Prefabricated box foundation adopting zoned assembly

A box-shaped foundation, prefabricated assembly technology, applied in basic structure engineering, construction and other directions, can solve the problems of inability to achieve one-time pouring, foundation construction and concrete pouring, etc., achieve good practicability and feasibility, and avoid construction difficulties. , the effect of large bending stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

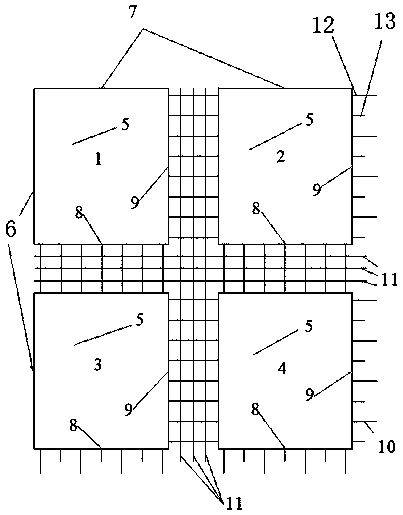

[0017] The implementation of the present invention will be described in detail in conjunction with the accompanying drawings.

[0018] First of all, it should be noted that the accompanying drawings only show a part of the prefabricated box-shaped foundation assembled in sub-regions, which is representative and aims to explain the present invention concisely, clearly and clearly, so the accompanying drawings cannot As a limitation of the invention.

[0019] figure 1 , figure 2 As shown, the prefabricated prefabricated box-shaped foundation assembled in different areas is composed of four sub-foundations, namely boundary sub-foundation 1, longitudinal sub-foundation 2, horizontal sub-foundation 3 and standard sub-foundation 4; Yes, placed at a corner of the prefabricated box-shaped foundation assembled in the sub-regions, multiple longitudinal sub-foundations 2 need to be made and arranged along the length direction of the prefabricated longitudinal retaining wall 7; multipl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com