Fabricated steel structure temporary working shed and mounting method thereof

A steel structure and assembly technology, applied in the direction of building structure, special buildings, small buildings, etc., can solve the problems of slow assembly and disassembly, inability to fully meet the requirements of rain and smash protection, and complex design, so as to facilitate workers' work , Quick assembly and disassembly, convenient assembly and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described in detail below in conjunction with specific examples, but the protection scope of the present invention is not limited by the specific examples, and the claims shall prevail. In addition, on the premise of not violating the technical solution of the present invention, any modification or change made to the present invention that can be easily realized by those skilled in the art will fall within the scope of the claims of the present invention.

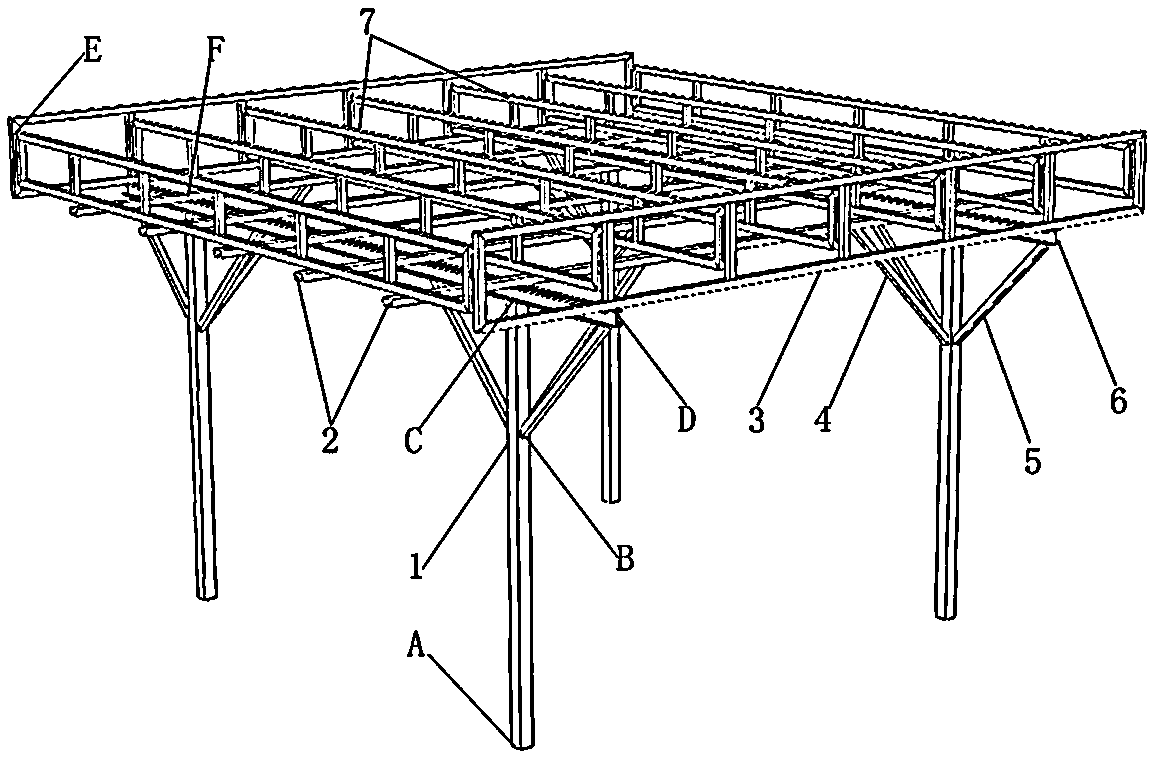

[0042] Such as figure 1 As shown, the prefabricated steel structure temporary work shed of the present invention includes longitudinal vierendeel trusses 3, transverse vierendeel trusses 7, purlins 2 and at least two assembled units.

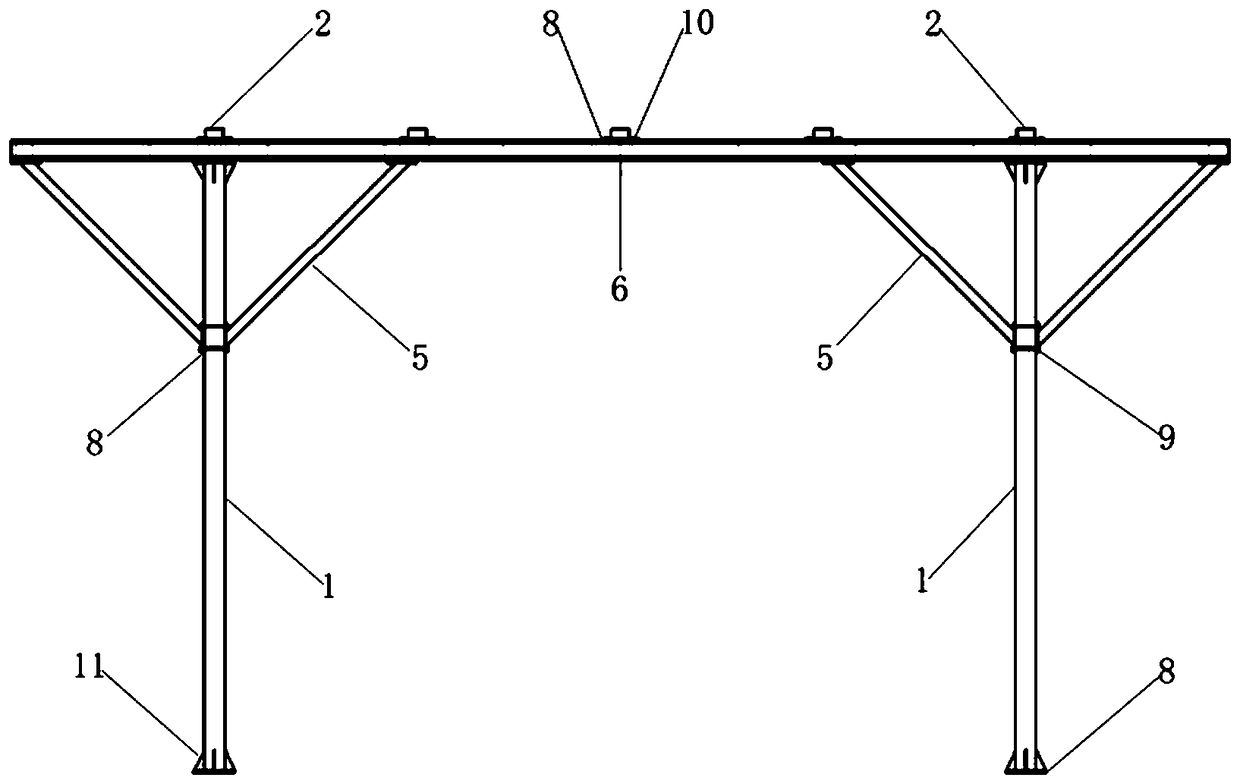

[0043] Such as figure 2 As shown, the assembly unit includes two square steel pipe columns 1, a double C-shaped I-beam 6 and ordinary bolts, and the two square steel pipe columns are installed on the two sides of the double C-shaped I-beam. end....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com