Castanea henryi fruit-shell removel and separation production system

A kind of technology of the chestnut husk and production system, which is applied in the direction of solid separation, separation of solid from solid by air flow, shelling, etc., can solve the problems of low efficiency, laborious, high damage rate, etc., achieve high efficiency, avoid manual The effect of sorting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] It should be noted that the features in the various embodiments of the present invention may be combined with each other in the absence of explicit limitation or conflict. The present invention will be described in detail below with reference to the accompanying drawings and examples.

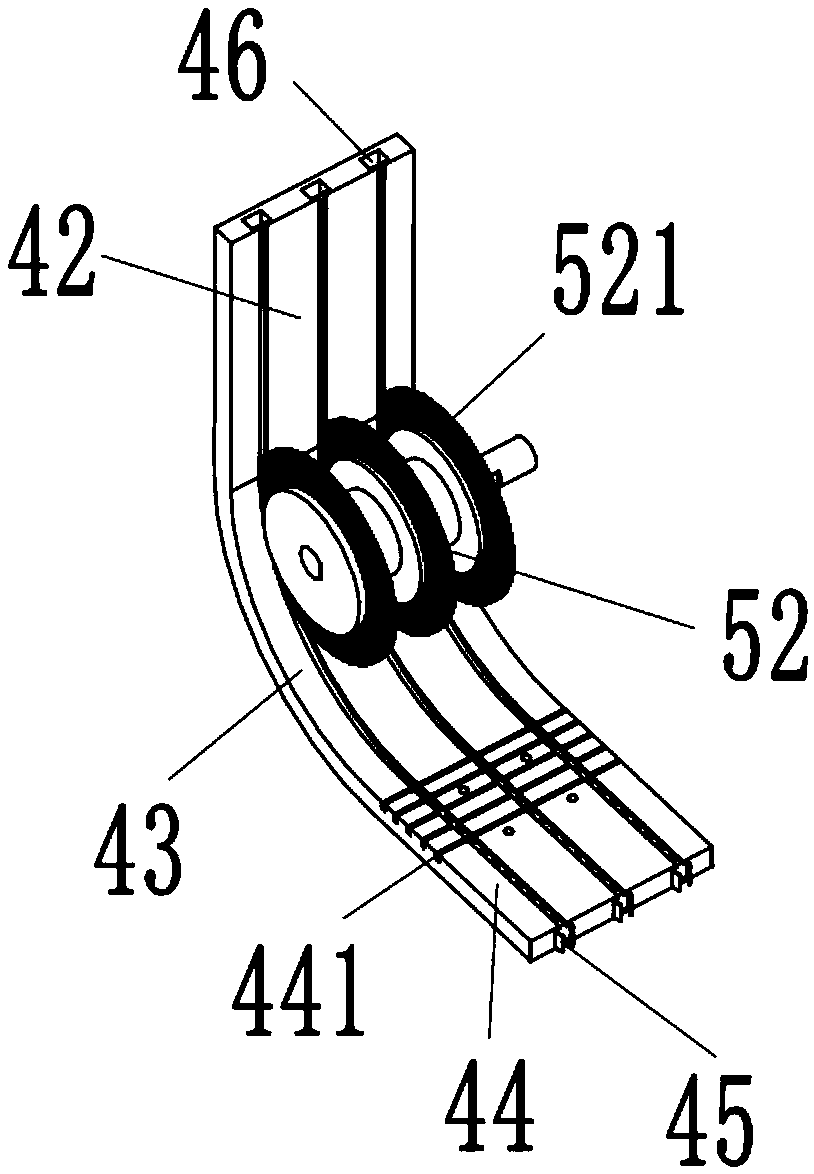

[0033] refer to Figure 1 to Figure 4 ,Such as figure 1 The shown a kind of chestnut husk separation production system includes: frame 1, screening device 2, feeding device 3, feeding guide rail 4, feeding device 5, adjustment mechanism 6, cutter assembly 7, shelling device 8 and chute 9, the screening device 2 is fixedly arranged on the upper part of the frame 1, the screening device 2 includes a material box 20, and a screen 21 is inclinedly provided in the material box 20 to filter the material Box 20 is upper chamber and lower chamber respectively, and described lower chamber is provided with a partition 22, and described partition board 22 divides lower chamber respectively left c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com