Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

52results about How to "In line with the concept of green construction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

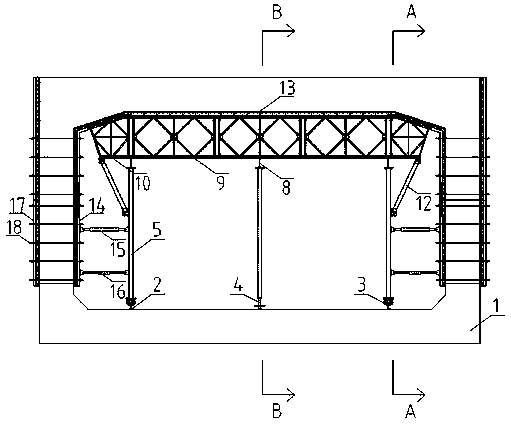

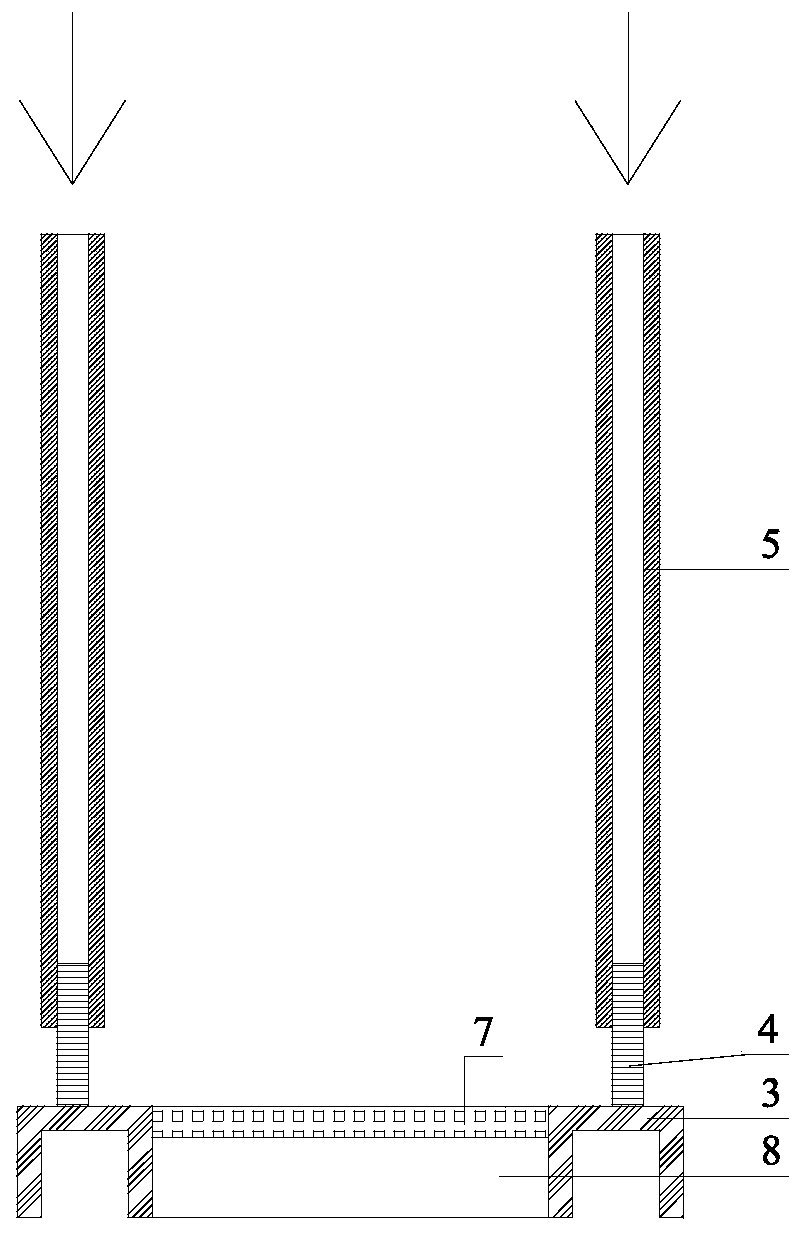

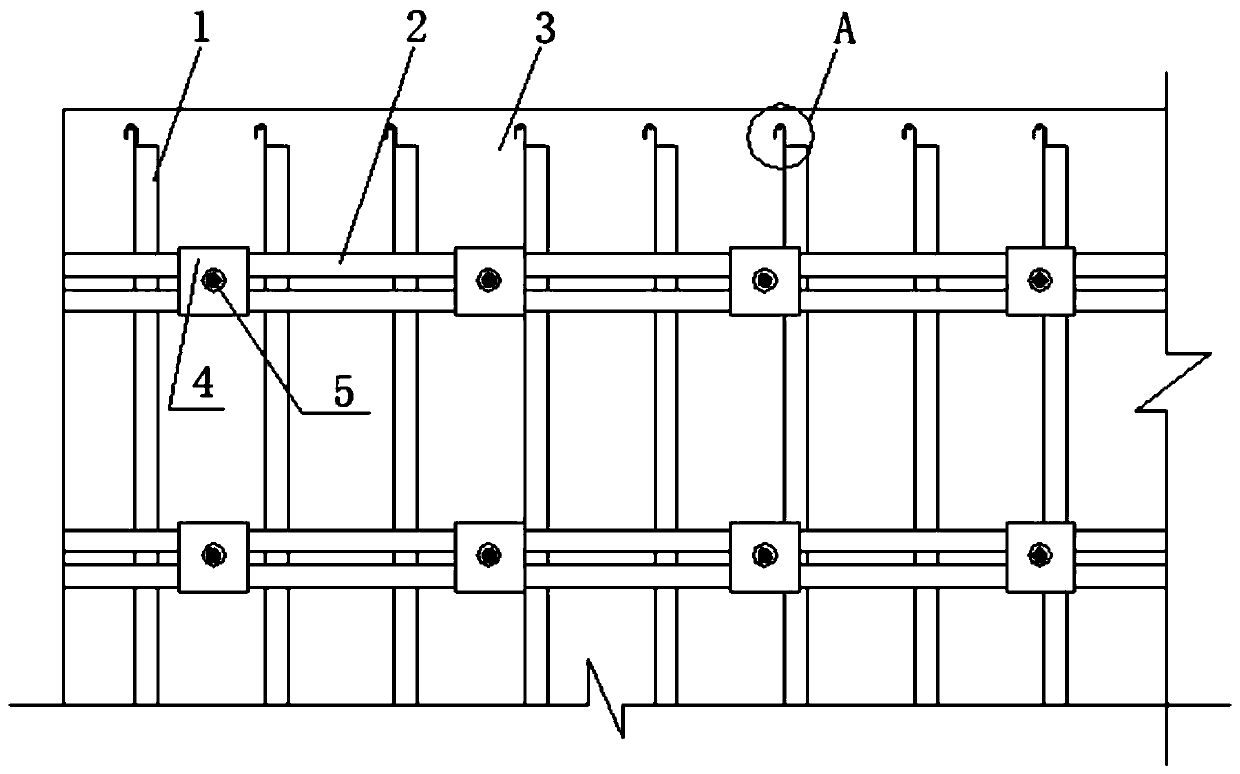

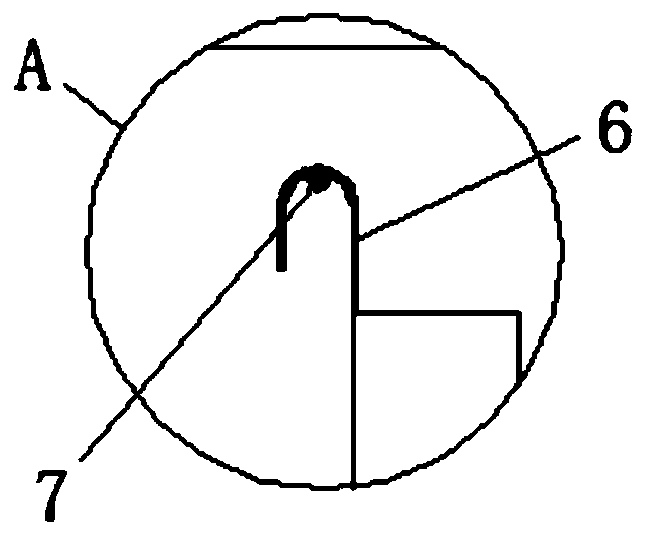

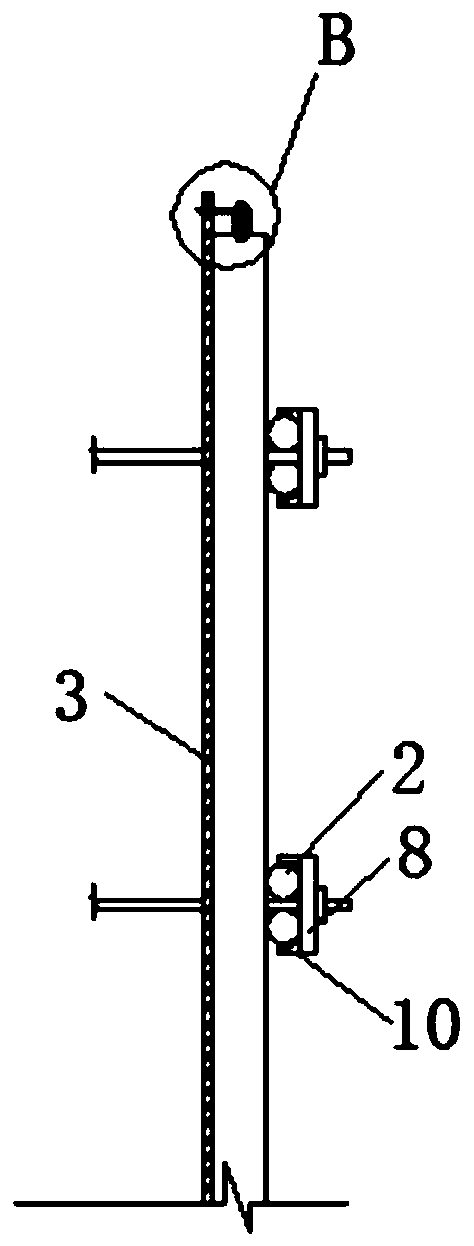

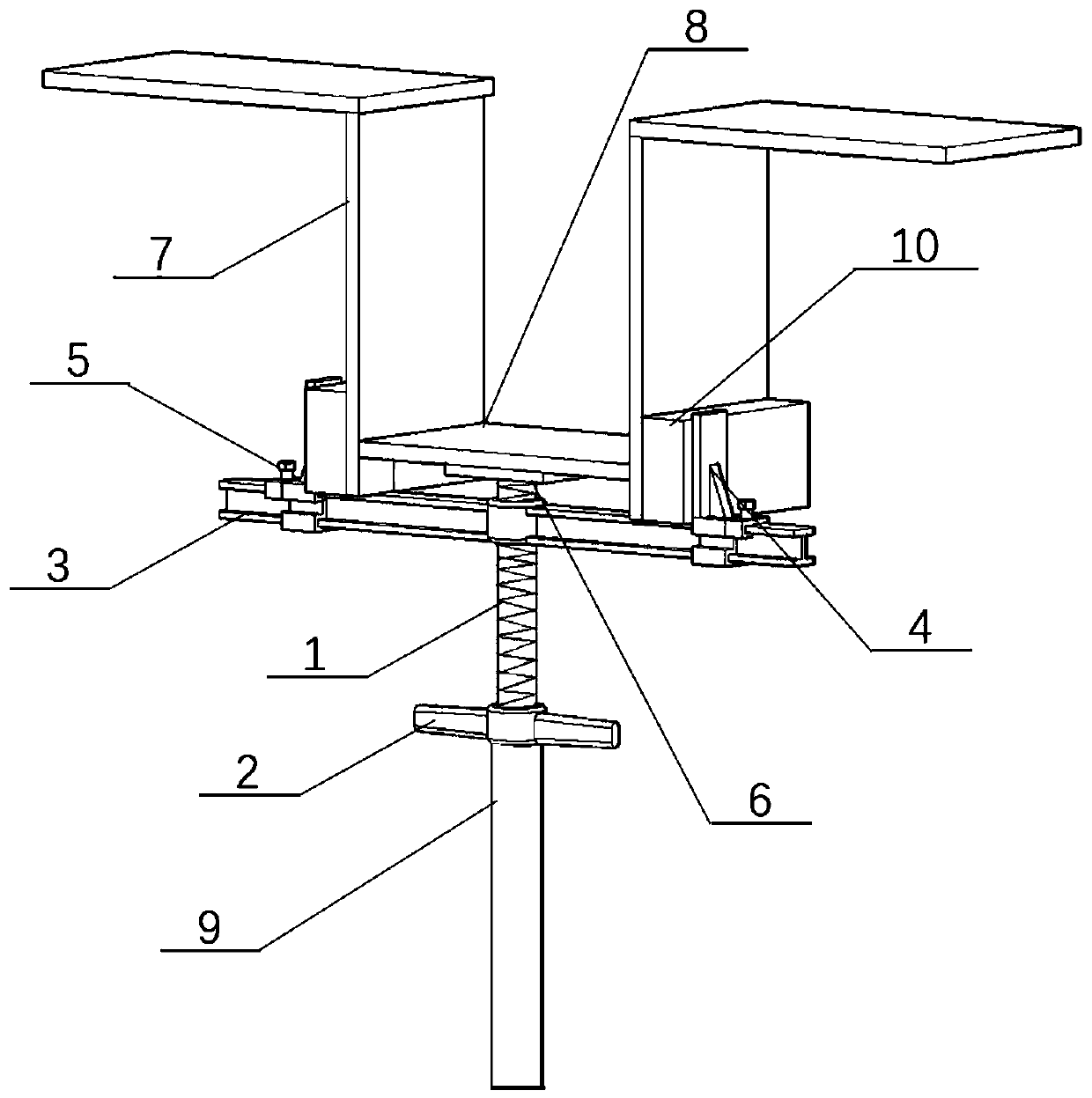

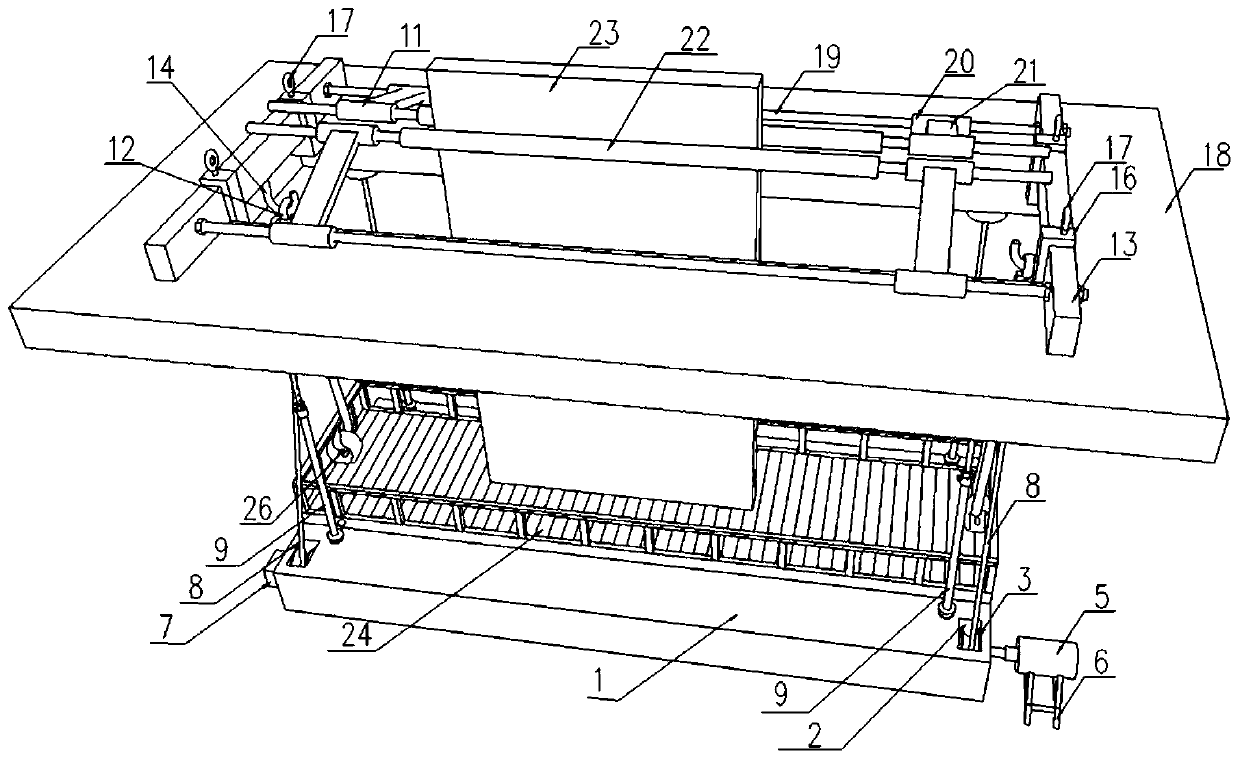

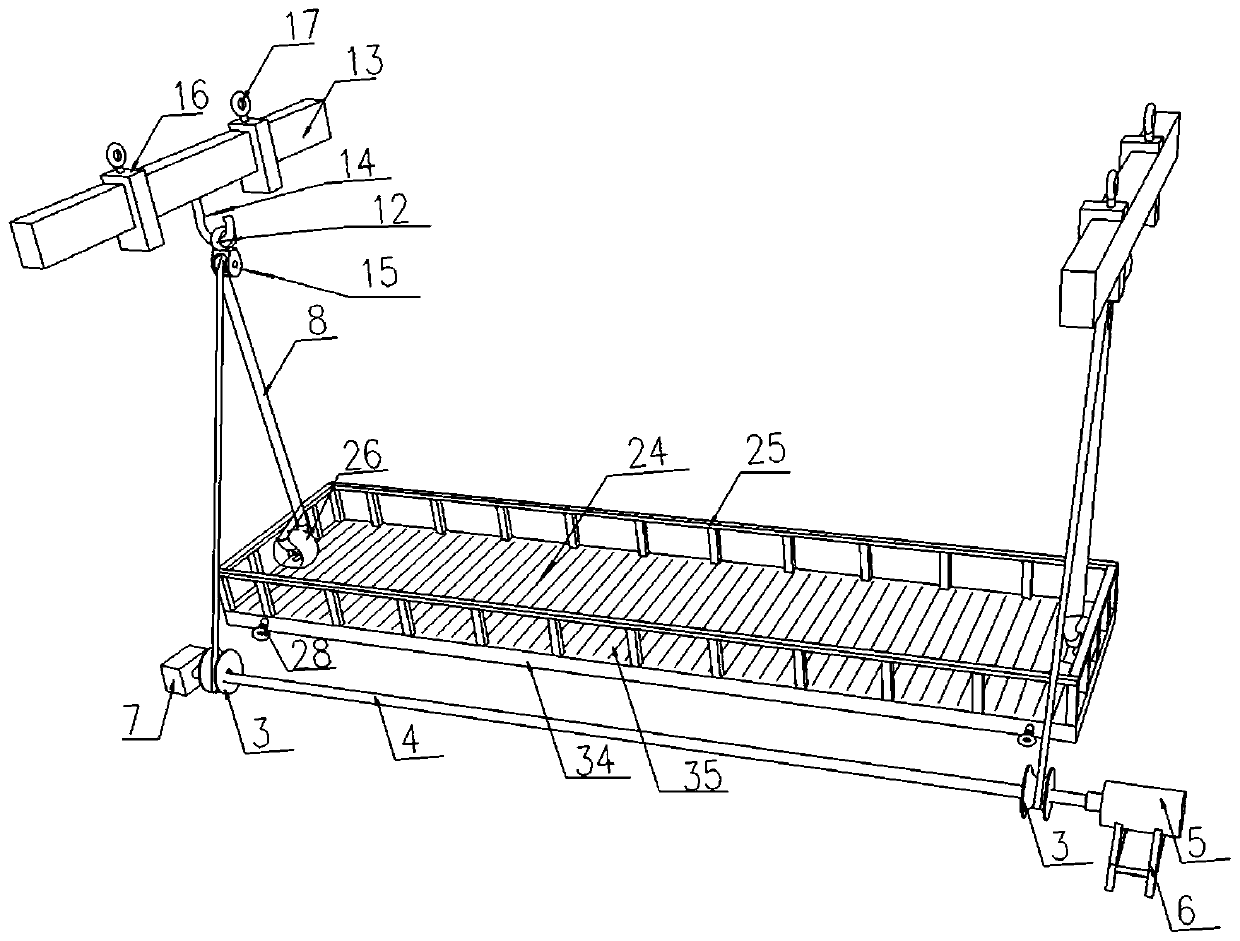

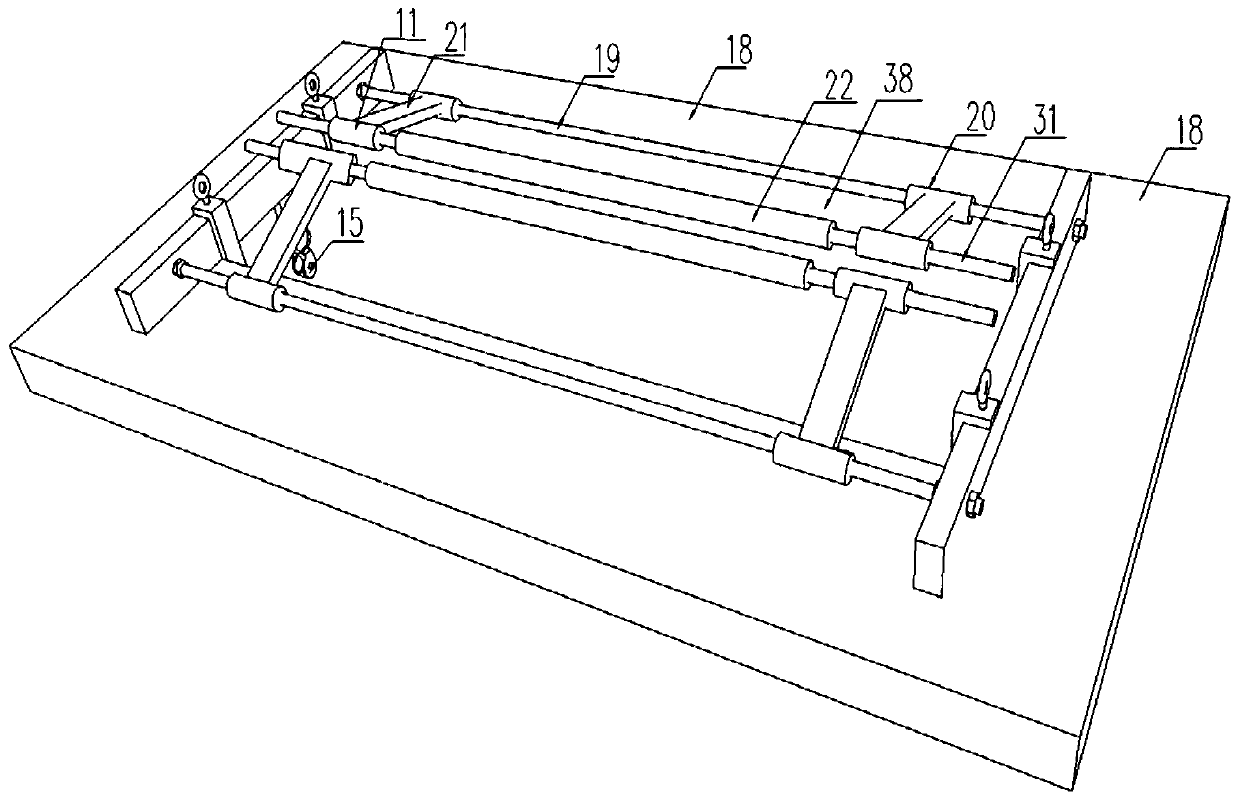

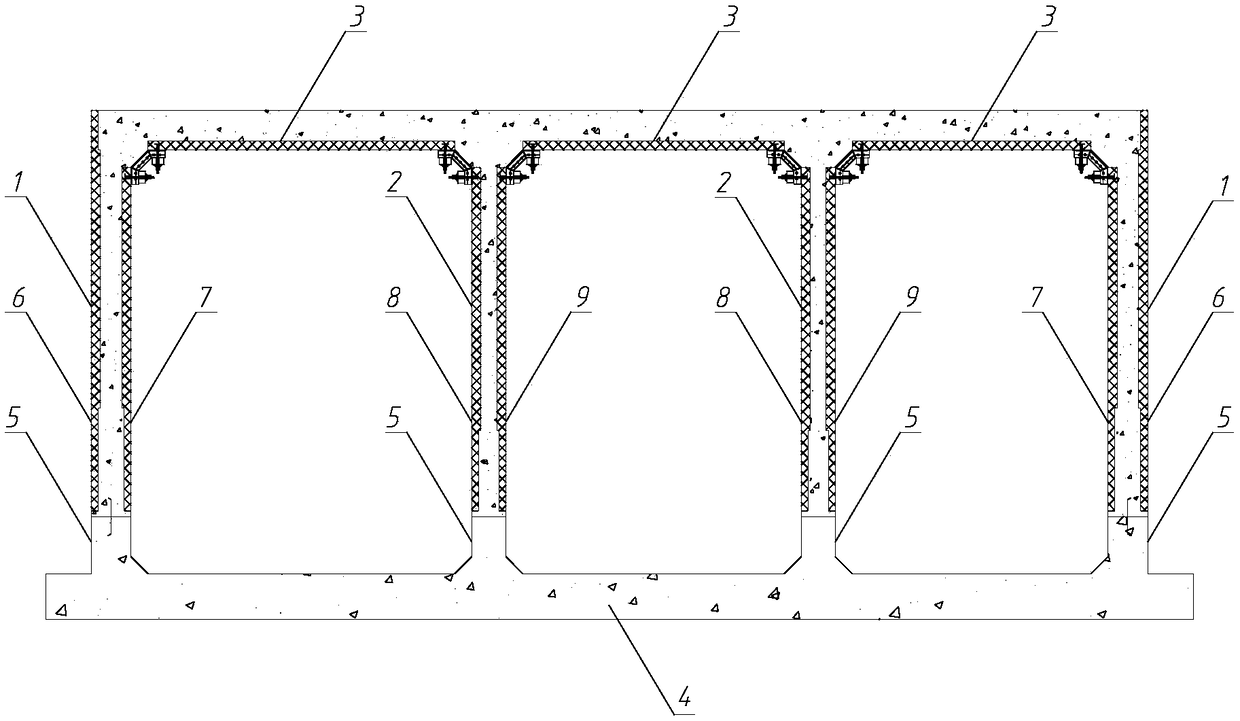

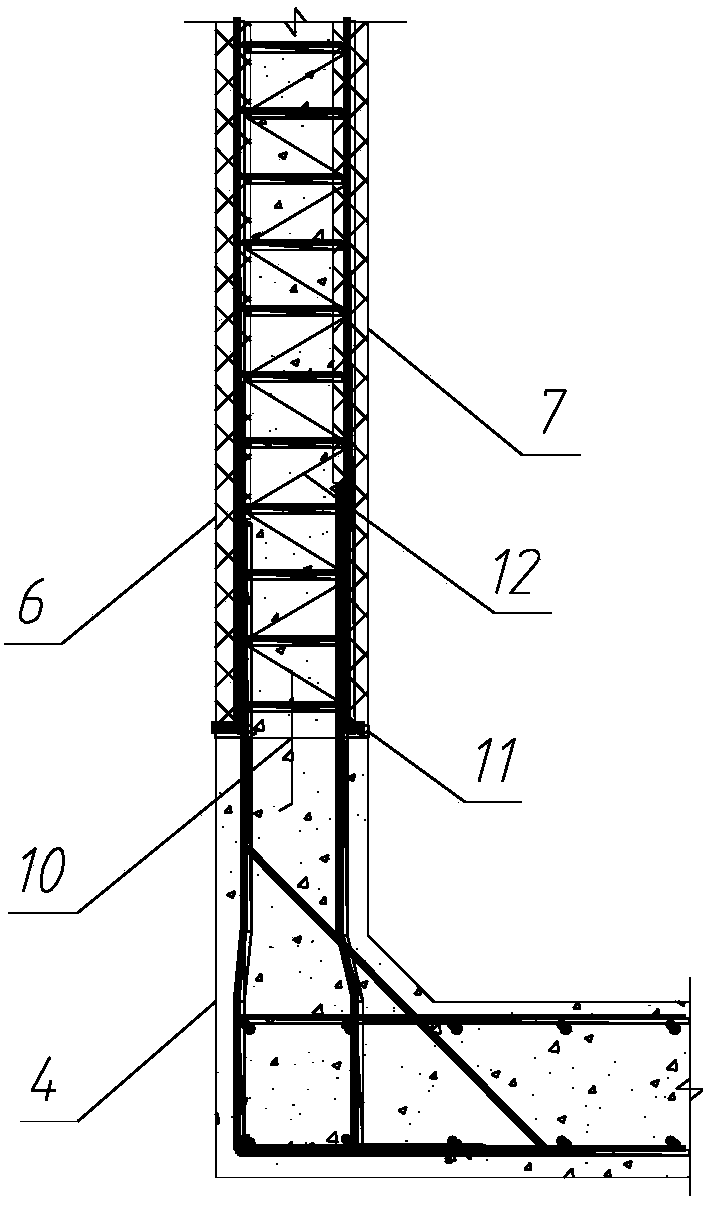

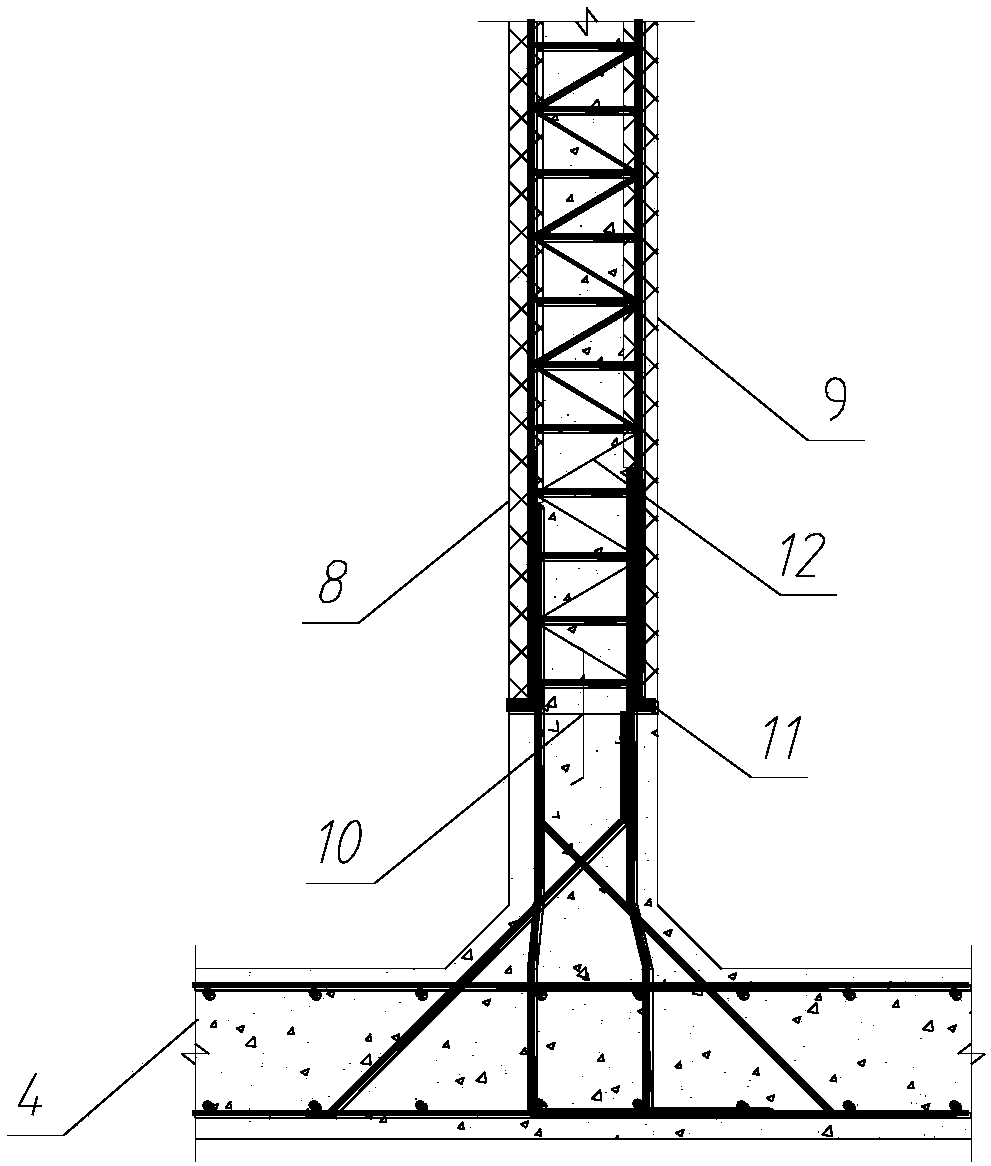

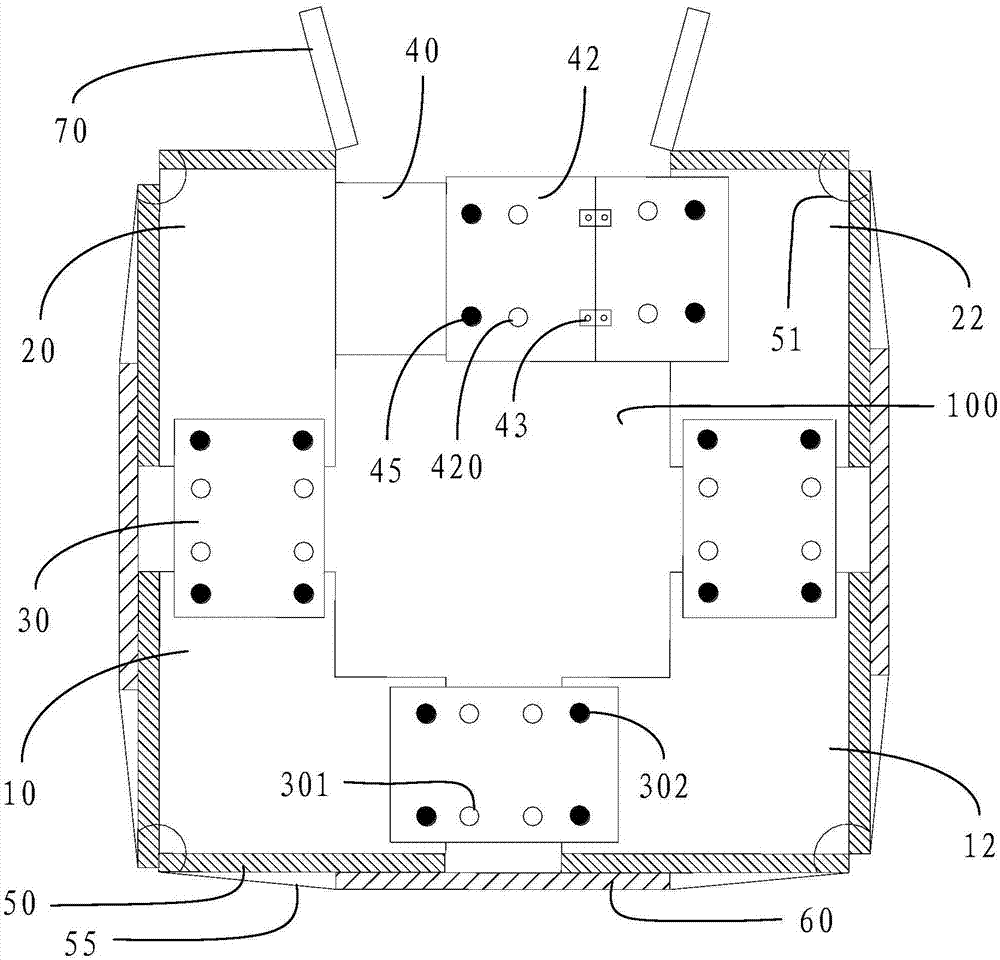

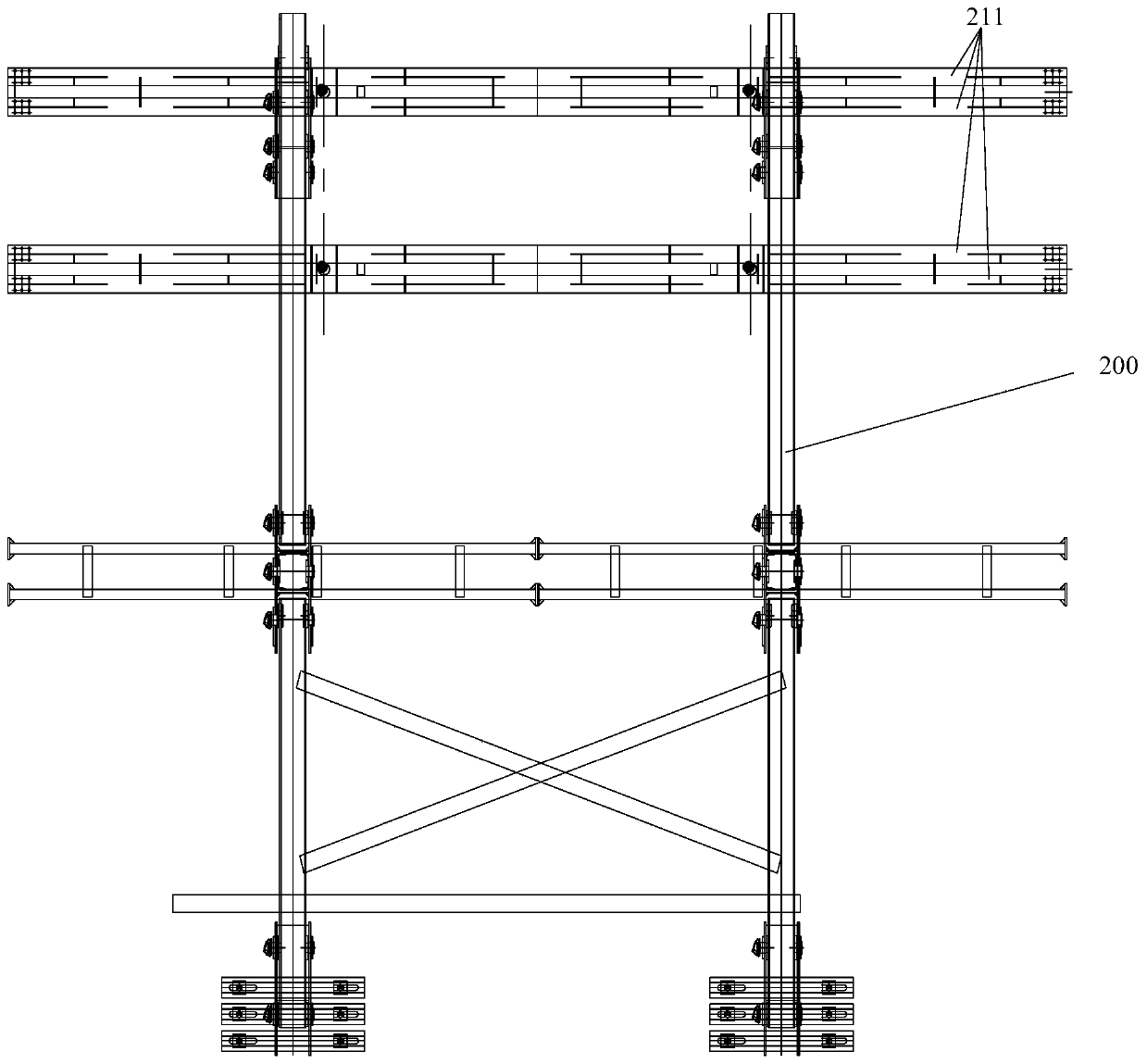

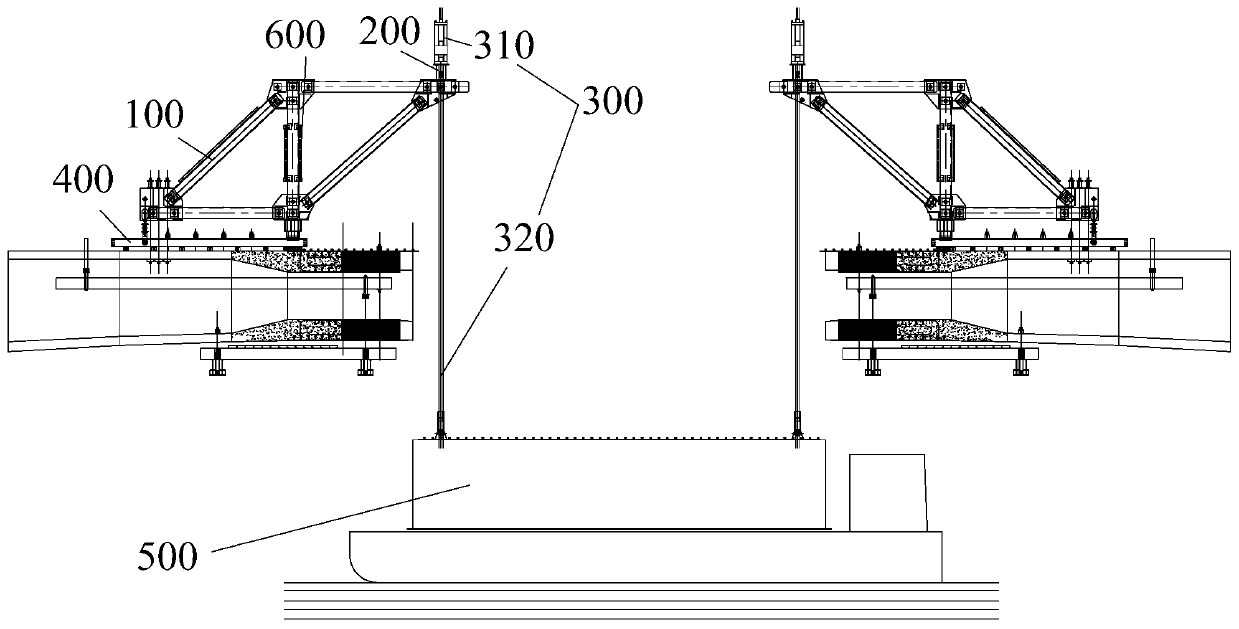

Fabricated trolley for box culvert construction and construction method thereof

PendingCN111424570AImprove pouring efficiencyRigid and stable supportArtificial islandsGround-workArchitectural engineeringStringer

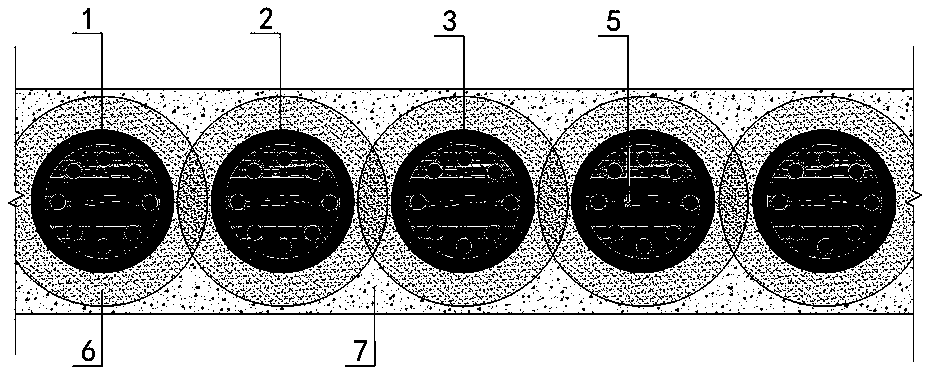

A fabricated trolley for box culvert construction is provided. Rails are longitudinally laid on a poured box culvert bottom plate, stand columns with walking wheels and stand columns with adjustable bottom supports A are arranged above the rails in a staggered mode, longitudinal beams are supported above the stand columns, a plurality of sets of bailey beams are erected above the longitudinal beams, and a top formwork is supported above the bailey beams; left and right ends of each bailey beam are connected with end trusses; the side faces of the stand columns are connected with side formworksthrough adjusting screws and jacks. The fabricated trolley is used for pouring a box culvert wall body and top plate concrete at the same time, the box culvert concrete pouring efficiency can be greatly improved, the inner surface and the outer surface of a poured box culvert are smooth, constructors can use the trolley conveniently, and all components of the trolley can be disassembled and installed quickly and are convenient to maintain.

