Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

87results about How to "Improve shelling effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Water-base paint specially for disappearing cast mold

InactiveCN1375365AGood paintabilityGood variable characteristicsFoundry mouldsFoundry coresBrown iron oxideEmulsion

The water-base dissolving mould casting special-purpose coating is formed from 700-850 portions of alumina, 150-300 portions of diatomaceous earth, 20-30 portions of bentonite, 0.5-2.,0 portions of industrial sodium carbonate, 5-15 portions of cellulose sodium, 30-40 portions of white emulsion, 10-20 portions of aluminium sulfate, 20-30 portions of iron oxide, 20-30 portions of starch, 0.1-0.2 portion of washing powder and 700-800 portions of water. Said coating possesses good imbibition property, good transmutation and flowability, uniform coating layer, high strength and other advantages.

Owner:黄述哲 +2

Method for preparing casting shell of fired mold

InactiveCN105414485AShorten roasting timeLow firing temperatureFoundry mouldsFoundry coresSurface layerNanotechnology

The invention discloses a method for preparing a casting shell of a fire mold. The method comprises a surface layer preparing step, a transition layer preparing step, a back layer preparing step, a dewaxing step and a roasting step. According to the method for preparing the casting shell of the fire mold, the roasting time of the shell is shortened, the roasting temperature of the shell is reduced, and energy can be saved; and the residue strength of the shell is reduced, the shell removing performance of the shell is improved, cleaning of the shell after casting is facilitated, and the production efficiency is improved.

Owner:HUZHOU NANFENG MACHINERY MFG

Kneading type peanut quick hulling device

InactiveCN107997194AFully shelledImprove shelling effectHuskingHullingMechanical engineeringEngineering

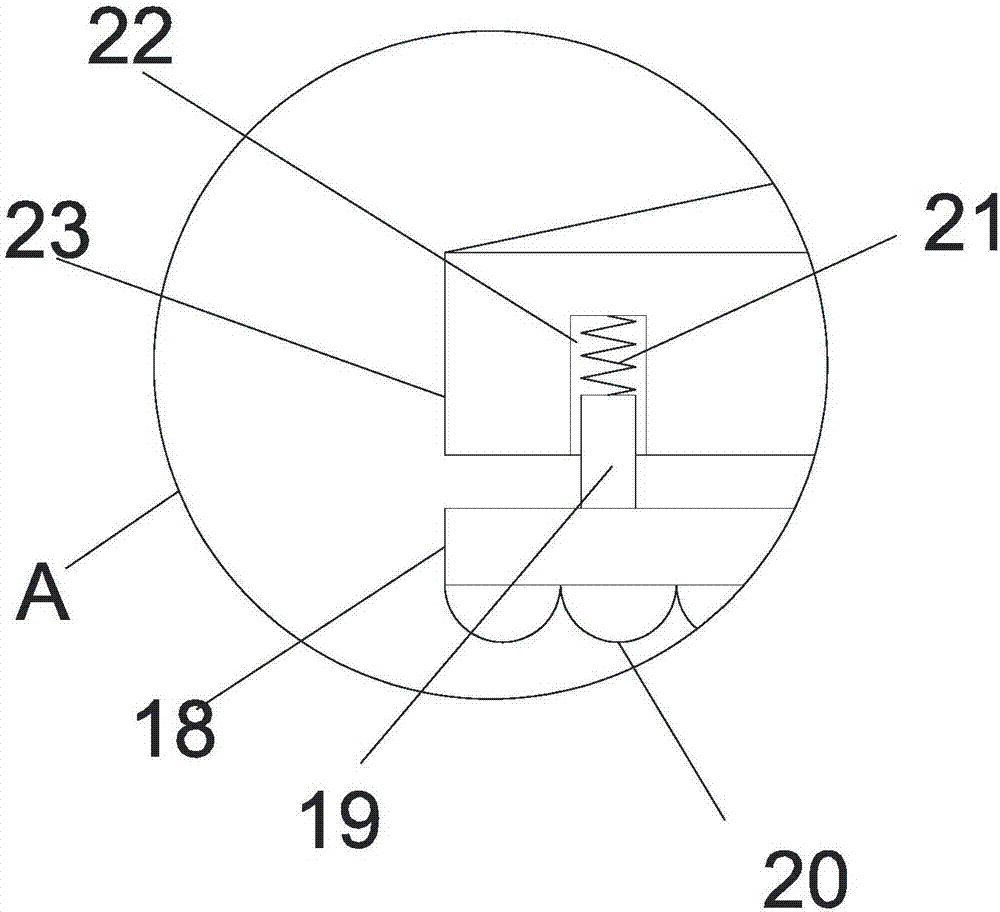

The invention discloses a kneading type peanut quick hulling device. The kneading type peanut quick hulling device comprises a frame, wherein a hulling groove is formed in the frame; a rotating motoris fixedly mounted on the frame; a driving belt wheel is coaxially and fixedly mounted on a driving rotating wheel, and a driven belt wheel is coaxially and fixedly mounted on a driven rotating wheel;a transmission belt is connected to the driving belt wheel and the driven belt wheel in a sleeving manner; a limiting sleeve is vertically and fixedly mounted at the bottom of the frame; and feedingpipes which are located directly over the hulling groove are vertically mounted on the frame. According to the kneading type peanut quick hulling device disclosed by the invention, through the combined motion of left-and-right motion and up-and-down motion of the hulling groove, the purpose that peanuts in the hulling groove are driven to perform kneading and hulling is realized; besides, a hulling pressing plate rotates, so that the hulling effect of the peanuts is further promoted; through the combined motions of the hulling grooves, the purpose that the peanuts are uniformly laid in the hulling groove is realized, so that the hulling of the peanuts is more comprehensive and sufficient; and in the hulling process, a sliding shaft slides up and down, and a sliding cavity is deformed to extend and compress, so that a good buffering and damping effect can be achieved on the hulling pressing plate, the hulling smoothness of the peanuts is improved, and the hulling quality is improved.

Owner:ZHENGZHOU SOUQU INFORMATION TECH CO LTD

High-efficiency peanut shelling device

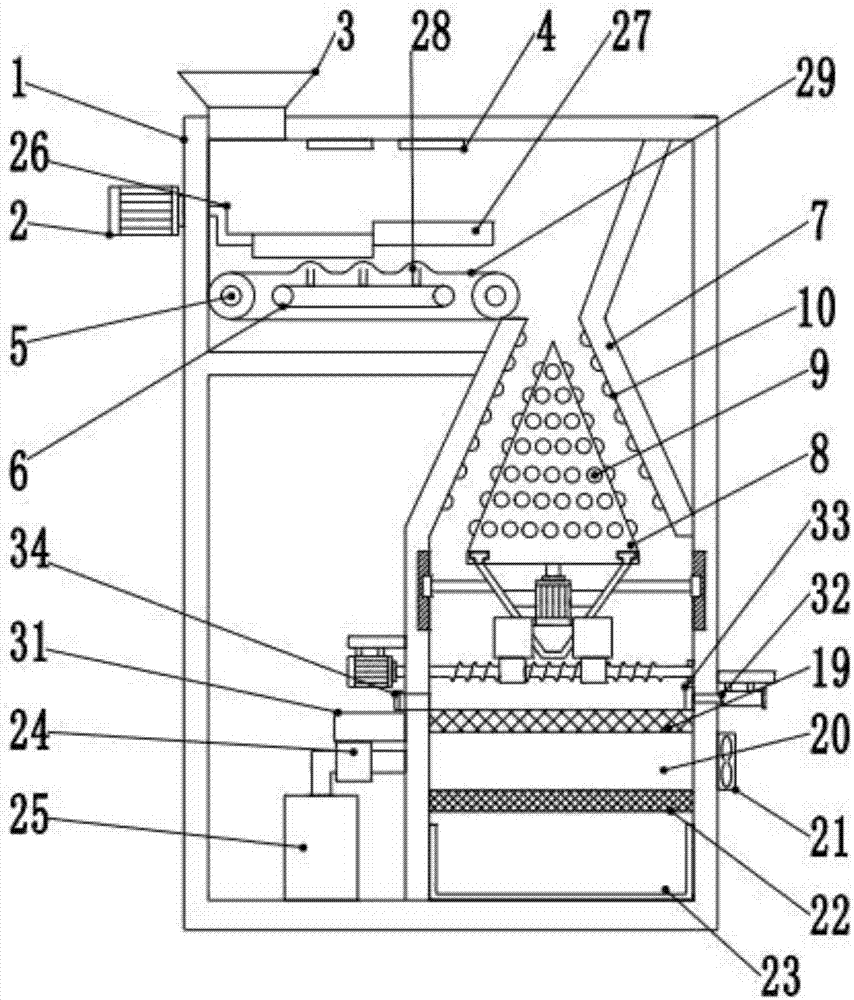

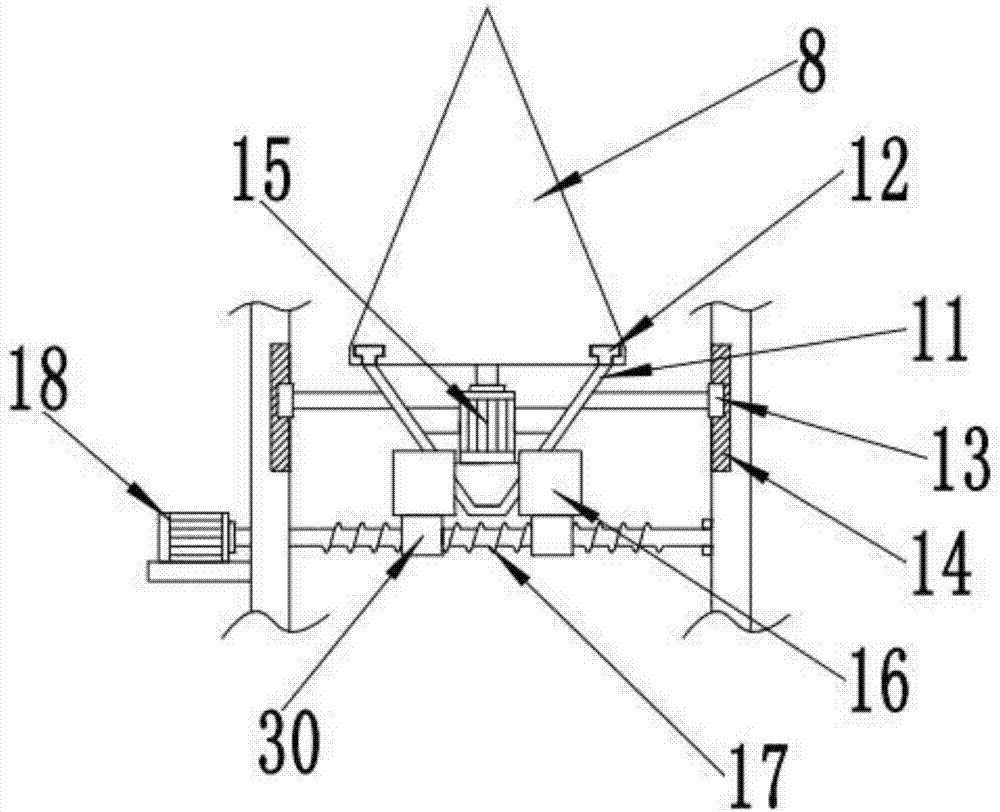

InactiveCN107692250AImprove shelling effectImprove shelling efficiencyHuskingHullingAgricultural engineeringThreaded rod

The invention discloses a high-efficiency peanut shelling device, which comprises a shell, a feeding hopper, a drying mechanism, a shelling mechanism, a screening mechanism and a collecting tank; a feeding hopper is arranged at the upper end of the shell, and a drying mechanism is arranged under the feeding hopper The lower end of the drying mechanism is provided with a shelling mechanism, and the shelling mechanism includes a shelling chamber, a tapered roller, a raised block A, a raised block B, a tapered groove, an extrusion block, a forward and reverse motor, a slider, Threaded rod and fixed block. A screening mechanism is arranged below the shelling mechanism, and the screening mechanism includes a first filter screen, a filter cavity, a blower, a second filter screen, a suction fan, a waste shell box, an electric telescopic rod, a push plate and a recovery chamber, and the lower end of the shelling mechanism A first filter is provided. The invention has simple mechanism and convenient operation, improves the peanut shelling efficiency, realizes the separation of peanut grains and peanut shells, and greatly reduces labor force.

