Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

41results about How to "Improve heating characteristics" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

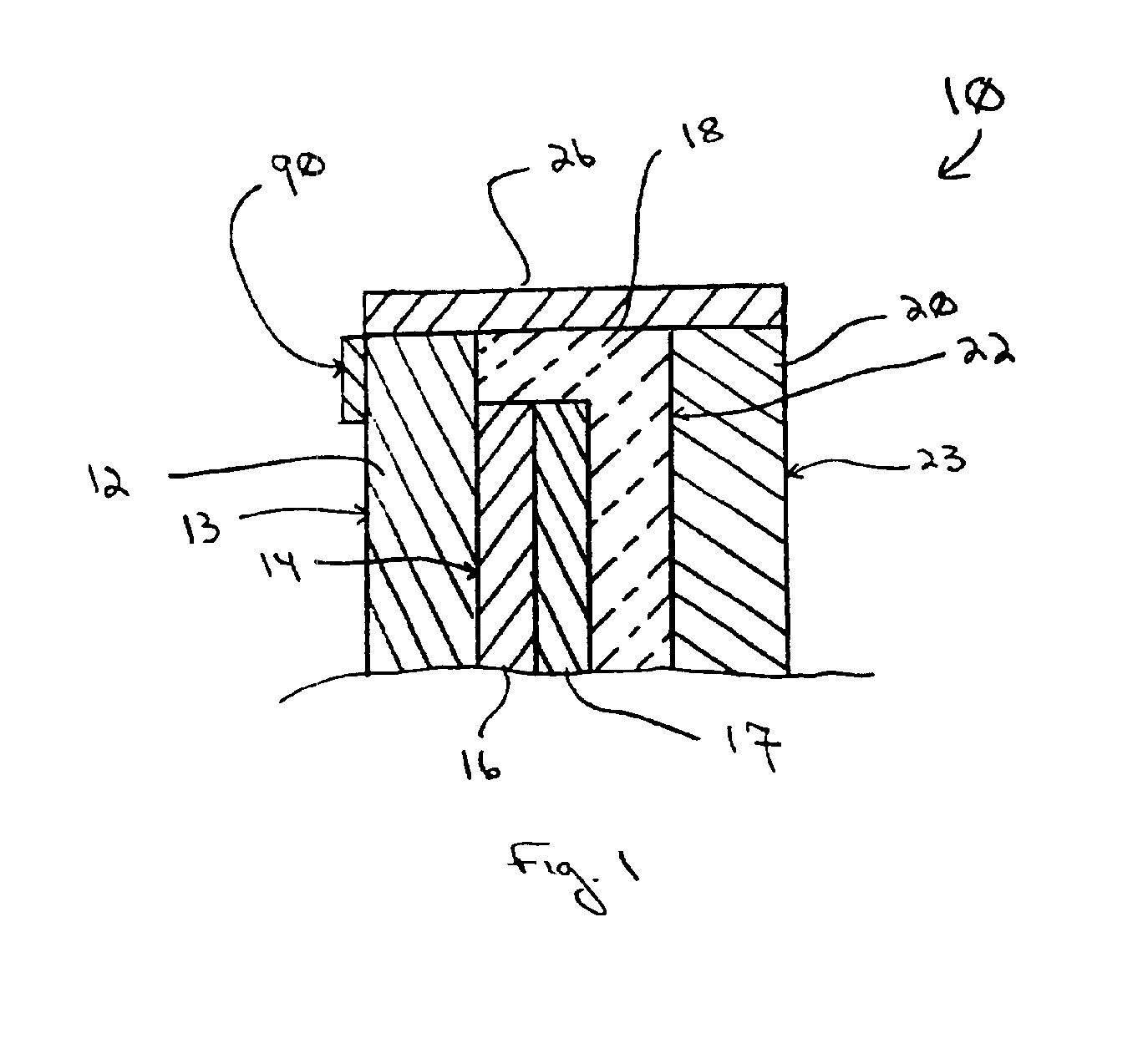

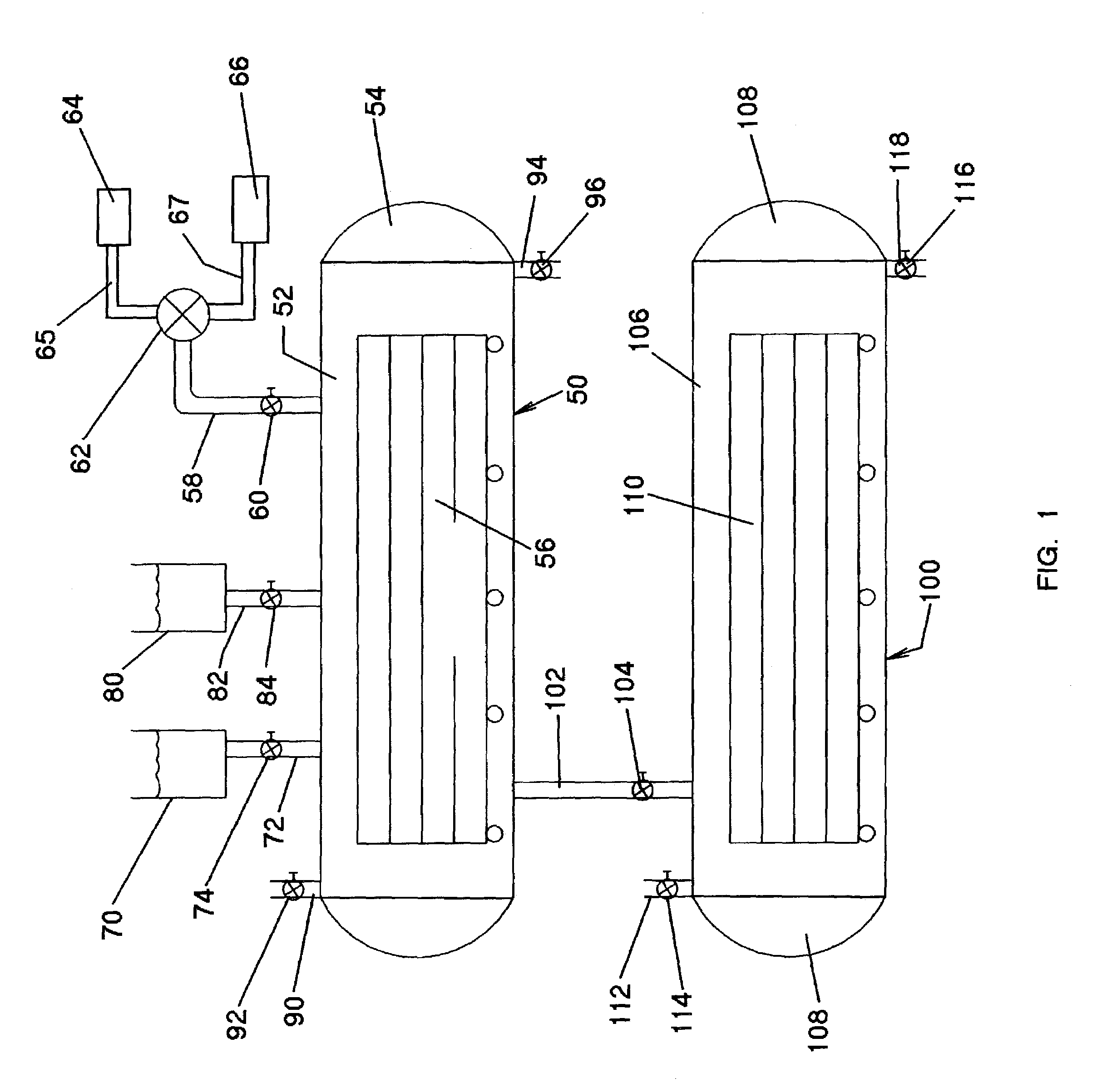

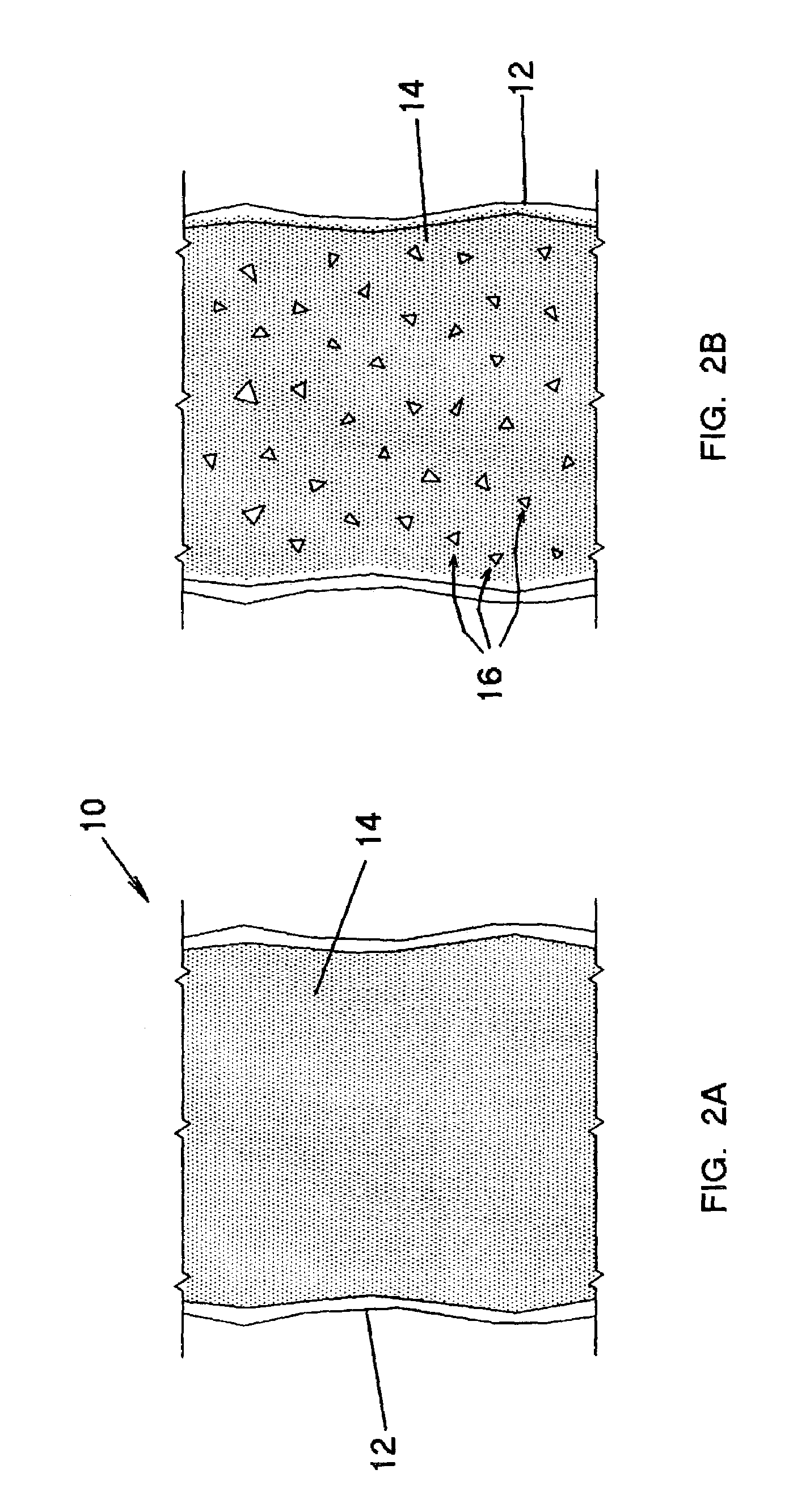

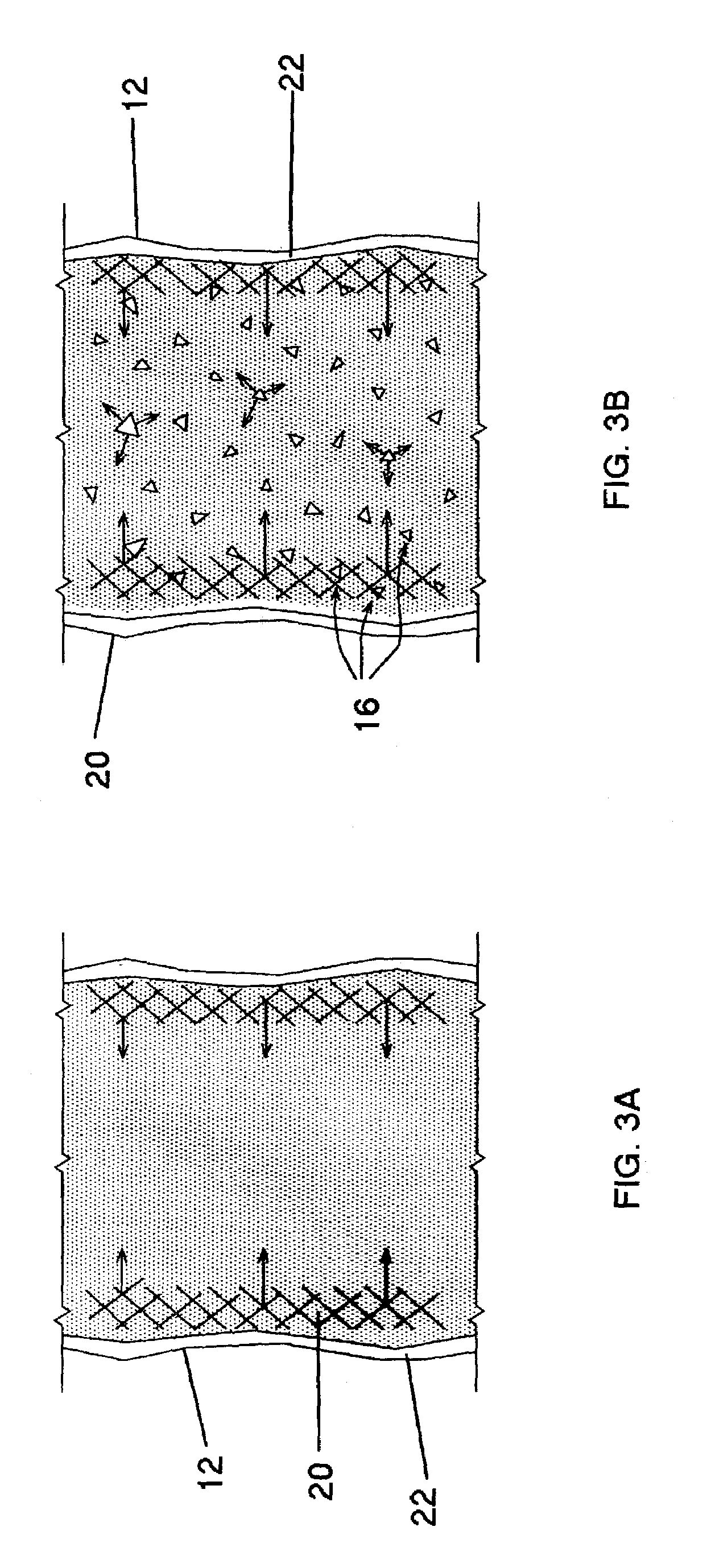

Method of making coated articles and coated articles made thereby

InactiveUS6869644B2Improve protectionImprove heating characteristicsVacuum evaporation coatingPretreated surfacesEmissivityMetallurgy

A method of making a coated substrate includes providing a substrate having a functional coating with a first emissivity value; depositing a coating material having a second emissivity value over at least a portion of the functional coating prior to heating to provide a coating stack having an emissivity value greater than the emissivity value of the functional coating; and heating the coated substrate.

Owner:VITRO FLAT GLASS LLC

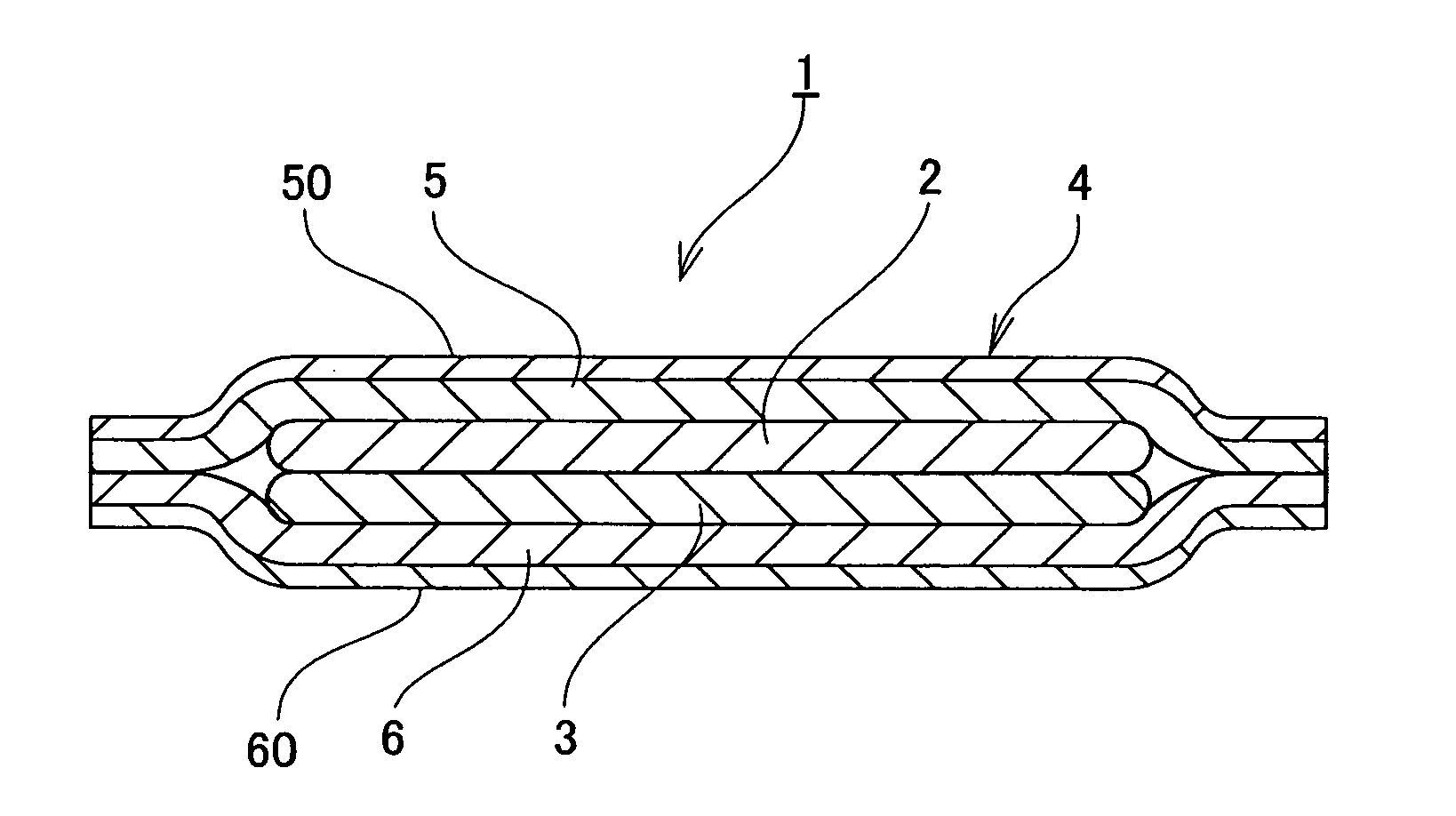

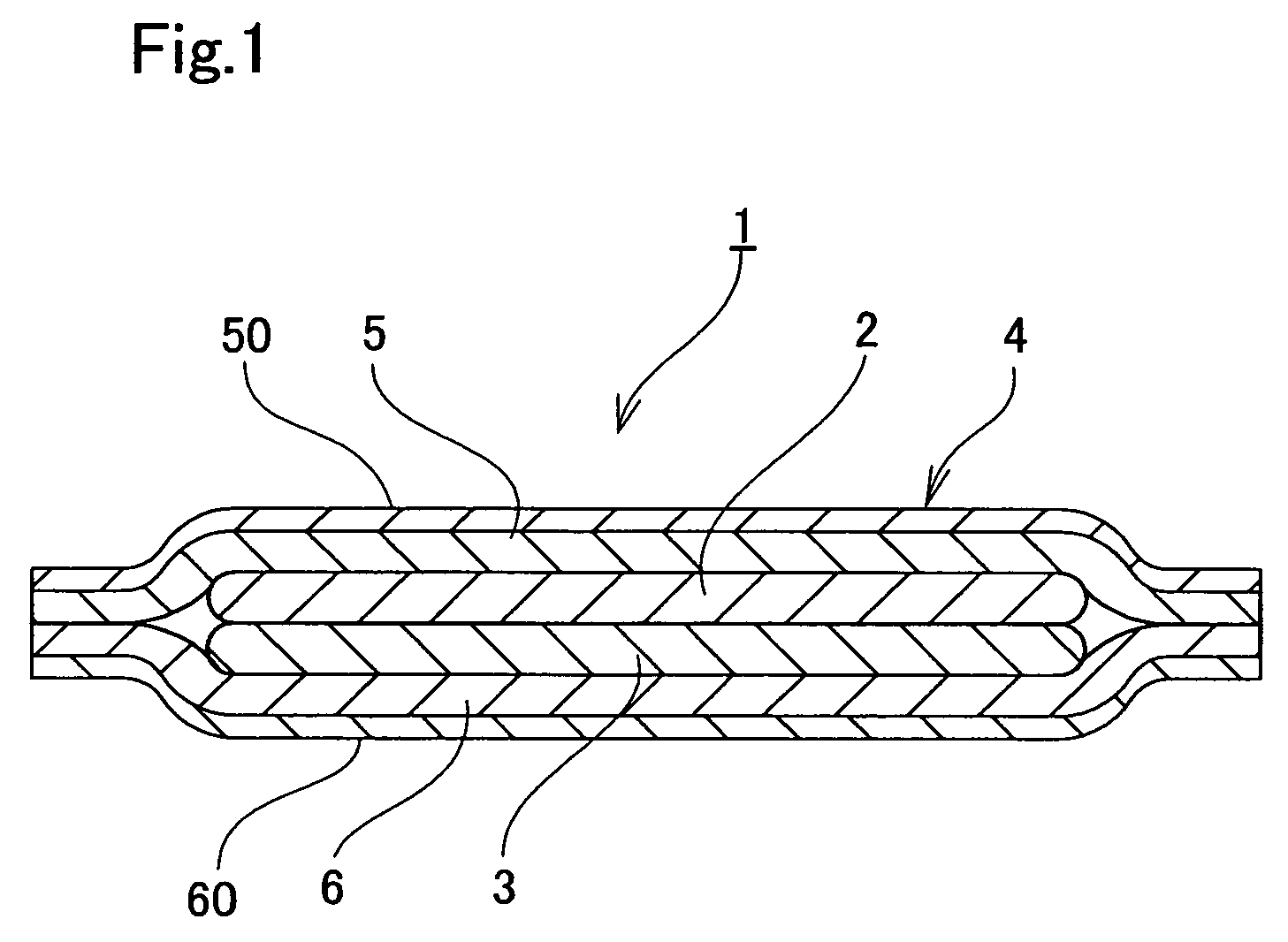

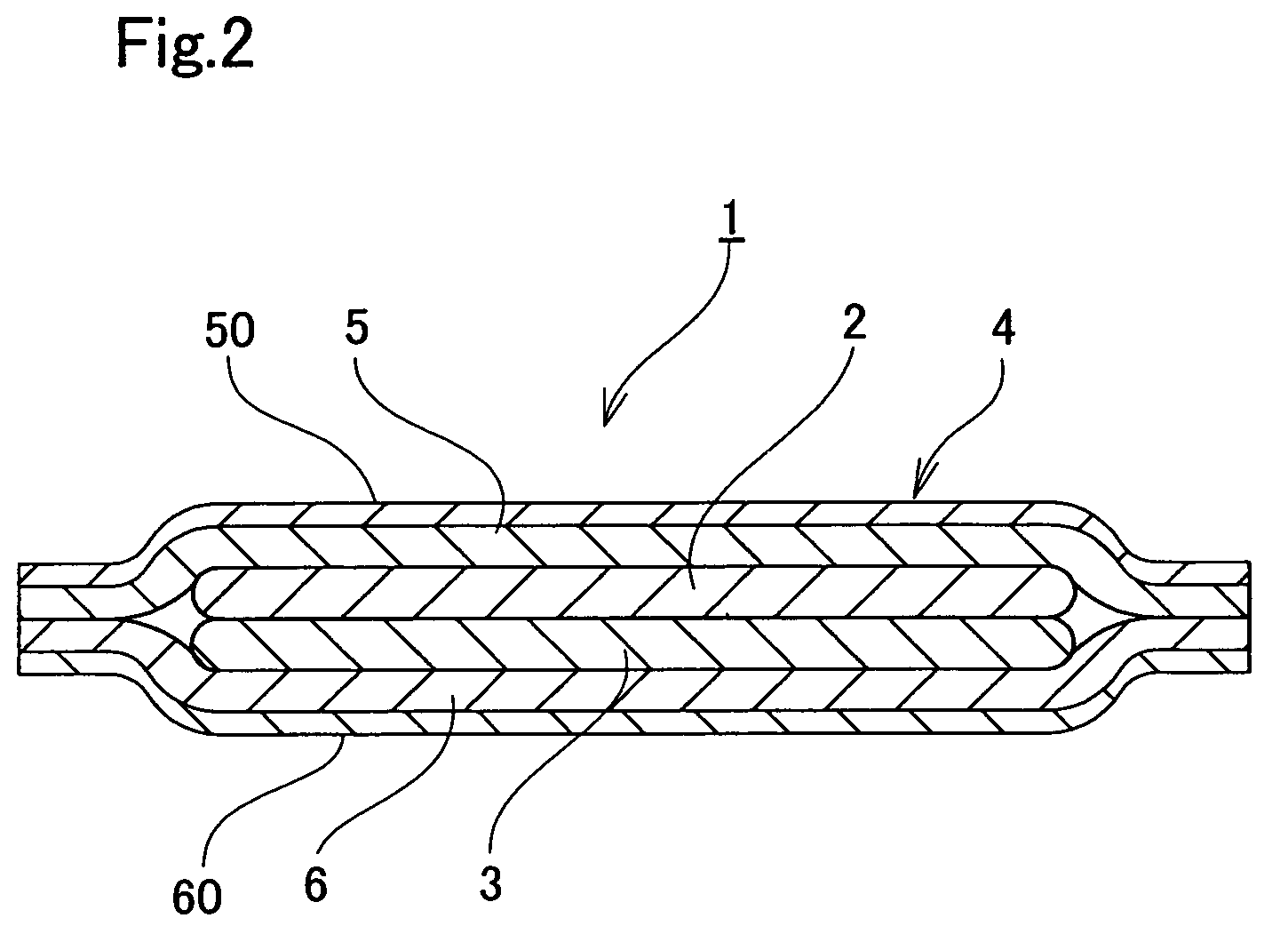

Warming tool in a sheet form

ActiveUS20070020412A1Improve heating characteristicsEasy to carryExothermal chemical reaction heat productionOther heat production devicesFiberPolymer science

A warming device of sheet form having (1) a heat generating sheet prepared by papermaking and containing an oxidizable metal, a moisture retaining agent, and a fibrous material and (2) an air permeable holder holding the heat generating sheet. The warming device has a thickness of 0.1 to 10 mm and a flexural strength of 0.01 to 0.3 N / cm. The sheet preferably has a thickness of 0.1 to 2.0 mm. The fibrous material preferably has a CSF of 600 ml or less.