Owner:GUANGXI ROAD CONSTR ENG GRP CO LTD +1

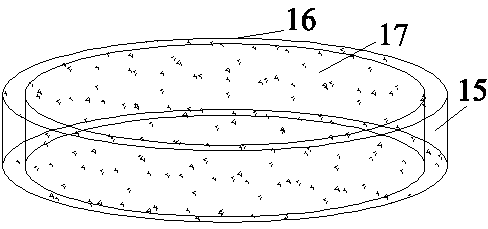

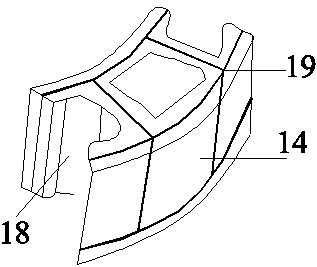

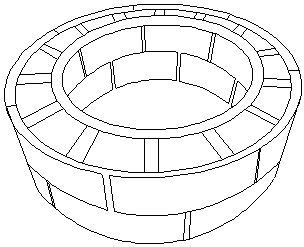

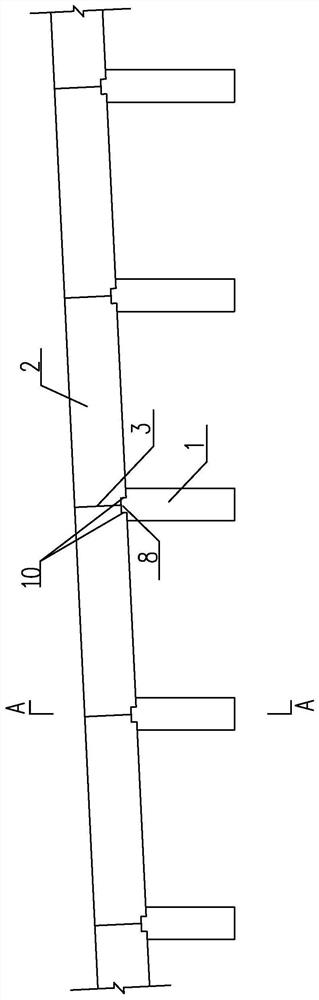

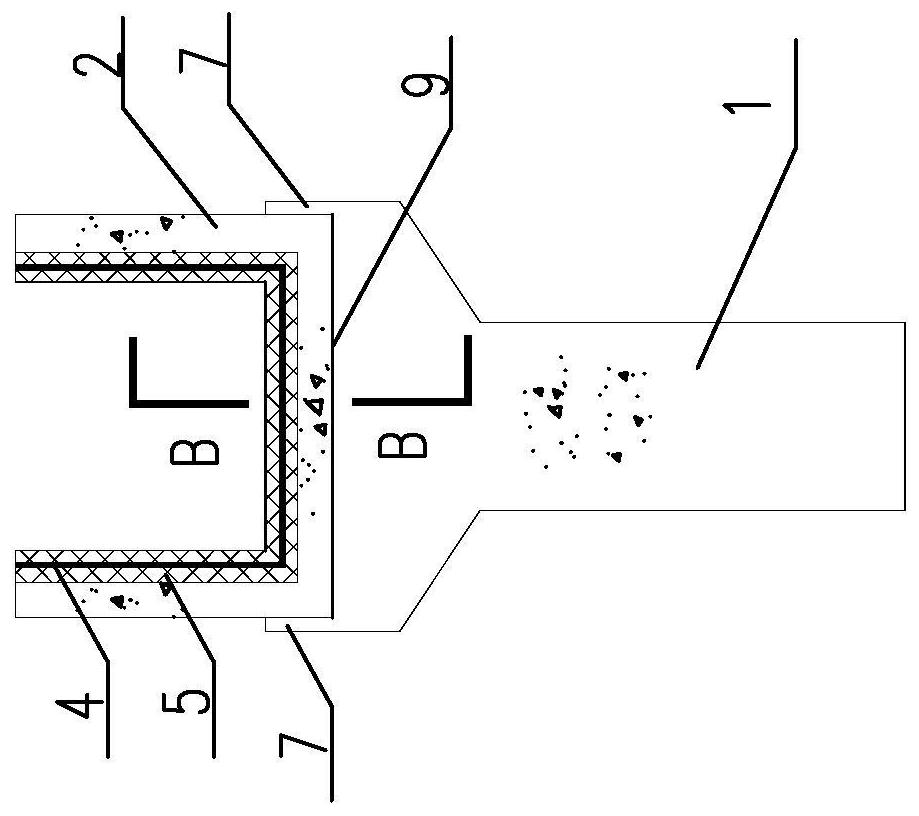

Heavy traffic road inspection well loop and construction method thereof

ActiveCN108560684ASave resourcesIn line with the concept of "green construction"Artificial islandsSewerage structuresBrickButt joint

The invention discloses a heavy traffic road inspection well loop and a construction method thereof. The well loop comprises an inspection well bottom portion, an inspection well middle portion, an inspection well upper portion, a well base, a nodular cast iron well lid and the like. A well wall is arranged between the inspection well bottom portion and a steel inner die and provided with a pipeline butt joint hole. The well base is installed on peripheral concrete for synchronously pouring a well base installation system. The nodular cast iron well lid is arranged at a well mouth of the upperside of the well base. The inspection well middle portion and the inspection well upper portion are internally provided with well loop reinforcement cages, and concrete is poured. A bottom base layeris arranged outside the inspection well bottom portion. A middle base layer is arranged outside the inspection well middle portion. An asphalt layer is arranged outside the inspection well upper portion. Through the technology, the obtained inspection well loop is large in bearing capacity, and the stability of the well wall in the construction process is ensured; the rapid positioning and fixingin the installation period of the well base are accelerated, and the construction method of the well loop is simple and convenient to implement, high in production efficiency and suitable for heavy traffic roads; due to the hollow design of arc-shaped concrete modularized bricks, resources can be saved.

Owner:ANHUI HIGHWAY BRIDGE ENG CO LTD

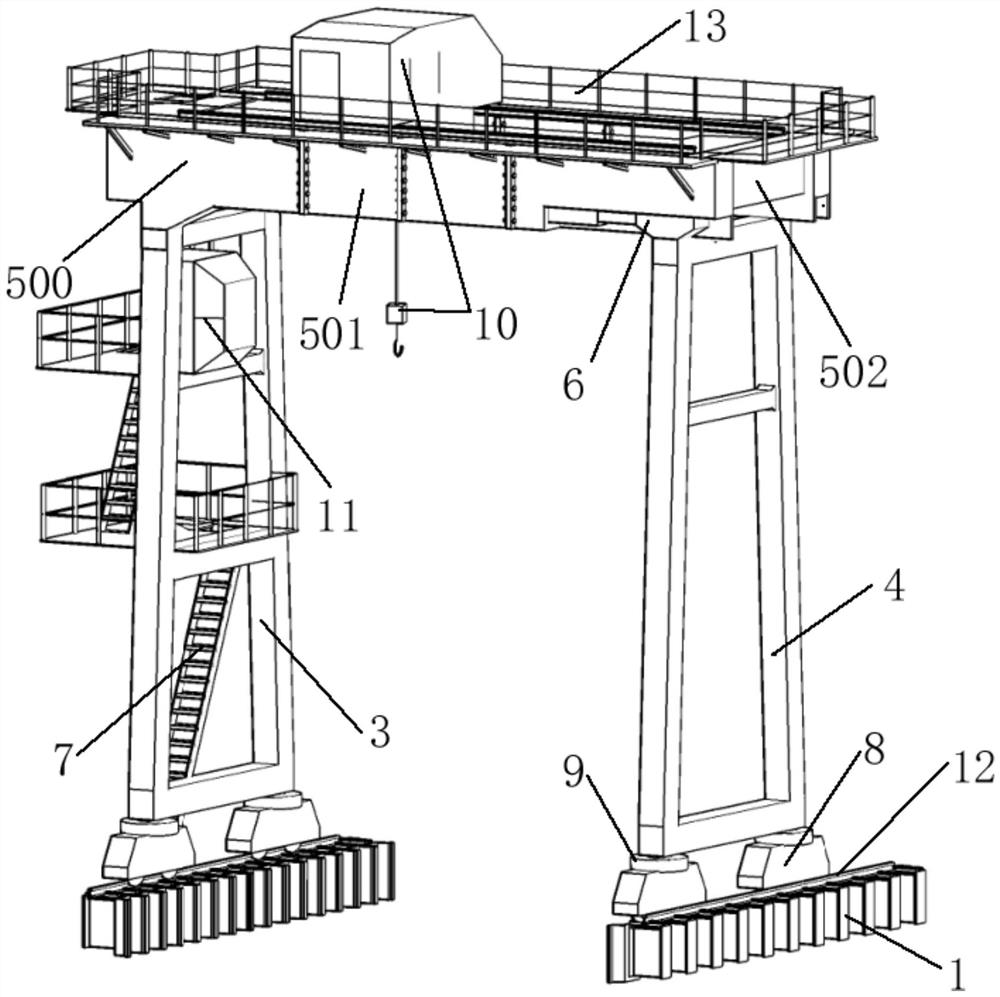

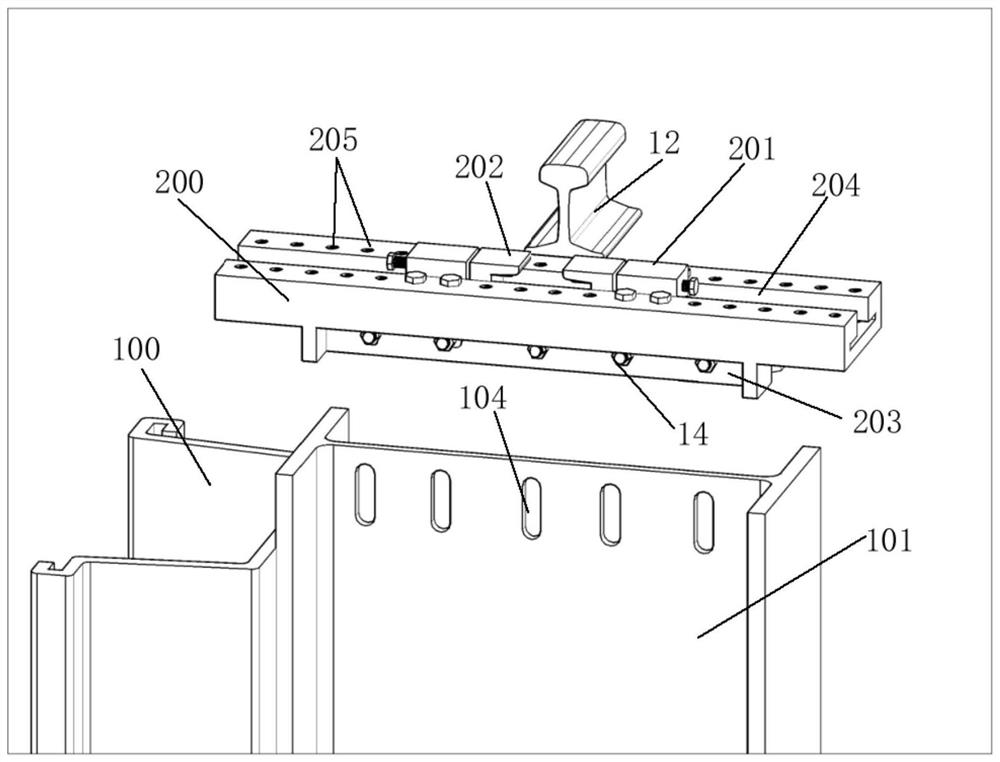

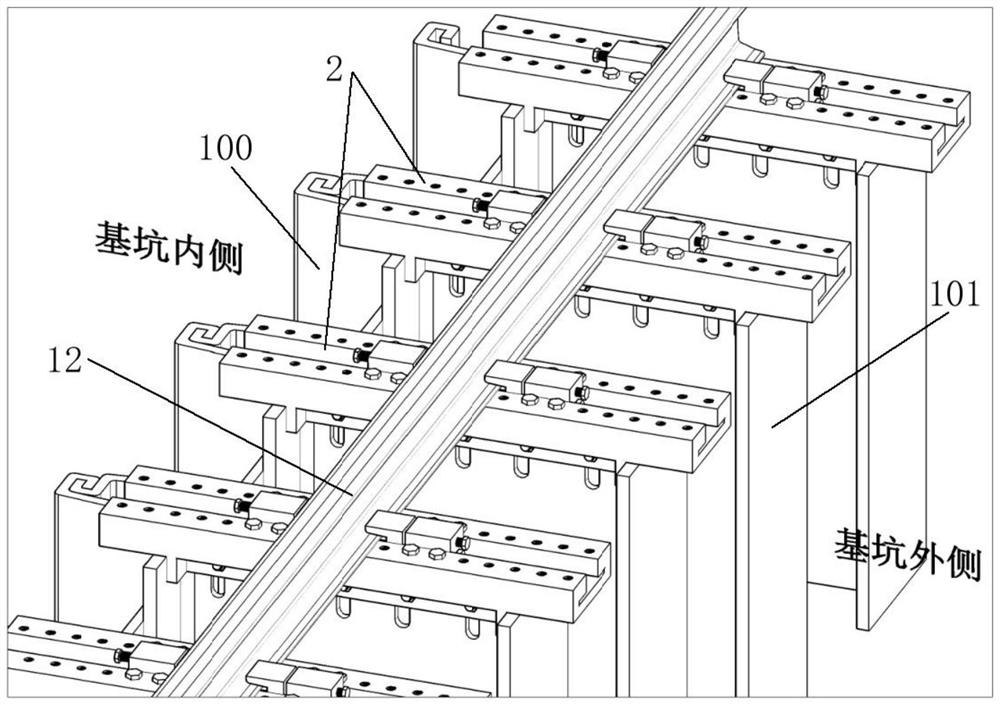

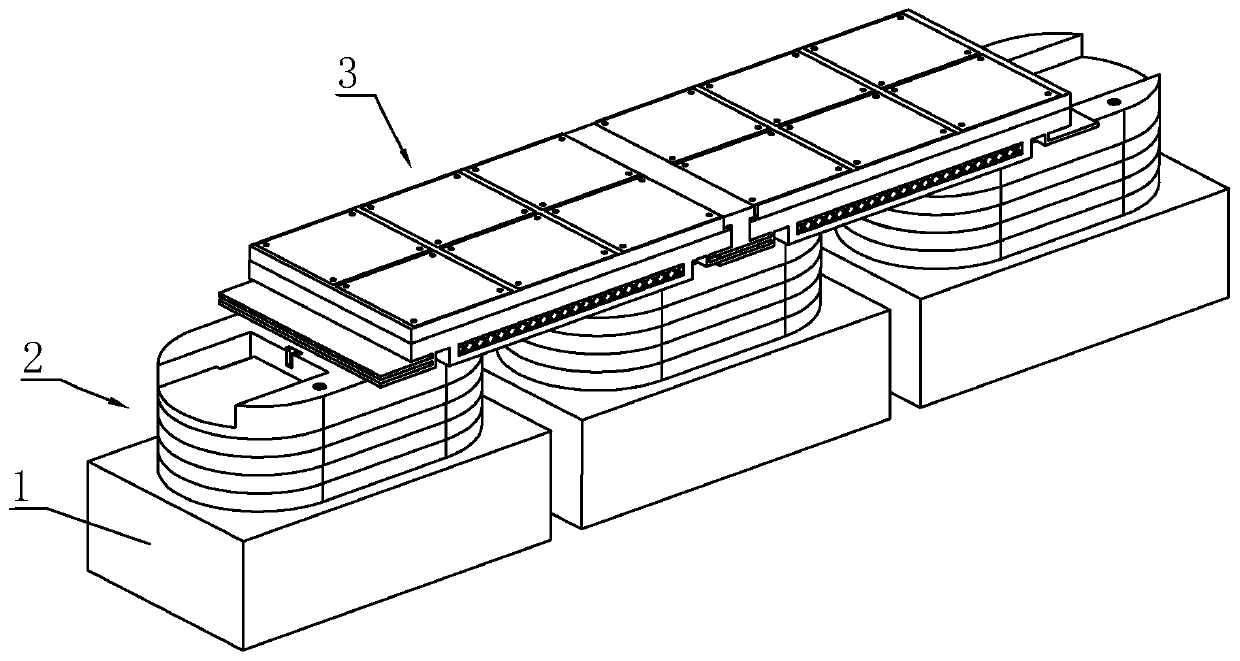

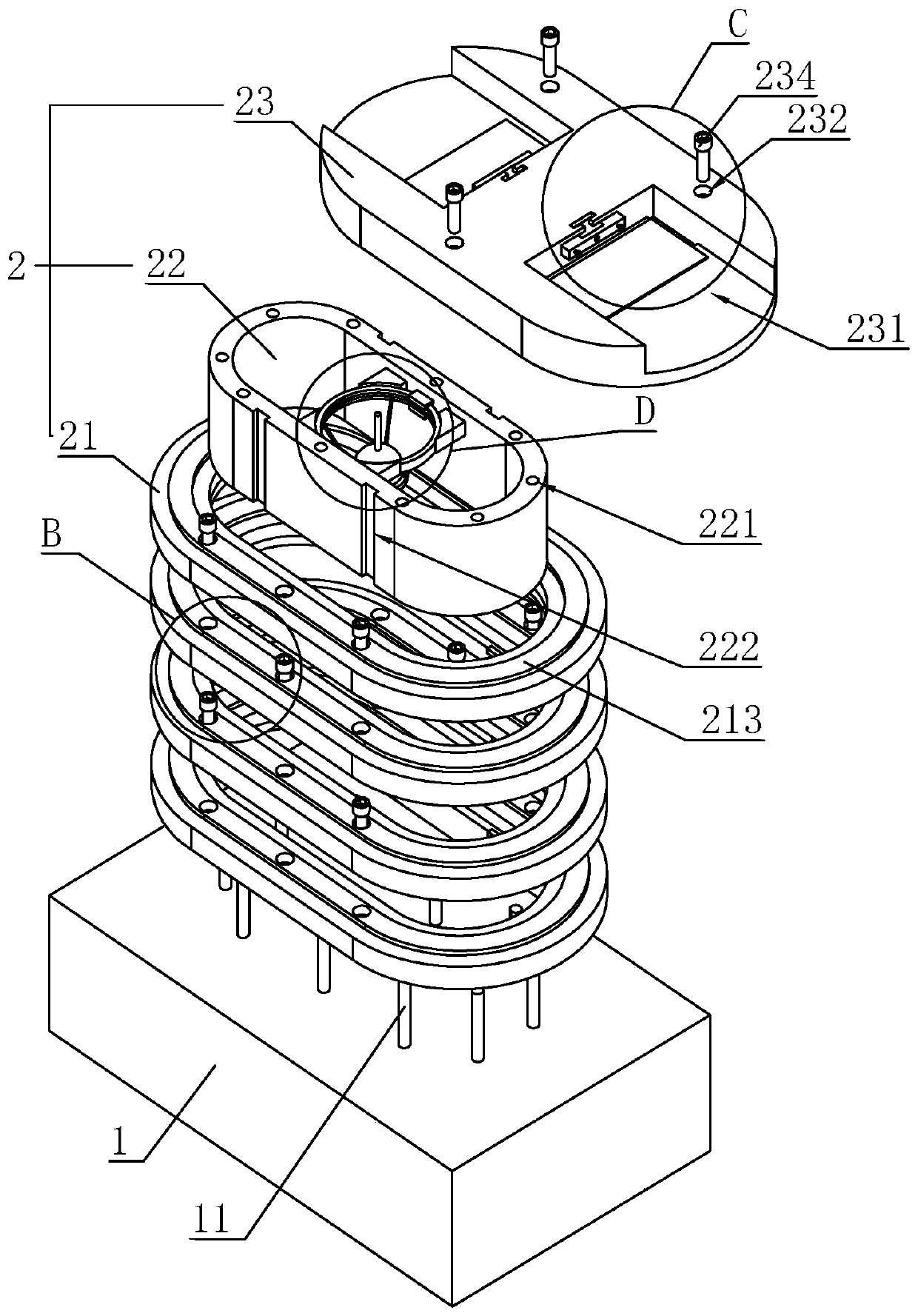

Underground comprehensive pipe gallery construction equipment and method

ActiveCN112627234ASmall footprintImprove section bending stiffnessArtificial islandsUnderwater structuresSteel platesPipe

The invention provides underground comprehensive pipe gallery construction equipment and construction method. The construction equipment comprises a foundation pit enclosure structure, a rail connector, a walking steel rail, and a portal lifting device. The foundation pit enclosure structure is formed by meshing a plurality of composite piles formed by combining U-shaped steel sheet piles and H-shaped steel supporting columns side by side; the rail connector comprises a base and two sets of rail positioning adjusting elements symmetrically installed on the base; the bottom of the rail connector is connected with H-shaped steel supporting column webs of the composite piles; steel rails are installed on the rail connector; the portal lifting device comprises a fixed supporting leg, a span adjusting supporting leg, a bridge frame connected with the two supporting legs, and a walking mechanism; and the portal lifting device is in sliding connection with walking steel rails through the walking mechanism. According to the underground comprehensive pipe gallery construction equipment and construction method, foundation pit supporting and hoisting equipment are combined into a whole and fully utilized with each other, so that the integrity of a supporting system is enhanced, the occupied area of steel rail arrangement is reduced, environmental pollution is reduced, and all equipment can be recycled after engineering construction is completed.

