Sludge low-temperature heat pump drying equipment

A low-temperature heat and sludge drying technology, used in lighting and heating equipment, heat pumps, dewatering/drying/concentrated sludge treatment, etc. Unsatisfactory and other problems, to achieve the effect of compact structure, small footprint, and improved dehumidification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

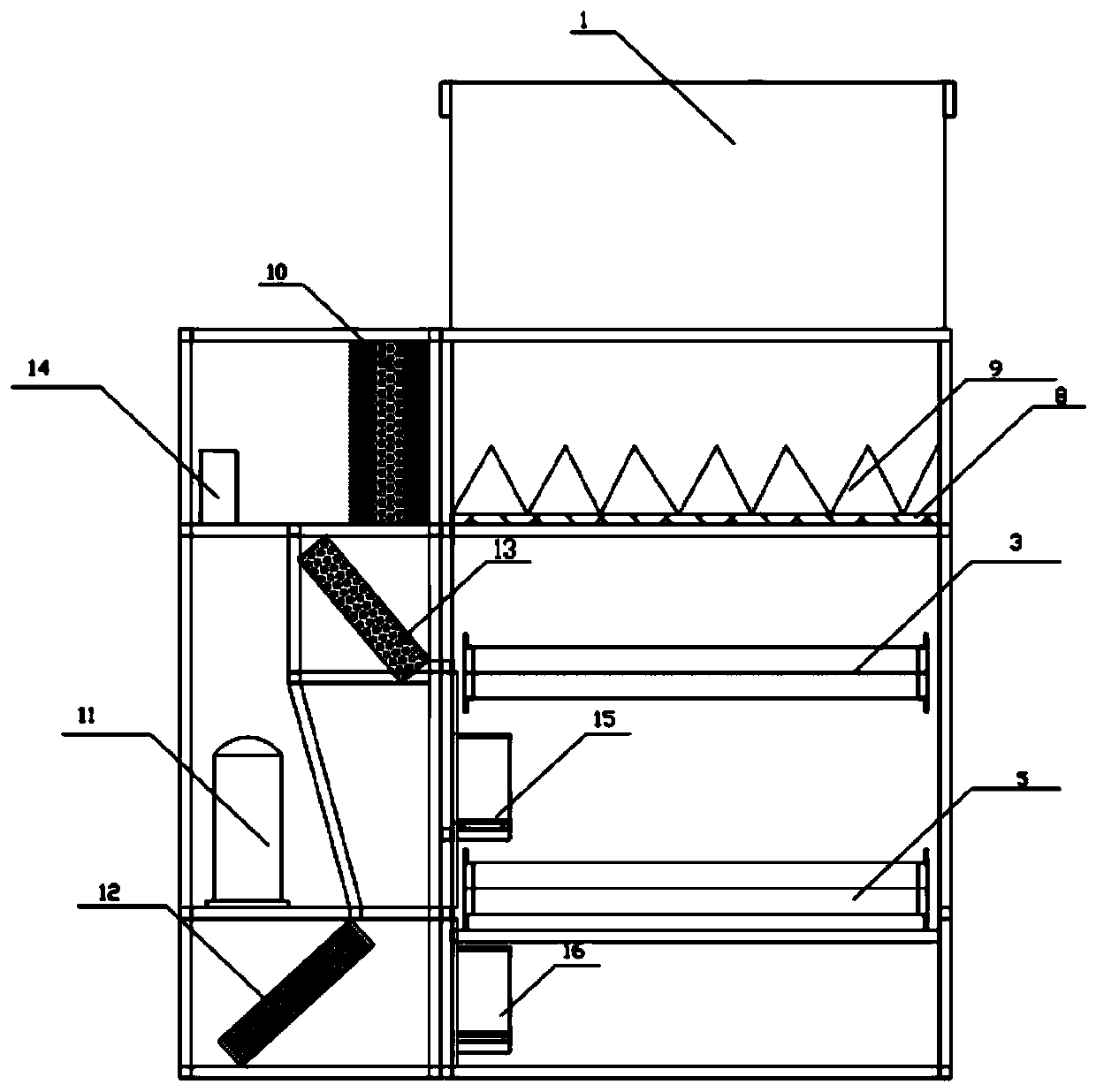

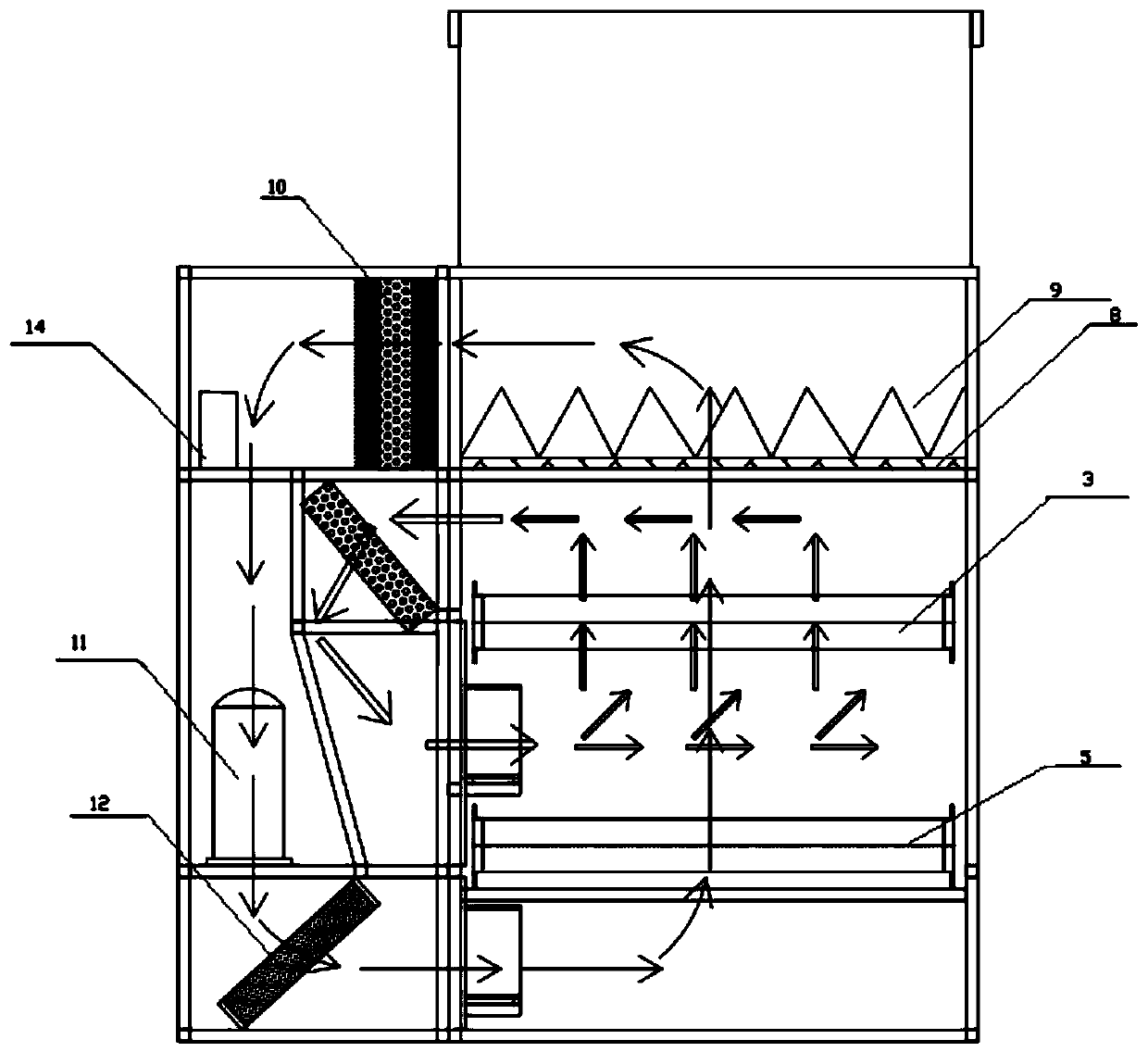

[0026] like Figure 1-4 As shown, a sludge low-temperature heat pump drying equipment described in the embodiment of the present invention includes a sludge drying chamber, a sludge feeding device is provided on the upper side of the sludge drying chamber, and a sludge feeding device is provided on one side of the sludge drying chamber. There is a heat pump system room, and a heat pump system is installed in the heat pump system room. The mud feeding and distributing device includes a mud feeding hopper 1 and a distributing machine 2 arranged from top to bottom. The sludge drying chamber is provided with a sludge inlet. The distributing machine 2 is connected with the sludge inlet, the bottom of the sludge drying chamber is provided with a sludge outlet, the upper part of the sludge drying chamber is provided with an air filter device, and the middle part of the sludge drying chamber is provided with several layers Conveying mesh belt, a discharge device is arranged below the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com