Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

43results about How to "Improve on-site assembly efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

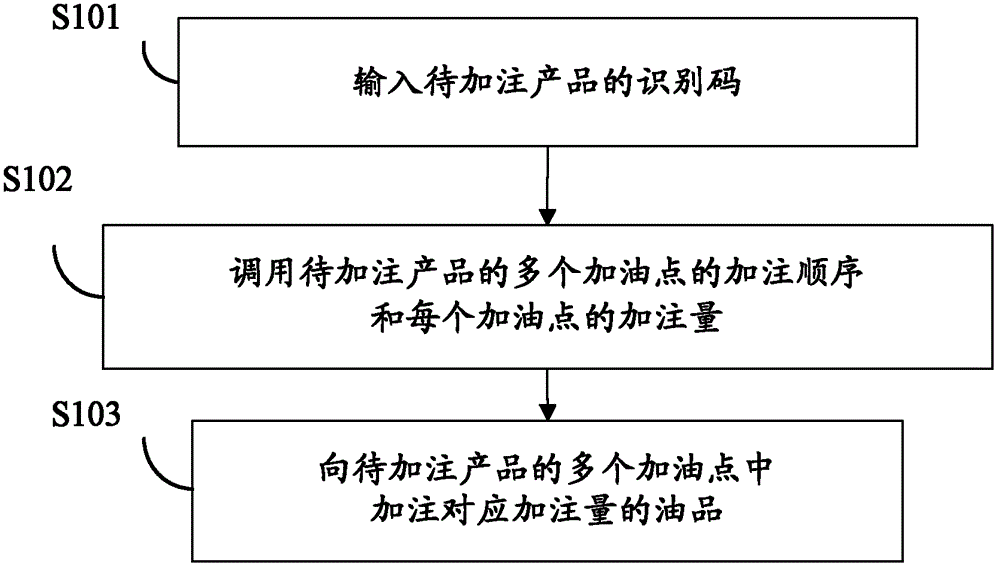

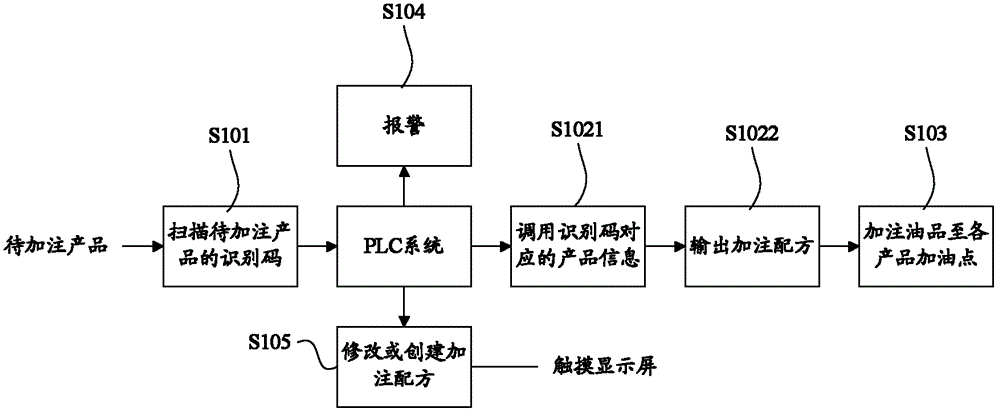

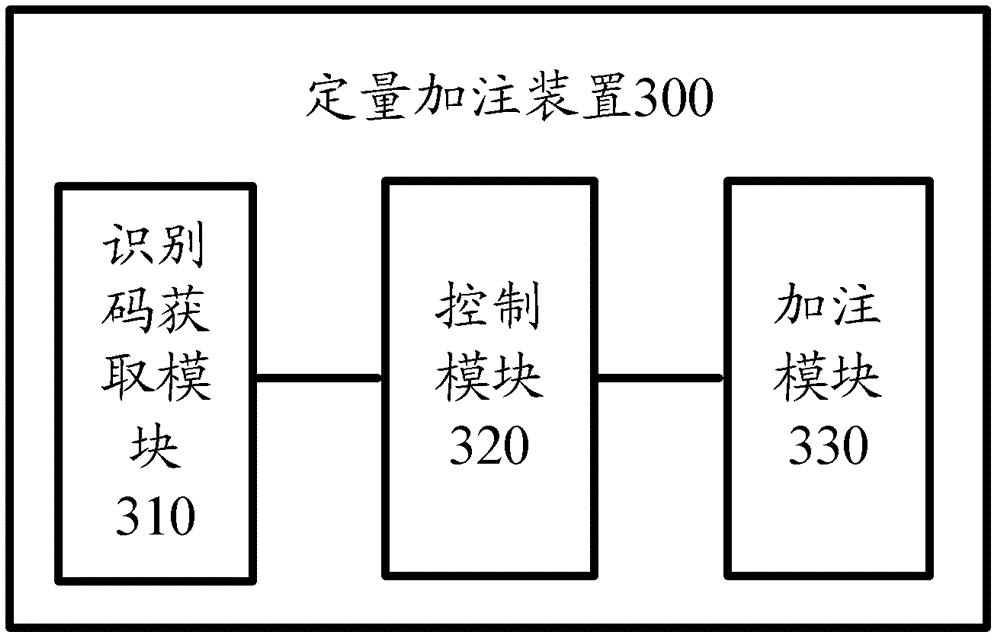

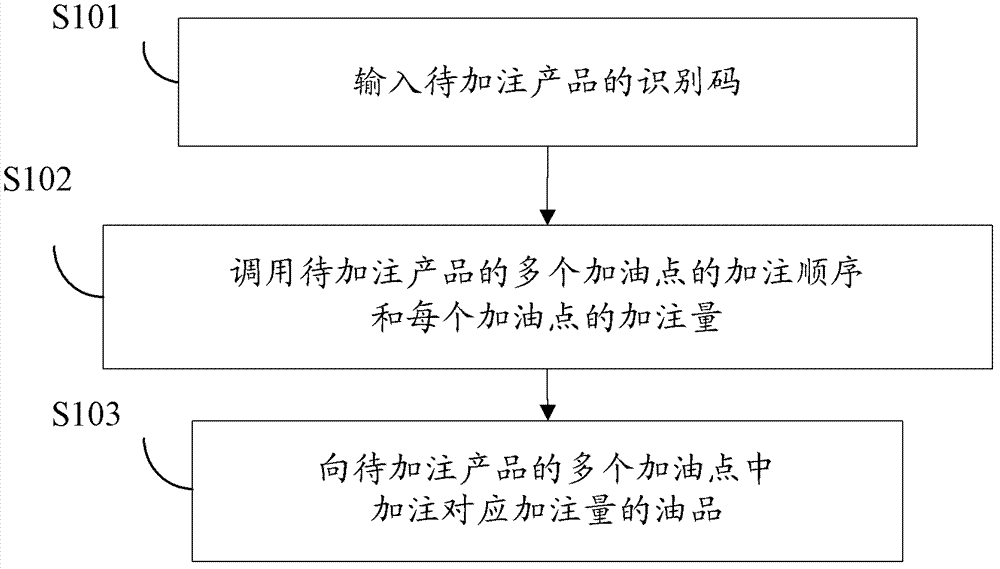

Quantitative filling method and device

ActiveCN102795203AGuaranteed filling qualitySimple and fast operationVehicle servicing/repairingProgramme control in sequence/logic controllersComputer moduleComputer science

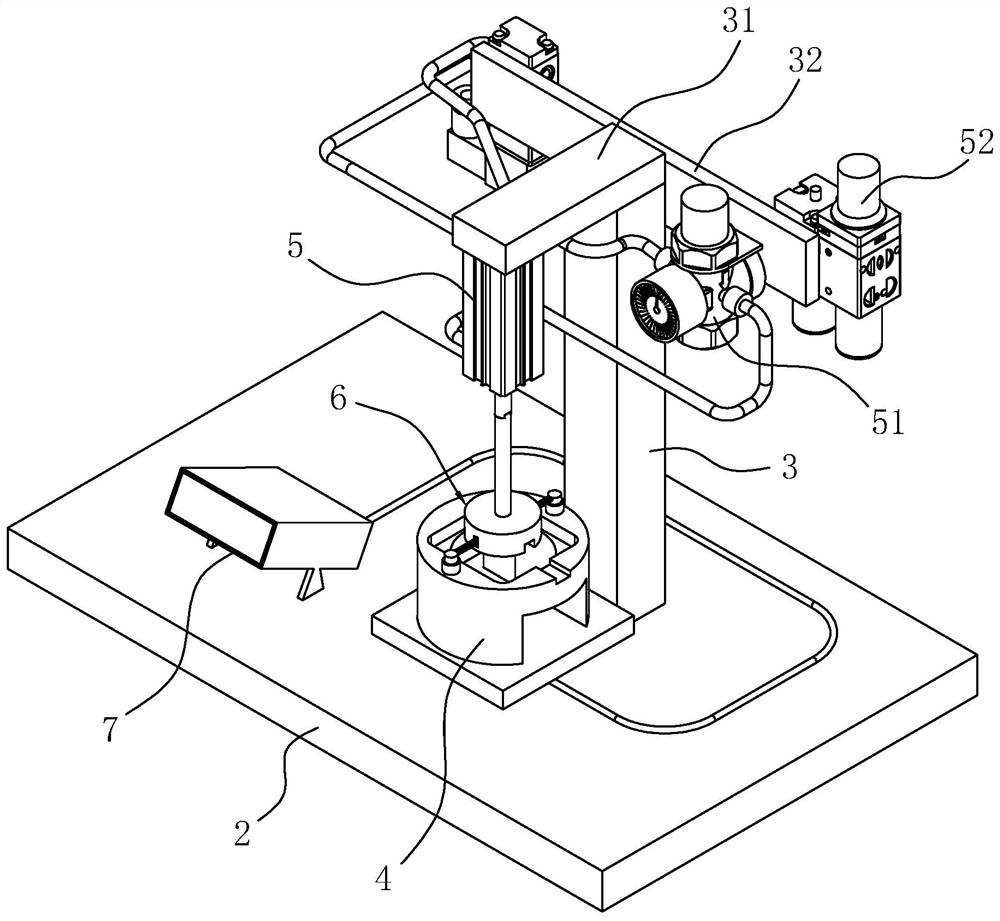

The invention discloses a quantitative filling device. The device comprises an identification code acquisition module for acquiring the identification code of a product to be filled, a control module and a filling module, wherein the control module is used for receiving the identification code of the product to be filled from the identification code acquisition module and calling a filling formula of the product to be filled according to the identification code of the product to be filled; according to the filling formula, the filling sequence of a plurality of oil filling points of the product to be filled and the filling quantity corresponding to each oil filling point are provided; and the filling module fills oil into a plurality of oil filling points of the product to be filled in corresponding quantities according to the filling sequence. The invention also discloses a quantitative filling method. By the quantitative filling device and the quantitative filling method, problems such as wrong filling and missed filling of the oil in the process of manufacturing automobiles are solved; the oil filling quality of the automobiles is guaranteed; the quantitative filling device is easy and convenient to operate, and the oil can be filled accurately, so that the on-site assembly efficiency is improved.

Owner:BEIQI FOTON MOTOR CO LTD

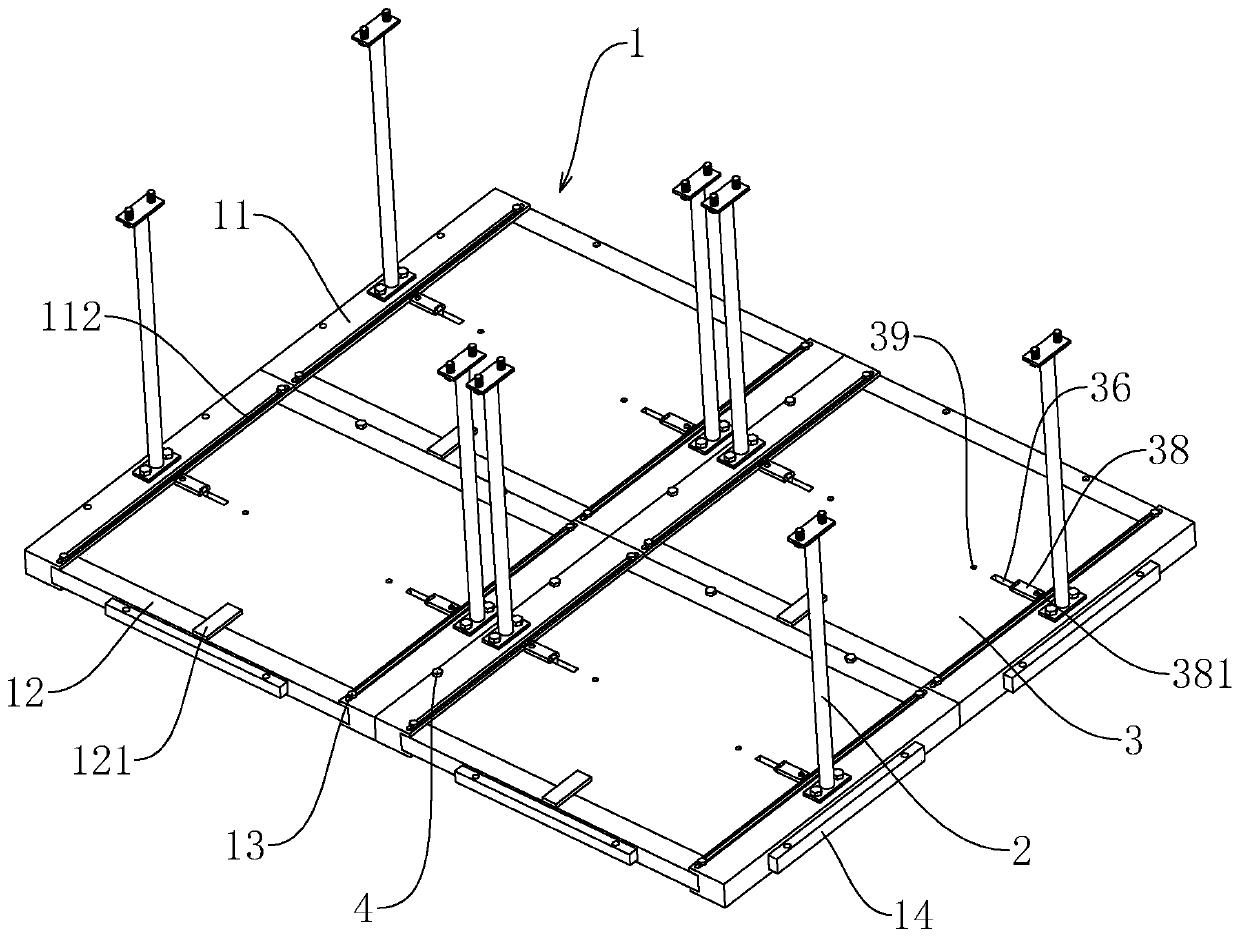

Multifunctional environment-friendly ceiling and mounting method thereof

The invention relates to the technical field of ceilings, and discloses a multifunctional environment-friendly ceiling and a mounting method thereof. The multifunctional environment-friendly ceiling comprises a plurality of keel frames connected through connecting bolts, lifting rods and bottom plates mounted in the keel frames, wherein the lifting rods are mounted on the keel frames, and one endsof the lifting rods are connected with the ceiling; and each keel frame comprises two mutually-parallel fixed rods and two mutually-parallel movable rods, every two movable rods are connected betweenthe two corresponding fixed rods and are perpendicular to the fixed rods, rotating grooves are formed in the two opposite end faces of every two fixed rods correspondingly, the two sides of each bottom plate are provided with rotating shafts rotationally connected into the two corresponding rotating grooves respectively, and the bottom plates are rotationally connected with the fixed rods throughthe rotating shafts; and a stop block is fixed to the upper part of one of the movable rods, and when rotating to be in a horizontal state, one of the bottom plates abuts against the lower side of the stop block and is in threaded connection with the stop block through a mounting bolt. The bottom plates do not need to be dismantled when pipelines between the bottom plates and the ceiling are overhauled, and the effects of convenient operation and high maintenance efficiency are achieved.

