Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

101results about How to "Improve textile efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Textile size combination

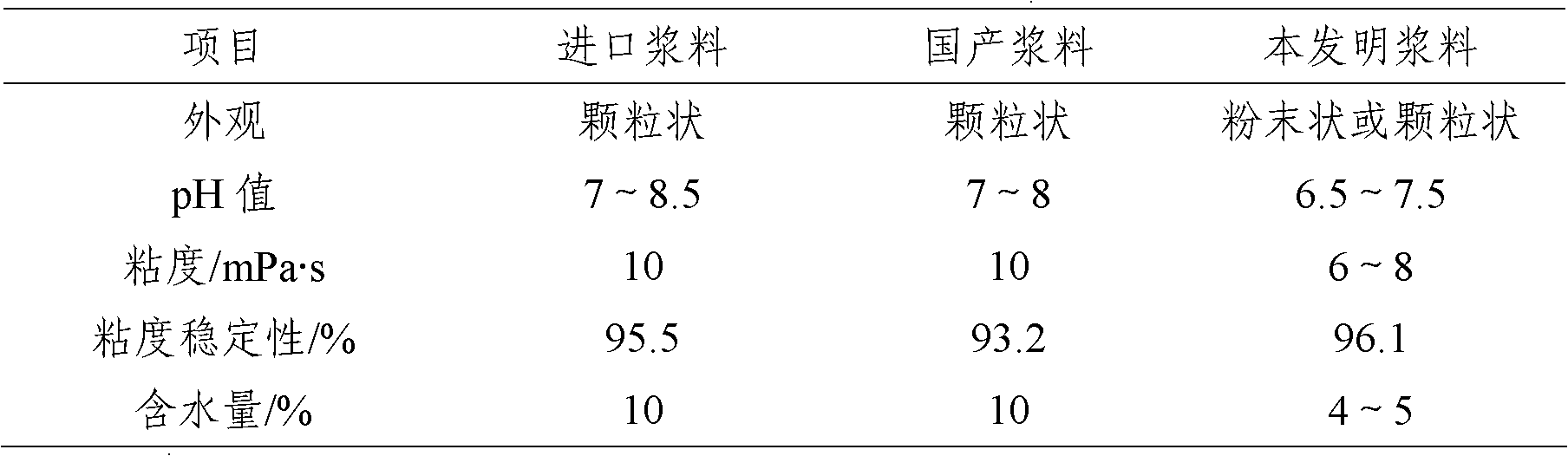

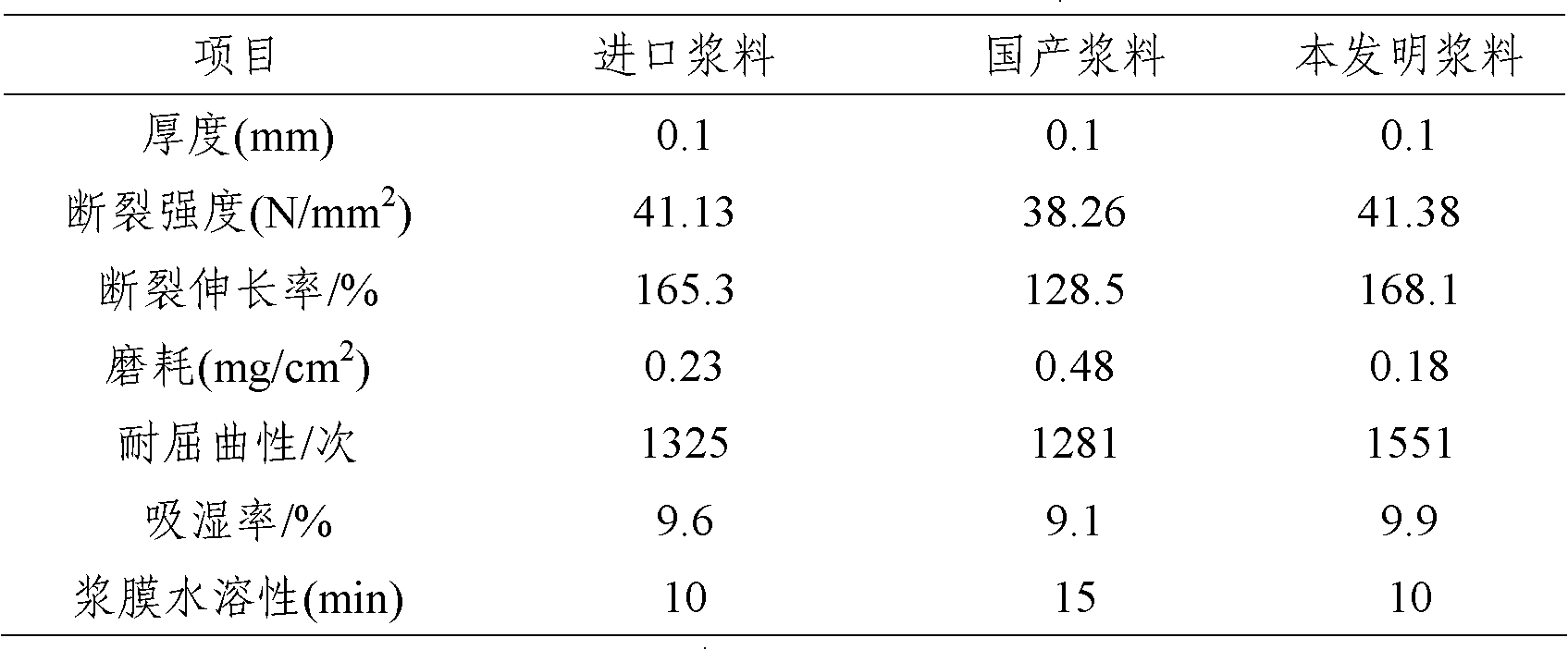

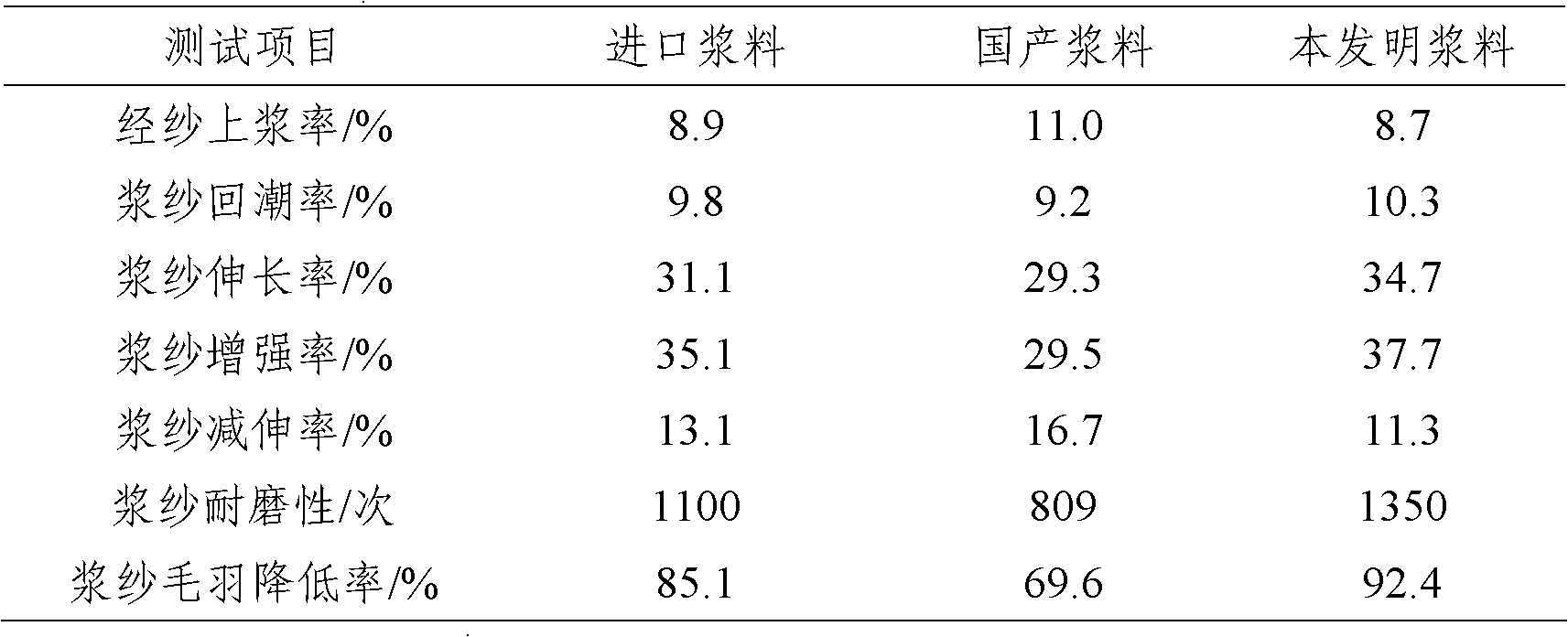

The invention provides a textile size combination which is prepared by mixing solid acrylate with nano SiO2 compound modified starch in proportion, wherein the solid acrylate is prepared by the following steps: mixing acrylonitrile, methyl acrylate, butyl acrylate, methyl methacrylate, acroleic acid, methacrylic acid with acrylamide in proportion, and enabling the mixed solvent to be subject to internal polymerization under the action of compound initiator and chain transfer agent, neutralizing with sodium hydroxide and drying; and the nano SiO2 compound modified starch is prepared by the following steps: sequentially acidifying, crosslinking and oxidizing starch, introducing surface-modified nano-level SiO2 and carrying out ultrasonic dispersion. The size can obviously improve the warp sizing performance and improve the weaving efficiency, can be completely replace PVA and imported sizes in the same amount or partial amount, and is widely used for the warp sizing of purified cotton, terylens, novel fibers and mixed yarns of various counts.

