PC wallboard mould used for concrete prefabricated component production line

A technology of prefabricated components and prefabricated wall panels, applied in molds, manufacturing tools, unloading devices, etc., can solve the problems of large land occupation, complex construction environment, and adverse effects of construction cost and construction time, so as to reduce repair costs and ensure molding The effect of improving quality and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] For ease of understanding, the attached Figure 1-8 , the concrete structure and working mode of the present invention are further described as follows:

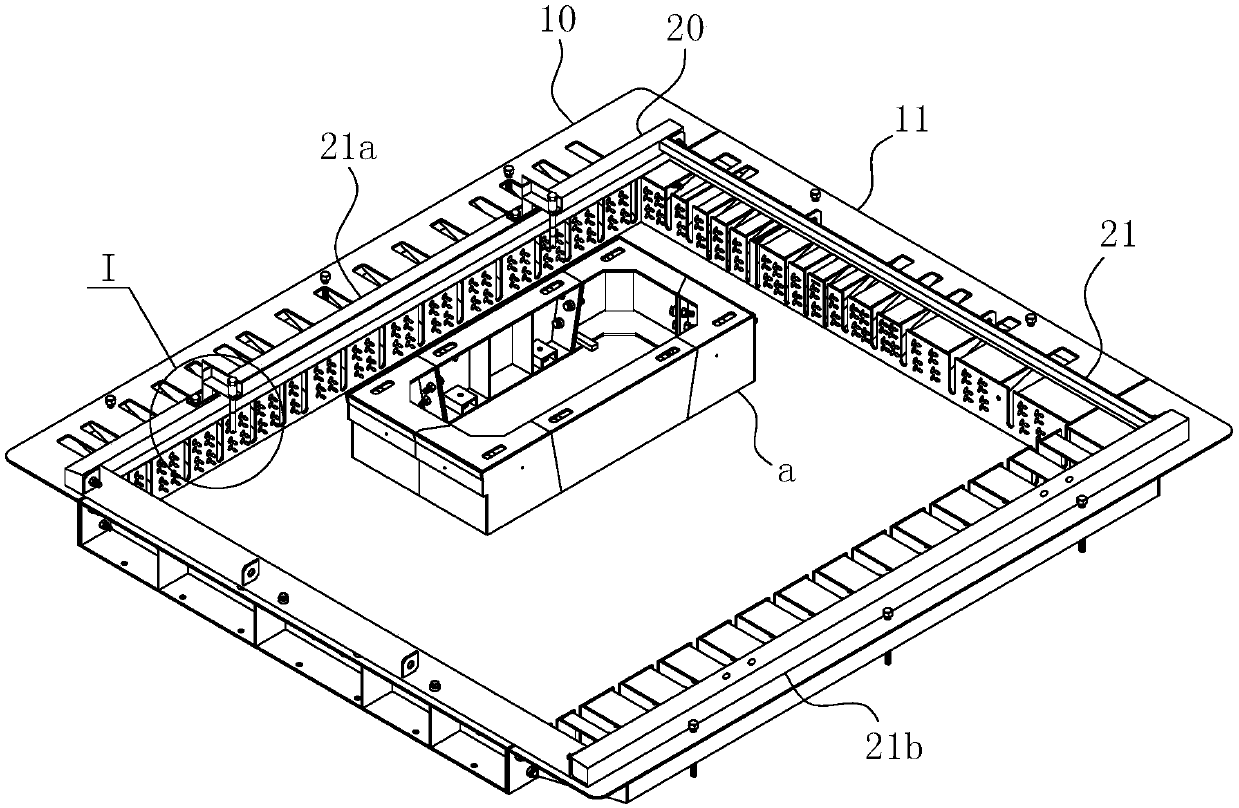

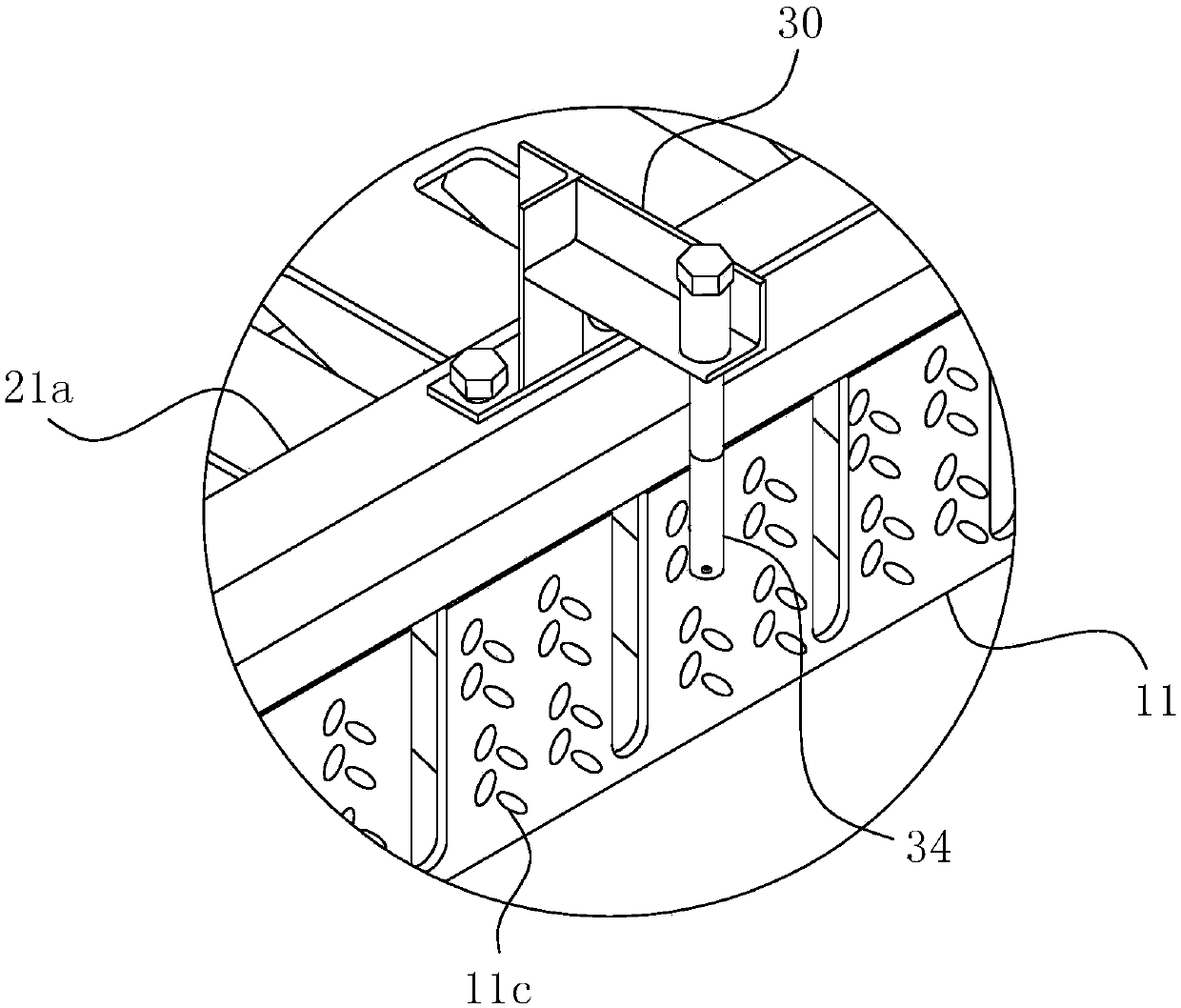

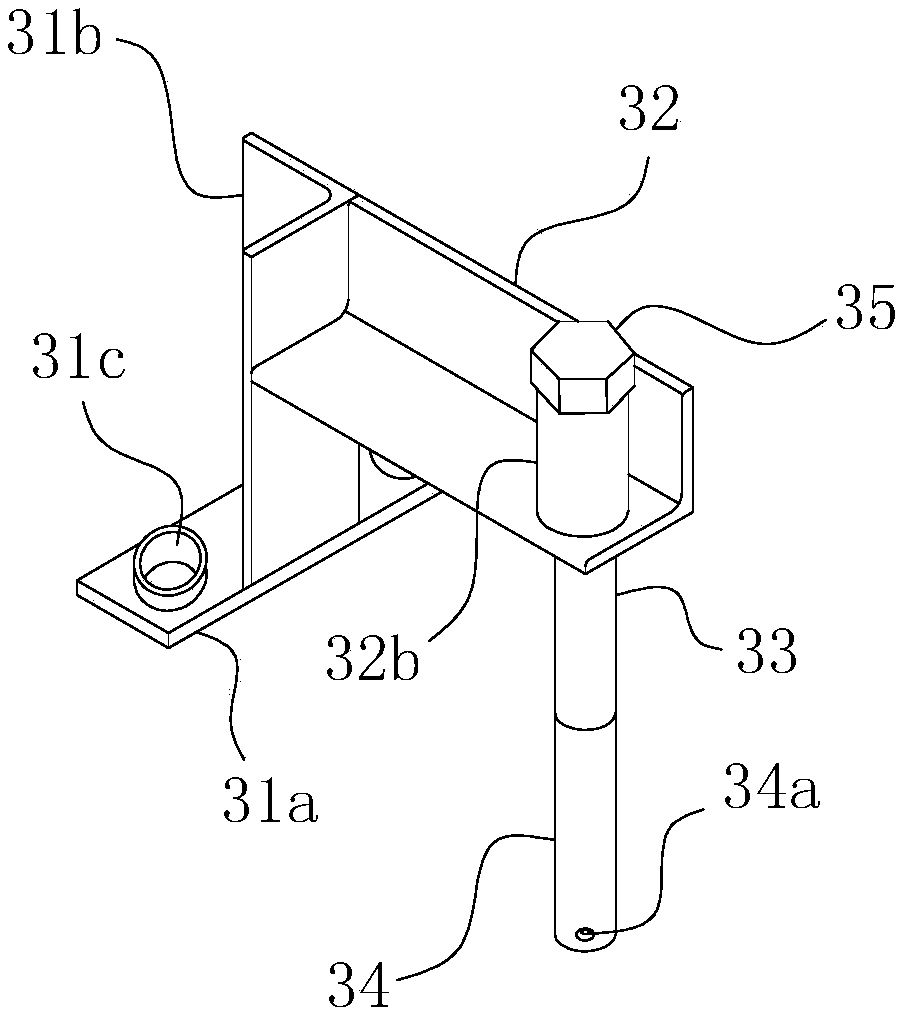

[0041] The specific application environment of the present invention is figure 1 shown as an example. figure 1 It is the PC wall panel mold used in the concrete prefabricated component production line, which includes the inner leaf wall module 10, the window opening module a for being arranged in the mold cavity of the inner leaf wall module 10, and the inner leaf wall module 10 Outer leaf wall module 20 at the top face. The window opening module a is the same as the inner leaf wall module 10 when in use, and is placed horizontally on a certain mold surface, and the mold surface is referred to as "base surface" here. The "vertical direction" described later refers to the direction perpendicular to the base plane. When the window hole module a and the inner leaf wall module 10 are as a whole figure 1 When shown on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com