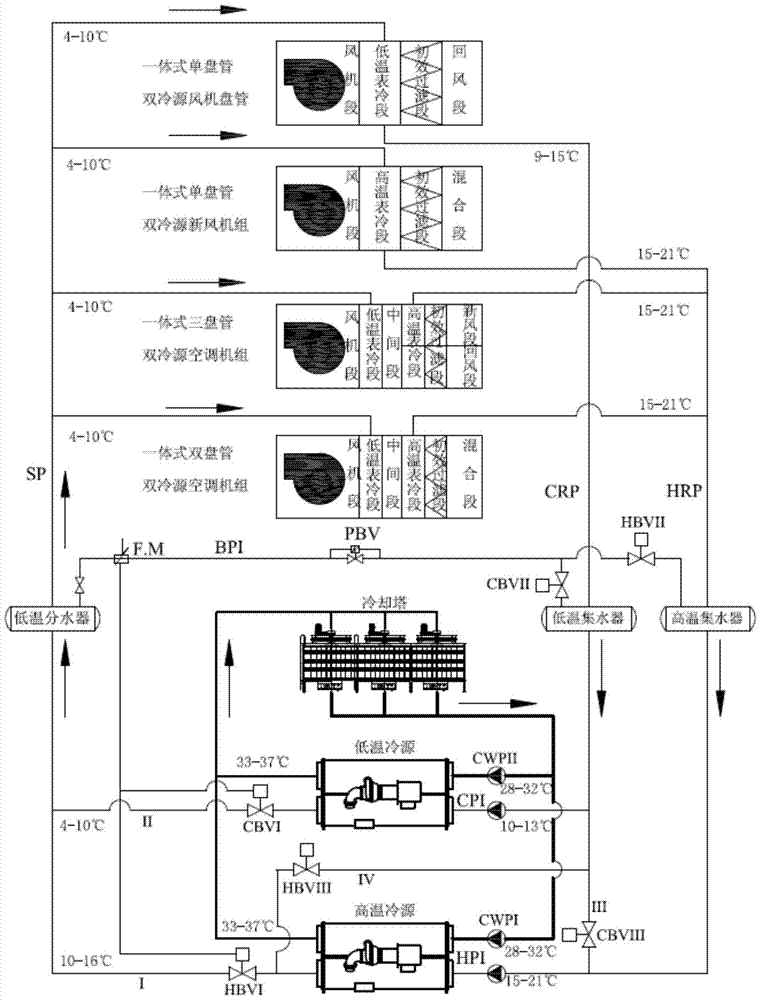

Dual cold source four-pipe air conditioning system

ActiveCN105222241BReduce energy consumptionIncrease load ratioMechanical apparatusLighting and heating apparatusSurface coolingTemperature Unit

The invention discloses a dual-cold source four-pipe-system air conditioner system. The dual-cold source four-pipe-system air conditioner system comprises air conditioner terminals provided with high-temperature surface cooling sections and low-temperature surface cooling sections and a cold source system for providing cooling capacity for the air conditioner terminals; the cold source system comprises a high-temperature cold source for providing the cooling capacity for the high-temperature surface cooling sections and a low-temperature cold source for providing the cooling capacity for the low-temperature surface cooling sections; the high-temperature cold source and the high-temperature surface cooling sections are connected through a high-temperature water supply pipeline provided with a high-temperature water segregator and a high-temperature water return pipeline provided with a high-temperature water collector; and the low-temperature cold source and the low-temperature surface cooling sections are connected through a low-temperature water supply pipeline provided with a low-temperature water segregator and a low-temperature water return pipeline provided with a low-temperature water collector. According to the dual-cold source four-pipe-system air conditioner system, under the precondition that the total capacity of a whole air conditioner water chilling unit is unchanged, the ratio of load borne by a high-temperature unit is increased to the greatest extent through reasonably allocating the ratio of the air conditioner load borne by the high-temperature unit and a low-temperature unit, so that the energy consumption of the cooling load of the whole air conditioner system is greatly lowered, and the air conditioner system is an energy-saving-type air conditioner system.

Owner:杭州绿程机电有限公司

Fluidized bed hydrogenation reaction equipment and fluidized bed hydrogenation method

ActiveCN108148620AEasy to separateSolve the resistanceChemical/physical processesHydrocarbon oils treatmentFluidized bedHydrogenation reaction

The invention belongs to the technical field of hydrogenation, and particularly relates to fluidized bed hydrogenation reaction equipment and a fluidized bed hydrogenation method. The fluidized bed hydrogenation reaction equipment comprises a fluidized bed hydrogenation reactor, a catalyst adding system and a catalyst adding pipeline, wherein the catalyst adding system comprises a catalyst storagetank and a catalyst delivering pipeline; the catalyst delivering pipeline communicates with the catalyst storage tank and inner space of the fluidized bed hydrogenation reactor; at least two valves are arranged on the catalyst delivering pipeline; the catalyst delivering pipeline between the two valves communicates with the catalyst adding pipeline by a hydrogen sulfide leakage prevention pipeline; and at least one valve is arranged on the hydrogen sulfide leakage prevention pipeline. By the fluidized bed hydrogenation reaction equipment, potential safety hazards caused by internal leakage due to frequent operation under special working conditions when a catalyst is added in a system are solved; the utilization rate of the reactor is further increased, the hydrogenation reaction effect isimproved, and the stability of operation of the device is improved; and the fluidized bed hydrogenation method is scientific and reasonable, and simple and practicable.