Owner:WUHAN SURVEYING GEOTECHN RES INST OF MCC

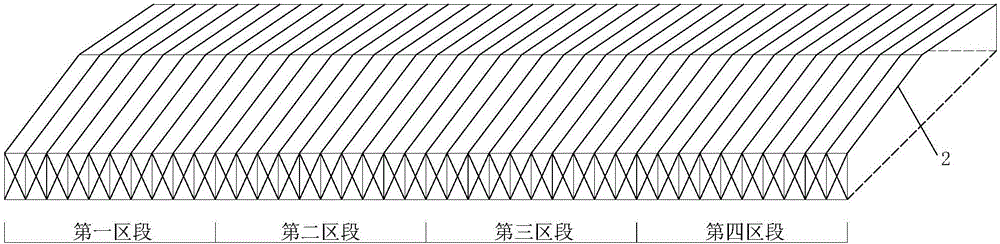

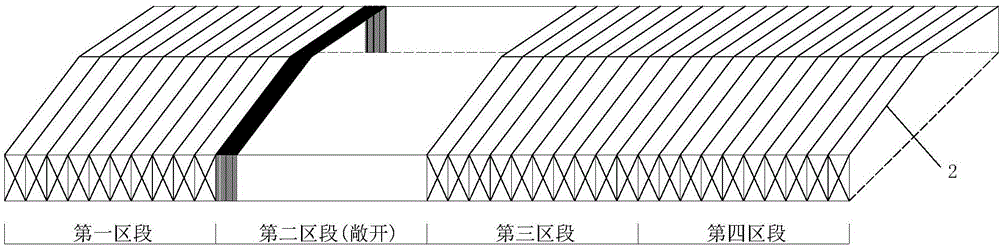

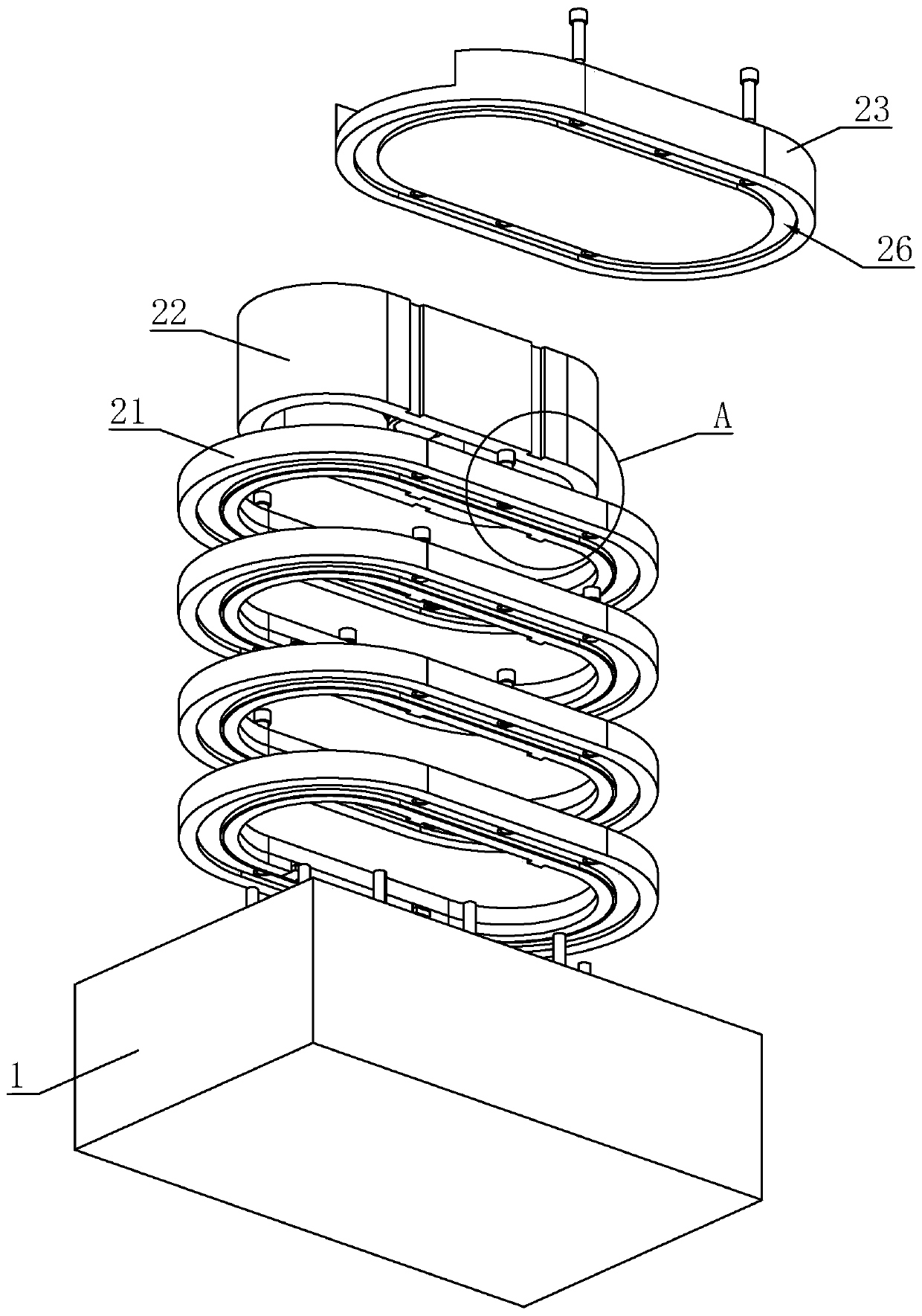

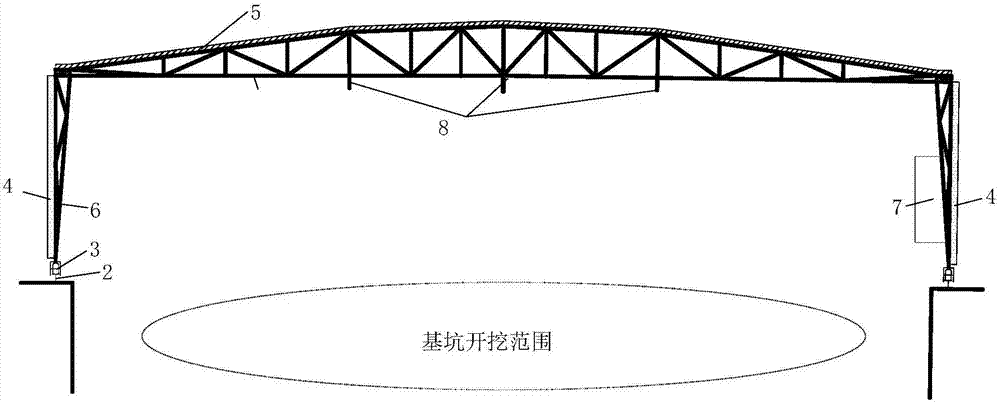

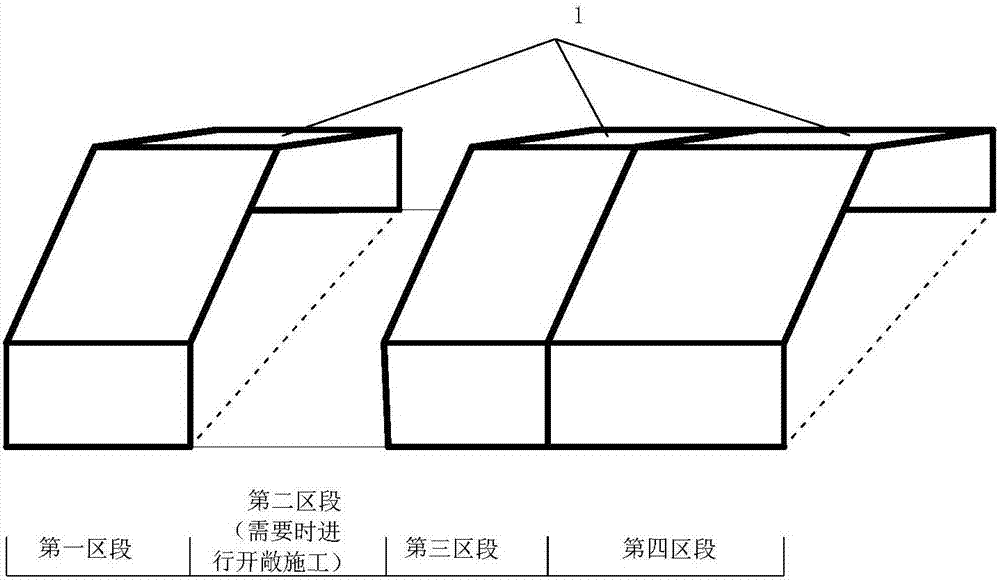

Dynamic closed construction method of subway station using fast folding shelters

InactiveCN106567552ALow costFast constructionTents/canopiesBuilding material handlingSubway stationClosed state

The invention discloses a dynamic closed construction method of a subway station using fast folding shelters. The method comprises: 1, a plurality of fast folding shelters are prepared, a construction range of a ground pit comprises a plurality of sections, and each section is covered by the corresponding fast folding shelter which is spread; 2, before excavation, the fast folding shelters are built on the ground and cover the whole construction range; 3, when a section needs to carry out operation demanding high clearance, the fast folding shelter corresponding to the section is quickly folded, so that the section is open, and the other sections are still subjected to operations demanding low clearance in a closed state; 4, when the operation demanding high clearance of the section ends, the corresponding fast folding shelter is spread; and 5, the step 3 and the step 4 are repeated until construction of all the sections is completed. The method maintains the advantages of closed construction methods of subway stations in the prior art which are environment-friendly and not restricted by weather, and has advantages such as high construction speed and low costs.

Owner:NO 2 CONSTR GRP CO LTD OF SHANGHAI CONSTR GRP

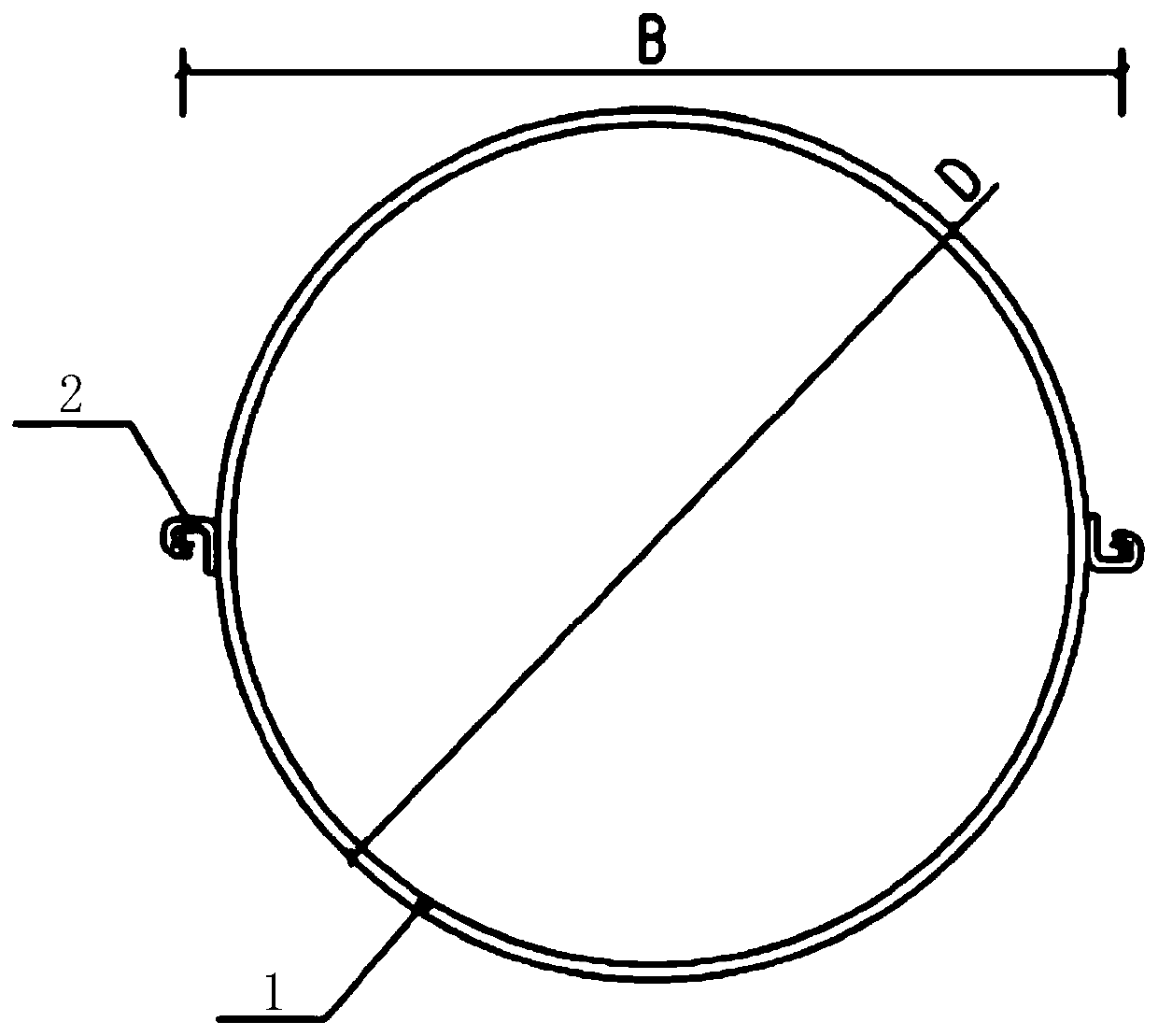

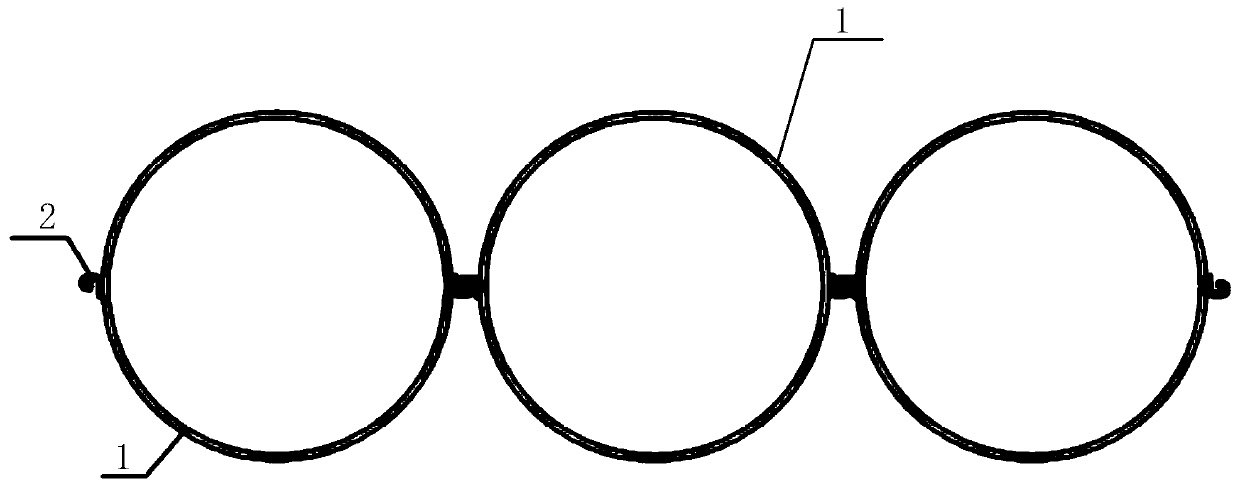

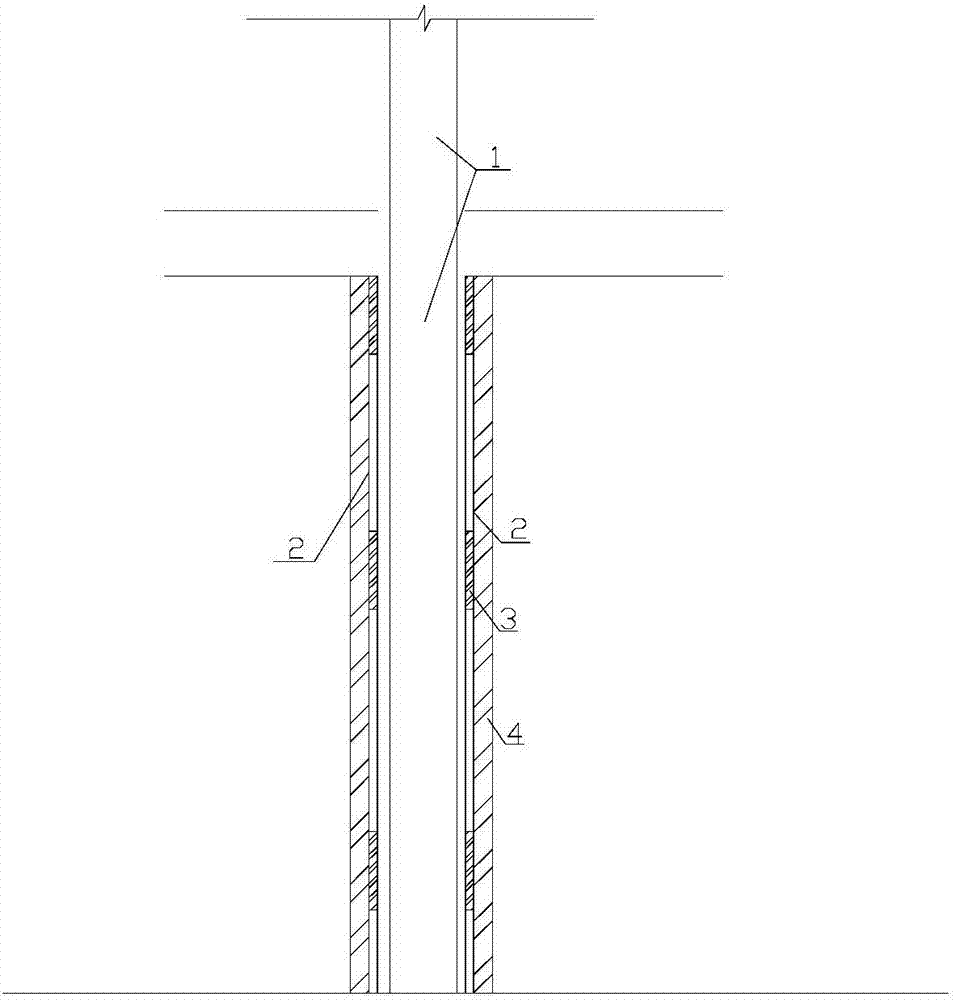

Steel pipe pile assembly, foundation pit retaining structure and construction method of foundation pit retaining structure

PendingCN110644472AHigh strengthIncrease stiffnessExcavationsBulkheads/pilesArchitectural engineeringPipe

The invention provides a steel pipe pile assembly and a foundation pit retaining structure. The steel pipe pile assembly comprises at least two steel pipe piles arranged in parallel and lock hook pairs matched with the steel pipe piles, wherein two lock hooks in each lock hook pair are distributed in axial symmetry relative to the matched steel pipe piles; the lock hooks of the two adjacent steelpipe piles are bitten for sealing, so that the two steel pipe piles are integrally connected and the gap between the two steel pipe piles is sealed. Foundation pit retaining is implemented through theabove steel pipe pile assembly to form the integrated steel pipe pile enclosure system integrating soil retaining and permeability resistance properties based on the good properties of high strength,high stiffness and high stability of the steel pipe pile assembly. In the pile sinking process, the steel pipe piles have the advantages of thin-wall driving and not obvious soil compaction effect. Moreover, the construction procedures are simple, and the construction efficiency is high. The steel pipe piles can be connected through the lock hooks. There is no need to arrange a waterproof curtainon the outside of a pit. The construction noise and construction waste are reduced. The steel pipe pile, the foundation pit retaining structure and the construction method of the foundation pit retaining structure are consistent with green construction.

Owner:SHANGHAI NO 4 CONSTR

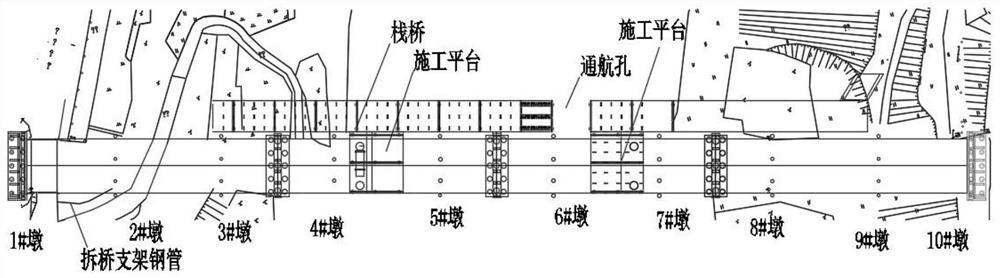

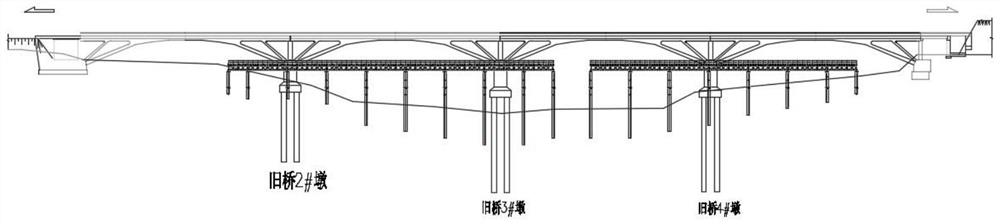

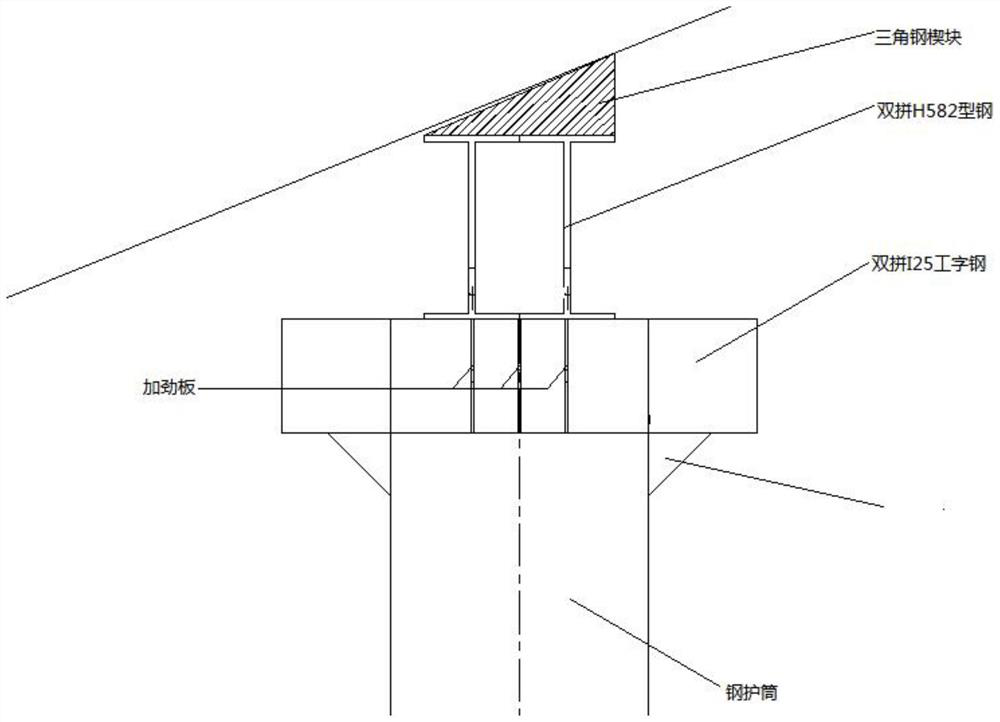

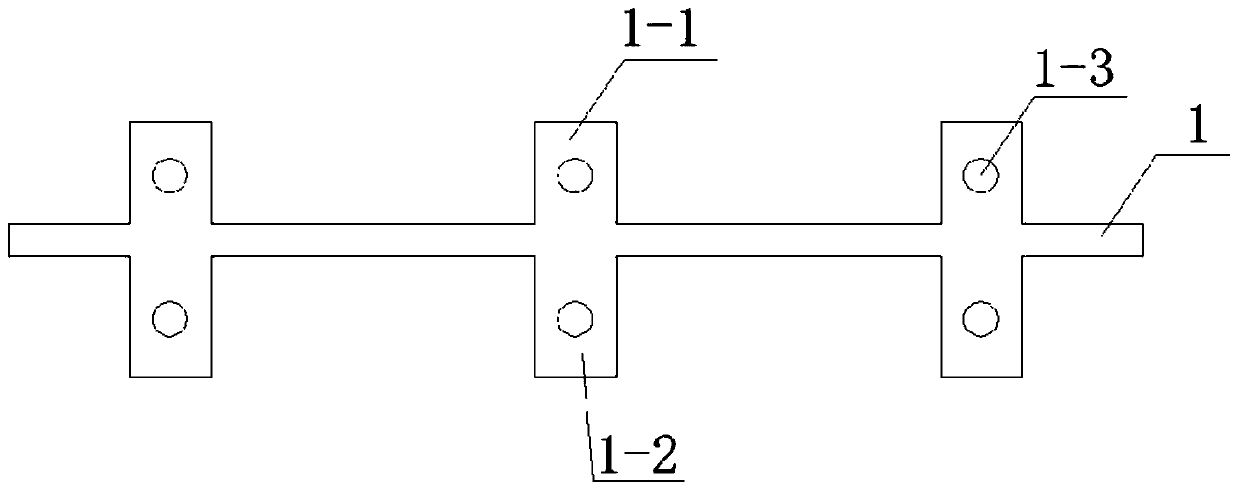

Unbalance-load-free quick dismantling method for multi-span concrete rigid frame arch bridge

ActiveCN111778883AThe removal method is safe and reliableDemolition bridge speed blockBuilding repairsBridge strengtheningMechanical crushingBridge deck

The invention discloses an unbalance-load-free quick dismantling method for a multi-span concrete rigid frame arch bridge. The method comprises the following steps: erecting an old bridge demolition construction trestle platform, erecting an old bridge arch rib supporting frame, demolishing bridge deck accessories, demolishing bridge deck slabs, demolishing transverse tie beams, demolishing main arch ribs, demolishing bridge piers and demolishing bridge abutment. The unbalance loading of the middle pier is eliminated by erecting the arch rib support frame, the scientific demolition sequence isset, and reasonable dismantling equipment is used, so the defects of secondary cleaning, large construction potential safety hazard, heavy dismounting noise and dust, heavy secondary cleaning pollution and the like after integral collapse by using large-scale mechanical crushing or blasting in a traditional demolition method are overcome, dismounting can be carried out safely, efficiently and environmentally friendly, the green construction concept is met, the purposes of reducing noise, reducing pollution and reducing disturbance to the surrounding environment are achieved, the old bridge dismounting construction technology is enriched, and good reference significance is achieved for similar projects.

