Concrete pipe pile for treating thaw collapse of island-shaped frozen soil foundation, and construction method of concrete pipe pile

A technology for concrete pipe piles and permafrost foundations, which is applied in foundation structure engineering, sheet pile walls, buildings, etc., can solve problems such as excessive heat, easy damage to the soil between piles, and damage to the stability of the permafrost layer, so as to promote the overall Load bearing capacity and the effect of improving load bearing characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention is described in further detail below in conjunction with accompanying drawing:

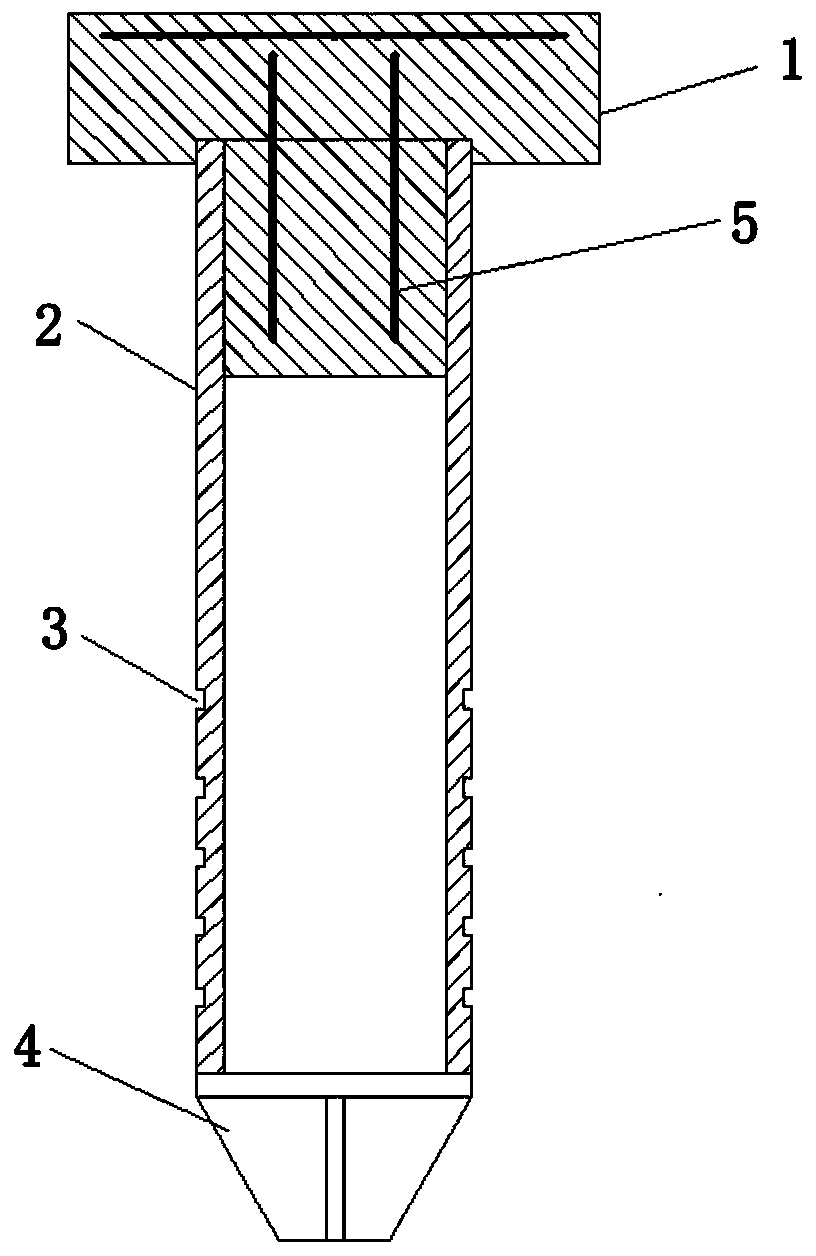

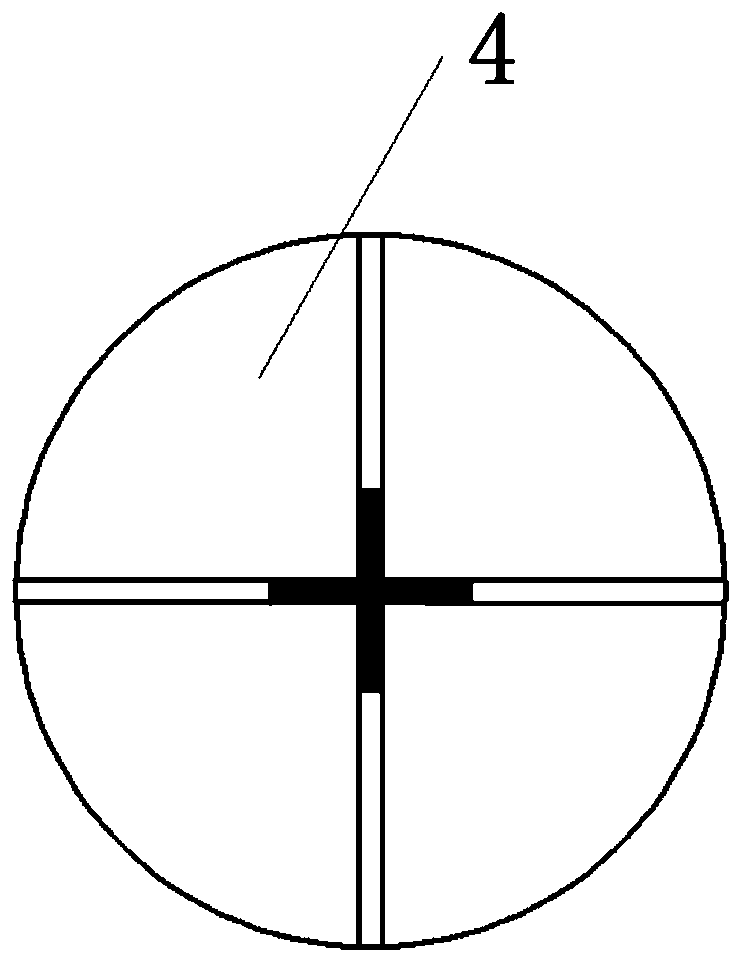

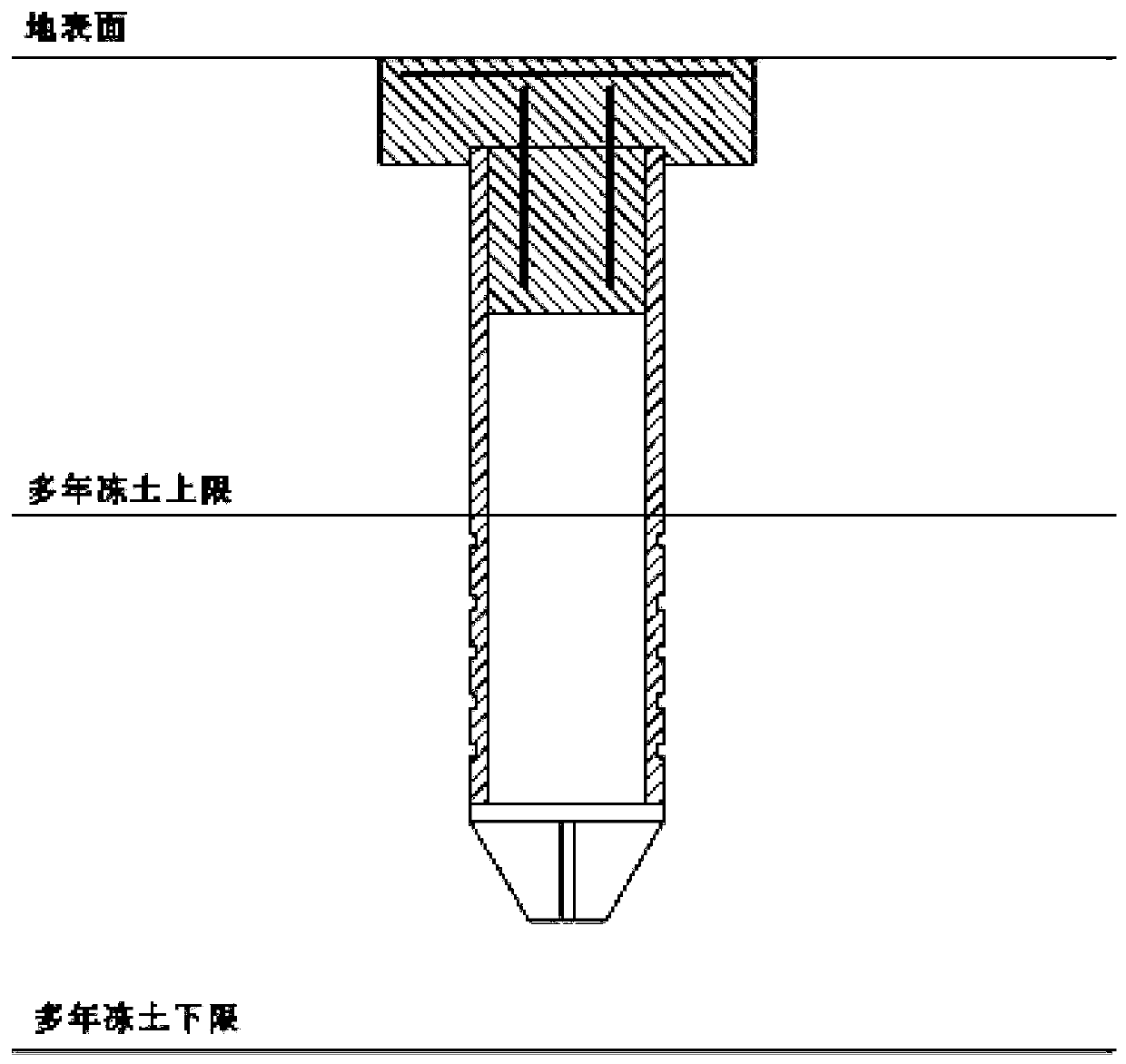

[0034] Such as figure 1 As shown, the concrete pipe pile of the present invention includes a pile cap 1, a pile column 2, a groove 3, a sharp bottom cross steel pile tip 4 and a reinforcement 5.

[0035] Pile cap 1 is made of C25 concrete poured on site. The size of pile cap 1 should meet the requirements of bending resistance, punching resistance and shear resistance. Generally, it is 3 to 3.5 times the outer diameter of the pile 2; the thickness of the pile cap 1 is generally not greater than the outer diameter of the pile 2, and it is not less than 10 cm into the top of the pile 2 to prevent the pile cap 1 from tilting and falling off. Reinforcement 5 is arranged according to two-way uniform length, and the top of the pile is provided with two parallel first reinforcements extending into the pile cap, the first reinforcement is parallel to the axis of the pile, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com