Construction method of arc beam by using adjustable arc beam molded formwork supporting structure

A construction method and stereotyped technology, applied in the field of construction engineering, can solve the problems of poor forming quality of circular arc beams, many consumables and wastes, easy to expand or burst molds, etc., so as to avoid inaccurate beam curvature and surface edges and corners , to ensure accuracy and reduce the effect of deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described in detail below with reference to the accompanying drawings and examples. The following examples are explanations of the present invention and are not limited to the following examples.

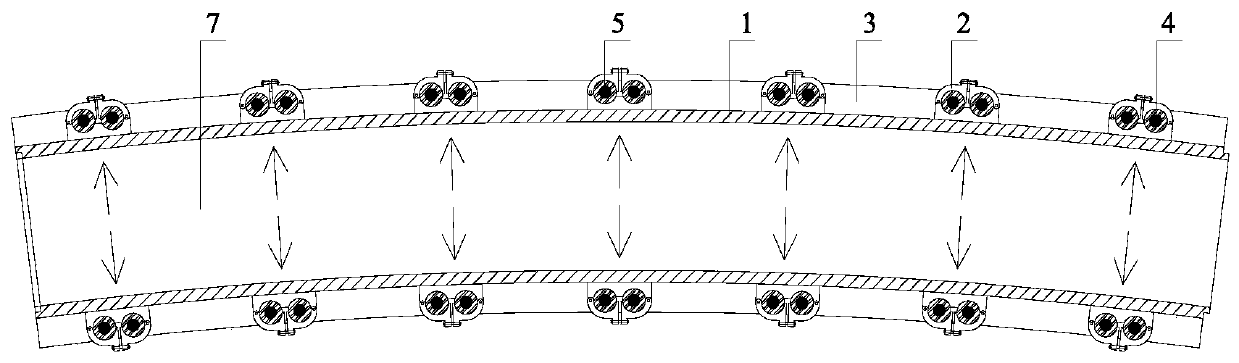

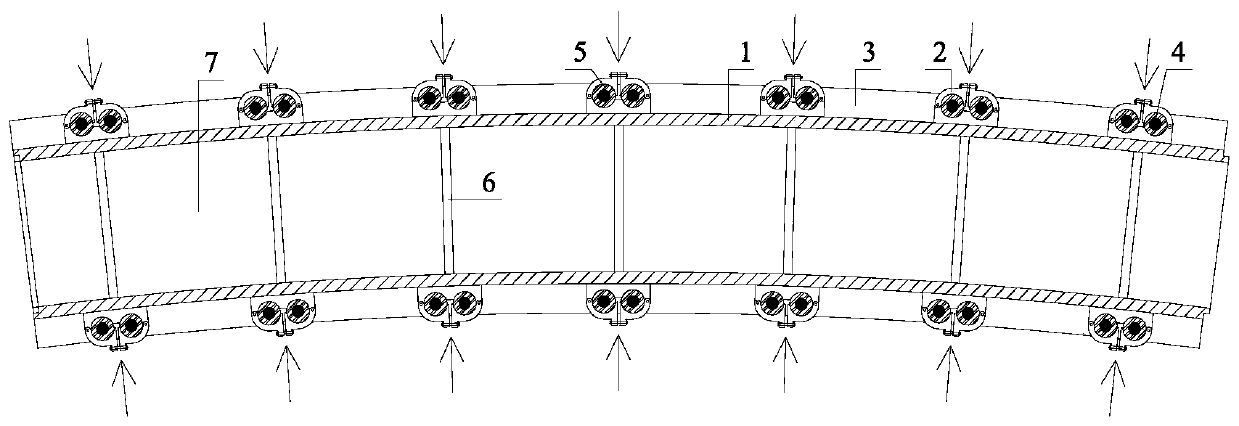

[0034] For a construction project, the cross-sectional size of the arc beam 21 is 250mm×600mm, the arc radius of the outer edge of the arc beam is 16600mm, and the arc radius of the inner edge is 16350mm. 21 and floor 22 integral pouring.