Owner:GUANGDONG PROVINCIAL CHANGDA HIGHWAY ENG

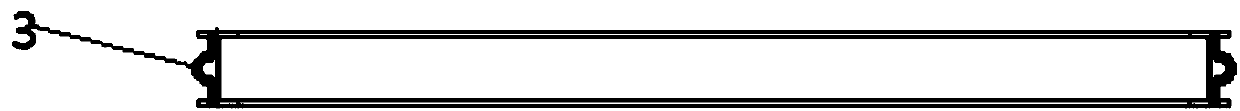

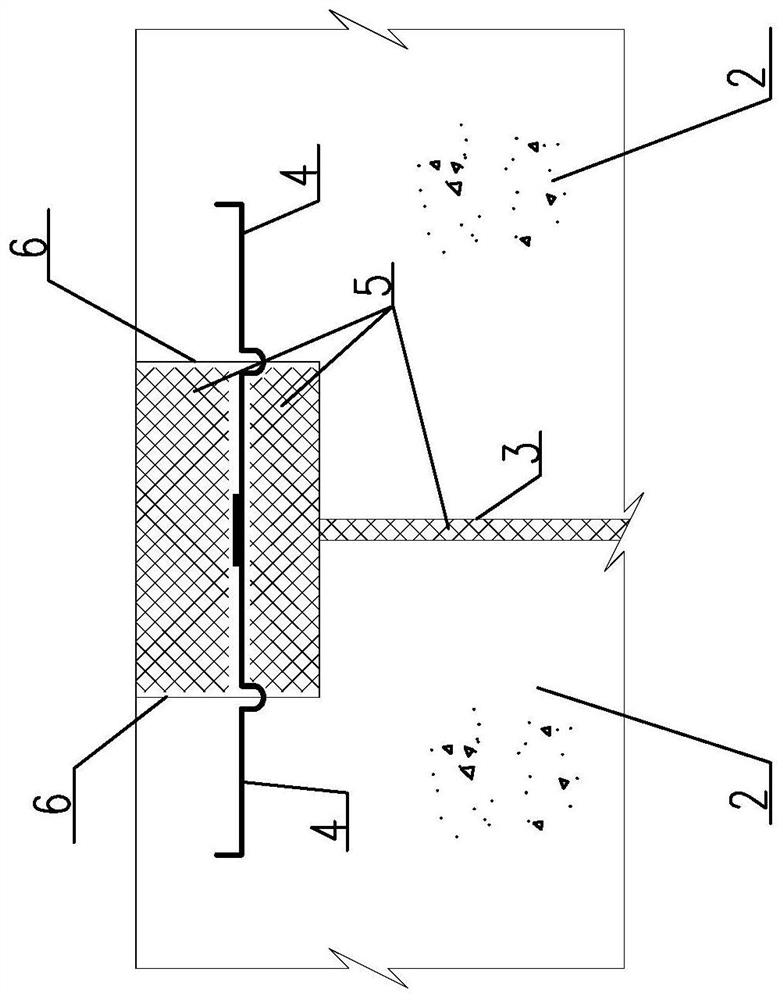

Manufacturing method and construction method of mud-leakage-prevention sealing device for wood formwork splicing seam

InactiveCN111206766AAvoid slurry leakageImprove molding qualityAuxillary members of forms/shuttering/falseworksForming/stuttering elementsArchitectural engineeringFlange

The invention discloses a manufacturing method and a construction method of a mud-leakage-prevention sealing device for a wood formwork splicing seam, and belongs to the technical field of building construction. The manufacturing method and the construction method comprise the following steps that 1, a seam blocking plate is made of a steel plate with the thickness of 1.0mm, a web plate of the seam blocking plate is a full-length plate, and an upper flange plate and a lower flange plate are symmetrically arranged at an interval; 2, holes are formed in the upper flange plate and the lower flange plate correspondingly; and 3, in the formwork mounting process, the seam blocking plate is clamped into a gap between every two adjacent formworks, meanwhile, the formwork surfaces where the upper flange plate and the lower flange plate are located are screwed up by adopting self-tapping screws, so that the formwork surfaces are tightly attached to the inner sides of the upper flange plate and the lower flange plate, then a formwork reinforcing system is installed, and concrete is poured after acceptance. According to the manufacturing method and the construction method, operation is simpleand easy to carry out, the construction speed is high, material waste is reduced, and the green construction concept is met.

Owner:CHINA MCC17 GRP

Assembly type steel structure-concrete combined bridge and construction method thereof

ActiveCN110396919AReduce damage rateStable structureBridge structural detailsBridge erection/assemblySteel frameBuilding construction

The invention relates to an assembly type steel structure-concrete combined bridge and a construction method thereof, and relates to the technical field of bridge construction. The assembly type steelstructure-concrete combined bridge comprises concrete piers and steel frame girders, wherein the side walls of the two sides of the concrete piers are correspondingly provided with placing grooves, the steel frame girders comprise steel girder supporting devices, steel girder bearing devices and steel girder plates, the bottoms of the placing grooves are connected with elastic blocks, and the elastic blocks are connected with the steel girder supporting devices; and male inserting plates and female inserting plates are arranged on the lower surfaces of the two steel girder plates on the sameconcrete pier correspondingly, the female inserting plates are matched with the male inserting plates in an inserted mode, the short edges of the female inserting plates and the short edges of the male inserting plates are connected with elastic parts, and the elastic parts extend to the part between the two steel girder plates and are connected with the opposite sides of the two steel girder plates. According to the assembly type steel structure-concrete combined bridge, due to arrangement of the male inserting plates, the female inserting plates, the elastic parts and the elastic blocks, theprobability of being damaged between the adjacent steel frame girders and between the steel frame girders and the concrete piers is reduced, the integral structure of the bridge is stable, and the probability of being damaged under the condition of an earthquake or large vibration is greatly reduced.

Owner:蓝海绿业生态建设股份有限公司

Pedestrian temporary steel bridge and micro steel pipe pile connecting structure and construction method thereof

InactiveCN108755389AMeet traffic requirementsReduce investmentBridge erection/assemblySheet steelEngineering

The invention discloses a pedestrian temporary steel bridge and micro steel pipe pile connecting structure and a construction method thereof. The pedestrian temporary steel bridge and micro steel pipepile connecting structure comprises a steel bridge frame support which is formed by welding longitudinal channel steel and transverse channel steel; an anti-skid steel plate is fixed on the surface of the steel bridge frame support; the two ends of the steel bridge frame support are fixed to a micro pile through bolts; and steel pipe guardrails are arranged on the two sides of the steel bridge frame support. According to the pedestrian temporary steel bridge and micro steel pipe pile connecting structure and the construction method thereof, as a fixing point does not need to be arranged for the erection of a temporary steel bridge, the construction input is saved, and the construction period is shortened; through adoption of bolt connection, the temporary steel bridge can be transferred to other construction sections or construction sites after being detached so that the pedestrian temporary steel bridge and micro steel pipe pile connecting structure conforms to a green construction concept; and as the connection mode provides a reliable force bearing point for the temporary steel bridge, the pedestrian temporary steel bridge and micro steel pipe pile connecting structure is safeand reliable, the cost is reduced, and the effect is improved.

Owner:SHANGHAI BAOYE GRP CORP

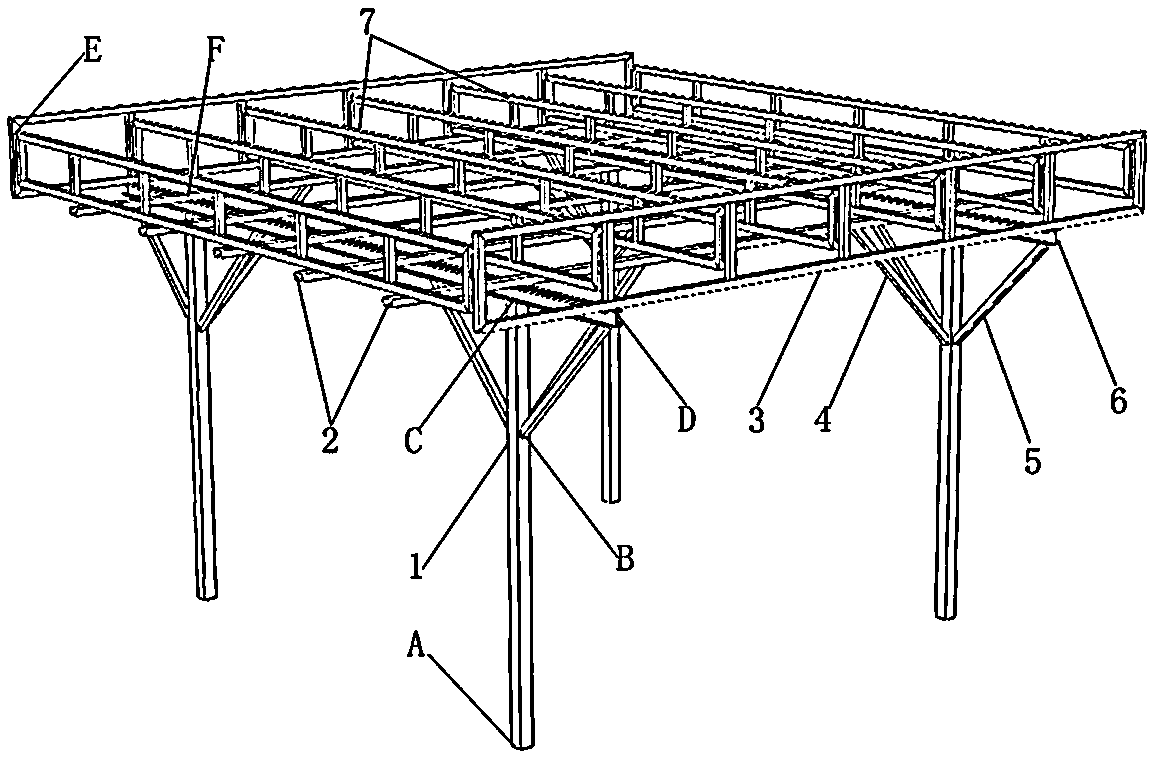

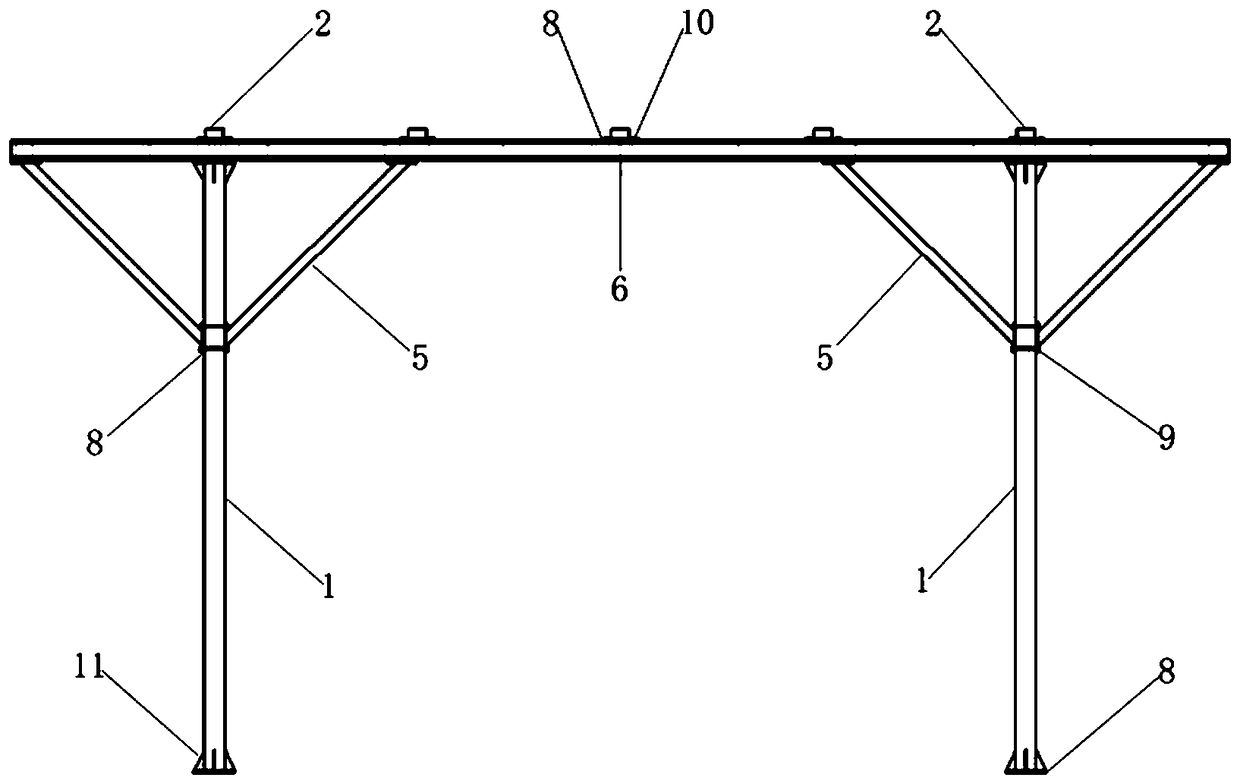

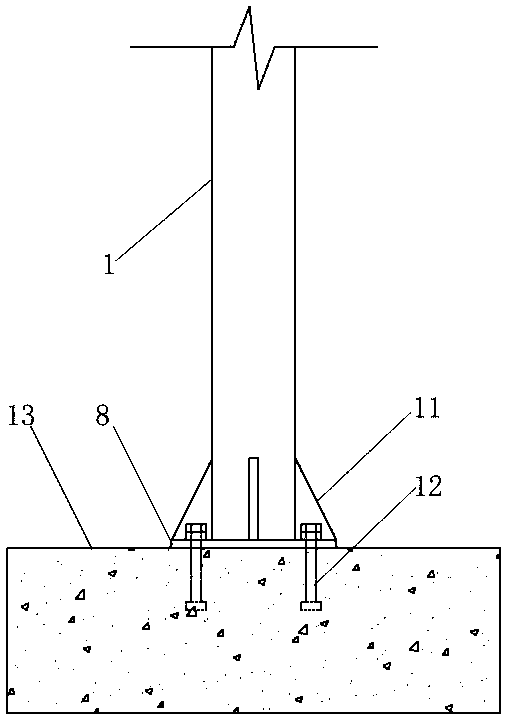

Fabricated steel structure temporary working shed and mounting method thereof

PendingCN108590242AImprove stabilityEasy assembly and disassemblySpecial buildingBuilding material handlingEngineeringFlange

The invention provides a fabricated steel structure temporary working shed and a mounting method thereof. The fabricated steel structure temporary working shed comprises longitudinal hollow trusses, transverse hollow trusses, a plurality of purlines and two or more assembling units; the assembling units are arranged in parallel and connected together through the purlines; the multiple purlines arearranged on double-spliced C-shaped I beams at equal intervals and perpendicular to the double-spliced C-shaped I beams; the longitudinal hollow trusses are connected to the upper flanges of the twoends of the double-spliced C-shaped I beams; the transverse hollow trusses are arranged on the purlines at equal intervals and perpendicular to the purlines; and the two ends of the transverse hollowtrusses are connected to the longitudinal hollow trusses. Components required by the fabricated steel structure temporary working shed can be prefabricated in a factory in advance and completely connected through bolts on site, welding is not needed, and the mounting and dismounting speeds are high; and vertical columns are located around, the middle working area is open, and thus operation of workers is facilitated.

Owner:SHENYANG JIANZHU UNIVERSITY

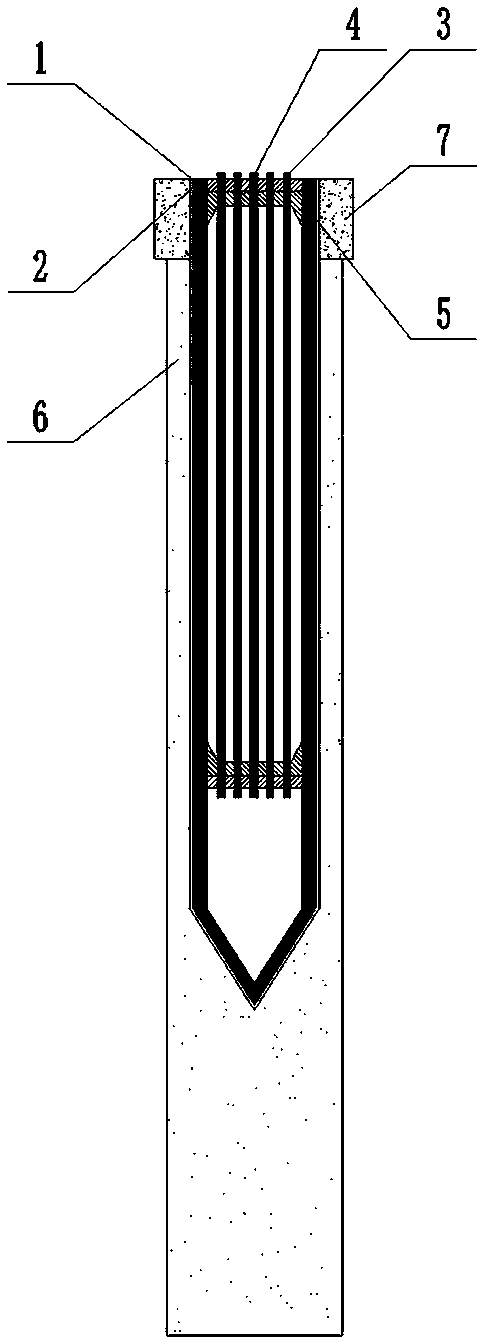

Steel pipe pile supporting structure capable of being recycled and construction method thereof

InactiveCN110528529AIncreased bending stiffnessEasy to pressExcavationsBulkheads/pilesPre stressFlexural rigidity

The invention discloses a steel pipe pile supporting structure capable of being recycled and a construction method thereof. The structure comprises a prestressed steel pipe pile, a thin iron skin pipeshell, a three-axis mixing pile and a crown beam. The prestressed steel pipe pile serves as the main stressed supporting component and can be recovered, the thin iron skin pipe shell is matched withthe prestressed steel pipe pile and are coated with lubricating oil, the steel pipe pile can be recovered and used, cement soil is formed after the three-axis mixing pile mixes a soil layer, the steelpipe pile is conveniently inserted, a waterproof curtain is formed after later-period hardening, the crown beam enables the supporting piles to be stressed together, and a whole is formed. Accordingto the steel pipe pile supporting structure capable of being recycled and the construction method thereof, the flexural rigidity of the steel pipe pile is improved through prestressed stranded steel wires, the pipe pile is conveniently inserted through the mixing pile, the prestressed steel pipe pile is recovered and used through a thin iron skin layer and the lubricating oil, the flexural rigidity of the steel pipe pile is effectively improved, the supporting depth is increased, meanwhile, the supporting structure is combined a the three-axis mixing pile curtain, the pipe pile is convenientlypressed in, and the steel pipe pile supporting structure and the construction method thereof can be widely applied to foundation supporting of building projects and municipal pipe gallery projects.

Owner:CHINA CONSTR THIRD ENG BUREAU GRP CO LTD

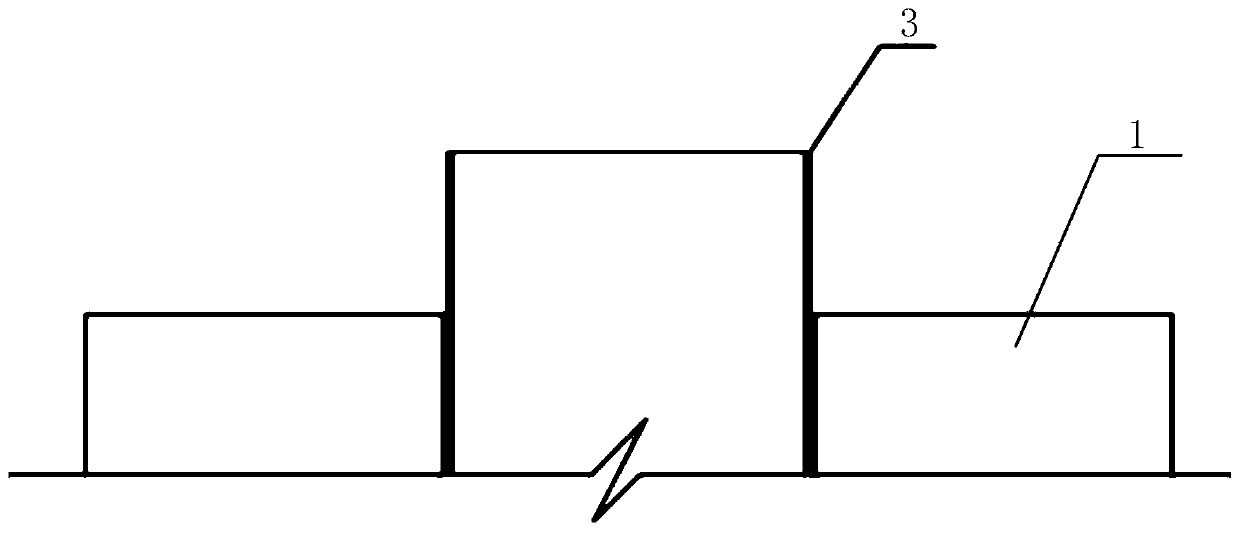

Detachable deck type steel bar truss laminated slab

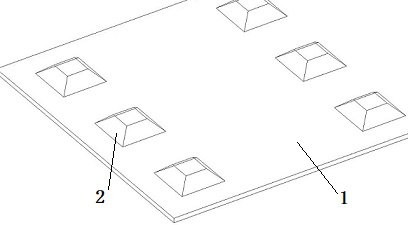

InactiveCN112031236AFlexible adjustment of structural mechanical propertiesMeet the needs of useFloorsLine tubingRebar

The invention discloses a detachable deck type steel bar truss laminated slab, and relates to the field of building structures. The problems that an existing steel bar truss prefabricated slab steel bar truss is wasted, the slab span is small, the number of supports is large, the slab thickness is large, electromechanical pipeline crossing is difficult, installation and construction are complex, and the construction period is prolonged are solved. According to the technical scheme, a steel bar truss in a conventional steel bar truss prefabricated slab is placed on the upper surface of a squarepyramid frustum protruding out of the upper surface of a prefabricated bottom plate; an embedded steel plate and a connecting steel bar are welded to a steel bar at the lower chord of the steel bar truss; the steel bar is anchored into the prefabricated bottom plate; the center line of a horizontal support at the bottom of the prefabricated bottom plate coincides with the center line of the protruding square pyramid frustum; and after post-poured concrete on the prefabricated bottom plate reaches the design strength, the connecting steel bar is cut off, and the steel bar truss is detached soas to be recycled next time.

Owner:朱辉祖

Construction method of arc beam by using adjustable arc beam molded formwork supporting structure

InactiveCN110453916AGuaranteed accuracyAvoid inaccurate beam radians and surface edges and cornersGirdersForms/shuttering/falseworksFloor slabFastener

The invention relates to a construction method of an arc beam by using an adjustable arc beam molded formwork supporting structure. The construction method is characterized in that the construction method comprises the following steps of assembling a beam formwork, erecting a scaffold, installing the beam formwork, installing a floor bottom formwork, and pouring concrete and maintenance. Accordingto the construction method, a vertical rib is fixed on a beam bottom formwork in a screw mode, and fasteners on the back side of a beam side formwork are buckled on the vertical rib one by one to complete the radian adjustment of the beam side formwork; split bolts are pulled and knotted to complete the assembly of the beam formwork; the beam formwork is hoisted as a whole, a bottom horizontal support of the beam formwork is clamped to a short vertical column, and puller bolts abut against the vertical ridge on the side face of the beam formwork to complete the installation of the beam formwork in a support system; and then the floor bottom formwork is installed, and the concrete is poured. The construction method has the advantages of accurate radian, convenient installation, overall firmness, less consumables, high turnover utilization rate, high recovery utilization rate, and significant economic and technical benefits.

Owner:杭州昂创科技有限公司

Construction method for maintenance of vertical concrete member

InactiveCN107386668AIn line with the concept of green constructionEasy to operateBuilding material handlingStructural engineeringWater spray

A construction method for maintenance of a vertical concrete member belongs to the technical field of building operations. The adopted construction steps are as follows: gluing a self-adhesive moisturizing material to the outside of the form stripped vertical concrete member; spraying water on the self-adhesive moisturizing material, and then repeatedly spraying water according to the drying degree of the self-adhesive moisturizing material to ensure that the moisturizing time reaches the number of days for concrete member maintenance as required by standards; and removing the self-adhesive moisturizing material from the vertical concrete member for recycling after the number of days for concrete member maintenance as required by standards. The following advantages are produced: the problems of high water consumption, not meeting the green construction requirements and the like in common water spraying maintenance for vertical concrete members such as walls and columns after the completion of pouring of concrete and form stripping are solved; and by spraying water on the moisturizing material, the purposes of maintaining the concrete structure and saving water are achieved.

