Material perpendicular lifting device

A vertical lifting and material technology, applied in the direction of lifting devices, lifting frames, building structures, etc., can solve the problems of large safety hazards, increased construction costs, low transportation efficiency, etc., and achieve high safety, save construction costs, and can be moved strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in detail below in conjunction with the accompanying drawings.

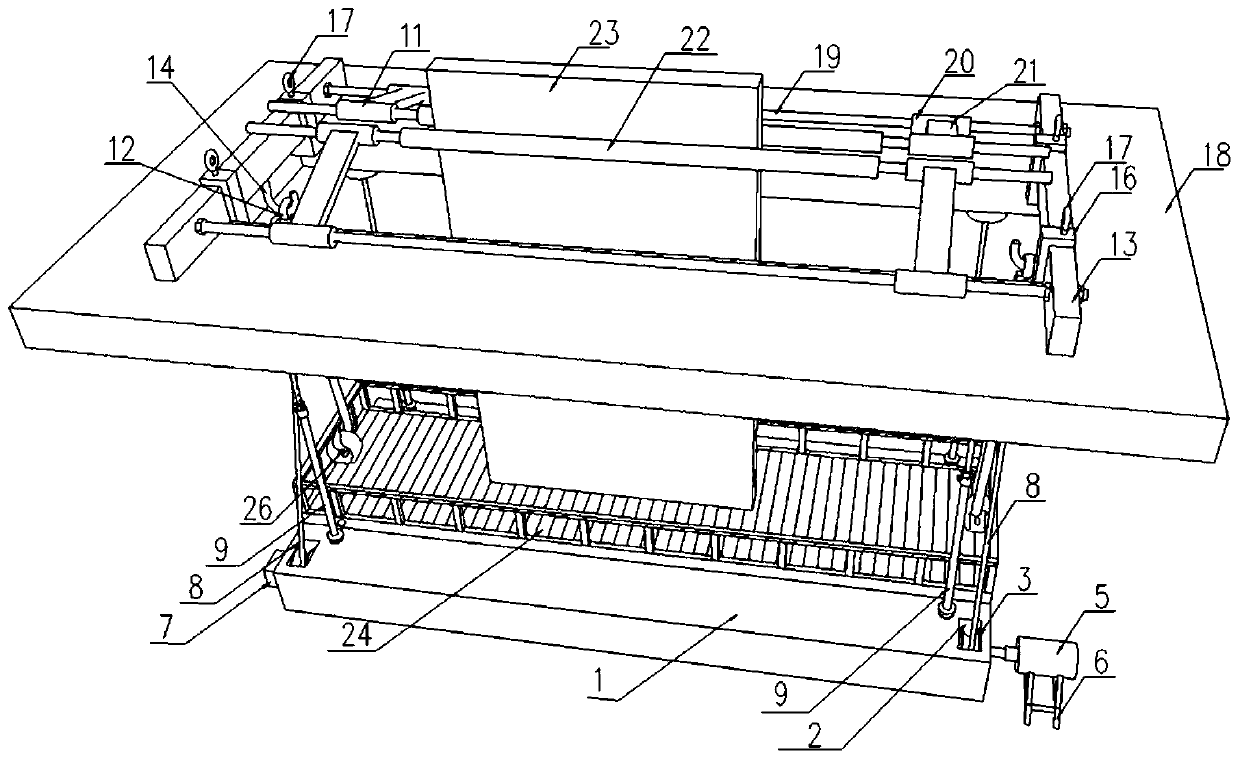

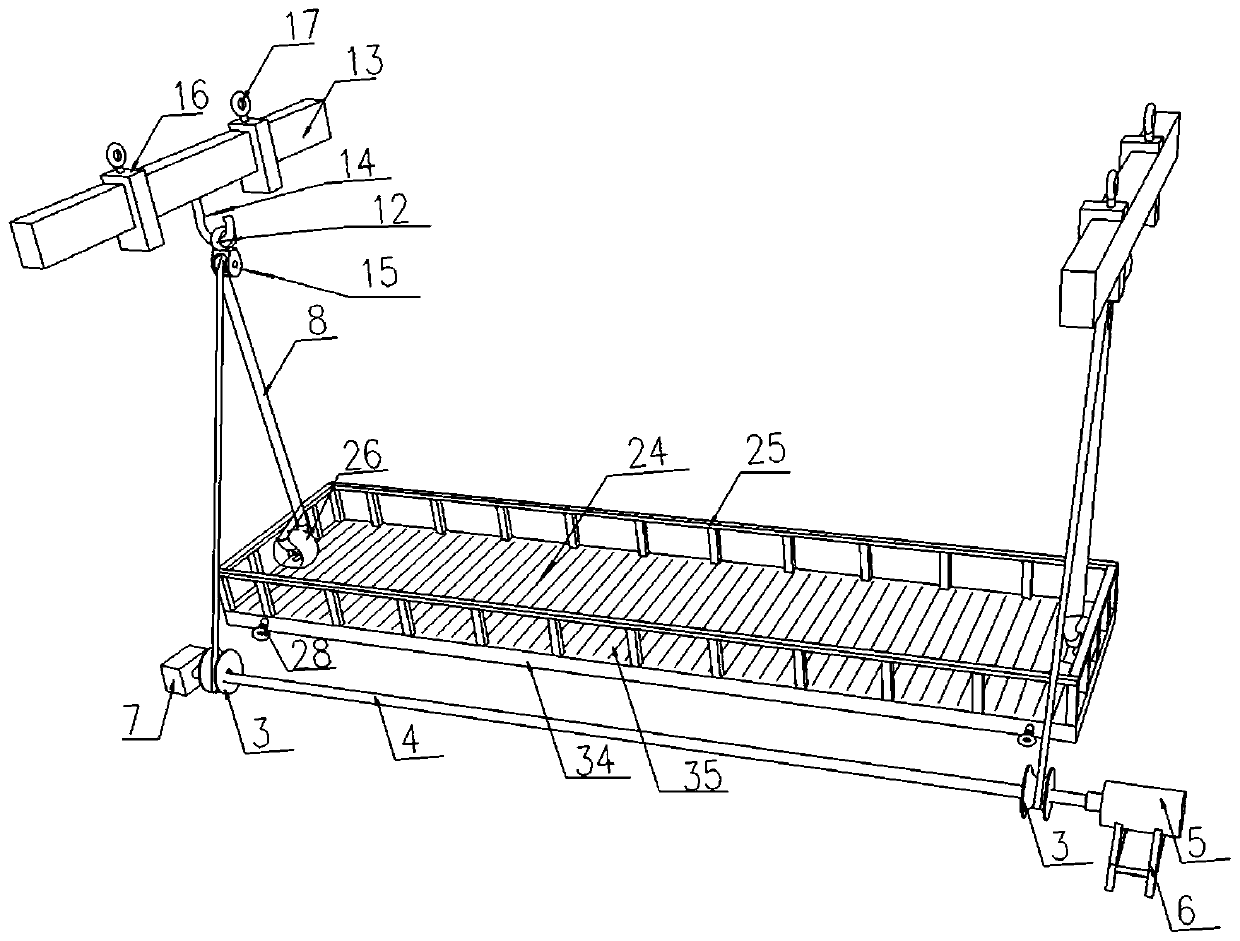

[0030] The structure of the material vertical lifting device provided in this embodiment is as follows: figure 1 As shown, it includes a hanging basket 24, a base 1, a support pole 9, a lifting mechanism, an engaging mechanism, a clamping mechanism and a guiding mechanism.