Owner:郑州味觉信息技术有限公司

Complete flow line production process for barley rice

InactiveCN103223361AImprove shelling effectImprove integrityGrain huskingGrain polishingBreakage rateImpurity

The invention discloses a complete flow line production process for barley rice. The complete flow line production process comprises the steps as follows: grading and unshelling; cooling; carrying out six-stage polishing; removing impurities; washing and spin-drying; sorting; carrying out size grading; carrying out color sorting and impurity removal; air-drying; and packaging. The complete flow line production process has the benefits as follows: the grading operation is carried out before the unshelling process, so that the unshelling effect of the barley rice is greatly improved, the breakage rate is reduced from 20% in the traditional processing mode of non impurity removal and grading to about 7% after impurity removal and grading, and the completeness of the barley rice is improved by 13%; the six-stage polishing process is adopted, so that the finish machining level of the barley rice is increased; and meanwhile, the whole process can be finished by 12 persons only in the flow line operation, so that the manpower is greatly saved and the production cost is reduced.

Owner:XINGREN HIGH QUALITY AGRI FINISHING DEV

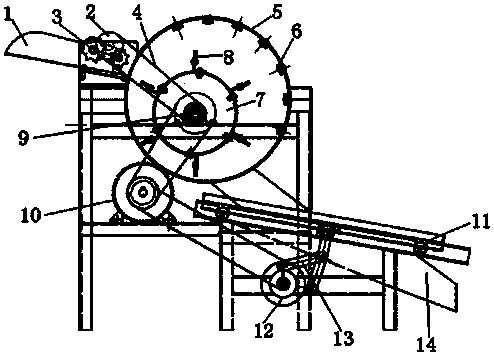

Sunflower seed shelling packaging machine

PendingCN109383863ACompact structureReasonable designWrapping material feeding apparatusWrapper twisting/gatheringEngineeringPackaging machine

The invention discloses a sunflower seed shelling packaging machine. The sunflower seed shelling packaging machine comprises a rack, wherein the rack is integrated with a shelling device and a packaging device, the shelling device comprises a box body, a scraping plate assembly and a half grid cage, the scraping plate assembly and the half grid cage are arranged in the box body, the scraping plateassembly is rotationally arranged above the half grid cage, a sunflower seed shell collection box communicated with the external portion of the box body and arranged inwards obliquely is arranged under the half grid cage, the portion, corresponding to the sunflower seed shell collection box, on the box body is provided with a first draught fan for blowing wind to the sunflower seed shell collection box, the lower portion of the inner side of the sunflower seed shell collection box is provided with a sunflower seed kernel collection plate used for collecting sunflower seed kernels, and the sunflower seed kernel collection plate is connected and communicated with the packaging device through a material guide funnel. The sunflower seed shelling packaging machine has the advantages that the structure is compact, the design is reasonable, shelling of sunflower seeds is integrated with packaging of the sunflower seeds, the processing efficiency is greatly improved, the labor intensity is reduced, the labor cost is reduced, and the sunflower seed shelling packaging machine is suitable for production and processing of large-batch sunflower seeds.

Owner:WUZHOU UNIV

Shell removing equipment for moso bamboo shoots

The invention provides shell removing equipment for moso bamboo shoots and relates to the field of agricultural products. The shell removing equipment for moso bamboo shoots comprises a semicircular barrel, wherein a slide rail groove is formed in the inner wall of the semicircular barrel, the left side of the semicircular barrel is fixedly connected with a fixing block, a tip connecting device isarranged on the fixing block, a tip shell removing device is arranged on the tip connecting device, a shell removing device is arranged in the semicircular barrel and located on the right side of thetip shell removing device, the right side of the semicircular barrel is fixedly connected with a fixing plate, a drive device is arranged at the back of the fixing plate, a rotating conveying deviceis connected onto the drive device. According to the shell removing equipment for moso bamboo shoots, a driving tooth disc rotates to drive bamboo shoots on a fixing stick to rotate, the bamboo shootscan be rotated, removing nails are contacted with outer shells of the bamboo shoots, the shell removal operation of bamboo shoots can be facilitated, and the shell removing effect of the bamboo shoots can be improved.

Owner:湖南金竹笋农业发展股份有限公司

Walnut shelling equipment

The invention relates to the field of food processing, and in particular relates to walnut shelling equipment, comprising a frame, a telescopic cylinder, a material filling bucket, a shell breaking mechanism and a shell removing mechanism, wherein the shell breaking mechanism comprises a shell breaking block, a shell breaking rod and a push-and-pull cylinder; the shell breaking block is hinged onto the frame; the telescopic cylinder is hinged with the shell breaking block; a channel is arranged in an inclined mode in the shell breaking block, the bottom of the channel is vertically arranged, the outlet diameter of the channel is smaller than the inlet diameter of the channel, and the inlet of the channel is communicated with the material filling bucket; the shell removing mechanism comprises a collecting box, a cone-shaped body, a baffle plate, a motor and a support bar, the motor is fixed to the frame, one end of the support bar is fixedly connected with the motor, the other end of the support bar is fixedly connected with the bottom of the cone-shaped body, a ribbed plate is arranged on the peripheral wall of the cone-shaped body, the baffle plate is arranged below the cone-shaped body, and an opening is arranged where the baffle plate is in contact with the side wall of the collecting box. The technical scheme can ensure that different sizes of walnut shells can be crushed, and simultaneously the shells can be sufficiently separated from the walnut meat.