Owner:BEIJING SHOUGANG CONSTR GROUP

Green fixing device for vertical template square steel of welded elbow and construction method of green fixing device

PendingCN111119477AHigh speedLow costForms/shuttering/falseworksAuxillary members of forms/shuttering/falseworksKeelRebar

The invention discloses a green fixing device for vertical template square steel of a welded elbow and a construction method of the green fixing device, and belongs to the technical field of construction. The green fixing device for the vertical template square steel of the welded elbow comprises a square steel keel. The front side of the square steel keel is in overlap joint with four secondary keels, and the back of the square steel keel is in overlap joint with the front of a template. According to the green fixing device for the vertical template square steel of the welded elbow, the square steel keel, a steel bar elbow, the secondary keels and fasteners are arranged, when the staff needs to fix the square steel keel to the template, then the fasteners are fixed to the template throughsplit bolts, and the fasteners and the split bolts are arranged, so that the green fixing device is low in cost and high in speed and can be recycled, the through-end head of the square steel keel iswelded to the steel bar elbow, installation and disassembly are convenient, construction is convenient, and labor cost input is low; and the scrap rate of the square steel keel is low, the number oftimes of turnover is high, the residual value is high, the material is saved, the use of square wood strips is reduced, the forest is protected, and the sustainable development of resources is achieved.

Owner:广西建工第五建筑工程集团有限公司

Construction method of sewage distribution main pipe network

InactiveCN112227514AGuaranteed StrengthFree from disturbanceSewerage structuresSewer pipelinesLine tubingArchitectural engineering

The invention discloses a construction method of a sewage distribution main pipe network, and belongs to the technical field of pipeline construction. A newly-built sewage lifting pump station and a newly-built sewage pressure conveying pipeline are included. The sewage pressure conveying pipeline comprises a land sewage pipeline, a river crossing pipeline, a road crossing pipeline, a submarine pipeline and a pump station outdoor rain sewage drainage pipeline. The land sewage pipeline adopts PE pipeline construction, the river crossing pipeline or the road crossing pipeline adopts PE tractionpipeline construction, and the submarine pipeline adopts offshore slotting buried pipe construction. In PE pipeline construction, materials are environmentally friendly, corrosion resistance is good,strength is high, and construction stability is guaranteed. In PE traction pipeline construction, pipelines are deeply buried, construction is safe, horizontal directional accurate drilling construction is adopted, and the pipeline construction efficiency is improved. In offshore slotting buried pipe construction, the elevation of the foundation base slot bottom is accurately controlled, and the foundation slot construction quality is guaranteed. Pipe land assembly welding and offshore butt joint are adopted, the construction period is shortened, the construction cost is reduced, and environmental pollution is reduced.

Owner:HANGZHOU MUNICIPAL CONSTR GRP CO LTD

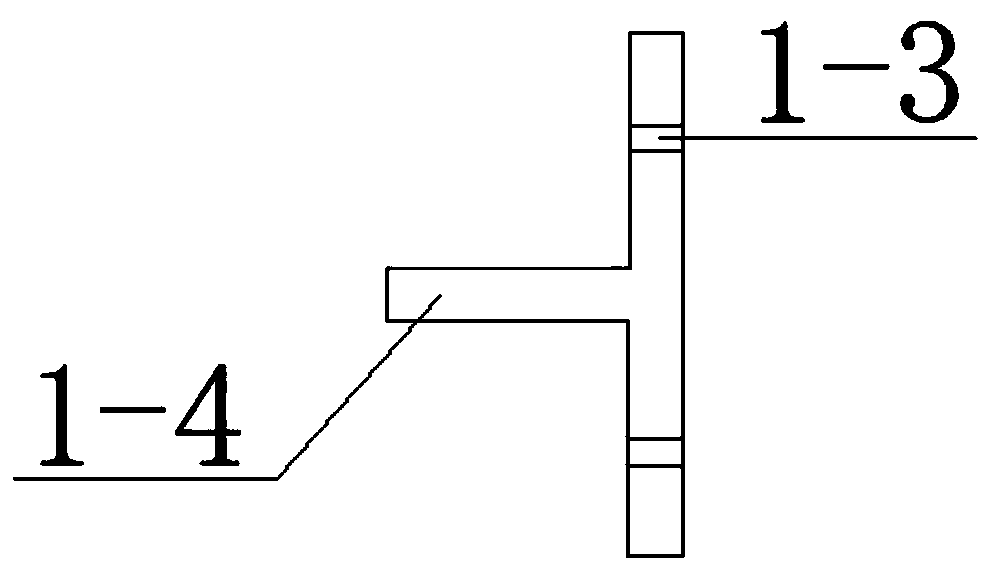

Beam bottom arching form supporting device

PendingCN111287450AEasy to makeAffordableForms/shuttering/falseworksAuxillary members of forms/shuttering/falseworksClassical mechanicsLong span

Owner:CCFED THE FIGTH CONSTR & ENG

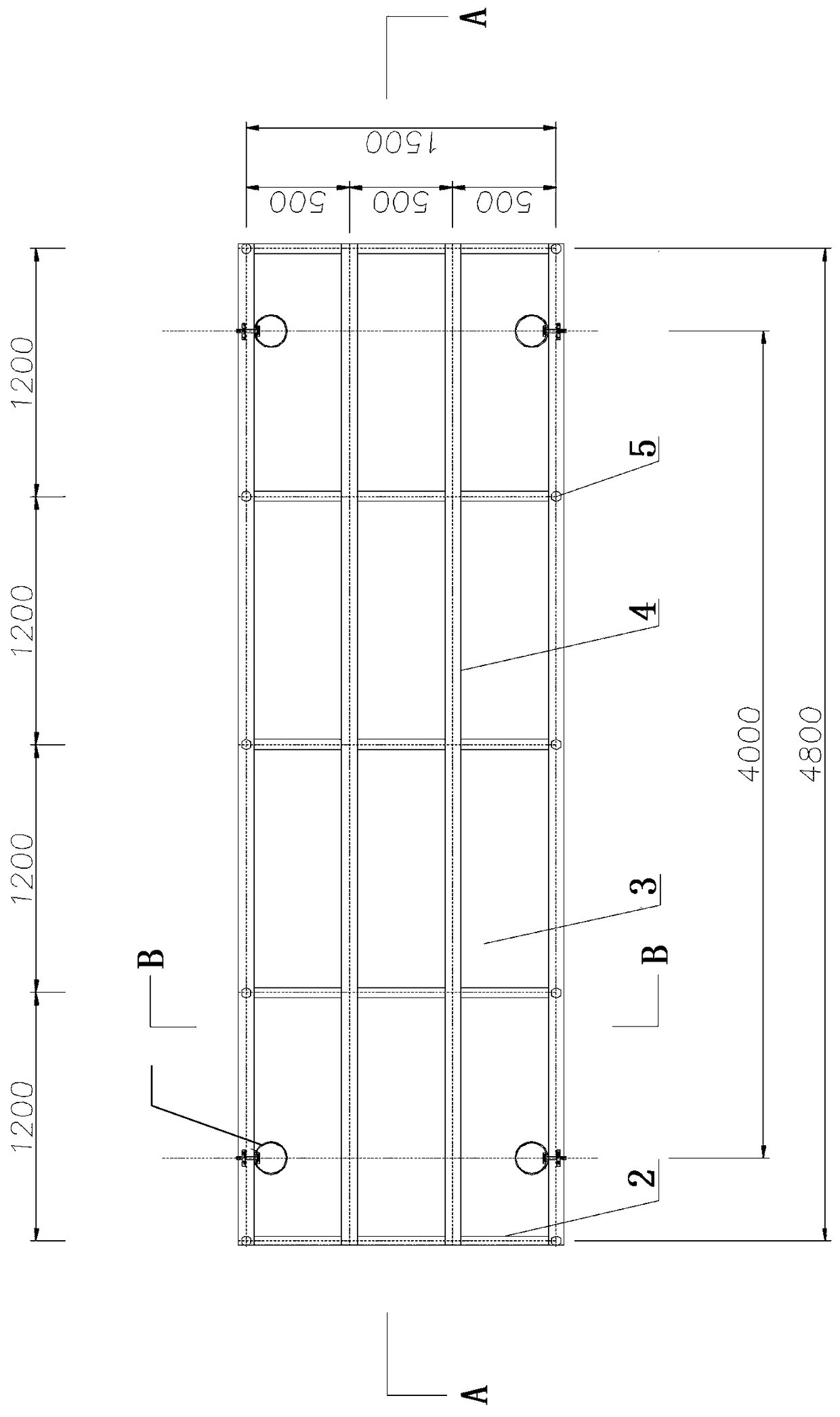

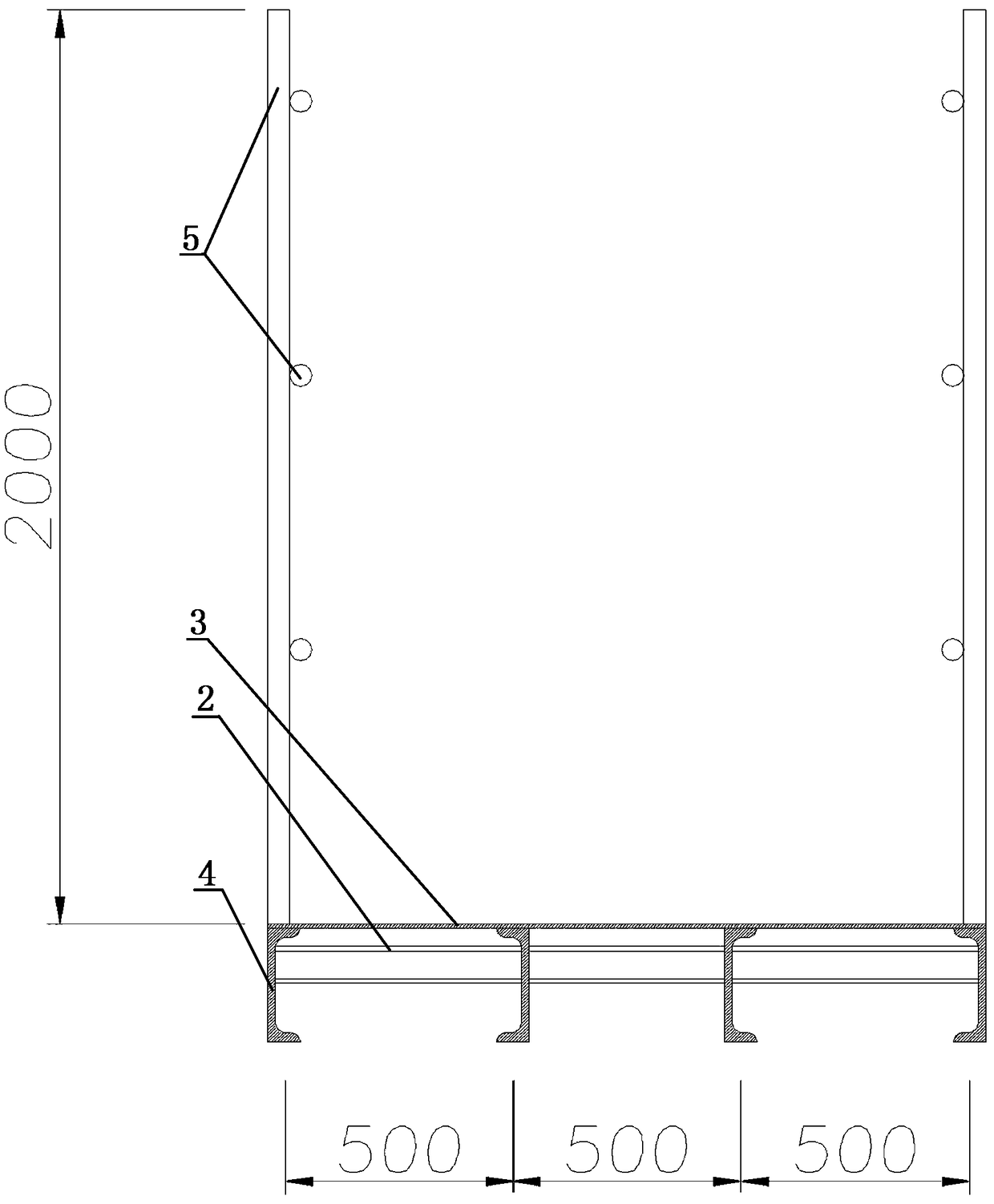

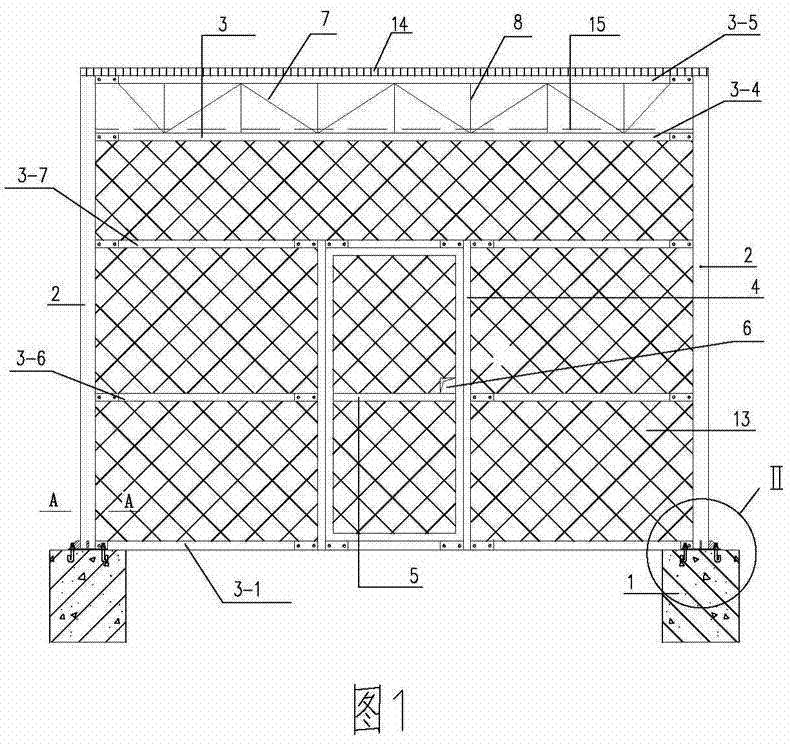

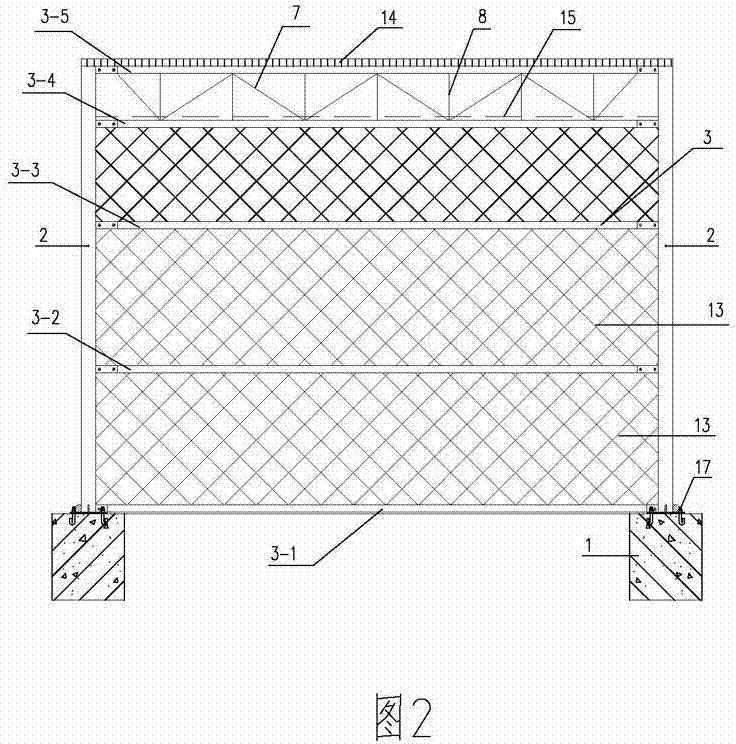

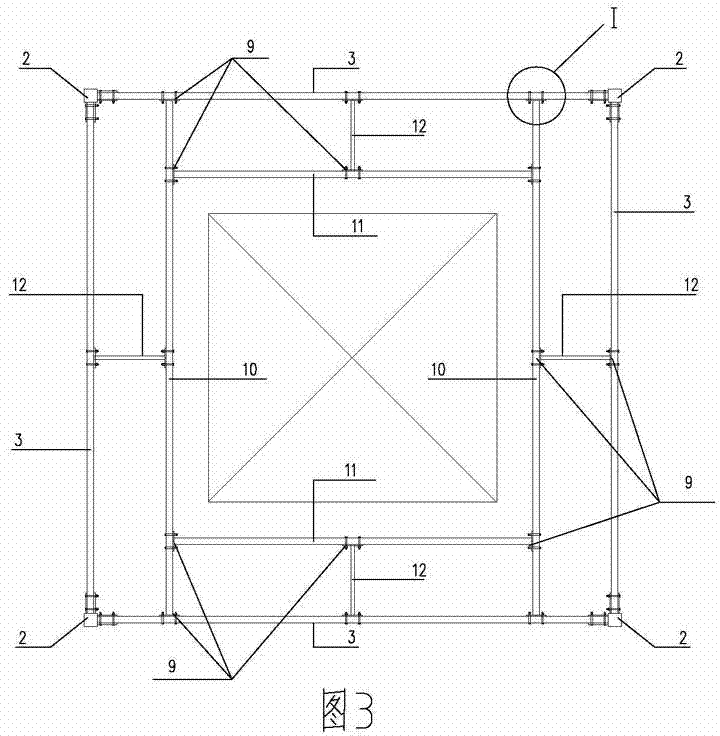

Reusable anti-climbing device at bottom layer of tower crane on building construction site

ActiveCN102900238AEasy to build and disassembleIn line with the concept of green constructionBuilding material handlingEngineeringTower crane

The invention relates to a reusable anti-climbing device at the bottom layer of a tower crane on a building construction site. The reusable anti-climbing device is formed by a steel structure framework; and the steel structure frame is composed of stand columns, truss girders, structural cross beams, a door frame, a door, inclined braces, upright poles, connecting pieces, long auxiliary beams, short auxiliary beams and short beams which are connected and combined through bolts and are respectively standard parts with unified specification. The stand columns are connected to four square ground foundations; and the door with a door lock is arranged in the front of the steel structure framework, a reinforcing mesh is laid at the periphery of the steel structure framework, an anti-falling scaffold board is laid on the roof of the upper layer of the steel structure framework, and a color steel plate is laid on the roof of the lower layer of the steel structure framework. The reusable anti-climbing device at the bottom layer of the tower crane on the building construction site is formed by combining the multiple standard parts which are designed according to conditions such as the sizes of standard knots of the tower crane and design codes for lightweight steel structures. The reusable anti-climbing device has the characteristics of being suitable for the sizes of the standard knots at the bottom layers of different tower cranes, capable of being freely combined, convenient, practical and low in cost, and saving labor and time. The reusable anti-climbing device is convenient to dismantle, is in line with a green construction idea and is safe to use on the site.