[0035] The arc beam construction method for finalizing the formwork structure by means of adjustable arc beams includes the following steps:

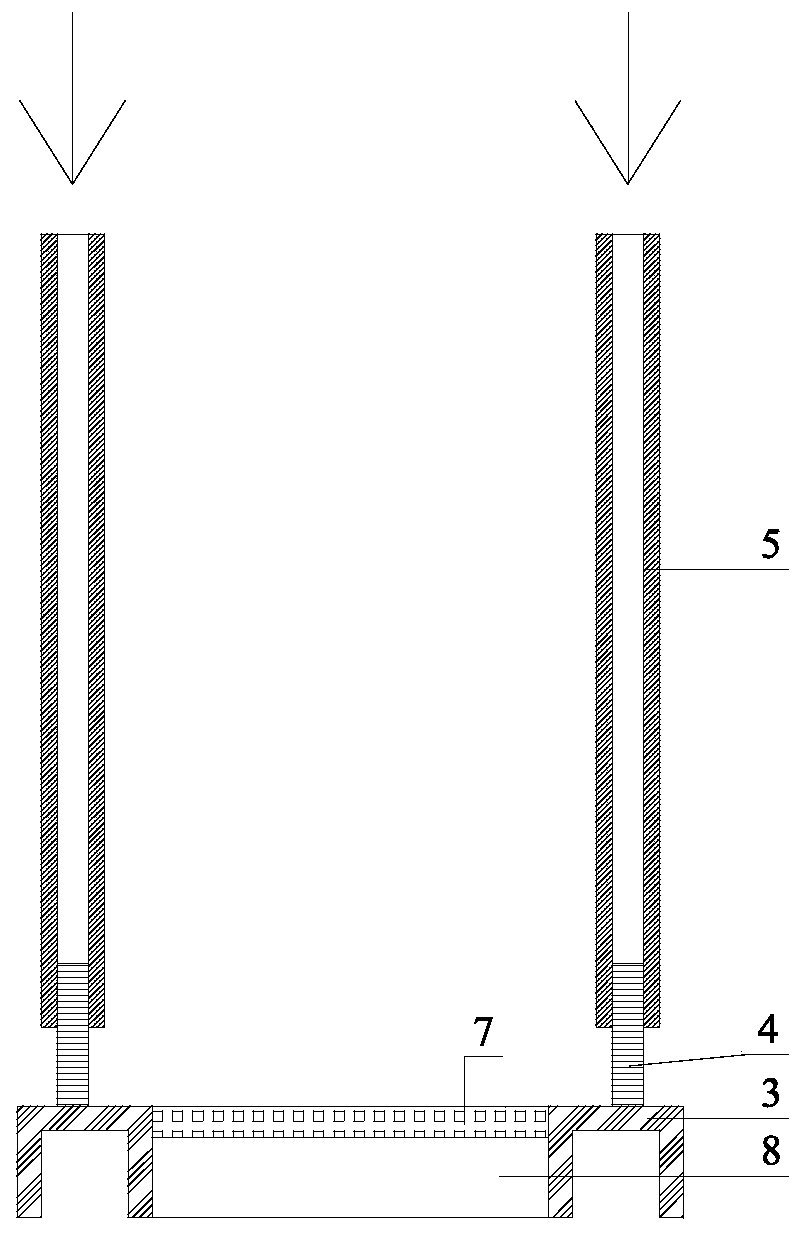

[0036] Step 1. Combine the attached figure 1 As shown, the horizontal support 3 on both sides is connected by the crossbeam 8, and the beam bottom mold 7 is laid on the crossbeam 8. The horizontal support 3 adopts U-shaped channel steel, and the notch of the U-shaped channel steel faces downward. The upper surface of the horizontal support 3 is provided with a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com