Owner:浙江青川装饰集团有限公司

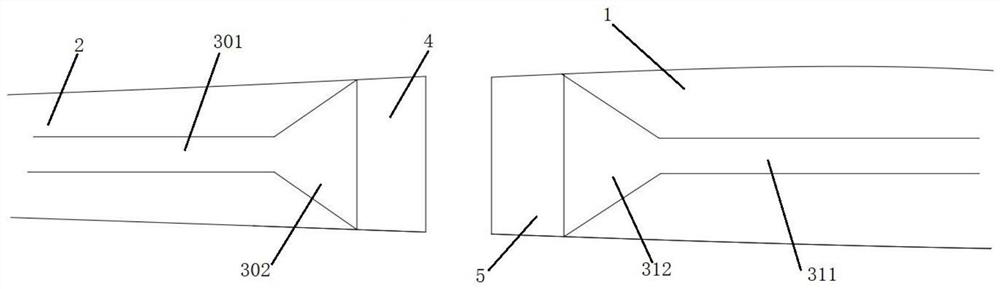

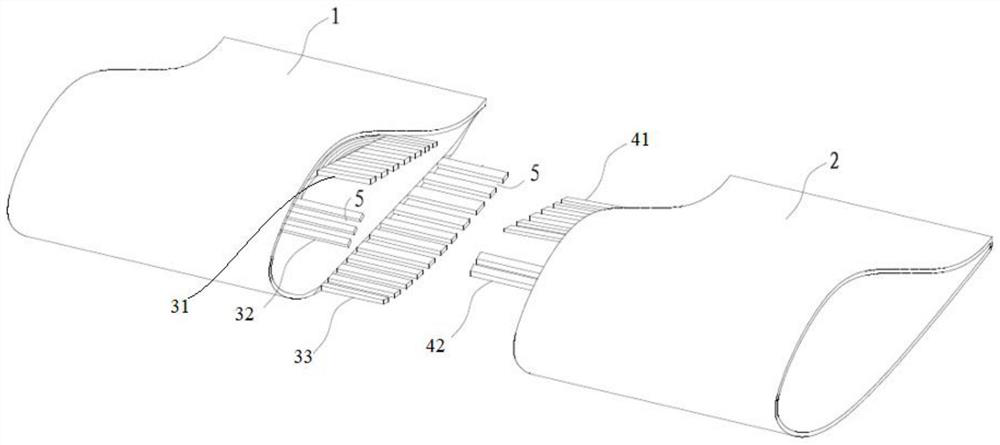

Sectional type fan blade and assembling method thereof

ActiveCN113137346AFirmly connectedIncrease production capacityFinal product manufactureWind motor assemblyStructural engineeringWind field

The invention discloses a sectional type fan blade and an assembling method thereof. The sectional type fan blade comprises a first blade section, a second blade section and a connecting assembly, wherein after the first blade section is connected with the second blade section through the connecting assembly, the first blade section, the connecting assembly and the second blade section form a whole; the connecting assembly comprises a socket piece, an insertion piece and a fixing assembly, a socket groove is formed in the socket piece, the insertion piece is matched with the socket groove, and the fixing assembly is used for fixing the relative position between the socket piece and the insertion piece; and one of the socket piece and the insertion piece is formed at the end, close to the second blade section, of the first blade section, and the other one of the socket piece and the insertion piece is formed at the end, close to the first blade section, of the second blade section. According to the sectional type fan blade, connection of the sectioned blades can be more reliable, the additional mass of the sectioned positions is light, and factory production and wind field on-site operation are facilitated.

Owner:SHANGHAI ELECTRIC WIND POWER GRP CO LTD

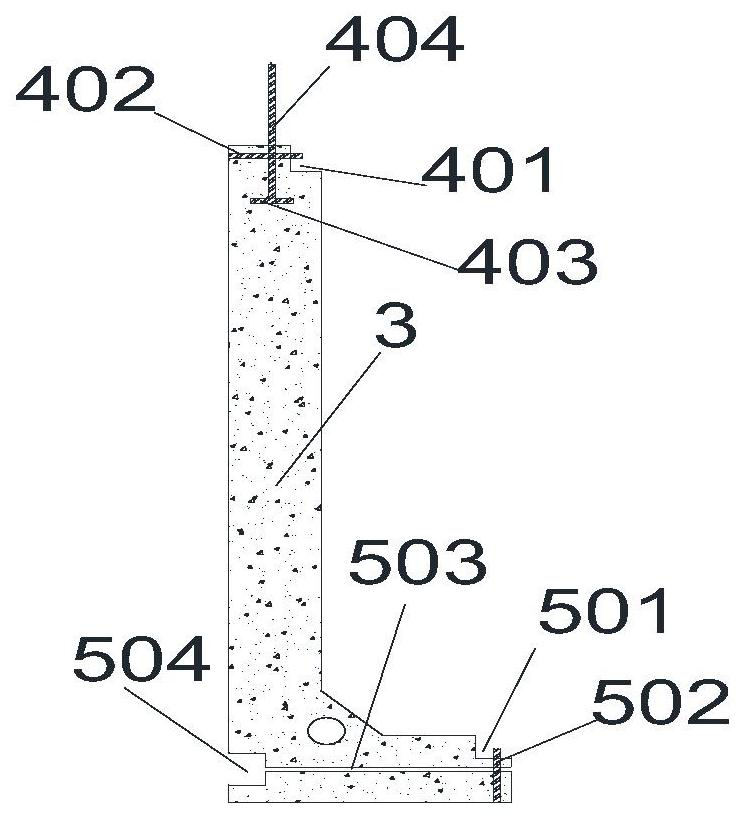

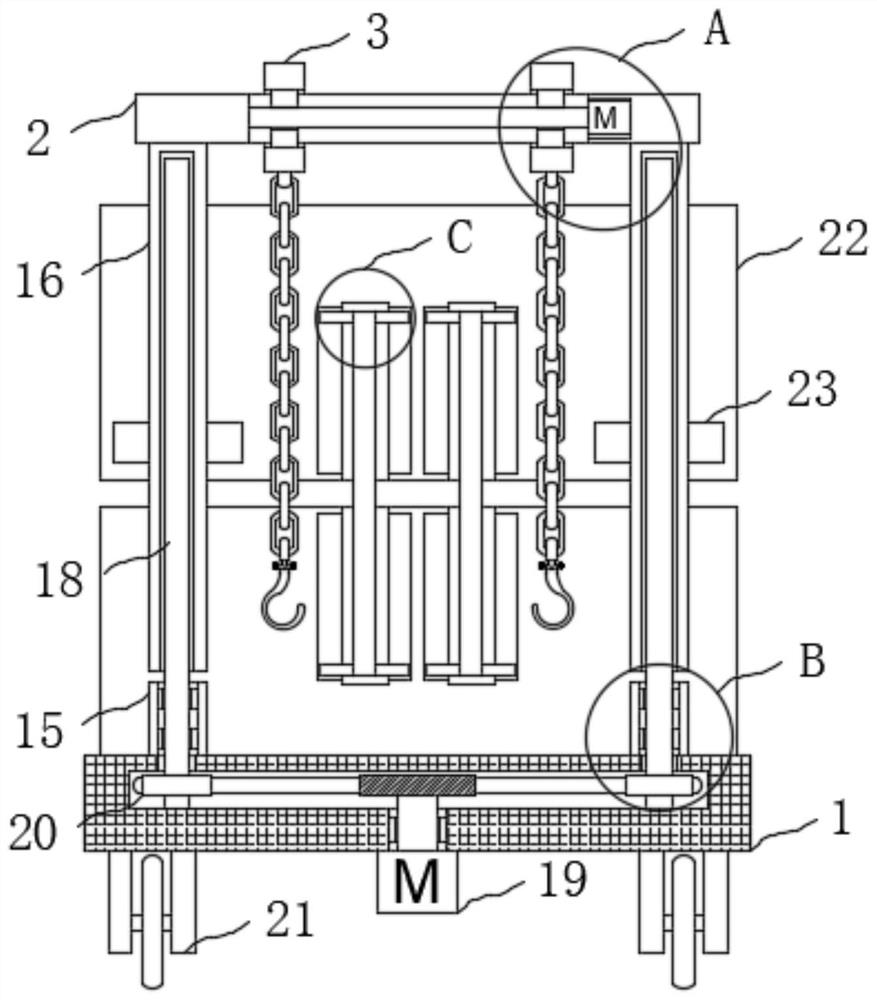

Annular concrete pole and segmented assembling method thereof

InactiveCN111852162AEasy to transportReduce the difficulty of on-site constructionBuilding constructionsTowersScrew thread

The invention discloses an annular concrete pole and a segmented assembling method thereof. The annular concrete pole is composed of multiple segments of branch pole bodies. Multiple columnar holes are formed in the axial direction of the top end face of each segment of branch pole body. Threaded grooves are formed in the hole walls of the columnar holes. Multiple inserting rods are arranged on the bottom end face of each segment of branch pole body. The positions of the inserting rods are in one-to-one correspondence to the positions of the columnar holes. Each inserting rod is composed of aninner core shaft and an outer shaft sleeve, the inner core shafts are fixedly connected with the bottoms of the branch pole bodies, the inner walls of the outer shaft sleeves are rotationally connected with the inner core shafts, and the outer diameter of each outer shaft sleeve is equal to the inner diameter of each columnar hole. Threaded strips are arranged on the outer walls of the outer shaft sleeves and can be completely screwed into the threaded grooves. According to the annular concrete pole, the segmented assembling method is adopted, transporting is convenient, and the field construction difficulty is reduced; and during assembling, only the branch pole bodies need to be lifted and aligned, threaded connection of adjacent segments can be completed through the self gravity of thebranch pole bodies, connecting firmness is guaranteed, and the field assembling efficiency is greatly improved.

Owner:安徽凯越电力杆塔有限公司

Novel oil-distributing valve block oil supply structure and lubricating oil supply station

InactiveCN105526485ASolve the oil spill problemSatisfy single point fuel supplyLubrication check valvesDrive motorOil supply

The invention discloses a novel oil-distributing valve block oil supply structure and a lubricating oil supply station. A compressor gearbox body and a drive motor are arranged on an oil tank body; the novel oil-distributing valve block oil supply structure is used as a connecting transition body between the gearbox body and a pipeline assembly; the novel oil-distributing valve block oil supply structure comprises a valve block main body, wherein an inner oil path used for circulating lubricating oil is arranged in the valve block main body; one side surface of the valve block main body is inwards provided with three oil supply holes communicated with the inner oil path, and the three oil supply holes are respectively communicated with a gear pair and two end bearings of the compressor gearbox body; the other side surface of the valve block main body is inwards provided with an oil inlet communicated with the inner oil path; the oil inlet is communicated with the pipeline assembly for flowing lubricating oil into the gearbox body through the oil inlet, the inner oil path and the oil supply holes respectively so as to lubricate the gear pair and the two end bearings. According to the technical scheme, leakage points can be reduced, the oil leakage problem of an oil supply point of the compressor is solved; and the novel oil-distributing valve block oil supply structure is simple to process and assemble, is convenient in unit assembly, and is convenient for a user to maintain and repair.

Owner:昆山三一环保科技有限公司

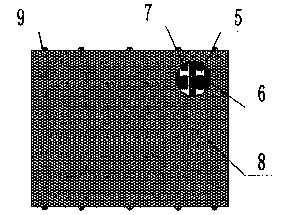

Block splicing type precast concrete box culvert and construction process thereof

InactiveCN111636316AReduce prefabrication costsReduce hoisting costsGround-workArchitectural engineeringPrecast concrete

The invention relates to the technical field of prefabricated culverts and particularly relates to a block splicing type prefabricated concrete box culvert and a construction process thereof. The culvert comprises a top plate culvert piece, a bottom plate culvert piece, a side plate culvert piece, an anchoring structure and a fastening structure, wherein the top plate culvert piece is of a cover body structure and covers the side plate culvert pieces, each side plate culvert piece is of an L-shaped structure and comprises a vertical end and a horizontal end, the vertical end supports the top plate culvert piece, the horizontal end is connected with the bottom plate culvert piece, the anchoring structure is arranged on the bottom plate culvert pieces and the side plate culvert pieces, the fastening structure is arranged on the top plate culvert pieces and the side plate culvert pieces, and fastening bolts are used for fastening connection of the top plate culvert pieces and the side plate culvert pieces. The culvert is advantaged in that aiming at defects in the prior art, construction cost is reduced, the risk in the transportation process is reduced, and construction efficiency isimproved.