Owner:仁怀市龙井葫芦种植专业合作社

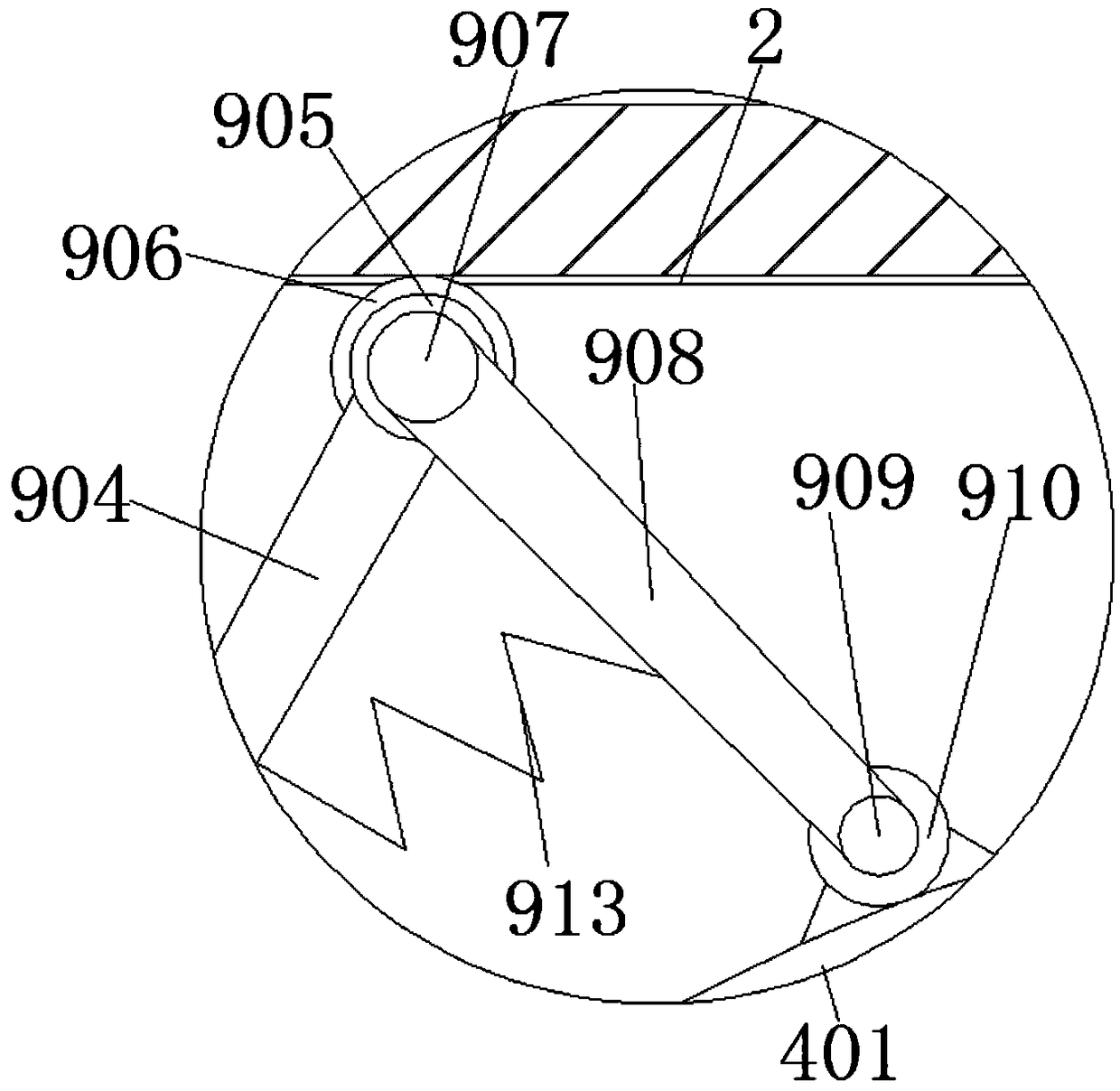

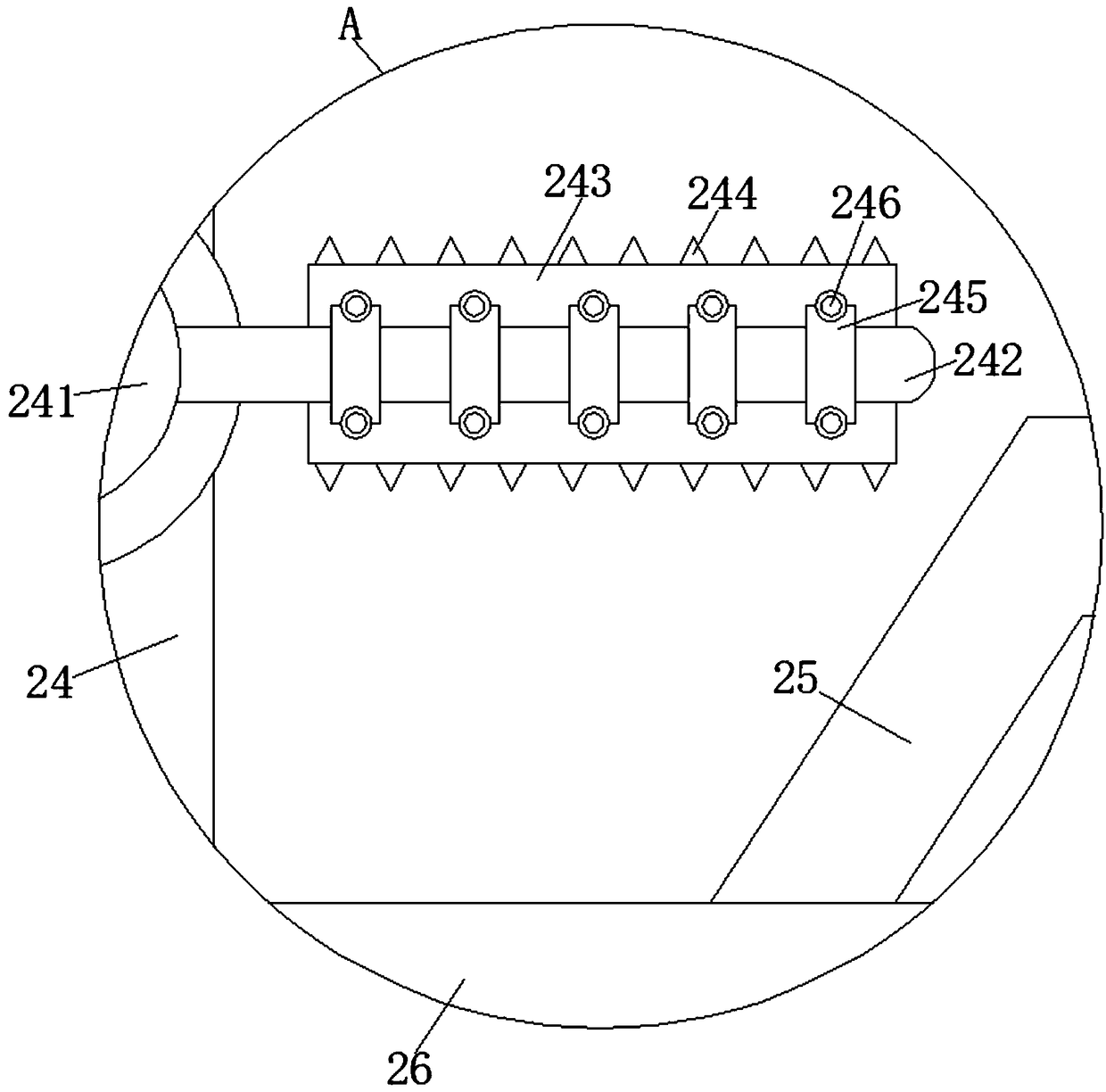

Shelling mechanism for camellia oleifera fruits

InactiveCN108552540AAvoid damageImprove shelling efficiencySievingScreeningCamellia oleiferaMechanical engineering

The invention relates to a shelling mechanism for camellia oleifera fruits. The shelling mechanism for camellia oleifera fruits comprises a machine frame; a shelling conveyor groove and a shelling barrel, which are in mutual cooperation, are arranged on the machine frame; an shelling conveyor auger is arranged in the shelling conveyor groove, and is connected with an auger motor; a shelling rotating shaft, which rotates forwards and backwards, is arranged in the shelling barrel, and is connected with a shelling rotating motor; a shelling rotating sleeve sleeves on the shelling rotating shaft;shelling material-receiving grooves, which are in cooperation with the shelling conveyor groove, uniformly sleeve on the shelling rotating sleeve; a lower part of the shelling rotating sleeve is a slope; and a shelling material outlet is formed at the lowest point of the slope. The purpose of the invention is to provide a shelling mechanism for camellia oleifera fruits in which the rotatable shelling material-receiving grooves and the shelling conveyor groove are adopted in cooperation so as to realize shelling of cracked camellia oleifera fruits by performing downward dropping and collision,and thus, the shelling mechanism for camellia oleifera fruits has improved shelling efficiency compared with manual shelling; moreover, damages on camellia oleifera seeds are also avoided so as to improve shelling effects.

Owner:DONGGUAN UNIV OF TECH

Rice breaking machine with novel efficient rice milling mechanism

PendingCN108554485AEasy to move up and downAdjustable distanceGrain huskingGrain polishingBroken riceEngineering

The invention discloses a rice breaking machine with a novel efficient rice milling mechanism. The rice breaking machine comprises a rice breaking machine shell, a feeding port formed in a top plate of the rice breaking machine shell, a milling roller is arranged on the upper part of the interior of the rice breaking machine shell, a milling disc is arranged just below the milling roller, a supporting plate in a circular ring shape is arranged at the bottom of the milling disc, a supporting rod is connected to the two opposite sides of the supporting plate, and the other end of the supportingrod extends to the outer side of the rice breaking machine shell. An electric hydraulic pushing rod is arranged below the bottom of the end, located on the outer side of the rice breaking machine shell, of the supporting rod, and the output end of the electric hydraulic pushing rod is connected with the supporting rod. The rice breaking machine is simple in structure and convenient to use, can adjust the position of the milling disc, not only solves the problems of broken rice and cracking in the rice milling process, does not damage rice hulls, but also improves the rice shelling effect, andhas the higher value for popularization and application.

Owner:重庆米之吉粮食有限公司

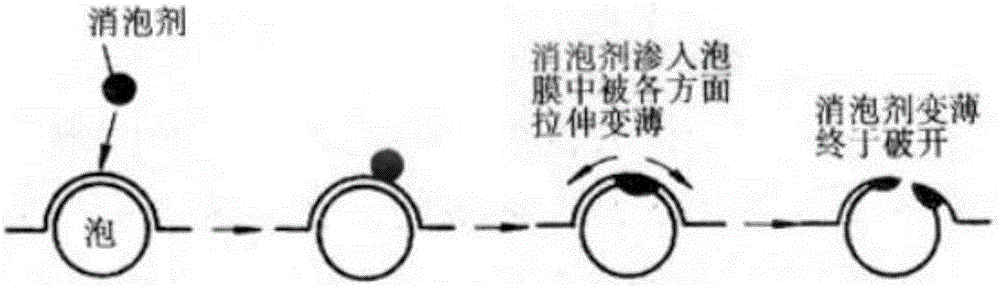

Transition layer coating for manufacturing shell of precision casting and preparation method of transition layer coating

ActiveCN105108054AImprove affinityAvoid wax corrosionFoundry mouldsFoundry coresThermal conductivityWetting

The invention relates to a transition layer coating for manufacturing a shell of a precision casting and a preparation method of the transition layer coating. The transition layer coating for manufacturing the shell of the precision casting consists of the following raw materials in part by weight: 10 parts of silica sol, 16-20 parts of zircon powder, 0.015-0.02 part of defoamer and 0.04-0.045 part of wetting agents. The flow cup viscosity value of the transition layer coating is 7-9s. The quality of the prepared shell is stable, the surface of the shell is compact, high-temperature strength is high, the dimensional accuracy of the casting is high, and surface quality of a product is good. Shelling property and fire resistance are good, and the shell is good in thermal conductivity, low in thermal expansion and excellent in thermal vibration stability. Moreover, the adding amount of the wetting agents and the adding amount of the defoamer are improved, and a transition layer has good breathability.

Owner:GAOMI YONGHE PRECISE CASTING

Processing technology of rice

The invention relates to a rice processing technology, which includes separating rice, removing impurities and dust, drying rice with hot air, shelling for the first time, removing impurities again, drying with cold air, shelling and removing impurities for the second time, and finally grading Packing after screening, polishing and sterilization. The invention removes impurities and dust from the rice, ensures cleanness and avoids damage to the rice by impurities. Two husking operations are set up, and the rice is effectively dried before the first husking, so that the husking effect is better, and at the same time, impurity removal and The cold drying operation removes the chaff doped in the rice, and utilizes the effect of thermal expansion and contraction to reduce the adhesion between the unhulled rice chaff and rice grains, making it easier to hustle and avoid damage to the rice. cause damage.

Owner:郭亚莲

Camellia seed winnowing, husking and crushing all-in-one machine

ActiveCN106497671AGuaranteed cleaning effectReduce cleaning timesFatty-oils/fats productionAgricultural engineeringWinnowing

The invention discloses a camellia seed winnowing, husking and crushing all-in-one machine comprising a feeding hopper, a bracket, a coarse screening mechanism, a roller husking mechanism, a fine screening mechanism, a blast mechanism, a material collecting hopper, a crushing mechanism and a discharge port; the feed hopper is arranged above the bracket, and the discharge port is arranged below the bracket; the coarse screening mechanism, the roller husking mechanism, the fine screening mechanism, the material collecting hopper and the crushing mechanism are arranged on the bracket from top to bottom successively; the bracket is provided with an air intake port; the air intake port is arranged below the fine screening mechanism; the blast mechanism is connected with the air intake port. The machine integrates winnowing, husking and crushing, a treated material blank can directly enter a material steaming and blank preparation process, and the purposes of saving labor, places and materials are achieved.

Owner:CHINA JILIANG UNIV

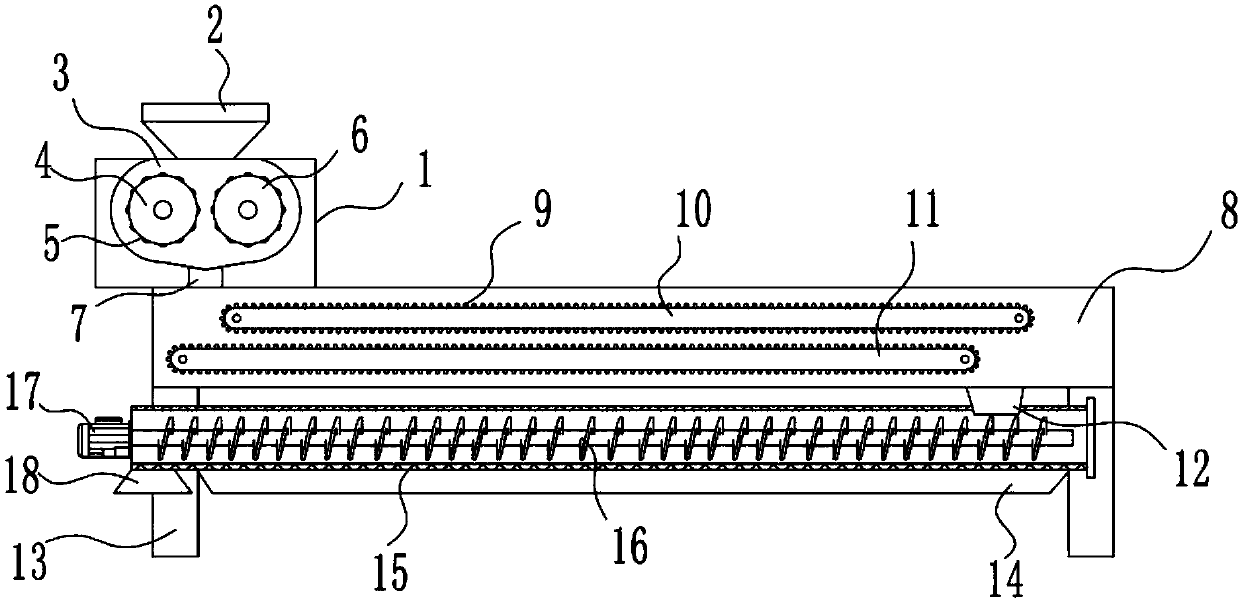

High-efficient horizontal-type shelling device for camellia oleifera fruits

InactiveCN107927811ACause some damagesImprove shelling effectHuskingHullingCamellia oleiferaEngineering

The present invention discloses a high-efficient horizontal-type shelling device for camellia oleifera fruits. The high-efficient horizontal-type shelling device comprises a crushing box, a shelling box and a body rack. The shelling box is arranged on the body rack, the crushing box used for squeezing and crushing of the camellia oleifera fruits is arranged on one end of the shelling box, a horizontal high-speed kneading belt and a low-speed kneading belt are arranged in the shelling box, a transmission speed of the high-speed kneading belt is greater than the transmission speed of the low-speed kneading belt, and a plurality of kneading ridges perpendicular to a movement direction of the two kneading belts are arranged on surfaces of the high-speed kneading belt and low-speed kneading belt. Beneficial effects are as follows: due to the fact that the camellia oleifera fruits in the shelling box are firstly squeezed and crushed by an active crushing roller and a driven crushing roller,the shelling effect is greatly improved and the shelling device does not cause harms on camellia oleifera seeds. At the same time, the high-speed kneading belt, the low-speed kneading belt and a cylindrical screen are horizontally designed, so that an overall height of the device is reduced and the shelling device facilitates material feeding of the shelling device for the camellia oleifera fruits.

