Camellia seed winnowing, husking and crushing all-in-one machine

An all-in-one machine and camellia seed technology, applied in the direction of fat oil/fat production, fat production, etc., can solve the problems of long-term storage of intermediate materials, inconvenient processing in the next process, and large area occupied by the site, so as to achieve labor saving and good production efficiency. Shelling effect, efficient separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

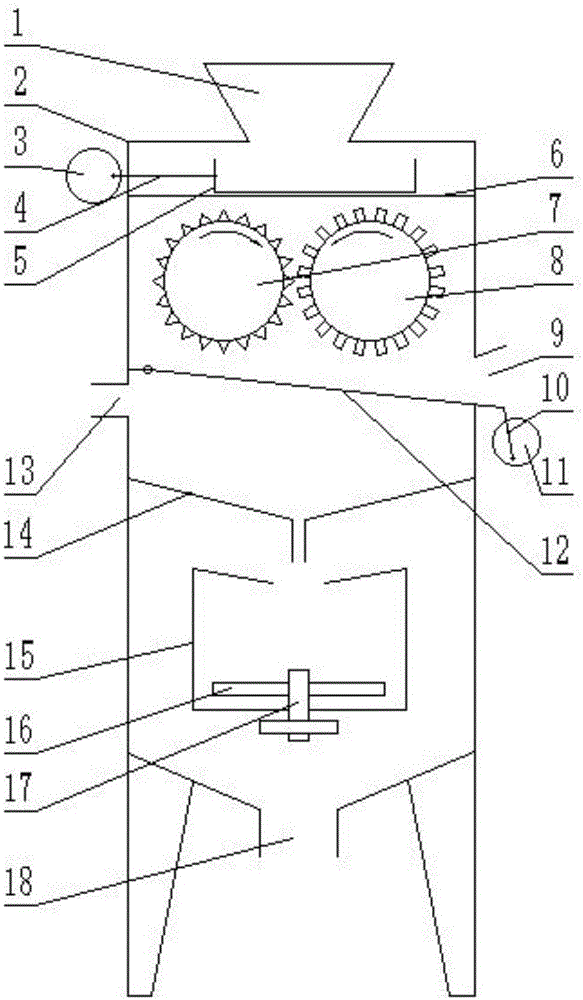

[0019] Embodiment 1: as figure 1 As shown, the present invention provides a kind of air separation and shelling and crushing integrated machine for camellia oleifera seeds, comprising: feed hopper 1, support 2, coarse sieve mechanism, roller shelling mechanism, fine sieve mechanism, blower mechanism, collecting hopper 14, crushing Mechanism and discharge port 18, the feed hopper 1 is arranged above the support 2, and the discharge port 18 is provided below the support 2; the rough screening mechanism, the roller shelling mechanism, the The fine screening mechanism, the collecting hopper 14 and the crushing mechanism are sequentially arranged on the support 2 from top to bottom; the support 2 is provided with an air inlet 13, and the air inlet 13 is arranged below the fine screening mechanism , the blower mechanism is connected to the air inlet 13 .

[0020] When the present invention is used for the pretreatment of camellia seeds, firstly, the camellia seeds are poured into t...

Embodiment 2

[0022] Embodiment 2: As a further improvement to Embodiment 1, the rough screening mechanism includes a slide rail 6, a rough screen 5, a first connecting rod 4 and a first eccentric wheel 3, and the slide rail 6 is arranged on the bracket 2, the coarse screen 5 is arranged on the slide rail 6, and the first eccentric wheel 3 is arranged outside the support 2, which is convenient for connecting the drive motor and the reduction mechanism. The first eccentric wheel 3 passes through the The first connecting rod 4 is connected with the coarse screen 5 . The mesh diameter of the rough screen 5 is selected as Φ15mm.

[0023] The roller shelling mechanism includes: a speed regulating motor, a first roller 7 and a second roller 8, the first roller 7 is connected with the first gear, and the second roller 8 is connected with the second gear , the first gear meshes with the second gear, the speed-regulating motor drives the first gear or the second gear to rotate through a transmissio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com