Slurry composition used for spinning, and preparation method and application thereof

A composition and slurry technology, applied in textiles and papermaking, abrasion-resistant fibers, fiber types, etc., can solve problems such as difficulty in operation, inconvenience in industrial production, and small laboratory tests, and achieve good permeability and improved Sizing performance, good water solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

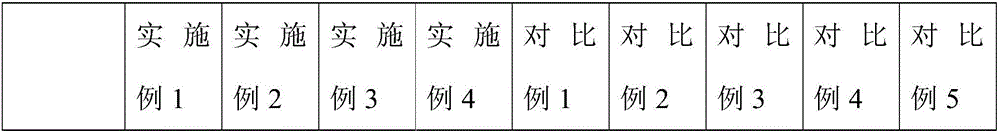

Examples

Embodiment 1

[0044] (1) Preparation of solid acrylate:

[0045] Add 100kg of hydrogenated polybutadiene di(meth)acrylate, 150kg of 1-adamantane (meth)acrylate and 250kg of methacrylic acid-2-ethyl sulfonate into the head tank, stir evenly and set aside;

[0046] Add 200kg of xylene, 100kg of cyclohexane, and 100kg of absolute ethanol to a 1000L high-level tank with stirring, mix well, weigh 5.6kg of benzoyl peroxide and 2.8kg of azobisisobutyronitrile and put them into the high-level tank respectively, and stir Uniform spare;

[0047] Add 1400kg of toluene, 700kg of cyclohexane, and 700kg of absolute ethanol in sequence to a 5000L glass-lined reactor equipped with a reflux condenser and mix them uniformly as a reaction solvent, then add 0.4kg of n-dodecanethiol and stir evenly, and heat up to 95°C , Add the monomers and initiators in the above two elevated tanks dropwise into the 5000L reaction kettle at the same time, and the dropwise addition is completed within 3 hours. After stirring...

Embodiment 2

[0053] (1) Preparation of solid acrylate:

[0054] Add 200kg of hydrogenated polybutadiene di(meth)acrylate, 100kg of 1-adamantane (meth)acrylate and 200kg of methacrylic acid-2-ethyl sulfonate into the head tank, stir evenly for later use;

[0055] Add 200kg of xylene, 100kg of cyclohexane, and 100kg of absolute ethanol to a 1000L high-level tank with stirring, mix well, weigh 5.6kg of benzoyl peroxide and 2.8kg of azobisisobutyronitrile and put them into the high-level tank respectively, and stir Uniform spare;

[0056] Add 1400kg of toluene, 700kg of cyclohexane, and 700kg of absolute ethanol in sequence to a 5000L glass-lined reactor equipped with a reflux condenser and mix them uniformly as a reaction solvent, then add 0.4kg of n-dodecanethiol and stir evenly, and heat up to 95°C , Add the monomers and initiators in the above two elevated tanks dropwise into the 5000L reaction kettle at the same time, and the dropwise addition is completed within 3 hours. After stirring...

Embodiment 3

[0062] (1) Preparation of solid acrylate:

[0063] Add 120kg hydrogenated polyisoprene di(meth)acrylate, 170kg norbornyl (meth)acrylate and 210kg methacrylic acid-2-ethyl sulfonate into the head tank, stir evenly for subsequent use;

[0064] Add 200kg of xylene, 100kg of cyclohexane, and 100kg of absolute ethanol to a 1000L high-level tank with stirring, mix well, weigh 5.6kg of benzoyl peroxide and 2.8kg of azobisisobutyronitrile and put them into the high-level tank respectively, and stir Uniform spare;

[0065]Add 1400kg of toluene, 700kg of cyclohexane, and 700kg of absolute ethanol in sequence to a 5000L glass-lined reactor equipped with a reflux condenser and mix them uniformly as a reaction solvent, then add 0.4kg of n-dodecanethiol and stir evenly, and heat up to 95°C , Add the monomers and initiators in the above two elevated tanks dropwise into the 5000L reaction kettle at the same time, and the dropwise addition is completed within 3 hours. After stirring for 0.5h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com