Owner:KAO CORP

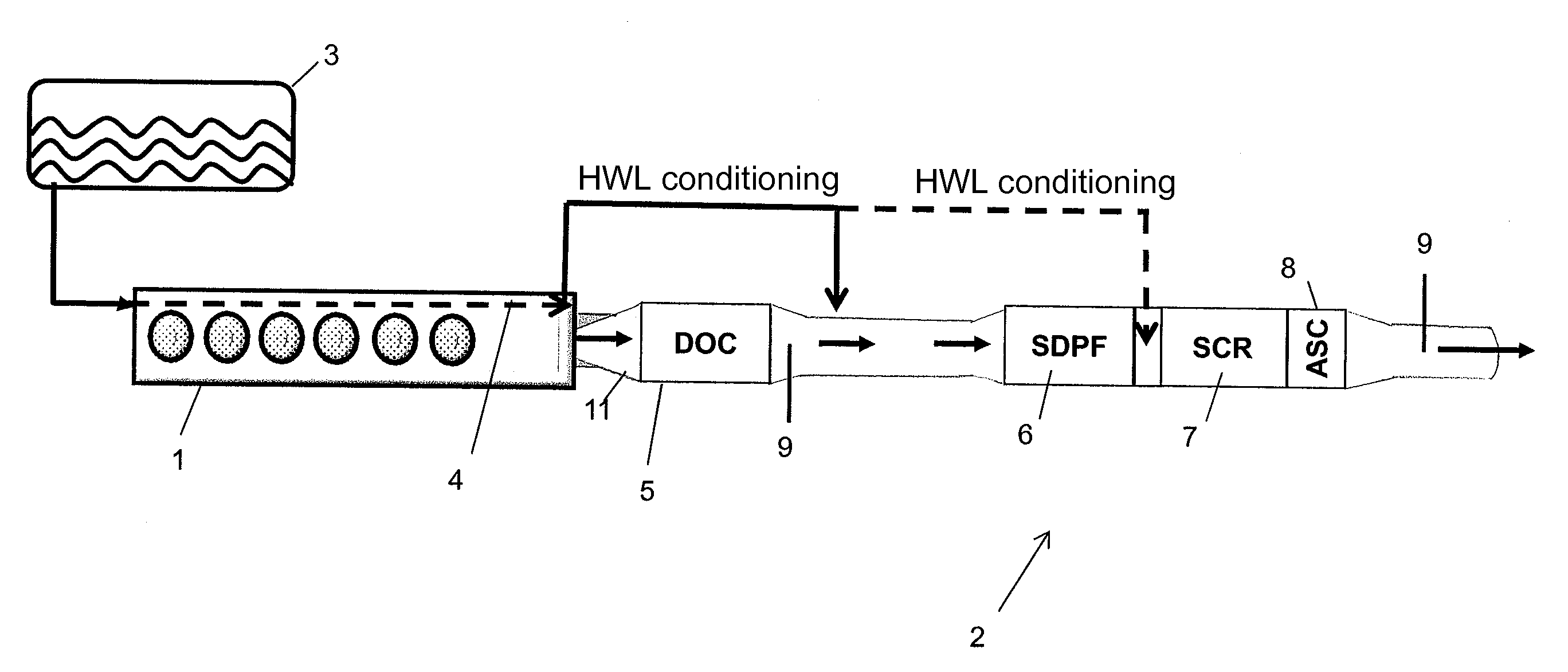

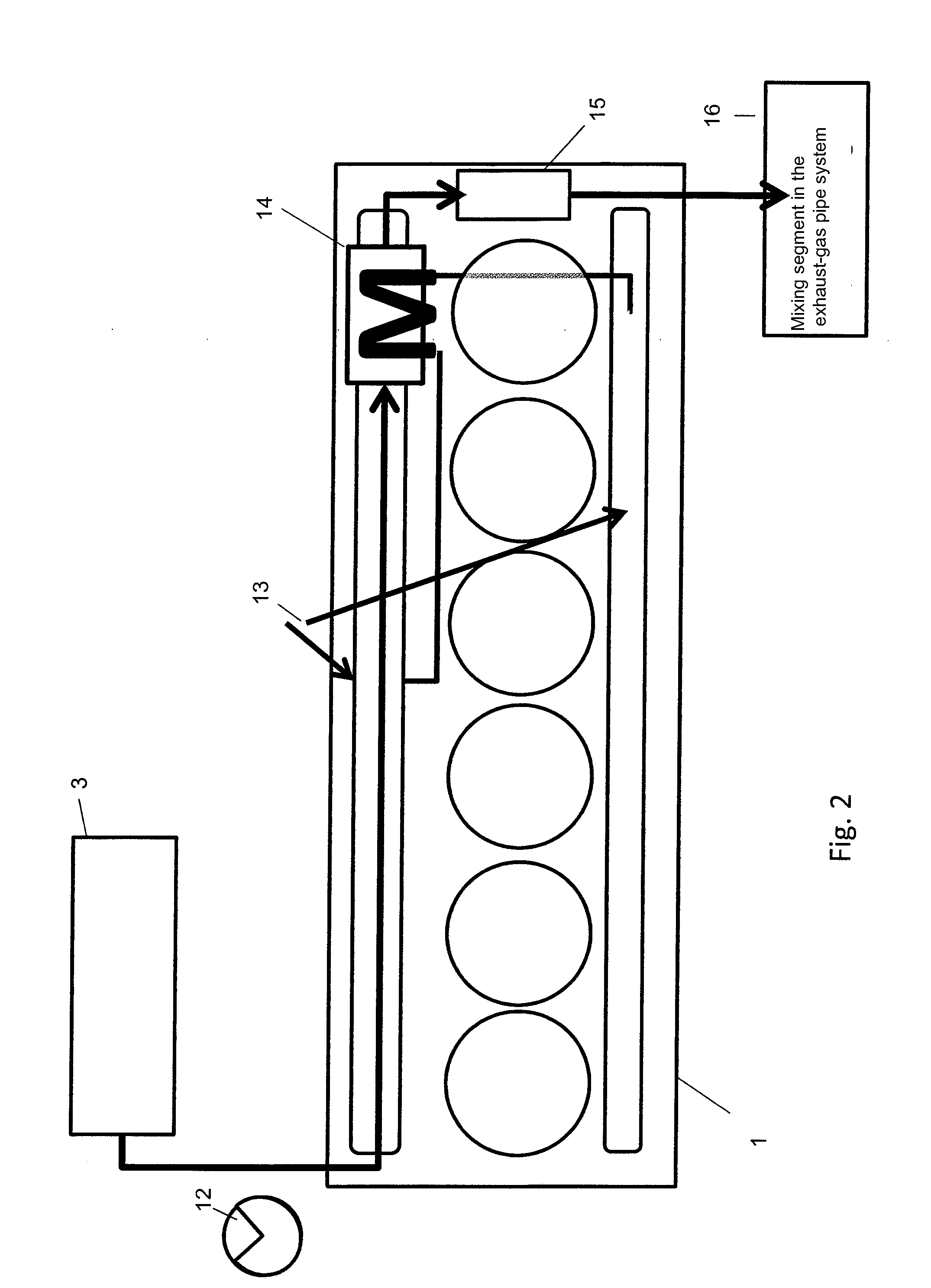

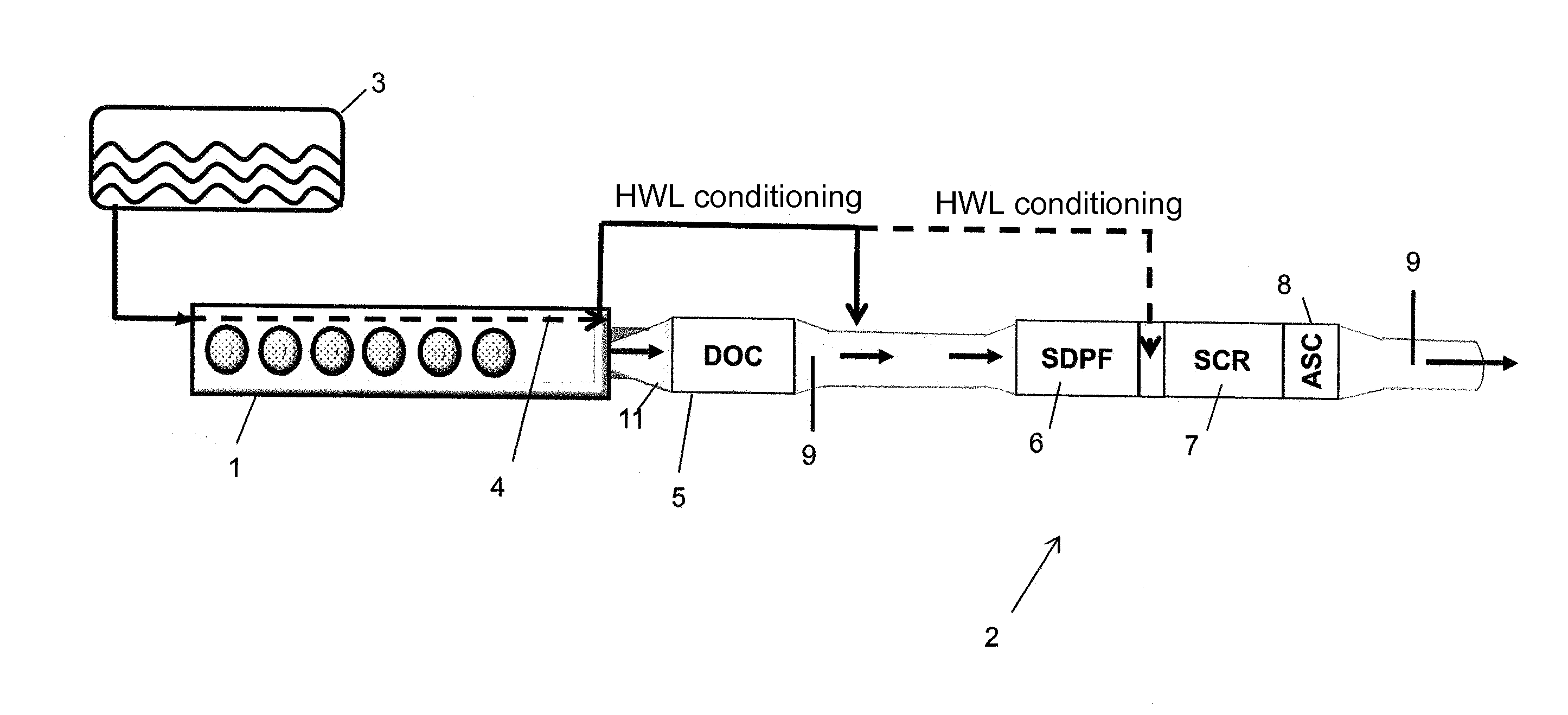

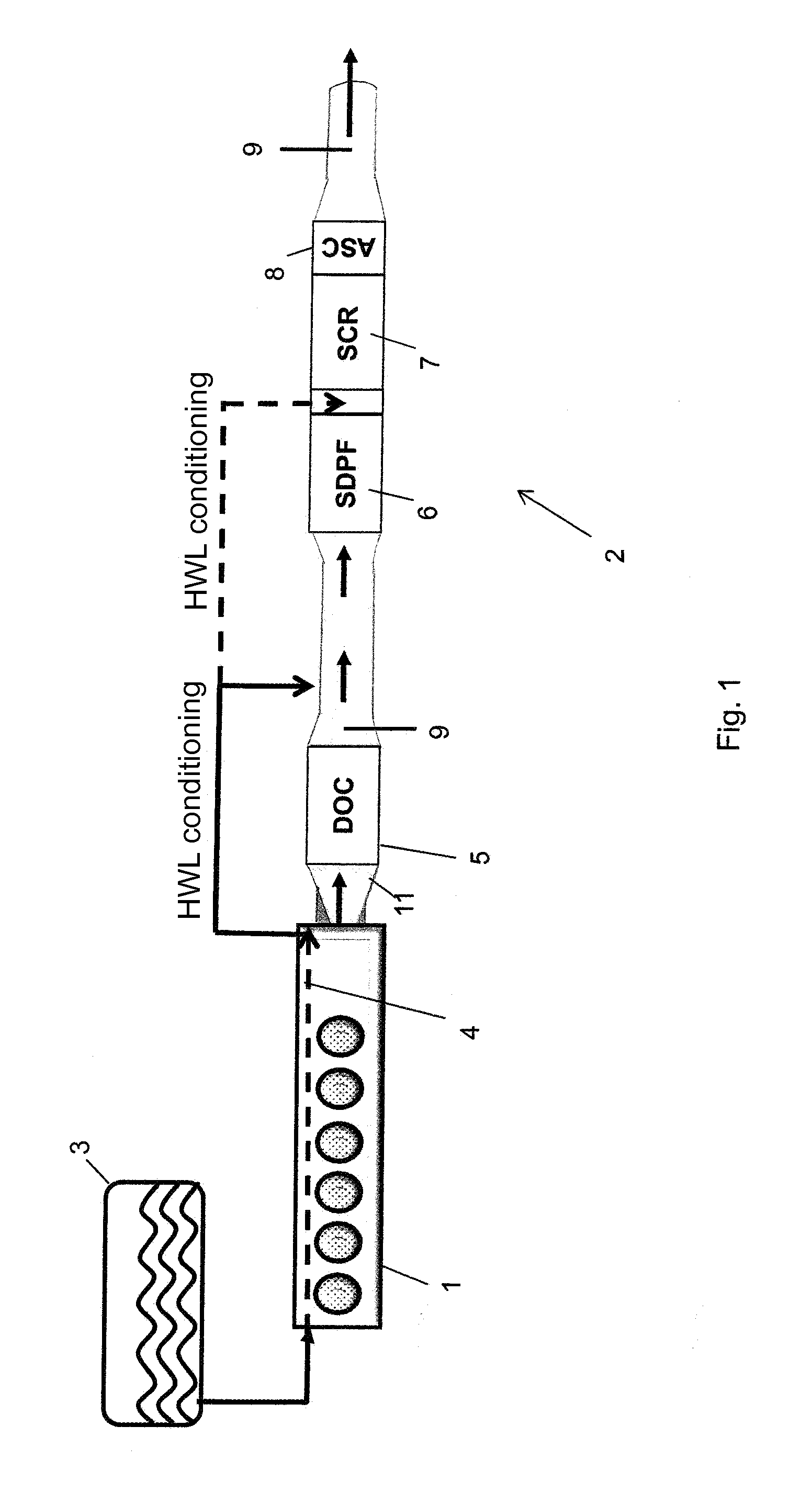

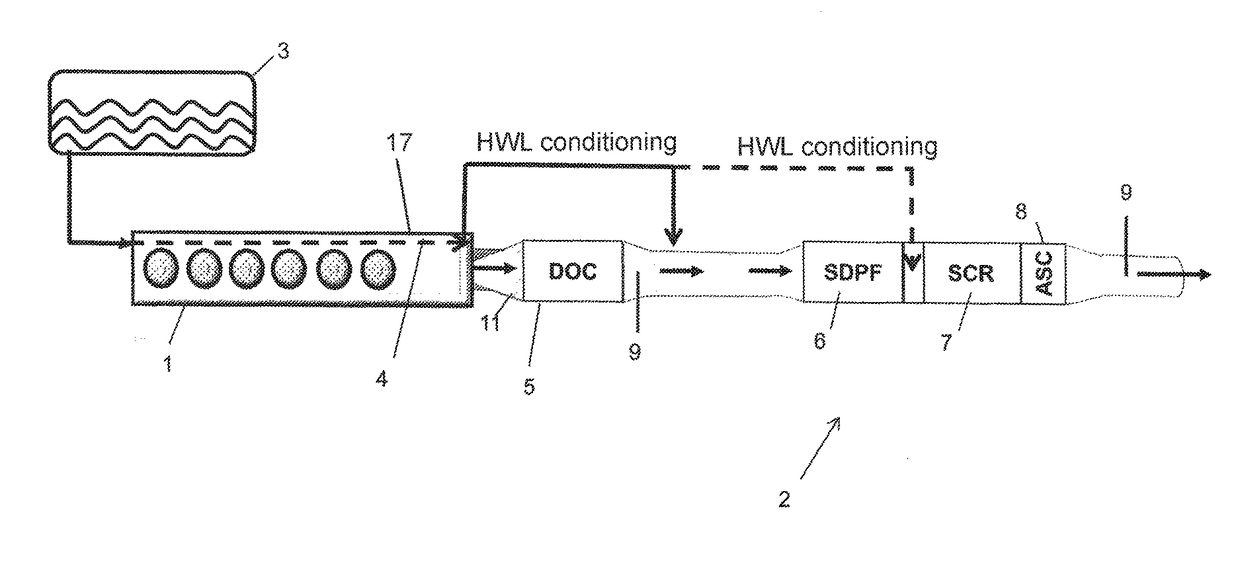

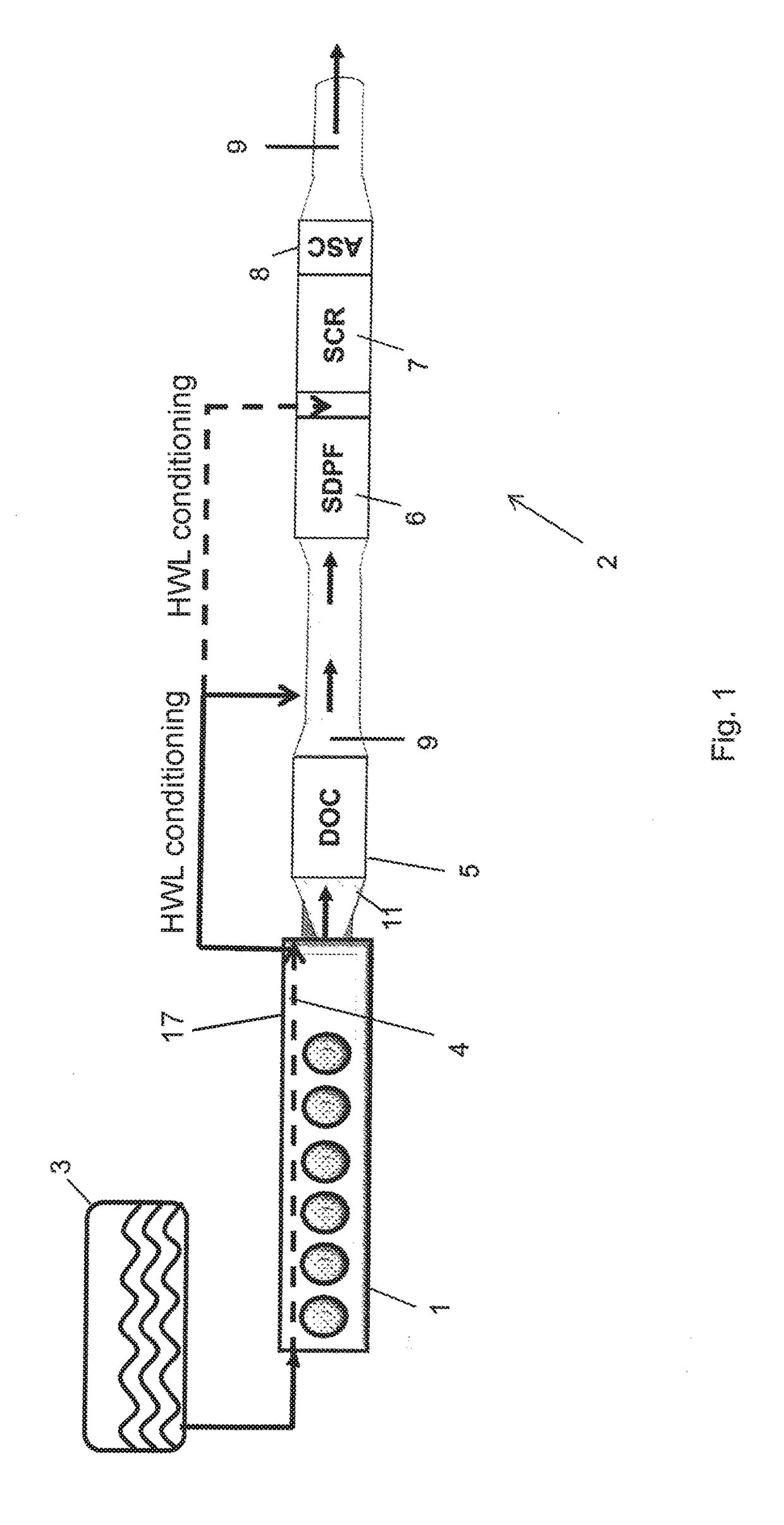

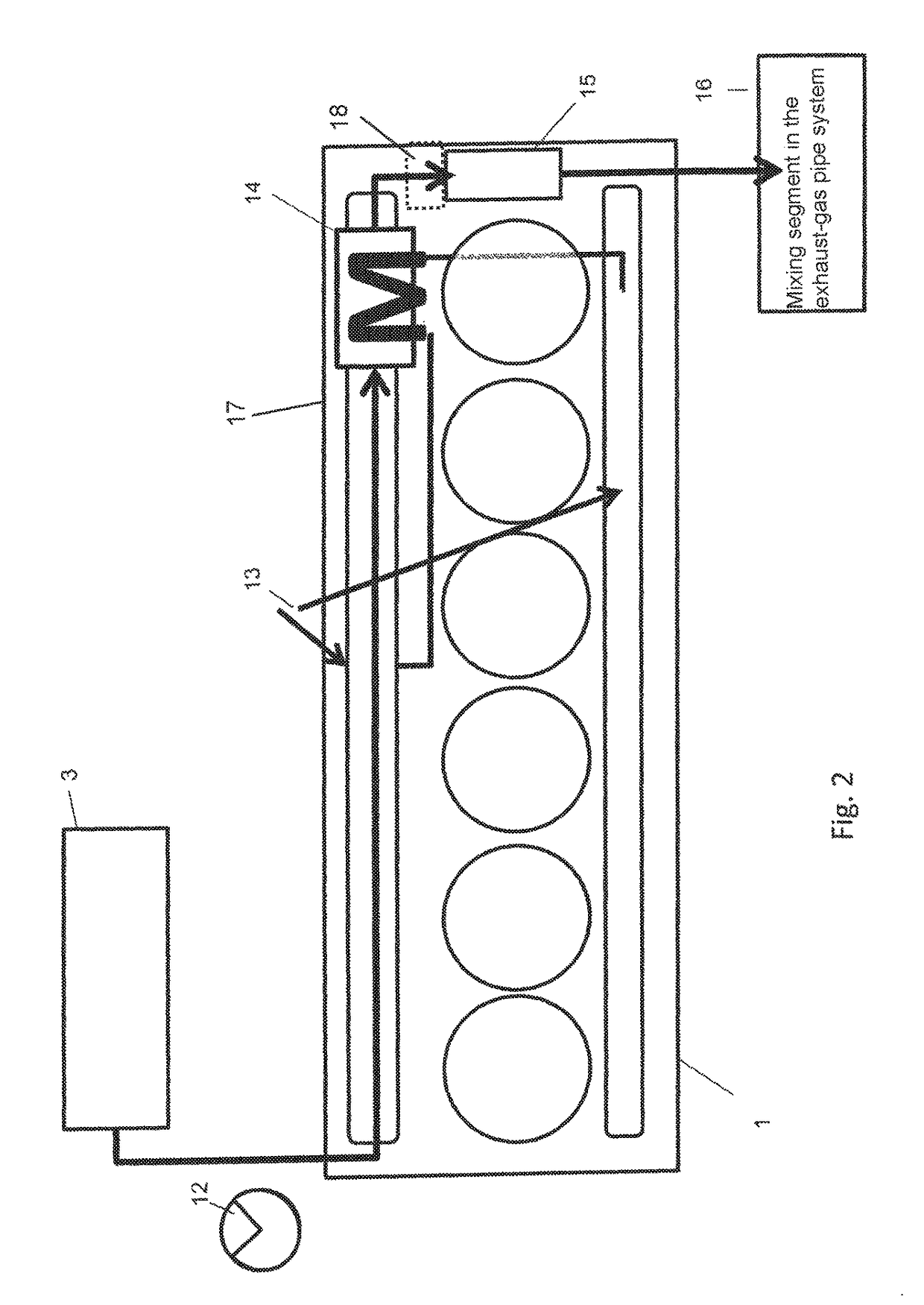

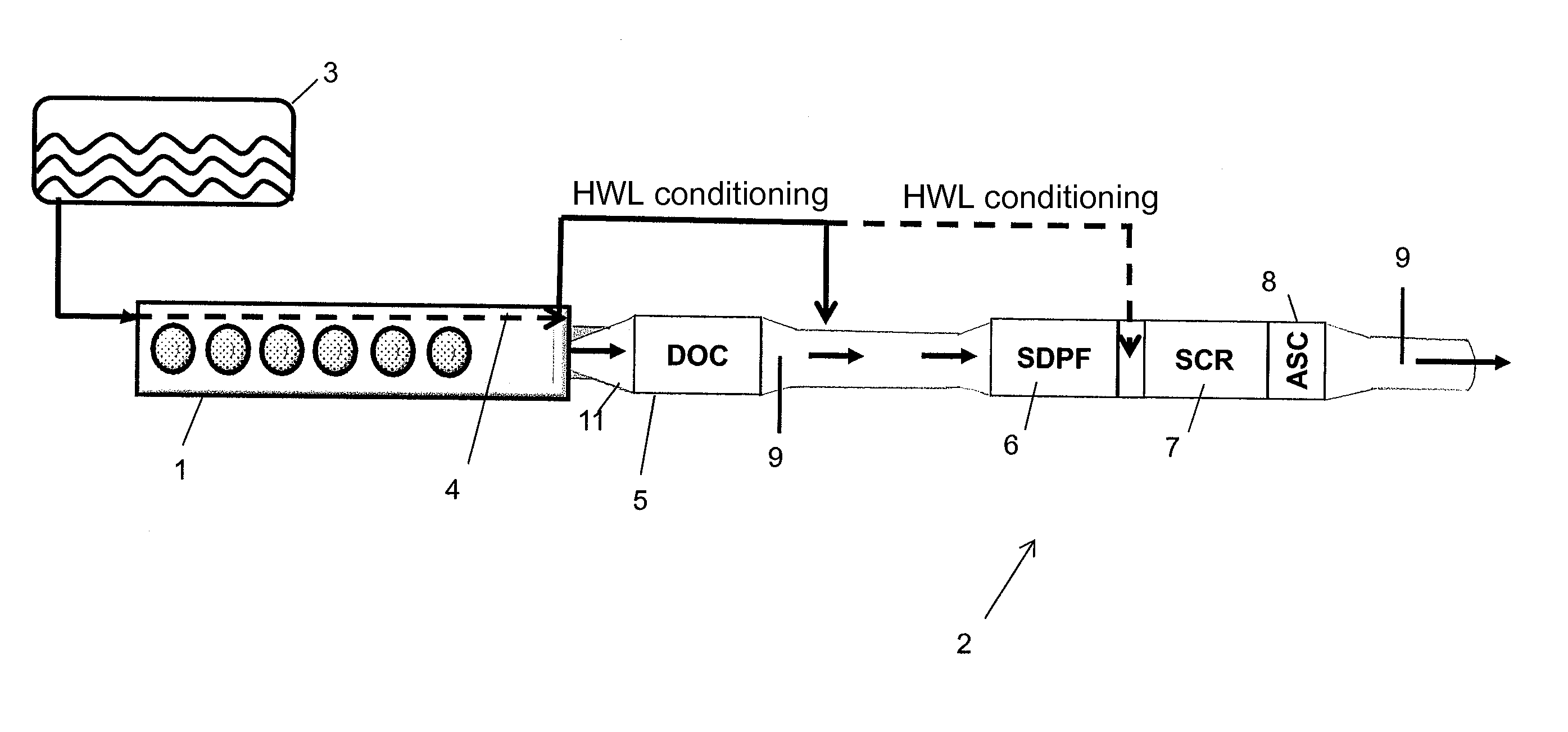

Method for the purification of diesel engine exhaust gases

ActiveUS20150231565A1Reduce ASCAvoid secondary emissionsGas treatmentInternal combustion piston enginesNitrogen monooxideNitrogen dioxide

A method in which the exhaust gas that is to be purified is passed through an exhaust-gas line containing a diesel oxidation catalyst (DOC) for the oxidation of residual gaseous hydrocarbons (HC) and carbon monoxide (CO) in order to form carbon dioxide (CO2) and for the at least proportional oxidation of the nitrogen monoxide (NO) contained in the exhaust gas in order to form nitrogen dioxide (NO2) is provided.

Owner:DEUTZ AG

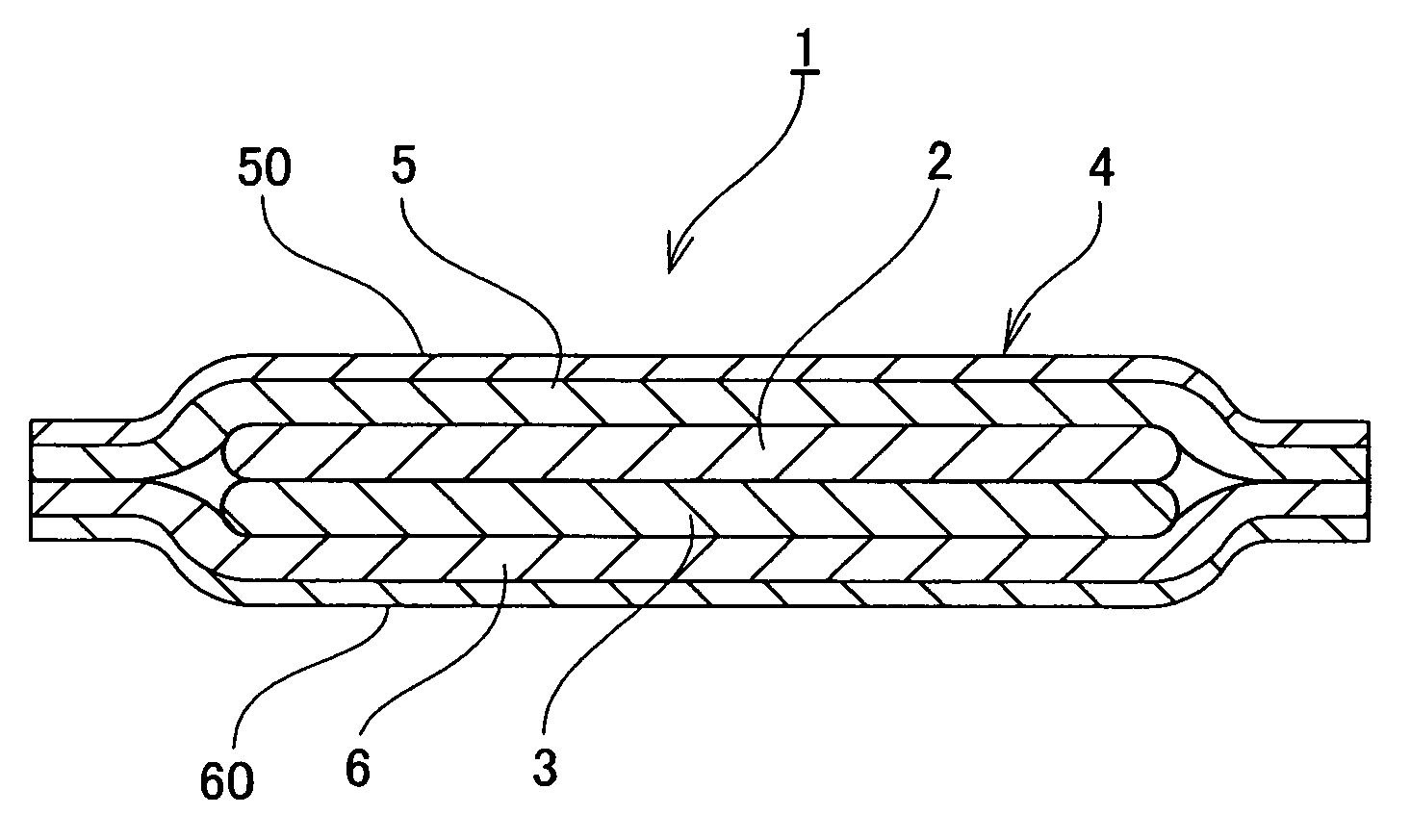

Carbon wire heating object sealing heater and fluid heating apparatus using the same heater

InactiveUS6885814B2Suppress generationUnevenness in heating is smallDomestic stoves or rangesDrying solid materials with heatFiberCarbon fibers

A carbon wire heating element sealing heater is provided. Therein, a carbon wire heating element using carbon fibers is sealed in a quartz glass member, wherein absorption water quantity of the carbon wire heating element is 2×10−3 g / cm3 or less.

Owner:TOKYO ELECTRON LTD +1

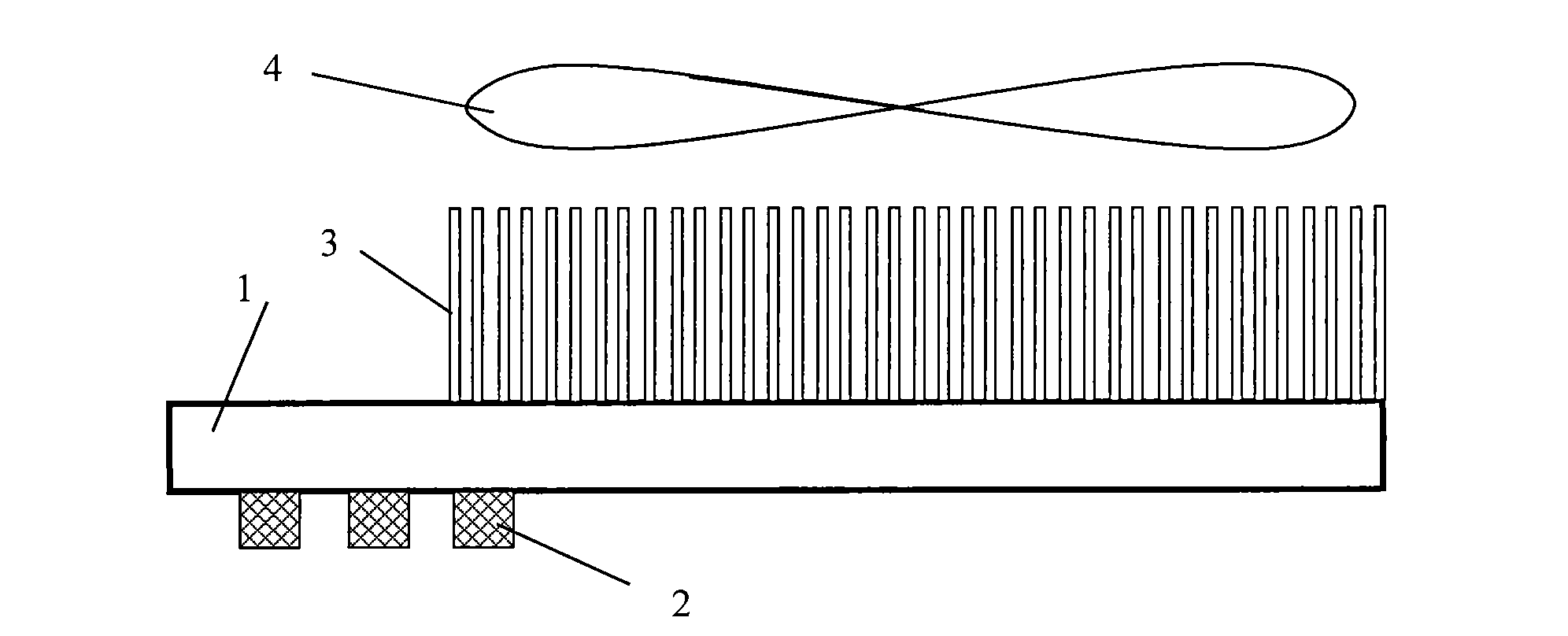

Novel LED and a high-power radiator of a radiating element

ActiveCN101515572AIncrease contact areaImprove heat transfer effectSemiconductor/solid-state device detailsSolid-state devicesMetallic materialsEvaporation

The invention relates to a novel LED and a high-power radiator of a radiating element, comprising flat plate heat pipes which are of two or more via-hole array flat plate structures arranged side by side; the via-hole array flat plate structures are formed by carrying out extrusion or punch forming on metal materials; the equivalent diameter of the via hole is 0.5-3mm; the via hole is filled with liquid propellant and both ends of the flat plate heat pipes are packaged by sealing; an evaporation section of the flat plate heat pipe contacts heating surfaces of the LED and the high-power radiating element and a condensation section thereof radiates through the radiating element. The novel LED and the high-power radiator of a radiating element overcome the disadvantages that the contact area of the existing circular heat pipes and the heating surfaces of the LED and the high-power radiating element is small, the equivalent resistance of heat conduction is large and the manufacturing process is complex, which have the advantages of high radiating efficiency and simple process.