Owner:JSTI GRP CO LTD +2

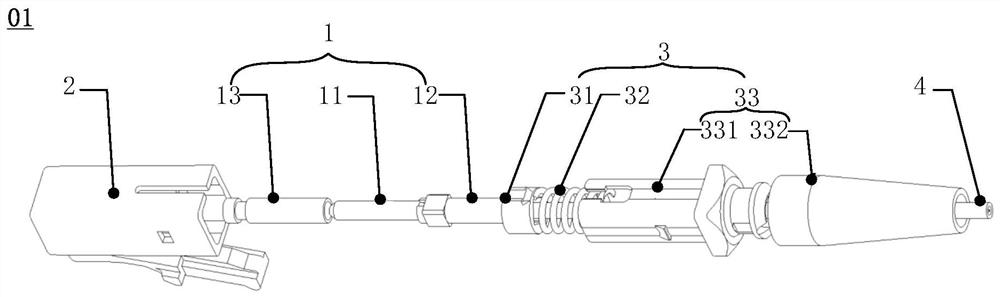

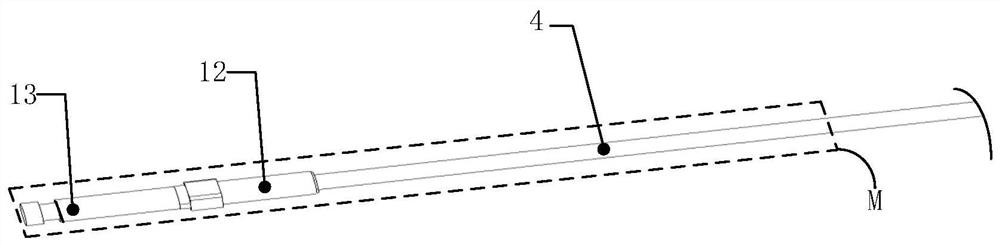

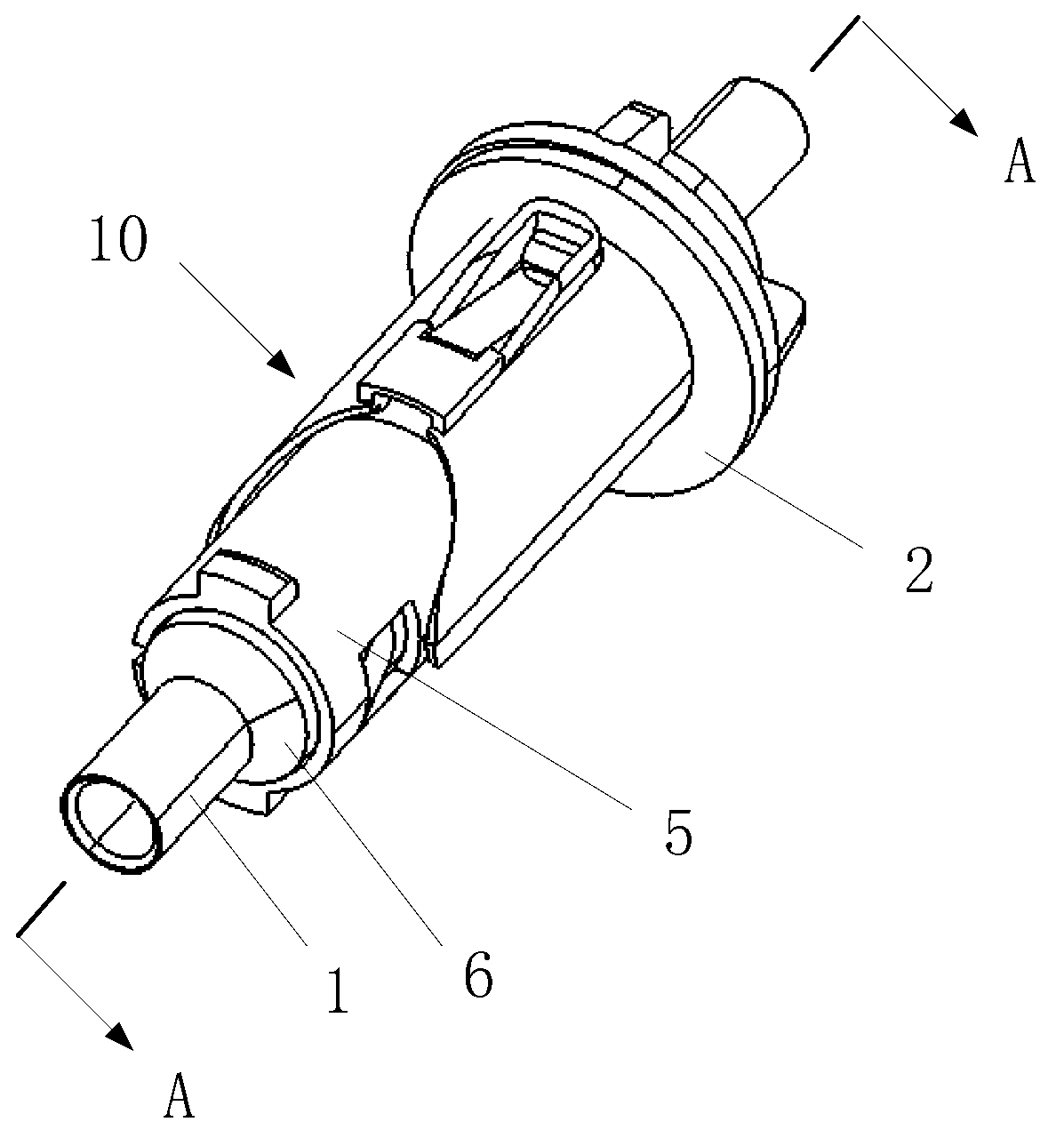

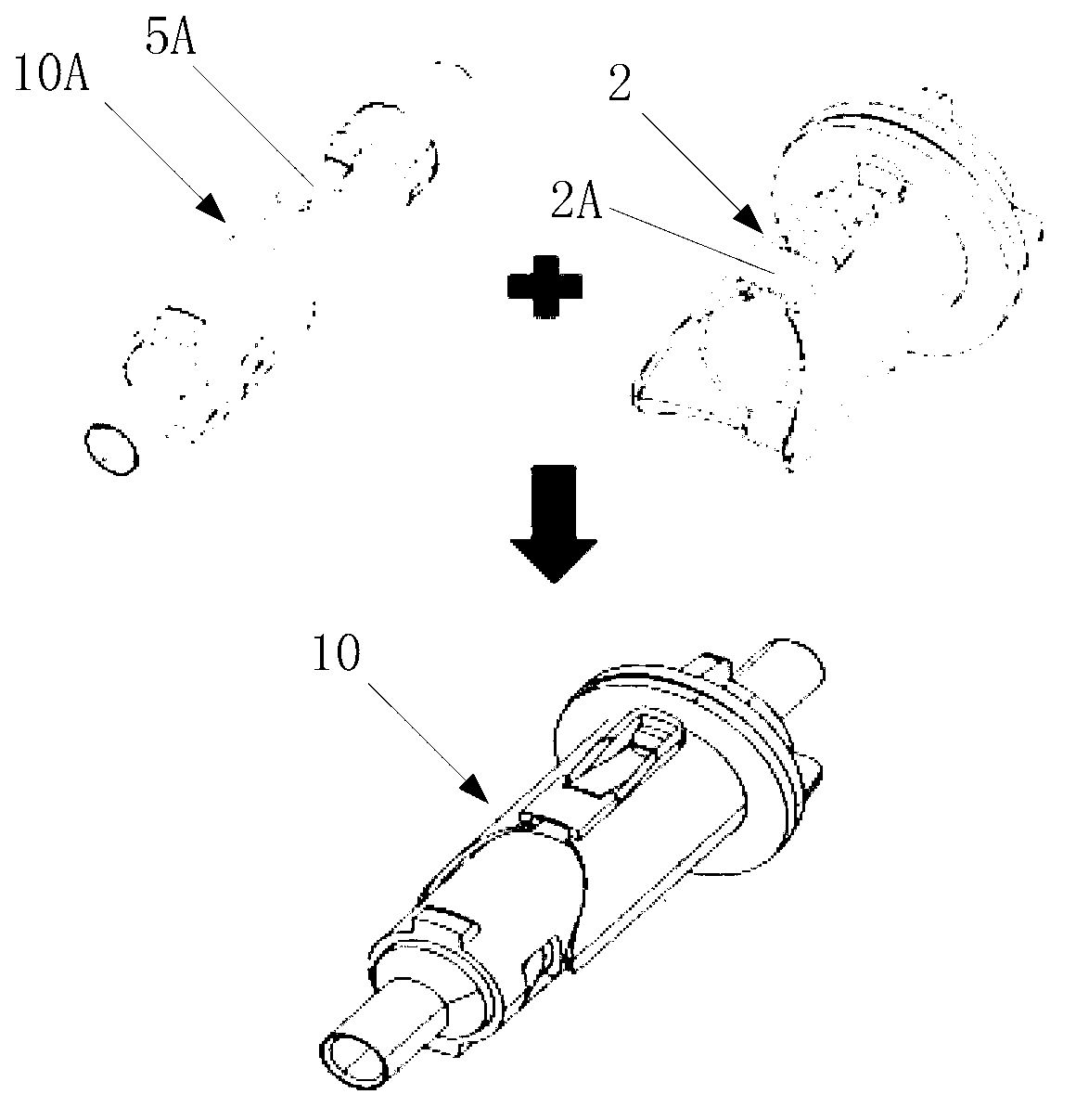

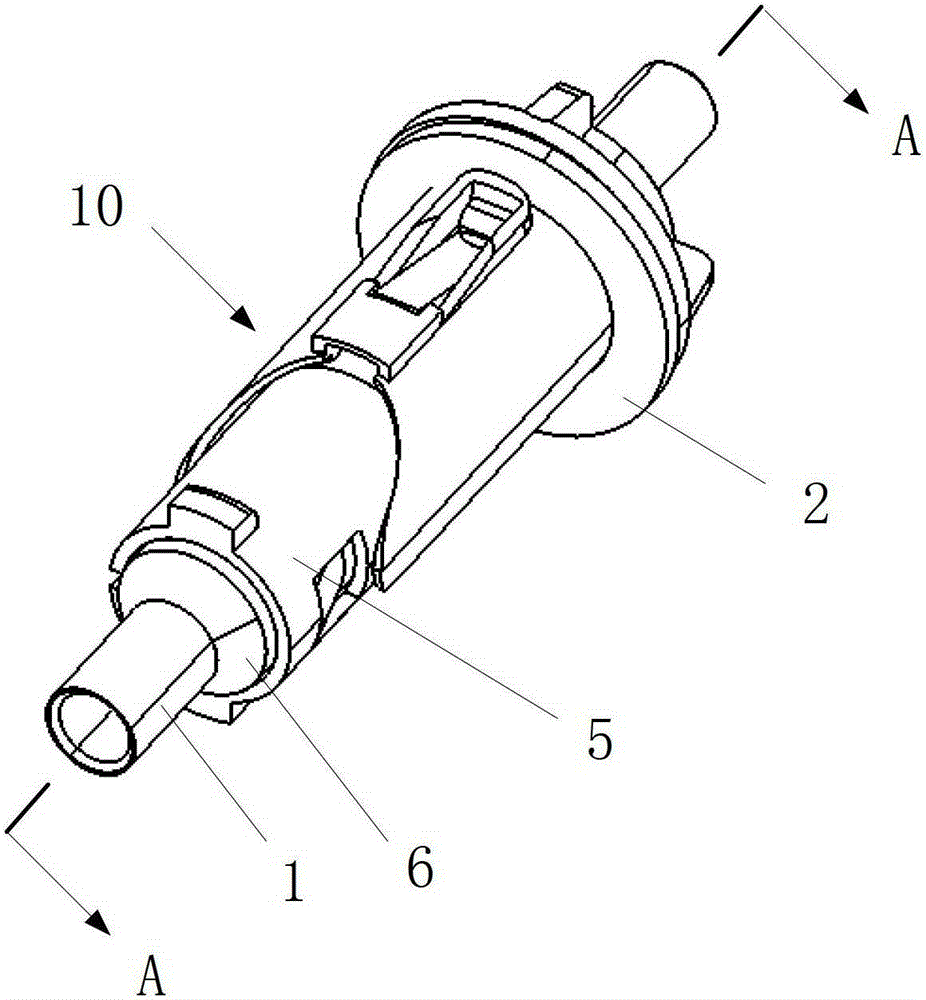

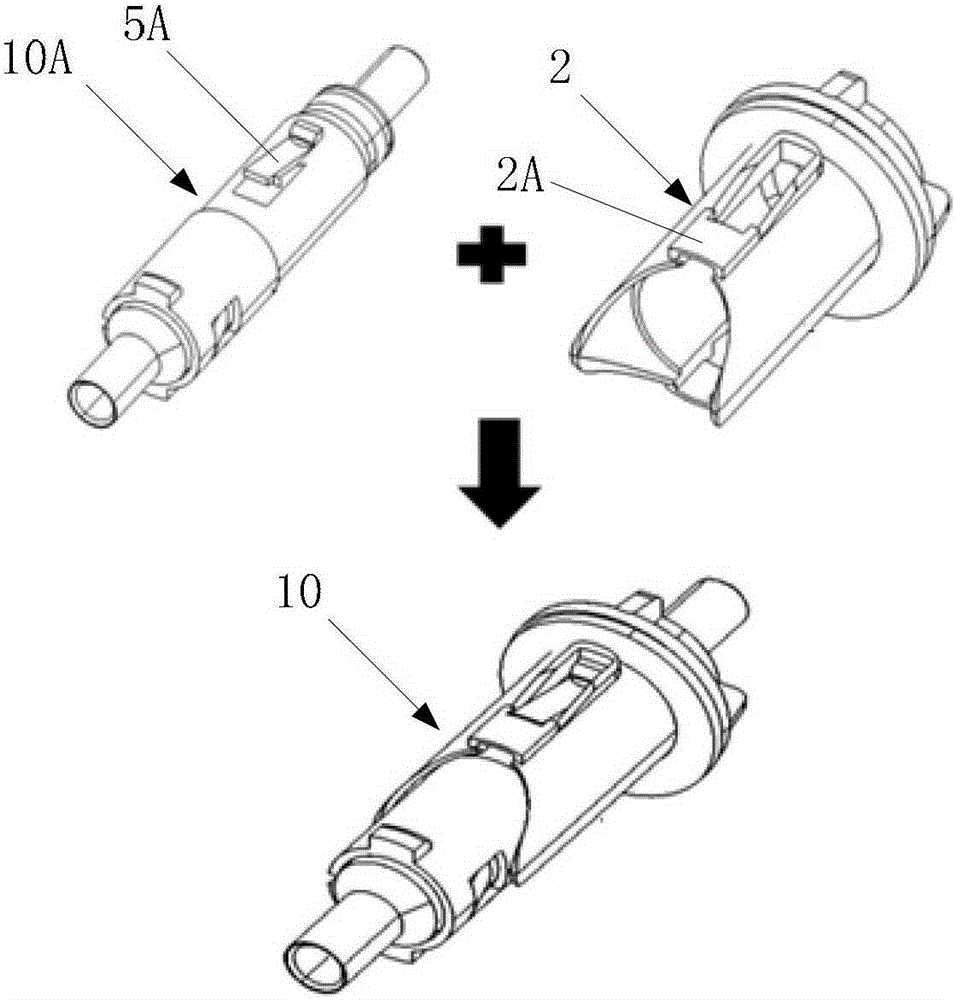

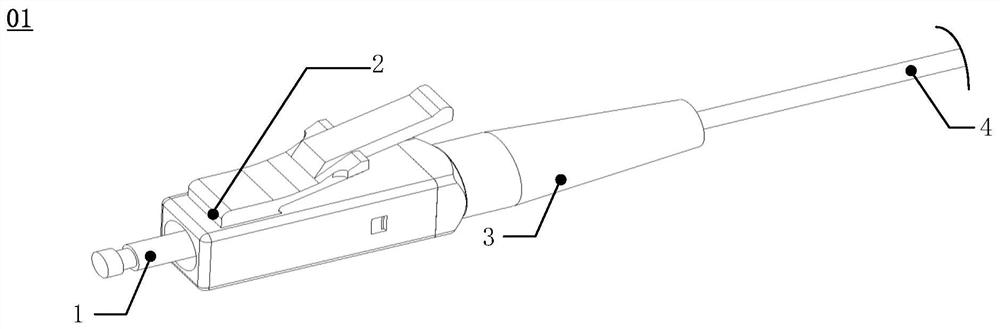

Optical connector

ActiveCN112230355AReduce the difficulty of assemblyMeet the needs of kitsOptical fibre/cable installationFibre mechanical structuresEngineeringMechanical engineering

The present invention provides an optical connector. The optical connector comprises: a tube-through assembly having at least one projection; a shell assembly which is arranged on the outer side of the tube-through assembly in a sleeving mode and provided with a first channel allowing the tube-through assembly to pass in the first direction, wherein the shell assembly is further provided with a first limiting structure, the first limiting structure is provided with a limiting face and a positioning face, and the limiting face is used for abutting against the end face of the protrusion and usedfor limiting the tube-through assembly in the second direction opposite to the first direction after the tube-through assembly rotates relative to the shell assembly. The positioning face is used forabutting against the surface of the protrusion and used for limiting the tube-through assembly and the shell assembly in the circumferential direction of the tube-through assembly. According to the optical connector, the shell assembly is provided with the first limiting structure, after the tube-through assembly rotates relative to the shell assembly, the tube-through assembly is limited throughthe abutting relation between the first limiting structure on the shell assembly and the protrusion, the assembling difficulty of the optical connector can be reduced, and therefore the on-site assembling efficiency is improved.

Owner:HUAWEI TECH CO LTD

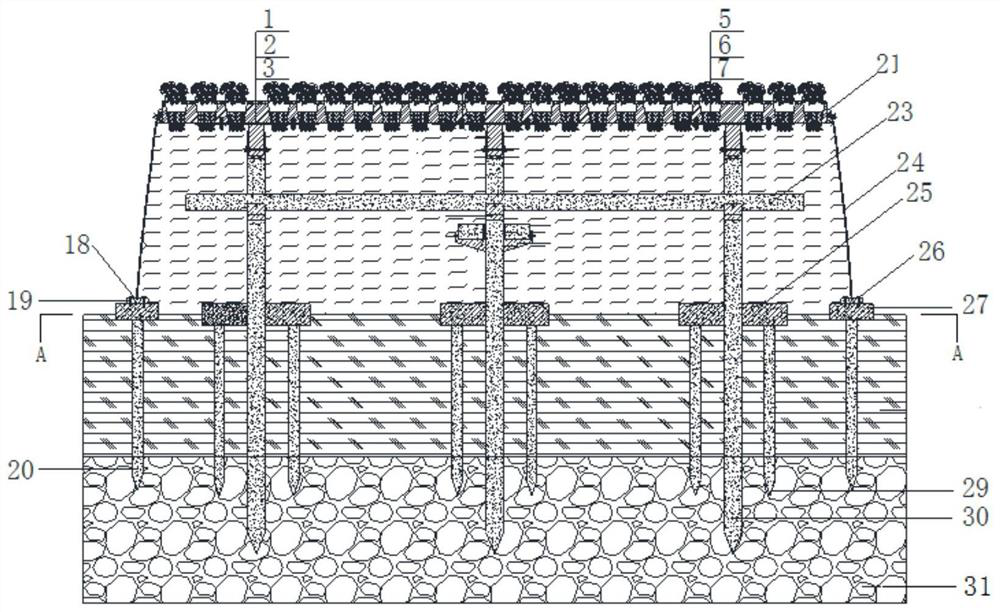

Construction method for aquatic plant compound biological floating island

ActiveCN109368794AIncreased durabilityAvoid displacement changesBiological water/sewage treatmentEngineeringSeedling

The invention relates to a construction method for an aquatic plant compound biological floating island. The method comprises the following steps: construction preparation: detecting planting soil andformulating construction steps; designing an integral structure of the biological floating island and preparing a prefabricated member; selecting plant seedlings, and transplanting the same to a feeding block body of the floating island; constructing a side anchor log system; constructing middle anchor log group piles; splicing and fixing a floating island model; and maintaining the aquatic plantfloating island. The biological floating island obtained by the construction method is good in durability, high in stability, high in construction efficiency and remarkable in economical and beneficial benefits.

Owner:HANGZHOU JIANGRUN TECH LIMITED

H-shaped steel beam bolt joint construction method

InactiveCN112376691ASimplify the construction processFor quick twistBuilding constructionsConstruction engineeringArchitectural engineering

The invention relates to an H-shaped steel beam bolt joint construction method. According to the H-shaped steel beam bolt joint construction method, in a steel structure deepening design stage, related simple measures are optimized into a design drawing, a processing factory conducts processing along with components, a connecting plate is fixed onto a steel beam by using a common bolt when the components leave the factory, part of mounting bolts are demounted during mounting on a site, the connecting plate is overturned, the steel beam is mounted, then high-strength bolt construction is conducted, mounting is quick, light and flexible, safety measures can be saved, and safety in the using process can be guaranteed; and by arranging temporary measures, on-site rapid positioning and mountingof full-bolt joints are guaranteed, meanwhile, the construction quality of the high-strength bolts is guaranteed, the construction cost is reduced while the working efficiency is improved, and the H-shaped steel beam bolt joint construction method is also suitable for construction of large steel beam web connecting plates.

Owner:中冶(上海)钢结构科技有限公司

Cable module and electrical connector

PendingCN109560431AEasy to fixSo as not to damageCoupling device detailsTwo-part coupling devicesElectromagnetic shieldingEngineering

The present invention discloses a cable module and an electrical connector having the same. The cable module comprises: a cable; a tubular connector sleeving the cable; and a gasket sleeving the cableand held in the tubular connector. The shielding braiding layer of the cable is backwards overturned on the gasket; the gasket has a tapered outer peripheral surface, the tubular connector has a tapered inner peripheral surface, and the shielding braiding layer of the cable can be extruded and fixed between the tapered outer peripheral surface and the tapered inner peripheral surface of the tubular connector. Therefore, in the invention, the shielding braiding layer of the cable can be reliably fixed without damaging of the shielding braiding layer of the cable so that the electromagnetic shielding effect of the electrical connector is improved. Besides, in the invention, the number of parts to be assembled of the electrical connector is small so that the field assembling efficiency of the electrical connector is improved.