Owner:上海竣铭化工工程设计有限公司

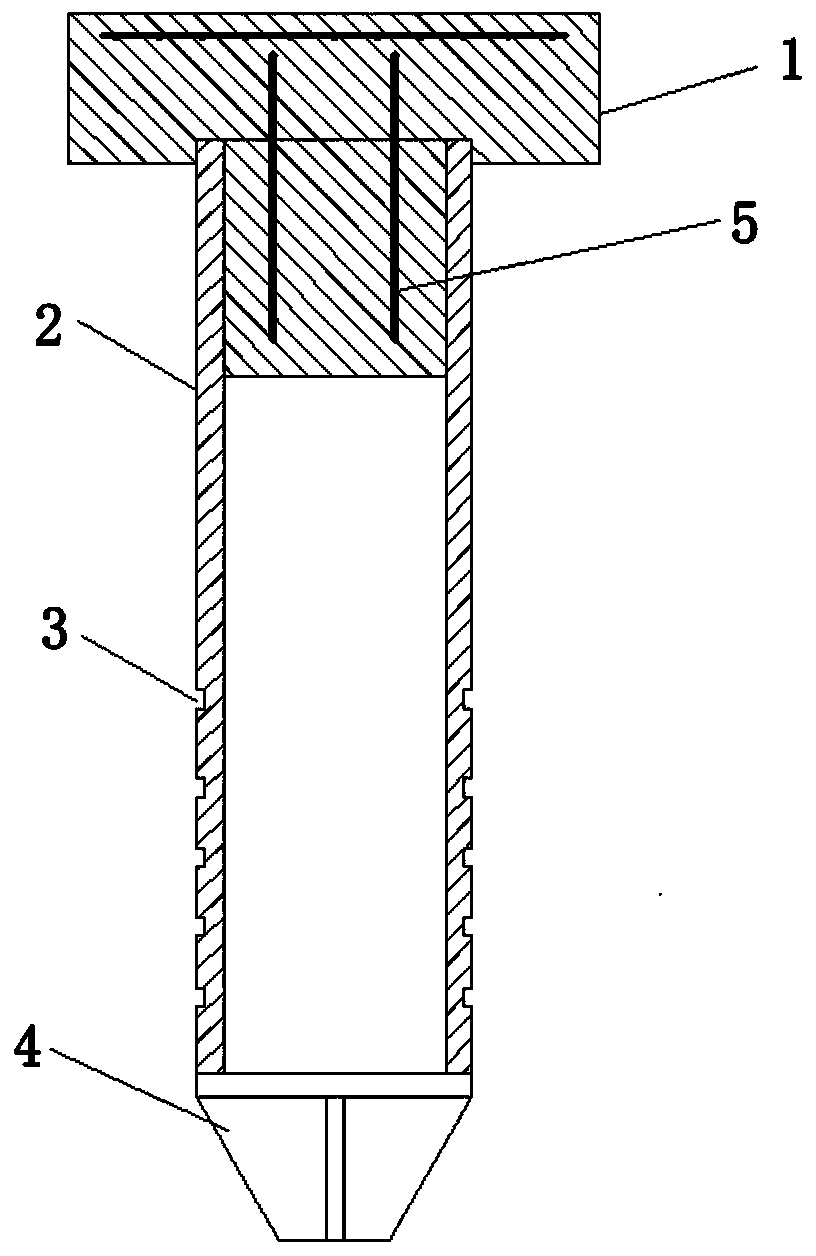

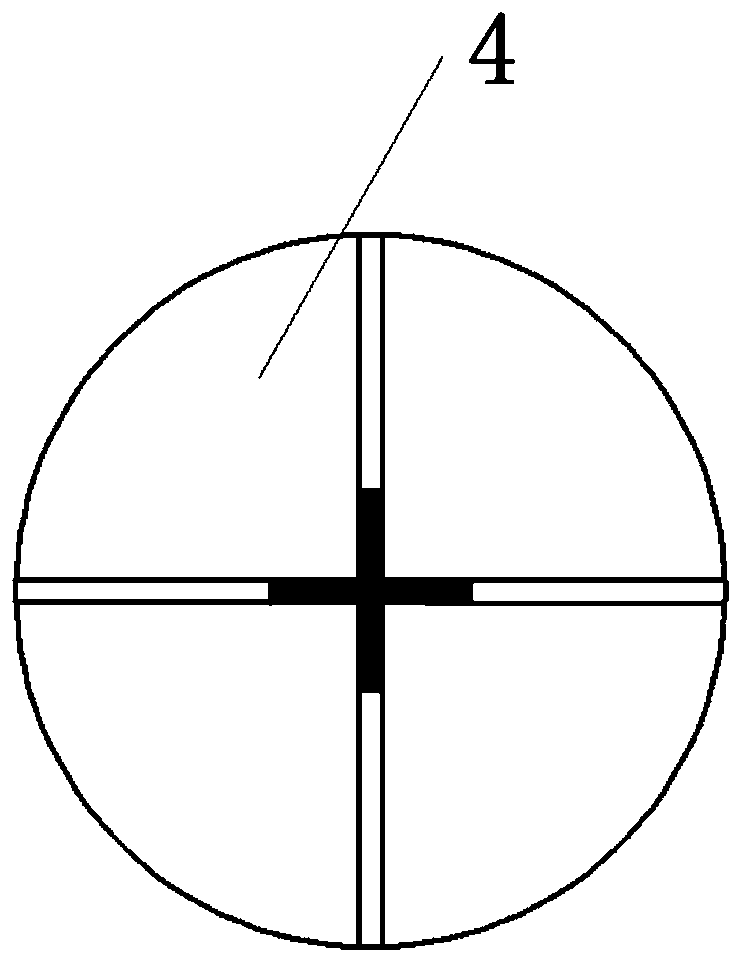

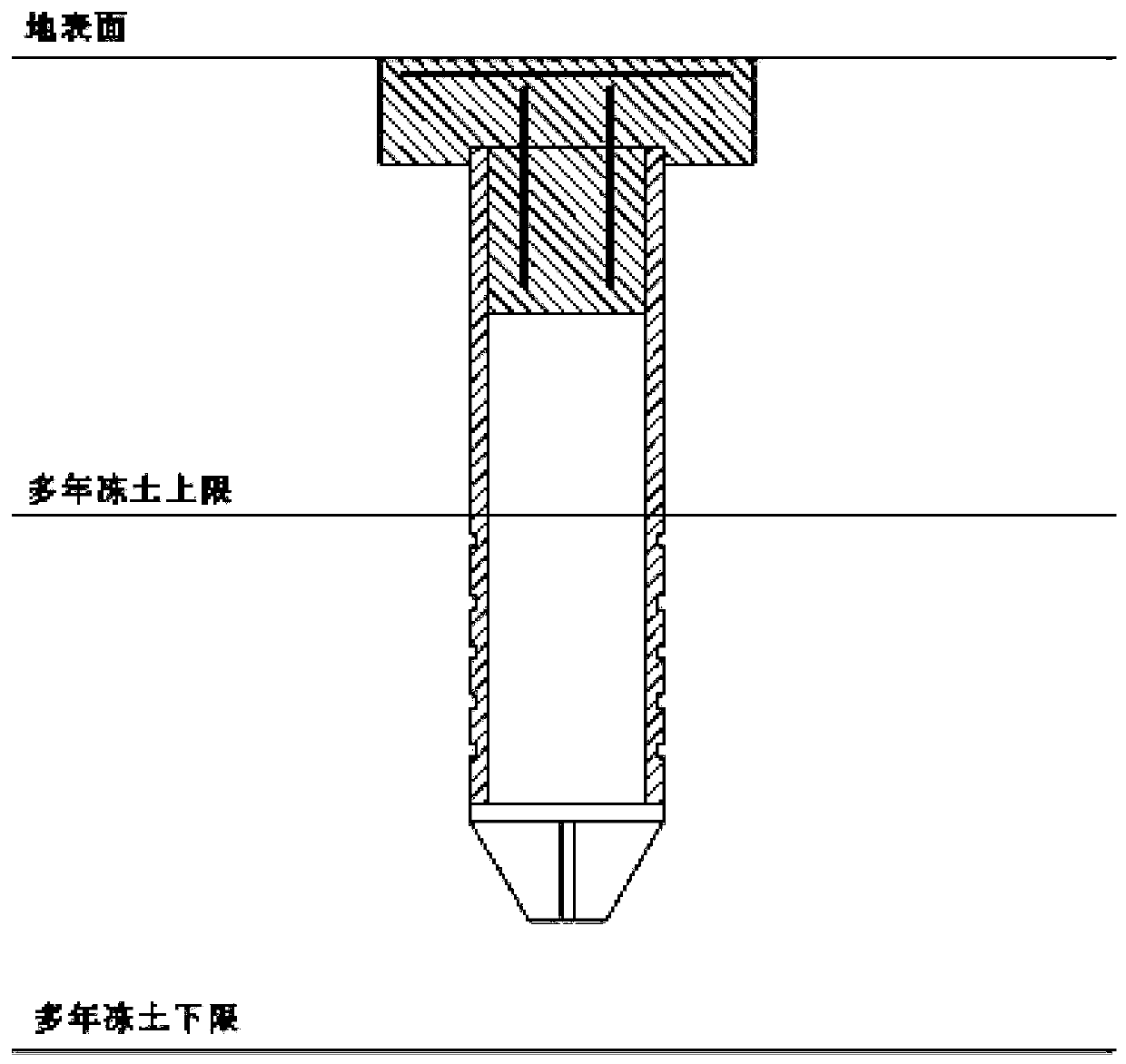

Concrete pipe pile for treating thaw collapse of island-shaped frozen soil foundation, and construction method of concrete pipe pile

PendingCN110206022AImprove cohesionHigh load-carrying propertiesBulkheads/pilesPile capCarrying capacity

The invention discloses a concrete pipe pile for treating thaw collapse of an island-shaped frozen soil foundation, and a construction method of the concrete pipe pile. The concrete pipe pile comprises a pile cap, a pile column and a pile tip which are sequentially connected; the end face area of the pile cap is larger than that of the pile column, the top of the pile column partially stretches into the bottom of the pile cap, the pile column is tubular, the top in the pile column and the pile cap are integrally connected, a plurality of grooves are formed in the peripheral face of the lower half part of the pile column, and the pile tip is made of cross-shaped conical steel; and when the pipe pile is arranged in the frozen soil foundation, the grooves of the pile columns are partially located below the upper limit of frozen soil, and the pile column stretches into the upper limit of the frozen soil by at least 3 m. Cohesion between the pile and a soil body and the bearing characteristic of soil between piles can be improved, and the carrying capacity of the foundation is improved.