Owner:HUBEI DAYA BIOLOGICAL TECH CO LTD

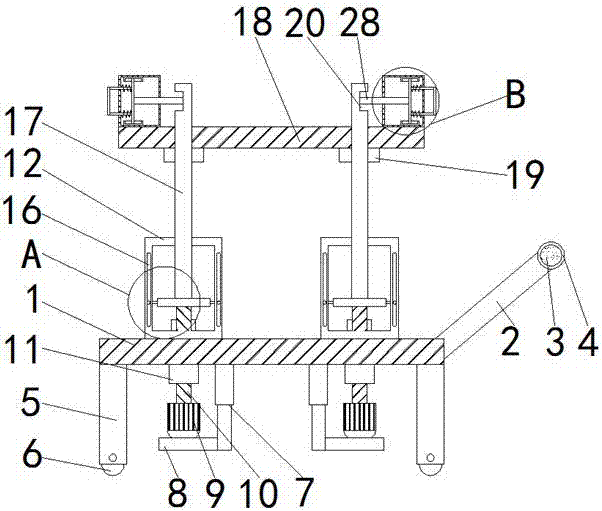

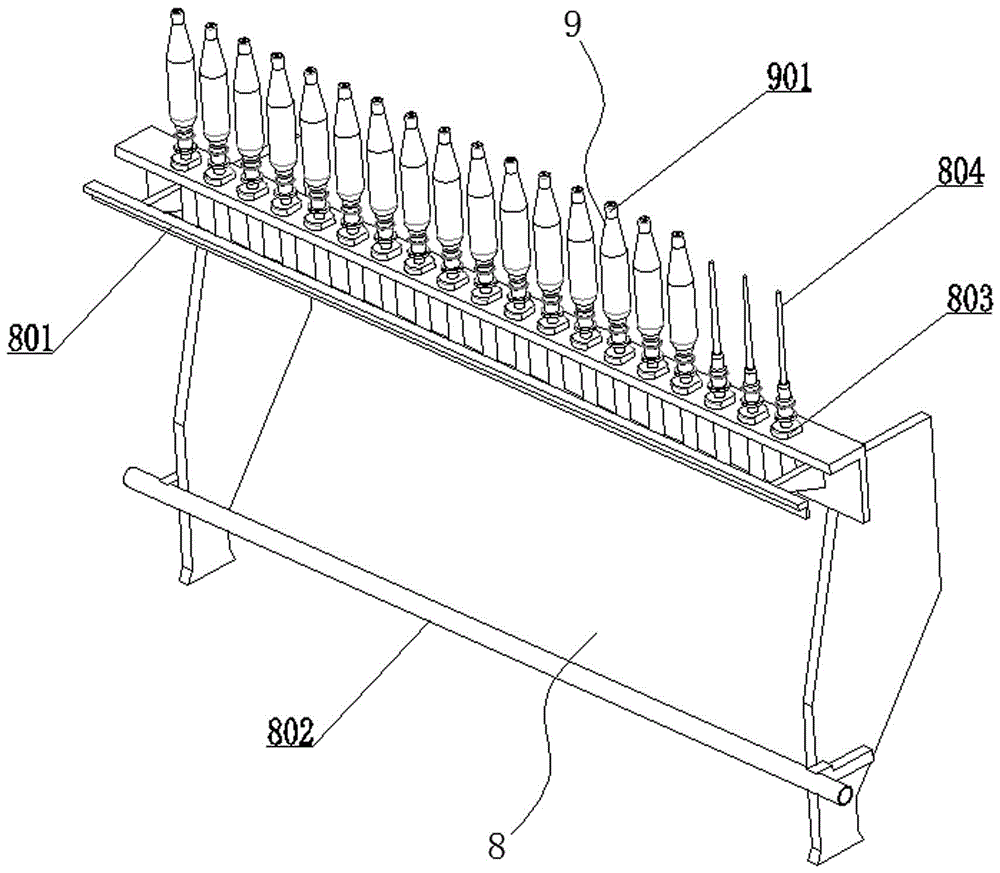

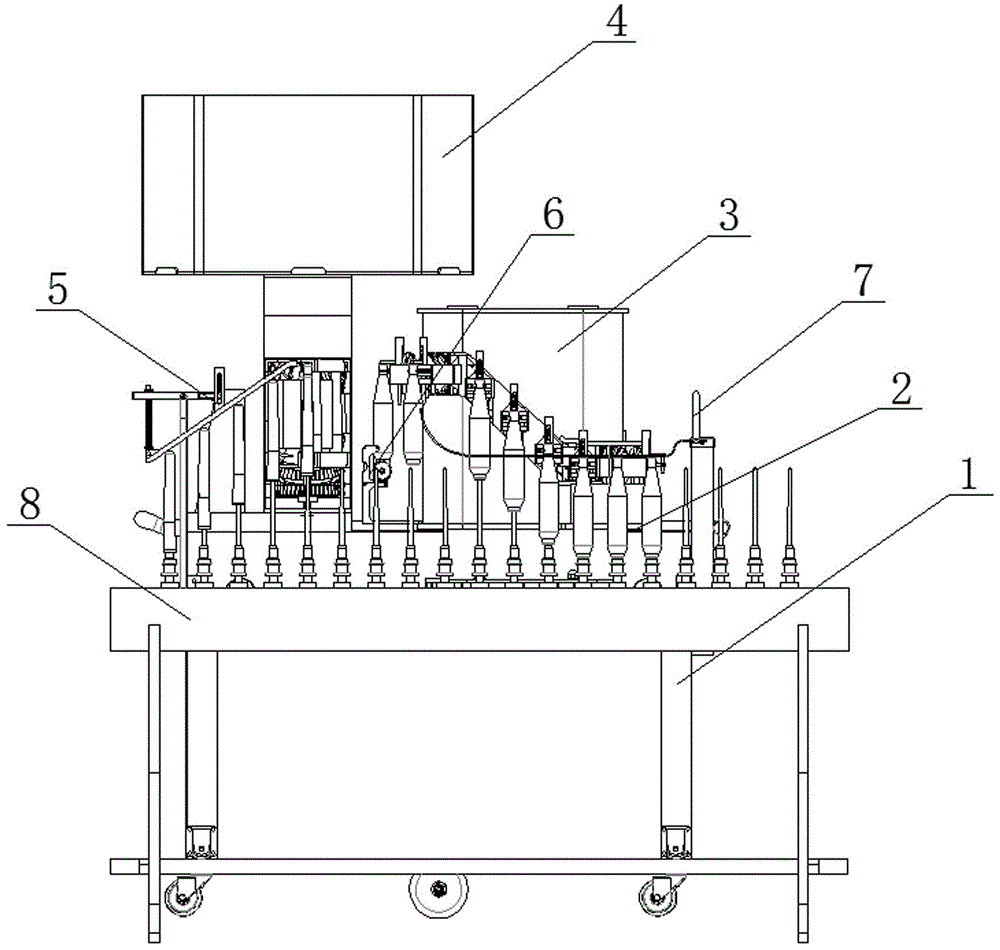

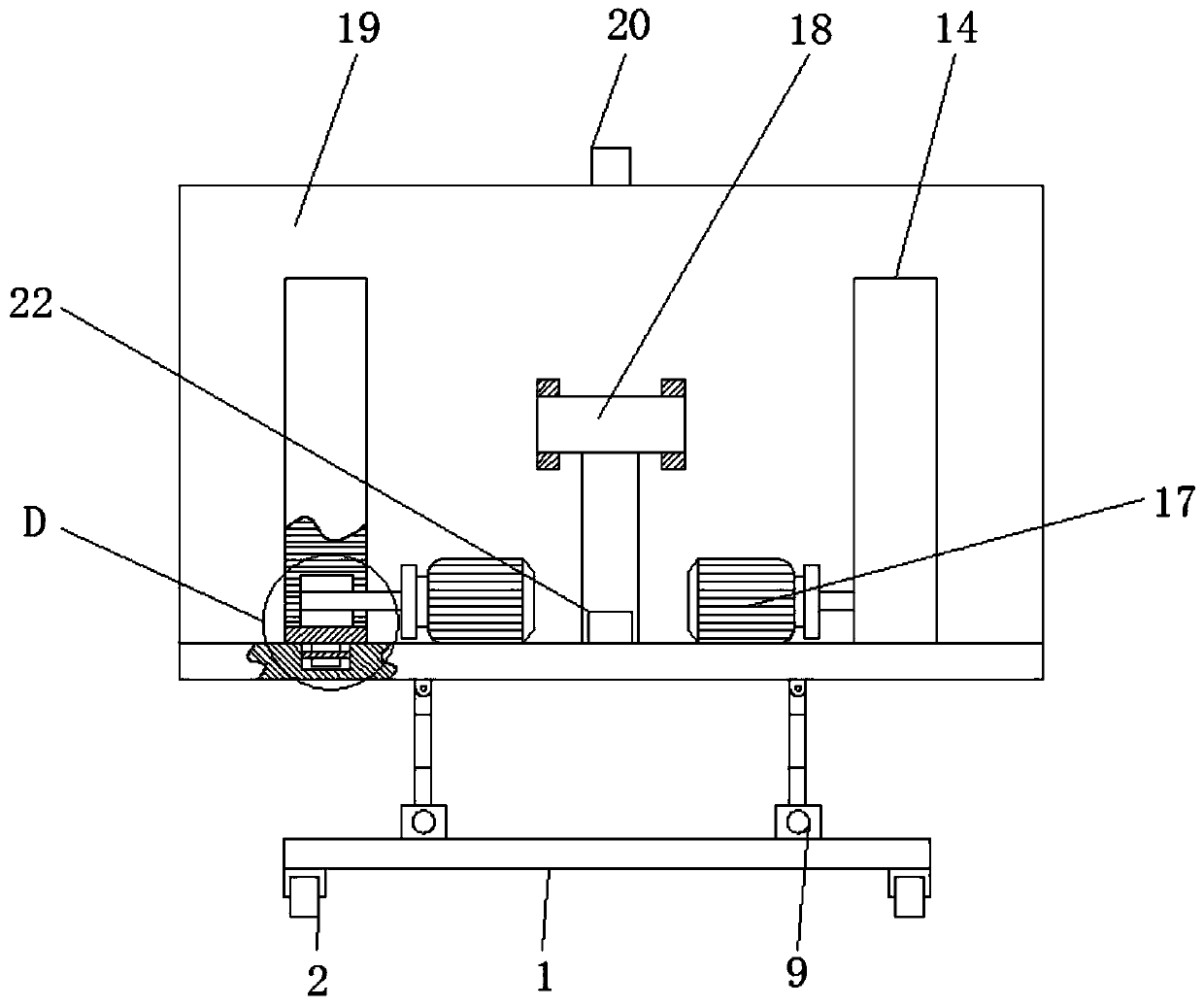

Textile machine with multiple yarn separation roller frames

InactiveCN109292538AHeight adjustableAvoid tangled crossFilament handlingWebs handlingYarnEngineering

The invention discloses a textile machine with multiple yarn separation roller frames, and relates to the technical field of textile machines. The textile machine comprises a stand; the middle part ofthe upper surface of the stand is fixedly connected with the yarn separation roller frames; a yarn feeding roller frame is fixedly connected to one end of the upper surface of the stand; a motor is arranged at the other end of the upper surface of the stand; yarn pressing roller support cylinders are arranged between the yarn separation roller frames and the yarn feeding roller frame; textile needle bases are arranged between the yarn separation roller frames and the motor; lifting devices are fixedly connected to one sides of the upper ends of the yarn pressing roller support cylinders; lifting rods are arranged at the top ends of the yarn pressing roller support cylinders; the top ends of the lifting rods are fixedly connected with fixed columns; rotating drums are rotationally connected to the upper ends in the yarn pressing roller support cylinders; rotating columns are arranged in the lifting devices; and rotating rods are arranged on the rotating columns. The textile machine with multiple yarn separation roller frames can adjust the heights of yarn pressing rollers to tightly press loosened yarns, so that the winding and the crossing of the yarns are prevented, and the textile efficiency is effectively improved.

Owner:湖州练市天龙纺织有限公司

Artificial fiber capable of releasing far infrared ray and process for preparing same

The invention discloses an artificial fiber and preparing method of releasable far-infrared ray, which comprises the following steps: preparing artificial fiber raw material and nanometer particle of releasable far-infrared ray ranged from 4-14 um; blending artificial fiber raw material and nanometer particle; dispersing artificial fiber evenly; preventing yarn spraying hole or outlet from blocking the weaving loom; making water molecular more active in the cell; accelerating blood circulation and metabolism.