Owner:ZHENGZHOU SOUQU INFORMATION TECH CO LTD

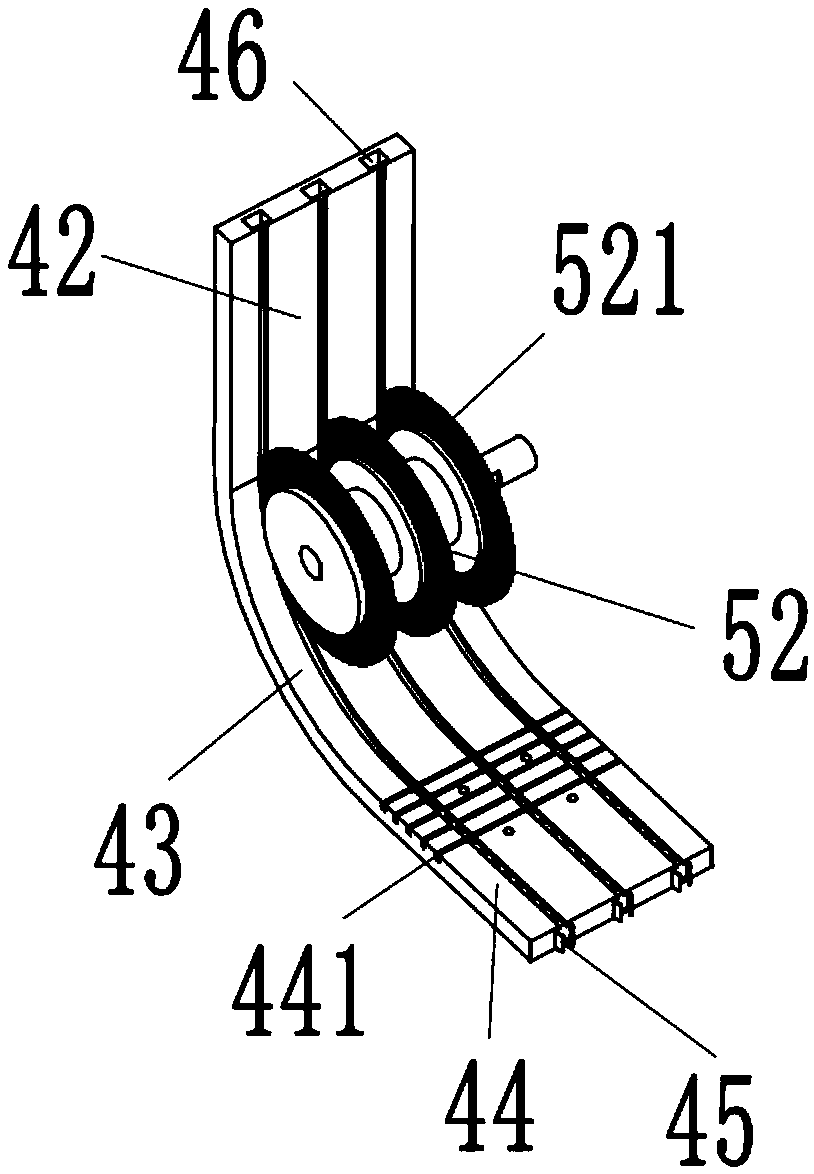

Camellia oleifera shell and seed separating system

The invention discloses a camellia oleifera shell and seed separating system. The system comprises a conveying device (10) and a shelling and sorting device, wherein the shelling and sorting device comprises a screening mechanism (20), a shelling mechanism (30), a conveying mechanism (40), a husk and seed separating mechanism (50) and a rack (60); the screening mechanism (20), the shelling mechanism (30), the conveying mechanism (40) and the husk and seed separating mechanism (50) are sequentially installed in the rack (60) from top to bottom; a feeding hole (601) is formed in the side, corresponding to the screening mechanism (20), of the rack (60); and a seed outlet hole (602) is formed in the position, corresponding to the shell and seed separating mechanism (50), of the rack (60). Thesystem has the advantages that camellia oleifera fruits of different sizes can be shelled at the same time, the shelling effect of camellia oleifera seeds is improved, and the production efficiency isimproved.

Owner:湖南省海华农业综合开发有限公司

Roller type fruit shell separating machine

The invention relates to the field of fruit shell separation equipment, and discloses a roller type fruit shell separating machine. The roller type fruit shell separating machine comprises a machine frame and a material conveying belt, and further comprises at least one roller which is arranged above the material conveying belt and stretches across the width direction of the material conveying belt, needle thorns are arranged on the peripheries of the rollers so as to pierce fruit shells on the material conveying belt and perform subsequent separation when the rollers rotate, the rotating direction of the rollers is the same as the running direction of the material conveying belt, and a distance is formed between the free end of each needle thorn on the rollers and the surface of the material conveying belt; and the roller type fruit shell separating machine further comprises slag discharging mechanisms which are arranged corresponding to the rollers, and the slag discharging mechanisms can strip the fruit shells on the needle thorns of the rollers. According to the fruit shell separating machine, the concept that a traditional fruit shell separating machine needle thorn plate is used for sorting shells through up-and-down periodic movement is subverted, then the mode by which the needle thorns are fully distributed on the surfaces of the rollers which do rotating motion, so that sorting of the fruit shells is always carried out through the needle thorns on the mixed fruit shell materials on the material conveying belt in the rotating process of the rollers, the material conveying belt can be used for continuous conveying, the needle thorns are orderly and densely arranged on the rollers, so that the separation efficiency and the separation rate of the fruit shells areensured.

Owner:HUNAN DASANXIANG TEA OIL CO LTD

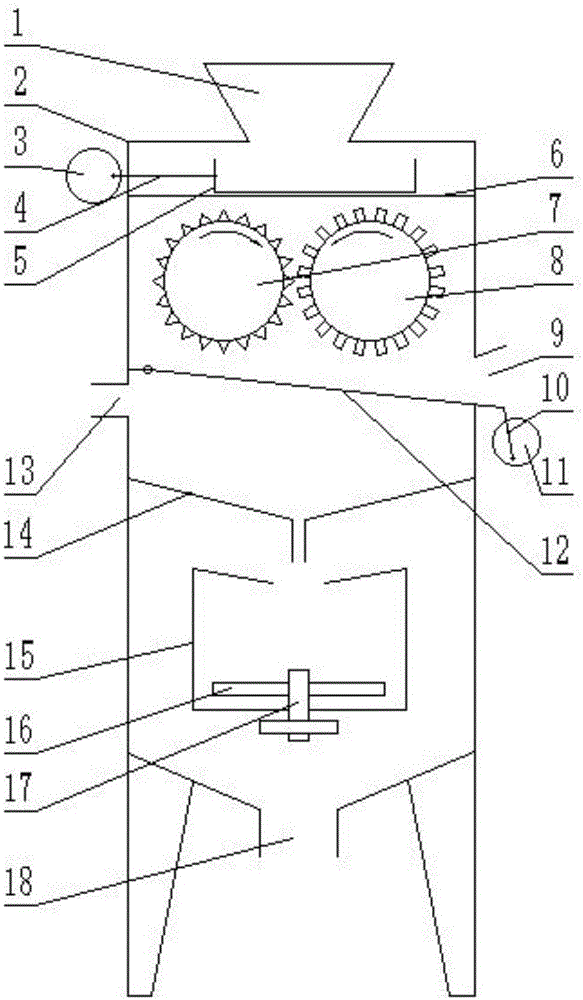

High-efficiency vertical type camellia oleifera fruit hulling device

InactiveCN108113015AImprove shelling effectGood shelling effectHuskingHullingEngineeringMechanical engineering

The invention discloses a high-efficiency vertical type camellia oleifera fruit hulling device. The high-efficiency vertical type camellia oleifera fruit hulling device comprises a feeding hopper anda hulling tank, wherein the feeding hopper is mounted at the top of the hulling tank; a crushing chamber which communicates with the feeding hopper is arranged in the hulling tank; a driving crushingroller and a driven crushing roller are mounted in the crushing chamber; a plurality of protrusions are respectively arranged on the surface of the driving crushing roller and the surface of the driven crushing roller; the driving crushing roller and the driven crushing roller are oppositely placed, and the rotating directions of the driving crushing roller and the driven crushing roller are opposite; a high-speed kneading belt and a low-speed kneading belt are arranged just below the crushing chamber; the transmission direction of the high-speed kneading belt is the same as that of the low-speed kneading belt; and the transmission speed of the high-speed kneading belt is higher than that of the low-speed kneading belt. The high-efficiency vertical type camellia oleifera fruit hulling device disclosed by the invention has the beneficial effects that camellia oleifera fruits entering a discharging channel are already firstly extruded and crushed by the driving crushing roller and the driven crushing roller, so that the hulling effect is greatly increased; and under the kneading action of the high-speed kneading belt and the low-speed kneading belt of which the speeds are different,the hulling effect of the camellia oleifera fruits is realized.

Owner:ZHENGZHOU SOUQU INFORMATION TECH CO LTD

Camellia fruit husking machine

InactiveCN108060007AImprove shelling efficiencyReduce shell contentFatty-oils/fats productionHuskingImpellerCentrifugation

The invention provides a camellia fruit husking machine, which at least comprises following devices arranged on a frame: a rolling device, a centrifugation device, a screening device, and a power device. The rolling device is arranged between the material inlet of the husking machine and the inlet of the centrifugation device. The centrifugation device at least comprises a rotation shaft, an impeller, and a centrifugation chamber. The impeller sleeves the rotation shaft, and the impeller and the rotation shaft are connected through key joint. A transmission device is arranged between the rotation shaft and the power device. The impeller and the rotation shaft are installed in the centrifugation chamber and can rotate in the centrifugation chamber. The rotation shaft is inclined to one side, which is close to the inlet, of the lower part of the centrifugation chamber. The rotation track of the blade of the impeller is in tangency with the inner wall of the centrifugation chamber. The side, which is far away from the inlet, of the bottom of the centrifugation chamber is provided with an outlet. The screening device is arranged under the outlet. The camellia fruit husking machine hasthe advantages that the structure is simple, the husking machine is convenient to use, the operation is stable, the husking rate is high, and tea seeds are not damaged.

