Prestress assembly type concrete frame supporting structure of wind turbine generator set

A technology for wind turbines and support structures, applied to towers, building types, buildings, etc., can solve problems such as unfavorable stress on node bolts and diagonal braces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

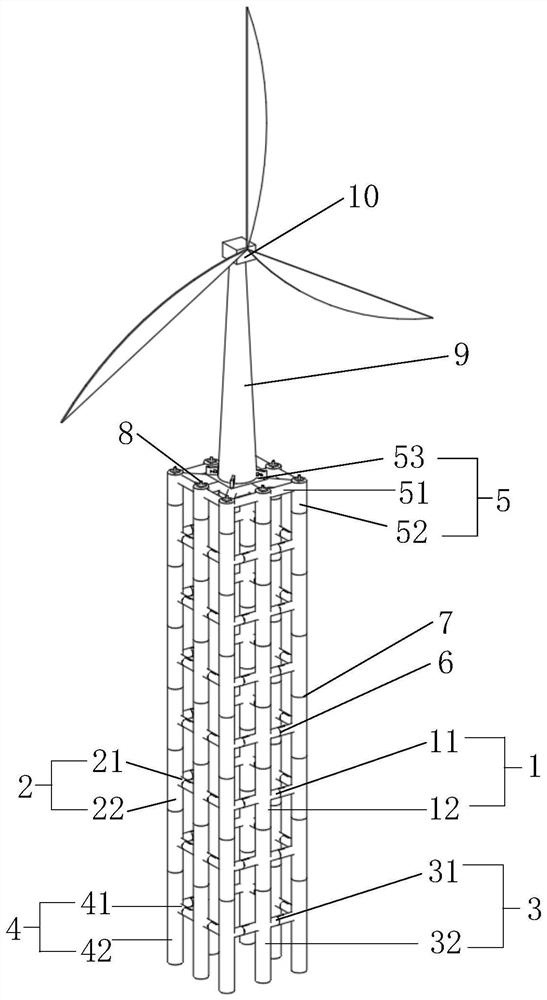

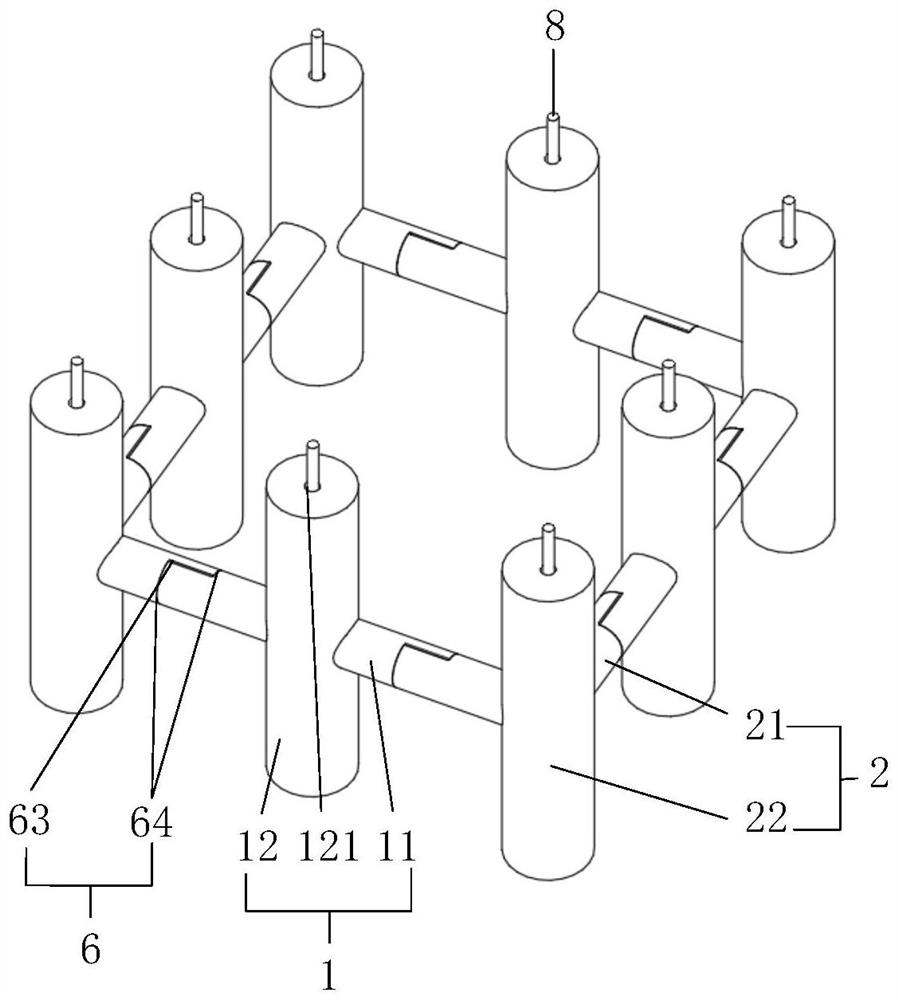

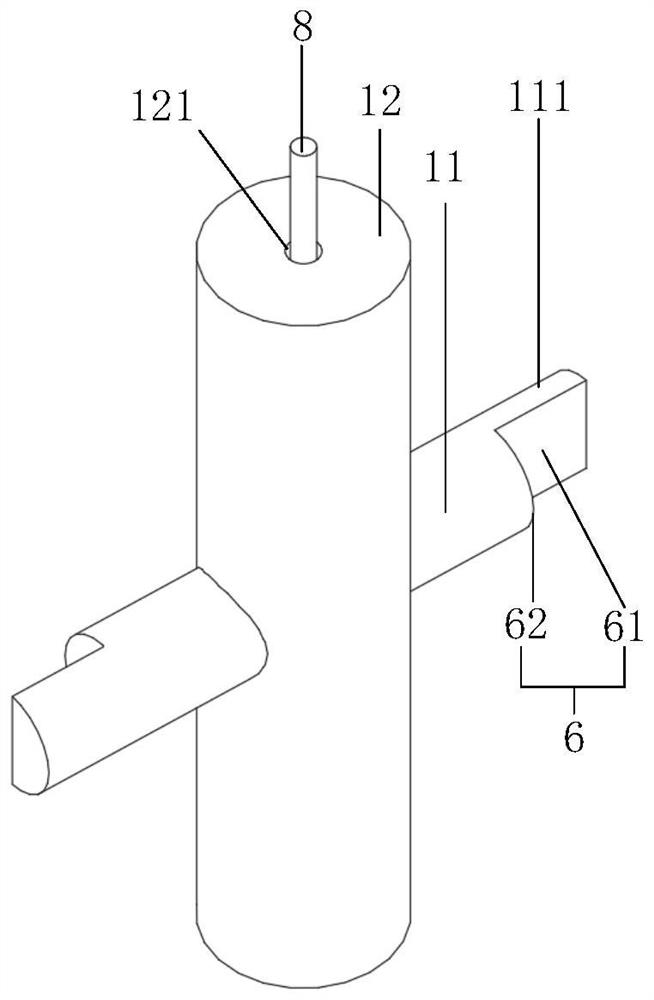

[0037] refer to Figure 1 to Figure 6 As shown, this embodiment discloses that the present invention provides a prestressed assembled concrete frame support structure for wind turbines. A steel tower 9 to be fixed is arranged on the top of the supporting structure, and a wind turbine 10 is installed on the top of the steel tower 9 .

[0038] Preferably, the support structure includes: a bottom support unit, a middle support unit, a top support unit and several prestressed steel strands 8 .

[0039] Wherein, the bottom support unit is a rectangular frame structure; the middle support unit is arranged on the upper end of the bottom support unit, and the middle support unit is composed of overlapping standard structural units; the top support unit is arranged on the middle support The top of the unit; each prestressed steel strand runs through the holes longitudinally arranged in the bottom support unit, middle support unit and top support unit respectively, and completes the lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com