Owner:蔡中岳

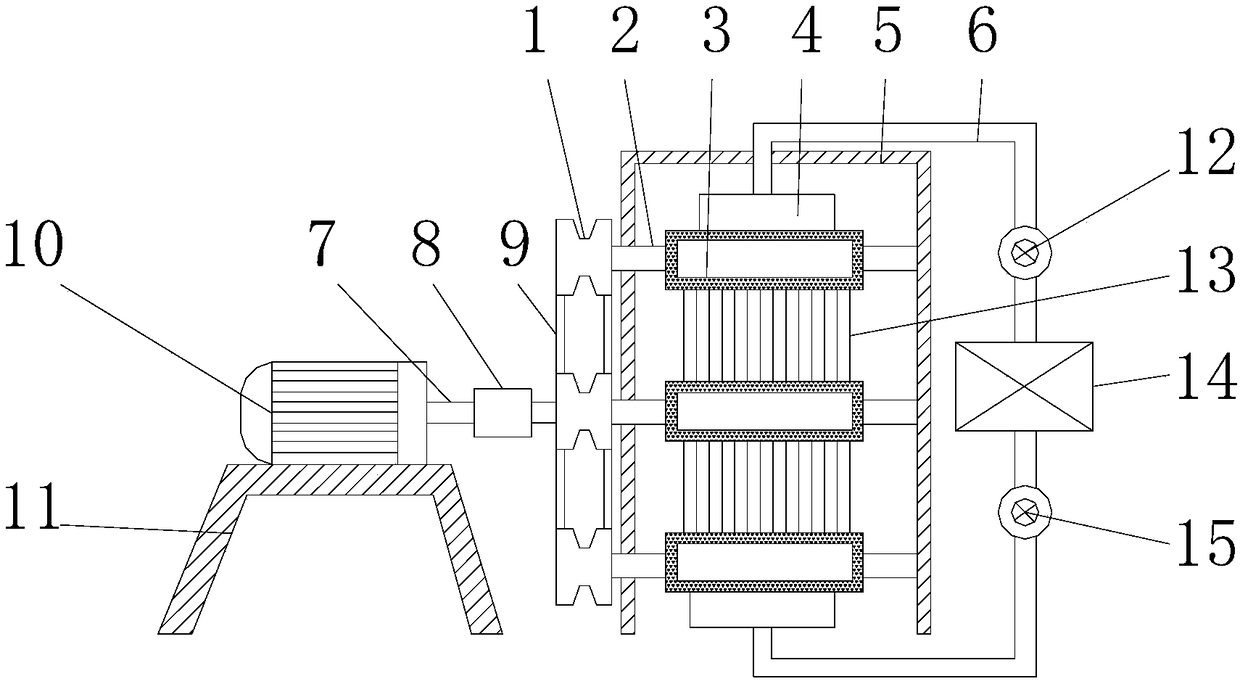

Coating method for DLC (diamond-like carbon) coating on spinning reed and equipment

InactiveCN102534614AImprove performanceExtended service lifeVacuum evaporation coatingSputtering coatingDlc coatingSpinning

The invention discloses a coating method for a DLC (diamond-like carbon) coating on a spinning reed. The coating method comprises the steps of preparing a metal depletion layer through a vacuum sputter coating or multi-arc ion beam technology and preparing the DLC coating through a vacuum ion coating technology. The invention further discloses equipment capable of applying the coating method. The invention has the outstanding effects as follows: the DLC coating is successfully applied to the spinning reed, so as to solve the problem on surface abrasion resistance of the reed and improve the film rigidity of the reed to HV0.025 2500 to 3500; and the DLC coating has the properties of abrasion resistance, corrosion resistance, high binding force and low friction coefficient, thereby effectively improving the property of the reed, prolonging the service life of the reed, improving the spinning efficiency, saving the spinning cost and ensuring the quality of textile products.

Owner:STARARC COATING TECH SUZHOU

Supporting frame for textile machinery

InactiveCN107830316AImprove textile efficiencyHeight adjustablePortable framesLifting framesArchitectural engineeringThreaded rod

The invention relates to the technical field of textile machinery, and discloses a support frame for textile machinery, comprising a base and a support plate, one side of the base is fixedly connected with a push rod, the bottom of the base is fixedly connected with a support leg, and the bottom of the support leg is provided with a Roller, one side of the outrigger is provided with a telescopic rod fixedly connected to the bottom of the base, the bottom of the telescopic rod is fixedly connected with a horizontal plate, the upper surface of the horizontal plate is fixedly connected with a motor, and the output end of the motor is fixedly connected with a threaded rod. The outer surface of the threaded rod is provided with a reducer, and the top of the base is fixedly connected with a frame. The present invention achieves the effect of conveniently adjusting the height of the support frame for textile machinery through the setting of telescopic sleeve rods, horizontal plates, motors, threaded rods, reducers, nuts, load-bearing plates, sliders and chutes, thereby facilitating The use of the bracing frame for the textile machine also improves the use efficiency of the bracing frame for the textile machine, thus improving the weaving efficiency of the textile machine.

Owner:泰兴市长江密封材料有限公司

Bobbin blanking and conveying device of fine spinning doffing machine

The invention relates to a bobbin blanking and conveying device of a fine spinning doffing machine. The bobbin blanking and conveying device of the fine spinning doffing machine is characterized by comprising an upper frustum guide disc mounting base, a lower frustum guide disc mounting base, more than two stages of frustum guide discs, a guide disc transmission shaft, a guide disc transmission gear, a guide disc power input gear, an insert tube power input gear and a bobbin cage, and a fussy bobbin bin does not need to reciprocate and shake the device, so that the influence of the bobbin bin on the doffing machine due to vibration while reciprocating and shaking is completely eradicated, and angular transformation of a bobbin in a controllable state is realized. The bobbin blanking and conveying device rotates into a 90-degree upright state through 'S'-shaped displacement from a 180-degree horizontal position, and by virtue of equal-pitch synchronous displacement of the guide discs and a spindle, the spindle is accurately inserted, so that variable-angle insert tube forms of existing various doffing machines are changed.

Owner:荣德明

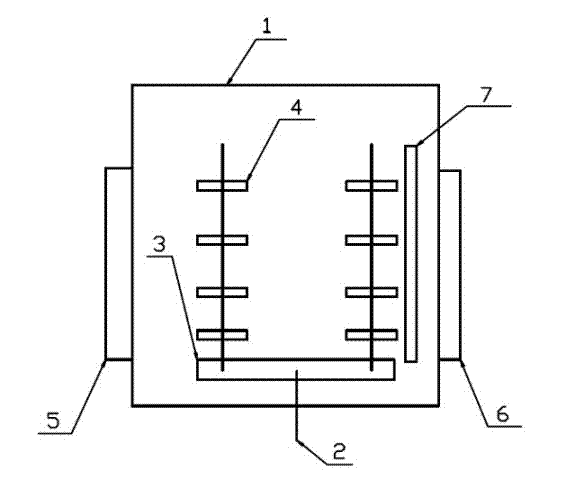

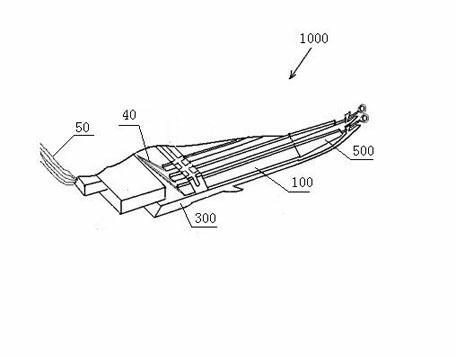

Modularized combined-type melt-spinning filament double-sided air blast cooling device

ActiveCN107190338AUniform cooling effectReal-time observation of working statusFilament/thread formingModular compositionThermal insulation

Disclosed is a modularized combined-type melt-spinning filament double-sided air blast cooling device. The device comprises a box body, a camera mechanism, and an air conditioner air introducing box, wherein fiber air blasting cooling cavities are arranged in the box body from left to right, air cooling cavities are formed corresponding to the left sides and right sides of the fiber air blasting cooling cavities, a thermal insulation bin enclosure frame is arranged at the top of the box body, the area located in the thermal insulation bin enclosure frame is a thermal insulation bin, a detection door is arranged corresponding to the front sides of all the fiber air blasting cooling cavities, and illuminating mechanisms are arranged at the upper portions of the left cavity walls and the right cavity walls of the fiber air blasting cooling cavities; the camera mechanism is arranged on the side, back to the right cavity walls of the fiber air blasting cooling cavities, of the left cavity walls of the fiber air blasting cooling cavities, or the side, back to the left cavity walls of the fiber air blasting cooling cavities, of the right cavity walls of the fiber air blasting cooling cavities, the air conditioner air introducing box is fixed to the box body, the box cavity of the air conditioner air introducing box is communicated with the air cooling cavities, and an air conditioner air inlet pipe at the left end of the air conditioner air introducing box is in pipeline connection with an air conditioner air supplying device. A uniform cooling effect between several strands of single-stranded fiber is guaranteed; the occupied space is saved, and the spinning efficiency is improved; the spinning effect is guaranteed; detection and protection are conveniently conducted.