Owner:丁晓红

Shelling and peeling device for peanut processing

The present invention discloses a shelling and peeling device for peanut processing. The shelling and peeling device comprises a body frame. A shell crushing box, a centrifuging bucket and a peeling chamber are arranged in the body frame, a material inlet hopper is arranged at a middle position of a top end of the shell crushing box, a plurality of transmission shafts are arranged on both left andright sides of the shell crushing box, crushing gears and transmission wheels are all arranged on the transmission shafts, the crushing gears on the both left and right sides are symmetrical to eachother, at the same time, certain gaps form between the crushing gears on the both left and right sides and the gaps are reduced from a top to a bottom, the upper and lower adjacent transmission wheelsare all connected by belts, and a first filtering net is arranged on a bottom part of the shell crushing box. Beneficial effects are as follow: based on different weights of peanut shells and peanutkernels, the peanut shells and peanut kernels are subjected to a centrifuging and separating work, and the shelling and peeling device reduces a damage rate of the peanut kernels and is good in shelling effects.

Owner:郑青飞

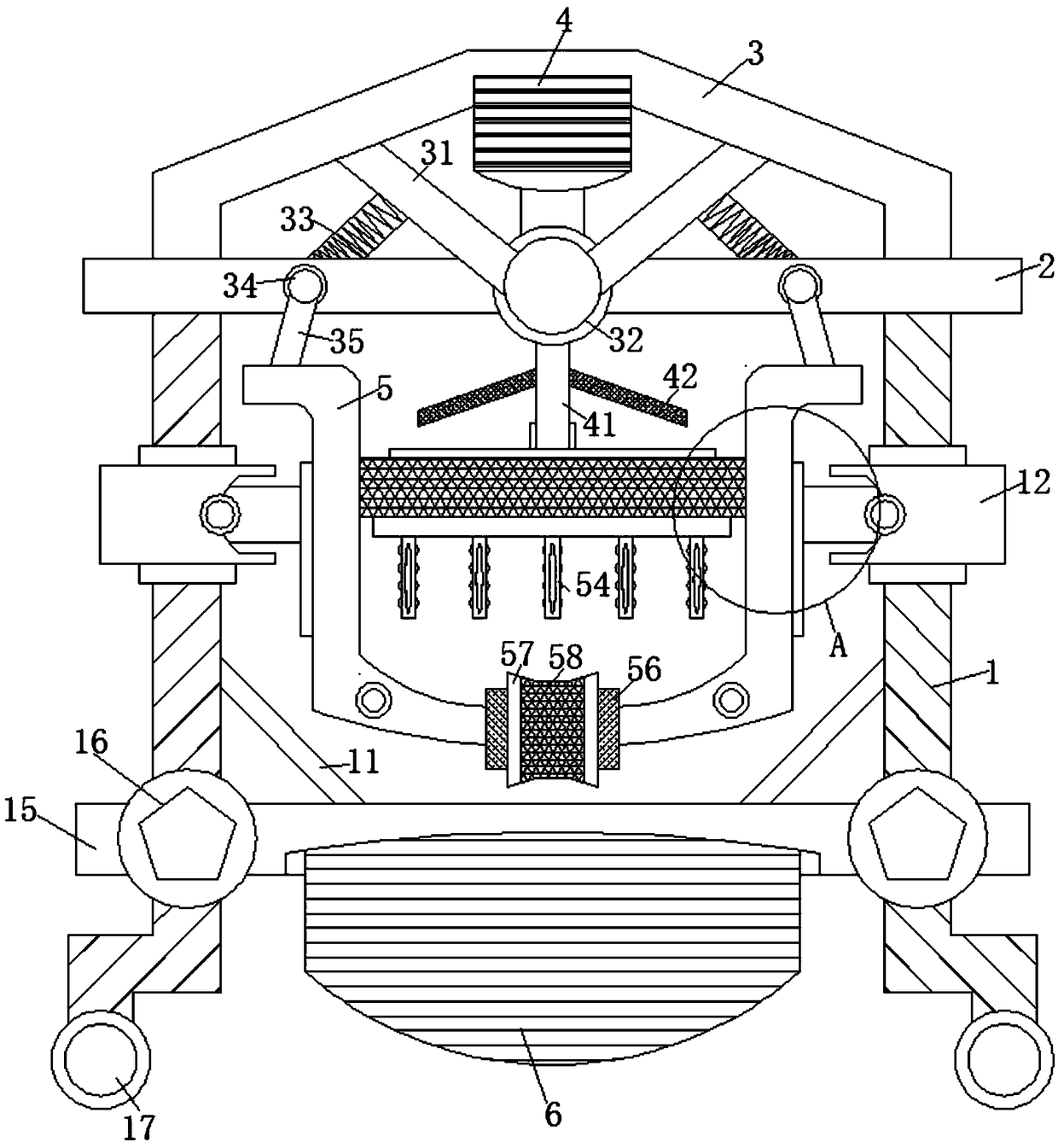

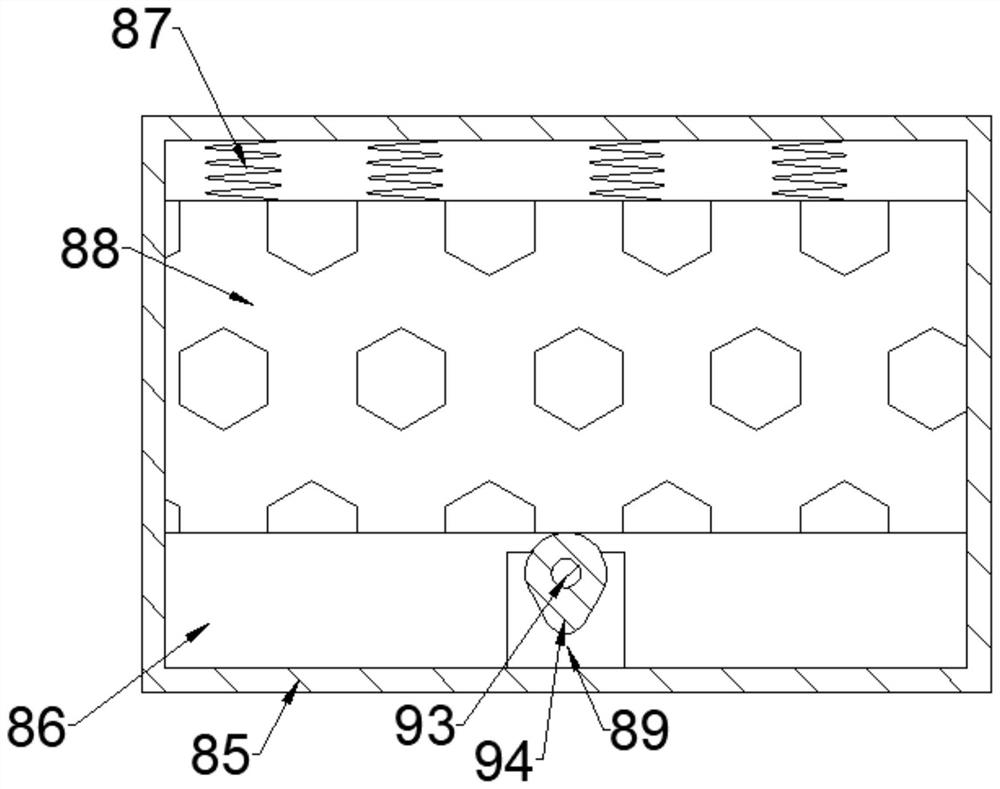

Collecting and processing device for pea dehulling and selection

InactiveCN109077338AImprove shelling effectImprove the effect of precision screeningSievingScreeningEngineeringMechanical engineering

The invention relates to the technical field of food processing and discloses a collecting and processing device for pea dehulling and selection. The collecting and processing device comprises a supporting-bearing device, wherein one end of the top of the supporting-bearing device is welded with two sides of the bottom of a top blocking mechanism, two sides, located at the top, of the top blockingmechanism are respectively welded with two sides of the bottom of a top limiting mechanism, the middle, located on the inner side of the top, of the top limiting mechanism is welded with a driving device, one end of an output shaft of the driving device is insert-connected into the inner cavity of a driving rotary shaft, two sides of the outer surface of the driving rotary shaft are welded with breaking driving blades, and a discharging processing structure is insert-connected to the middle of the inner cavity of a screen net disc. Peas needing dehulling are put in a force-borrowing swing processing device, the driving device drives the breaking driving blades, breakage processing can be conducted on the peas, the force-borrowing swing processing device is driven to perform swing processing by utilizing the rotation power of the driving rotary shaft, and the effect of finely screening peas can also be improved.