Owner:TYCO ELECTRONICS (SHANGHAI) CO LTD +1

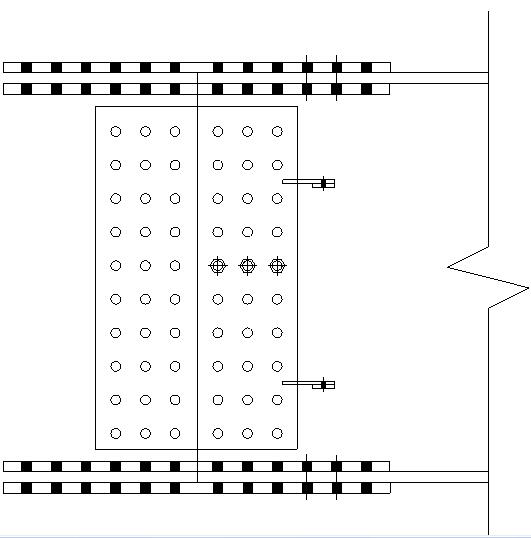

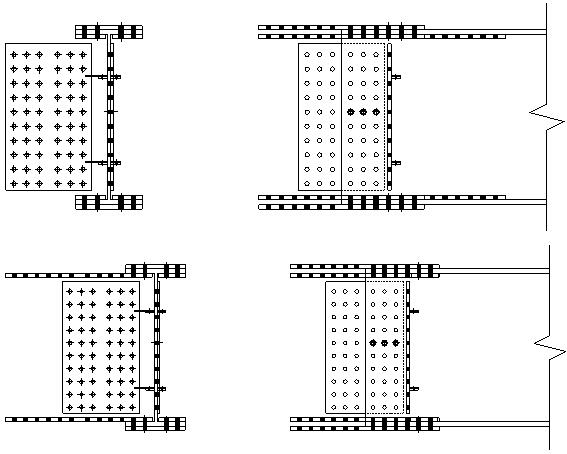

Prefabricated wall board positioning hole tool for concrete prefabricated component production line

PendingCN107718242AThe purpose of precise splicing and pouringPrecise and fast brush splicing pouring purposesMoulding surfacesMould auxillary partsBuilding productProduction line

The invention belongs to the technical field of building products and particularly relates to a prefabricated wall board positioning hole tool for a concrete prefabricated component production line. The prefabricated wall board positioning hole tool comprises a base, a transverse support arm is arranged at the base in an extending mode, and a penetration hole is formed in the top end of the transverse support arm. The tool further comprises a positioning cylinder and a threaded sleeve, the top end face of the positioning cylinder is fixedly connected to the lower hole end face of the penetration hole in an abutting mode, and the positioning cylinder and the penetration hole are coaxially arranged / formed. An inner thread is arranged at a sleeve cavity of the threaded sleeve, a positioning bolt penetrates through the penetration hole and the positioning cylinder from top to bottom, and the positioning bolt and the threaded sleeve are matched in a threaded mode so as to enable the top endface of the threaded sleeve to abut against the bottom end face of the positioning cylinder. The height of the matching face of the threaded sleeve and the positioning cylinder is equal to or smallerthan the maximum grouting height of a mold cavity. According to the prefabricated wall board positioning hole tool for the concrete prefabricated component production line, when prefabricated wall bodies are formed, the equal height of the constructed prefabricated wall bodies can be ensured, and the coplanar later-period assembly requirement can be met, so that the assembly efficiency and accuracy of the prefabricated wall bodies can be greatly improved.