Owner:CHANGSHU GOLD SPRING CHEM FIBERS & KNITTINGS

Textile sizing agent composition used for polyester fabric as well as preparation method and application of textile sizing agent composition

ActiveCN105755825AImprove wear resistanceStrong buckling resistanceAbrasion resistant fibresPolyesterAcrylonitrile

The invention relates to textile sizing agent composition used for a polyester fabric as well as a preparation method and an application of the textile sizing agent composition. The composition is formed by mixing acrylate composition with nano SiO2 composite modified starch, wherein the acrylate composition consists of (A) a (methyl) acrylate compound selected from one or more of (methyl) acrylate modified silicone oil, alkyl (methyl) acrylate with alkyl with more than 12 carbon atoms and polyalkylene glycol (methyl) acrylate with the number-average molecular weight of more than 400, (B) a (methyl) acrylate compound with ester bonded with alicyclic alkyl with more than 6 carbon atoms, (C) acrylonitrile, (D) a composite initiator and (E) a chain transfer agent; and the nano SiO2 composite modified starch is prepared by acidifying, cross-linking and oxidizing starch, introducing nano SiO2 subjected to surface modification and performing ultrasonic dispersion. The sizing agent is capable of remarkably improving the warp sizing performance and the spinning efficiency, thereby being suitable for warp sizing of the polyester fabric.

Owner:SHANGHAI YONGZI FASHION

Production technology for easily torn cloth with satin weaves

The invention discloses a production technology for easily torn cloth with satin weaves. The production technology comprises the following steps: cationic FDY and cationic DTY are selected for standby application; the cationic DTY serving as warp yarn is soaked in size, taken out and dried; upper and lower parts of the warp yarn are separated, sheds are formed, and the cationic DTY serving as weft yarn is introduced into the sheds formed by the warp yarn; the warp yarn and the weft yarn are subjected to shedding with a textile machine, and the easily torn cloth with the satin weaves is formed. The production technology for the easily torn cloth with the satin weaves adopts a simple preparation method, the cationic FDY with high spinnability, good uniformity and extremely low shrinkage and end breakage rate is taken as the warp yarn and can be wound on a high-speed warping machine, the spinning efficiency is high, an aqueous acetic acid solution is used as slashing size, and the corrosion resistance of the easily torn cloth is improved greatly; the produced easily torn cloth is good in breathability, soft, comfortable, attractive in appearance, convenient to use and low in cost, can be widely applied to various industries, and can be used for treating superficial fungal infection of skin when taken as medical easily torn cloth.

Owner:HUZHOU XINXI FIVE STAR SILK CO LTD

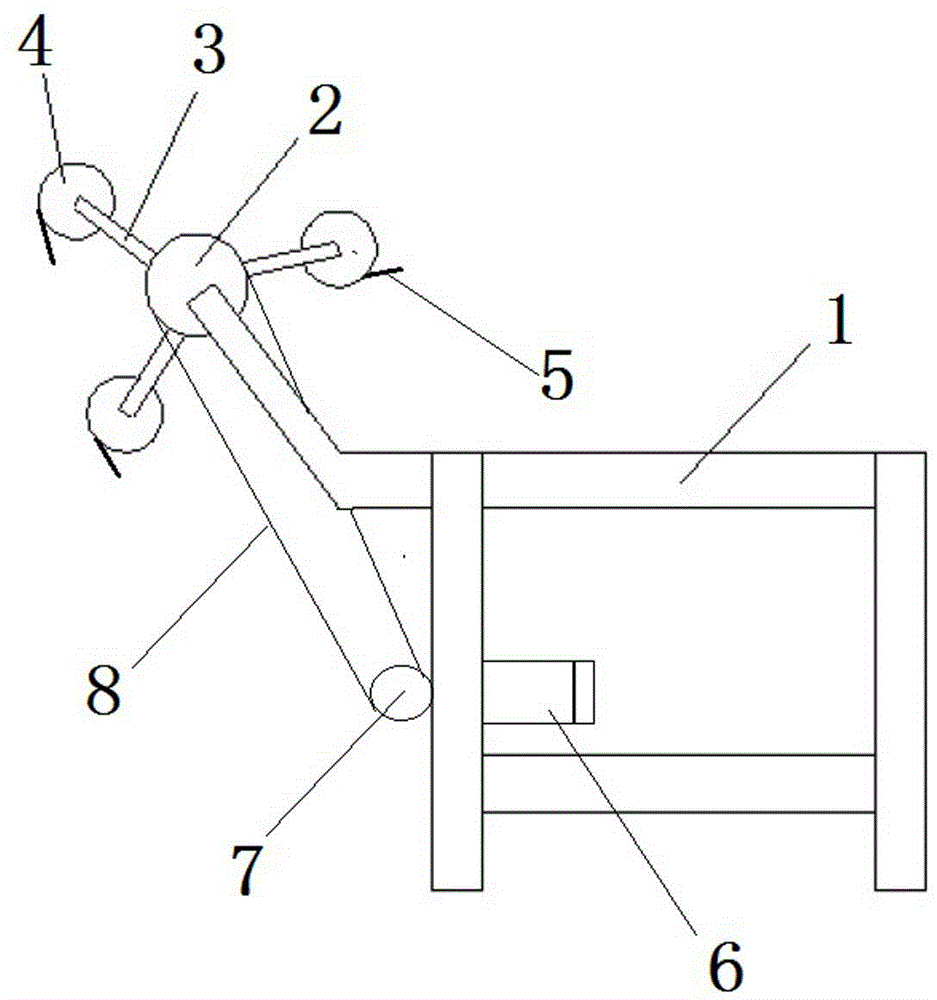

Improved Textile Machine Winding Device

PendingCN106064760ANot easy to go offlineImprove textile efficiencyFilament handlingDrive motorEngineering

The invention discloses an improved winding device for a textile machine, comprising a bracket, an end of the bracket is provided with a motor-driven rotating shaft, and a plurality of supporting arms are arranged on the rotating shaft at uniform intervals along the rotating shaft. A take-up roller is arranged on the take-up roller, a wire fixer is arranged on the take-up roller, a drive motor is installed in the bracket, and the drive shaft of the drive motor is connected with the drive roller, and the drive roller and the rotating shaft are conveyed by a belt Connection, because the winding device of a textile machine of the present invention is provided with a plurality of support arms at uniform intervals along its circumference on the rotating shaft, and the support arms are provided with take-up rollers, which can be used to realize the winding by relying on the rotation of the rotating shaft. The on-line replacement of the rollers does not need to stop the textile machine, and the yarn fixer is used to fix the textile thread when taking up the thread, so that it is not easy to fall off the thread, so the spinning efficiency of the present invention is high.

Owner:王敏

Yarn anti-breaking impurity removal conveying device for textile production

InactiveCN110937456AAvoid breakingImprove textile efficiencyFilament handlingFibre cleaning/openingYarnElectric machinery

The invention discloses the technical field of textile equipment, and provides a yarn anti-breaking impurity removal conveying device for textile production. The yarn anti-breaking impurity removal conveying device for textile production comprises a conveying frame, a yarn feeding assembly comprises a yarn feeding motor fixedly mounted on the bottom of the conveying frame, the output end of the yarn feeding motor is fixedly connected with a yarn feeding shaft, the outer wall of the wire feeding shaft is fixedly connected with a mounting chassis, a damping assembly is arranged on the mounting chassis, the top of the conveying frame is rotatably connected with a detection roller, the outer wall of the yarn feeding shaft is in threaded connection with a pressing disc, a bobbin is arranged between the pressing disc and the mounting chassis, an impurity removal assembly comprises an impurity removal box, material openings are formed in two side walls of the impurity removal box, the lower portions of the material openings are slidingly provided with buffer upper rollers, the side walls of the material openings are fixedly connected with supporting frames, the middles of the supporting frames are rotatably connected with twisting shafts, the outer walls of the twisting shaft are fixedly connected with diagonal bracing frames, a buffer lower roller is rotatably connected between the diagonal bracing frames, and an impurity removal brush is fixedly connected to the middle of the impurity removal box. Yarn breaking is avoided, textile efficiency is improved, the yarn after impurityremoval treatment is lustrous, flat and free of impurity, and the textile quality is improved.