Owner:崔永平

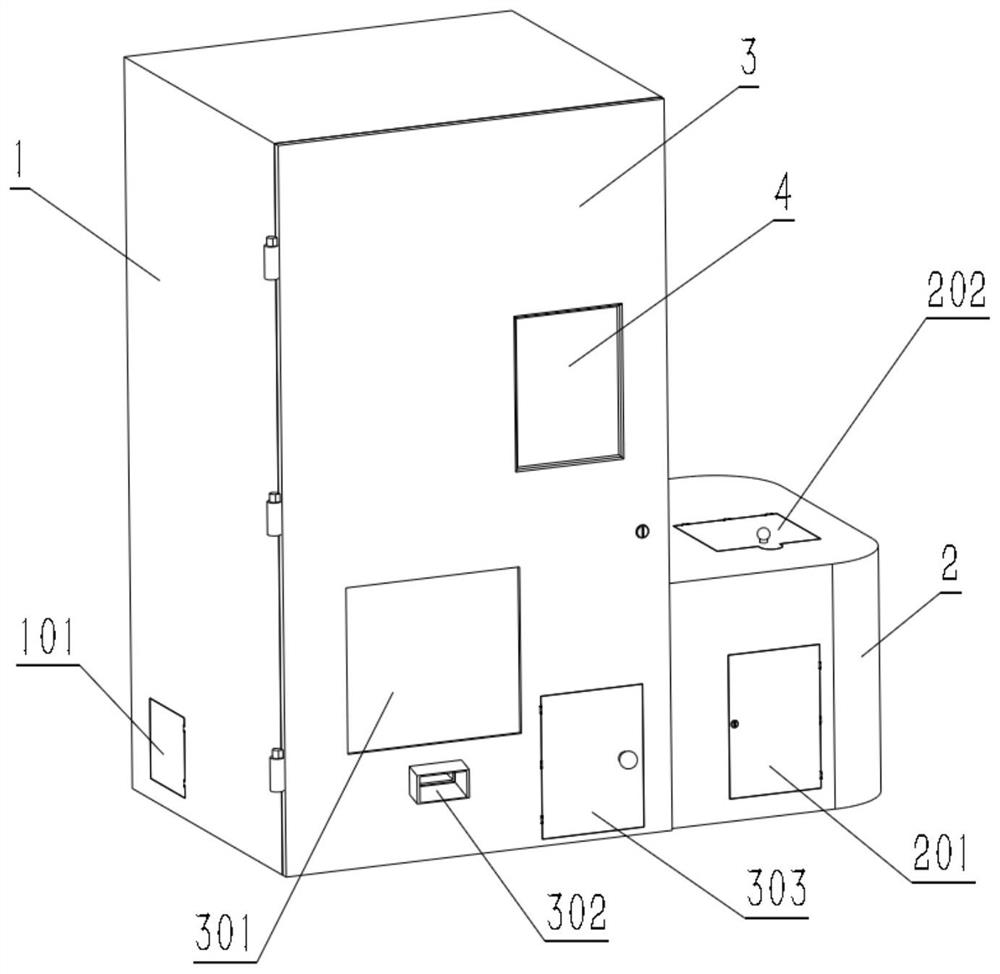

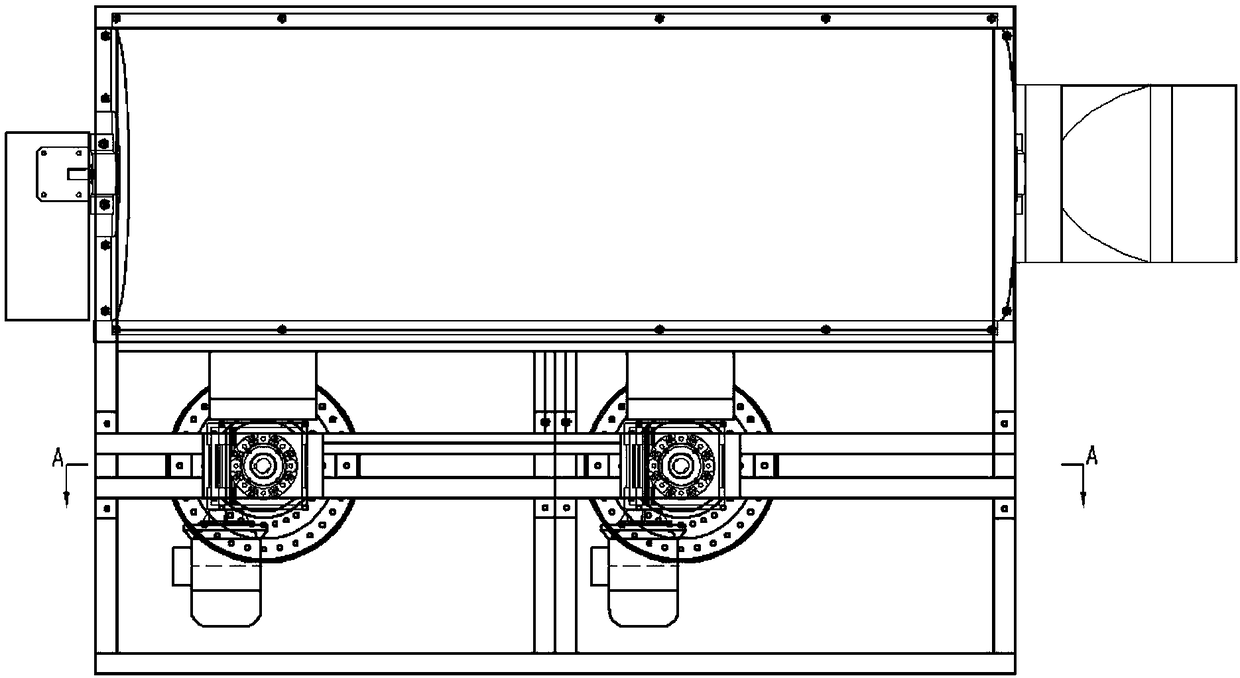

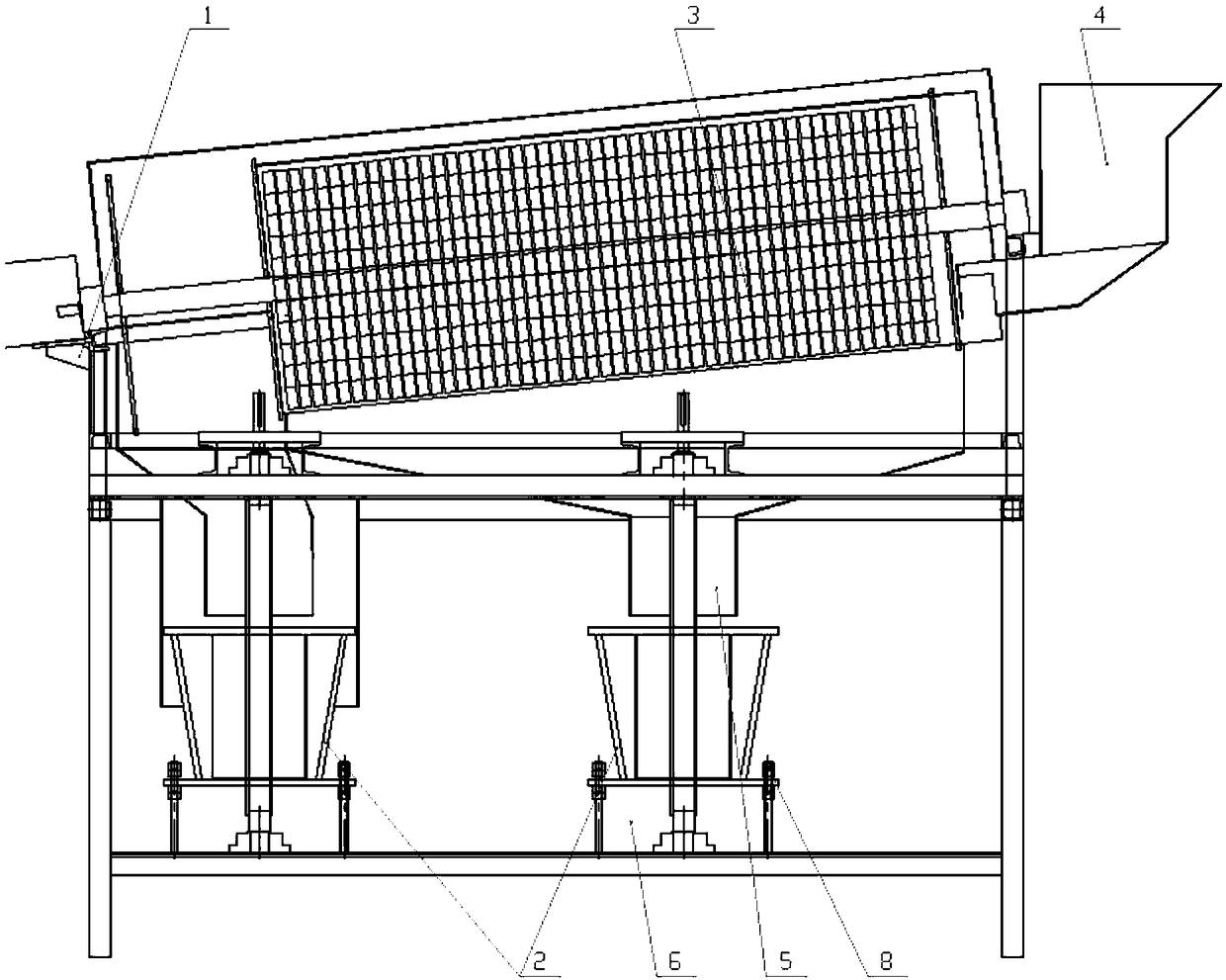

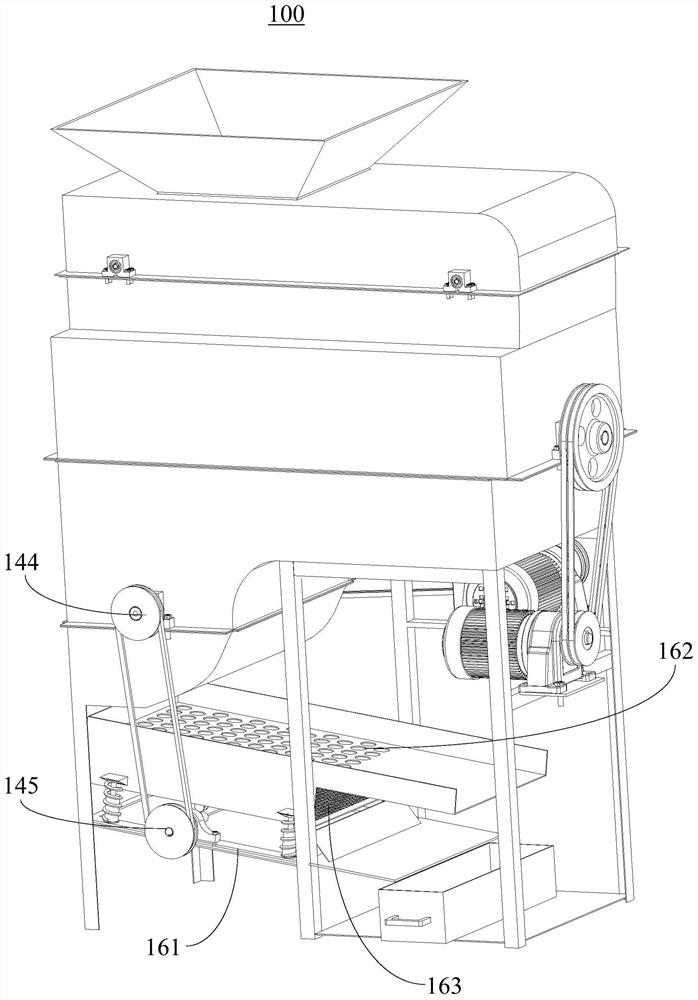

Intelligent self-service rice husking machine

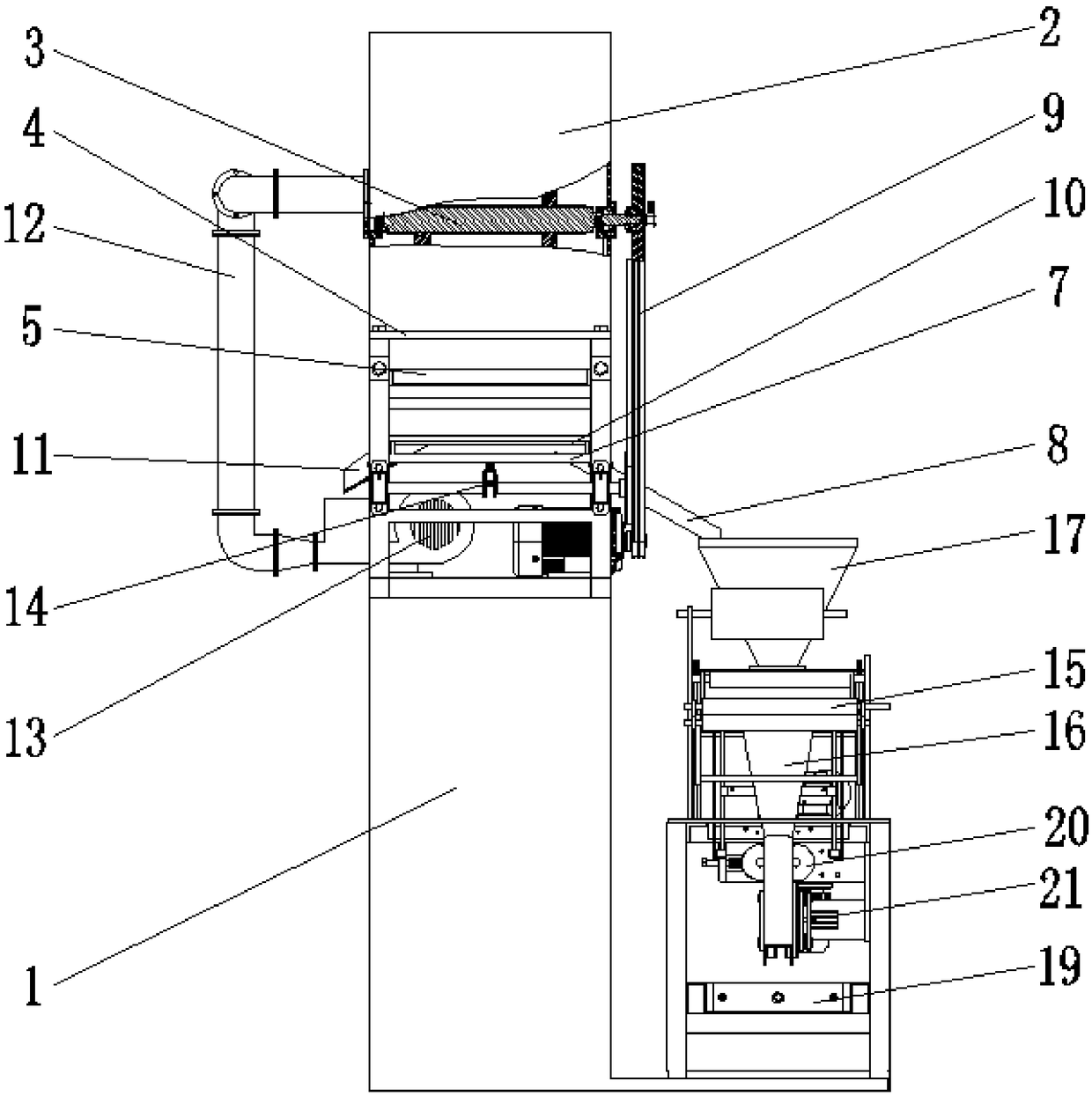

ActiveCN113617415AEasy to take awayEasy to handleGrain treatmentsAgricultural engineeringProcess engineering