Owner:ANHUI BAOYE CONSTR ENG GRP CO LTD

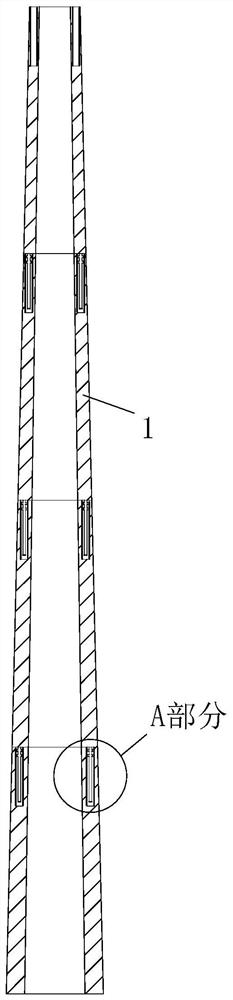

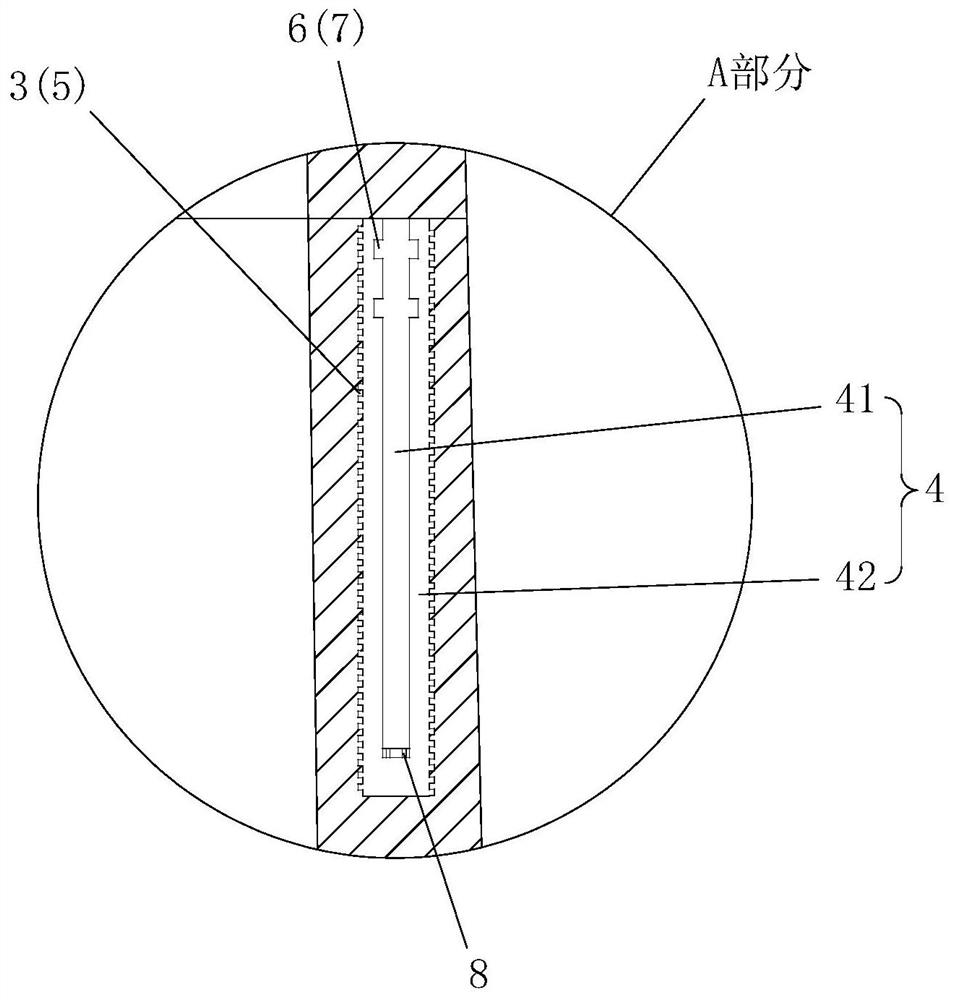

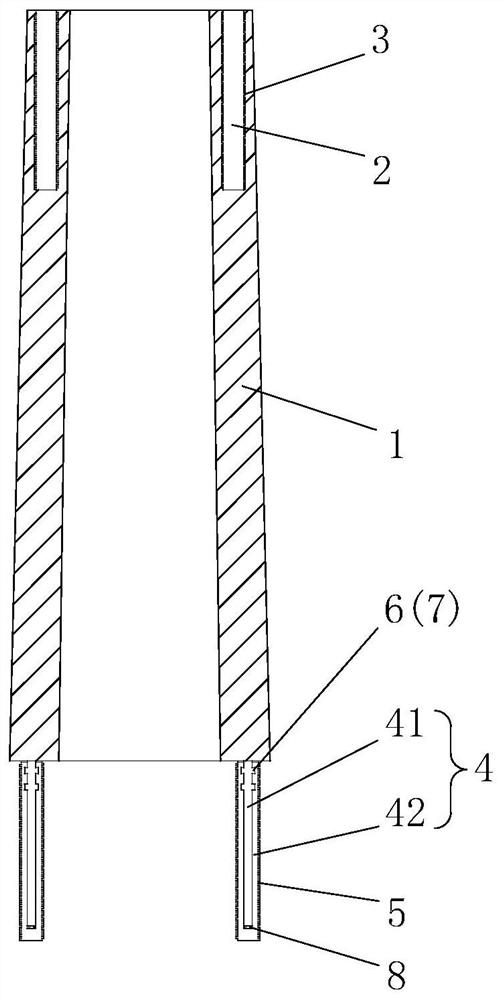

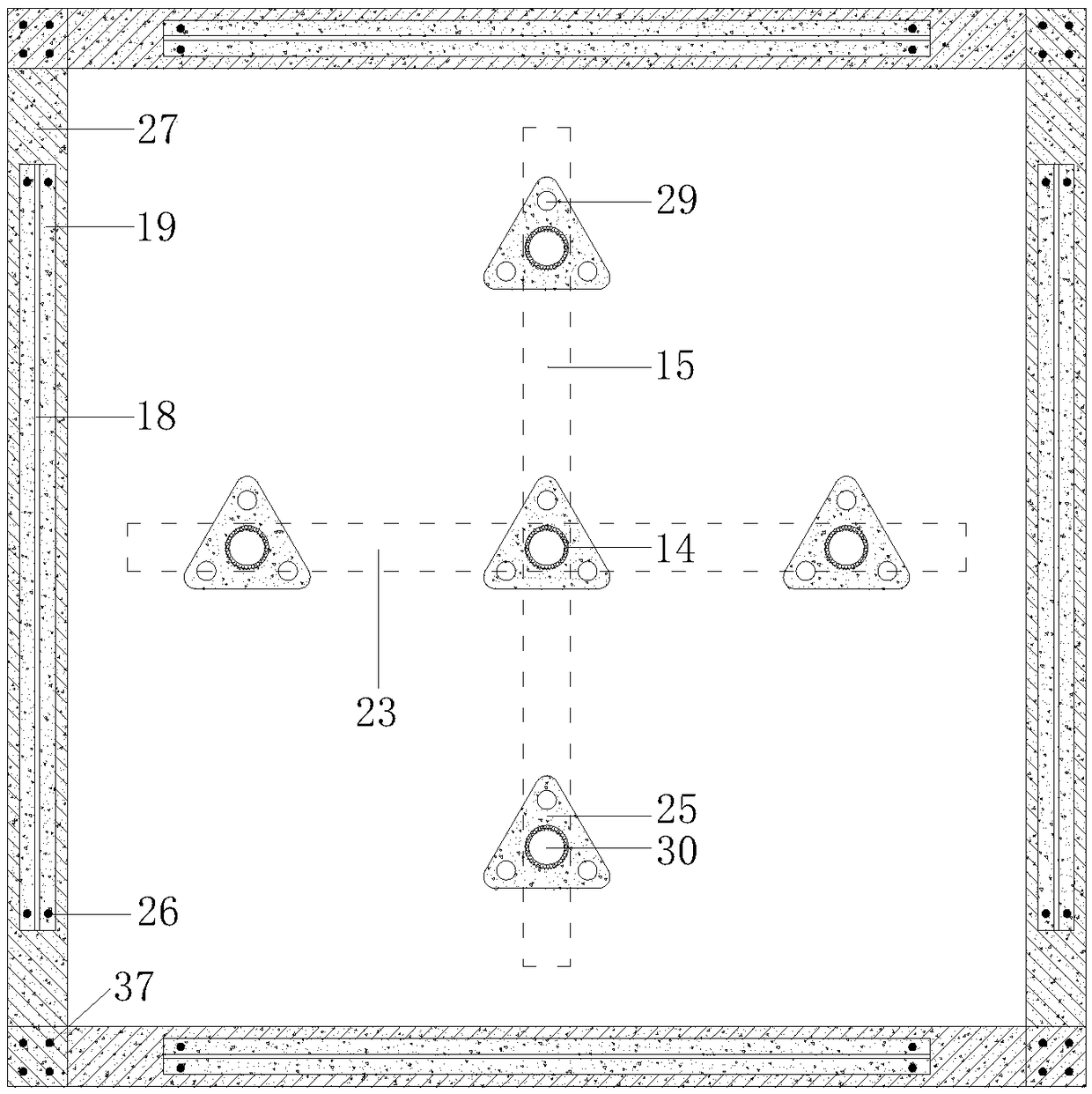

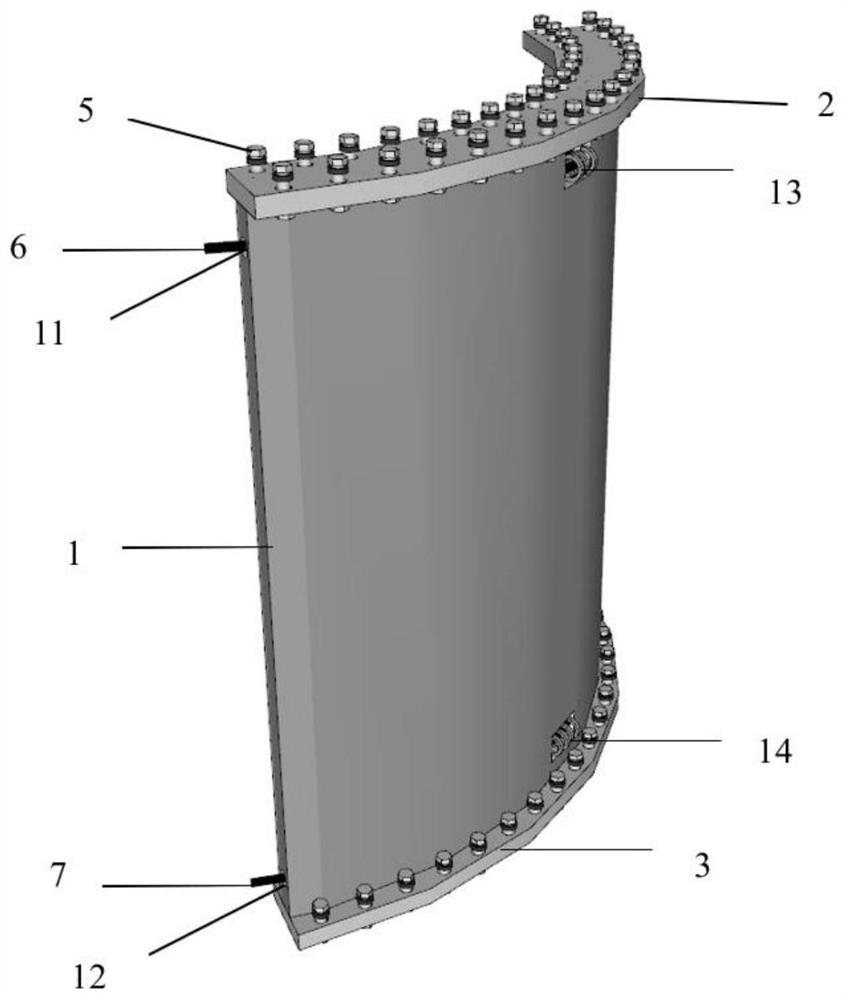

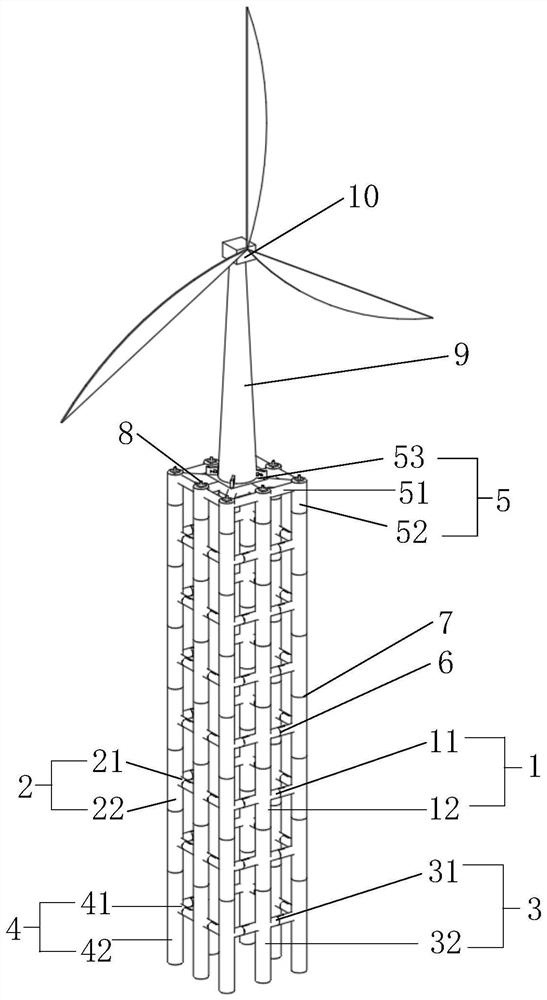

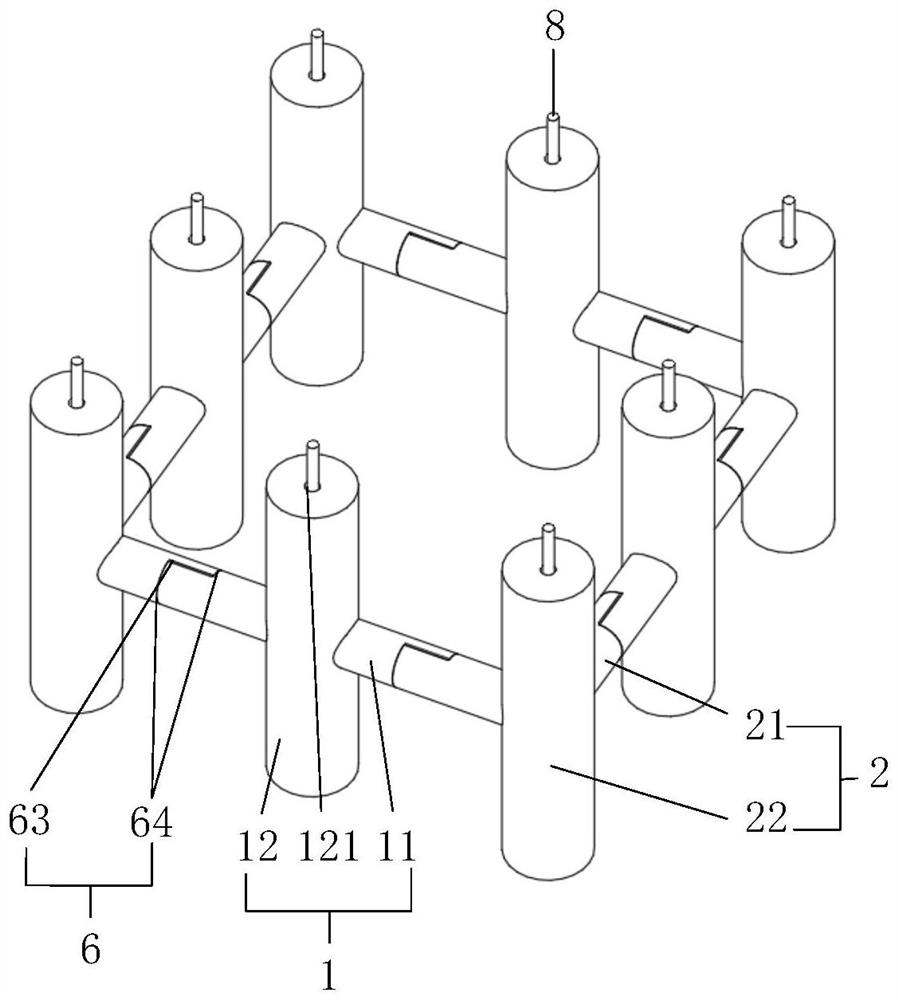

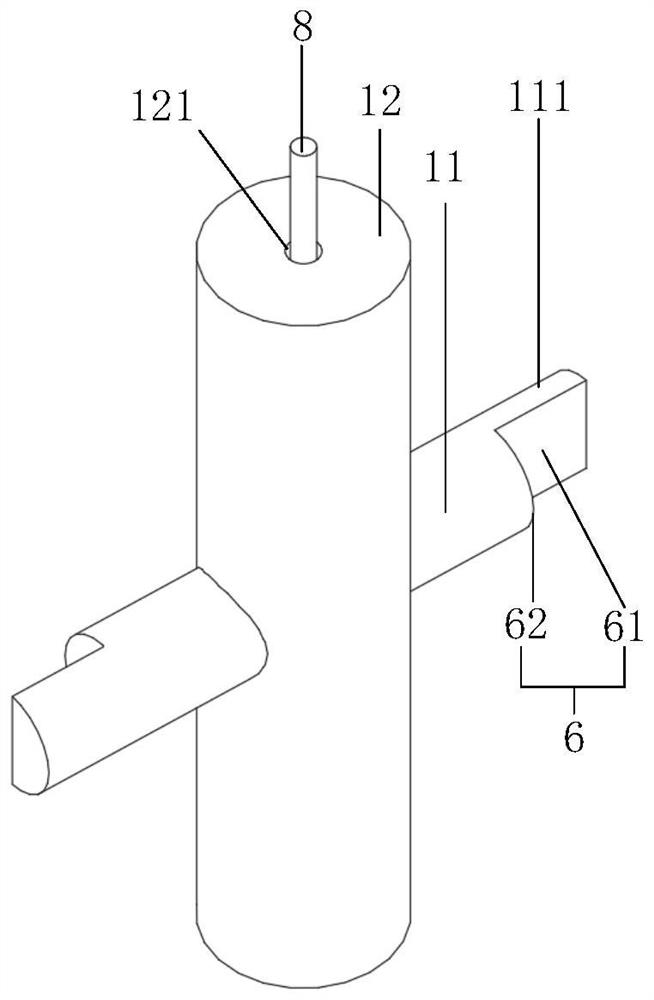

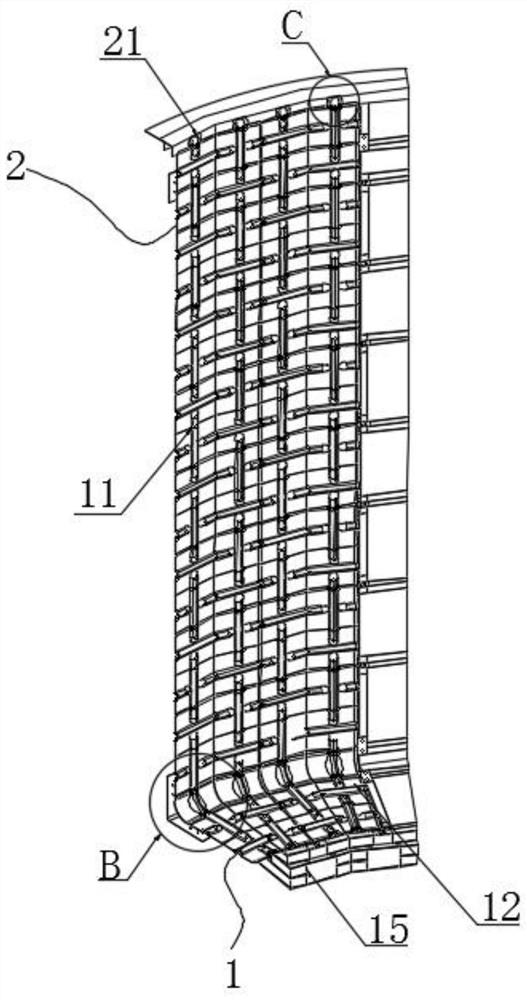

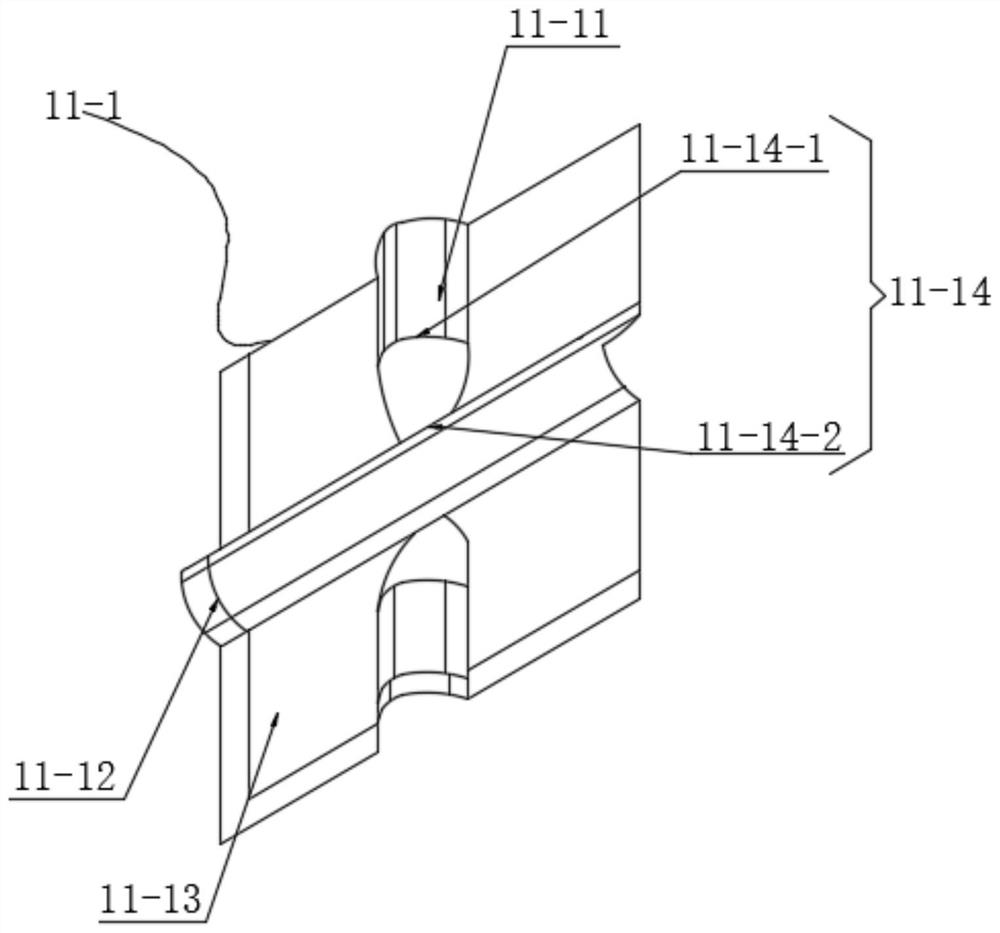

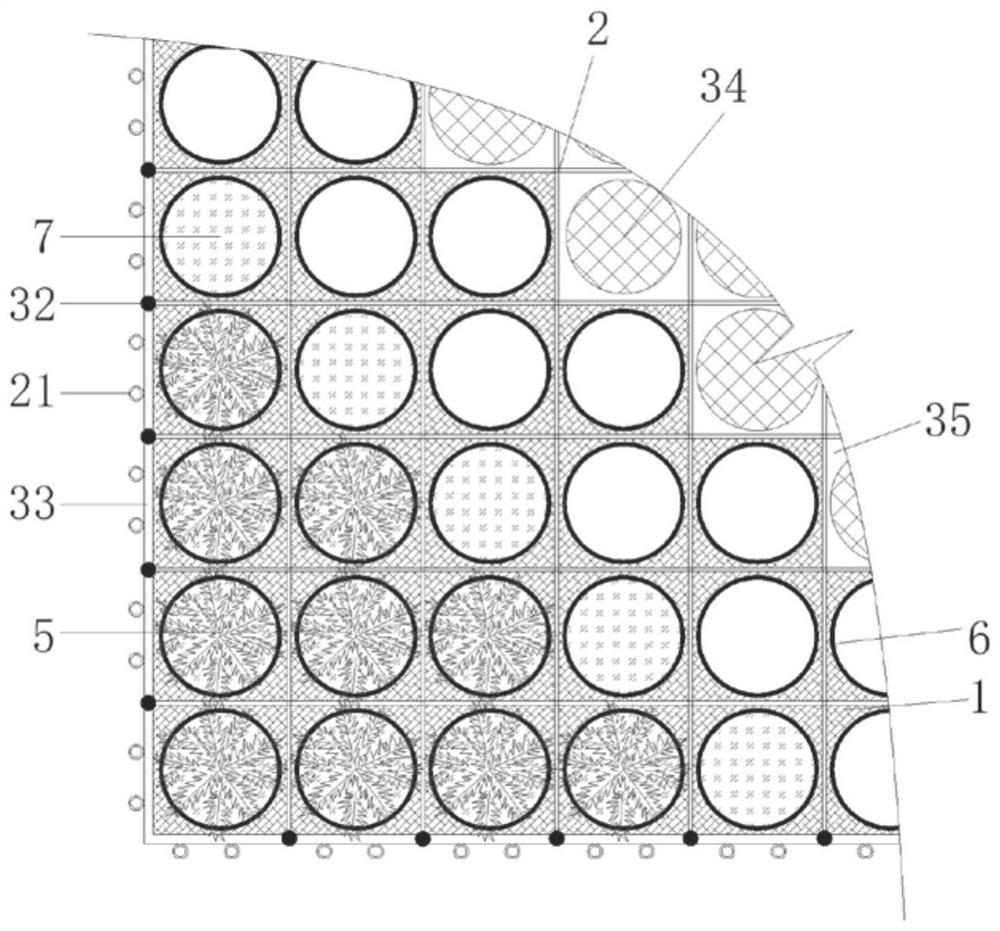

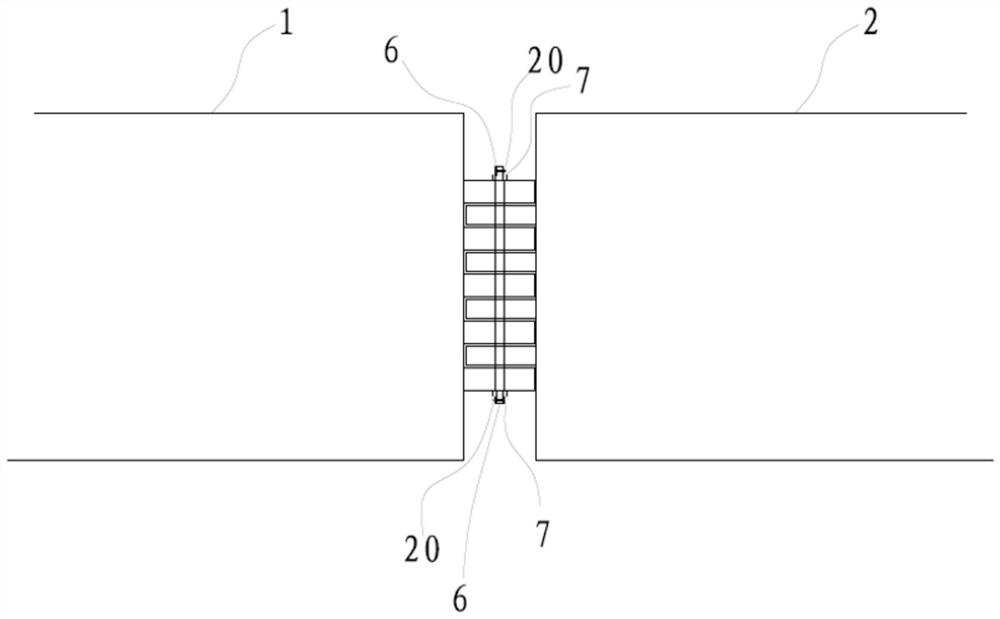

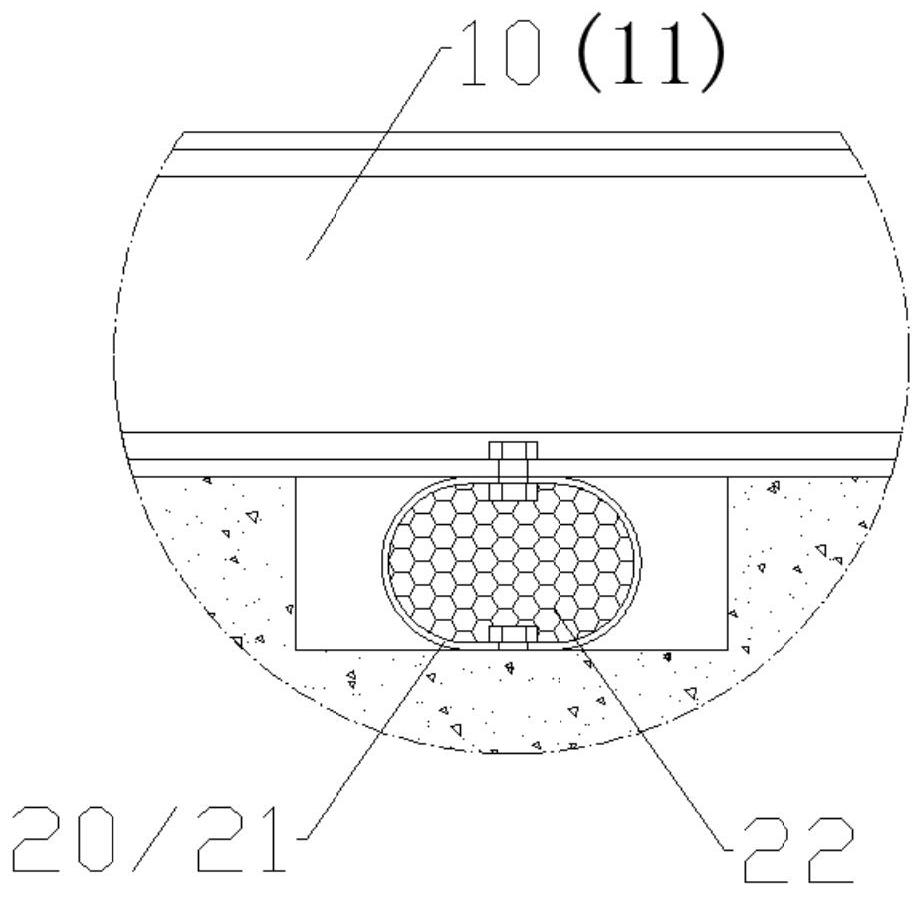

Circular-section concrete supporting structure of fabricated wind turbine generator

PendingCN112412707AImprove on-site assembly efficiencyImprove assembly efficiencyWind motor supports/mountsWind energy generationRebarPre stress

The invention discloses a circular-section concrete supporting structure of a fabricated wind turbine generator. The circular-section concrete supporting structure comprises at least one structural unit, wherein each structural unit comprises a concrete tower section, tower section inner longitudinal steel bars, an upper flange plate, a lower flange plate, an upper prestressed steel strand, a lower prestressed steel strand and high-strength bolts; the tower section inner longitudinal steel bars, the upper flange plates and the lower flange plates are integrally cast to form an integral frame;concrete is poured between the upper flange plates and the lower flange plates and wraps the tower section inner longitudinal steel bars; a plurality of structural units are annularly connected through the upper prestressed steel strands and the lower prestressed steel strands in a pre-tensioning mode; and a plurality of structural units are vertically connected through the upper flange plates andthe lower flange plates by means of the high-strength bolts to form a conical whole. According to the circular-section concrete supporting structure, the integrity and installation of a concrete tower are effectively improved while the requirements for factory fragment prefabrication and on-site integral assembly are met.

