Splitting method of laminated assembly type pipe gallery

A prefabricated, pipe gallery technology, applied in water conservancy projects, artificial islands, underwater structures, etc., can solve the problems of long exposure time of potential safety hazards in foundation pits, increasing the difficulty of factory prefabrication, and high requirements for hoisting equipment. The effect of reducing the investment of steel bar operators, reducing the workload of binding, and improving the quality of waterproofing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

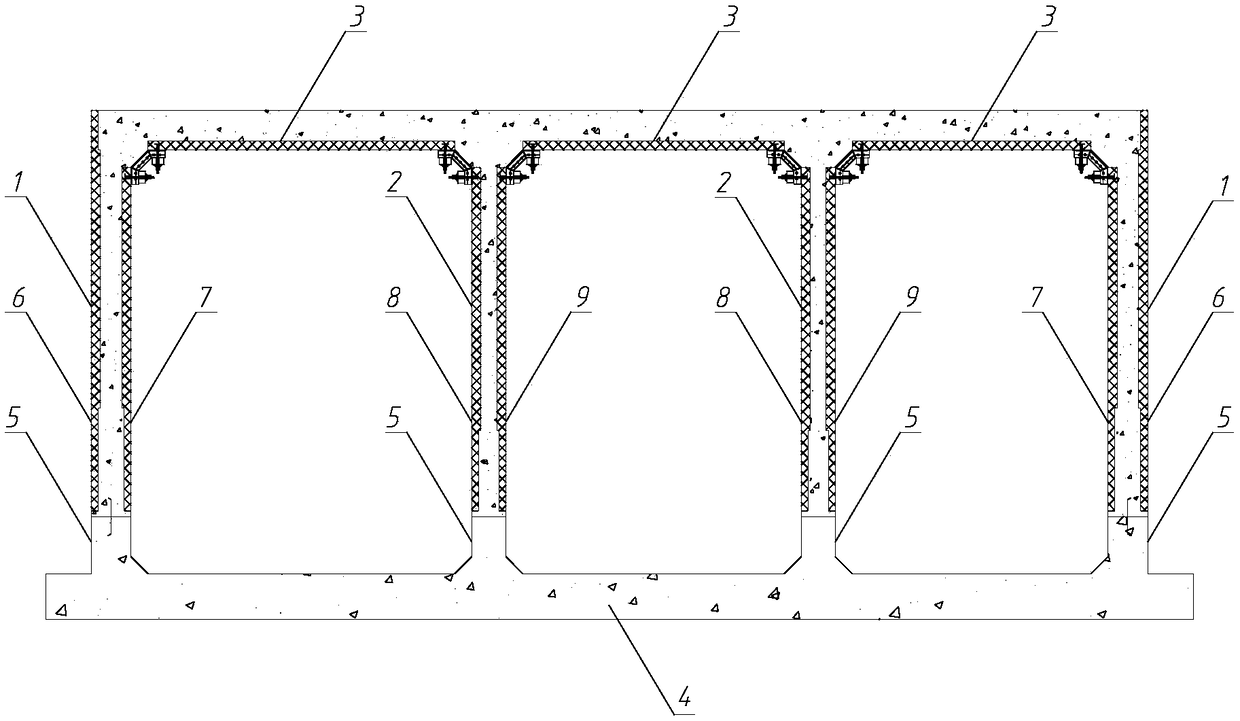

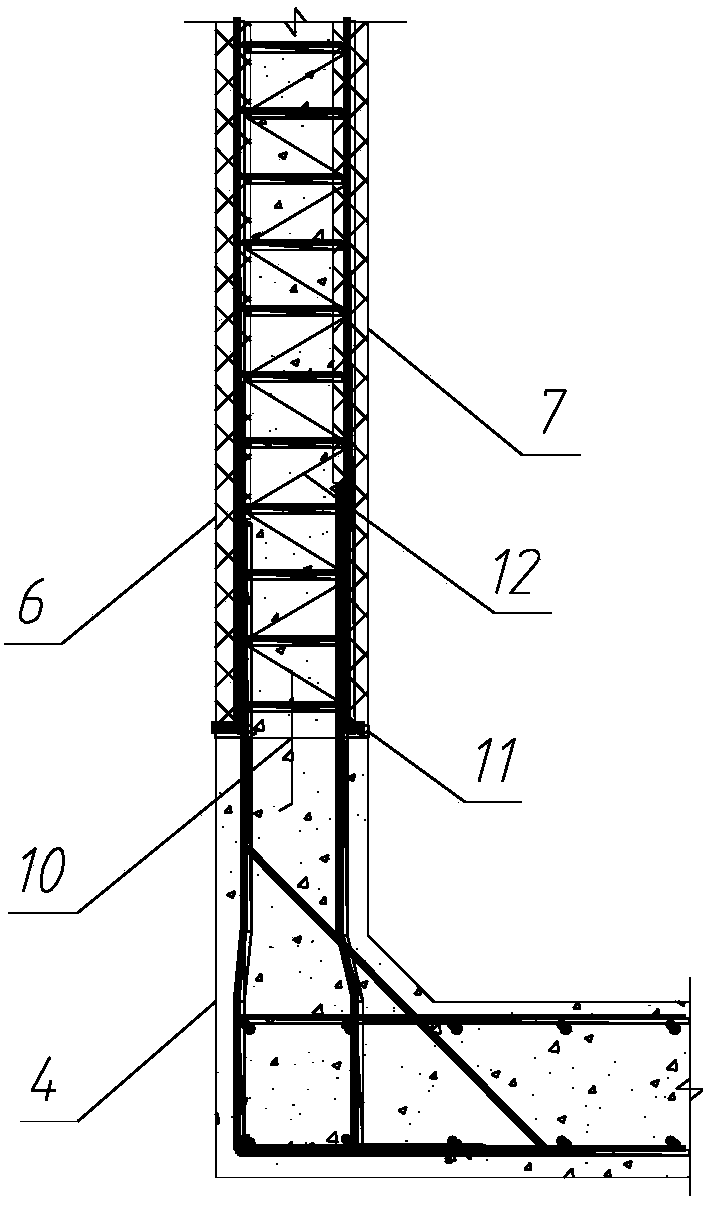

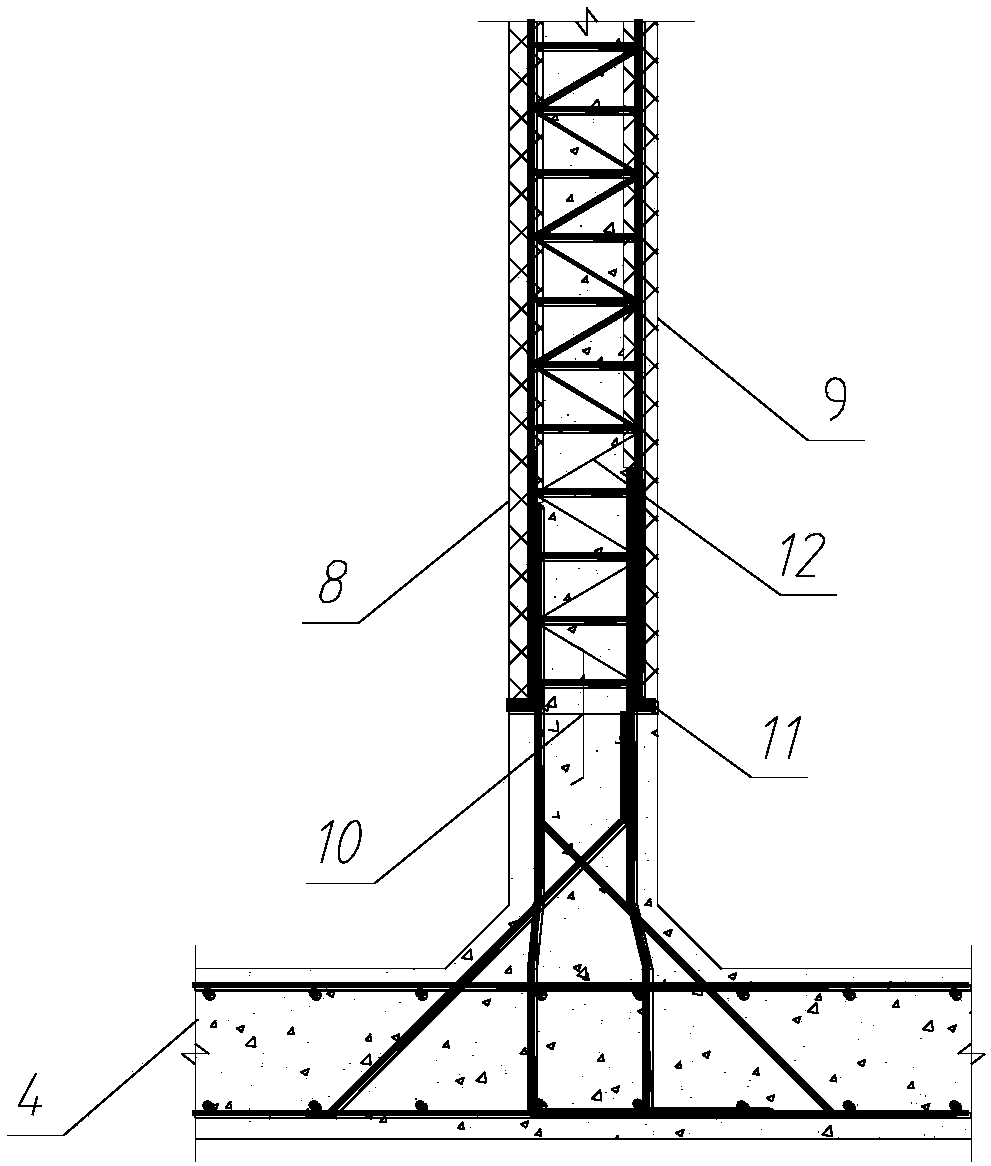

[0020] Combine below Figure 1 to Figure 8 , the present invention is described in further detail.

[0021] A method for splitting a superimposed assembly pipe gallery, comprising the following steps:

[0022] a. Divide the gallery body into several sections of pipe galleries, and according to the structural force characteristics of the pipe gallery, split each section of pipe gallery into superimposed double-layer wall panels, superimposed single-layer roof 3 and cast-in-place bottom slab 4, each section The pipe gallery has seven prefabricated components, including four superimposed double-layer wall panels and three superimposed single-layer roof panels 3, and the four superimposed double-layer wall panels include two superimposed double-layer exterior wall panels 1 and two A superimposed double-layer partition wall panel 2;

[0023] b. The cast-in-place bottom plate 4 is connected to the two superimposed double-layer exterior wall panels 1 and the two superimposed double...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com