Owner:CHANGAN UNIV

Solar-ground source heat pump coupled energy supply system with double buried pipe groups

ActiveCN106196714BAchieve thermal balanceLong runSolar heating energyHeat pumpsCouplingEnergy supply

The invention relates to a solar energy-ground source heat pump coupling type energy supply system provided with two buried pipe groups. The solar energy-ground source heat pump coupling type energy supply system provided with the two buried pipe groups is characterized in that the energy supply system comprises a solar heat collector, a heat-storage water tank, a ground source heat pump unit, the first buried pipe group, the second buried pipe group, a building tail end device, a heat-collection circulating water pump, a heat-storage circulating water pump, a ground source side circulating water pump, a first heat-storage control valve, a second heat-storage control valve, a first ground source side control valve, a second ground source side control valve, a first pipe group flow regulation valve, a second pipe group flow regulation valve, a first pipe group heat meter and a second group pipe heat meter; the solar heat collector is sequentially connected with the heat-storage water tank and the heat-collection circulating water pump through pipelines, namely a heat collection cycle is formed, and hot water generated by solar energy is collected; and the hot water outflow end of the heat-storage water tank is sequentially connected with the first heat-storage control valve, the heat-storage circulating water pump, the first buried pipe group, the second heat-storage control valve and the backflow end of the heat-storage water tank through pipelines, so that a heat storage cycle is formed.

Owner:河北泓宇能源科技有限公司

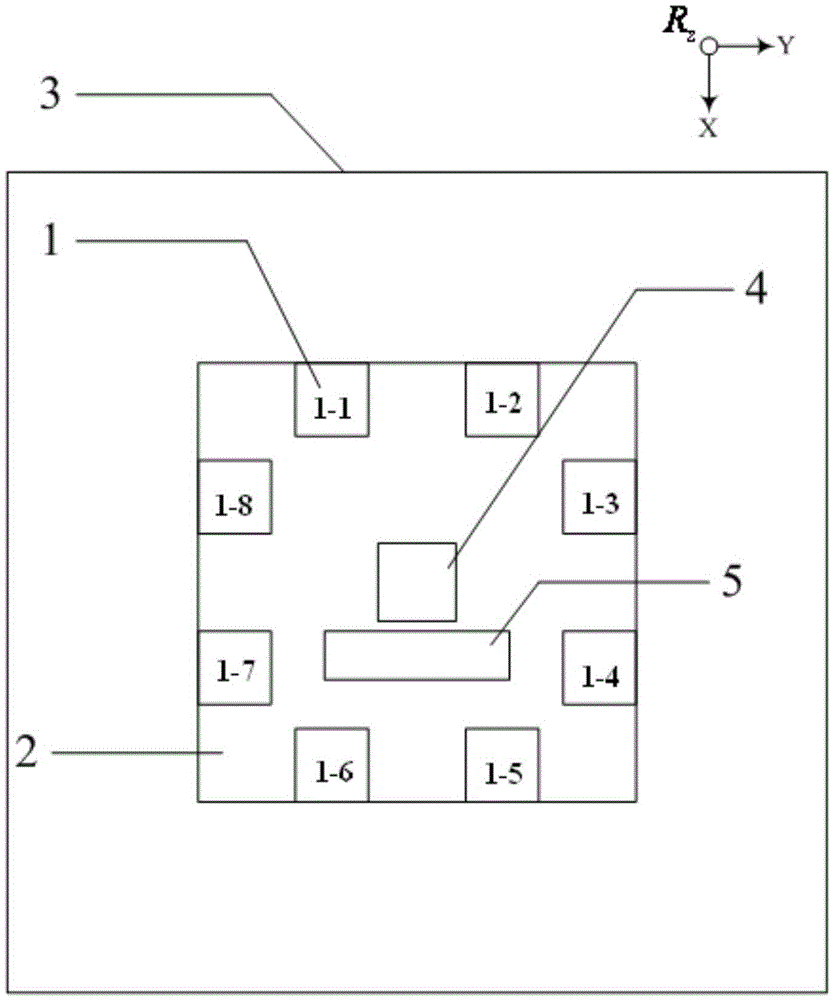

Large-scale air bearing translation device driven by plasma propulsion

InactiveCN104002996BIncrease load ratioLarge thrustCosmonautic condition simulationsSimulator controlGratingLoad ratio

The invention relates to a large-range gas floating translation device based on plasma boosting driving and belongs to the field of aerospace direction ground physical simulation and space gesture adjusting. The gas floating translation device is mainly used for achieving translation in a gas floating environment on a two-dimension plane. The gas floating translation device comprises a plasma driver, a translation table body, a measuring mechanism, a controller and an electric energy converting device. A plane grating sensor measures current gesture signals in real time and sends the signals to the controller. The controller carries out computing and sends controlled quantity to each plasma booster which is used as an executing mechanism, and accordingly free motion of the translation table body on the two-dimension plane in three freedom degrees of X, Y and Rz can be achieved. The large-range gas floating translation device has the advantages of being high in system load ratio, high in efficiency and long in working time.