Owner:CHONGQING UNIV

PC wallboard mould used for concrete prefabricated component production line

PendingCN107738340AThe purpose of precise splicing and pouringPrecise and fast brush splicing pouring purposesDischarging arrangementMouldsBuilding productProduction line

The invention belongs to the technical field of building products, in particular to a PC wallboard mould used for a concrete prefabricated component production line. The mould comprises an inner cavity wall module, an outer cavity wall module and a positioning hole module, wherein the positioning hole module comprises a base; a transverse supporting arm is extended from the base; a penetrating hole is formed in the top end of the transverse supporting arm; the positioning hole module further comprises a positioning barrel and a threaded sleeve; the top end surface of the positioning barrel isfixedly connected to the lower hole end surface of the penetrating hole in a resisting mode, and the positioning barrel and the penetrating hole are coaxially formed; inner threads are arranged at a sleeve cavity of the threaded sleeve; a positioning bolt passes through the penetrating hole and the positioning barrel, and is in threaded fit to the threaded sleeve; and a matched surface of the threaded sleeve and the positioning barrel is higher than or equal to or lower than the top end surface of the outer cavity wall module. The mould has the advantages of being simple, convenient and quickto operate, and low in manufacturing cost, so that later-stage assembly needs at equal height and the same plane of a manufactured prefabricated wallboard can be guaranteed while the prefabricated wallboard is formed.

Owner:ANHUI BAOYE CONSTR ENG GRP CO LTD

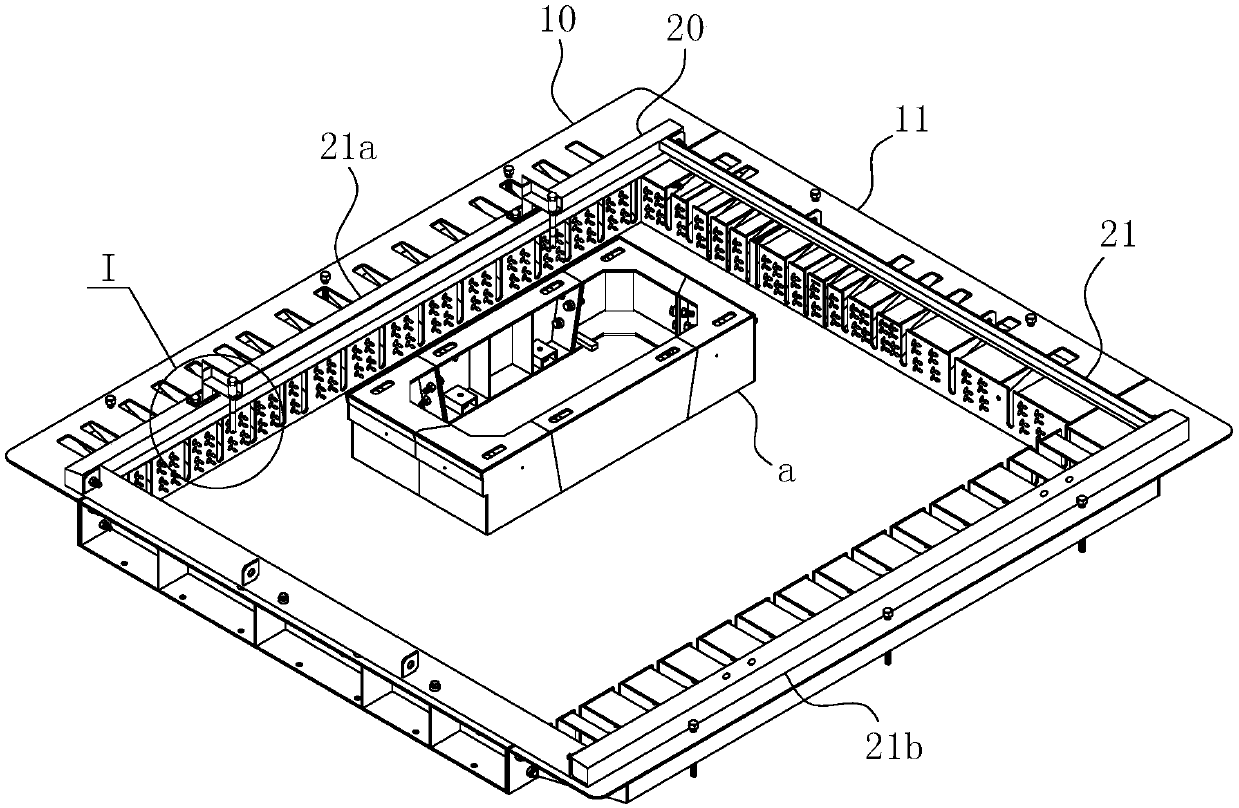

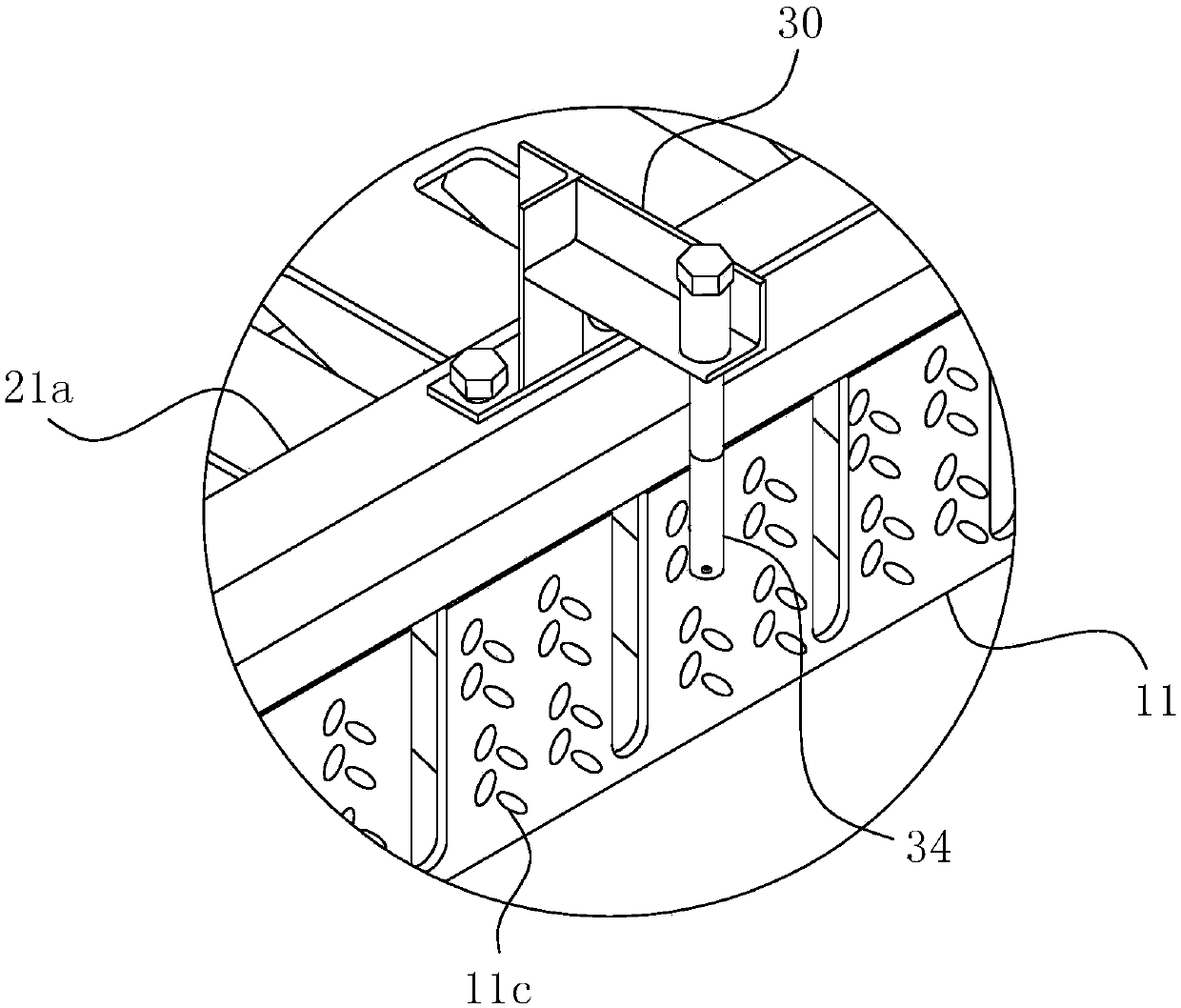

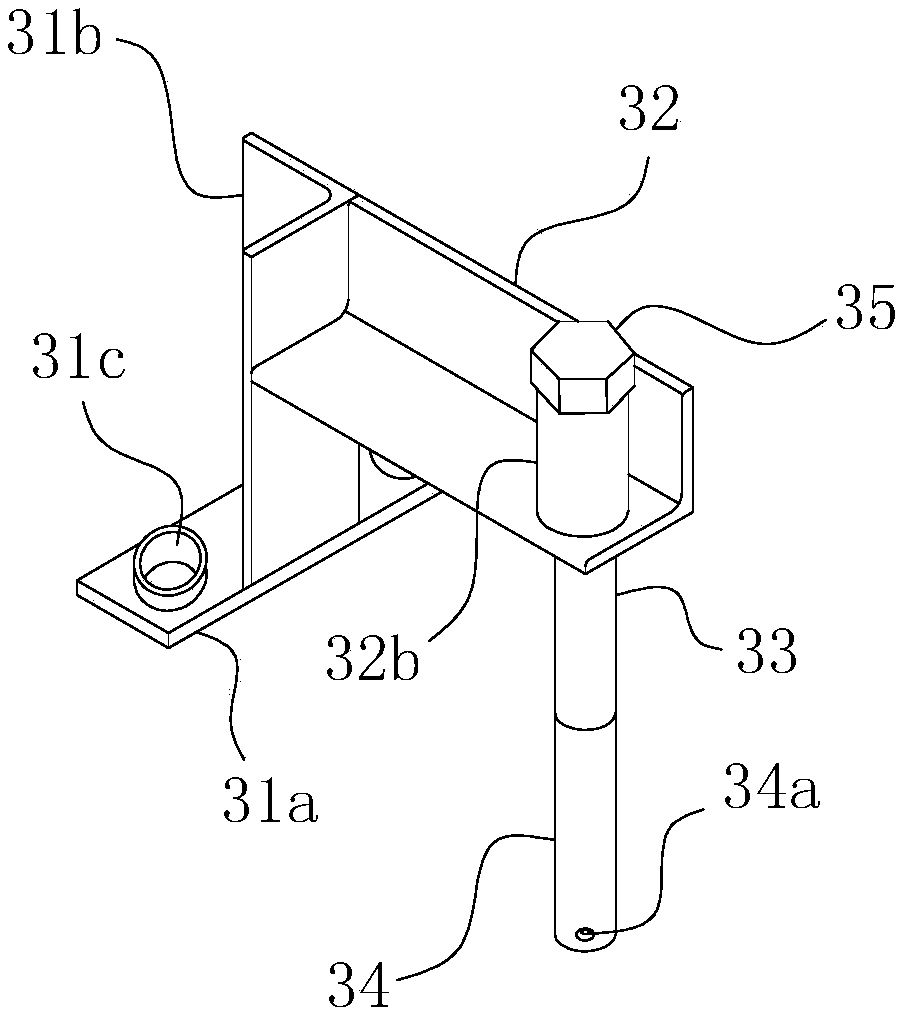

Prestress assembly type concrete frame supporting structure of wind turbine generator set

The invention discloses a prestress assembly type concrete frame supporting structure of a wind turbine generator set, the top end of a supporting structure is provided with a steel tower to be fixed, the top end of the steel tower is provided with the wind turbine generator set, and the supporting structure comprises a bottom-layer supporting unit, a middle-layer supporting unit, a top-layer supporting unit and a plurality of prestressed steel strands. The bottom-layer supporting unit is of a rectangular frame body structure; the middle-layer supporting unit is arranged at the upper end of the bottom-layer supporting unit, and the middle-layer supporting unit is formed by overlapping a plurality of standard structure units; the top-layer supporting unit is arranged at the top end of the middle-layer supporting unit; and the prestressed steel strands penetrate through hole bodies longitudinally formed in the bottom-layer supporting unit, the middle-layer supporting unit and the top-layer supporting unit correspondingly, and longitudinal connection and fixation of the bottom-layer supporting unit, the middle-layer supporting unit and the top-layer supporting unit are completed. By means of the supporting structure, the problem that node bolts and inclined struts in a traditional lattice type tower are unfavorable in stress is effectively solved.