Owner:GUANGWEI HETONG ENERGY TECH BEIJING CO LTD

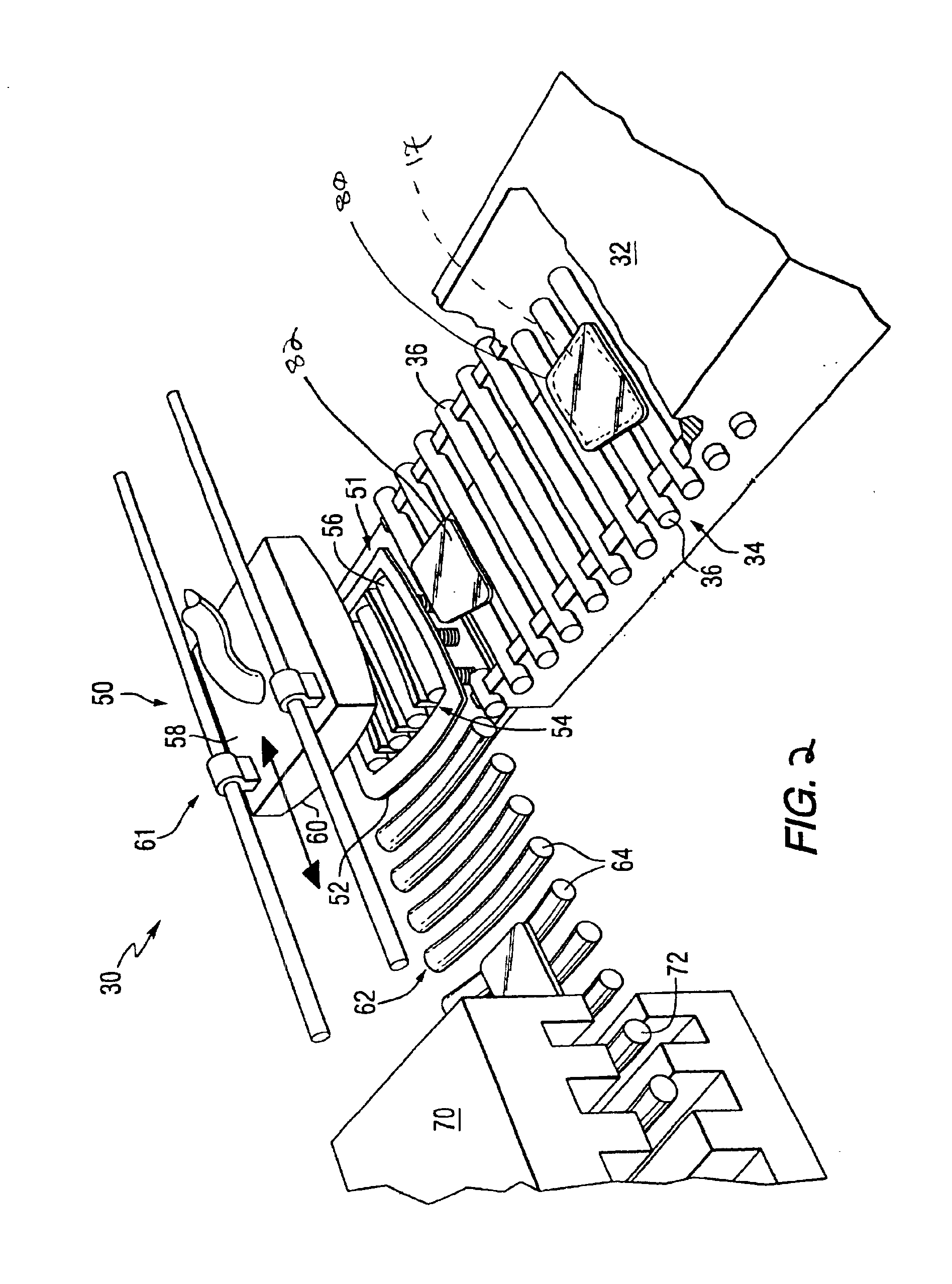

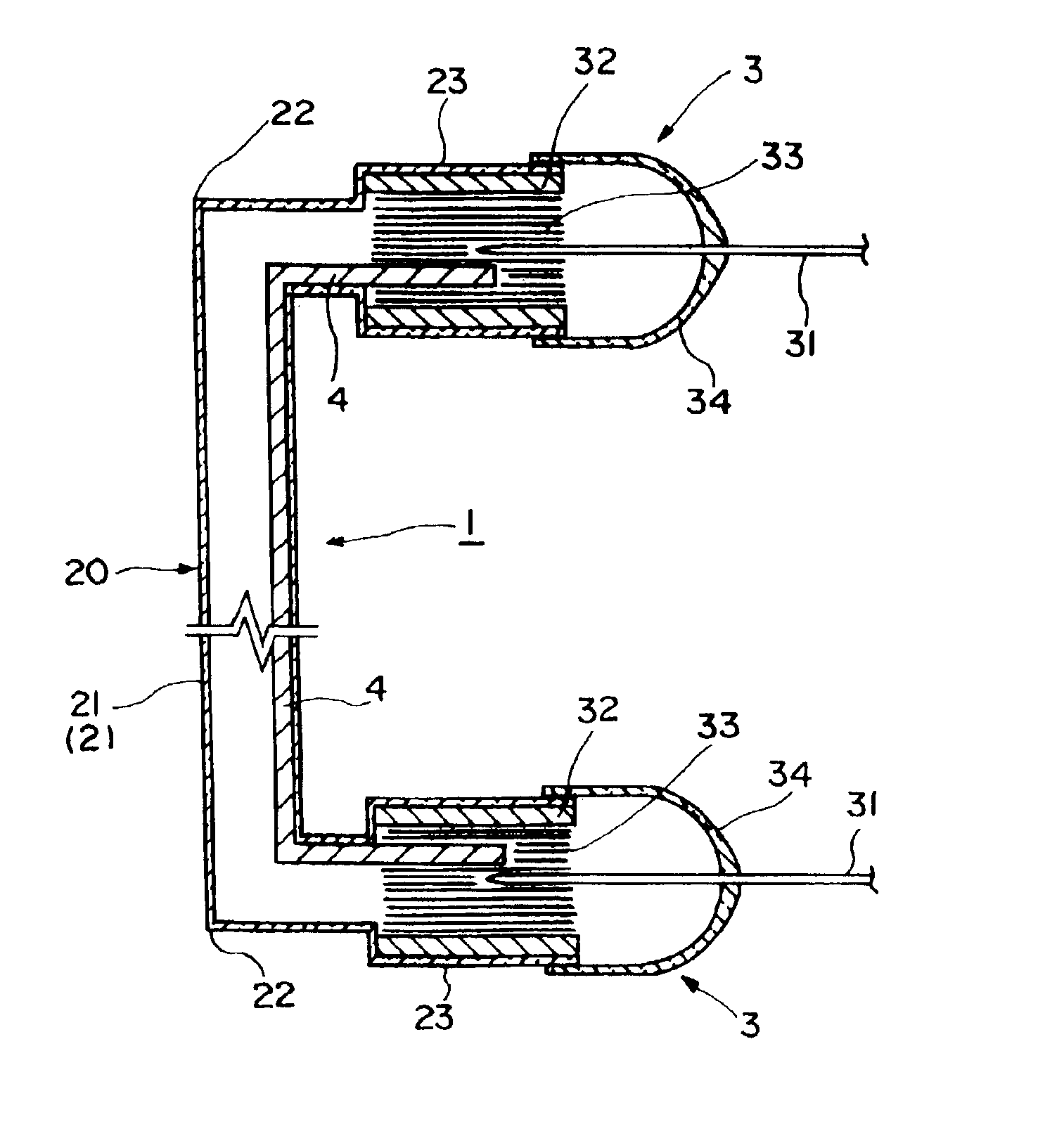

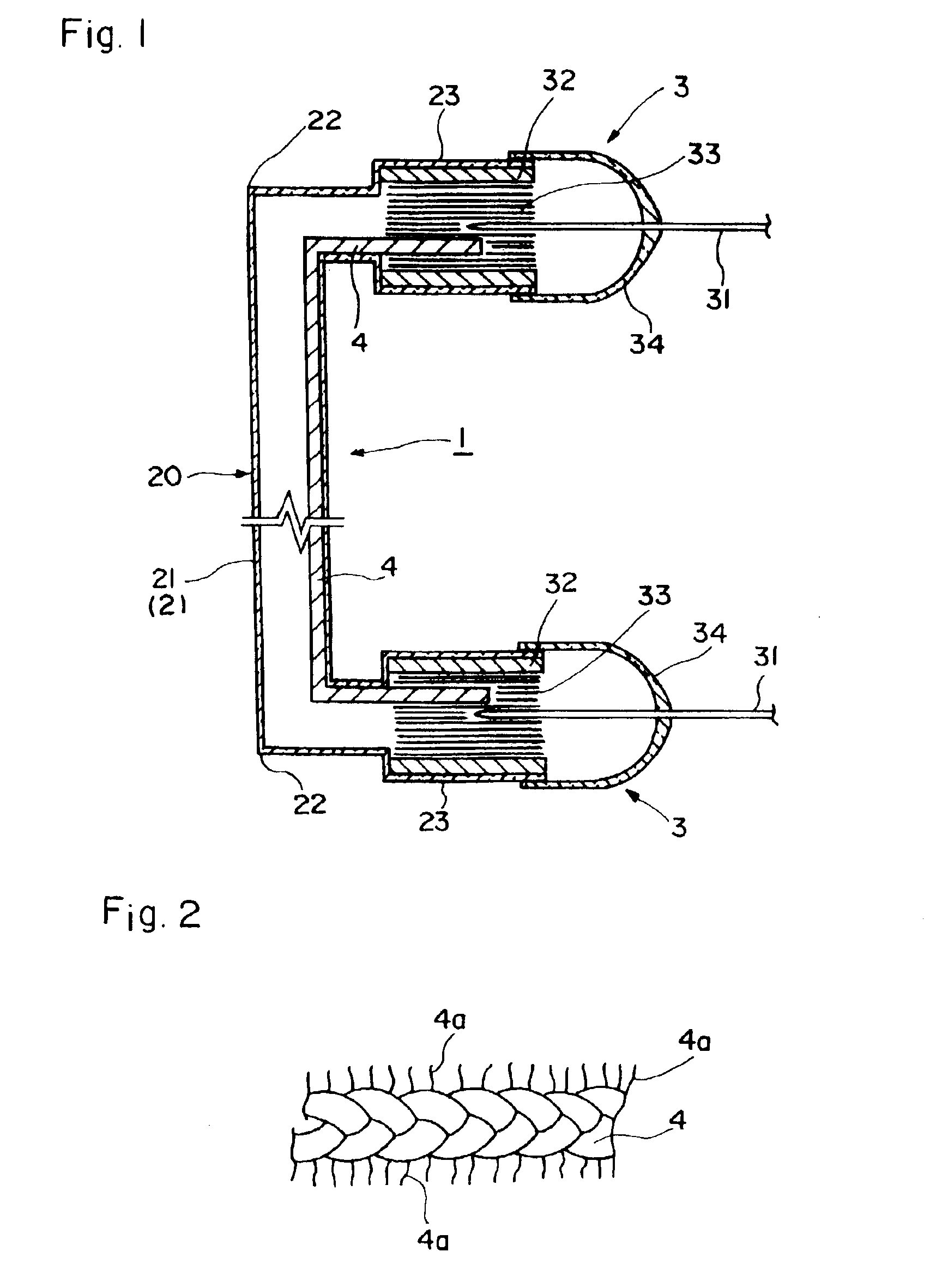

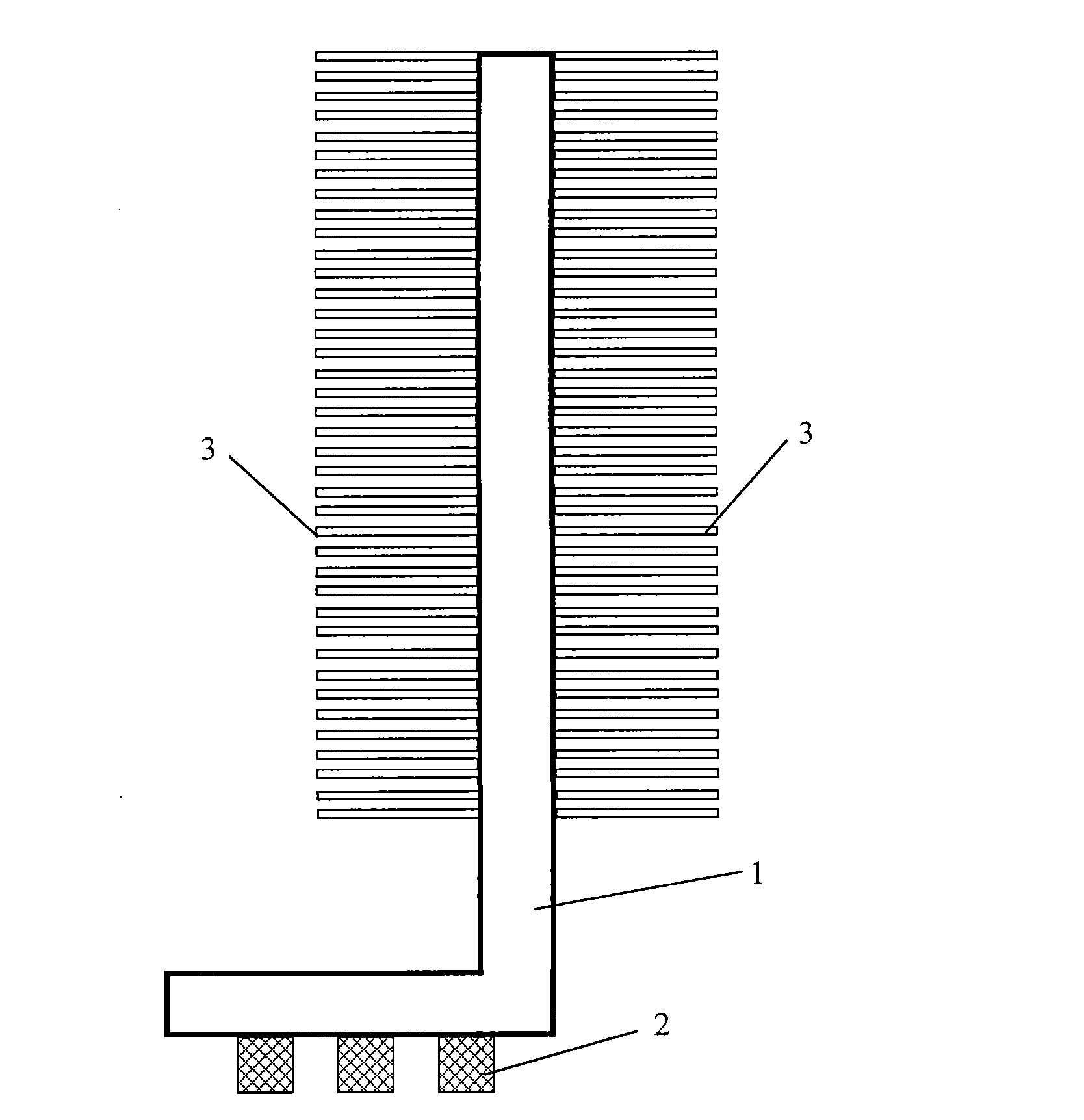

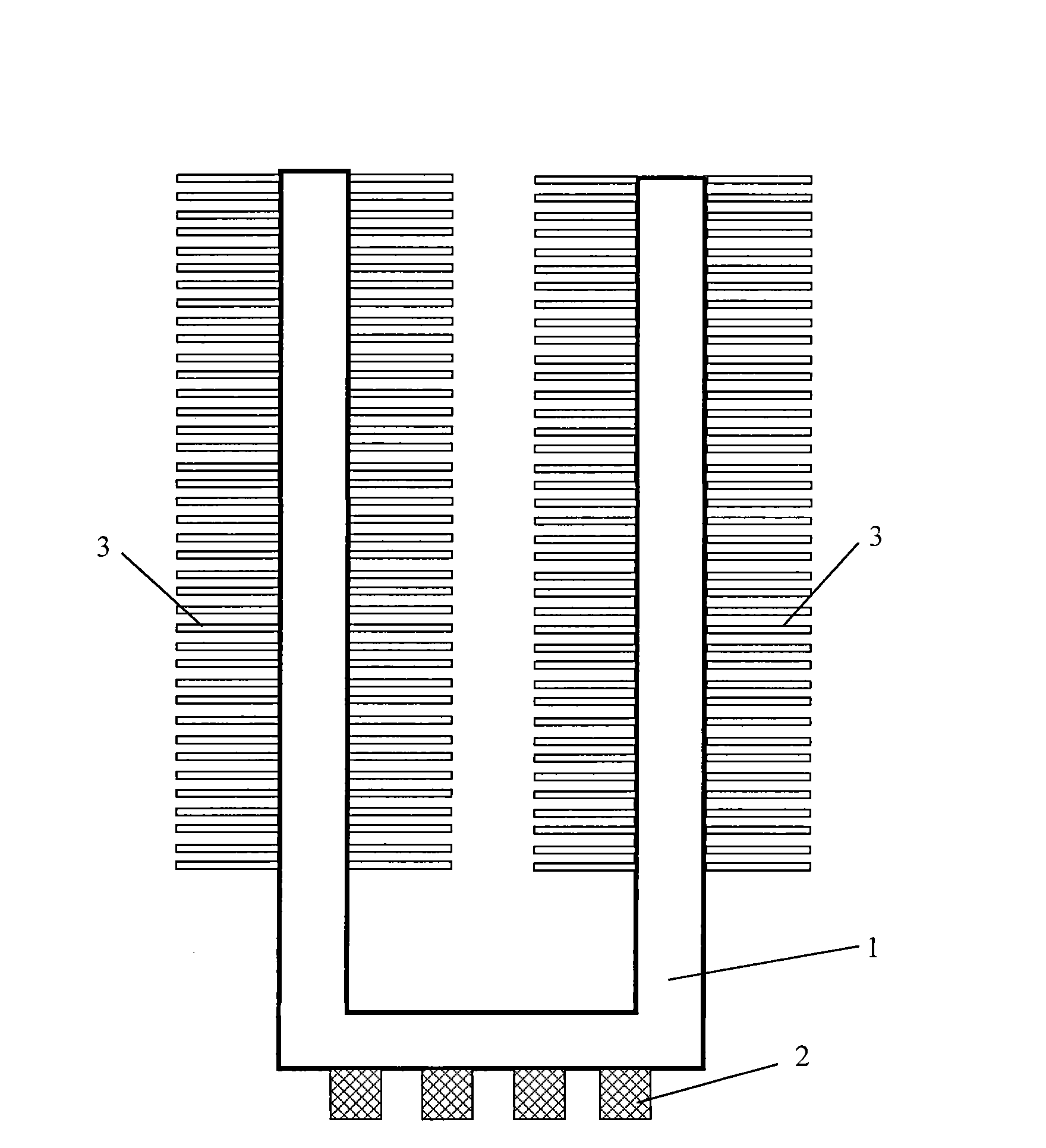

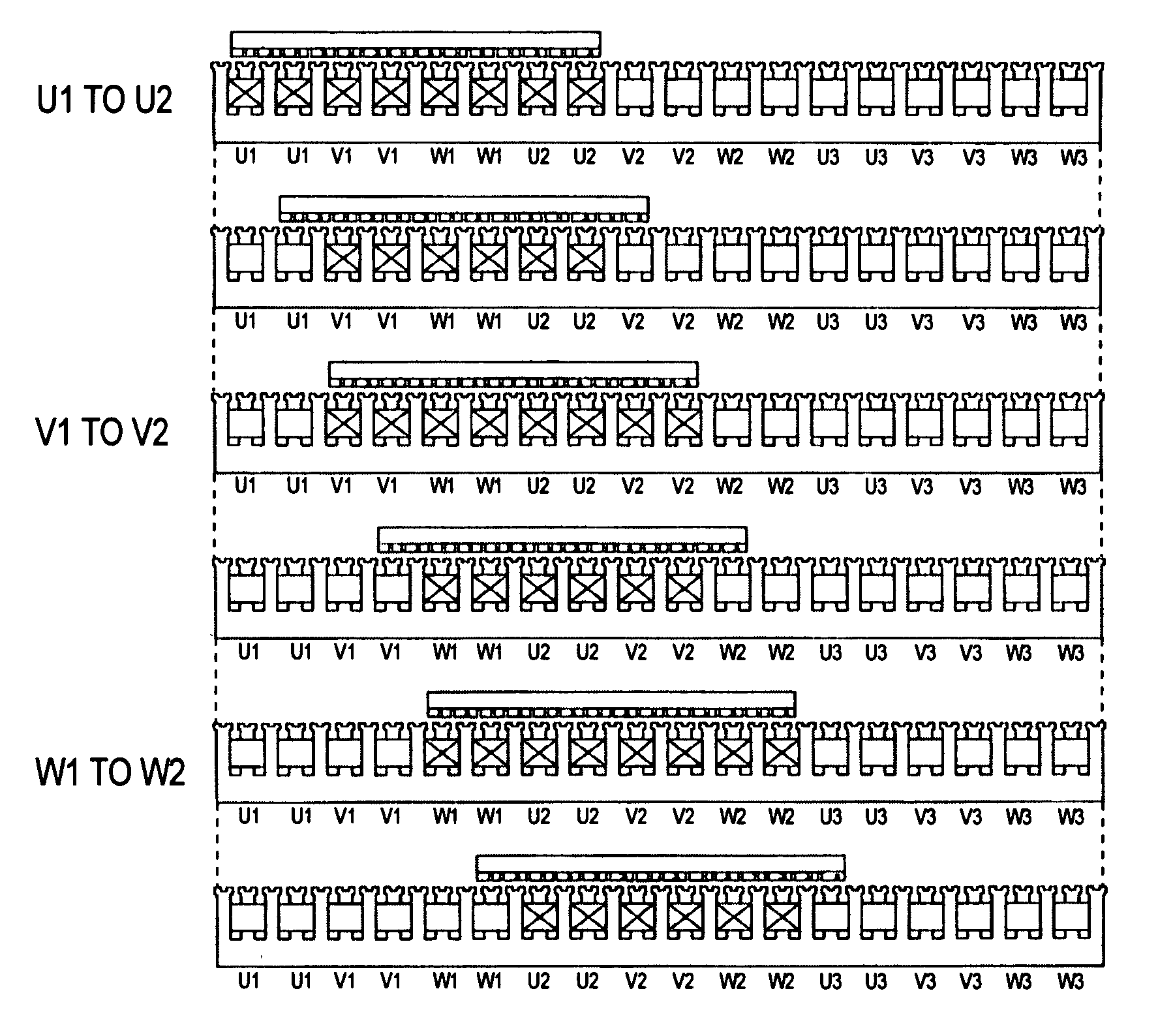

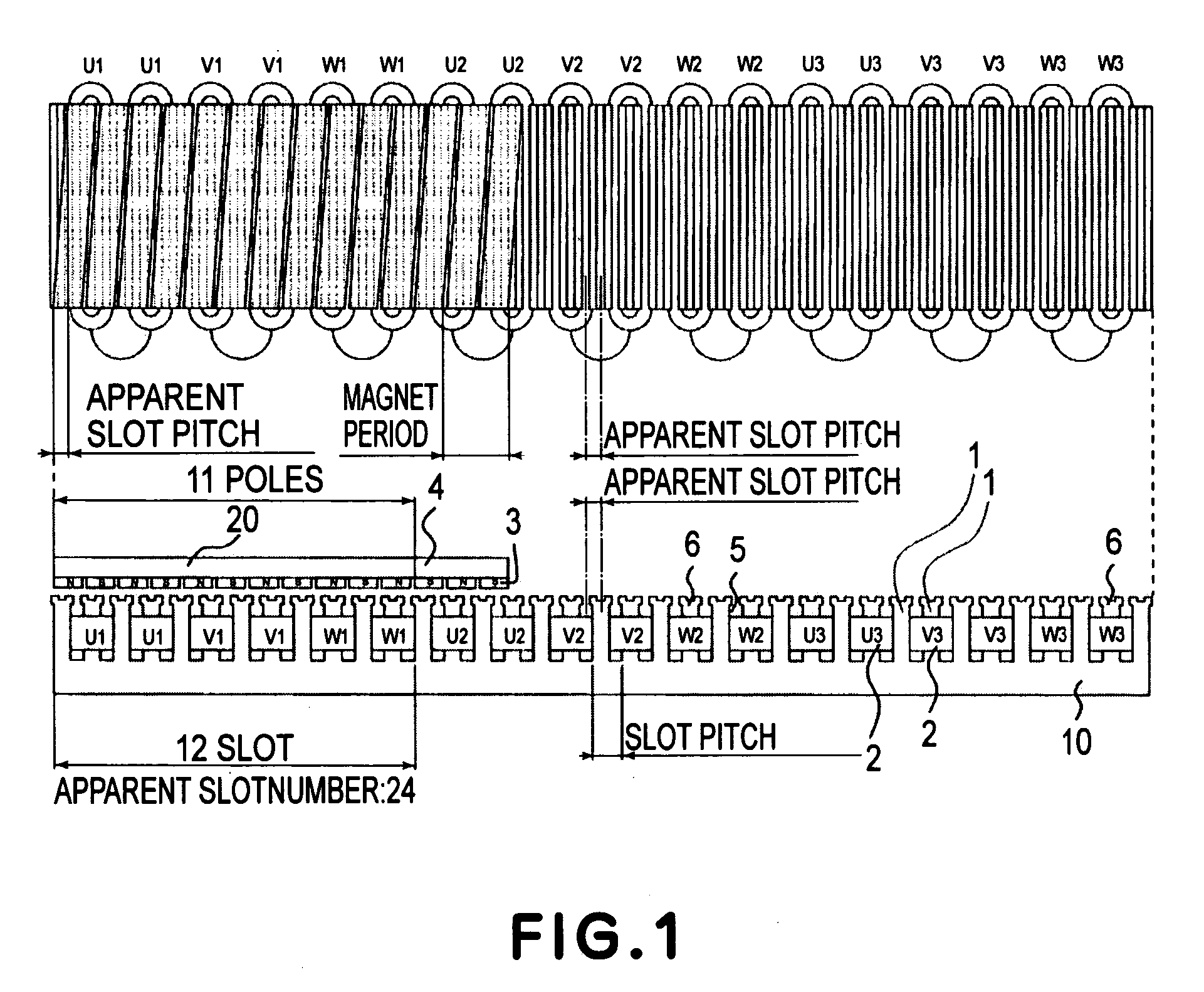

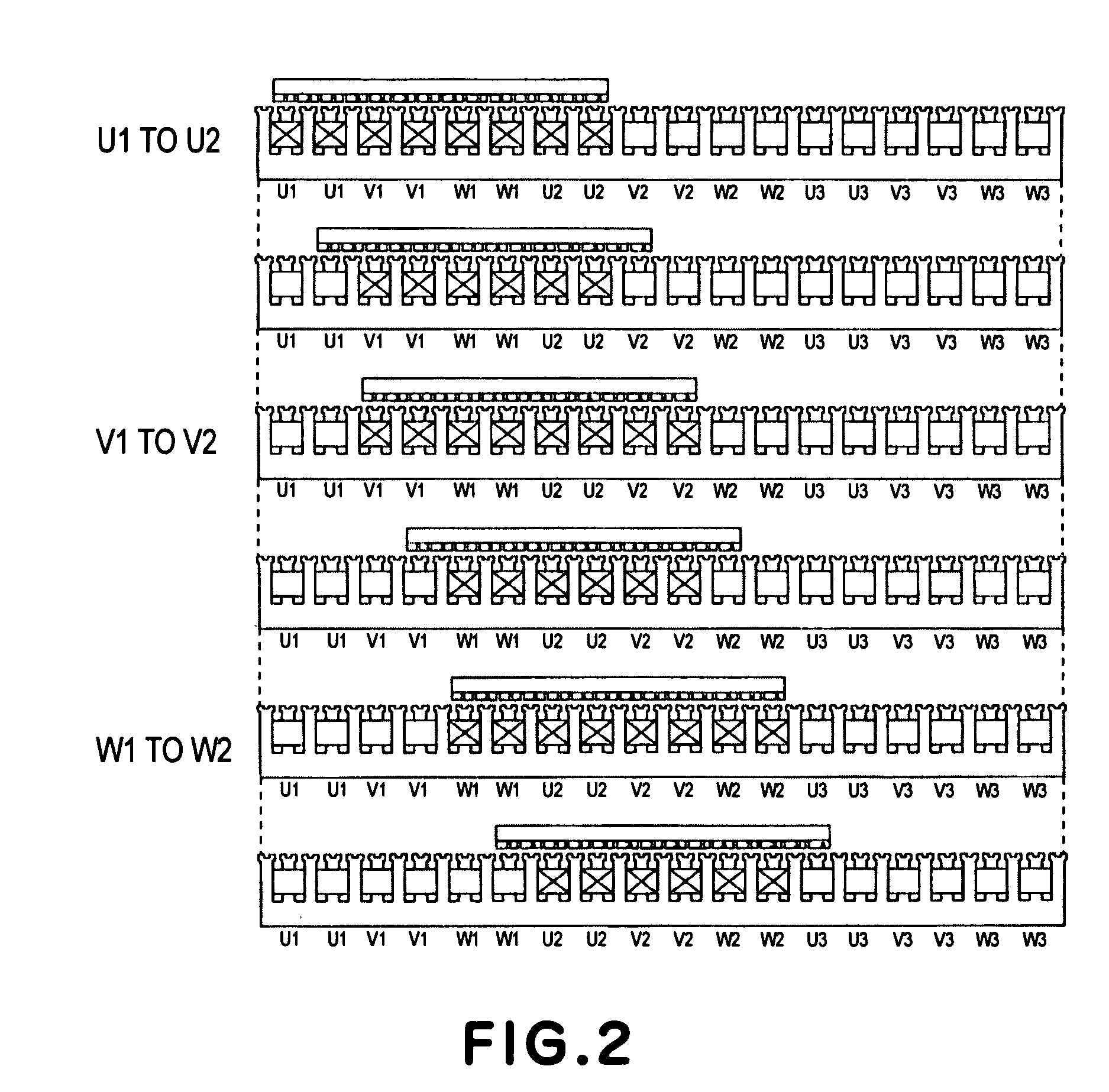

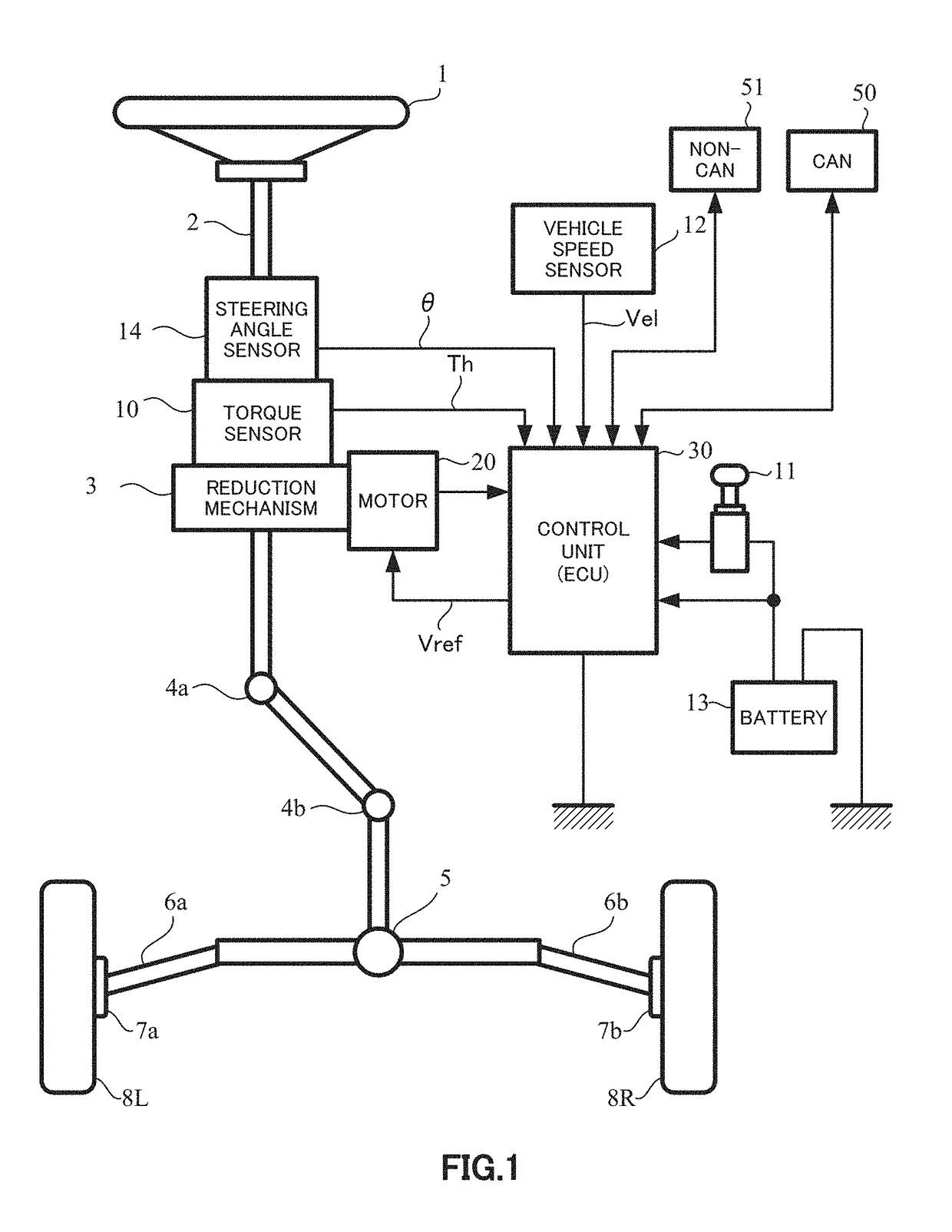

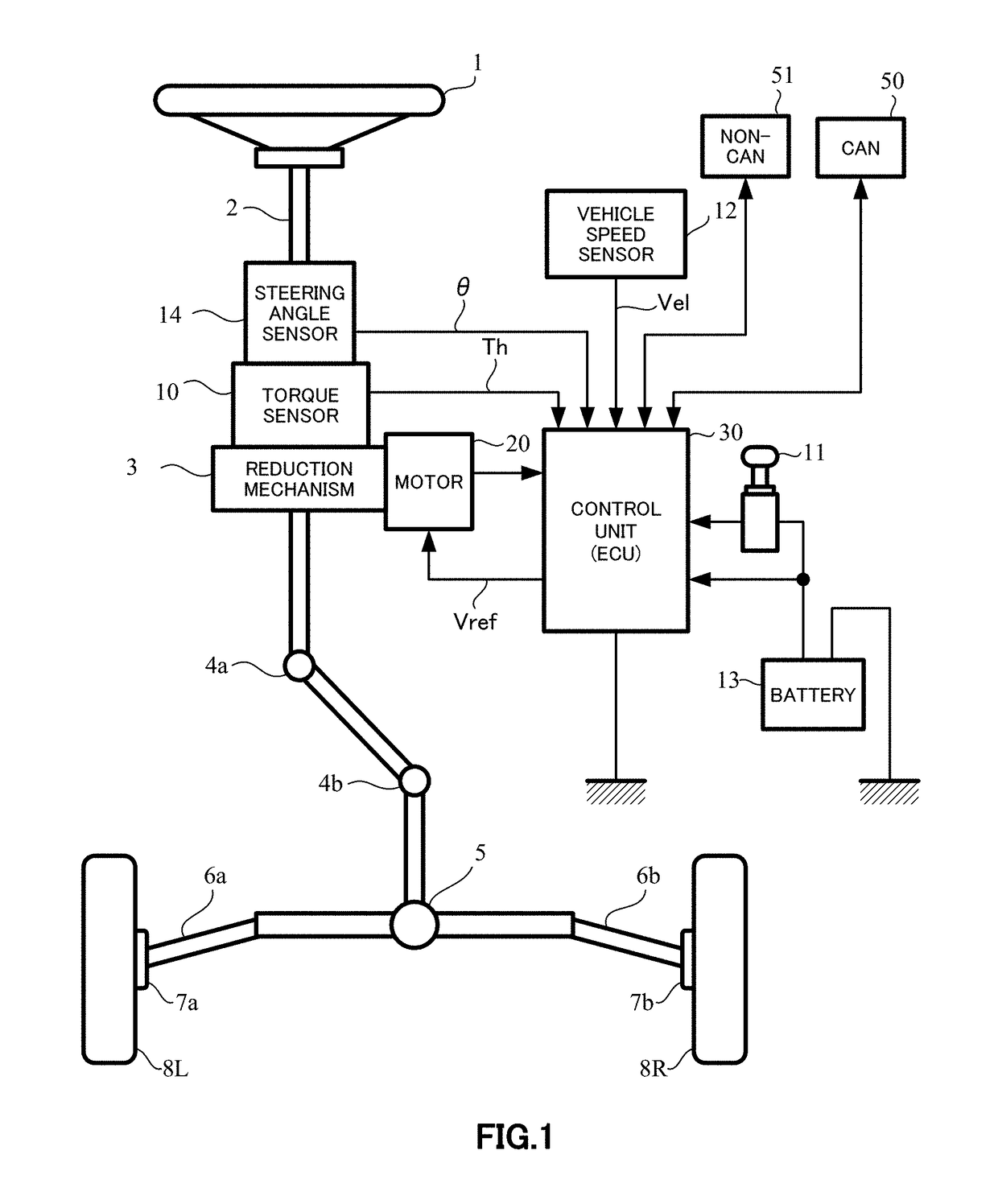

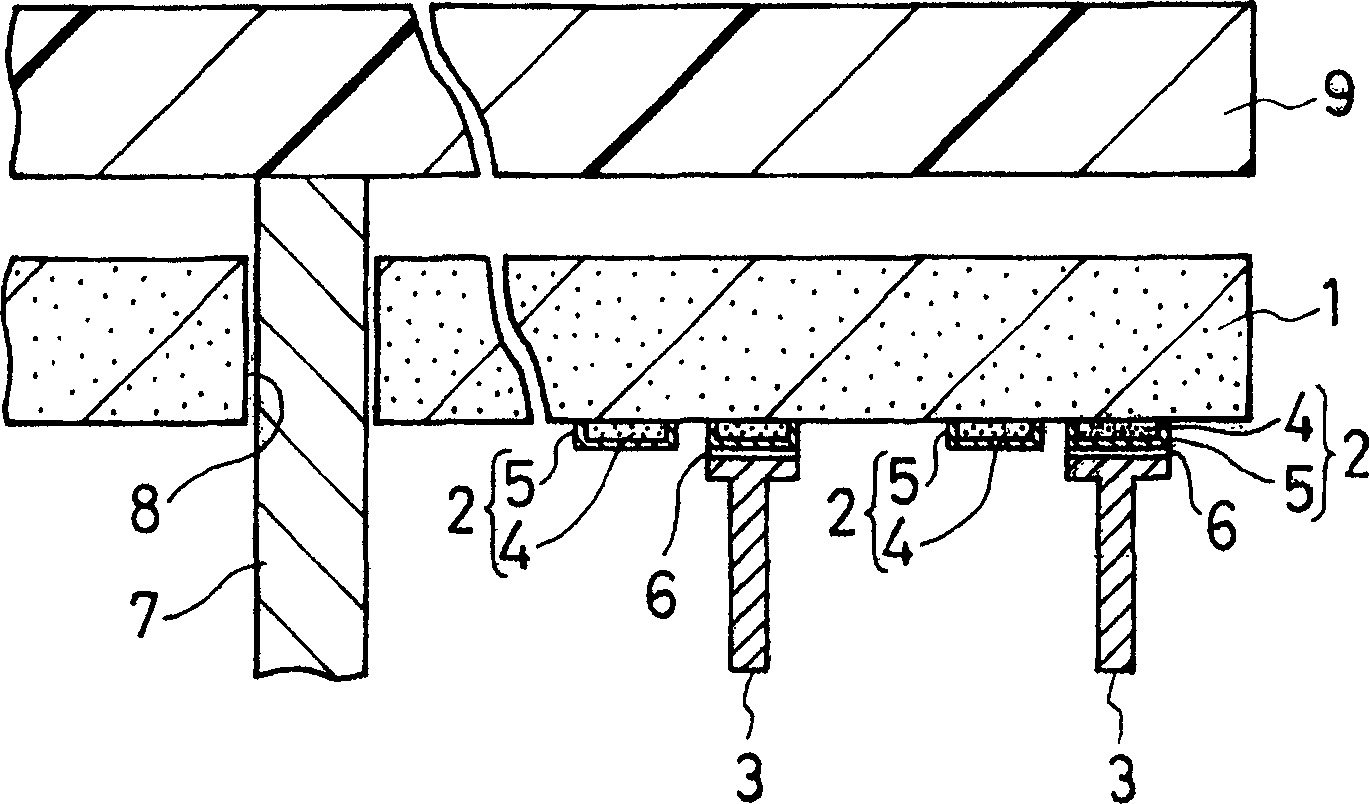

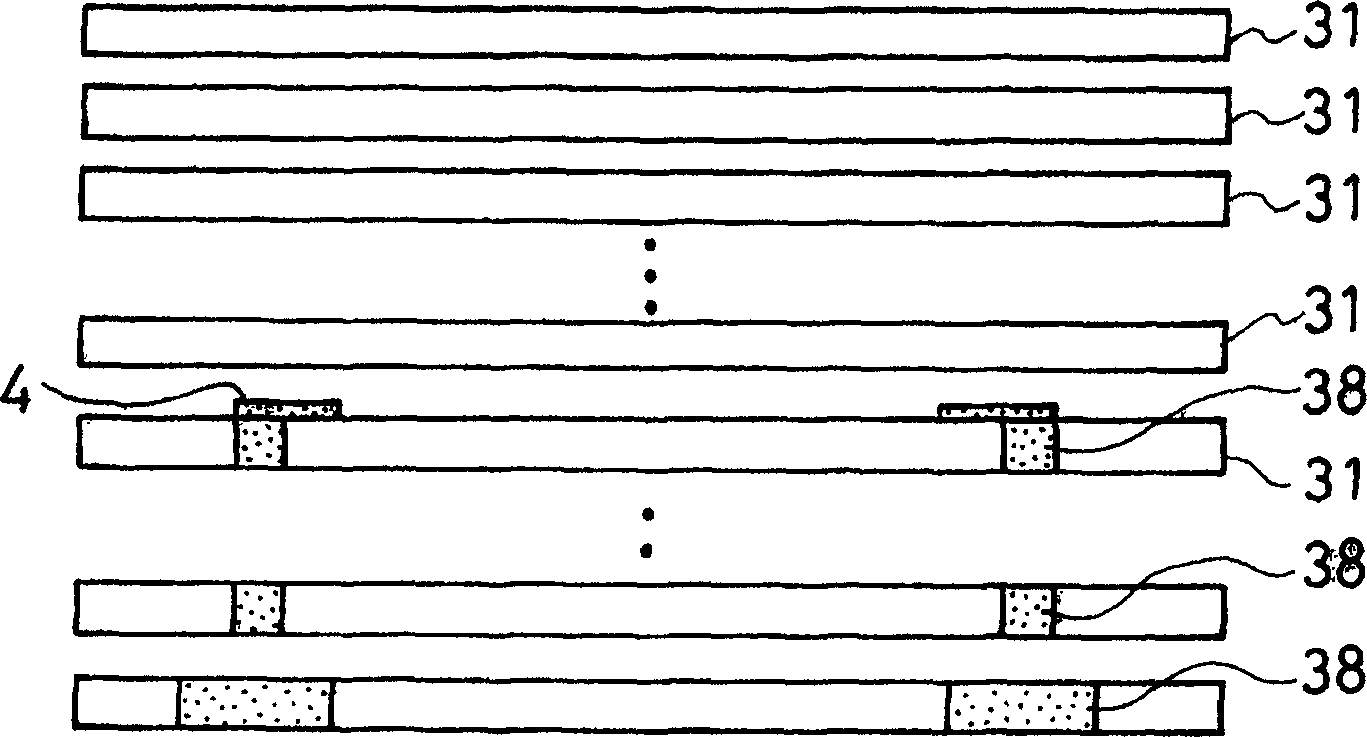

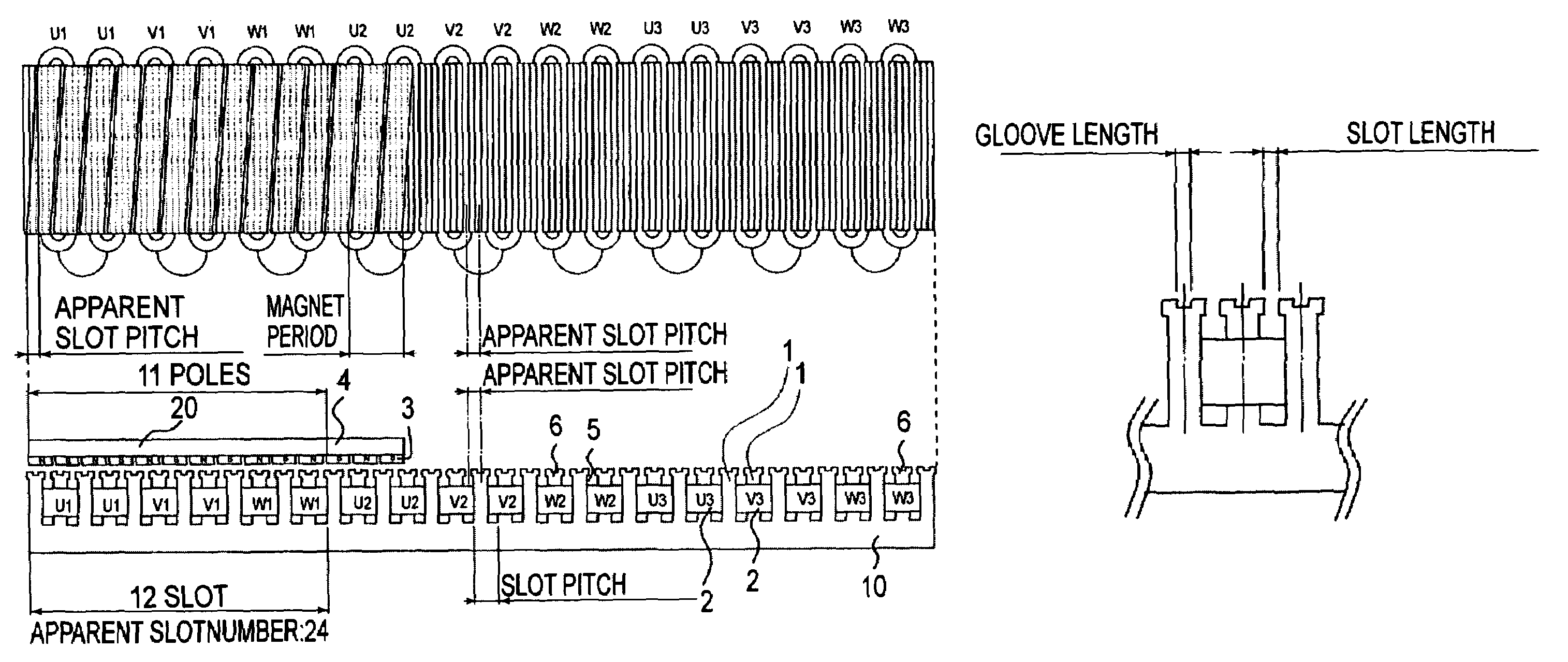

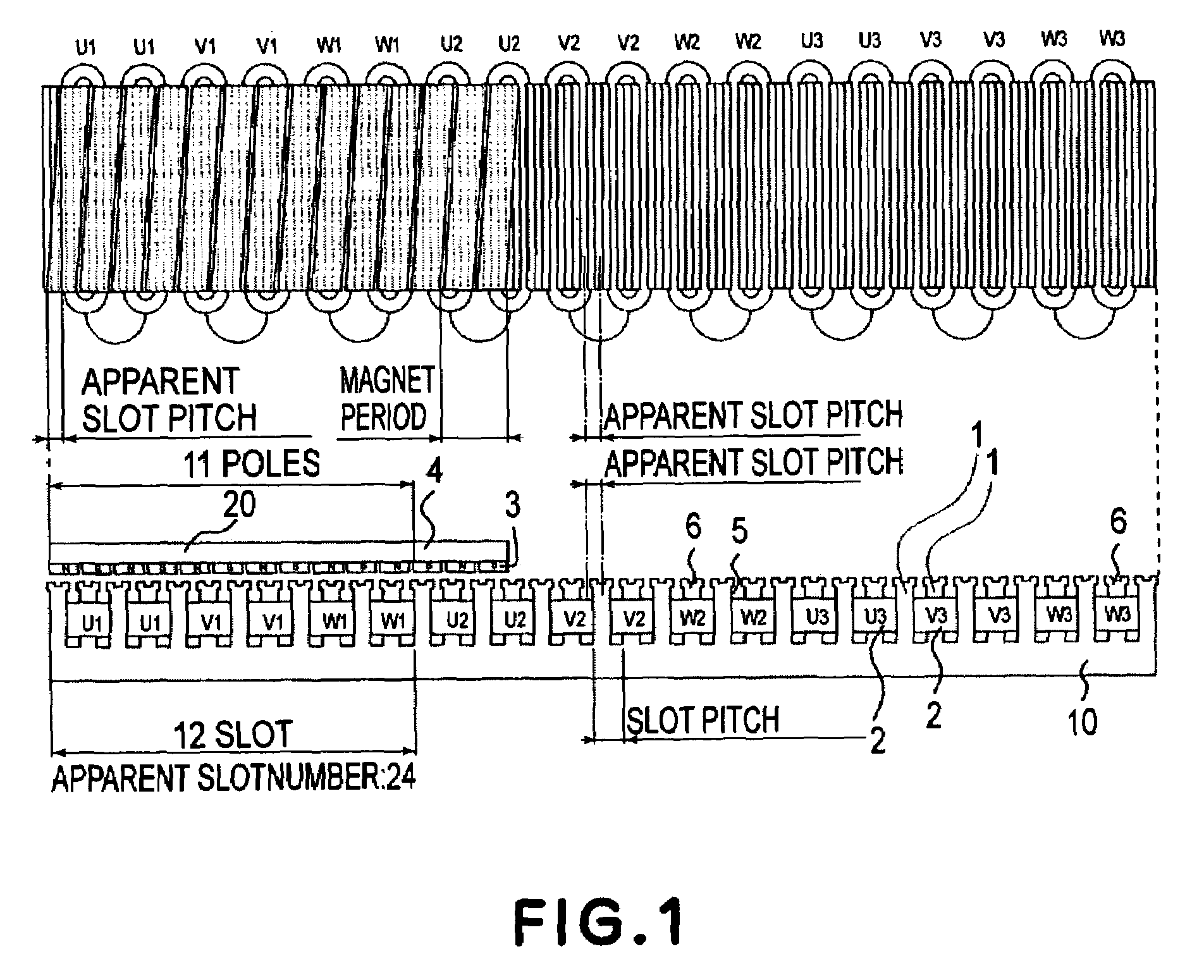

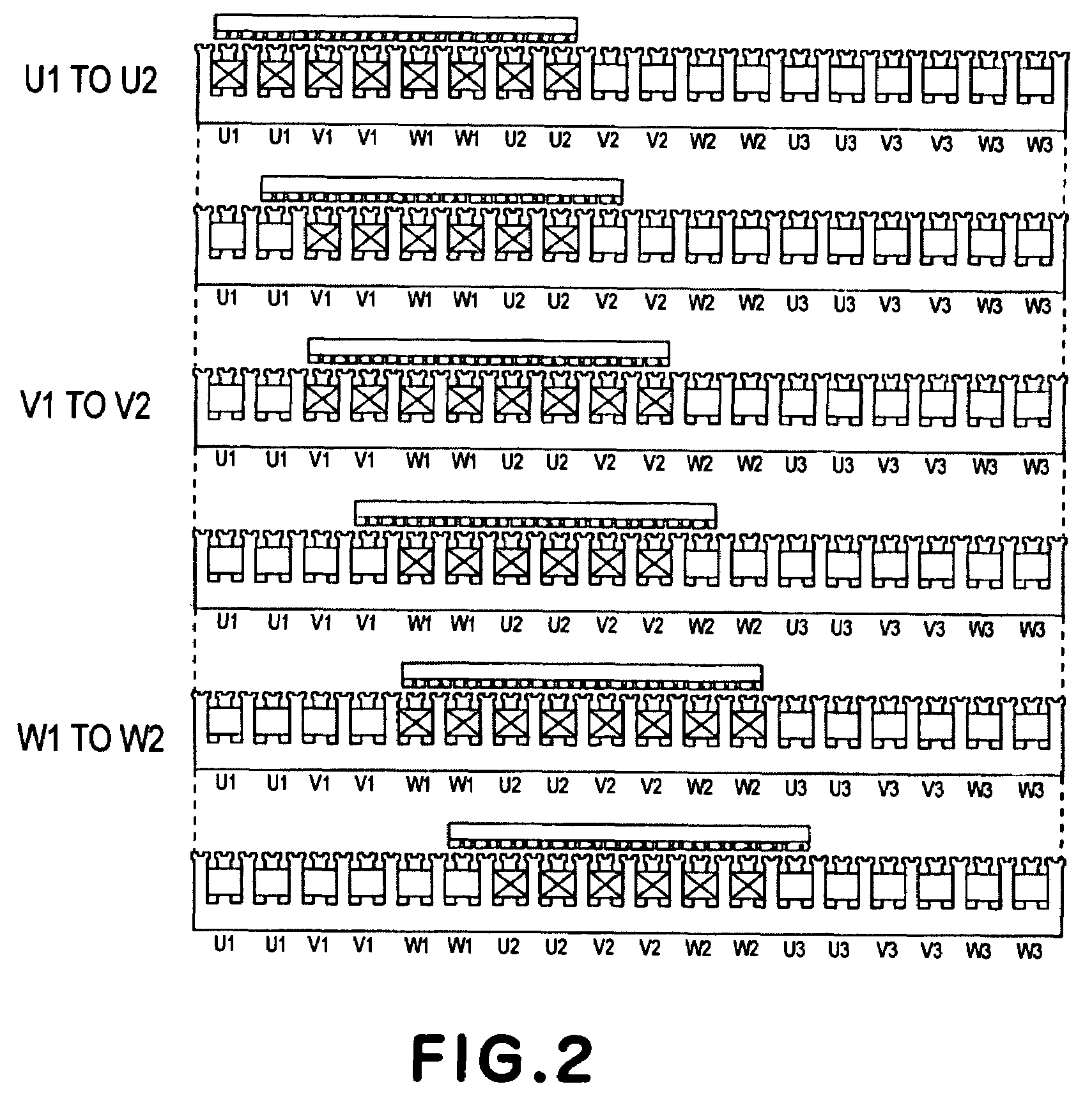

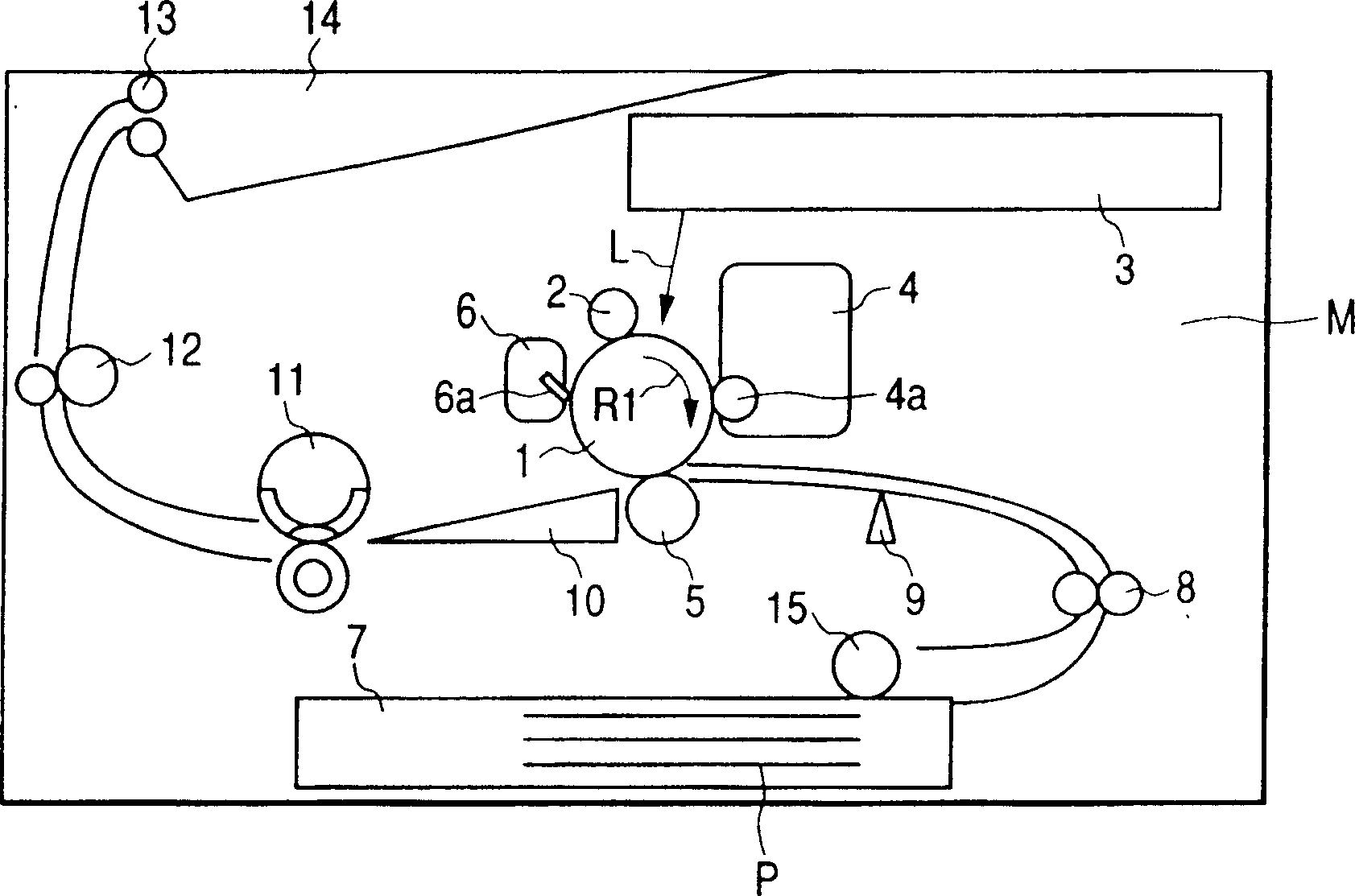

Linear motor, exposure apparatus using the same, and device manufacturing method

InactiveUS20050134122A1Shorten apparent slot pitchImproved in heat generation characteristicManufacturing dynamo-electric machinesPhotomechanical exposure apparatusEngineeringLinear motor

In a movable magnet-type linear motor including a stator 10 having a plurality of iron core elements 1 arranged at a certain slot pitch and a movable part 20 having a magnet 3 which is movable in an arrangement direction, a single or a plurality of pseudo-slots 6 are provided between adjacent slots 5 and the iron core element and the magnet are relatively skewed by an approximately apparent slot pitch including the pseudo-slot, whereby cogging becomes substantially zero to improve a heat generation characteristic.