Owner:义乌市煊辉服饰有限公司

Dyeing device for multi-winding-drum textile machine

InactiveCN108217335AImprove textile efficiencyReduce energy consumptionFilament handlingDrive motorTextile yarn

The invention discloses a dyeing device for a multi-winding-drum textile machine. The dyeing device comprises a textile frame, a driving motor is mounted on one side of the textile frame, and a supporting seat is arranged below the driving motor; an output shaft end is fixed to one side of the driving motor and rotatably connected with a driving wheel through a coupling, one side of the driving wheel is connected with textile winding drums through a rotating shaft, and spraying openings are formed in the upper ends and the lower ends of the textile winding drums correspondingly; the spraying openings are connected with a dyeing mechanism through a dyestuff tube, and the dyeing mechanism is arranged on the right side of the textile frame; and a first switch valve and a second switch valve are mounted at the upper end and the lower end of the dyestuff tube correspondingly, a drying device is mounted on the top of the textile frame, and a bearing is mounted at the hinged position of the textile frame and the rotating shaft. According to the dyeing device for the multi-winding-drum textile machine, the textile efficiency can be improved by arranging the multiple sets of winding drums,meanwhile, the dyeing mechanism is equipped, so that drying treatment of textile yarns is convenient, and the practicability of the dyeing device is improved.

Owner:响水县嘉禾纺织制衣有限公司

Yarn breakage detection device, system and detection method

The invention discloses a yarn breakage detection device and system and a detection method. A light-emitting part is arranged on a metal dropper, the outage shutdown function of a loom is reserved, and on the basis, a yarn breakage position can be accurately indicated when yarn is broken. A detection circuit is improved, when the dropper falls and makes contact with a dropper beam to form an electric access, a power supply voltage is switched from high voltage to low voltage, and a stable working voltage is provided for the light-emitting part while shutdown of the loom is not affected. According to the yarn breakage detection system, optical detection is conducted on a light source, the broken yarn is automatically positioned, broken ends of the broken yarn are sucked out through a brokenyarn suction unit, the workload of workers is reduced, and the textile production efficiency is effectively improved; the detection device can be directly and additionally arranged on the existing loom, and the loom does not need to be greatly changed; the implementation cost is relatively low, the idle time of the loom due to shutdown is reduced, and meanwhile, the weaving productivity and the weaving efficiency are improved.

Owner:THE HONG KONG POLYTECHNIC UNIV

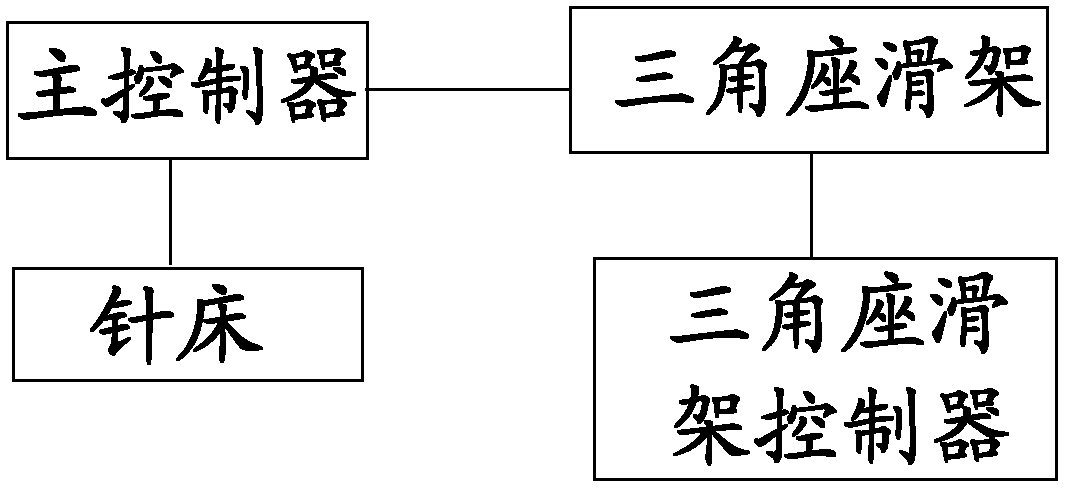

Computerized flat knitting machine knitting control system

The invention relates to the technical field of computerized flat machines, and discloses a computerized flat knitting machine needle selection control system. The system comprises a cam carriage, a master controller, a cam carriage controller and at least one needle bed; the cam carriage controller is used for controlling a needle selection device and a knitting cam of a needle; the master controller is used for controlling the needle bed to move along the movement direction of the cam carriage or the reverse direction while controlling the cam carriage to move and controlling the needles on the needle bed to move front and back; while knitting high-quality knit fabric, the master controller controls the cam carriage to move at constant speed, and controls the needle bed to move along a direction reverse to the movement direction of the cam carriage at constant speed; when a knit tissue changes from a plain knitted fabric into a spiral knitted fabric, the master controller controls the needle bed to move along the movement direction of the cam carriage, or controls the needle bed to do deceleration motion along the direction reverse to the movement direction of the cam carriage.

Owner:浙江汉菲针织机械有限公司

Small-sized textile machine rack

The invention discloses a small-sized textile machine rack. The small-sized textile machine rack comprises a textile chamber; wherein, a wiring shaft is arranged inside the textile chamber; a transmission belt is arranged on a transmission shaft; a main shaft is arranged on one end of the transmission belt; the main shaft is mounted on one end of a motor; wire collecting shafts are installed between the tops of a first bracket and a second bracket; one side of the first bracket is provided with a carrying handle through a first hinge; hinge brackets are respectively arranged at the bottoms of the first bracket and the second bracket; supporting legs are arranged below the hinge brackets through a second hinge; a storage tank is arranged between the supporting legs. The small-sized textile machine rack, disclosed by the invention, is small in overall design; the support legs at the bottom of the rack are connected through the second hinge, so that the support legs can be controlled to fold; the carrying handle is arranged at the one side of the first bracket through the first hinge; according to the design of the rack, the rack can be folded, so that the carrying of the rack is convenient.

Owner:CHANGXING COUNTY DAWEI TEXTILE CO LTD

Linen yarn textile machine frame

InactiveCN107881632AHeight adjustableEasy to useLoomsContinuous wound-up machinesYarnArchitectural engineering

The invention relates to the technical field of textile machinery and discloses a linen yarn textile machine frame. The linen yarn textile machine frame comprises a base and a supporting plate, wherein one side of the base is fixedly connected with a push rod; supporting legs are fixedly connected to the bottom of the base; rollers are arranged at the bottoms of the supporting legs; telescopic loop bars which are fixedly connected to the bottom of the base are arranged on one sides of the supporting legs; transverse plates are fixedly connected to the bottoms of the telescopic loop bars; a motor is fixedly connected to the upper surface of the transverse plates; the output end of the motor is fixedly connected with a threaded rod; a reducer is arranged on the outer surface of the threadedrod; and a frame is fixedly connected to the top of the base. According to the arrangement of the telescopic loop bars, the transverse plates, the motor, the threaded rod, the reducer, nuts, bearing plates, slide blocks and chutes, an effect of conveniently adjusting the height of the linen yarn textile machine frame is achieved, so that convenience is brought to use of the linen yarn textile machine frame. Meanwhile, the service efficiency of the linen yarn textile machine frame is improved, and the textile efficiency of textile machinery is improved.