Owner:CHONGQING UNIV

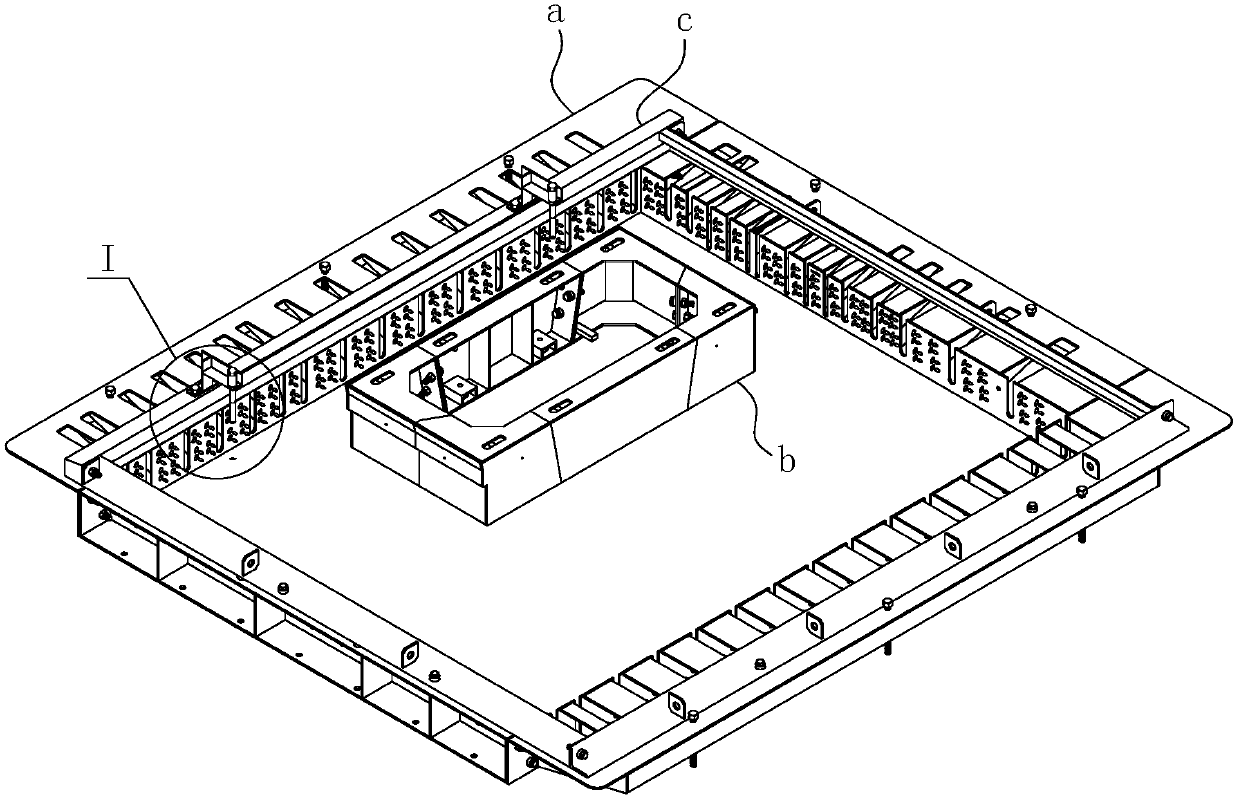

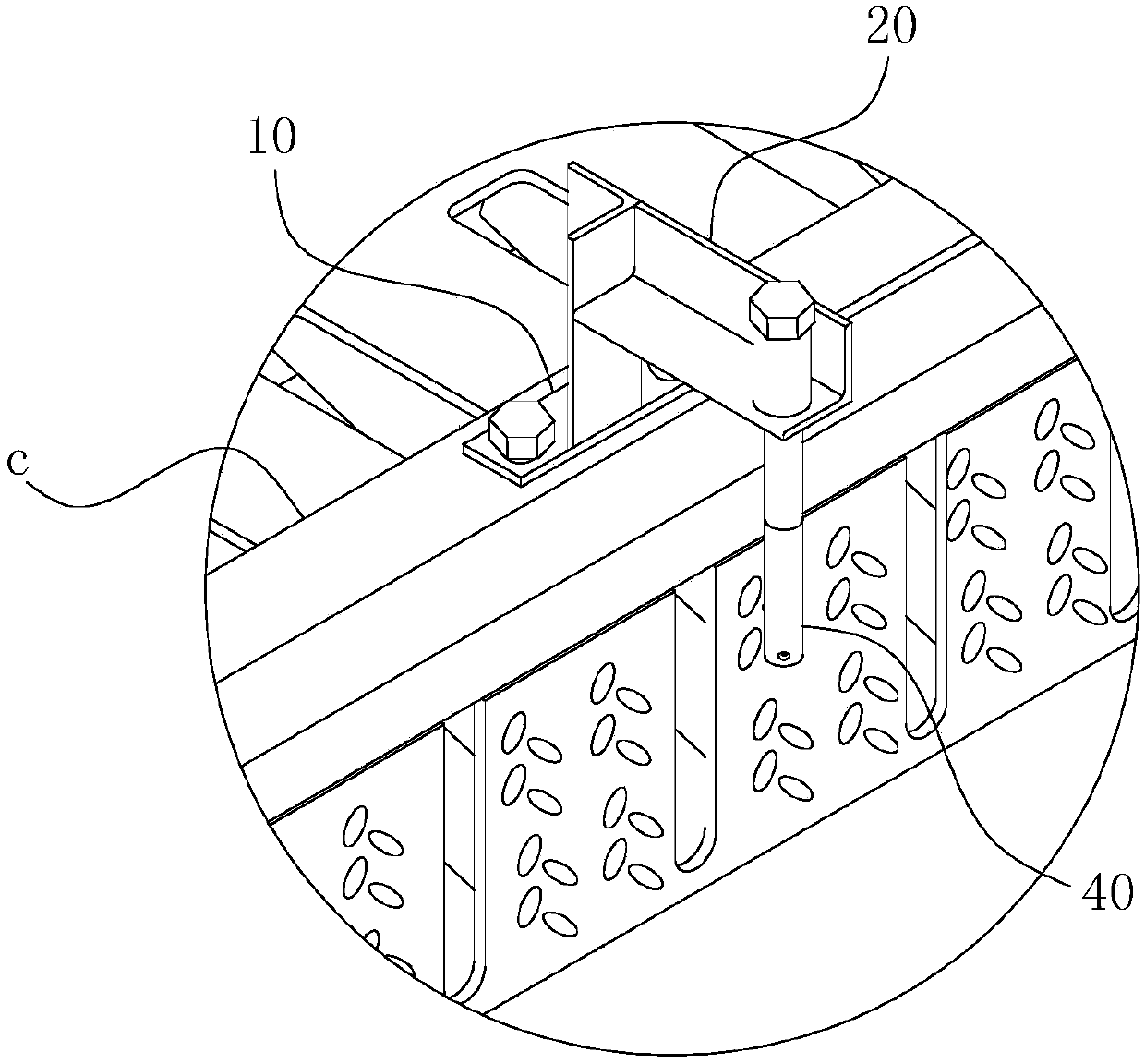

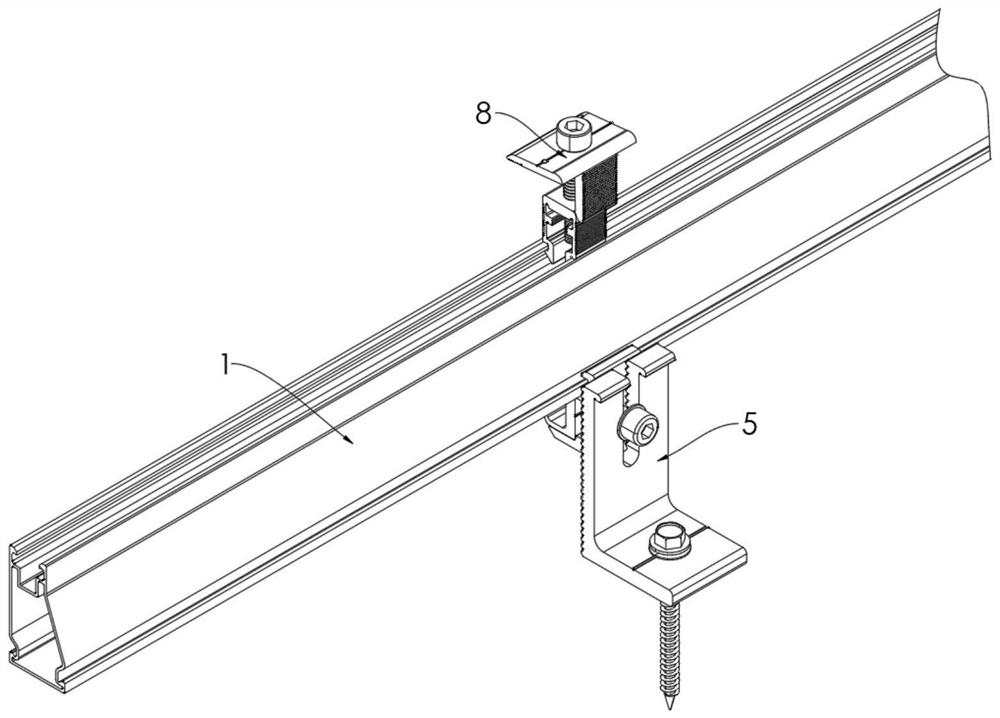

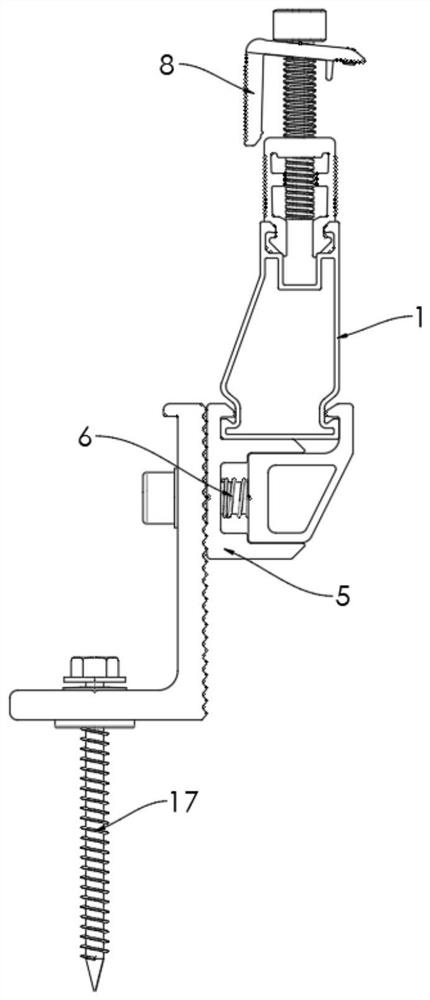

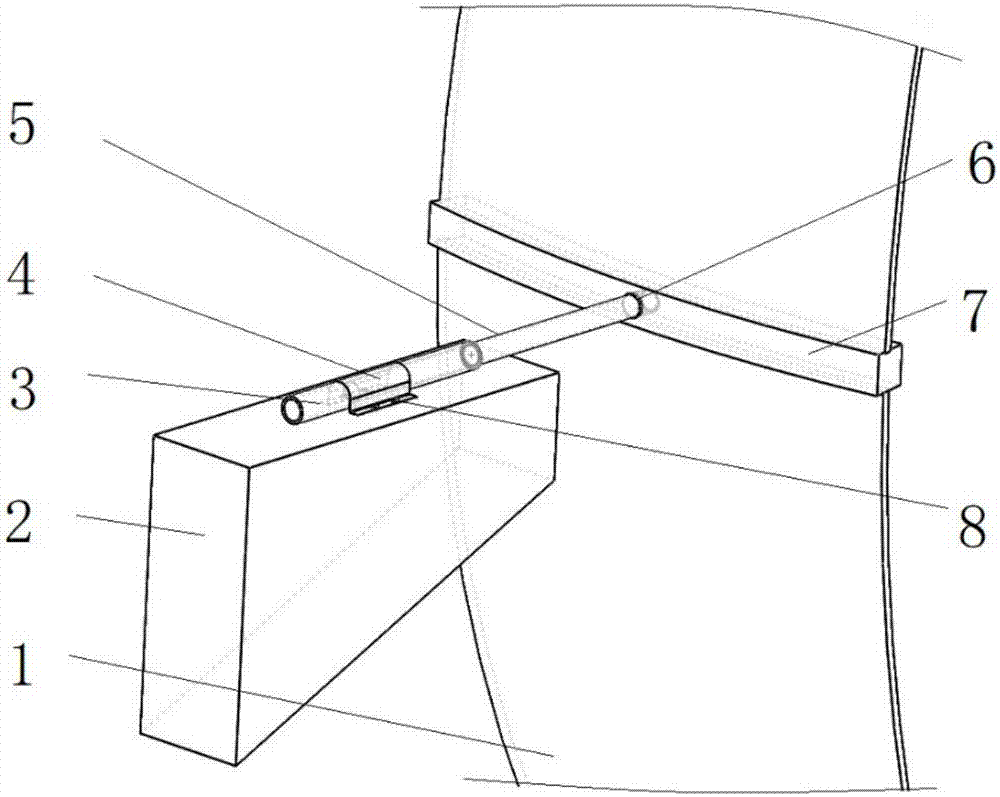

Roof photovoltaic panel support

PendingCN113794431AEasy to installImprove on-site assembly efficiencyPhotovoltaic supportsNon-rotating vibration suppressionStructural engineeringMechanical engineering

The invention relates to a roof photovoltaic panel support, and the support comprises a guide rail, wherein the guide rail comprises a guide rail base, a front side plate and a rear side plate, the front side plate and the rear side plate are fixedly connected to the two sides of the guide rail base, corresponding buckling grooves are formed in the two sides of the guide rail base in an inward concave mode respectively, and a corresponding mounting groove is formed between the top of the front side plate and the top of the rear side plate; a guide rail installation mechanism which comprises an installation seat plate, wherein a fixed clamping block is fixedly arranged on the installation seat plate, a movable clamping block is movably installed in an assembly groove of the fixed clamping block, and the top of the fixed clamping block and the top of the movable clamping block are provided with buckling protruding edges used for being buckled into the buckling grooves respectively; and a photovoltaic panel pressing mechanism which comprises a guide rail clamping block fixedly arranged in the mounting groove, wherein a photovoltaic panel pressing block used for pressing the photovoltaic panel is arranged on the upper side of the guide rail clamping block, and a corresponding pressing screw rod is installed in a communicating hole of the photovoltaic panel pressing block in a penetrating mode. According to the invention, the installation efficiency can be effectively improved, and the installation stability of the photovoltaic panel can be effectively ensured.

Owner:厦门华谱科技有限公司

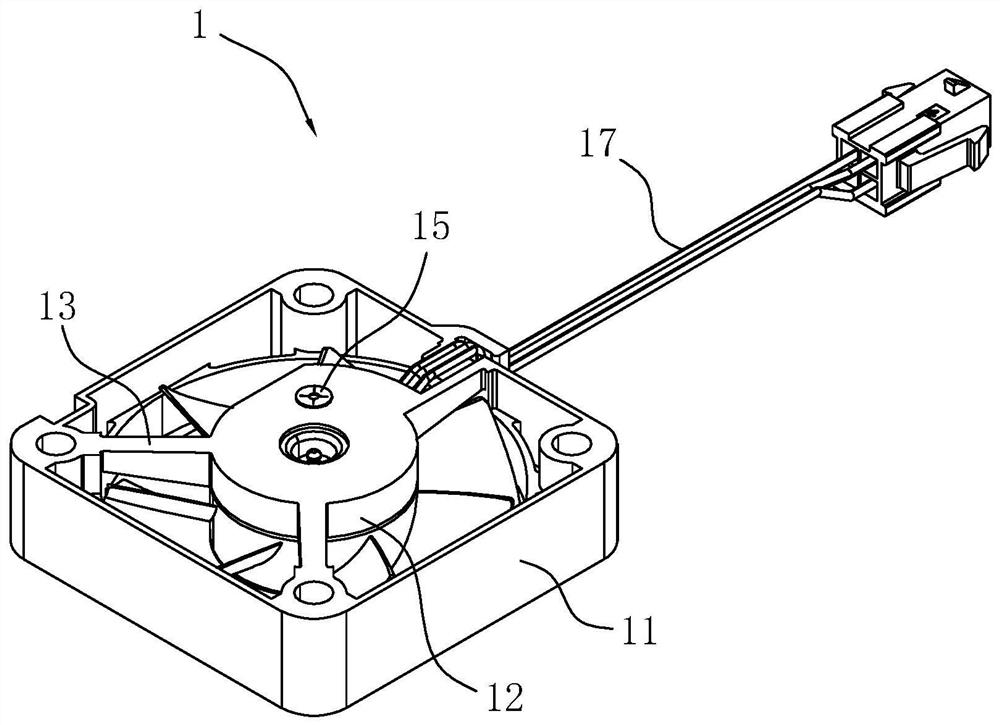

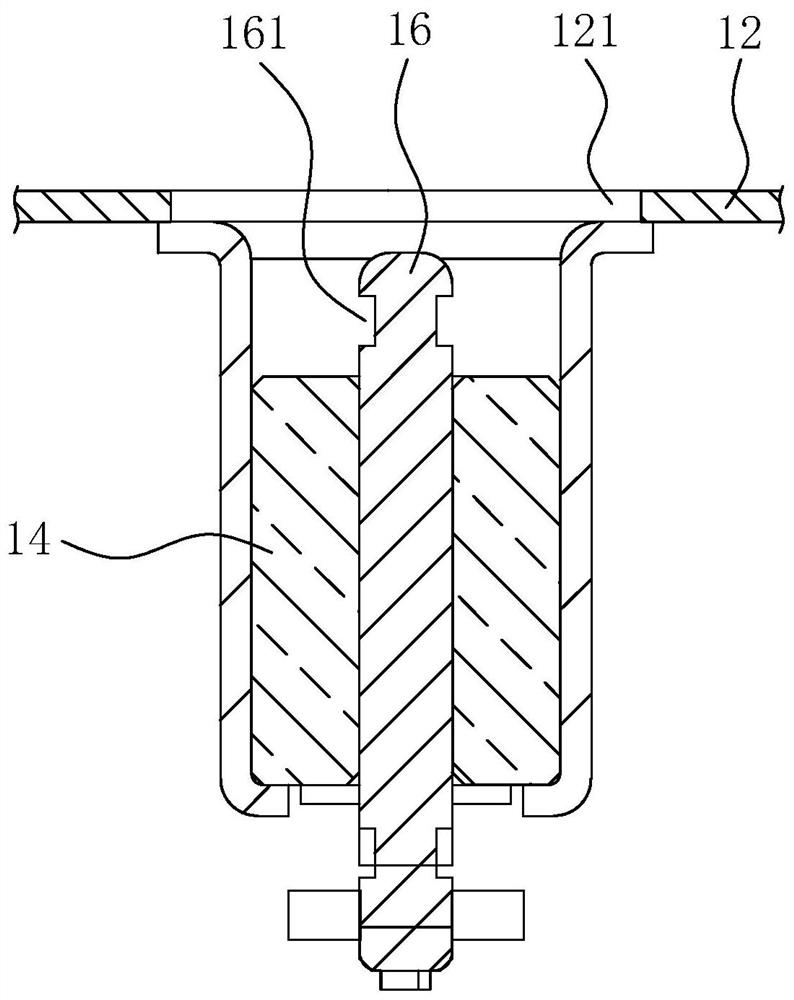

Wire drawing head of filler cap and automobile

ActiveCN103129634AImprove on-site assembly efficiencyAvoid cutsSuperstructure subunitsVisibilityEngineering

The invention discloses a wire drawing head of a filler cap and an automobile and belongs to the field of automobiles. The wire drawing head of the filler cap comprises a support, a rivet, a tower base, a compressed spring, a tower shade and a sheath, wherein the rivet extends into the wire drawing head from one end of the support and is fixedly riveted, the tower base is connected onto the outer portion of the rivet and one end of the support in sleeved mode and is used for supporting the tower shade, the compressed spring is arranged between the support and the tower base, the tower shade is connected onto the other end of the tower base and the other end of the support in sleeved mode, the sheath is connected onto the outer portion of the tower shade in sleeved mode, and an elastic reverse clamping structure is arranged between the sheath and the tower shade. The automobile comprises the filler cap and the wire drawing head of the filler cap, wherein the wire drawing head of the filler cap is externally arranged on the filler cap. The wire drawing head of the filler cap effectively improves visibility during installation, leads installation to be easy, improves production takt, and can effectively avoid potential safety hazards such as hand cutting of the installation personnel. In addition, the wire drawing head of the filler cap has the advantages of being simple in integral structure and high in reliability.