Owner:HARBIN INST OF TECH

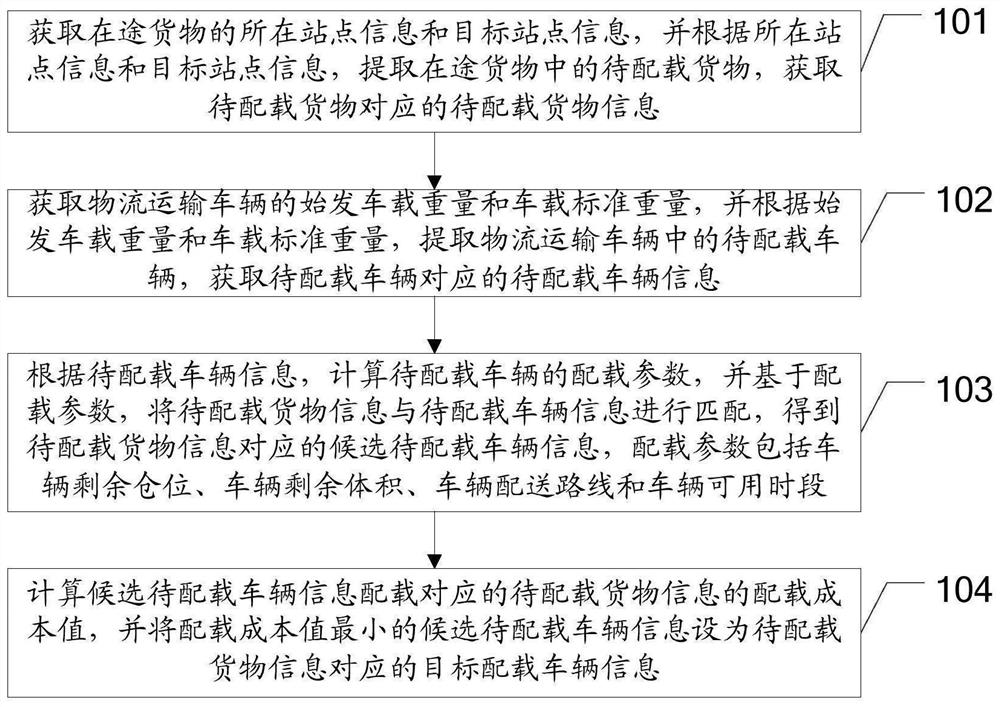

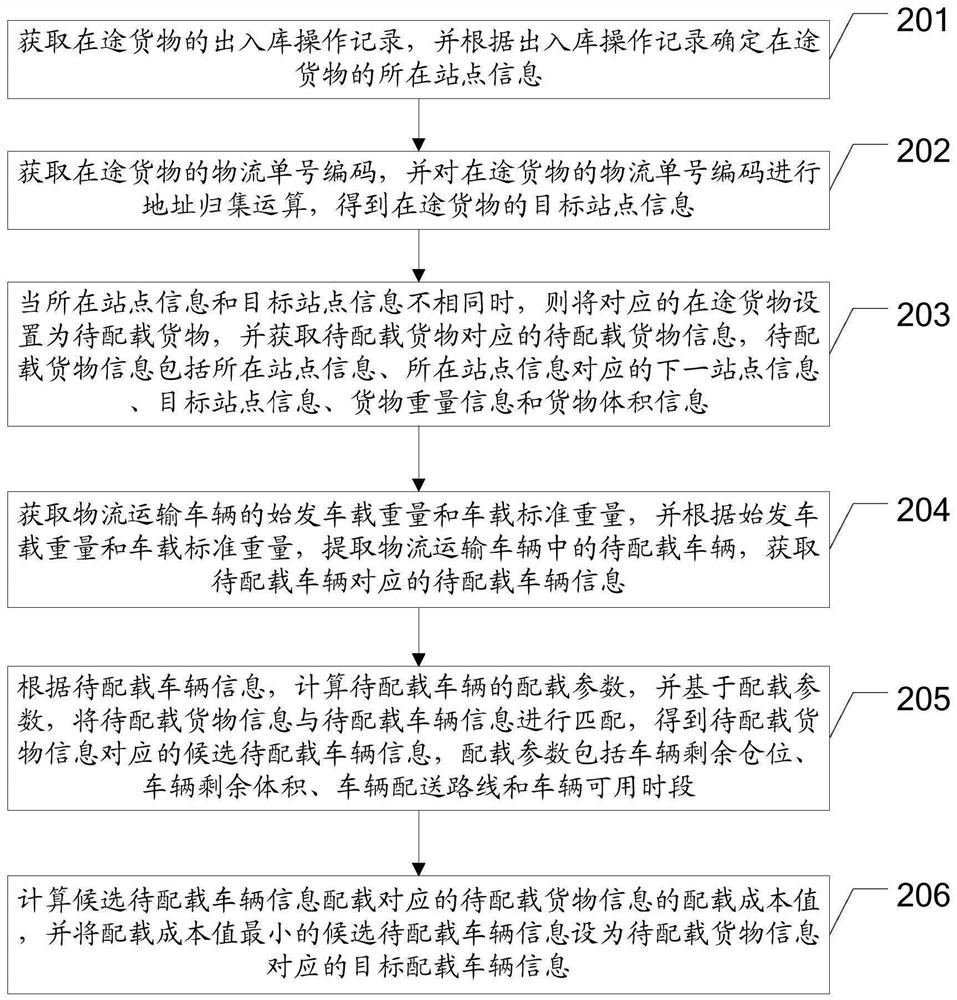

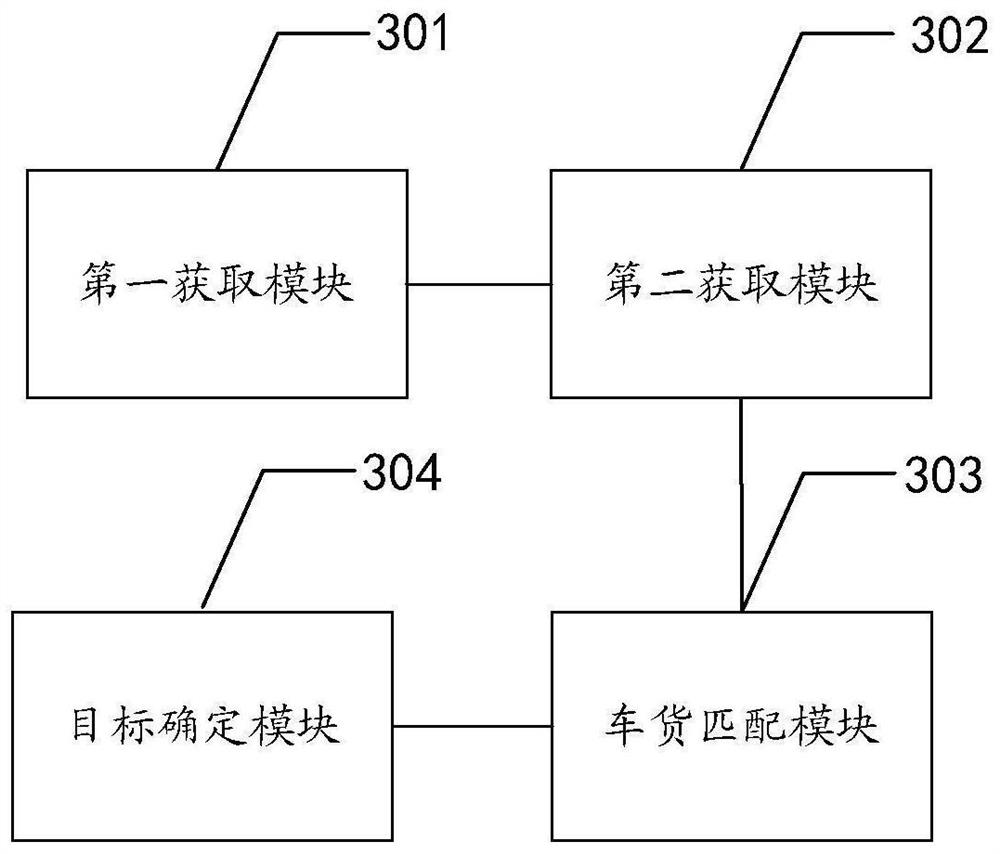

Cargo stowage method, device and equipment for logistics transportation vehicle and storage medium

The invention relates to the technical field of intelligent logistics transportation, and discloses a cargo stowage method, device and equipment for a logistics transportation vehicle and a storage medium, which are used for improving the cargo stowage rate. The cargo stowage method of the logistics transportation vehicle comprises the following steps: acquiring information of a station where an in-transit cargo is located and information of a target station, and obtaining information of a cargo to be stowage; obtaining the starting vehicle load capacity and the vehicle-mounted standard weight of the logistics transportation vehicles, and according to the starting vehicle load capacity and the vehicle-mounted standard weight, extracting to-be-loaded vehicles in the logistics transportation vehicles to obtain information of the to-be-loaded vehicles; obtaining a vehicle remaining space, a vehicle remaining volume, a vehicle delivery route and a vehicle available time period, and matching the to-be-loaded cargo information with the to-be-loaded vehicle information to obtain candidate to-be-loaded vehicle information; and calculating the stowage cost value of the to-be-stowage cargo information corresponding to the stowage of the candidate to-be-stowage vehicle information, and setting the candidate to-be-stowage vehicle information with the minimum stowage cost value as the target stowage vehicle information.

Owner:SHANGHAI DONGPU INFORMATION TECH CO LTD

A high-strength and light-weight multi-layer carbon fiber special-shaped bulkhead panel

The invention discloses a high-strength and lightweight multi-layer carbon fiber special-shaped bulkhead panel. The panel includes an outer panel, a structural foam sandwich, and an inner panel from the outside to the inside. The outer panel, the structural foam sandwich, and the inner panel The plates are bonded with each other by gluing or vacuum introduction method, the outer cover plate is made of at least 4 layers of carbon fiber cloth, and the inner cover plate is made of at least 2 layers of carbon fiber cloth. As a result, the edges of each layer of carbon fiber cloth of the outer cover panel and the inner cover panel are overlapped and glued and pressed together. The panel of the cabin body manufactured by adopting the laying design of the present invention has the advantages of corrosion resistance, high load ratio, low density and light weight, and the laying design of the present invention is simple in structure and strong in operability.