Owner:CHINA CONSTR FIRST BUILDING GRP CORP LTD +1

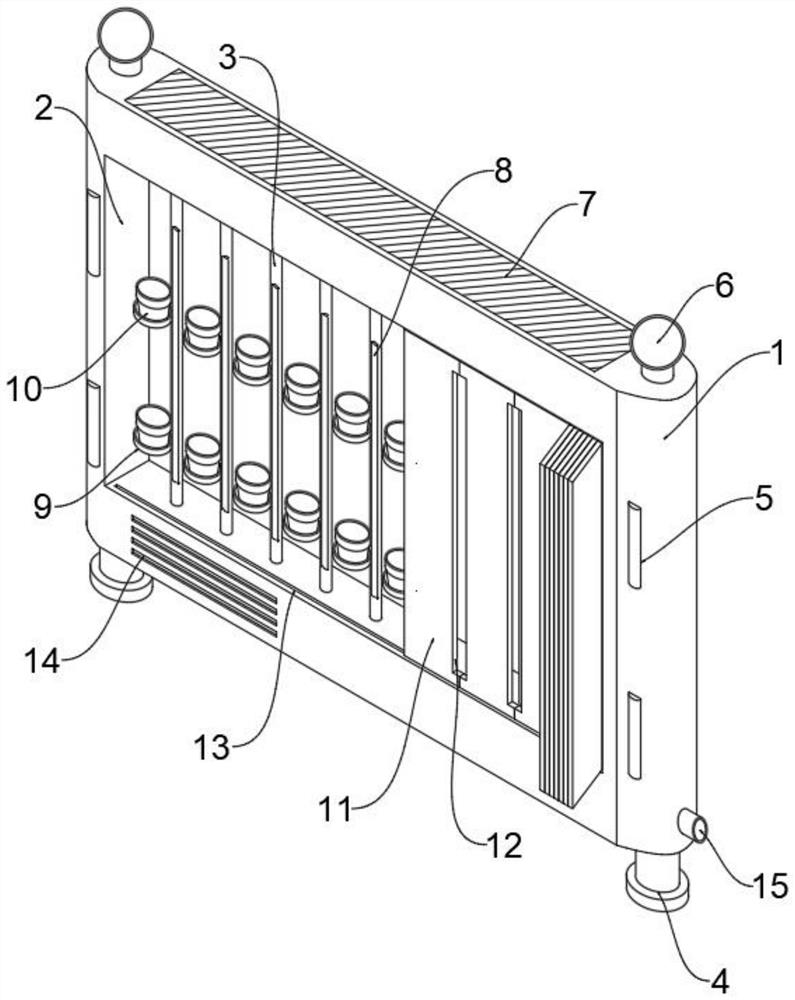

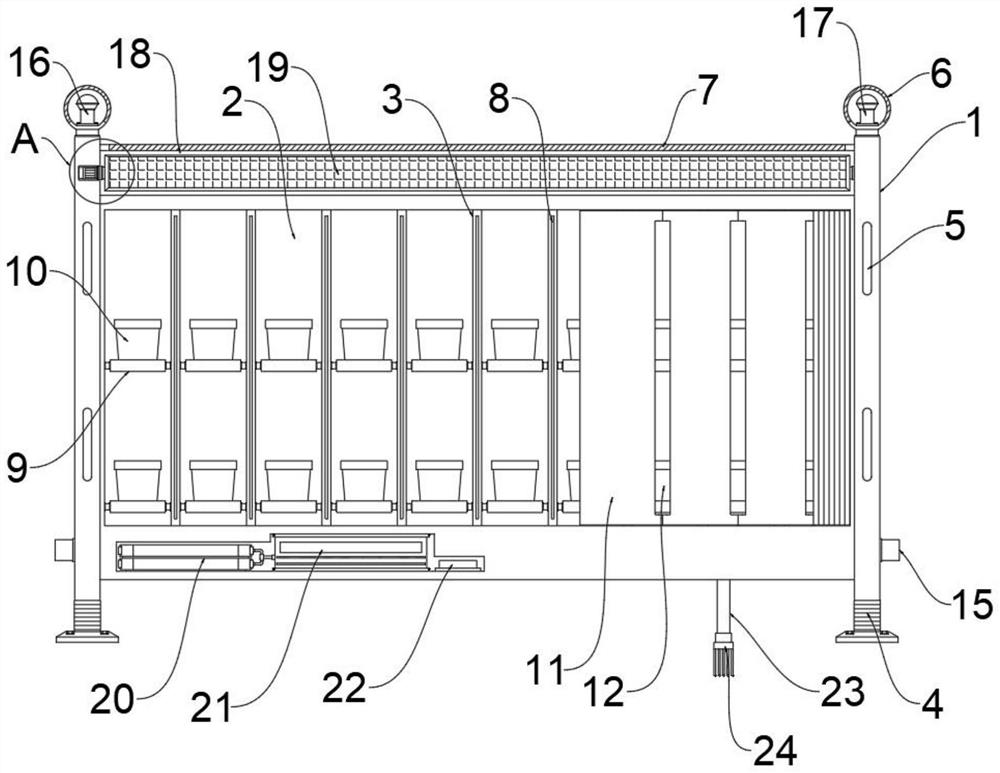

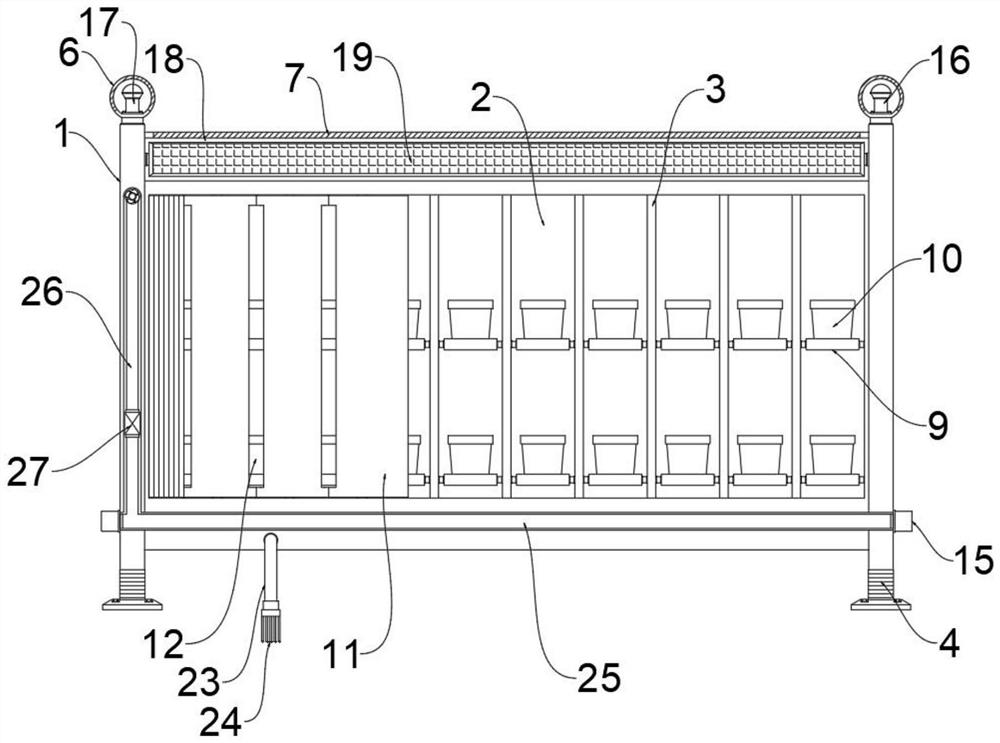

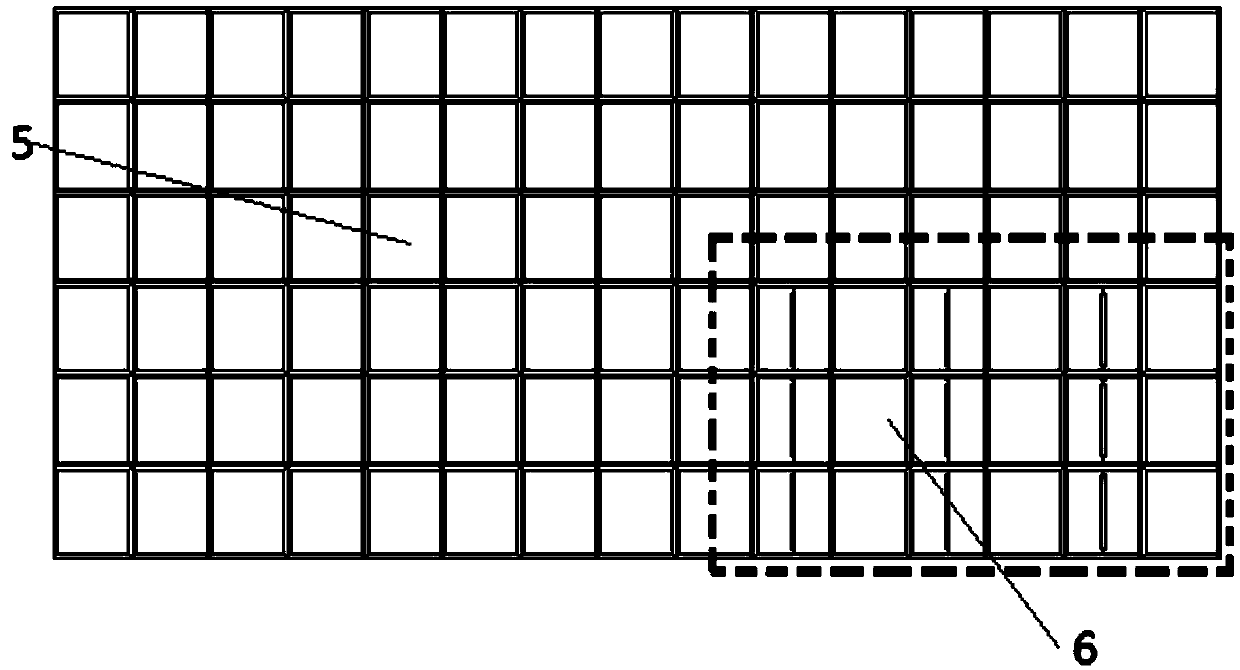

Energy-saving type greening decorative guardrail and energy-saving method thereof

PendingCN114319195AImprove the protective effectRealize the supplyPhotovoltaic supportsBatteries circuit arrangementsGreeningStructural engineering

The invention discloses an energy-saving type greening decorative guardrail and an energy-saving method thereof, relates to the technical field of decorative guardrails, and aims to solve the problem of how to realize greening construction on the premise of ensuring energy conservation and environmental protection of an existing greening decorative guardrail. A greening cavity is formed in the guardrail body, a plurality of fixing columns distributed at equal intervals are arranged in the greening cavity, green plant containing cylinders are fixedly installed between the adjacent fixing columns, folding protection plates are installed at the front end and the rear end of the greening cavity, and an installation cavity is formed above the greening cavity. A mounting cavity is formed in the upper end of the guardrail body, a solar photovoltaic panel is mounted in the mounting cavity, rotating adjusting shafts are fixedly arranged on the two sides of the solar photovoltaic panel correspondingly, a top plate is arranged above the solar photovoltaic panel, supporting balls are mounted on the two sides of the upper end of the guardrail body correspondingly, and a storage battery, a photovoltaic inverter and a controller are arranged below the greening cavity correspondingly; the two sides of the upper end of the main water pipe are both connected with water conveying branch pipes.

Owner:安徽澳永金属制品有限公司

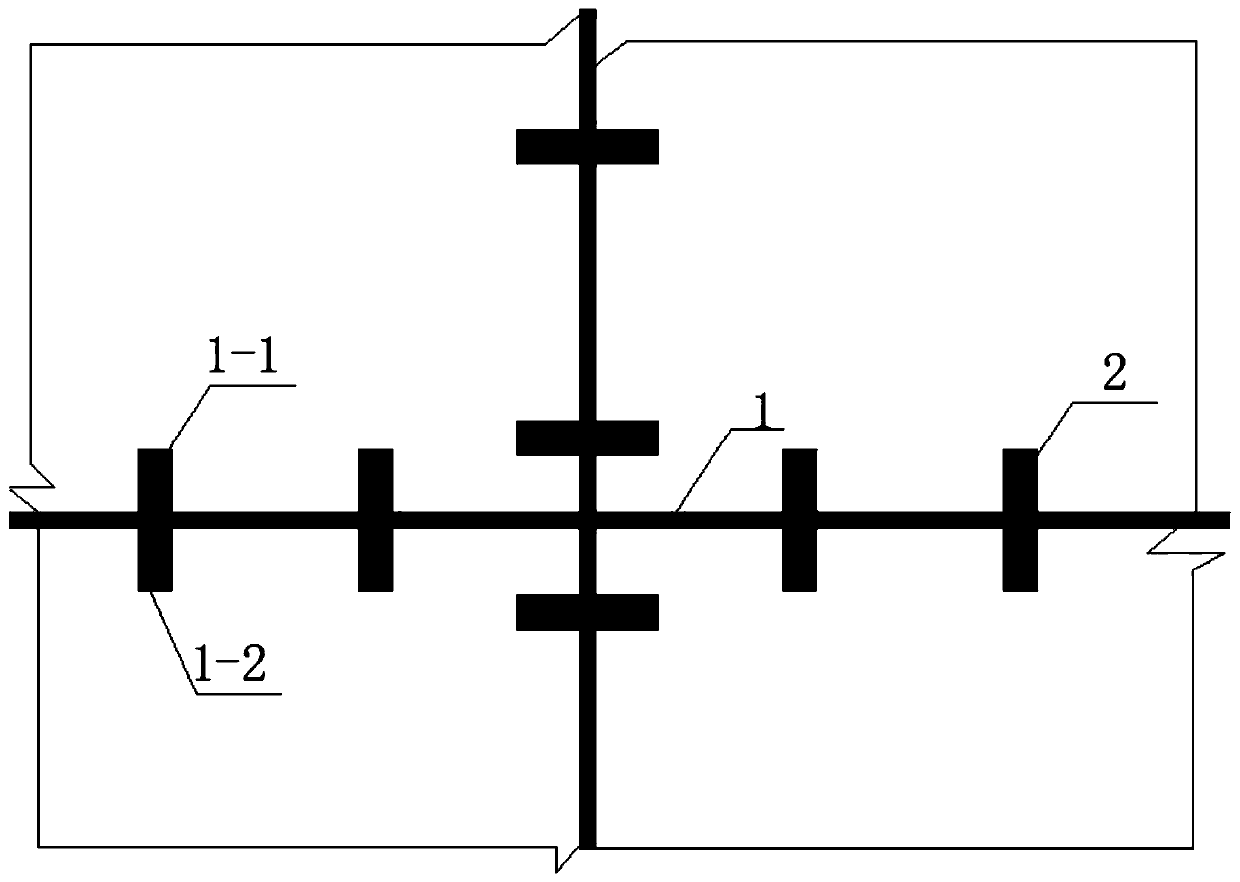

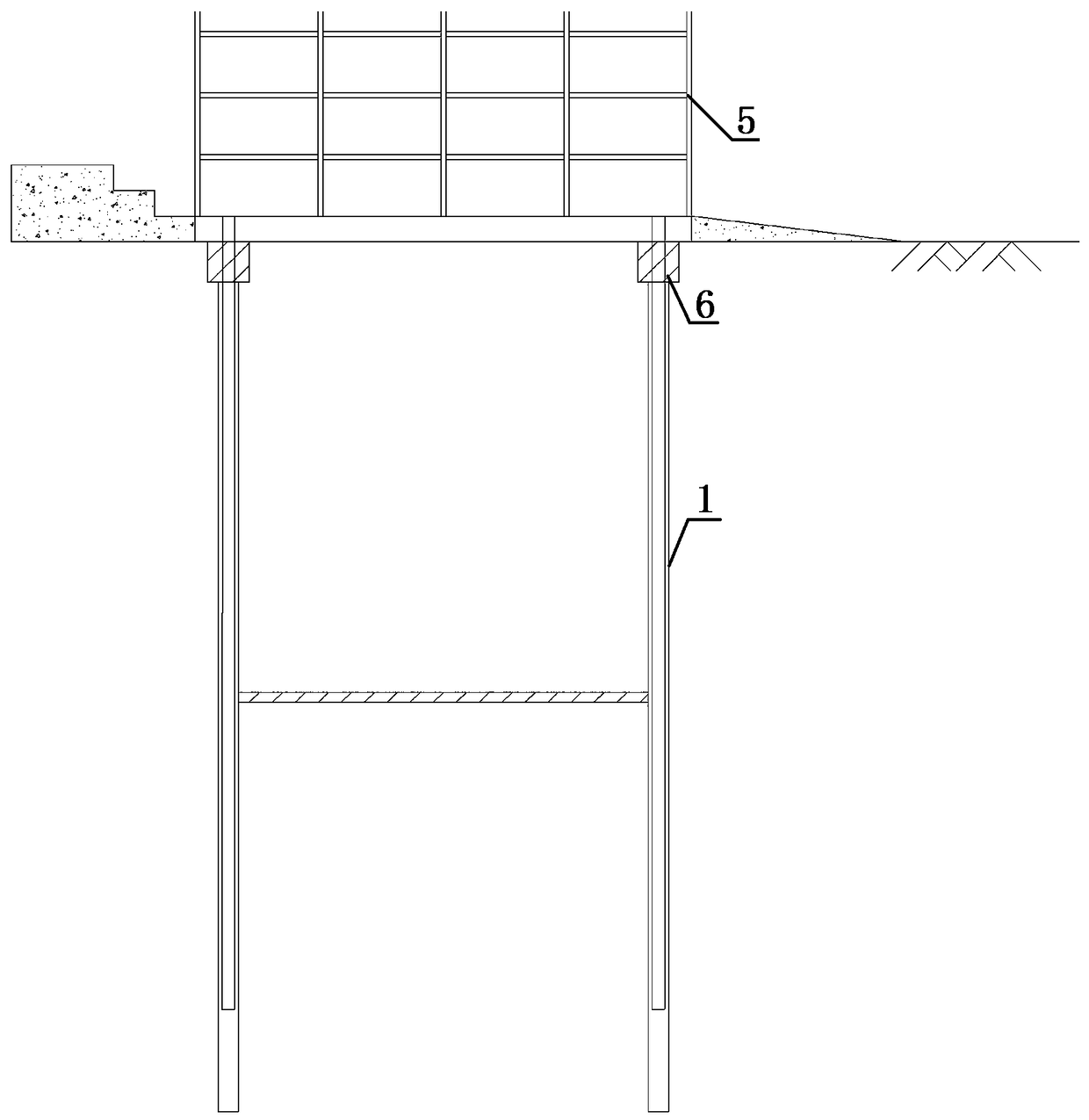

Prefabricated assembled reinforcing steel bar processing field and manufacturing method thereof

InactiveCN109252711AReduce dosageEmission reductionBuilding material handlingIndustrial buildingsEngineeringRebar

The invention discloses a prefabricated assembled reinforcing steel bar processing field. The prefabricated assembled reinforcing steel bar processing field comprises a plurality of first prefabricated plates, each of the first prefabricated plates comprises a frame and concrete poured in the frame, the frames are formed by H-shaped steel, and the first prefabricated plates are assembled to form the prefabricated assembled reinforcing steel bar processing field. The prefabricated assembled reinforcing steel bar processing field assembled by prefabricated plates on site is simple and quick to construct and can be used repeatedly for multiple times, and construction waste output caused by processing fields of reinforcing steel bar construction or woodworking is reduced remarkably, construction time is shortened, and construction cost is saved. The invention further provides a manufacturing method of the prefabricated assembled reinforcing steel bar processing field. By the aid of the manufacturing method, the prefabricated assembled reinforcing steel bar processing field is simple and convenient to construct, and construction efficiency is improved.

Owner:SHANGHAI BAOYE GRP CORP

Mobile shelter suitable for subway station construction and construction method

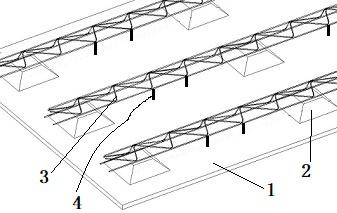

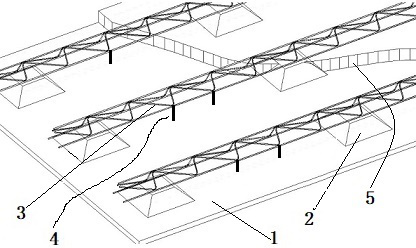

InactiveCN107503522AConvenient lightingEasy constructionTents/canopiesBuilding material handlingEngineeringSubway station

The invention discloses a mobile shelter suitable for subway station construction and a construction method. The mobile shelter comprises a plurality of shelter units arranged above a foundation pit, guiding rails are arranged on the ground on the two sides of the foundation pit, the length of each guiding rail is larger than the sum of the widths of all the shelter units by at least the width of one shelter unit, each shelter unit comprises a truss structure, side surface supports arranged on the two sides of the truss structure, a ceiling clad material layer arranged above the truss structure and a motor, sliding wheels matched with the guiding rails are arranged at the lower ends of the side surface supports, each motor can drive the corresponding side surface support to move along the corresponding guiding rail, and opening or covering of different segments of the foundation pit is achieved by the shelter units moving along the guiding rails. According to the mobile shelter, the truss structures are adopted, compared with existing folding shelters, the mobile shelter has the advantages that the stiffness and the reliability are higher, and the span of the shelter can be increased; negative impacts on a surrounding environment in noise, dust and illumination are low, so that the idea of green construction is conformed.

Owner:NO 2 CONSTR GRP CO LTD OF SHANGHAI CONSTR GRP

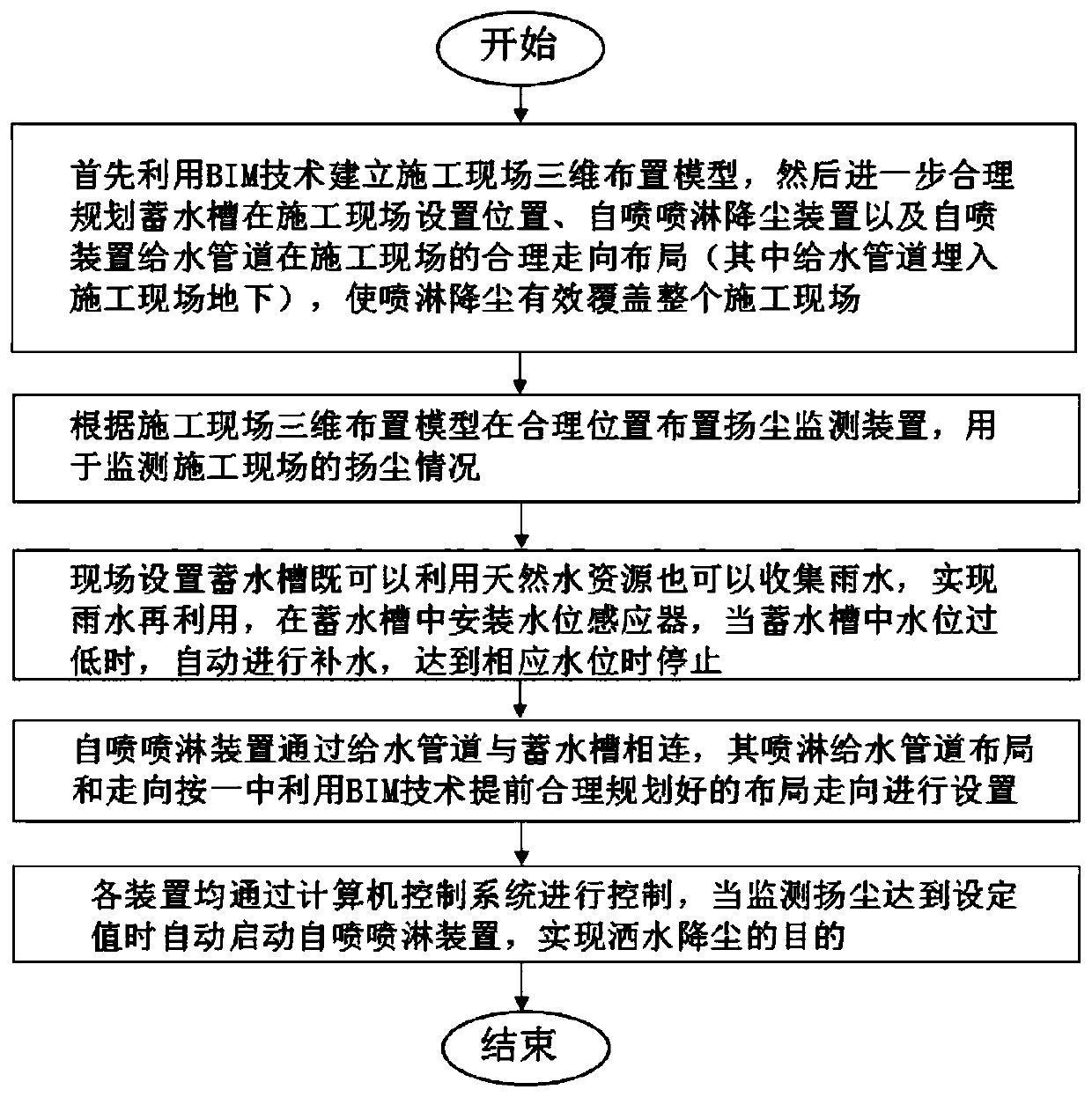

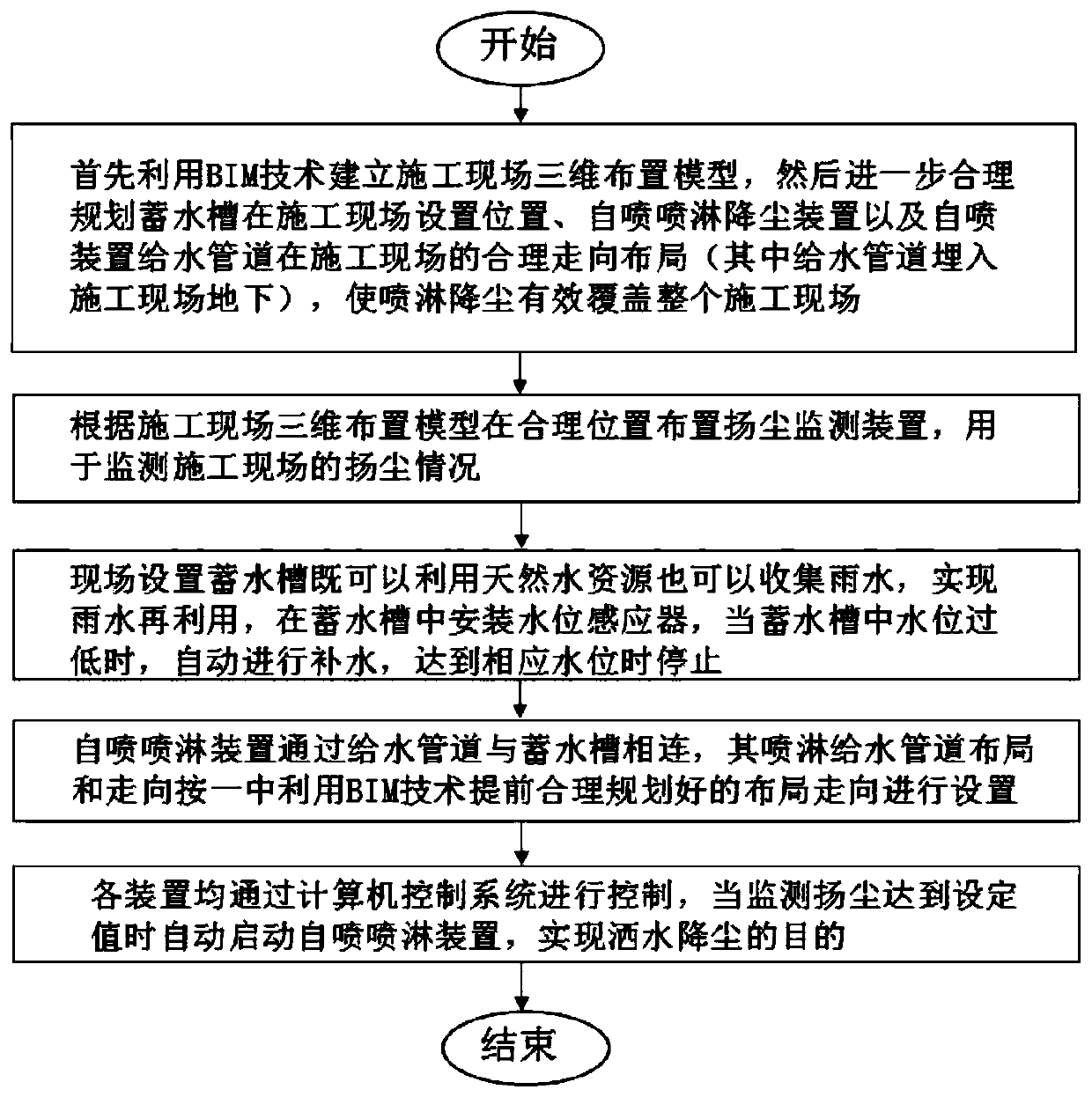

Method for preventing and controlling flying dust on construction site based on BIM technology

InactiveCN109914319AIn line with the concept of green constructionObvious benefits of engineering constructionGeneral water supply conservationRoad cleaningComputer control systemWater storage tank

The invention discloses a method for preventing and controlling flying dust on a construction site based on a BIM technology, and belongs to the technical field of construction. The invention comprises the following steps of step 1, first, establishing a three-dimensional layout model of the construction site by using the BIM technology, and then further rationally planning the location of a waterstorage tank at the construction site; step 2, arranging a flying dust monitoring device at a reasonable position according to the three-dimensional layout model of the construction site to monitor the flying dust on the construction site; step 3, arranging the water storage tank on the site to use natural water resources and collect rainwater; step 4, connecting a self-sprinkler device to the water storage tank through a water supply pipe; step 5, controlling each device through a computer control system, and when the flying dust is monitored to reach a set value, automatically starting theself-sprinkler device to achieve the purpose of sprinkling water and settling dust. The invention effectively reuses natural water resources and rainwater resources, conforms to the concept of green construction, responds to national environmental protection, and brings obvious benefits to project construction.