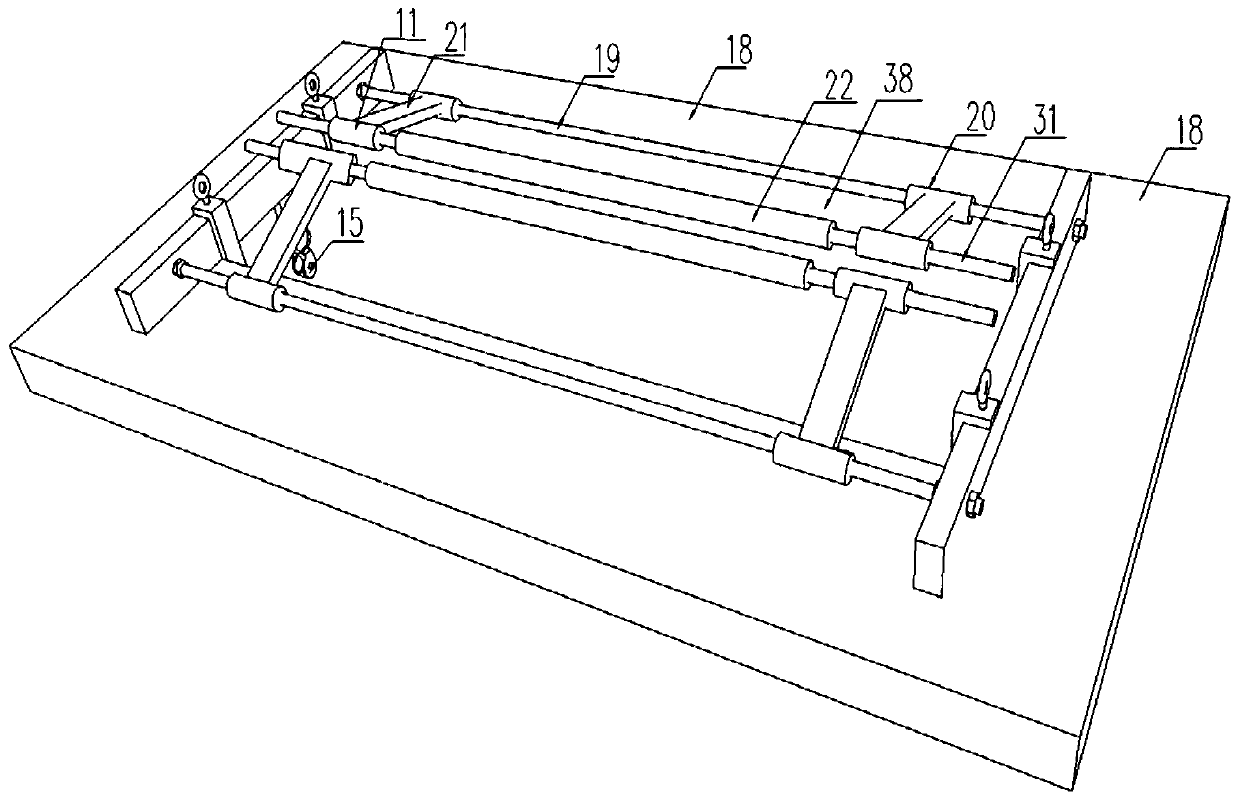

[0031] A square reserved hole 38 is reserved on the floor 18 , the base 1 is located directly below the reserved hole 38 , and the base 1 is placed on the ground or the floor below the floor 18 . The base 1 is square, and a placement hole is provided in the base 1 near the side wall in the length direction of the base, and the two ports of the placement hole are respectively located on the side walls in the width direction of the base. The top of the base 1 is symmetrically provided with two placement slots 2, and the two placement slots 2 are connected to the placement holes respectively.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com