Owner:衡阳泰豪通信车辆有限公司

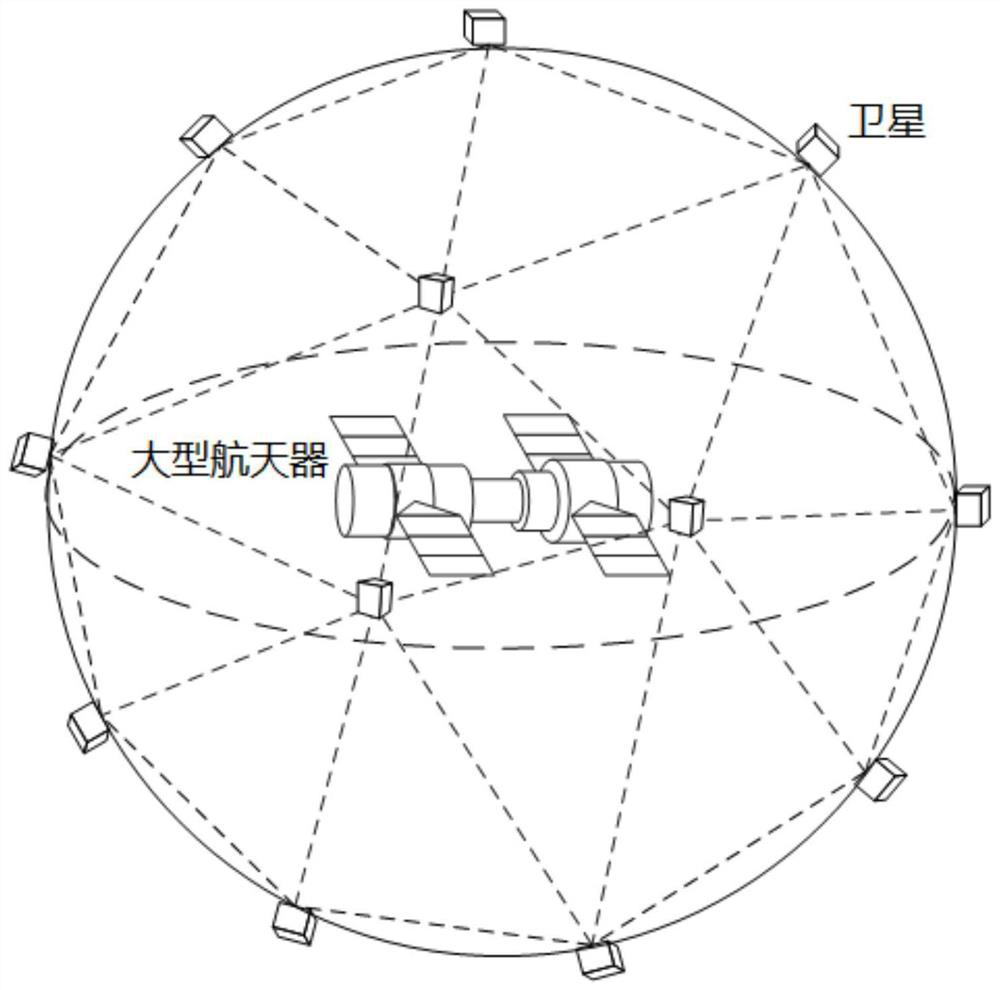

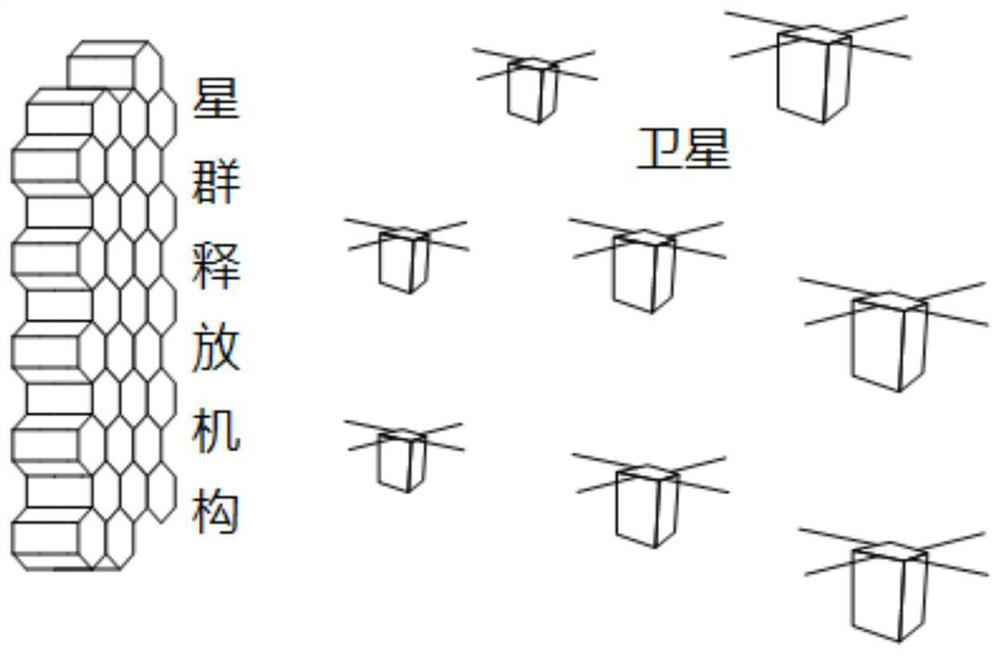

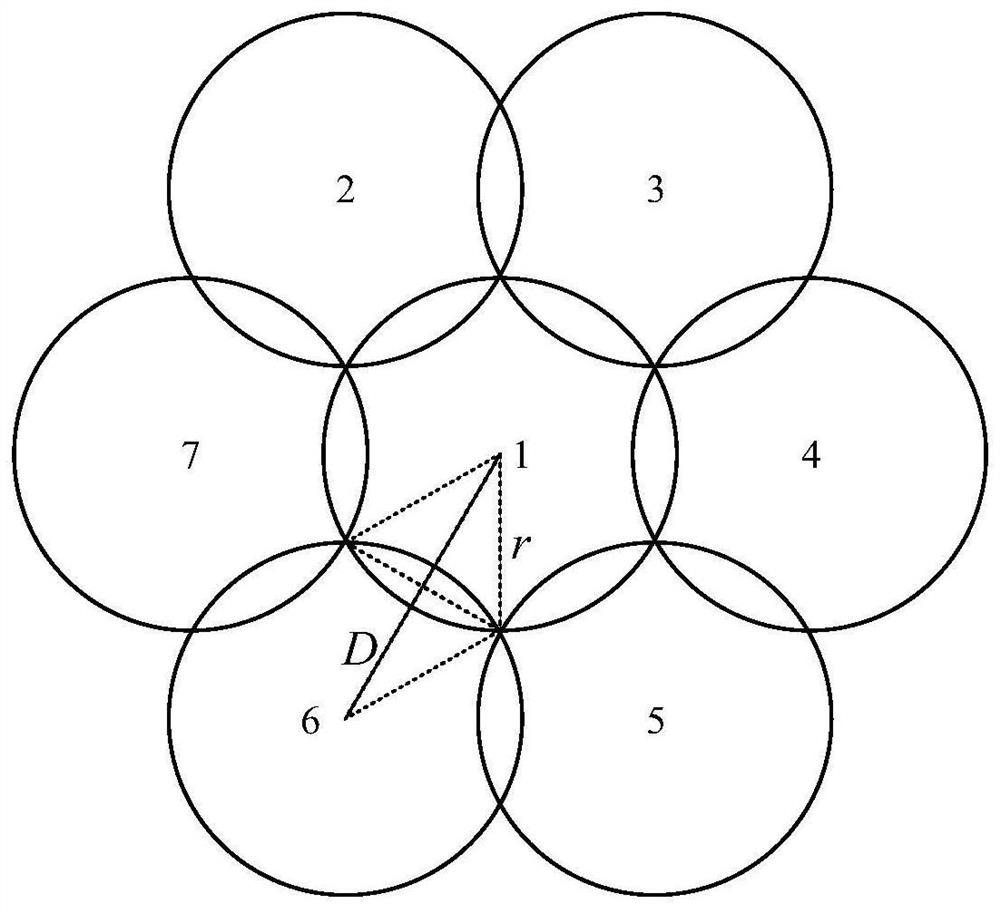

Global monitoring method for large spacecraft based on bionic micro-nano constellation

ActiveCN109189090BRealize global monitoringGood value for moneyPicture taking arrangementsElectromagnetic wave reradiationMonitoring methodsRemote sensing

The invention discloses a large-scale spacecraft global monitoring method based on a bionic micro-nano constellation. The method includes: releasing the micro-nano constellation through a honeycomb-like release mechanism; through a micro-nano constellation space layout control method based on a bionic potential function, Make the constellation evenly distributed on the enveloping sphere with the spacecraft as the center; adjust the attitude of the constellation to realize the monitoring of the spacecraft or its external environment; receive the monitoring data of the constellation, summarize and process it, and send it to the micro-nano constellation Monitoring instructions; determine the satellites that need to be recovered through the constellation life prediction and fault diagnosis, and recover them through the recovery mechanism. Other satellites in the constellation will change their positions under the action of the potential function to make up for the vacancy of the monitoring field of view of the exiting satellites, and realize the reconstruction of the constellation . The monitoring method of the present invention has a large monitoring field of view, comprehensive information, high monitoring efficiency, and strong environmental adaptability, and can realize the non-dead-angle patrol inspection of large spacecraft by monitoring constellations, and realize three-dimensional, panoramic, and real-time global inspection of large spacecraft Monitor the effect.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Double cold source three pipe air conditioning system