The invention relates to an intelligent self-service rice husking machine. According to the intelligent self-service rice husking machine, a rice bin providing convenience for people to put rice is designed, the rice in the rice bin can be blown into a temporary storage tank in a main machine box through an air blowing conveying pipe, then the rice gradually enters a husking device through the temporary storage tank to be husked, the rice husking effect can be improved through unique design of a rice husking barrel and a rice husking shaft, and blockage and damage to rice are avoided. Then the rice and bran can be effectively separated through a stirring and bran removing barrel, the cleanliness of the rice is guaranteed, and meanwhile an arranged belt type spiral blade can also avoid extrusion and abrasion to the rice; according to the needs of a user, if the user needs the bran, the bran can be discharged into a cloth bag so that the user can take away the bran conveniently, if the user does not need the bran, the bran can be directly discharged into a bran collecting bin to be collected in a unified mode, compression is conducted through a pushing and pressing device, and the stock increasing and later recycling treatment are facilitated.

Owner:苏州苏芡禾农产品专业合作社

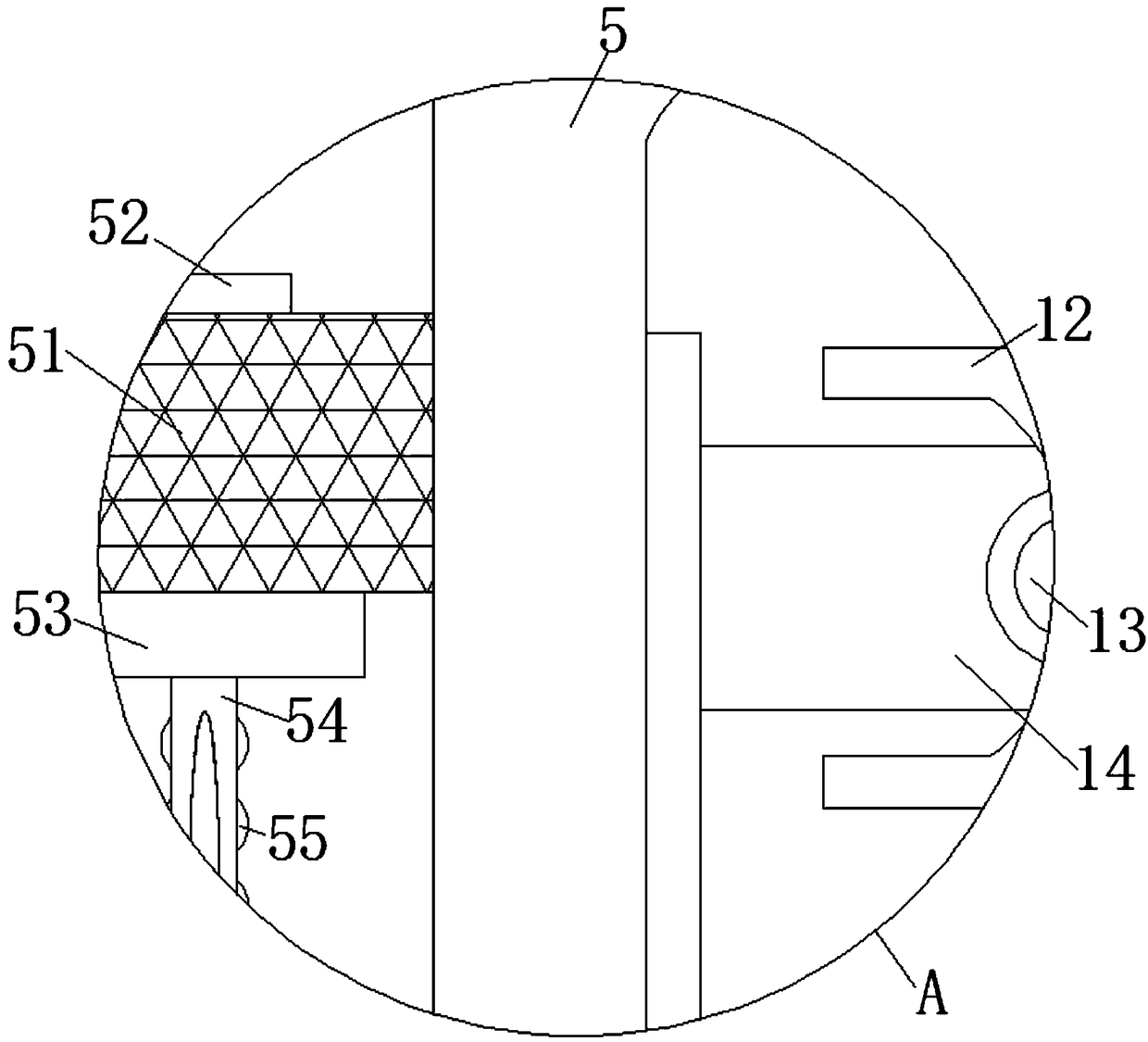

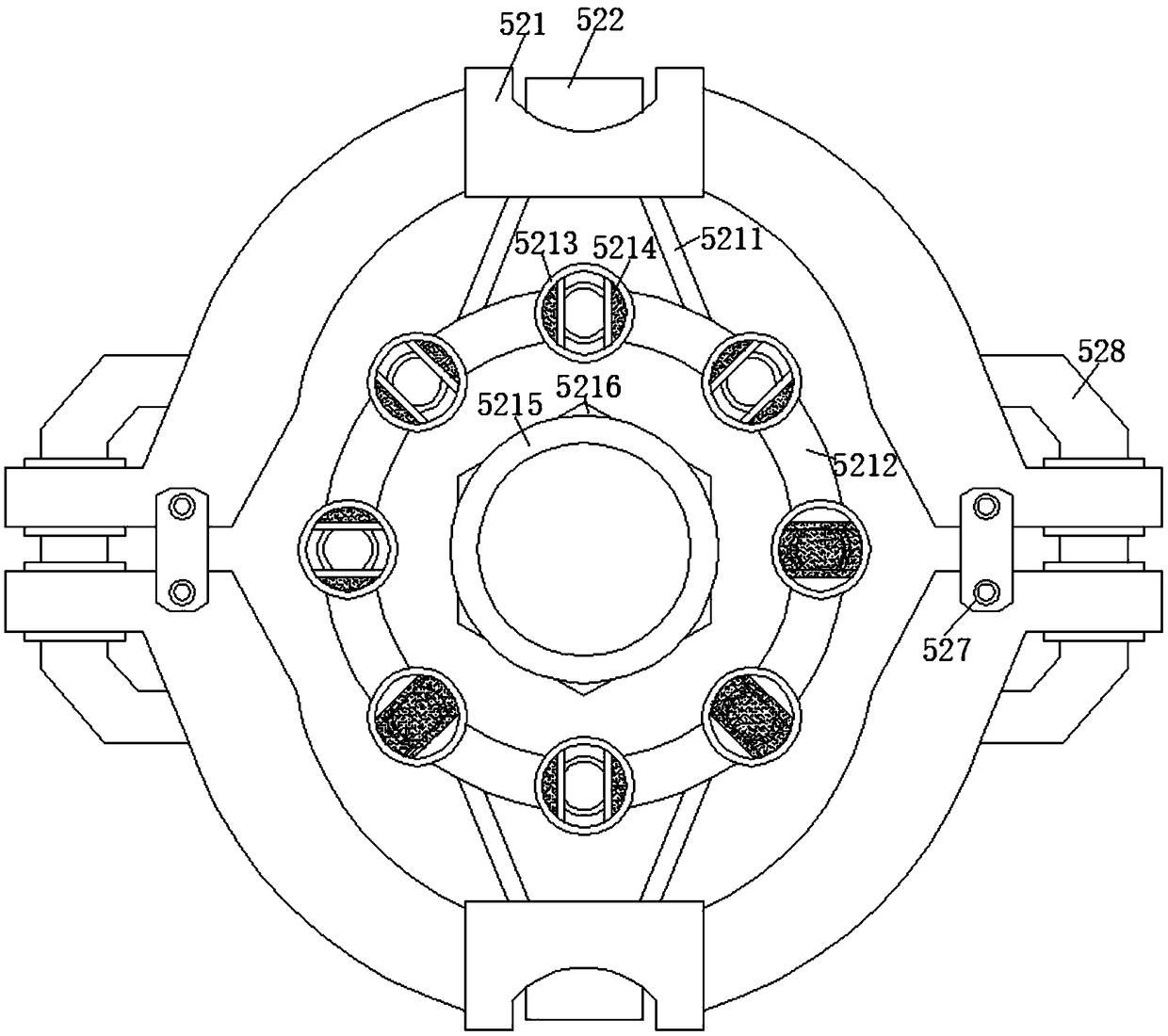

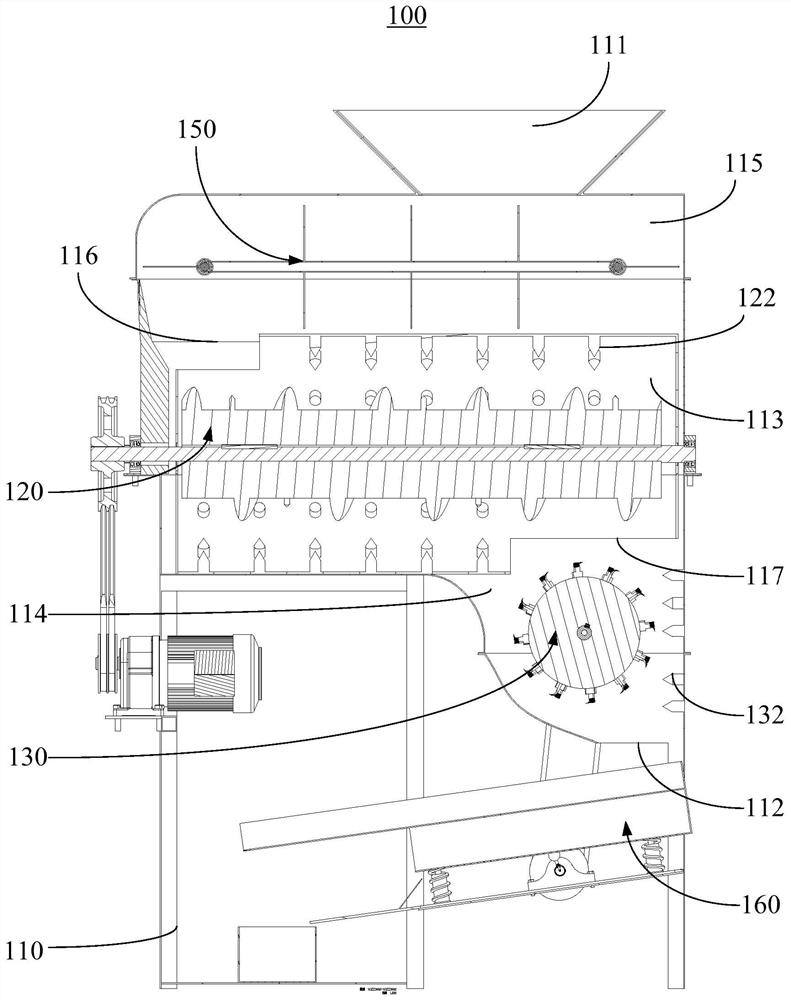

Camellia fruit shelling system

PendingCN108903002AIncreased versatilityImprove shelling effectSievingGas current separationEngineeringSieve