Owner:CANON KK

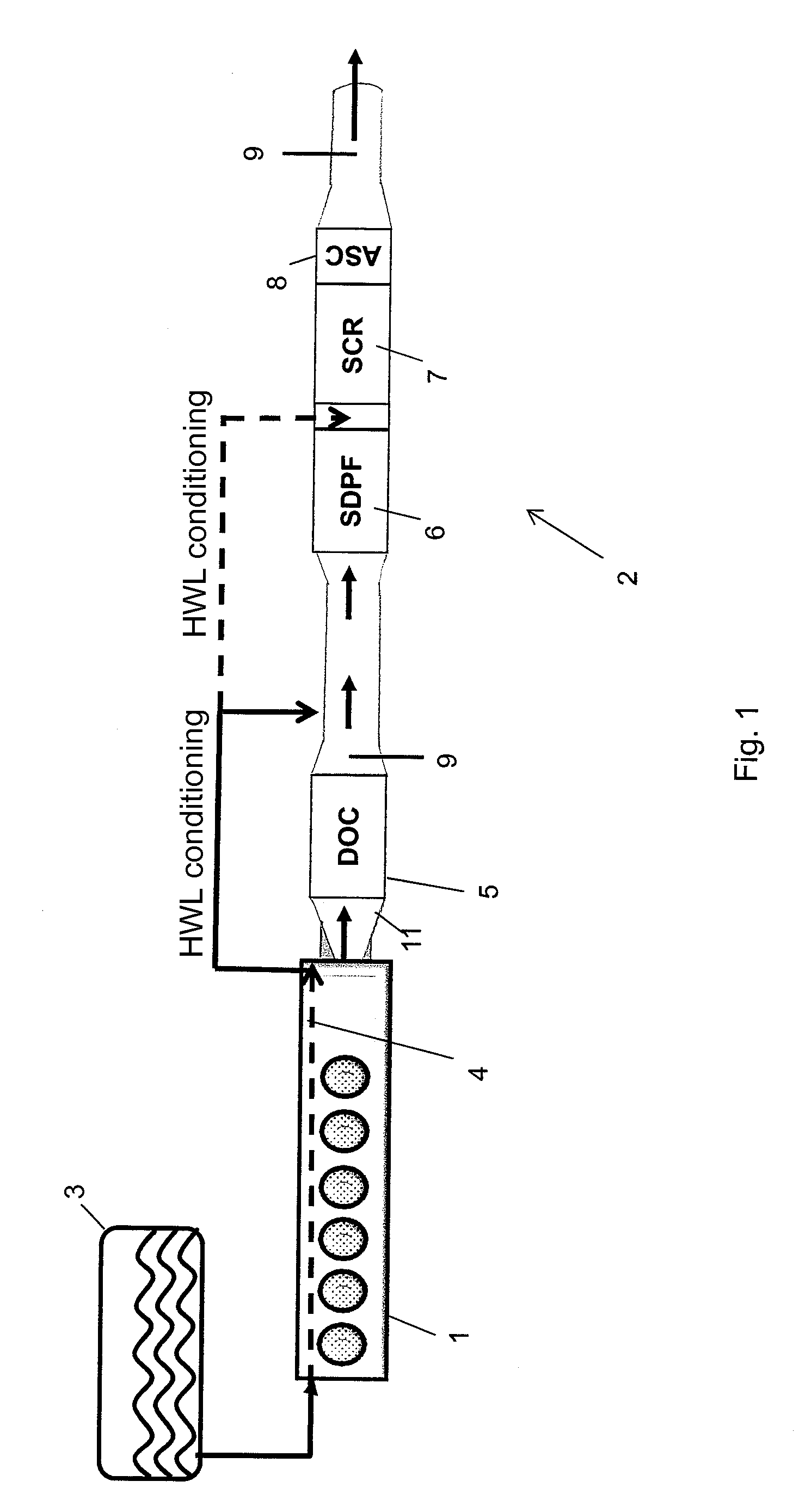

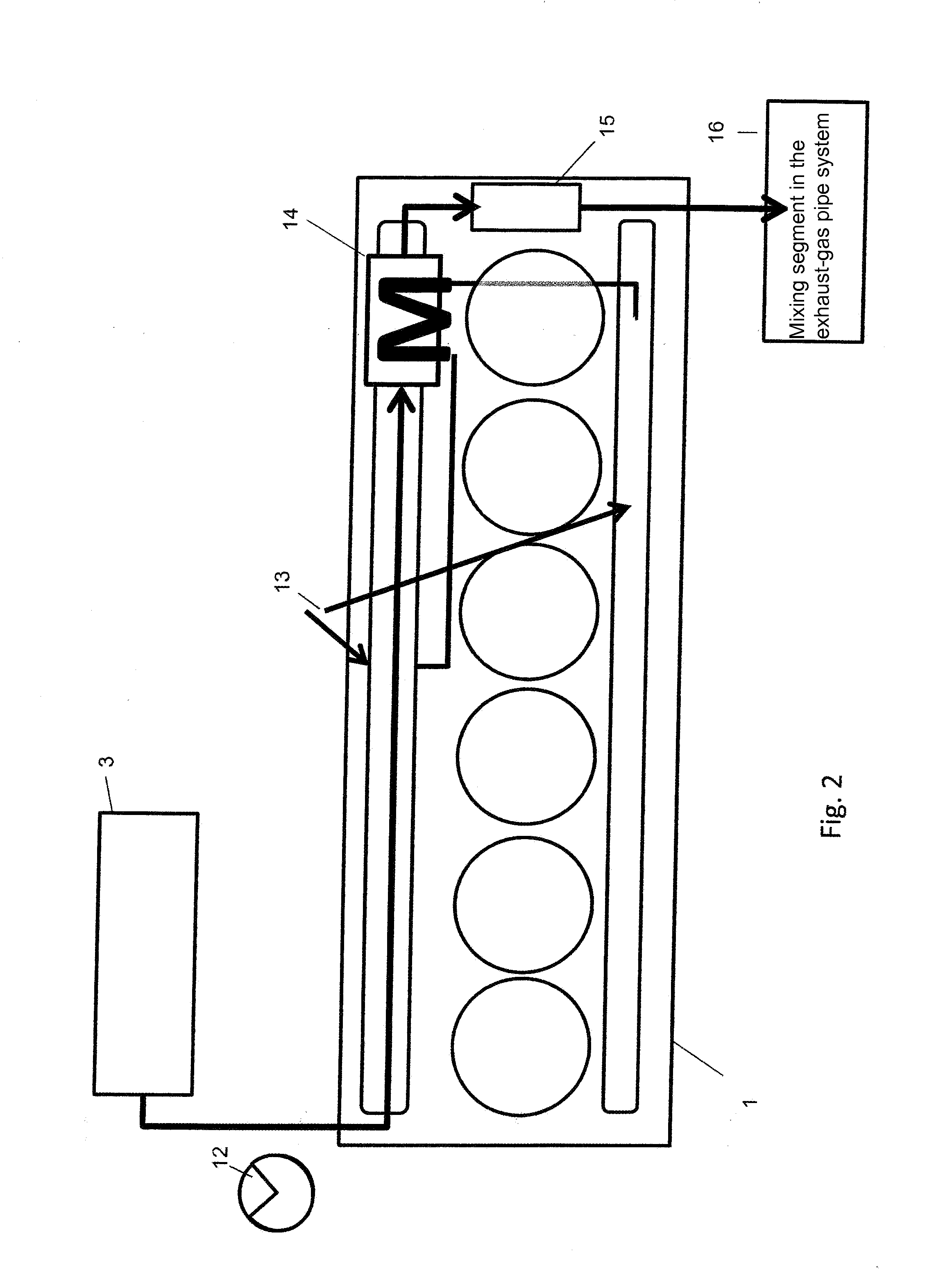

Internal combustion engine

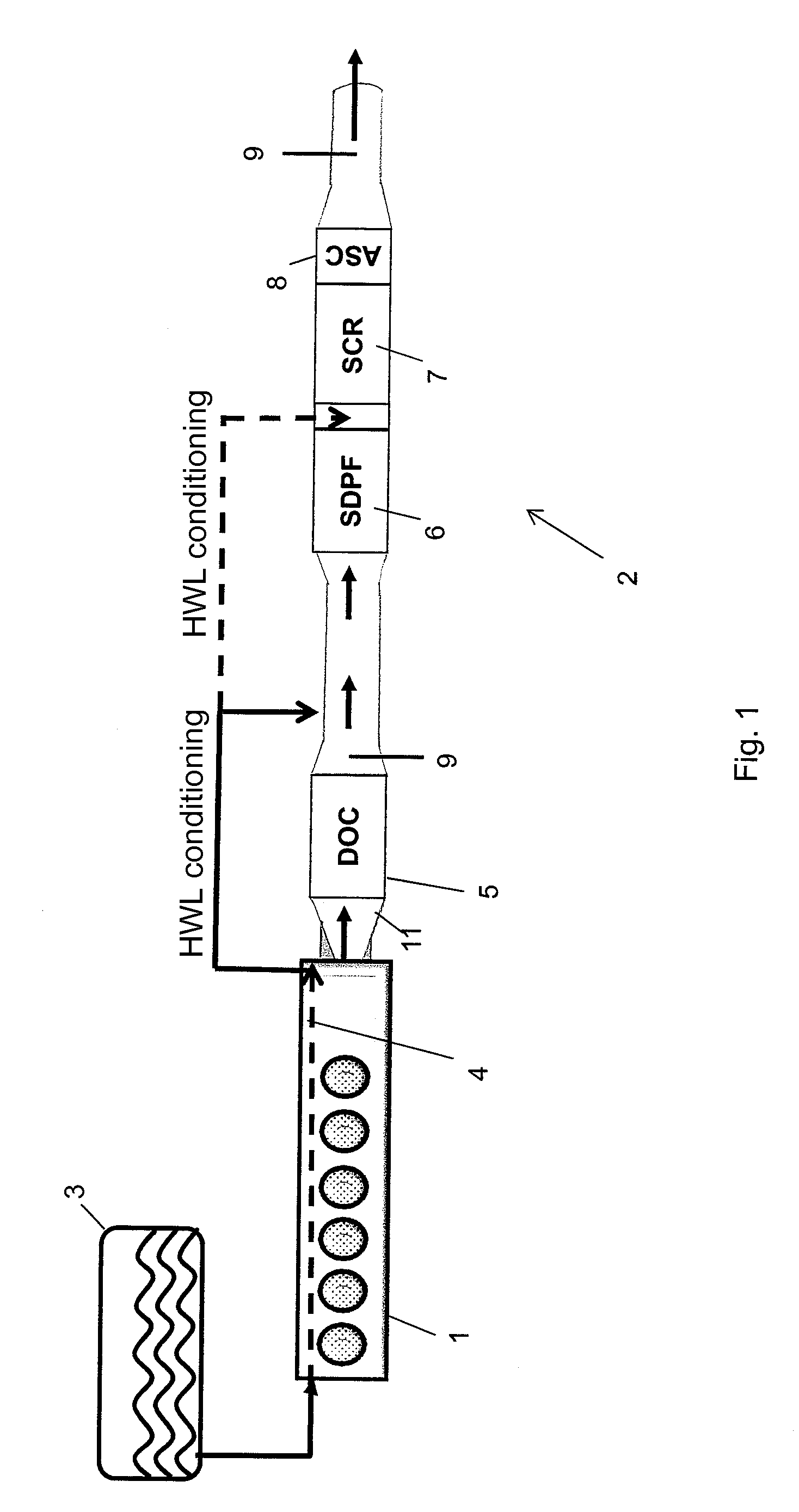

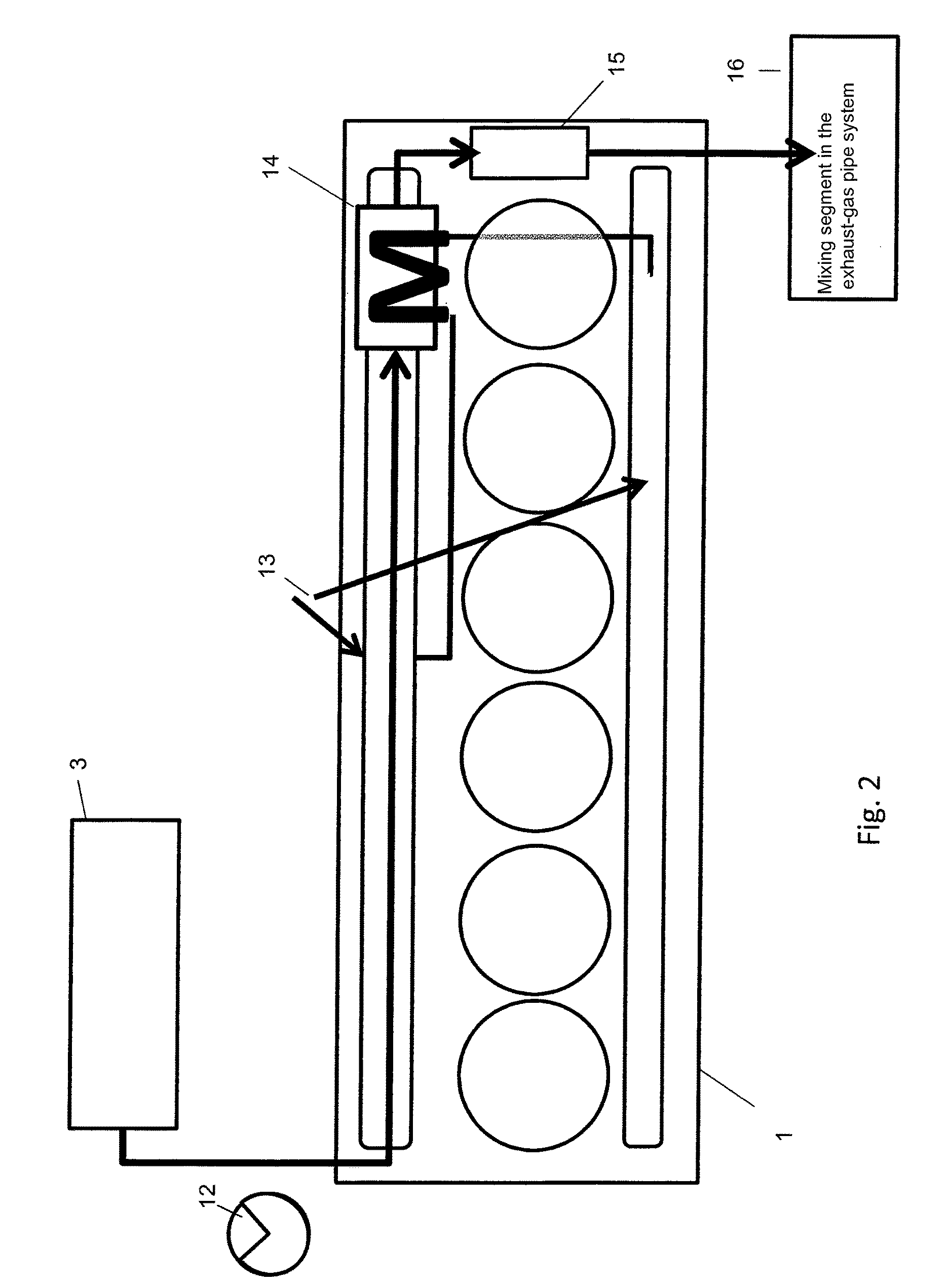

ActiveUS20150231564A1Eliminate needImprove processing and hydrolysisCombination devicesInternal combustion piston enginesLine tubingAfter treatment

An internal combustion engine, including at least one exhaust-gas line having at least one device for the after-treatment of the exhaust gas and at least one urea-water solution tank, whereby the urea-water solution tank 3 is located close to the engine, is provided.

Owner:DEUTZ AG

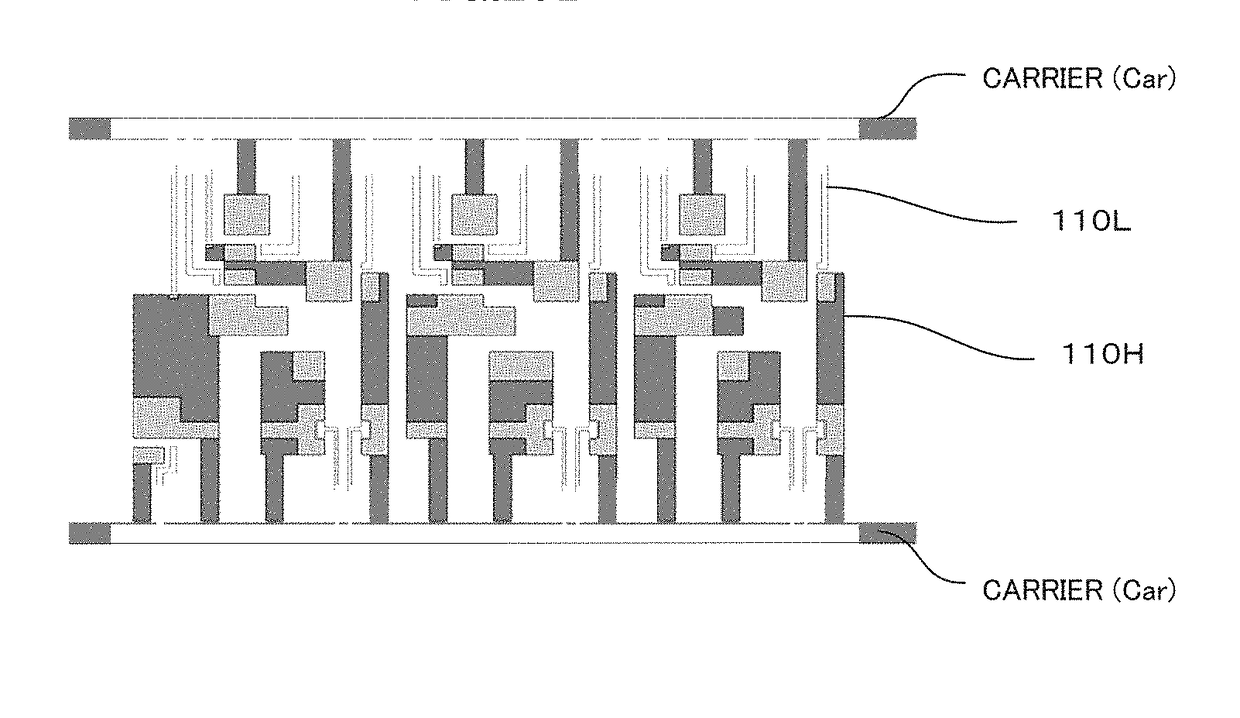

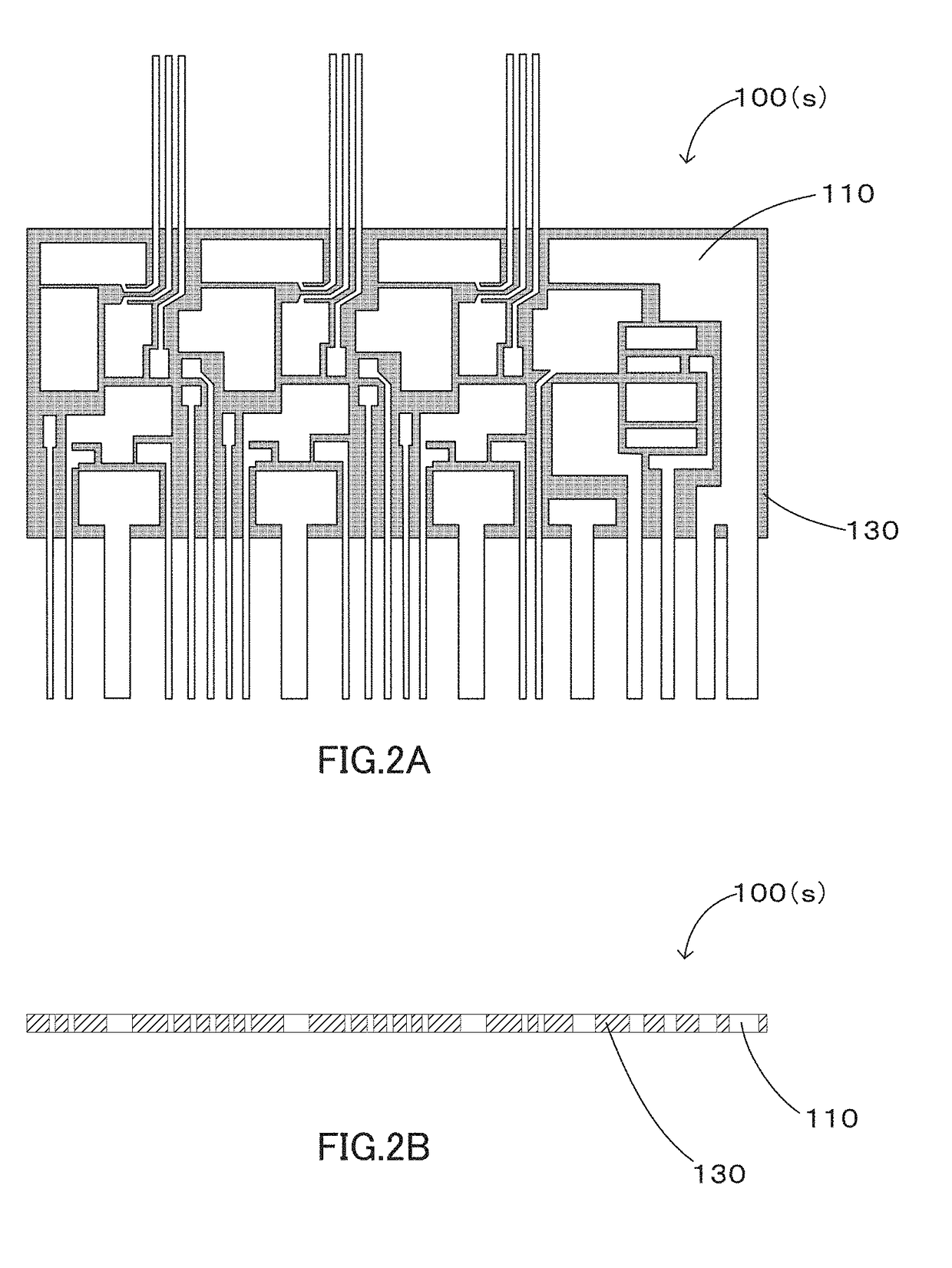

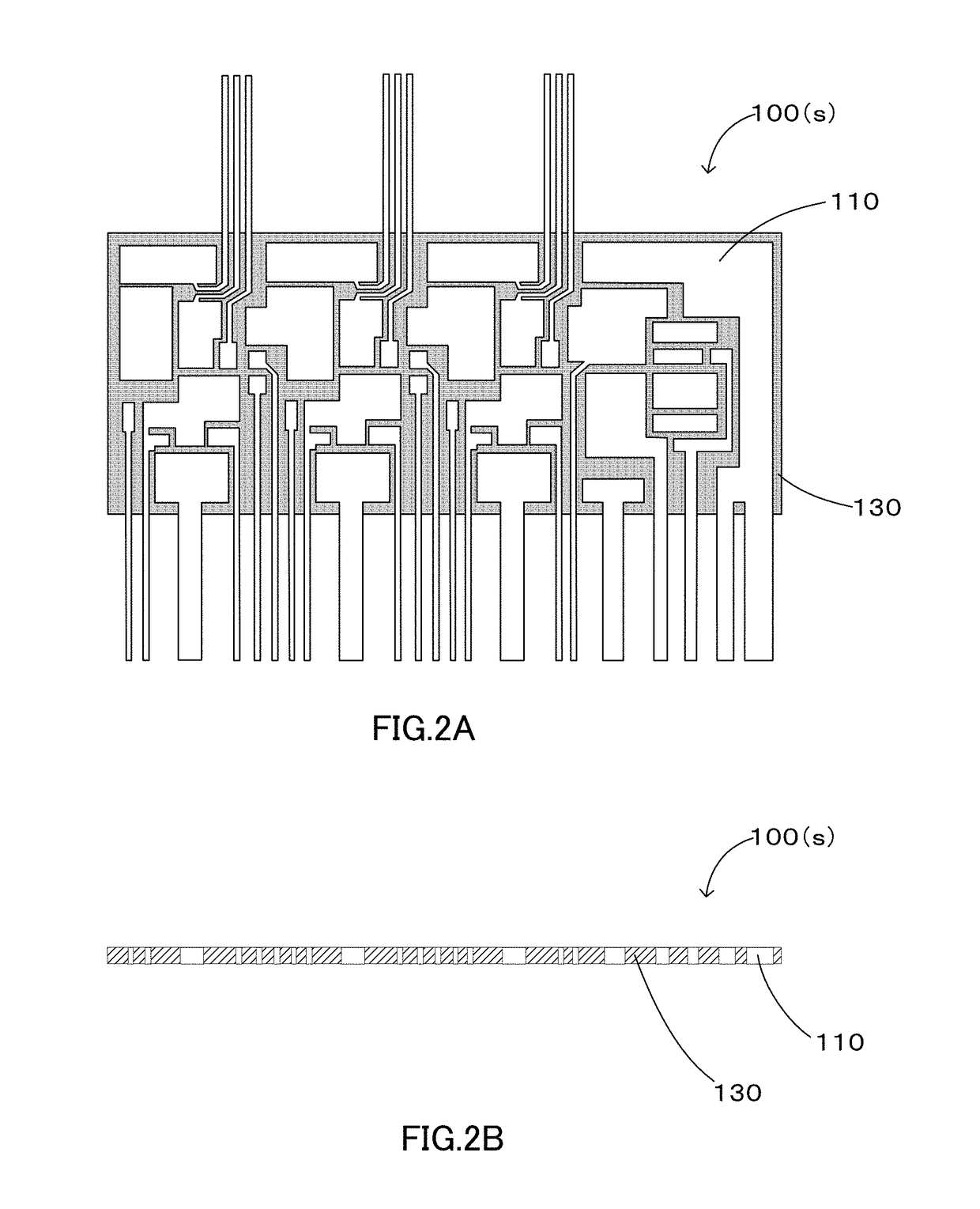

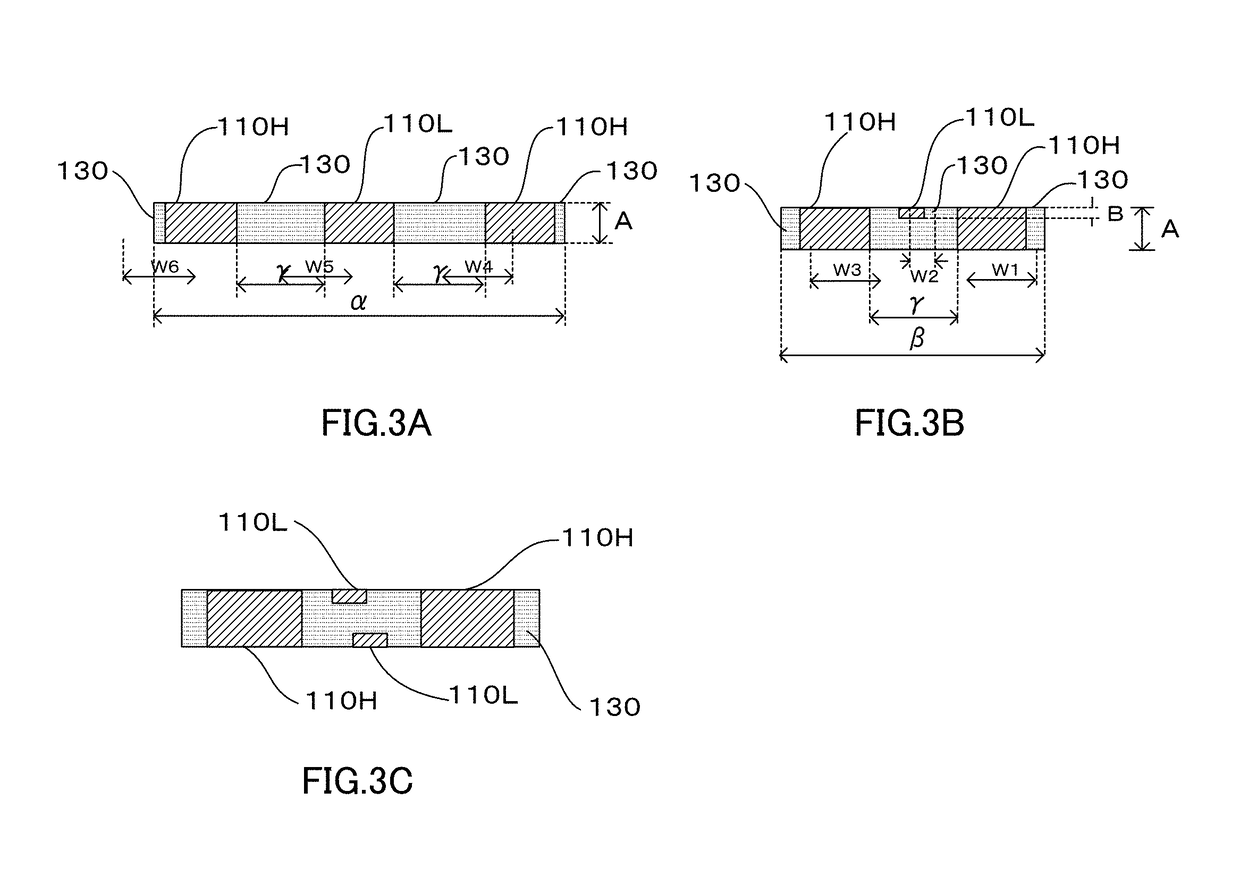

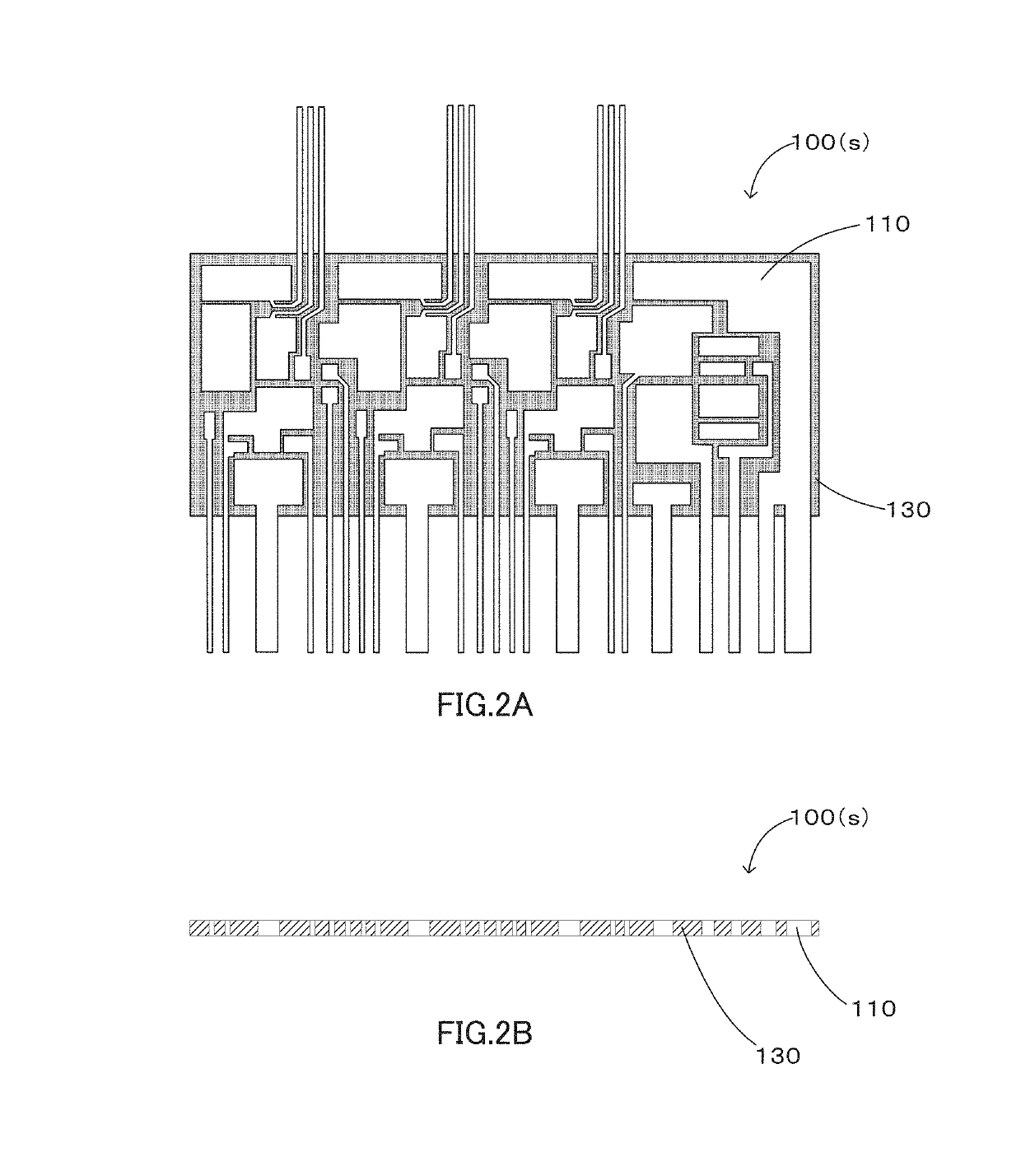

Electronic part mounting heat-dissipating substrate

InactiveUS20170309555A1Reduce resistanceHeat suppressionAssociation with control/drive circuitsResistor terminals/electrodesEngineeringLead frame

[Problem] An object of the present invention is to provide an electronic part mounting heat-dissipating substrate which enables a circuit for which a power semiconductor in which a large current flows is used to reduce the wiring resistances of a large power operation and improve the heat dissipation.[Means for Solving] The present invention is an electronic part mounting heat-dissipating substrate which comprises lead frames of wiring pattern shapes formed by conductor plate and an insulating member 130 which is provided between the lead frames 110, wherein a plate surface of a part arrangement surface of said conductor plate and a top surface of said insulating member at a side of said part arrangement surface form one continuous surface, the lead frames have different thicknesses, the thick lead frame 110H is used for a large current signal and the thin lead frame 110L is used for a small current signal, a plate surface of a back surface of the part arrangement surface and a top surface of the insulating member at a side of the back surface at the part arrangement surface-side are formed in an identical plane.

Owner:NSK LTD

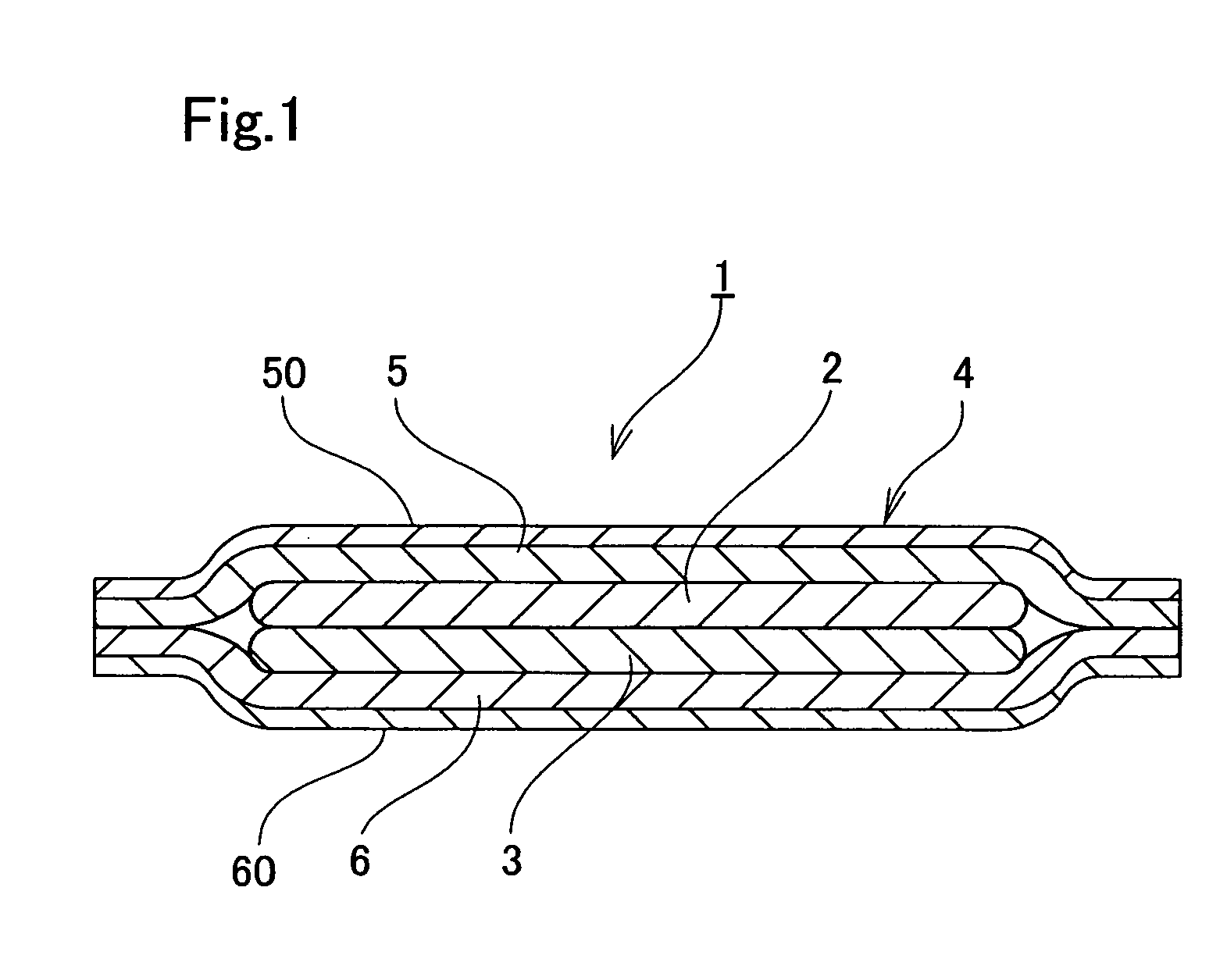

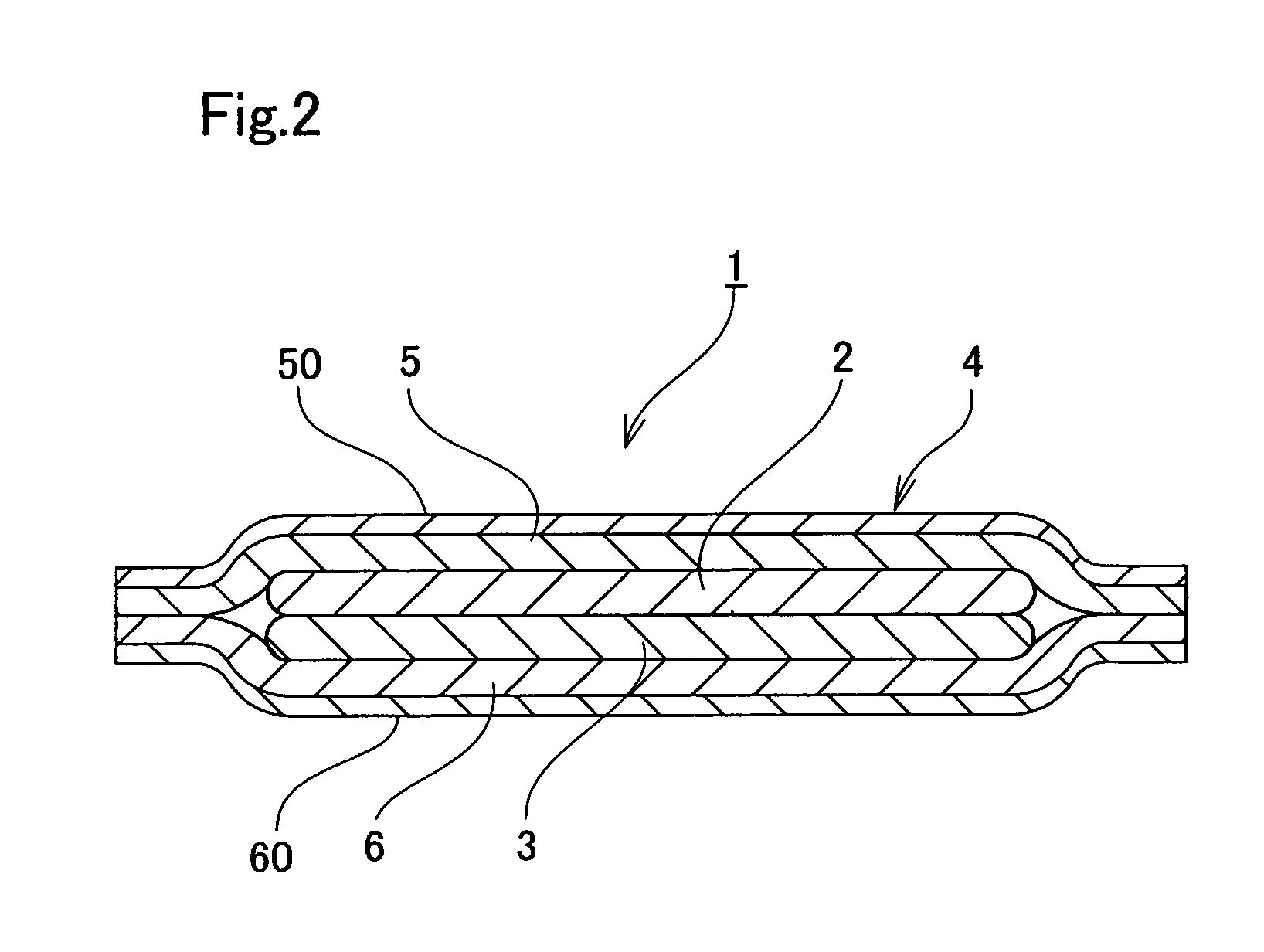

Warming tool in a sheet form

ActiveUS8256412B2Improve heating characteristicsEasy to carryExothermal chemical reaction heat productionOther heat production devicesFiberPolymer science

A warming device of sheet form having (1) a heat generating sheet prepared by papermaking and containing an oxidizable metal, a moisture retaining agent, and a fibrous material and (2) an air permeable holder holding the heat generating sheet. The warming device has a thickness of 0.1 to 10 mm and a flexural strength of 0.01 to 0.3 N / cm. The sheet preferably has a thickness of 0.1 to 2.0 mm. The fibrous material preferably has a CSF of 600 ml or less.