Owner:盐城金科亚麻纺织有限公司

Anti-knotting textile equipment

InactiveCN108178026AAvoid skewAvoid easy knot problemsFilament handlingFunction indicatorsGear wheelEngineering

The invention discloses anti-knotting textile equipment which comprises a fixed base. The anti-knotting textile equipment further comprises an orienting mechanism, a tensioning mechanism and a windingmechanism which are arranged at the top of the fixed base. The tensioning mechanism comprises a first driving device and guide plates which are vertically installed at the two sides of the top of thefixed base. The guide plates are located at the two sides of the first driving device. A fixing rack capable of moving up and down is installed at the top of the first driving device. A pulley is installed inside the fixing rack in a rotating mode. Two sets of steel wires arranged side by side are wound onto the pulley. One ends of the steel wires are connected to the top of the fixed base. A balanced lifting plate is horizontally arranged among the four guide plates. Two sets of gears are further installed at the two sides of the balanced lifting plate. The sides, close to the balanced lifting plate, of the four guide plates are all provided with vertical racks. The anti-knotting textile equipment is reasonable in design, the tensioning degree of processed textile products can be accurately controlled, different numbers of the textile products can be positioned and adjusted, the guide effect is good, knotting of the textile products can be prevented and the textile quality and efficiency are improved.

Owner:苏州朦井纺织科技有限公司

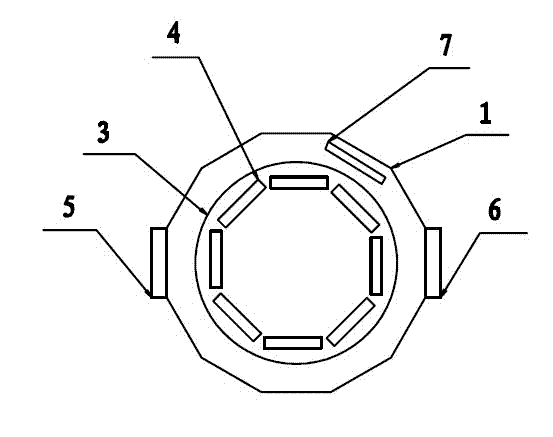

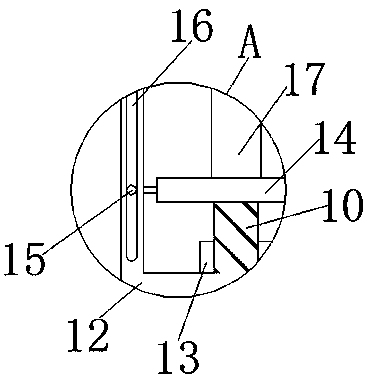

Dual-driving system and driving method of piezoelectric ceramic driving sheet for needle selector

InactiveCN102691164AIncrease swing speedImprove textile efficiency and qualityWeft knittingPiezoelectric/electrostrictive devicesElectric fieldElectricity

The invention relates to a dual-driving system of a piezoelectric ceramic driving sheet for a needle selector. The dual-driving system provided by the invention comprises dual-chip piezoelectric ceramic driving sheets, a base and power supplies. The dual-driving system is characterized in that the power supplies comprise a power supply for providing a positive electric field to one piezoelectric ceramic sheet within a same time period and a power supply for providing a negative electric field to another piezoelectric ceramic sheet, wherein the negative electric field is lower than a coercive electric field of the other piezoelectric ceramic sheet. The invention also provides a driving method of the piezoelectric ceramic driving sheet for the needle selector. The dual-driving system and the driving method thereof provided by the invention have the advantages that when the positive electric field is applied to one piezoelectric ceramic sheet for the piezoelectric ceramic driving sheet, the negative electric field is applied to the other piezoelectric ceramic sheet, so that not only can the swinging strength of the piezoelectric ceramic sheets be increased, but also the applied positive electric field can be lowered appropriately, thus improving and prolonging the safety and the service life of the piezoelectric ceramic sheet applied with the positive electric field.

Owner:芮国林 +1

Automatic cotton yarn spinning machine

The invention discloses an automatic cotton yarn spinning machine. The automatic cotton yarn spinning machine comprises a spinning machine body and a base, the base comprises a base plate, a support plate and a mounting plate, multiple symmetrically distributed universal wheels are arranged at the bottom of the base plate, multiple symmetrically distributed first hydraulic cylinders are arranged on the top of the base plate, first telescopic rods are connected to the tops of the first hydraulic cylinders, the support plate is arranged on the tops of the first telescopic rods, multiple uniformly distributed first support columns and second support columns are arranged on the top of the support plate, the second support columns are arranged on the inner sides of the first support columns, the mounting plate is connected to the tops of the first support columns, the spinning machine body is fixed to the top of the mounting plate, and a dust collection device is arranged on the spinning machine body. The automatic cotton yarn spinning machine is simple in structure and has the good damping effect; meanwhile, dust generated when the spinning machine works can be reduced, the dust collection effect is good, and the spinning efficiency and the product quality are improved.

Owner:SUZHOU MEILU TEXTILE MASCH ELECTRONICS CO LTD

Textile mechanical device being convenient to move

The invention discloses a textile mechanical device being convenient to move. The textile mechanical device comprises a roller and circular discs and the like. The roller is arranged between the two circular discs. Rotating wheels are connected with the circular discs; and a support frame is arranged at the rotating wheels. An indication light is arranged at the right side of the support frame; and the support frame and a work bench are fixed by reinforcing plates. Screws are arranged on the reinforcing plates; and a motor is arranged at the lower part of the work bench. An operation panel isarranged at one side of the work bench; control buttons are arranged at the lower part of the operation panel; a waste port is formed at one side of the control buttons; and a textile rolling shaft isarranged below the waste port and is arranged at the left side of the control buttons. A bending plate is arranged below the work bench at one side of the textile rolling shaft; and a mobile base isarranged below the textile rolling shaft. The textile mechanical device is convenient to move; the textile efficiency is improved; the silk thread quality is improved; and the finished textile products can be stored temporarily.

Owner:苏州陆创纺织有限公司

Worsted doffing machine

The invention relates to a worsted doffing machine. The worsted doffing machine comprises a rack moving trolley, an electrical equipment control box, an inserting and drawing tube positioning power device, a tube drawing device, a pipe inserting device, a yarn pressing device, a chopping composite yarn cutting device and a pipe pressing device. After corresponding, vertical and parallel positioning with a fine spinning machine spindle blade inserting and drawing station is completed on a trolley box through a spindle pitch positioning device, a walking support device and a walking parallel positioning device, a trolley walking driving device is driven to travel along an upper creel and a lower creel of a fine spinning machine, by combining the condition that a crawler-type positioning driving belt is meshed with each ingot phase of the fine spinning machine, feeding is conducted along a fine spinning machine track, and meanwhile integrated operation of tube drawing, tube inserting, yarn pressing, yarn cutting and tube pressing corresponding to the yarn pressing device, the tube drawing device, the chopping composite yarn cutting device, the tube inserting device and the tube pressing device corresponding to each spindle blade is accurately controlled.

Owner:荣德明

Winding device for weaving machine

InactiveCN102505293ARealize online replacementImprove textile efficiencyLoomsEngineeringMechanical engineering

The invention discloses a winding device for a weaving machine. The winding device comprises a bracket, wherein a rotating shaft driven by a motor is arranged at the end of the bracket. The winding device is characterized in that: a plurality of supporting arms are uniformly arranged on the rotating shaft along the circumferential direction at intervals; and a winding roller is arranged on each supporting arm. The winding device is high in weaving efficiency.

Owner:WUJIANG KESHIDA TEXTILE

Tube drawing device of spinning doffer

The invention relates to a tube drawing device of a spinning doffer. The tube drawing device comprises a tube drawing frame assembly, a tube drawing power transmission assembly and a mechanical arm grabbing and interlocking force eliminating assembly. The tube drawing device has the advantages that the whole tube drawing process adopts a pure mechanical mode, each working node is reliable in operation action, accurate in beat, small in size and lightweight, and transformation of an existing spinning frame structure is not needed; the tube drawing device is small in power load, fast tube drawing using a single motor or using manual trolley pushing without a motor can be performed, and damage-free doffing of bobbins and spindles can be achieved.