Owner:CHERY AUTOMOBILE CO LTD

Fuel filler cap cable head and automobile

ActiveCN103129634BImprove on-site assembly efficiencyAvoid cutsSuperstructure subunitsEngineeringAutomotive fuel

The invention discloses a wire drawing head of a filler cap and an automobile and belongs to the field of automobiles. The wire drawing head of the filler cap comprises a support, a rivet, a tower base, a compressed spring, a tower shade and a sheath, wherein the rivet extends into the wire drawing head from one end of the support and is fixedly riveted, the tower base is connected onto the outer portion of the rivet and one end of the support in sleeved mode and is used for supporting the tower shade, the compressed spring is arranged between the support and the tower base, the tower shade is connected onto the other end of the tower base and the other end of the support in sleeved mode, the sheath is connected onto the outer portion of the tower shade in sleeved mode, and an elastic reverse clamping structure is arranged between the sheath and the tower shade. The automobile comprises the filler cap and the wire drawing head of the filler cap, wherein the wire drawing head of the filler cap is externally arranged on the filler cap. The wire drawing head of the filler cap effectively improves visibility during installation, leads installation to be easy, improves production takt, and can effectively avoid potential safety hazards such as hand cutting of the installation personnel. In addition, the wire drawing head of the filler cap has the advantages of being simple in integral structure and high in reliability.

Owner:CHERY AUTOMOBILE CO LTD

Metal inner tank structure of a membrane cryogenic storage tank

ActiveCN112253986BNot affectedReduce moldVessel geometry/arrangement/sizeNon-pressured vesselsLongitudinal waveHeat Avoidance

The invention discloses a metal inner tank structure of a membrane type cryogenic storage tank, comprising a tank bottom and a tank wall, the tank wall is welded by a base plate, the tank bottom is in an approximately circular structure, the tank bottom is spliced by the base plate and The splicing gap is filled by the peripheral special-shaped plate. The base plate is composed of a basic unit or several basic units. The basic unit is composed of a flat plate and longitudinal waves and transverse waves on the plate. The longitudinal waves and transverse waves are both concave on one side. In the protruding arched structure, the longitudinal wave and the transverse wave are vertically interlaced and connected together through a smooth transition of a curved surface, and both the longitudinal wave and the transverse wave are in a smooth transition with the surrounding flat plates through a curved surface. The metal inner tank structure of the membrane cryogenic storage tank can avoid stress concentration during thermal expansion and cold contraction, and only a small number of molds are required for manufacturing, which can improve on-site assembly efficiency during assembly.

Owner:宇欧围护技术(上海)有限公司

Casing pipe type support structure of organic glass detector

The invention discloses a casing pipe type support structure of an organic glass detector. The casing pipe type support structure of the organic glass detector is used for supporting an organic glassball body of the organic glass detector on a wall body; and the organic glass ball body is provided with an equator thick plate. The casing pipe type support structure comprises metal casing pipes, pressing plates, support rods and rubber washers, wherein a plurality of uniformly distributed holes matched with the support rods are formed in a circumferential direction of the equator thick plate; one ends of the support rods are put into the holes; the other ends of the support rods stretch into the metal casing pipes; the rubber washers are arranged between the holes in the equator thick plateand the support rods; and the pressing plates fix the metal casing pipes onto a wall body through a plurality of bolts. According to the casing pipe type support structure of the organic glass detector provided by the invention, the occurrence of the phenomena of poor positioning, structure deformation and stress concentration caused by manufacture deviation during an installation process of thedetector is avoided, and the safety and the reliability of the detector are improved. The shading coefficient is reduced, and the neutrino detection precision is improved. The on-site assembly efficiency is improved.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Quantitative filling method and quantitative filling device

ActiveCN102795203BGuaranteed filling qualitySimple and fast operationVehicle servicing/repairingProgramme control in sequence/logic controllersComputer scienceCode acquisition

The invention discloses a quantitative filling device. The device comprises an identification code acquisition module for acquiring the identification code of a product to be filled, a control module and a filling module, wherein the control module is used for receiving the identification code of the product to be filled from the identification code acquisition module and calling a filling formula of the product to be filled according to the identification code of the product to be filled; according to the filling formula, the filling sequence of a plurality of oil filling points of the product to be filled and the filling quantity corresponding to each oil filling point are provided; and the filling module fills oil into a plurality of oil filling points of the product to be filled in corresponding quantities according to the filling sequence. The invention also discloses a quantitative filling method. By the quantitative filling device and the quantitative filling method, problems such as wrong filling and missed filling of the oil in the process of manufacturing automobiles are solved; the oil filling quality of the automobiles is guaranteed; the quantitative filling device is easy and convenient to operate, and the oil can be filled accurately, so that the on-site assembly efficiency is improved.

Owner:BEIQI FOTON MOTOR CO LTD

Tank bottom structure of a metal inner tank of a membrane cryogenic storage tank

ActiveCN112145954BNot affectedReduce yield damageVessel manufacturingVessel wallsLongitudinal waveDeep drawing

The invention discloses a tank bottom structure of a metal inner tank of a membrane type cryogenic storage tank. The bottom of the tank is approximately circular in structure. unit or several basic units, the substrate is welded or deep-drawn (deep-drawn), the basic unit is composed of a flat plate, a longitudinal wave and a transverse wave on the plate, and the longitudinal wave and the transverse wave are both recessed on one side In the protruding arched structure, the longitudinal wave and the transverse wave are vertically interlaced and connected together through a smooth transition of a curved surface, and both the longitudinal wave and the transverse wave are in a smooth transition with the surrounding flat plates through a curved surface. The tank bottom structure of the metal inner tank of the membrane cryogenic storage tank can avoid stress concentration during thermal expansion and contraction, and only a small number of molds are required for manufacturing, which can improve on-site assembly efficiency during assembly.

Owner:宇欧围护技术(上海)有限公司

Construction method of aquatic plant composite ecological floating island

ActiveCN109368794BIncreased durabilityAvoid displacement changesBiological water/sewage treatmentEnvironmental resource managementEnvironmental engineering

The construction method of the aquatic plant composite ecological floating island includes the following steps: construction preparation, testing of planting soil, and formulation of construction steps; design of the overall structure of the ecological floating island, preparation of prefabricated components; selection of plant seedlings, transplanting To the body of the floating bed nutrition bowl; construction of the side anchor pile system; construction of the middle anchor pile group; splicing and fixing the shape of the floating bed; maintenance of the floating island of aquatic plants, and the durability of the ecological floating island obtained through the construction method Good, high stability, high construction efficiency, outstanding economic and technical benefits.

Owner:HANGZHOU JIANGRUN TECH LIMITED

Mounting device for motor assembly

ActiveCN113410967AImprove assembly efficiencyAvoid interferenceManufacturing dynamo-electric machinesElectric machineryMotor shaft

The invention relates to a mounting device for motor assembly, and relates to the technical field of motor production equipment, the mounting device comprises a base and a support, the base is fixedly provided with a die holder, and the die holder is provided with a positioning groove for placing a motor; a pressing die and a power piece are installed on the support, the pressing die is located over the positioning groove, the power piece can drive the pressing die to move close to the positioning groove, the pressing die is provided with a pressing column used for applying pressure to the end cover of the motor, and the end of the pressing column is provided with a receding hole allowing the end of a rotating shaft of the motor to stretch into. The mounting device has the advantage that a miniature motor shaft cover can be efficiently and stably assembled.

Owner:SHANGHAI JIANDONG TECH CO LTD

Assembly type machine room construction method based on DDCI system

ActiveCN113239546AStrong interactionReduce repetitive workDesign optimisation/simulationResourcesDesign standardProcess engineering

The invention discloses an assembly type machine room construction method based on a DDCI system, and the method comprises the following steps: S1, collecting the latest construction drawing and related drawing set specifications of the whole project, collecting the model, size, appearance and other accurate and detailed data of all equipment and valve parts related to prefabrication in a machine room, and building an information family library. The invention has the advantages that smooth interaction of information among different systems can be guaranteed, a large amount of repetitive work is reduced, efficiency is improved, deepening design standards can be formed, module standardized design, standardized splitting and assembly type assembly are achieved, industrial production can be carried out, errors caused by human errors during installation can be reduced, overall deviation is effectively eliminated, the single pipe section and system overall deviation during on-site construction assembly is reduced, the assembly proficiency of workers is enhanced, and the on-site assembly efficiency is improved.

Owner:THE FOURTH OF CHINA EIGHTH ENG BUREAU

Sectional type fan blade connecting structure, sectional type fan blade and assembling method

PendingCN114526194AImprove connection strengthImprove carrying capacityWind motor assemblyRenewable energy generationEngineeringStructural engineering

The invention discloses a sectional type fan blade connecting structure, a sectional type fan blade and an assembling method. The sectional type fan blade connecting structure is characterized in that a first socket piece, a second socket piece and a fixing assembly are arranged, and the first socket piece is arranged at one end of a first blade section; the second socket component is arranged at one end of the second blade section; the first socket component and the second socket component are opposite and are arranged in a mutually crossed and staggered manner to form a connecting part, and the fixing component is arranged at the connecting part to fix the first socket component and the second socket component. According to the connecting structure, connection of the segmented blades is more reliable, the additional mass of the connecting area is light, and factory production and wind field on-site operation are facilitated.

Owner:SHANGHAI ELECTRIC WIND POWER GRP CO LTD

Self-resetting connecting joint between steel frame and composite wallboard and fabricated building thereof

PendingCN114562036AEffective absorptionEffective consumptionWallsPassive housesSteel frameMechanical engineering

The invention provides a self-resetting connecting joint between a steel frame and a composite wallboard and a fabricated building thereof. The composite wallboard connecting joint comprises the steel frame, the composite wallboard and a self-resetting connecting piece. The composite wallboard is arranged on the frame through the plurality of self-resetting connecting pieces; the self-resetting connecting piece comprises a middle cylinder body; the cross section of the middle cylinder is in a long circle shape, and the middle cylinder comprises two straight line sections arranged in parallel and two arc sections symmetrically arranged on the two sides. And the middle barrel is fixedly connected with the frame and the composite wallboard through the two linear sections respectively. According to the structural form of the self-resetting connecting piece, energy can be effectively absorbed and consumed, the self-resetting connecting piece has certain self-resetting capacity, particularly, residual deformation of the structure after unloading in the early stage is basically zero, and residual deformation of the structure after loading is still small. And the permanent damage of the structure can be effectively reduced through reduction of residual deformation, the loss of the structure is reduced, and the repairability of the structure is improved.

Owner:SHENZHEN YJY BUILDING TECH +2

Beam-column joint of a layered fabricated steel structure

The invention discloses a beam-column joint of a layered assembled steel structure, which comprises an upper-layer column (1), a lower-layer column (2), and a main beam (1) installed between the upper-layer column (1) and the lower-layer column (2). 3); a middle column (5) is welded at the junction of the main beam (3) with the upper column (1) and the lower column (2), and a main beam (3) is welded on one side of the middle column (5), Its upper and lower ends are respectively welded with an upper flange (51) of a central column and a lower flange (52) of the central column, and the bottom of the upper column (1) is welded with an upper column that is opposite to the upper flange (51) of the central column. A flange (11), the top of the lower column (2) is welded with a lower column flange (21) which is connected with the lower flange (52) of the central column. The invention has simple structure, direct force transmission, clear force of each part, convenient industrialized manufacturing and on-site assembly, greatly reduced on-site assembly workload, improved on-site assembly efficiency, and low comprehensive cost.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Fabricated steel structure self-heat-preservation composite concrete structural system and forming method

The invention discloses a fabricated steel structure self-heat-preservation composite concrete structural system and a forming method. The fabricated steel structure self-heat-preservation composite concrete structural system comprises foundations, vertical columns, crossbeams, floor slabs, a shear wall and a roof which are each provided with a steel structural plate, a steel structural column, aheat-preservation layer and a protection layer. The steel structural plates, the steel structural columns, the heat-preservation layers and the protection layers are of an integrated structure, the steel structural plates and the steel structural columns are located in the heat-preservation layers, and the protection layers are located on the outer sides of the heat-preservation layers. The foundations, the vertical columns, the crossbeams, the floor slabs, the shear wall and the roof are each provided with a connecting plate and formed by pouring of fabricated steel structures and self-heat-preservation concrete of various volumes and weights through a special pouring technology according to the different strength and the self-heat-preservation requirements, and the self-heat-preservationconcrete can achieve the effects of fire, rust, corrosion and water resistance, heat preservation and heat insulation.

Owner:德州智能电气设备有限公司

an optical connector

ActiveCN112230355BReduce the difficulty of assemblyMeet the needs of kitsOptical fibre/cable installationFibre mechanical structuresEngineeringMechanical engineering

An optical connector, comprising: a pipe-through assembly, the pipe-through assembly has at least one protrusion; a housing assembly sleeved on the outside of the pipe-through assembly, and the housing assembly has a structure for the pipe-through assembly to pass through along a first direction The first channel; the shell assembly also has a first limiting structure, the first limiting structure has a limiting surface and a positioning surface, the limiting surface is used to abut against the end surface of the protrusion, and is used to pass through the pipe assembly relative to the shell. After the body assembly is rotated, the pipe threading assembly is limited along the second direction opposite to the first direction; the positioning surface is used to abut against the raised surface, and is used to align the pipe threading assembly and the pipe threading assembly along the circumferential direction of the pipe threading assembly. The housing assembly is limited. The optical connector is provided with a first limiting structure on the housing component, and after the tube passing component is rotated relative to the housing component, the abutting relationship between the first limiting structure on the housing component and the protrusion is used to form the through tube component The limit can reduce the difficulty of assembling the optical connector, thereby improving the efficiency of on-site assembly.

Owner:HUAWEI TECH CO LTD

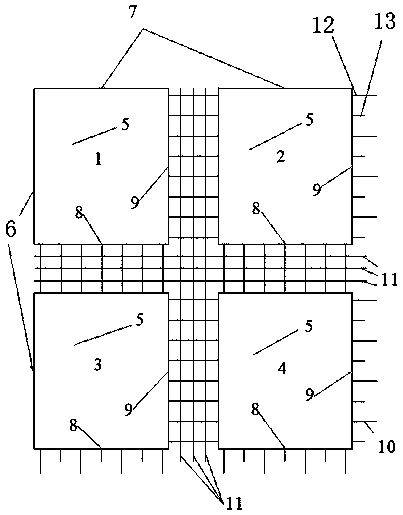

Prefabricated box foundation adopting zoned assembly

InactiveCN108331001AIncreased bending stiffnessImprove integrityFoundation engineeringRebarSevere weather

The invention provides a prefabricated box foundation adopting zoned assembly, and belongs to the technical field of construction projects. The prefabricated box foundation comprises boundary sub-foundations, longitudinal sub-foundations, horizontal sub-foundations and standard sub-foundations, wherein protruding bars are reserved in thickness directions of prefabricated foundation top plates, prefabricated horizontal retaining walls, prefabricated longitudinal retaining walls, prefabricated longitudinal partition walls, prefabricated horizontal partition walls and prefabricated foundation bottom plates and used for connecting the adjacent sub-foundations, and the protruding bars are reserved in a long-short alternate distribution manner; connecting reinforcements are arranged between theadjacent sub-foundations which are integrated by concrete pouring, and the whole foundation is formed. According to the prefabricated box foundation adopting zoned assembly, the multiple sub-foundations are prefabricated in a factory and then are spliced and connected at the construction site to form the integral box foundation, so that side operation time is shortened greatly, site assembly efficiency is high, influence of severe weather can be avoided, and the prefabricated box foundation has good practicability and feasibility.

Owner:SHANXI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com