Owner:KAO CORP

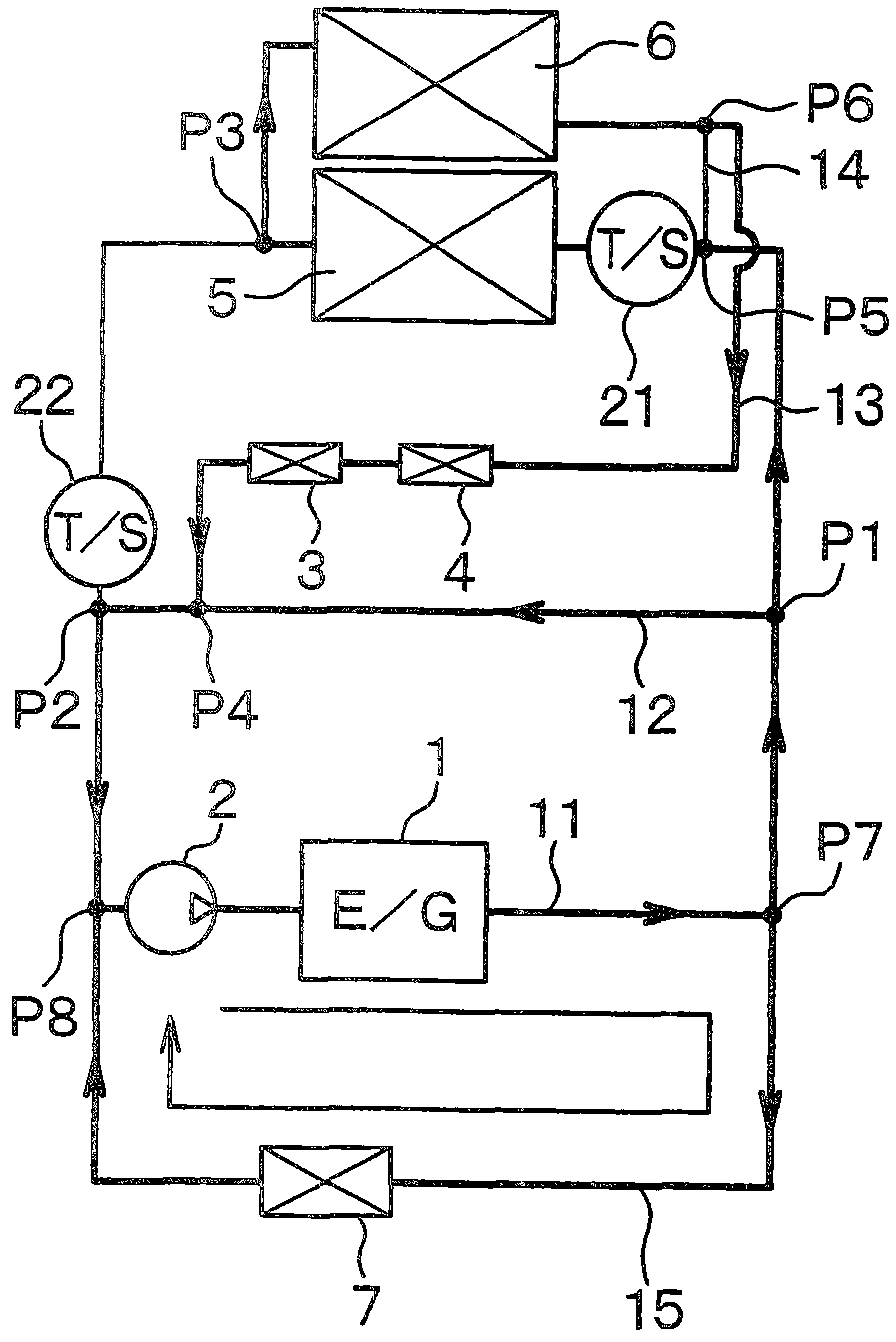

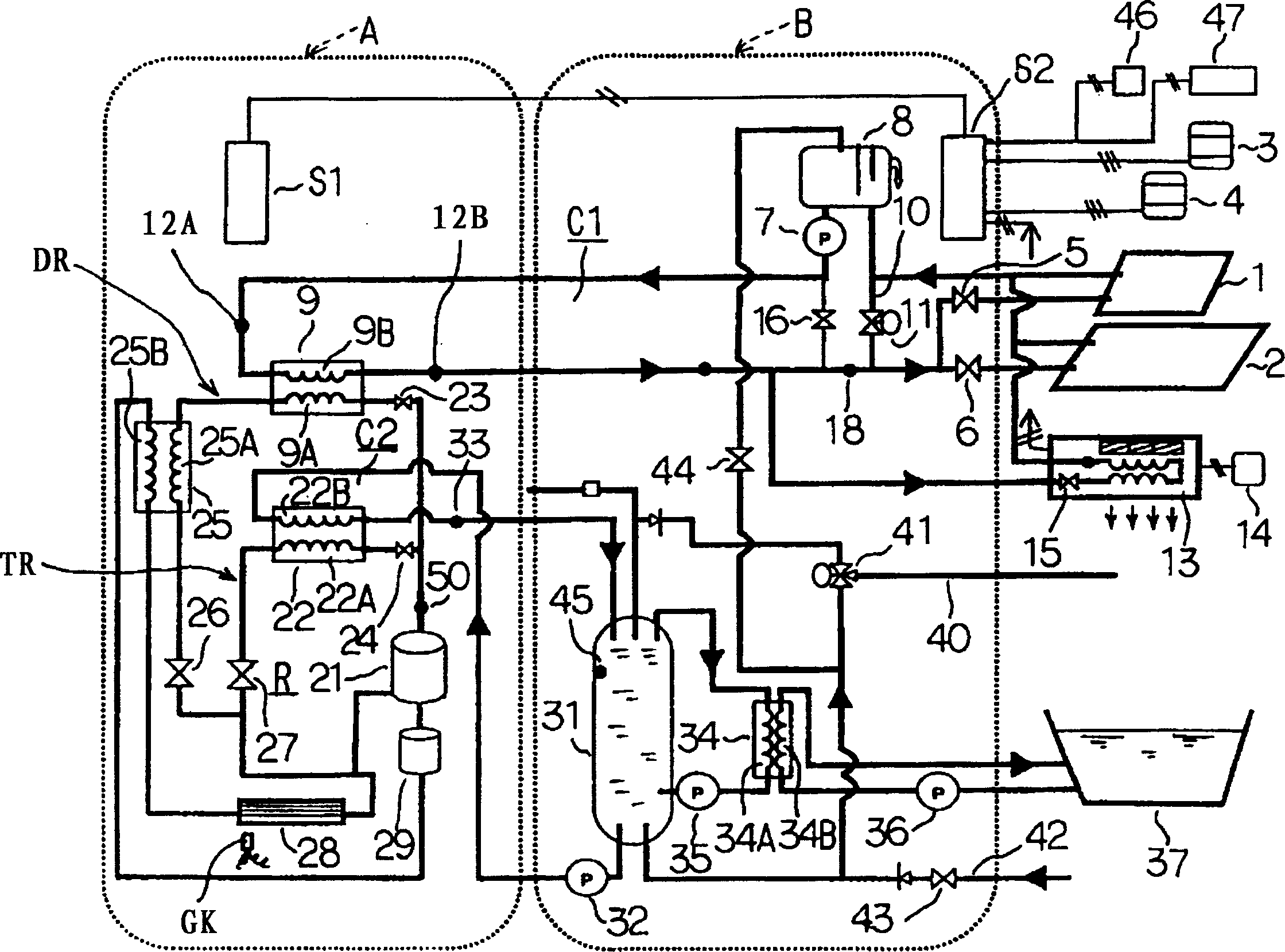

Cooling system for vehicle

InactiveCN102582418AWithout compromising fuel efficiencyImprove heating characteristicsLiquid coolingAir-treating devicesEngineeringHeat spreader

Owner:DENSO CORP

Exothermic enamel glaze, and exothermic container coated with same

InactiveCN102548920AImprove heating characteristicsGentrificationThin material handlingThermal energyVitrification

The present invention relates to an exothermic container to be used in a microwave oven which cooks foods using a magnetron. The exothermic container absorbs a portion of the microwaves generated by the magnetron and generates heat to cook foods in the cooking chamber of the microwave oven. The exothermic container to be used in the microwave oven is produced by the steps of providing an exothermic enamel glaze, coating a metal container to be produced into an enameled container (low carbon steel plate, aluminum, and stainless steel to be produced into an enameled container) with the exothermic enamel glaze provided in the previous step, drying the resulting structure, firing the resulting structure to vitrify same, and cooling the resulting structure, to thereby achieve improved resistance against hot temperatures, improved exothermic performance,; and higher quality as compared to conventional exothermic container products (silicon rubber and ferrite). A method for producing the exothermic enamel glaze involves mixing or adding (MnZn-based, MgCuZn-based, NiZn-based) ferrite, having high magnetic permeability, and alloy powders of (Fe-Si-based, Fe-Si-Al-based, Fe-Si-B-based, Fe-Si-B-Co-based, Fe-Ni-based, etc.) soft magnetic metal materials to the glaze (glass frit) commonly used in enameling, to thereby provide the glaze with exothermic properties for absorbing microwaves (2.45GHz) and for converting the absorbed microwaves into thermal energy in a microwave oven.

Owner:YOU&I TECH

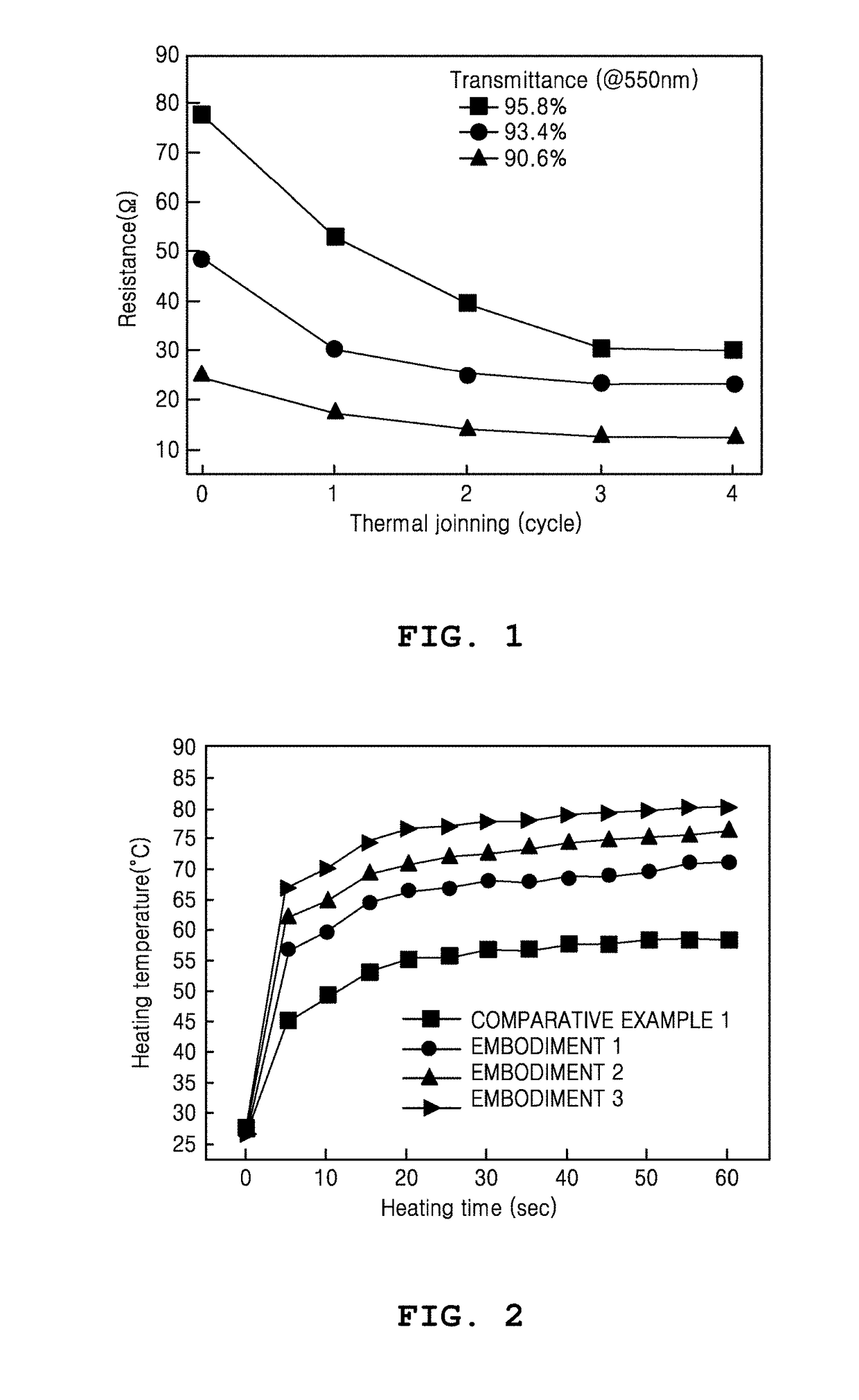

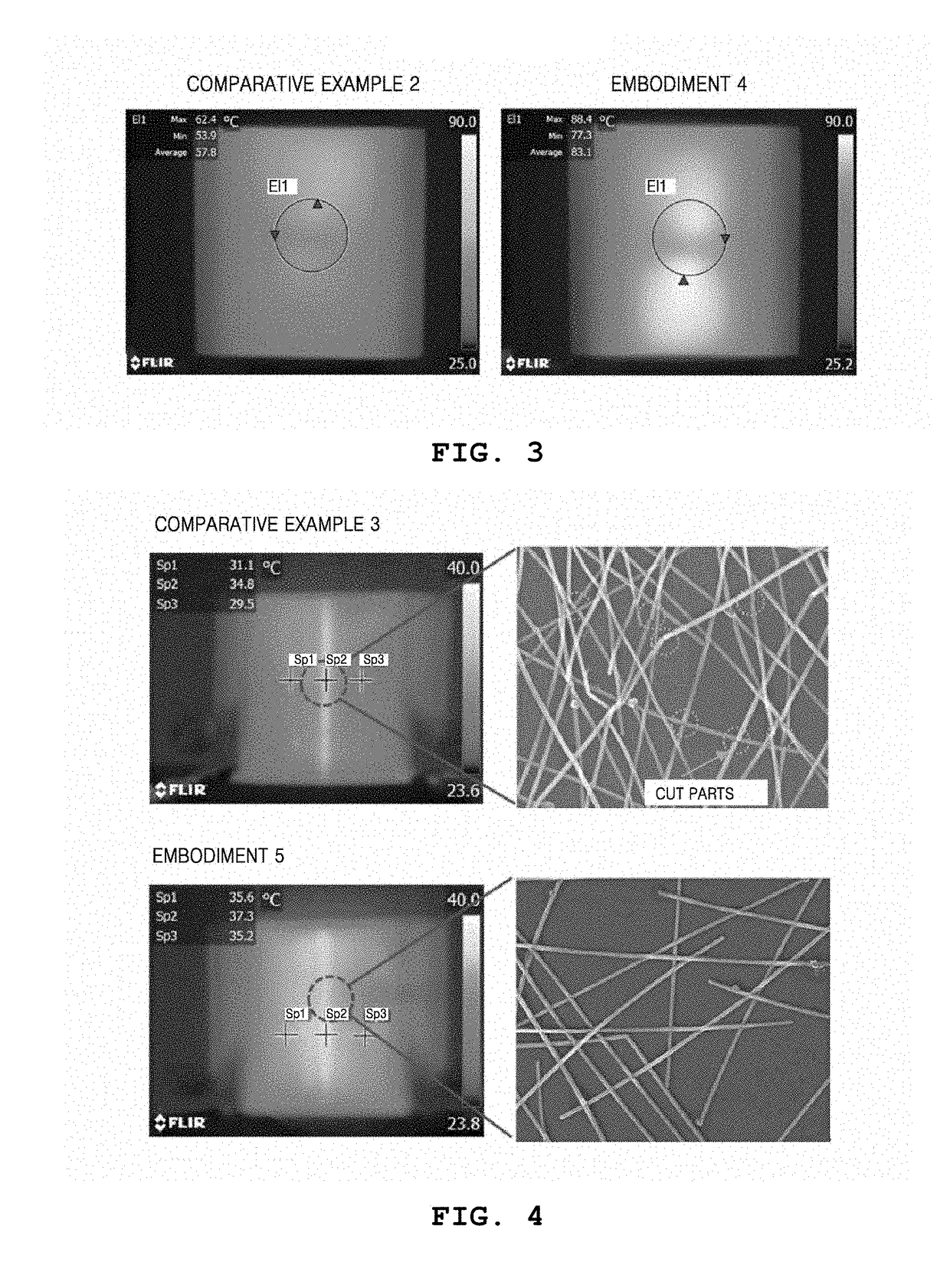

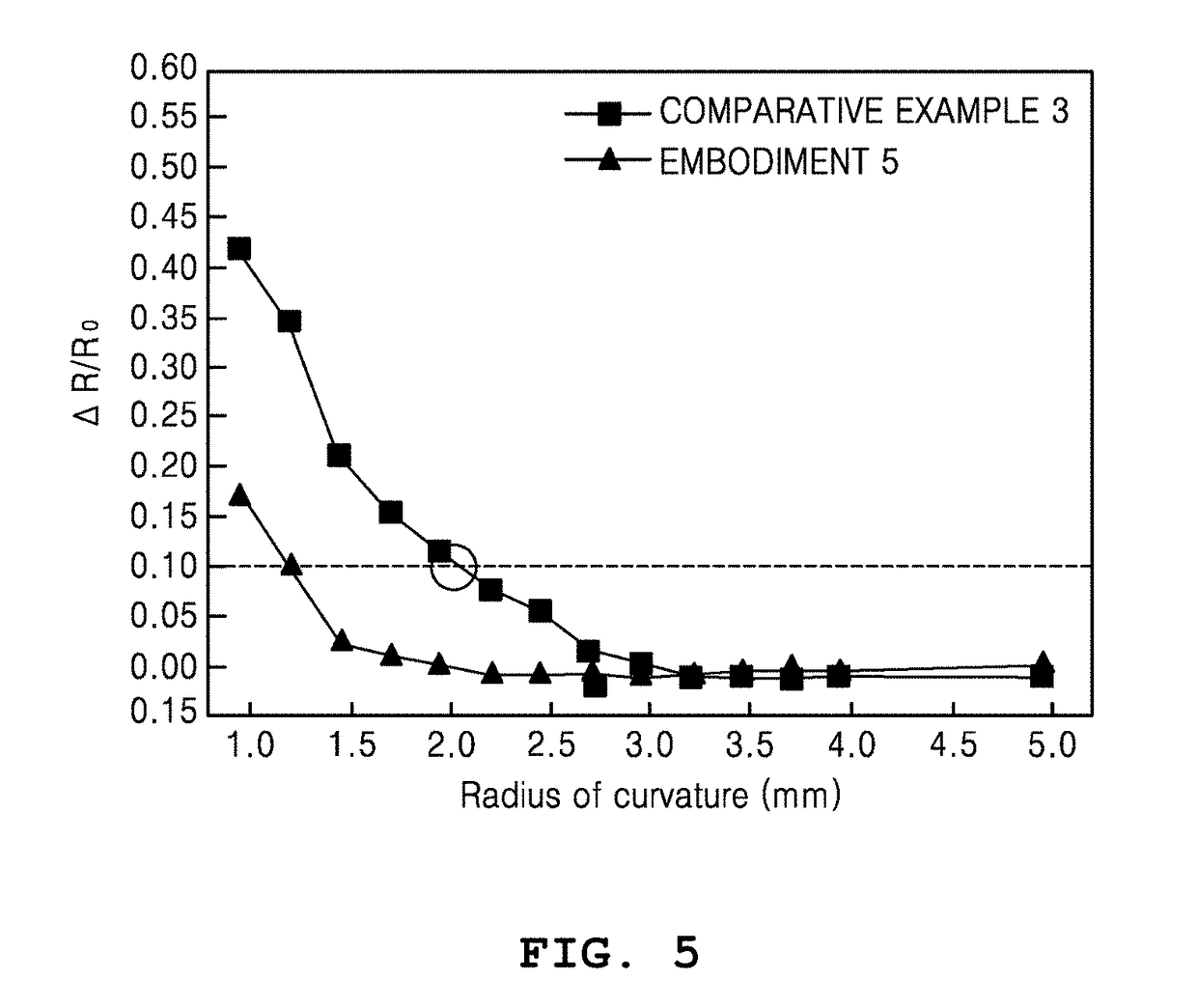

Metal nanowire heater and method of fabricating the same

ActiveUS20180352611A1Increase processing costDesign freedomMaterial nanotechnologyTransparent/reflecting heating arrangementsPhase changeIonic liquid

Provided is a method of fabricating a metal nanowire heater, the method including a coating step of coating, on a substrate, a coating film containing laser-etchable and low-melting-point metal nanowires, a thermal joining step of enhancing connection between contact parts of the metal nanowires due to a chemical and physical action occurring when an ionic liquid is phase-changed, by supplying the ionic liquid onto the coating film and applying heat from outside, and an electrode forming step of forming electrodes on the coating film.

Owner:KOREA INST OF SCI & TECH

Method of increasing latent heat storage of wood products

InactiveUS6933016B1Improve heat storage capacityIncrease heat releaseWood treatment detailsPretreated surfacesLatent heat storageEngineering

The heat storage capacity of natural cellulosic products is increased by injecting nucleating products and / or heat storing material into unfilled cells thereby increasing the amount of material that can undergo phase change for transferring latent heat.

Owner:SYKES JR MARVIN E

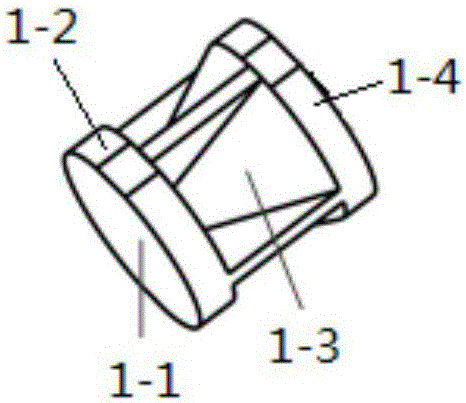

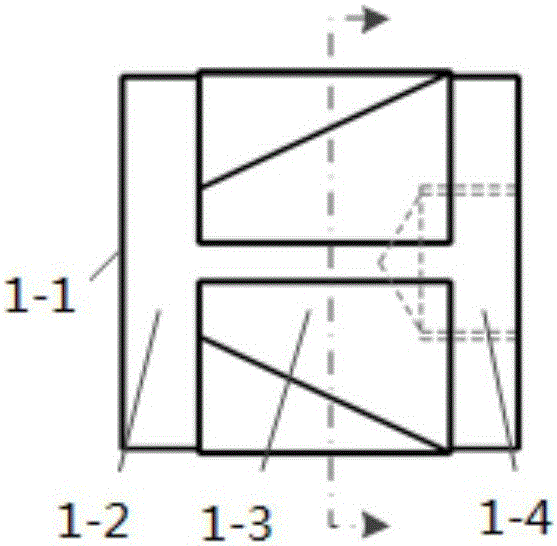

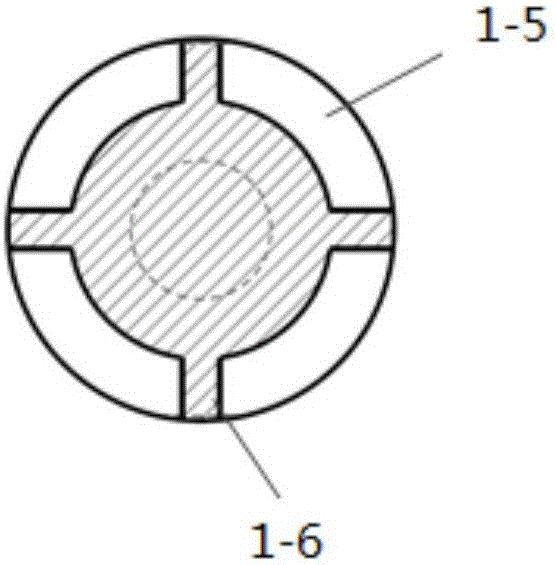

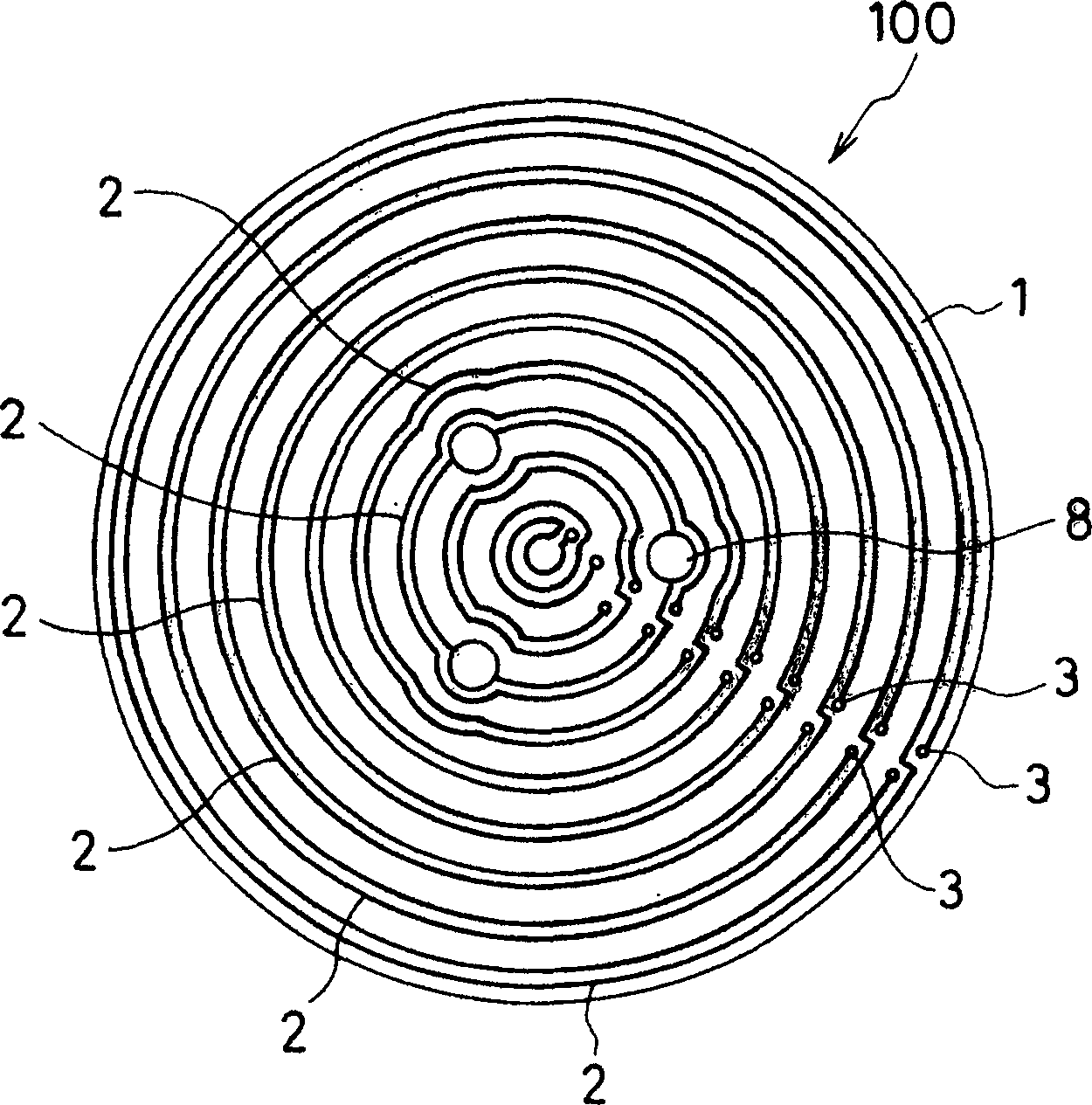

High-energy-efficiency piezoelectric ultrasonic transducer and end cover thereof

ActiveCN106076793ALarge amplitudeAvoid bending deformationMechanical vibrations separationUltrasonic sensorHigh energy

The invention discloses a high-energy-efficiency piezoelectric ultrasonic transducer and an end cover thereof. The whole end cover is arranged to be of a cylinder structure and comprises an end cover front, an end cover middle and an end cover tail which are arranged coaxially. The end cover front is provided with an output end face. The end cover tail is provided with a fixing part. The end cover middle is of a combined hollow structure and comprises a cross-section transition section. The cross-section transition section is in a circular truncated cone shape or a right trapezoidal platform shape. A large end with the large area and a small end with the small area serve as the two ends of the cross-section transition section. The large end of the cross-section transition section is connected with the end cover tail. The small end of the cross-section transition section is connected with the end cover front. The outer wall of the cross-section transition section is supported on the end cover front by means of a plurality of rib plates uniformly distributed in the peripheral direction. Thus, by reasonably designing mass distribution of the end cover of the transducer, the mass load of the output end face is reduced, in comparison with a traditional solid end cover, by means of the overall arrangement, under the same input power, the amplitude of the output end face can be increased, and the output efficiency is improved beneficially.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

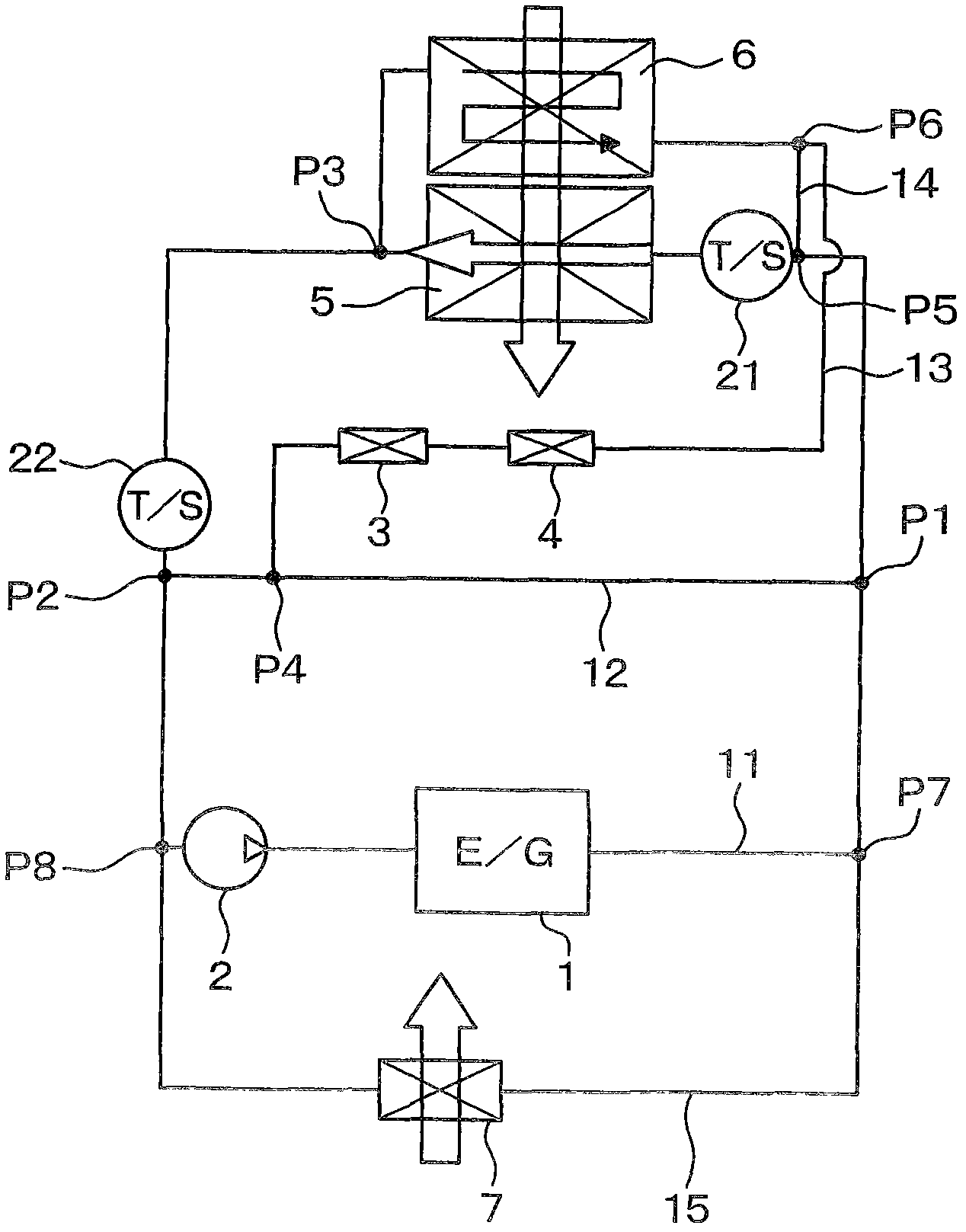

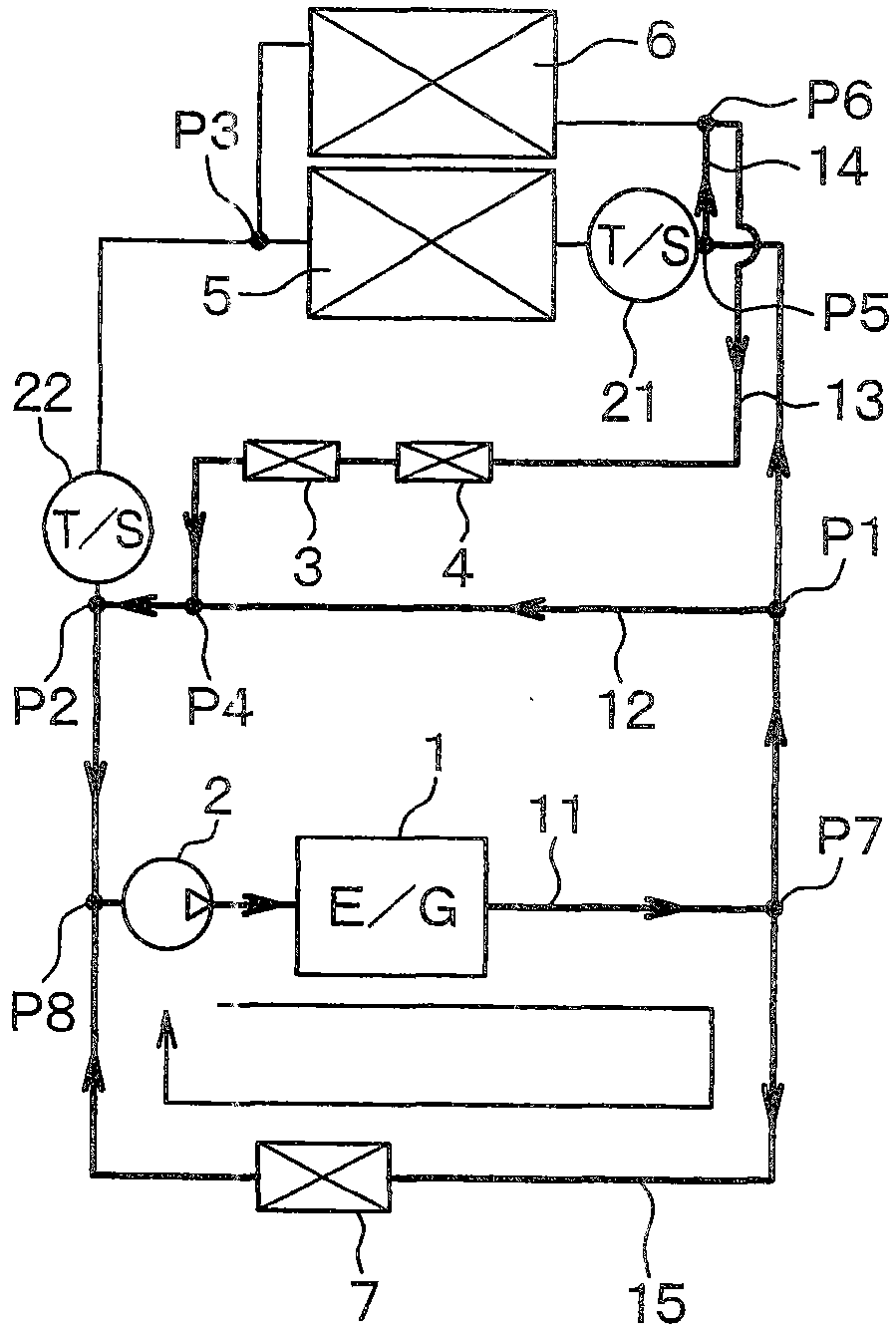

Heat pump type hot-water heating apparatus

InactiveCN1755199AIncrease temperatureImprove heating characteristicsFluid heatersHeat recovery systemsRefrigerantEngineering

PROBLEM TO BE SOLVED: To improve heating property at starting operation by giving priority to a heating side in distributing compressor capability at the beginning of starting hot water storing operation and heating operation at the same time while sorting refrigerant into both a hot water storage water refrigerant heat exchanger and a heating side water refrigerant heat exchanger.SOLUTION: This heat pump hot water supply heating device comprises a hot water storage side heat pump refrigerant circuit TR, a heating side heat pump refrigerant circuit DR, a hot water storage circuit C2 for circulating hot water in a hot water storage tank 31 for boiling-up, a heating circuit C1 for circulating heating hot water into a heating terminal for heating operation, and a control device S1 for controlling the openings of a hot water storage side flow control valve 27 and a heating side flow control valve 26 to sort the flow of the refrigerant from a compressor into the hot water storage heat pump refrigerant circuit and the heating side heat pump refrigerant circuit. The control device makes the opening of the heating side flow control valve in the heating side heat pump refrigerant circuit greater than the opening of the hot water storage side flow control valve in the hot water storage side heat pump refrigerant circuit at the beginning of starting hot water storing operation and heating operation at the same time.