ActiveCN105240958BReduce energy consumptionIncrease load ratioMechanical apparatusSpace heating and ventilation safety systemsTemperature UnitWater pipe

The invention discloses a dual-cold-source three-pipe-system air conditioner system. The dual-cold-source three-pipe-system air conditioner system comprises an air conditioner terminal and a cold source system, wherein the cold source system comprises a high-temperature cold source and a low-temperature cold source; the outlet of the high-temperature cold source and the outlet of the low-temperature cold source are separately connected with a water supply pipe with a low-temperature water segregator, and the outlet of the water supply pipe is connected with the cold source inlet of the air conditioner terminal; the cold source outlet of a fan coil in the air conditioner terminal is connected with the inlet of the low-temperature cold source through a low-temperature water return pipe; a branch with a valve is arranged between the low-temperature water return pipe and the high-temperature water return pipe; the other cold source outlets of the air conditioner terminal are connected with the inlet of the high-temperature cold source through the high-temperature water return pipe; and the outlet of the high-temperature cold-source is also connected with the inlet of the low-temperature cold source. By adopting the dual-cold-source three-pipe-system air conditioner system, under the precondition that the total volume of the whole air conditioner water chilling unit is unchanged, the ratio of load borne by a high-temperature unit is improved to the greatest extent through reasonably allocating the ratios of the air conditioner load borne by the high-temperature unit and a low-temperature unit, so that the energy consumption of the cooling load of the whole air conditioner system is greatly lowered, and the air conditioner system is an energy-saving-type air conditioner system.

Owner:杭州绿程机电有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com