Owner:荣德明

Slurry composition used for spinning, and preparation method and application thereof

ActiveCN105908503AImprove wear resistanceImprove sizing effectAbrasion resistant fibresMethyl groupSulfonic acid ester

The invention relates to a slurry composition used for spinning, and a preparation method and application thereof. The composition is prepared in a way that an acrylic ester composition and nanometer SiO2 compound modified starch are mixed, wherein the acrylic ester composition is prepared from (A), (B), (C), (D) and (E); the (A) is (methyl) acrylate which are selected from (methyl) acrylate modified silicone oil, alkyl (methyl) acrylate having an alkyl of which the carbon number is 12 or above, and poly alkylene glycol alkyl (methyl) acrylate of which the number-average molecular weight is 400 or above, (B) is (methyl) acrylic compound which is subjected to ester bonding with alicyclic ring hydrocarbyl of which the carbon number is 6 or above, (C) is methacrylic acid-2-sulfonic acid ethyl ester, (D) is composite initiator and (E) is chain transfer agent; the nanometer SiO2 compound modified starch is prepared in a way that starch is subjected to acidification, crosslinking, oxidization, and the introduction of nanoscale SiO2 subjected to surface modification and ultrasonic dispersion. The slurry can obviously improve warp sizing performance and improve spinning efficiency, and can be widely suitable for the warp sizing of pure cotton, terylene, fiber and blended yarn.

Owner:江苏品源知识产权运营有限公司

Intelligent machine capable of conveniently and automatically replacing telescopic arm

InactiveCN106958097AAvoid separationEasy to separateAuxillary devicesArchitectural engineeringIntelligent machine

The invention discloses an intelligent machine for convenient and automatic replacement of telescopic arms, comprising a first telescopic arm body and a second telescopic arm body, the second telescopic arm body is located on the right side of the first telescopic arm body, and the first telescopic arm body is located on the right side of the first telescopic arm body. A connecting block 1 is fixedly connected to the right end of the arm body, and a connecting block 2 matching the connecting block 1 is fixedly connected to the left side of the second telescopic arm body. The present invention achieves the effect of cooperating with the receiving block 2 to support the connecting rod 2 by setting the connecting rod 1, and can fix the connecting block 1 and the connecting block 2 together through the cooperation of the blocking rod 1 and the clamping block 1, preventing the connecting block 1 from The second connecting block is separated, and because of the simple structure, the stopper rod one can be quickly separated from the clamping block one, thereby facilitating the separation of the connecting block one and the second connecting block, thereby facilitating the replacement of the first telescopic arm and the second telescopic arm, improving the replacement The efficiency of the first telescopic arm and the second telescopic arm thus indirectly improves the efficiency of weaving.

Owner:浙江高派机器人科技有限公司

Sizing agent composition for ramie fabric and preparing method and application thereof

ActiveCN105926289AImprove wear resistanceStrong buckling resistanceGrip property fibresAbrasion resistant fibresPolymer scienceMethyl group

The invention relates to a sizing agent composition for ramie fabric and a preparing method and application thereof. The composition is formed by mixing an acrylic ester composition and nanometer SiO2 composite modified starch. The acrylic ester composition is composed of one or more (methyl) acrylic ester compounds (A) selected from (methyl) acrylic ester modified silicone oil, alkyl (methyl) acrylic ester provided with alkyl with the number of carbon atoms being over 12, and poly alkylene (diol) (methyl) acrylic ester with the number-average molecular weight being over 400, a (methyl) acrylic ester compound (B) in ester linkage with alicyclic alkyl with the number of carbon atoms being over 6, methacrylic acid-2-sulfoacid ethyl ester (C), a composite initiator (D) and a chain transfer agent (E). The nanometer SiO2 composite modified starch is prepared in the mode that the starch is subjected to acidification, cross linking and oxidation, nanoscale SiO2 subjected to surface modification is introduced, and then ultrasonic dispersion is carried out. The sizing agent can improve the warp sizing performance obviously and improve spinning efficiency, and is suitable for warp sizing of the ramie fabric.

Owner:江苏品源知识产权运营有限公司

Mechanical hand grabbing and interlocking force eliminating combined device of spinning doffer

The invention relates to a mechanical hand grabbing and interlocking force eliminating combined device of a spinning doffer. The mechanical hand grabbing and interlocking force eliminating combined device is characterized by comprising a mechanical hand grabbing device and an interlocking force eliminating device, a pure mechanical mode is adopted in the whole bobbin drawing process, operation of all worknodes is reliable in action and accurate in rhythm, the combined device is small in size and light in weight, and an existing spinning structure does not need to be improved. Power load is small, a cart can be pushed with a single motor or pushed manually without a motor to fast draw a bobbin, and doffing is achieved without damage to the bobbin or a spindle.

Owner:荣德明

Automatic light-chasing cloth airing device for spinning

ActiveCN110849092AMobile and flexibleEasy to operateDrying chambers/containersDrying solid materialsBevel gearTextile technology

The invention relates to the technical field of spinning, and discloses an automatic light-chasing cloth airing device for spinning. The automatic light-chasing cloth airing device comprises a base. Universal wheels are fixedly connected with the four corners of the bottom of the base. Slide grooves are formed in the top of the base. A first slider is slidingly connected into each slide groove. Alifting rod is hinged and connected to the top of each first slider. A helical tooth rod is fixedly connected with the outer portion of each first slider. The top of each helical tooth rod is meshed and connected with a bevel gear. An adjusting shaft is fixedly connected into each bevel gear. A shell is movably connected with the outer portion of each adjusting shaft. A rotary knob is fixedly connected with the outer portion of each adjusting shaft. A second slider is hinged and connected to the top of each lifting rod. An installing plate is slidingly connected with the outer portions of thesecond sliders. By means of the universal wheels, the position of the airing device can be conveniently and effectively adjusted at any time, the airing device is flexible to move and easy to operate,and the flexibility of the airing device is increased.

Owner:SUZHOU WANG YONGHENG SILK SCI & TECH CULTURE CO LTD

Spinning sizing agent composition and preparing method and application thereof

ActiveCN105926288AImprove wear resistanceStrong buckling resistanceGrip property fibresAbrasion resistant fibresMethacrylateFiber

The invention relates to a spinning sizing agent composition and a preparing method and application thereof. The composition is prepared by mixing an acrylate composition and a nanometer SiO2 composite modified starch, wherein the acrylate composition is prepared from a (methyl) acrylate compound selected from one or more of (methyl) acrylate-modified silicone oil, alkyl (methyl) acrylate with alkyl with the number of carbon atoms being 12 or above and poly alkylene glycol (methyl) acrylate with the number-average molecular weight being 400 or above, a (methyl) acrylate compound in ester linkage with alicyclic alkyl with the number of carbon atoms being 6 or above, acrylonitrile, a composite initiator and a chain transfer agent, and the nanometer SiO2 composite modified starch is obtained by carrying out acidification, cross-linking and oxidation on starch, introducing surface-modified nano-scale SiO2 and then carrying out ultrasonic dispersing. The sizing agent can remarkably improve the sizing performance of warp yarns and the spinning efficiency and can be widely applied to sizing of warp yarns made of pure cotton, polyamide, fibers and blended yarns.

Owner:青岛纺友纺织科技股份有限公司

Pipe inserting and pulling positioning power device of fine-spinning doffing machine

The invention relates to a pipe inserting and pulling positioning power device of a fine-spinning servo doffing machine. The pipe inserting and pulling positioning power device comprises a positioning movable connecting base, a curved rolling wheel bearing, a crawler-type positioning transmission belt, a pipe pulling power belt wheel, a pipe pulling power main transmission shaft, a pipe inserting power driving belt wheel, a tooth-shaped transmission belt, a pipe inserting power driven belt wheel, a pipe inserting power transmission shaft, a crawler-type positioning linear motor, a crawler-type positioning linear motor fixing seat, a crawler-type positioning linear motor driving fixing seat, a linear sliding rod, a linear sliding rod fixing seat and a linear sliding rod bearing; the crawler-type positioning transmission belt is engaged with each spindle of a fine spinning machine; and the device is used for feeding along a rail of the fine spinning machine and subsequent pipe inserting and pulling power is provided for each corresponding spindle rod through accurate control.

Owner:荣德明

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com