Owner:SANYO ELECTRIC CO LTD +1

Electronic part mounting heat-dissipating substrate

InactiveUS10192818B2Reduce resistanceHeat suppressionAssociation with control/drive circuitsElectrical measurement instrument detailsElectrical conductorEngineering

Owner:NSK LTD

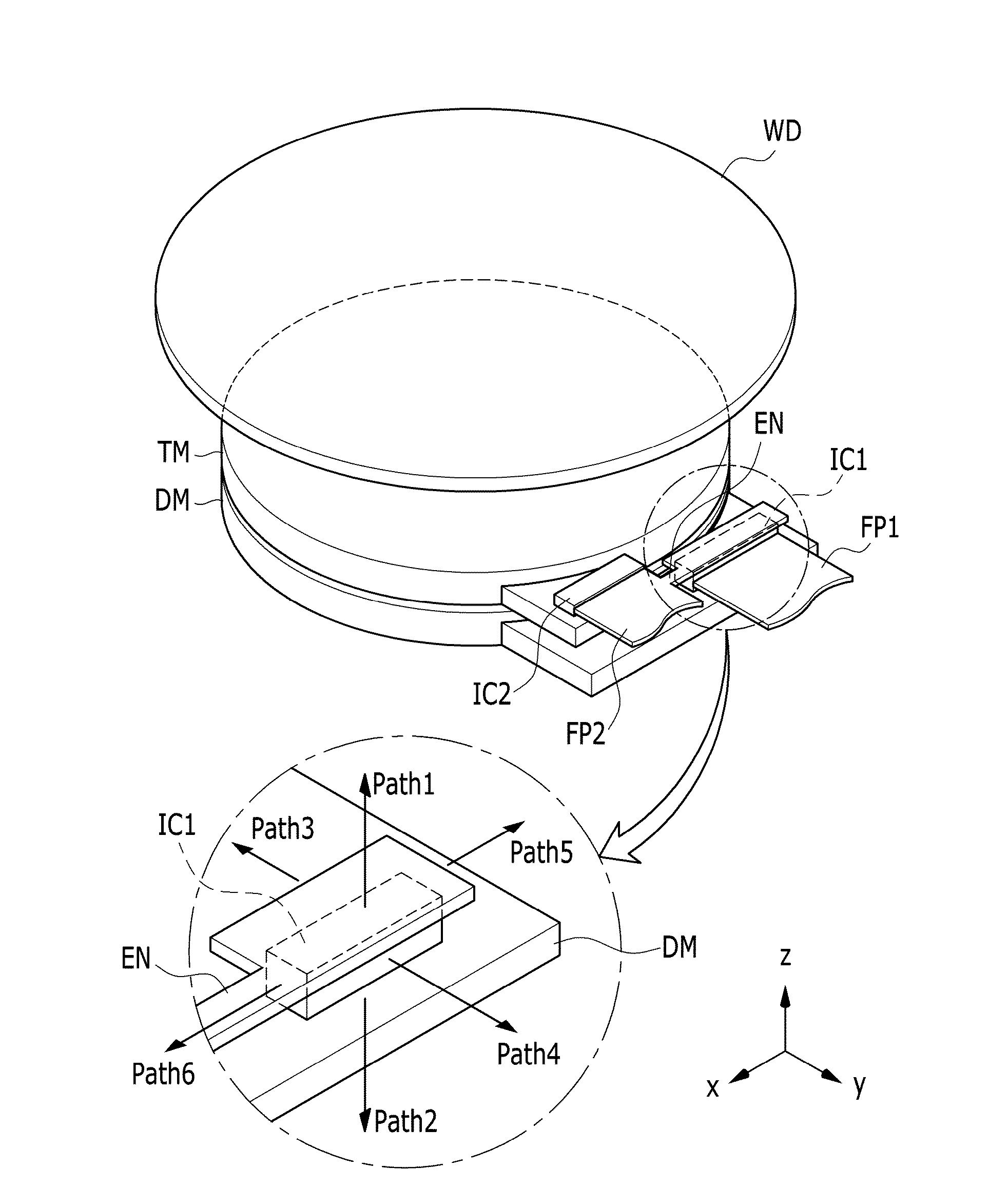

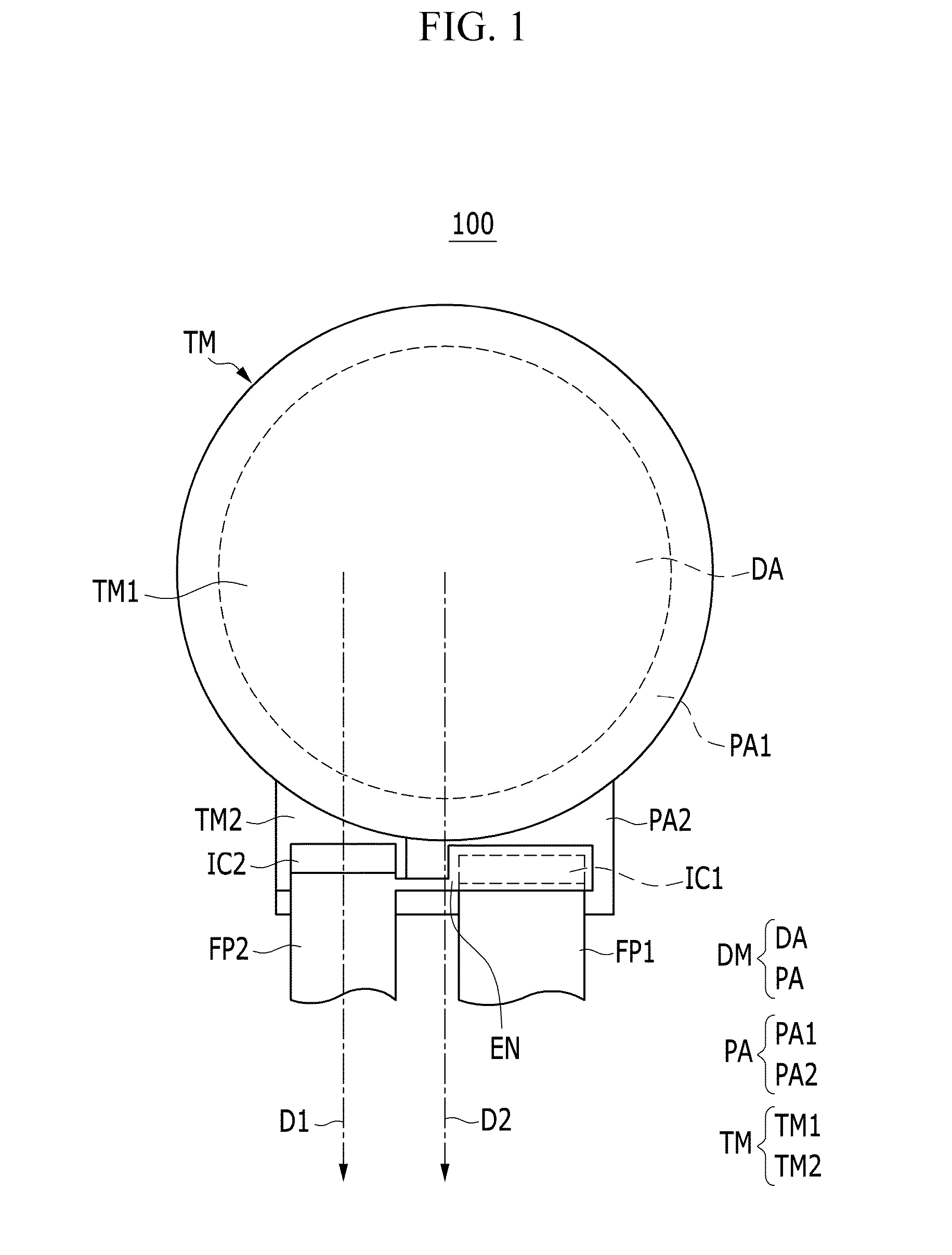

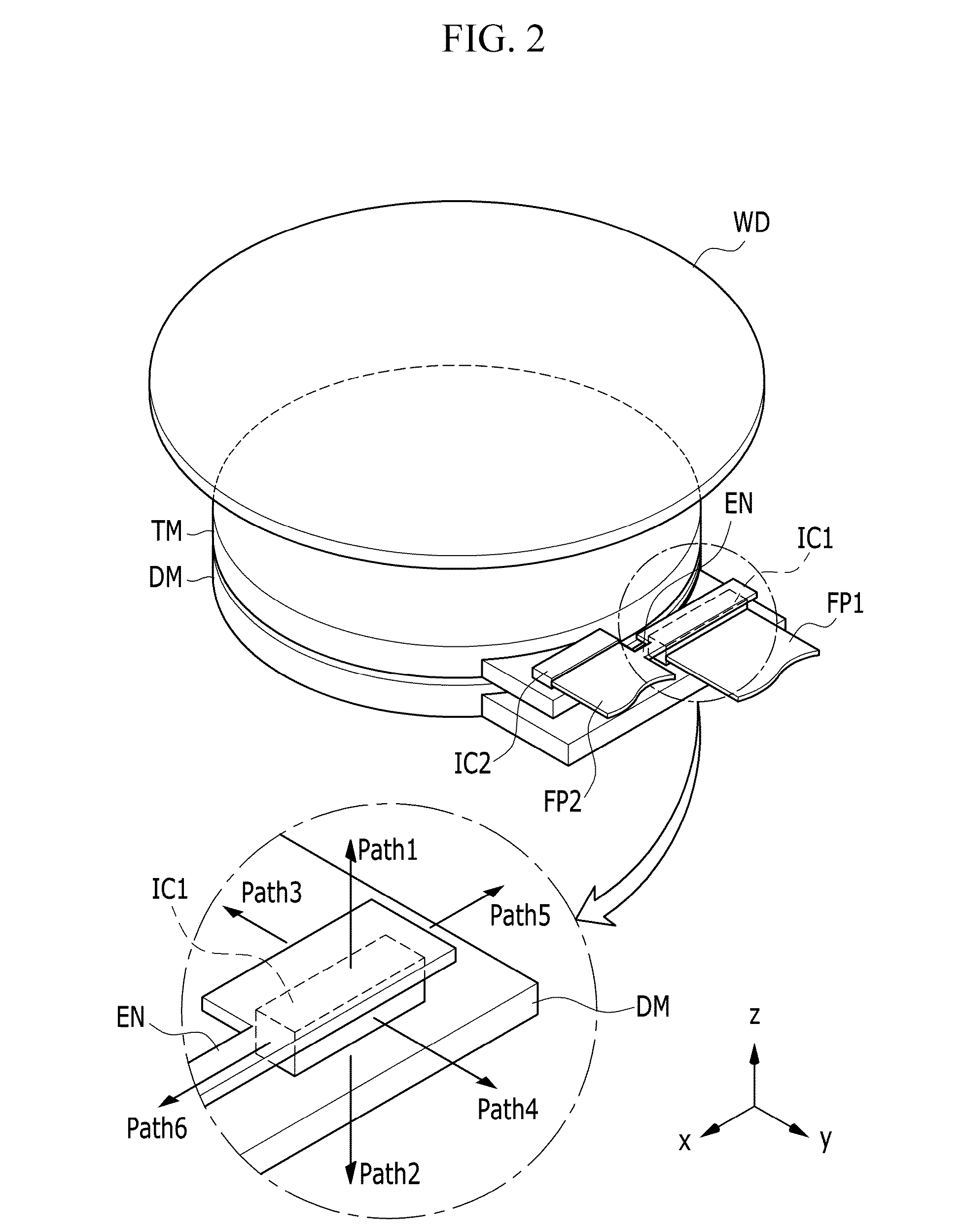

Organic light emitting diode display

InactiveUS20160225830A1Improve featuresReduce and minimize heatSolid-state devicesDetails for portable computersDisplay deviceEngineering

An organic light emitting diode display includes: display area where an image is not displayed, the non-display area including a first driver IC; a touch module above the display module and including a second driver IC; a first flexible printed circuit board (PCB) connected to the first driver IC; and a second flexible printed circuit board (PCB) connected to the second driver IC and including an extension configured to be in contact with the first driver IC.

Owner:SAMSUNG DISPLAY CO LTD

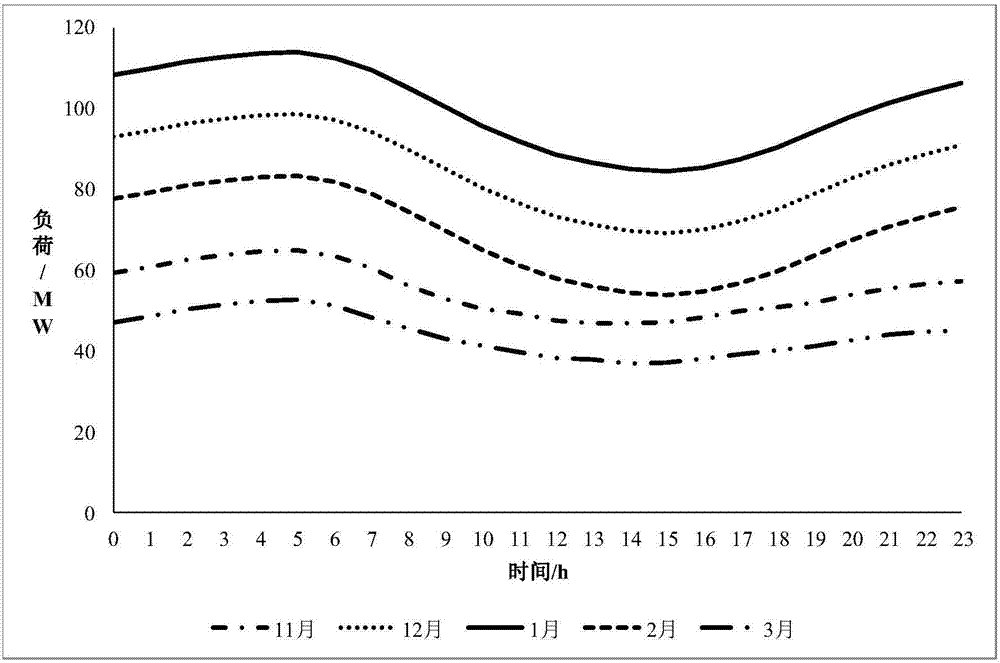

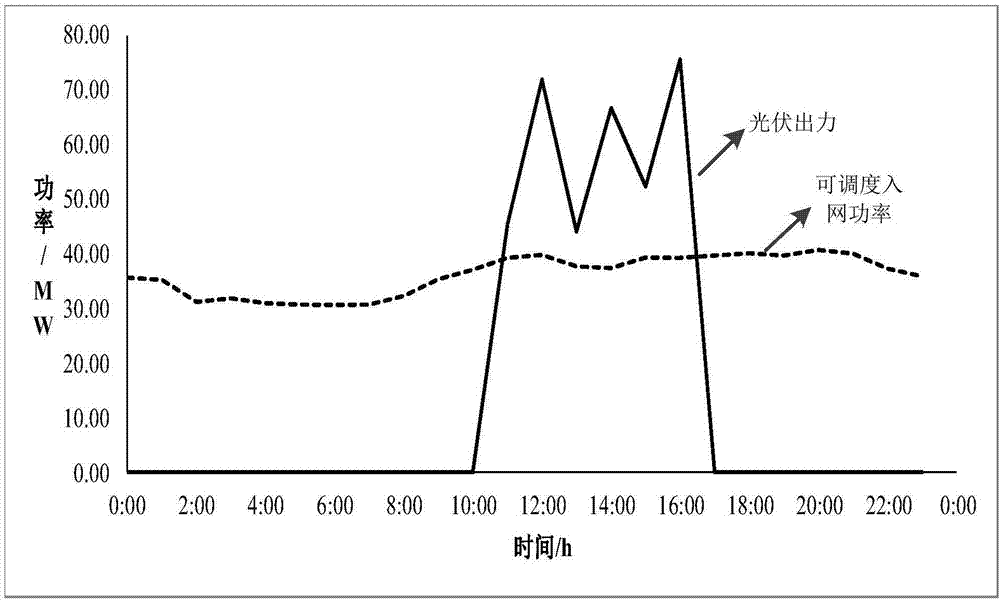

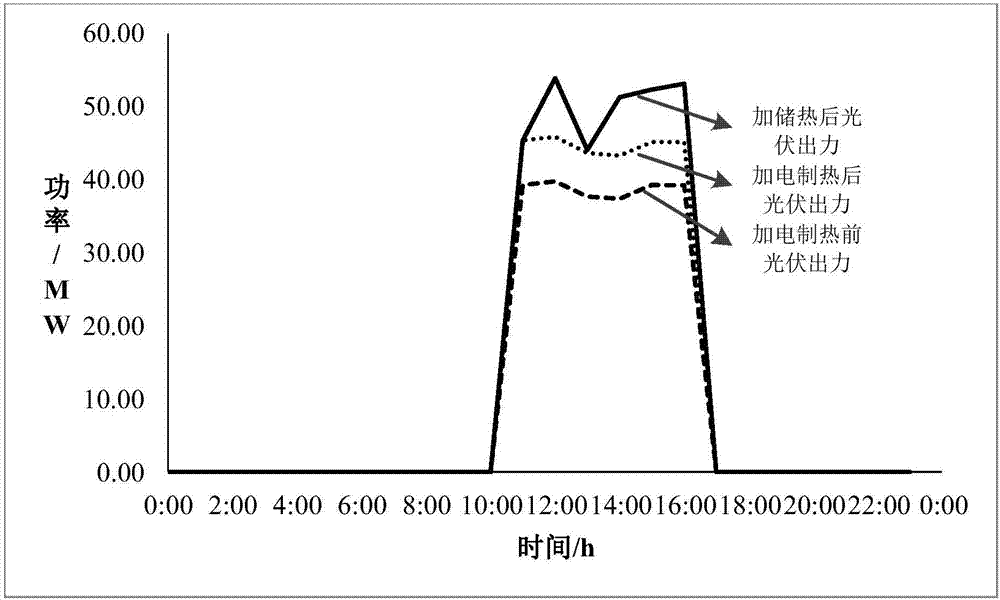

Method of solving problem of photovoltaic energy consumption by using heat storage system

InactiveCN107453707AImprove consumption levelImprove heating characteristicsPhotovoltaicsEnergy industryElectricity priceEconomic benefits

The invention discloses a method of solving the problem of photovoltaic energy consumption by using a heat storage system. The traditional coal-fired heating is changed into electric heating in a photovoltaic surplus area to break the rigid constraint of "ordering power by heat" of a coal-fired co-generation unit, and the space for photovoltaic consumption can be effectively increased. On the basis of electric heating, a heat storage system is adopted, the photovoltaic output characteristics, load characteristics and electricity prices are taken into account, minimizing the cost of heat-supply enterprises in a scheduling cycle is taken as the goal, the scheduling heat storage operation state is optimized, the heat supply characteristics of the heat-supply enterprises are improved from the time dimension, the level of photovoltaic energy consumption is further enhanced and meanwhile the economic benefits of the heat-supply enterprises are ensured.

Owner:SHANGHAI ELECTRIC POWER DESIGN INST

Internal combustion engine

ActiveUS9656210B2Improve processing and hydrolysisSufficient amountInternal combustion piston enginesExhaust apparatusAfter treatmentInternal combustion engine

An internal combustion engine, including at least one exhaust-gas line having at least one device for the after-treatment of the exhaust gas and at least one urea-water solution tank, whereby the urea-water solution tank 3 is located close to the engine, is provided.

Owner:DEUTZ AG

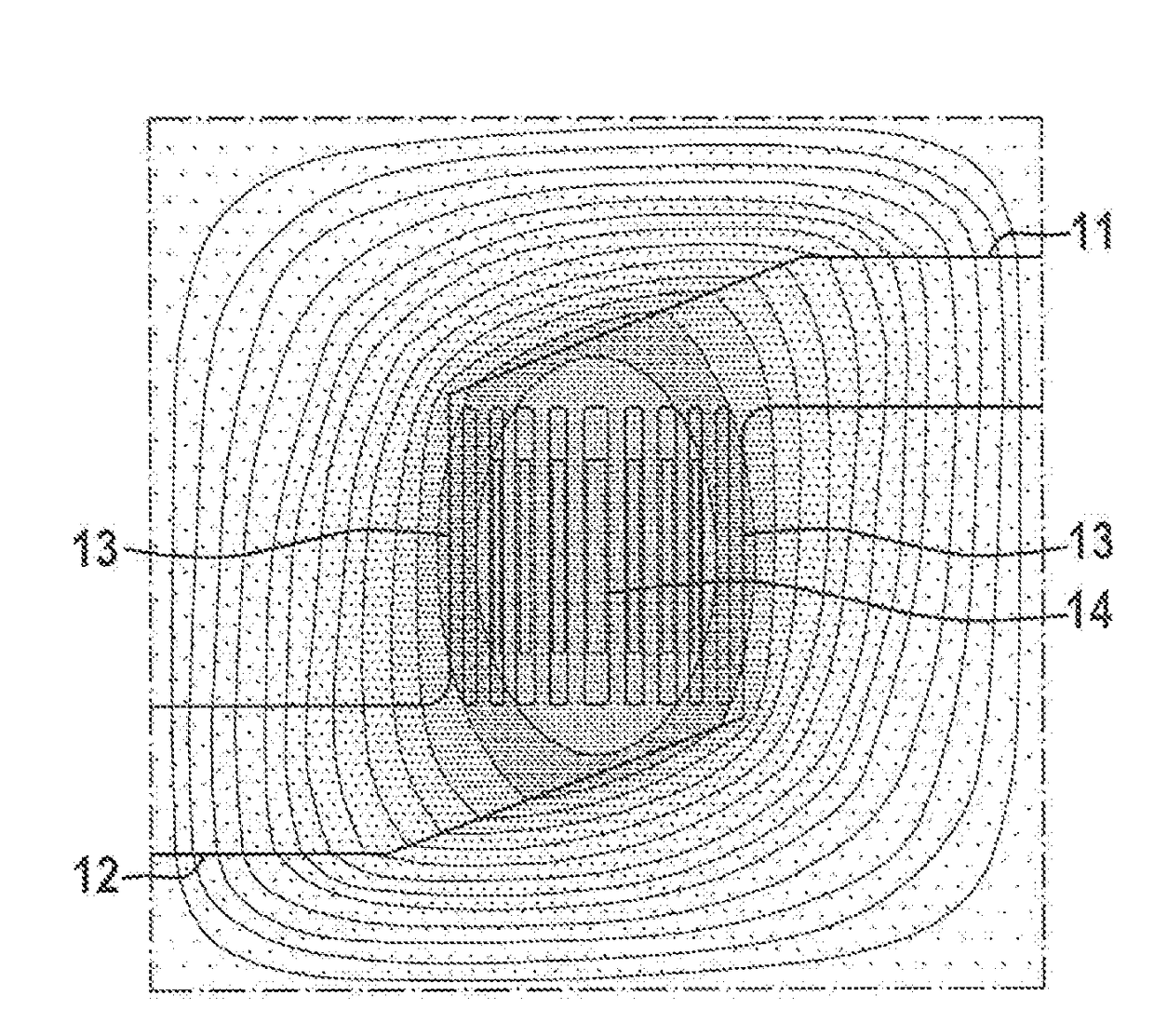

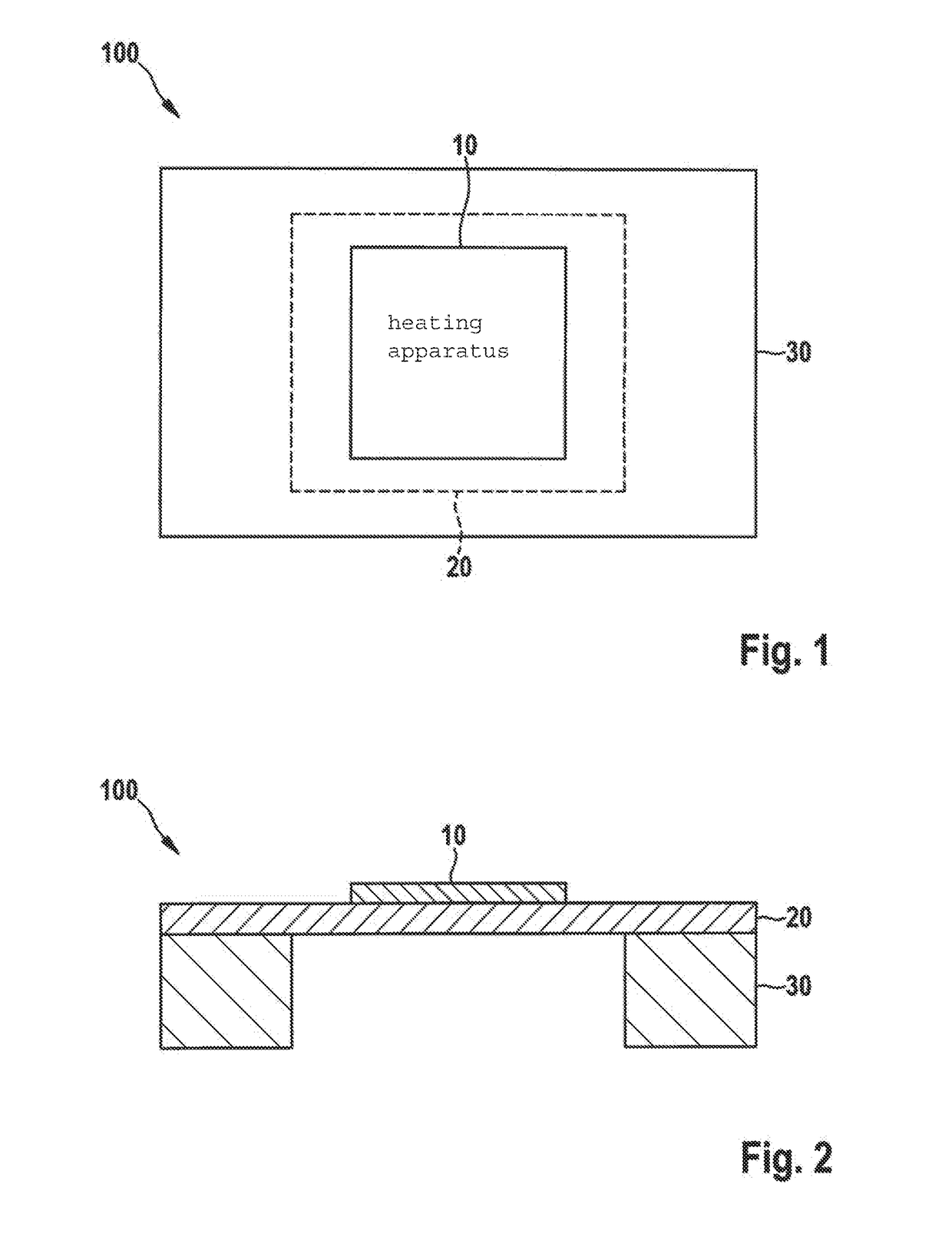

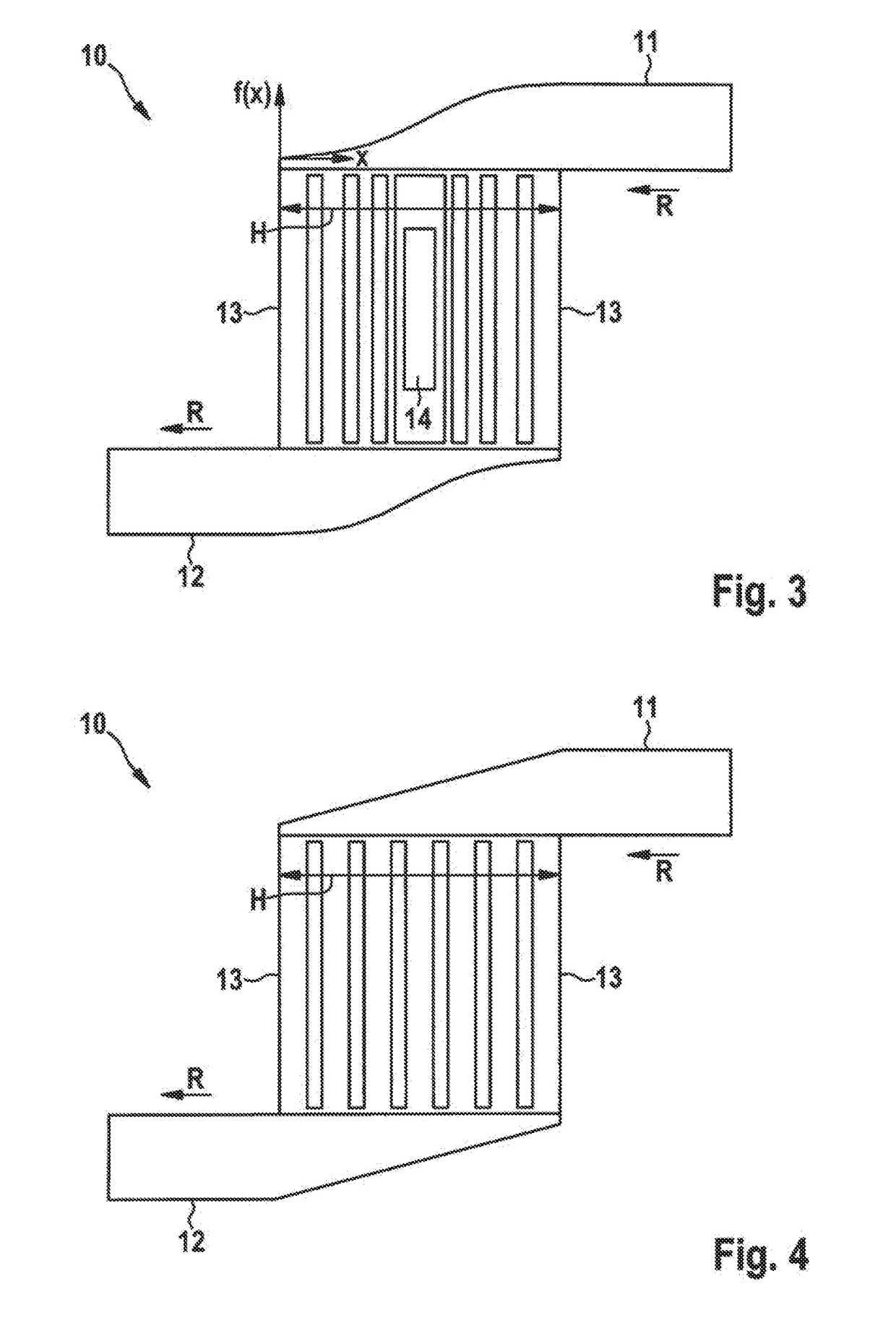

Heating apparatus for a MEMS sensor

ActiveUS20170129768A1Increase widthReduce widthAnalysing gaseous mixturesHeating element materialsPower flowEngineering

A heating apparatus for a MEMS sensor, comprising a metallic supply lead element for electric current; a metallic return lead element for electric current; and a defined number of metallic heating elements configured between the supply lead element and the return lead element, a substantially constant electrical current density being configurable in the supply lead element, in the return lead element, and in the heating elements.