Owner:CHINA MCC17 GRP

Material perpendicular lifting device

PendingCN111115495AReduce volumeEasy to installLifting framesBuilding material handlingFloor slabWire wheel

The invention discloses a material perpendicular lifting device. The material perpendicular lifting device comprises a lifting basket, a base, a supporting vertical rod, a lifting mechanism and a clamping mechanism, the base is located under a floor slab, the floor slab is connected with the base through the supporting vertical rod, the clamping mechanism comprises two clamping rods, two horizontal overturning mechanisms and two anti-overturning mechanisms, the two horizontal overturning mechanisms are connected with the lifting mechanism, the two clamping rods are connected with the two horizontal overturning mechanisms, the two anti-overturning mechanisms are connected with the two horizontal overturning mechanisms, the two anti-overturning mechanisms are connected with the two clampingrods, the lifting mechanism comprises a retracting and paying off mechanism, two wire ropes and two fixed pulley assemblies, each fixed pulley assembly comprises a pulley bracket and a fixed pulley, the two pulley brackets are symmetrically installed on the clamping mechanism, the retracting and paying off mechanism comprises two wire wheels and a power mechanism, the power mechanism drives the two wire wheels to retract and release the wires and is connected with the base, the two wire ropes are wound on the two wire wheels correspondingly, and the two wire ropes are connected with the lifting basket through the fixed pulleys. The material perpendicular lifting device is simple in structure and can transport materials to the floor slab safely.

Owner:WUHAN CONSTR ENG

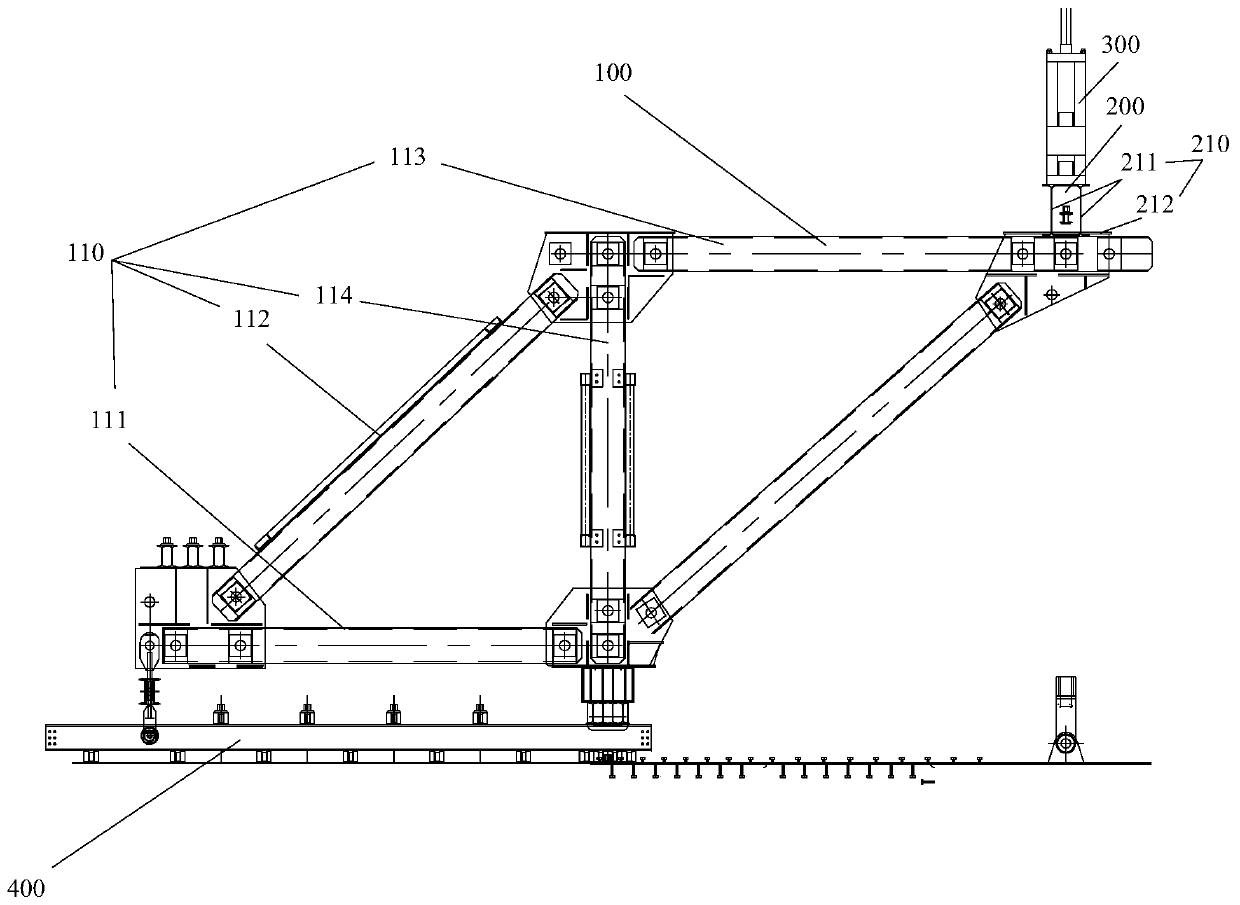

Construction equipment and method for an underground comprehensive pipe gallery

ActiveCN112627234BIncreased load-bearing capacityGood water stop effectArtificial islandsUnderwater structuresSupporting systemTrackway

The invention provides construction equipment and a construction method for an underground comprehensive pipe gallery. The construction equipment includes a foundation pit enclosure structure, track connectors, walking rails and gantry lifting devices; the foundation pit enclosure structure includes a plurality of composite piles composed of U-shaped steel sheet piles and H-shaped steel pillars interlocked side by side , the track connector includes a base and two sets of track positioning adjustment members symmetrically installed on the base, the bottom of the track connector is connected with the H-shaped steel pillar web of the composite pile, and rails are installed on the track connector; The device includes a fixed outrigger, a span adjustment outrigger, a bridge frame connecting the two outriggers and a traveling mechanism, and the gantry lifting device is slidingly connected with the traveling rail through the traveling mechanism. The invention combines foundation pit support and hoisting equipment into one body, and makes full use of each other, which not only enhances the integrity of the support system, but also reduces the occupied area of rail laying, reduces environmental pollution, and after the construction is completed, All equipment is recyclable.

Owner:WUHAN SURVEYING GEOTECHN RES INST OF MCC

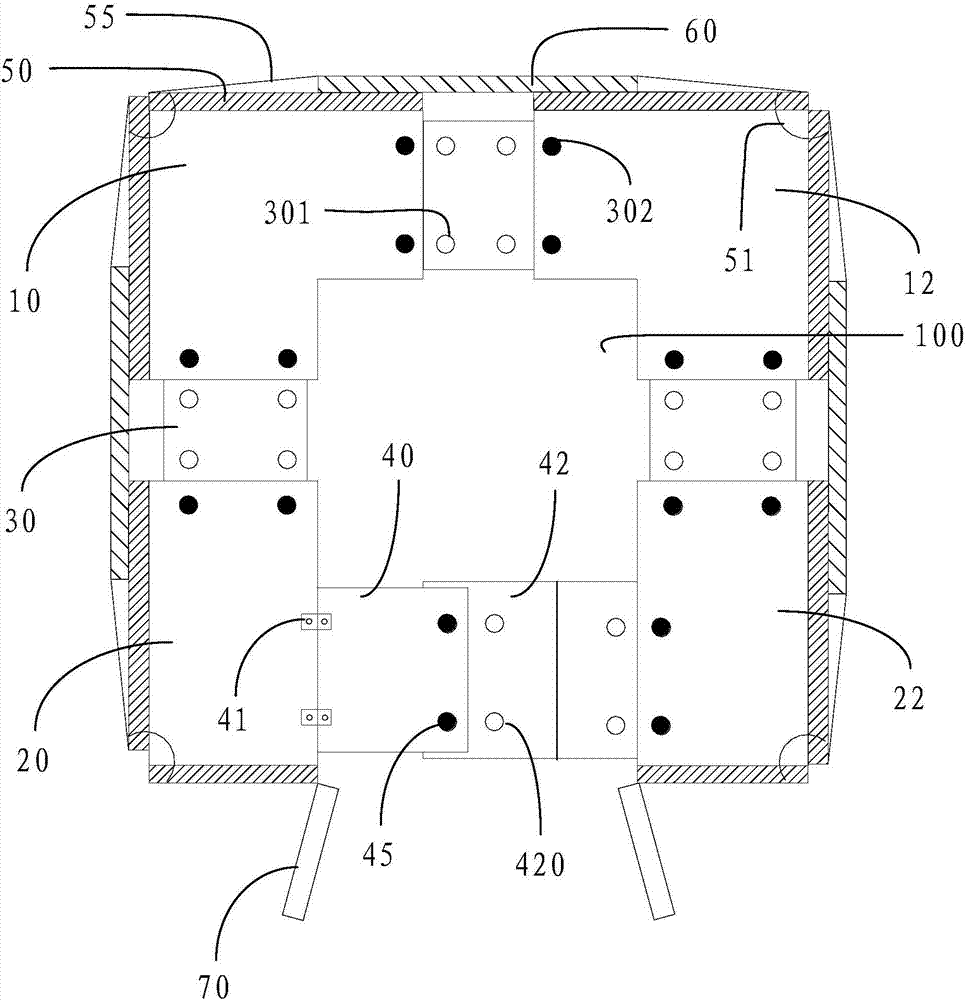

Splitting method of laminated assembly type pipe gallery

InactiveCN109403373AReduce weightLower requirementArtificial islandsUnderwater structuresEngineeringMechanical engineering

The invention relates to a splitting method of a laminated assembly type pipe gallery. The splitting method comprises the following steps that a, a gallery body is divided into a plurality of tube galleries, wherein each section of pipe gallery is divided into a laminated double-layer wallboard, a laminated single-layer top plate and a cast-in-place bottom plate; b, the cast-in-place bottom plateis connected with the laminated double-layer wallboard through an upward-turning guide wall arranged on the side edge of the width direction of the cast-in-place bottom plate, the laminated single-layer top plate is connected with the laminated double-layer wallboard through a U-shaped sleeve hoop to form a hidden beam connection; c, respectively grooves and joints are arranged between the overlapped type single-layer top plates and the overlapped type double-layer wall plates of the adjacent two-section pipe gallery, then every two adjacent tube galleries are connected through a hidden beam arranged in the groove and a hidden column at the joint position, and a plurality of sections of pipe gallery which are connected are integrally poured to form a gallery body. According to the splitting method, the weight of the single component is light, the difficulty of factory prefabrication and on-site assembly is reduced, the requirements for hoisting equipment are reduced, and the advantagesof saving the production cost, the transportation cost and the on-site construction cost are achieved.

Owner:THE 4TH CONSTR ENG CO LTD OF CHINA RAILWAY NO 4 ENG GRP +1

Drawing and inserting type aerial welding platform and installing method thereof

ActiveCN107081550AImprove turnaround timesThe size of the space can be adjustedWelding/cutting auxillary devicesAuxillary welding devicesSteel columnsAgricultural engineering

The invention discloses a drawing and inserting type aerial welding platform. The drawing and inserting type aerial welding platform is arranged on the periphery of a steel column and is in a rectangular shape. The drawing and inserting type aerial welding platform comprises a first flat plate, a second flat plate, a third flat plate and a fourth flat plate, all of which are located at the four corners of the welding platform. An adjusting sliding plate is connected between the third flat plate and the first flat plate, an adjusting sliding plate is connected between the first flat plate and the second flat plate, and an adjusting sliding plate is connected between the second flat plate and the fourth flat plate. An upper overturning plate and a lower overturning plate are connected between the third flat plate and the fourth flat plate. The adjusting sliding plates and the lower overturning plate are provided with a plurality of sets of connecting holes. According to a drawing and inserting type welding platform installing method, the first flat plate, the second flat plate, the third flat plate, the fourth flat plate, the upper overturning plate and the lower overturning plate are sequentially installed, and a hollow platform is formed and arranged on the periphery of the steel column in a sleeving manner from top to bottom and is fixed. According to the other drawing and inserting type welding platform installing method, the installed upper overturning plate and the installed lower overturning plate are overturned, a U-shaped platform is formed and then arranged on the periphery of the steel column in a sleeving manner from back to front, and the upper overturning plate and the lower overturning plate are restored and fixed.

Owner:CHINA CONSTR EIGHT ENG DIV CORP LTD

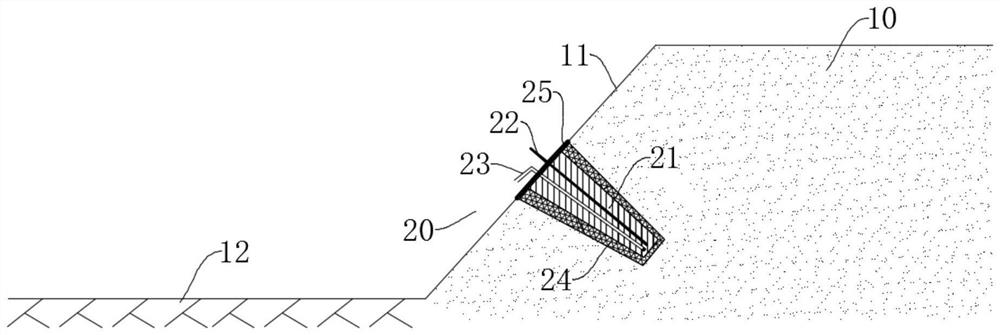

Loose stratum reinforcing device and construction method thereof

PendingCN114197464AImprove work efficiencySatisfy the use effectExcavationsBulkheads/pilesSlurryBuilding construction

According to the loose stratum reinforcing device and the construction method thereof, the loose stratum reinforcing device comprises a plurality of reinforcing assemblies arranged on the side slope face in a loose stratum, each reinforcing assembly comprises a hole cavity formed in the side slope face and arranged in the loose stratum, and a rigid piece and a spray pipe are arranged in each hole cavity; and slurry is poured into the hole cavity through the spraying pipe so as to extrude the loose stratum, and a reinforcing layer annularly arranged on the rigid piece is formed so as to reinforce the loose stratum. The structure is particularly suitable for loose stratum foundation pit slope supporting operation, a traditional drilling and grouting type rigid piece wall is effectively improved, the using effect under the loose stratum condition can be met, the loose stratum foundation pit slope supporting operation efficiency is improved, the structure is simple, construction is safe and reliable, cost is effectively saved, and the construction period is effectively shortened; the required materials can be obtained locally, waste is avoided, and the green construction concept is met.

Owner:MCC TIANGONG GROUP

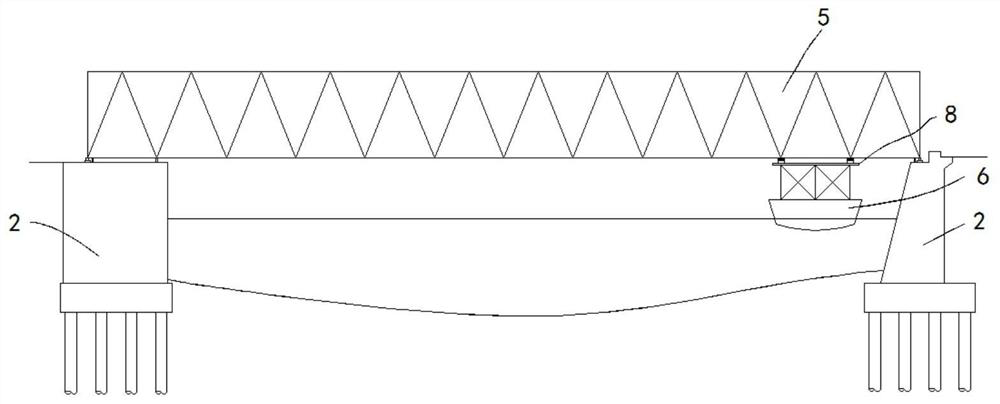

A floating erection method of a bridge

ActiveCN112482246BBalanced and easy to controlControl balanceBridge erection/assemblyClassical mechanicsAbutment

The present application relates to a floating erection method of a bridge, comprising the following steps: setting an installation platform next to the abutment on one side of the bank; assembling a rotating device on the abutment; assembling a beam body on the installation platform , and connect one end of the beam body with the rotating device; connect the tugboat with the beam body, and drive the beam body to rotate around the abutment to a set position through the tugboat; drop the beam. This method assembles the beam body on the installation platform without setting up temporary structures such as guide beams and brackets beside the pier, which simplifies the construction steps; the tugboat supports one end of the beam body by using the buoyancy of the water, and the other end passes through the rotation of the bank. The device is supported to form a force-bearing structure in a simply supported state. When the tugboat is driving the beam body to rotate, the beam body is in a simply supported equilibrium state, which is easy to control and is not prone to overturning, which improves safety; The addition of permanent structures such as the prestressed structure of the cap and the rotating structure of the pier column reduces the difficulty of construction.

Owner:中铁大桥局第七工程有限公司

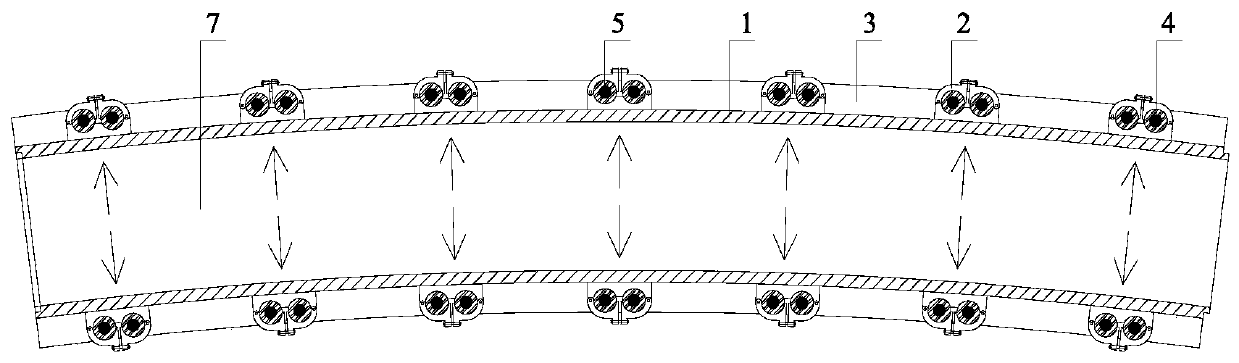

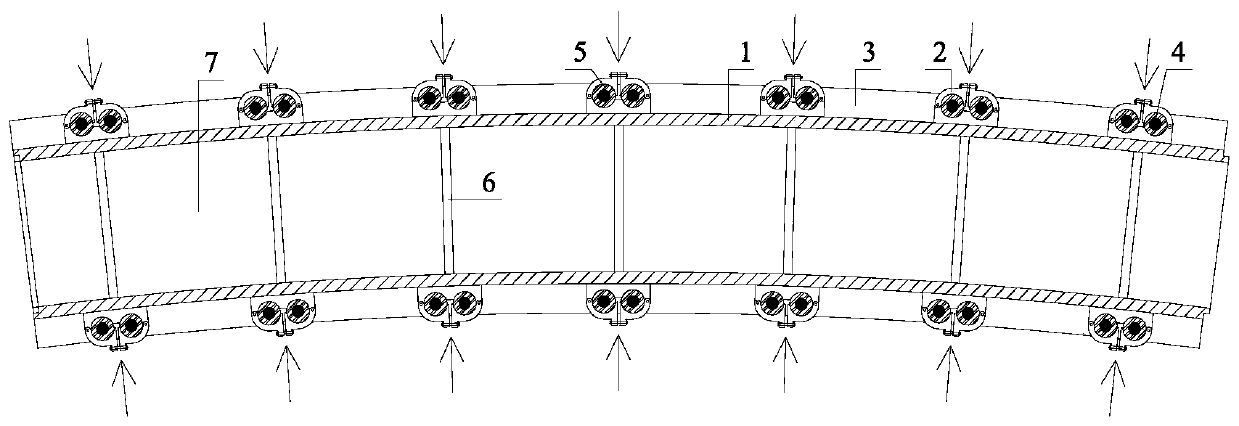

Synchronous lifting system and method for large-span continuous box girder closure

InactiveCN110878527AShorten the suspension timeReduce consumptionBridge erection/assemblyControl engineeringStructural engineering

The invention discloses a synchronous lifting system and method for large-span continuous box girder closure. The synchronous lifting system for large-span continuous box girder closure comprises a base body, a fixing device and a lifting device. The fixing device is arranged on the base body, and the lifting device is arranged on the fixing device and used for stably lifting the box girder. The lighting lamp comprises a lamp body and a lifting hook device arranged on the lamp body. The lifting hook mechanism further comprises a fixing mechanism connected with the mounting mechanism. First through holes are formed in the two mounting faces, and the fixing mechanism is connected to the first through holes in a penetrating mode. The system has good properties of high strength, high rigidityand high stability. Synchronous lifting is achieved, uniform stress of the box girder structure and the lifting device is guaranteed, the construction speed is high, the efficiency is high, and the navigation closure time of a navigation channel can be shortened to the maximum extent. Entrance and exit and energy consumption during installation of the floating crane are reduced. The problems thatin the prior art, when a floating crane is installed, construction shakes, a box girder is distorted and deformed, and the installation accuracy is not high are solved.

Owner:SHANGHAI NO 4 CONSTR

An assembled fishway and construction method

ActiveCN111042075BImprove construction efficiencyReduce time spent working at heightsBarrages/weirsClimate change adaptationWater stopArchitectural engineering

The invention provides an assembled fishway and a construction method, mainly comprising multi-section fish pond structural unit components and fish pond lower supporting structural columns supporting the fish pond structural unit components; the cross section of the fish pond structural unit components is consistent with the fishway, and the fish pond structural unit components It includes the bottom plate and the fishway groove walls on both sides; the fish pond structural unit components are prefabricated components in the factory; the integral fishway is formed by splicing several fish pond structural unit components; a water-stop structure is set between adjacent fish pond structural unit components. The invention improves the construction efficiency and construction quality of the fishway, reduces construction interference with the main structure, accelerates construction progress, reduces construction safety risks, and saves construction investment.

Owner:POWERCHINA HUADONG ENG COPORATION LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com