The invention discloses a camellia fruit shelling system. The camellia fruit shelling system comprises a machine frame; a squirrel-cage sieve and a shelling unit are arranged on the machine frame; a feeding port and graded material outlets are arranged on the squirrel-cage sieve; the shelling unit comprises an outer cylinder and an inner cylinder which are vertically arranged in mutually sleeved connection; the outer cylinder is shaped like an inverted cone; a side wall of the outer cylinder is composed of a plurality of flexible rollers which are uniformly distributed on the circumference ofthe outer cylinder and arranged along the generatrix of the cone; the flexible rollers can freely roll around the axes of themselves; a flexible roller rolling and shell-rubbing passageway is formed between the flexible rollers and an outer wall of the inner cylinder; guiding thread is formed on the outer wall of the inner cylinder; and the squirrel-cage sieve and the inner cylinder are respectively driven to rotate by corresponding power systems. The camellia fruit shelling system adopting the structure has the advantages of being high in efficiency, good in effects and low in camellia seed damage rate.

Owner:HUNAN ACAD OF FORESTRY

Cooling and inner wall lubricating device for magnesium alloy continuous casting liquid-solid converter

The invention discloses a cooling and inner wall lubricating device for a magnesium alloy continuous casting liquid-solid converter. The cooling and inner wall lubricating device comprises an inner wall which is formed by splicing a plurality of layers of curves, and a back plate is matched with the inner wall to form a junction face in which cooling water can be introduced. The inside of the junction face is divided into a plurality of cooling areas from top to bottom, and each cooling area is provided with an independent water inlet and a water outlet. Gaps are reserved between the splicing faces, formed by the curves, on the inner wall, and the gaps communicate with lubricating oil through holes formed in the back plate to provide a lubricating channel between a magnesium alloy coagulating shell and the inner wall. According to the cooling and inner wall lubricating device, cooling and lubricating are both combined into the inner wall and the back plate, the cooling water can be introduced into the junction face to cool the inner wall, and the heat of molten state magnesium alloy in the inner wall is taken away, so that the temperature of a contact part is lowered to be below a solidification level, and a liquid-solid converting effect is achieved. The friction force of a casting blank shell and the inner wall of a coagulator can be lowered, the shell removing effect of casting blanks is improved, and the throwing speed of the casting blanks is improved.

Owner:CHINA NAT HEAVY MACHINERY RES INSTCO

Chinese chestnut harvesting and shelling device

The invention discloses a Chinese chestnut harvesting and shelling device. The equipment comprises a box body, wherein a placement space is formed in the box body, a collection mechanism is arranged in the placement space, and the collection mechanism comprises a dust suction box fixedly connected to the inner wall of the upper side of the placement space; a dust suction cavity is formed in the dust suction box, a first motor is fixedly connected to the inner wall of the left side of the dust suction cavity, and a first driving shaft is rotatably connected to the right end face of the first motor; and an impeller is fixedly connected to the first driving shaft, and a filter screen connected to the inner wall of the rear side of the dust suction cavity is arranged on the right side of the impeller. According to the Chinese chestnut harvesting and shelling device, the size of Chinese chestnut fruits is measured through a measuring block, the cutting depth of a cutting blade is adjusted according to the size of the Chinese chestnut fruits, and accordingly shells of the Chinese chestnut fruits can be well cut; and on the basis that Chinese chestnuts are not damaged, the shells of the Chinese chestnut fruits can be well broken, the Chinese chestnuts and the shells are conveniently separated later, and a better shelling effect is achieved.

Owner:广州蓝碧农业科技有限公司

Processing treatment equipment capable of dehulling and separating cedar seed husks

The invention relates to the technical field of Chinese herbal medicine processing, and discloses processing treatment equipment capable of dehulling and separating cedar seed husks. The processing treatment equipment comprises a dehulling treatment device. A feeding micro-processing device is connected to the position, at the middle of the top, of the dehulling treatment device in an inserted mode, positioning supporting fixing devices are welded to the positions, on the outer surfaces of the two sides of the bottom, of the dehulling treatment device correspondingly, one ends of the bottoms of the two positioning supporting fixing devices are connected to the two sides of the outer surface of a collecting treatment device in an inserted mode correspondingly, and the middle of the top of the collecting treatment device is connected with the middle of the bottom of the dehulling treatment device in an inserted mode through a material collecting pipe. According to the processing treatment equipment capable of dehulling and separating the cedar seed husks, the cedar seed husks which need to be dehulled are put into the feeding micro-processing device, the cedar seed husks can be scattered, meanwhile, the cedar seed husks can be subjected to tegument breaking treatment through centrifugal force generated by a built-in structure, then through combination use of the built-in structure of the dehulling treatment device, the cedar seed husks can be dehulled, and cedar seeds of the cedar seed husks are separated.

Owner:山东东方健康产业发展有限公司

Method for accelerating shelling of cotton seedlings

InactiveCN106471941BWon't hurtShorten the emergence periodSeed and root treatmentCotton cultivationAqueous solutionSeedling

The invention provides a method for accelerating shelling of cotton seedlings. The method comprises the following steps: a, preparing of a soaking solution; b, soaking of seeds; c, planting of cotton seeds; d, preparing of a shelling solution; e, shelling of the cotton seedlings. The method is characterized by soaking the cotton seeds in a glycerin water solution for a certain time before planting cotton, then planting the soaked cotton seeds, and spraying the cotton seedlings with cotton shells by using the glycerin water solution containing polysorbate 20 after bursting out of earth, thus removing the cotton shells within a shorter time. The method provided by the invention is simple, is easy to master and cannot damage cotton; meanwhile, the seedling emergence stage of the cotton seeds is shortened; dwarf of cotton plants is promoted to a certain degree; meanwhile, the seedling emergence rate of the cotton seeds is increased.

Owner:INST OF IND CROPS HENAN ACAD OF AGRI SCI

Primary layer coating for manufacturing shell of precision casting and preparation method of primary layer coating

ActiveCN105108053AHigh affinityHigh surface finishFoundry mouldsFoundry coresThermal expansionFire resistance

The invention relates to a primary layer coating for manufacturing a shell of a precision casting and a preparation method of the primary layer coating. The primary layer coating is prepared from the following raw materials in part by weight: 10 parts of silica sol, 38-42 parts of zircon powder, 0.04 part of wetting agents and 0.015 part of defoamer. The flow cup viscosity value of the primary layer coating is 48-57s. The quality of a prepared shell is stable, the surface of the shell is compact, high-temperature strength is good, the dimensional accuracy of the casting is high, and the surface quality of a product is good. Shelling property and fire resistance are good, and the shell is good in thermal conductivity, low in thermal expansion and excellent in thermal vibration stability. Moreover, the adding amount of the wetting agents and the adding amount of the defoamer are increased, and a primary layer has good breathability.

Owner:GAOMI YONGHE PRECISE CASTING

Castanea henryi fruit-shell removel and separation production system

ActiveCN108686942AAvoid manual sortingImprove efficiencyGas current separationHuskingEngineeringMechanical engineering

The invention discloses a castanea henryi fruit-shell removel and separation production system. The castanea henryi fruit-shell removel and separation production system comprises a machine frame, a screening device, a feeding device, a material conveying guide rail, a material shifting device, a cutter assembly and a shell removal device, wherein the screening device, the feeding device, the material conveying guide rail, the material shifting device, the cutter assembly and the shell removal device are arranged on the machine frame. The screening device can realize two-stage screening. A semi-cylindrical cover shell is arranged on a material outlet of a material box of the screening device, and the semi-cylindrical cover shell communicates with the material box. The feeding device is arranged in the semi-cylindrical cover shell. A plurality of T-shaped grooves penetrating through both ends of the material conveying guide rail are formed in the material conveying guide rail. The feeding device can feed the castanea henryi located in the material box into the T-shaped grooves. The material shifting device enables the castanea henryi to move along the T-shaped groove. A plurality ofcutters of the cutter assembly can extend into corresponding cutting grooves on the material conveying guide rail to carry out cutting treatment on the castanea henryi. The shell removal device is arranged at the discharging end of the material conveying guide rail, and the castanea henryi after shell removal is sent into a chute under the action of the shell removal device. Therefore, the castanea henryi with different specifications can achieve the effects of good shell removal effect and low damage rate.

Owner:ZHEJIANG IND & TRADE VACATIONAL COLLEGE

Rice processing equipment

The invention discloses rice processing equipment. The rice processing equipment comprises a baseboard, the upper end face of the baseboard is provided with a column and a supporting vertical rod, a slant board is fixedly arranged between the column and the supporting vertical rod, a feeding device for driving rice to be fed is arranged in the slant board, and a rice hulling device for hulling therice is arranged below the feeding device. The equipment is simple in structure, the feeding device and the rice hulling device are adopted, and the automatic feeding process of the hulled rice is achieved; moreover, convenient-to-detach and convenient-to-maintain structural design is adopted, rollers with the same rotation direction are utilized for efficiently hulling the rice, efficient hull and impurity separation is achieved, the equipment processing effect is effectively improved, maintenance and installation by personnel are facilitated, the burden of the personnel is lowered, more convenience is brought to subsequent processing of rice of other types, and no other impurities are mixed.

Owner:余杏花

Fresh lotus seedpod shelling device

The invention discloses a fresh lotus seedpod shelling device. The device comprises a base, a pre-shelling mechanism, a full-shelling mechanism and a driving device, and the base is provided with a feeding port, a discharging port, a pre-shelling cavity and a full-shelling cavity; the pre-shelling mechanism is used for breaking shells of fresh lotus seedpods in the pre-shelling cavity to form a plurality of lotus seedpod blocks; the full-shelling mechanism is used for breaking the lotus seedpod blocks in the full-shelling cavity, so that lotus seeds are separated from fibrous membranes; and the driving device is used for driving the pre-shelling mechanism and the full-shelling mechanism to move. According to the fresh lotus seedpod shelling device, by arranging the pre-shelling mechanism,shells of the fresh lotus seedpods can be broken, the fibrous membranes cannot be damaged to a large extent, and therefore the structural integrity of the lotus seeds cannot be damaged; and by arranging the full-shelling mechanism, the fibrous membranes can be broken, so that the lotus seeds are separated from the fibrous membranes, and the structural integrity of the lotus seeds cannot be damaged. The pre-shelling mechanism is matched with the full-shelling mechanism, so that the shelling effect can be optimized while the shelling efficiency is improved.

Owner:WUHAN POLYTECHNIC UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com