Owner:ROBERT BOSCH GMBH

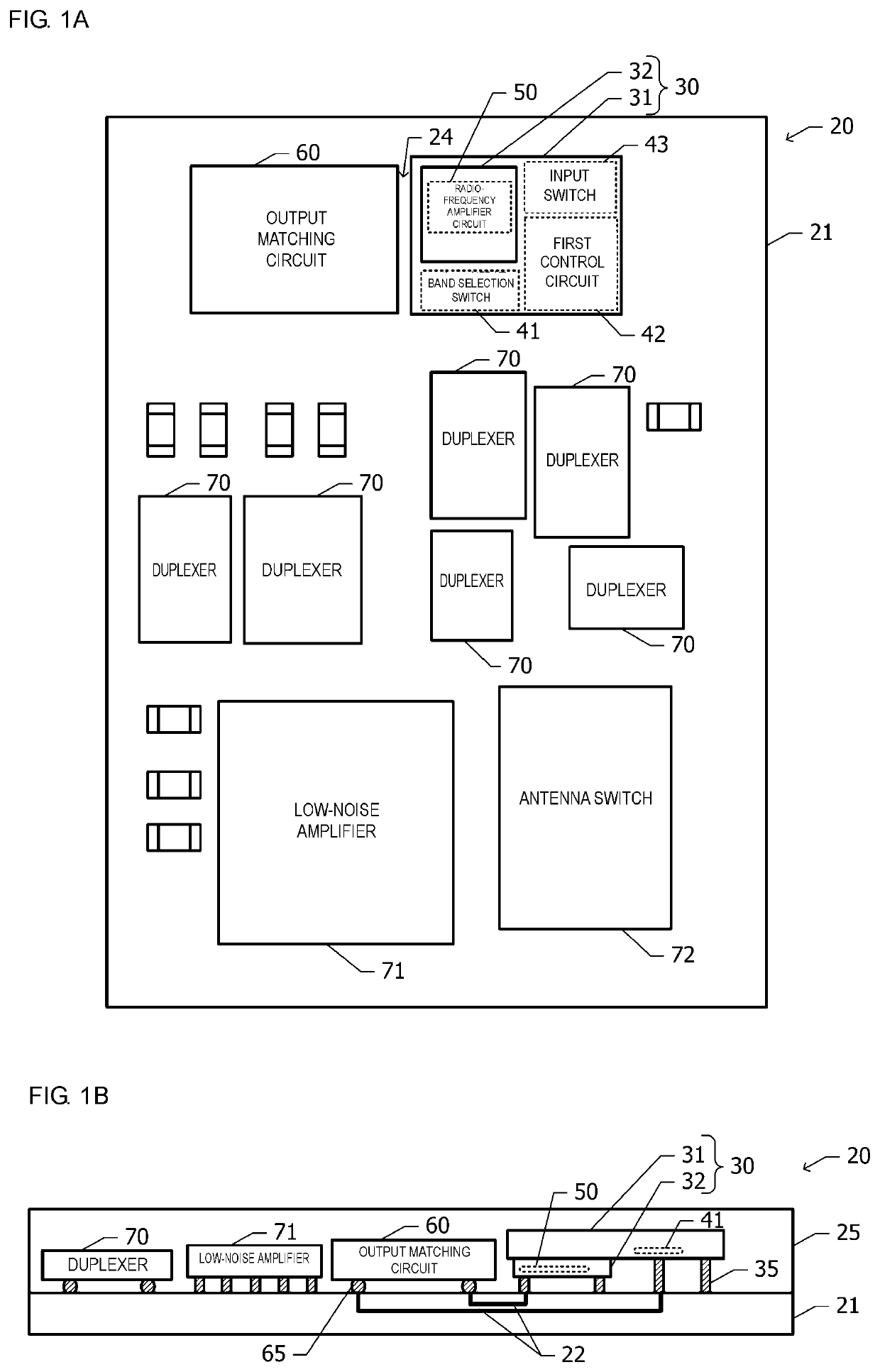

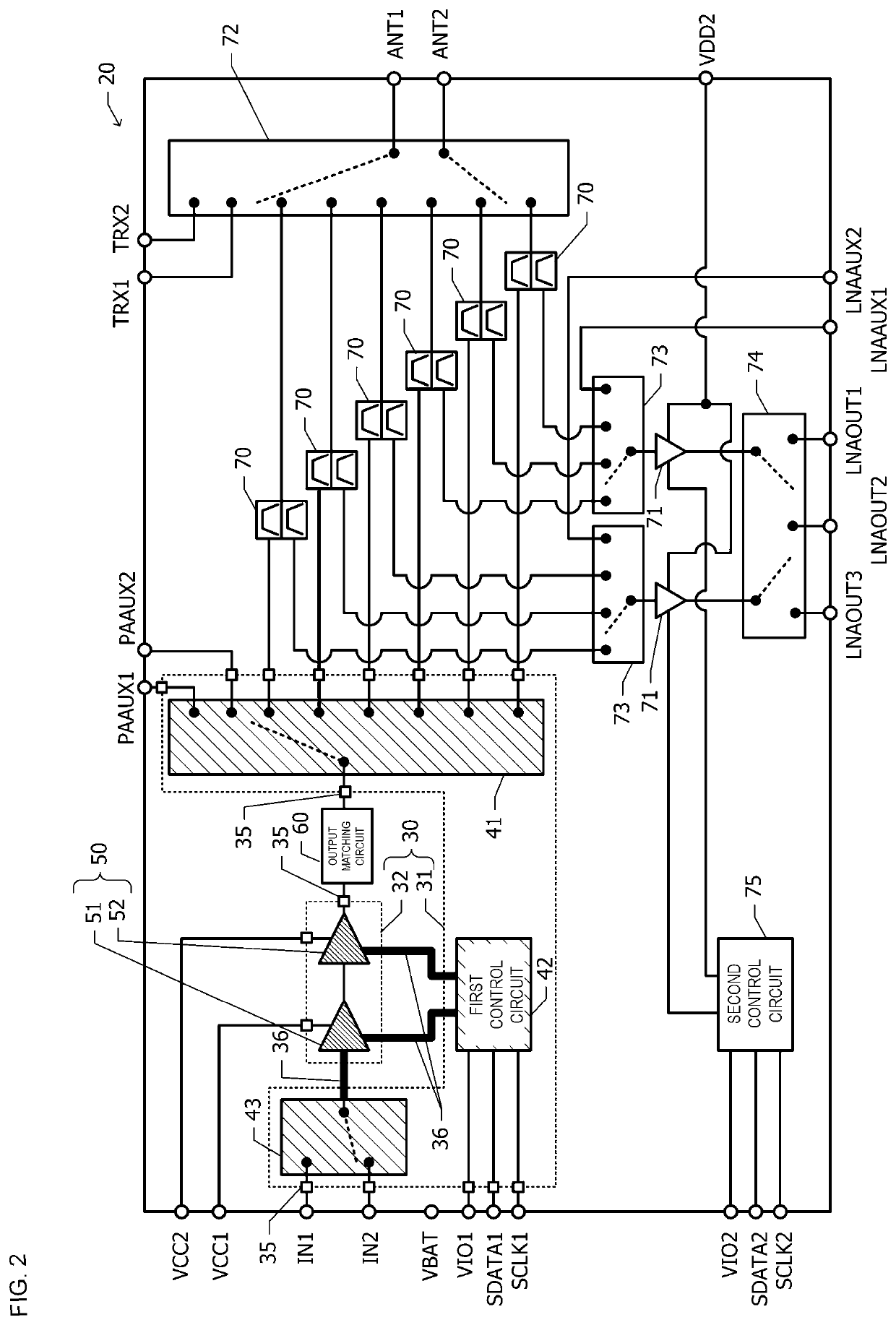

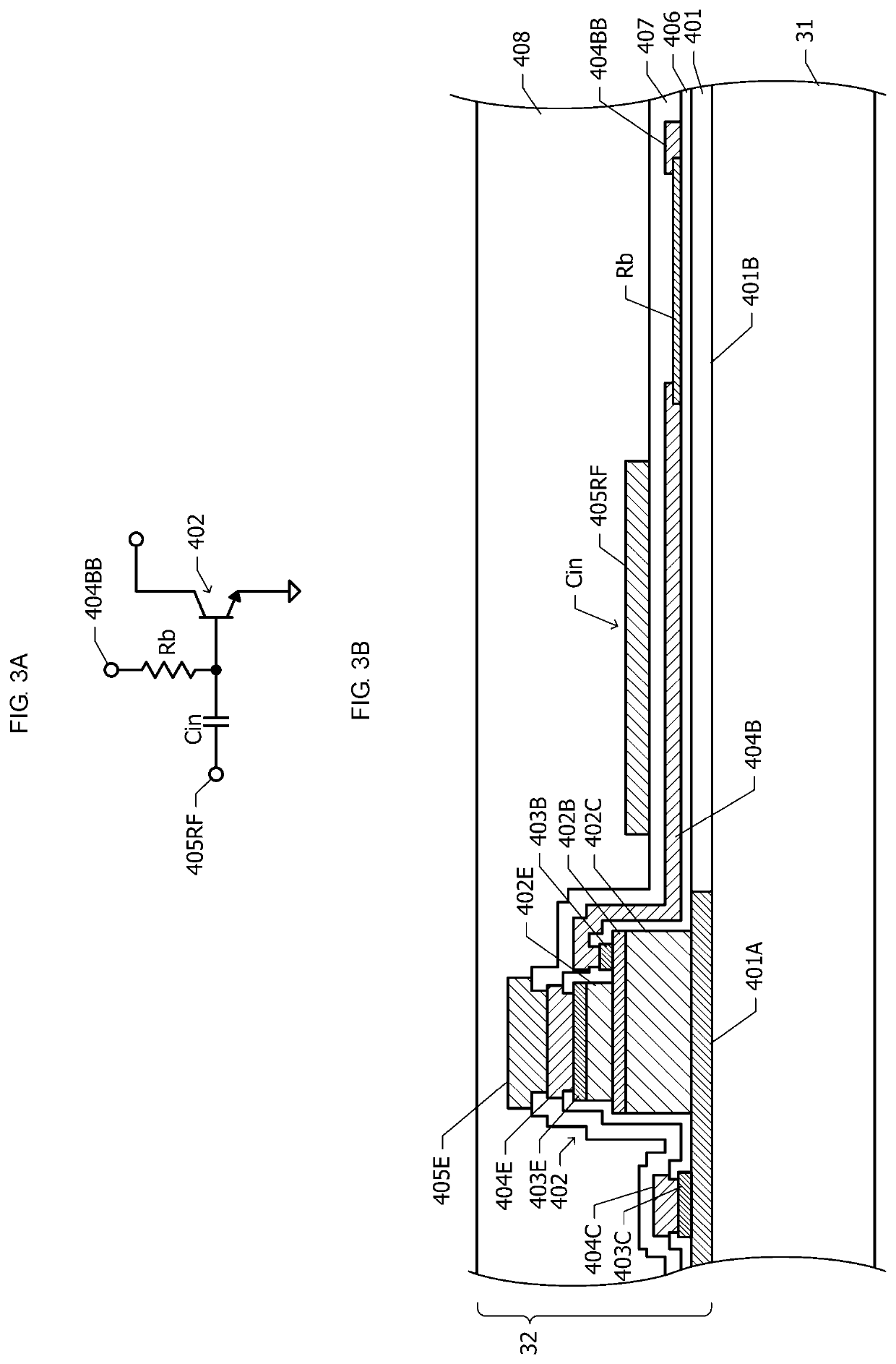

Radio-frequency module

PendingUS20220189893A1Improve featuresGrowth inhibitionGated amplifiersSemiconductor/solid-state device detailsDevice materialHemt circuits

A semiconductor device including a radio-frequency amplifier circuit and a band selection switch is mounted on or in a module substrate. An output matching circuit coupled between the radio-frequency amplifier circuit and the band selection switch is on or in the module substrate. The semiconductor device includes a first member at which the band selection switch having a semiconductor element made of an elemental semiconductor is formed and a second member joined to the first member in surface contact therewith. The radio-frequency amplifier circuit including a semiconductor element made of a compound semiconductor is formed at the second member. Conductive protrusions are raised from first and second members. The semiconductor device is mounted on or in the module substrate with the conductive protrusions interposed therebetween, and in plan view, is in close proximity to the output matching circuit or overlaps a passive element constituting the output matching circuit.

Owner:MURATA MFG CO LTD

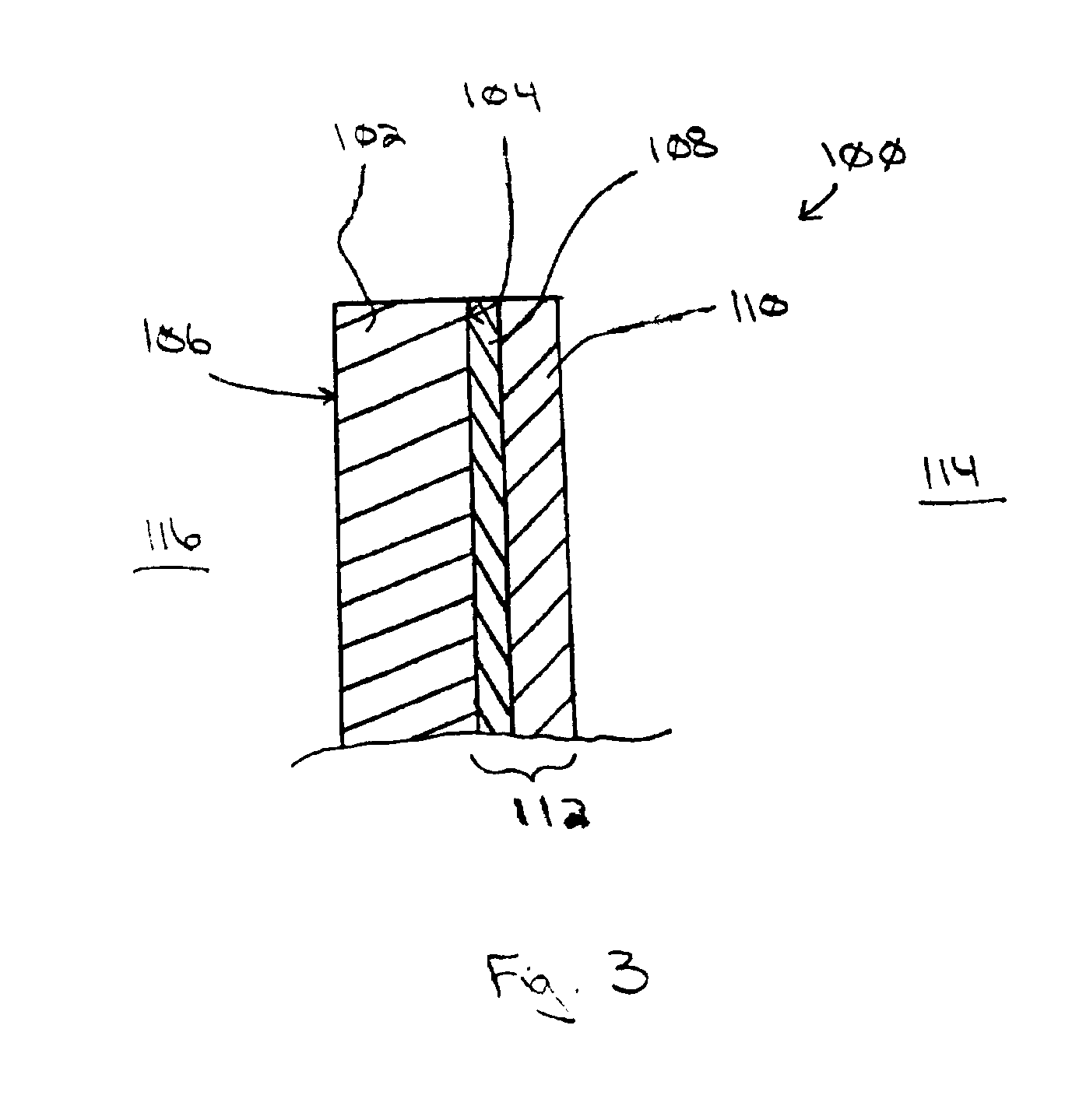

Ceramic heater

InactiveCN1549655AEasy temperature controlImprove heating characteristicsHeating element materialsCarbideNitride

A ceramic heater is featured as that heater which is formed by sintered metal granules and metal oxide if necessary is set on surface or in internal of ceramic base plate structured by nitride ceramic or carbide ceramic. In addition, paste made of mixed metal granules and metal oxide is used as electric conducting paste.

Owner:IBIDEN CO LTD

Linear motor, exposure apparatus using the same, and device manufacturing method

InactiveUS7362013B2Reducing cogging to zeroImprove heating characteristicsMagnetic circuitManufacturing dynamo-electric machinesLinear motorMagnet

In a movable magnet-type linear motor including a stator having a plurality of iron core elements arranged at a certain slot pitch and a movable part having a magnet 3 which is movable in an arrangement direction one or more pseudo-slots are provided between adjacent slots, and the iron core element and the magnet are relatively skewed by an approximately apparent slot pitch including the pseudo-slot.

Owner:CANON KK

Electronic part mounting heat-dissipating substrate

InactiveUS10249558B2Reduce resistanceHeat suppressionAssociation with control/drive circuitsSemiconductor/solid-state device detailsEngineeringLead frame

An electronic heat-dissipating substrate including: lead frames of wiring pattern shapes on a conductor plate; and an insulating member between the lead frames. A plate surface of the lead frames and a top surface of the insulating member form one continuous surface. The part arrangement surface is on both surfaces of the electronic part mounting heat-dissipating substrate, a reductant circuit which includes at least similar dual-system circuit is formed on the electronic part mounting heat-dissipating substrate, a first-system circuit of the dual-system circuit is formed on a first surface of the electronic part mounting heat-dissipating substrate, a second-system circuit of the dual-system circuit is formed on a second surface of the electronic part mounting heat-dissipating substrate, and the common lead frames used in a portion of a circuit wiring are used to the first surface and the second surface of the electronic part mounting heat-dissipating substrate.

Owner:NSK LTD

Method for the purification of diesel engine exhaust gases

ActiveUS9561470B2Best possible cost-effectivenessImprove energy efficiencyGas treatmentInternal combustion piston enginesNitrogen monooxideNitrogen dioxide

A method in which the exhaust gas that is to be purified is passed through an exhaust-gas line containing a diesel oxidation catalyst (DOC) for the oxidation of residual gaseous hydrocarbons (HC) and carbon monoxide (CO) in order to form carbon dioxide (CO2) and for the at least proportional oxidation of the nitrogen monoxide (NO) contained in the exhaust gas in order to form nitrogen dioxide (NO2) is provided.

Owner:DEUTZ AG

Exothermic enamel glaze, and exothermic container coated with same

InactiveCN102548920BImprove heating characteristicsGentrificationThin material handlingAlloyCeramic glaze

The invention relates to a heating container used in a microwave oven using a magnetron to cook food. The heating container absorbs a part of the high-frequency wave generated by the magnetron and generates heat, and uses the high-frequency wave to cook the food in the cooking room of the microwave oven. In the present invention, the exothermic enamel glaze is produced, and the above-mentioned manufactured exothermic enamel glaze is coated on a container made of metal material for enamel (steel plate for low-carbon enamel, aluminum, stainless steel), dried, and then vitrified and fired. , cooling, and produce a heating enamel container for microwave ovens. Therefore, compared with existing heating container products (silicone rubber + ferrite), it can withstand high temperatures, has higher heating performance, and can achieve high-grade. The method for manufacturing the heat-generating enamel glaze is characterized in that, in the glaze (vitreous Frit) commonly used in enamel treatment, ferrites with high magnetic permeability (MnZn class, MgCuZn class, NiZn class, etc.) are added separately or mixed. type) and metal soft magnetic material (Fe-Si type, Fe-Si-Al type, Fe-Si-B type, Fe-Si-B-Co type, Fe-Ni type) alloy powder to produce A heat-generating enamel glaze that absorbs microwaves (2.45GHz) in a microwave oven and converts them into heat energy.

Owner:YOU&I TECH

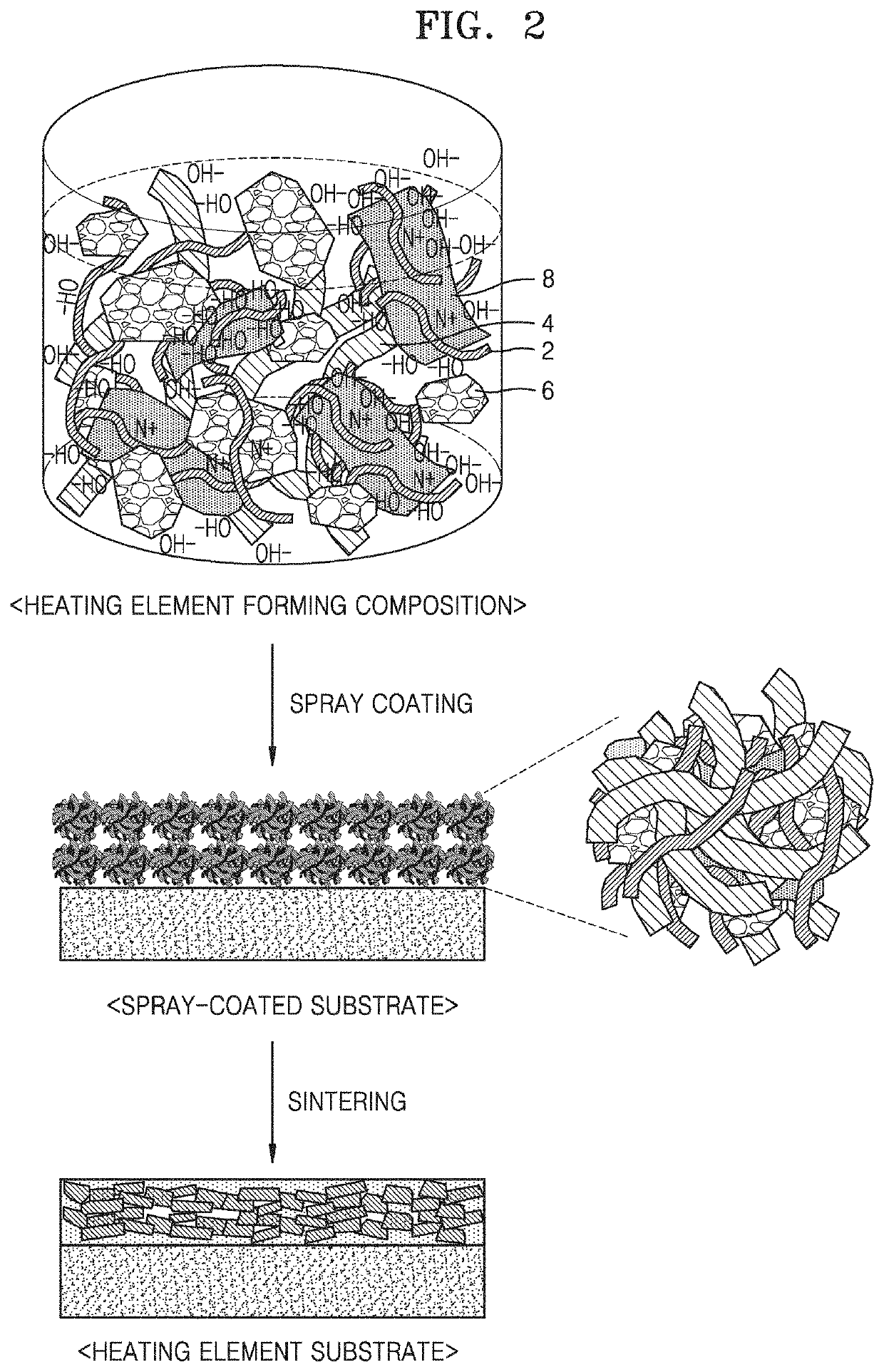

Heating element, manufacturing method thereof, composition for forming heating element, and heating apparatus

ActiveUS10779362B2Improve conductivityImprove heating characteristicsCoatingsHeating element materialsInorganic fillerElectrically conductive

A heating element includes a plurality of matrix particles and a conductive inorganic filler disposed at interfaces between the plurality of matrix particles to provide a conductive network.

Owner:SAMSUNG ELECTRONICS CO LTD

Backlight unit and display device

ActiveUS20210341788A1Reduce thicknessImprove image qualityOptical light guidesNon-linear opticsImaging qualityDisplay device

A backlight unit and a display device including the backlight unit are discussed. By arranging at least one electronic element for driving a light source and the backlight unit on a surface where the light source is disposed in a printed circuit and arranging a pattern having a reflective characteristic in an area where the electronic element is disposed, an image quality of the backlight unit can be maintained and a design structure of the backlight unit can be simplified. In addition, the light source and the electronic element can be disposed on a same surface of the printed circuit so that a space is not present between an opposite surface of the surface of the printed circuit where the light source is disposed and a cover bottom, so the performance of a heat dissipation can be improved in an area where the light source or the electronic element overlaps.

Owner:LG DISPLAY CO LTD

Electronic part mounting heat-dissipating substrate

InactiveUS10388596B2Reduce resistanceHeat suppressionAssociation with control/drive circuitsResistor terminals/electrodesPower flowLead frame

Owner:NSK LTD

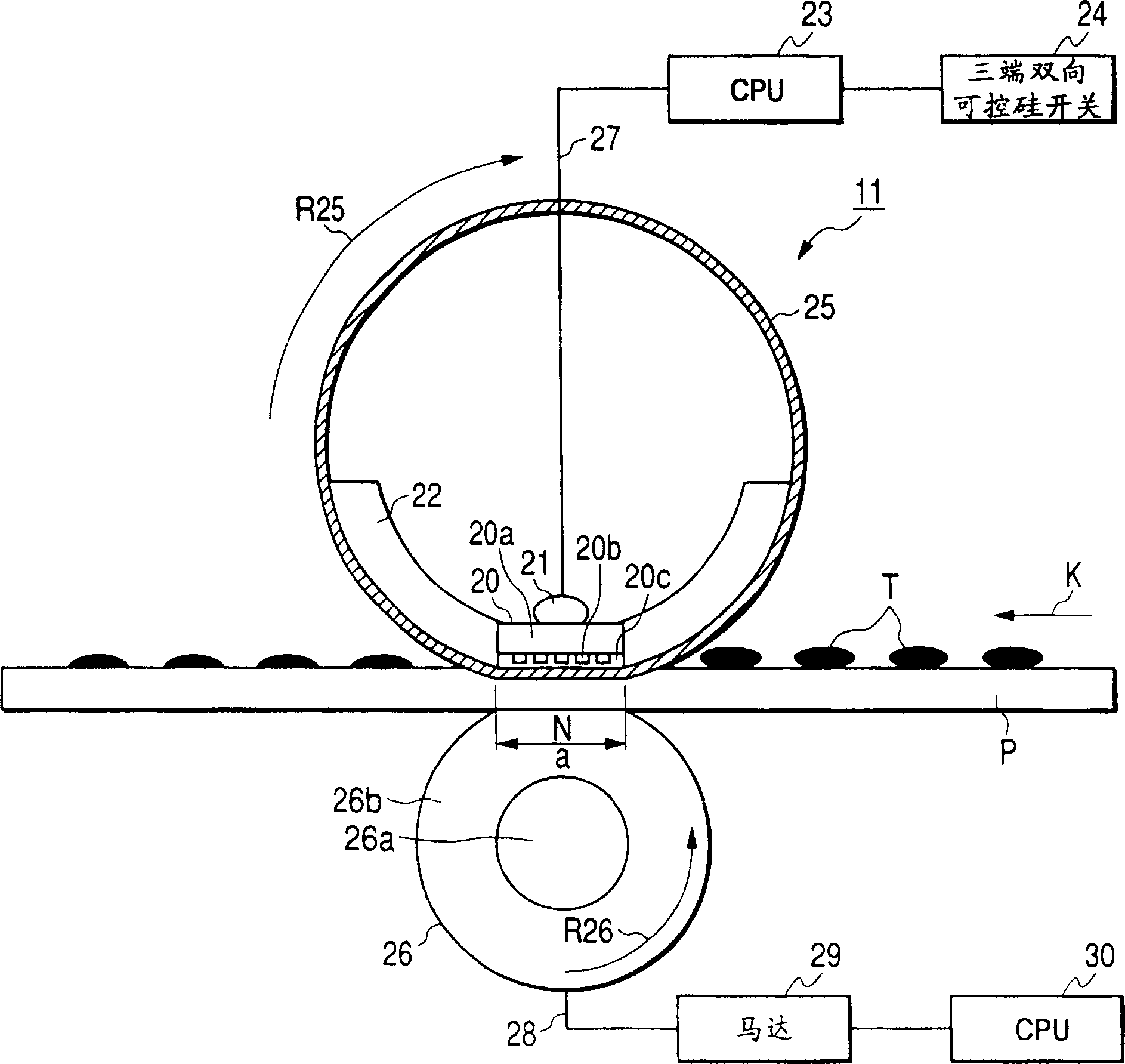

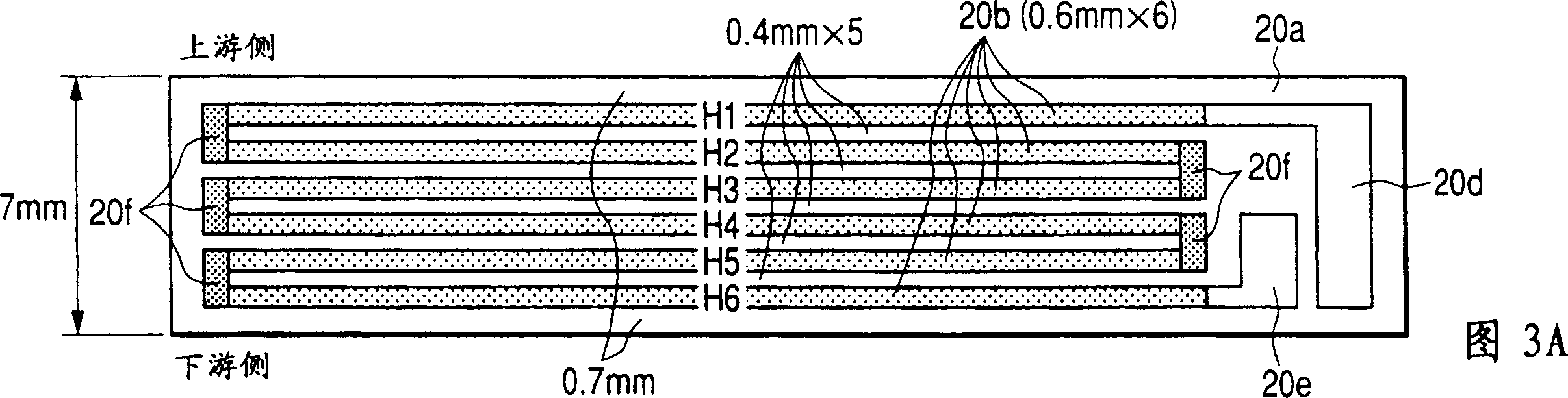

Heater for forming base plate with thermal resistance and image heating apparatus using the same heater

InactiveCN1272676CReduce volumeImprove heating characteristicsElectrographic process apparatusHeating element materialsElectrical resistance and conductanceCompact dimension

A heater, or an image heating apparatus including the heater includes a substrate, heat generating resistors formed at least in a cycle path on the substrate, and current supply electrodes provided at electrical ends of the heat generating resistors, wherein plural heat generating resistors are connected in parallel to at least one of the current supply electrodes. Thus there can be obtained a heater having excellent heat generating characteristics even in a compact dimension and an image heating apparatus utilizing such heater.

Owner:CANON KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com